Chromium oxide loaded titanium dioxide photocatalyst as well as preparation method and application thereof

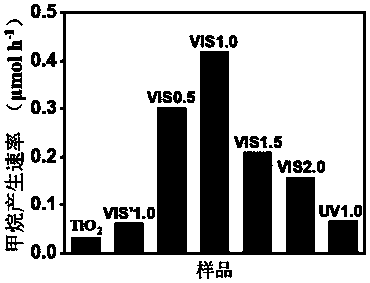

A technology of titanium dioxide and chromium oxide, applied in the field of titanium dioxide photocatalyst, can solve the problems of complex loading process, serious carrier recombination, low energy conversion efficiency of pure TiO2, and achieve the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

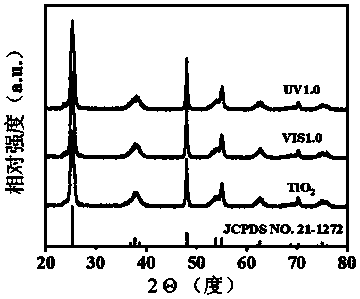

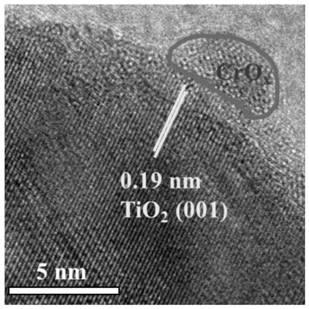

[0027] The invention provides a preparation method of titanium dioxide photocatalyst supported by chromium oxide, comprising:

[0028] A) preparation of titanium dioxide nanosheets by hydrothermal method;

[0029] B) dispersing the titanium dioxide nanosheets in water to obtain a titanium dioxide suspension; mixing an aqueous potassium chromate solution with the titanium dioxide suspension, and ultrasonically dispersing to obtain a chromium precursor solution;

[0030] C) Visible light deposition is performed on the chromium precursor solution, and after the light deposition is completed, the titanium dioxide photocatalyst supported by chromium oxide is obtained after washing, freezing and drying.

[0031] The invention provides a method for preparing a titanium dioxide photocatalyst supported by chromium oxides. Firstly, titanium dioxide nanosheets are prepared by a hydrothermal method.

[0032] According to the present invention, the preparation of titanium dioxide nanoshee...

Embodiment 1

[0076] Step 1. TiO 2 Preparation of nanosheets.

[0077] Similar to Comparative Example 1. Preparation of anatase TiO by classical hydrothermal method 2 For nanosheets, put 30ml tetrabutyl titanate and 9ml hydrofluoric acid solution into a 100ml polytetrafluoroethylene reactor, mix well, put the reactor into an oven, and react at 180°C for 48h. After the reaction, the product was washed several times with absolute ethanol and deionized water, then dried at 70° C. and taken out for use.

[0078] Step 2, preparation of chromium precursor solution.

[0079] Similar to Step 2 of Comparative Example 2. TiO prepared in step 1 2 Take 150mg and put it into 100ml deionized water, stir for 30min and ultrasonic for 3min. Dissolve 67 mg of potassium chromate in 10 ml of deionized water to prepare potassium chromate solution, take 0.5 ml of freshly prepared potassium chromate solution, add TiO 2 suspension, then stirred for 30 minutes, and ultrasonicated for 30 seconds to obtain a c...

Embodiment 2

[0086] Step 1. TiO 2 Preparation of nanosheets.

[0087] Similar to Comparative Example 1. Preparation of anatase TiO by classical hydrothermal method 2 For nanosheets, put 30ml tetrabutyl titanate and 9ml hydrofluoric acid solution into a 100ml polytetrafluoroethylene reactor, mix well, put the reactor into an oven, and react at 180°C for 48h. After the reaction, the product was washed several times with absolute ethanol and deionized water, then dried at 70° C. and taken out for use.

[0088] Step 2, preparation of chromium precursor solution.

[0089] Similar to Step 2 of Comparative Example 2. TiO prepared in step 1 2 Take 150mg and put it into 100ml deionized water, stir for 30min and ultrasonic for 3min. Dissolve 67 mg of potassium chromate in 10 ml of deionized water to prepare potassium chromate solution, take 0.25 ml of freshly prepared potassium chromate solution, add TiO 2 suspension, then stirred for 30 minutes, and ultrasonicated for 30 seconds to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com