Liquid accelerated agent for sprayed concrete and preparation method of liquid accelerated agent

A technology of sprayed concrete and quick-setting agent, which is applied in the field of concrete admixture and admixture, which can solve the problems of poor application effect and achieve the effects of improving early strength, improving cement adaptability and shortening setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

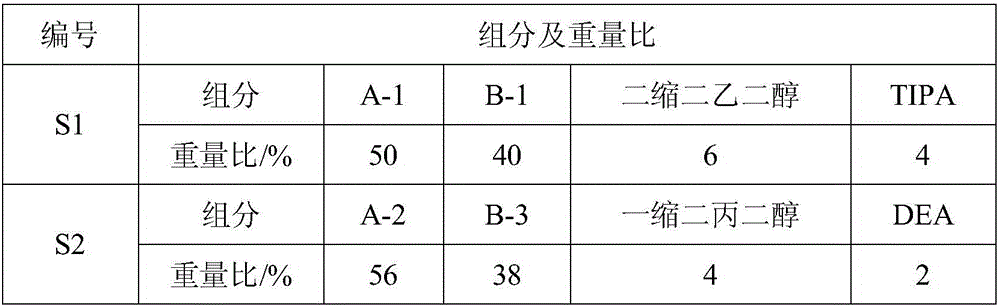

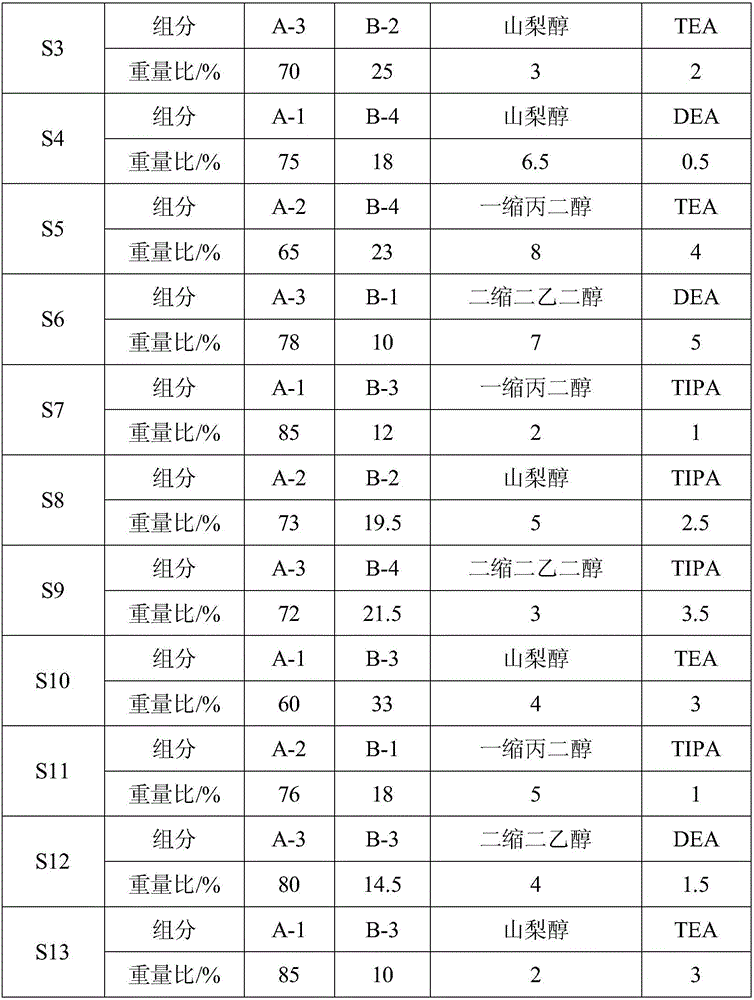

Examples

preparation example Construction

[0023] Step 1. Preparation of sodium aluminate solution

[0024] Prepare sodium aluminate solution according to the raw materials and process parameters shown in the table below. The preparation method is as follows: first dissolve sodium hydroxide into water, then add aluminum hydroxide to the sodium hydroxide solution under heating conditions, and stir the reaction until hydrogen Aluminum oxide dissolves completely.

[0025] Table 1 Sodium aluminate solution

[0026] Numbering Alkali aluminum molar ratio Alumina concentration temperature reflex reaction time / h A-1 1.50 20.0% 100℃ 3.0 A-2 1.37 26.5% 95℃ 3.2 A-3 1.2 30.0% 90℃ 5.0

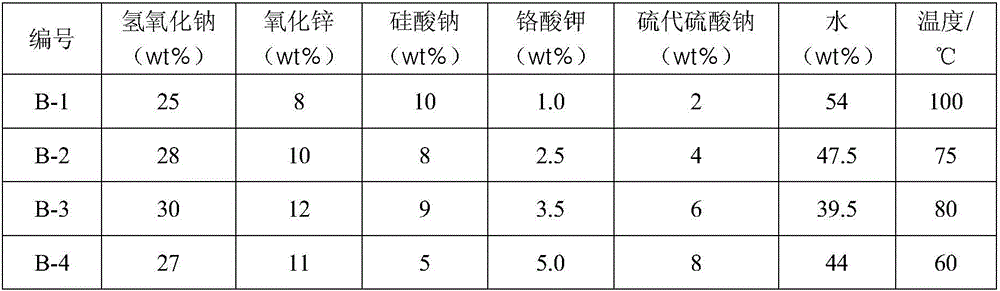

[0027] Step 2. Preparation of Modifier Solution

[0028] The modifier solution was prepared according to the raw materials and process parameters shown in the table below. The preparation method is to firstly dissolve sodium hydroxide into water, then add sodium silicate under heating condition and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com