High-toughness and high-cohesiveness C210 ultrahigh-strength hybrid fiber concrete and preparation method thereof

A high-cohesion, hybrid fiber technology, used in clay preparation devices, chemical instruments and methods, climate sustainability, etc., can solve problems such as inability to achieve toughening effects, reduce construction costs, achieve reuse, and improve resistance. The effect of folding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

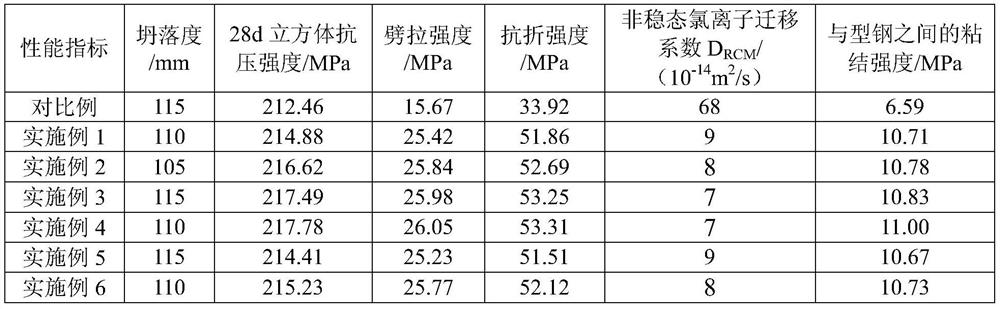

Examples

Embodiment 1

[0102] 1) Add 17 parts by mass of water reducer and 33 parts by mass of nano-titanium / graphene oxide dispersion into two-thirds of the total water, which is recorded as mixed solution 1; 12 parts of shrinkage reducing agent and 2.5 parts of antifoaming agent are added to one-third of the total water, which is recorded as mixed solution 2; 22 parts of carboxy-modified polyvinyl alcohol polymers are prepared for later use; the total water is 95 parts; Among them, the nano-titanium / graphene oxide dispersion consists of 1 part of graphene oxide powder and 0.1 part of nano-TiO 2 Made; carboxy-modified polyvinyl alcohol polymer is prepared from raw materials according to mass percentage: carboxy-modified polyvinyl alcohol 37.5%, water 61%, polyacrylate defoamer 1.5%;

[0103] 2) Mix 6.5 parts of ramie fiber, 895 parts of gravel, 735 parts of sand, 535 parts of cement, 75 parts of fly ash, 85 parts of straw ash, 98 parts of silica fume, 5 parts of nano silicon, 12.3 parts of basalt f...

Embodiment 2

[0112] 1) Add 17.5 parts by mass of water reducer and 35 parts by mass of nano-titanium / graphene oxide dispersion into two-thirds of the total water, which is recorded as mixed solution 1; 12.5 parts of shrinkage reducing agent and 2.9 parts of antifoaming agent are added to the water of one-third of the total water volume, which is recorded as mixed solution 2; 21 parts of carboxyl-modified polyvinyl alcohol polymers are prepared for later use; the total water volume is 90 parts; Among them, the nano-titanium / graphene oxide dispersion consists of 1 part of graphene oxide powder and 0.2 part of nano-TiO 2 Made; carboxy-modified polyvinyl alcohol polymer is prepared from raw materials according to mass percentage: carboxy-modified polyvinyl alcohol 39%, water 60%, polyacrylate defoamer 1%;

[0113] 2) 6.7 parts of ramie fiber, 890 parts of gravel, 740 parts of sand, 525 parts of cement, 75 parts of fly ash, 90 parts of straw ash, 95 parts of silica fume, 4.8 parts of nano silic...

Embodiment 3

[0121] 1) Add 18 parts by mass of water-reducing agent and 36 parts by mass of nano-titanium / graphene oxide dispersion into two-thirds of the total water, which is recorded as mixed solution 1; 13 parts of shrinkage reducing agent and 2.5 parts of antifoaming agent are added to the water of one-third of the total water volume, which is recorded as mixed solution 2; 20.5 parts of carboxy-modified polyvinyl alcohol polymers are prepared for later use; the total water volume is 90 parts; Among them, the nano-titanium / graphene oxide dispersion is composed of 1.5 parts of graphene oxide powder and 0.1 part of nano-TiO 2 Made; carboxy-modified polyvinyl alcohol polymer is prepared from raw materials according to mass percentage: carboxy-modified polyvinyl alcohol 37%, water 62%, polyacrylate defoamer 1%;

[0122] 2) Mix 6.6 parts of ramie fiber, 895 parts of gravel, 740 parts of sand, 530 parts of cement, 80 parts of fly ash, 85 parts of straw ash, 100 parts of silica fume, 4.9 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com