Patents

Literature

231 results about "Potassium chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium chromate is the inorganic compound with the formula (K₂CrO₄). This yellow solid is the potassium salt of the chromate anion. It is a common laboratory chemical, whereas sodium chromate is important industrially. It is a class two carcinogen as it contains hexavalent chromium.

Method for rapidly preparing graphene in large quantities by utilizing graphite oxides

InactiveCN102502611ASimple processExcellent microwave absorbing mediumGrapheneNanotechnologyPotassium dichromatePotassium manganate

The invention aims at providing a preparation method for rapidly obtaining graphene in large quantities. On the basis of obtaining graphite oxides, the molecular thermodynamic movement of groups such as hydroxyl groups (-OH), carboxylic groups (-COOH) and the like which are generated on the surfaces of graphite oxide layers through oxidization can be induced and stimulated through microwave treatment so as to produce a momentary unsteady state, so that Van der Waals binding force between graphite layers is damaged, and graphene can be rapidly obtained in large quantities. The graphite oxides are obtained through the oxidization of metal salt such as potassium permanganate, potassium dichromate and the like as well as strong protonic acid such as concentrated sulphuric acid, concentrated nitric acid and the like, and then microwave irradiation is carried out under the conditions that the power ranges from 2 to 10 kW, the vacuum pressure ranges from 0.01 to 0.06 MPa and so on, so that microwave cleavage of the graphite oxides can be accomplished within 2 to 10 seconds, and graphene with less than ten layers can be obtained rapidly in large quantities. The preparation method can also control the layer number or the thickness of graphene products by controlling the concentration and the oxidation time of oxidizing mediums as well as the power, the degree of vacuum and the like of the microwave irradiation.

Owner:SOUTHEAST UNIV

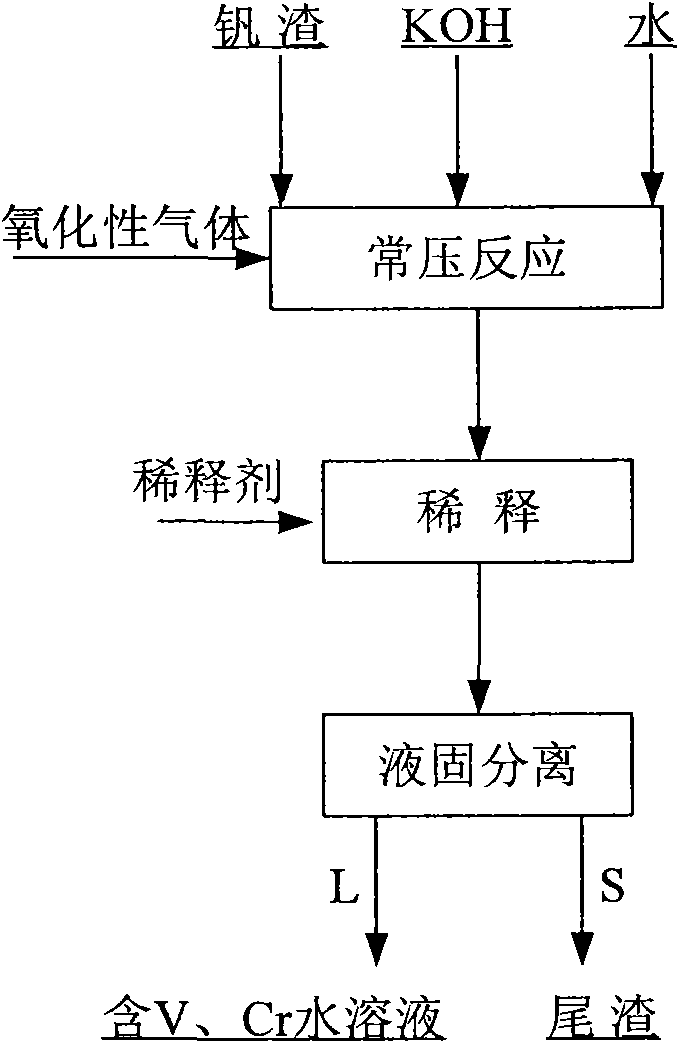

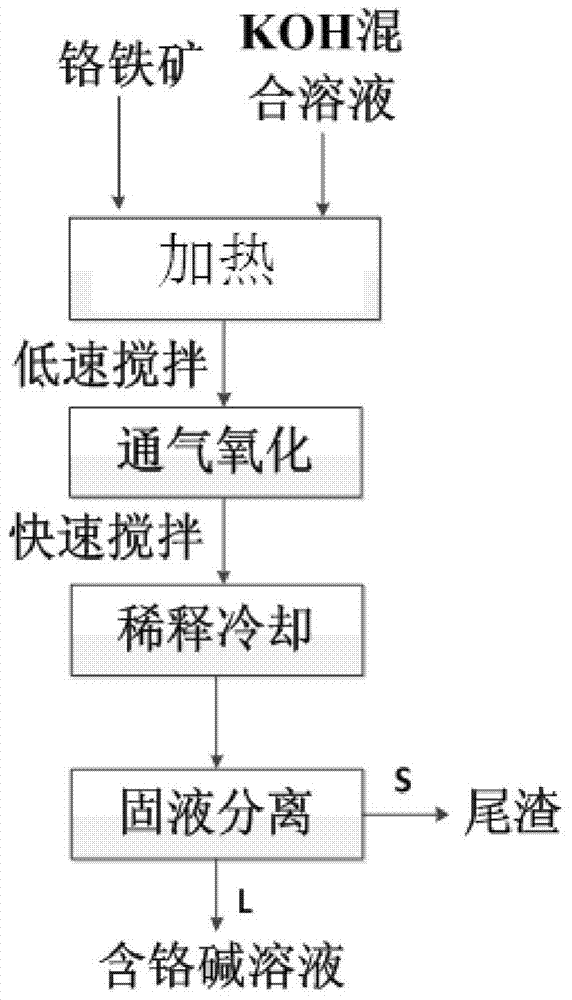

Method for decomposing vanadium slag with solution of potassium hydroxide under normal pressure

InactiveCN101812588ALow reaction temperatureImprove resource utilizationProcess efficiency improvementMass ratioSlag

The invention relates to a method for decomposing vanadium slag with solution of potassium hydroxide under normal pressure, which comprises the following steps: adding the vanadium slag or pre-treated vanadium slag, water and KOH into a reactor, controlling the mass ratio of the KOH to the vanadium slag and the concentration of solution of KOH, performing oxidation reaction in the presence of oxidizing gas, and controlling the reaction temperature and reaction time in the reaction process; diluting the obtained reaction slurry with a diluting agent to obtain mixed slurry which contains potassium hydroxide, potassium vanadium, potassium chromate and tailings; and performing filtering separation on the mixed slurry to obtain the tailings and vanadium and chromium-containing aqueous solution. The method is only operated under normal pressure, is easy to perform and has high safety; the operation temperature is far lower than the traditional vanadium extraction temperature; the extraction rate of vanadium is high; and synchronous extraction of chromium in the vanadium slag can be realized. The total amount of the vanadium in the tailings is 0.2-1 weight percent (based on the amount of V2O5) and the total amount of the chromium is 0.2-1 percent (based on the amount of Cr2O3).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

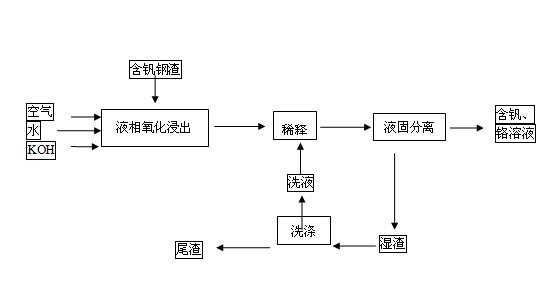

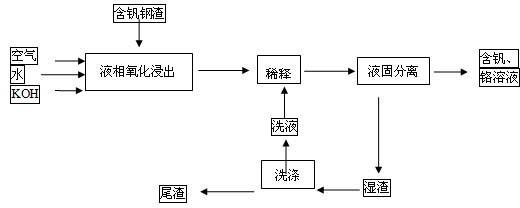

Method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide

ActiveCN102071321AHigh single recovery rateReduce productionProcess efficiency improvementSlagPotassium

The invention relates to a method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide, and belongs to the technical field of metallurgy. The invention adopts a technical scheme that: the steel slag together with water and potassium hydroxide is added into a reactor, the mixture is decomposed under normal pressure, and then the obtained reaction slurry is cooled and diluted by a diluent to obtain mixed slurry containing the potassium hydroxide, potassium vanadate, potassium silicate, potassium chromate and tailings; the alkalinity of the potassium hydroxide in the mixed slurry is controlled to be more than or equal to 100g / L, the mixed slurry is filtered and separated while the temperature is kept to be 80 to 130 DEG C to obtain the tailings and vanadium and chromium-containing water solution. The method has the advantages that: the high-temperature roasting is avoided, the reaction time is shortened, the single high-efficientextraction and simultaneous extraction of the vanadium and the chromium are realized; atmospheric pollutant as Cl2, HCl, dust, SO2 and the like caused by roasting are effectively avoided in the vanadium extraction process; and compared with the conventional roasting process, the generated amount and the discharged amount of waste water are effectively reduced, and clean production is realized.

Owner:HEBEI IRON AND STEEL

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

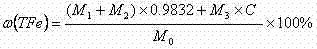

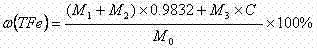

Method for measuring iron content in steel slag

The invention provides a method for measuring iron content in steel slag. The method includes grinding and screening a steel slag sample by multiple times; completely separating granular metal substances from slag in the steel slag sample; measuring the mass of the granular metal substances by a physical process; measuring iron content of the slag by a titanium trichloride and potassium dichromate volumetric process; and computing the full iron content of the steel slag sample via data of the iron content of the slag and the mass of the granular metal substances. The method has the advantages of convenience in operation, high accuracy of the measured iron content and good stability, repeatability and accuracy of a measuring result. Besides, as proved by tests, the method is reliable and practical, and the requirement on measuring iron content in steel slag in daily life can be met.

Owner:WUKUN STEEL

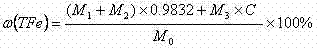

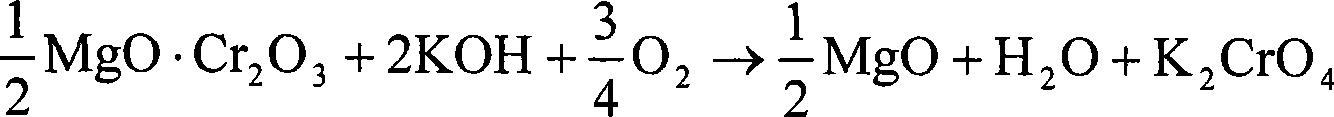

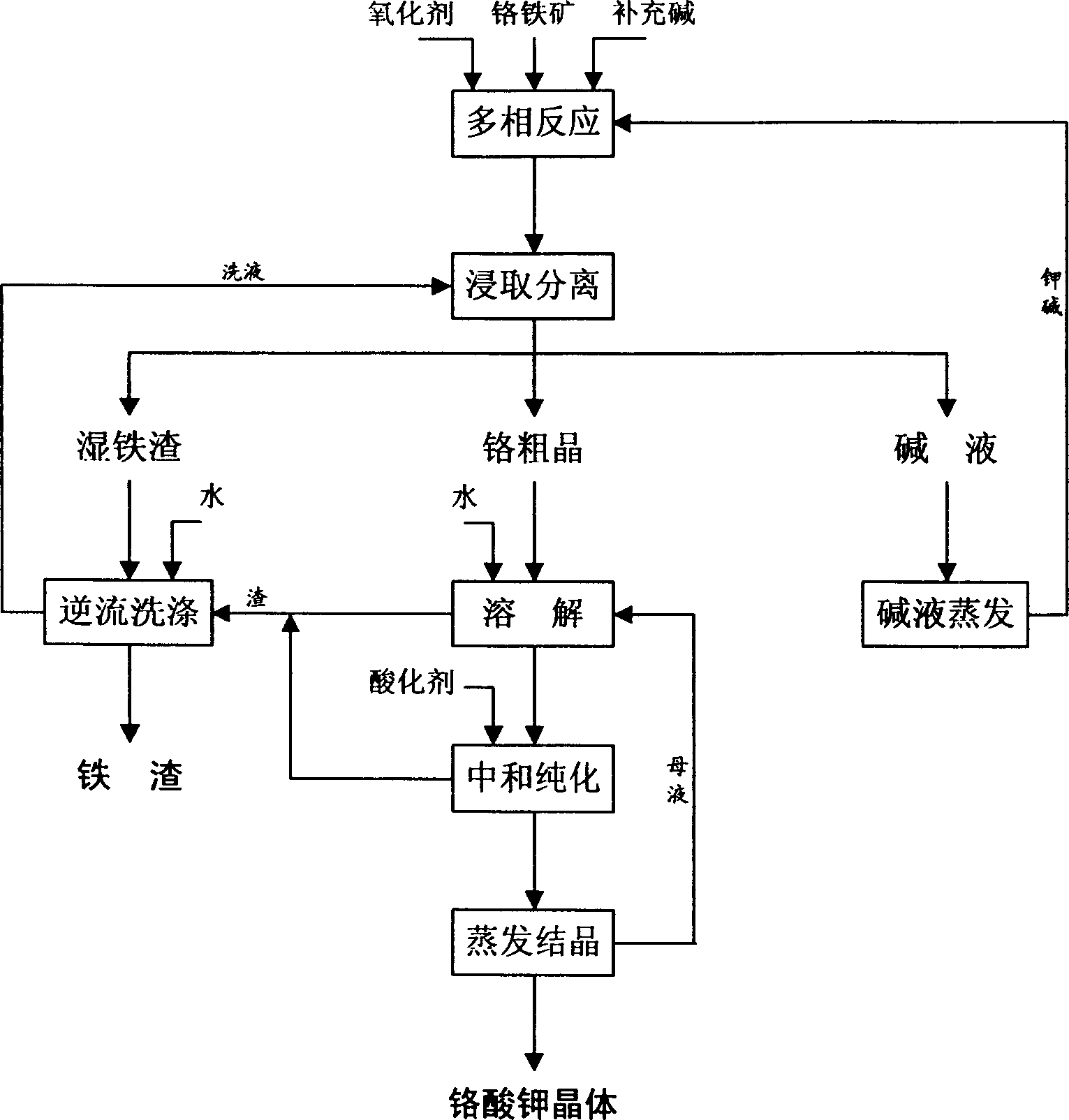

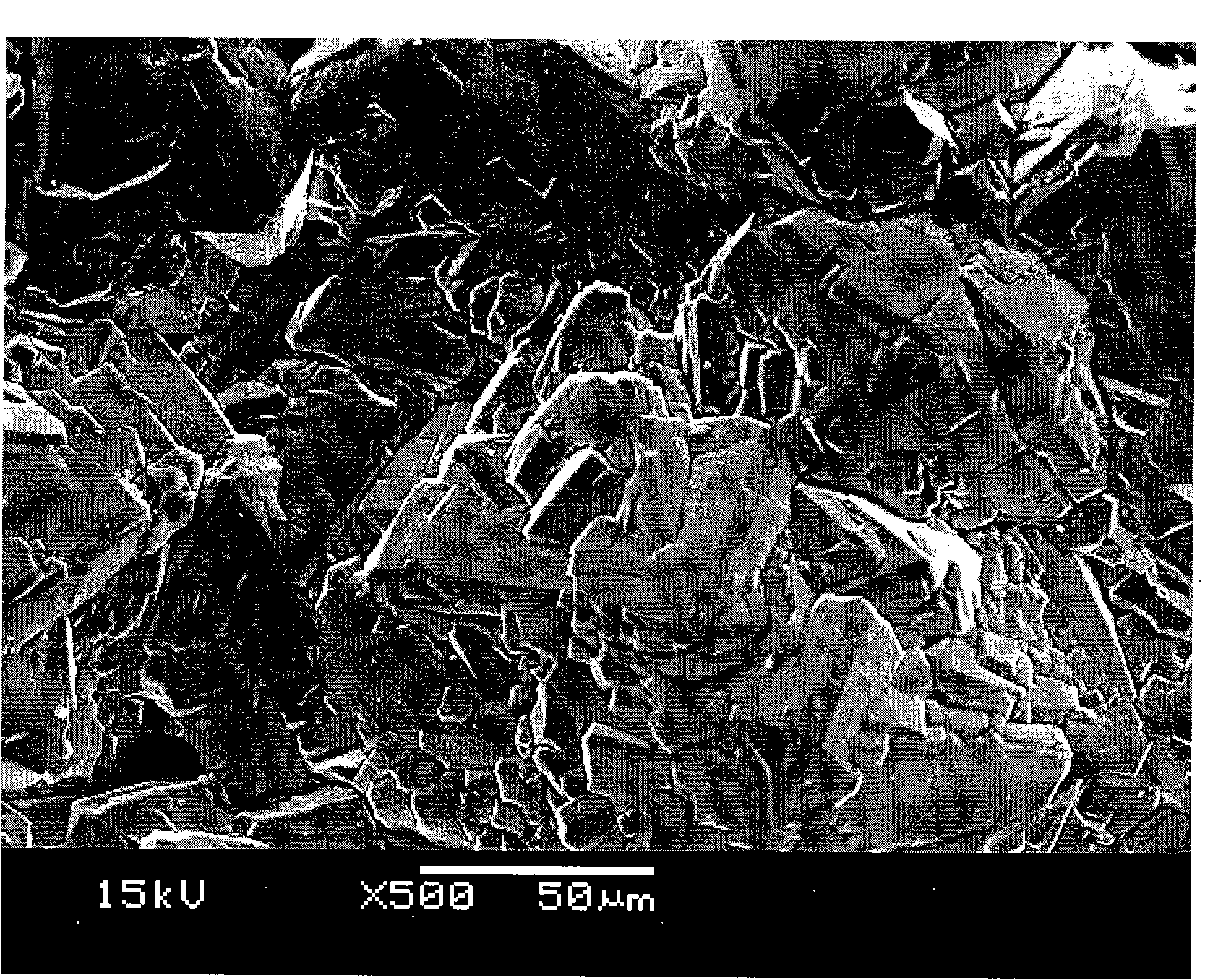

Clean production method for preparing potassium chromate from chromic iron

InactiveCN101481144AImprove liquidityReduced corrosion resistance requirementsChromates/bichromatesForeign matterPotassium nitrate

The invention belongs to the field of a method for producing chromic salt, in particular relates to a method for producing and cleaning potassium chromate. The method comprises the steps that chromite is reacted with oxidant with a chemical dose inside KOH-KNO3-H2O medium to obtain a mixed resultant of reaction containing alkali liquor, potassium chromate and slag after reaction, wherein the mass ratio of KOH and chromite is 1:1 to 2:1, and the mass ratio of KNO3 and chromite is 0.5:1 to 2:1. Through the leaching of the mixed resultant of reaction, the phases of potassium chromate macrocrystal-alkali liquor containing potassium nitrate-slag are separated, foreign matters in the solution are removed, the mixture is evaporated and crystallized, the obtained potassium chromate crystal is eluted and the pure product of potassium chromate is obtained. The percent conversion of chromium is higher than 99 percent and the rate of containing chromium in slag is less than 0.2 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of preparing chromium oxide using precarbonation wet reducing potassium chromate or sodium chromate

InactiveCN1410356AIncrease acidityImprove the reduction conversion rateChromium trioxideSucrosePotassium

A process for preparing chromium oxide from potassium (or sodium) chromate by the pre-carbonating and wet reduction method includes such steps as preparing the aqueous solution of potassium (or sodium) chromate, pre-carbonating by CO2 gas, reducing by a reducer to obtain the hydrate of chromium oxide, filtering, drying, high-temp. calcining under protection of inertial gas, washing and drying to obtain the alpha-Cr2O3.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process

InactiveCN104971594AEfficient removalReduce equipment costsDispersed particle separationAir quality improvementPotassium manganateSlurry

The invention discloses a gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process. According to the process, ozone is used as a gas-phase oxidant to oxidize one part of nitric oxide in flue gas into high-valence-state nitric oxide capable of being absorbed by slurry; any one or a mixture solution of more of hydrogen peroxide, sodium hypochlorite, sodium chlorite, sodium chlorate, sodium persulfate, potassium chlorate, potassium hypermanganate and potassium dichromate is sprayed to be used as a liquid-phase oxidant to oxidize the residual high-valence-state nitric oxide in the flue gas into the high-valence-state nitric oxide; and the flue gas enters an absorption tower and a magnesium hydroxide solution is sprayed to absorb the high-valence-state nitric oxide. Compared with the prior art, the process firstly adopts two times of oxidization of a gas phase and a liquid phase and a magnesium oxide wet process is used for absorbing so that a target of efficiently removing the nitric oxide is realized; and by virtue of the technical scheme, the use amount of the ozone is reduced, the equipment cost and operation cost are reduced and the denitration efficiency is improved and can reach more than or equal to 93%.

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

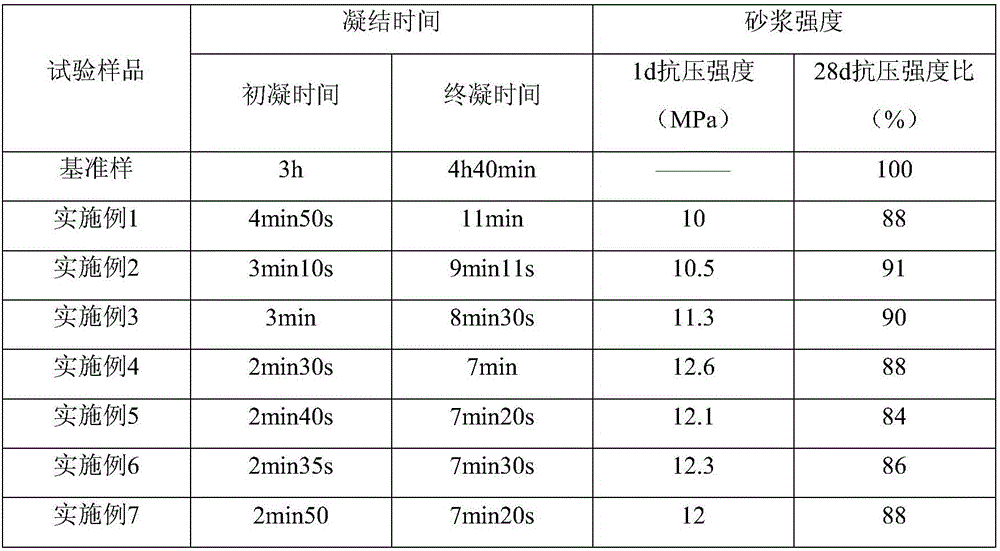

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Cavity corrosion proof zinc-rich paint and preparing method thereof

InactiveCN101100569AAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nanotubeSODIUM SILICATE SOLN

A zinc-enriched coating against cavity corrosion and its production are disclosed. The coating consists of carbon nanometer tube: 0.3-4 wt%, nanometer zinc powder 3-8 wt%, and organic resin additive 12-30 wt%. The process is carried out by reflux decontaminating for carbon nanometer tube by mixed acid, soaking in diluted lithium aqueous glass, centrifugal treating, collecting or mixing carbon nanometer tube with silicon acid, ball grinding, adding carbon nanometer tube into lithium silicate-sodium silicate solution, adding into organic resin, heavy potassium chromate solution, FC80, methyl-methoxide, multifunctional accessories and de-foaming agent while agitating to obtain coating component A, mixing ordinary zinc powder with nanometer zinc powder proportionally to obtain coating component B, and mixing component A with component B proportionally to obtain final product.

Owner:HUAZHONG NORMAL UNIV

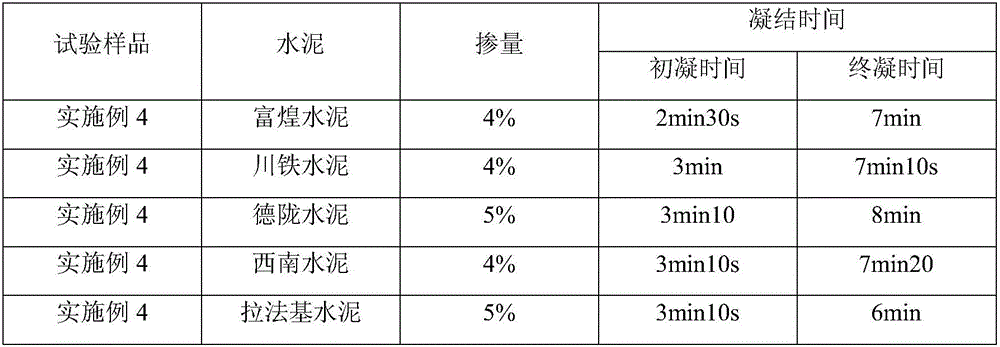

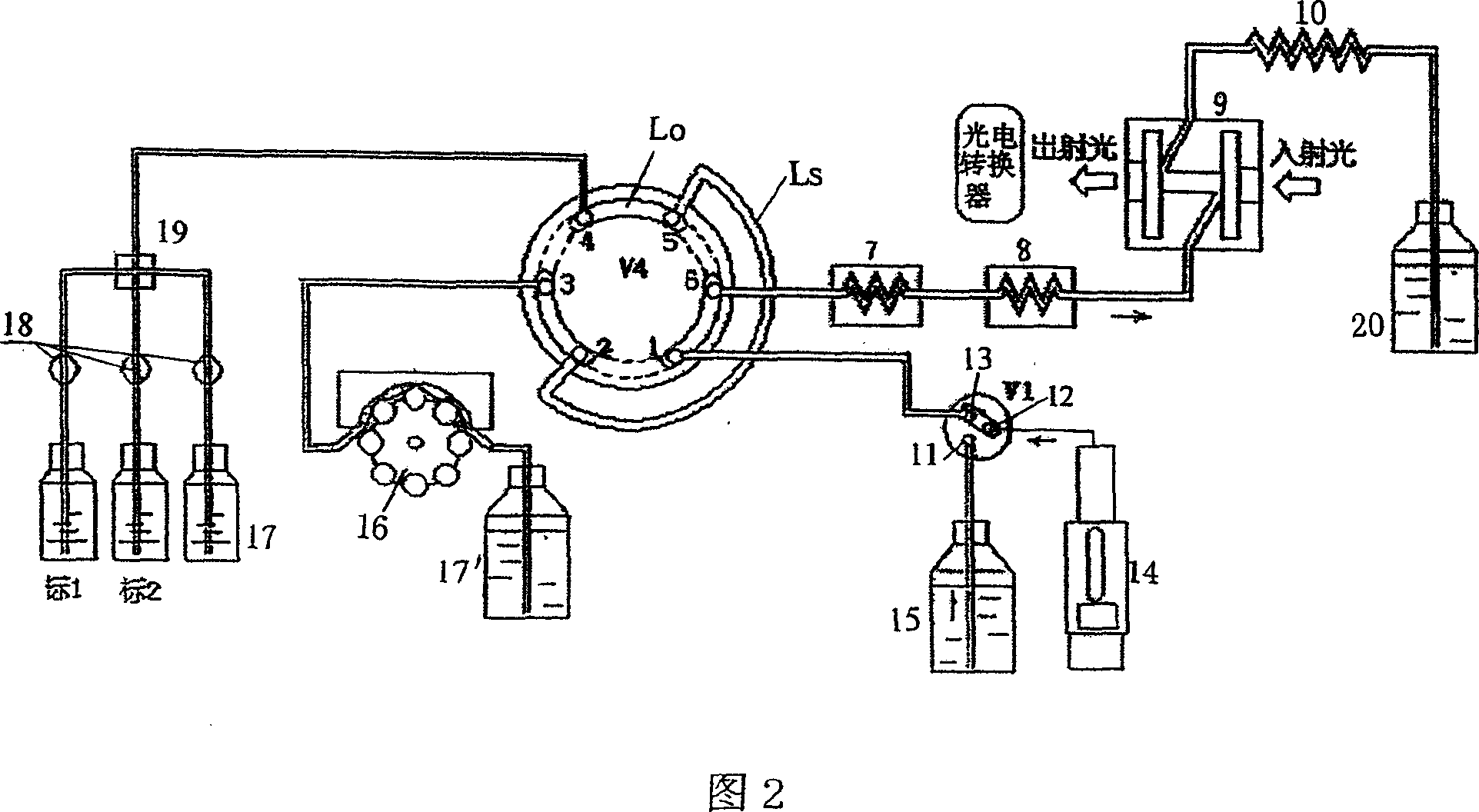

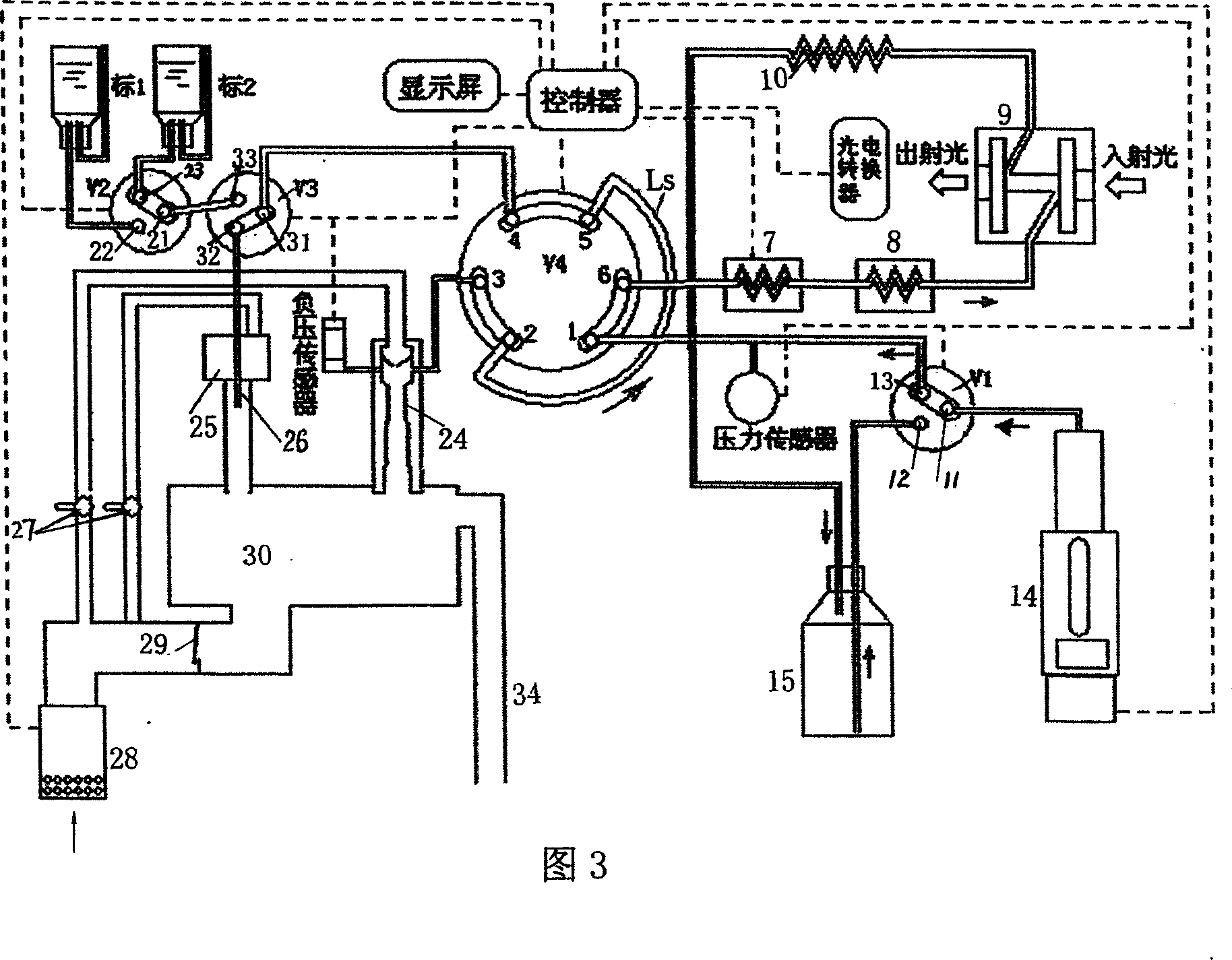

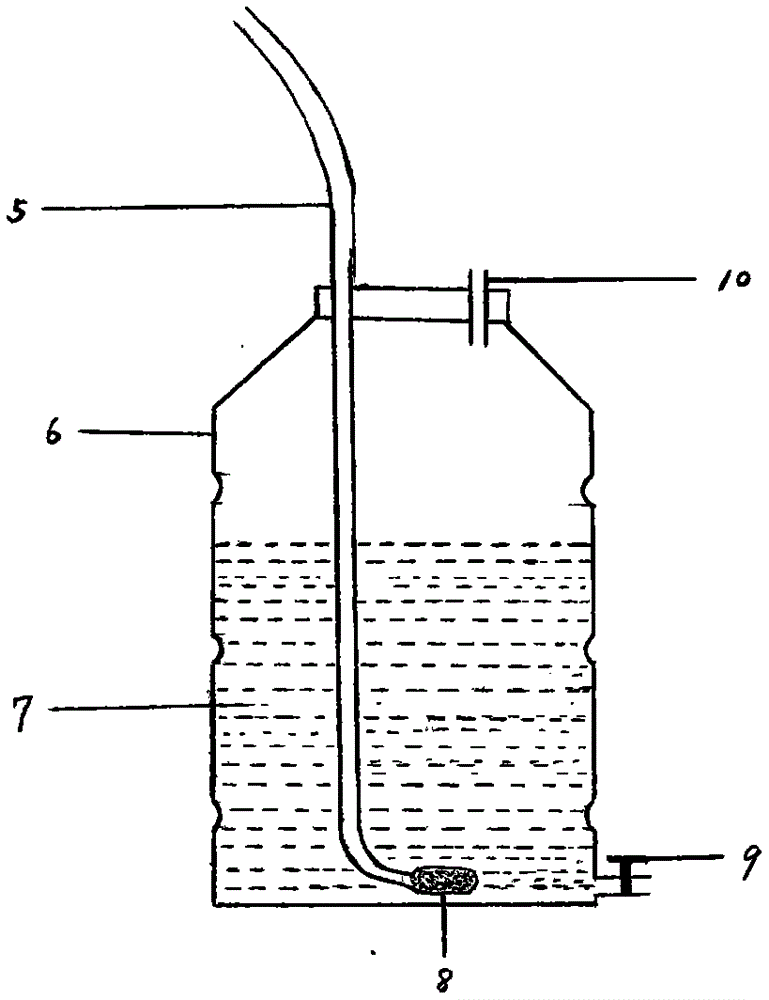

Method for fastly analyzing chemical oxygen demand by high-pressure flowing injection

InactiveCN101074924AImprove damping performanceAvoid it happening againWithdrawing sample devicesMaterial analysis by optical meansPhotoelectric conversionHigh pressure

A method for quickly analyzing COD by high-pressure flow-injection includes using solution of heavy potassium chromate-diluted sulphuric acid as current-carrying liquid, injecting said current-carrying liquid into pipeline of capillary tube continuously by constant-flow pump, injecting quantitative water sample into current-carrying liquid by injection valve, expanding water sample in current-carrying liquid, flowing water sample in following with current-carrying liquid through reactor and water box as well as colorimetric circulation pool in sequence then utilizing single-color illumination and photoelectric conversion to test out COD.

Owner:DELIN ENVIRONMENTAL PROTECTION TECH

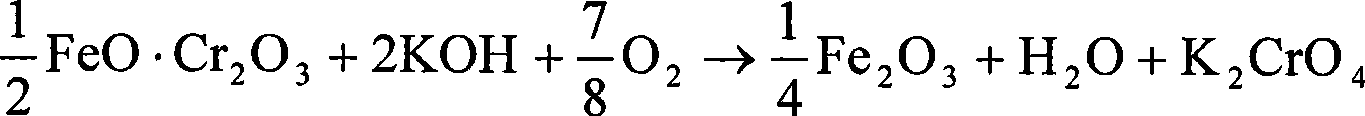

Method for producing light-weight magnesium carbonate by using phosphate tailings with high magnesium content

InactiveCN102653408ASave resourcesReduce manufacturing costProductsReagentsHigh magnesiumCarbonization

The invention discloses a method for producing light-weight magnesium carbonate by using phosphate tailings with high magnesium content. The method comprises the following steps of: calcining the phosphate tailings with high magnesium content into calcined dolomite at a high temperature; mixing the calcined dolomite and water according to a certain proportion to obtain a slaking solution; supplementing water of a certain proportion into the slaking solution, feeding gas with carbon dioxide into the solution, and performing carbonization reaction to obtain a carbonized solution; after the reaction is finished, filtering the carbonized solution to obtain filtrate, namely a magnesium potassium chromate solution; performing pyrolysis on the magnesium potassium chromate solution, thus obtaining magnesium carbonate sediments; and filtering and drying the sediments to obtain the light-weight magnesium carbonate product. By using the method, waste is turned into treasure, so that magnesium resources in the phosphate tailings with high magnesium content are recycled; the process is simple and low in cost; and the economic and environmental benefits are remarkable.

Owner:WENGFU (GRP) CO LTD

Clean production method of potassium chromate

InactiveCN1410358AObvious superiorityReduce energy consumptionChromates/bichromatesReaction temperatureAqueous solution

A clean process for preparing potassium chromate includes such steps as reaction of chromite on oxidant in the aqueous solution of KOH to obtain a mixture of alkali solution, chromium salt and iron dregs, immersion extracting, separating coarse crystal of potassium chromate from ion dregs, and alkali solution, dissolving the said coarse crystal, removing impurities and crystallizing. Its advantages are low reaction temp. (250-400 deg.C), high Cr recovering rate (20%) and reduced quantity of Cr dregs.

Owner:中蓝义马铬化学有限公司

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

Method for extracting chromium from chromite by leaching

ActiveCN104726705ALow in chromiumEmission reductionProcess efficiency improvementPotassiumPotassium hydroxide

The invention relates to a method for extracting chromium from chromite by pressure leaching, which comprises the following steps: mixing chromite and / or pretreated chromite with a potassium hydroxide water solution, a potassium carbonate water solution and a potassium metaaluminate water solution to obtain an original slurry; adding the original slurry into a high-pressure autoclave, introducing oxidizing gas, and carrying out pressure leaching oxidizing reaction to obtain a reaction slurry; and carrying out solid-liquid separation to respectively obtain iron-rich tailings and a solution containing potassium chromate, potassium hydroxide, potassium carbonate, potassium aluminate and other water-soluble impurity components. The method has the advantages of greatly lower reaction temperature and low energy consumption, and effectively lowers the production cost, and the maximum chromium extraction yield can reach 97% above. Besides, the volume of the high-pressure autoclave can be 200L, and the reaction medium has the same proportioning as the industrial circulating liquor, so that the process is very close to the industrial process and can easily implement industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

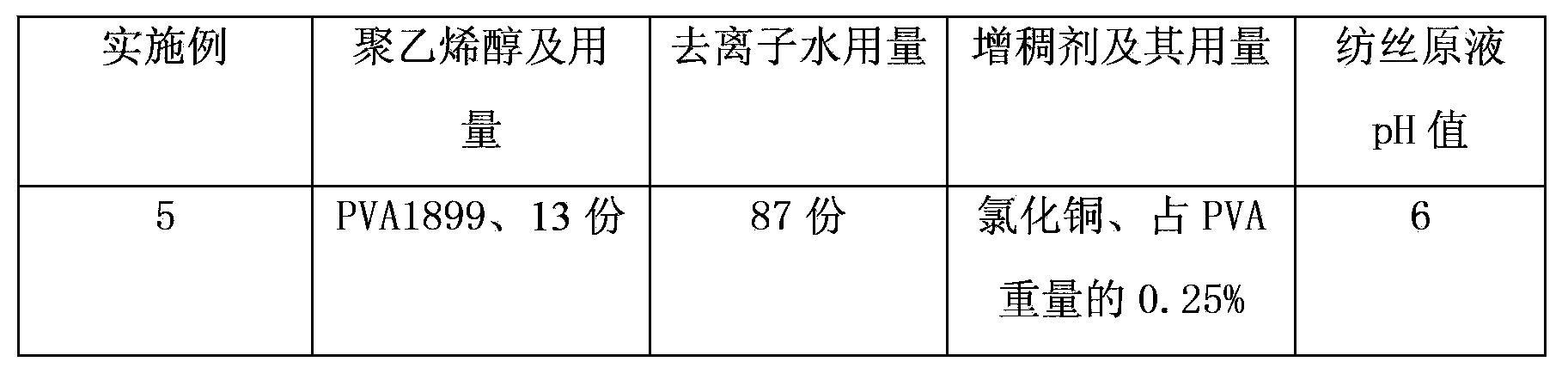

Fine-denier or superfine-denier polyvinyl alcohol fiber and preparation method thereof

ActiveCN103388189AImprove spinnabilityReduce the amount addedArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberCopper nitrate

A preparation method of a fine-denier or superfine-denier polyvinyl alcohol fiber comprises the following steps: dissolving 10-15 parts of polyvinyl alcohol in 85-90 parts of deionized water at 95-98DEG C for 2-5h to form a homogeneous solution, adding a thickening agent having a weight being 0.1-2% of the weight of polyvinyl alcohol, adjusting the pH value of the homogeneous solution to 3-6.5 through using acetic acid, and allowing the viscosity of the homogeneous solution to 5000-30000cp in order to prepare a polyvinyl alcohol spinning stock solution, wherein the thickening agent comprises anyone of boric acid, borax, copper sulfate, copper chloride, copper nitrate, sodium chromate, potassium chromate and titanium sulfate; moulding the spinning stock solution to obtain a nascent fiber; and post-processing the nascent fiber to prepare the polyvinyl alcohol fiber. The low-concentration polyvinyl alcohol spinning stock solution has the advantages of good spinnability, good storage stability, stable and continuous spinning process, and relatively few phenomena of broken filaments; and the yield is above 95%. The obtained fiber has a low linear density in a range of 0.16-1.00dtex, a tensile strength of 5-8cN / dtex and an elongation at break of 5-15%, and the Rp value of the obtained formalized fiber is 110-125DEG C.

Owner:CHINA PETROCHEMICAL CORP +2

Method for determining total iron by titanium trichloride

InactiveCN102519958AEasy to operateAccurate measurementMaterial analysis by observing effect on chemical indicatorToxic materialSodium tungstate

The invention belongs to the technical field of methods for determining total iron and particularly relates to a method for determining total iron by titanium trichloride. The invention aims to solve the technical problems and provide the method for determining the total iron by the titanium trichloride, which has simple and convenient process without discharging toxic substances. The method for determining the total iron by the titanium trichloride comprises the following steps: (1) melting a sample and then leaching the smelt sample by acid; (2) by adopting sodium tungstate as an indicator, adding the titanium trichloride into the leached solution until tungsten blue is generated, and dropping potassium dichromate solution until the blue is disappearer; and (3) by adopting sodium diphenylamine sulfonate as an indicator, performing titration with potassium dichromate standard solution, and calculating the content of the total iron according to consumption volume of the potassium dichromate standard solution. The method for titration of the total iron by the titanium trichloride has the advantages of more accurate measuring result, higher qualified rate and less analytical error.

Owner:攀枝花钢企米易白马球团有限公司

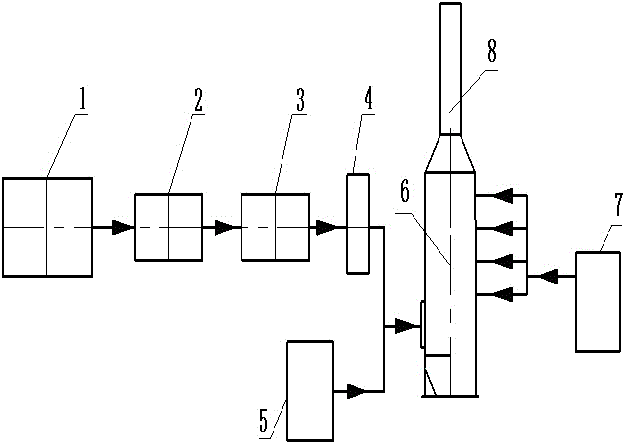

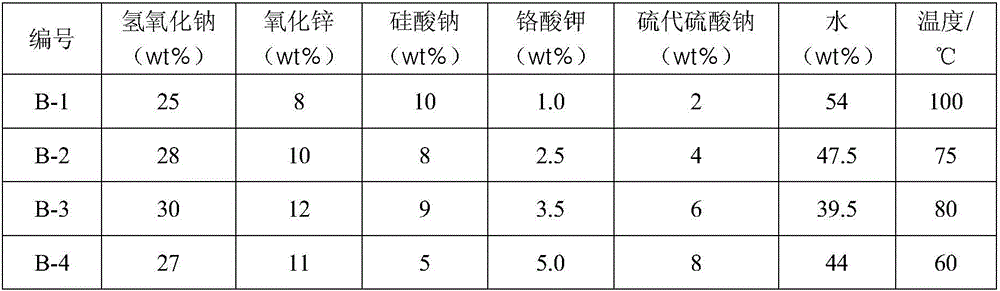

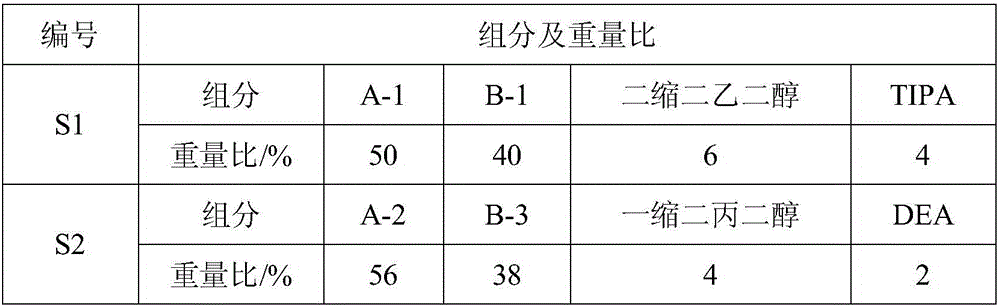

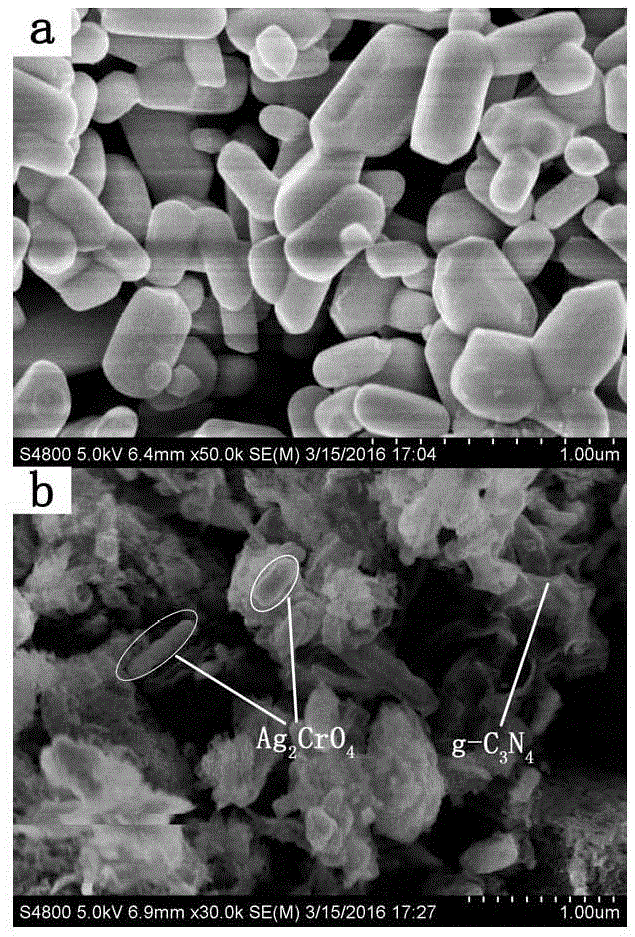

Liquid accelerated agent for sprayed concrete and preparation method of liquid accelerated agent

The invention discloses a liquid accelerated agent for sprayed concrete and a preparation method of the liquid accelerated agent. The liquid accelerated agent for the sprayed concrete uses aluminate as a main component and is compounded with silicate, sulfate, amphoteric metal ions, polyatomic alcohol and alcohol amine. The preparation method of the liquid accelerated agent for the sprayed concrete comprises the following steps: firstly, preparing a sodium aluminate solution from aluminum hydroxide and a sodium hydroxide solution; secondly, dissolving sodium silicate into the sodium hydroxide solution, and adding zinc oxide, sodium thiosulfate and potassium chromate to obtain a modifier solution; finally, compounding the two solutions with the polyatomic alcohol and the alcohol amine to obtain the liquid accelerated agent. According to the liquid accelerated agent for the sprayed concrete, disclosed by the invention, the coagulation time of the sprayed concrete can be further shortened, and the adaptability of cement is improved; the liquid accelerated agent has a good coagulation accelerating effect on initially-hydrated premixed concrete, the coagulation time of the concrete can be remarkably shortened, and the early strength is improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Surface treatment method for silicon carbide ceramic

ActiveCN104876648AImprove surface wettabilityImprove interfacial bond strengthPotassium cyanidePotassium ferricyanide

The invention belongs to the surface treatment technology of materials. By adopting a method of combining surface control corrosion and surface coupling, surface control corrosion of the silicon carbide ceramic is realized in a relatively mild condition, so that the interface bonding property of the silicon carbide ceramic and an organic system is improved. The surface treatment method for silicon carbide ceramic provided by the invention comprises the following steps: pre-treatment; surface treatment; and post-treatment. By using one or a combination system of a potassium dichromate aqueous solution, a mixed aqueous solution of potassium dichromate and potassium hydroxide and a mixed aqueous solution of potassium ferricyanide and potassium hydroxide as a surface corrosion liquid, the mass concentration is between 5% and 50%, and the ceramic is soaked for 2-8 hours at the room temperature. The treatment method can be used for remarkably improving the surface wettability of the silicon carbide ceramic and improving the interface bonding strength of the silicon carbide ceramic / fiber-reinforced resin-based composite material, is simple to operate and easy to control, and is suitable for treatment of the bonding face of the silicon carbide ceramic and the organic system, particularly the technical field of processing of silicon carbide ceramic / fiber-reinforced resin-based composite material.

Owner:山东三达科技发展有限公司 +1

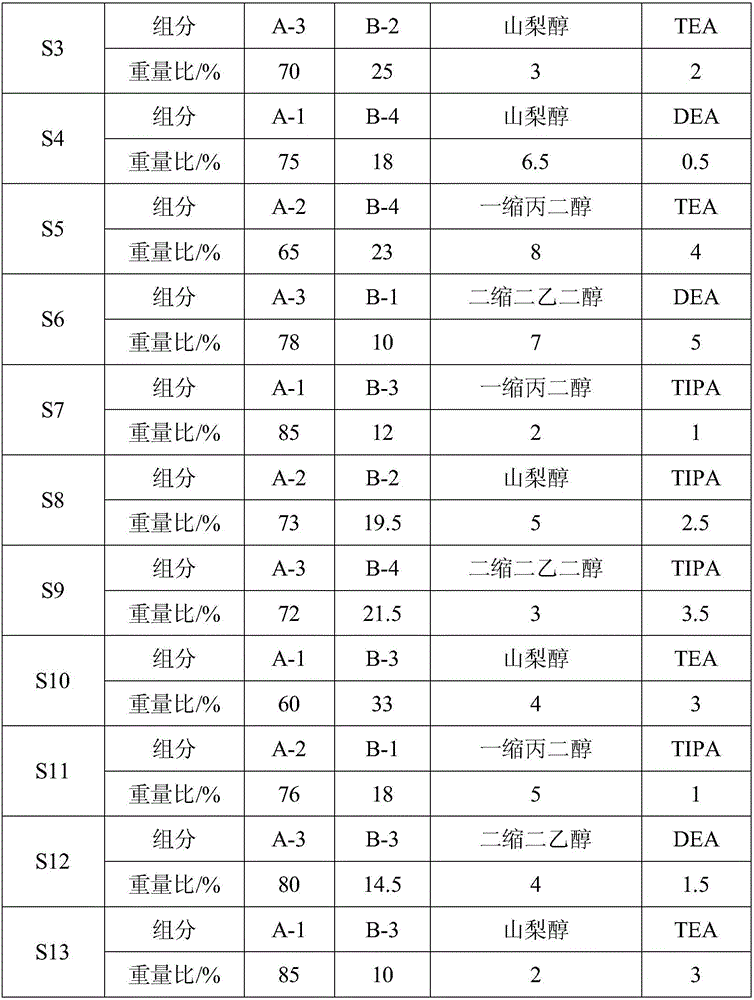

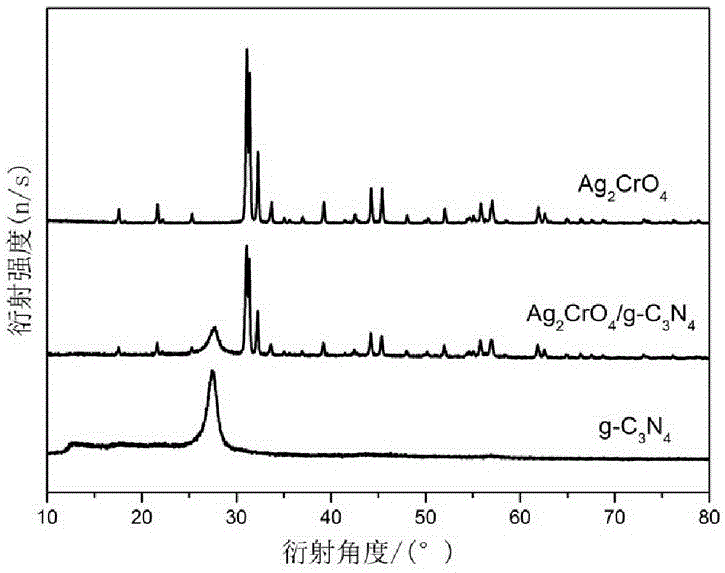

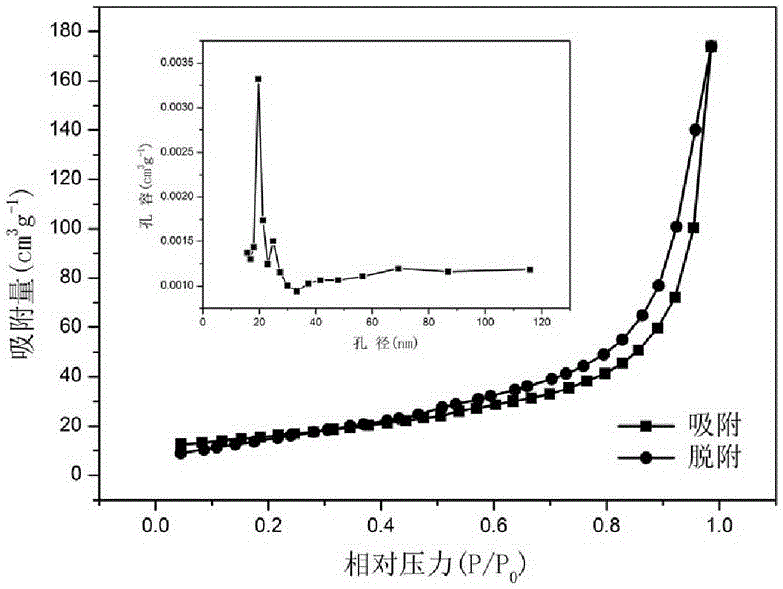

Ag2CrO4-loaded g-C3N4 composite photocatalyst and preparation method and application thereof

InactiveCN105944747AEasy to separateImprove photocatalytic performanceCatalyst carriersWater/sewage treatment by irradiationNanoparticlePhysical chemistry

The invention discloses a Ag2CrO4-loaded g-C3N4 composite photocatalyst and belongs to the technical field of functional composite photocatalysts. A g-C3N4 nanosheet is used as a carrier, and the g-C3N4 nanosheet carrier is modified with Ag2CrO4 nanoparticles. A preparation method of the composite photocatalyst includes following steps: adding the g-C3N4 nanosheet into water for ultrasonic dispersion to form a g-C3N4 nanosheet suspension, and adding silver nitrate to obtain mixed liquid of Ag+ and g-C3N4; adding potassium chromate into the mixed liquid of Ag+ and g-C3N4, and stirring to obtain the composite photocatalyst. The composite photocatalyst is high in photocatalytic activity and stability, the preparation method is simple and low in cost and energy consumption, the composite photocatalyst can be used for photocatalytic degrading of dye wastewater, and application is simple in method and high in removal rate.

Owner:HUNAN UNIV

Method for modifying aluminium profile for buildings

InactiveCN103820776AStable internal performanceImprove performanceMetallic material coating processesSodium sulfateMaterials science

The invention relates to modification of aluminium profiles and in particular relates to a method for modifying an aluminium profile for buildings. The method comprises the steps of smelting aluminium ingots into molten aluminium, adding mixed powder of zirconium-coated titanium dioxide and zirconium-coated silicon dioxide, maintaining the materials at a melting temperature for 3-5 hours, pouring the materials into a mold with a temperature above 600 DEG C under the pressure of 1.1-1.5MPa, and cooling and insulating so as to obtain the aluminium profile through demolding; preparing a modifying agent from 20-40 parts of sodium fluoride, 30-60 parts of ammonium bifluoride, 10-20 parts of potassium permanganate, 40-50 parts of potassium chromate, 15-25 parts of zinc phosphate, 8-18 parts of sodium nitrate, 5-12 parts of praseodymium chloride, 10-16 parts of ethylenediamine tetraacetic acid, 7-14 parts of malic acid, 8-12 parts of sodium dodecyl benzene sulfate, 6-13 parts of nickel sulfate, 15-25 parts of triethanolamine, 5-10 parts of reducing agents containing alkali metals, 7-13 parts of chlorinated polypropylene or polyolefin substrate adhesion promoter and 500-900 parts of water by weight, and controlling the pH value to be 3-4, thus obtaining the modifying agent; dipping and drying twice to obtain a modified aluminium profile. The prepared aluminium profile is bright and soft, has excellent corrosion resistance and is safe and environment-friendly.

Owner:MERLAN INT GRP H K

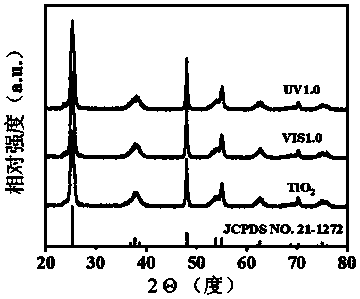

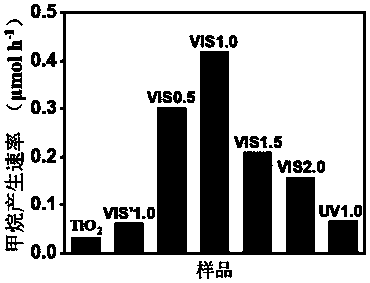

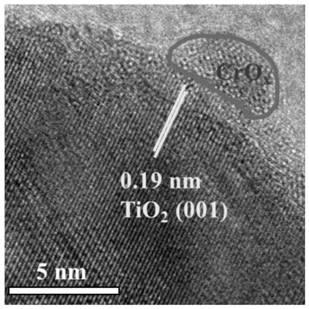

Chromium oxide loaded titanium dioxide photocatalyst as well as preparation method and application thereof

ActiveCN111450820AHigh selectivityEasy to prepareHydrocarbon from carbon oxidesCatalyst activation/preparationPtru catalystPhysical chemistry

The invention provides a preparation method of a chromium oxide loaded titanium dioxide photocatalyst with an excellent carbon dioxide reduction performance. The preparation method comprises the following steps: preparing titanium dioxide nano sheets by a hydrothermal method; dispersing the titanium dioxide nano sheets in water to obtain a titanium dioxide suspension; mixing a potassium chromate water solution with the titanium dioxide suspension, carrying out ultrasonic dispersion to obtain a chromium precursor solution; carrying out visible light deposition on the chromium precursor solution, and cleaning, freezing and drying to obtain the chromium oxide loaded titanium dioxide photocatalyst after the light deposition is finished. According to the preparation method, a main catalyst namely anatase type titanium dioxide nano sheets is prepared through a classical hydrothermal method, and then the chromium oxide co-catalyst loaded titanium dioxide photocatalyst is prepared through a visible light deposition method. The rate of generating methane by photocatalytic reduction of carbon dioxide is 0.42 [mu]mol h<-1>, and the selectivity of methane is up to 98%. The synthesis method issimple and is beneficial to popularization and application in industrial production.

Owner:UNIV OF SCI & TECH OF CHINA

Method for producing super conducting heat pipe

InactiveCN1673663AImprove explosive powerLong rangeIndirect heat exchangersHeat transfer modificationManganeseSodium superoxide

The production process of superconductive heat pipe includes the following steps: mixing any two of sodium superoxide, potassium dichromate or sodium, and strontium chromate, adding hydrochloric acid to react, adding water while heating to dissolve, cooling to crystallize, adding mercurochrome and dissolving in distilled water to prepare No. 1 medium; mixing any two of sesqui manganese hydride potassium dichromate or sodium, monocrystal silicon, beryllium oxide, barium oxide and sodium peroxide, adding titanium trichloride or butyl Rodan solution, letting stand to laminate, centrifuging to obtain crystal, diluting with absolute ethanol to obtain No. 2 medium; heating the No. 1 medium in metal pipe to exhaust air; adding No. 2 medium into the No. 1 medium, further heating and sealing metal end. Thus prepared superconductive pipe can meet the requirement of large heat supplying system.

Owner:刘锡汉

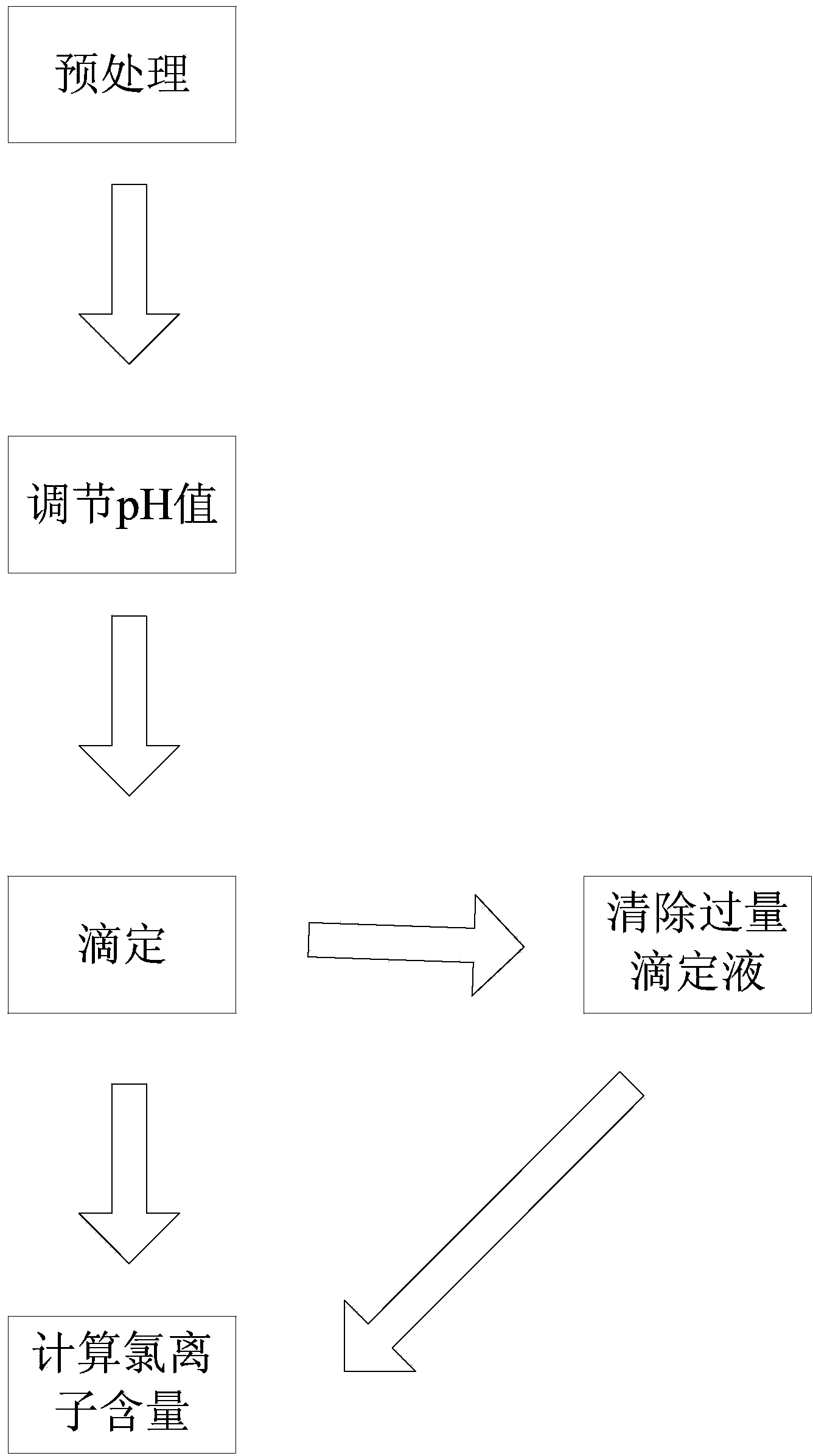

Method for measuring chloride ion in acidity plating solution

InactiveCN103852466ALow priceEasy to manageMaterial analysis by observing effect on chemical indicatorPotassium rhodanideAlkalinity

The invention provides a method for measuring chloride ions in an acidity plating solution. The method comprises the steps of adding sodium hydroxide in the acidity plating solution, adjusting the pH value of the plating solution to alkalinity, removing precipitate generated in the plating solution, adjusting the pH value of a certain amount of filtered plating solution to be 9-10 with nitric acid, titrating with a silver nitrate solution to a terminal point by using potassium chromate as an indicator, titrating with potassium rhodanide by using ammonium ferric sulfate as the indicator when the silver nitrate solution is excessive, and calculating the content of chloride ions in the acidity plating solution. By adopting the method for measuring the chloride ion in the acidity plating solution, the content of the chloride ions in the acidity plating solution can be rapidly and accurately measured on the scene and in a small-and-medium size lab, an expensive analytical instrument is not required, the method is convenient and rapid, and has the time-saving effect, and the analysis result is accurate and reliable. Reaction measuring substances are all regular chemicals, low in cost and toxicity and convenient to manage and use.

Owner:AMPHENOL TIANJIN ELECTRONICS

Waterproof corrosion-resistant photocuring paint

InactiveCN104987790AImprove anti-corrosion performanceImprove waterproof and anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsAntioxidantAluminium hydroxide

The invention discloses waterproof corrosion-resistant photocuring paint. The paint comprises, by weight, 15-40 parts of acrylic emulsion, 3-10 parts of polyurethane, 0.5-5 parts of rosin modified phenolic resin, 0.5-2 parts of triethoxyisobutylsilane, 0.5-1.7 parts of carboxymethylcellulose, 0.6-0.9 parts of hydroxypropyl methyl cellulose, 1-4 parts of dipropylene glycol methyl ether, 2-4 parts of potassium chromate, 4-6 parts of aluminium hydroxide, 2-6 parts of preservatives, 1-4 parts of barium sulfate, 2-5 parts of antioxidants, 6-14 parts of photoinitiators, 3-6 parts of defoaming agents, 2-7 parts of a molybdenum compound, 2-6 parts of sodium sulfate and 16-23 parts of water. The photocuring paint has the advantages of being short in curing time, low in curing temperature and low in volatile component, and meanwhile the coating is good in waterproof performance and corrosion resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Culture medium and culture method for culturing amphora ovalis by using wastewater in canning plant

InactiveCN104017730ALow costReduce outputUnicellular algaeMicroorganism based processesPhosphateArginine

The invention discloses a culture medium and a culture method for culturing amphora ovalis by using wastewater in a canning plant, and the culture medium and the culture method can be used for treating the wastewater in the canning plant with low cost, utilizing wastes and obtaining microalgae with important bait value. The amphora ovalis traditionally cultured by adopting a Liao's improved culture solution and an open runway pool is slow in growth, low in yield, easy to contaminate and low in benefit, whereas aerated culture with transparent 1.5cm<3> cylindrical food-grade plastic drums is capable of realizing low cost and quick growth, avoiding pollution contamination and is easy to operate; the wastewater in the canning plant, sodium silicate, ammonium ferric citrate, ammonium molybdate, potassium chromate, fish meal, sodium carboxymethyl cellulose, L-arginine, potassium dihydrogen phosphate, medical stone meal, 920-type plant growth substance, vitamin S-3 solution, M-F trace element solution, sodium thioglycollate and the like are added in the culture medium, namely organic fertilizers and inorganic fertilizers are used together, so that the nutrition is more comprehensive and balanced, the growth rate of the amphora ovalis is greatly improved, and the yield is improved by 420%.

Owner:LINYI UNIVERSITY

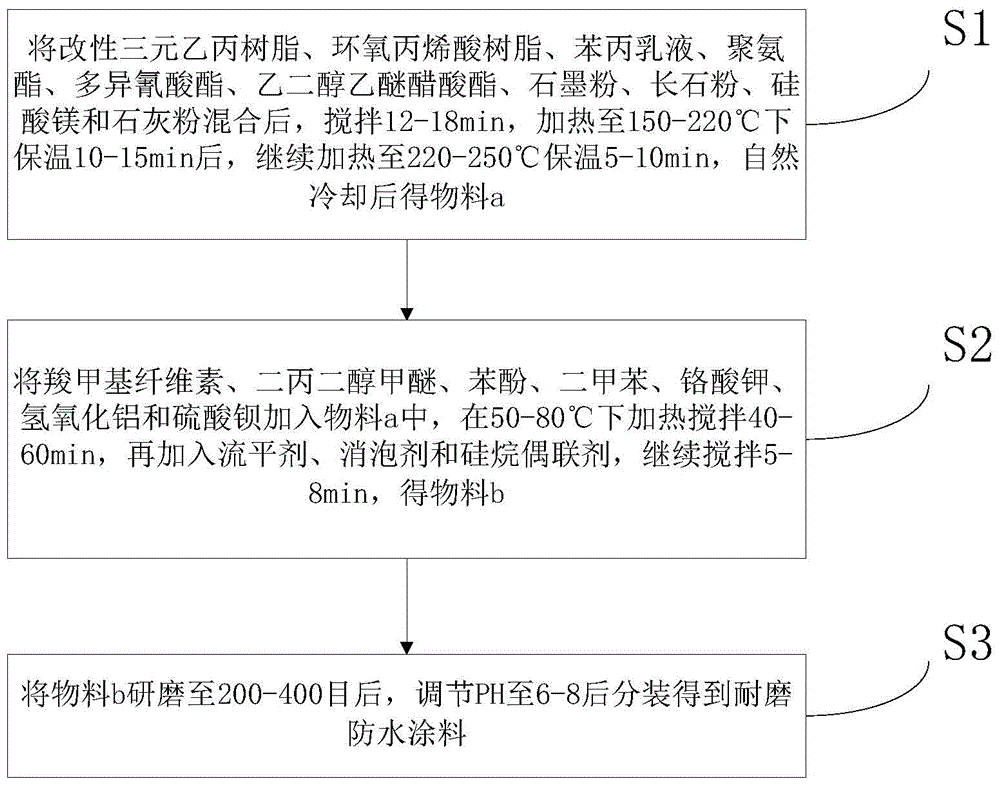

Abrasion-resistant waterproof coating for building outer wall and method for preparing the same

InactiveCN104946029AExtended service lifeLow costPolyurea/polyurethane coatingsAcrylic resinAluminium hydroxide

The invention discloses an abrasion-resistant waterproof coating for a building outer wall. The abrasion-resistant waterproof coating comprises, by weight parts, 60-80 parts of modified EPDM resin, 30-60 parts of epoxy acrylic resin, 20-40 parts of styrene-acrylic emulsion, 10-30 parts of polyurethane, 5-15 parts of polyisocyanate, 2-8 parts of ethylene glycol monoethyl ether acetate, 3-8 parts of graphite powder, 2-6 parts of feldspar powder, 1-5 parts of magnesium silicate, 2-6 parts of phenol, 3-5 parts of carboxymethyl cellulose, 2-5 parts of hydroxypropyl methylcellulose, 3-7 parts of dipropylene glycol methyl ether, 2-8 parts of phenol, 3-7 parts of xylene, 2-6 parts of potassium chromate, 1-3 parts of aluminum hydroxide, 2-4 parts of barium sulfate, 1-3 parts of flatting agent, 2-6 parts of defoamer and 1-5 parts of silane coupling agent. The invention further discloses a method for preparing the abrasion-resistant waterproof coating for the building outer wall. The abrasion-resistant waterproof coating for the building outer wall is excellent in abrasion resistance, good in waterproof performance, long in service life and low in cost.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

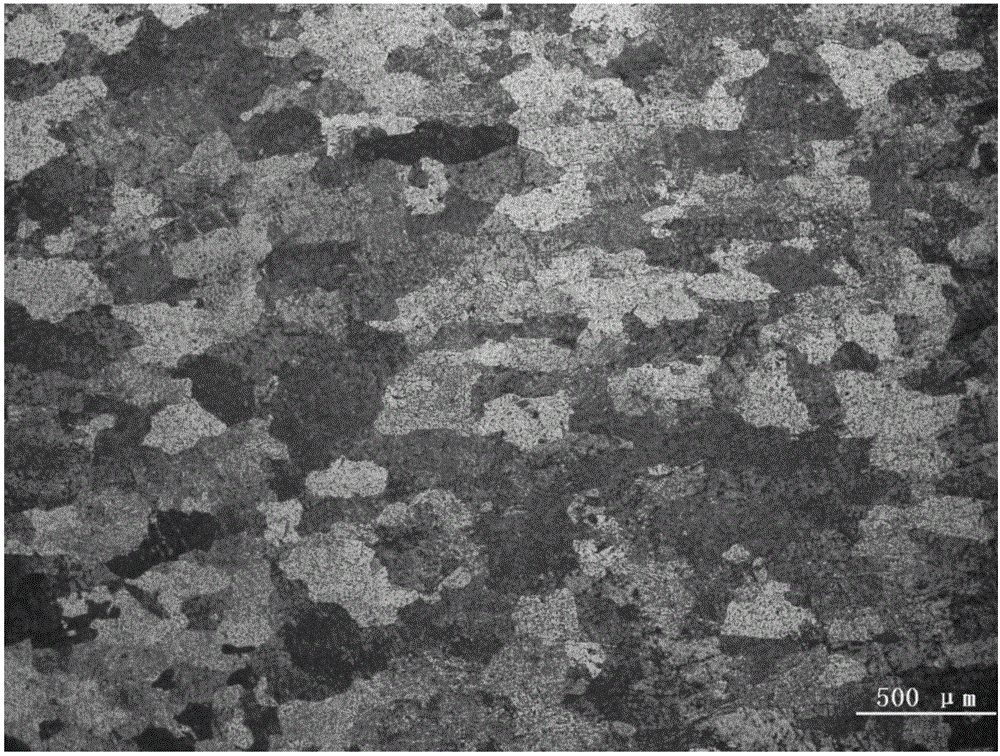

Pure aluminum grain size corrosive agent as well as preparation method and corrosion showing method thereof

ActiveCN106498399ASimple and fast operationNo heating requiredPreparing sample for investigationParticle size analysisGrain boundaryCorrosion

The invention relates to a pure aluminum grain size corrosive agent as well as a preparation method and a corrosion showing method thereof. The pure aluminum grain size corrosive agent consists of the following components: 5 to 7 g of K2CrO4, 6 to 10 ml of nitric acid, 1ml of a saturated picric acid water solution, 0.4 to 0.6 ml of hydrofluoric acid, 4 to 8 ml of hydrochloric acid and 18 to 22 ml of water. A pure aluminum matrix is a simplex alpha solid solution, different phases exist in the alpha solid solution, and a grain boundary is generated after corrosion; after adopting an existing corrosive agent and an existing corrosion method, a pure aluminum crystal boundary difficultly has obvious level differences and is poor in corrosion effect. The pure aluminum grain size corrosive agent provided by the invention is formed by compounding the nitric acid, the hydrofluoric acid, the hydrochloric acid, potassium chromate and picric acid; and with a suitable concentration, the K2CrO4 can simultaneously play the effects of an oxidant and a mordant, can corrode the crystal boundary, can also colorize alpha grains of different phases and can make the crystal boundary be more obvious and clear in cooperation with the effect of the picric acid.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

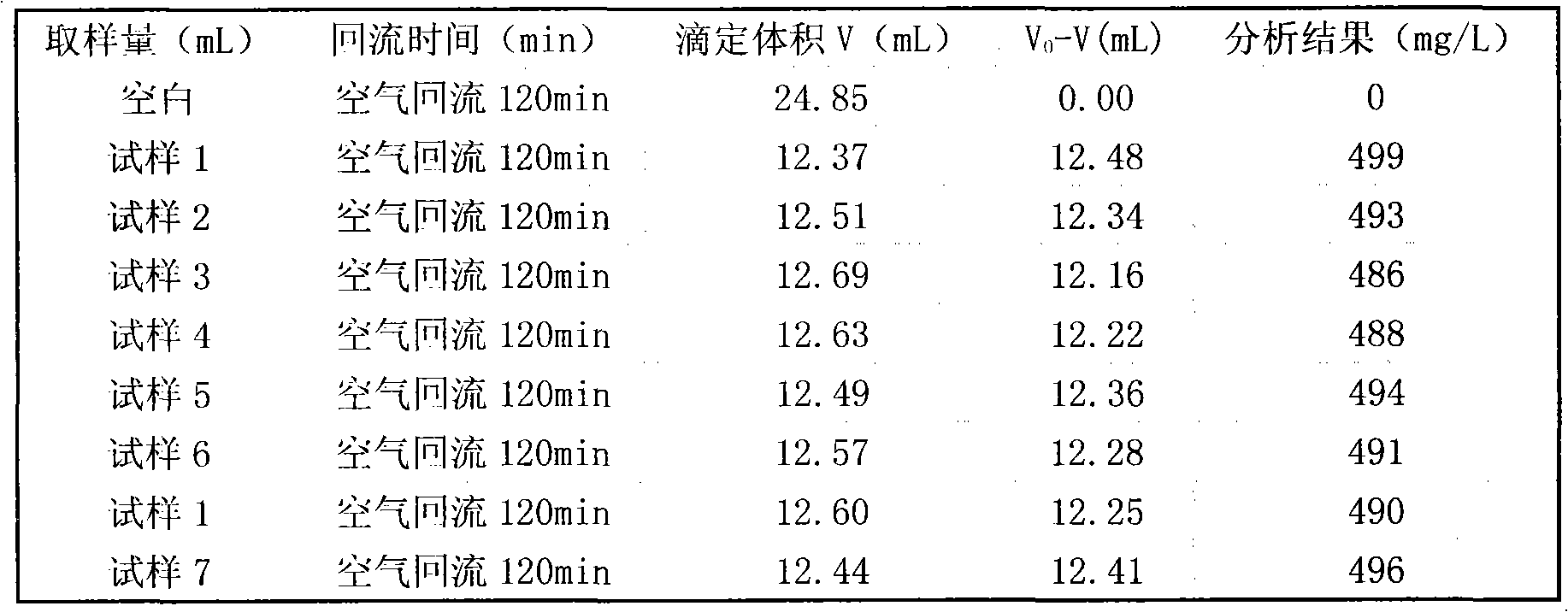

Air flow-back detection method for chemical oxygen demand (COD) in water

InactiveCN101858869ASmall footprintShort heating timeMaterial analysis by observing effect on chemical indicatorAmmonium ferrous sulfatePhenanthroline

The invention relates to an air flow-back detection method for chemical oxygen demand (COD) in water. The method comprises the following steps of: adjusting the temperature of a COD constant temperature heater to between 170 and 180 DEG C; putting a water sample in a heating tube; simultaneously adding potassium dichromate standard solution, solution of sulfuric acid-silver sulfate and a plurality of small explosion-proof ceramic pieces into the heating tube and slightly shaking the heating tube; connecting a condensation tube to the heating tube; placing the heating tube in a heating hole to heat; flowing back the solution for 2 hours after boiling; taking the heating tube and the condensation tube out and naturally cooling the tubes; washing the wall and the ground of the condensation tube with pure water; taking the condensation tube down and adding the condensation tube into a stirrer; adding water to 140ml and performing electromagnetic stirring on the solution; adding a phenanthroline indicator into the solution dropwise; titrating the solution with solution of ammonium ferrous sulfate; finishing the titration when the color of the solution changes from yellow to blue to red brown; and recording the consumed volume of the solution of ammonium ferrous sulfate. The COD constant temperature heater adopted by the method has the advantages of small occupied space, constant temperature, simple maintenance, reliable performance, safe use and high detection accuracy.

Owner:HANGZHOU HUAJI ENVIRONMENT DETECTION TECH

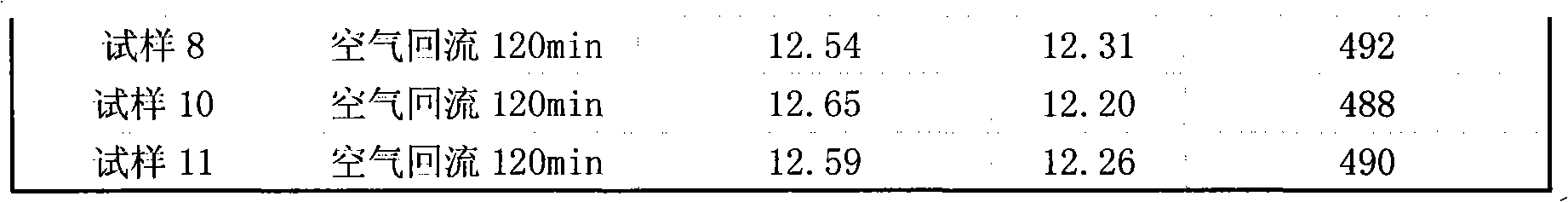

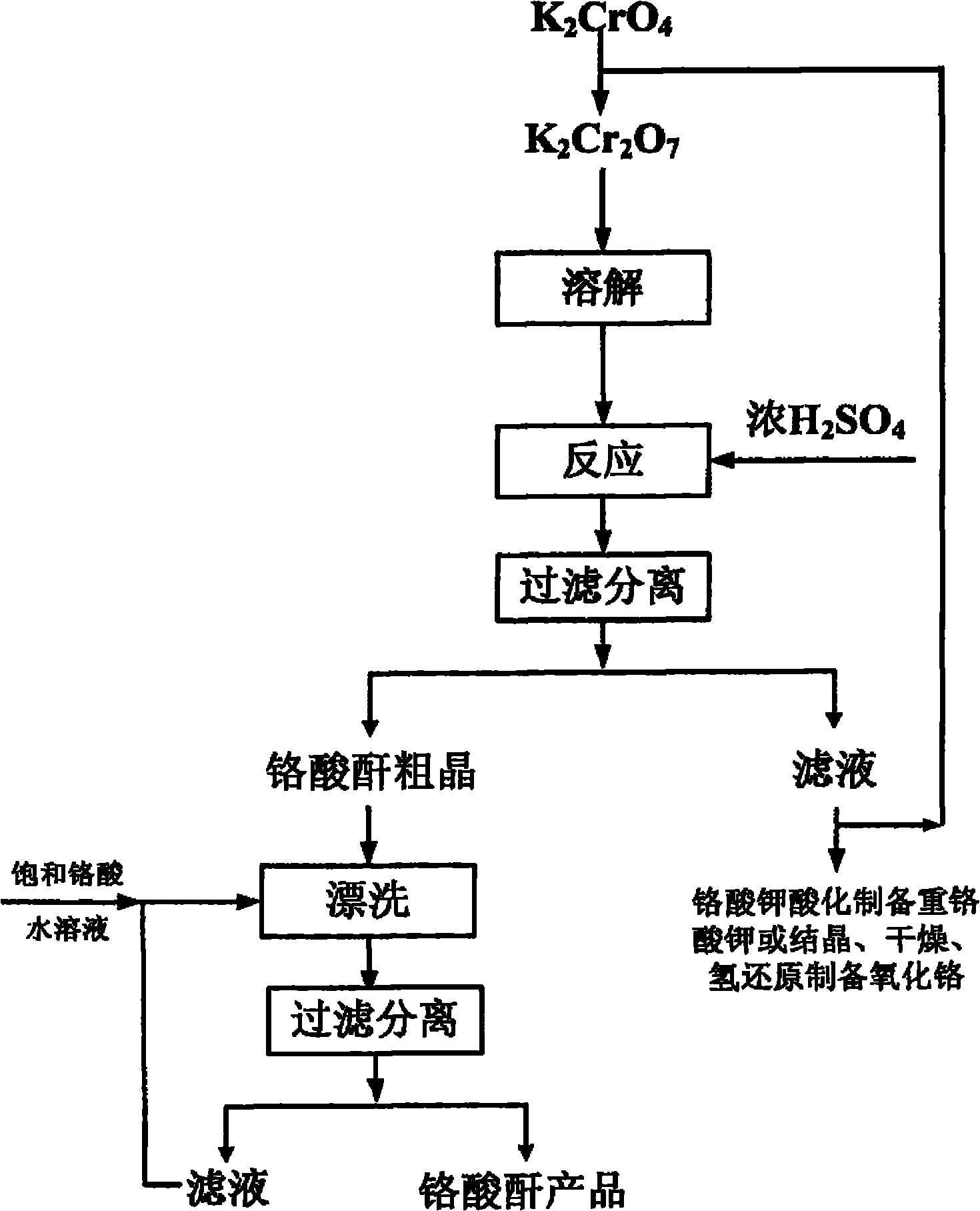

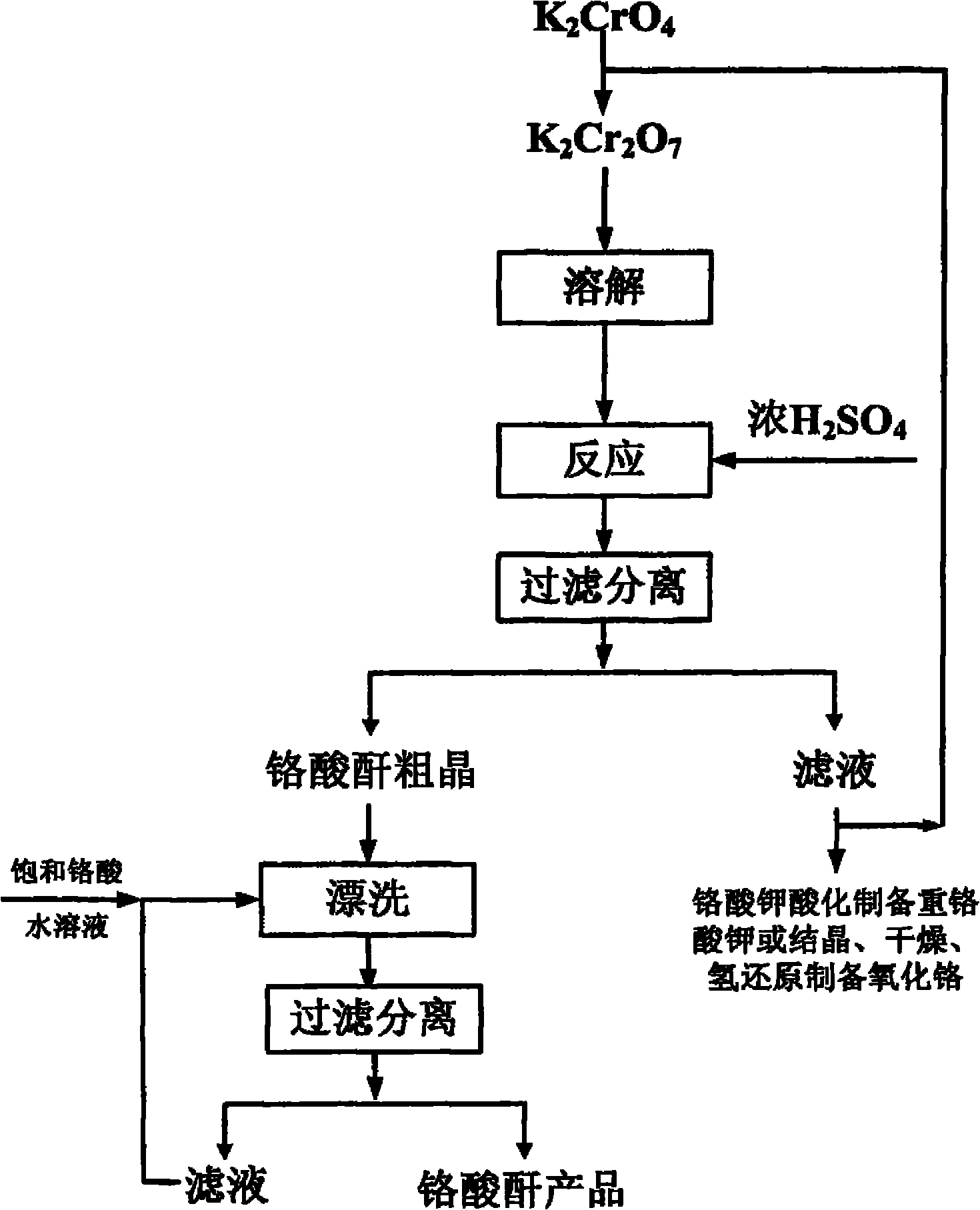

Method for preparing chromic anhydride from potassium chromate

InactiveCN102020316AAchieve regenerationRealize closed loopChromium trioxideDecompositionPotassium dichromate

The invention relates to a method for preparing chromic anhydride from potassium chromate. The method comprises the following steps: 1) dissolving and acidizing the potassium chromate to obtain saturated potassium dichromate solution; 2) adding concentrated sulfuric acid in the potassium dichromate solution in the step 1 so that the mole ratio of the dichromate solution to the concentrated sulfuric acid is 1:1-7, stirring, reacting for 0.5-2 hours at the temperature of 20-150 DEG C, precipitating chromic anhydride crystals, filtering to obtain chromic anhydride macro crystals and mother liquor; 3) feeding 40%-60% of mother liquor in the step 2) back to the step 1) for the acidification of the potassium chromate, and carrying out crystallization and reduction on the residual parts to prepare chromic oxide; and 4) rinsing and filtering the chromic anhydride macro crystals in the step 2) with saturated chromic anhydride solution to obtain the chromic anhydride crystals and filtrate, recycling the filtrate to rinse the chromic anhydride macro crystals, and drying the chromic anhydride macro crystals to obtain the chromic anhydride. The invention has the advantages that the method is operated at the temperature lower than the decomposition temperature of the chromic anhydride and under normal pressure, and the obtained product has the advantages of high quality, high yield and low energy consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com