Patents

Literature

561 results about "Potassium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium phosphate is a generic term for the salts of potassium and phosphate ions including...

Organ preservative solution containing trehalose, anti-oxidant, cations and an energy source

InactiveUS6365338B1Maintain their viabilityImproved organ viabilityDead animal preservationChemistryAdenosine

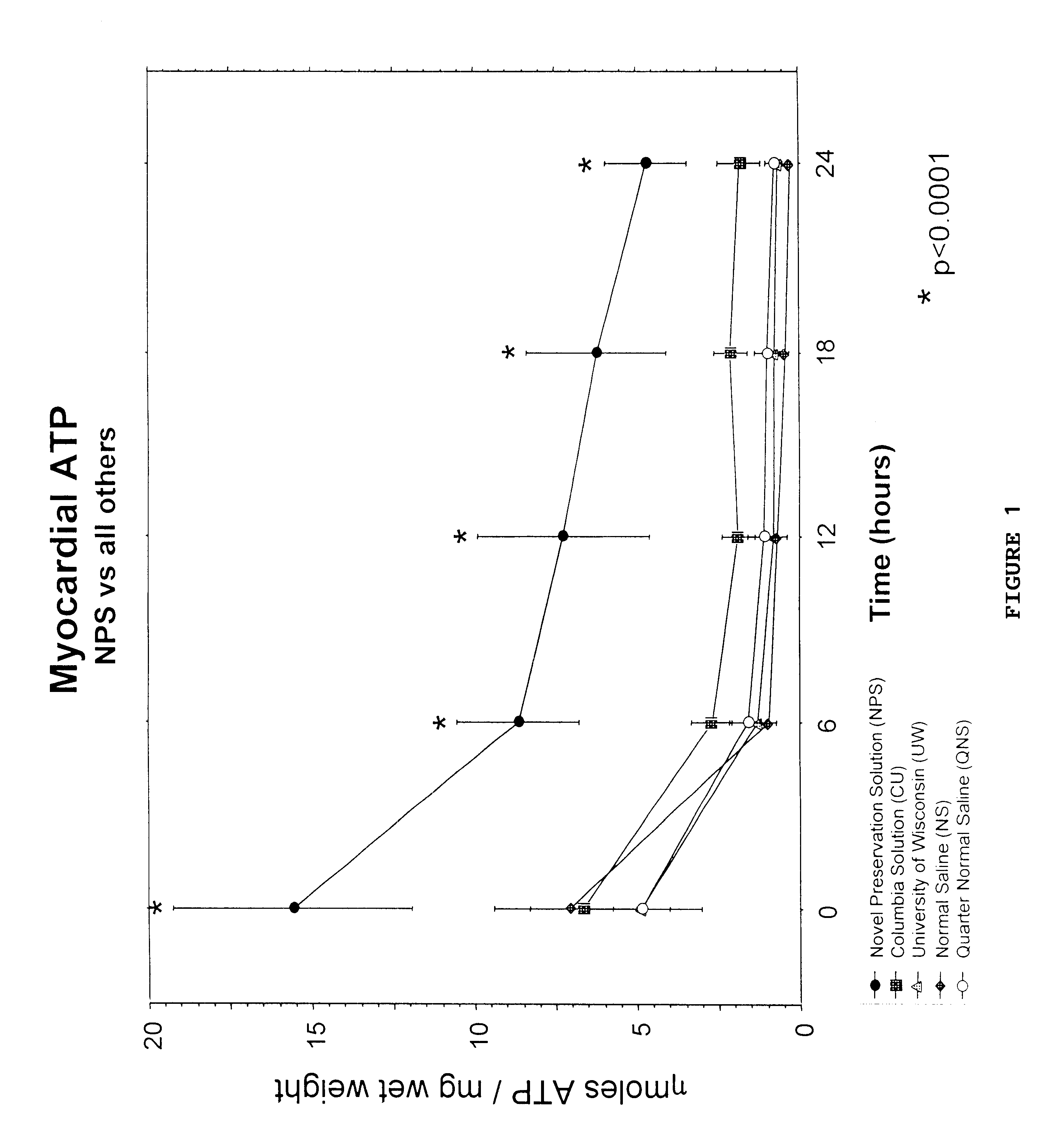

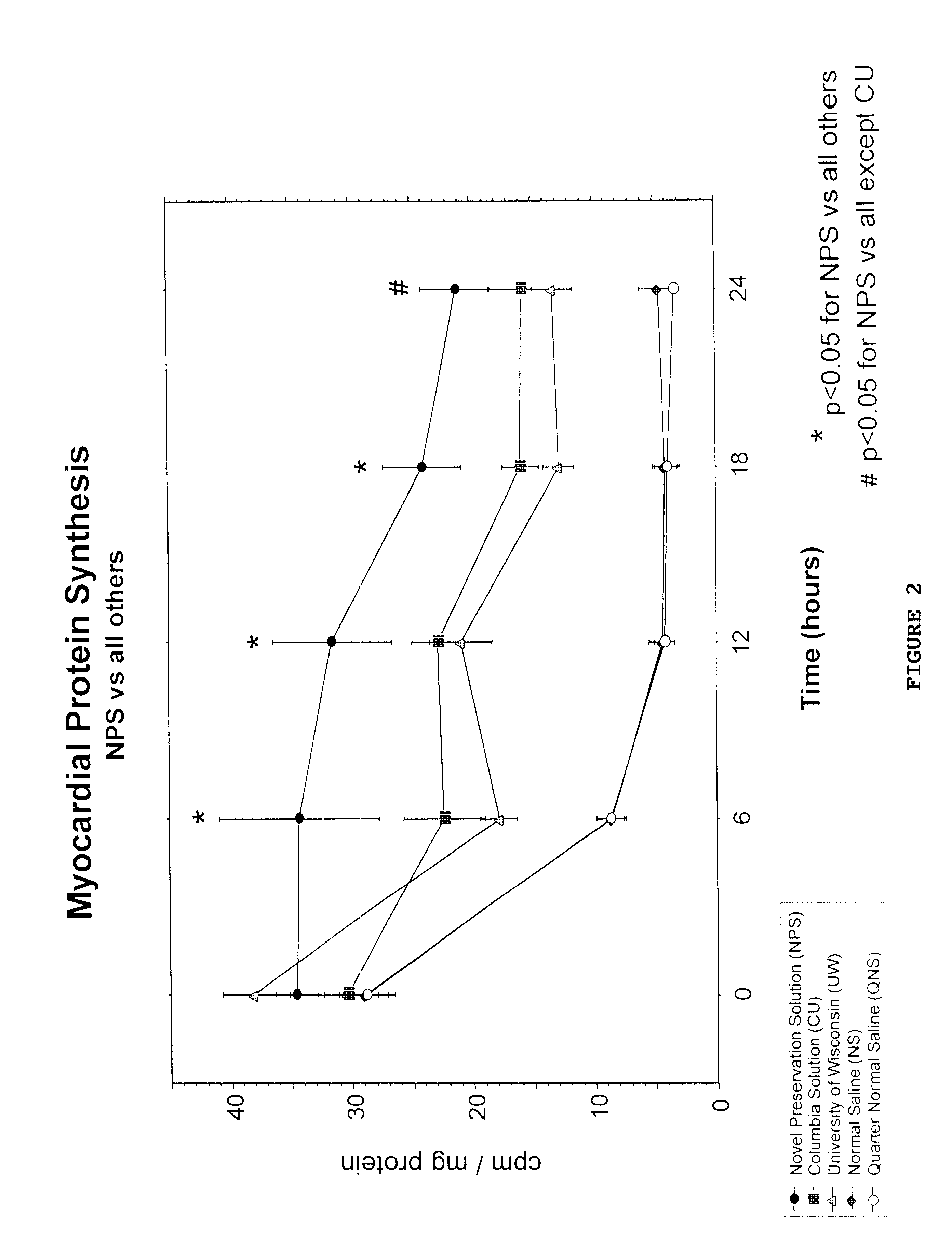

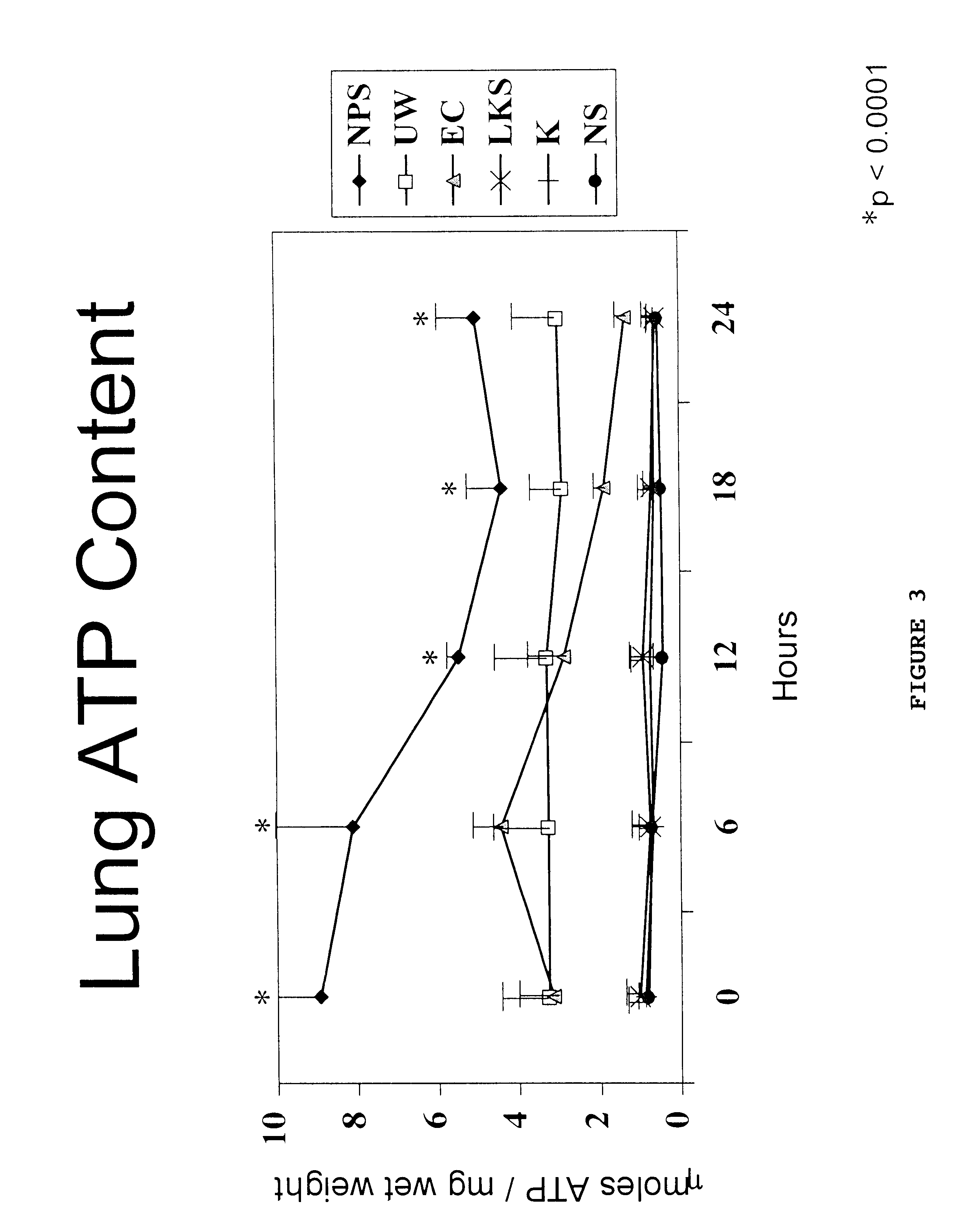

The present invention is organ and tissue preservation solutions that provide improved viability of an organ such as a heart or lung, or portion of the organ, for storage and transplantation. In particular, a solution contains trehalose, magnesium sulfate, calcium chloride, heparin, dextran, nitroglycerin, adenosine, L-arginine, allopurinol, reduced glutathione, db-cylic AMP and potassium phosphate.

Owner:BULL DAVID A +3

Liquid fertilizer with pyroligneous liquor and oxalacetic liquor and production thereof

InactiveCN1778773AMagnesium fertilisersFertilisers by pryogenic processesRare-earth elementPlant regulators

A liquid fertilizer containing wood vinegar liquid or oxalic vinegar liquid and its production are disclosed. The liquid fertilizer consists of urea 1í½20.0%, potassium phosphate 1í½20.0%, potassium nitrate 1í½20.0%, lime nitrate 0.1í½10.0%, magnesium sulfate 0.1í½5.0%, ferrous sulfate 0.1í½5.0%, manganous sulfate 0.1í½5.0%, zinc sulfate 0.1í½5.0%, cupric sulfate 0.1í½5.0%, boron sand or boric acid 0.1í½2.0%, sodium molybdate or ammonium molybdate 0.1í½1.0%, plant hormone or plant regulator, rare earth element or humus acid or pesticide auxiliaries etc. The process is carried out by proportioning and mixing. It can improve bacterium inhibiting and plant growth regulating functions.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Organic selenium biologics and its preparation method, and method for producing selenium-rich vegetable using the same

InactiveCN1594234AIncrease multipleBio-organic fraction processingOrganic fertilisersSodium bicarbonateManganese

The invention discloses an organic selenium biologics and its preparation method, and method for producing selenium-rich vegetable using the same, wherein the preparation is prepared from water and the following components (by weight percentage) through mixing and fermentation, selenium dioxide : sodium hydrogen carbonate : methionine : brown sugar : carbamide : monobasic potassium phosphate : magnesium sulfate : manganese sulfate : calcium chloride = 35-45 : 35-45 : 10-20 : 45-55 : 1-10 : 1-10 : 1-4 : 1-4 : 1-10, the method of application comprises, diluting the organic selenium biologics to 50-200 times by charging water, spraying diluted organic selenium biologics liquid onto the vegetable leaves, stems or roots. The vegetable exerted by the organic selenium biologics contains rich selenium.

Owner:吴敦虎 +2

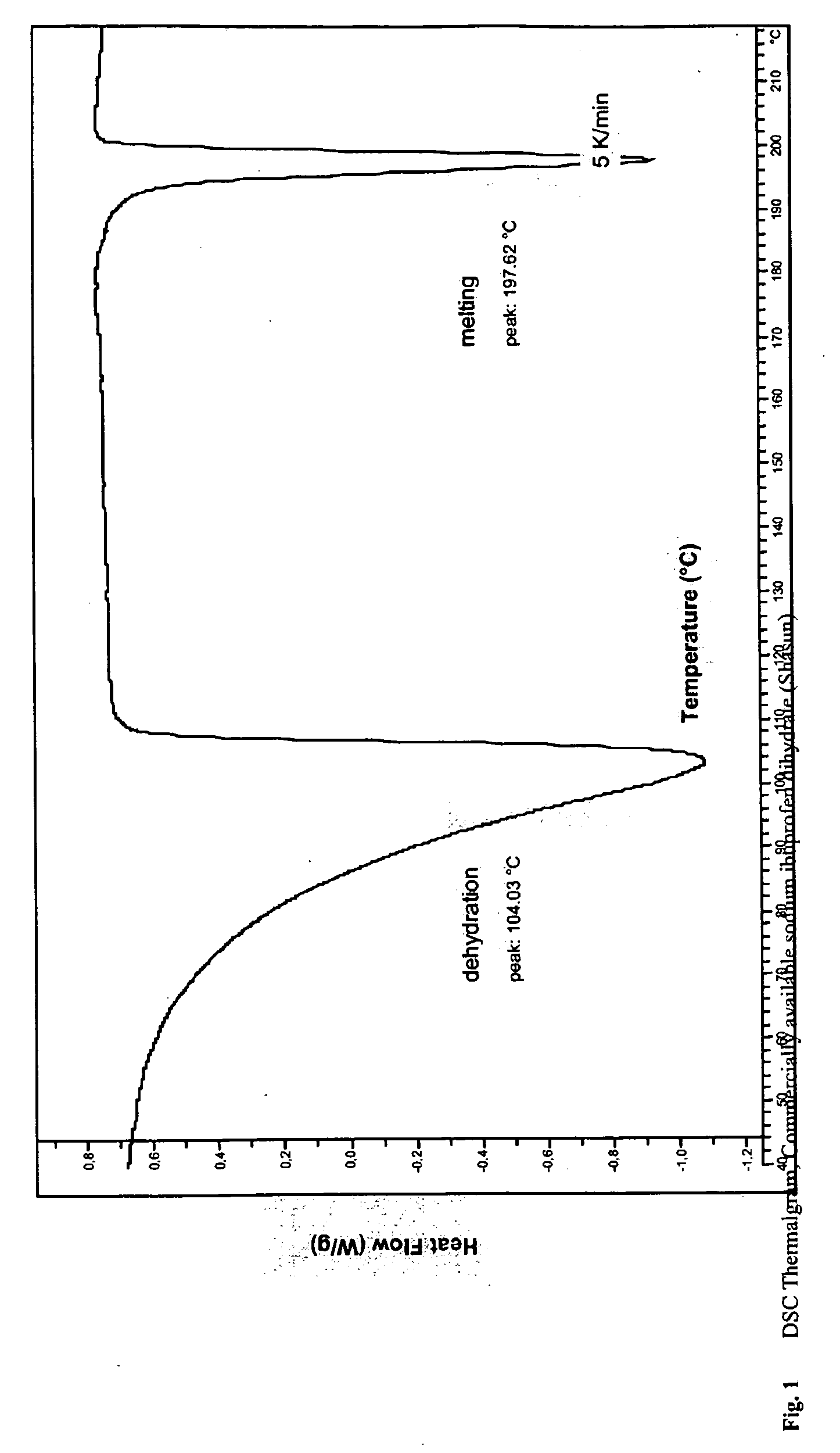

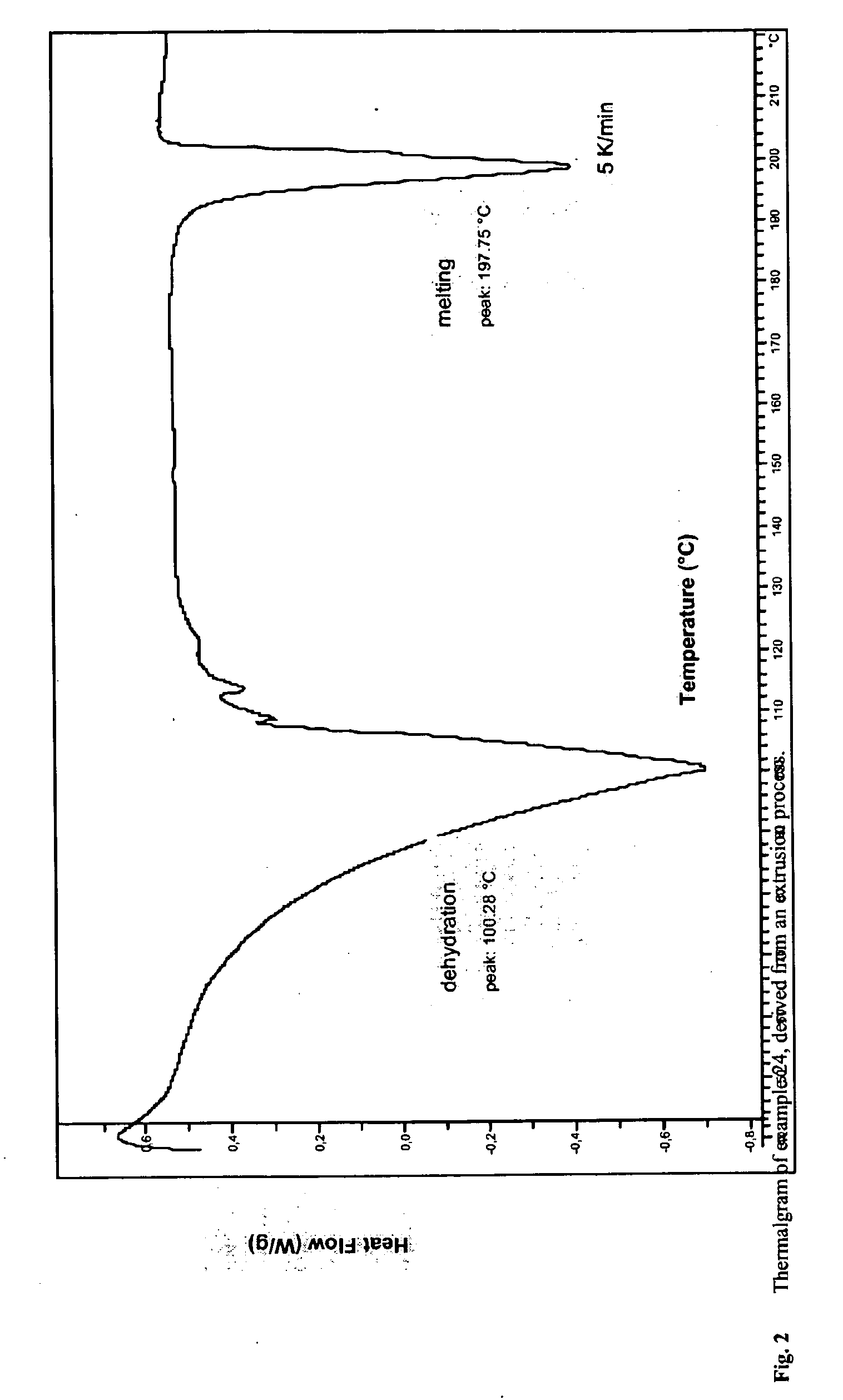

Solubilized ibuprofen

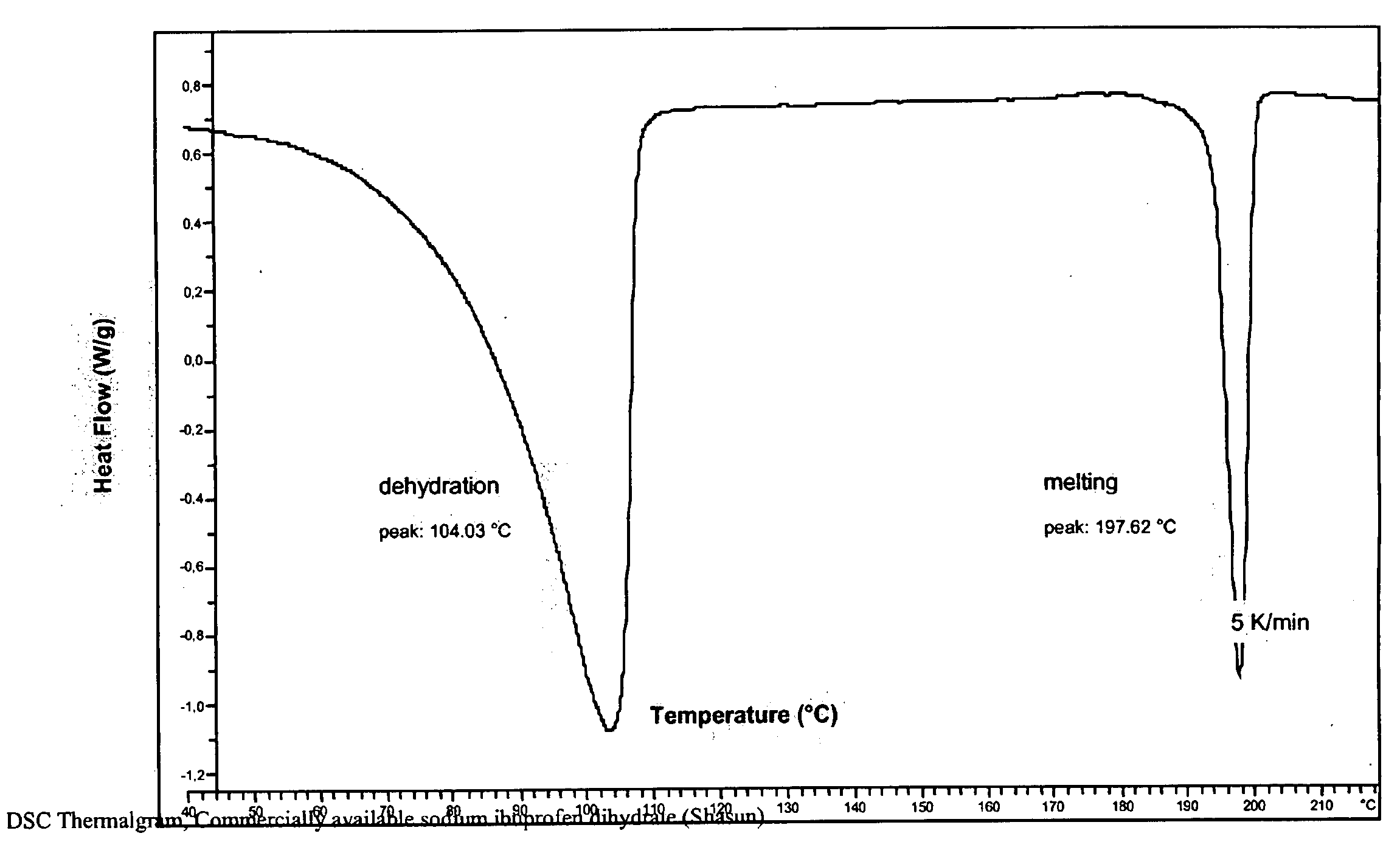

ActiveUS20090175940A1Easy to produceIncreased blood levelsBiocideOrganic compound preparationSolubilityPotassium hydroxide

A process for producing a solubilized ibuprofen, preferably in the form of a granulate, the process comprising the steps of: providing a mixture comprising solid ibuprofen and a first base selected from the group consisting of sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium glycinate, potassium glycinate and tribasic sodium and potassium phosphates and mixtures thereof, and reacting the ibuprofen and the first base in essentially dry state. The obtainable granulate and the pharmaceutical compositions and dosage forms that may be produced therefrom are distinguished by their high solubility and rapid disintegration and dissolution in aqueous media, by their good flow properties and compressibility, by rapidly achieving onset of analgesic effect.

Owner:LOSAN PHARMA GMBH

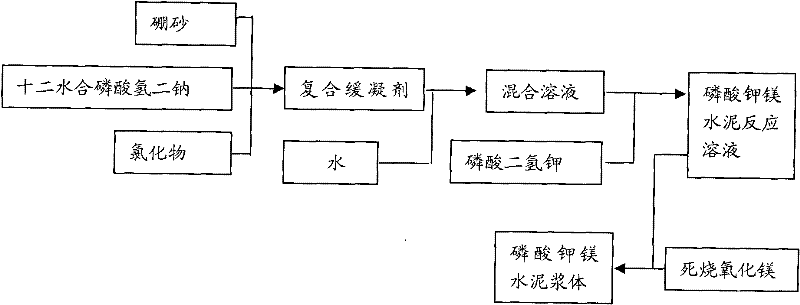

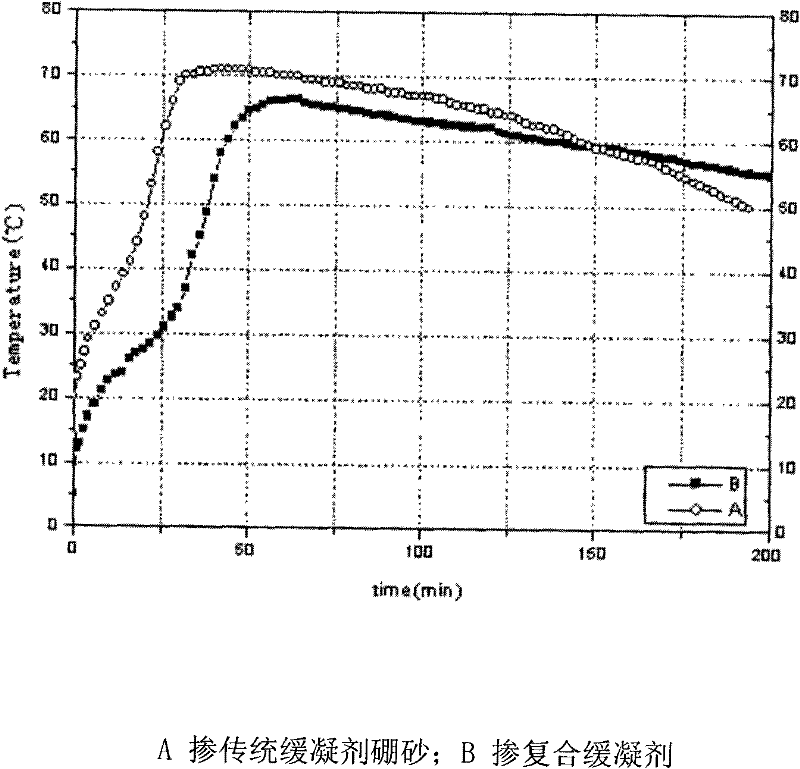

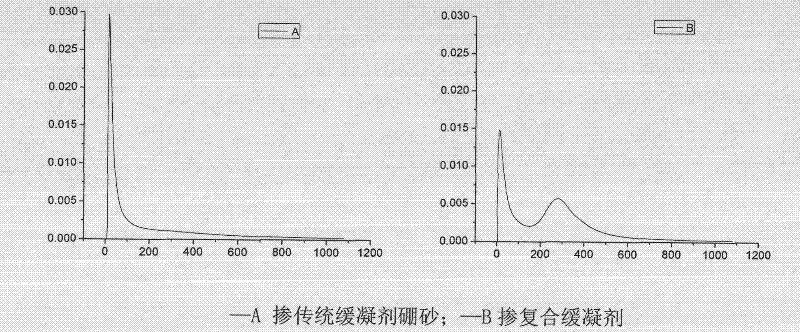

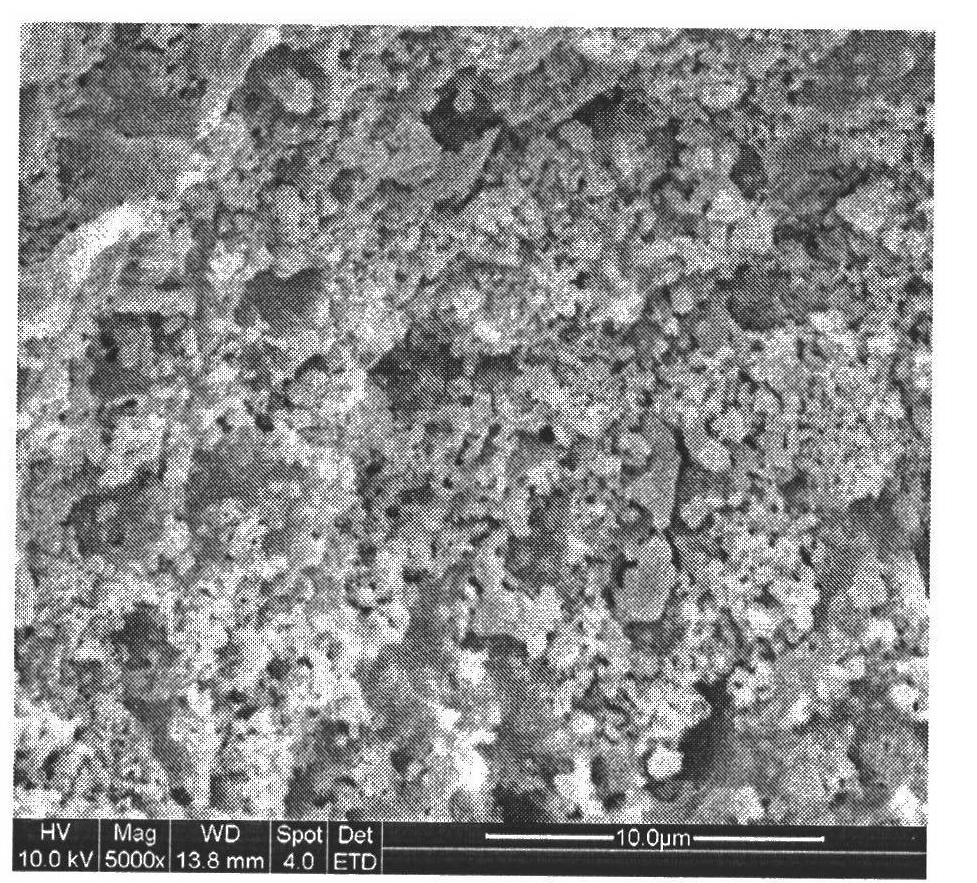

Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

InactiveCN102234200AEffective adjustment of clotting timeEffective control of clotting timeControl setOperability

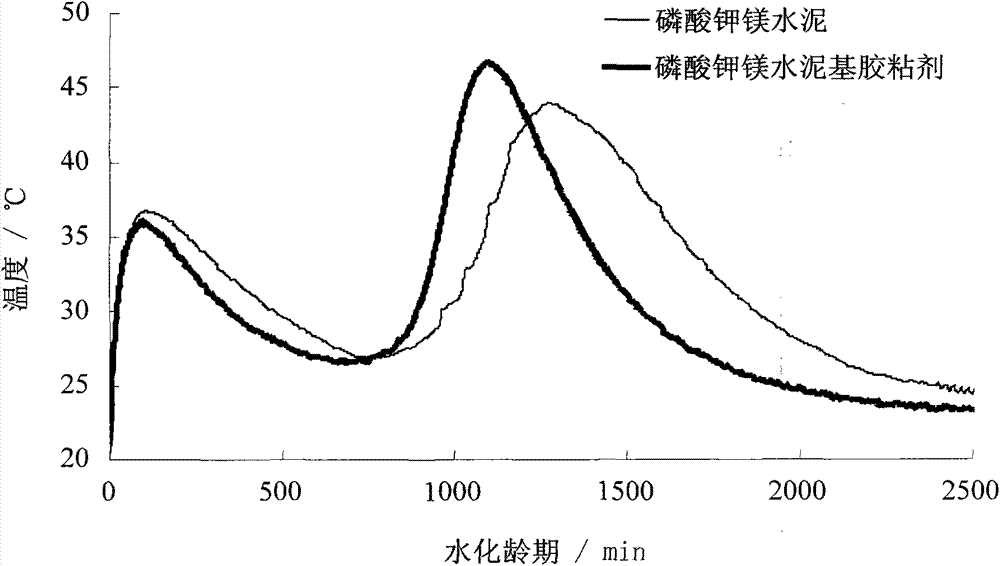

The invention relates to a method for controlling the setting time and early hydration speed of magnesium potassium phosphate cement, and belongs to an early strength quick hardening cement cementing material. A composite retarder can effectively adjust the setting time of magnesium potassium phosphate cement slurry, and the setting time of the magnesium potassium phosphate cement slurry can be effectively controlled in the range of 10 minutes to 6 hours by adjusting the content of chloride and disodium hydrogen phosphate dodecahydrate in the composite retarder, so that the problems of a limited retarding effect, low operability and the like are solved; the composite retarder can change the hydration heat release characteristic of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement slurry doped with the conventional retarder borax has a hydration heat release peak at the initial reaction stage and has a high heat release speed and large heat release amount, and the magnesium potassium phosphate cement doped with the composite retarder has two hydration heat release peaks and has small hydration heat release amount at the initial hydration stage; and the doped composite retarder improves the microstructure and later strength of a hardened magnesium potassium phosphate cement body, so that enough construction operable time can be ensured while the magnesium potassium phosphate cement slurry has early strength and is quickly hardened.

Owner:苏州诚开新材料有限公司

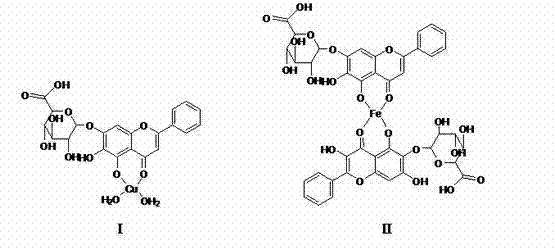

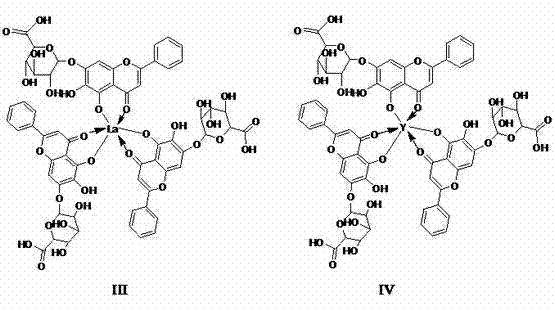

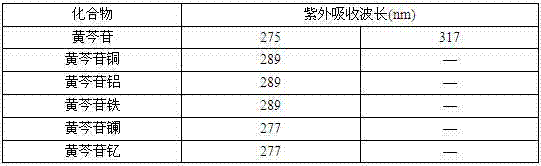

Baicalin metal complex and preparation method and application thereof

InactiveCN102516341AReduce pollutionAvoid it happening againAntibacterial agentsGroup 1/11 organic compounds without C-metal linkagesDipotassium hydrogen phosphateSodium acetate

The invention discloses a baicalin metal complex of which the molecular formula is (C21H17O11) xM (H2O) y, wherein M in the formula is Cu (II), x is 1 and y is 2; or M is Fe (III), x is 2 and y is 0; or M is La (III) or Y (III), x is 3 and y is 0. The preparation method comprises the following steps: adding aqueous alkali into baicalin until the baicalin and alkali (sodium bicarbonate, potassium bicarbonate, sodium formate, potassium formate, sodium acetate, potassium acetate, disodium hydrogen phosphate, dipotassium hydrogen phosphate, sodium phosphate or potassium phosphate) are just completely reacted, then adding metal salt (copper salt, ferric salt, lanthanum salt or yttrium salt) for reaction to obtain the baicalin metal complex. The baicalin metal complex has obviously stronger antibacterial and antitumor activities than the baicalin, can be used for preparing antibacterial drugs and antitumor drugs, and has good development and application prospects. In the preparation method, an organic solvent is not used, a strong basic condition is not adopted, and the method is simple and feasible, is green and environment-friendly and has the advantages of low cost, high product purity and high yield.

Owner:SOUTHWEST UNIVERSITY

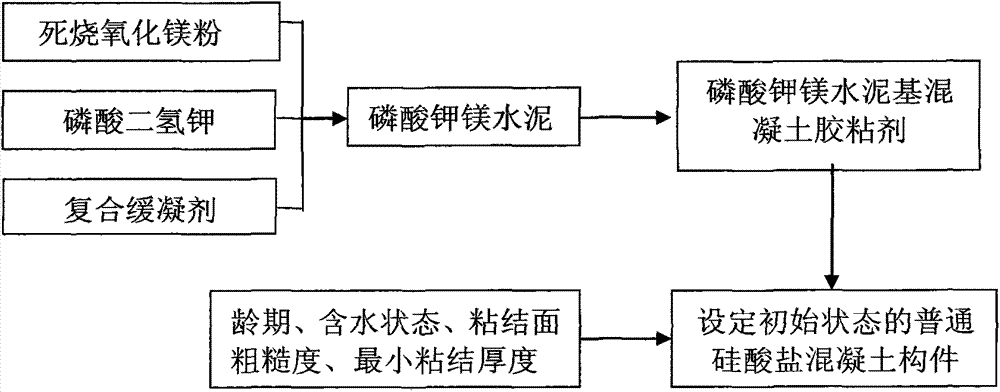

Magnesium potassium phosphate cement-based concrete adhesive and preparation method thereof

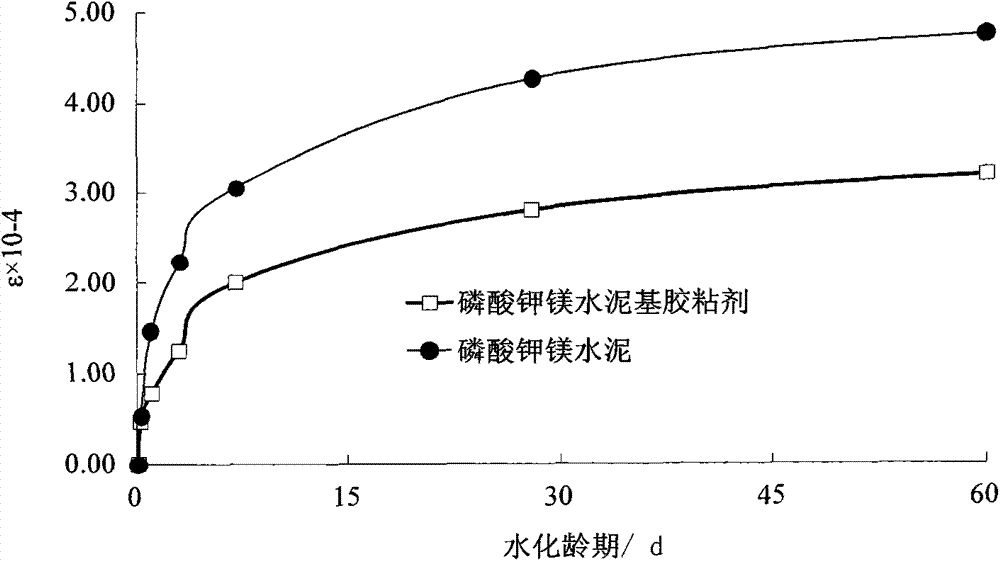

The invention discloses a magnesium potassium phosphate cement-based concrete adhesive and a preparation method thereof. The preparation method of the magnesium potassium phosphate cement-based concrete adhesive comprises the following steps: firstly, taking 50-70 parts by mass of dead-burned magnesia powder as an alkali component and 30-50 parts by mass of monopotassium phosphate as an acid component, and doping 6-10 parts by mass of complex retarder to prepare magnesium potassium phosphate cement, wherein the complex retarder is composed of sodium tetraborate, sodium phosphate dibasic dodecahydrate and inorganic chlorine salt in mass ratio of (2-4):(4-8):(2-5); secondly, preparing the magnesium potassium phosphate cement-based concrete adhesive by taking 5-15 parts by mass of limestone powder, 10-20 parts by mass of coal ash and 70-85 parts by mass of magnesium potassium phosphate cement. The complex retarder effectively delay condensation time of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement guarantees higher early strength, and the coal ash and limestone powder guarantee stable growth of strength and improve volume stability.

Owner:YANCHENG INST OF TECH +1

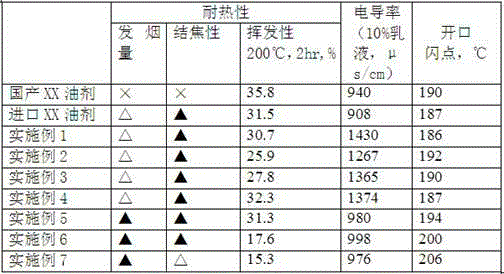

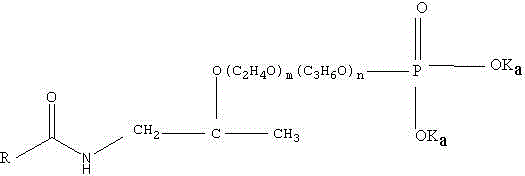

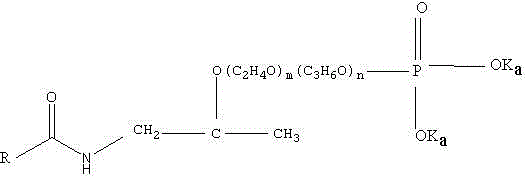

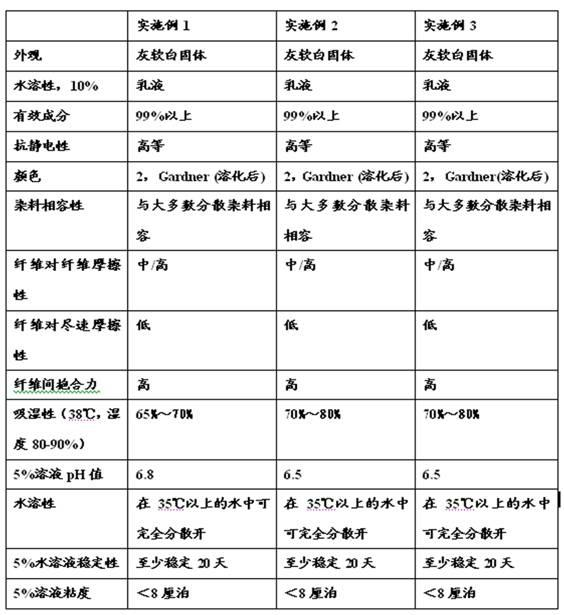

Novel civil oiling agent composition for FDY polyester filament yarn and preparation method for novel civil oiling agent composition for FDY polyester filament yarn

The invention relates to a novel civil oiling agent composition for a FDY polyester filament yarn and a preparation method for the novel civil oiling agent composition for the FDY polyester filament yarn. The novel civil oiling agent composition is prepared from the following components in percentage by weight: 2-15% of an antistatic agent composition, 2-15% of a tow collecting agent, 30-80% of a lubricating agent, 15-30% of an emulsifier and 1-5% of a regulating stabilizer, wherein the antistatic agent composition consists of a component A and a component B, the component A is fatty acid monoisopropanolamine polyoxyethylene polyoxypropylene ether potassium phosphate which accounts for 3-7% (in percentage by weight) of the oiling agent composition, and the component B is an anionic surfactant or an ampholytic surfactant. The novel civil oiling agent composition disclosed by the invention is good in antistatic performance in a spinning process, uniform in oiling, excellent in spinning property, good in heat resistance, low in tarring degree, less in residues on a stick, and low in oiling rate; moreover, the performances of the spinning tows are good.

Owner:ZHEJIANG HUANGMA TECH

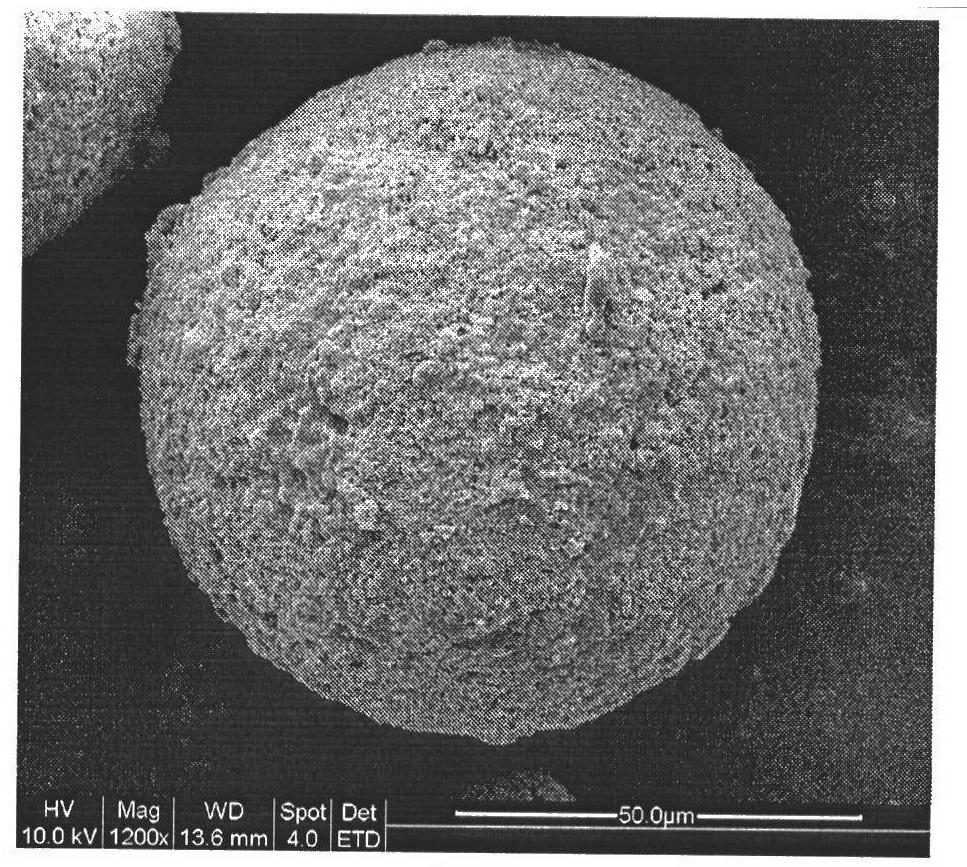

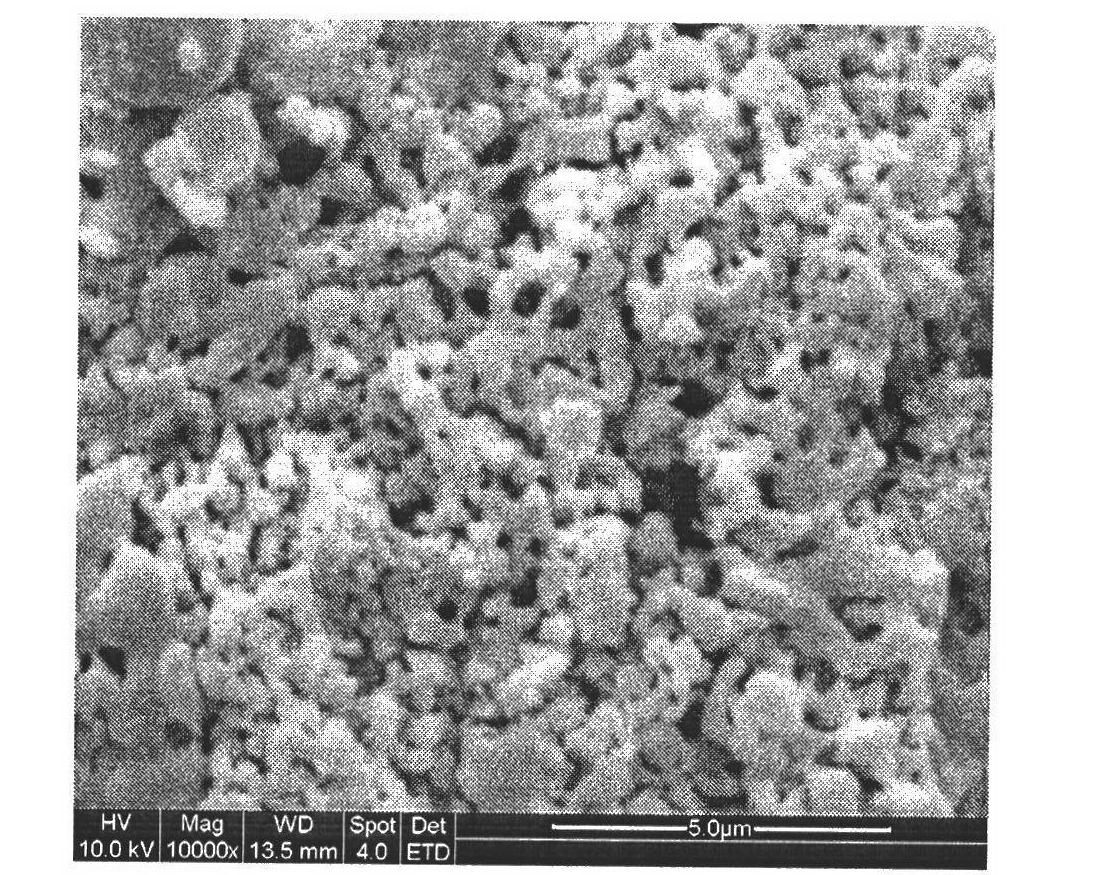

Hole channel amplification method of porous ceramic microballoon sphere

ActiveCN102557714ALarge apertureImprove mass transfer efficiencyCeramicwareChromatographic separationSodium phosphates

The invention discloses a hole channel amplification method of a porous ceramic microballoon sphere for liquid chromatography, which enables silica, zirconium dioxide or titanium dioxide powder to serve as ceramic framework materials, enables nanometer powdered carbon, ammonium chloride, polyving akohol, urea, polyethylene glycol, sodium chloride, sodium sulfate, sodium phosphate, potassium phosphate, potassium chloride, potassium sulfate and the like to serve as porogen, and prepares macropore ceramic microballoon spheres through reversed phase suspension and high temperature sintering. The specific steps are as following: (1) preparing ceramic slurry, enabling the ceramic framework materials, the porogen and sodium alginate solution to be mixed; (2) preparing the porous ceramic microballoon sphere, enabling the ceramic slurry to be conducted reversed phase suspension and dispersion in an oil phase, adding saturation calcium chloride solution in a dropping mode, solidifying to from the sphere, and molding by high temperature sintering; and (3) removing residual porogen, enabling the ceramic microballoon sphere to be soaked in water, hydrochloric acid or sodium hydroxide solution, shaking to dissolve the residual porogen. The microballoon sphere developed by the method has the advantages of having rigidity, and being big in hole diameter and good in spherical degree, and the microballoon sphere can be used for substrates of large biological molecule chromatographic separation media.

Owner:嘉兴千纯生物科技有限公司

Nylon oiling agent

The invention discloses a nylon oiling agent, which is composed of mineral oil, hexadecyl potassium phosphate, dodecyl phosphate diethanol ammonium salt, castor oil polyoxyethylene (40) ester and sorbitan stearate. The nylon oiling agent has the advantages of reasonable formula, good use effect and low production cost.

Owner:张兴良

Ammonium potassium phosphate composite water-soluble fertilizer

The invention discloses an ammonium potassium phosphate composite water-soluble fertilizer which is prepared from the following components in parts by weight: 5-30 parts of nitrogen source, 10-20 parts of phosphorus source, 10-50 parts of potassium source and 4-20 parts of microelement mixture. The microelement mixture comprises nutrients of a sulfur source, a boron source, a zinc source and an iron source. The prepared fertilizer has the advantages of favorable solubility, high solution rate and no impurity, and is suitable for various trickle irrigation plants. According to the invention, the fertilizer can be properly and directly applied to the root system centralized layer in proper time, and is applied slightly and frequently, so that the fertilizer application is regular and positioned; and thus, the fertilizer can be conveniently absorbed by crops, thereby reducing the crop loss, fully displaying the fertilizer efficiency, improving the soil and obviously increasing the yield.

Owner:新疆阳光天雨生物科技有限公司

Oil agent for chopped polyester fiber

The invention relates to an oil agent for chopped polyester fiber. The oil agent is prepared by mixing the following components in percentage by weight: 25-35% of isooctyl stearate, 5-15% of sodium diethyl ethanol sulfonate succinate, 3-5% of sorbitan oleate, 15-25% of dodecyl polyoxyethylene ether (5), 8-12% of dodecyl polyoxyethylene ether (10), 8-12% of potassium POE (polyoxyethylene) alkyl phosphate, 3-5% of softener A, 3-5% of fatty alcohol ethylene oxide and 1-8% of regulator. The oil agent provided by the invention has the advantages of excellent emulsion stability, antistatic property and smoothness as well as high oil film strength, and is suitable for production of chopped polyester fiber or chopped cotton polyester fiber which has high total tow denier number and can be spun at high speed. In addition, because the oil agent has low production cost and very large use amount, the economic benefit is obvious.

Owner:SUZHOU SHENGDEZHU TECH DEV +1

Cold-resistant cypress breeding method

InactiveCN1806513ASolve the problem of asexual reproductionSimple methodSeed and root treatmentForestryRoot growthPlastic mulch

The invention relates to a method for breeding cold resistant draping thread cedar, which can meet demand of sight plant in cold area of minus 18 Deg. C, comprising following steps: immersing seed which stored at temperature under 0 Deg. C for at least 10 months, then sowing, covering with film, spraying mono-basic potassium phosphate mixture when autumn tip is over 10 cm after seedling growing out to promote branch mature, then cutting, treating seed bed firstly, cutting draping thread cedar branch secondly, immersing in mixture of root-growth and sterilizing, furrow cutting or ridge cutting, covering with film and shading to maintain proper soil humidity and air humidity until seedling grows out, then replanting for growth. The invention is characterized by simple method, good breeding effect and high breeding rate, which solves problem of asexual propagation for draping thread cedar and develops a bright future for sight-seeing plant application.

Owner:王录顺

Cesium-rubidium-potassium monolithic flameproof glass and preparation method

The invention discloses cesium-rubidium-potassium monolithic flameproof glass and a preparation method. The preparation method comprises a process of carrying out chemical strengthening on glass, wherein chemical strengthening is carried out by placing the glass in molten salts and carrying out ion exchange by a two-step method; in the first step, the molten salt is a mixture of potassium nitrate, rubidium nitrate, potassium fluoride and potassium hydroxide, the exchange temperature is 320-360 DEG C and the heat-insulation time is 2 hours; and in the second step, the molten salt is a mixture of potassium nitrate, cesium nitrate, aluminum oxide, boron fluoride, potassium carbonate and potassium phosphate, the exchange temperature is 500 DEG C and the heat-insulation time is 3 hours. The monolithic flameproof glass product prepared by the method is stable in quality and excellent in fire resistance; in the fire resistance test, the invalidation of the monolithic flameproof glass is caused by final softening and collapsing instead of heat bursting destruction; and the fire resistance time is 120 minutes.

Owner:SHENYANG JIANZHU UNIVERSITY

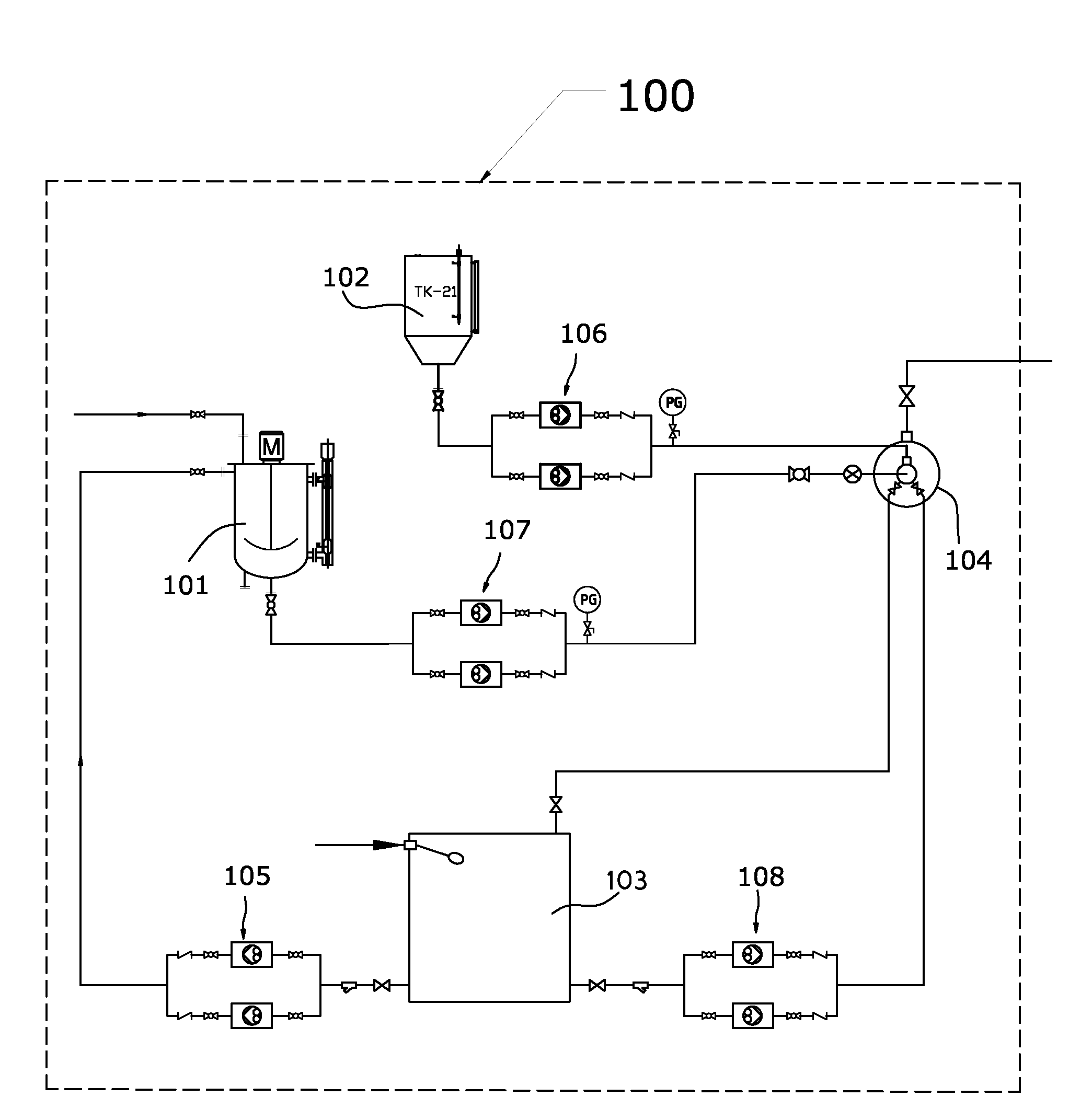

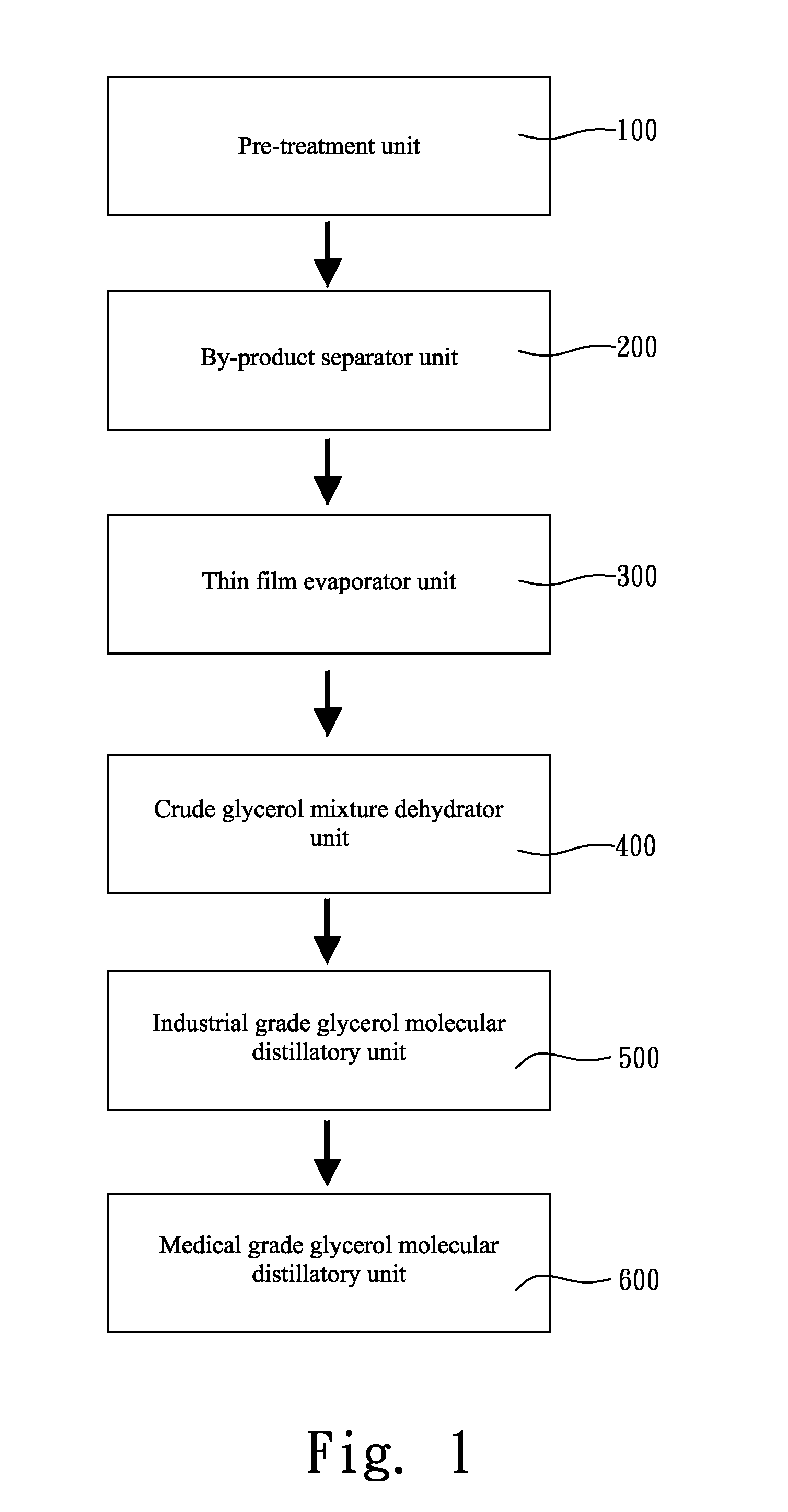

Glycerol (Medical Grade) Preparation Method using a By-Product of a Bio-Diesel Process

A glycerol preparation method for preparation of medical grade glycerol from a by-product of a bio-diesel process by means of thin film evaporation and molecular distillation include a first stage phosphoric acid chemical reaction process and a posterior by-product centrifugal separation process to have the phosphoric acid chemical reaction by-product be separated into free fatty acid, potassium phosphoric acid, and a crude glycerol and methanol mixture. The crude glycerol and methanol mixture is further processed through a first step of thin film evaporation process where methanol is reclaimed, a second step of thin film evaporation process where the mixture is dehydrated, a third step of molecular distillation process where an industrial grade glycerol of purity over 95% is extracted, and a fourth step of molecular distillation process where a medical grade glycerol of purity in exceed of 99.75% that meets USP / BP standards is extracted.

Owner:CHANG WEI MING

Cigarette paper additive, preparation method and application thereof

InactiveCN101775759AImprove suction qualityEffective pH adjustmentSurface covering paperNon-fibrous pulp additionPotassiumTar

The invention discloses a cigarette paper additive, a preparation method and application thereof. The cigarette paper additive of the invention comprises the following ingredients in mass percent: 40 to 50 percent of potassium phosphate, 20 to 30 percent of potassium citrate, 20 percent of apple potassium, 10 percent of glucose and citric acid solution, wherein the citric acid solution is used for regulating the pH value of the accessory agent solution to the required range. The invention belongs to the improvement of the existing cigarette paper. When the cigarette paper adopting the cigarette paper additive of the invention is made into cigarette finished products, the pH value of the mainstream smoke can be regulated to a certain degree, the smoking quality of the cigarette can be effectively improved, and at the same time, the contents of the tar and the carbon monoxide in the mainstream smoke can be effectively reduced.

Owner:CHINA TOBACCO GUANGDONG IND

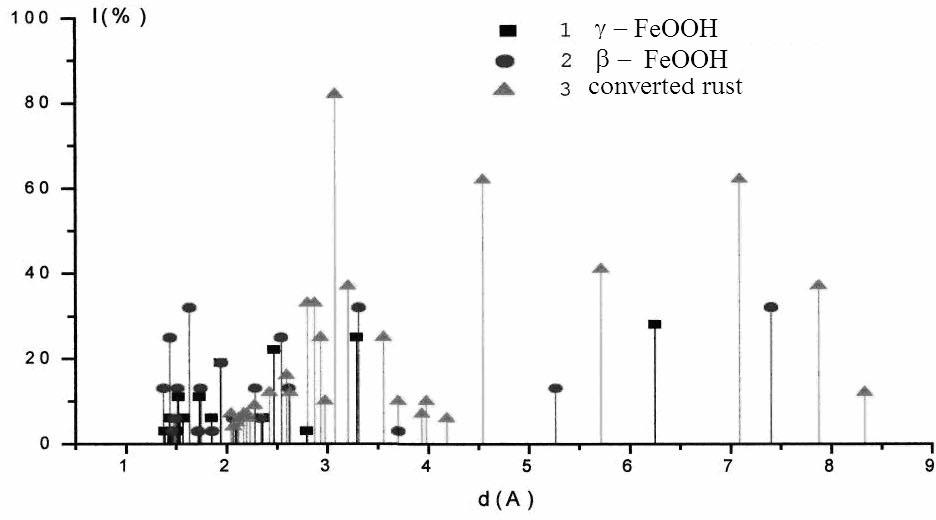

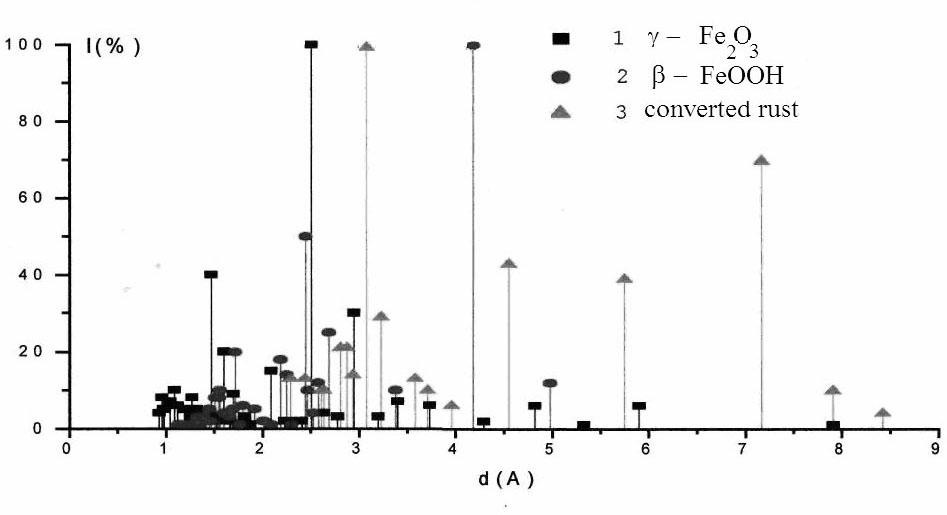

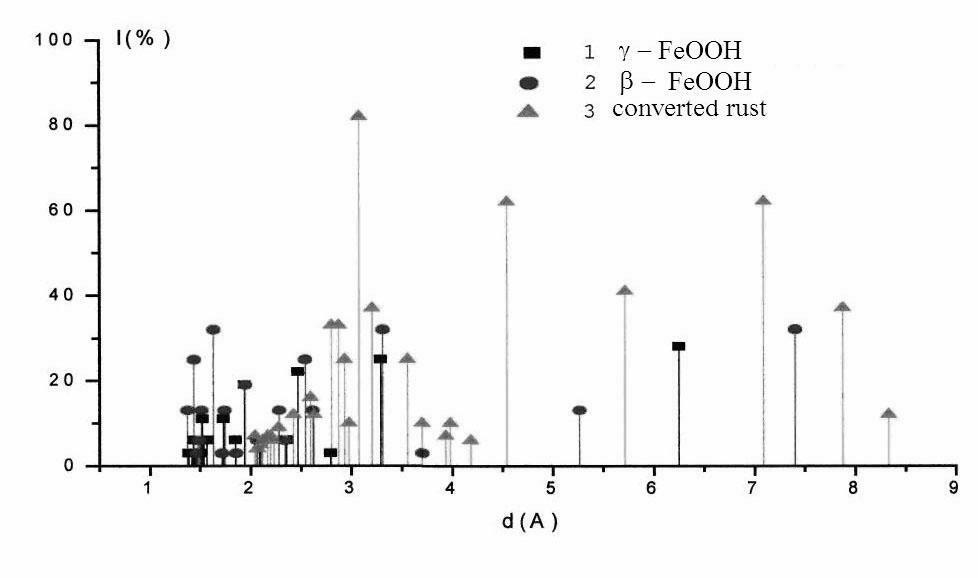

High-efficiency iron rust conversion agent

InactiveCN102618860AHas anti-rustAvoid Galvanic CorrosionMetallic material coating processesHexamethylenetetramineSodium phosphates

The utility model relates to a high-efficiency iron rust conversion agent, and belongs to the field of an antirust paint. The iron rust conversion agent comprises the following raw materials by weight: 0.1-10% of zinc oxide, 20-40% of phosphoric acid, 0.5-15% of dichromate, 0.5-10% of phosphate, 0.1-10% of corrosion inhibitor, and 50-70% of solvent, wherein the dichromate is potassium dichromate or sodium dichromate; the phosphate is sodium phosphate or potassium phosphate; the corrosion inhibitor is urotropine or urea; and the solvent is water or ethanol. The preparation method comprises the steps as follows: sequentially adding the solvent, the phosphoric acid, the dichromate, the phosphate, the corrosion inhibitor and the zinc oxide to a glass cup under persistently stirring according to the mass ratio, and dissolving for 10-20 min. The production method bases on the dissolving of the solid reactants in the phosphoric acid solution. The phosphorized film formed by iron rust conversion has the effects of preventing rust and fixing remnant rust, and the formed phosphorized layer protective film is long-acting, and stable in atmospheric environment, lubricating oil and organic solvent, has high adhesion, can be used as a primer, has dielectric properties, and can prevent electro-chemical corrosion on the metal surface.

Owner:ZHEJIANG OCEAN UNIV

Soil-improving continuous-cropping-resistant compound fertilizer for vegetables and preparation method thereof

InactiveCN106380335AMaintain fertilityImprove fertilityCalcareous fertilisersAlkali orthophosphate fertiliserContinuous croppingPolyvinyl alcohol

The invention discloses a soil-improving continuous-cropping-resistant compound fertilizer for vegetables. Raw materials of the compound fertilizer comprise, by weight, 10-15 parts of urea, 10-12 parts of ammonium nitrate, 15-20 parts of potassium phosphate, 10-15 parts of calcium magnesium phosphate fertilizer, 3-5 parts of potassium sulfate, 1-3 parts of calcium chloride, 2-4 parts of carbonized rice husk, 3-5 parts of peat, 1-3 parts of attapulgite, 5-8 parts of guano, 15-20 parts of Chinese medicine residue, 10-15 parts of soybean meal, 10-20 parts of plant ash, 3-5 parts of EM bacterial powder and 8-10 parts of polyvinyl alcohol. The invention also discloses a preparation method of the above soil-improving continuous-cropping-resistant compound fertilizer for vegetables. The compound fertilizer has rich nutrients. through cooperation of organic fertilizer, carbonized rice husk, peat, attapulgite, EM bacterial powder and polyvinyl alcohol, the product helps improve soil, adjust soil pH and maintain soil fertility from three aspects of water retention, air permeability and fertilizer efficiency maintenance. With the cooperation of the Chinese medicine residue, the product helps inhibit and kill insect disease, promote healthy growth of vegetables and avoid continuous-cropping and insufficient nutrition of vegetables.

Owner:ANHUI SIERTE FERTILIZER IND

Etching solution for high-transmittance anti-dazzle glass, and preparation method thereof

The invention discloses an etching solution for high-transmittance anti-dazzle glass, and a preparation method thereof. Raw materials of the etching solution comprise hydrofluoric acid, ammonium fluoride, ammonium bifluoride, magnesium fluoride, aluminum fluoride, calcium fluoride, calcium hydrogen fluoride, potassium hydrogen fluoride, ammonium chloride, zinc chloride, sodium acetate, barium sulfate, sodium fluoroborate, ammonium fluoroborate, sodium phosphate, ammonium biphosphate, potassium phosphate, ethylene diamine tetraacetic acid, nitrilotriacetic acid, a viscosity regulator, a surfactant, a sulfuric acid solution and water. The preparation method of the etching solution for high-transmittance anti-dazzle glass has the advantages of mild process and mild conditions, and the etching solution for high-transmittance anti-dazzle glass, prepared through the method, has the advantages of good stability, high transmittance and atomization rate, and good anti-dazzle effect.

Owner:广东金品科技有限公司

Method for preparing cathode material of tin - copper - nickel alloy in use for batteries

InactiveCN101093884ALow costWide variety of sourcesAlkaline accumulator electrodesLithium electrodeCalcium edetate

The technical scheme includes electroplating and vacuuming steps. Constituents of bath are: disodium calcium edetate, potassium sodium tartrate, potassium pyroborate, nickel sulphate, sodium stannate, and distilled water. Under condition of current density 0.2-1.0A / dm2, copper film electrode covered by tin nickel alloy is prepared after 0.2 -60min electroplating procedures. Vacuuming step includes procedures: placing copper film electrode covered by tin nickel alloy to vacuum drying oven; in vacuum degree 760-380mm mercury column, at 100-180 deg.C, processing 1 - 5h, and preserving heat for 24h. After cooling, cathode material of tin - copper - nickel alloy is prepared. The material possesses excellent discharge performance, and charging and discharging cyclical stability, and high first discharge capacity reached to 600mAh / g active matter. The disclosed cathode material is applicable to lithium ion battery, lithium battery, especially film type battery etc.

Owner:FUJIAN NORMAL UNIV

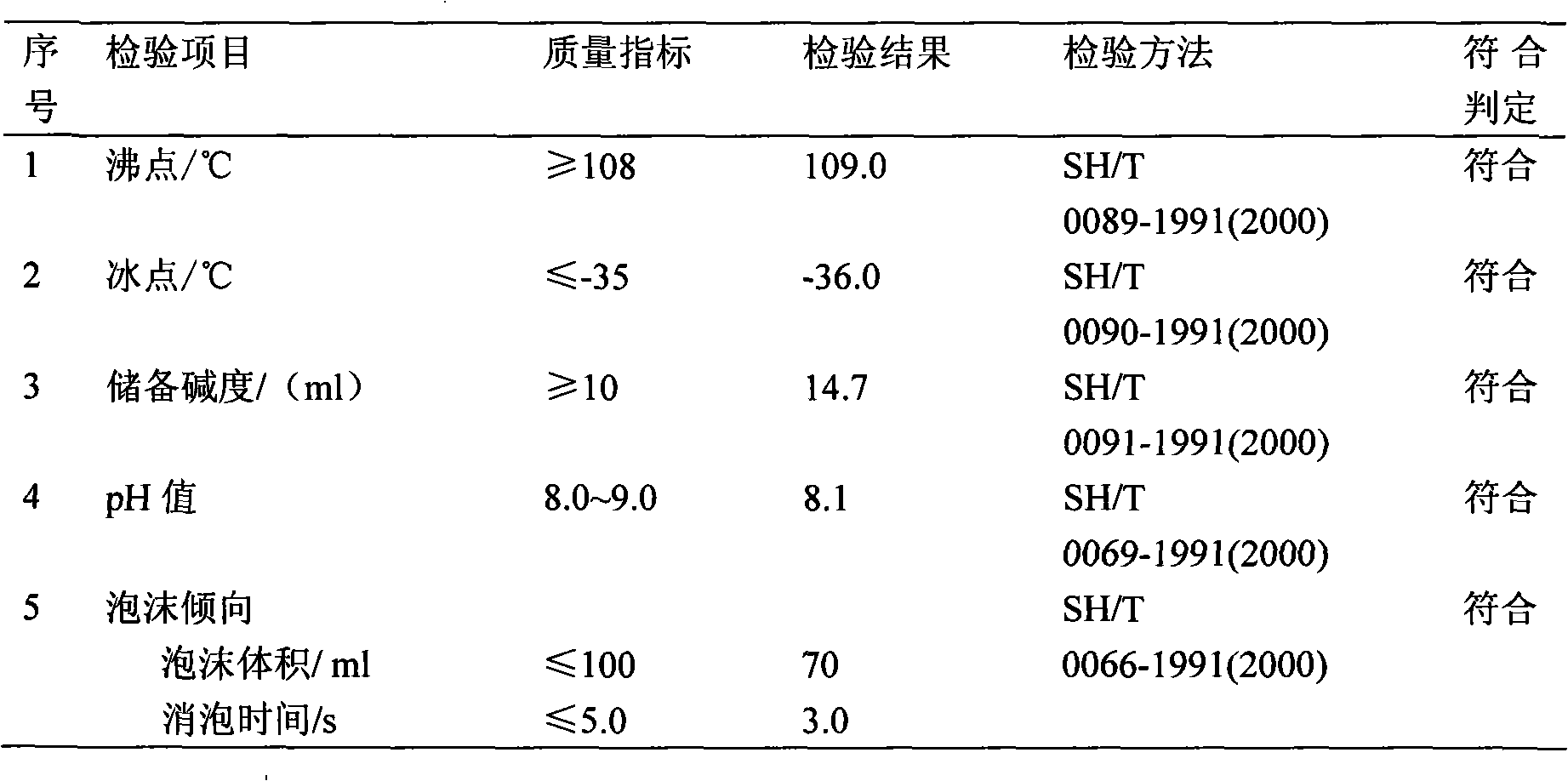

Low silicon content coolant liquid applicable to aluminum radiator of heavy-duty commercial vehicle engine

ActiveCN101602936AImprove heat transfer and cooling performanceMachines/enginesHeat-exchange elementsWater jacketAdipate

The invention relates to low silicon content coolant liquid applicable to an aluminum radiator of a heavy-duty commercial vehicle engine, and belongs to coolant liquid. The coolant liquid comprises the following raw materials in portion by weight: 36 to 52 portions of terylene grade glycol, 1.0 to 1.5 portions of mannite, 0.3 to 0.7 portion of phenylformic acid, 0.7 to 0.9 portion of adipate, 0.1 to 0.2 portion of methylbenzotriazole, 0.05 to 0.1 portion of p-nitrobenzoic acid, 0.001 to 0.004 portion of polyether, 0.3 to 0.7 portion of potassium phosphate, 0.2 to 0.25 portion of sodium nitrite, 0.25 to 0.3 portion of sodium nitrate, 0.5 to 1.0 portion of borax, 0.007 to 0.02 portion of sodium silicate, 0.45 to 0.68 portion of sodium hydroxide, and distilled water for fixing the volume to 100 portions. The coolant liquid contributes to improvement of heat exchange and cooling performance of a water jacket of the engine, is more adapted to an aluminum water tank radiator, is adapted to sedans and light vehicles, and is more adapted to heavy-duty commercial vehicles.

Owner:CHANGCHUN YONGCHANG PETROCHEM

Method for preparing culture medium of beech mushrooms and needle mushrooms by utilizing waste material of agaric culture medium

ActiveCN102633563AReduce pollutionAchieve recyclingHorticultureFertilizer mixturesBiotechnologyAgaric

The invention provides a method for preparing a culture medium of beech mushrooms and needle mushrooms by utilizing a waste material of an agaric culture medium. The method comprises the following steps: (1) collecting and materializing treatment for the waste material of the agaric culture medium: selecting a qualified fungus bag for debagging, crushing under tiny wet state, adding a modifier while crushing to adjust a pH value to be 6.0-7.0, and standing in sunlight for exposing 2-8 days or drying for 6-12 hours at 65-75 DEG C until the water content is 10%-13% for later use, and (2) nutrient balancing preparing for the culture medium: taking 65-75% of processed agaric waste materials, 10-25% of bran or rice bran, 2% of bean flour, 5-10% of corn flour, 0.5% of white sugar, 1-2% of calcium superphosphate or potassium phosphate, 1-2% of gypsum and 0.5-1% of magnesium sulfate, and then adding water until the water content is 55%-65%, and uniformly stirring after an absorbing nutritional solution of 0.3-2.5% nutritional type biopolymer is saturated. According to the method, the cost is low, the yield is high, the waste is efficiently reused and the environmental pollution is reduced.

Owner:黑龙江省诚美盛世知识产权运营有限公司

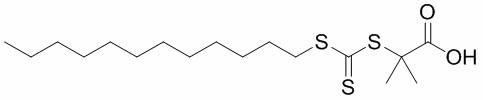

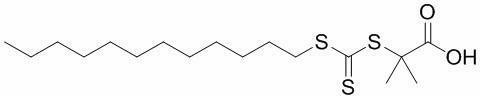

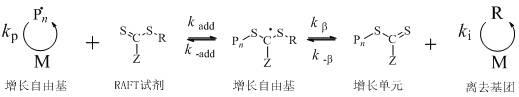

Preparation method for efficient chain transfer agent trithiocarbonate used for RAFT (reversible addition-fragmentation chain transfer) polymerization

InactiveCN102690217AThe synthesis method is simpleHigh purityOrganic chemistryDistillationDissolution

The invention belongs to the field of polymer nano biological medicinal materials, particularly relates to a preparation method for efficient chain transfer agent trithiocarbonate used for RAFT polymerization. The method is characterized in that the chemical formula of the trithiocarbonate is C17H32O2S3, and comprises the following steps: adding potassium phosphate, a solvent and carbon bisulfide into a round-bottom flask for reaction 1-3 hours; adding do-decyl mercaptans to conduct addition reaction for 1-3 hours; and finally adding 2-bromine isobutyric acid to conduct esterification reaction for 13-24 hours. The brilliant orange trithiocarbonate can be obtained from the reacted solvent subjected to procedures of reduced pressure distillation for removal, dissolution, extraction, and washing, wherein the mass ratio of the potassium phosphate to the carbon bisulfide is 1:(1-3), as well as the mass ratio of the do-decyl mercaptans to the carbon bisulfide, and the mass ratio of the 2-bromine isobutyric acid to the carbon bisulfide are also 1: (1-3). According to the method provided by the invention, the synthesizing is simple, the purification is convenient, and the stability of the product is good. Moreover, the RAFT polymerization has an efficient chain transfer effect. Therefore, the method is favorable for advancing the RAFT large-scale industrial production, and has an extensive application prospect.

Owner:TONGJI UNIV

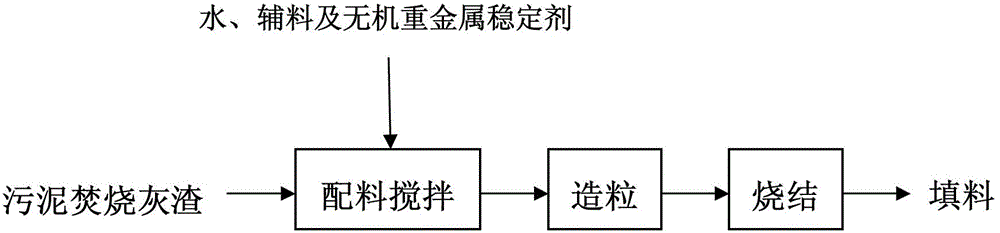

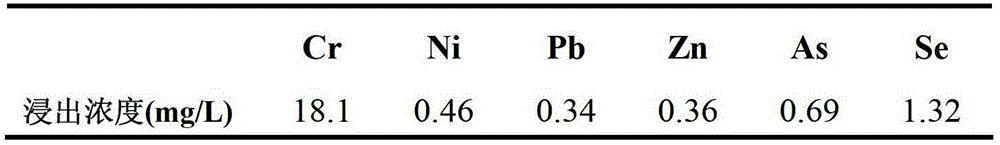

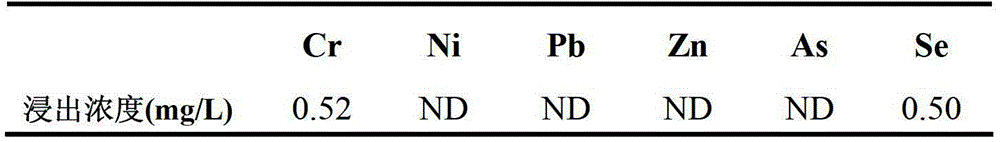

Heavy metal stabilizing method in process of preparing filler by chemical sludge burning ash

ActiveCN103145403AImprove stabilityLow leaching rateCeramic materials productionClaywaresPhosphateSludge

The invention relates to a heavy metal stabilizing method in a process of preparing filler by chemical sludge burning ash. An inorganic heavy metal stabilizer is prepared by using calcium oxide and potassium dihydrogen phosphate to prepare a calcium potassium phosphate cementing material supplemented by bentonite; the chemical sludge burning ash is used as a raw material, clay or shale is used as an auxiliary material, and a small amount of the inorganic heavy metal stabilizer is doped; and the raw material, the auxiliary material and the inorganic heavy metal stabilizer are mixed according to a certain proportion and stirred by adding water, pelletted and sintered to prepare the filler with small heavy metal leaching rate. The invention provides the heavy metal stabilizing method which is in good stabilizing effect and has universality to different heavy metal components and shapes. The process for preparing the filler by using the chemical sludge burning ash doped with the inorganic heavy metal stabilizer has the advantages of low operating cost, short disposal period, small secondary pollution, high degree of resources and the like compared with the conventional chemical sludge treatment and disposal manner.

Owner:NANJING UNIV OF TECH

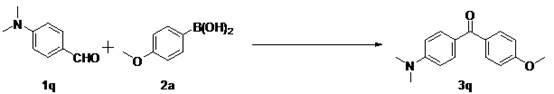

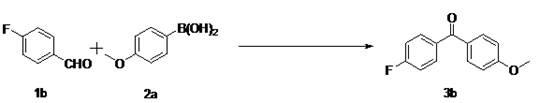

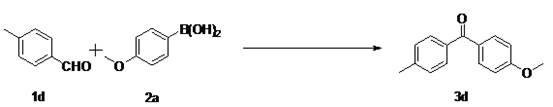

Method for preparing aryl ketone

ActiveCN102153434AMild reaction conditionsReduce usageCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystRuthenium Compounds

The invention relates to the field of catalysis, in particular to a method for preparing aryl ketone through reacting aldehyde with aryl boric acid under the catalysis of a ruthenium catalyst. In the method, an organic phosphide is used as a ligand, potassium phosphate is used as alkali, pinacolone or acetone is used as an additive, toluene or / and water is (are) used as a solvent(s), aldehyde and aryl boric acid which are used as reaction substrates react at 95-100 DEG C for 10-24h in the presence of a ruthenium compound used as a catalyst to prepare aryl ketone, wherein the catalyst is one of [Ru(cymene)Cl2]2, [Ru(CO)3Cl2]2, RuH2(CO)PPh3, Ru2(OAc)4, [Ru(benzene)Cl2]2, Ru(S-BINAP)Cl2 or Ru3(CO)12. In the invention, the used catalyst has relatively low price and low toxicity, thereby reducing the preparation cost and being more environmentally friendly.

Owner:铜陵市官作文化有限公司

Plant nutrient solution and preparation method thereof

InactiveCN107353142AIncrease productionComparable performanceSuperphosphatesMagnesium fertilisersCalcium nitrate tetrahydratePhosphoric acid

The invention provides a plant nutrient solution and a preparation method thereof. The plant nutrient solution is mainly prepared from, 380-420 parts of potash nitrate, 80-100 parts of potassium phosphate, 50-70 parts of hybridized adsorbing agent, 180-220 parts of epsom salt, 1.8-2.2 parts of manganese sulfate monohydrate, 2-3 parts of boric acid, 12-18 parts of Ferric sodium ethylene diamine tetraacetate, 380-420 parts of calcium nitrate terahydrate, 0.3-0.5 part of blue copperas, 0.8-1.2 parts of heptahydrate, 0.006-0.010 part of ammonium octamolybdate, 0.001-0.005 part of calcium superphosphate, 0.0008-0.0012 part of sodium chloride, 0.0008-0.0012 part of sodium molybdate and 0.0015-0.0025 part of ferrous sulfate. The plant nutrient solution is suitable for all plant growth, and the plant yield can be effectively increased; the plant nutrient solution can be used for fish culture and suitable for fish growth.

Owner:王福权

Delayed coagulation method of kalium-based magnesium phosphate cement

ActiveCN102659450AEffective adjustment of clotting timeControllable clotting timeMagnesium phosphatePotassium

The invention discloses a delayed coagulation method of kalium-based magnesium phosphate cement, and aims to delay the coagulating time of the magnesium phosphate cement to improve hydration degree and mechanical property of the cement. The delayed coagulation method includes the steps of firstly, adding water in alkaline phosphate to dissolve the same and secondly, adding kalium-based magnesium phosphate cement into the alkaline phosphate solution. The doping mass of the alkaline phosphate accounts for 2-6% of mass of magnesium compound, potassium phosphate and boron oxide in the kalium-based magnesium phosphate cement. By the aid of dipotassium phosphate, coagulating time of the magnesium phosphate cement can be optionally adjusted in 20 minutes to 50 minutes, and the magnesium phosphate cement can be suitably used as quick repair material for civil structures at normal temperature. By the aid of tripotassium phosphate, the coagulating time of the kalium-based magnesium phosphate cement can be optionally adjusted in 40 minutes to 2.5 hours, and the kalium-based magnesium phosphate cement is suitable for various projects at normal and high temperatures.

Owner:NANJING UNIV OF TECH

Process for producing potassium phosphate with wet phosphoric acid

InactiveCN101759168ALow purityReduce manufacturing costPhosphorus compoundsO-Phosphoric AcidHigh energy

The invention relates to a process for producing potassium phosphate with wet phosphoric acid. The process comprises the following steps that: 1) wet phosphoric acid is put into an ultrasonic reactor for ultrasonication at the temperature of 2-80 degree centigrade with the reaction time of 10-120 minutes; then the product is cooled to be at room temperature and precipitates are leached, thus obtaining a filter liquor; 2) potassium hydroxide, potassium carbonate or potassium bicarbonate is used to regulate the PH value of the filter liquor and generate precipitates, and a new filter liquor obtained after filtering is concentrated, evaporated, crystallized and then separated, thus obtaining potassium phosphate. The process is characterized in that wet phosphoric acid with low purity, purity and cost, lead-bearing material and potassium chloride are used as raw materials to react and generate potassium phosphate, which reduces production cost. Impurities in the raw materials interact and generate insoluble precipitates, and the insoluble precipitates can be easily separated. In the simple process, products are generated only by concentrating and crystallizing a neutralizer; potassium phosphate is directly prepared by utilizing phosphoric acid with the concentration of 5-40%, which solves the problems of low consistency of wet phosphoric acid and high energy consumption for concentration.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Building microorganism biological self-repairing heat-preservation mortar and preparation method thereof

The invention discloses building microorganism biological self-repairing heat-preservation mortar and a preparation method thereof. The mortar comprises the following raw materials: 100 parts of a mineralized microorganism bacterial liquid, 100 parts of a microorganism nutrient liquid, 50-100 parts of expanded perlite, 50-100 parts of pearlife, 50-100 parts of superfine expanded perlite of 80-120meshes, 1-2 parts of a polypropylene fiber, 1-4 parts of HPMC (hydroxy propyl methyl cellulose), 10-40 parts of redispersibile latex powder, 1-4 parts of polyphenyl granules and 5-10 parts of potassium magnesium phosphate cement. The building microorganism biological self-repairing heat-preservation mortar disclosed by the invention has the characteristics of being low in heat conduction coefficient, high in strength, good in cracking resistance, good in durability, and the like, meanwhile is free of conventional cement, and has the characteristics of being green and environmentally-friendly.The microorganism heat-preservation mortar is applicable to heat-preservation plastering engineering such as heat-preservation transformation of various existing old buildings and reinforced concreteof new buildings.

Owner:山西晟科微生物建材科技有限公司

Fertilizer special for navel orange and preparation method thereof

InactiveCN105110996AReduce pollutionHigh sweetnessFertilizer mixturesMonosodium glutamateAgricultural science

The invention discloses a fertilizer special for navel orange and a preparation method thereof. The fertilizer comprises, by weight, 100-150 parts of silkworm excrement, 70-100 parts of banana stem power or grained segments, 40-60 parts of monosodium glutamate residue, 30-50 parts of urea, 15-25 parts of tripotassium phosphate, 8-12 parts of magnesium sulfate, 6-10 parts of calcium sulfate, 4-8 parts of borax, 3-5 parts of ammonium molybdate, 3-5 parts of cellulase, 4-7 parts of Bacillus subtilis, and 1-2 parts of actinomycetes. The fertilizer has the advantages that fertilizer efficacy is fast and long, stress resistance is high, fertilizer availability is high, nutrients are complete, elements are reasonably matched and the cost is lower; by using the fertilizer, yield of navel orange is greatly increased, sweetness, taste and nutritional value are also greatly improved, and the fertilizer has good economic benefit, social benefit and ecological benefit and is suitable for large-scale popularization.

Owner:黄尤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com