Magnesium potassium phosphate cement-based concrete adhesive and preparation method thereof

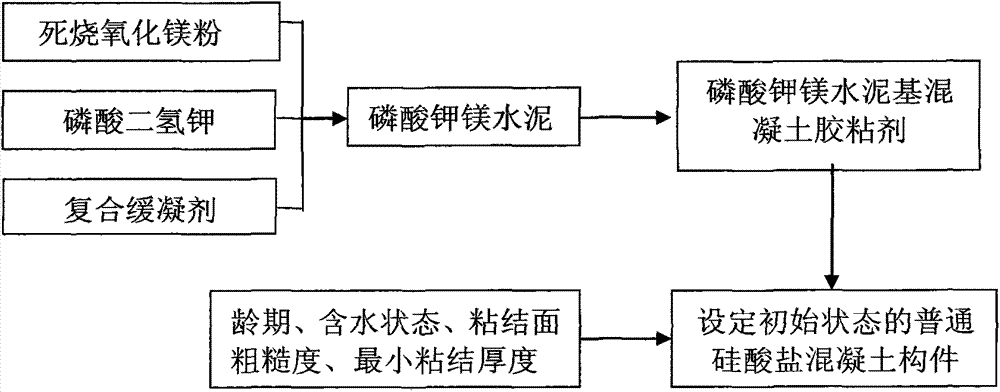

A potassium magnesium phosphate cement and adhesive technology, applied in the field of potassium magnesium phosphate cement-based concrete adhesive and its preparation, and the preparation of new high-performance concrete adhesives, can solve the problem of high volume bond strength, early strength, cohesiveness and compatibility Poor performance, coagulation cannot be effectively controlled, etc., to achieve the effect of solving strength shrinkage, low cost, and controllable coagulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

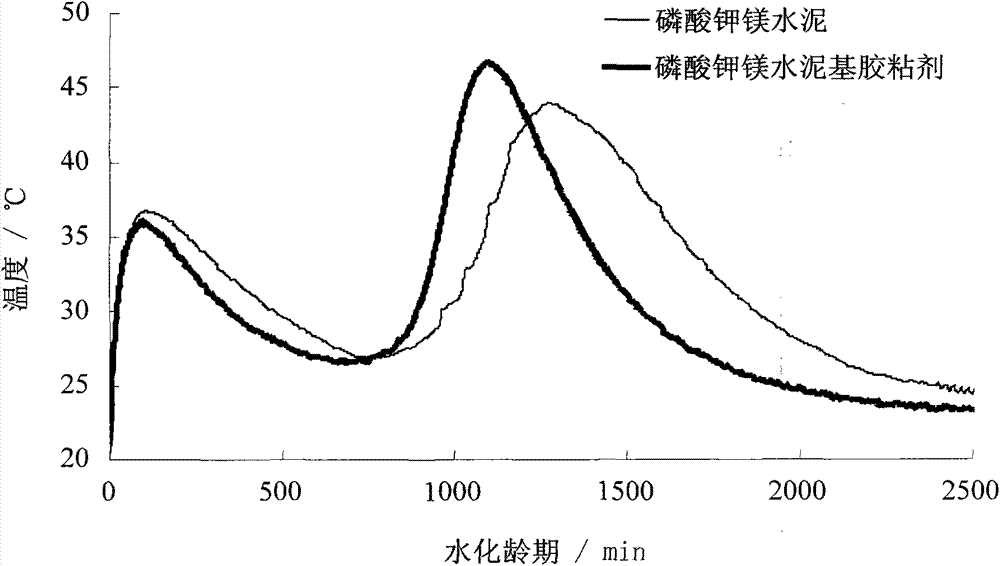

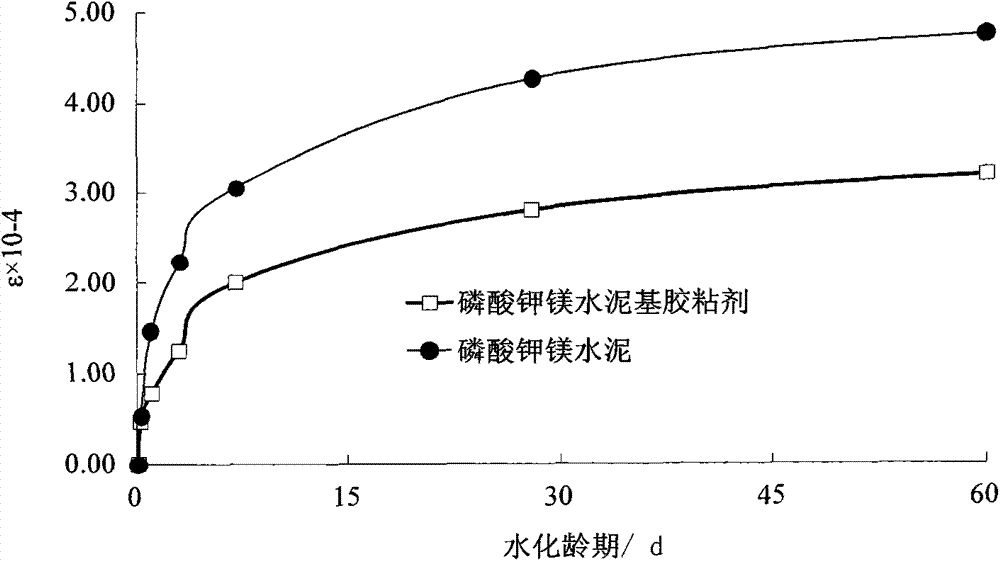

[0026]Get 67 mass parts of dead-burned magnesia powder and 33 mass parts of potassium dihydrogen phosphate, and add 10 mass parts of composite retarder (sodium tetraborate: disodium hydrogen phosphate dodecahydrate: inorganic chloride salt mass ratio=2 :6:3) Prepare potassium magnesium phosphate cement with setting time greater than 1 hour. Then take 11 parts by mass of limestone powder, 11 parts by mass of fly ash and 78 parts by mass of magnesium potassium phosphate cement, add 13 parts by mass of tap water, and use NJ-160A cement slurry mixer to stir at a slow speed for about 2 minutes to make the adhesive Stir the components evenly, then stir rapidly for 3-4 minutes to obtain a slurry of potassium magnesium phosphate cement-based concrete adhesive, and form a compressive strength test piece of 30mm×30mm×30mm, a shrinkage deformation test piece of 25mm×25mm×280mm and a 40mm×40mm ×160mm bonded flexural strength test piece (take a 40mm×40mm×160 ordinary Portland cement mortar...

Embodiment 2

[0032] Embodiment 2: get the dead-burned magnesium oxide powder of 70 mass parts and the potassium dihydrogen phosphate of 30 mass parts, the composite retarder (sodium tetraborate: sodium hydrogen phosphate dodecahydrate: inorganic chloride salt) of 9 mass parts =2:4:2) Prepare potassium magnesium phosphate cement with setting time greater than 1 hour. Then take 8 parts by mass of limestone powder, 8 parts by mass of fly ash and 84 parts by mass of magnesium potassium phosphate cement, add 12 parts by mass of tap water, and use NJ-160A cement slurry mixer to stir at a slow speed for about 2 minutes to make the adhesive Stir the components evenly, then stir rapidly for 3-4 minutes to obtain the potassium magnesium phosphate cement-based concrete adhesive slurry, and form a bonded flexural strength test piece of 40mm×40mm×160mm (take a hydration age of more than 28 days 40mm×40mm× 160 ordinary Portland cement mortar specimen, cut from the middle, treat the bonding surface with ...

Embodiment 3

[0036] Embodiment 3: get the dead-burned magnesium oxide powder of 70 mass parts and the potassium dihydrogen phosphate of 30 mass parts, the composite retarder (sodium tetraborate: sodium hydrogen phosphate dodecahydrate: inorganic chloride salt) of 9 mass parts =4:8:5) Prepare potassium magnesium phosphate cement with setting time greater than 1 hour. Then take 8 parts by mass of limestone powder, 8 parts by mass of fly ash and 84 parts by mass of magnesium potassium phosphate cement, add 12 parts by mass of tap water, and use NJ-160A cement slurry mixer to stir at a slow speed for about 2 minutes to make the adhesive Stir the components evenly, then stir quickly for 3-4 minutes to obtain the potassium magnesium phosphate cement-based concrete adhesive slurry, and form a 40mm×40mm×160mm bonded flexural strength test piece (take a hydration age greater than 28 days 40mm×40mm× 160 ordinary portland cement mortar specimen, cut from the middle, treat the roughness of the bonding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com