Manufacturing method of waste plastic regeneration particles

A technology for waste plastics and production methods, applied in the direction of coating, etc., can solve the problems of reducing the yield of raw materials, uneven size of intermediate products, blockage of the throat of the extruder, etc., so as to improve the yield of raw materials, increase economic benefits, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: add detergent in waste and old plastic washing water, detergent prescription is powdery sodium dodecylbenzene sulfonate by weight ratio: bleaching agent: caustic soda is 3: 10: 87, prepares 100 kilograms of detergents , use powdered sodium dodecylbenzene sulfonate, bleaching agent, and caustic soda to be respectively 3 kilograms, 10 kilograms, and 87 kilograms, and waste plastics are put into this washing water for soaking and cleaning.

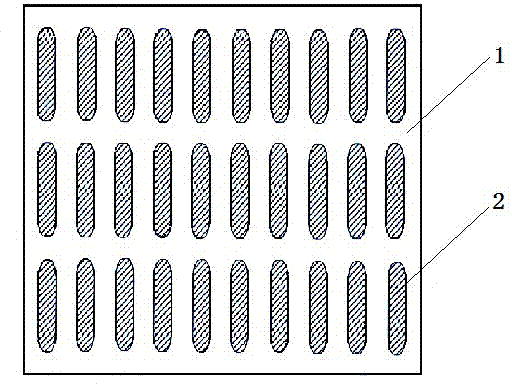

[0010] The cleaned waste plastics are crushed by the crusher. The sieve holes 2 on the sieve plate 1 of the crusher are three rows, and the size of the sieve holes is 3cm×12cm. One" font.

[0011] The waste plastic regenerated granules are produced by the above method.

[0012] The production of 1 ton of recycled materials only needs to consume 500 degrees of electricity, and only 1,120 kilograms of waste plastics are consumed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com