Cooking fume cleaning integrated machine

An oil fume purification and all-in-one machine technology, which is applied in the field of oil fume purification, can solve the problems of poor purification effect of kitchen oil fume and achieve the effects of improved filtering effect, low water consumption and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

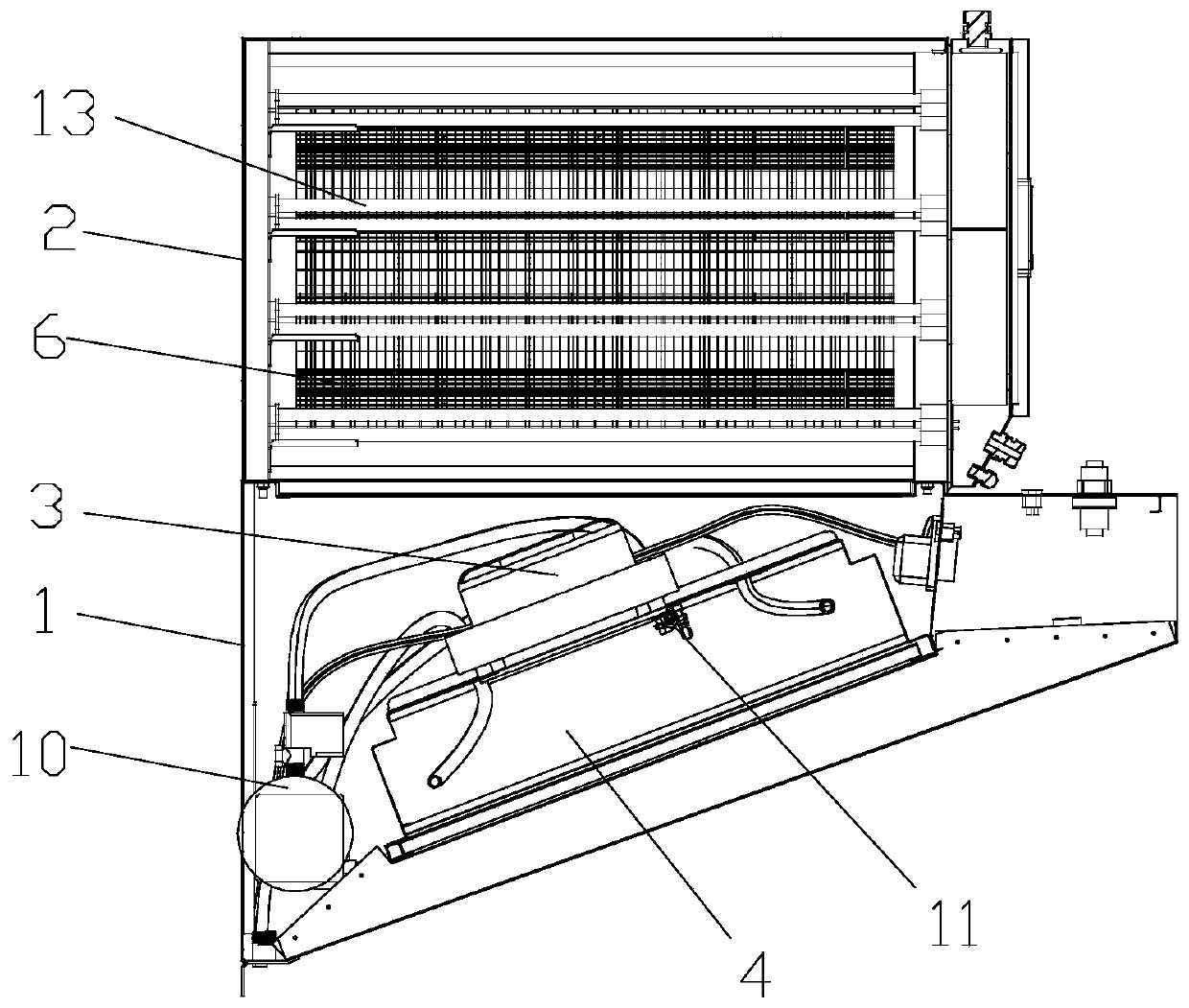

[0031] The present invention will be further described below in conjunction with accompanying drawing:

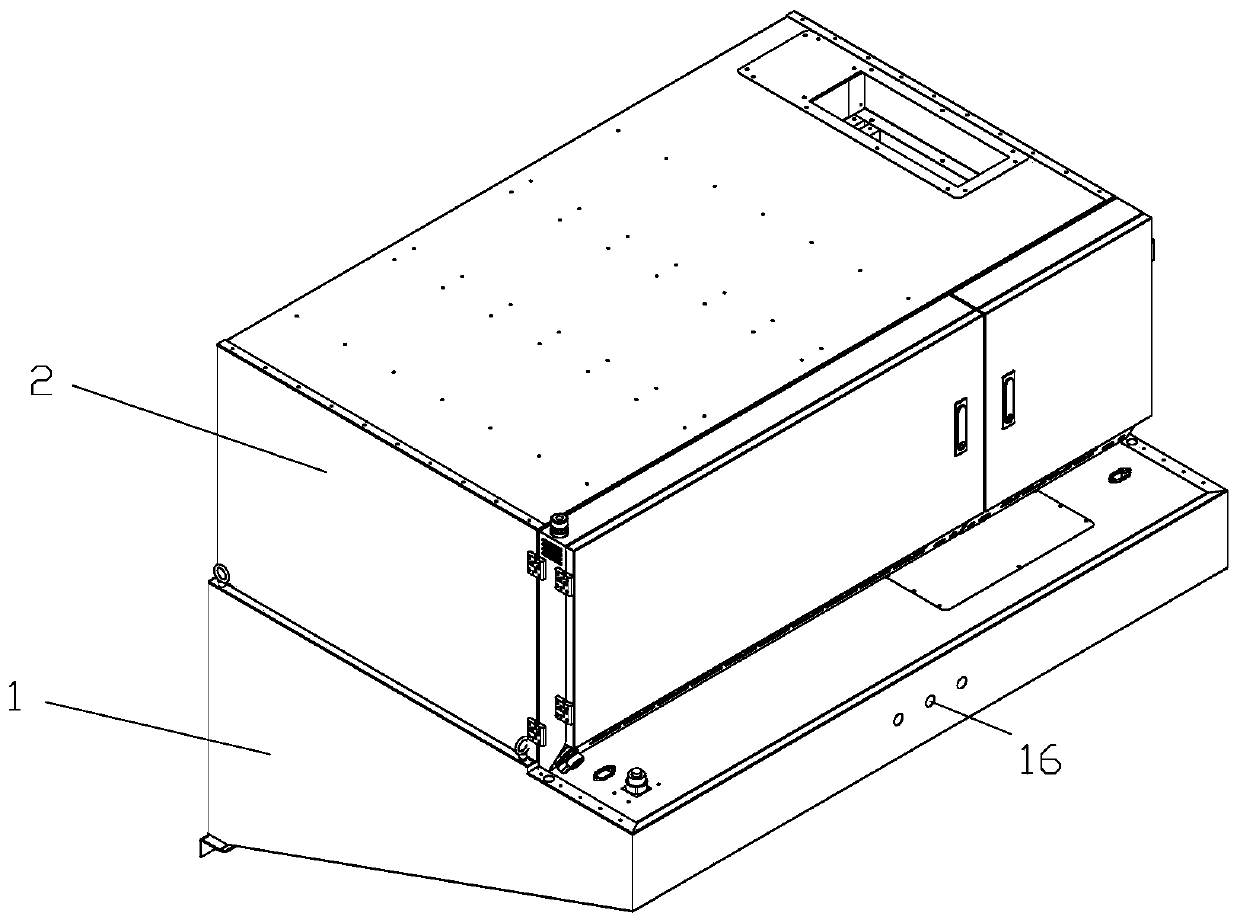

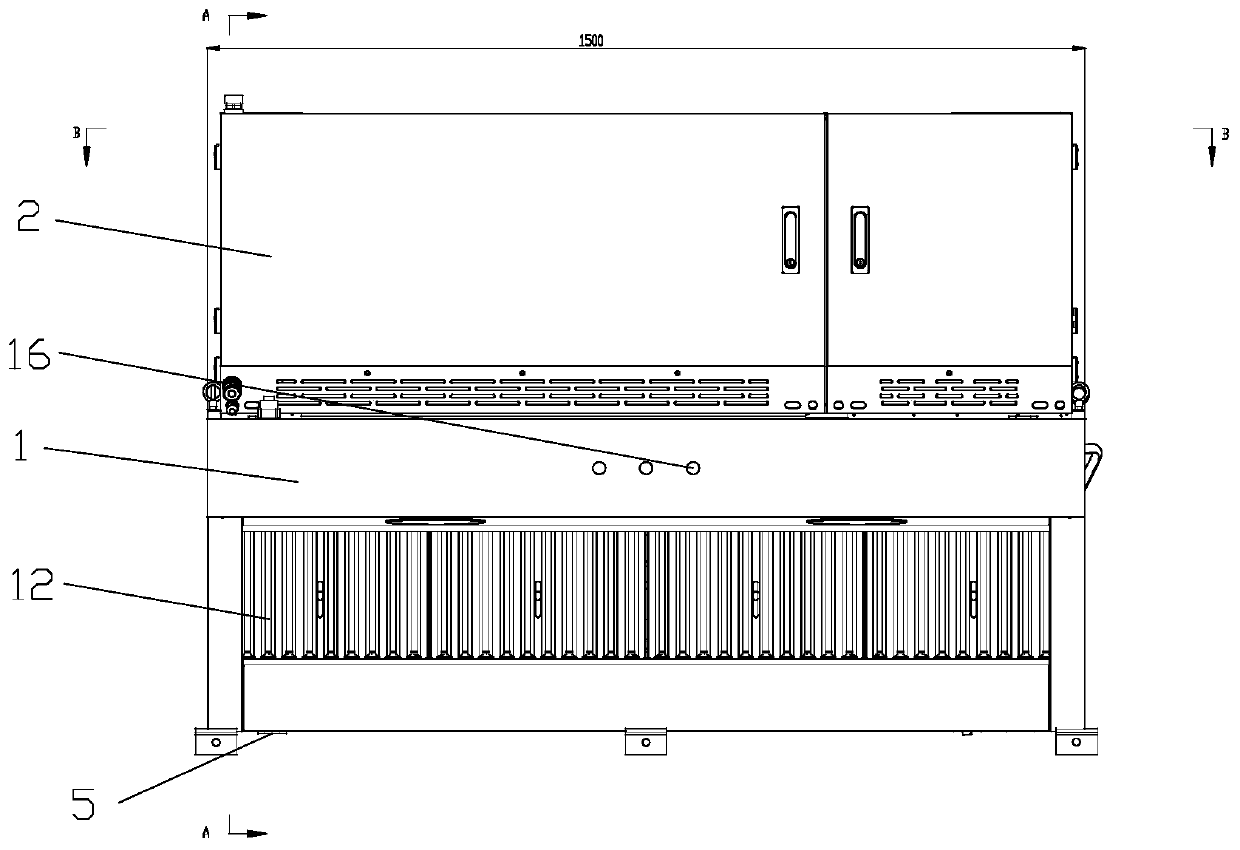

[0032] Referring to the accompanying drawings: the oil fume purification integrated machine in this embodiment includes the oil fume separation box 1 and the smoke decomposition box 2 at the bottom. The smoke decomposition box 2 is located above the oil fume separation box 1 and is connected. An oil throwing pan 3 for self-cleaning, a condenser 4 is provided under the oil throwing pan 3, the upper and lower sides of the condenser 4 pass through and the cooling end face faces the oil fume below, the bottom of the oil fume separation box 1 is provided with an oil tank for collecting waste oil, and the bottom of the oil tank is provided There is an oil outlet 5.

[0033] There is an outlet on the top of the oil fume separation box 1 and it is connected with the inlet of the smoke decomposition box 2. In the smoke decomposition box 2, there are high and low voltage electric fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com