Patents

Literature

111results about How to "Increased splitting tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

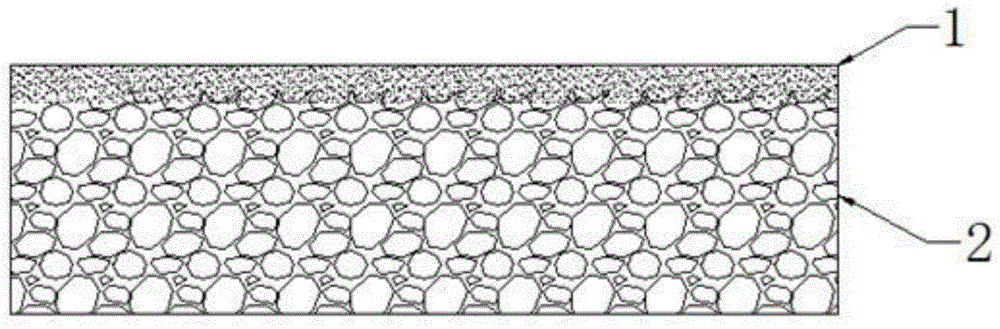

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

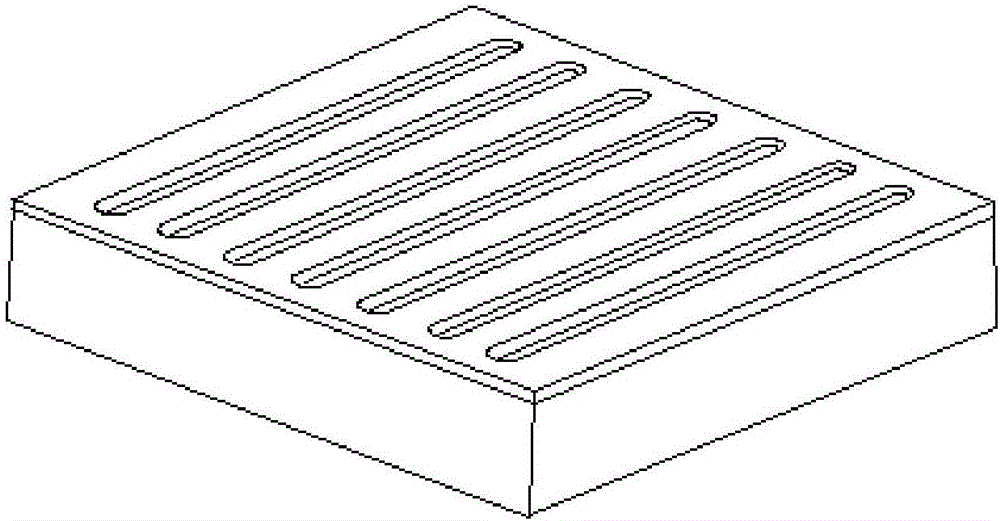

Cement polymer based high-temperature concrete permeable pavement bricks and manufacturing method thereof

The invention provides cement polymer based high-temperature concrete permeable pavement bricks and a manufacturing method thereof and belongs to the field of road surface pavement materials. Each cement polymer based high-temperature concrete permeable pavement brick is prepared from a permeable base layer and a permeable surface layer, wherein the permeable base layer is prepared from 290 to 345 parts of cement A, 0 to 6 parts of ultra-light aggregate A, 1630 to 1765 parts of coarse aggregate, 255 to 290 parts of sand, 0.50 to 0.85 part of polymer emulsion A, 0.35 to 0.50 part of an interface reinforcing agent A and 0 to 0.65 part of a loose soil constriction resisting agent; the permeable surface layer is prepared from 390 to 425 parts of cement B, 0 to 2 parts of ultra-light aggregate B, 0 to 7.5 parts of micro-pore fine aggregate, 1350 to 1400 parts of wear-resisting fine aggregate, 0.65 to 0.85 part of polymer emulsion B, 0.65 to 0.95 part of an interface reinforcing agent B, 8 to 13 parts of a deicer salt scaling resisting and alkali adsorption agent and 15 to 17 parts of pigment. According to the cement polymer based high-temperature concrete permeable pavement bricks, all technological performances of the permeable bricks are comprehensively improved.

Owner:葛兆明 +3

Method for preparing pavement base material by stabilizing iron tailings by novel soil stabilizer

ActiveCN104152148AStrong oxidationImprove solubilitySolid waste managementOrganic fertilisersMicrowaveChipseal

The invention discloses a method for preparing a pavement base material by stabilizing iron tailings by a novel soil stabilizer. The preparation method of the novel soil stabilizer comprises the following steps: diluting a TerranZyme bio-enzyme soil stabilizer with water by 10-100 times, adding solid CaCl2 with mass being 5%-10% that of diluting liquid and acidified water glass with mass being 5%-10% that of the diluting liquid, heating to 30-50 DEG C by microwaves, reacting for 20-60 minutes, and performing mixed modification to obtain the novel soil stabilizer. The novel soil stabilizer can be used for stabilizing the iron tailings to prepare the pavement base material. The method for preparing the pavement base material comprises the following steps: uniformly mixing cement, gravel and the iron tailings with the novel soil stabilizer according to a mass ratio of 5: 30: 68: 2 to obtain an inorganic mixture, adding 1.5kg / m<3> of polypropylene fibers, and uniformly mixing to obtain the pavement base material. All technical indexes of the pavement base material meet the national standard requirements, the utilization rate of the iron tailings is high, the environmental problem caused by piling of a large quantity of the iron tailings and mining of pavement gravel materials is solved, and economic benefits are obtained.

Owner:CENT SOUTH UNIV

Hybrid fiber reinforced concrete, and preparation method and application thereof

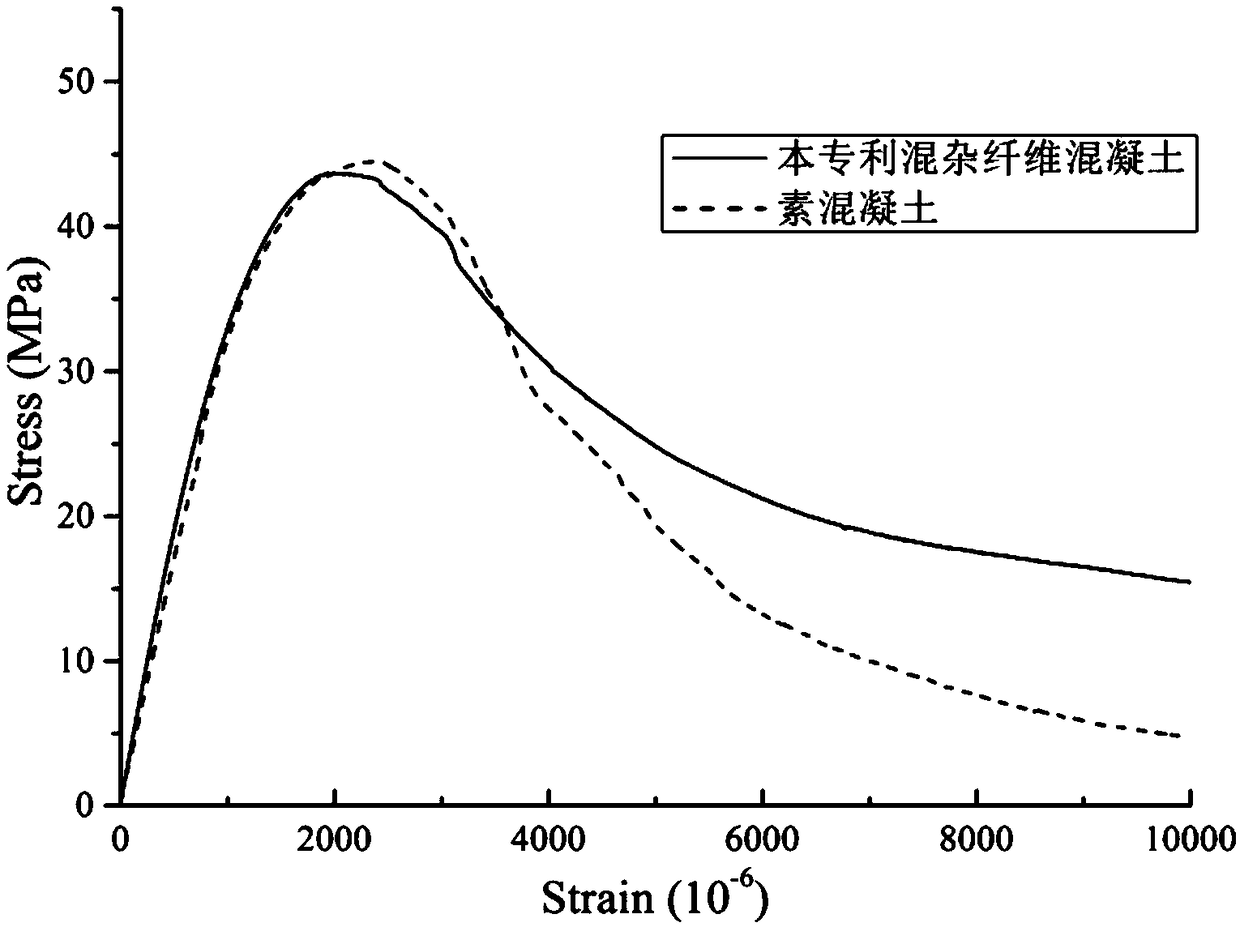

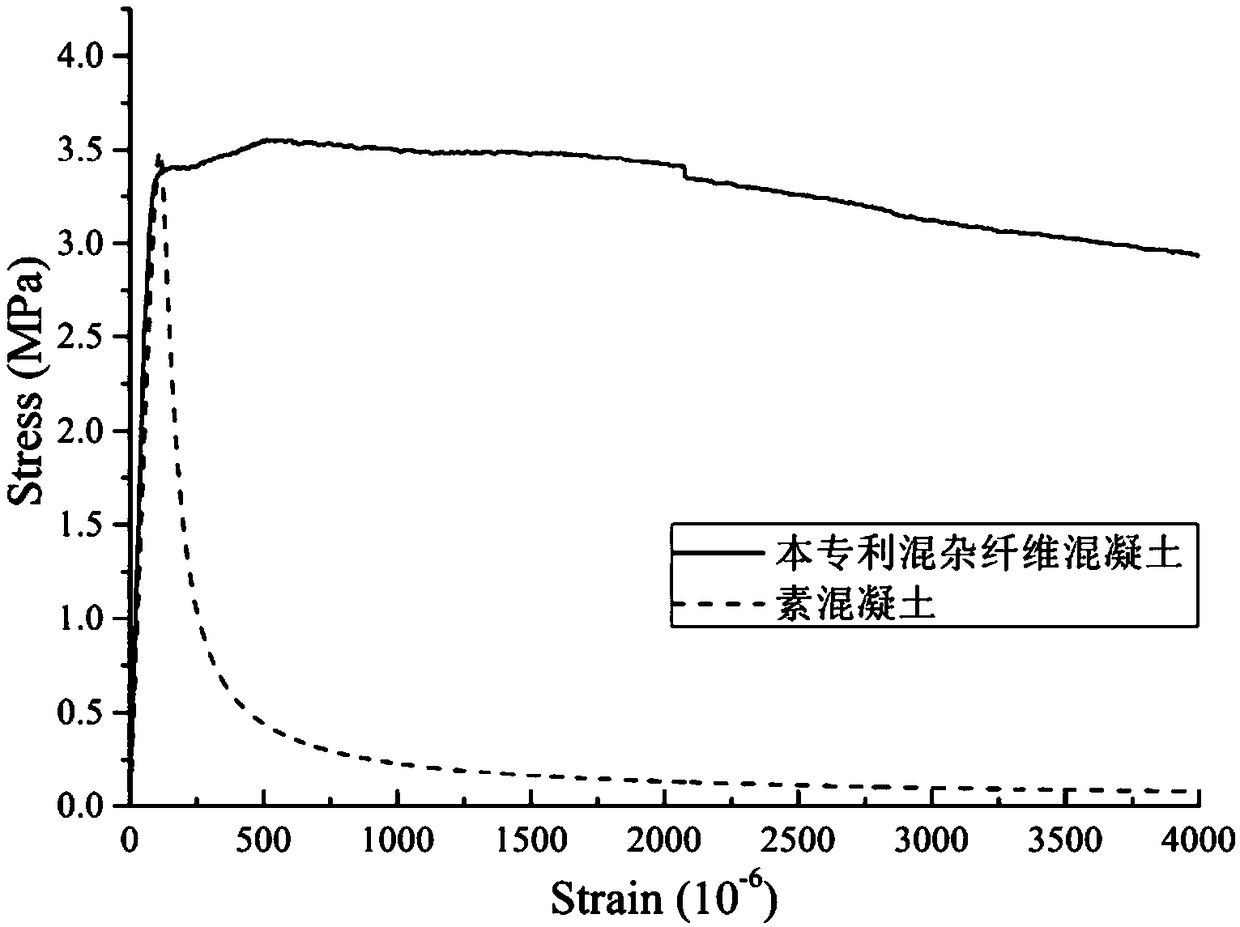

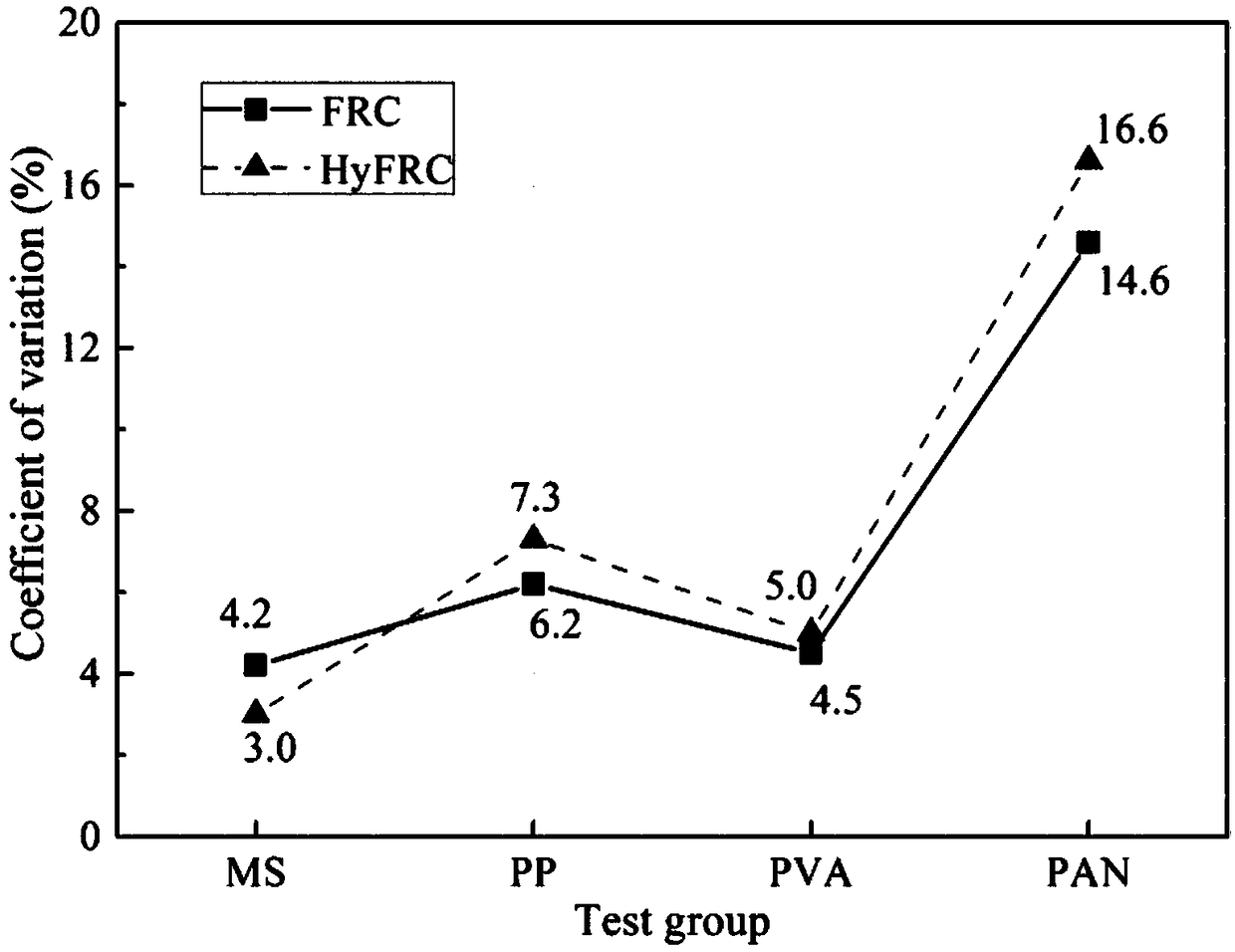

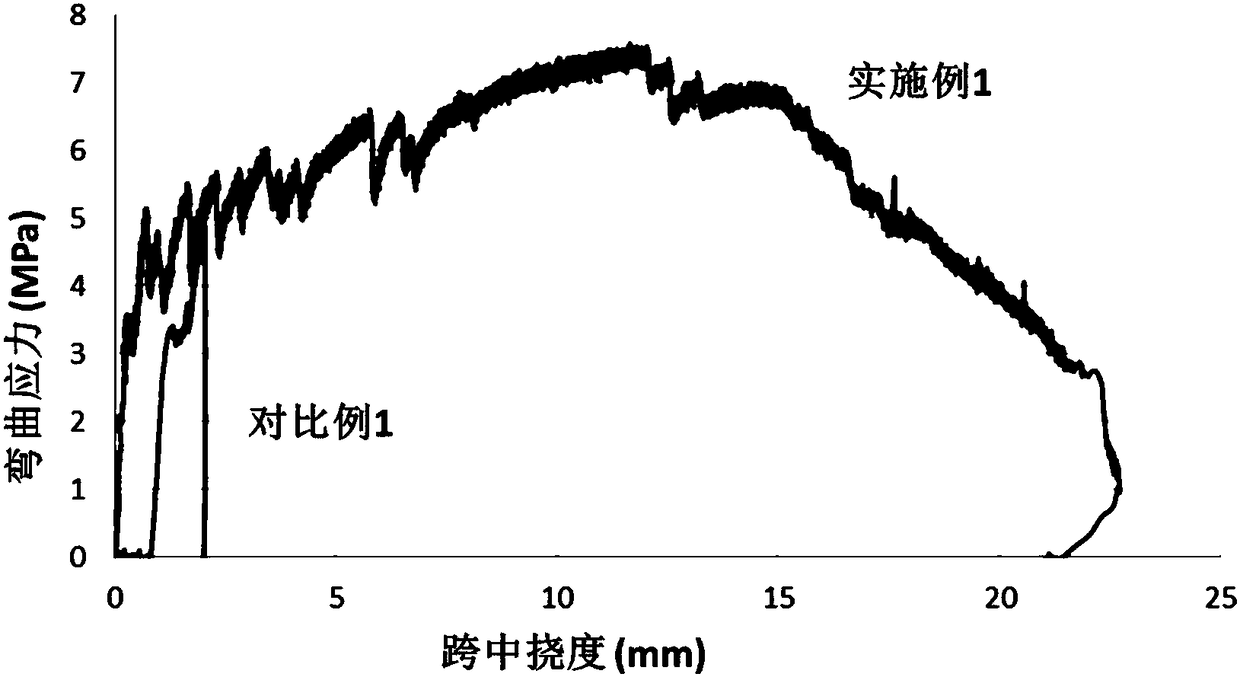

The invention provides hybrid fiber reinforced concrete, and a preparation method and an application thereof. The hybrid fiber reinforced concrete comprises cement, a coarse aggregate, a fine aggregate, steel fibers, polyvinyl alcohol fibers, a water reducer and water. The preparation method comprises the following steps: adding the steel fibers into the coarse aggregate to obtain a first mixed material; adding the fine aggregate and cement into the first mixed material to obtain a second mixed material; adding the polyvinyl alcohol fibers into the second mixed material to obtain a third mixedmaterial; and mixing the water and the water reducer to obtain a mixed solution, and adding the mixed solution into the third mixed material to obtain the hybrid fiber reinforced concrete. The invention provides the most optimum criterion of parameters at multi-performance target, and establishes the optimum scoring system of parameters. The optimum fiber combination and doping amount are screened according to the system, that is, 1.3% by volume of steel fibers and 0.2% by volume of polyvinyl alcohol fibers are compounded. Compared with plain concrete with a same basic mix proportion, the mechanical property of the hybrid fiber reinforced concrete is enhanced obviously.

Owner:TONGJI UNIV

PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and use method thereof

ActiveCN108129102AHigh mechanical strengthImprove impact resistanceAdditive manufacturing apparatusAdditive ingredientPortland cement

The invention relates to PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and a use method thereof. Through being metered in parts by weight, the concrete is preparedfrom the following ingredients including 0.8 to 1.2 parts of fast hardening ordinary Portland cement, 0.96 to 1.44 parts of grade F fly ash, 0.64 to 0.96 part of quartz sand (with the particle diameter range being 0.075 to 0.15mm), 0.29 to 0.43 part of water, 0.005 to 0.01 part of water reducing agents, 0.0017 to 0.0018 part of PVA fiber and 0.0043 to 0.0078 part of basalt fiber. According to thematerials of the concrete, the PVA fiber and the basalt fiber are used for optimizing and improving the intensity and the toughness of the concrete material; the printing performance is high; the intensity is high; the cost is low; the practical engineering application of the 3D printing concrete can be favorably promoted.

Owner:HEBEI UNIV OF TECH

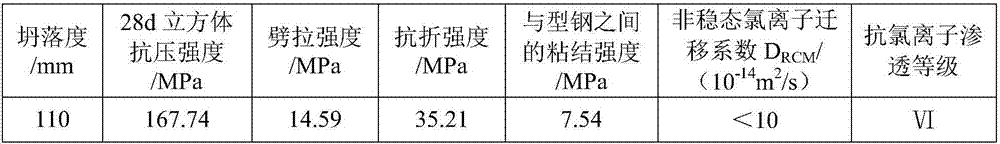

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

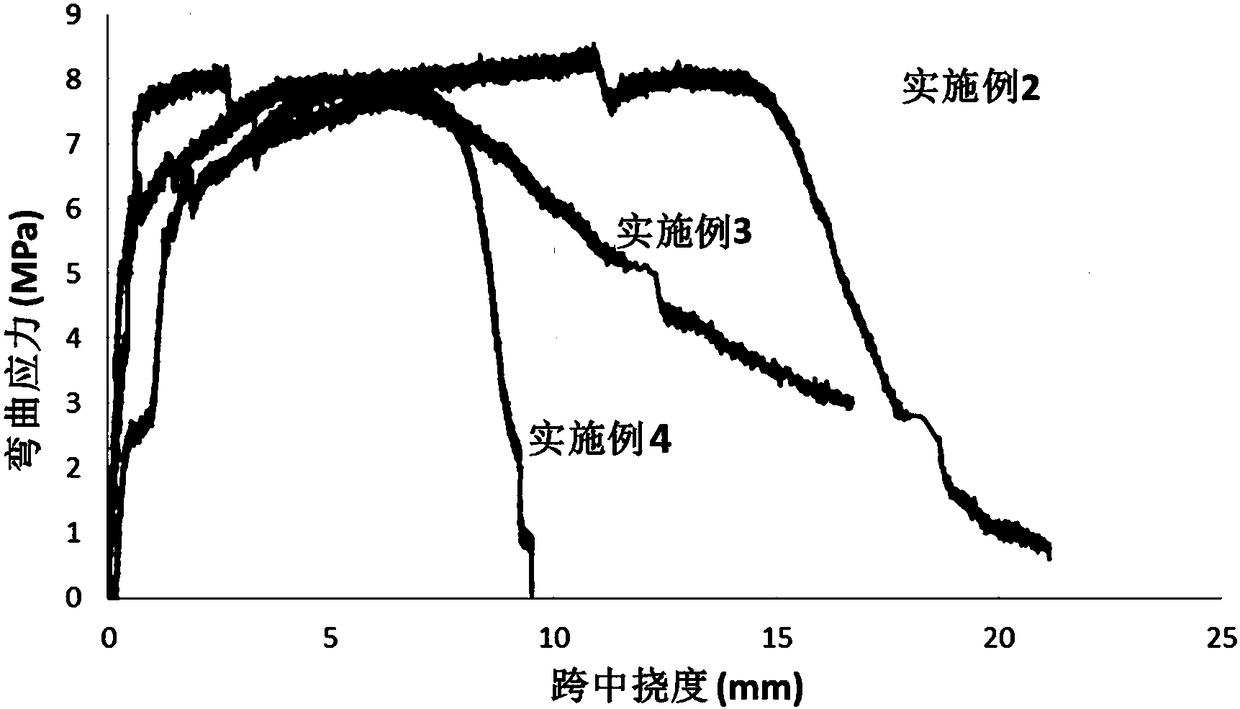

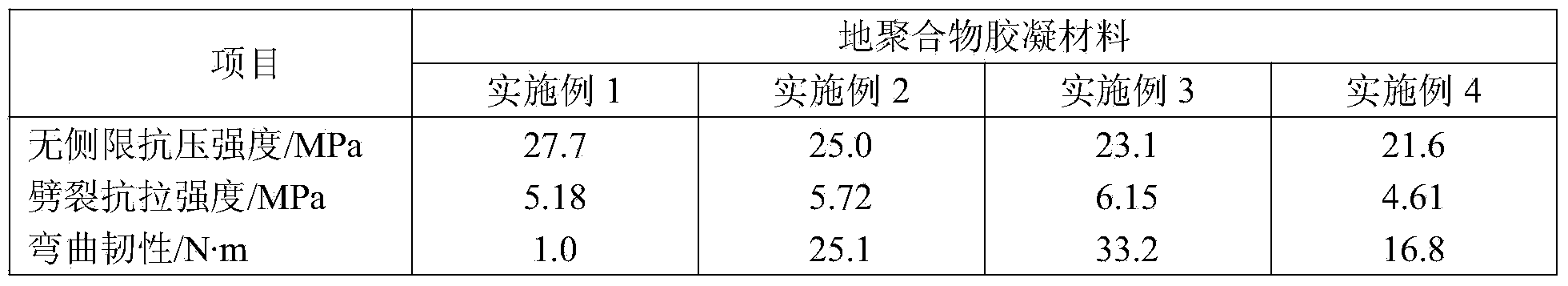

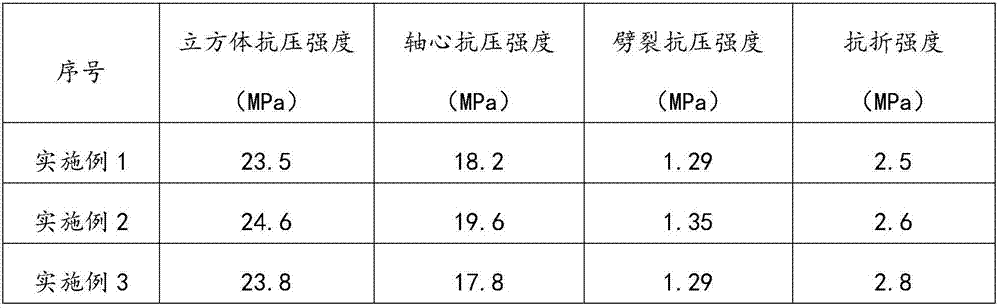

Corn straw fiber enhanced fly ash polymer gel material and preparation method thereof

The invention discloses a corn straw fiber enhanced fly ash polymer gel material and a preparation method thereof. In the preparation method, the corn straws are mixed into an alkali-excited fly ash polymer gel material, and then the mixture is subjected to certain maintenance conditions so as to enable the material system to have good properties. The corn straw, namely a waste which has not been effectively utilized, is used to enhance a poly gel material prepared from an industrial waste fly ash. A novel way is provided for waste utilization, the environment burden is relieved, the energy consumption is reduced, and the material performances are strengthened. The corn straw fiber enhanced fly ash polymer gel material is an unfired and clinker-free material, is a zero-carbon-emission environment-friendly engineering material, is according with the social development trend, and has a good social benefit and economic benefit.

Owner:SOUTHEAST UNIV

New ultrafine sand concrete

ActiveCN102093001AReduce internal defectsImprove structural featuresSolid waste managementWater reducerFiber

The invention discloses new ultrafine sand concrete. The new ultrafine sand concrete comprises the following components in parts by weight: 1.3 parts of cementing material, 1.5 parts of fine aggregate, 4 parts of coarse aggregate, 0.01 part of high efficiency water reducing agent and 0.32 part of water. The ultrafine sand concrete also contains expanding agent, water reducing agent, grinding aid, surfactant and reinforced fiber. By adopting the coordination of various components, particularly adding the reinforced fiber in the ultrafine sand concrete disclosed by the invention, the technical defect of the prior art that concrete is easy to crack can be overcome, the anti-seepage function of concrete can be enhanced and the cracking of concrete can be inhibited.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG

Sisal fiber enhanced coral concrete and preparation method thereof

The invention discloses sisal fiber enhanced coral concrete and a preparation method thereof. The concrete consists of coral concrete and sisal fibers, wherein the coral concrete is in the level C30, and each cubic meter of the coral concrete consists of 315-360 kilograms of cement, 90-135 kilograms of silica fume, 830 kilograms of sand, 716 kilograms of coral and 180 kilograms of seawater; the mass sum of the cement and the silica fume is 450 kilograms. The sisal fiber enhanced coral concrete is prepared by pouring cement, silica fume, sand and coral into an agitating machine for agitating, adding the sisal fibers for uniform dry agitating, and then adding the seawater for agitating. The concrete disclosed by the invention is high in splitting tensile strength and breaking strength, and has the characteristics of energy conservation, environment friendliness, low manufacturing cost, low heat conduction property, zero electromagnetic interference and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

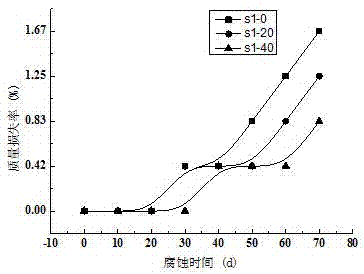

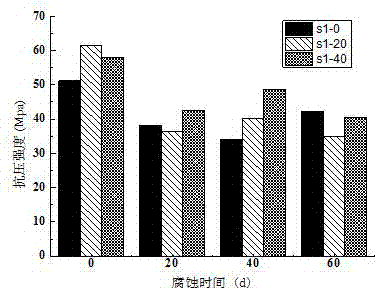

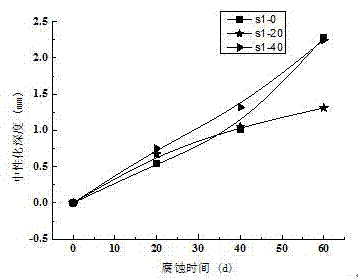

Lithionite slag admixture and its preparation method and use

The invention discloses a lithionite slag admixture and its preparation method and use. The lithionite slag admixture is prepared from lithionite slag and diatomite. The preparation method of the lithionite slag admixture comprises drying at a low temperature of 105 DEG C, drying at a high temperature of 300 DEG C and grinding. The mixture of a lot of lithionite slag and concrete is used as a concrete admixture replacing cement and can be used for preparation of C30-C60 eco-friendly high-performance concrete products with different strength. The high-performance concrete product has later compressive strength greatly larger than that of common concrete and has the largest later compressive strength increasing rate of 46.64%. The lithionite slag admixture has substantial acid rain corrosion resistance, has a mass loss late of 51.3% and 34.3% that of the common concrete, has a low concrete compressive strength loss late, has the average compressive strength 1.23 times that of the common concrete, has obvious later acid rain resistance and has neutralization depth of 57.5% that of the common concrete. The lithionite slag concrete has high carbonization resistance and splitting tensile strength and low chloride ion permeability.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Enhanced anti-cracking self-repairing concrete and preparation method thereof

The invention discloses enhanced anti-cracking self-repairing concrete and a preparation method thereof, and relates to the technical field of building materials. The concrete is C30 concrete and comprises, by weight, 154-164 parts of cement, 36-44 parts of fly ash, 262-290 parts of fine aggregates, 613-677 parts of coarse aggregates, 41.8-46.2 parts of water, 1.6-2.2 parts of fibers, 7.6-16.8 parts of repairing agents and 18-20 parts of anti-cracking anti-seepage agents. The concrete improves crack resistance and can effectively restrain cracking and continuously and automatically repair micro-cracks or micro-damage of the concrete caused by various reasons, the mechanical property of the concrete before being damaged can be recovered, economy and durability of the concrete are improved,and the service life of the concrete is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

Self-cooling infrared asphalt mixture and preparation method thereof

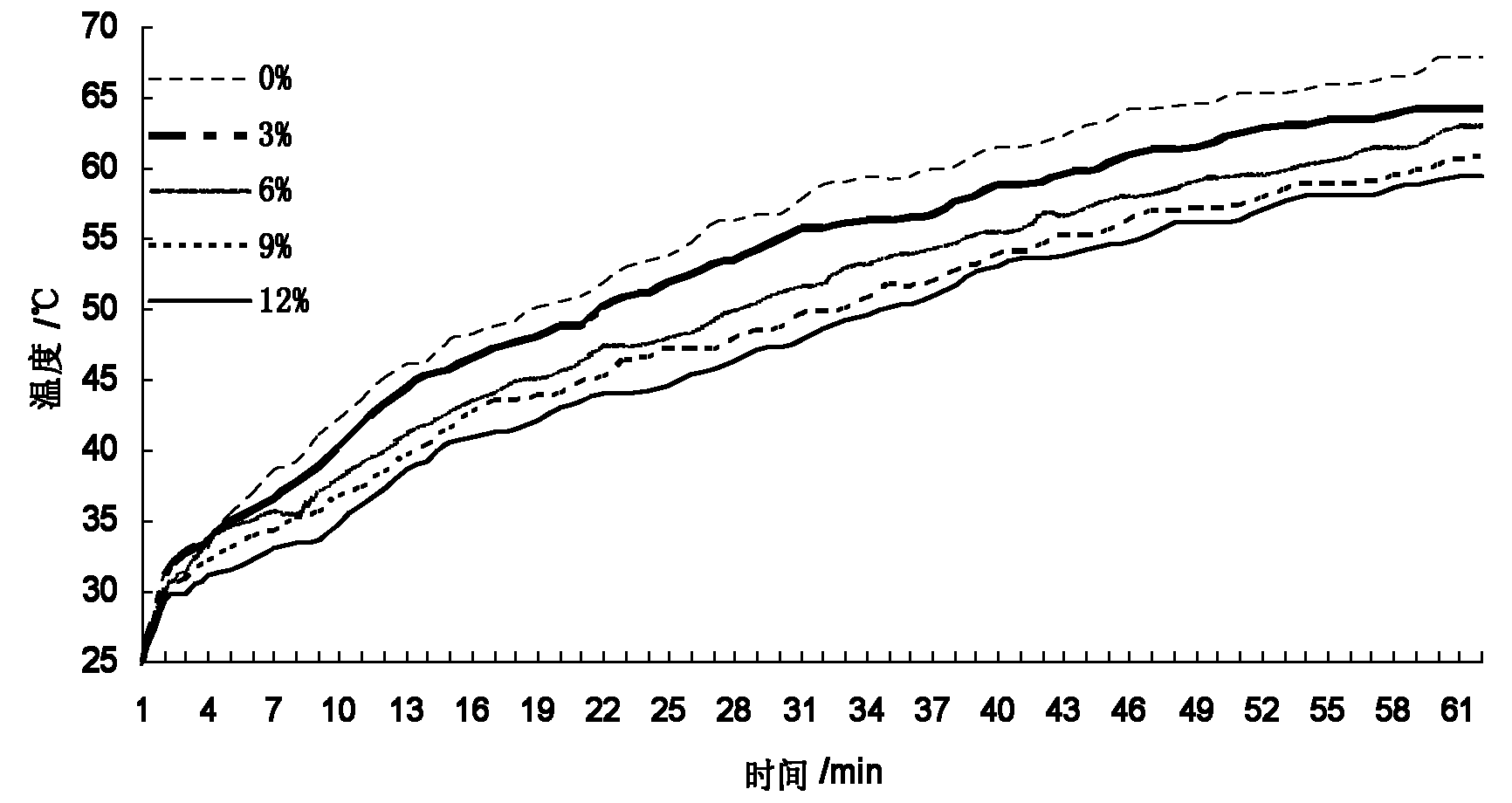

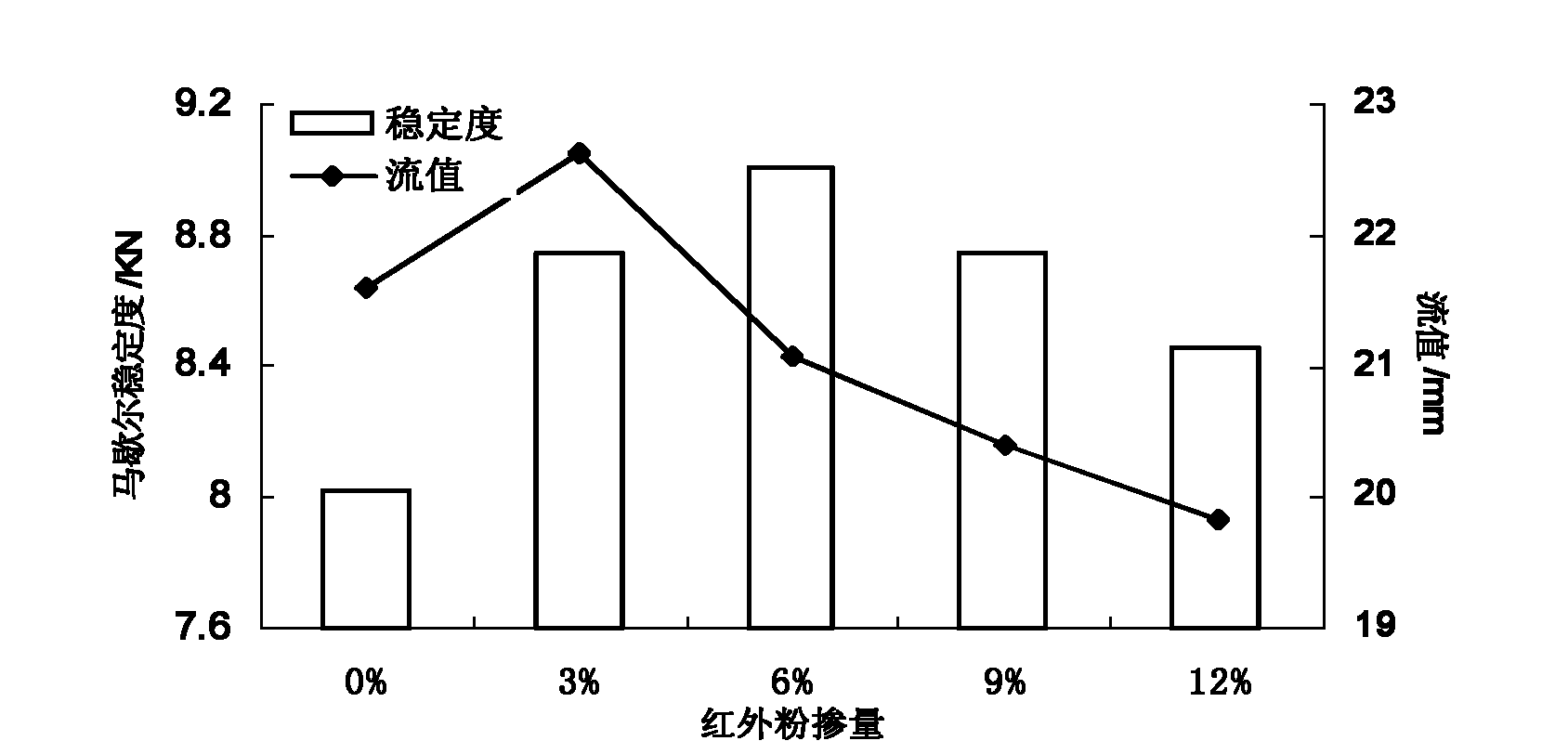

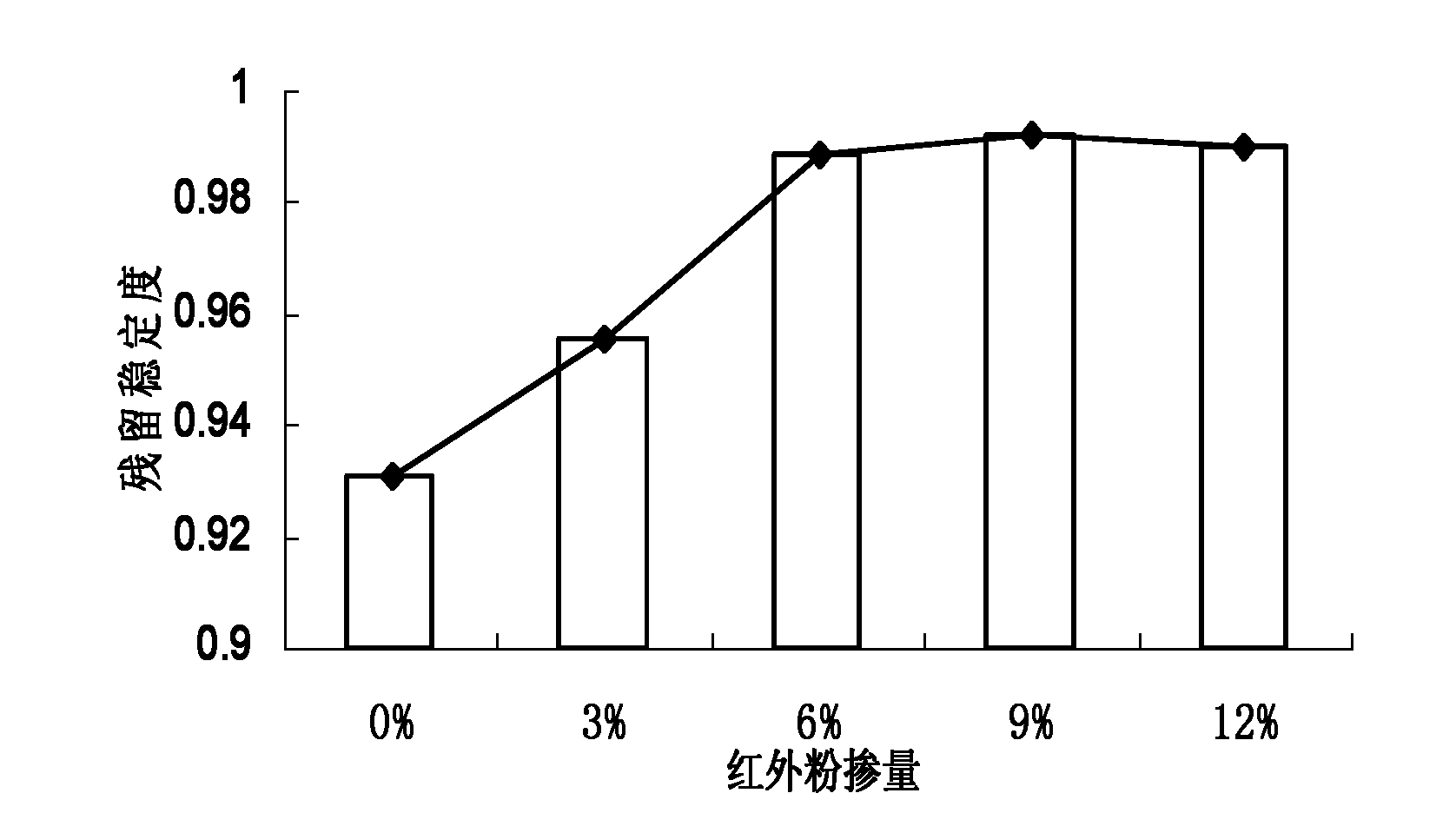

InactiveCN102070312AImprove adsorption capacityEasy to adsorb More adsorptionClimate change adaptationAsphaltMaterials science

The invention discloses a self-cooling infrared asphalt mixture and a preparation method thereof. The self-cooling infrared asphalt mixture comprises asphalt and coarse and fine aggregates. The invention is characterized in that the asphalt mixture contains infrared powder, and the weight ratio of the infrared powder in the self-cooling infrared asphalt mixture is 3-12%. The preparation method of the self-cooling infrared asphalt mixture comprises the following steps: (1) evenly mixing the infrared powder and mineral powder; (2) preheating the evenly mixed infrared powder and mineral powder obtained in the step (1) to 180-190 DEG C; (3) putting the coarse and fine aggregates into a mixer, and then, adding the evenly mixed infrared power and mineral powder obtained in the step (2) for dry mixing, wherein the dry mixing time is at least 10 seconds; and (4) adding asphalt for wet mixing after dry mixing, wherein the wet mixing time is at least 45 seconds, and the mixing is not finished until the evenness is achieved and all coarse and fine aggregates are applied on the asphalt. According to the invention, the temperature of the mixture is lowered, and simultaneously, the integrity and stability of the mixture are enhanced; and the invention is favorable for reducing the heat accumulation of the urban atmosphere and relieving the urban heat island effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sound-insulating environment-friendly polypropylene fiber pebble concrete and preparation method thereof

ActiveCN106220051AImprove heat resistanceGood chemical stabilityCeramicwareCompressive resistanceFoaming agent

The invention discloses a sound-insulating environment-friendly polypropylene fiber pebble concrete and a preparation method thereof. The concrete mainly comprises pebble, a foaming agent, a sound insulation agent, polypropylene fiber, cement, aggregate and a high-efficiency water reducer, wherein the polypropylene fiber mainly comprises a polypropylene raw material, a coupling agent, a dispersant, a fire retardant and a coloring agent. The preparation method comprises the following steps: crushing and drying of the polypropylene resin raw material; mixing of the raw material and various additives; melted extrusion; hot-roller drawing; high-temperature oil bathing; surface treatment; thermal setting; and cooling, cutting and packaging. The polypropylene fiber pebble concrete prepared in the invention has good heat resistance, chemical stability, good sound insulation performance and strong resistance to acid and alkali; the physical and mechanical properties of the polypropylene fiber pebble concrete are greatly improved compared with common concrete; and a building formed by pouring of the polypropylene fiber pebble concrete has good mechanical properties like compressive strength, static elastic constant, splitting tensile strength and rupture strength.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

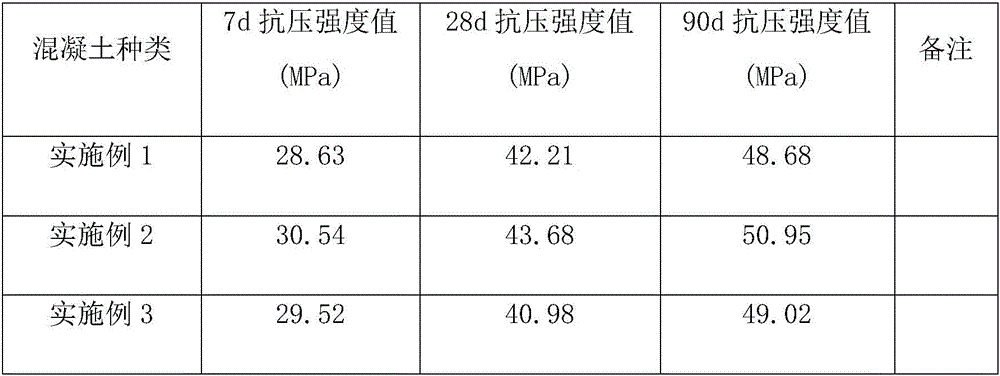

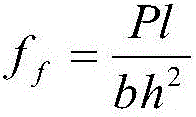

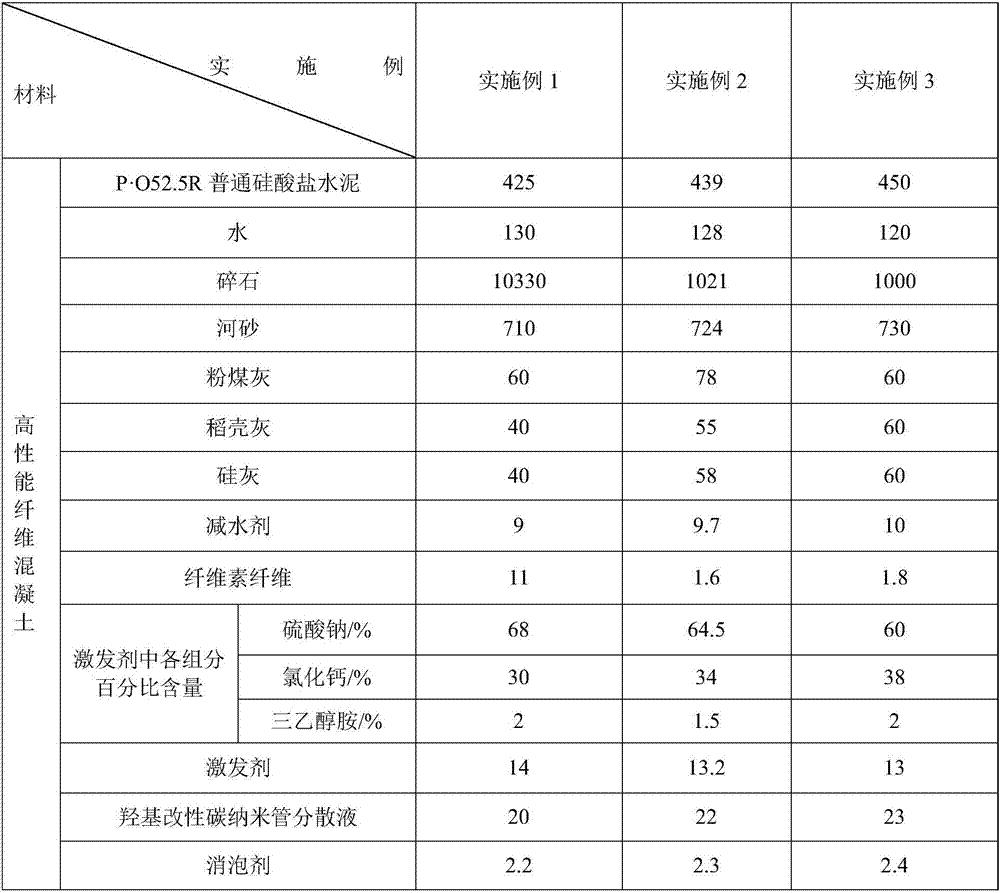

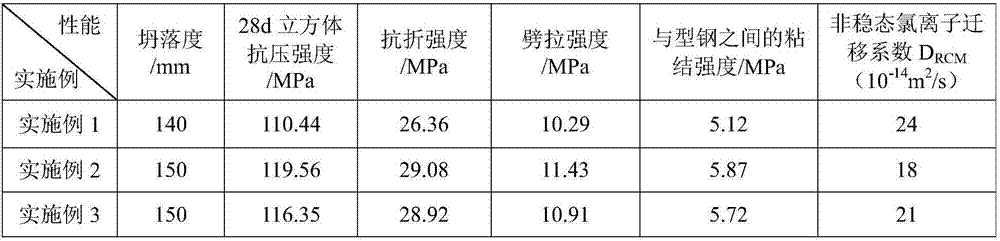

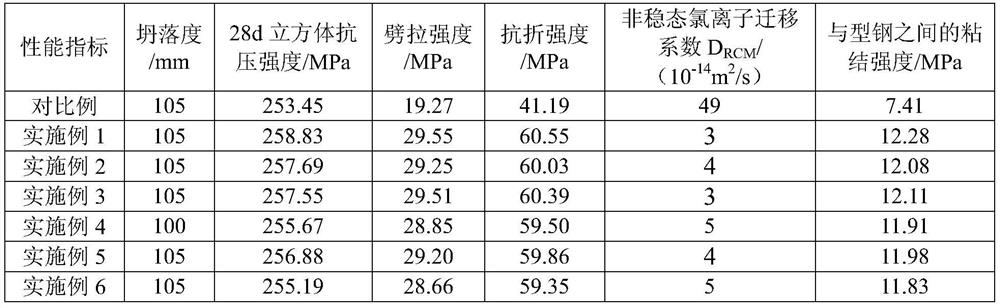

High-performance fiber concrete with C110 strength grade and preparation method thereof

The invention discloses high-performance fiber concrete with a C110 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 425 to 450 parts of cement, 120 to 130 parts of water, 710 to 730 parts of river sand, 1000 to 1030 parts of crushed stones, 60 to 90 parts of fly ash, 40 to 60 parts of rich husk ash, 40 to 60 parts of silicon ash, 9 to 10 parts of a water reducing agent, 13 to 14 parts of an exciting agent, 1.1 to 1.8 parts of cellulose fibers, 20 to 23 parts of a hydroxyl-modified carbon nanotube dispersion solution and 2.2 to 2.4 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel. The high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

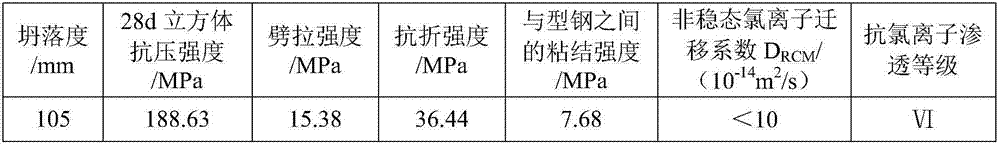

Ultrahigh-strength and high-performance fiber concrete with C180 strength grade and preparation method thereof

ActiveCN107352913AImprove volume stabilityInhibit plastic shrinkageSolid waste managementIonFlexural strength

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C180 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 505 parts of cement, 70 parts of water, 1000 parts of crushed stones, 770 parts of fine aggregate, 70 parts of fly ash, 78 parts of rich husk ash, 118 parts of silicon ash, 15 parts of a water reducing agent, 10 parts of an exciting agent, 1.7 parts of cellulose fibers, 43 parts of a hydroxyl-modified carbon nanotube dispersion solution, 45 parts of a graphene oxide dispersion solution and 2.7 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 188.63MPa, the flexural strength reaches 36.44MPa, the splitting tensile strength reaches 15.38MPa, the bonding strength with the section steel reaches 7.68MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Use of fly ash synthesized channel joint impervious material for preparing highway asphalt mixture

The invention discloses an application of known flyash-compounded channel seam permeation resistant material on preparing a road asphalt mixed material. A modified asphalt mixing material using flyash-compounded channel seam permeation resistant material as a cementation material comprises normal pulverized stone, stone crumb, sand, slag, mineral powder and the asphalt mixing material used as thecementation material. The asphalt mixing material used as the cementation material in the asphalt mixing material accounts for 30 to 100 weight parts of the asphalt weight, and is replaced by the flyash-compounded channel seam permeation resistant material and the like of the same weight parts. The asphalt mixing material prepared by using the flyash-compounded channel seam permeation resistant material as the cementation material increases the using ways of the high additional value of the flyash, reduces the economic cost of the asphalt mixing material and improves the using performance of the asphalt mixed material. The mixed asphalt material has excellent road surface performance, simple technology, convenient use and easy popularization.

Owner:NORTHWEST A & F UNIV

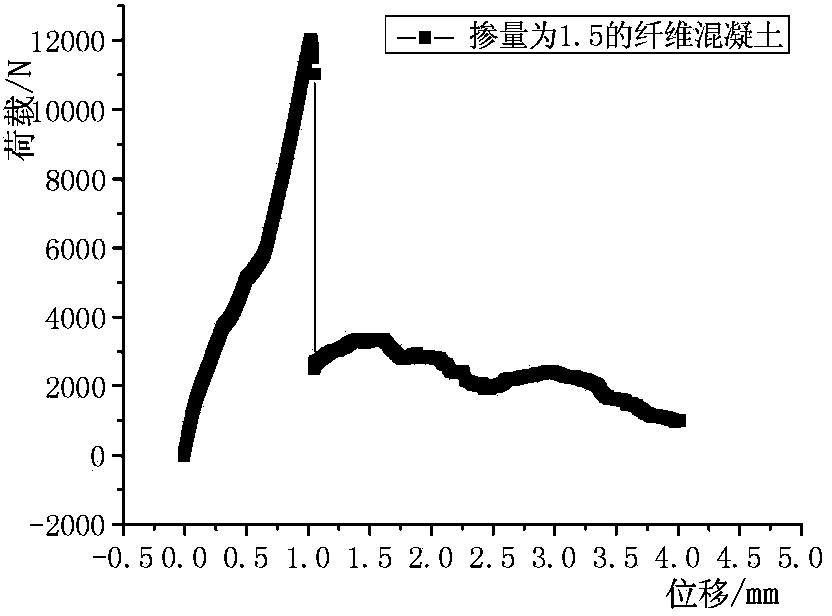

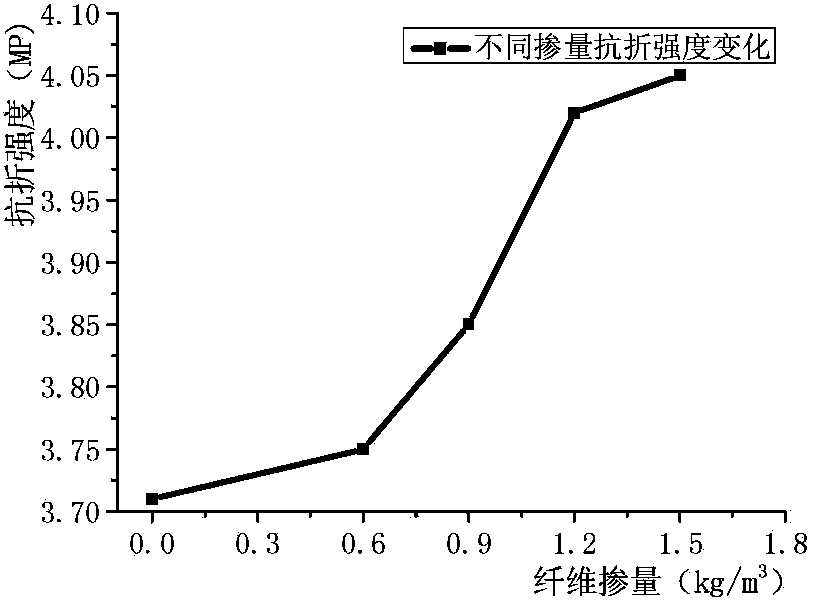

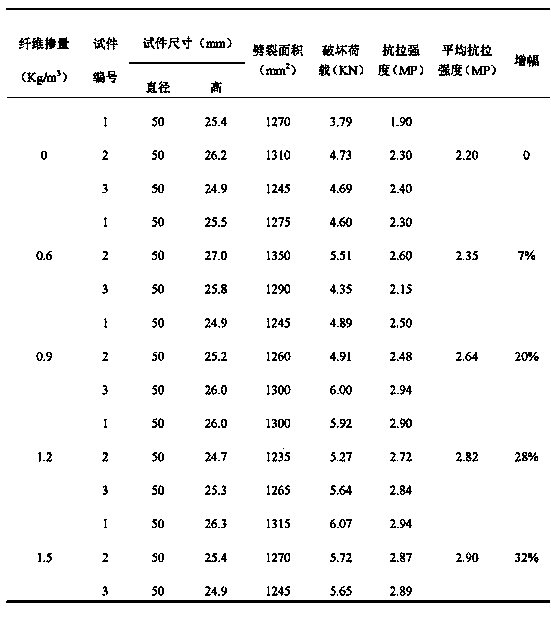

Sprayed concrete

InactiveCN103360005AIncreased splitting tensile strengthImprove flexural strengthShotcreteMaterials science

The invention discloses a sprayed concrete comprising the components of cement, sand, pebbles, water, an accelerating agent and bundle-shaped monofilament polypropylene fibers. By utilizing the bundle-shaped monofilament polypropylene fibers with the mixing amount of 0.9kg / m<3>-1.5kg / m<3>, the splitting tensile strength and the rupture strength of the concrete can be effectively improved so as to meet the needs of civil engineering under mine.

Owner:解波

Method for preparing anti-freezing abrasion-resistant baking-free brick by hematite tailing-slag-phosphate tailing sand

The invention discloses a method for preparing an anti-freezing abrasion-resistant baking-free brick by hematite tailings-slag-phosphate tailing sand. The method includes the steps: drying steel slagand slag in a baking oven, placing mixture into a ball grinder to grind the mixture into ultra-fine powder, placing steel slag powder, slag powder, limestone powder and phosphogypsum into a cement mortar stirrer to dryly stir mixture, adding water to wetly stir mixture, and adding phosphate tailing sand to stir mixture to prepare a slag-phosphate tailing sand mixed material; adding hematite tailings, aggregate and cementing materials into the cement mortar stirrer to dryly stir mixture, adding additives, water, pretreated glass fibers, modified steel fibers and the slag-phosphate tailing sandmixed material to wetly stir mixture, adding the stirred material into a stainless steel die, setting forming pressure on a microprocessor control electric-liquid pressure tester, performing pressingformation, setting steam-cure temperature and wet and heat curing, and naturally curing to prepare the baking-free brick. The baking-free brick has excellent permeability resistance, freezing resistance, abrasion resistance, softening resistance and alkali resistance.

Owner:枞阳县天筑新型建筑材料有限公司

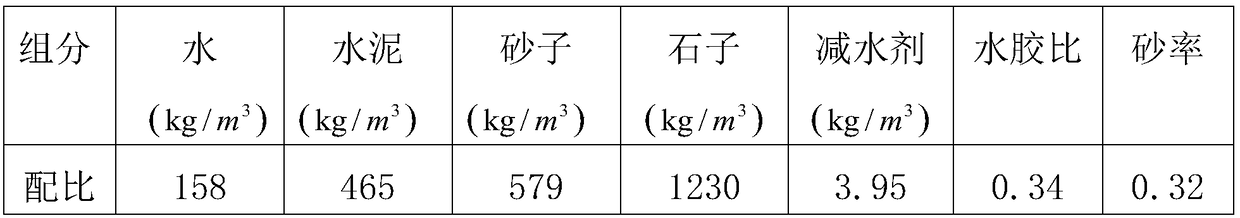

Mixed basalt fiber reinforced concrete and preparation method thereof

ActiveCN109369091AHigh compressive strengthIncreased splitting tensile strengthReinforced concreteFlexural strength

The invention discloses mixed basalt fiber reinforced concrete. The mixed basalt fiber reinforced concrete comprises chopped basalt fiber bundles, and the volume content of the chopped basalt fiber bundle is 0.1-0.8%; and the volume content of chopped basalt fibers is 0.1-0.2%. The chopped basalt fiber bundles are better matched with aggregate with the conventional size, thus the great compactnessis formed between the chopped basalt fiber bundles and a concrete matrix, and the bonding performance between the chopped basalt fiber bundles andwith the concrete is improved greatly; gaps between the aggregate and as well as gaps between the aggregate and the chopped basalt fiber bundles can be better filled with the chopped basalt fibers, thus generation and development of concrete microcracksare inhibited, the effects of enhancing strength and toughness are achieved, and the basic mechanical properties, such as compression resistance, splitting tensile resistance and flexural resistance,of the concrete are improved; and according to the mixed basalt fiber reinforced concrete, the compressive strength is improved by 15% or above, the flexural strength is improved by 1770% or above, the splitting tensile strength is improved by 110% or above, the durability of the concrete is improved, and good application prospects are achieved.

Owner:HENAN VOCATIONAL & TECHN COLLEGE OF COMM +1

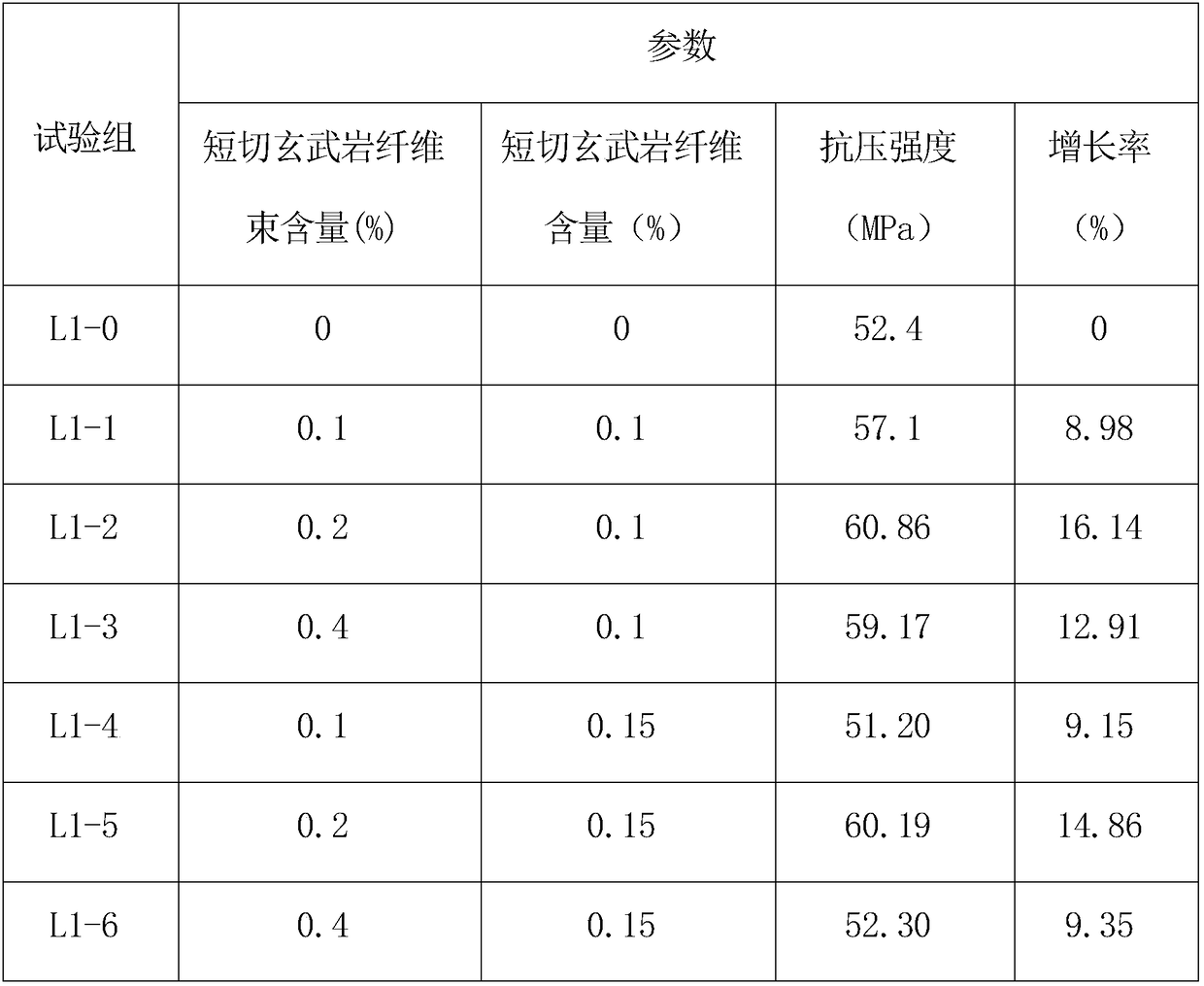

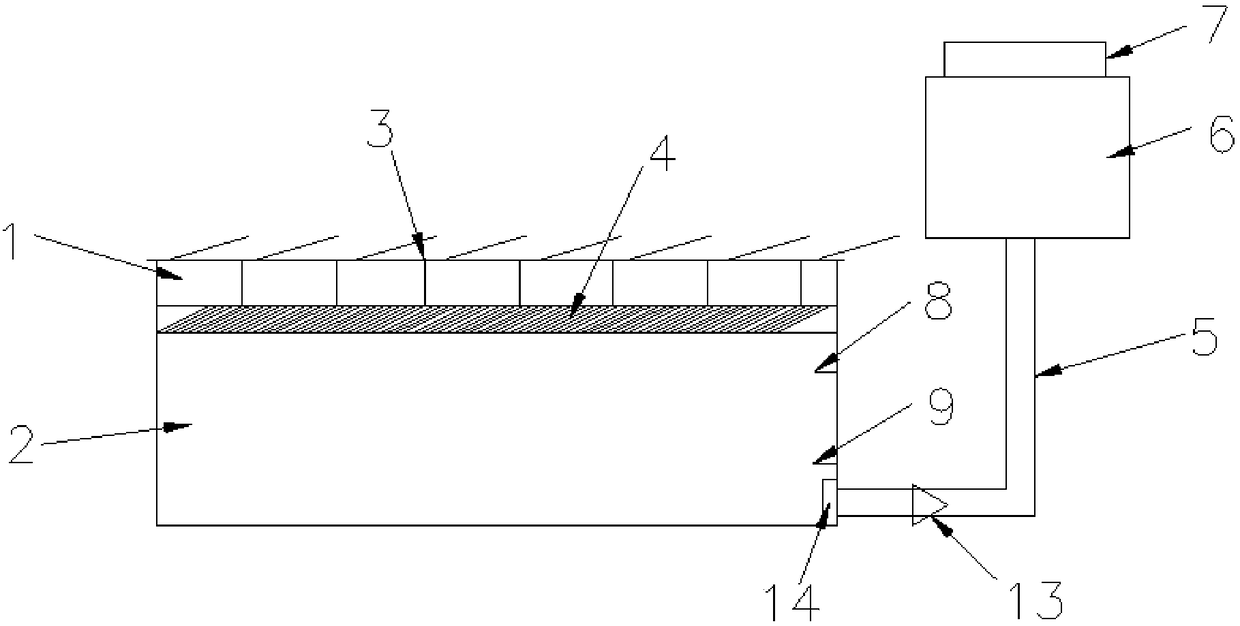

Sponge city planning ecological rainwater collecting and treatment system

InactiveCN108331074AAchieve reuseFast collection, processing and recyclingProgramme controlGeneral water supply conservationBrickWater resources

The invention discloses a sponge city planning ecological rainwater collecting and treatment system comprising water permeable bricks and rainwater collecting boxes; the water permeable bricks are laid flat under the ground layer, the rainwater collecting box is installed under the water permeable bricks, and a filter is arranged between the lower surface of the water permeable bricks and the rainwater collecting box; the rainwater collecting box is connected to the external recycling box through a drain pipe, and a control box is fixedly mounted on the side wall of the recycling box. The structure principle of the invention is simple, and the rapid collection and treatment of rainwater can be realized, and the rainwater can be reused, thereby saving water resources.

Owner:张栩晨

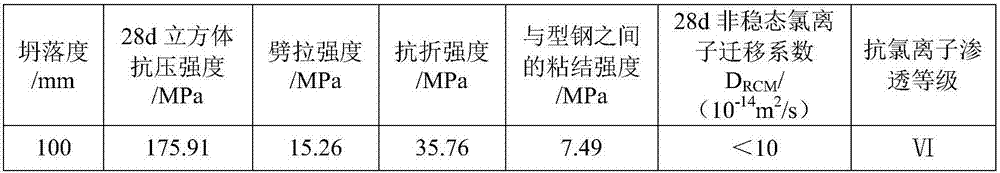

Ultrahigh-strength and high-performance fiber concrete with C170 strength grade and preparation method thereof

ActiveCN107352912AOvercoming brittlenessOvercome crackingSolid waste managementModified carbonFlexural strength

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C170 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 497 parts of cement, 74 parts of water, 1000 parts of crushed stones, 760 parts of fine aggregate, 80 parts of fly ash, 75 parts of rich husk ash, 111 parts of silicon ash, 14.4 parts of a water reducing agent, 10 parts of an exciting agent, 1.6 parts of cellulose fibers, 41 parts of a hydroxyl-modified carbon nanotube dispersion solution, 42 parts of a graphene oxide dispersion solution and 2.6 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 175.91MPa, the flexural strength reaches 35.76MPa, the splitting tensile strength reaches 15.26MPa, the bonding strength with the section steel reaches 7.49MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-content hybrid fiber concrete bulletproof and explosionproof brick and preparation method thereof

The invention discloses a high-content hybrid fiber concrete bulletproof and explosionproof brick. The brick is prepared from, by mass, 14.21% of steel fibers, 0.04% of polypropylene fiber, 19.00%-19.80% of cement, 5.40%-5.80% of water, 17.00%-18.00% of sand, 37.50%-38.50% of crushed stone, 2.60%-3.00% of silica fume, 2.00% of fly ash and 0.45% of efficient water reducing agent. The high-content hybrid fiber concrete bulletproof and explosionproof brick has the advantages that the brick body has excellent dynamic and static mechanical properties of compression resistance, tensile resistance, bending resistance, shock resisting penetration, shock resisting toughness and the like, and the purpose of resisting bullets and preventing an explosion are achieved.

Owner:HUANGHE S & T COLLEGE

High-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024189AHigh tensile strengthHigh elastic modulusSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (550-560): (760-770): (830-840): (65-70): (103- 108): (125-135): (5.4-5.6): (70-75): (20-21): (16-17): (3-3.3): (14.5-15): (7.5-8): (13.3-13.6): (21-21.5): (22-23.5): (42-46). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property and durability of the concrete and the bonding property between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Building waste recycled concrete and preparation method thereof

The invention discloses building waste recycled concrete and a preparation method thereof, and belongs to the technical field of building materials. The building waste recycled concrete is prepared from the following raw materials in parts by weight: 50-70 parts of building waste recycled aggregate, 10-20 parts of a reinforcing agent, 5-15 parts of a water reducer, 10-20 parts of a curing agent, 5-15 parts of mineral powder, 30-90 parts of cement, 100-150 parts of water and 10-20 parts of polyamide. The building waste recycled concrete is high in strength, is stable in quality, is long in service life, is low in cost, can change waste into valuable things, is environmentally friendly and energy-saving, and has very good economic benefits and wide social benefits.

Owner:钟传新

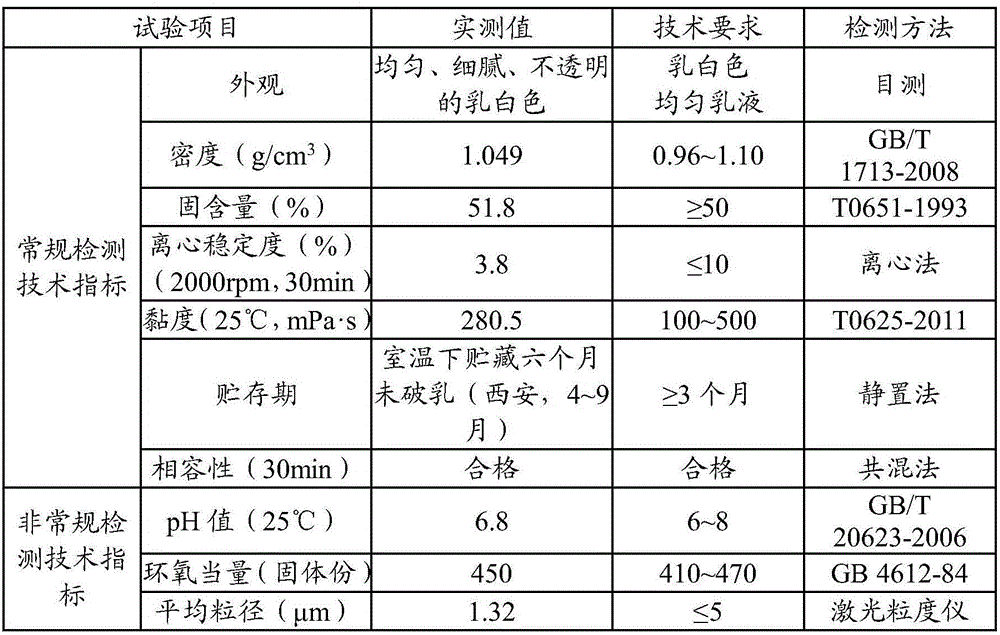

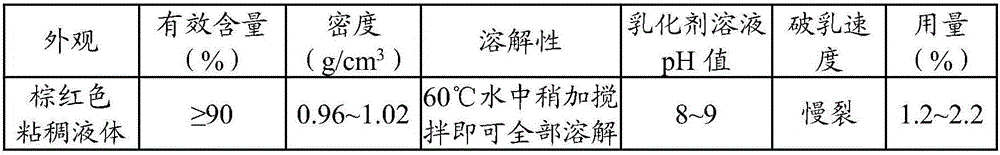

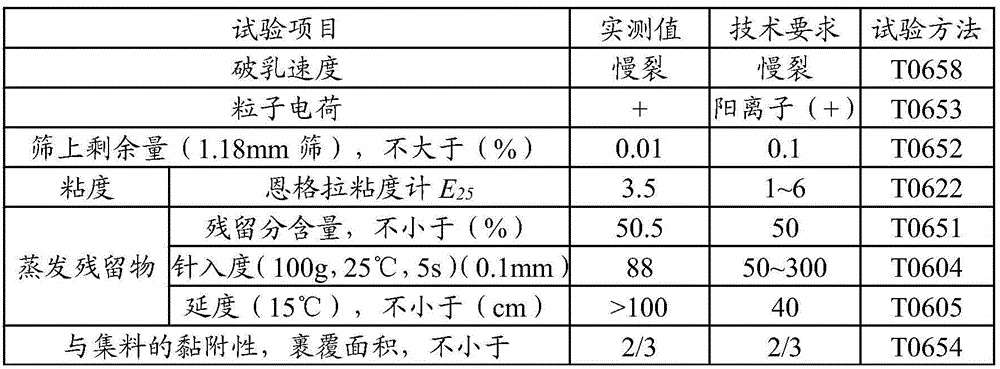

Material for treating pavement segregation

ActiveCN105860439AImprove thermal stabilityRealize "upper blocking and lower blockingBuilding insulationsEpoxyEmulsion

The invention provides a material for treating pavement segregation. The material for treating pavement segregation is prepared from, by weight, 30-60 parts of waterborne epoxy resin emulsion, 20-50 parts of positive ion emulsified asphalt and 10-30 parts of a waterborne curing agent. The material for treating pavement segregation can be free of the bleeding phenomenon in the using process, is liquid at the room temperature, and is low in viscosity and good in fluidity, and reasonable operable time is available. The good fluidity of the emulsion is utilized, emulsion is made to seep downwards, a gap in a segregation part is filled with the emulsion after demulsification, and the material is well bonded to a structural layer after seeping down, and is good in self-strength, so that a good interlayer bonding effect is achieved, and the purpose of sealing the upper portion, blocking the lower portion and carrying out proper strengthening on the segregation part is achieved. Besides, a cured product of the material for treating pavement segregation has good thermal stability, the starting thermal weight loss temperature of the cured product can reach 300 DEG C, the contact angle can reach 113 degrees, and the evaporation residue contact angle of emulsified asphalt is smaller than 99 degrees.

Owner:CHANGAN UNIV

High-performance fiber concrete at C60 strength grade and preparation method thereof

ActiveCN107445548APrevent pulling outImprove energy consumptionSolid waste managementFiberUltimate tensile strength

The invention discloses high-performance fiber concrete at a C60 strength grade and a preparation method thereof. The concrete comprises the following components in parts by mass: 360-380 parts of cement, 145-160 parts of water, 700-720 parts of river sand, 1020-1040 parts of gravel, 80-125 parts of fly ash, 40-60 parts of rice hull ash, 6-7.5 parts of a water reducing agent, 9-10 parts of a shrinkage reducing agent, 12.5-14 parts of an excitant, 1.1-1.8 parts of cellulosic fibers, 16-20 parts of a carboxyl butadiene styrene polymer an 1.7-1.8 parts of an antifoaming agent. The prepared concrete has high toughness and excellent durability, has high bonding strength with section steel, can effectively achieve the cooperative working performance between the section steel and the concrete when applied to a section steel and concrete combined structure, and overcomes the defects that the adhesive property between the section steel and the concrete is poor and respective mechanical properties of the two cannot be fully achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

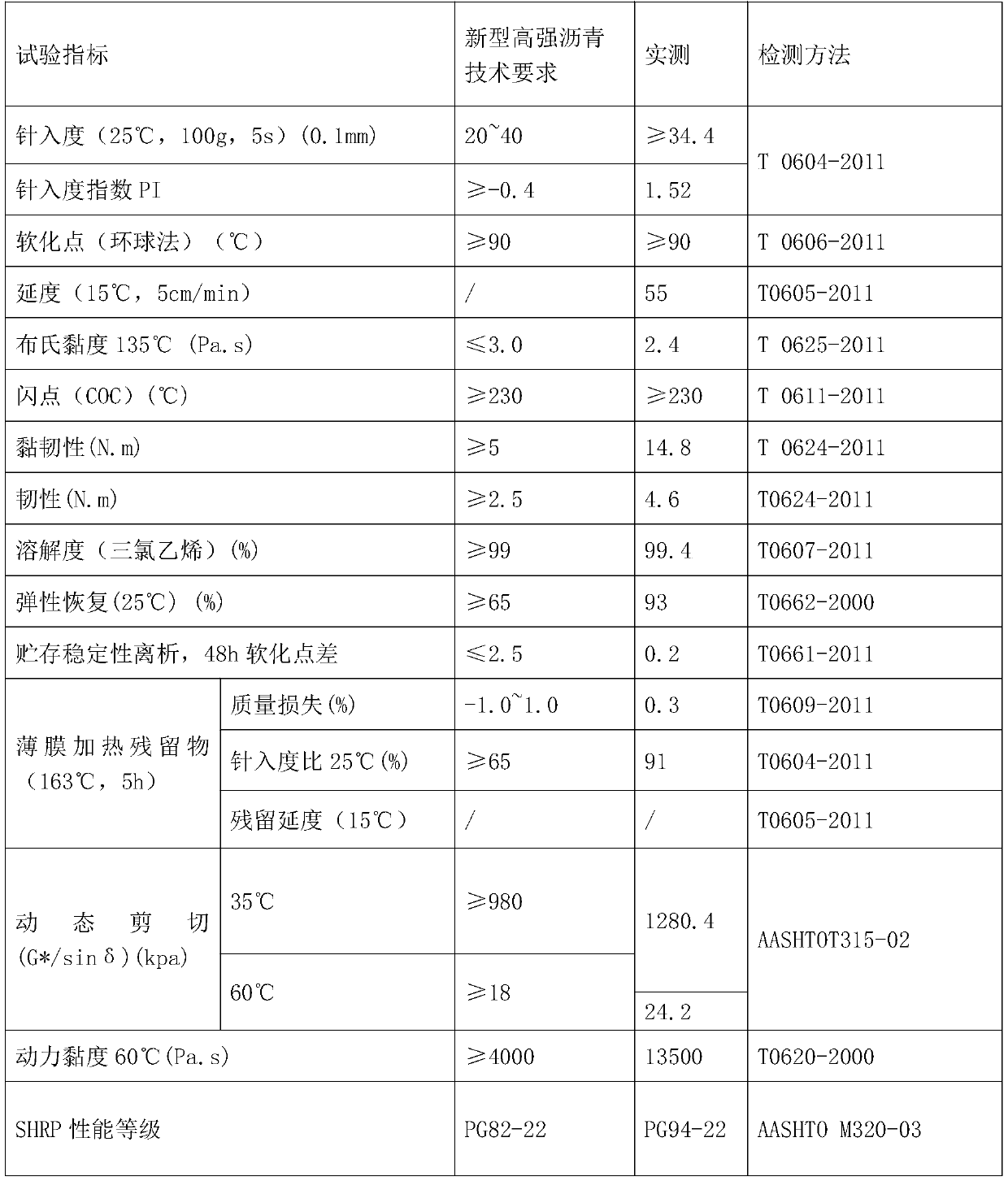

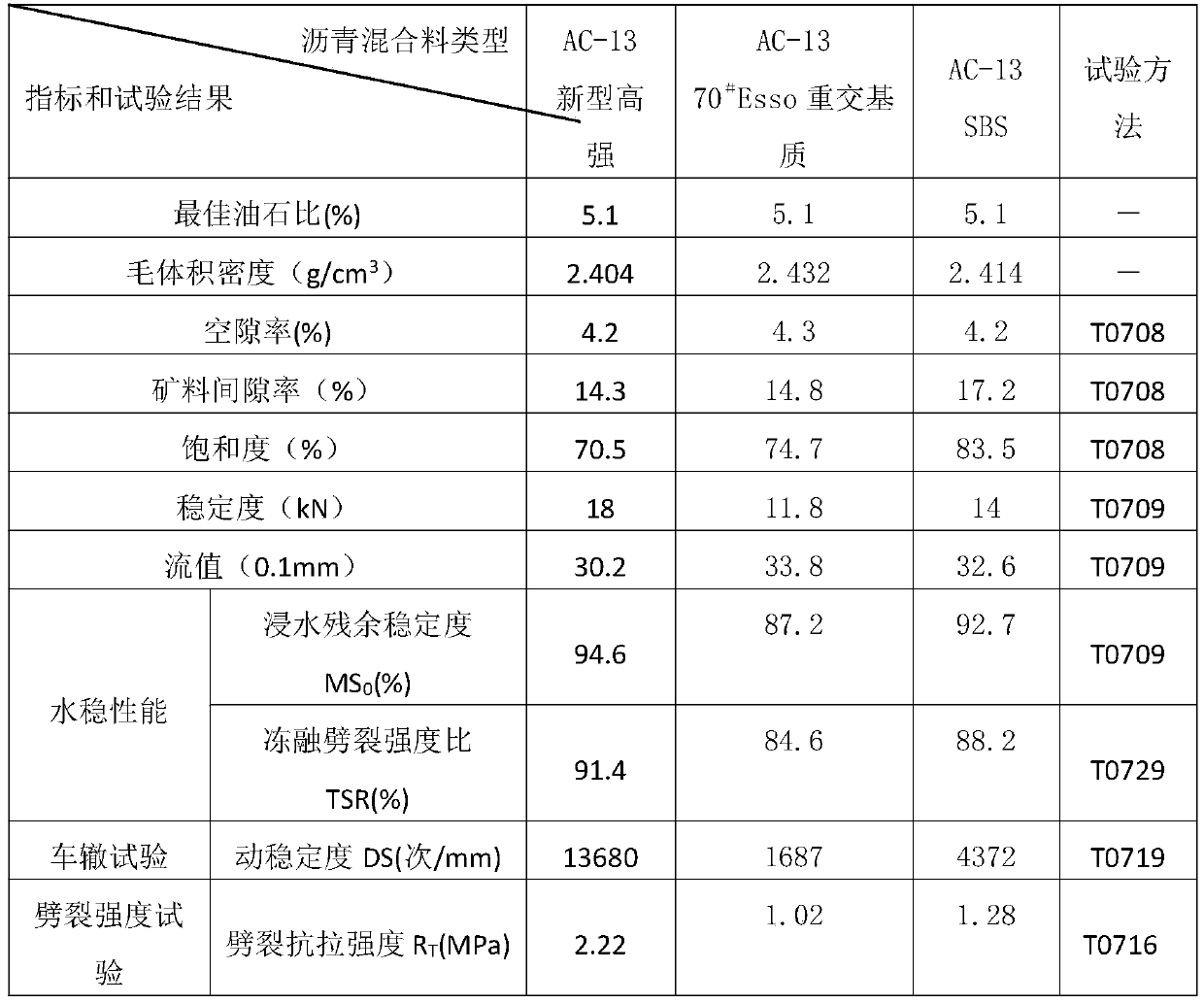

Novel high-strength anti-rutting modified asphalt and preparation method thereof

InactiveCN109735125AIncreased splitting tensile strengthExtended service lifeBuilding insulationsEconomic benefitsHigh intensity

The invention discloses a novel high-strength anti-rutting modified asphalt which comprises a 70#Esso heavy duty bitumen, a modifier and an additive; the additive comprises an anti-rutting agent, a stabilizer and a cosolvent; the mass percent of the components is as follows: 80-95% of 70#Esso heavy duty bitumen, 1-10% of modifier, 1-10% of anti-rutting agent, 0.1-5% of stabilizer and 1-10% of cosolvent. The invention also discloses a preparation method for the novel high-strength anti-rutting modified asphalt. The modified asphalt prepared according to the invention has an excellent high-strength anti-rutting property and high splitting tensile strength, is capable of effectively prolonging service life of road materials and increasing driving comfort level of vehicles and has high economic benefit.

Owner:广西交通职业技术学院

Nano-metakaolin recycled concrete and preparation method thereof

InactiveCN112960953ALow costHigh compressive strengthSolid waste managementBreaking strengthKaolin clay

The invention relates to nano-metakaolin recycled concrete and a preparation method thereof. The nano-metakaolin recycled concrete is prepared from the following raw material components in parts by weight: 11 to 19 parts of nano-metakaolin, 361 to 1203 parts of recycled coarse aggregate, 601 to 842 parts of natural coarse aggregate, 354 to 373 parts of cement, 619 parts of sand and 211 to 225 parts of water. The recycled concrete has the advantages of high compressive strength, high breaking strength, high splitting tensile strength and high toughness, is low in raw material cost, and lays a foundation for wide application of the recycled concrete.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Fiber for cement concrete

The invention discloses a fiber for cement concrete, which comprises the following constituents that the water cement ratio is 0.35-0.45; the glue sand ratio is 1:0.5-1:1.2; the content of high-efficiency expansive agent is 8-10 percent of the dosage of cement; the content of the high-efficiency water reducing agent is 0.5-1 percent of the dosage of the cement; and the content of polypropylene fibers is 1 m, and 0.8-1.2kg of the polypropylene fibers are doped in sand pulp. The invention also discloses a production method of the fiber. The fiber is a high-strength prestressed anchor grouting material having high rupture strength, compressive strength and tensile strength, small brittleness, good cracking resistance and impermeability and high bonding shearing strength and bondability strength.

Owner:赵文平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com