High-efficiency iron rust conversion agent

A conversion agent, rust technology, applied in the direction of metal material coating process, etc., can solve the problems of poor construction performance, low conversion efficiency and anti-corrosion performance of rust conversion agent, achieve high adhesion, prevent electrochemical corrosion, and broad market space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

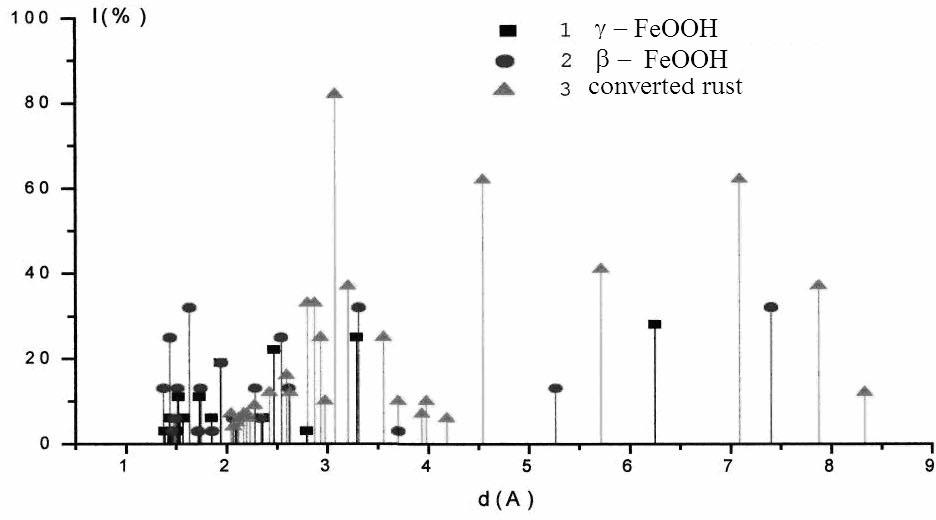

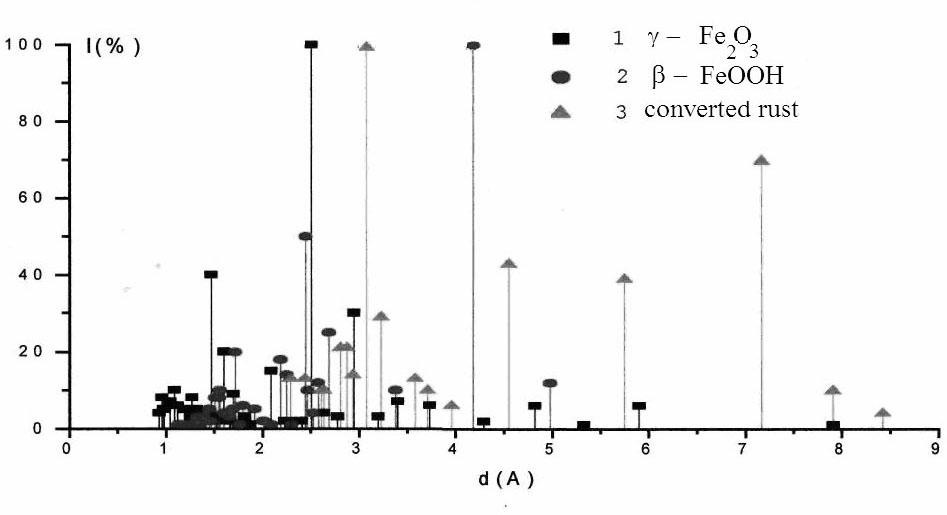

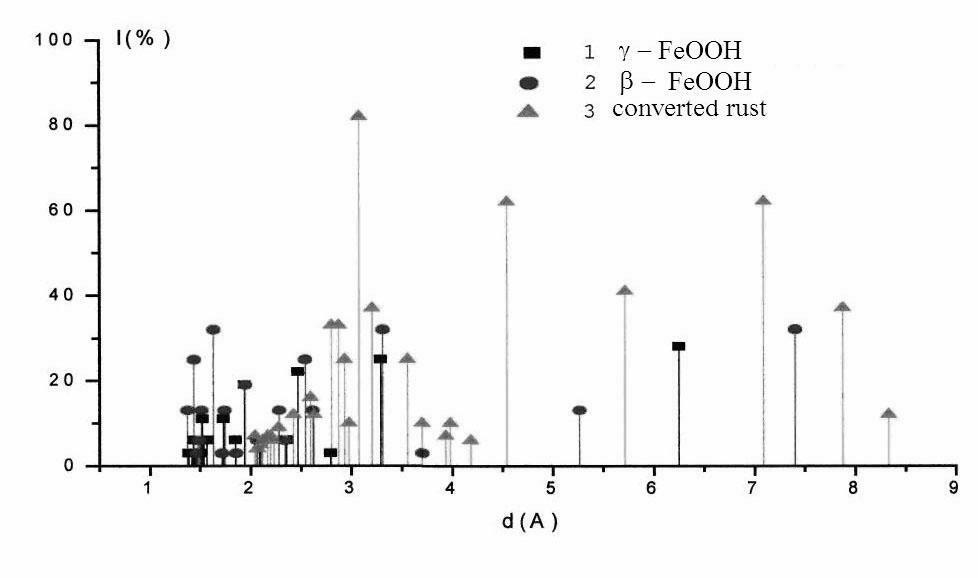

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] A high-efficiency rust conversion agent is prepared from the following raw materials in mass ratio: 0.5% zinc oxide, 40% phosphoric acid, 0.5% potassium dichromate, 2% sodium phosphate, 1% hexamethamine, and 56% water.

[0018] The preparation method is: add deionized water, phosphoric acid, sodium phosphate, urotropine, zinc oxide and potassium dichromate into the glass according to the order and mass ratio under continuous stirring, and the above dissolution time is 10-20 minutes. .

[0019] The method of use of the present invention: use metal brushes, sandpaper and other mechanical methods to remove powder floating rust on the surface of the steel plate, and degrease if necessary. Apply the conversion agent to the surface of the steel plate by brushing or spraying. Air dry after application. This transforming agent needs 2-3 times to trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com