Air conditioner fin cleaning agent and preparation method thereof

A technology for air-conditioning fins and cleaning agents, applied in the direction of inorganic non-surface active cleaning compositions, etc., can solve the problems of loss of heat dissipation function, decay, and brittle aluminum fins of equipment, so as to overcome easy corrosion and save energy. , Significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

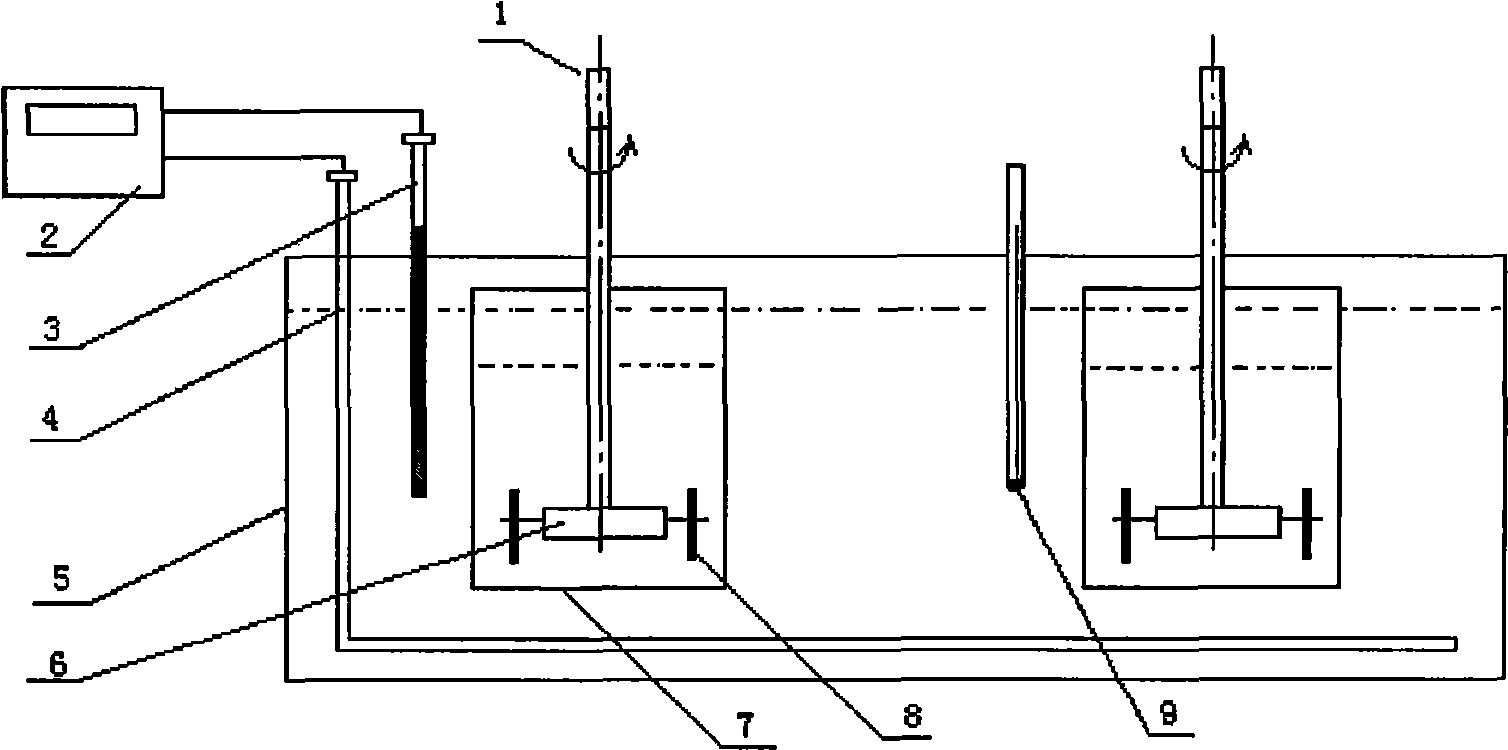

Image

Examples

Embodiment 1

[0035] Air conditioner fin cleaning agent is made from the following components in weight percentage: 10kg of nitric acid, 0.5kg of potassium chromate, 0.5kg of AES, 50.1kg of OP-50.1kg, and 88.9kg of water.

[0036] Preparation:

[0037] a. Take half of the amount of water, add nitric acid while stirring at room temperature, and then stir for 3 minutes after adding, to obtain aqueous solution a;

[0038] b. Take the other half of the water, heat it to 50°C, add potassium chromate, AES, OP-10 in turn, stir well until the solid particles are completely dissolved, then cool it to room temperature to obtain the aqueous solution b.

[0039] c. Slowly add the uniformly stirred aqueous solution a into the aqueous solution b, stir thoroughly for 3 minutes until uniform, and the finished product is prepared.

Embodiment 2

[0041] The cleaning agent for air conditioner fins is made from the following components in percentage by weight: 13kg of nitric acid, 0.6kg of potassium chromate, 0.7kg of AES, 60.3kg of OP-6, and 85.4kg of water.

[0042] Preparation method: the stirring time in step a is 4 min; the heating temperature in step b is 55° C.; the stirring time in step c is 4 min; the others are the same as in Example 1.

Embodiment 3

[0044] Air conditioner fin cleaning agent is made from the following components in weight percentage: 15kg of nitric acid, 0.8kg of potassium chromate, 0.8kg of AES, 70.5kg of OP-70.5kg, and 82.9kg of water.

[0045] Preparation method: the stirring time in step a is 5 min; the heating temperature in step b is 60° C.; the stirring time in step c is 5 min; the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| descaling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com