Environmental-protection lubricating water-based cutting fluid

A lubricating water and cutting fluid technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor stability, achieve strong stability, excellent calcium soap dispersion and hard water resistance, and excellent cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

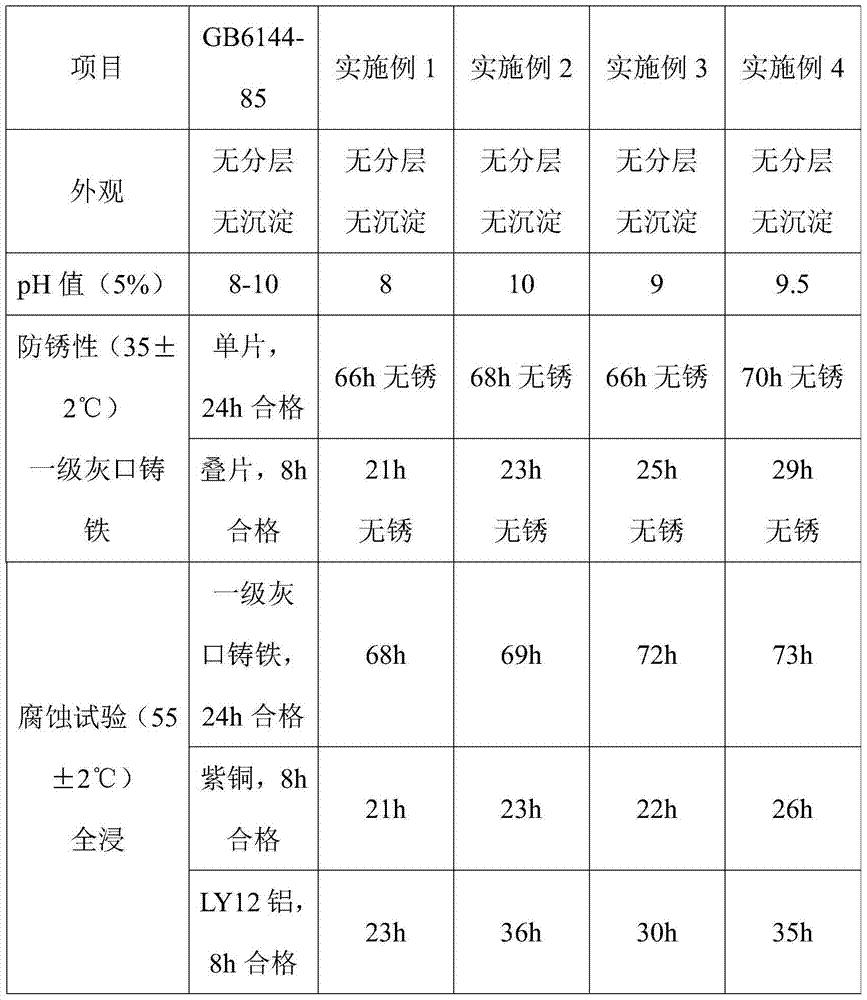

Examples

Embodiment 1

[0016] The environment-friendly lubricating water-based cutting fluid of the present invention, its raw material comprises by weight: 8 parts of sodium rosinate, 25 parts of rosin amine glucosyl ester surfactants, 10 parts of rosin amine polyoxyethylene ethers, 12 parts of polyaniline water-based preservatives 15 parts, 15 parts of oleic acid triethanolamine soap, 3 parts of triethanolamine, 10 parts of diisopropanolamine, 10 parts of sodium carbonate, 15 parts of hydrophilic alcohol, 3 parts of fungicide, 5 parts of defoamer, 3 parts of stabilizer, 100 parts of water.

Embodiment 2

[0018] The environment-friendly lubricating water-based cutting fluid of the present invention, its raw material comprises by weight: 20 parts of sodium rosinate, 15 parts of rosin amine glucose ester surfactant, 5 parts of rosin amine polyoxyethylene ether, 18 parts of polyaniline water-based preservative 5 parts, 5 parts of oleic acid triethanolamine soap, 8 parts of triethanolamine, 3 parts of diisopropanolamine, 15 parts of sodium carbonate, 1 part of tripropylene glycol, 2 parts of ethylene glycol, 2 parts of triethylene glycol, 6 parts of fungicide, 2 parts of defoamer, 10 parts of sodium carboxymethylcellulose, and 80 parts of water.

Embodiment 3

[0020] The environment-friendly lubricating water-based cutting fluid of the present invention, its raw material comprises by weight: 16 parts of sodium rosinate, 21 parts of rosin amine glucosyl ester surfactant, 8 parts of rosin amine polyoxyethylene ether, 16 parts of polyaniline water-based preservative 11.5 parts of oleic acid triethanolamine soap, 6 parts of triethanolamine, 7 parts of diisopropanolamine, 13 parts of sodium carbonate, 13 parts of triethylene glycol, 5.6 parts of fungicide, 4 parts of defoamer, 3 parts of carboxymethyl starch 4 parts of gum, 96 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com