Patents

Literature

102results about How to "Fast degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for surface treating calender copper foil of printing circuit board

InactiveCN101074484AFast degreasingGood degreasing effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilNickel alloy

A method for treating calendaring copper foil surface of printing circuit board is carried out by pre-treating by weak alkali mixed oil remover with Na2CO3, Na3PO4 and Na2SiO3, primary coarse treating, electroplating copper by electroplating liquid containing copper ion, H2SO4 and arsenic ion, clad treating by barrier, zinc-nickel alloy clad treating, passivating and electroplating chromium clad treating to obtain final product. It has better combination with printing base plate and corrosion resistance.

Owner:SHANGHAI UNIV

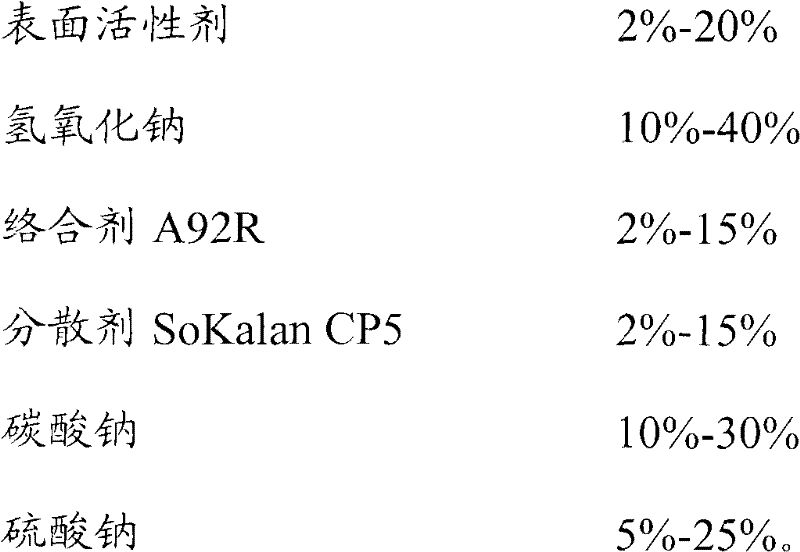

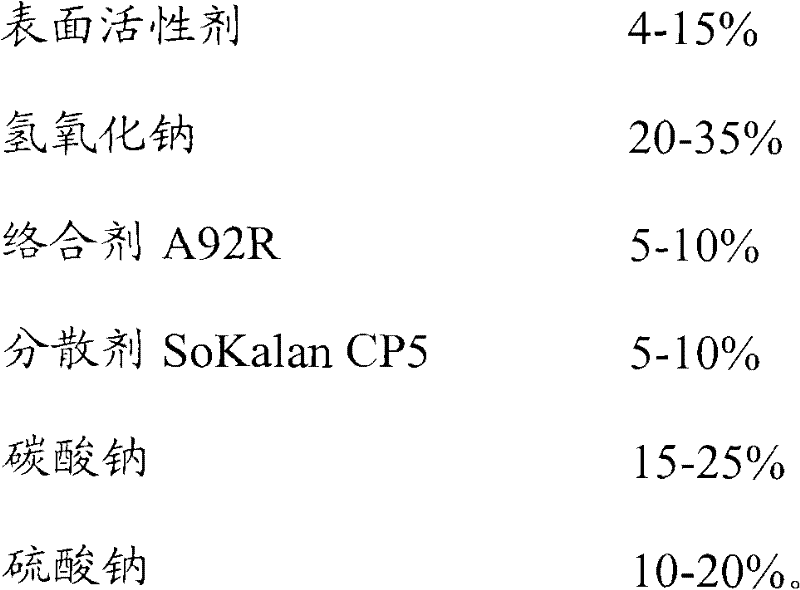

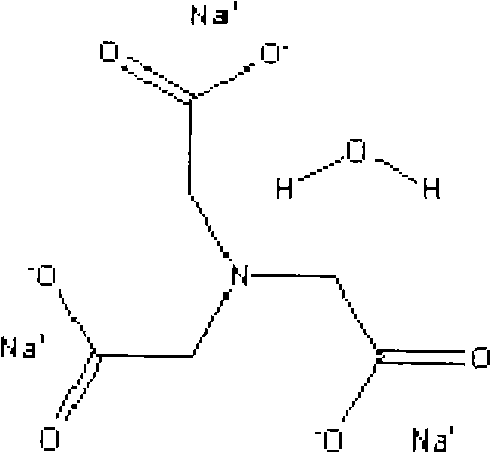

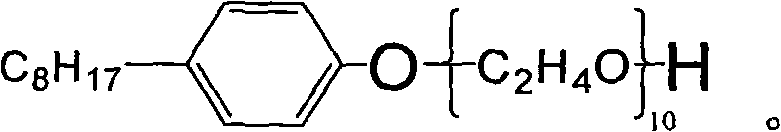

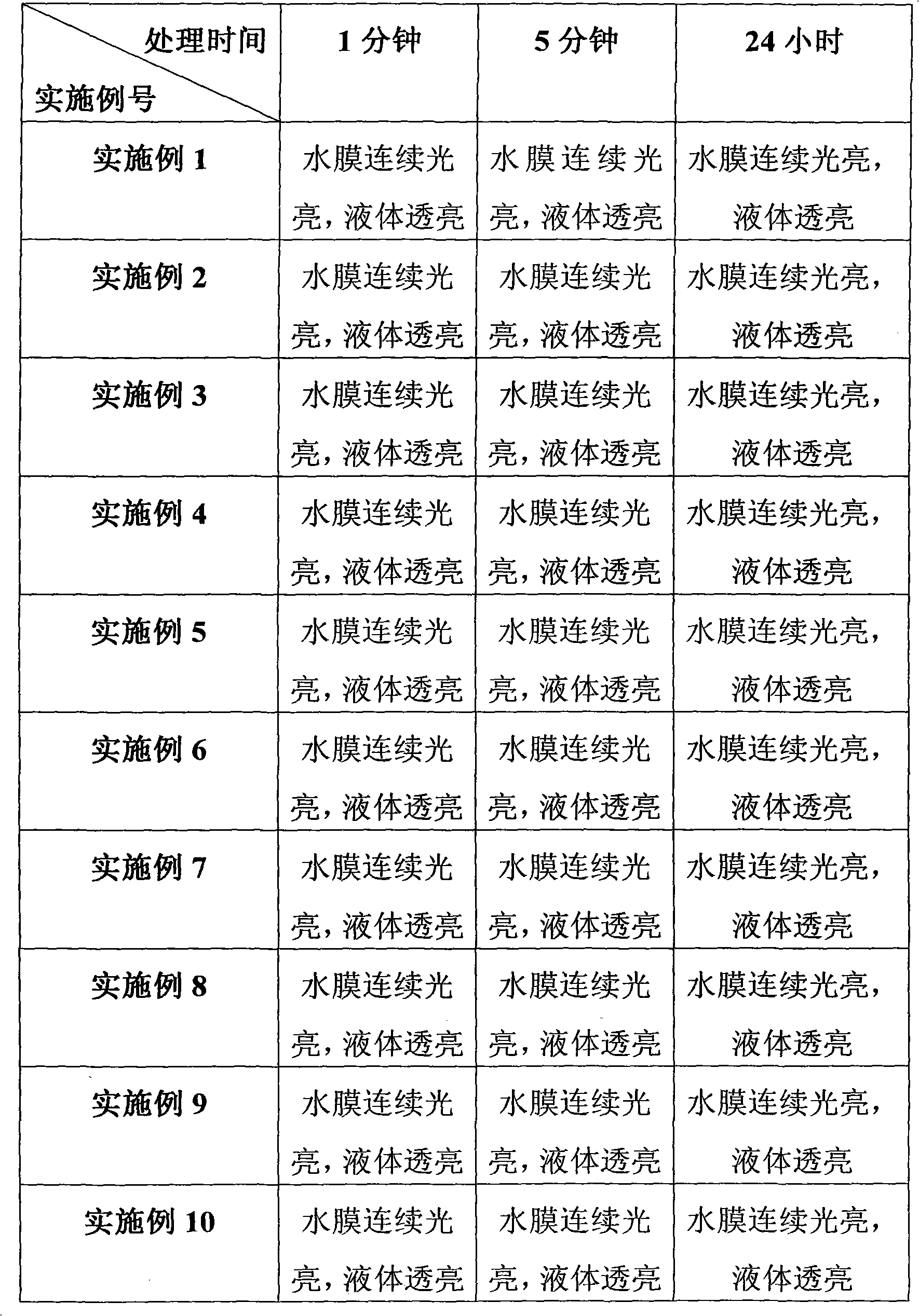

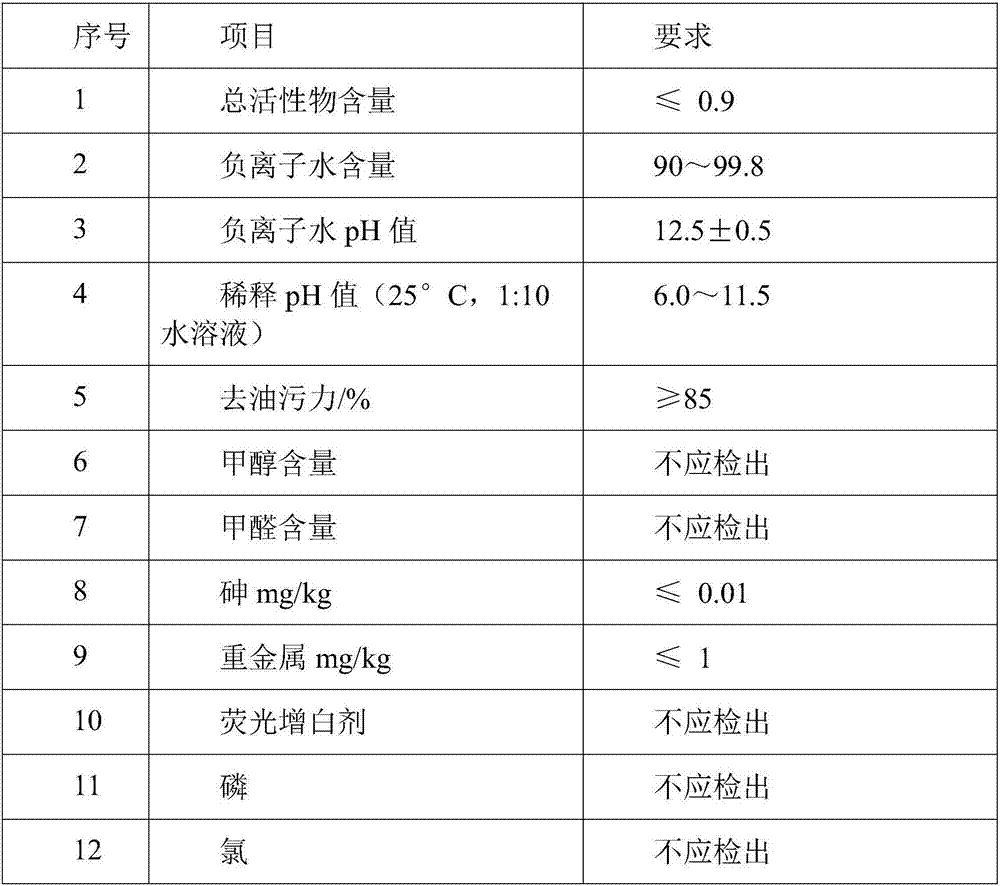

Phosphorus-free degreasing powder, production process and phosphorus-free degreasing process thereof

The present invention relates to phosphorus-free degreasing powder. The phosphorus-free degreasing powder comprises, by mass, 2-20% of a surfactant, 10-40% of sodium hydroxide, 2-15% of a complexing agent A92R, 2-15% of a washing assistant SoKalan CP5, 10-30% of sodium carbonate, and 5-25% of sodium sulfate. The phosphorus-free degreasing liquid prepared by the phosphorus-free degreasing powder of the present invention does not contain phosphorus, and has characteristics of environment-friendly property, good cleaning effect, wide application range, and long service life, and the generated wastewater is easy to treat.

Owner:东莞市宝中实业发展有限公司

Low temperature electrolytic cleaning agent particularly suitable for secondary cold-rolled steel strip

The invention relates to a low temperature electrolytic cleaning agent particularly suitable for secondary cold-rolled steel strips, and is mainly characterized in that the cleaning agent comprises the following components in percentage by weight: sodium hydroxide 20-40%, auxiliary cleaning agent 10-40%, moisture enhancing agent 5-10%, polyether emulsifier 5-30%, chelating agent 1-10%, and antifoaming agent 1-7%, the concentration of the cleaning agent during cleaning is 2-4.5%, and the temperature of the cleaning agent during cleaning is 30-40 DEG C. The cleaning agent can effectively remove the oil stains on the surface of secondary cold-rolled steel strips. The low temperature electrolytic cleaning agent provided by the invention has the advantages of low working temperature, rapid cleaning (the cleaning of the secondary cold-rolled steel strips is finished within 3-6 seconds), no scaling during use, low foam formation, and high stain removal capacity.

Owner:YANSHAN UNIV

Degreasing agent for permanent magnet material

The invention relates to a degreasing agent for a permanent magnet material. The water-soluble degreasing agent comprises alkaline materials, a cleaning auxiliary agent and a surface active agent, wherein the alkaline materials are selected from at least two of sodium hydroxide, potassium hydroxide, sodium carbonate, sodium hydrogen carbonate, trisodium phosphate or sodium pyrophosphate; the cleaning auxiliary agent is selected from at least one of organic polybasic phosphonic cleaning auxiliary agents, or a mixture of at least one of the organic polybasic phosphonic cleaning auxiliary agents and at least one of inorganic phosphate cleaning auxiliary agents; and the surface active agent is a low-foam non-ionic surface active agent. According to the invention, the degreasing agent provided by the invention has good wettability, permeability and emulsibility, high degreasing speed, higher grease dirt capacity and long service life, and can prevent grease dirt from being adsorbed again; and meanwhile, by using the non-ionic surface active agent, the foam is little, the washing performance is superior, the water can be softened, and the corrosion of the permanent magnet material in the degreasing agent can be avoided.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

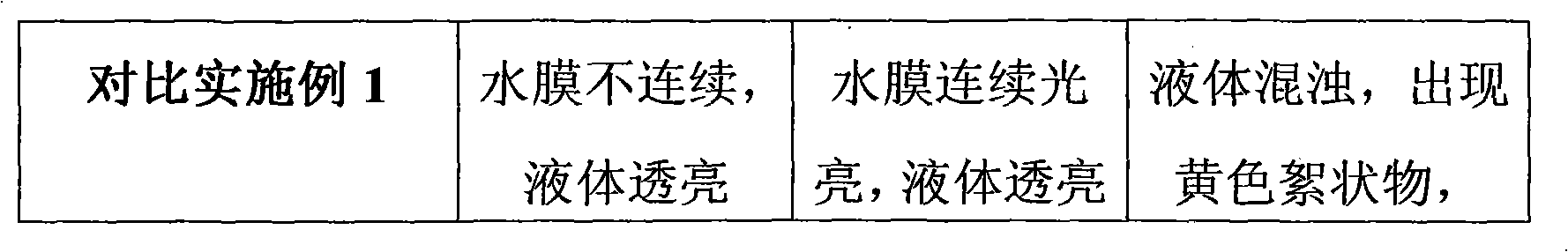

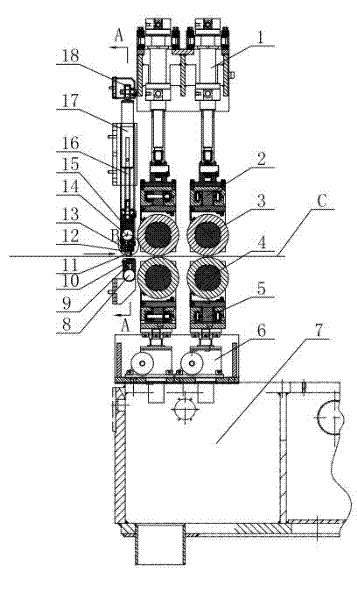

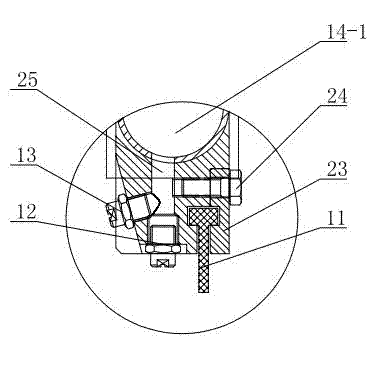

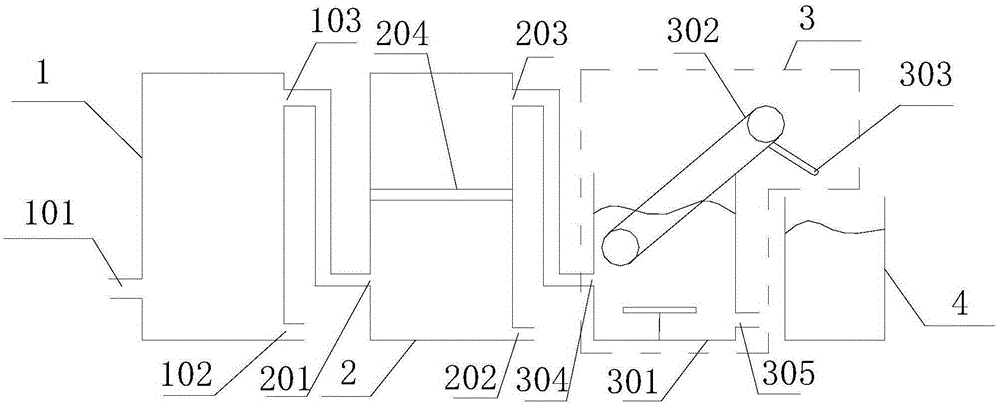

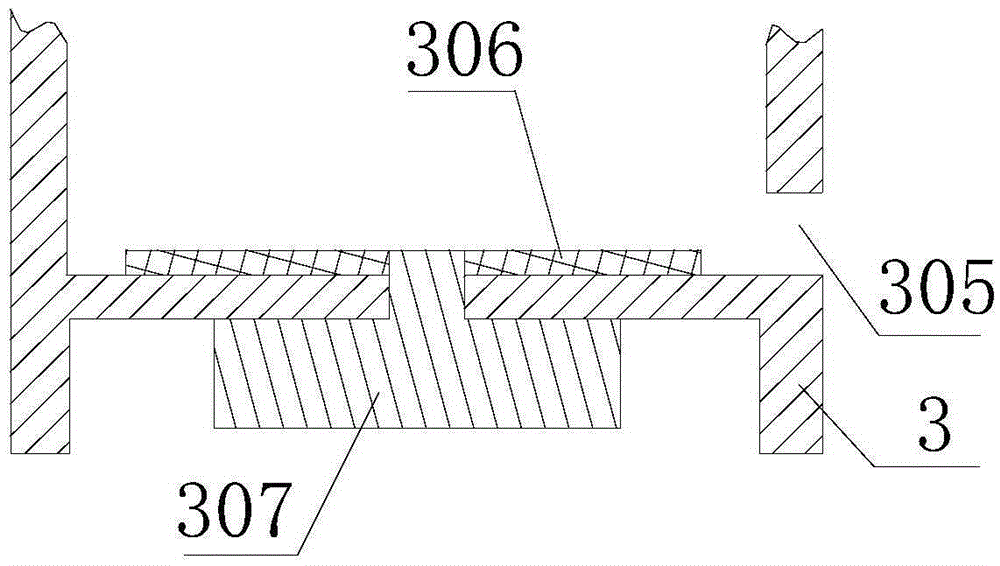

Device for removing oil on surface of belt material

InactiveCN102397892AFast degreasingSafe and reliable degreasing performanceWork treatment devicesCleaning using toolsSpray nozzleStrip steel

The invention relates to a device for removing the oil on the surface of belt material. The device comprises a machine stand, nozzle mechanisms, a scraping plate mechanism, a rubber roller mechanism and an air purging device. The air pursing device drives the nozzle to blow out dry compressed air without a stop; the upper surface and the lower surface of the belt material can be simultaneously and efficiently purged by the simultaneous purging of multiple equally and parallelly arranged and inclined nozzle mechanisms; the residual tiny impurities on the surface of the belt materials can be scrapped by the one-time scrapping and extruding of the T-shaped scraping plate; the rubber roller is driven by the warping and friction of the strip steel, as a result, the upper rubber roller and the lower rubber roller can be clamped on the upper surface and the lower surface of the belt material to process grinding. The invention is featured in fast responding speed, rational structure design, reliable use and low loss.

Owner:无锡市桥联冶金机械有限公司

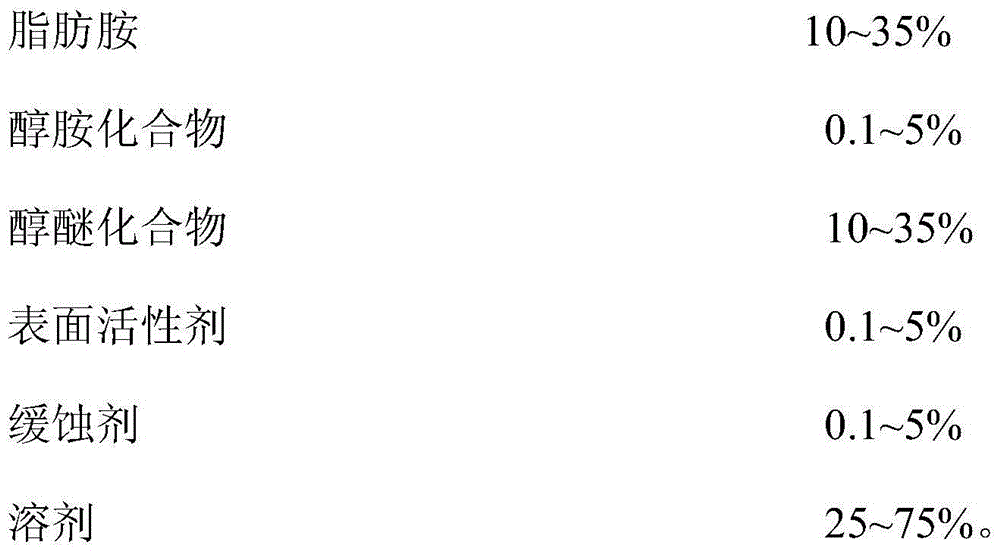

Water-based cleaning solution for cleaning printed circuit board and preparation method thereof

ActiveCN104893834AEasy to rinseAffect subsequent processesSurface-active detergent compositionsDetergent compounding agentsWater basedOzone layer

The invention relates to a water-based cleaning solution for cleaning a printed circuit board, which is prepared from the following raw materials: 10-35% of fatty amine, 0.1-5% of alcohol amine compound, 10-35% of alcohol ester compound, 0.1-5% of surfactant, 0.1-5% of corrosion inhibitor and 25-75% of solvent. The cleaning solution is good in cleaning performance, free of damaging an ozone layer, and good in environment friendliness. The preparation method of the cleaning solution comprises the following processing steps: weighting materials of certain formula quantities according to a formula; adding the solvent in a reactor, adding the alcohol amine compound in the reactor and stirring uniformly; adding fatty amine in the reactor and stirring uniformly; adding the alcohol ester compound in the reactor and stirring uniformly; adding the surfactant in the reactor and stirring uniformly; and adding the corrosion inhibitor in the reactor and stirring uniformly to obtain the product. The method is simple in process, easy to operate and high in production efficiency.

Owner:东莞市伟思化学科技有限公司

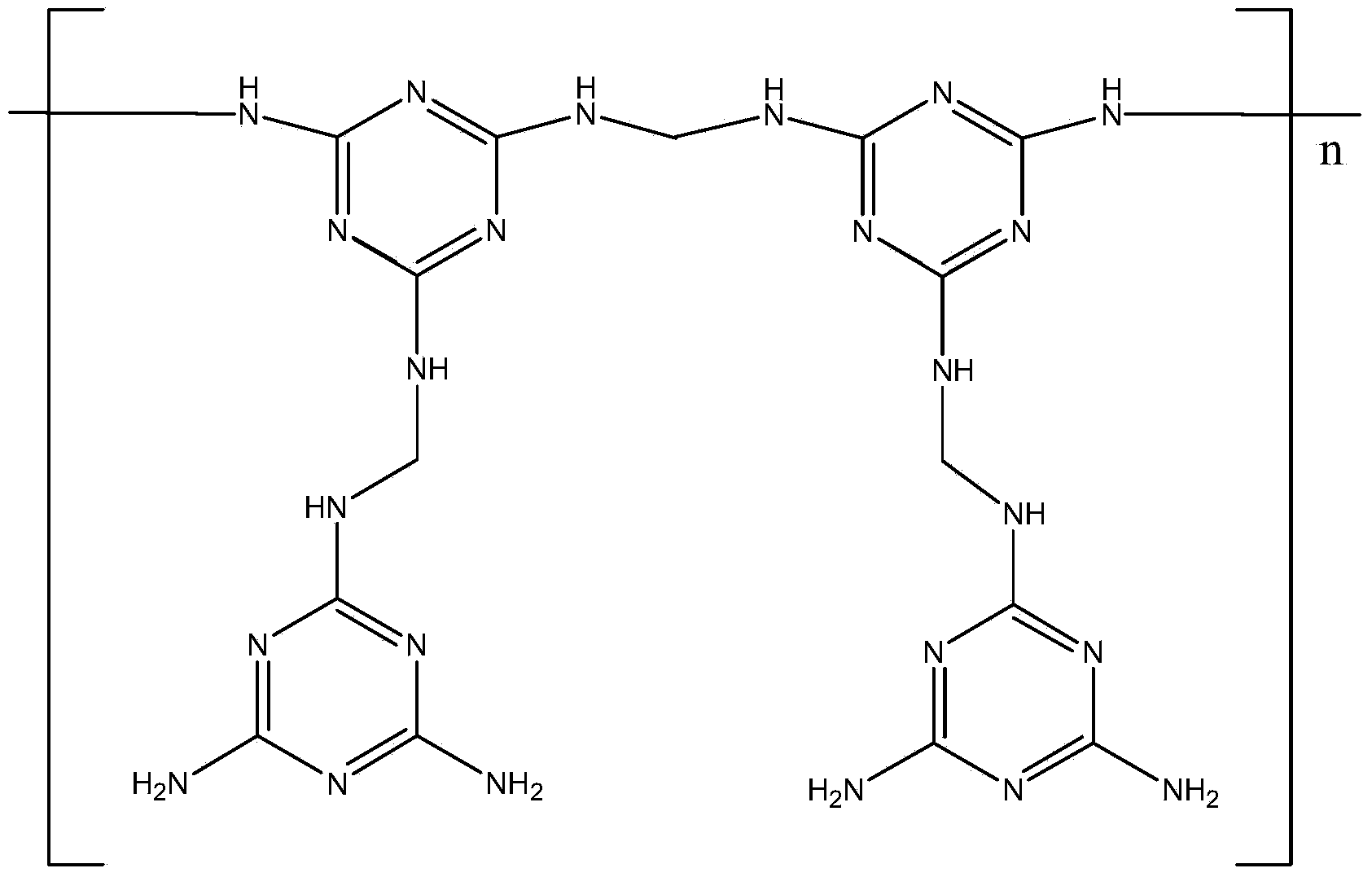

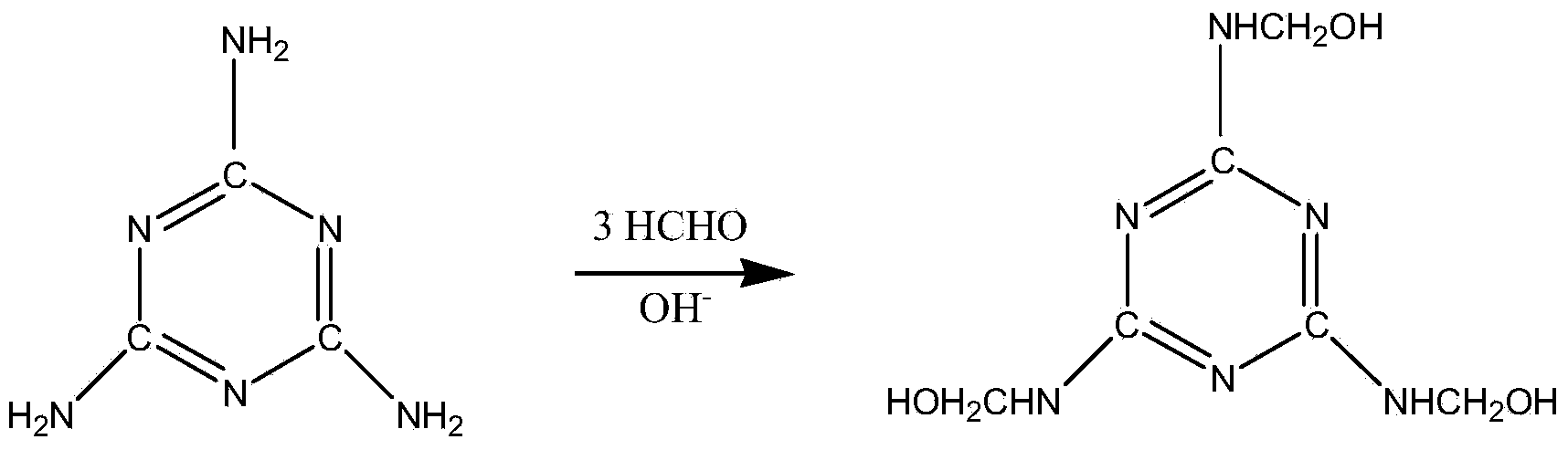

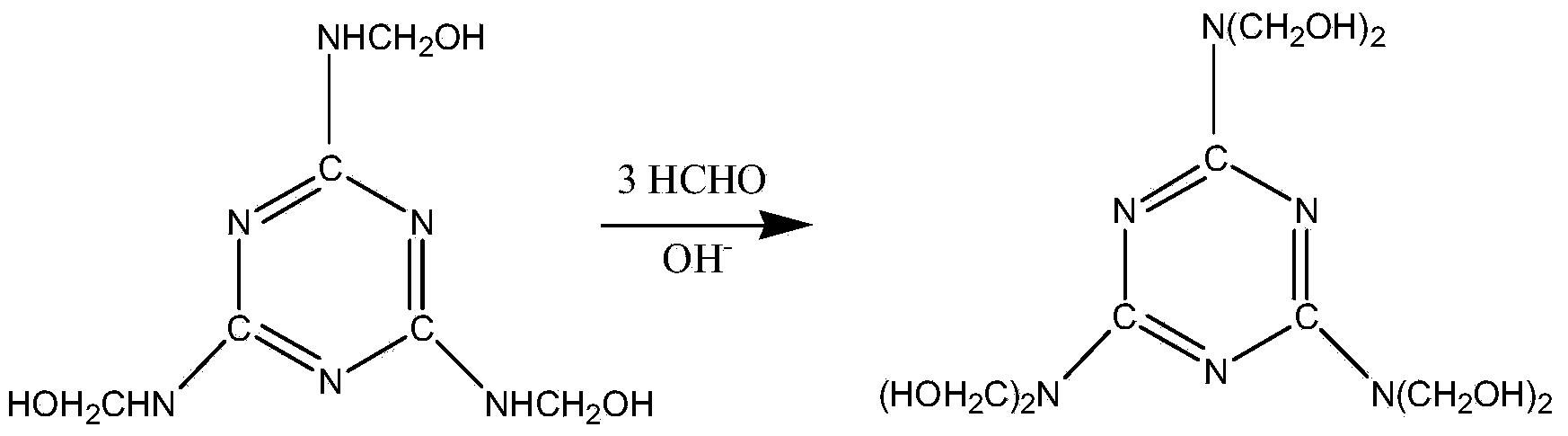

Cationic polymer as well as preparation method and application thereof

ActiveCN103450430AHigh cationic degreeHigh molecular weightFatty/oily/floating substances removal devicesLiquid separationTextile fiberDemulsifier

The invention discloses a cationic polymer as well as a preparation method and application thereof. The cationic polymer is prepared by the following five process steps in sequence: metering and mixing, hydroxymethylation reaction, polycondensation, inhibition reaction and free formaldehyde elimination. The cationic polymer has the advantages of high cationic degree, high molecular weight, long storage life and low formaldehyde content, and can serve as a flocculating agent, a reverse-phase demulsifier, a water reducing agent for concrete or a treating agent of textile fibers.

Owner:GUANGZHOU ZHENQING ENVIRONMENTAL PROTECTION TECH

Ceramic earphone and manufacturing method thereof

The invention provides a method for manufacturing a ceramic earphone. The method comprises the following steps: pressurizing and mixing ceramic powder and an organic adhesive to form slurry, wherein the organic adhesive comprises 60-90 mass parts of POM, 10-20 mass parts of PE, 10-20 mass parts of EVA, 10-20 mass parts of PW and 5-10 mass parts of SA; extruding and granulating the slurry, thereby obtaining injection molding particles; performing injection molding on the injection molding particles by using a ceramic earphone mold, and generating a green body; performing catalytic degreasing on the green body, wherein the catalyst refers to 50-90 percent of nitric acid in the catalytic degreasing step; and sintering the degreased green body. According to the method disclosed by the invention, the organic adhesive with the components is adopted, and catalytic degreasing is performed in the subsequent step by using nitric acid, so that the production cycle is greatly shortened, the defects such as softening deformation and cracking are overcome, and the yield is improved.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Additive for industrial phosphate-free degreaser and industrial phosphate-free degreaser containing the additive

InactiveCN1888040AImprove permeabilityStrong emulsifying abilityInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSodium metasilicateVegetable oil

The present invention relates to metal material detergent, and is especially one kind of industrial phosphate-free degreaser. The industrial phosphate-free degreaser consists of additive 0.1-10 wt%, sodium carbonate 35-65 wt%, anhydrous sodium metasilicate 20-50 wt% and octyl phenol polyethenoxy ether 0.5-5 wt%. The present invention has very powerful stain penetrating and emulsifying capacity, excellent effect of eliminating mineral oil and vegetable oil from metal surface, low treating temperature and fast oil eliminating speed, and is especially suitable for use in industry closed spraying and painting production line.

Owner:江涛

Water clarifier mixed system for treating sewage containing polymer

ActiveCN105692780AFast degreasingEfficient degreasingWaste water treatment from quariesFatty/oily/floating substances removal devicesEthylenediamineGlycerol

The invention a water clarifier mixed system for treating sewage containing polymer. A mixed water clarifier for treating the sewage containing polymer comprises a cationic type water clarifier and a non-ionic type water clarifier, wherein the cationic type water clarifier is at least one of glycerol-epichlorohydrin-triethylamine polymer, dimethylamine-epichlorohydrin-ethylenediamine polymer, polyaluminium chloride and poly-ferric sulfate; the non-ionic type water clarifier is polyether amine grafted polyether and / or polyethylene polyamine grafted polyether; the mass ratio of the cationic type water clarifier to the non-ionic type water clarifier is 1:10-1. The mixed water clarifier has the advantages that the mixed water clarifier can be used for fast and efficiently deoiling the sewage, the deoiling and solid removing efficiency of the water clarifier can be guaranteed, the mixed water clarifier is also applicable to the sewage with high oil content, and inverse demulsification can be achieved to reduce the oil content in floc; when the mixed water clarifier is used, inverse demulsification can be achieved to reduce the oil content in the floc during water clarifier flocculation and water clarifying, and the generated floc is non-sticky, and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

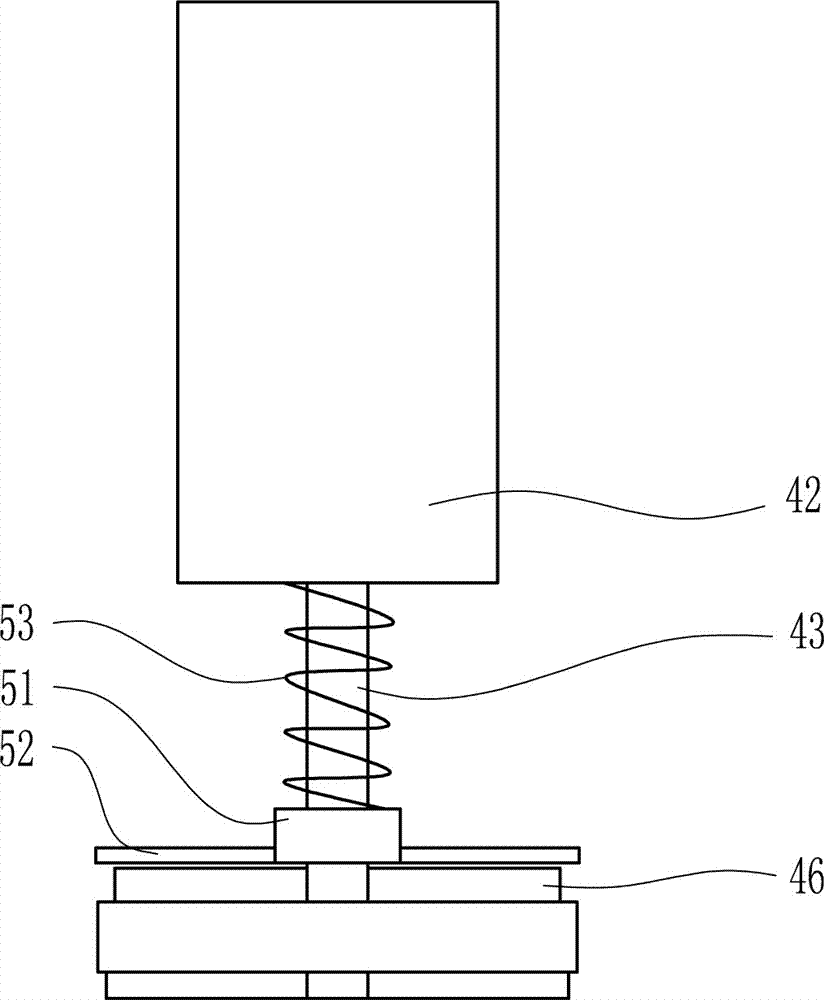

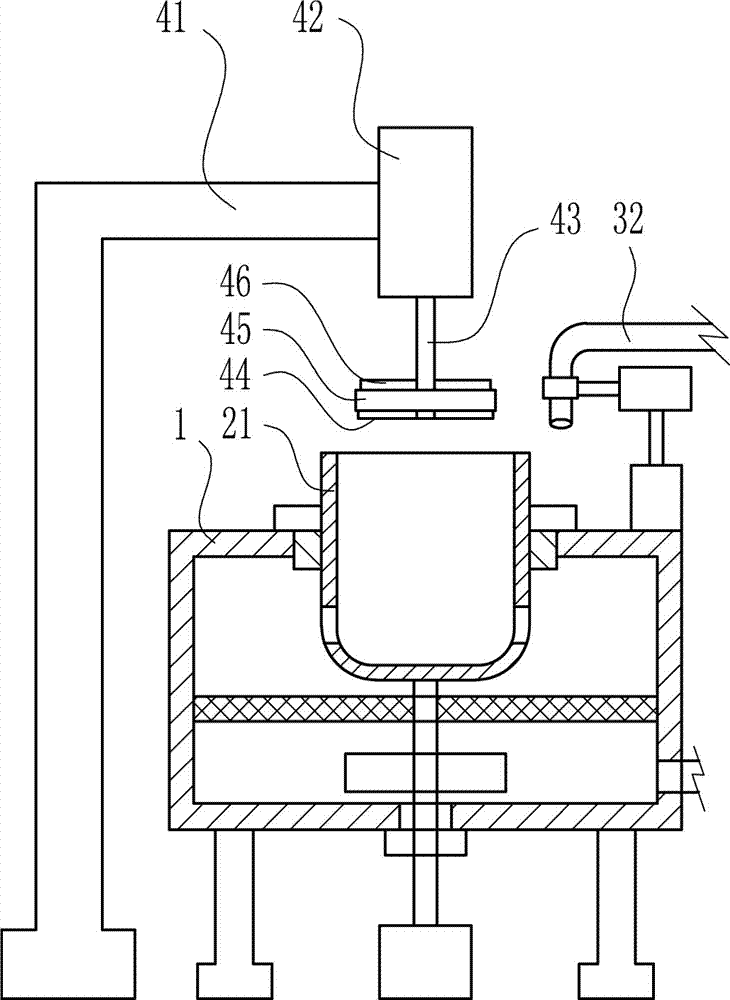

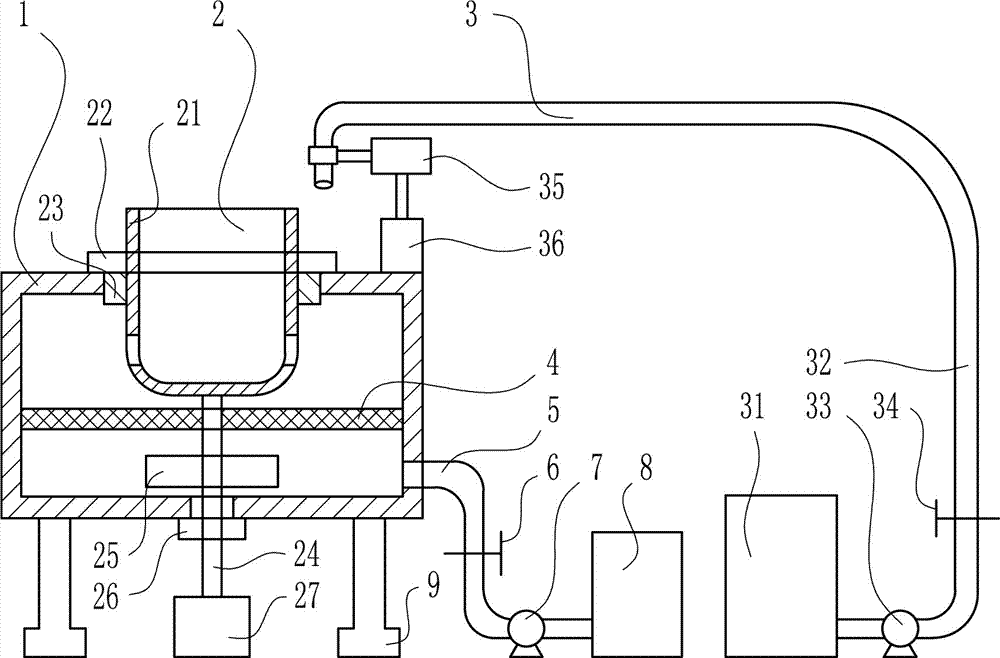

Rapid deoiling device for rare earth feed liquid

ActiveCN107217160AFast degreasingReduce manufacturing costProcess efficiency improvementFuel tankRare earth

The invention relates to a deoiling device, in particular to a rapid deoiling device for rare earth feed liquid. The rapid deoiling device for rare earth feed liquid for solving technical problems comprises a deoiling box, a rotating device, a feed liquid collection device, a filter cloth, a connection pipe, a first valve and the like. The rotating device is installed on the deoiling box, the feed liquid collection device is arranged on the right side of the deoiling box, the filter cloth is in screw connection with the lower portion of the inner side wall of the deoiling box, the lower portion of the right side wall of the deoiling box is in welded connection with the left end of the connection pipe, and the connection pipe communicates with the deoiling box. According to the rapid deoiling device for rare earth feed liquid, by combining the filter cloth, the rotating device and the feed liquid collection device, rare earth feed liquid can be rapidly deoiled.

Owner:徐玉玉

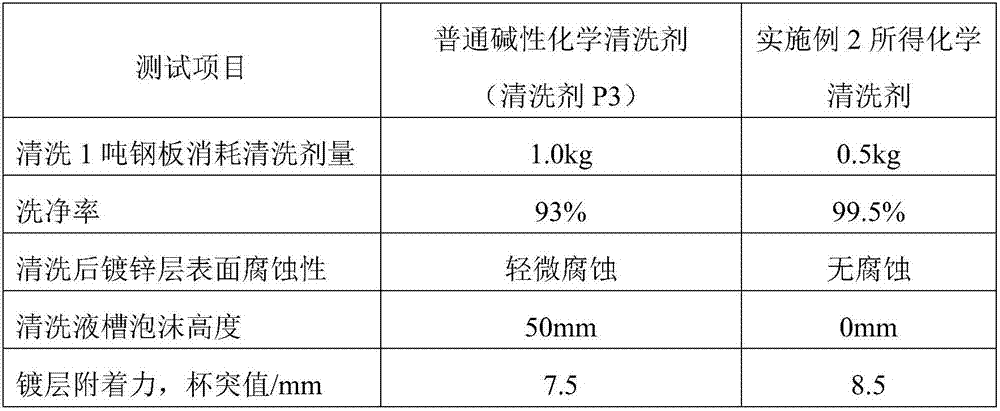

Alkaline chemical cleaning agent for electrogalvanizing pretreatment

The invention provides an alkaline chemical cleaning agent for electrogalvanizing pretreatment. The alkaline chemical cleaning agent for electrogalvanizing pretreatment comprises, by mass, 15%-35% of sodium hydroxide, 25%-55% of sodium carbonate, 5%-30% of trisodium phosphate, 5%-15% of sodium benzoate, 3%-10% of sodium citrate, 5%-15% of polyoxyethylene nonyl phenyl ether surface active agent and 0.5%-2% of polyether type antifoaming agent. The alkaline chemical cleaning agent can effectively restrain generation of foams in the sprinkling process and is rapid in degreasing, high in dirt removing capacity, good in cleaning effect, high in pH value buffering capacity, stable in hard water, long in service life, wide in application temperature range and capable of effectively improving the adhesive force of an electrogalvanizing layer. The alkaline chemical cleaning agent can meet the requirements, for the time and cleaning efficiency of cleaning pretreatment of a galvanizing substrate, of a large-scale electrogalvanizing production technology and has important industrial popularization significance.

Owner:武汉钢铁有限公司

Preparation method and application of coix seed extract

InactiveCN109170532AInhibit blood sugar riseImprove starch removal rate and degreasing rateOther chemical processesCombustible gas purificationIonic strengthEmulsion

The invention relates to a preparation method of a coix seed extract. The method comprises the steps as follows: S1, drying and crushing coix seeds to obtain coix seed flour; S2, removing starch and fat in the coix seed flour through acid treatment and addition of a degreasing agent; S3, performing dynamic superhigh-pressure microfluidization treatment on coix seed pulp to promote dissolution extraction of polysaccharide and protein in the coix seed pulp; S4, adjusting the mass concentration of the coix seed pulp, adding an ionic strength regulator to regulate the ionic strength of the coix seed pulp, and adjusting the pH of the coix seed pulp; S5, adding an organic polymer adsorbent to the coix seed pulp to adsorb protein and polysaccharide agglomerates; S6, performing standing and filtration, collecting a filtered-out organic polymer adsorbent, and sequentially eluting polysaccharide and protein; and S7, removing starch and grease again through low-temperature settlement and centrifugal degreasing to finally prepare a coix seed emulsion containing polysaccharide and protein. The prepared coix seed emulsion is compounded into instant compound coix seed flour.

Owner:福建拓天生物科技有限公司

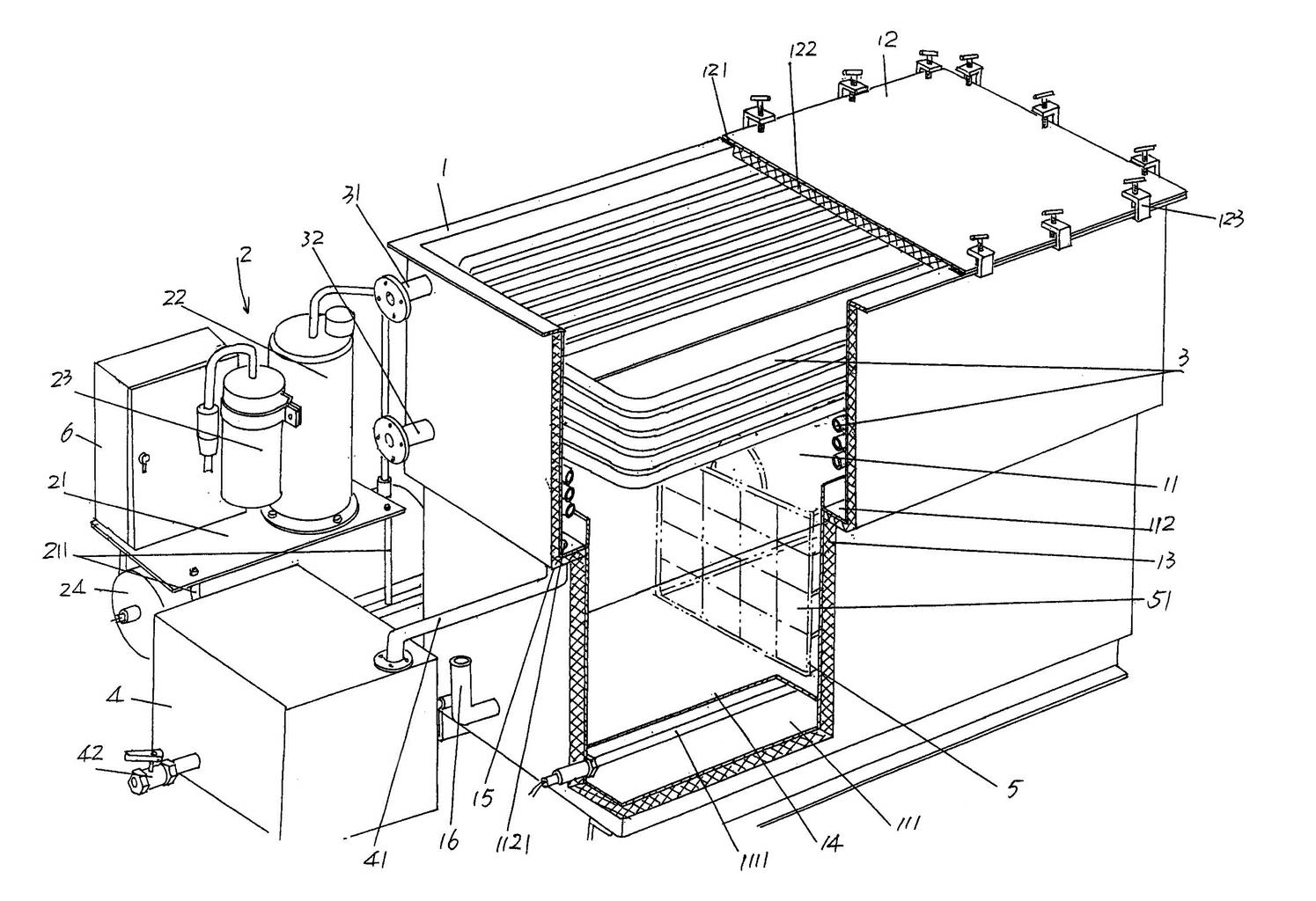

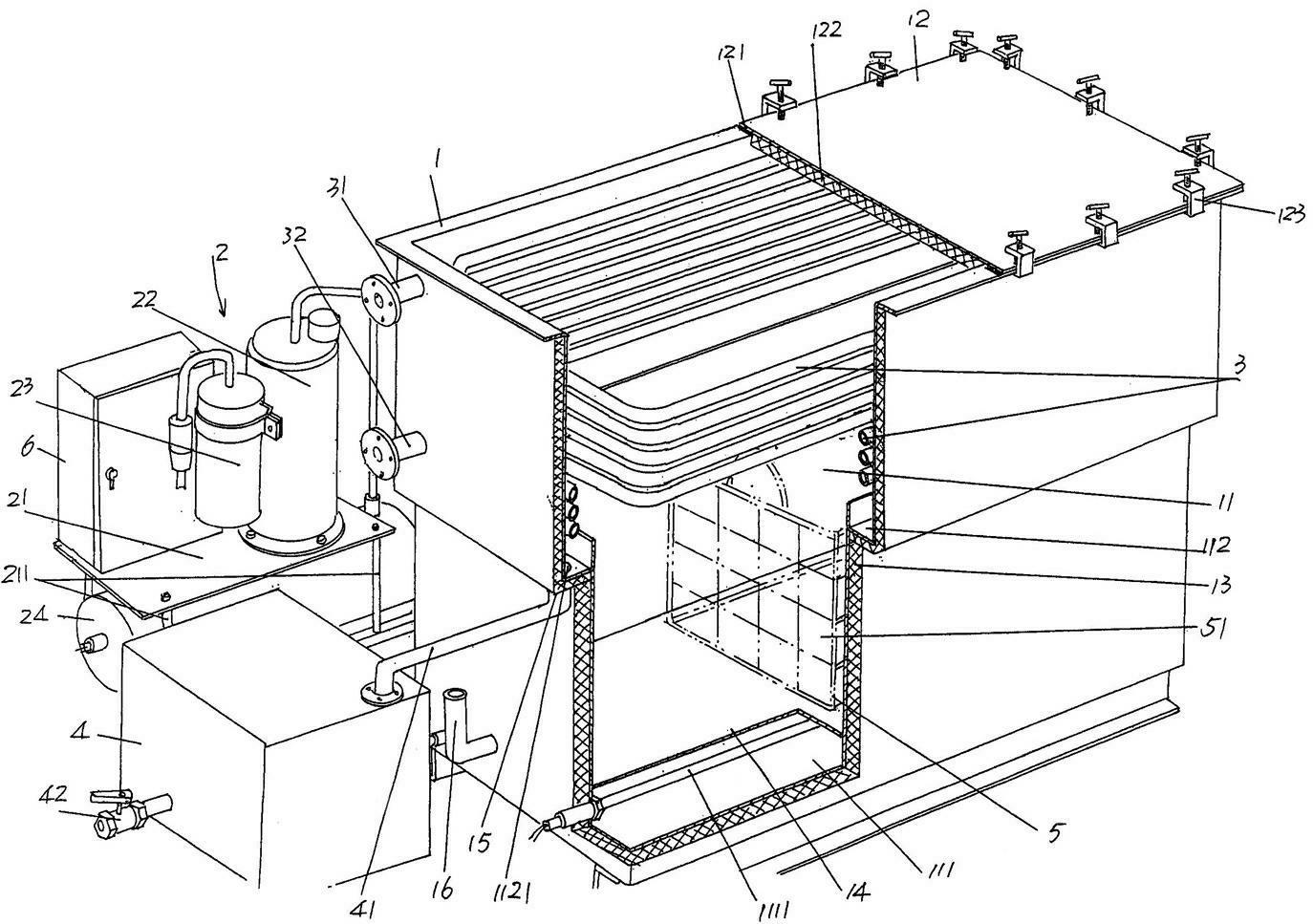

Degreasing machine with solvent recovery function

InactiveCN102581284AGuaranteed temperatureShorten heating timeVapor condensationThermodynamicsProcess engineering

A degreasing machine with a solvent recovery function belongs to the technical field of degreasing equipment for degreasing powder metallurgy injection molding blanks. The degreasing machine comprises a box, a refrigerating unit, a condensing coil and a solvent collecting box, a heating clamp cavity is formed on the lower portion of a box cavity of the box, a heating device is arranged in the heating clamp cavity, a liquid collecting channel is formed on the inner wall close to the middle of the box cavity in the height direction, and a liquid outlet hole is arranged at the bottom of the liquid collecting channel. The refrigerating unit is arranged on one side of the box. The condensing coil is laid on the inner peripheral wall of the box cavity and corresponds to the upper side of the liquid collecting channel, and a liquid inlet and a liquid outlet of the condensing coil are connected with the refrigerating unit. The solvent collecting box is arranged on one side of the box and is connected with the liquid outlet hole in a matched manner through a solvent collecting pipe. The degreasing machine has the advantages that heating effect is fine, degreasing speed is fast, the temperature of the box cavity in a heating state can be guaranteed so as to shorten the heating time of the heating device and increase solvent extraction speed, the degreasing machine is environment-friendly, and resources are saved.

Owner:宝得粉末注射成形(常熟)有限公司

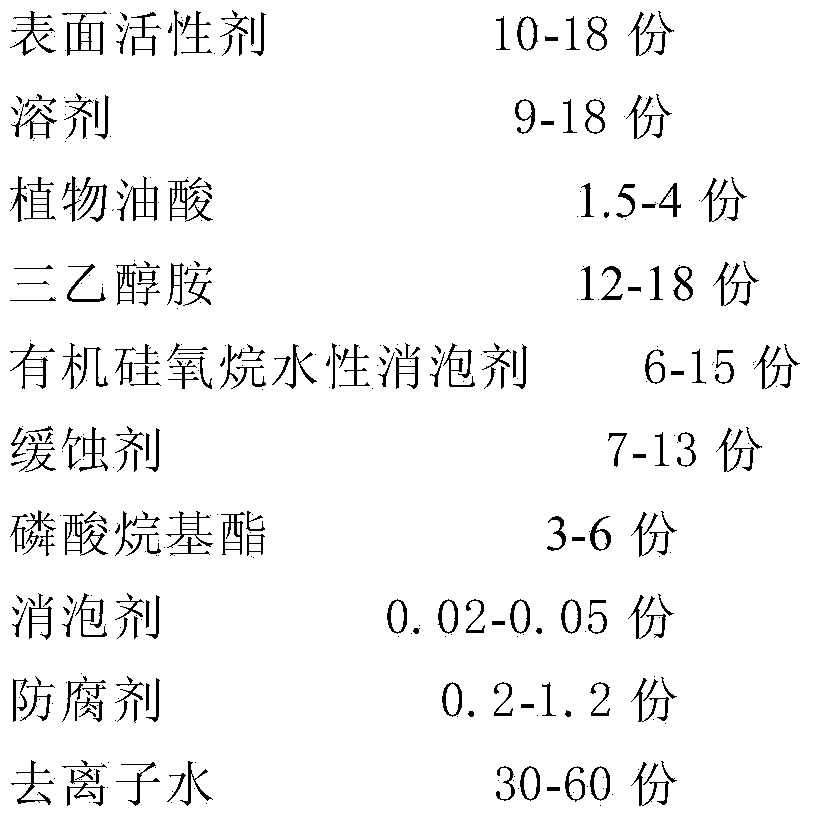

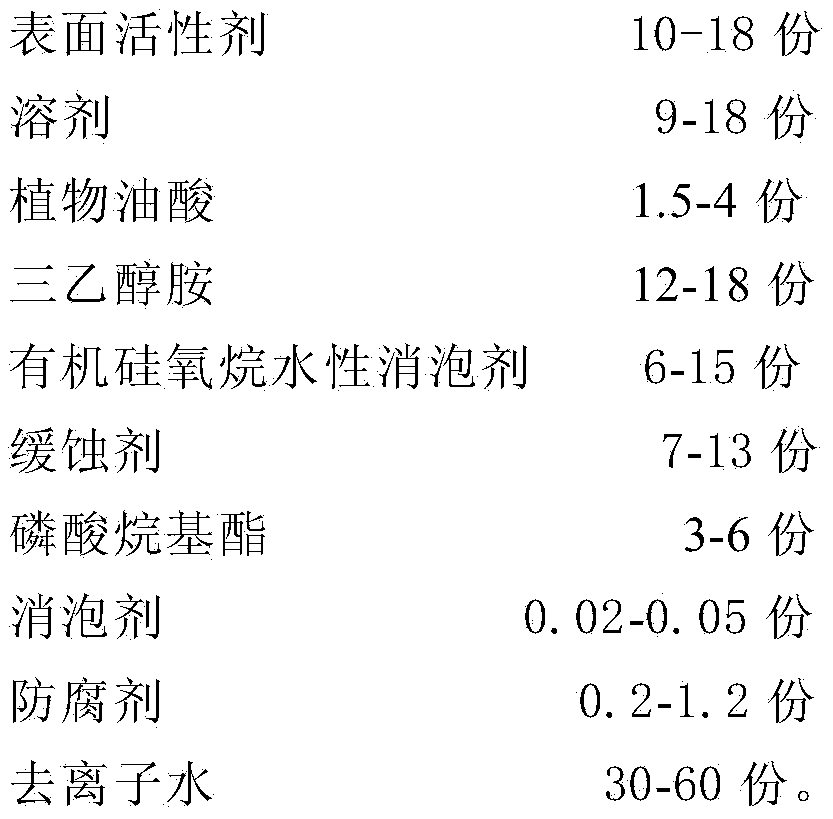

Special metal cleaning agent for water-based reactive aluminum product and preparation method thereof

The invention relates to a special metal cleaning agent for a water-based reactive aluminum product. The special metal cleaning agent is prepared from a surfactant, a solvent, plant oleic acid, triethanolamine, organosiloxane, a corrosion inhibitor, alkyl phosphate, a defoamer 575, a preservative 1227, deionized water and the like. The metal cleaning agent disclosed by the invention is non-toxic, harmless and pollution-free, is harmless to human, is corrosion-free to the surface of the aluminum product, is odorless during long-time use, does not deteriorate, has extremely excellent cleaning and antirusting functions, particularly cleans thick and hard deposited carbon and stubborn stains thoroughly, does not corrode aluminum products of various models and is applicable to ultrasonic machine cleaning, spraying machine cleaning, handed soak rinsing and the like, and the natural antirusting time of workpieces is over 60 days after cleaning.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

Water-based normal-temperature rust-removal rust-proof liquid and preparation method thereof

ActiveCN103882451AFast degreasingQuick rust removalMetallic material coating processesSODIUM METAPHOSPHATESodium phosphates

The invention relates to a water-based normal-temperature rust-removal rust-proof liquid, which is prepared from the following active ingredients in parts by weight: 1-2 parts of zinc oxide, 2-3 parts of manganese dioxide, 2-3 parts of citric acid, 22-24 parts of E-12 epoxy resin, 6-8 parts of sodium hexametaphosphate, 1-2 parts of dimethyl formamide, 2-3 parts of catechol, 1-2 parts of sodium dodecyl benzene sulfonate, 13-15 parts of bisphenol A epoxy acrylate, 1-2 parts of disodium edetate dihydrate, 4-5 parts of auxiliaries and 300 parts of water. The rust-proof liquid can fast remove oil and rust at normal temperature, and can be corrosion-resistant and antibacterial, a thin film can be formed on a metal surface by using organic polymer resin and a chelating agent so as to isolate air and achieve the oxidization prevention effect, and the corrosion-inhibition and rust-proof effects are better, the thin film is easy to remove with water, thus being energy-saving and environment-friendly.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

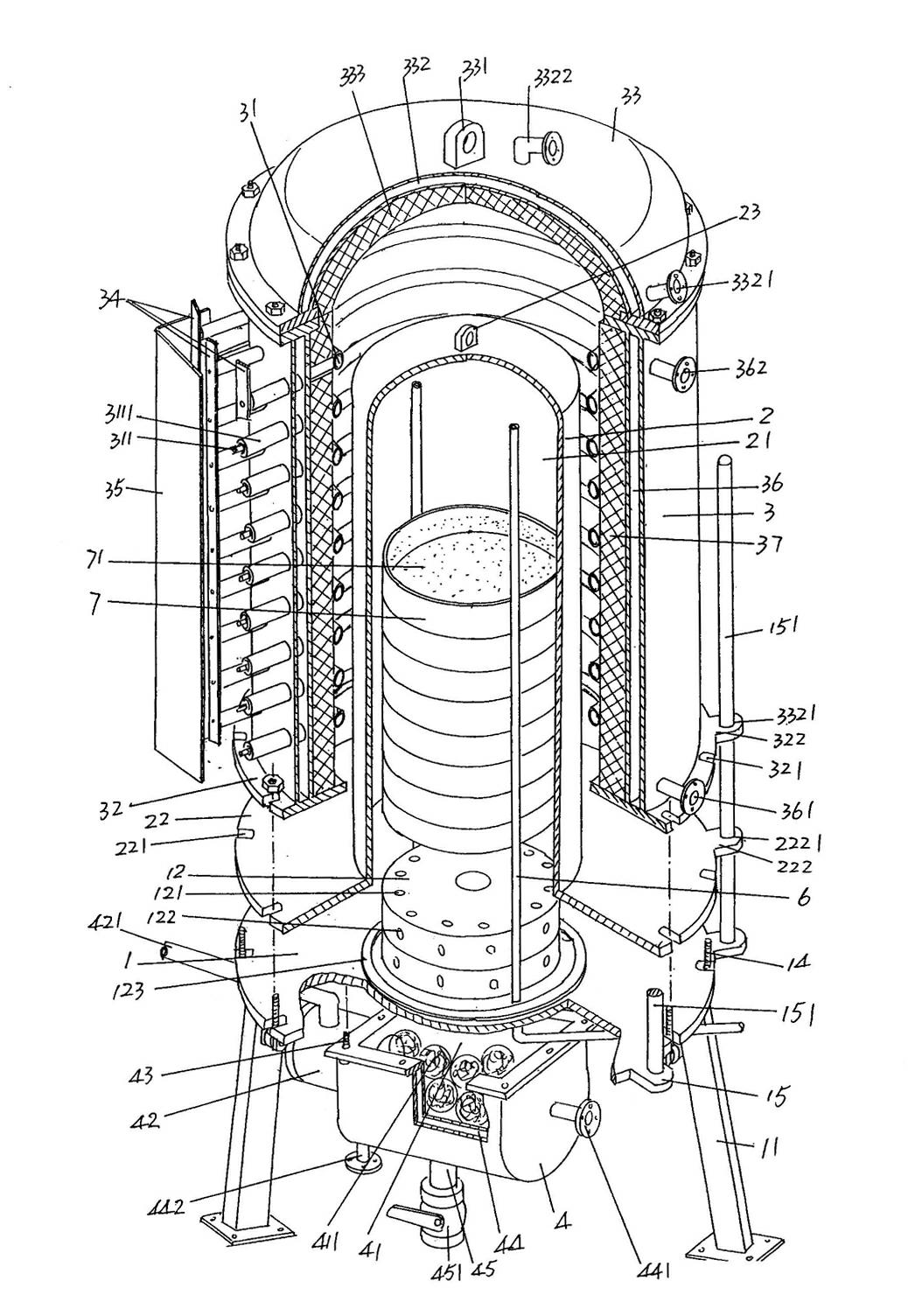

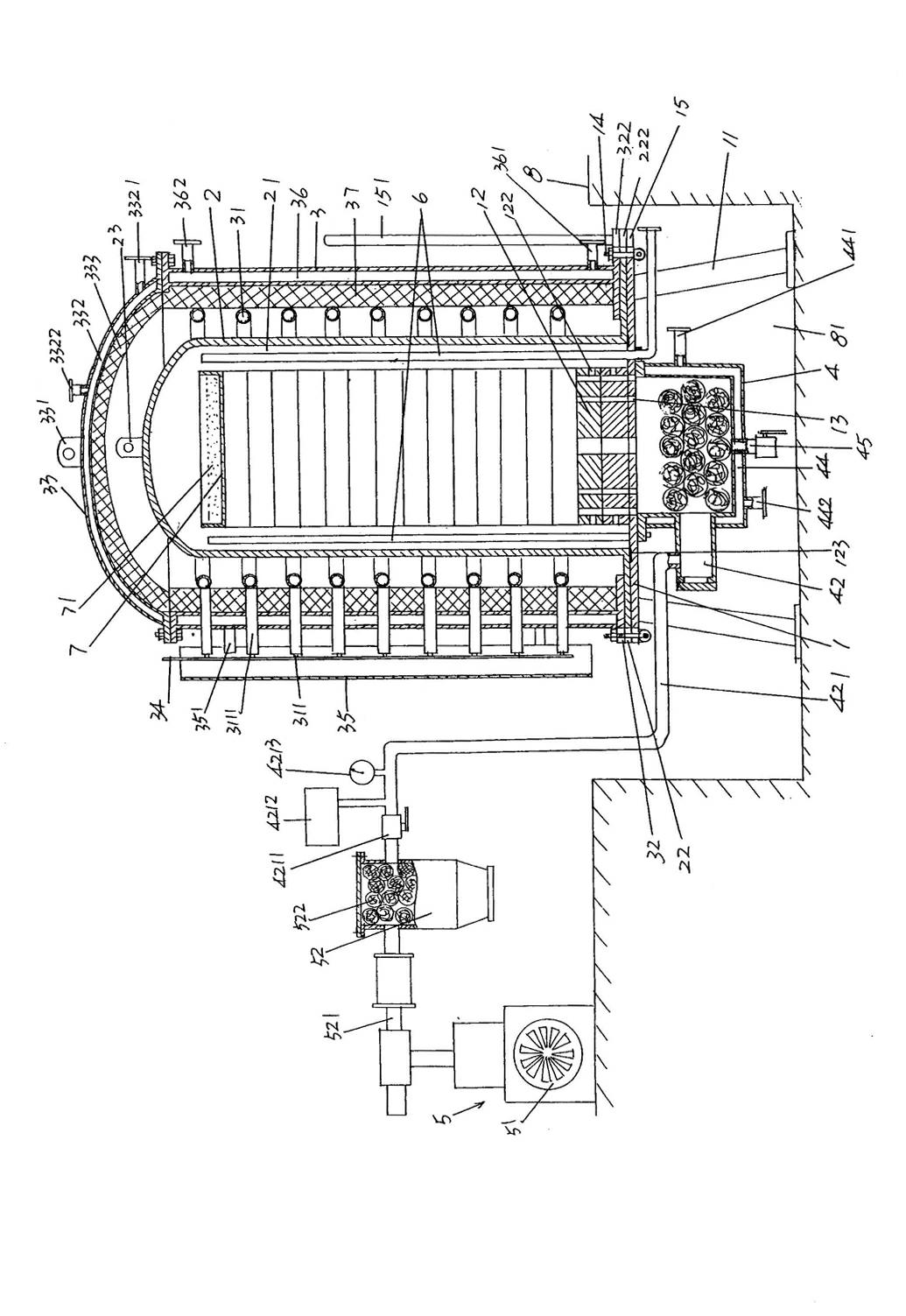

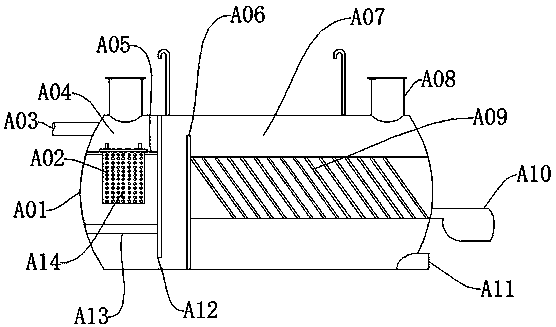

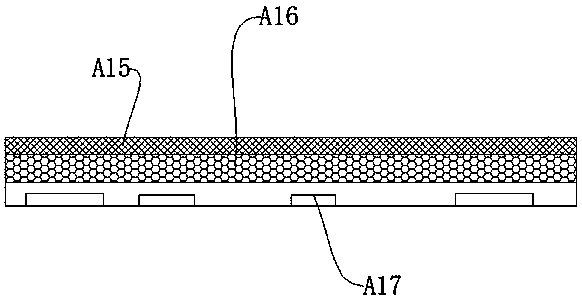

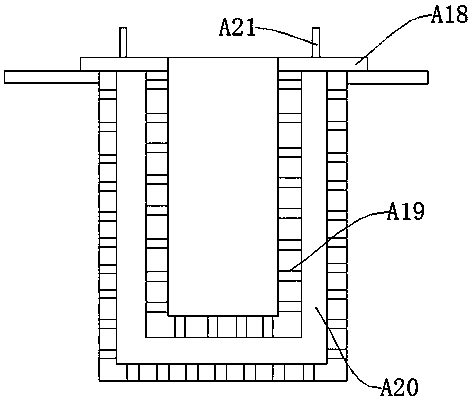

Degreasing device

The invention discloses a degreasing device and belongs to the field of the degreasing device of a powder metallurgy injection molding part. The degreasing device comprises a furnace pipe platform, a furnace pipe, a furnace body, a trap, a vacuumizing mechanism and a protective gas introducing tube, wherein the center of one side of the furnace pipe platform is provided with a base; the base is provided with a longitudinal through hole; the side surface of the base is provided with lateral through holes; the furnace pipe is arranged on the furnace pipe platform; the furnace body is sheathed at the exterior of the furnace pipe; a group of electric heating rods are laid in the inner wall of the furnace body; the trap is fixed on the center of one side of the furnace pipe platform; the vacuumizing mechanism is arranged on one side of the furnace body; one end of the protective gas introducing tube extends into the furnace pipe cavity; the other end of the protective gas introducing tube is connected with a protective gas source device; the trap is provided with a containing cavity; a first clean ball is arranged in the containing cavity; the trap is provided with a trap jacket; one side of the trap jacket is connected with a water inlet joint; the bottom of the trap jacket is adapted with a water outlet joint; the center of the bottom of the trap is adapted with a degreasing hole; and the degreasing hole is provided with a valve. The degreasing device has the advantages that the degreasing speed can be improved, the degreasing device is favorable for loading and discharging, and is convenient to replace, energy-saving and environmentally-friendly.

Owner:宝得粉末注射成形(常熟)有限公司

Electroplating base material degreasing agent and preparation method thereof

The invention discloses an electroplating base material degreasing agent and a preparation method thereof and relates to a degreasing agent, and in particular relates to the technical field of surface pretreatment of plated workpieces. The degreasing agent contains the following substances per liter: 100.0-300.0 grams of phosphoric acid, 2.0-5.0 grams of sodium gluconate, 2.0-5.0 grams of sodium tripolyphosphate, 1.0-4.0 grams of water softener, 0.2-0.5ml of emulsifying agent and the balance of water. The preparation method comprises the steps of dissolving the phosphoric acid, the sodium gluconate, the sodium tripolyphosphate, the water softener and the emulsifying agent in the water at the ratio, fully stirring and dissolving. The degreasing agent disclosed by the invention does not adopt an alkaline solution and has the characteristics of low temperature, low concentration, acidity, little chemical component types, rapidness, cleanliness and high efficiency in degreasing, capability of saving lots of energy and low cost; the degreasing agent is particularly suitable for degreasing neodymium-iron-boron permanent magnet materials.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Environment-friendly microorganism degreasing agent

The invention discloses an environment-friendly microorganism degreasing agent, and belongs to the technical field of chemical industry. The microorganism degreasing agent consists of two ingredients A and B, wherein the ingredients A comprise the following ingredients in parts by weight: 20 to 30 parts of sodium carbonate, 0.2 to 1.6 parts of sodium alkyl benzene sulfonate, 0.1 to 0.5 parts of nonylphenol polyoxyethylene ether, 10 to 15 parts of isopropanol, 1 to 10 parts of organic silicon defoamer and 20 to 30 parts of water, and the ingredients B comprise the following ingredients in parts by weight: 3 to 15 parts of peptone, 4 to 9 parts of glucose, 15 to 20 parts of microbial strains, 5 to 10 parts of biological enzyme, 10 to 15 parts of soluble starch and 30 to 40 parts of water. A preparation method comprises the steps that after the ingredients B are uniformly mixed, the culture is carried out for 1 to 3 days at 30 to 40 DEG C, seed solution is obtained, the seed solution and the ingredient A are mixed and stirred uniformly, and the microorganism degreasing agent is obtained. The microorganism degreasing agent has the characteristics that a glass or plastic surface is not damaged, the degreasing speed is high, the degreasing efficiency is high, safety and environment protection are realized, and the like.

Owner:张锦碧

Degreasing agent for avoiding bonding of cold rolled sheet steel in cover annealing and using method of degreasing agent

InactiveCN102691068AAvoid stickingBinding has no effectFurnace typesHeat treatment furnacesBinding forceDefoaming Agents

The invention discloses a degreasing agent for avoiding bonding of cold rolled sheet steel in cover annealing and a using method of the degreasing agent. The degreasing agent comprises the following components in percentage by weight: 20% to 25% of sodium hydroxide, 64% to 70% of positive sodium silicate, 3% to 5% of sodium carbonate, 5% to 10% of trisodium phosphate, 0.3% to 1% of nonionic surfactant and 0.1% to 0.5% of defoaming agent. The degreasing agent disclosed by the invention can be used for thoroughly cleaning various greasy dirt adhered to the surface of the cold rolled sheet steel and reserving a silicate membrane with proper thickness on the surface of the sheet steel so as to effectively avoid the bonding of the sheet steel in the cover annealing; and the membrane has on influence on properties such as the binding force of a coating, the processing of a steel plate, and the like. In addition, when the degreasing agent disclosed by the invention is used, the steel plate does not need to be immersed in the degreasing agent in advance, the modern quick unit degreasing can be implemented, the speed reaches 300m / min to 400m / min or above, and the degreasing is efficient and quick, so that the greasing agent is completely suitable for a modern quick unit coil degreasing line.

Owner:武钢集团有限公司

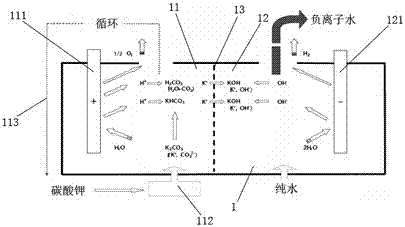

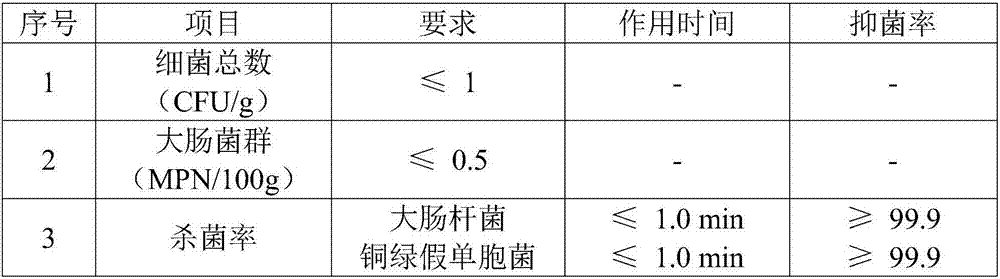

Method for preparing hydroxide anionic water used for removing greasy dirt, cleaning, sterilizing and disinfecting

InactiveCN107059041AFast degreasingRapid sterilizationInorganic/elemental detergent compounding agentsBiocideWater useElectrolysis

The invention discloses a method for preparing hydroxide anionic water used for removing greasy dirt, cleaning, sterilizing and disinfecting. The method comprises the following steps: preparing a box body, wherein the box body is divided into a cathode electrode box and an anode electrode box through a cationic resin film in the box body; inserting a cathode electrode into the cathode electrode box; circularly pouring pure water electrolyte containing a potassium carbonate catalyst into the anode electrode box in order to keep the pH of liquid in the anode electrode box equal to a preset value; inserting a cathode electrode into the cathode electrode box, and pouring pure water into the cathode electrode box; when in running, the following steps are carried out: applying 24-45V direct current or pulse current to the cathode electrode and the anode electrode to electrolyze to gradually generate high electrolyzing current, and the water molecule of the pure water in the cathode electrode box is electrolyzed and separated into hydroxide anions and hydrogen ions; the hydrogen ions are converted into hydrogen after collecting electrons from the cathode electrode and then the hydrogen overflows; in addition, after the concentration of hydroxide generated at the cathode electrode reaches the specific pH (12.5+ / -0.5), anionic water is pumped from the cathode electrode through a water pump, and pure water is pumped into the cathode electrode box for next anionic water production.

Owner:深圳市量子水生态科技有限公司

Metal powder injection molding feed and preparation method thereof

InactiveCN108202139AGood liquidityFast degreasingTransportation and packagingMetal-working apparatusParaffin oilsPolyethylene glycol

The invention discloses a metal powder injection molding feed and a preparation method thereof. The injection molding feed comprises 2200 iron-based alloy powder and forming agents comprising, by weight, 7-9 parts of paraffin, 2-4 parts of photothermal stabilizers, 5-7 parts of polyethylene, 3-5 parts of polyethylene glycol, 5-7 parts of stearic acid and 72-74 parts of polyformaldehyde, and the injection molding feed is prepared from the 2200 iron-based alloy powder and the forming agents according to the ratio of 90:10-92:8. The metal powder injection molding feed is applied to the injectionmolding technology of alloy products, and has the advantages of high fluidity, degreasing rate, density, molding stability, and dimensional stability of products, etc.

Owner:DONGGUAN HUAJING POWDER METALLURGY

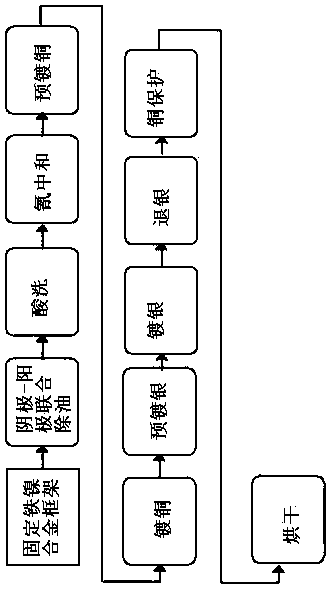

Method for electroplating copper and sliver on iron-nickel alloy frame

The present invention discloses a method for electroplating copper and sliver on an iron-nickel alloy frame. The method is characterized by comprising: 1, fixing an iron-nickel alloy frame; 2, carrying out cathode-anode combined degreasing; 3, carrying out acid washing; 4, carrying out cyanogen neutralization; 5, pre-plating copper; 6, plating copper; 7, pre-plating silver; 8, plating silver; 9, deplating sliver; 10, carrying out copper protection; and 11, drying, and taking the iron-nickel alloy frame from the bracket so as to complete the electroplating process. According to the present invention, the method has advantages of good electroplating effect and low cost.

Owner:TAIZHOU HUALONG ELECTRONICS

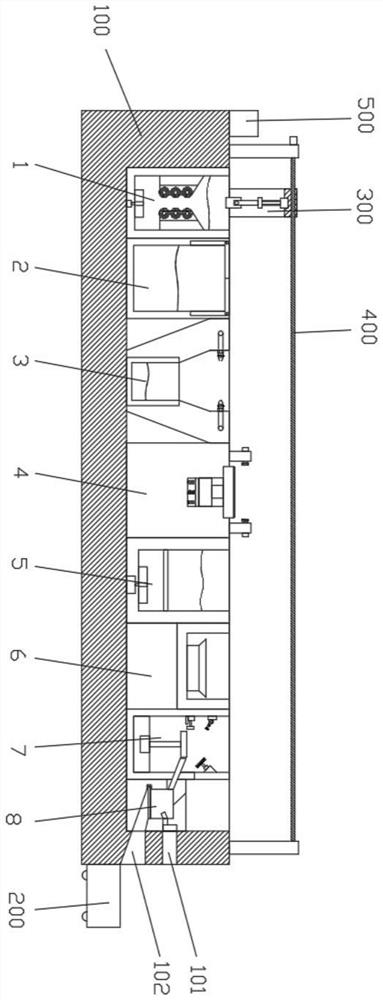

Automobile metal part surface treatment process and equipment

ActiveCN113560145AExtended service lifeImprove bindingPolishing machinesPretreated surfacesProcess engineeringMechanical engineering

The invention discloses an automobile metal part surface treatment process and equipment. A degreasing mechanism, a pickling mechanism, a first cleaning mechanism, a polishing mechanism, a second cleaning mechanism, a drying mechanism, a spraying mechanism and a cooling mechanism are sequentially mounted in a treatment process cabinet, and a moving mechanism and a clamping mechanism are mounted outside the treatment process cabinet. The surface of an automobile metal part is subjected to degreasing, acid pickling, first-time cleaning, polishing, second-time cleaning, drying, spraying, cooling and other treatment in sequence, so that the surface of the automobile metal part is smoother, meanwhile, the abrasion resistance of the surface of the automobile metal part is improved, and the efficiency of the overall treatment process can be further improved through integrated equipment, and through mechanical control, the labor intensity is reduced, and the labor cost is saved.

Owner:安徽誉林汽车部件有限公司

Environment-friendly sewage degreasing device and use method thereof

InactiveCN108128932AEasy to cleanEasy to separateFatty/oily/floating substances removal devicesTreatment involving filtrationOil and greaseBiochemical engineering

The invention provides an environment-friendly sewage degreasing device and a use method thereof. The environment-friendly sewage degreasing device comprises a tank body, an oil collector, a treatingpond and a filtering plate, wherein a water inlet pipe is arranged outside the tank body; an oil storage barrel is arranged at one side, away from the water inlet pipe, of the outer part of the tank body; a water outlet pipe is arranged at the lower end of the oil storage barrel; a ventilation pipe is arranged at the upper end of the tank body; the oil collector is arranged inside the tank body; handles are arranged at the upper end of the oil collector; flanges are arranged at the lower end of each handle; a sealing plate is arranged at the lower end of each flange; an inner barrel through hole is formed in the inner side of the lower end of each sealing plate. By means of the sewage degreasing device, oil can be quickly separated from sewage, and working efficiency of grease in the sewage is greatly improved; an oil collecting device can realize filtering of large-particle solid wastes, can be detached, is convenient to clean and is more sufficient in filtering; by arranging a filtering plate, sterilizing and odor removing effects can be realized while oil removal and better environment-friendly property is realized.

Owner:刘述珍

Rapid belt type oil-water separation apparatus

The present invention discloses a rapid belt type oil-water separation apparatus, which comprises a precipitation barrel, a solid-liquid separation barrel, an oil-water separator and an oil storage barrel, wherein the lower end of the precipitation barrel is provided with a first liquid inlet and a sand discharging port and the upper end is provided with a first liquid outlet, the lower end of the solid-liquid separation barrel is provided with a second liquid inlet and a mud discharging port and the upper end is provided with a second liquid outlet, the interior is provided with a filtration screen for isolating the solid-liquid separation barrel, the second liquid inlet is communicated to the first liquid outlet, the oil-water separator comprises a liquid storage barrel, a conveying belt and an oil scraping plate, and a screw propeller is arranged below the liquid storage barrel and is driven to rotate by a motor positioned below the liquid storage barrel. According to the present invention, the floating oil is taken away by the belt, such that the oil removing is rapid, and the cooling liquid can be used as soon as possible; and the screw propeller is arranged below the belt, such that the floating oil away from the belt can be rapidly close to the belt after the liquid is stirred so as to rapidly remove the floating oil.

Owner:重庆鼎赫煌房地产经纪有限公司

Environment-friendly degreasing agent

The invention discloses an environment-friendly degreasing agent, which comprises two components A and B, and the composition ratio of the raw materials of the two components is as follows: component A: 4-7 parts of sodium silicate, 2-2 parts of polyethylene glycol 4 parts, 2‑5 parts of fatty acid methyl ester ethoxylate, 4‑6 parts of fatty alcohol polyoxyethylene ether, 2‑4 parts of sodium dodecylsulfonate, 1‑3 parts of polyoxyethylene octylphenol ether, 5-10 parts of soluble starch, 50-60 parts of water; component B: 2-5 parts of glucose, 3-5 parts of agar, 5-10 parts of microbial strains, 3-5 parts of biological enzyme, 30-40 parts of water. The degreasing agent of the invention has the advantages of low residue, environmental protection, fast degreasing speed and high degreasing efficiency.

Owner:何瑞云

Red gum water-based cleaning agent

InactiveCN108998298AEasy to rinseEasy to handleOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsWater basedEther

The invention discloses a red gum water-based cleaning agent including, by mass, 10-20% of propylene glycol ether, 10-20% of ethylene glycol ether, 10-20% of acetate, 10-30% of dibasic acid ester, 5-10% of ethanol amine, 10-20% of isopropanol, and 5-25% of deionized water. During use for removing red gum, the product can rapidly and effectively dissolve the components of cured red gum; and under the cooperative effect of the components in the cleaning agent, the cleaning agent is high in oil removal speed and has good cleaning effect, wherein residues are easy to wash away after the cleaning.The cleaning agent is stable and safe in use performance and cleaning waste liquid is easy to treat, so that the product is safe, environment-friendly and stable.

Owner:惠州市兴都化工科技有限公司 +1

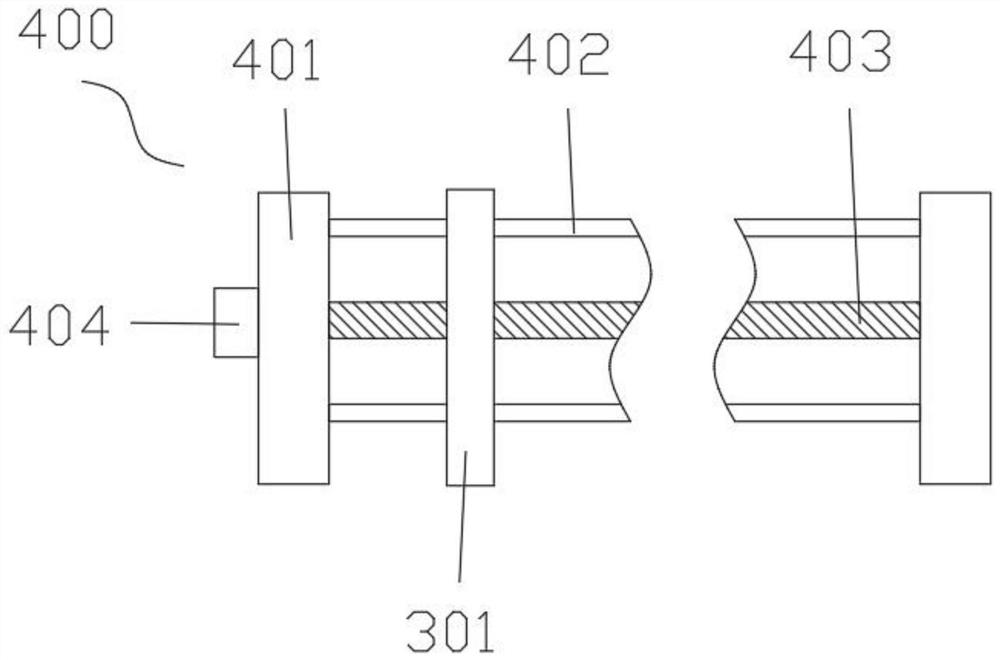

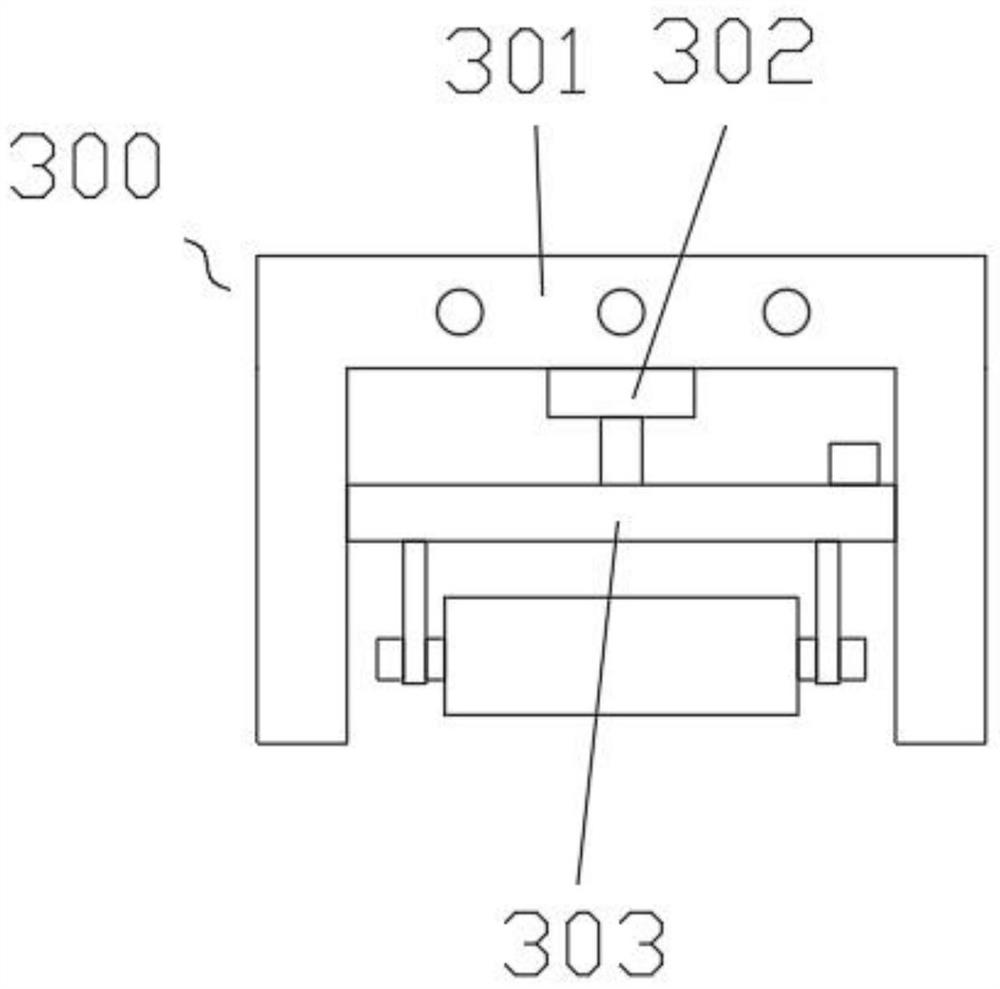

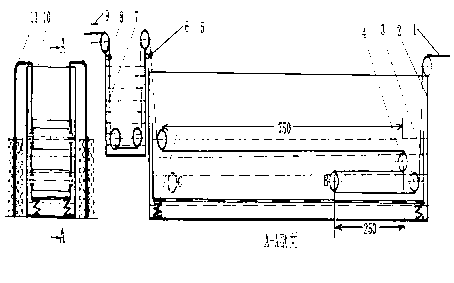

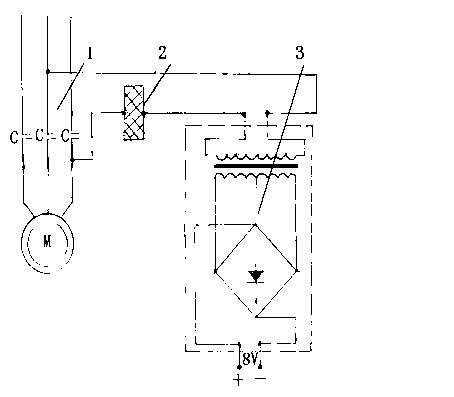

Copper strip electrochemical oil removal method in clad-welding method copper-clad aluminum wire production line and device thereof

The invention relates to a copper strip electrochemical oil removal method in a clad-welding method copper-clad aluminum wire production line and a device thereof. Specifically, according to the shortcoming that oil stains on the surface of a copper strip in the clad-welding method copper-clad aluminum wire production line can not be thoroughly cleaned, the invention discloses a copper strip electrochemical oil removal agent formula, an oil removal method and a device thereof. A copper strip is processed in a normal-temperature oil removal agent for about 10 seconds, and then the oil stains can be thoroughly removed. The copper strip oil removal device provided by the invention has the structural characteristics that the device is provided with a rectifying power supply; the copper strip is processed for at least 10 seconds in the oil removal agent in the clad-welding production lines at different operation speeds; when the production line stops, the copper strip automatically leaves the oil removal agent; and the copper strip after oil removal is cleaned and dried immediately.

Owner:大连通发诚信科技有限公司

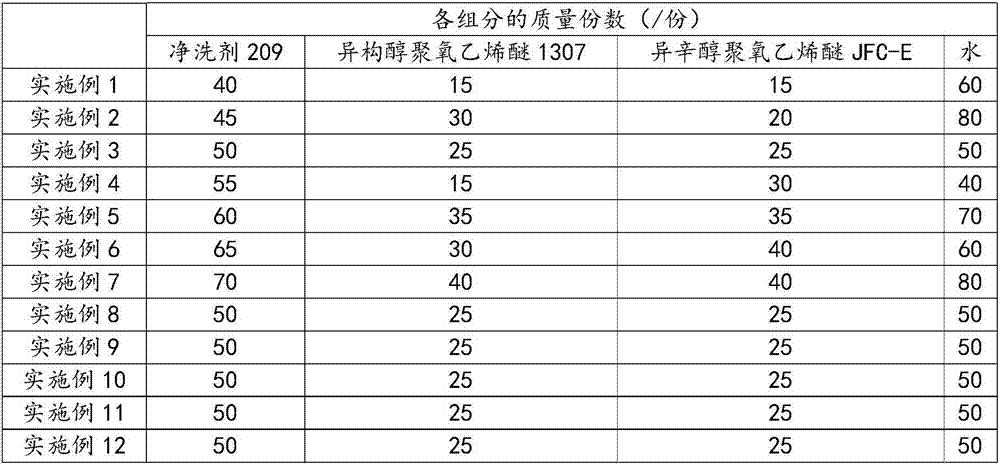

Large smoke exhaust super strong oil stain cleanser and preparing method

InactiveCN106929198AIncrease brightnessBeautiful colorInorganic/elemental detergent compounding agentsSurface-active detergent compositionsLotionCleansing Agents

The invention belongs to the field of cleansers, particularly relates to a large smoke exhaust super strong oil stain cleanser and a preparing method. The large smoke exhaust super strong oil stain cleanser is characterized by being prepared from, by mass, 40-70 parts of a detergent, 15-40 parts of alcohol ethoxylate, 15-40 parts of isooctyl alcohol polyoxyethylene ether and 50-70 parts of water, the 40-70 parts of the detergent, the 15-40 parts of alcohol ethoxylate, the 15-40 parts of isooctyl alcohol polyoxyethylene ether and the 50-70 parts of the water which are put into a container, and stirring evenly, so that the large smoke exhaust super strong oil stain cleanser can be used after full dissolving. Compared with traditional washing through sodium hydroxide, according to a smoke exhaust stainless steel cover, the oil removal speed is drastically and obviously increased, the cleaning rate is obviously increased, after the adoption of the large smoke exhaust super strong oil stain cleanser, oil stains are not hardened, not adhesive and easy to clean and do not clog a sewer, and the smoke exhaust stainless steel cover after washing finishes is very good in brightness and very attractive.

Owner:朱英强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com