A kind of heavy bamboo floor press device

A floor and press technology, applied in wood compression, wood processing equipment, manufacturing tools, etc., can solve the problems of excessive production time, increase product cost, etc., and achieve the effect of ensuring surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

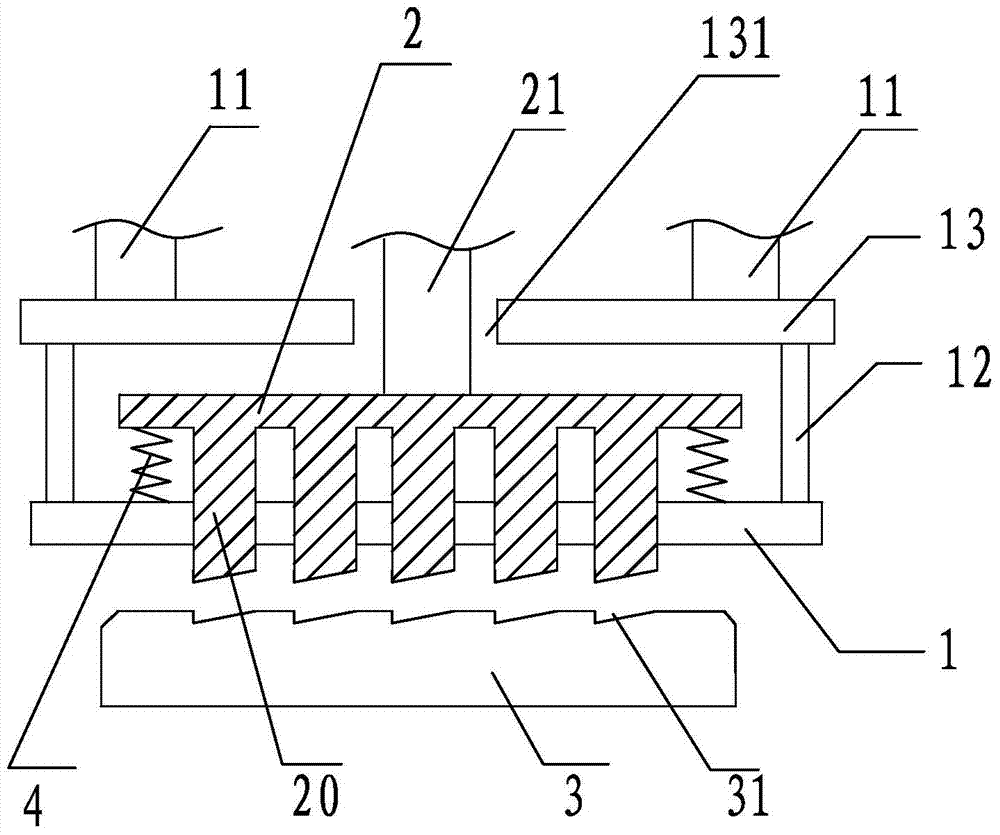

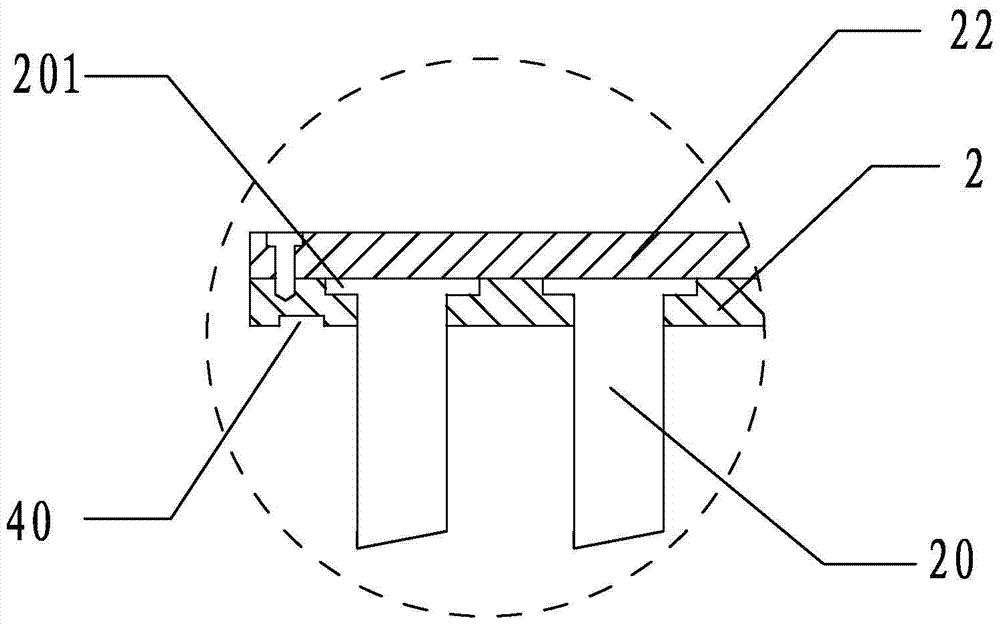

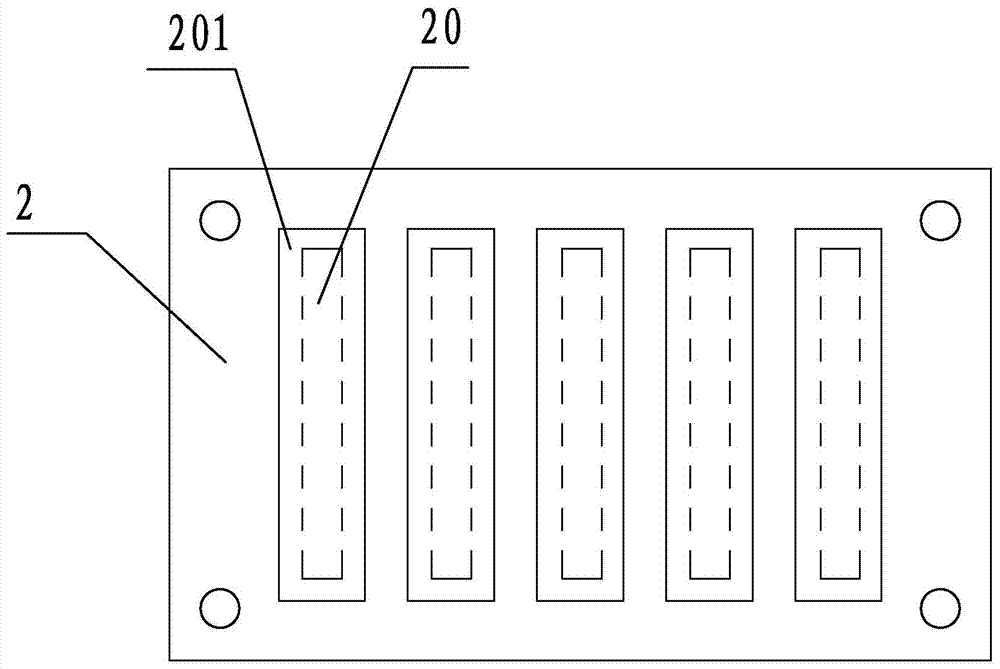

[0017] Embodiment 1: as Figure 1 to Figure 3 Shown, a kind of heavy bamboo floor press device, press device is arranged on the top of the heavy bamboo floor 3 to be processed, is provided with the first press plate 1 above the heavy bamboo floor, is provided with the second press plate 2 above the first press plate, the second The bottom of the pressing plate is provided with more than two protrusions 20, the lowest end of the protrusions extends from the bottom of the first pressing plate, the lowest end surface of the protrusions matches the shape of the groove 31 of the heavy bamboo floor to be processed, and the first pressing plate is provided with The perforation for the up and down movement of the bump is fitted with a gap between the perforation and the bump, and the gap between the fit is between 0mm and 0.5mm. A return spring 4 is provided between the first pressure plate and the second pressure plate. The top of the pressing plate is provided with a first driving d...

Embodiment 2

[0021] Embodiment 2: as Figure 4 As shown, the difference from Example 1 is that the shape and structure of the bumps are different. The cross-section of the bumps is circular, and the flange is also circular, and when the bumps are distributed, not only multiple The bumps are also provided with a plurality of bumps in the front and rear directions. The surface of the heavy bamboo floor pressed by the bumps not only has a prominent anti-slip effect, but also has a very good visual effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com