Fast-degreased feed for injection molding of titanium powder and titanium product of fast-degreased feed

An injection molding and titanium powder technology, applied in the field of titanium powder injection molding feed and its titanium products, can solve the problems of unfavorable industrialized production, poor dimensional accuracy, deformation of degreasing blanks, etc., to avoid powder glue separation, high production efficiency, The effect of improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

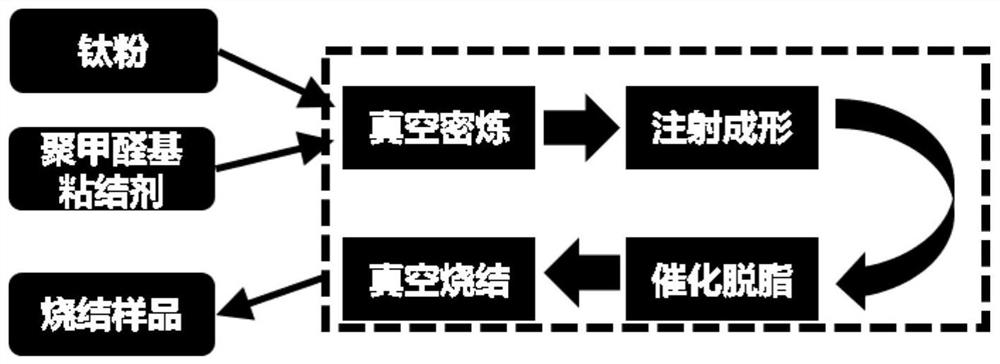

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a rapid degreasing titanium powder injection molding feedstock and its titanium products, the raw materials of which are composed of titanium powder and a binder.

[0038] The binding agent accounts for 19% of the total mass of the feeding material, and the mass percentages of each component of the binding agent are respectively 0.5% of stearic acid, 0.5% of vinylbisstearamide, 5% of paraffin wax, and 6% of high-density polyethylene , polypropylene 4%, ethylene-vinyl acetate copolymer 2%, polyoxymethylene 82%.

[0039] A preparation method for fast degreasing titanium powder injection molding feed can be realized through the following steps:

[0040] S1. Weigh the titanium powder and activated dispersant, lubricant, framework agent and filler according to the mass ratio, and then add the weighed titanium powder and the components of the binder into the vacuum internal mixer in sequence.

[0041] S2. Adjust the banburying temperature to 170° C.,...

Embodiment 2

[0050] This embodiment provides a rapid degreasing titanium powder injection molding feedstock and its titanium products, the raw materials of which are composed of titanium powder and a binder.

[0051] The binding agent accounts for 19% of the total mass of the feeding material, and the mass percentages of each component of the binding agent are respectively 0.5% of stearic acid, 0.5% of vinylbisstearamide, 3% of paraffin wax, and 5% of high-density polyethylene , polypropylene 4%, ethylene-vinyl acetate copolymer 2%, polyoxymethylene 85%.

[0052] A preparation method for fast degreasing titanium powder injection molding feed can be realized through the following steps:

[0053] S1. Weigh the titanium powder and activated dispersant, lubricant, framework agent and filler according to the mass ratio, and then add the weighed titanium powder and the components of the binder into the vacuum internal mixer in sequence.

[0054] S2. Adjust the banburying temperature to 165°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com