Fatlute reducing oil containing or polymer and oil containing sewage treatment method and degradable flocculation agent system

A treatment method and technology for oily sewage, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve great economic value, ecological benefits, and efficient oil removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

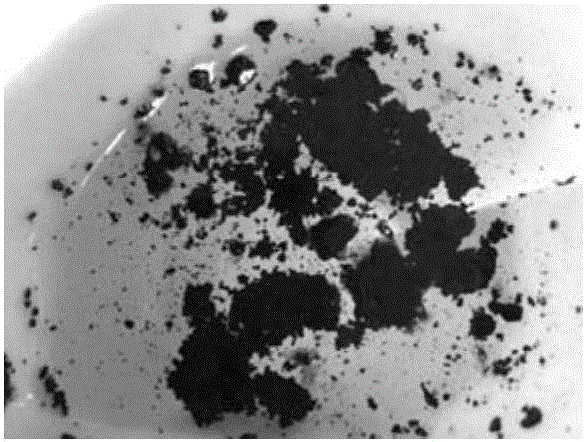

Image

Examples

Embodiment 1

[0050] Embodiment 1, degradable agent system treats oily sewage;

[0051] Oily sewage water samples were provided by Bohai Oilfield, with an oil concentration of 5000mg / L. Take 100mL of oily sewage at 20°C and pour it into a 100ml dehydration bottle, and keep warm at 65°C for 40min. Polyacryloxyethyltrimethylammonium chloride (molecular weight is 10 4-5 , cationic degree is 40%) polyethyleneimine (molecular weight 1200) is prepared into the aqueous solution that mass fraction is 1% respectively, according to flocculant dosage 250mg / L oily sewage, polyethyleneimine (molecular weight 1200) 50mg / L oily sewage Dosage: Add the above prepared aqueous solution to 100ml of sewage sample respectively, shake the dehydration bottle by hand 30 times, and let it stand for 2 minutes.

Embodiment 2

[0059] Embodiment 2, degradable agent system treatment of poly-containing oily sewage

[0060] The water samples of polymer-containing oily sewage are provided by Bohai Oilfield. The concentration of polymer-containing oily sewage is 150mg / L, and the concentration of oil is 5000mg / L. At 20°C, take the oily sewage containing polymers and pour it into a 2L dehydration bottle, and keep it warm at 65°C for 20 minutes. Polyacryloxyethyltrimethylammonium chloride mother liquor (molecular weight is 10 4-5 , cationic degree is 60%, mass concentration 40%) polyethyleneimine (molecular weight 1200, mass concentration 30%), according to the amount of flocculant 250mg / L, polyethyleneimine (molecular weight 1200) 50mg / L contains the amount of poly-sewage , add the above prepared aqueous solution to 2L of sewage samples respectively, 12 bottles as a group, shake the dehydration bottle by hand 30 times, and let it stand for 2 minutes.

Embodiment 3

[0066] Embodiment 3, degradable agent system treatment of poly-containing oily sewage

[0067] The water samples of polymer-containing oily sewage are provided by Bohai Oilfield. The concentration of polymer-containing oily sewage is 150mg / L, and the concentration of oil is 5000mg / L. At 20°C, take the oily sewage containing polymers and pour it into a 2L dehydration bottle, and keep it warm at 65°C for 20 minutes. Acryloyloxyethyltrimethylammonium chloride-allylamine copolymer (molecular weight is 10 4-5 , the cationic degree is 60%, the mass concentration is 50%), according to the amount of flocculant 250mg / L poly-oily sewage, the aqueous solution prepared above is added to 2L sewage sample, 12 bottles as a group, test 5 groups, shake off by hand After the water bottle is used 30 times, let it stand for 2 minutes.

[0068] The relationship between sludge residue (after oil removal) and the original weight ratio over time is: 10h-88%, 16h-76%, 24h-64%, 48h-53%, 96h-29%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com