Patents

Literature

59results about How to "Efficient degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

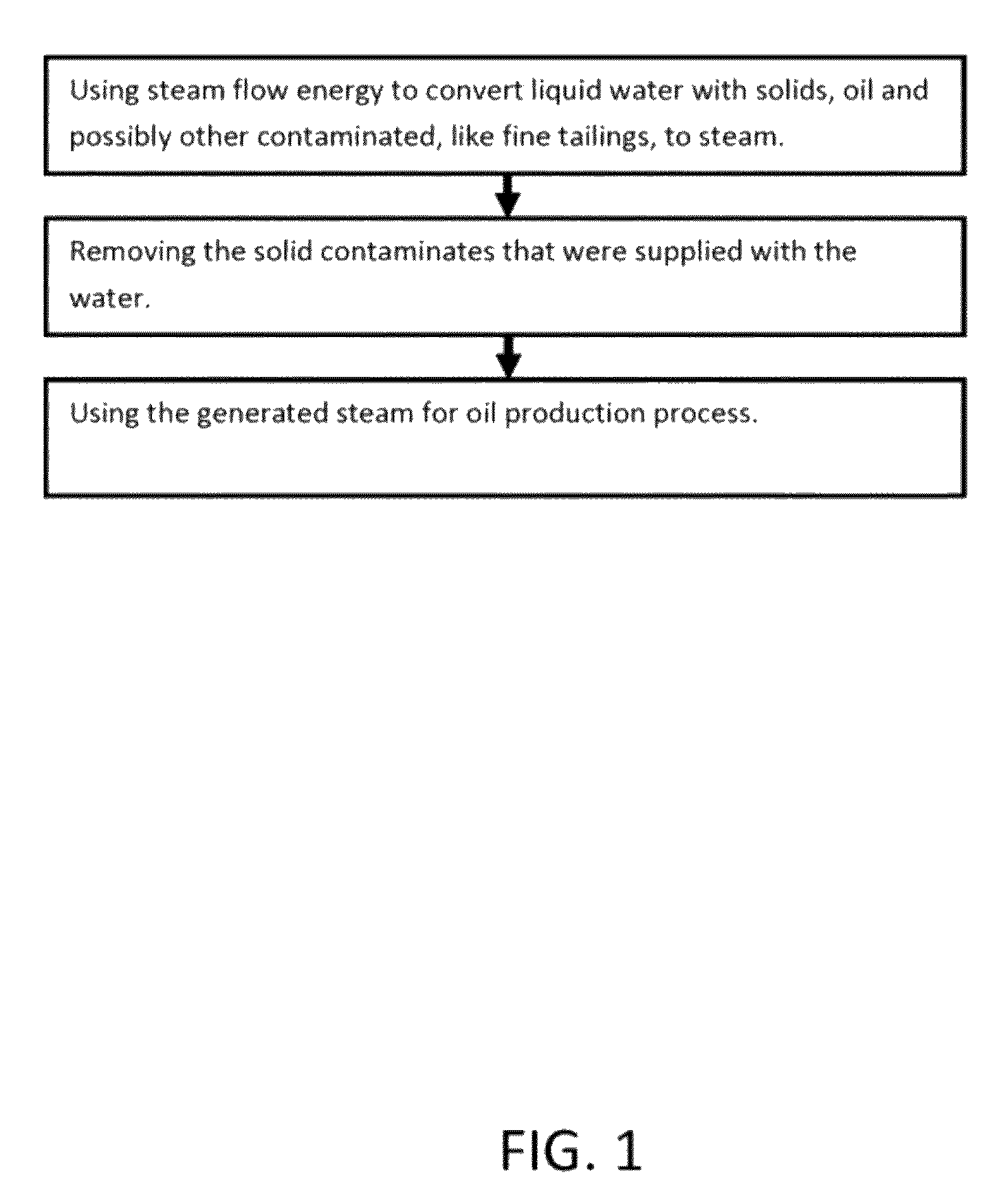

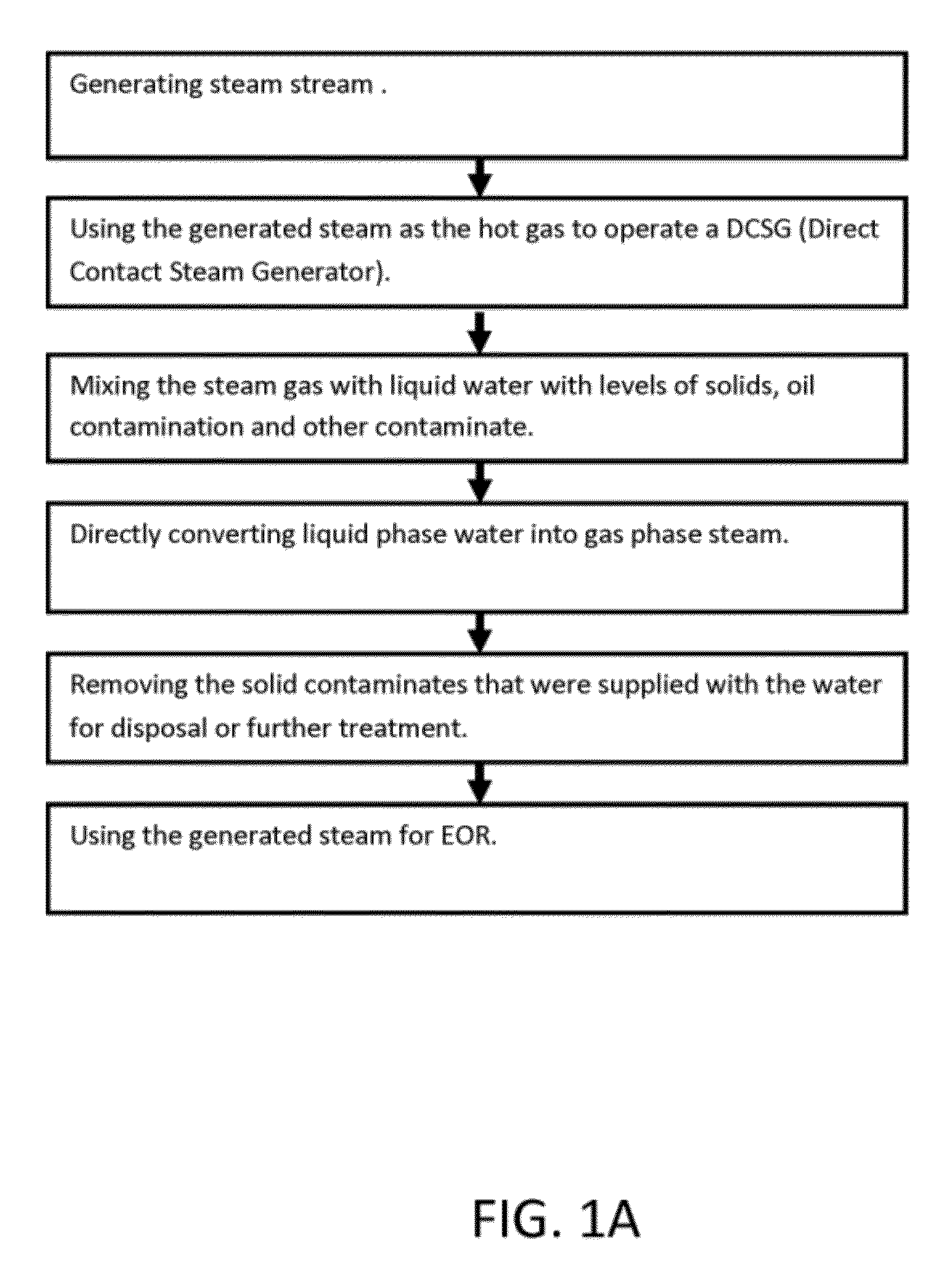

Steam driven direct contact steam generation

InactiveUS20120000642A1Efficient degreasingLow efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionInjection wellOil production

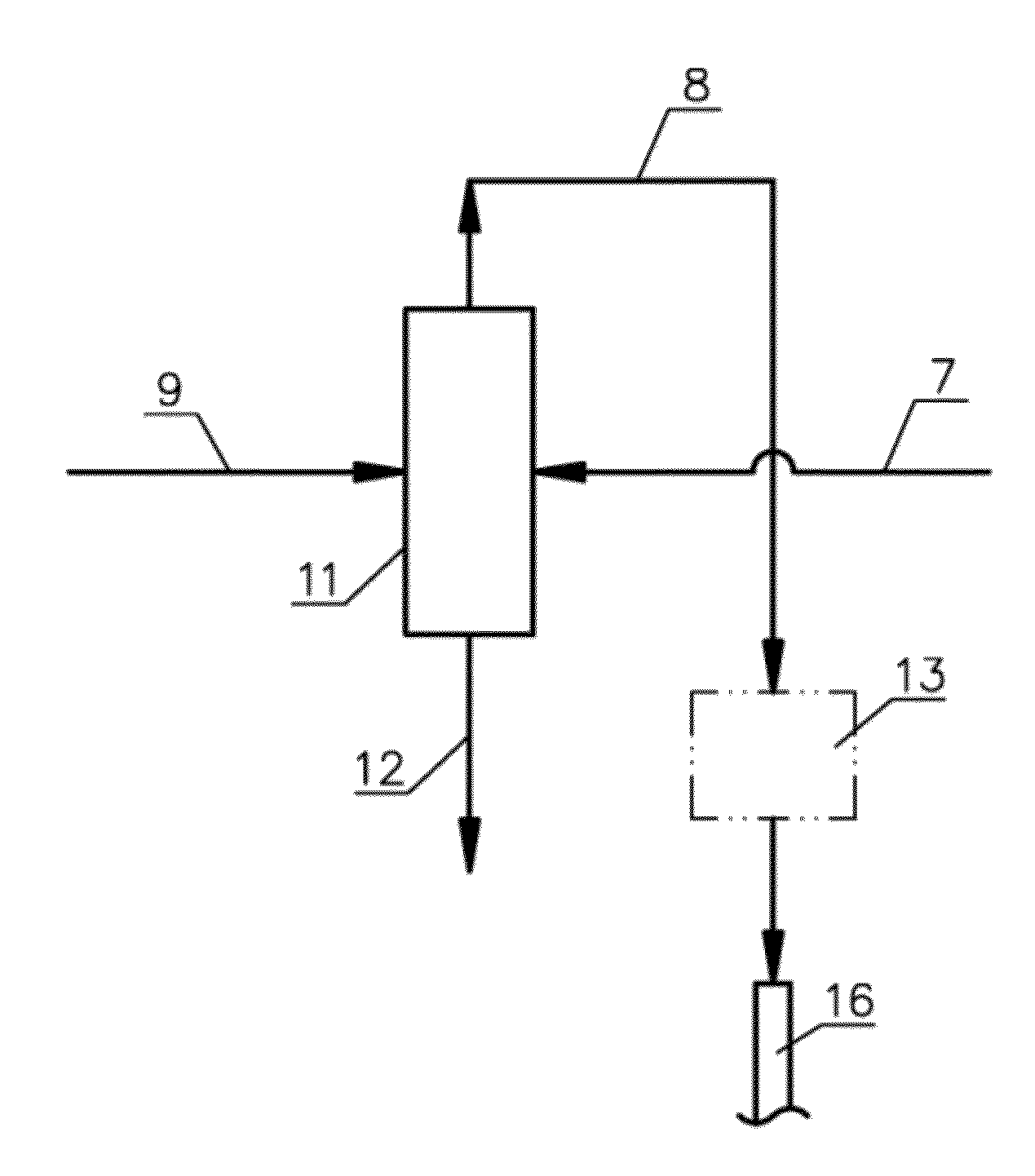

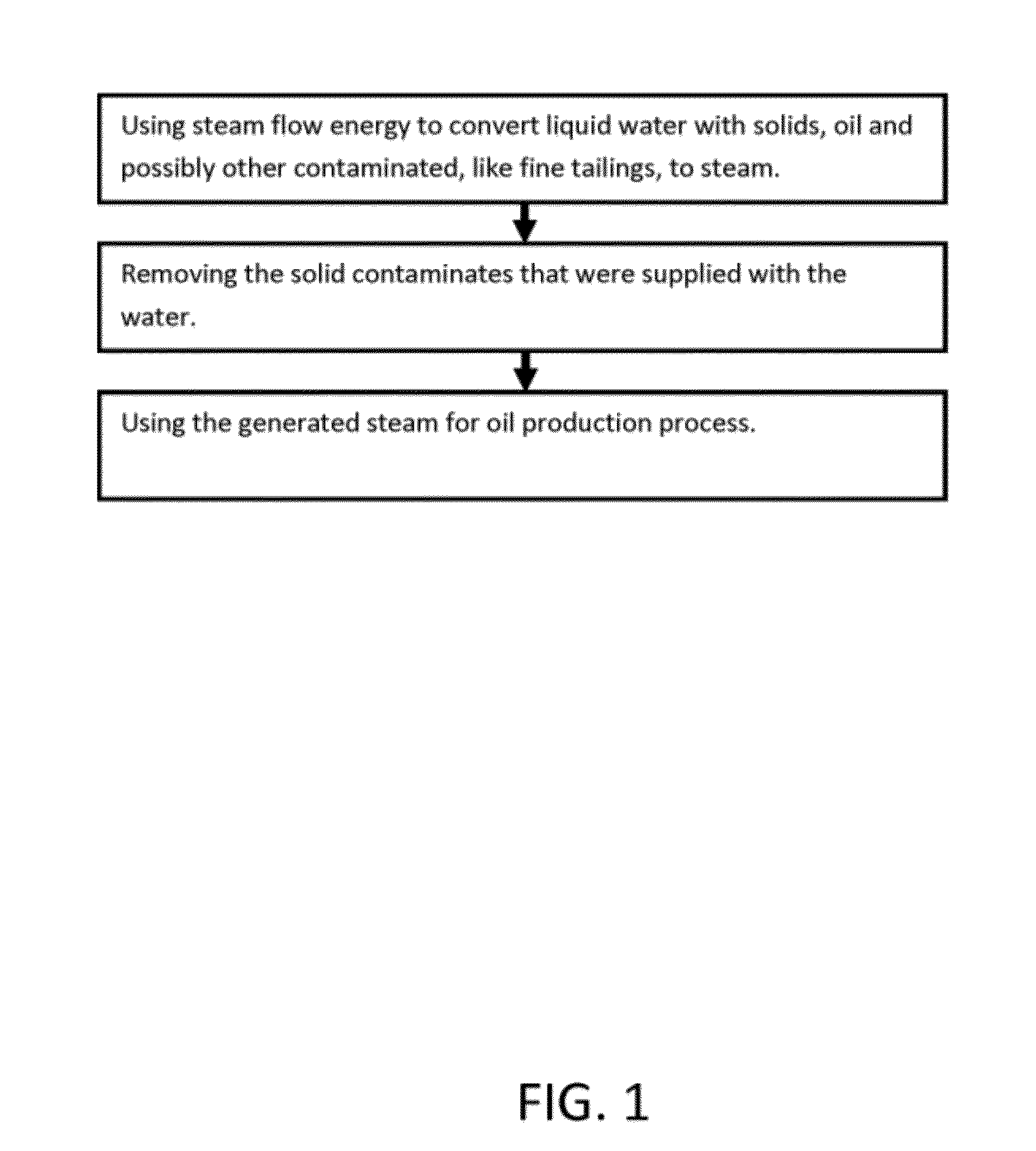

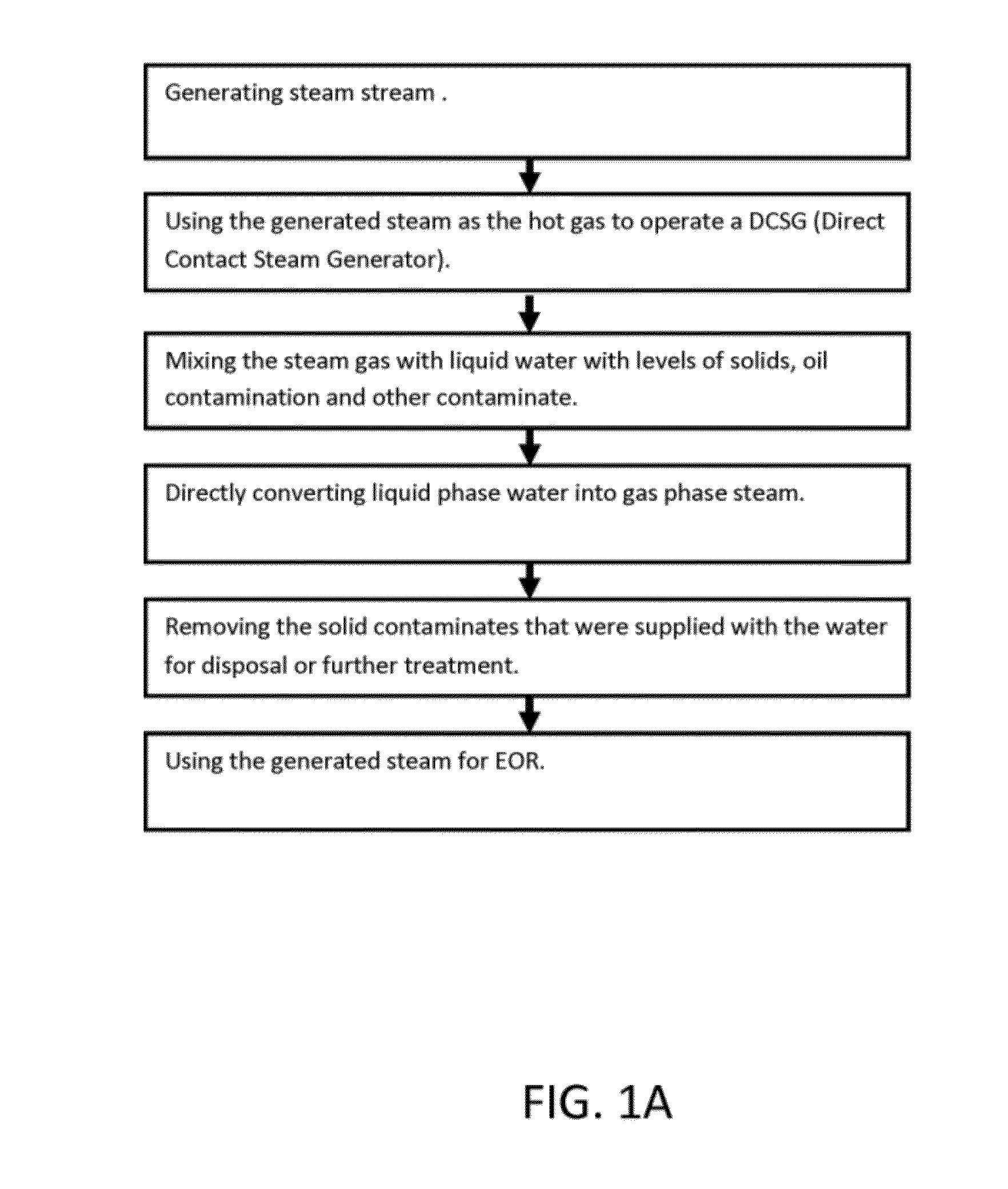

The present invention is a system and method for steam production for oil production. The method includes generating steam, mixing the steam with water containing solids and organics, separating solids, and injecting the steam through an injection well or using it above ground for oil recovery, such as for generating hot process water. The system includes a steam drive direct contact steam generator. The water feed of the present invention can be hot produced water separated from a produced oil emulsion and / or low quality water salvaged from industrial plants, such as refineries and tailings from an oilsands mine.

Owner:EX TAR TECH

Cleaning method and combination

InactiveCN101230310AEfficient degreasingLess irritatingCationic surface-active compoundsNon-ionic surface-active compoundsCleaning methodsSURFACTANT BLEND

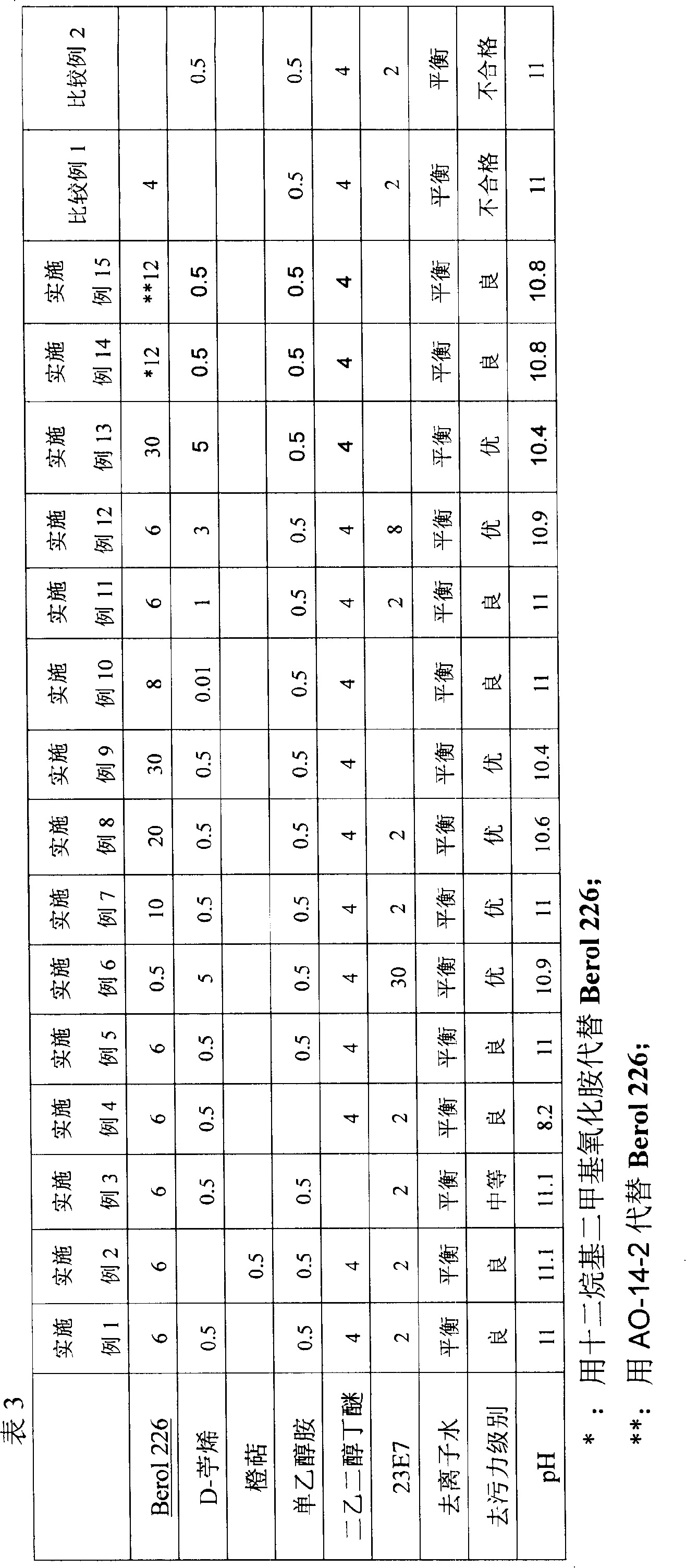

The invention relates to a cleanser combination which contains cationic surfactant and citrus essential oil constituent, which relates to a method using the combination to remove dirt from the surface of basic material. The cleanser combination includes: (a) cationic surfactant, the weight of which is 0.5-30 percent of the combination; (b) citrus essential oil, the weight of which is 0.01-5 percent of the combination; (c) equilibrium amount of carrier.

Owner:3M INNOVATIVE PROPERTIES CO

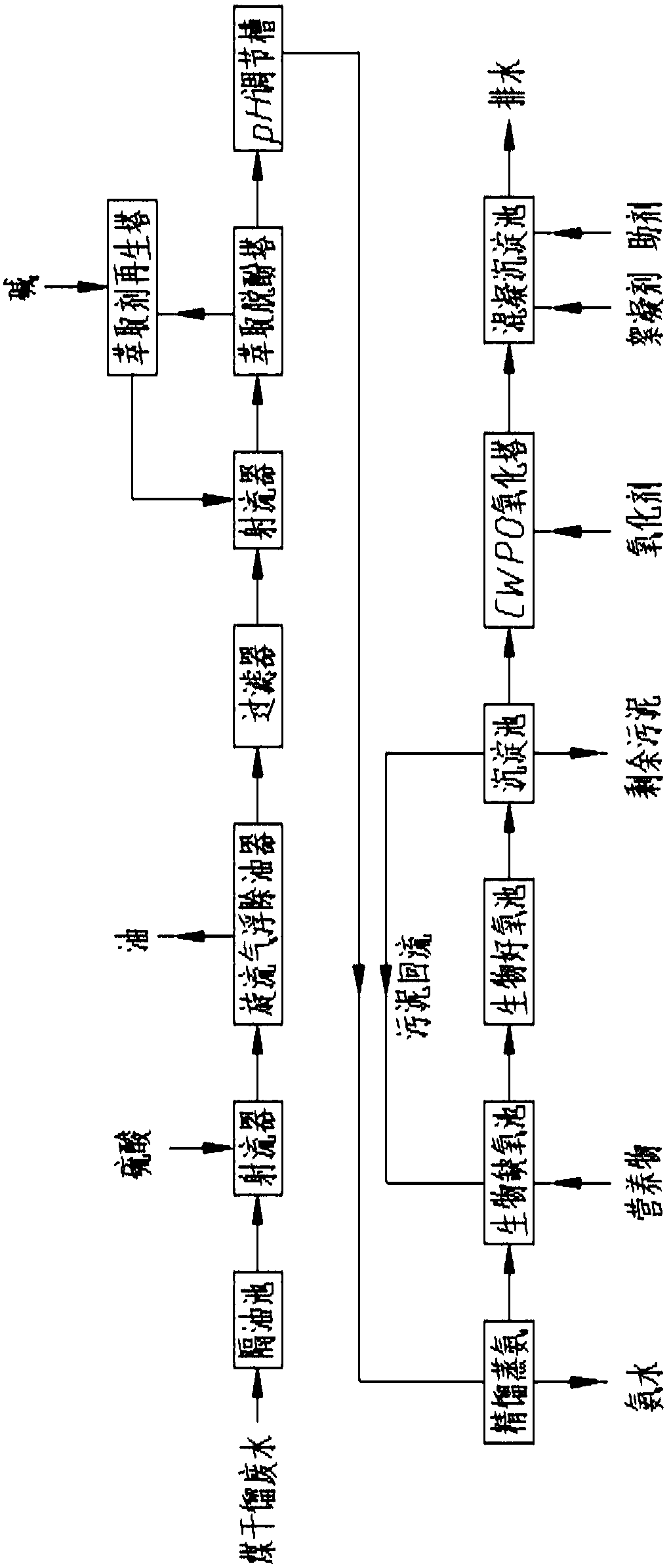

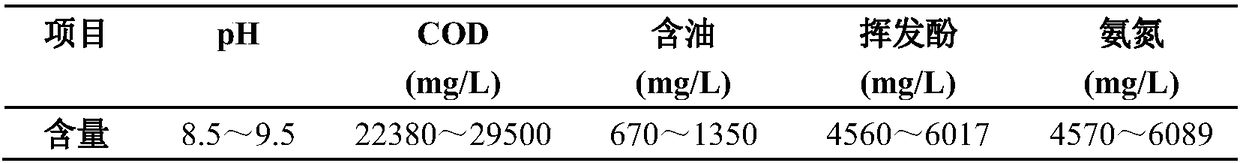

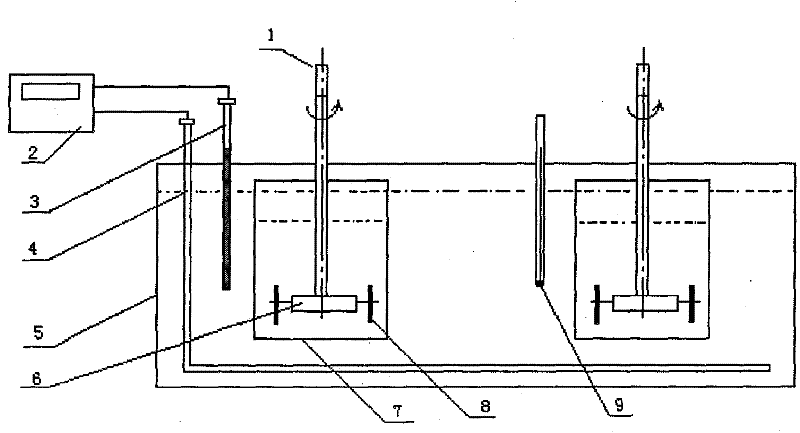

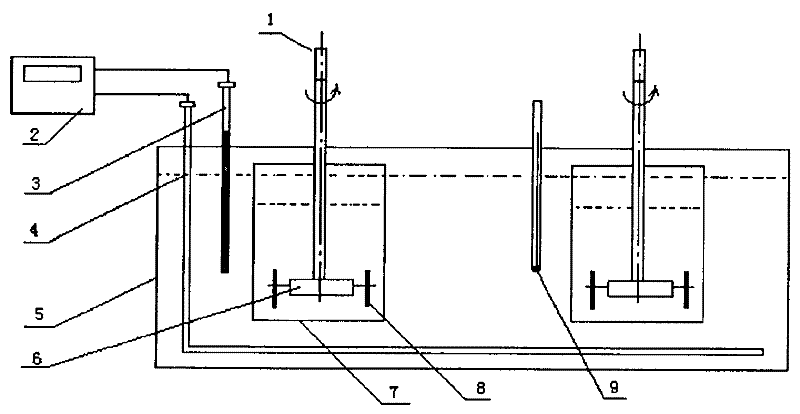

Method for treatment of wastewater from dry distillation of coal

ActiveCN108147612AHigh efficiency of extraction and removal of phenolsReduce extraction timeFatty/oily/floating substances removal devicesWater contaminantsChemical industryOxygen deprivation

The invention provides a method for treatment of wastewater from dry distillation of coal. By adopting a technology of combining units of oil isolation, cyclone air flotation, filtration, extraction dephenolization, rectification and ammonia distillation, biological oxygen deprivation, SBR oxidation, CWPO oxidation, coagulation sedimentation and the like, the method can effectively remove organicpollutants like coal tar, ammonia nitrogen and phenols in the wastewater from dry distillation of the coal, wherein the oil removal rate of a cyclone air flotation unit reaches 93.8%; the volatile phenol removal rate of an extraction dephenolization unit reaches 98.3%; and the ammonia nitrogen removal rate of a rectification and ammonia distillation unit reaches 95.8%. The method provided by the invention has mature technology, is stable and reliable, can treat the wastewater from dry distillation of the coal to reach the direct discharge requirements of the Emission Standard of Pollutants forCoking Chemical Industry GB16171-2012, and has popularization values.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Liquid detergent composition

ActiveUS20170121637A1Not provide slippery feelingEfficient degreasingNon-ionic surface-active compoundsOrganic detergent compounding agentsDistilled waterSURFACTANT BLEND

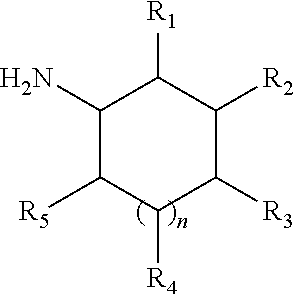

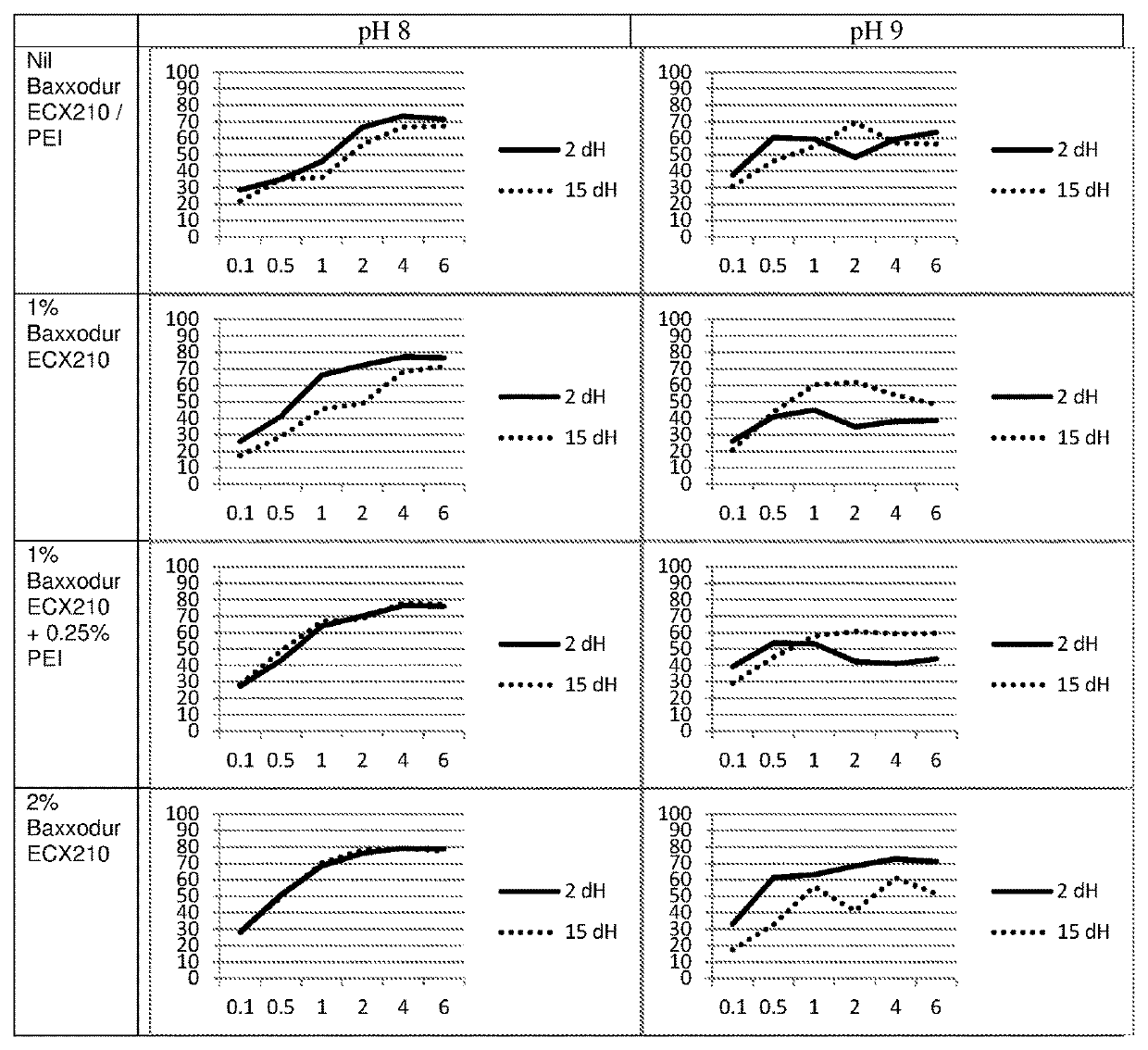

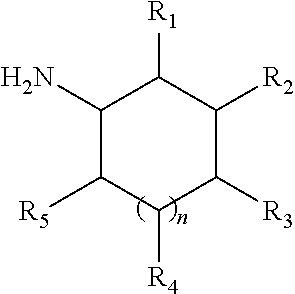

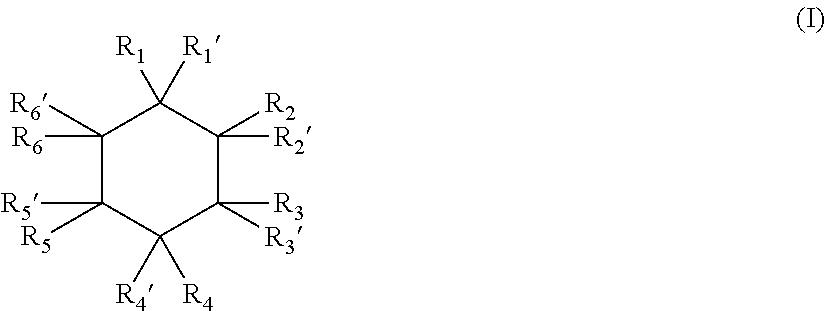

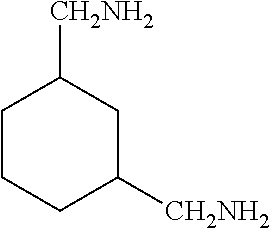

A liquid detergent composition having a pH of from 7.1 to less than 8.9 as measured at 10% solution in distilled water at 20° C. wherein the composition includes a surfactant system, the surfactant system including an anionic surfactant and a primary co-surfactant selected from the group consisting of amphoteric surfactant, zwitteronic surfactant and mixtures thereof wherein the anionic surfactant and the primary co-surfactant are in a weight ratio of from less than 10:1 to more than 2.5:1 and wherein the composition further includes a specific cyclic amine.

Owner:THE PROCTER & GAMBLE COMPANY

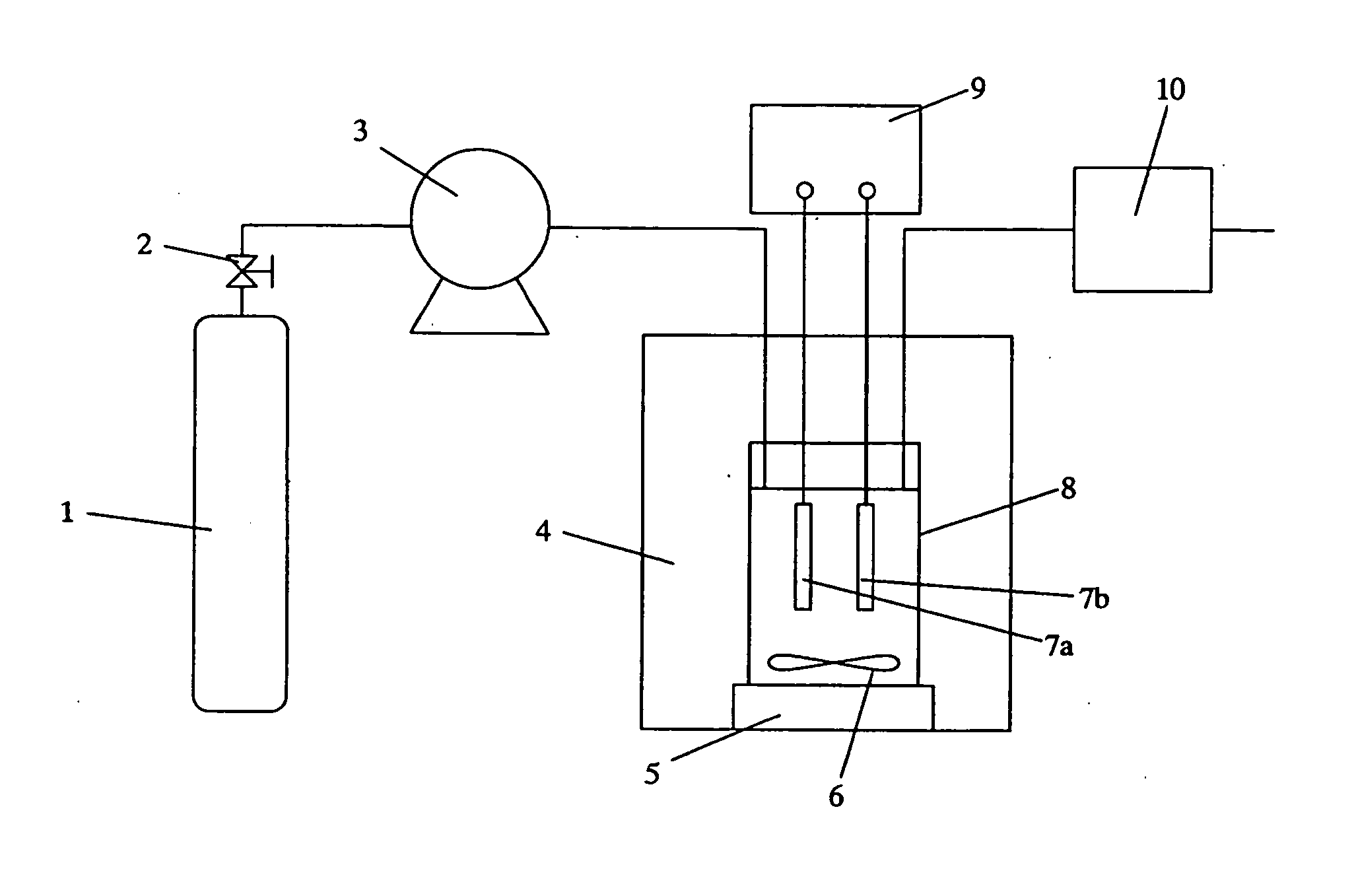

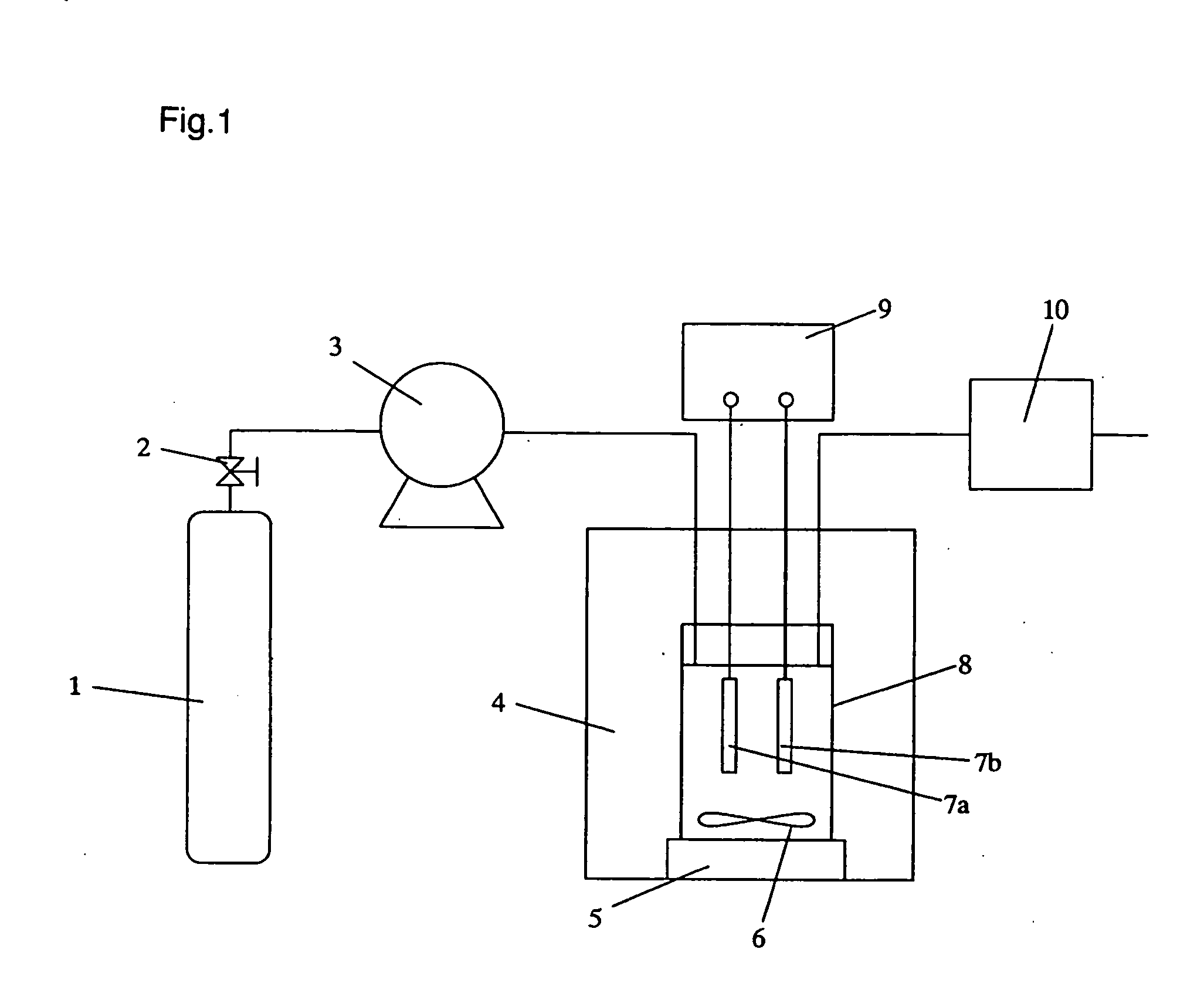

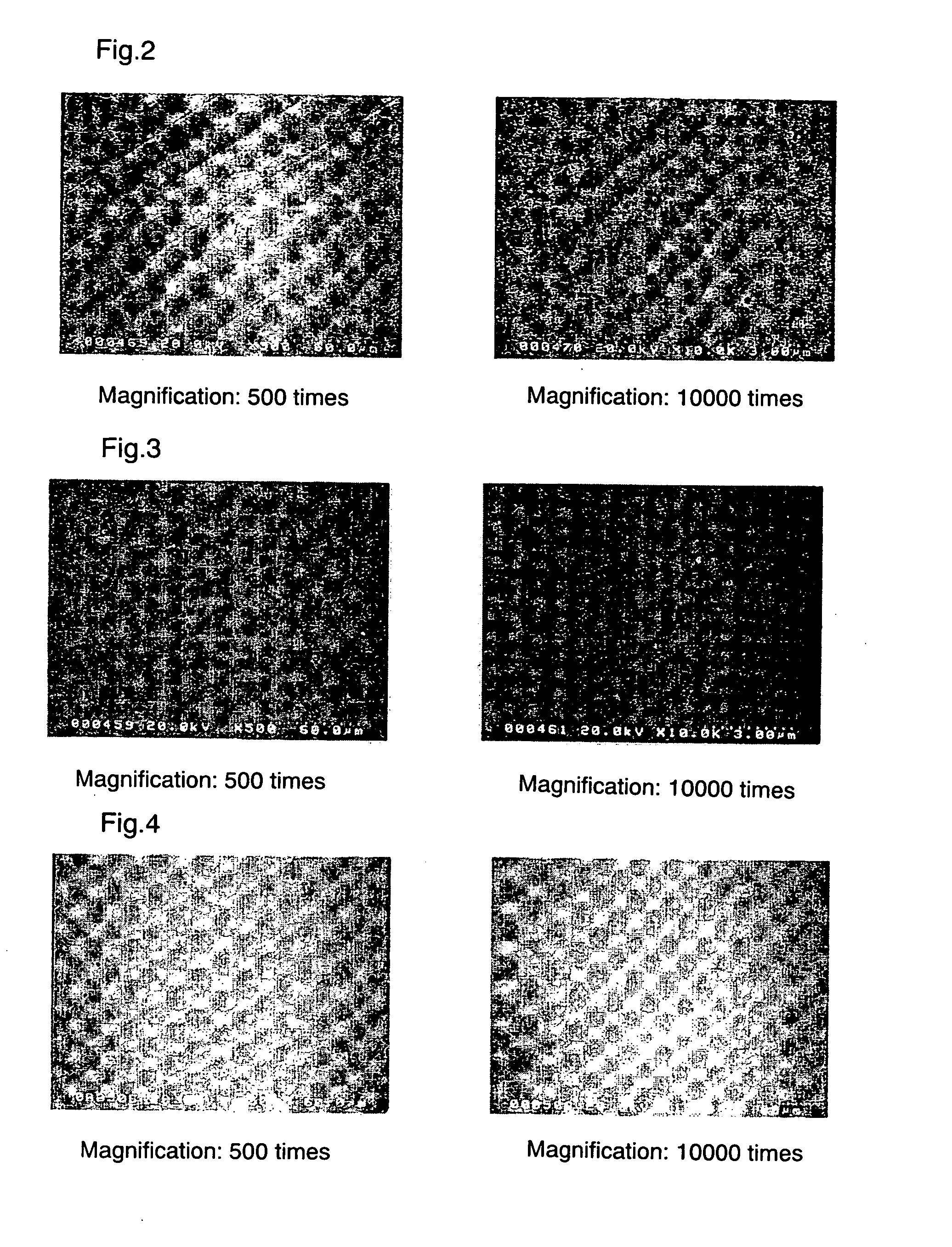

Electroplating in presence of co2

InactiveUS20070175763A1Preferable wettabilityThe pre-processing process is simplePressurized chemical processElectrochemical responseChemical reaction

The present invention provides a method for conducting electroplating in the presence of CO2 and a metal salt-containing aqueous solution, wherein the CO2 is in the form of liquid, subcritical or supercritical, the method being characterized in that a nonionic compound having a CO2-affinitive moiety is further added to the system where the aqueous solution and CO2 coexist. The method of the present invention improves the efficiency of the electrochemical reaction process and enables formation of an excellent metal film.

Owner:DAIKIN IND LTD

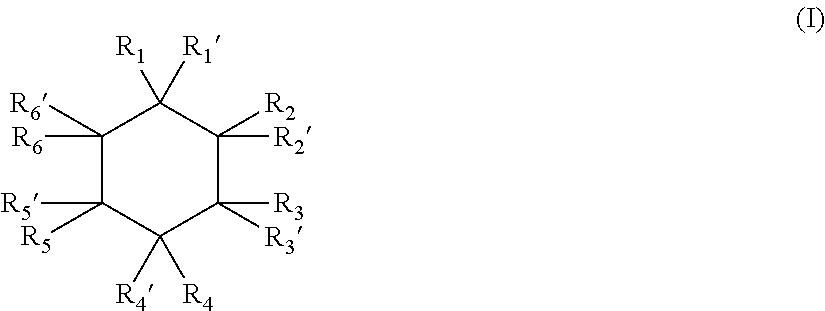

Laundry detergent composition

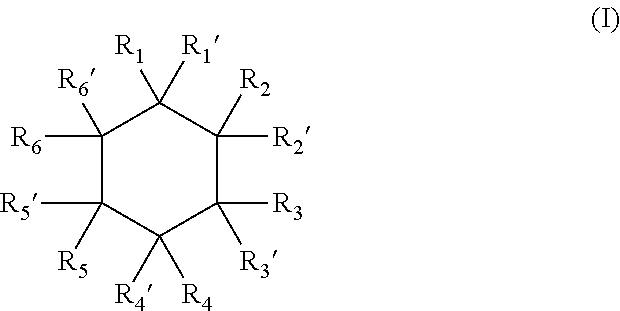

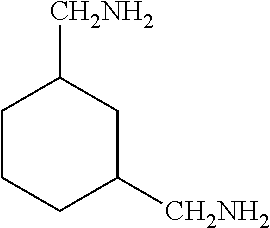

InactiveUS20170015943A1Efficient degreasingGood removal effectOrganic detergent compounding agentsNon-ionic surface-active compoundsDiamineLaundry detergent

Owner:THE PROCTER & GAMBLE COMPANY

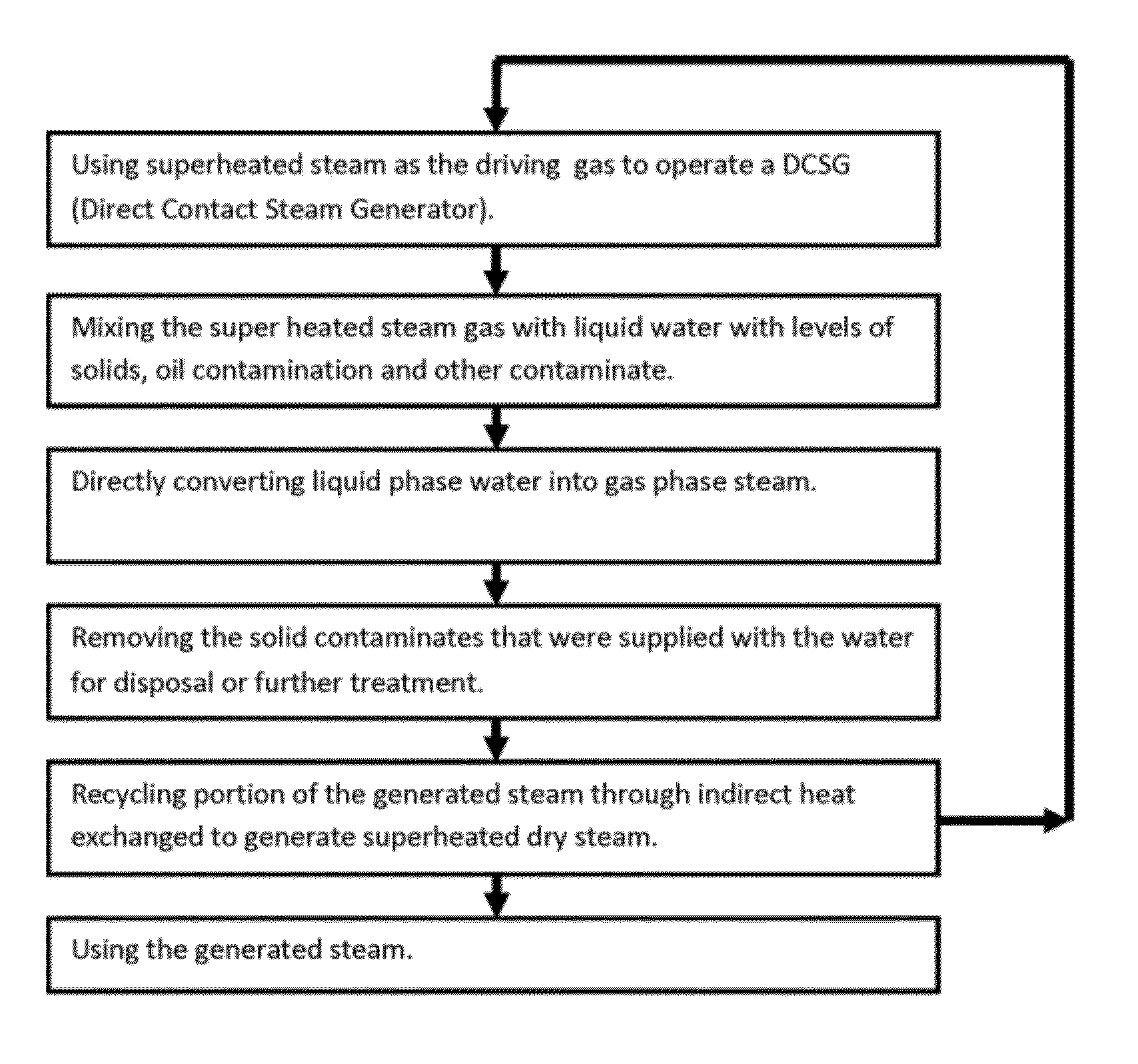

Steam driven direct contact steam generation

InactiveUS9114406B2Efficient degreasingLow efficiencyFluid removalEvaporationAbove groundOil emulsion

The system and method for steam production for oil production. The method includes generating steam from an indirect heat exchange system, mixing the steam with water containing solids and organics, separating solids, and injecting the steam through an injection well or using it above ground for oil recovery, such as for generating hot process water. The system includes a steam drive direct contact steam generator. The water feed can be hot produced water separated from a produced oil emulsion and / or low quality water salvaged from industrial plants, such as refineries and tailings from an oilsands mine.

Owner:EX TAR TECH

Water clarifier mixed system for treating sewage containing polymer

ActiveCN105692780AFast degreasingEfficient degreasingWaste water treatment from quariesFatty/oily/floating substances removal devicesEthylenediamineGlycerol

The invention a water clarifier mixed system for treating sewage containing polymer. A mixed water clarifier for treating the sewage containing polymer comprises a cationic type water clarifier and a non-ionic type water clarifier, wherein the cationic type water clarifier is at least one of glycerol-epichlorohydrin-triethylamine polymer, dimethylamine-epichlorohydrin-ethylenediamine polymer, polyaluminium chloride and poly-ferric sulfate; the non-ionic type water clarifier is polyether amine grafted polyether and / or polyethylene polyamine grafted polyether; the mass ratio of the cationic type water clarifier to the non-ionic type water clarifier is 1:10-1. The mixed water clarifier has the advantages that the mixed water clarifier can be used for fast and efficiently deoiling the sewage, the deoiling and solid removing efficiency of the water clarifier can be guaranteed, the mixed water clarifier is also applicable to the sewage with high oil content, and inverse demulsification can be achieved to reduce the oil content in floc; when the mixed water clarifier is used, inverse demulsification can be achieved to reduce the oil content in the floc during water clarifier flocculation and water clarifying, and the generated floc is non-sticky, and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Plastic surface detergent

InactiveCN101368140AThe formula is scientific and reasonableSimple production processInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsIonChemistry

The invention provides a cleaner for the plastic surface, comprising phosphate, surface active agent, pH value regulator and deionized water; the weight percentage of all the components is as follows: 5 percent to 10 percent of the phosphate, 5 percent to 10 percent of the surface active agent, 1 percent to 6 percent of the pH value regulator and the rest is the deionized water; the pH value of the mixing liquid of the components is 9 to 10; the cleaner has the functions of high efficiency and easy cleaning to the plastic surface, can clean the oil stain on the plastic surface completely, also can shorten the cleaning time and improve the working efficiency; the cleaner is an alkaline water-soluble cleaner, does not contain harmful material to the human body, meets the requirements of environment protection, has low corrosion to the equipment, effectively reduces the production cost and has safe and reliable use; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Environment-friendly water-based metal cleaner

The invention discloses an environment-friendly water-based metal cleaner. The environment-friendly water-based metal cleaner comprises the following components: 4-10g / L of surfactant, 1-10g / L of alkali compound, 1-10g / L of nitrate, 1-10g / L of phosphate and 1-5g / L of amine salt. By adopting the cleaner, the oil removing effect on the surface of a workpiece is increased, simultaneously the corrosion to the workpiece is low and the cleaning residual solution hardly causes environmental pollution.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

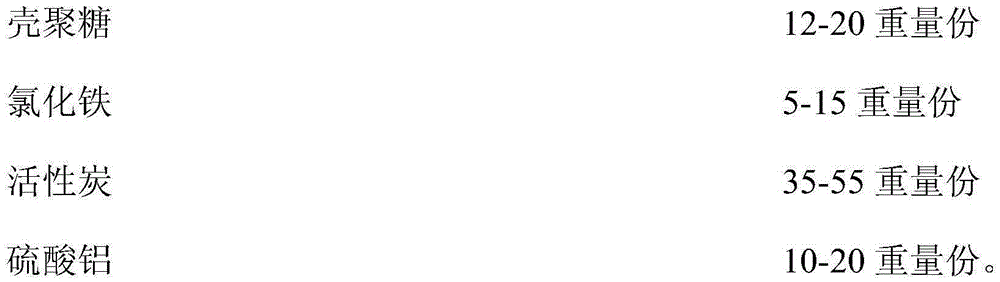

Wastewater treatment agent and application of wastewater treatment agent

InactiveCN105253972AImprove adsorption capacityEfficient functionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationMedicineTurbidity

The invention provides a wastewater treatment agent and application of the wastewater treatment agent. The wastewater treatment agent mainly is prepared from the following ingredients in parts by weight: 12 to 20 parts by weight of chitosan, 5 to 15 parts by weight of ferric chloride, 35 to 55 parts by weight of active carbon and 10 to 20 parts by weight of aluminum sulfate. The wastewater treatment agent has the advantages that when the wastewater treatment agent is applied to wastewater treatment, and the adding quantity is 200mg / L, the wastewater turbidity removal rate can reach more than 95 percent; the total phosphorus removal rate can reach more than 90 percent; the COD removal rate can reach more than 33 percent; the BOD removal rate can reach more than 78 percent; in addition, the raw material resources of the wastewater treatment agent are rich; the cost is low; a better market application prospect is realized.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Domestic sewage treatment agent and preparation method thereof

ActiveCN107758823AGood flocculation effectFast hydrolysisWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPorous carbonTherapeutic effect

The invention discloses a domestic sewage treatment agent and a preparation method of the domestic sewage treatment agent. The domestic sewage treatment agent comprises the following raw materials inparts by weight: 12-15 parts of polyferric chloride, 20-30 parts of meerschaum, 5-10 parts of modified silkworm excrement based porous carbon material, 10-15 parts of sodium hydroxide, 12-15 parts ofpolyacrylamide, 10-15 parts of sodium carbonate and 1-5 parts of bio-based porous composite material. According to the treatment agent, two novel biological carbon materials are added, so that the adsorption purification capacity of the sewage treatment agent is improved; the treatment agent can effectively treat domestic sewage of residents under matching of the other raw materials, and is good in treatment effect, lower in cost and stable in performance; and treated pollution reaches a national sewage discharge standard.

Owner:SHANGHAI ZHONGHAILONG NEW ENERGY

Air conditioner fin cleaning agent and preparation method thereof

InactiveCN101544930AGood energy saving effectOvercoming the disadvantages of being easily corrodedInorganic non-surface-active detergent compositionsParticulatesSurface cleaning

The invention belongs to the technical field of metal surface cleaning and in particular discloses an air conditioner fin cleaning agent and a preparation method thereof. The cleaning agent is mainly prepared by mixing water and the following components by weight percentage: 10 to 15 percent of nitric acid, 0.5 to 0.8 percent of potassium chromate, 0.5 to 0.8 percent of sodium ethoxylated alkyl sulfate, and 0.1 to 0.5 percent of polyoxyethylene octylphenol ether. The preparation method comprises the following steps: taking water in half of the amount, adding the nitric acid into the water, and uniformly stirring the nitric acid and the water to obtain an aqueous solution a; taking the other half amount of water, sequentially adding the potassium chromate, the odium ethoxylated alkyl sulfate and the polyoxyethylene octylphenol ether into the water, fully stirring the mixture till solid particles dissolve completely, and obtaining an aqueous solution b; and slowly adding the uniformed stirred aqueous solution a into the aqueous solution b, fully stirring the aqueous solution a and the aqueous solution b till the mixed solution is uniform, and obtaining a finished product. The cleaning agent is excellent in cleaning and energy-saving effect and avoids corrosion influences on equipment surface substantially.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

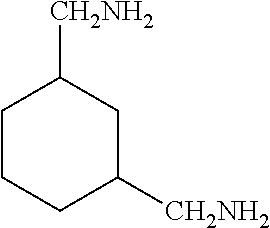

Liquid detergent composition

ActiveUS20170121636A1Not provide slippery feelingEfficient degreasingOrganic detergent compounding agentsNon-ionic surface-active compoundsDistilled waterDiamine

A liquid detergent composition having a pH of from 7.1 to 7.9 as measured at 10% solution in distilled water at 20° C. wherein the composition includes a surfactant system, the surfactant system including an anionic surfactant and a primary co-surfactant selected from the group consisting of amphoteric surfactant, zwitteronic surfactant and mixtures thereof wherein the anionic surfactant and the primary co-surfactant are in a weight ratio of from less than about 10:1 to more than about 2.5:1 and wherein the composition further includes a specific cyclic diamine.

Owner:THE PROCTER & GAMBLE COMPANY

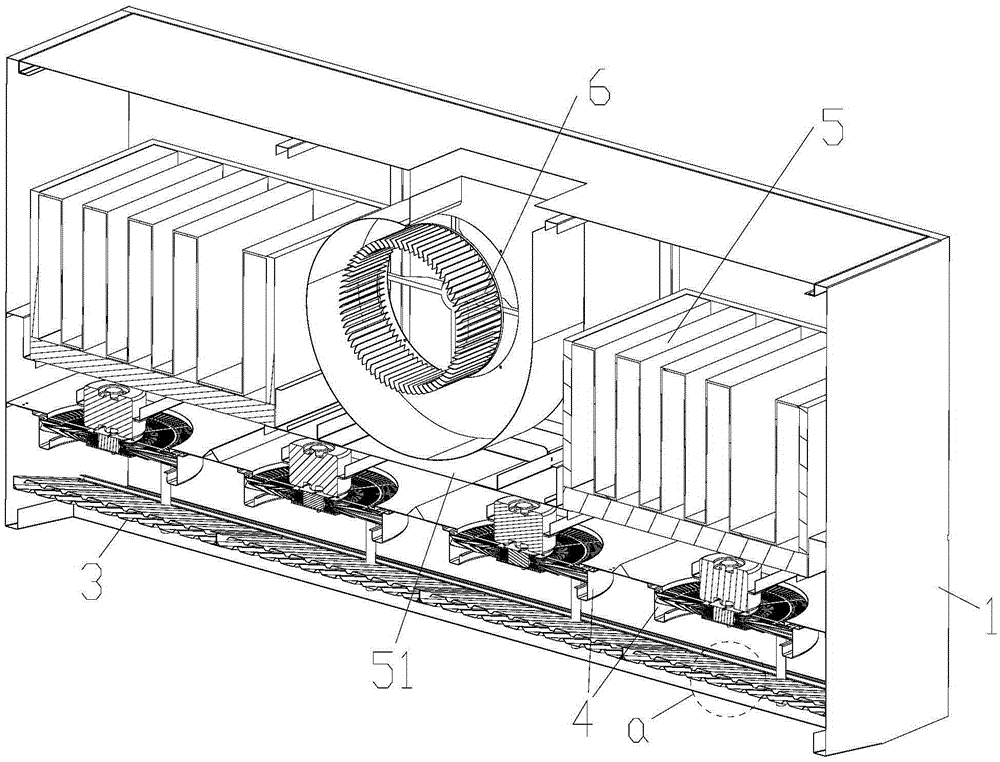

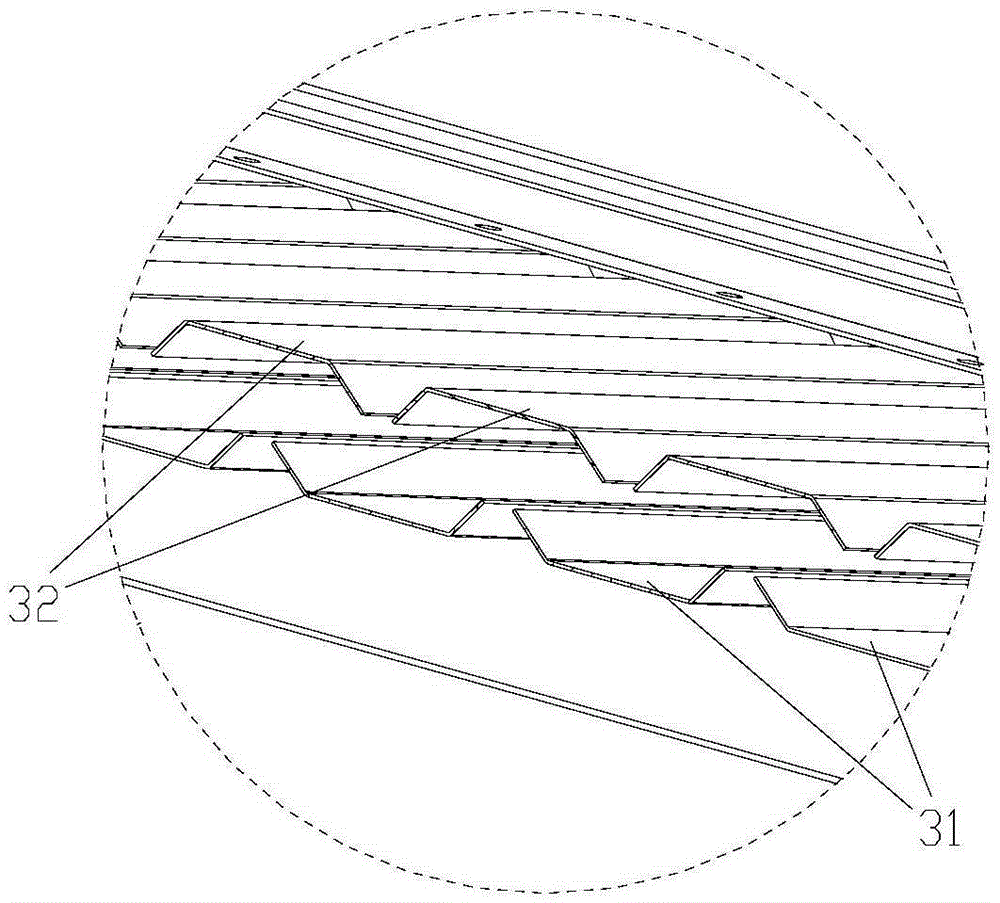

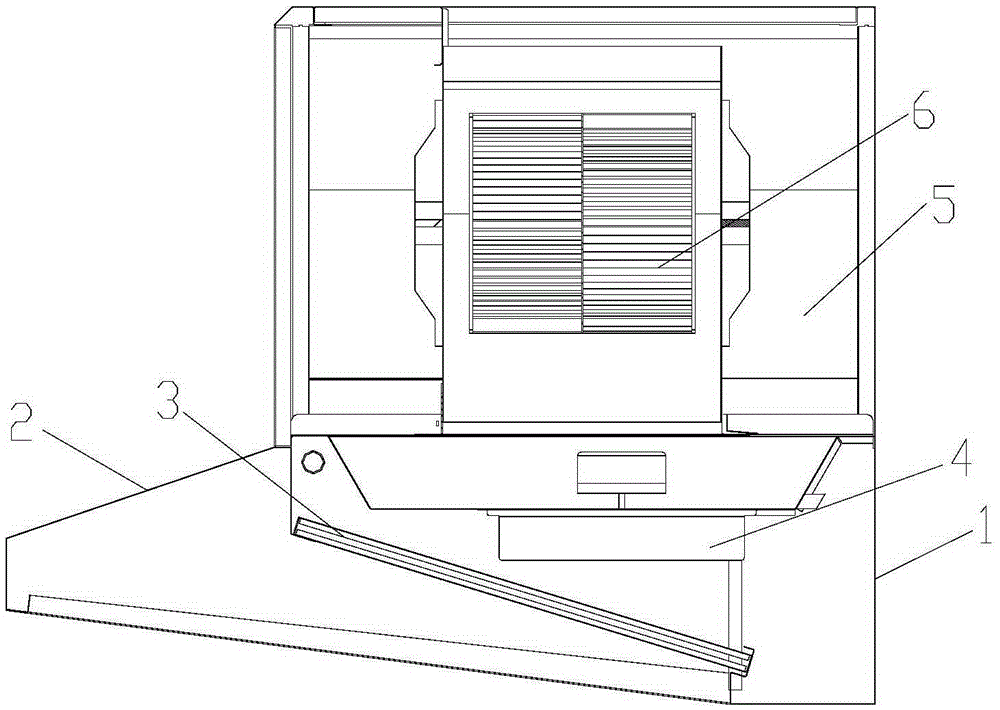

Steam-liquid separating assembly for removing oil and smoke and multistage filter device

ActiveCN105381655AGood effectEfficient degreasingCombination devicesGas treatmentSmokePetroleum engineering

The invention discloses a steam-liquid separating assembly for removing oil and smoke and a multistage filter device. The steam-liquid separating assembly comprises an oil baffling plate (41), wherein an accommodation hole (411) is arranged in the middle part of the oil baffling plate (41) and is provided with a flanging (412) that stretches downwards; an oil collecting hood (43), which is fixed on the lower lateral surface of the oil baffling plate (41), wherein the edge of the inner side of the oil collecting hood (43) is provided with an oil collecting groove (431); a separating disc (42), which is arranged between the oil baffling plate (41) and the oil collecting hood (43), and a transmission motor (44), which is fixedly connected to the middle of the separating disc (42); wherein the external diameter of the separating disc (42) is larger than the diameter of the accommodation hole (411), and the internal diameter of the oil collecting groove (431) is smaller than the diameter of the accommodation hole (411). The provided assembly and device have the advantages of simple structure, high oil removing efficiency, and easy assembly, disassembly and maintenance.

Owner:广州海蓝环保科技有限公司

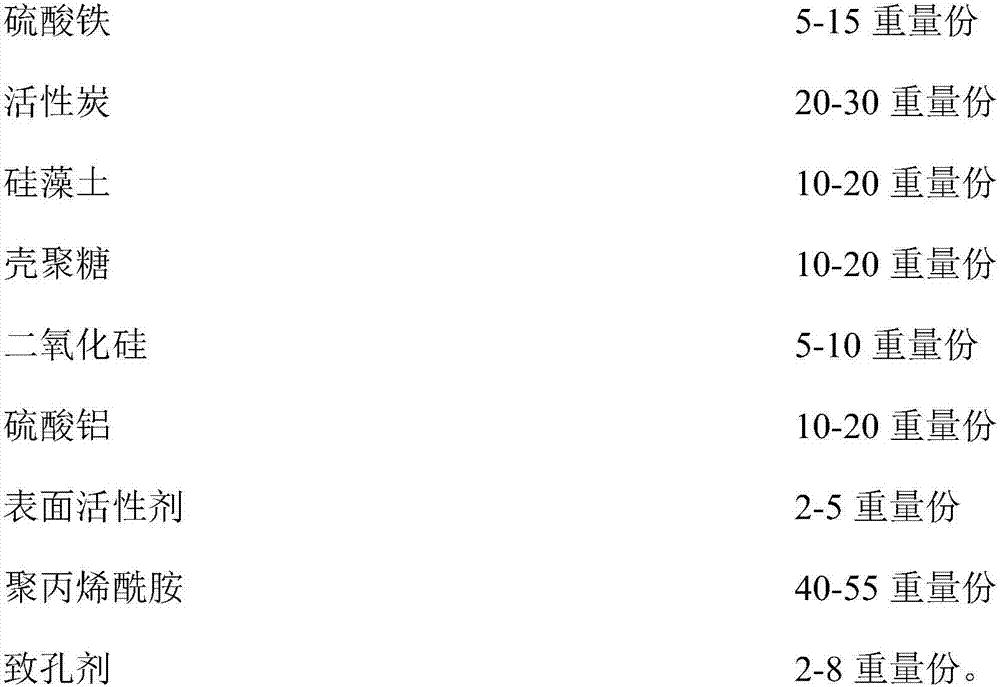

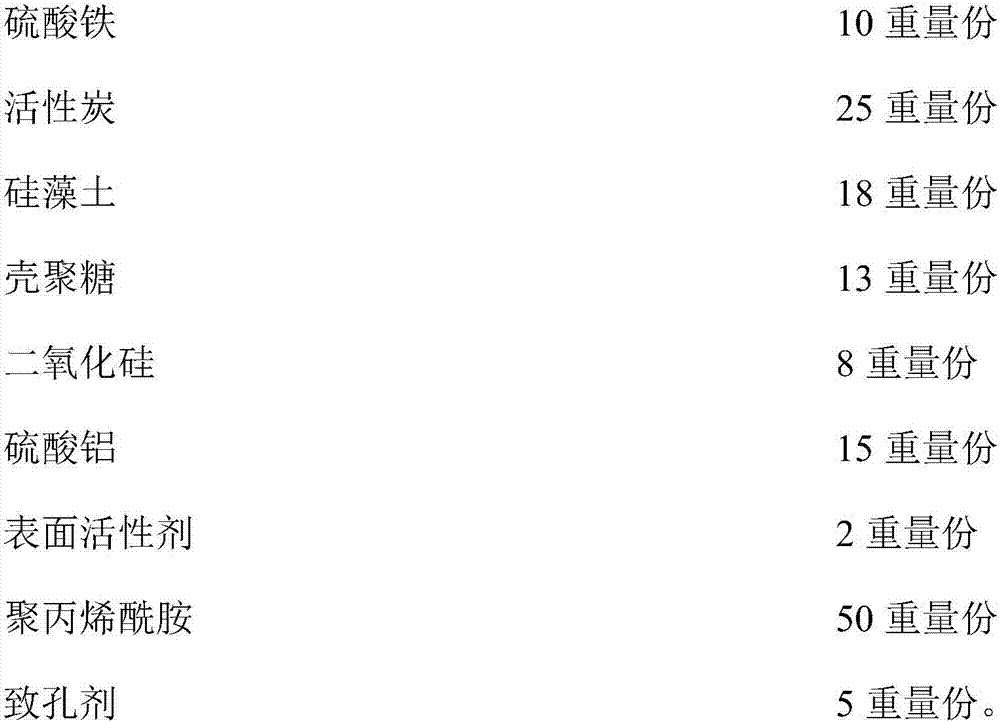

Water purifying composition, and preparation method and application thereof

InactiveCN107162142AAdsorptiveCoagulationSpecific water treatment objectivesWater contaminantsIron sulfateActivated carbon

The invention provides a water purifying composition and a preparation method and application thereof. The water purifying composition mainly comprises, by weight, 5 to 15 parts of iron sulfate, 20 to 30 parts of activated carbon, 10 to 20 parts of diatomite, 10 to 20 parts of chitosan, 5 to 10 parts of silicon dioxide, 10 to 20 parts of aluminum sulfate, 2 to 5 parts of a surfactant, 40 to 55 parts of polyacrylamide and 2 to 8 parts of a pore-forming agent. When 200 mg of the water purifying composition provided by the invention is applied to treatment of each L of wastewater, the removal rate of effluent turbidity can reach 95% or above; the removal rate of total phosphorus can reach 90% or above; the removal rate of COD can reach 34% or above; the removal rate of BOD is 78% or above; and antibacterial performance reaches 81% or above. The water purifying composition uses widely available raw materials, is low in cost and has good market prospects.

Owner:朱燕萍

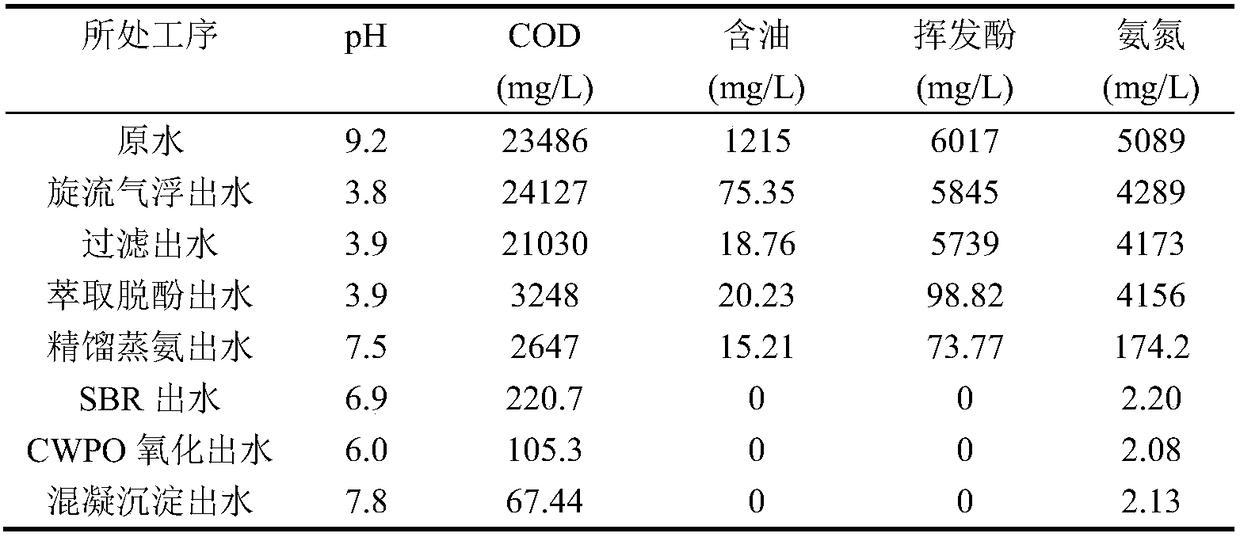

Optimized surfactant ratio for improved rinse feel

InactiveUS20150344821A1Good squeaky feelEfficient degreasingNon-ionic surface-active compoundsAmpholytes/electroneutral surface-active compoundsOrganic chemistrySURFACTANT BLEND

Owner:THE PROCTER & GAMBLE COMPANY

Liquid detergent composition

ActiveUS10611985B2Efficient degreasingRobust dilutionNon-ionic surface-active compoundsOrganic detergent compounding agentsActive agentSurface-active agents

A liquid detergent composition having a pH of from 7.1 to less than 8.9 as measured at 10% solution in distilled water at 20° C. wherein the composition includes a surfactant system, the surfactant system including an anionic surfactant and a primary co-surfactant selected from the group consisting of amphoteric surfactant, zwitteronic surfactant and mixtures thereof wherein the anionic surfactant and the primary co-surfactant are in a weight ratio of from less than 10:1 to more than 2.5:1 and wherein the composition further includes a specific cyclic amine.

Owner:THE PROCTER & GAMBLE COMPANY

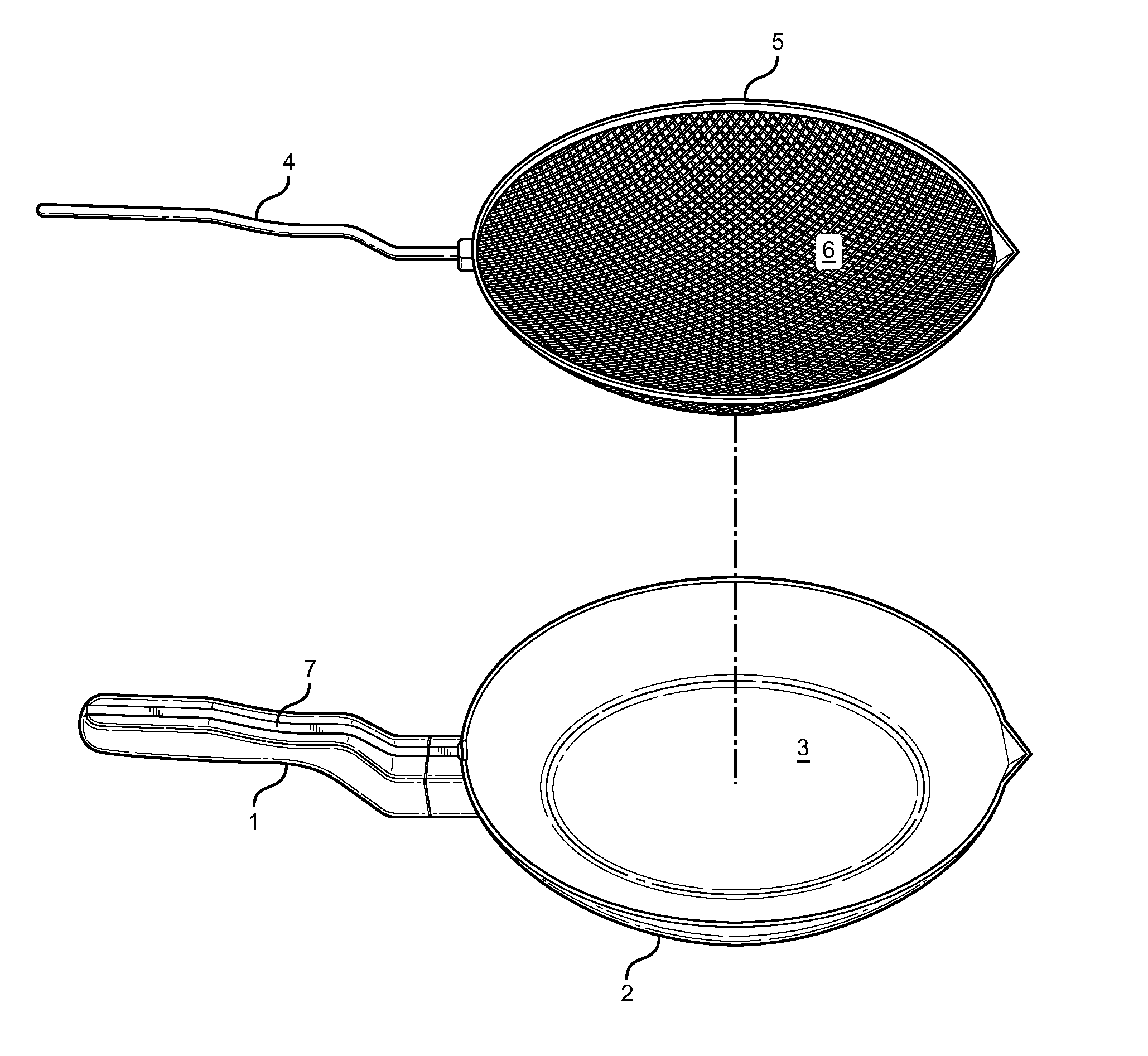

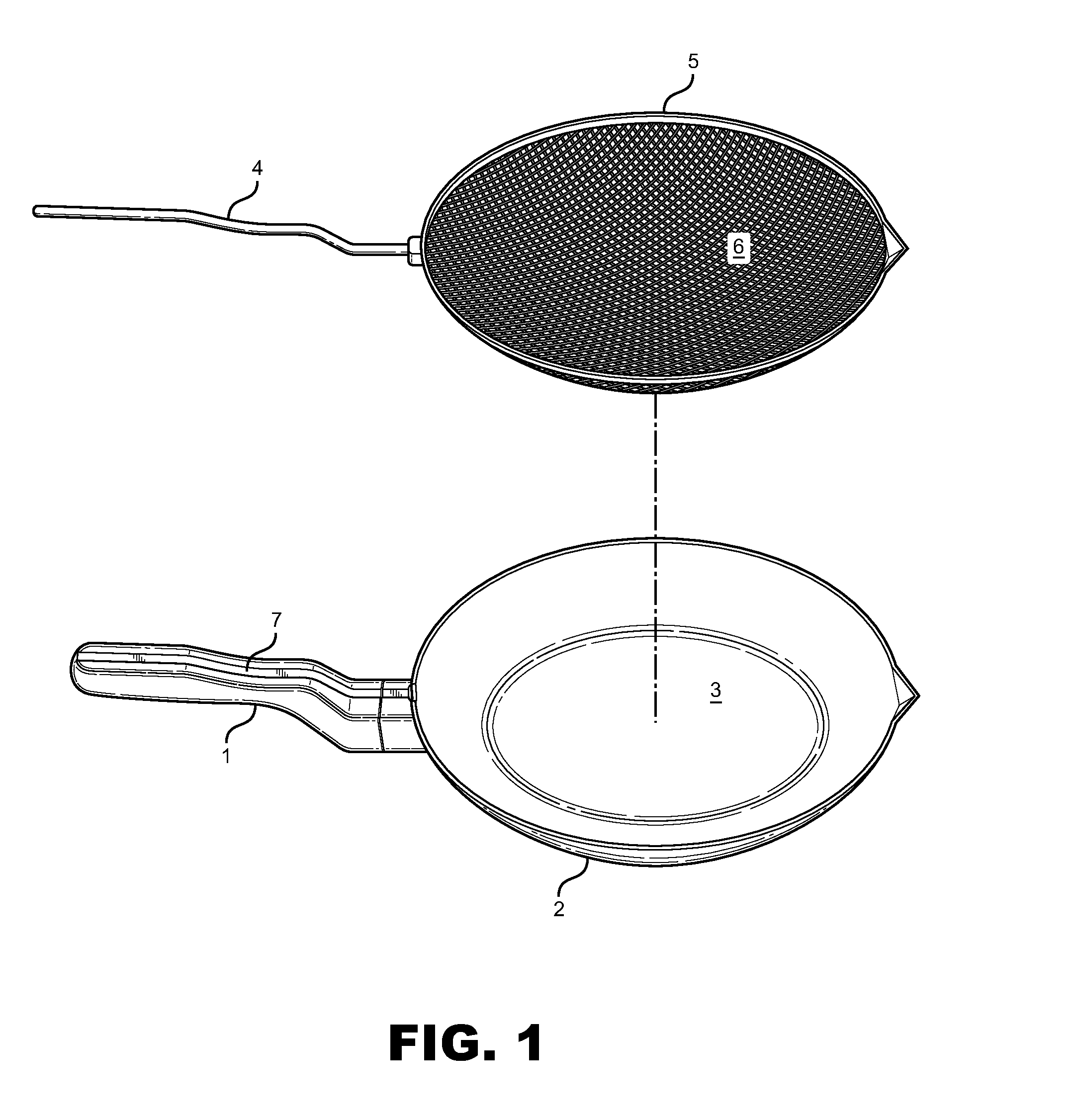

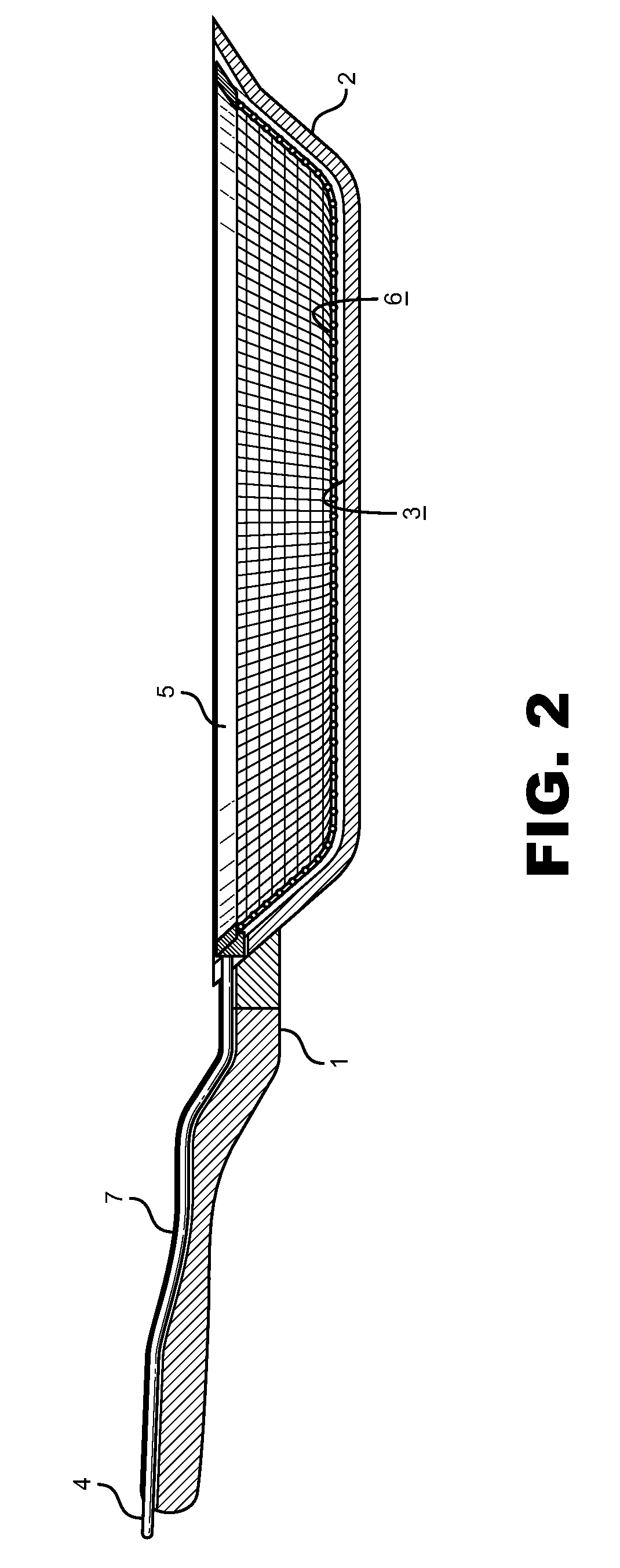

Straining Skillet

InactiveUS20110185916A1Facilitate easeSafe and efficient transmissionFood preservationCooking vesselsEngineeringMeal

An improved cooking device to assist in preparation of meals. A self-contained straining skillet allows the food to be cooked in a concave skillet insert containing a plurality of apertures, which may then be lifted to drain the grease and fat into the lower receiving skillet. Both the lining skillet and the receiving skillet may contain pour spouts to allow for effective transfer of grease. The receiving skillet, alone or with the lining skillet insert, may be used with standard size stove burners.

Owner:PENNY PHILLIP

Air conditioner fin cleaning agent and preparation method thereof

InactiveCN101544930BGood energy saving effectOvercoming the disadvantages of being easily corrodedInorganic non-surface-active detergent compositionsParticulatesSurface cleaning

The invention belongs to the technical field of metal surface cleaning and in particular discloses an air conditioner fin cleaning agent and a preparation method thereof. The cleaning agent is mainly prepared by mixing water and the following components by weight percentage: 10 to 15 percent of nitric acid, 0.5 to 0.8 percent of potassium chromate, 0.5 to 0.8 percent of sodium ethoxylated alkyl sulfate, and 0.1 to 0.5 percent of polyoxyethylene octylphenol ether. The preparation method comprises the following steps: taking water in half of the amount, adding the nitric acid into the water, and uniformly stirring the nitric acid and the water to obtain an aqueous solution a; taking the other half amount of water, sequentially adding the potassium chromate, the odium ethoxylated alkyl sulfate and the polyoxyethylene octylphenol ether into the water, fully stirring the mixture till solid particles dissolve completely, and obtaining an aqueous solution b; and slowly adding the uniformed stirred aqueous solution a into the aqueous solution b, fully stirring the aqueous solution a and the aqueous solution b till the mixed solution is uniform, and obtaining a finished product. The cleaning agent is excellent in cleaning and energy-saving effect and avoids corrosion influences on equipment surface substantially.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

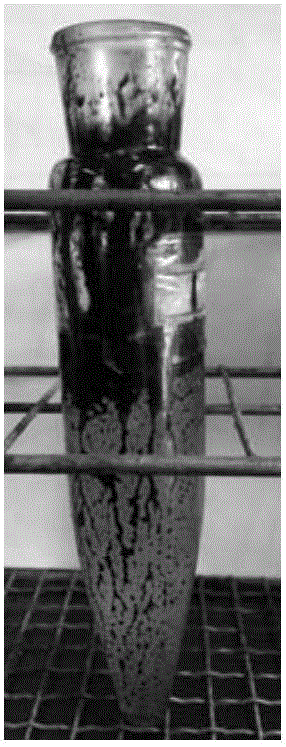

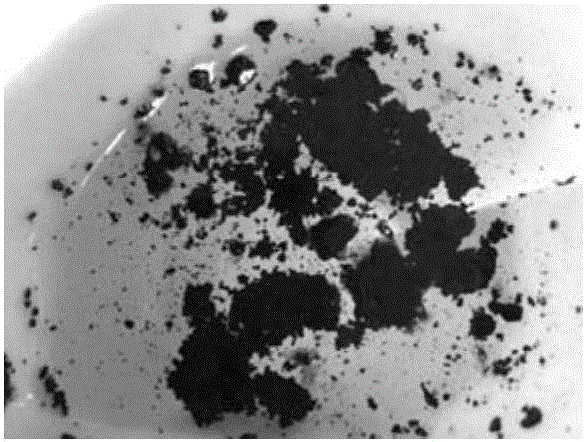

Method for extracting active protein from moringa oleifera seeds

InactiveCN106701873AImprove antioxidant capacityEfficient removalPeptide preparation methodsFermentationWater bathsActive agent

The invention provides a method for extracting active protein from moringa oleifera seeds. The method comprises steps as follows: pretreatment: the moringa oleifera seeds are dried in the sun and peeled off, white spherical inner seeds are obtained, soaked with deionized water, dried, subjected to superfine grinding and sieved; degreasing: a degreasing agent and an active agent are added to inner seed powder, the materials are stirred, left to stand and filtered, blocky powder is obtained, and the powder is air-dried and then is sieved; extraction of active protein: a Tris-HCl buffer solution is added to the sieved powder, a mixed solution is stirred and subjected to water-bath heating, an enzymolysis agent and a cosolvent are added, the solution is stirred continuously and centrifuged, a supernatant is taken, a precipitation agent is added to the supernatant, the mixture is left to stand and filtered, and active protein in the moringa oleifera seeds is obtained; the active protein is freeze-dried for storage. Efficient degreasing is realized through improvement of a pretreatment process, the extraction rate of active protein is remarkably increased, and the effect of the extracted active protein is excellent.

Owner:ZHEJIANG OCEAN UNIV

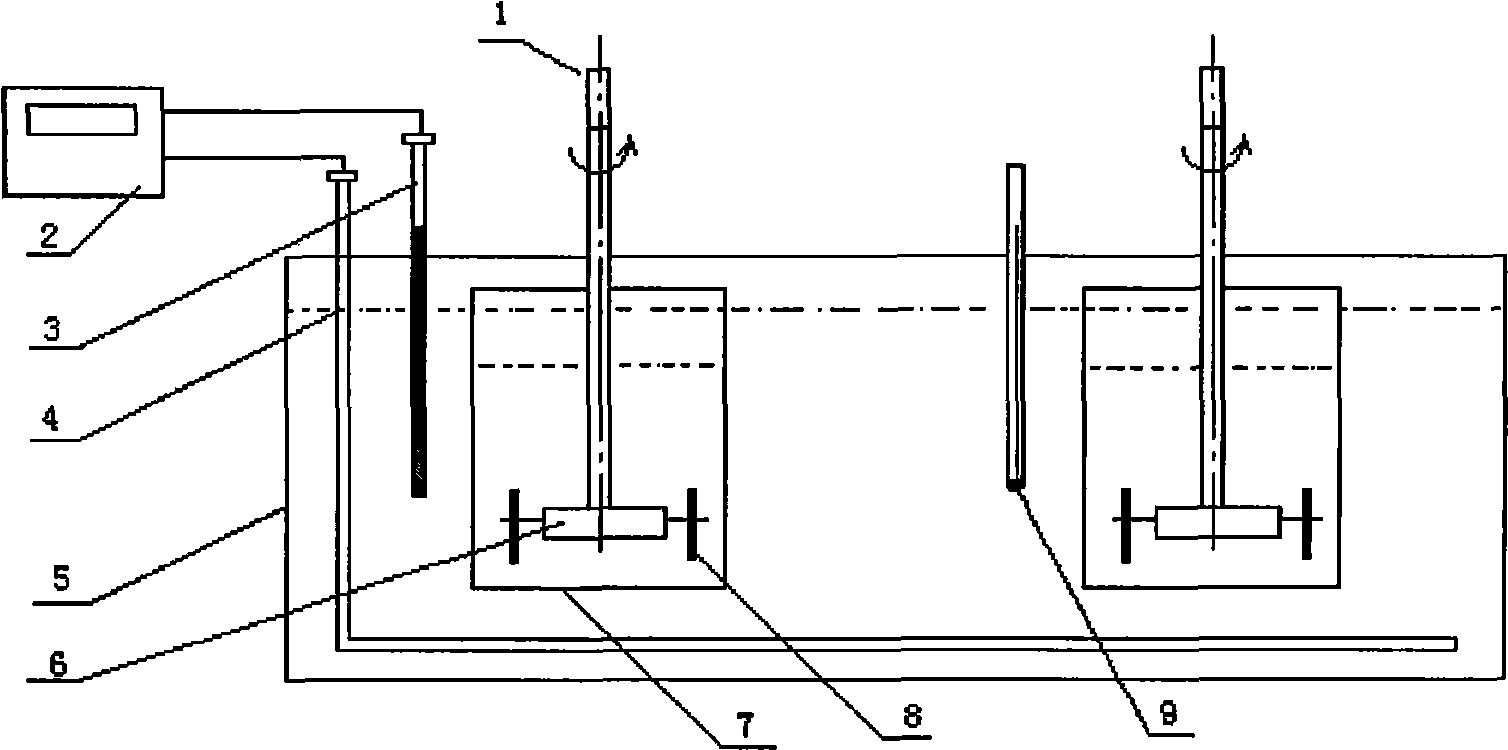

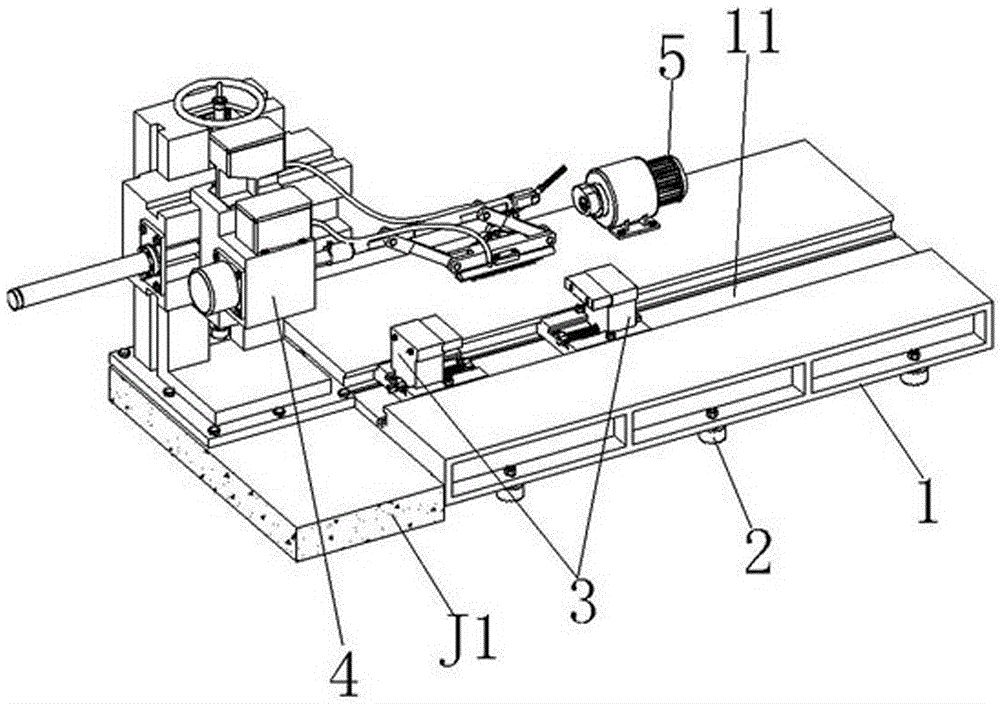

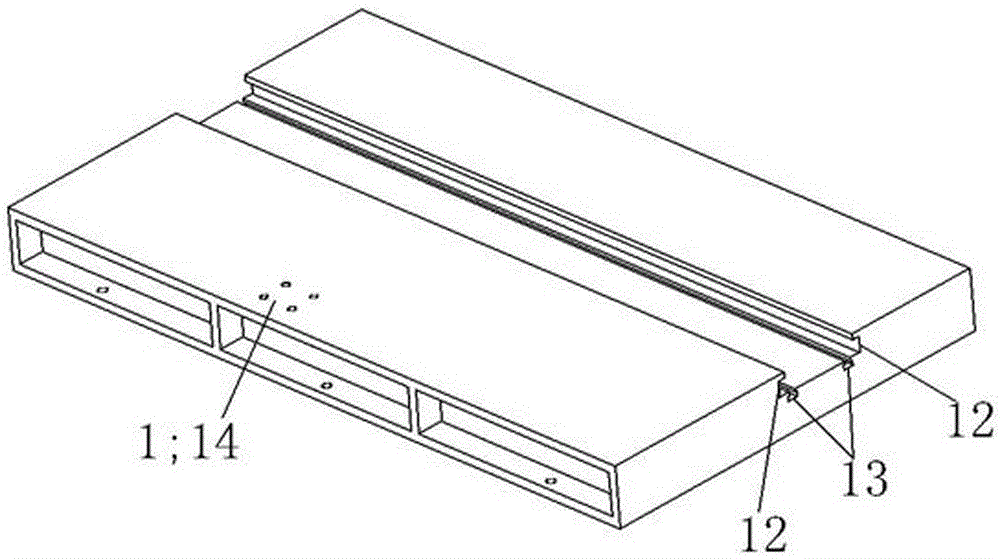

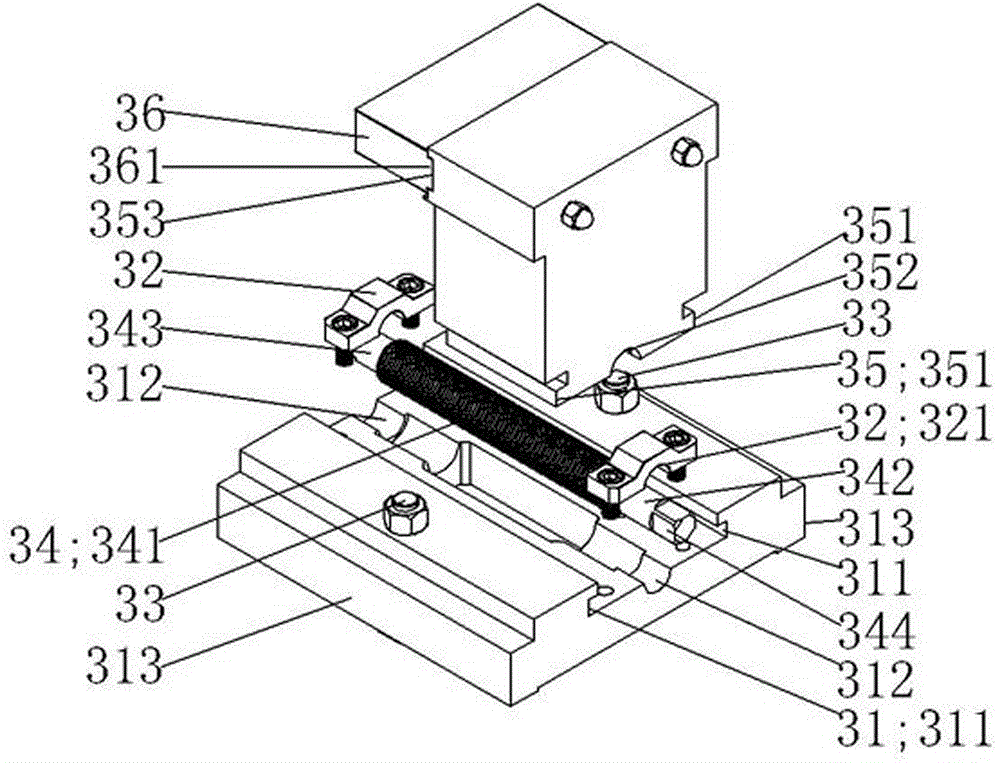

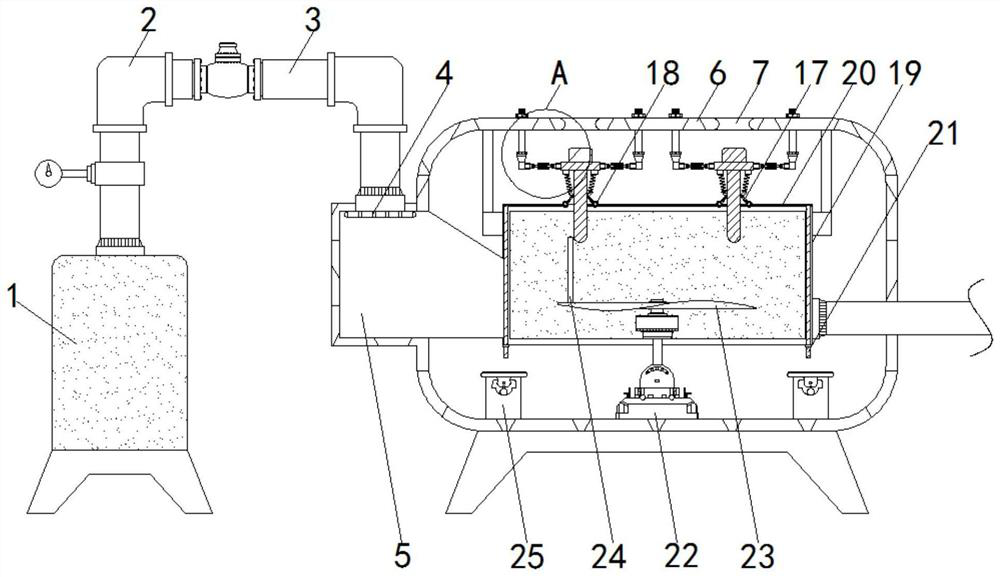

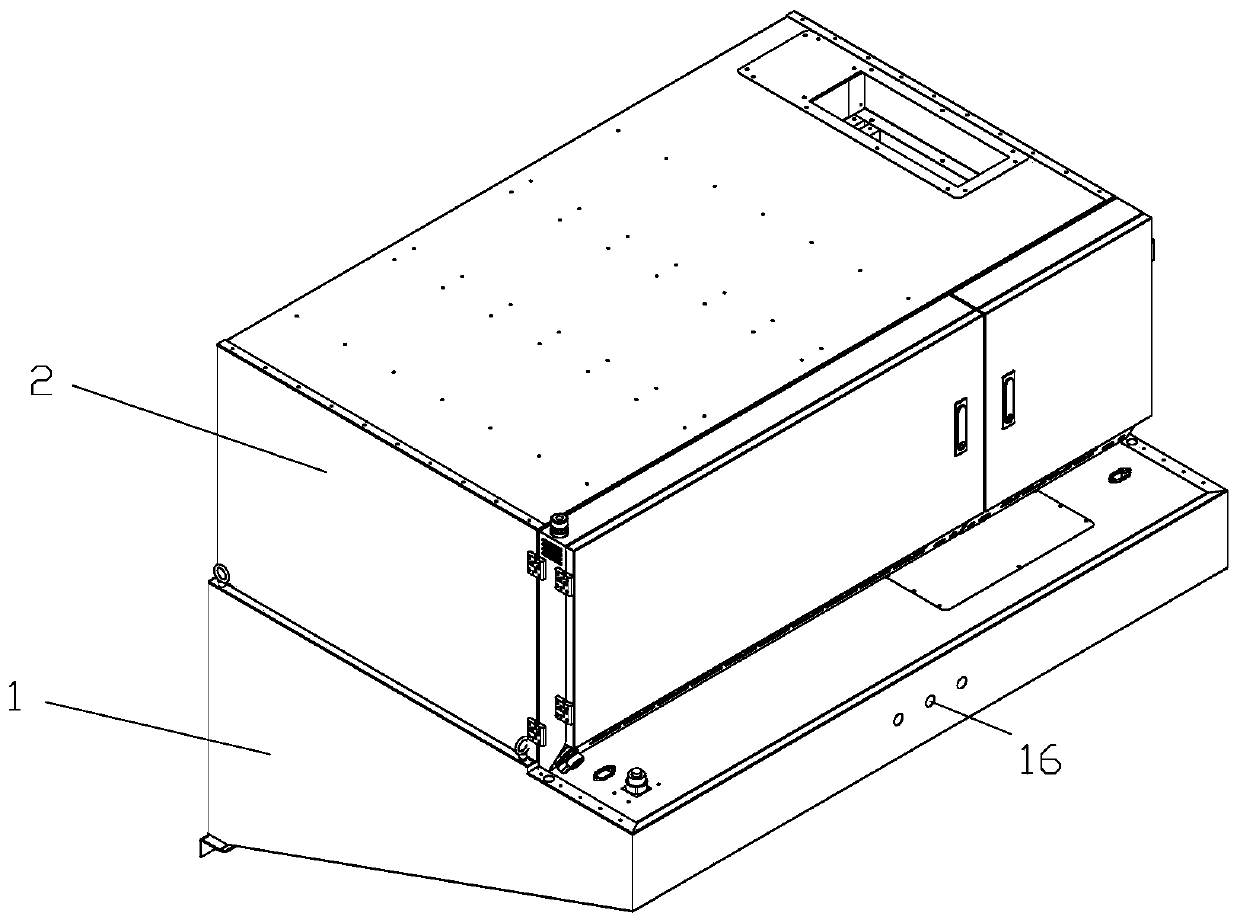

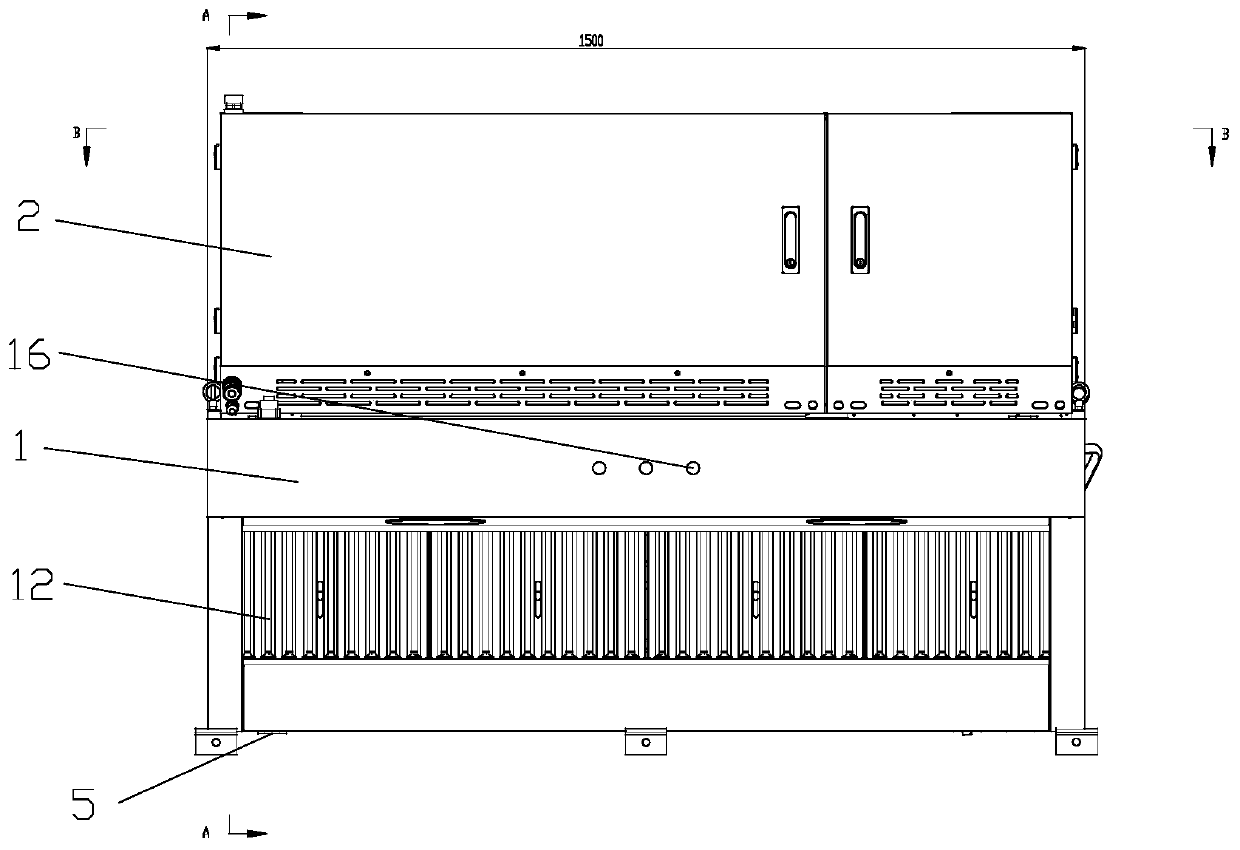

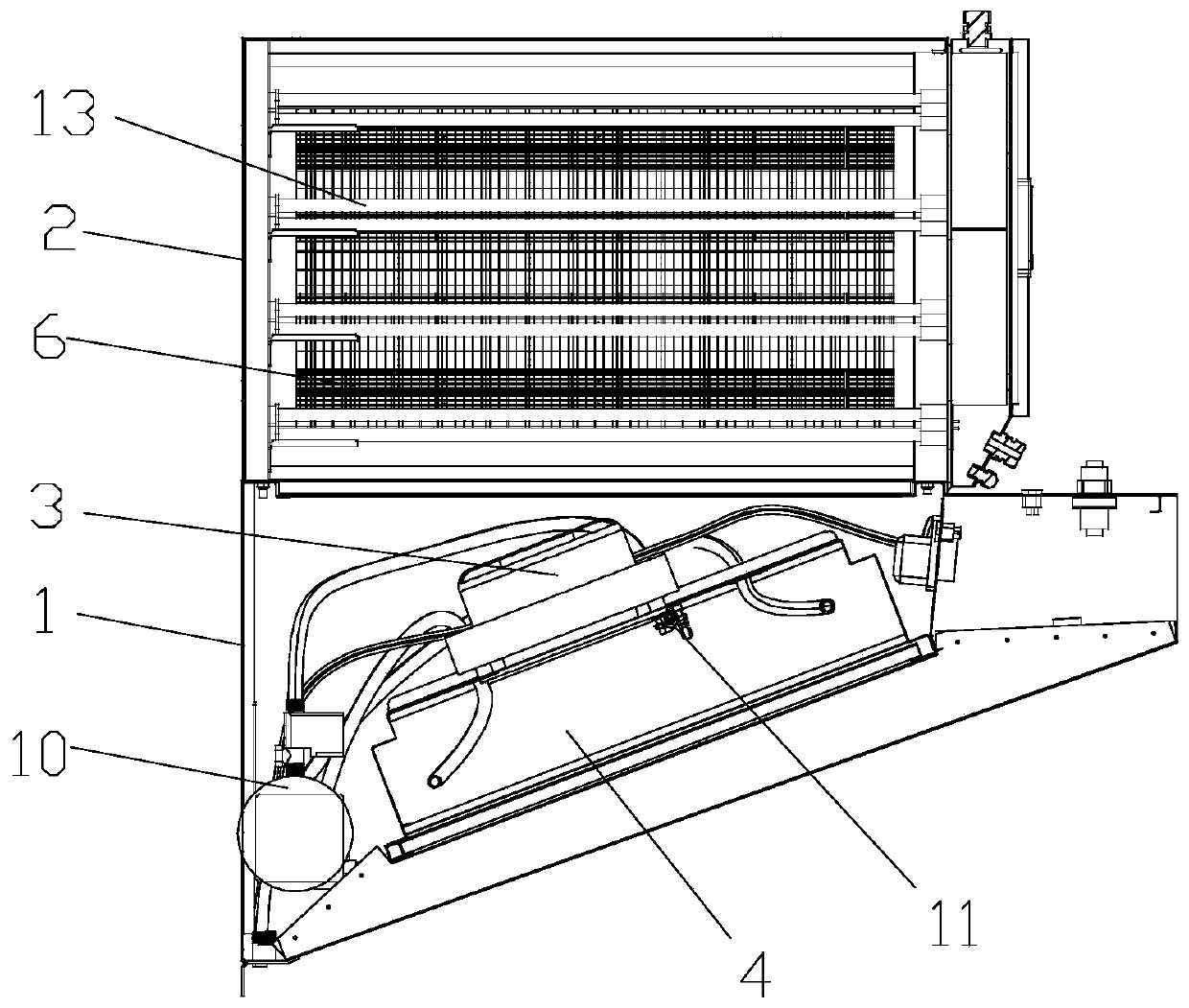

Large-scale Babbitt bearing casting machine

InactiveCN105772696AEfficient rust removalEfficient degreasingCasting cleaning apparatusMolten metal conveying equipmentsMechanical equipmentLayer removal

The invention discloses a large-scale Babbitt bearing casting machine and aims to provide casting mechanical equipment in the field of metal casting. The casting machine comprises a base, damping pads, two clamping pinchers, a painting device, and a vibrator, wherein the two clamping pinchers are horizontally arranged oppositely and fixedly connected in a middle groove formed in the base; the painting device is fixedly connected to a foundation; the vibrator is fixedly connected with a plane which is arranged on the base; the amount of the damping pads is six, and the damping pads are all arranged on the bottom face of the base. According to the technical scheme of the large-scale Babbitt bearing casting machine, wind pressure is used as the power, by means of the wiggle, rotation and reciprocating rectilinear movement of painting tools in the painting device, operations such as rust removal, oxide layer removal, degreasing and tin coating can be conducted efficiently; vibration casting is adopted, and the casting quality is improved. By means of the large-scale Babbitt bearing casting machine, casting efficiency can be improved effectively, and the working conditions of workers can be largely improved and labor intensity of the workers can be largely relieved; the casting machine is simple in structure, convenient to repair and low in equipment investment.

Owner:KUNMING UNIV

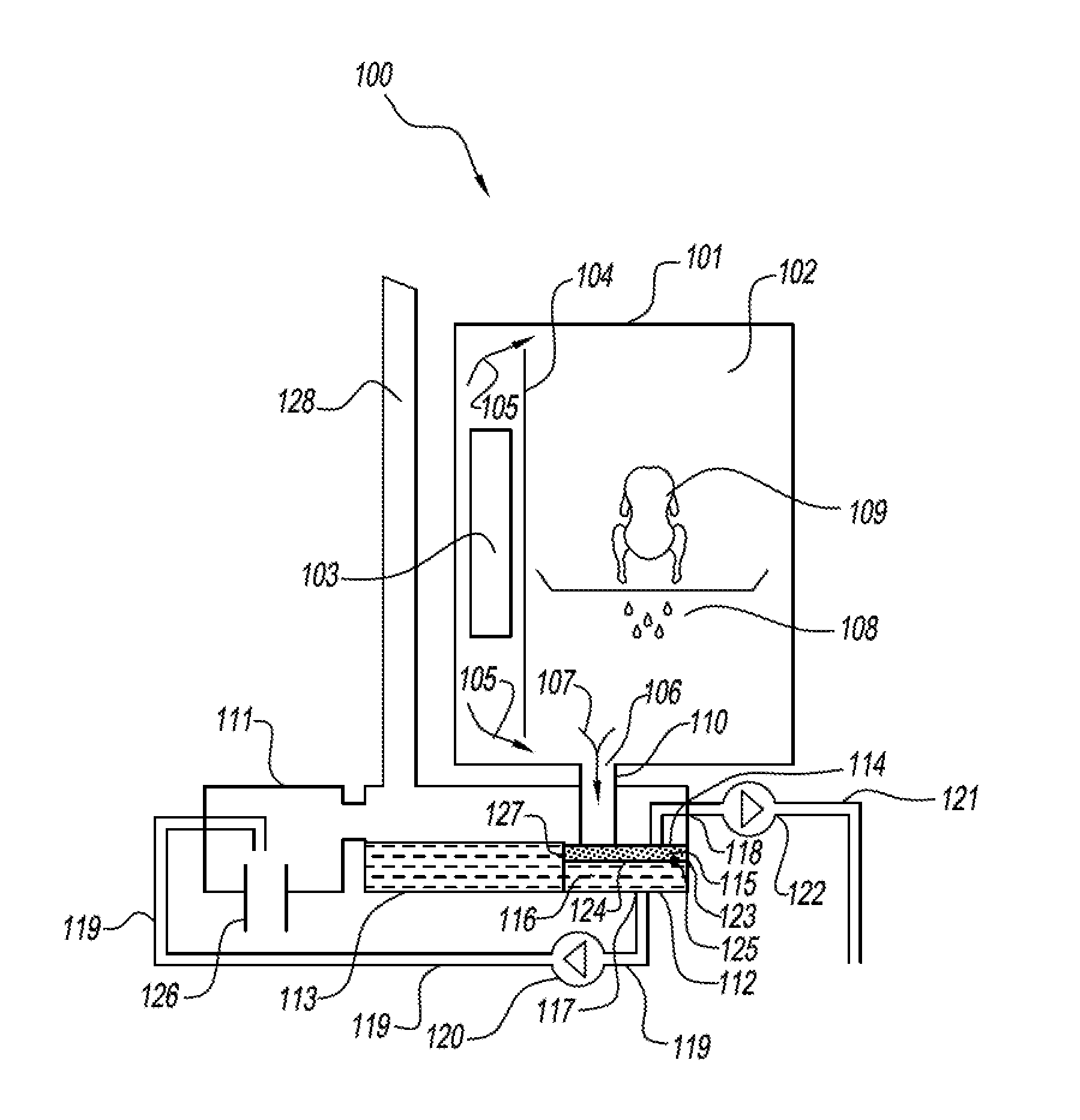

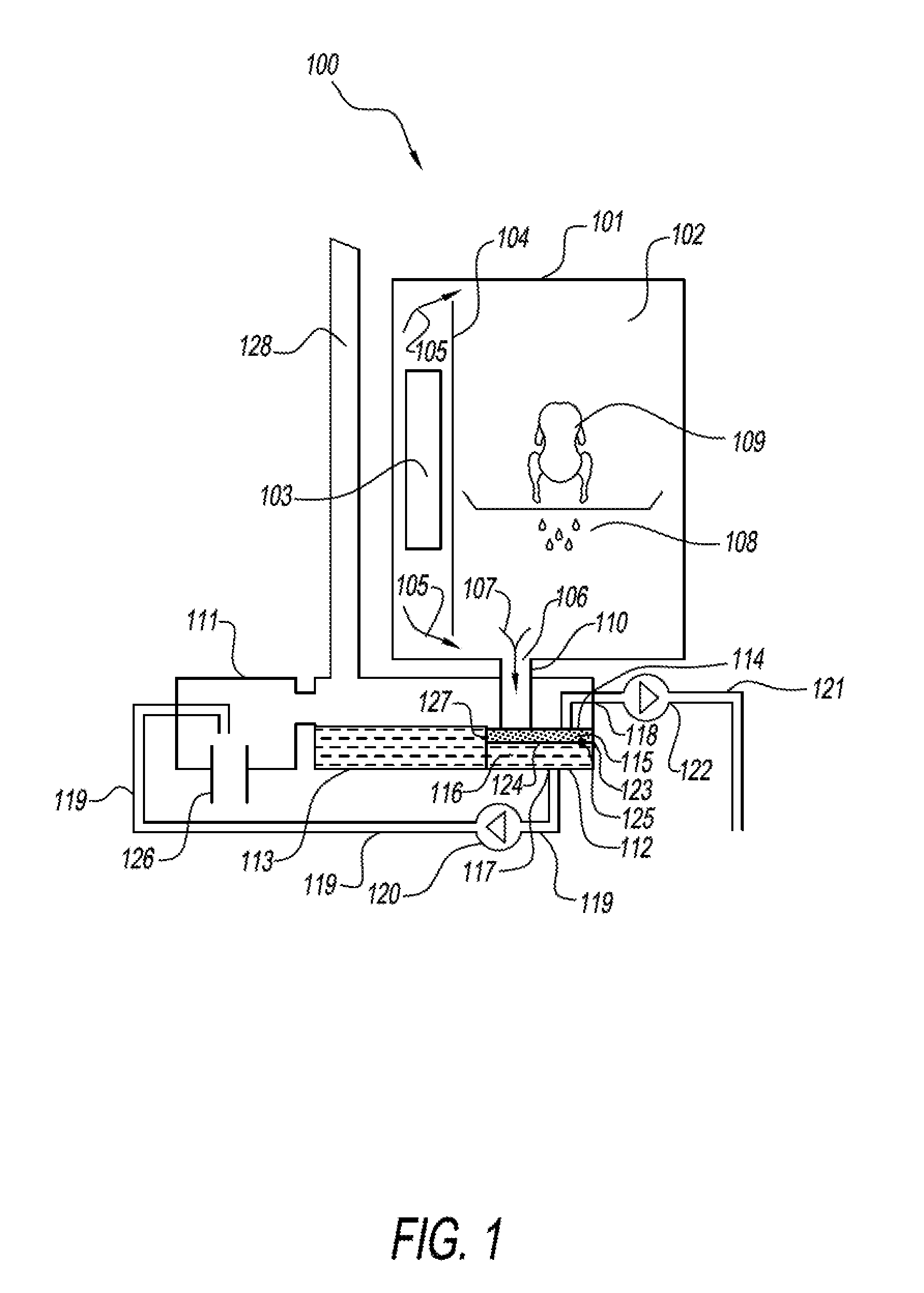

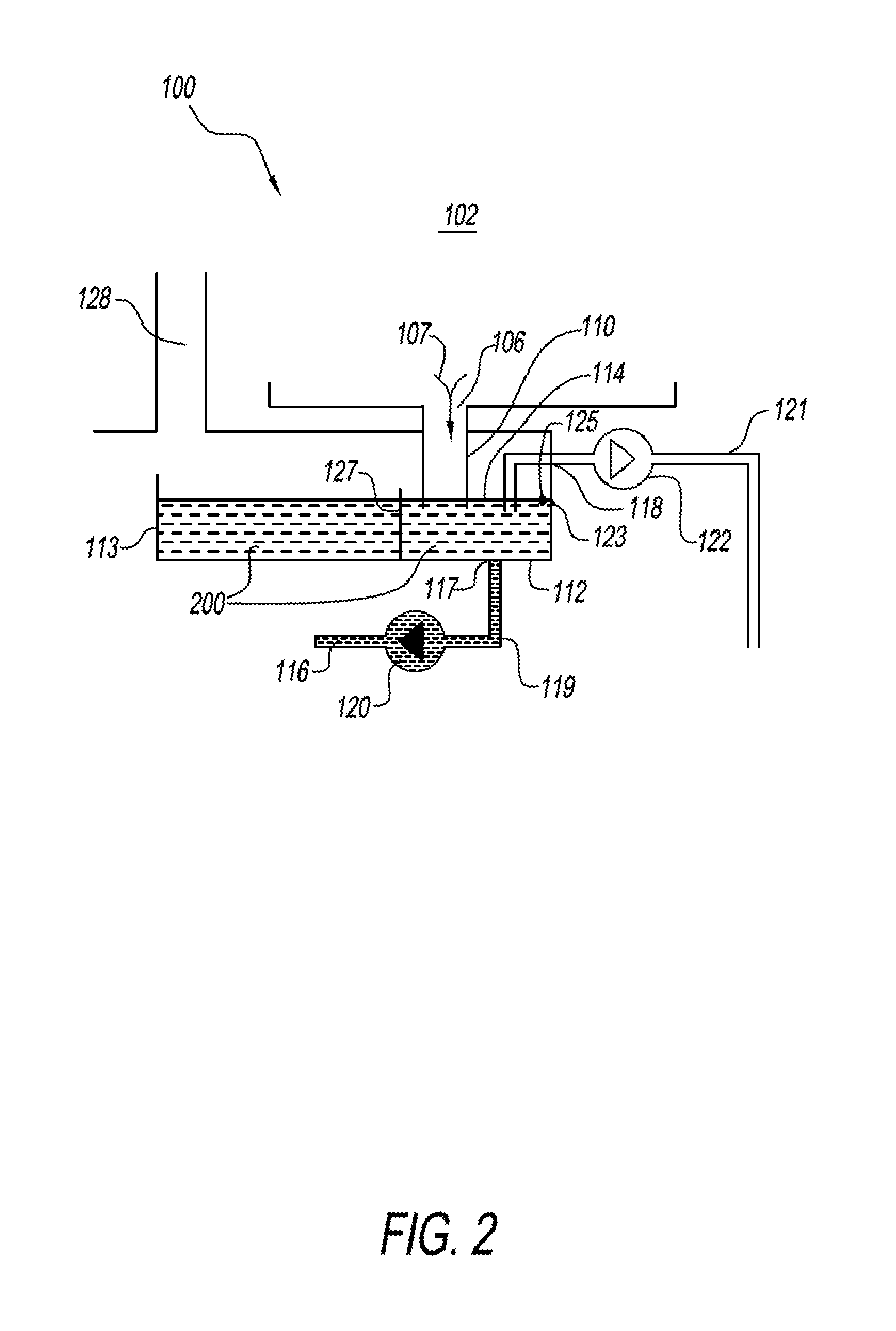

Method and appratus for grease seperation during a cooking cycle

ActiveUS20160198884A1Efficient degreasingBoiling over preventionDomestic stoves or rangesAtmospheric airFluid interface

Disclosed are methods and apparatuses for grease separation during a cooking cycle of a food product in a cooking device. The methods and apparatuses perform grease separation by bifurcating the cooking cycle. In a first portion of the cooking cycle, in which the system is closed to ingress of the atmosphere by creating a water barrier in a collector box to seal a cooking chamber in which the food product is cooking, all cooking fluids exiting the cooking device pass into the water barrier. In a second portion of the cooking cycle, the collector box is emptied and the system is opened to capture all cooking fluids exiting the cooking device in the collector box. During the open portion, a grease / cooking fluid interface is monitored and the captured cooking fluids, containing a high percentage of grease, are pumped out of the collector box.

Owner:WELBILT DEUT GMBH

Liquid detergent composition

ActiveUS10689598B2Efficient degreasingRobust dilutionOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentDistilled water

A liquid detergent composition having a pH of from 7.1 to 7.9 as measured at 10% solution in distilled water at 20° C. wherein the composition includes a surfactant system, the surfactant system including an anionic surfactant and a primary co-surfactant selected from the group consisting of amphoteric surfactant, zwitteronic surfactant and mixtures thereof wherein the anionic surfactant and the primary co-surfactant are in a weight ratio of from less than about 10:1 to more than about 2.5:1 and wherein the composition further includes a specific cyclic diamine.

Owner:PROCTER & GAMBLE CO

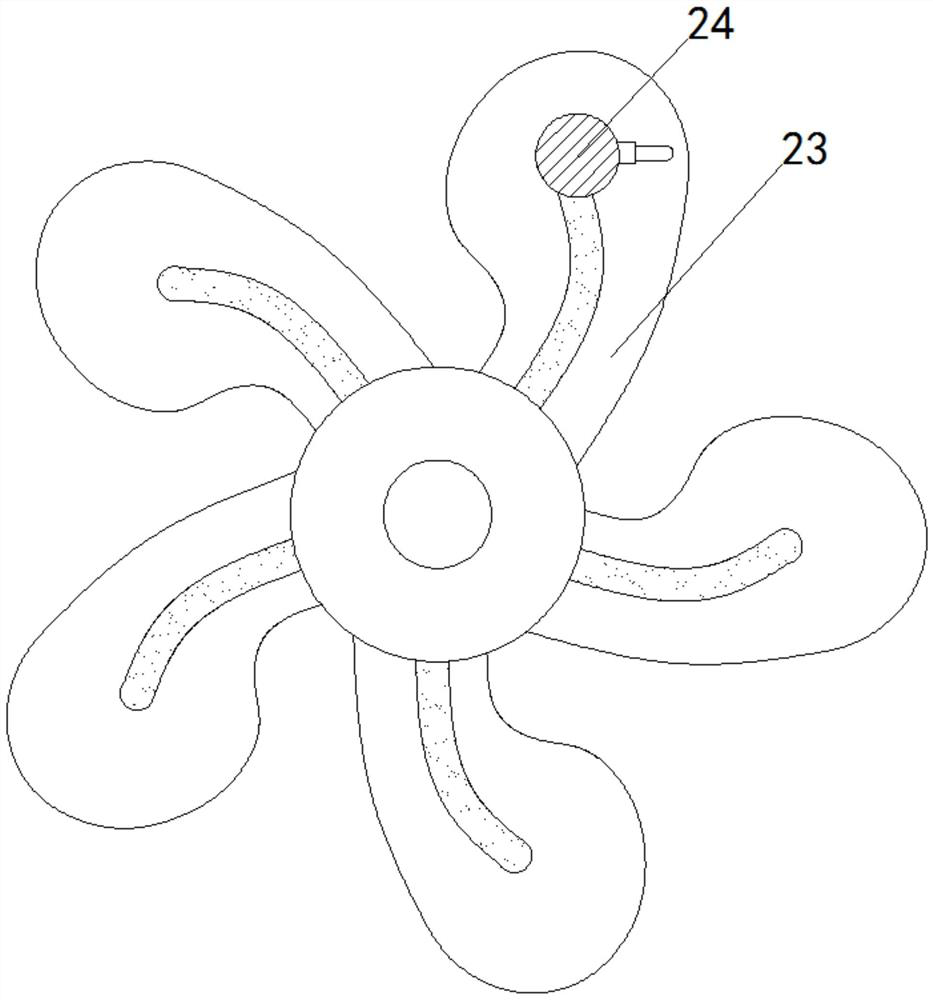

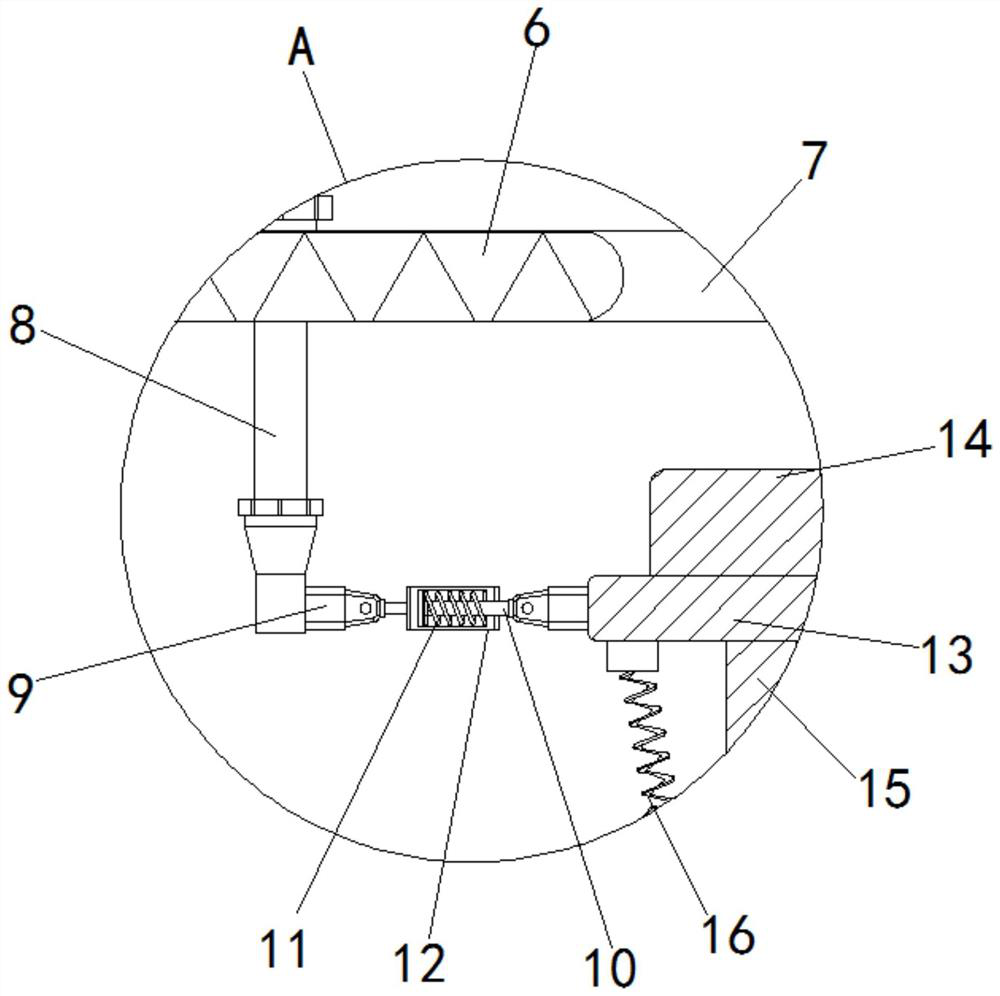

Chemical waste oil extraction device for refining chemical sewage

ActiveCN112028174APrevent solidificationIncrease contact surfaceFatty/oily/floating substances removal devicesLiquid separationWater trapWastewater

The invention relates to the technical field of chemical engineering, and discloses a chemical waste oil extraction device for refining chemical sewage. The device comprises a sewage tank, a water inlet pipe is fixedly mounted at the top end of the sewage tank, a water outlet pipe is fixedly mounted at one end, away from the sewage tank, of the water inlet pipe, a filter screen is fixedly mountedat one end, away from the water inlet pipe, of the water outlet pipe, and a water guide box is fixedly mounted on the outer wall of the water outlet pipe. According to the device for extracting the chemical waste oil in the chemical wastewater, a motor and fan blades are used in cooperation, so that when the motor works, the output shaft of the motor drives a heating block to rotate, the heating block heats oily water in an oil removal box, and industrial oil is prevented from being solidified; the fan blades are driven to rotate when the heating block rotates, and grooves are formed in the inner walls of the fan blades, so that in the rotating process of the fan blades, the grooves can increase rotation of sewage in the oil removal box, small vortexes are formed in the center of the bottom end of the oil removal box, the oil dipping contact surface of an oil dipping rod is larger, and therefore the oil removing process can be conducted more efficiently.

Owner:SHANDONG ZHENGHE STEEL PLASTIC PROFILE

Cooking fume cleaning integrated machine

PendingCN109899851ASpeed up the flowIncrease contact areaDomestic stoves or rangesLighting and heating apparatusModular compositionLow voltage

A cooking fume cleaning integrated machine comprises a cooking fume separating box and a fume decomposing box which are arranged at the bottom part, wherein a group of oil throwing plates are arrangedin the cooking fume separating box, and a condenser is arranged at the lower parts of the oil throwing plates; an oil groove is formed in the bottom part of the cooking fume separating box, and an oil outlet is formed in the bottom part of the oil groove; a high and low voltage electric field, a filtering part and an air blower are sequentially distributed in the smoke decomposing box along a smoke marching route; an outlet of the air blower is connected to an outlet of the smoke decomposing box; a group of filtering plates is arranged on the filtering part, and filtering layers are arrangedon the filtering plates; and the filtering plates are connected from top to bottom in an end-to-end manner to form folding line wave shape. The machine is reasonable and compact in structure; drainingand treating are integrated; the problem of monitoring in use is avoided; the machine is arranged at the front for cleaning, so that low-attitude exhausting is achieved; the energy is obviously saved; the inside is automatically washed, and additional washing is avoided; 99% of smell can be removed; the machine is easily managed and durable; and the machine is subjected to modular combination, and the technical processes are the fewest; a small space is occupied; the mounting and dismounting are convenient; the environment is protected; and various cooking works apply.

Owner:浙江远旺电力设备有限公司

Fatlute reducing oil containing or polymer and oil containing sewage treatment method and degradable flocculation agent system

ActiveCN106219714AEfficient degreasingGreat economic value and ecological benefitsWater/sewage treatment by flocculation/precipitationAmmonium chloride mixtureSewage

The invention provides a fatlute reducing oil containing or polymer and oil containing sewage treatment method. The method comprises the steps that a degradable cationic flocculation agent is added into oil containing or polymer and oil containing sewage, and the degradable cationic flocculation agent is an acryloyloxyethyl trimethyl ammonium chloride polymer. The method further can comprise the steps that while or after the degradable cationic flocculation agent is added into the oil containing or polymer and oil containing sewage, a degradation promoter is added into the system. The degradation promoter is selected from one or more of organic amine, K2CO3 and ammonium persulfate. The mass ratio of the degradable cationic flocculation agent to the degradation promoter is 50:(0-50). The ratio of the total use amount of the degradable cationic flocculation agent and the degradation promoter to the oil containing or polymer and oil containing sewage can be 200 mg to 400 mg. The agent system can be used for fast and efficient oil removal of the sewage, the oil removal and solid removal efficiency of the agent is guaranteed, and meanwhile generated alum floc can be reduced by itself.

Owner:CNOOC TIANJIN BRANCH +1

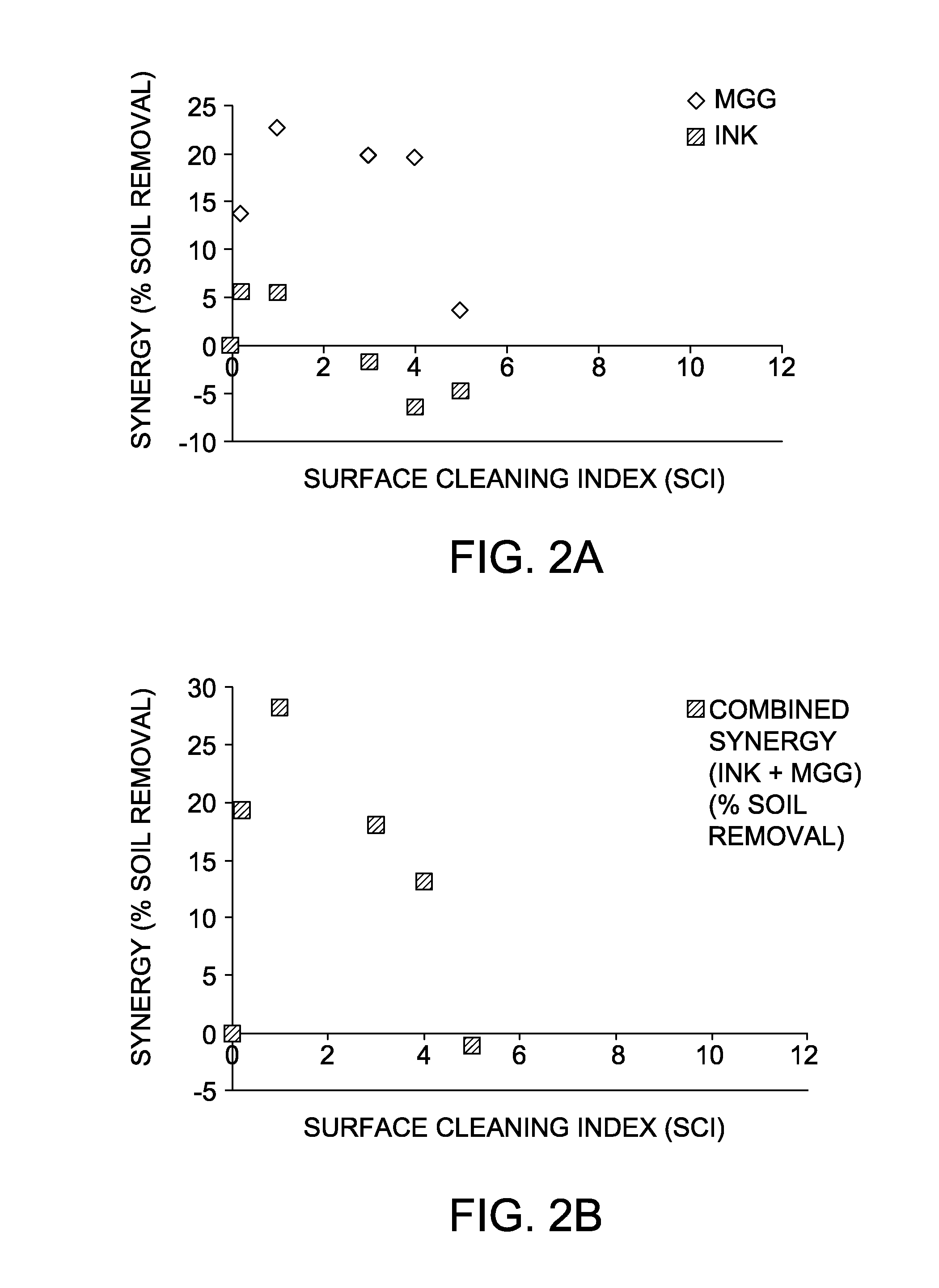

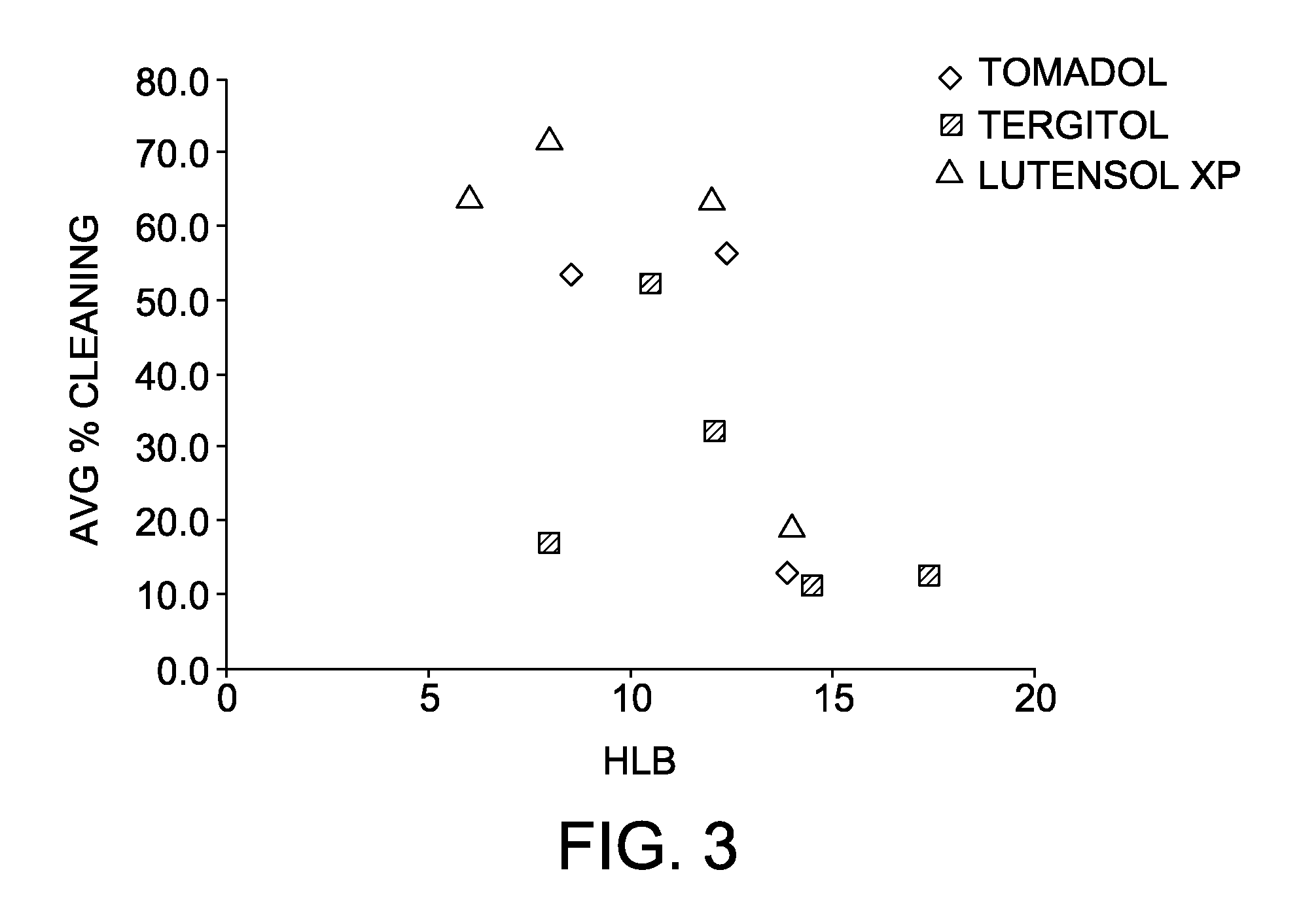

Cleaning composition having improved soil removal

ActiveUS20140274851A1Easy to cleanEfficient degreasingCosmetic preparationsMake-upEffective surfaceGlycol ethers

Cleaning compositions including a non-ionic surfactant and a glycol ether are disclosed. These cleaning compositions are useful as liquid cleaners or de-greasers for animate surfaces, such as skin. The cleaning compositions provide improved cleaning and removal of soils without the use of certain VOCs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Manufacturing method of waste plastic regeneration particles

The invention relates to a manufacturing method of waste plastic regeneration particles. A washing agent is added to waste plastic washing water; sieve pores in a crush screen piece are in three rows; and a seat tool and a moving tool are mounted in the form of a straight line; and the manufacturing method has the advantages as follows: a little amount of powder materials generated in the waste plastic crushing procedure are singly granulated, the washing degree can be increased, the product color and appearance are improved, the grade is increased and sales revenue is increased; in addition, the screening uniformity can be improved, the extruding speed of a granulator is increased and power consumption is reduced; and thermal degradation in the granulating procedure is avoided, so that the product yield of raw materials is further increased.

Owner:永善县原生源废旧再生资源利用有限公司

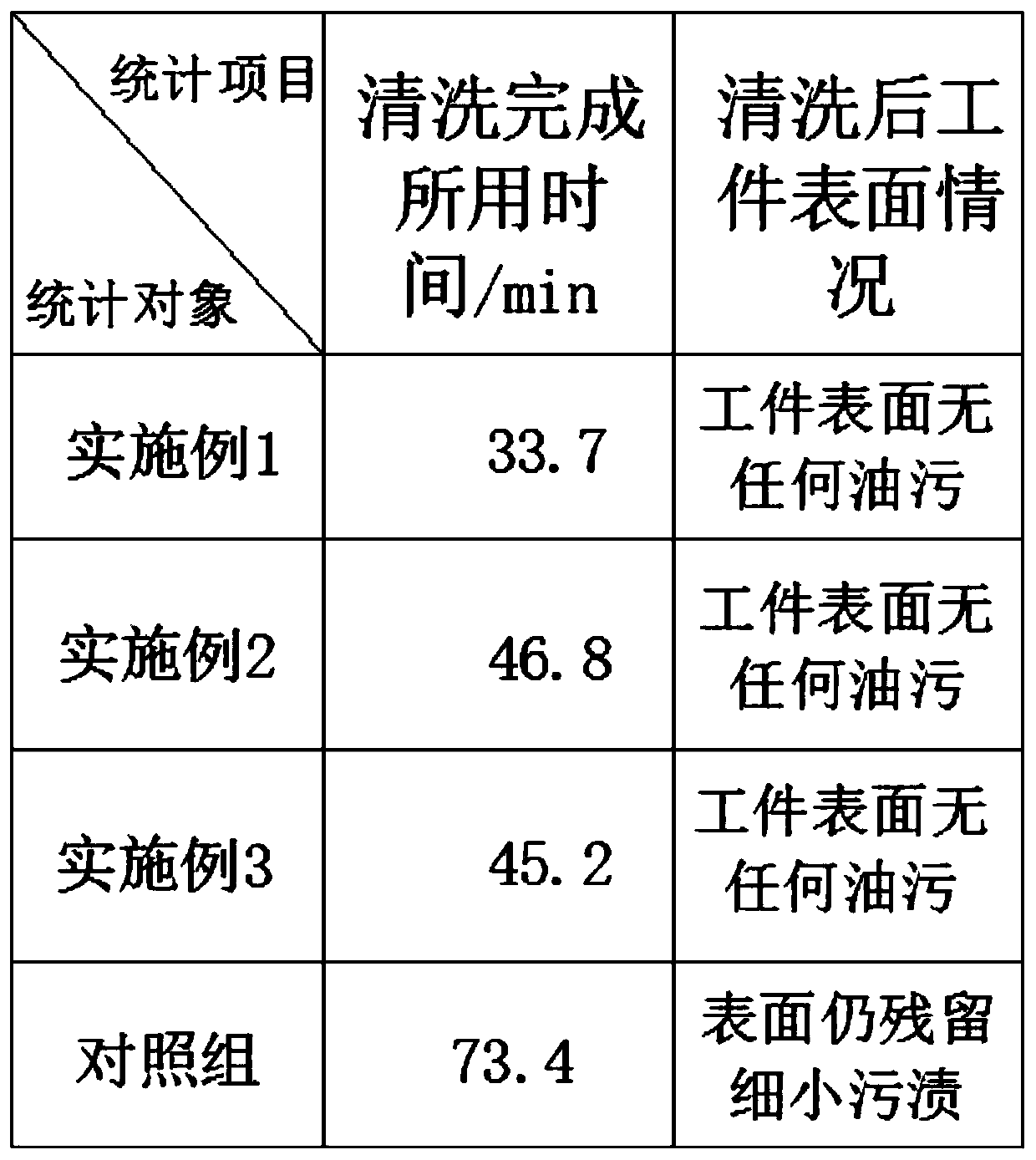

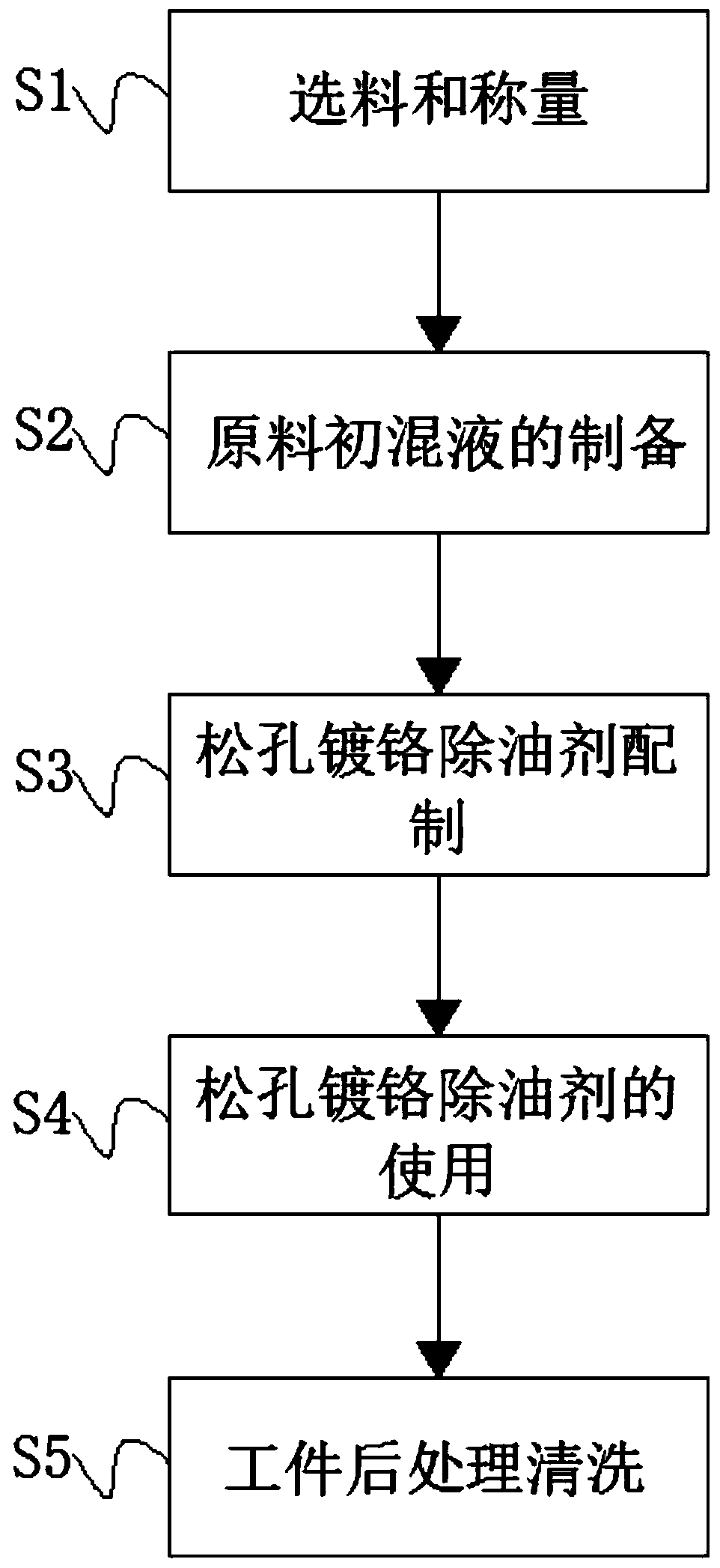

Formula for degreasing for spongy chromium plating and preparation method thereof

The invention discloses a formula for degreasing for spongy chromium plating and a preparation method thereof. The formula comprises the following raw materials by weight percent: 40-50 parts of whellote gas, 10-20 parts of hydrocarbon cleaning agents, 1-3 parts of borax, 5-10 parts of corrosion inhibitors, 1-5 parts part of antirust agents, 1-5 parts of surfactants and the balance water. The invention relates to the technical field of electroplating machining. According to the for degreasing for the spongy chromium plating and the preparation method thereof, components of a degreasing agent can be improved to quickly dissolve machining oil stains on the surface of a workpiece to be treated, so that the purpose of quickly and fully degreasing by matching the degreasing agent with an ultrasonic cleaning method is well achieved, and the effect of quickly and efficiently degreasing the workpiece to be cleaned is realized; and the degreasing agent has a good degreasing effect and the cleaning time is short, so that the success rate of spongy chromium plating is well ensured, and the spongy chromium plating of workpieces by people is thus greatly facilitated.

Owner:河池市机务材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com