Formula for degreasing for spongy chromium plating and preparation method thereof

A technology of loose hole chrome plating and formula, which is applied in the field of electroplating processing, can solve the problems that the success rate of loose hole chrome plating cannot be guaranteed, the rapid degreasing treatment of workpieces to be cleaned, and long cleaning time can not be realized, so as to facilitate the loose hole chrome plating work of workpieces , fast and efficient degreasing treatment, good degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

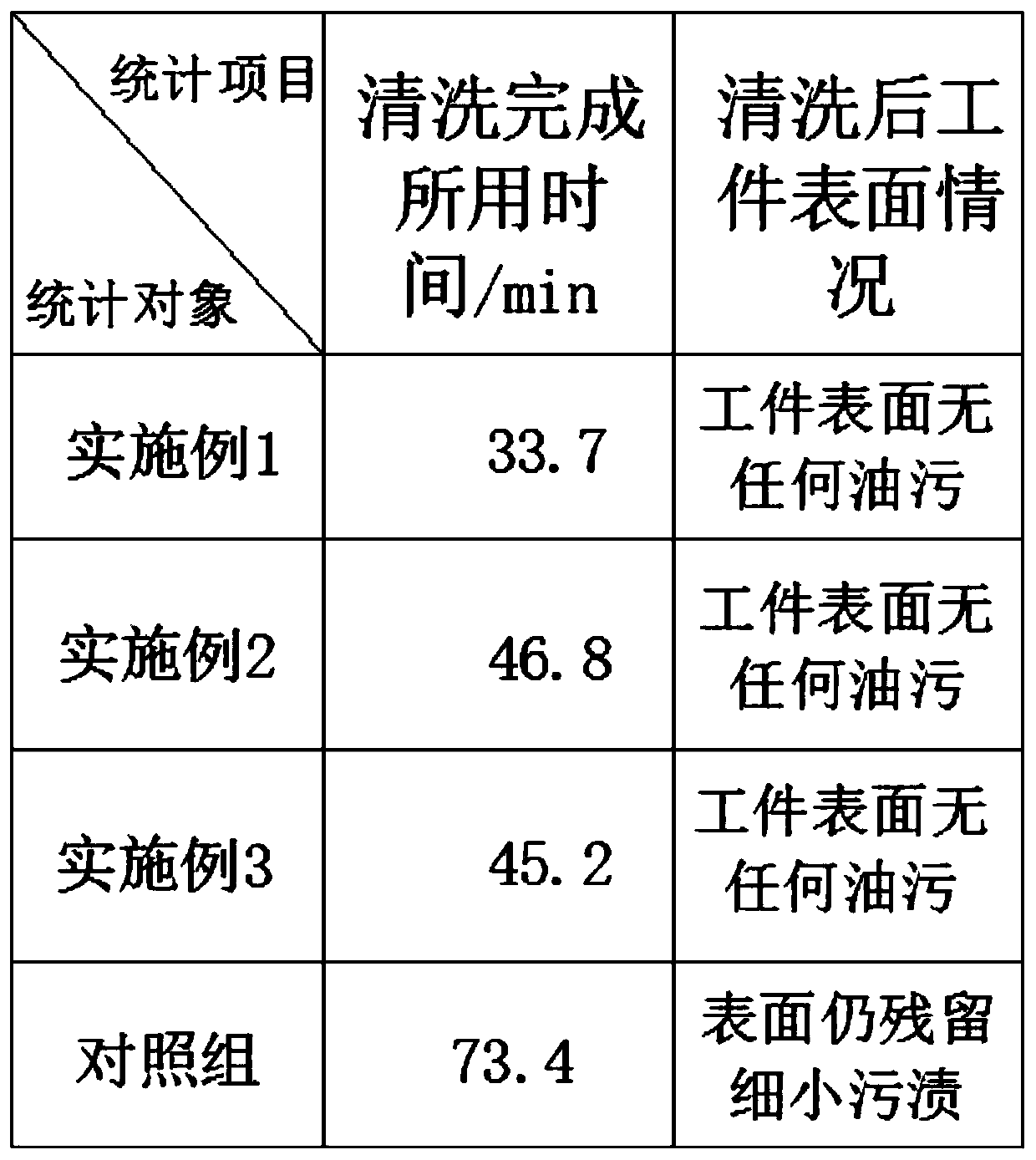

Examples

Embodiment 1

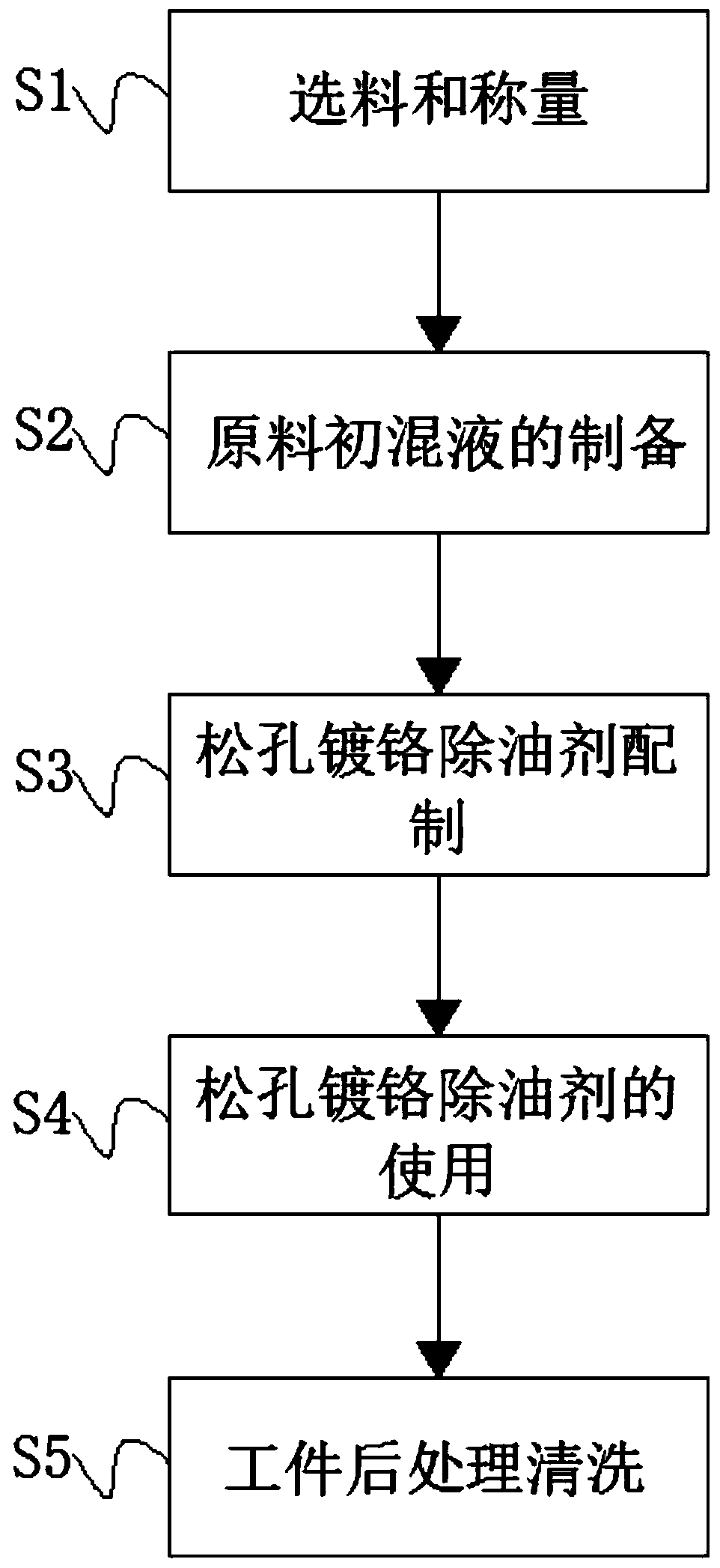

[0029] S1. Material selection and weighing: First, measure 45 parts of white electric oil, 15 parts of hydrocarbon cleaning agent, 2 parts of borax, 7 parts of corrosion inhibitor, 3 parts of rust inhibitor and 3 parts of surfactant, and the measured components are added to the storage tank for storage for preparation and use. The hydrocarbon cleaning agent is a residual solvent obtained by distilling crude oil treatment process. The corrosion inhibitor is amino The composition of trimethylene phosphonic acid and hydroxyethylene diphosphonic acid, the surfactant is a nonionic polyacrylamide solvent;

[0030] S2. Preparation of raw material mixed liquid: then pour the white electric oil, hydrocarbon cleaning agent and borax weighed in step S1 into the mixing and stirring equipment in sequence, and add clear water, with the speed at 250r / min and the temperature at 37°C Stir for 25 minutes to fully dissolve borax in the white electric oil and the hydrocarbon cleaning agent, and f...

Embodiment 2

[0035] S1. Material selection and weighing: First, measure 40 parts of white electric oil, 10 parts of hydrocarbon cleaning agent, 1 part of borax, 5 parts of corrosion inhibitor, 1 part of rust inhibitor and 1 part of surfactant, and add the measured components into the storage tank for storage for preparation and use. The hydrocarbon cleaning agent is a residual solvent obtained by distilling crude oil treatment process. The corrosion inhibitor is amino Trimethylene phosphonic acid, surfactant is nonionic polyacrylamide solvent;

[0036] S2. Preparation of raw material mixed liquid: then pour the white electric oil, hydrocarbon cleaning agent and borax weighed in step S1 into the mixing and stirring equipment in sequence, and add clear water at a speed of 200r / min and a temperature of 35°C Stir for 200min at lower temperature to fully dissolve the borax in the white electric oil and the hydrocarbon cleaning agent, and fully mix the white electric oil and the hydrocarbon clea...

Embodiment 3

[0041] S1. Material selection and weighing: First, measure 50 parts of white electric oil, 20 parts of hydrocarbon cleaning agent, 3 parts of borax, 10 parts of corrosion inhibitor, 5 parts of rust inhibitor and 5 parts of surfactant, and the measured components are added to the storage tank for storage for preparation and use. The hydrocarbon cleaning agent is a residual solvent obtained by distilling crude oil treatment process, and the corrosion inhibitor is hydroxyl Ethylene diphosphonic acid, surfactant is nonionic polyacrylamide solvent;

[0042] S2. Preparation of the primary mixed liquid of raw materials: then pour the white electric oil, hydrocarbon cleaning agent and borax weighed in step S1 into the mixing and stirring equipment in sequence, and add clear water, with the speed at 300r / min and the temperature at 40°C Stir for 30 minutes to make the borax fully dissolve in the white electric oil and the hydrocarbon cleaning agent, and fully mix the white electric oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com