Patents

Literature

40results about How to "No bulge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water base non-chrome zinc-aluminium coating and methods for preparing and using same

ActiveCN102911534AMeet the requirements of environmental regulationsHydrogen embrittlement will notLiquid surface applicatorsCoatingsWater basedHazardous substance

The invention relates to a water base non-chrome zinc-aluminium coating and methods for preparing and using the same. The coating is prepared by proportionally mixing a component A and a component B; the component A contains 50-150g / L of lamellar metal powder, 145-290ml / L of organic solvent, 10-200ml / L of deionized water, 10-36ml / L of reducing agent and 5-15ml / L of wetting agent; and the component B contains 60-240ml / L of deionized water, 20-75ml / L of binding agent, 8-22ml / L of thickening agent, 4-8ml / L of silicon compound and the balance of the organic solvent. The method for preparing the water base non-chrome zinc-aluminium coating comprises the steps of: weighing the lamellar metal powder proportionally to be mixed uniformly, and then adding the organic solvent to be mixed uniformly for later use; mixing the reducing agent with the wetting agent, adding an appropriate amount of the deionized water to be mixed uniformly, and then adding the lamellar metal powder liquid to prepare the component A; proportionally weighing the thickening agent, the binding agent and the silicon compound, and adding the organic solvent to be mixed uniformly to prepare the component B; and mixing the prepared component A and the prepared component B according to the ratio of 2:1, and stirring unit uniform, thus obtaining the coating. The method for using the water base non-chrome zinc-aluminium coating is that the coating is coated on a part to be treated, and the baking temperature is increased to 360 DEG C so as to solidify and crosslink the coating to form a dense protective layer. The coating has the corrosion resistance which reaches 840 hours of a neutral salt spray test and over 96 hours of a heat resistance test, the usage amount of harmful substances is greatly reduced, and the working environment is improved.

Owner:翊鹏(湖北)实业有限公司

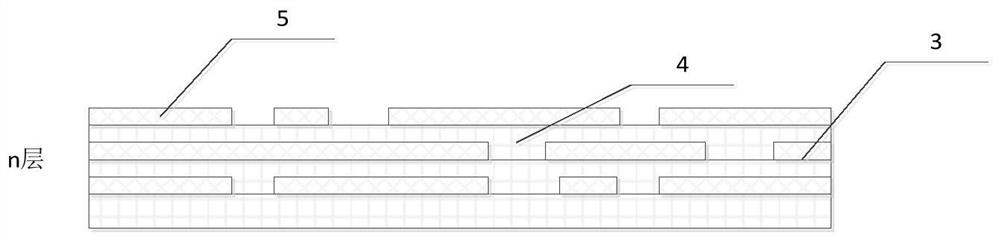

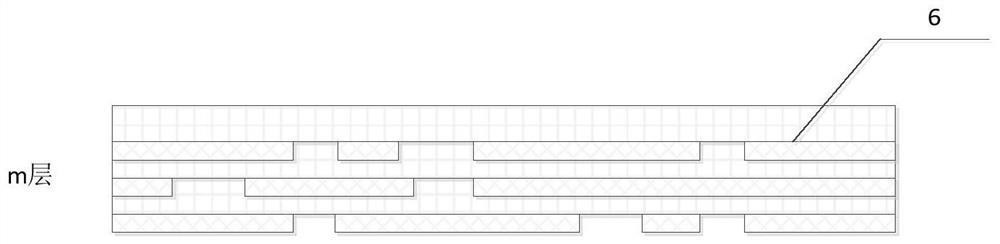

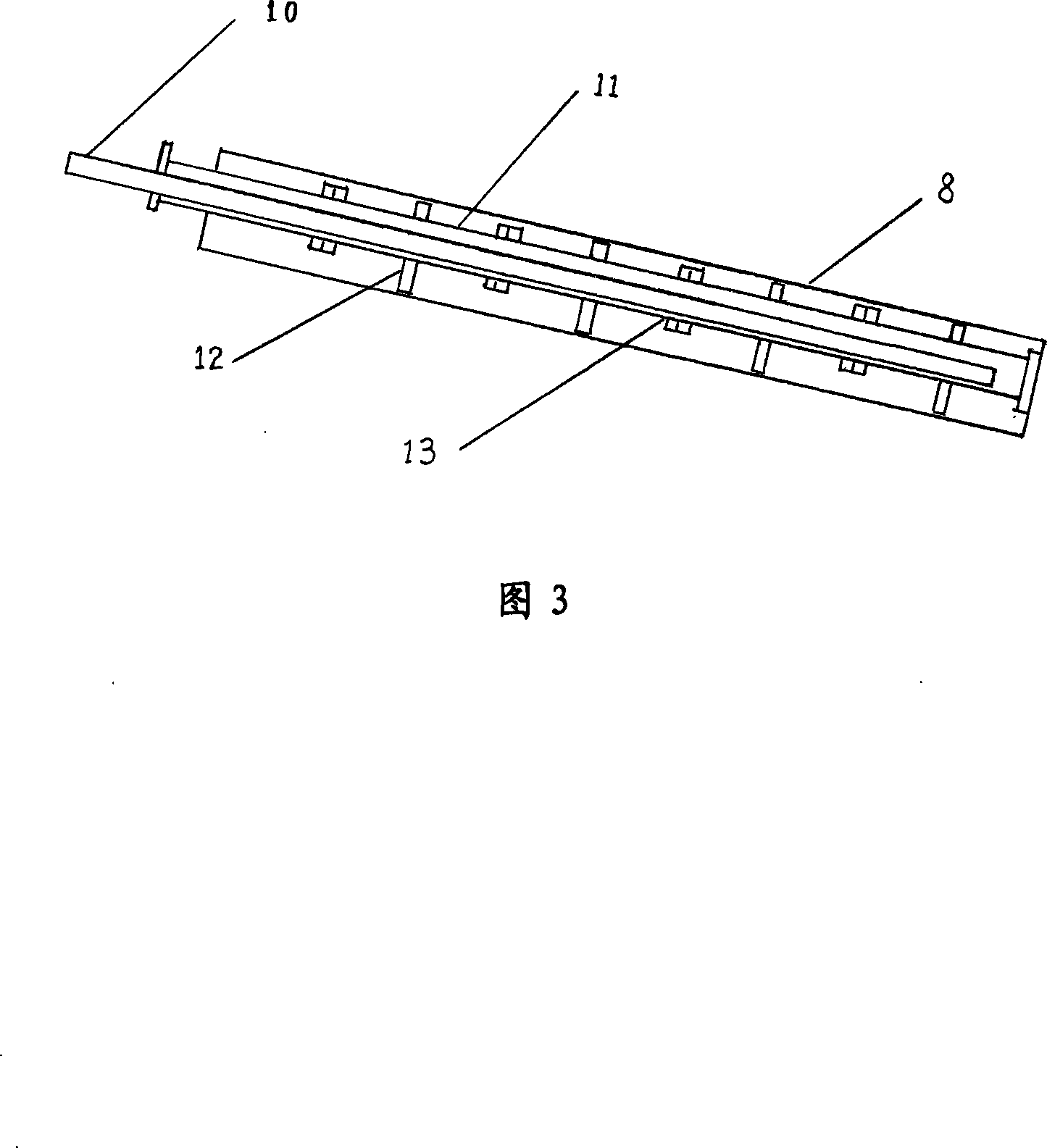

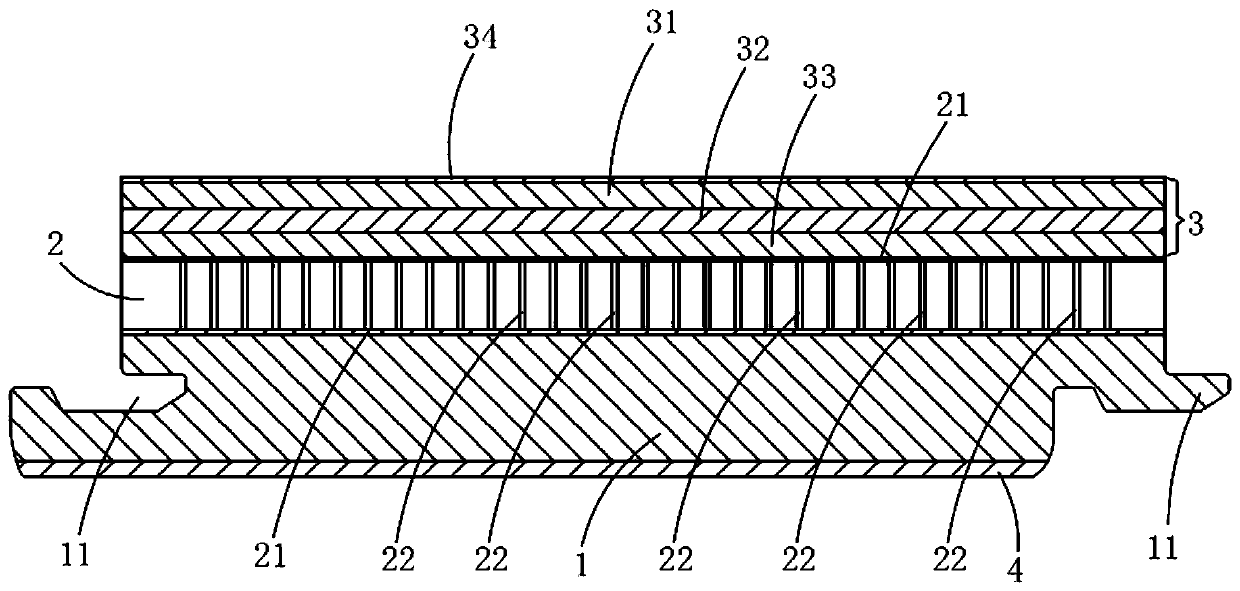

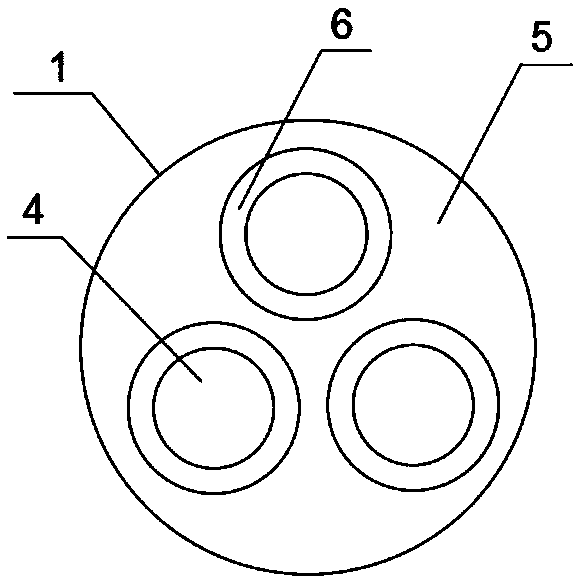

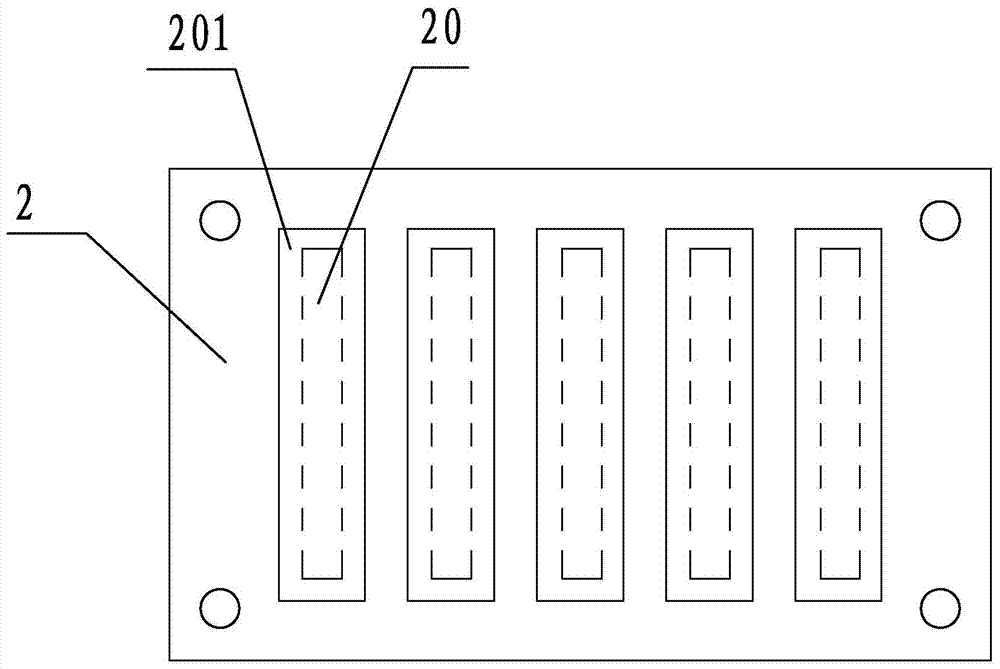

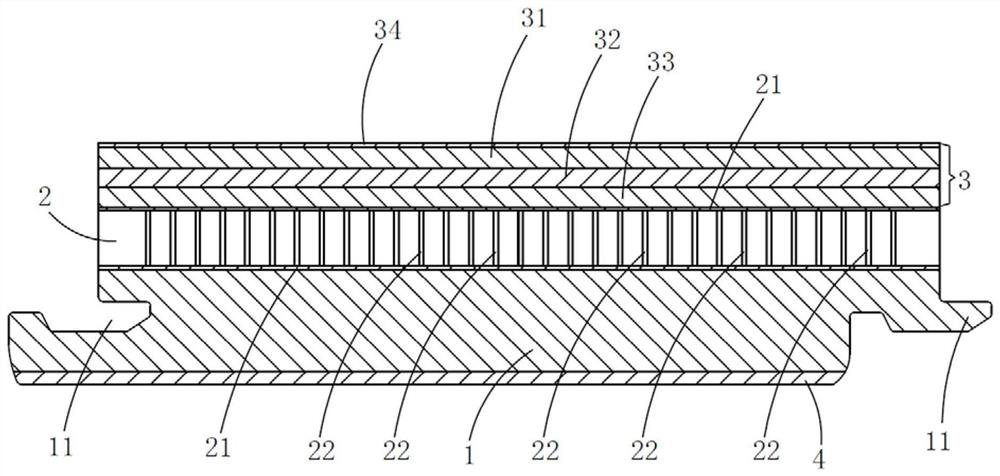

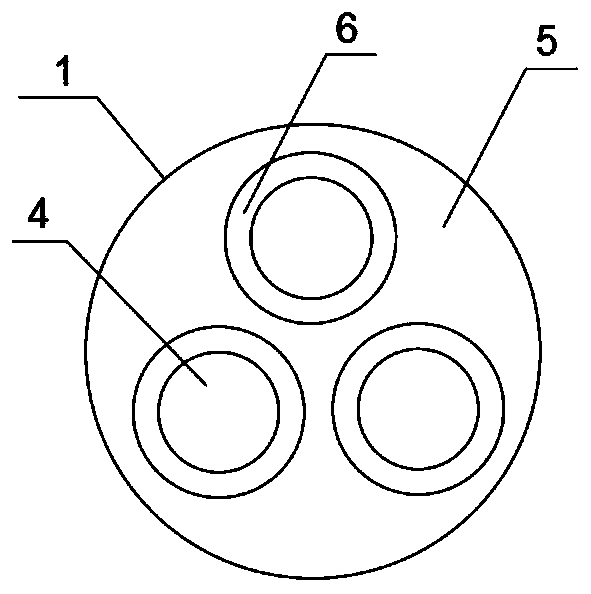

Printed circuit board with embedded micro-channels and preparation method of printed circuit board

ActiveCN113056087AAchieving Density CoolingImprove cooling effectPrinted circuit aspectsPrinted circuit manufactureHigh densityEngineering

The invention discloses a printed circuit board with embedded micro-channels. The printed circuit board comprises an embedded micro-channel metal core plate, wherein the top part of the embedded micro-channel metal core plate is provided with n wiring layers I, the bottom part of the embedded micro-channel metal core plate is provided with m wiring layers II, and the printed circuit board is provided with a liquid inlet and a liquid outlet which are communicated with the micro-channel. The structure has efficient heat dissipation capability, can realize transmission of high-density electrical signals, and meets the application requirements of high-density integrated high-power electronic devices.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

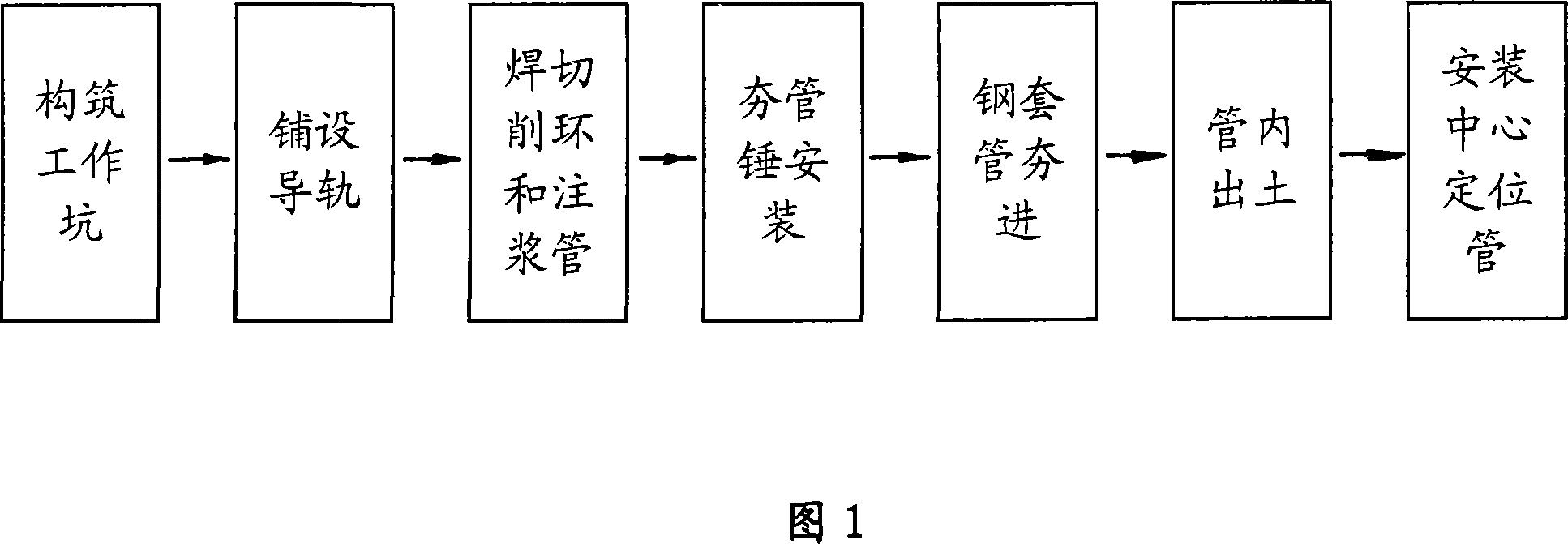

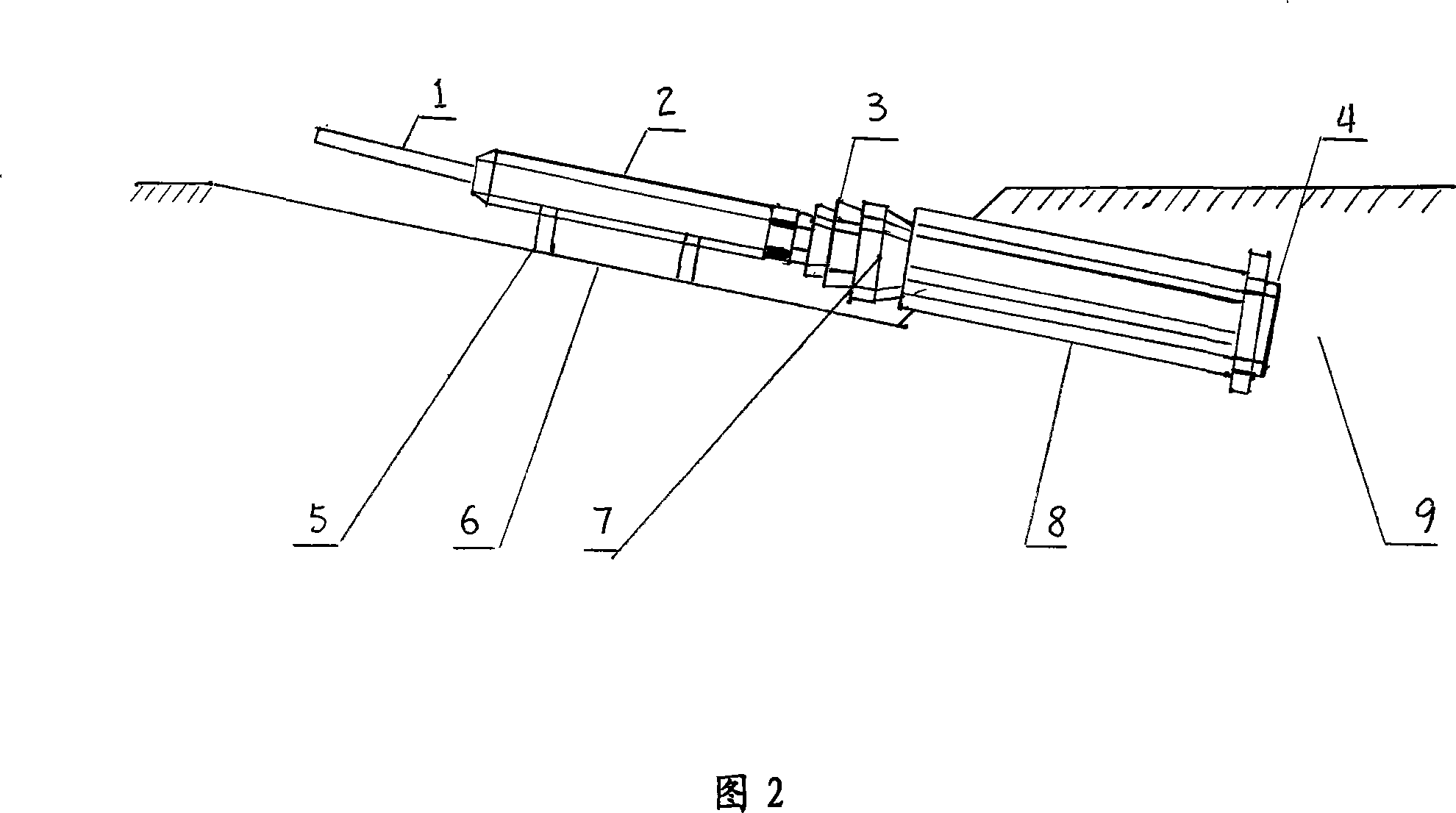

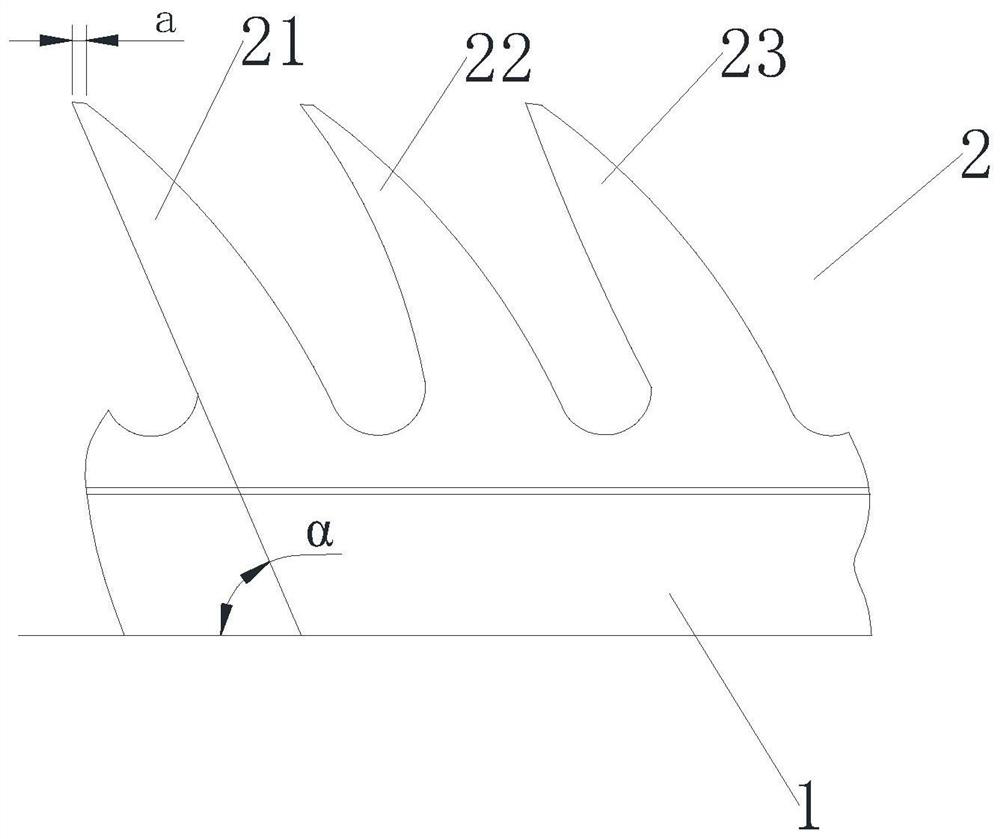

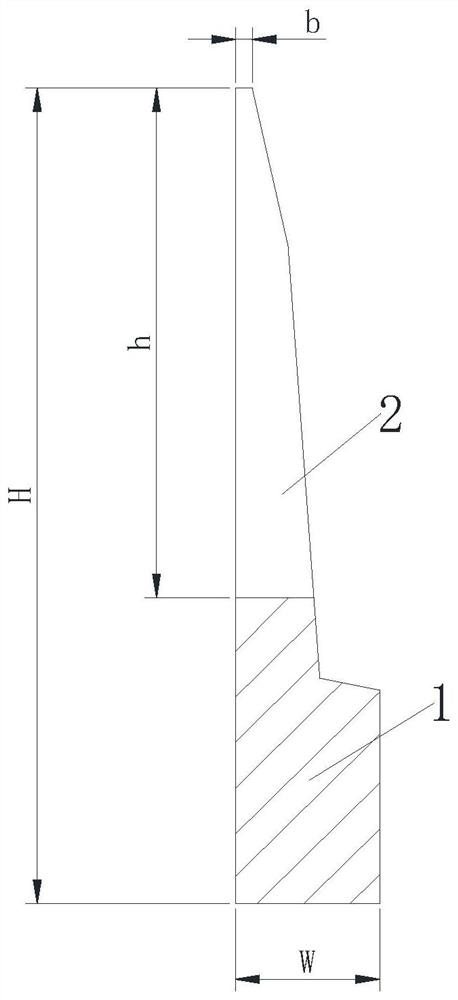

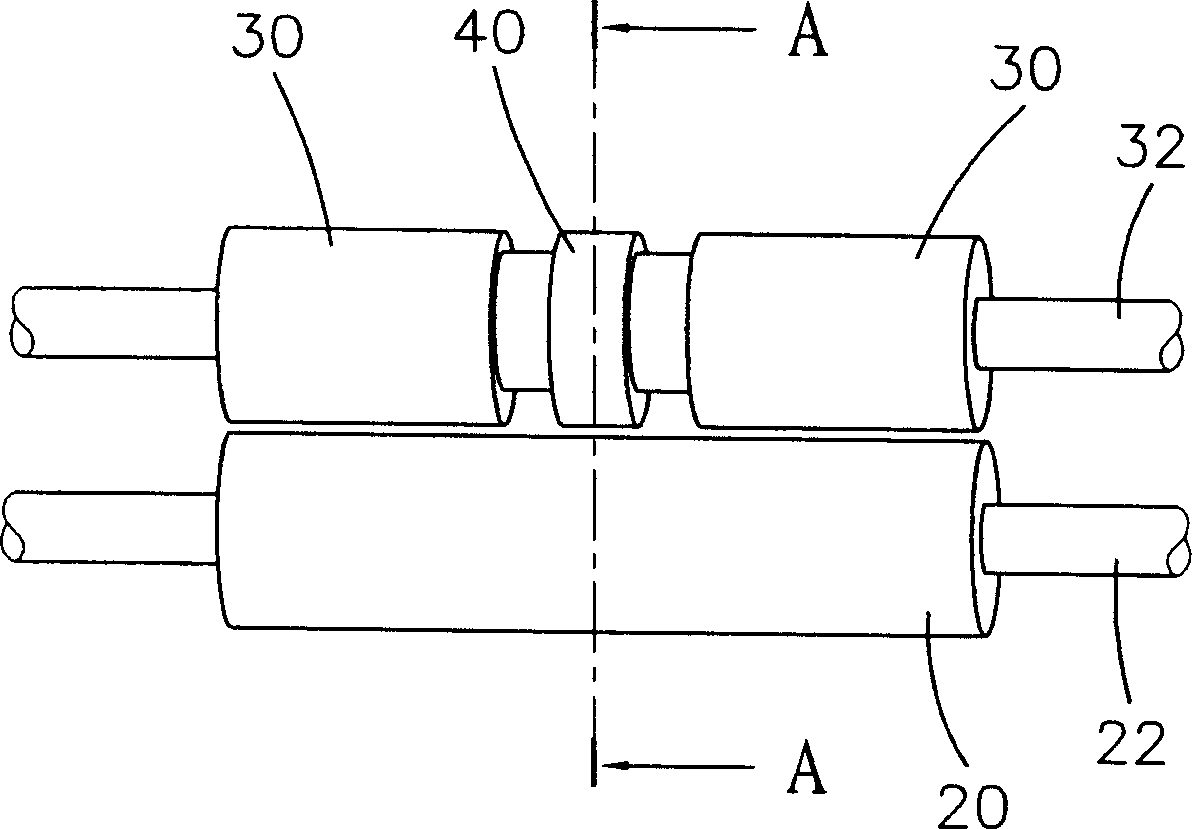

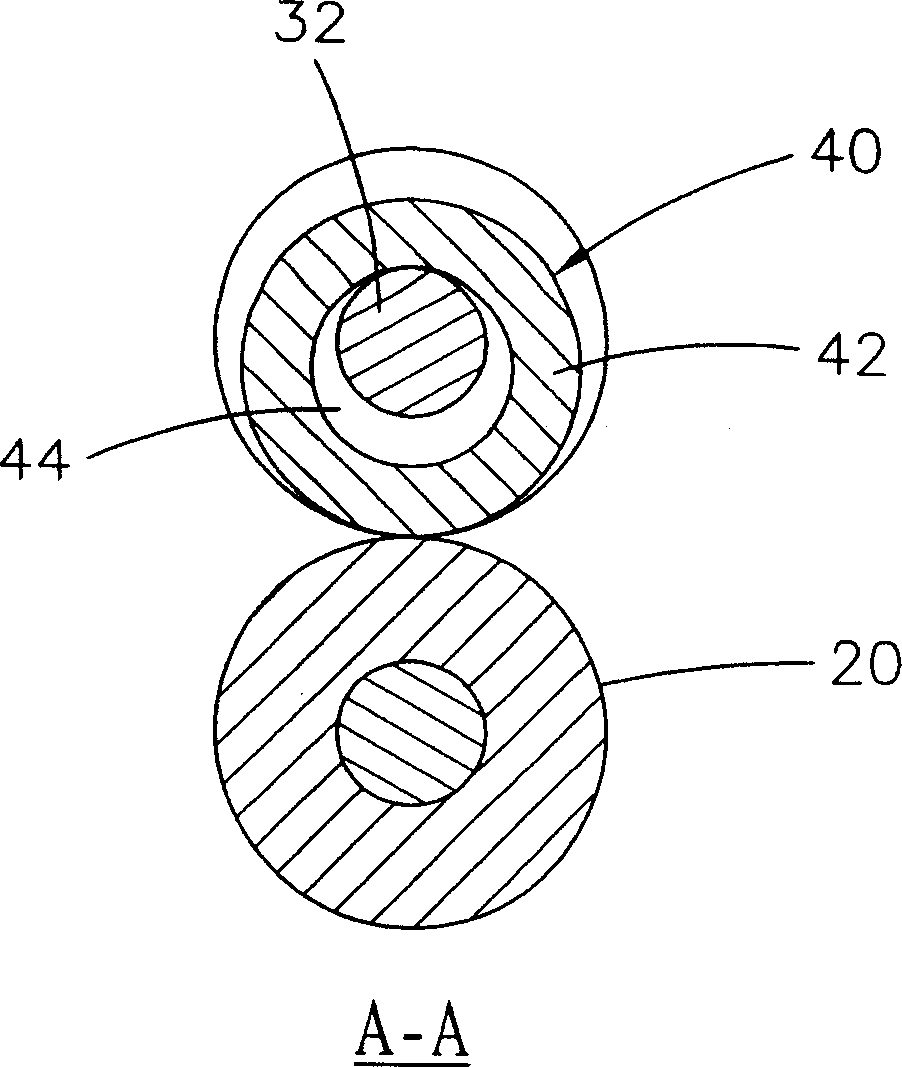

A process for horizontal directional drill passing through and tampering casing for separating gravel

The present invention relates to piping no dig construction technique. The level orienting drill pass through tamping bushing separation egg gravel technique first need to build a work pit, its improvement is that: it has the following steps: (1) laying rail; (2) mounting tamping pipe hammer; (3) tamping steel bushing; (4) digging out earth from the bushing; (5) mounting a central position pipe. The technique combines the tamping bushing construction technique with the level orienting drill construction technique, solves the problem that the construction can not be proceeded caused by the unsteady of the ground at two ends of earth in and out points in the level orienting drill construction, and has the following characteristics: (1) adapting to piping for multiple earth layers, backfill layers, running sand layers and various gravel containing ground layers. (2) The ground will not generate apophysis or sedimentation phenomenon, the ground layer adaptability is strong, piping speed is fast and can be to 25m / h. (3) the construction occupies small ground. The tamping bushing construction work surface is in the orienting drill pass through drill ground, occupies small ground, has small earth cubic, and convenient in operation.

Owner:CHINA PETROLEUM PIPELINE BUREAU

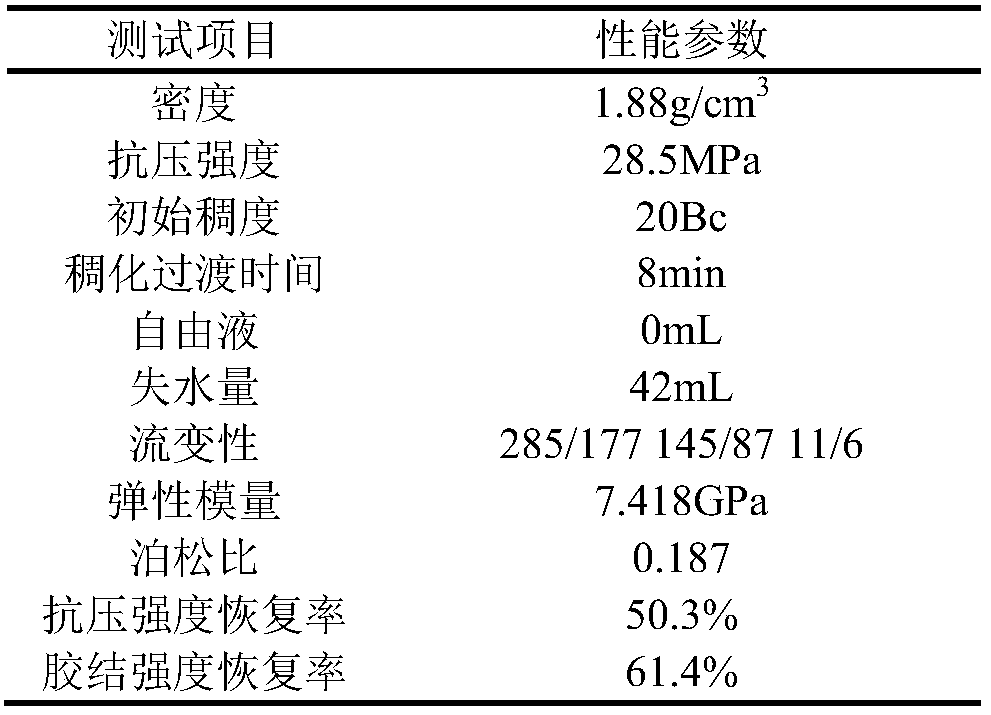

Oil gas-responsive active self-repairing cement slurry system

ActiveCN109180084AExcellent anti-gas channeling performanceImprove rheologyDrilling compositionFresh water organismCement slurry

The invention relates to an oil gas-responsive active self-repairing cement slurry system. The system comprises, by weight, 100 parts of oil well cement, 43.0-47.0 parts of freshwater, 2.0-4.0 parts of a self-repairing agent, 1.0-2.0 parts of a fluid loss agent, 0.2-0.5 part of a dispersant, 0.2-1.0 part of a set retarder and 0.2-0.5 part of a defoamer. The oil gas-responsive active self-repairingcement slurry system has the advantages of good rheology, strong self-repairing ability, good elasticity and toughness, adjustable thickening time, stable performances, simple formula composition andsimple on-site construction, and can automatically plug oil gas channels without artificially intervening the ground when a shaft cement ring has micro-cracks and micro-annulus gaps to restore the completeness and the interfacial cementing ability of the cement ring in order to achieve the purpose of preventing the annular pressure of a sleeve.

Owner:CHINA PETROCHEMICAL CORP +3

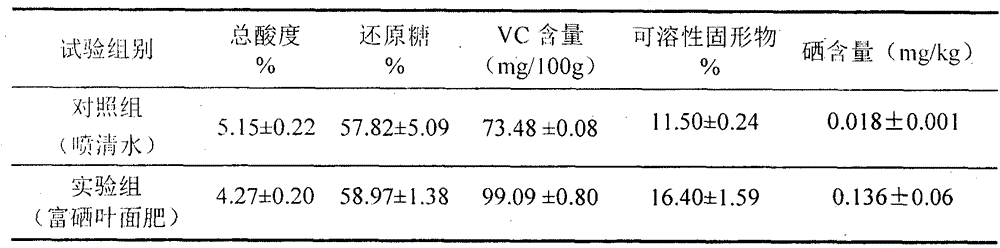

Leaf fertilizer suitable for producing selenium-enriched kiwi fruits and application method of leaf fertilizer

ActiveCN105237239AIncrease loadImprove physiological activityFertilising methodsFertilizer mixturesSolubilityActinidia

The invention relates to a leaf fertilizer suitable for producing selenium-enriched kiwi fruits and an application method of the leaf fertilizer. The leaf fertilizer with relatively high solubility is prepared through the steps of proportioning urea, potassium fulvate, sodium selenite and sodium dodecyl benzene sulfonate according to the required ratio, spraying, drying, smashing, sieving and the like, wherein 30-50g of selenium is contained in each kg of the leaf fertilizer. The leaf fertilizer is solid and is prepared into a mother solution with a certain selenium concentration before being used, and the diluted liquid leaf fertilizer is sprayed in the initial fruiting period and the expansion period of the kiwi fruit trees. The fertilizer is scientific in active component ratio, convenient to transport and carry, simple in application method and capable of remarkably increasing the selenium content of the kiwi fruits and improving the nutrient quality of the fruits, is suitable for wide kiwi fruit production areas in China, is used for producing selenium-enriched kiwi fruits and is not only economic and effective, but also safe and convenient.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

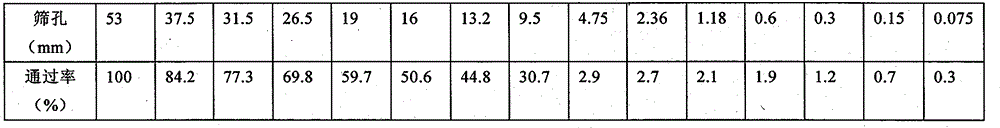

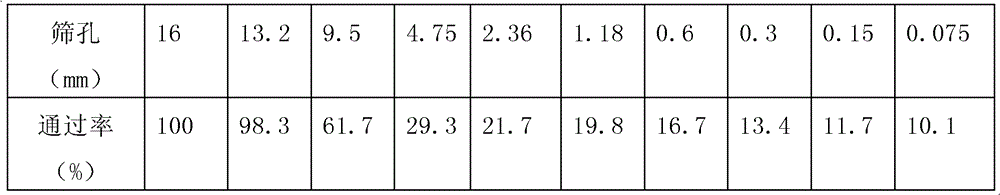

Use of fly ash synthesized channel joint impervious material for preparing highway asphalt mixture

The invention discloses an application of known flyash-compounded channel seam permeation resistant material on preparing a road asphalt mixed material. A modified asphalt mixing material using flyash-compounded channel seam permeation resistant material as a cementation material comprises normal pulverized stone, stone crumb, sand, slag, mineral powder and the asphalt mixing material used as thecementation material. The asphalt mixing material used as the cementation material in the asphalt mixing material accounts for 30 to 100 weight parts of the asphalt weight, and is replaced by the flyash-compounded channel seam permeation resistant material and the like of the same weight parts. The asphalt mixing material prepared by using the flyash-compounded channel seam permeation resistant material as the cementation material increases the using ways of the high additional value of the flyash, reduces the economic cost of the asphalt mixing material and improves the using performance of the asphalt mixed material. The mixed asphalt material has excellent road surface performance, simple technology, convenient use and easy popularization.

Owner:NORTHWEST A & F UNIV

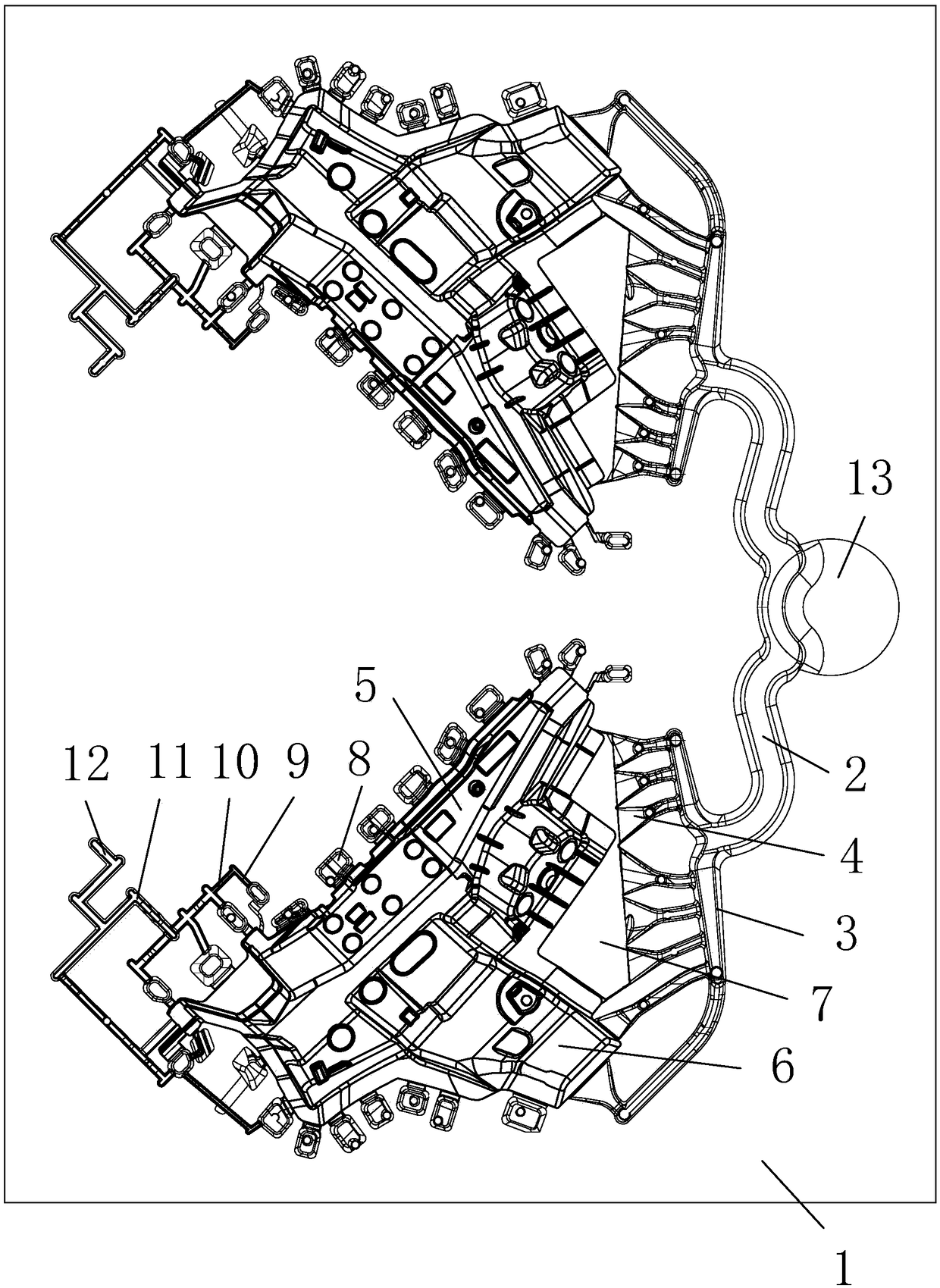

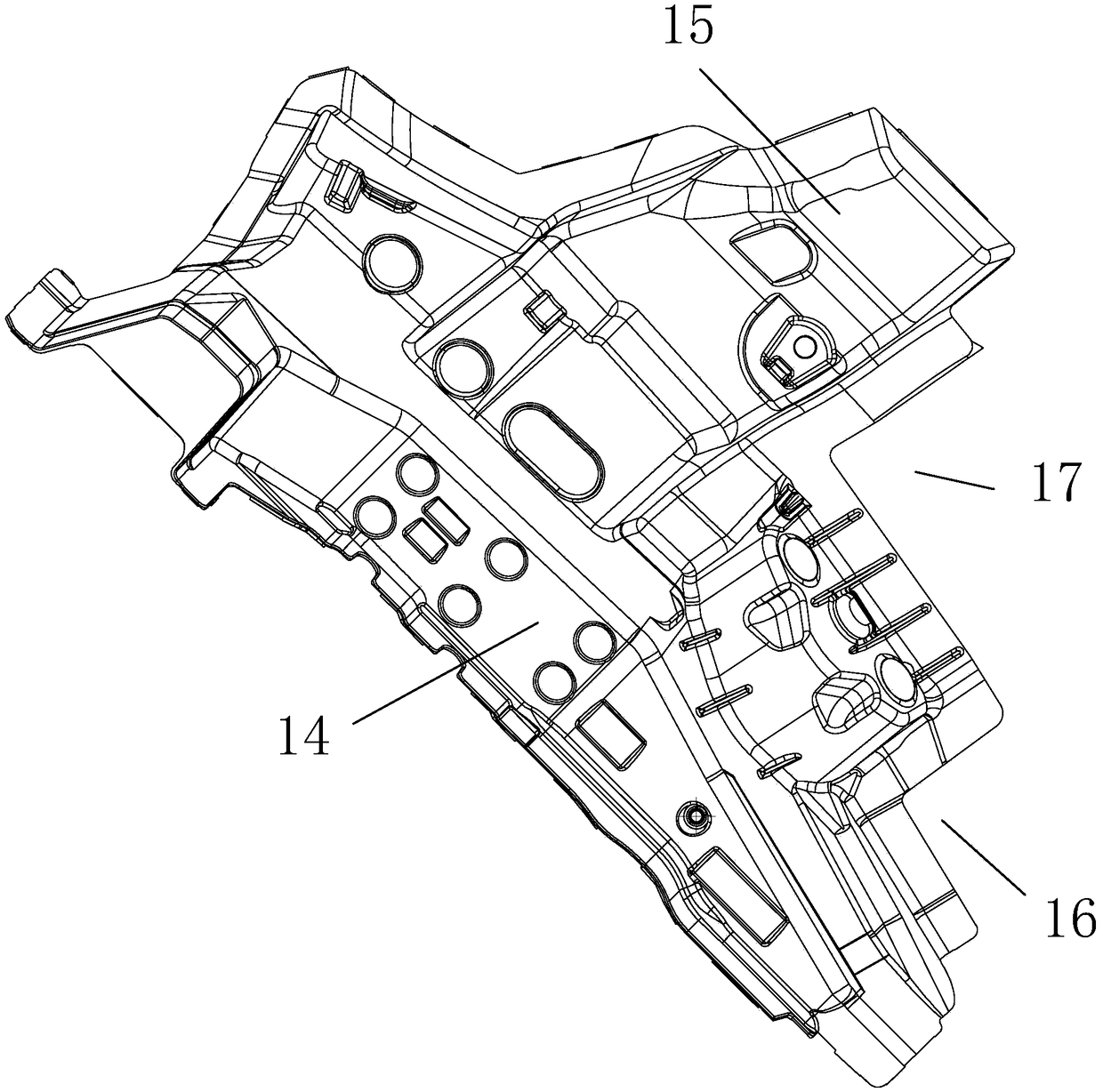

Pouring exhaust system of automobile component die-casting die and arrangement method

The invention relates to a pouring exhaust system of an automobile component die-casting die and an arrangement method. The pouring exhaust system of the automobile component die-casting die comprisesa die-casting die body and cavities, wherein the one or more cavities are formed in the die-casting die body, and each cavity is provided with a sprue, a cross gate and multiple flow gates. Each cavity comprises a main body cavity, a side body cavity, an auxiliary gating cavity and multiple cinder ladle cavities, wherein the inner ends of each auxiliary gating cavity communicate with one end of the corresponding main body cavity, one side of the corresponding main body cavity and one side of the corresponding side body cavity. The inner end of each flow gate communicates with the outer end ofthe corresponding side body cavity or the outer end of the corresponding auxiliary gating cavity. The thickness of each auxiliary gating cavity and the thickness of each flow gate are each 0.7-0.85 times the wall thickness of each die-casting die cavity. The sectional area of each sprue is less than that of the corresponding cross gate. The sectional area of each cross gate is less than the totalsectional area of the multiple flow gates. Each cinder ladle cavity communicates with the periphery of the corresponding main body cavity or the corresponding side body cavity. By means of the pouring exhaust system of the automobile component die-casting die, air holes cannot be generated inside die castings; and the surfaces of the die castings obtained after T6 treatment cannot bulge.

Owner:宁波埃利特模具制造有限公司

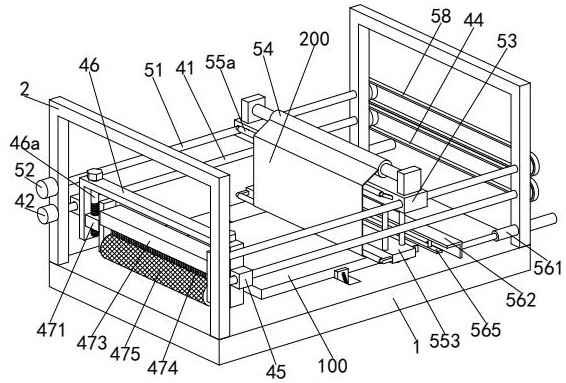

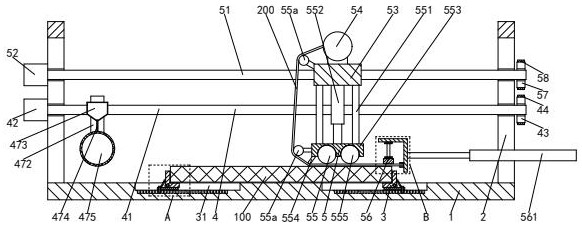

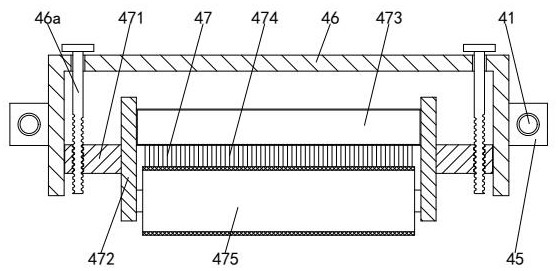

Composite processing machine for composite glass wool board preparation

The invention relates to the technical field of composite glass wool board preparation and processing, in particular to a composite processing machine for composite glass wool board preparation. The composite processing machine comprises a workbench, U-shaped frames, a clamping mechanism, a gluing mechanism and a paper pasting mechanism, wherein the clamping mechanism is arranged on the upper end face of the workbench; and the U-shaped frames in left-right symmetry are arranged at the upper end of the workbench, and the gluing mechanism and the paper pasting mechanism are arranged between the U-shaped frames. According to the composite processing machine for composite glass wool board preparation, composite glass wool boards with various specifications can be clamped and fixed in a movable adjusting mode, and meanwhile, it is ensured that the upper end faces of the composite glass wool boards with different specifications can be evenly coated with glue in a detachable mode; and according to the composite processing machine for composite glass wool board preparation, when plastic surface paper is attached to the composite glass wool boards, the plastic surface paper is pressed and rolled, so that it is ensured that the plastic surface paper is tightly attached to the composite glass wool boards without the bulging phenomenon.

Owner:江苏金圣棋盘玻璃科技发展有限公司

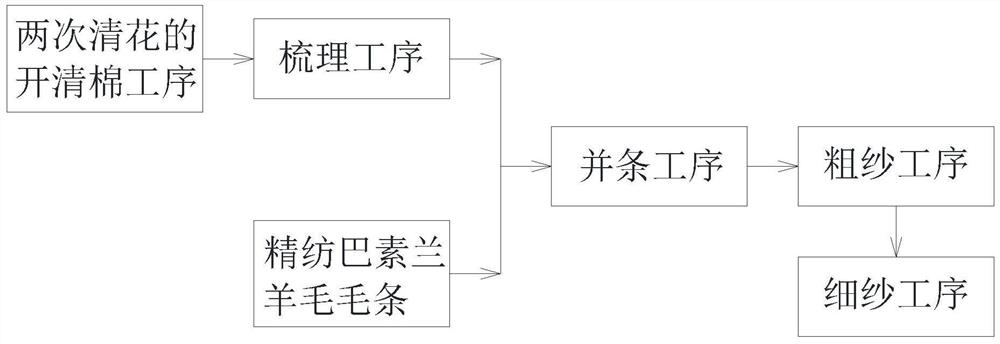

Comfortable stretch yarn and wool blended yarn and production process thereof

PendingCN112981644AHigh recoveryGood shape retentionTextile treatment with treating outlet contectDyeing processWoolPolymer chemistry

The invention discloses a comfortable stretch yarn and wool blended yarn. The comfortable stretch yarn and wool blended yarn is characterized by comprising comfortable stretch yarn fibers, worsted basolan wool and anti-pilling acrylic fibers. The invention further discloses a production technology of the comfortable stretch yarn and wool blended yarn. The production technology of the comfortable stretch yarn and wool blended yarn sequentially comprises the steps of preparing comfortable stretch yarn and acrylic fiber blended cotton slivers, preparing worsted basolan wool tops, drawing, roving and spinning; the preparation of the comfortable stretch yarn and acrylic fiber blended cotton slivers comprises an opening picking process and a carding process; in the opening picking process, the comfortable stretch yarn fibers and the anti-pilling acrylic fibers are subjected to first-time blowing, mixed fibers obtained after first-time blowing are packaged, and second-time blowing is carried out. According to the comfortable stretch yarn and wool blended yarn and the production process thereof, after the prepared blended yarn is made into a sweater, the resilience of the sweater can be greatly improved. And when the sweater is hung, bumps are hardly generated, so that the shape preserving property of the sweater is good.

Owner:桐乡市君诺纺织品有限公司

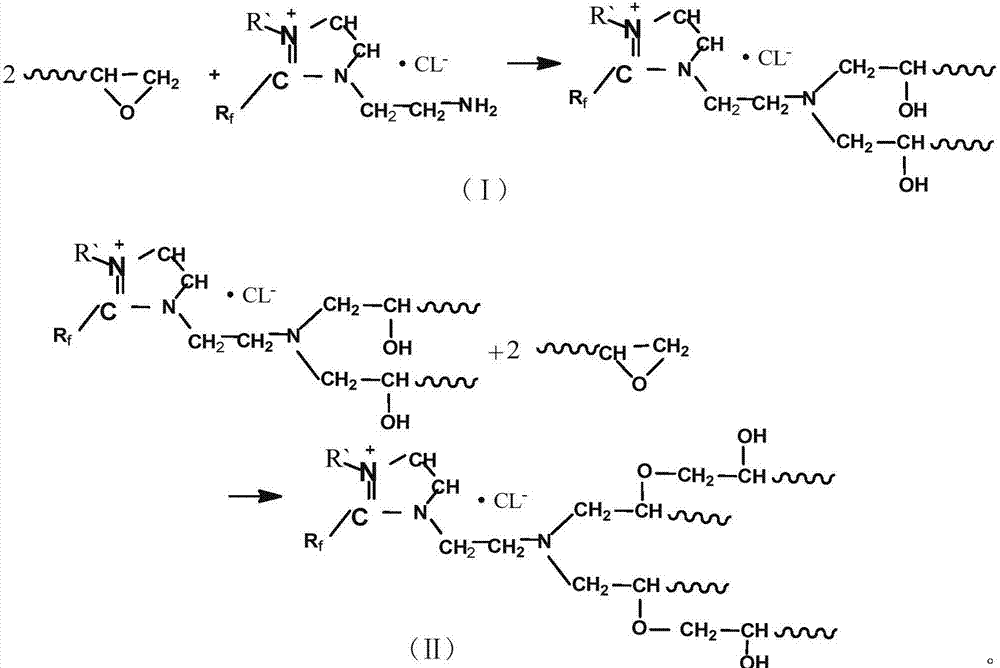

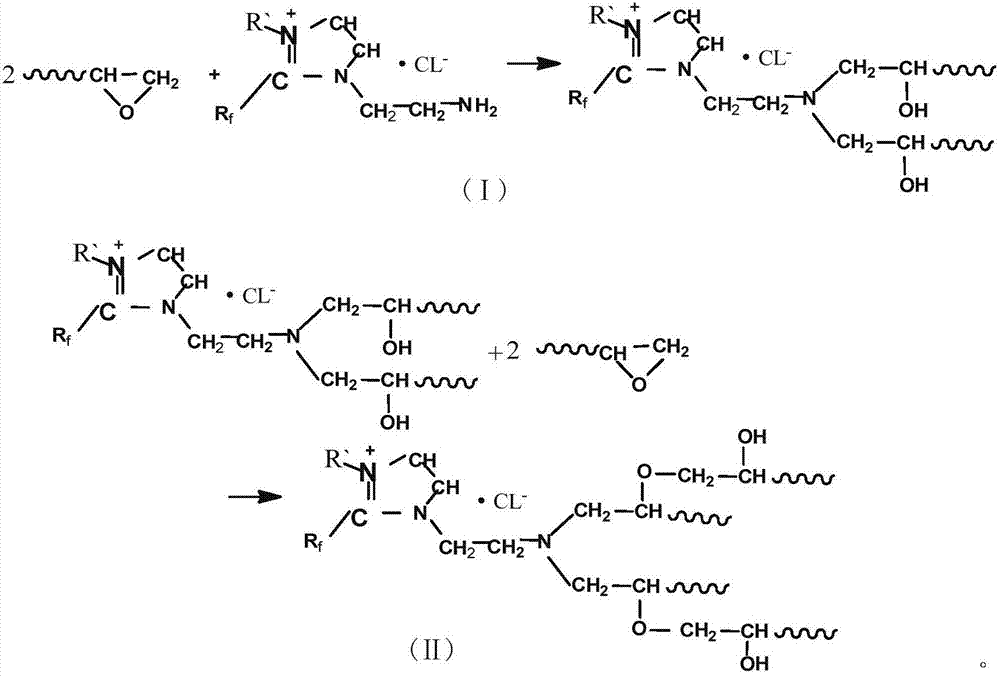

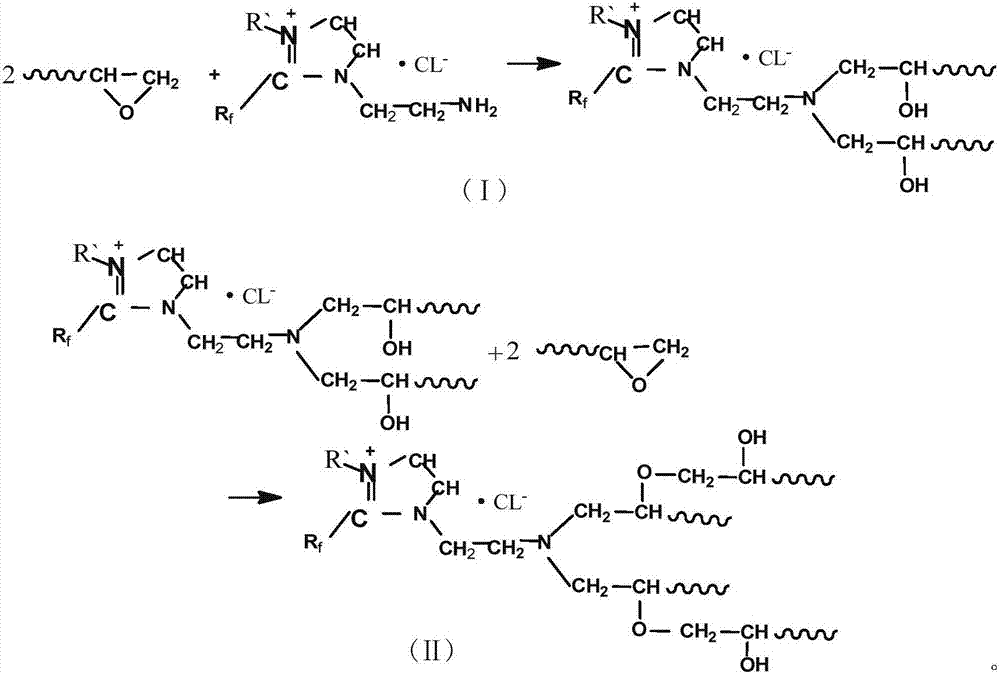

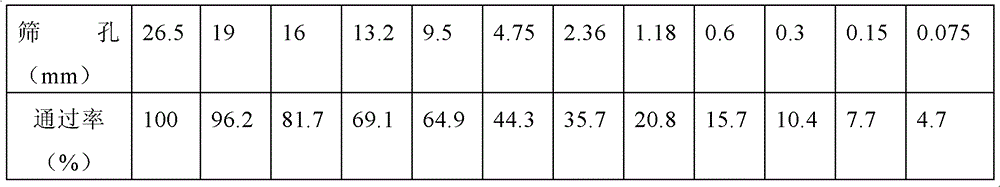

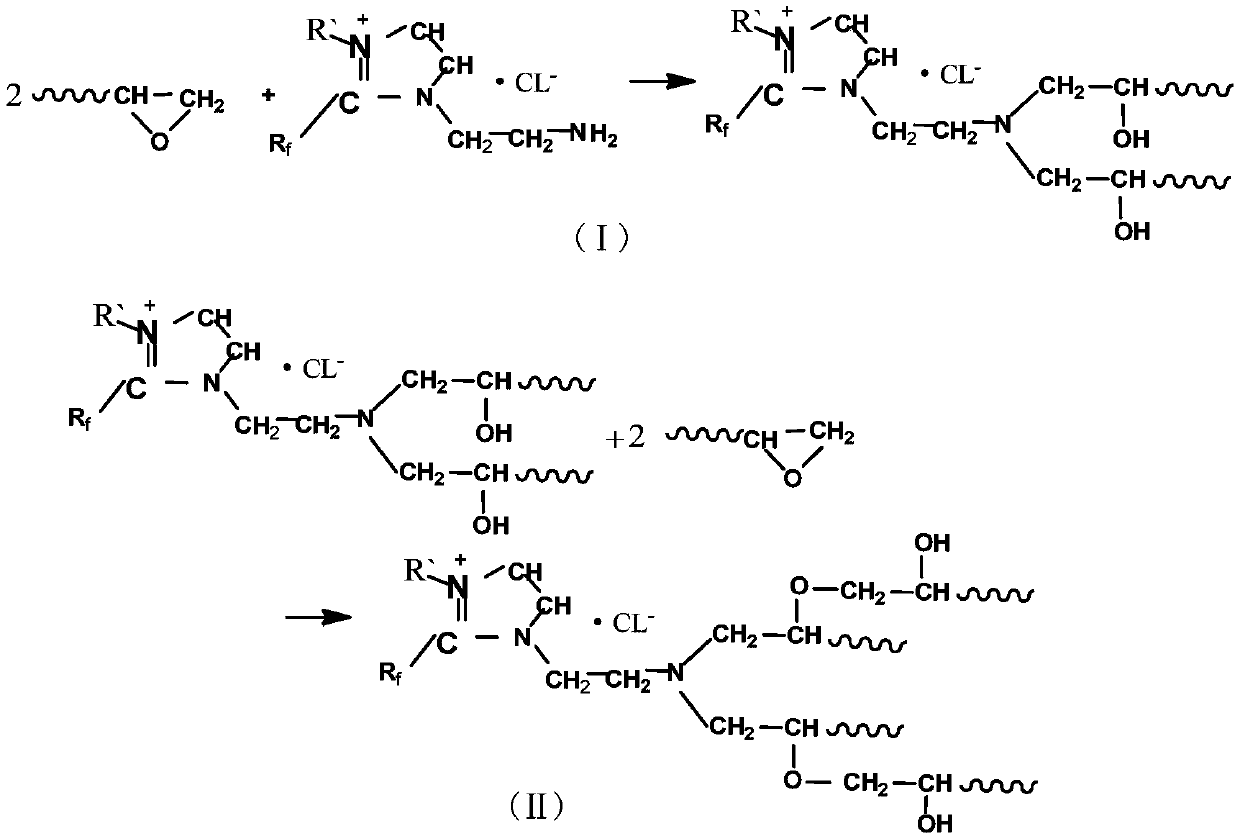

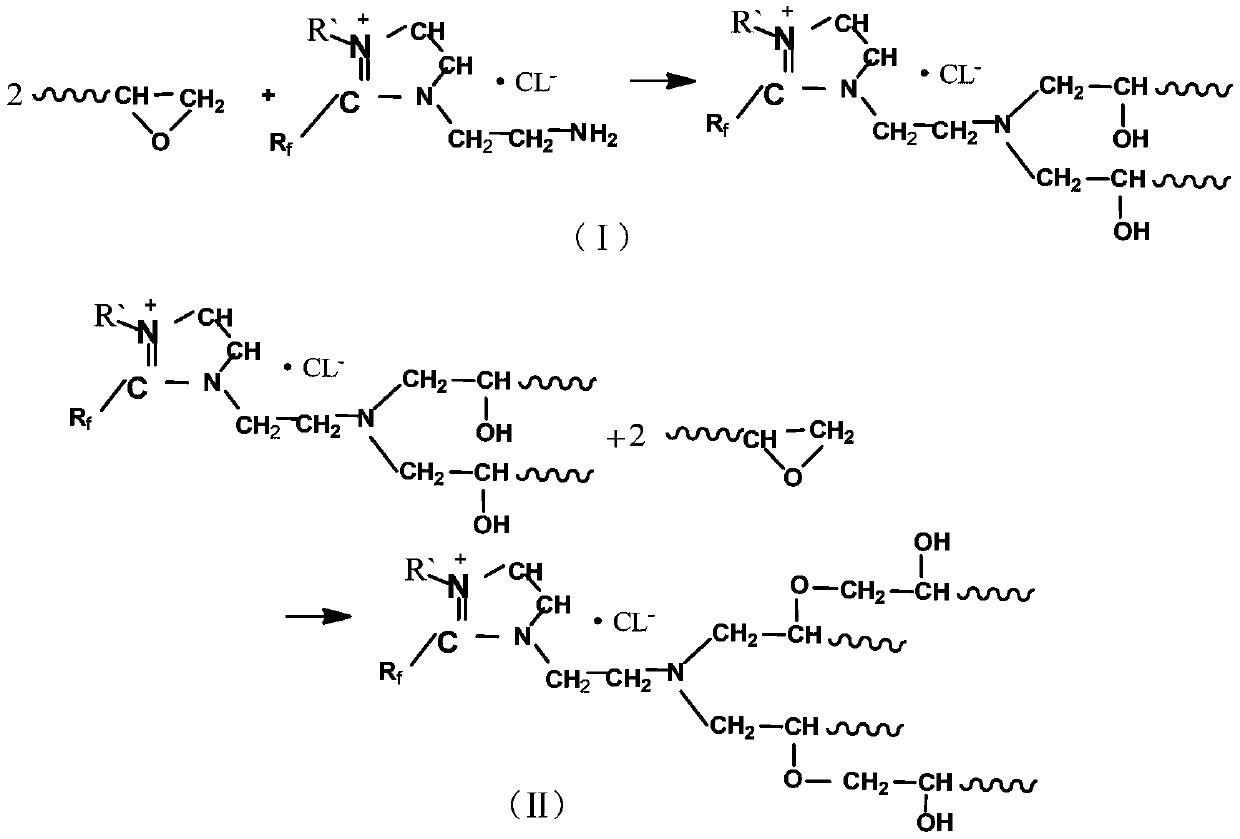

Preparation method for perfluorocarbon modified heat-conduction heavy anti-corrosion coating suitable for heating water-containing crude oil

ActiveCN107418371AGood conditionNo peelingAnti-corrosive paintsEpoxy resin coatingsEpoxyHexagonal boron nitride

The invention relates to a preparation method for a perfluorocarbon modified heat-conduction heavy anti-corrosion coating suitable for heating water-containing crude oil. The preparation method comprises the following steps: mixing epoxy resin, n-butanol, dimethylbenzene, graphite powder, hexagonal boron nitride and a leveling agent according to the mass ratio of 58: 35-39: 85-90: 20-25: 20-25: 1-1.5 to obtain a component A; uniformly mixing and stirring polyamide resin, the n-butanol, the dimethylbenzene and perfluorocarbon imidazoline quaternary-ammonium salt according to the mass ratio of 20-25: 13-18: 33-38: 10-30 to obtain a component B; and mixing the component A and the component B according to a mass ratio of 3: 1, stirring uniformly, and curing for 15-20 minutes at the normal temperature to obtain the perfluorocarbon modified heat-conduction heavy anti-corrosion coating. The coating has good oil-proof and water-proof properties and excellent anti-corrosion property and heat-conduction property, meanwhile has low cost and high adhesive force, and can be used for preventing corrosion of an outer layer of a metal pipe for heating the water-containing crude oil for a long time.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

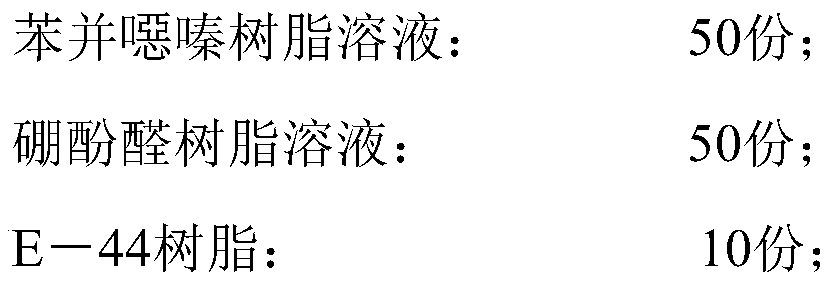

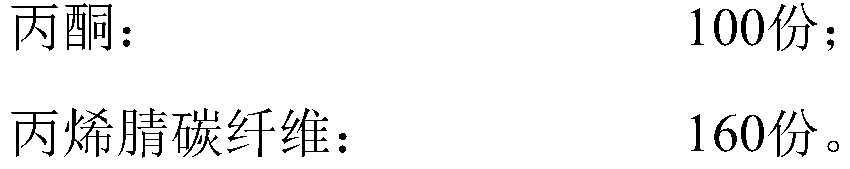

Benzoxazine resin-based composite material with ablation resistance and heat insulation and forming method of benzoxazine resin-based composite material

InactiveCN110499000ACuring shrinkage is smallSmall coefficient of thermal expansionThermal insulationResin matrix

The invention provides a benzoxazine resin-based composite material with ablation resistance and heat insulation and a forming method of the benzoxazine resin-based composite material. The benzoxazineresin-based composite material comprises the components: in parts by weight, 30-40 parts of benzoxazine resin, 60-70 parts of boron phenol resin, 100 parts of acetone and 160 parts of acrylonitrile carbon fiber, and curing is performed at a temperature of 200-210 DEG C and a pressure of 4-15 MPa for 20-30 min. On the premise that no reduction of ablation resistance of nozzles and performance of heat-insulation expansion sections, linings of partitions, outer linings of the partitions, backings of the partitions and other components of solid rocket engines is ensured, the defect rate of products is reduced, the toughness of the resin matrix is improved, and the subsequent processability of molded products is improved.

Owner:西安长峰机电研究所

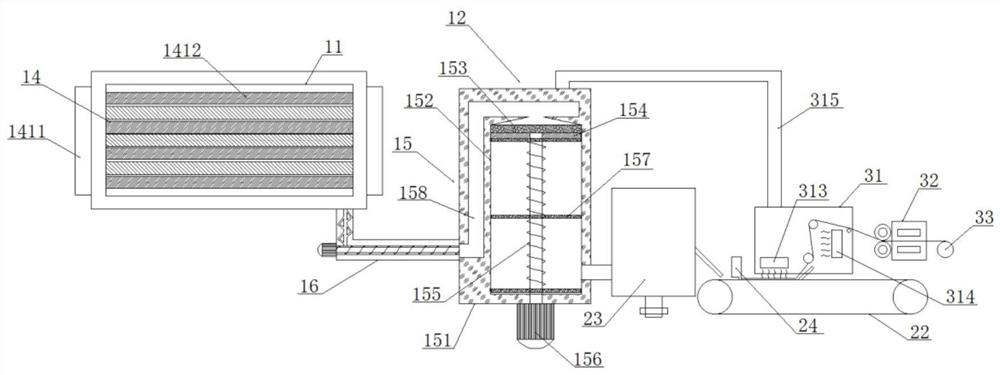

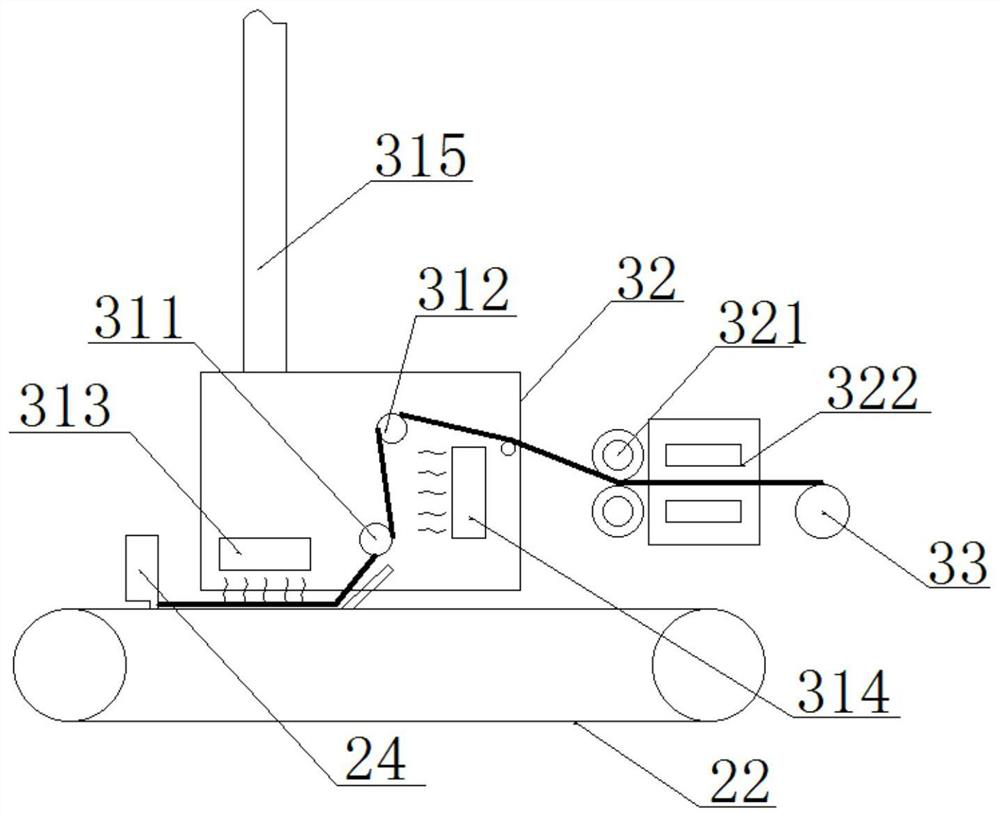

Ceramic substrate casting processing equipment

ActiveCN113414854ANo bulgeContribute to the generationCeramic shaping apparatusClay processing apparatusGear wheelCeramic substrate

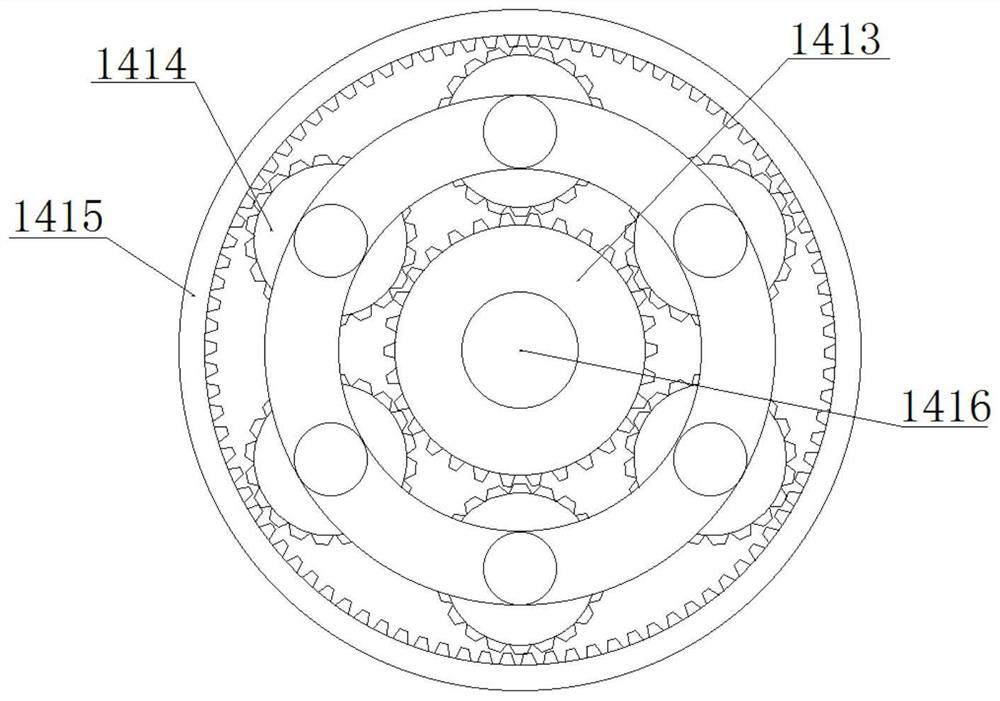

The invention discloses ceramic substrate casting processing equipment which comprises a raw material treatment device, a forming device and a post-treatment device. The raw material treatment device comprises a main mixer and an auxiliary mixer, a first mixing mechanism is arranged in the main mixer, a second mixing mechanism is arranged in the auxiliary mixer, and a connecting pipe is arranged between the main mixer and the auxiliary mixer. The forming device comprises a casting rack, a conveying belt arranged on the casting rack, a feeding box arranged on the conveying belt and a scraper arranged on the casting rack, the feeding box is connected with the auxiliary mixer, and the post-treatment device is arranged on one side of the conveying belt. The first mixing mechanism comprises a crushing and screening part and an initial mixing part, the initial mixing part wraps the outer side of the crushing and screening part, the crushing and screening part comprises symmetrically-arranged driving discs and grinding columns movably arranged on the driving discs, center wheels are arranged in the middles of the driving discs, multiple gears engaged with the center wheels and outer gear rings engaged with the gears are arranged on the edges, and through holes are formed in the center wheels.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

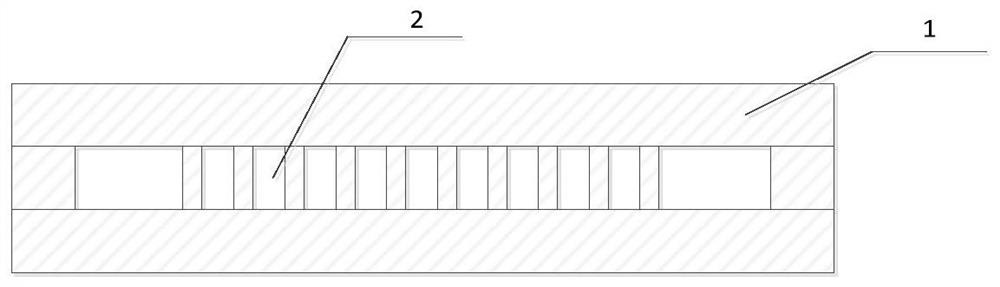

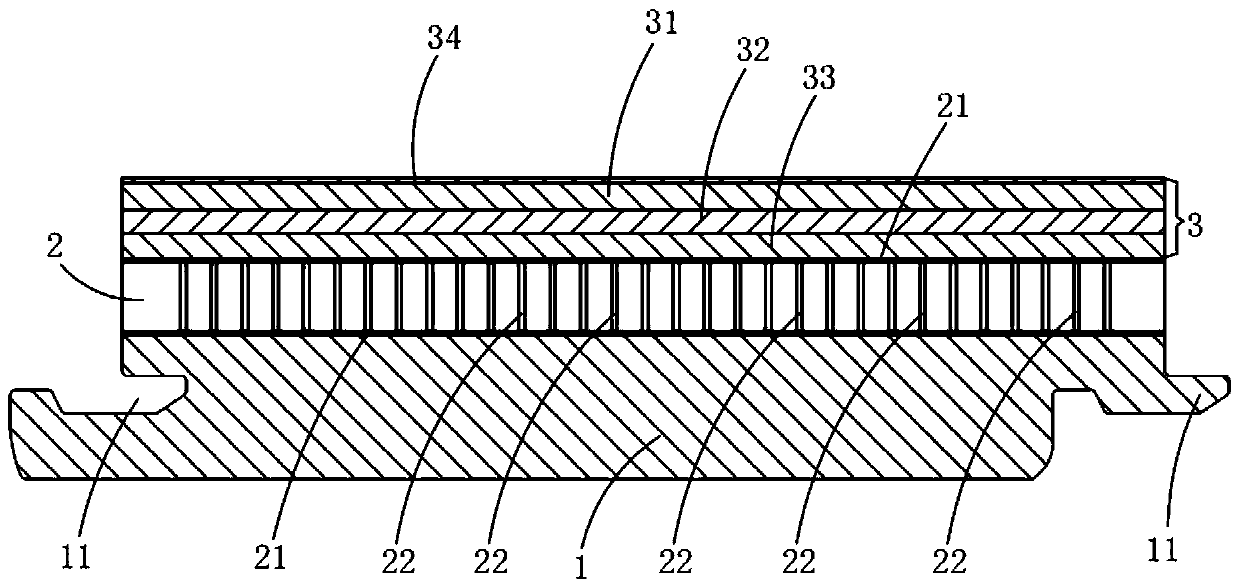

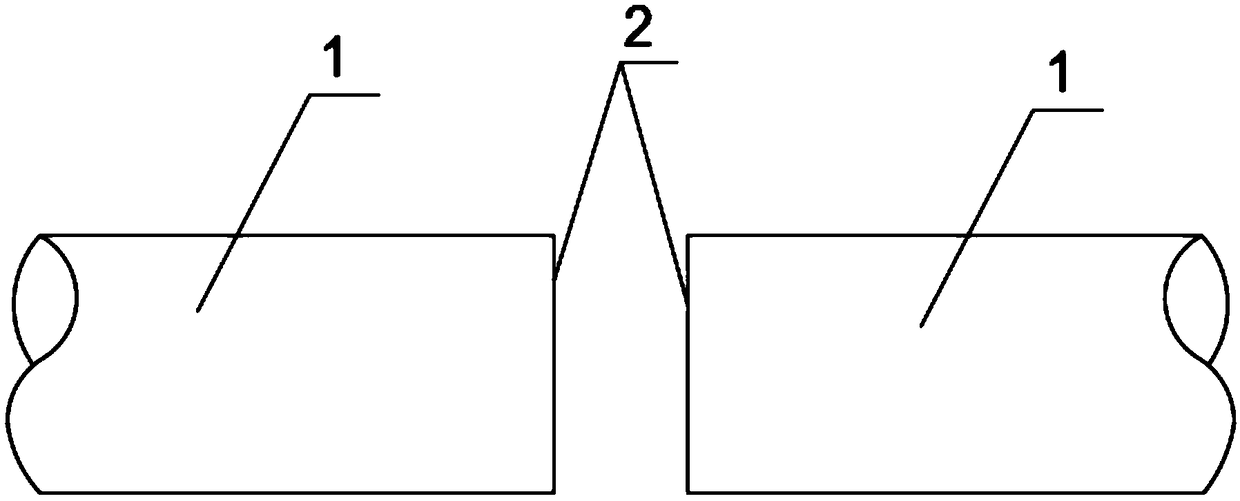

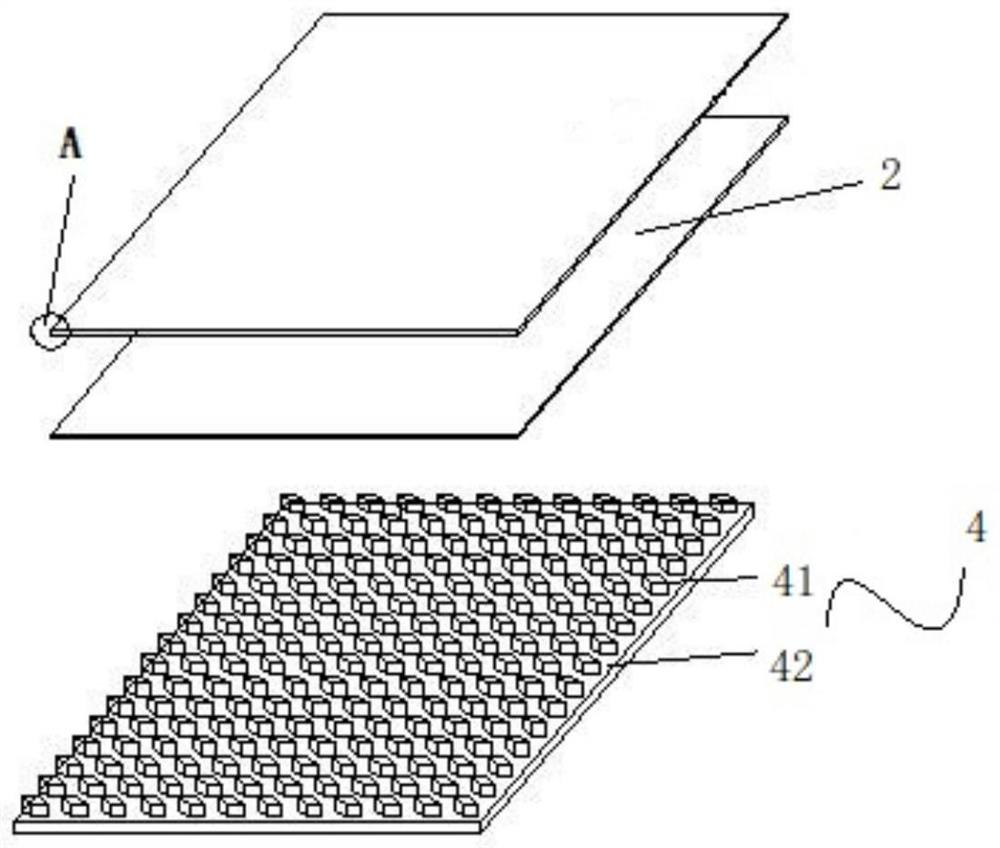

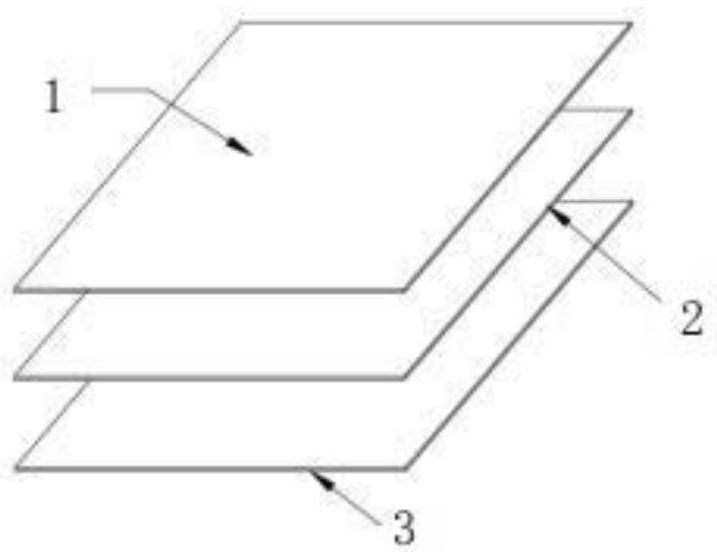

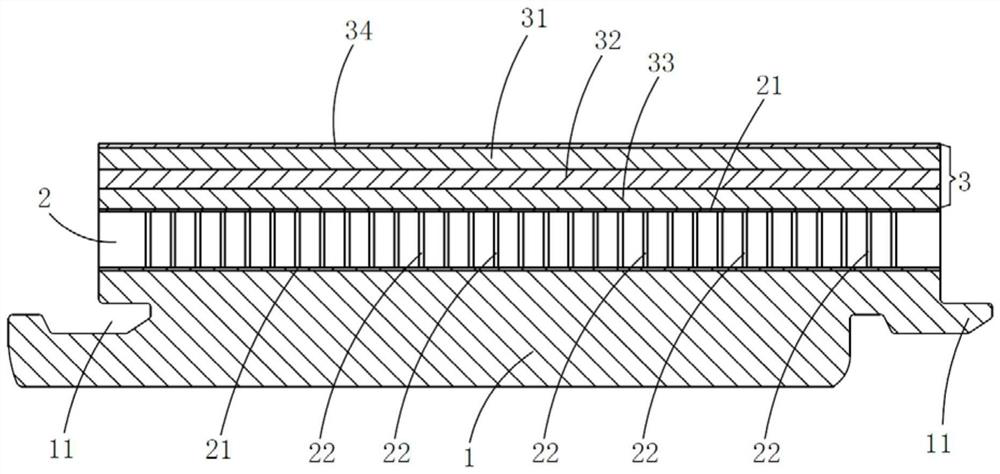

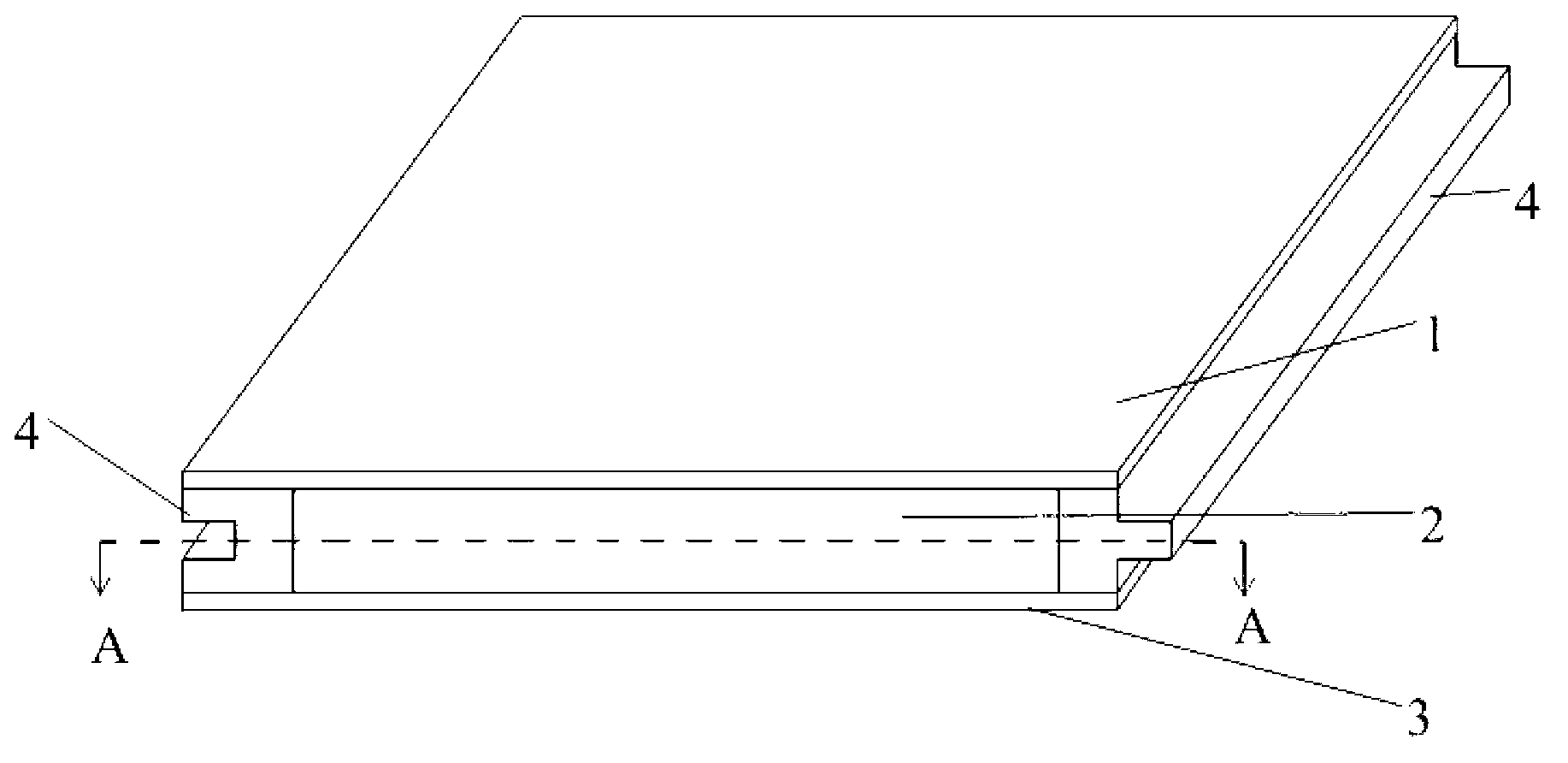

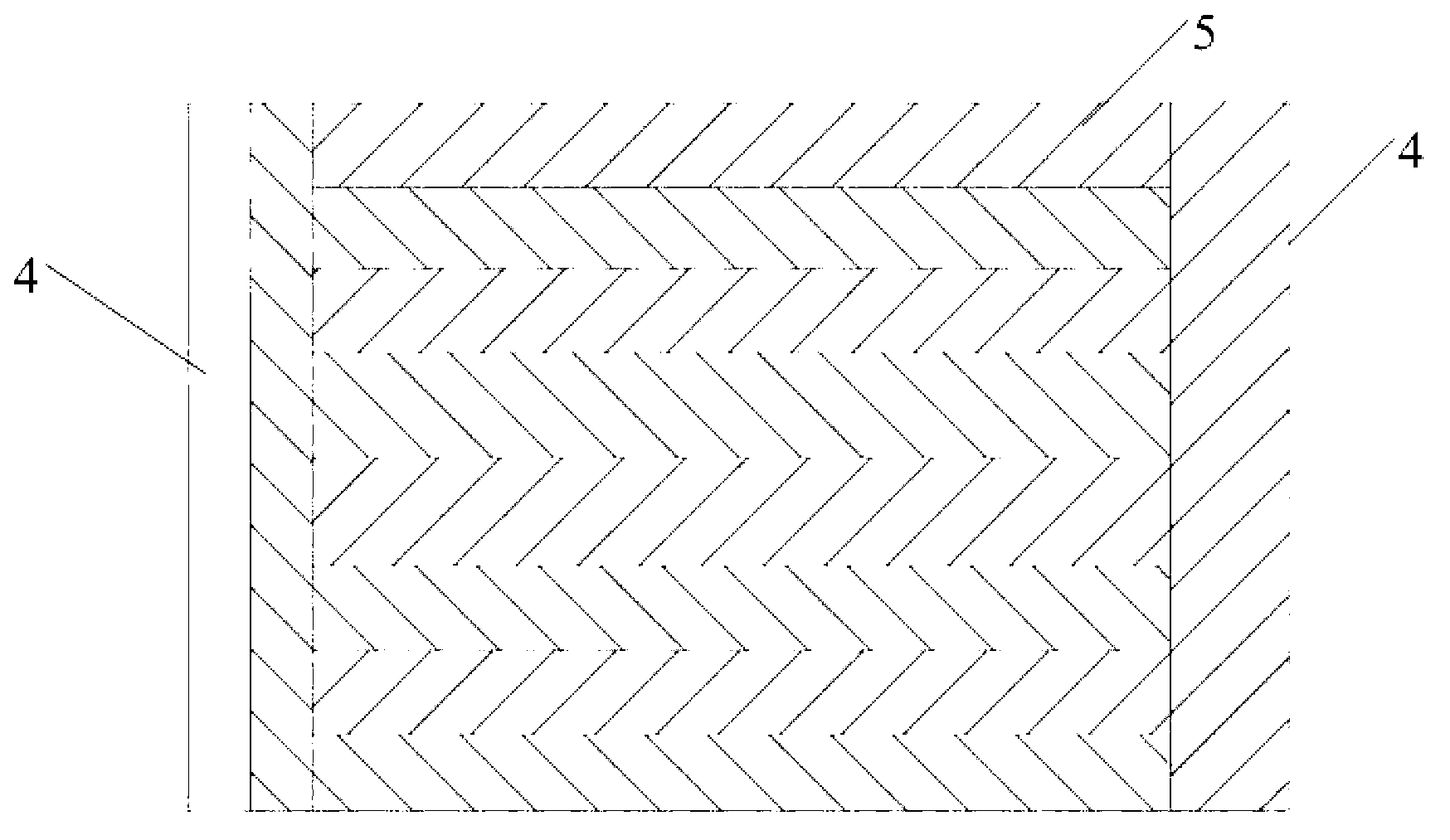

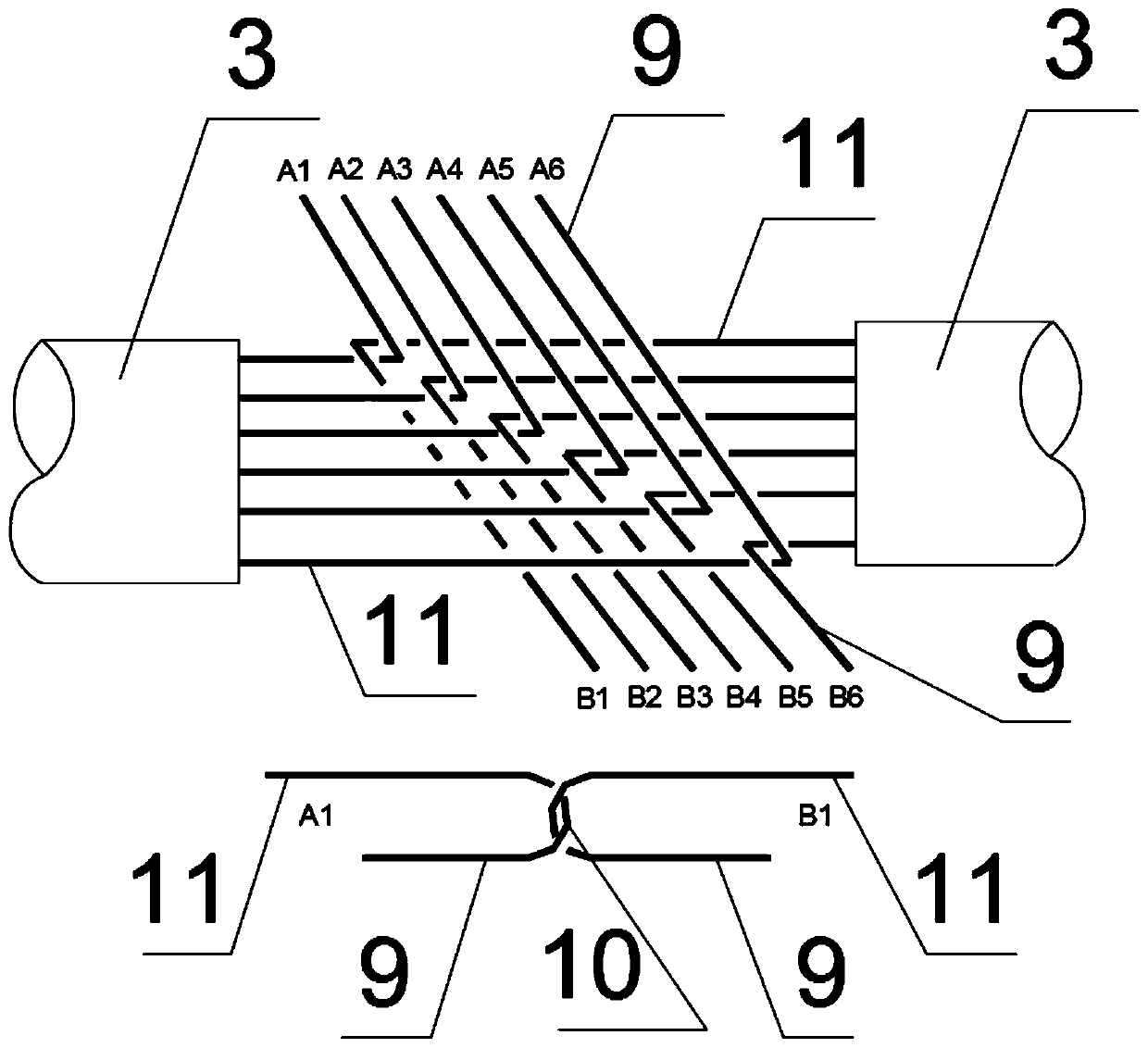

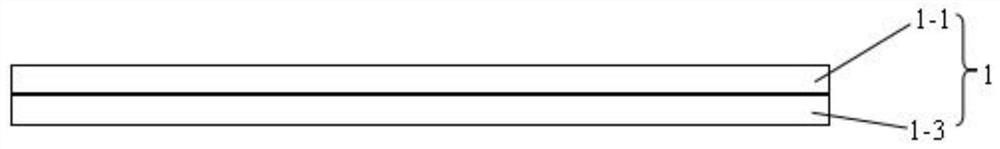

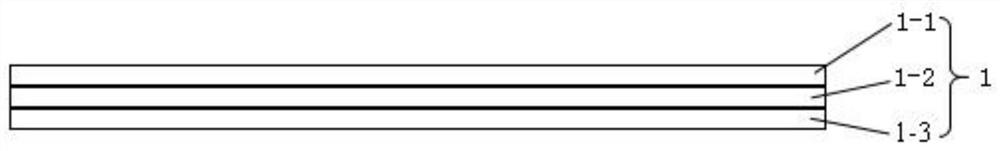

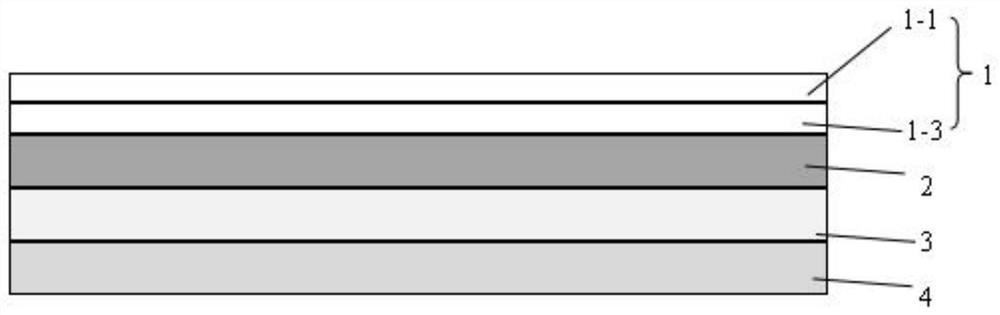

Waterproof and wear-resistant composite flooring and production method

ActiveCN110573341AShorten the production cycleSimple processLamination ancillary operationsCovering/liningsWear resistantMaterial resources

A waterproof and wear-resistant composite flooring and production method is disclosed and comprises the following steps: a PVC composite layer prefabricated part (3) is made, and corona treatment andpunching treatment are performed on the cushion layer (2); finally, the PVC composite layer prefabricated part (3), the cushion layer (2) and the waterproof base material layer (1) are composited intoone at a time. The method is simple in technology, easy in implementation, short in production cycle, and low in production cost. Manpower and material resources needed in production processes can bereduced, obtained waterproof and wear-resistant composite flooring is simple in structure and high in water resistance and wear resistance and can be prevented from being easily swollen or layered ordeformed.

Owner:建泰有限公司

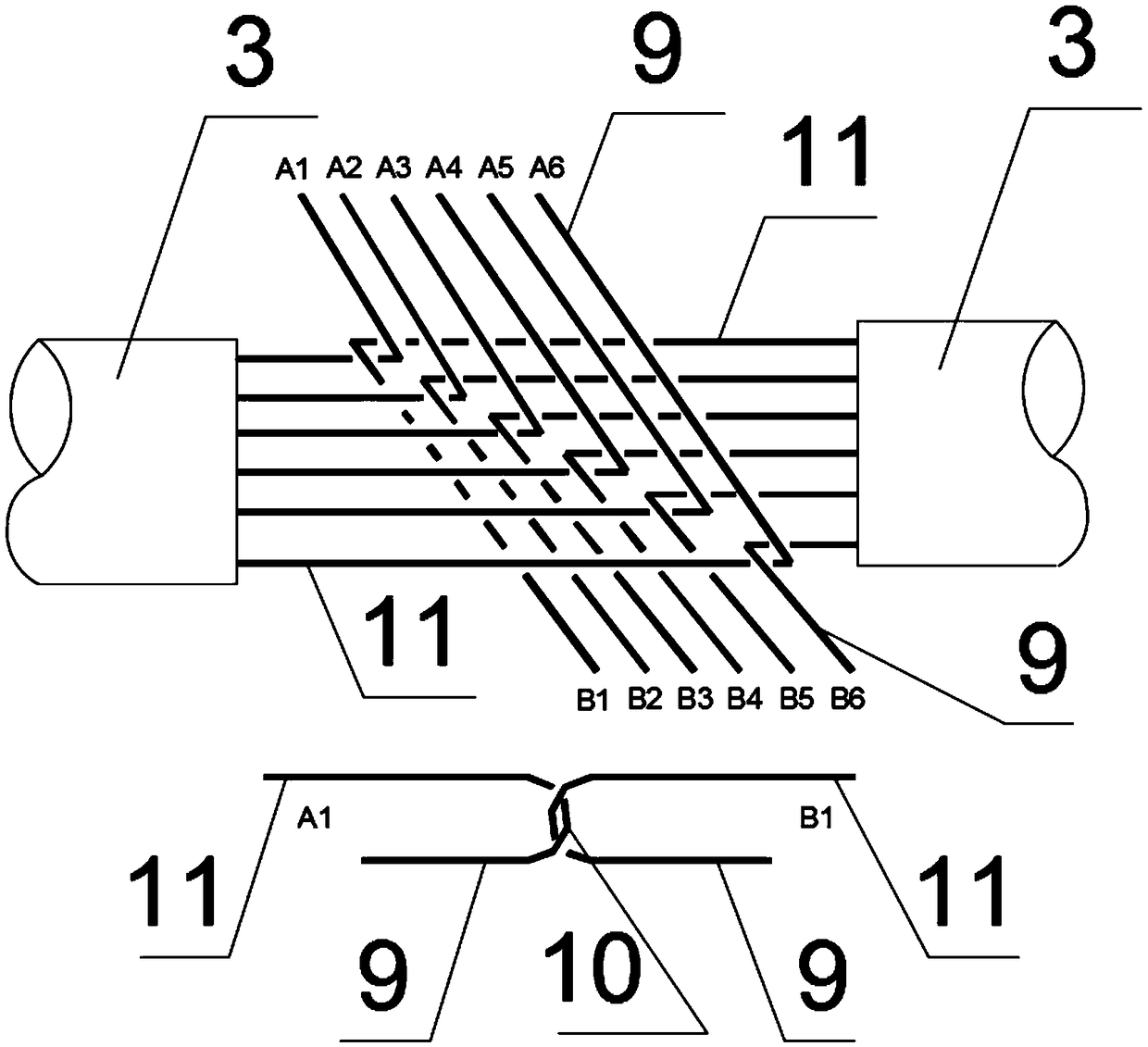

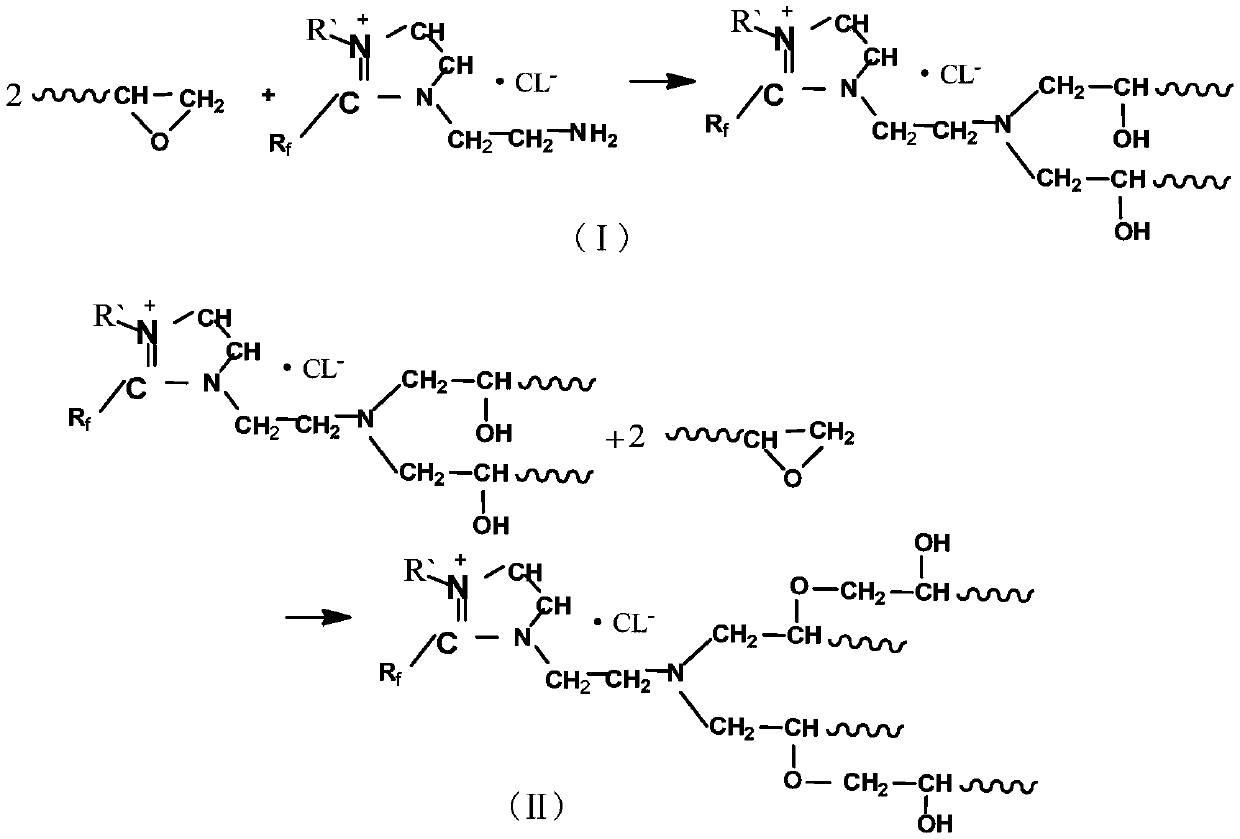

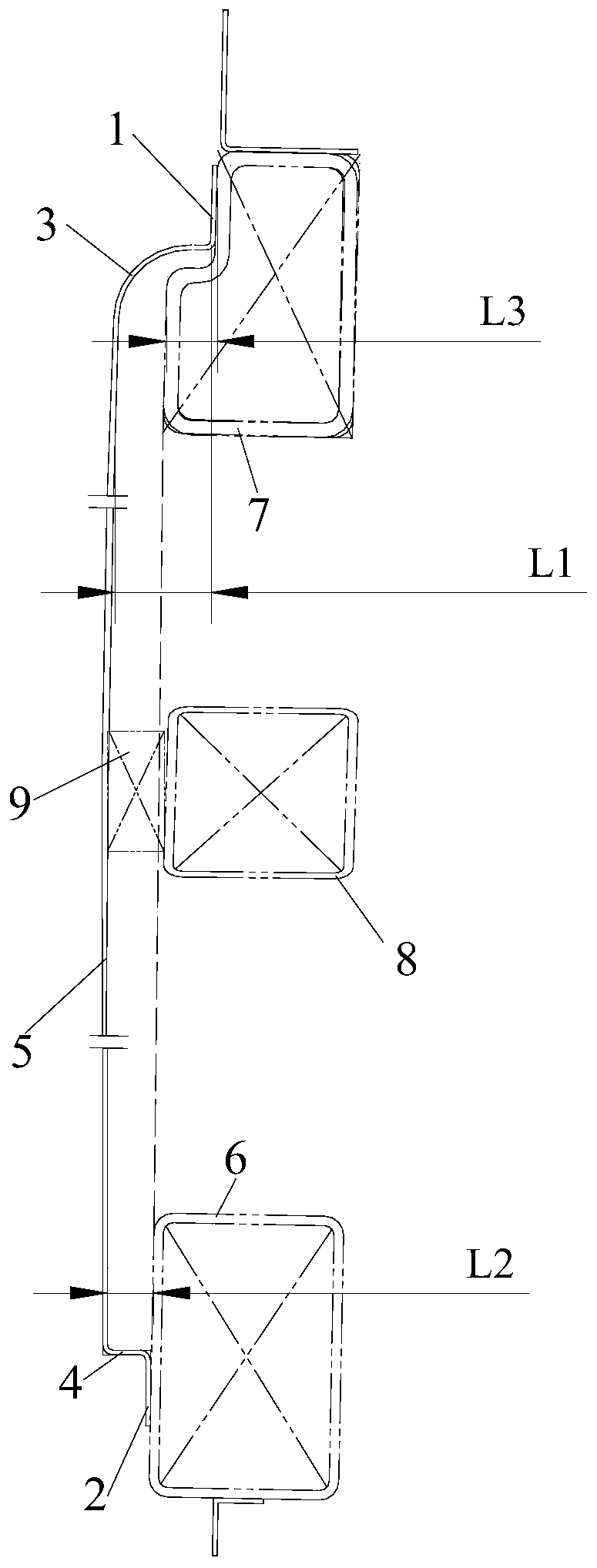

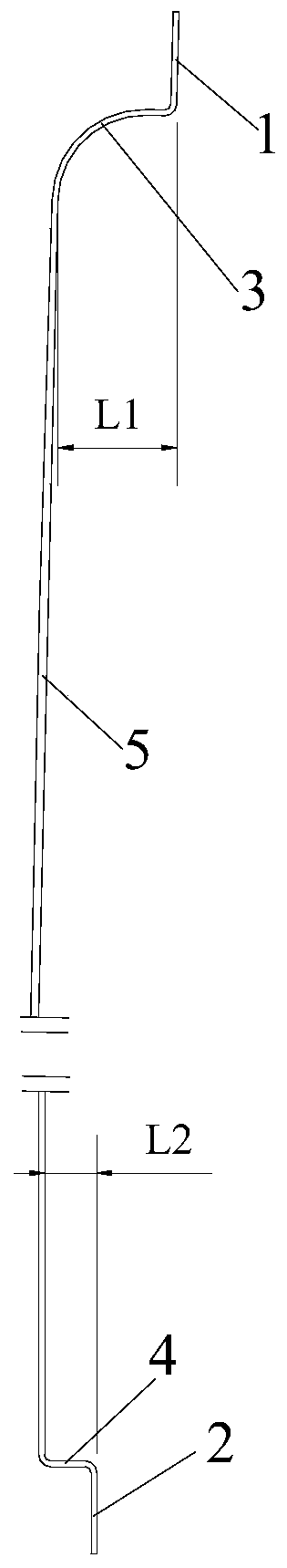

Drag cable connection process method

ActiveCN109390833AGuaranteed tensile stressEnsure construction safetyLine/current collector detailsElectrical conductorEngineering

Owner:CHINA HUAYE GROUP

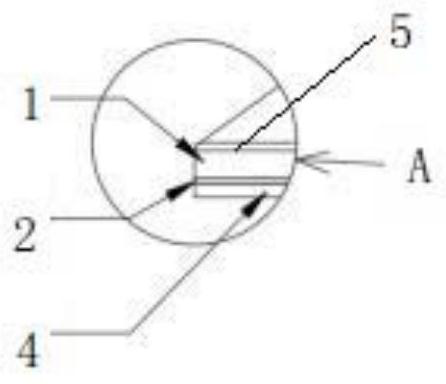

Film pasting method for LED module and display screen

InactiveCN112078125ANo bulgeThere will be no problem of warped cornersIdentification meansPolymer scienceGlass chip

The invention provides a film pasting method for an LED module. The film pasting method comprises the following steps of material selecting, specifically, a toughened glass sheet, coiled OCA optical cement, a coiled film material and the LED module are prepared; antireflection film plating, specifically, the toughened glass sheet is placed in a vacuum environment, and an antireflection film is plated on the top surface and / or the bottom surface of the toughened glass sheet by adopting a vacuum evaporation method; film pasting, specifically, the film material is pasted to the bottom surface ofthe toughened glass sheet plated with the antireflection film through the OCA optical cement; and fitting, specifically, the toughened glass sheet pasted with the film material is fitted to the surface of the LED module through the OCA optical cement. According to the film pasting method for the LED module, the film material is attached between the toughened glass sheet and the LED module, and because the toughened glass sheet applies downward pressure on the LED module, the film material can be made not to generate the problem of film material bulging or edge corner warping in the packaging,transporting and working processes; and by means of the manner that vacuum antireflection film plating is performed on the surface of the toughened glass sheet, on the one hand, the transmittance of amask can be improved, on the other hand, dazzling light generated by the surface of the mask by external light rays can be avoided, and the visual experience of audiences is improved.

Owner:HUIZHOU DURWY INTELLIGENT TECH CO LTD

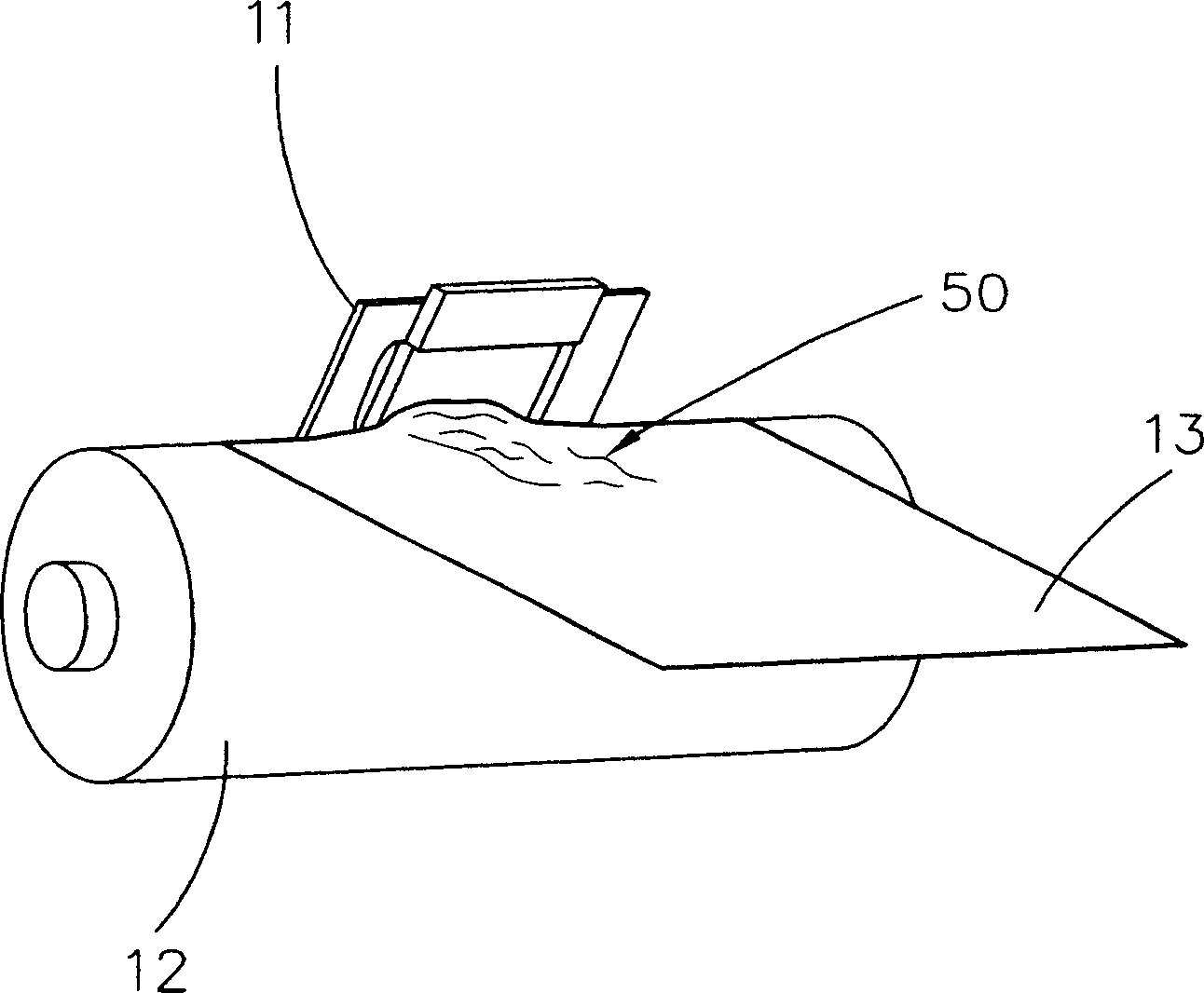

Paper separating mechanism for automatic paper feeder

Owner:AVISION PRECISION IND (SUZHOU) CO LTD

A kind of heavy bamboo floor press device

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

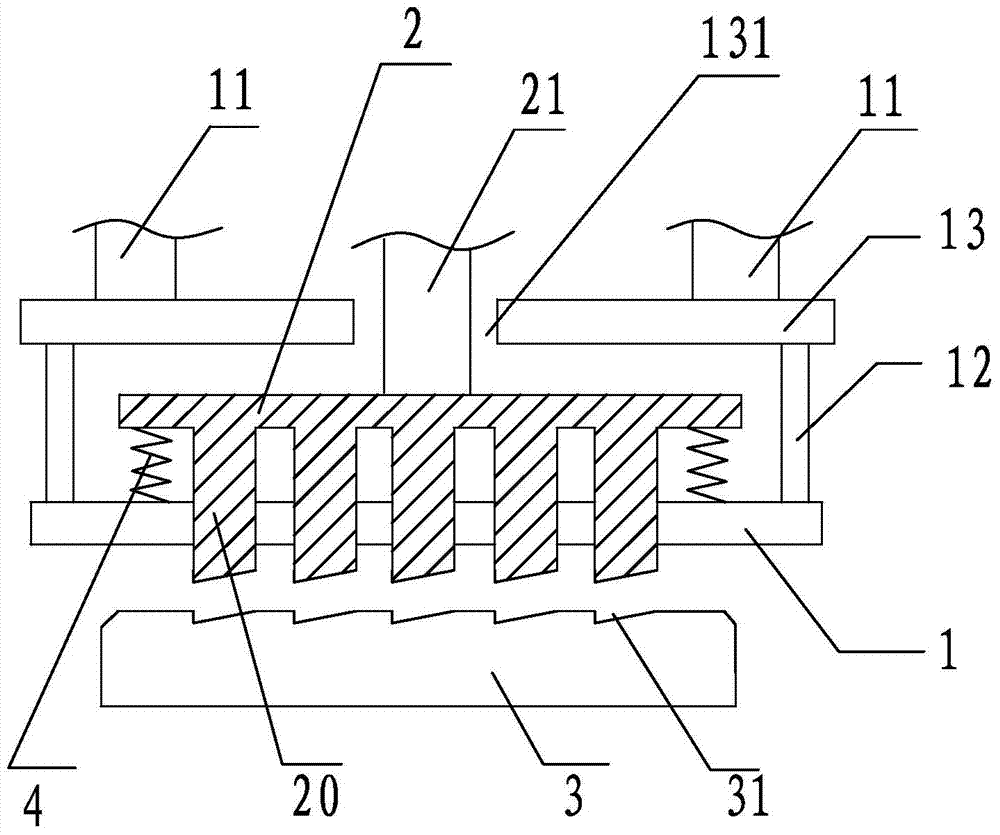

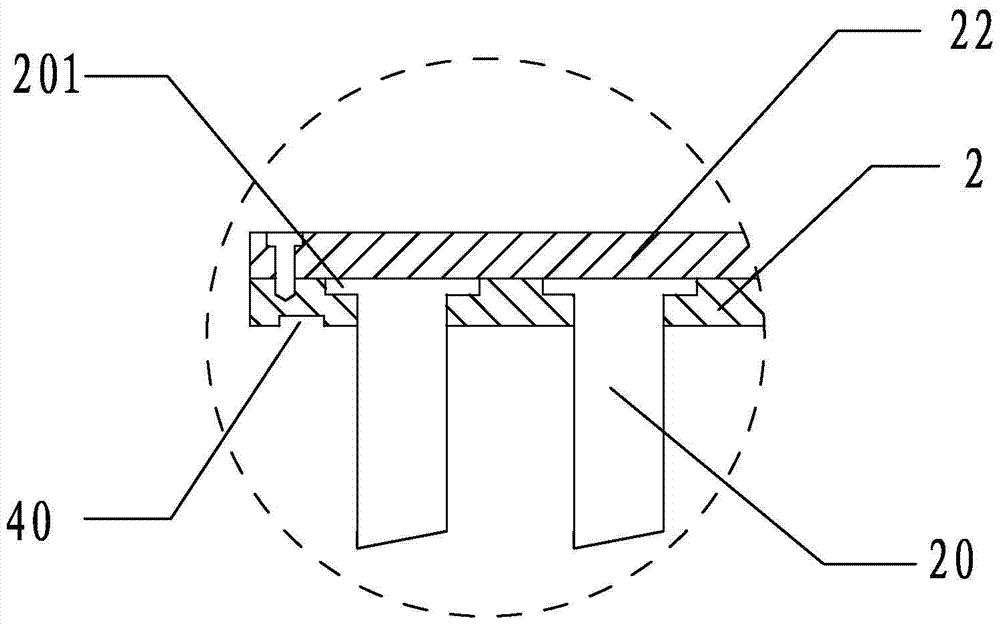

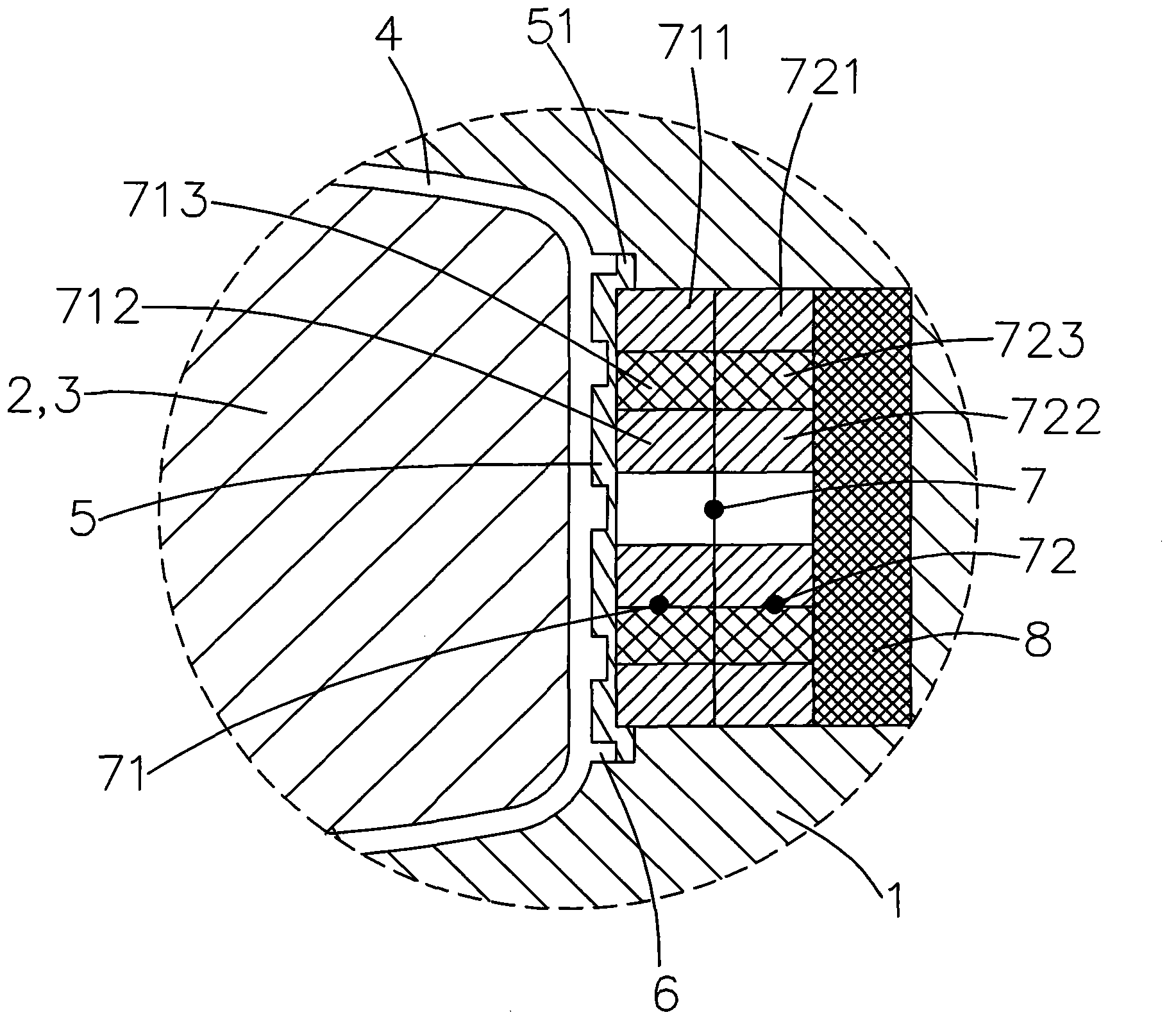

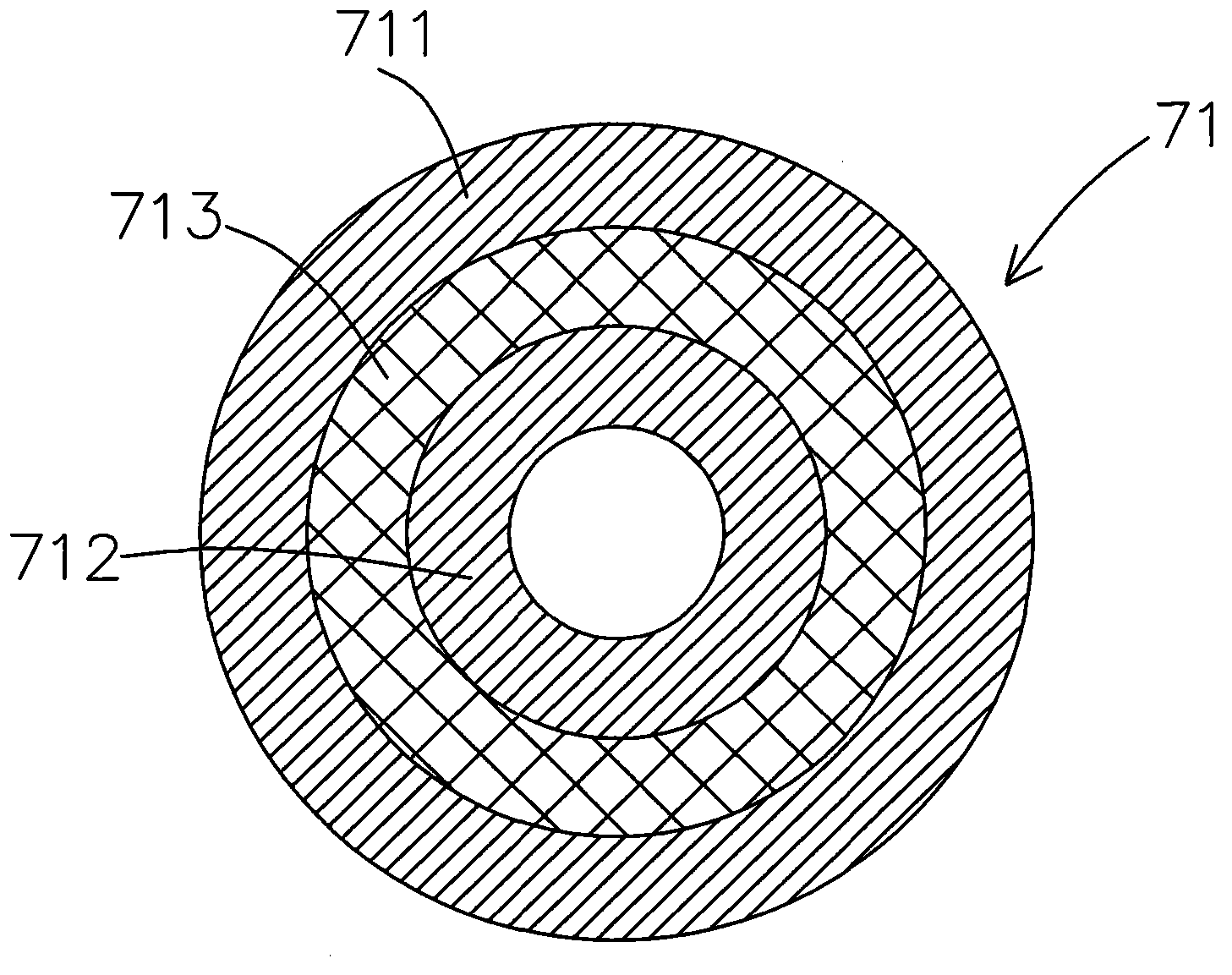

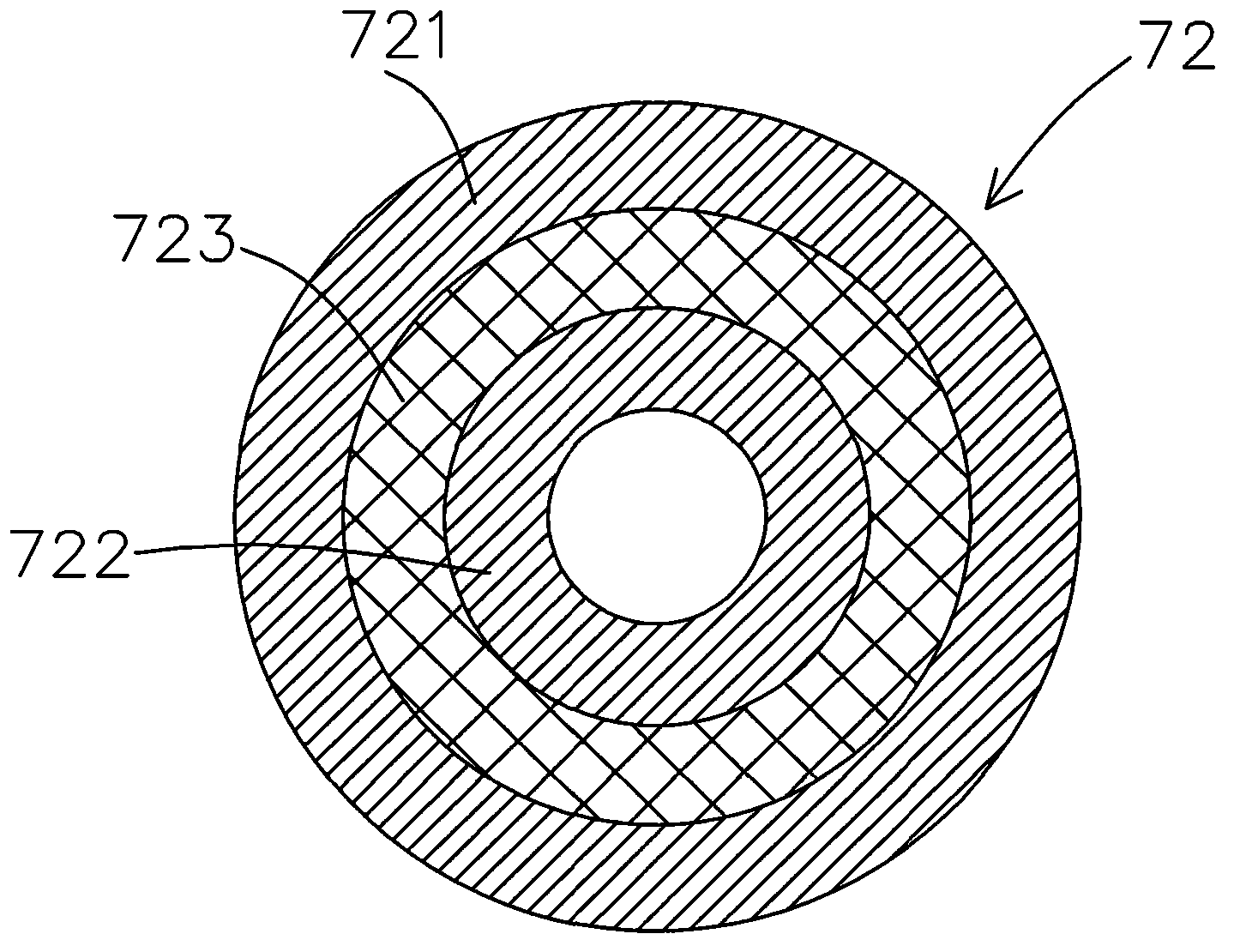

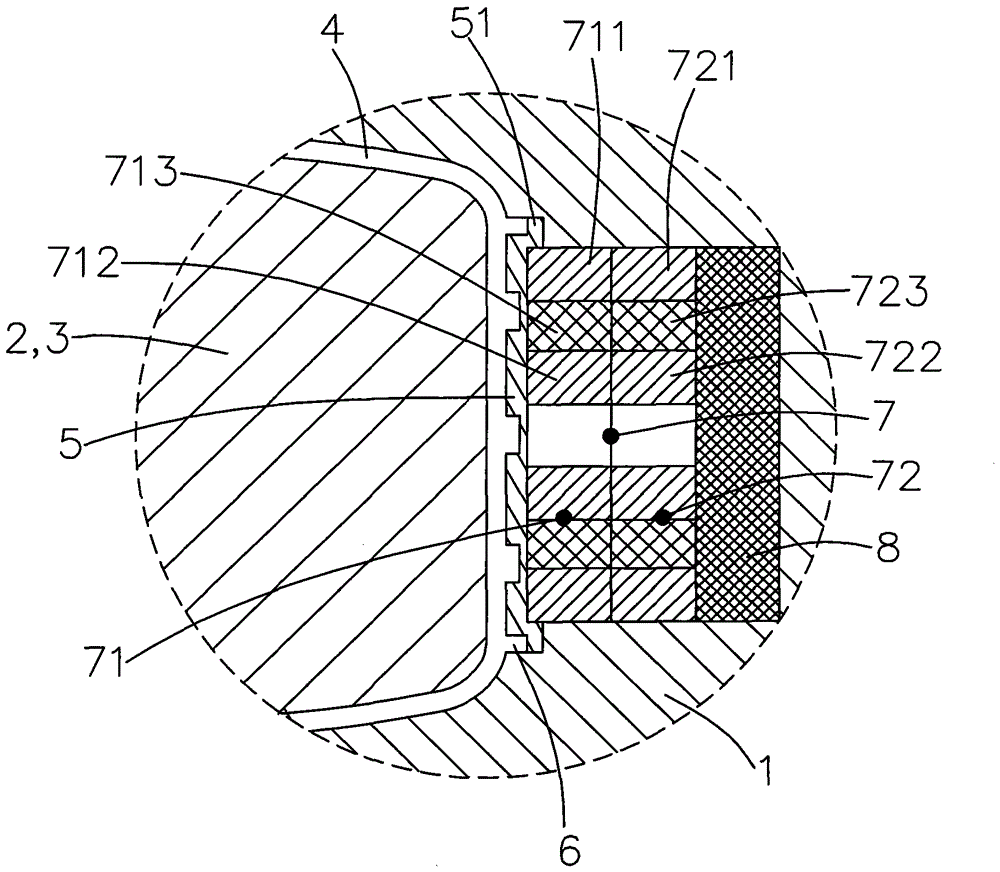

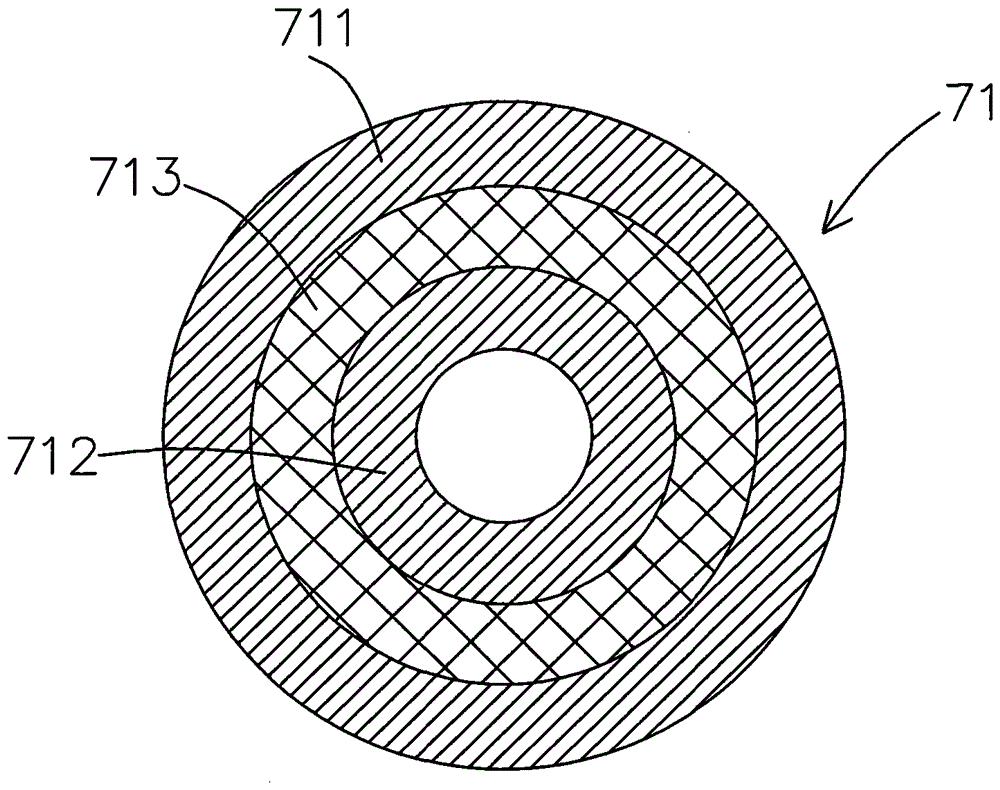

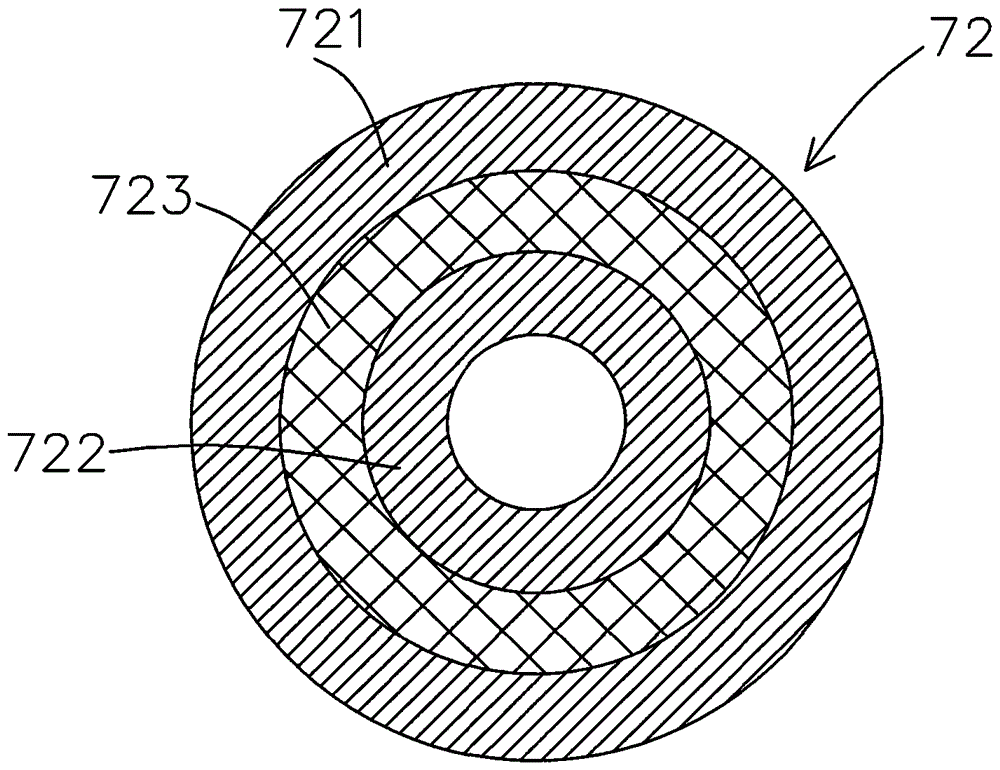

Pressure casting pre-buried type forming device of composite bottom pot

A pressure casting pre-buried type forming device of a composite bottom pot comprises a concave die and a convex die. A pot body die is arranged on the convex die. A concave die cavity corresponding to the pot body die is formed in the concave die. A locating groove used for placing a composite bottom sheet is formed in the bottom of the concave die cavity. A magnetic absorbing mechanism used for absorbing the bottom face of the composite bottom sheet is arranged at the bottom of the locating groove. The pressure casting pre-buried type forming device of the composite bottom pot can firmly absorb the whole bottom face of the composite bottom sheet on the surface through the magnetic absorbing mechanism, can conduct circle management and location on the outer circumference wall of the composite bottom sheet through the locating groove, so that locating is firm and reliable, side swing and outward protruding, caused by impact of jet flows, of the composite bottom sheet can be avoided. Moreover, the pressure casting pre-buried type forming device ensures that bottom faces of formed products are smooth and level, and free of inclination and bulge, and greatly improves the product percent of pass. Further, the device is simple in structure and low in manufacture cost.

Owner:JH LEICAST COOKWARE CO LTD

Die-casting pre-buried molding device for compound bottom pot

A die-casting pre-embedded molding device for a double-bottomed pot, comprising a die and a punch, the punch is provided with a pot model, and the die is provided with a concave cavity corresponding to the pot model, the The bottom of the concave mold cavity is provided with a positioning groove for placing the composite film, and the bottom of the positioning groove is provided with a magnetic attraction mechanism for absorbing the bottom surface of the composite film. On the one hand, the forming device of the present invention firmly absorbs the entire bottom surface of the composite film on its surface through the magnetic suction mechanism, and on the other hand, it also performs full-circle positioning on the outer peripheral wall of the compound film through the positioning groove, so the positioning is firm and reliable, and can avoid Under the impact of the jet, the compound film will appear sideways and convex, which ensures that the bottom surface of the product after molding is smooth and flat, without inclination and bulge, which greatly improves the qualified rate of the product. In addition, the device has a simple structure and low manufacturing cost.

Owner:JH LEICAST COOKWARE CO LTD

A waterproof and wear-resistant composite floor and its production method

ActiveCN110573341BShorten the production cycleSimple processCovering/liningsLamination ancillary operationsMaterial resourcesWear resistance

A method for producing a waterproof and wear-resistant composite floor. First, a PVC composite layer prefabricated part (3) is manufactured, and then a cushion layer (2) is subjected to corona treatment and punching treatment, and finally the PVC composite layer prefabricated part (3), The upholstery layer (2) and the waterproof base layer (1) are combined into one body at one time, the process is simple, easy to implement, the production cycle is shortened, the manpower and material resources required for the production process are reduced, and the production cost is reduced, and the waterproof and wear-resistant product obtained The composite floor not only has a simple structure, but also has very good waterproof and wear-resistant properties, and the waterproof and wear-resistant composite floor will not produce bulges, and it is not easy to delaminate or deform.

Owner:建泰有限公司

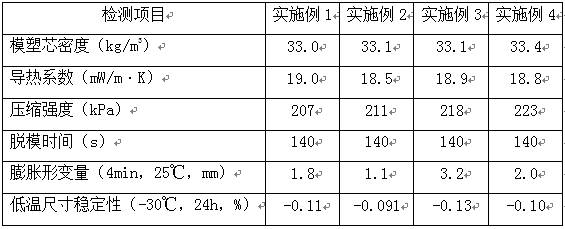

A kind of rigid polyurethane foam material for refrigerator and preparation method thereof

The invention provides a rigid polyurethane foam material for a refrigerator as well as a preparation method of the rigid polyurethane foam material. The polyurethane foam material comprises a white material and a black material, wherein the white material comprises a polyalcohol composition and an aid; the polyalcohol composition is prepared from the following raw materials in parts by weight: 15to 40 parts of aromatic amine polyether polyol, 15 to 60 parts of sorbitol polyether polyol, 10 to 20 parts of glycerol polyether polyol, 5 to 15 parts of castor oil polyether polyol and 5 to 15 parts of polyester polyol; the aid comprises the following components in parts by weight: 2 to 4 parts of a foam stabilizer, 1.5 to 2.5 parts of water, 2 to 3 parts of a catalyst and 15 to 20 parts of a foaming agent; the black material is isocyanate; the weight ratio of the white material to the black material is 1:(1.08-1.25). The polyurethane foam provided by the technical scheme is rapid in demolding, low in heat-conducting coefficient and high in compression strength. The refrigerator using the foam has high production efficiency and high heat-insulating property, and avoids the phenomenon that a backboard is bulged.

Owner:NANJING HONGBAOLI POLYURETHANE

Solid wood structural geothermal floor

The invention relates to a floor, in particular to a solid wood structural geothermal floor which comprises a surface layer, an internal layer and a bottom layer, wherein a decorative layer can be arranged on the surface layer; the internal layer is formed by connecting a plurality of transverse wood plates in a finger joint way; and tongue-and-groove wood plates are respectively arranged on the left longitudinal side and the right longitudinal side of the internal layer, and integrally glued with the internal layer. According to the solid wood structural geothermal floor provided by the invention, the internal layer is formed by connecting the transverse wood plates in the finger joint way, so that the transverse expansion rate and the shrinkage factor of the internal layer are greatly reduced, the phenomenon of swelling, twisting, loosing or cracking and the like of the floor is reduced, the service life of the floor is prolonged, the demands of the solid wood structural geothermal floor to an integral wood plate are reduced based on the finger joint technology; and moreover, the transverse wood plates are the leftovers of fast growing woods or high-level woods, so that the national natural resources are greatly saved.

Owner:浙江林昌木业有限公司

Use of fly ash synthesized channel joint impervious material for preparing highway asphalt mixture

InactiveCN101481233BQuality improvementIncreased test stabilitySolid waste managementSlagMixed materials

Owner:NORTHWEST A & F UNIV

A preparation method of fluorocarbon-modified heat-conducting heavy-duty anti-corrosion coating suitable for heating crude oil containing water

ActiveCN107418371BGood conditionNo peelingAnti-corrosive paintsEpoxy resin coatingsEpoxyHexagonal boron nitride

The invention relates to a preparation method for a perfluorocarbon modified heat-conduction heavy anti-corrosion coating suitable for heating water-containing crude oil. The preparation method comprises the following steps: mixing epoxy resin, n-butanol, dimethylbenzene, graphite powder, hexagonal boron nitride and a leveling agent according to the mass ratio of 58: 35-39: 85-90: 20-25: 20-25: 1-1.5 to obtain a component A; uniformly mixing and stirring polyamide resin, the n-butanol, the dimethylbenzene and perfluorocarbon imidazoline quaternary-ammonium salt according to the mass ratio of 20-25: 13-18: 33-38: 10-30 to obtain a component B; and mixing the component A and the component B according to a mass ratio of 3: 1, stirring uniformly, and curing for 15-20 minutes at the normal temperature to obtain the perfluorocarbon modified heat-conduction heavy anti-corrosion coating. The coating has good oil-proof and water-proof properties and excellent anti-corrosion property and heat-conduction property, meanwhile has low cost and high adhesive force, and can be used for preventing corrosion of an outer layer of a metal pipe for heating the water-containing crude oil for a long time.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

A kind of dragging cable connection process method

ActiveCN109390833BEasy to dragGuaranteed tensile stressLine/current collector detailsElectrical conductorEngineering

Owner:CHINA HUAYE GROUP

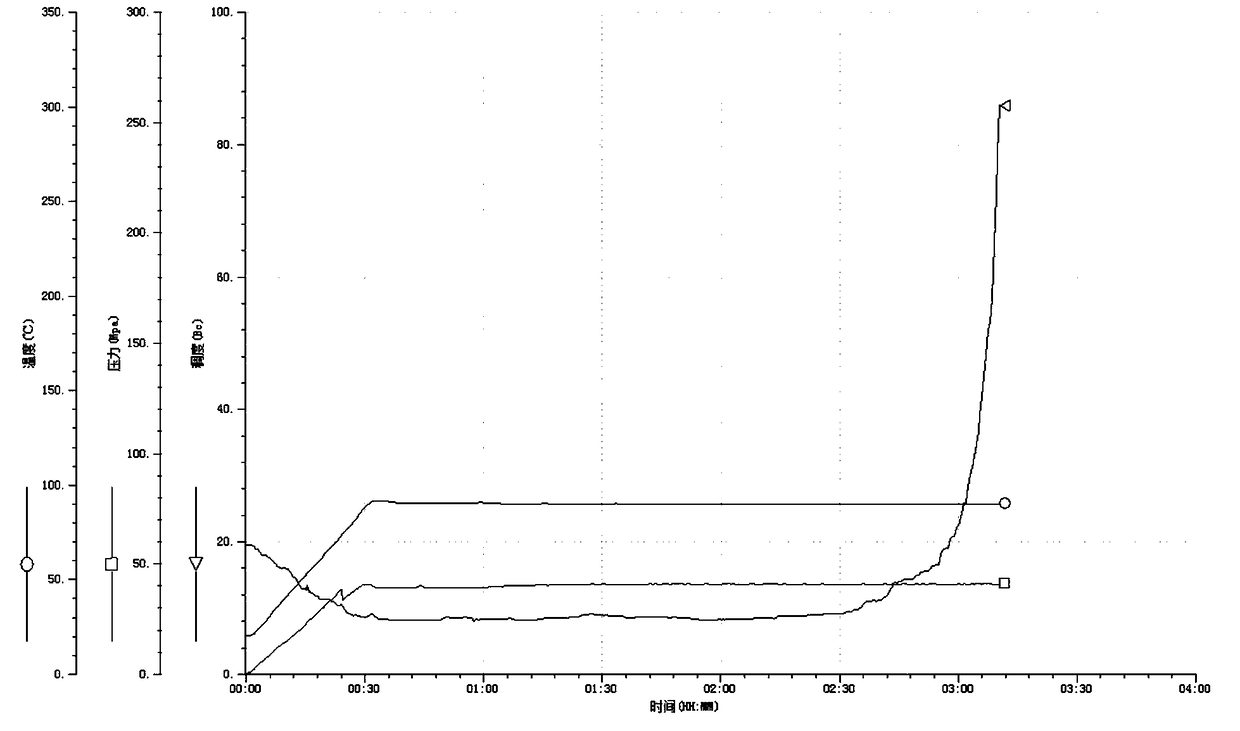

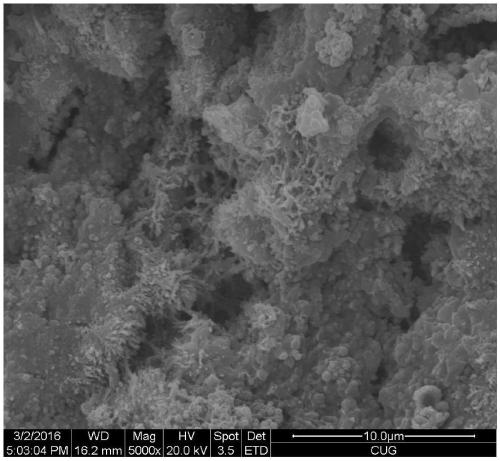

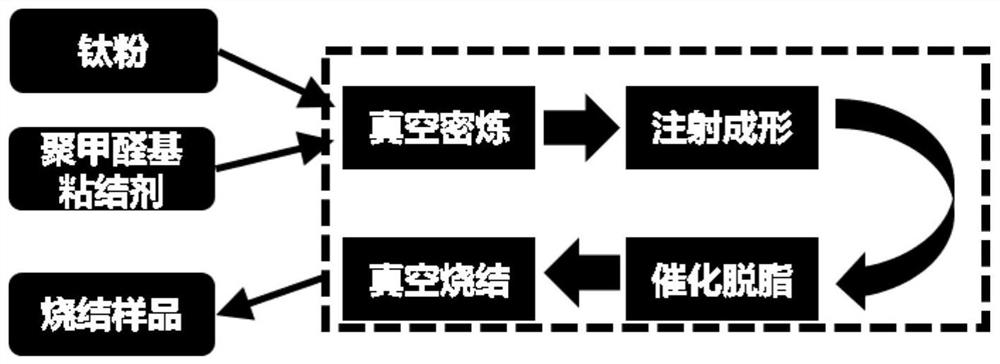

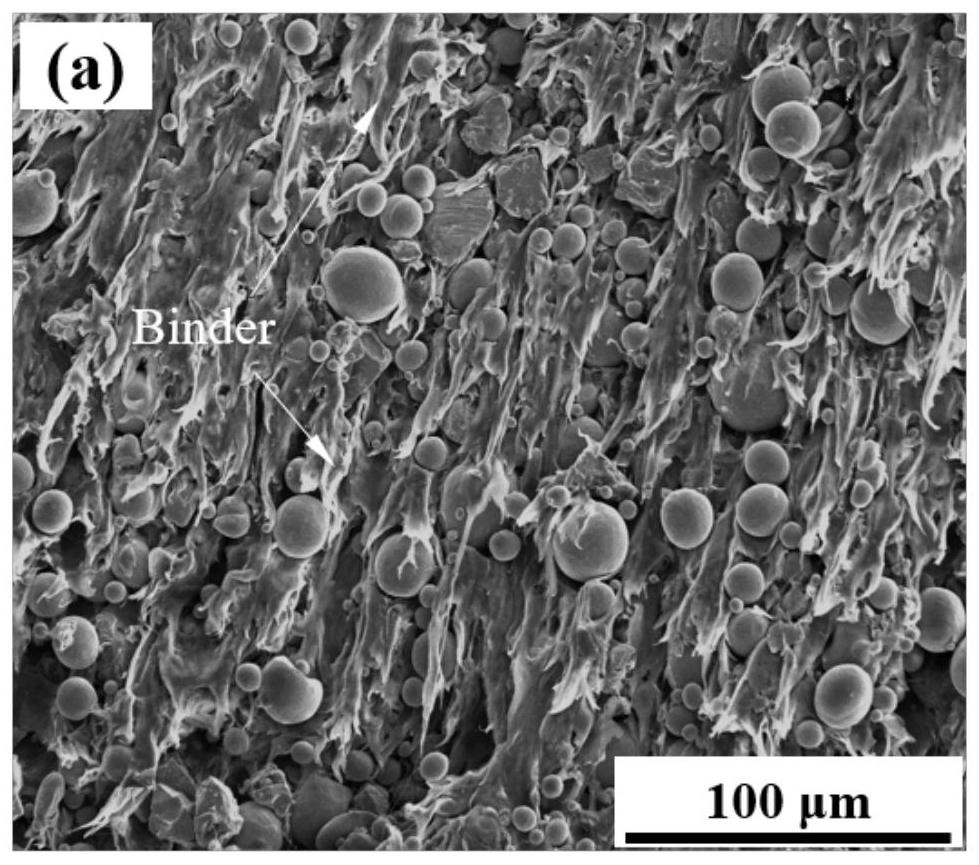

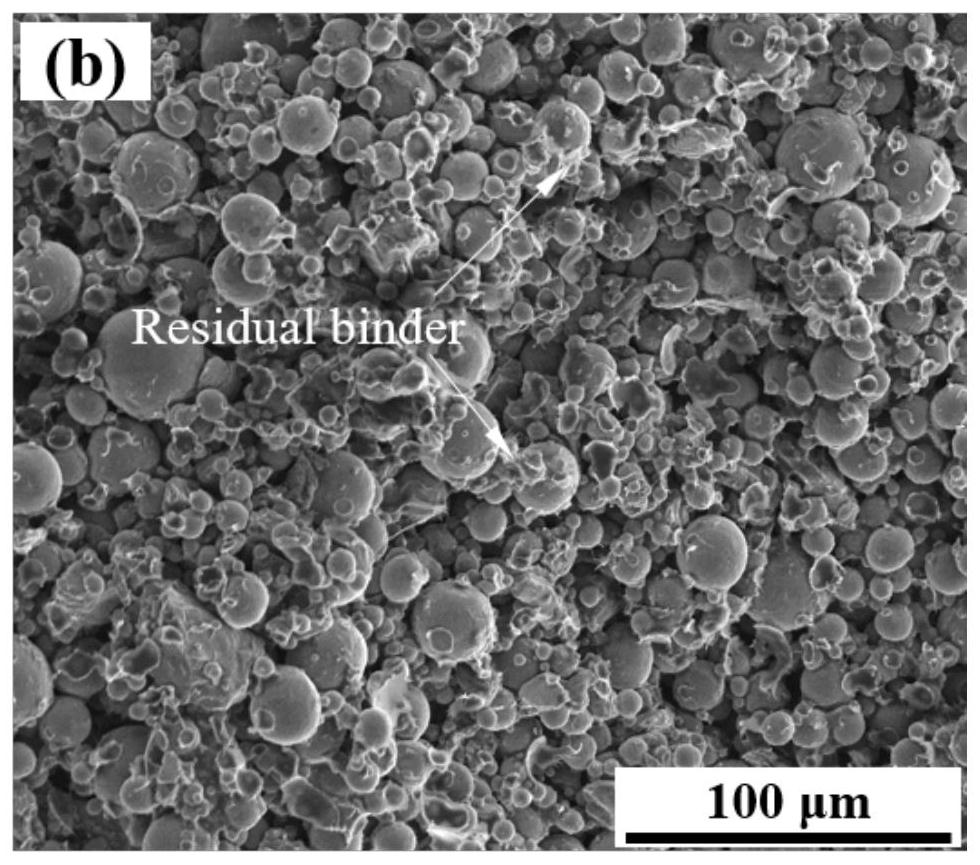

Fast-degreased feed for injection molding of titanium powder and titanium product of fast-degreased feed

The invention discloses a fast-degreased feed for injection molding of titanium powder and a titanium product of the fast-degreased feed. The feed is composed of the titanium powder and a binder, wherein the average particle size of the titanium powder is 10 to 20 [mu]m; and the binder accounts for 10 to 20 percent of the total mass of the feed, and comprises the following components in percentage by mass: 0.5 to 2 percent of an activating dispersant, 1 to 5 percent of a lubricating agent, 5 to 15 percent of a skeleton agent and 80 to 90 percent of a filling agent. The feed for injection molding is obtained by uniformly mixing the activating dispersant, the lubricating agent, the skeleton agent, the filling agent and the titanium powder together according to a certain proportion, and then carrying out granulating or crushing. The catalytic degreasing rate of the feed reaches 73.10 percent within 3 hours and reaches 85.50 percent being close to the theoretical catalytic degreasing rate within 5 hours, thermal degreasing is carried out in the early stage of sintering, and the final degreasing rate is 99.9 percent. A prepared degreased blank has few defects and good shape retention, and is greatly improved compared with a wax-based feed. The finally-sintered titanium product is free of deformation, smooth in surface, free of bumps, high in size precision and surface precision and excellent in mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

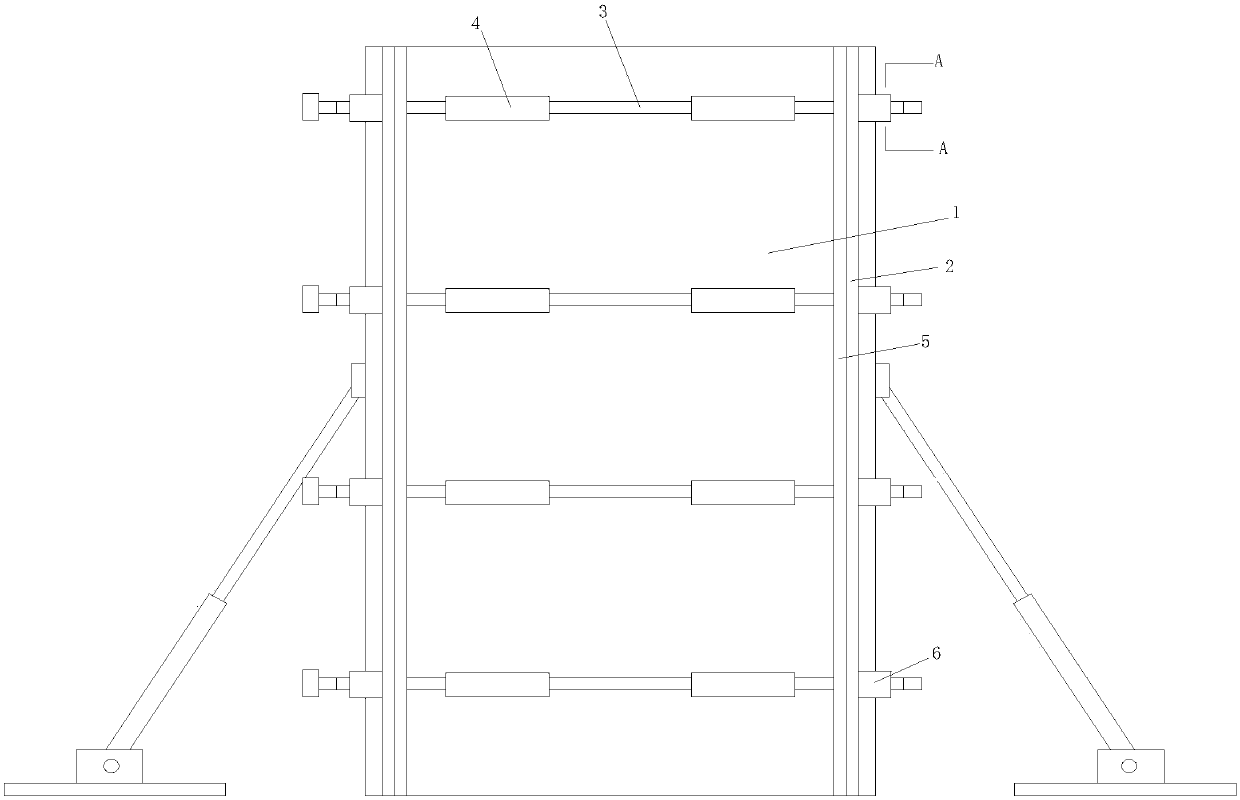

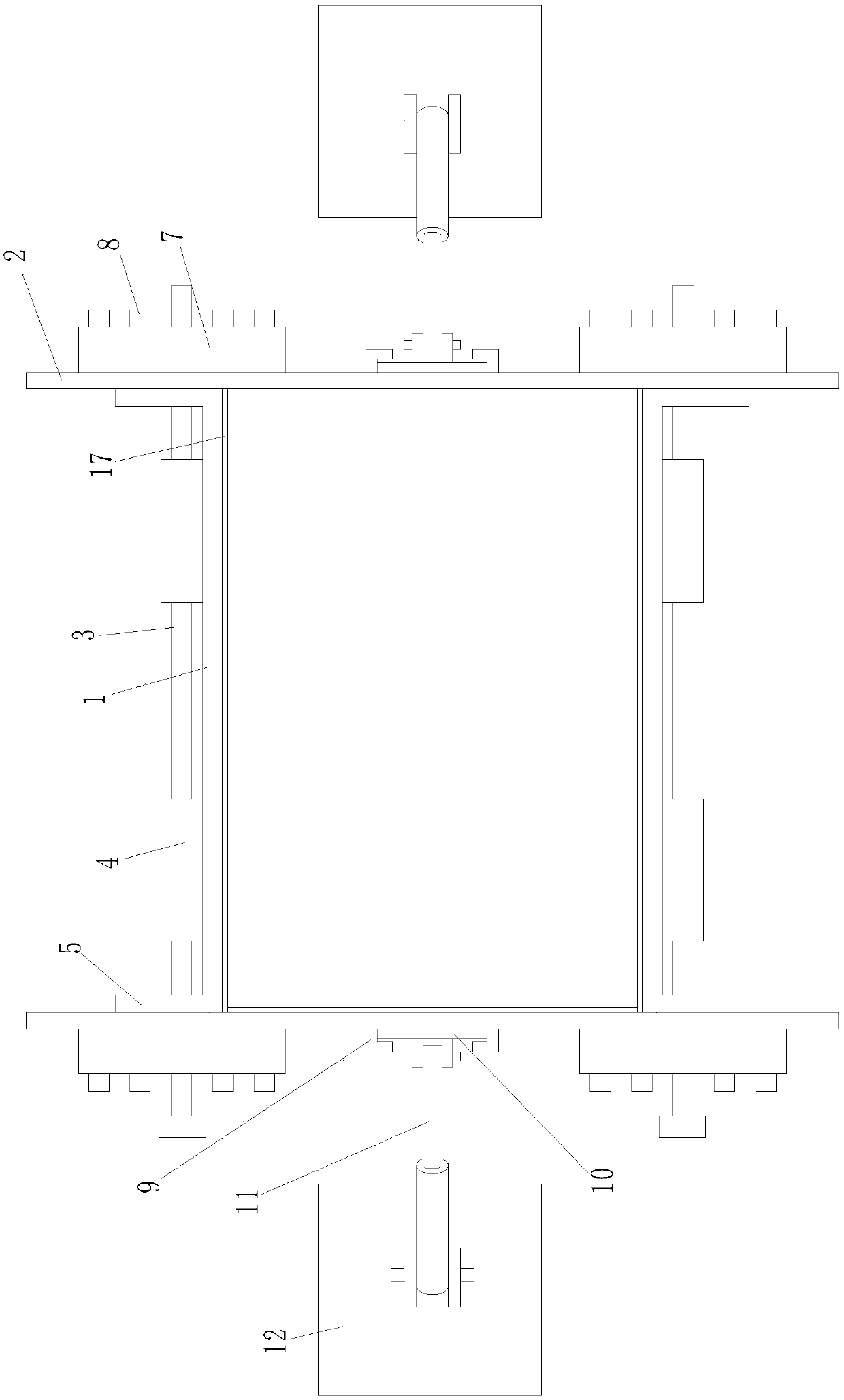

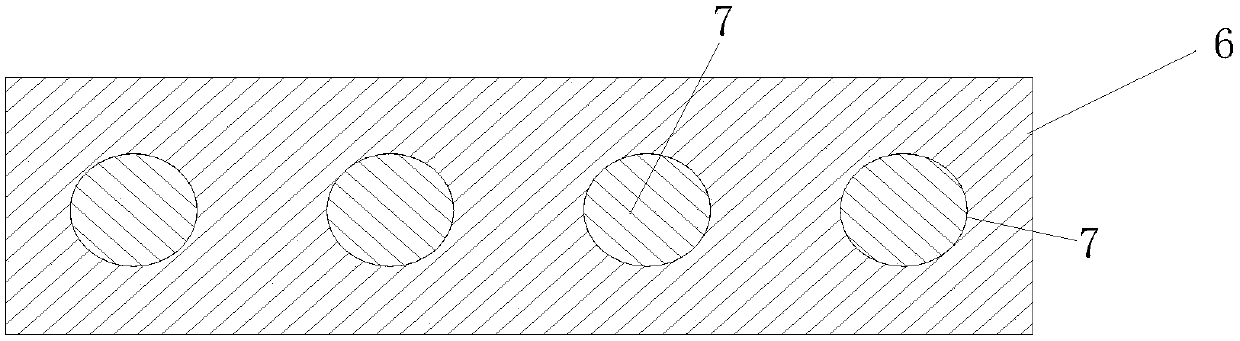

Anti-deformation pouring mold for building supporting column and pouring construction method thereof

The invention discloses an anti-deformation pouring mold for a building supporting column. The anti-deformation pouring mold comprises two parallel inner side templates (1) and two parallel outer sidetemplates (2), wherein a prismatic pouring space is formed by the two inner side templates (1) and the two outer side templates (2), the inner side templates (1) are arranged between the two outer side templates (2) and are perpendicular to the outer side templates (2), and the side edges of the inner side templates (1) are in contact with the outer side templates (2); and the outer side surfaceof each outer side template (2) is provided with an inner side template fixed supporting assembly, and each inner side template fixed supporting assembly penetrates through the outer side plate and isfixedly connected with the outer surface of the inner side template (1). The anti-deformation pouring mold provided by the invention has the advantages that the defects of the prior art can be overcome, and the structure design is reasonable and novel.

Owner:青建集团股份公司

Preparation method for composite modified facing protective layer, and power generation building material containing composite modified facing protective layer

InactiveCN112756240AAchieve aestheticsGuaranteed light transmission rateAlkali metal silicate coatingsSpecial surfacesBuilding materialWater resistance

The invention discloses a preparation method for a composite modified facing protective layer. The preparation method comprises the following step (1) of coating base materials on a carrier by spraying, and baking the carrier; and the step (2) of coating surface materials on the bottom layer by spraying, and baking the bottom layer. The base materials and the surface materials are both prepared from inorganic light diffusants and water glass, the mass proportions of the inorganic light diffusants and the water glass in the base materials and the surface materials are different, and the particle sizes of the inorganic light diffusants in the base materials and the surface materials are different. Due to the difference of the particle sizes and mass concentrations of light diffusant materials of different layers in a multi-layer structure, longitudinal distribution of media is not uniform, a scattering phenomenon is very easy to occur, and the haze is improved while the light transmittance is ensured. A method of coating one layer and baking one layer is adopted, and since each layer is thin, on one hand, water vapor is easy to release, and on the other hand, water vapor needing to be released is less; the problem of surface bulging in the baking process is solved, and the problem of water resistance of water glass is solved through a baking process.

Owner:PHOTON TECH KUNSHAN CO LTD

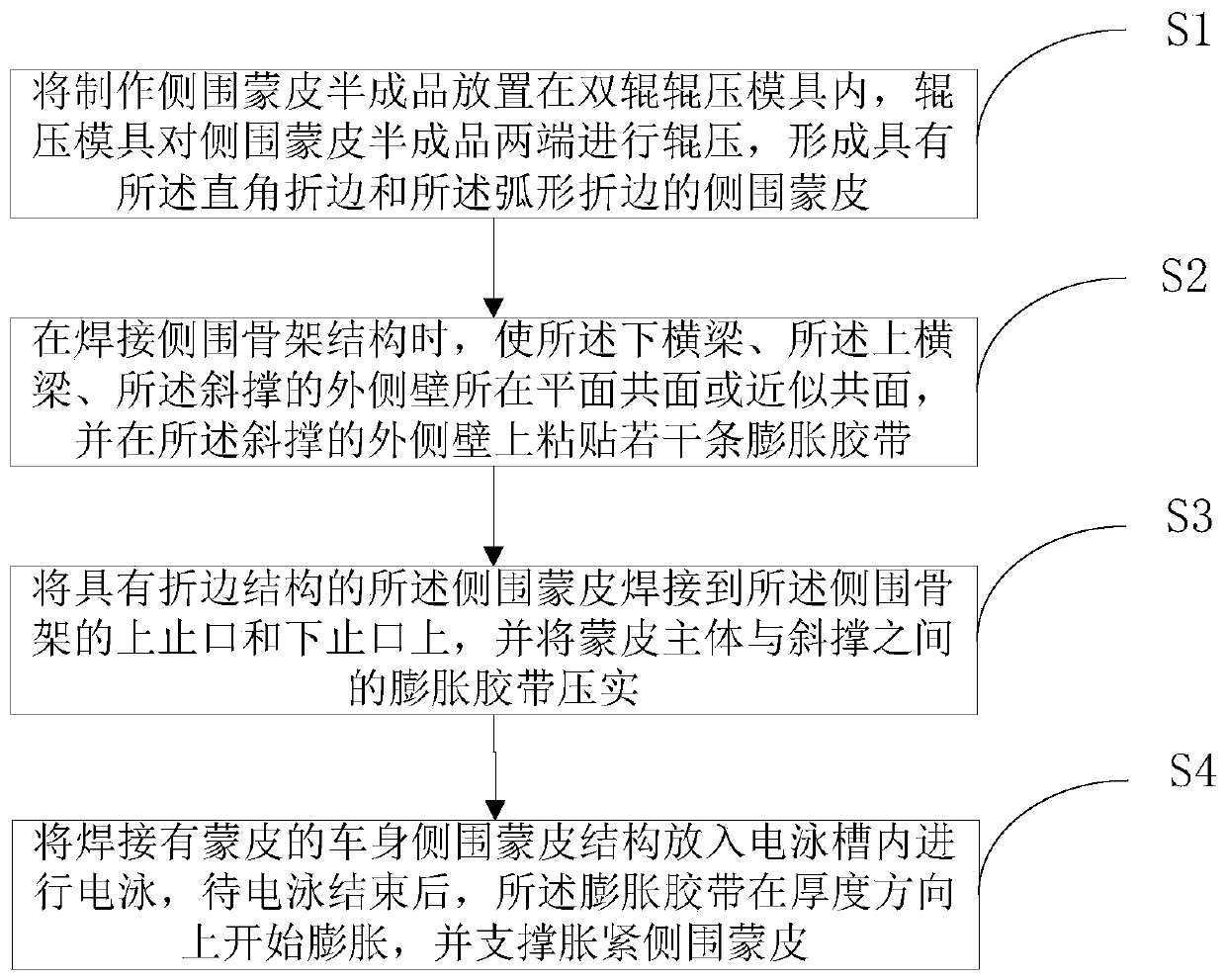

Passenger car body side skin structure and skin process

The invention discloses a passenger car body side skin structure and a skin process. The passenger car body side skin structure is characterized in that a side frame comprises an upper cross beam, a lower cross beam and a plurality of inclined supports, expansion materials are arranged on the outer side walls of the inclined supports, the side skin comprises a skin main body, an upper spigot and a lower spigot, the upper spigot is connected with the step surface of the upper cross beam, and the lower spigot is connected with the outer side wall of the lower cross beam. According to the car body side skin structure and the skin process, an edge folding mechanism on a side skin can improve the strength of the end surface of the side skin, a fault-tolerant gap is formed after the side skin and a cross beam are welded so that the influence of splashing and deformation caused by unevenness of the cross beam and welding on the flatness of the skin can be reduced, in addition, the filling materials are arranged on the inclined supports so that the flatness of the appearance of the side skin of a passenger car can be improved, and the attractiveness of the appearance can be improved to meet the requirements of the current market.

Owner:ANHUI ANKAI AUTOMOBILE

Fluorocarbon paint

InactiveCN109749536AIn line with the development trendStrong adhesionCoatingsVinyl etherAcrylic resin

The invention relates to fluorocarbon paint. The fluorocarbon paint comprises, by weight, 75-85 parts of tetrafluoroethylene-vinyl ether copolymerized fluorocarbon resin, 30-60 parts of acrylic resin,2-4 parts of hexamethylene diisocyanate trimer, 1-7 parts of adipic dihydrazide, 3-5 parts of calcined kaolin, 1-3 parts of carbon nanotubes, 1-4 parts of titanium dioxide, 1-2 parts of magnesium oxide, 1-2 parts of waterproof agent, 1-3 parts of phenyl salicylate and 1-3 parts of polyethylene wax. The fluorocarbon paint has the advantages that after film forming and solidification, the paint ishigh in adhesive force, excellent in chemical corrosion resistance, good in mechanical performance, capable of avoiding bulging and falling off even in a harsh environment and long in service life; the paint is low in VOC content, the VOC content to meet the standards in GB18582-2008, the paint conforms to paint development trend, the production cost of the paint is lower than that of water-basedfluorocarbon paint with the same performance, and the paint is high in economic benefits.

Owner:刘佳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com