Environment-friendly water-based metal cleaner

A cleaning agent and metal-based technology, which is applied in the field of industrial cleaning, can solve the problems of shortened service life of equipment, influence of equipment filtration and heat exchange effects, economic losses, etc., to prevent over-corrosion, excellent degreasing effect, and small environmental hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Use the following process to carry out the following treatment on the same two 304 stainless steel sheet samples:

[0019] 1) Preparation of treatment solution: Add 3g / L of nonylphenol polyoxyethylene ether (TX-4) and 4g / L of dodecyl dimethyl benzyl ammonium chloride (1227) to two surfactants L sodium hydroxide, 1g / L potassium nitrate, 3g / L sodium metaphosphate, 2g / L triethanolamine dissolved in deionized water;

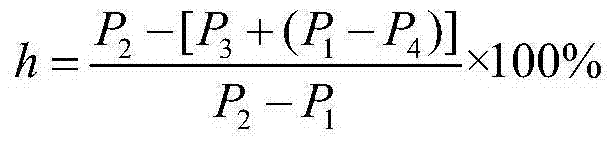

[0020] 2) Sample pretreatment: weigh the sample P 1 , and then submerged in artificial oil, took out and weighed P 2 ;

[0021] 3) Degreasing: Put the oiled workpiece in the treatment solution at 55°C for 6 minutes, then wash it for 6 minutes, take it out, wash it in deionized water at 55°C for 10 times, dry it and weigh it again. 3 , and then the sample was washed with absolute ethanol and dried and weighed P 4 ;

[0022] Result analysis:

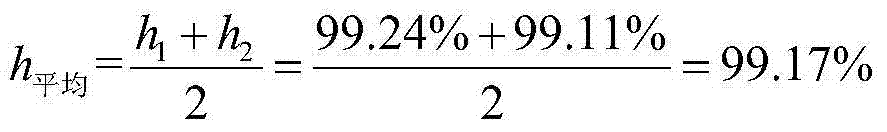

[0023] Sample 1: P 1 =7.8021g, P 2 =7.8807g,P 3 =7.8017g, P 4 =7.8011g;

[0024] Sample 2: P 1 =7.8204g,P 2...

Embodiment 2

[0032] The same two Q235A steel sheet samples were treated as follows by the following process:

[0033] 1) Preparation of treatment solution: 2g / L nonylphenol polyoxyethylene ether (TX-4) and 2g / L dodecyldimethylbenzyl ammonium chloride (1227) were added into 6g / L L ammonia water, 2g / L ammonium nitrate, 3g / L potassium pyrophosphate, 1g / L triethanolamine borate fat dissolved in deionized water;

[0034] 2) Sample pretreatment: weigh the sample P 1 , and then submerged in artificial oil, took out and weighed P 2 ;

[0035] 3) Degreasing: Put the oiled workpiece in the treatment solution at 55°C for 6 minutes, then wash it for 6 minutes, take it out, wash it in deionized water at 55°C for 10 times, blow it dry, and then weigh it. 3 , and then the sample was washed with absolute ethanol and dried and weighed P 4 ;

[0036] Result analysis:

[0037] Sample 1: P 1 =7.9104g, P 2 =7.9984g,P 3 =7.9105g,P 4 =7.9103g;

[0038] Sample 2: P 1 =7.9172g,P 2 =8.0020g,P 3 =7.918...

Embodiment 3

[0046] The same two Q235A steel sheet samples were treated as follows by the following process:

[0047] 1) Prepare treatment solution: add 5g / L nonylphenol polyoxyethylene ether (TX-4) and 3g / L dodecyldimethylbenzyl ammonium chloride (1227) to two surfactants L sodium hydroxide aqueous solution, 5g / L sodium nitrate, 5g / L sodium metaphosphate, 3g / L triethanolamine dissolved in deionized water;

[0048] 2) Sample pretreatment: weigh the sample P 1 , and then submerged in artificial oil, took out and weighed P 2 ;

[0049] 3) Degreasing: Put the oiled workpiece in the treatment solution at 55°C for 6 minutes, then wash it for 6 minutes, take it out, wash it in deionized water at 55°C for 10 times, blow it dry, and then weigh it. 3 , and then the sample was washed with absolute ethanol and dried and weighed P 4 ;

[0050] Result analysis:

[0051]Sample 1: P 1 =7.9214g, P 2 =7.8624g, P 3 =7.8218g,P 4 =7.8212g;

[0052] Sample 2: P 1 =7.9270g,P 2 =8.0231g, P 3 =7.826...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com