Patents

Literature

547 results about "Triethanolamine oleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The viability of the arthroaleuriospores of auxarthron reticulatum was diminished 15-62% by triethanolamine oleate as compared with control spores in distilled water or physiologic saline. it also incr spore dispersion, which was facilitated by sonic & hand agitation of the suspensions.

Multiple-effect type water-based synthesized cutting solution and preparation thereof

InactiveCN101323813AExtended service lifeImprove extreme pressure and anti-wearLubricant compositionWater basedCleansing Agents

The invention relates to a multi-effect water-based composite cutting / grinding fluid which consists of water-soluble oil, cleaning agent, extreme pressure antiwear agent, antirust, antibacterial agent, complexant, solubilizer and anstatic agent. The water-soluble oil is the mixture of aminoethyl alcohol and triethanolamine oleate, the cleaning agent is anionic surfactant or nonionic surfactant, the extreme pressure antiwear agent is one or two of additives A, B, C, D, E and F, the antirust is benzotriazole and sodium benzoate, the antibacterial agent is boric acid and borax, the complexant is EDTA and the solubilizer is urea. The cutting / grinding fluid with various improved performances is non-toxic and tasteless, is an environment-friendly product and has no harm to human body and the skin of users; the operating cycle is normally more than 6 months.

Owner:大连弘瑞化工有限公司

Metal bearing water-based cleaning agent and preparation method and application thereof

The invention discloses a metal bearing water-based cleaning agent and a preparation method and application thereof. The cleaning agent comprises the following components in percentage by mass: 2 to 8 percent of fatty alcohol polyoxyethylene ether, 2 to 8 percent of alkylphenol polyoxyethylene ether, 3 to 10 percent of fatty acid alkanolamide, 5 to 25 percent of triethanolamine oleate, 10 to 22 percent of triethanolamine, 5 to 18 percent of monoethanolamine, 0.5 to 3 percent of alkyl sodium sulfonate, 0.01 to 0.5 percent of benzotriazole, 1 to 2 percent of disodium ethylene diaminetetraacetate and 3.5 to 71.49 percent of water. During use, the cleaning agent is prepared into 2 to 10 percent working solution, and a bearing part is ultrasonically cleaned, rinsed, subjected to spray washing and dried to meet the cleaning degree standard and the finished product vibration value standard. The product is environment-friendly, does not influence a bearing material, is prepared from readily available raw materials, has low cost, can replace the conventional cleaning gasoline and kerosene, reduces the potential safety hazard, avoids environmental pollution, and saves energy.

Owner:白马轴承技术(洛阳)有限公司 +1

Light-weight and high-strength magnesium oxysulfate foamed plate and preparation method thereof

The invention provides a light-weight and high-strength magnesium oxysulfate foamed plate which is obtained with magnesium oxysulfate as a cementing material. The foamed plate is prepared from, by weight, 40-50 parts of light-calcined magnesia, 40-50 parts of a magnesium sulfate heptahydrate solution, 1.5-3 parts of a modifying agent, 5-6 parts of a foaming agent, 1.5-2.5 parts of foam stabilizer, 1-2 parts of a waterproof agent, 0.5-1 part of a water reducing agent and 2-3 parts of polypropylene fibers. The modifying agent is prepared from one or more of citric acid, boric acid, phosphoric acid and sodium citrate. The foaming agent is hydrogen peroxide with the mass concentration being 25-30%. The foam stabilizer is triethanolamine oleate aqueous emulsion with the mass concentration being 8-10%. The absolute dry bulk density of the magnesium sulfate foamed plate is lower than 200 kg / m<3>, the absolute dry comprehensive strength is 0.7 MPa or above, a heat conduction coefficient is lower than 0.045 W / (m.K), the magnesium sulfate foamed plate has the advantages of being light in weight, high in strength, good in hole structure, good in heat-preserving and sound insulating effect, free of active magnesia and good in fire resistance and having no corrosion effect on metal, and the light-weight and high-strength magnesium oxysulfate foamed plate is particularly suitable for serving as a fireproof door and internal wall heat-preserving and heat-insulating material. The invention further provides a preparation method of the magnesium oxysulfate foamed plate.

Owner:广东龙湖科技股份有限公司

Rapid wax removing agent

InactiveCN102010806ASurface-active non-soap compounds and soap mixture detergentsSurface cleaningSS - Stainless steel

The invention relates to a cleaning agent, in particular to a rapid wax removing agent, which is a liquid composition used for cleaning the surface of metal (such as stainless steel), particularly metal products (parts) of complex shapes by using ultrasonic waves or soaking. When used, the rapid wax removing agent is prepared into 3 to 5 percent aqueous solution of the rapid wax removing agent; and the aqueous solution of the rapid wax removing agent is combined with ultrasonic waves or manual cleaning so as to finish cleaning operation at certain temperature. The rapid wax removing agent comprises the following components in percentage by weight: 16 to 25 percent of triethanolamine oleate soap, 10 to 15 percent of coconutt diethanol amide, 8 to 17 percent of additive, 2 to 3 percent of aids, and 40 to 64 percent of purified water. The liquid composition has the characteristics of high dispersibility, high efficiency of removing oil, wax and asphalt, high cleaning speed, and high adaptability (various polishing agents and metals), can be dissolved in water rapidly, and is a non-toxic and nonirritating metal surface cleaning agent. The liquid composition has the obvious characteristics of low cost and long service life.

Owner:彭美东

Antibacterial aerated brick and making method thereof

InactiveCN103833278AImprove foam stabilization performanceGuaranteed StrengthCeramicwareBrickPhosphoric acid

Owner:广州市明忠建筑材料有限公司

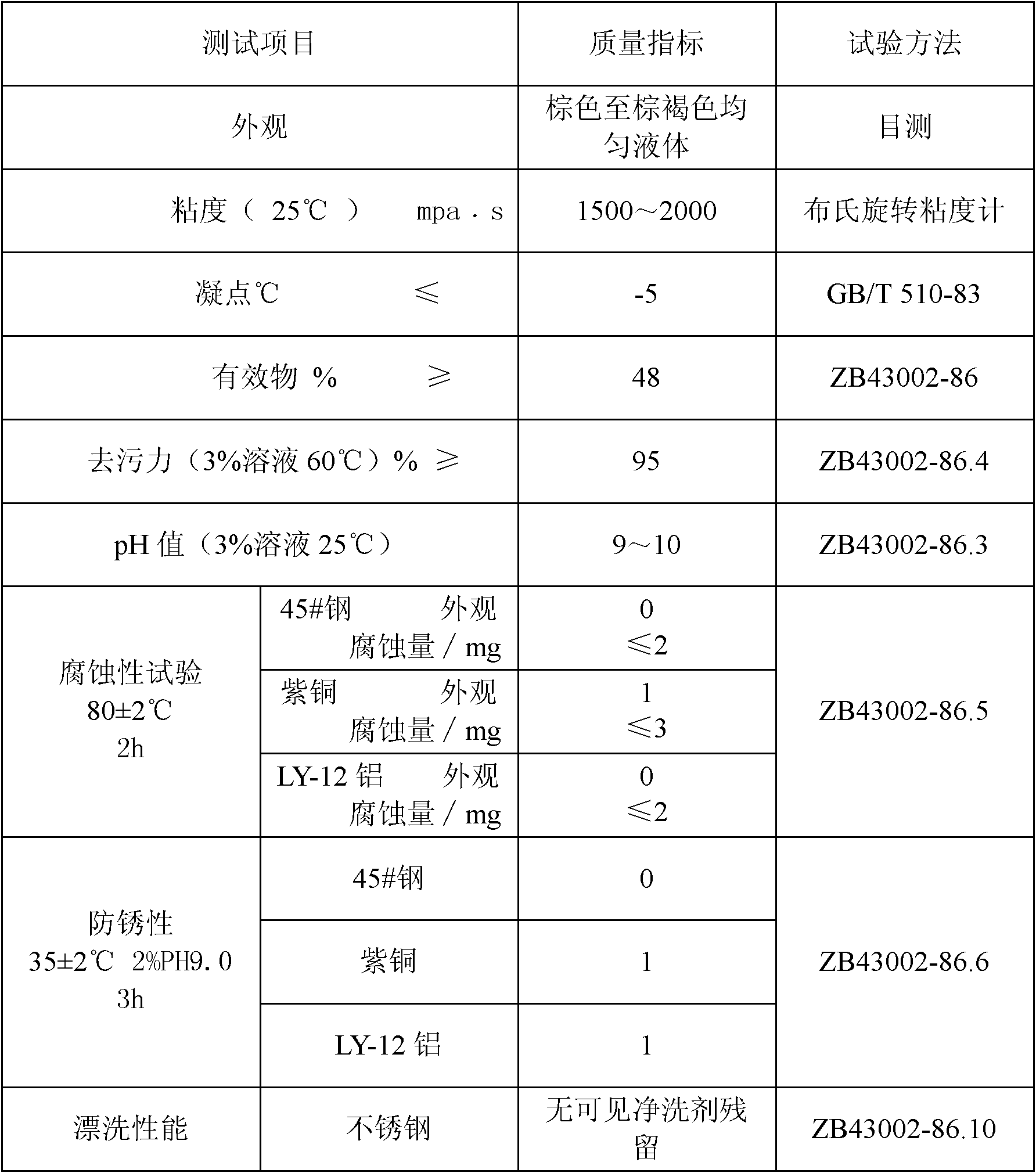

Water-based metal cleaner and preparation method thereof

The invention discloses a water-based metal cleaner and a preparation method thereof. The water-based metal cleaner is prepared from sodium dodecylbenzene sulfonate, fatty alcohol-polyoxyethylene ether, alkylphenol polyoxyethylene, triethanolamine oleate, triethanolamine, 3-methyl-3-methoxy-1-butanol, polyphosphate, silicate, glycerol, primary sodium alkyl sulfate, isooctyl phosphate, benzotriazole, polyethylene glycol, dimethylaminoethyl methacrylate, 2-hydroyl-3-sulfopropyl starch ether and deionized water; the preparation method of the water-based metal cleaner comprises the following steps: firstly, adding a surfactant and the triethanolamine oleate to the glycerol, heating and stirring, next, adding the triethanolamine, the 3-methyl-3-methoxy-1-butanol, the polyphosphate and the silicate, adding the primary sodium alkyl sulfate, the isooctyl phosphate, the benzotriazole and the polyethylene glycol under the conditions of stirring and preserving heating, and finally adding the rest components under the conditions of stirring and preserving heating, and heating and stirring to obtain the cleaner. The water-based metal cleaner has excellent cleaning performance and relatively high corrosion inhibition period.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

High temperature resistant well-cementing spacer fluid and preparation method thereof

ActiveCN104449606AGood thickeningGood suspensionDrilling compositionSodium BentoniteSuspending Agents

The invention relates to a high temperature resistant well-cementing spacer fluid and a preparation method thereof. The spacer fluid consists of: 100 parts by weight of fresh water, 2-8 parts by weight of a suspending agent, 2-10 parts by weight of a diluents, 25-400 parts by weight of a weighting agent, and 1-15 parts by weight of a flushing agent. Specifically, the suspending agent is composed of 100 parts by weight of OCMA bentonite, 2 parts by weight of hydroxypropyl guar gum and 8 parts by weight of xanthan gum; the diluent is composed of 100 parts by weight of sodium lignin sulfonate and 20 parts by weight of sulfonated tannin; the flushing agent consists of 40 parts by weight of fatty alcohol-polyoxyethylene ether, 40 parts by weight of triethanolamine oleate and 20 parts by weight of sodium tripolyphosphate; and the weighting material is barite. The spacer fluid has stable performance under 180DEG C high temperature condition, still has good rheological performance under the premise of ensuring the system good suspension stability, is compatible with conventional cement slurry and drilling fluid systems, improves the rheological properties of drilling fluid, enhances the displacement efficiency, and reinforces the cementation quality of a cement ring with a well cementation first interface and a second interface.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

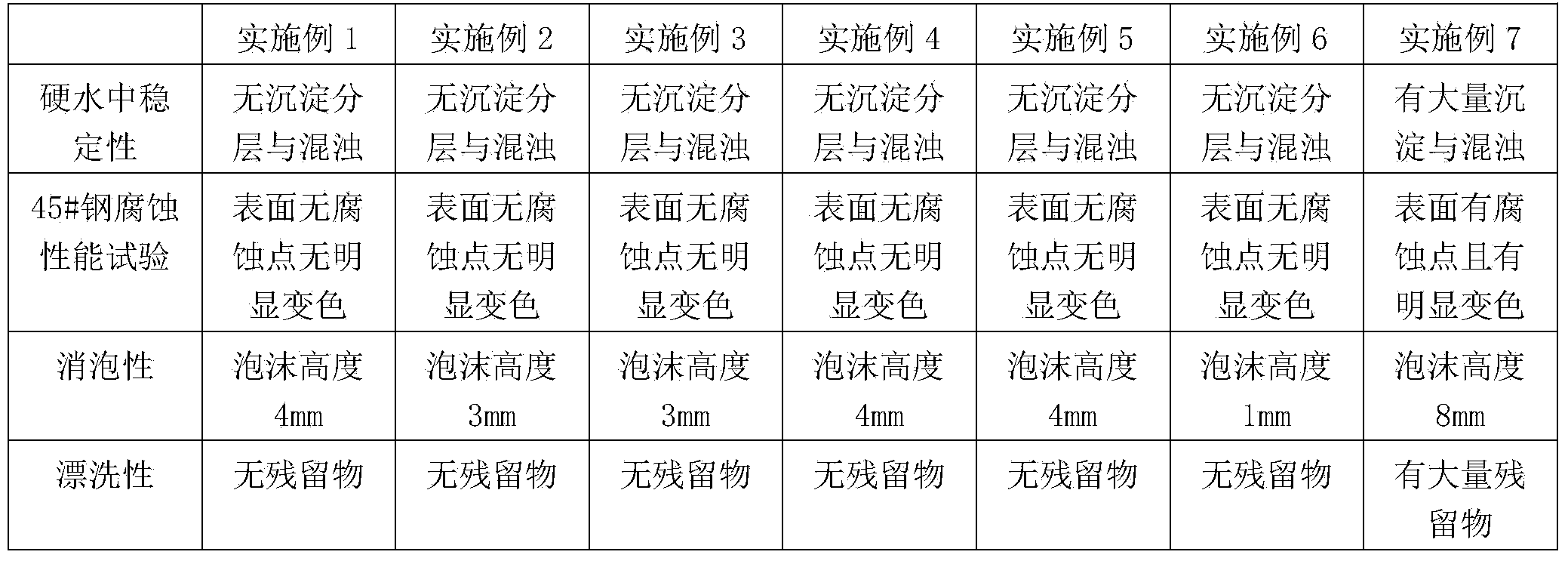

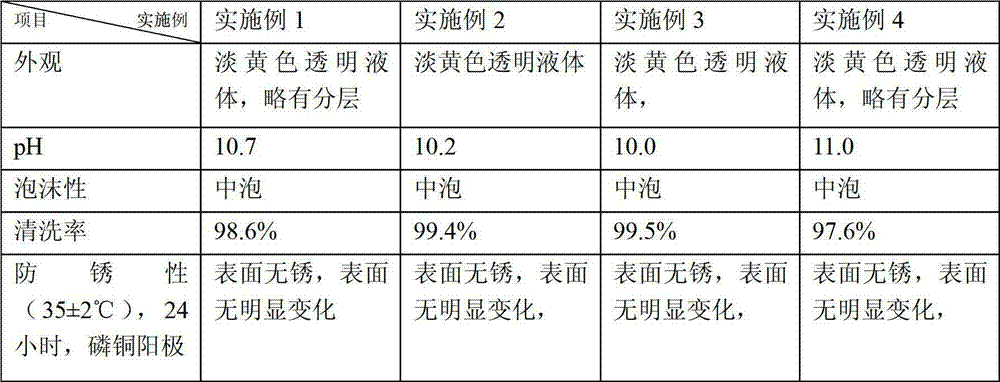

Water-based phosphor copper anode cleaning agent and preparation method thereof

The invention discloses a water-base phosphor copper anode cleaning agent and a preparation method thereof. The phosphor copper anode cleaning agent comprises, by weight, 25.5-28% of a mixed surfactant, 2.5-5% of rust-proof constituents, 0.5-2% of a chelating agent, 10-15% of an inorganic assistant, and the balance water. The mixed surfactant consists of a nonionic surfactant and an anionic surfactant, and AEO-9, polyoxyethylene sorbitan fatty acid ester-80 (tween-80), triethanolamine oleate and a JFC are mixed to form the nonionic surfactant. Under the common action of the surfactant, the inorganic assistant and a rust-proof agent, the cleaning agent can be cleaned at a normal temperature, dirts on the surface of a phosphor copper anode can be removed quickly, the cleanliness is high, no residual organic matter exists on the surface, the cleaned phosphor copper anode can be used for electrofacing of a circuit board directly, and no activating treatment is required. Besides, no phosphate or biological degradation-resistant surfactant are contained, and no ecological pollution is caused.

Owner:佛山市承安集团股份有限公司 +1

A water-based metal cleaning agent and a preparing method thereof

InactiveCN107779893AThe formula is scientific and reasonableStrong degreasing abilityWater basedSodium stearate

A water-based metal cleaning agent and a preparing method thereof are disclosed. The cleaning agent includes, by weight, 15-20 parts of polyoxyethylene alkyl ether, 15-20 parts of octylphenol polyoxyethylene ether, 10-12 parts of sodium citrate, 10-12 parts of sodium stearate, 10-15 parts of sodium dodecyl sulfonate, 8-15 parts of triethanolamine oleate, 15-20 parts of coconut fatty acid diethanolamide, 3-5 parts of sodium silicate, 3-5 parts of carboxymethylcellulose, 2-4 parts of a defoamer and 80-100 parts of water. The polyoxyethylene alkyl ether, the octylphenol polyoxyethylene ether, thesodium dodecyl sulfonate are firstly dissolved into the water, then the sodium citrate, the sodium stearate, the sodium silicate, the triethanolamine oleate, the coconut fatty acid diethanolamide andthe carboxymethylcellulose are added in order according to the ratio, the mixture is stirred until the mixture is in a semitransparent state, finally the defoamer is added into the mixture, and the mixture is fully stirred. The cleaning agent is scientific and reasonable in formula, high in cleaning power, safe, environmentally friendly, simple and convenient to operate and low in cost.

Owner:天佑京铁轨道技术有限公司 +1

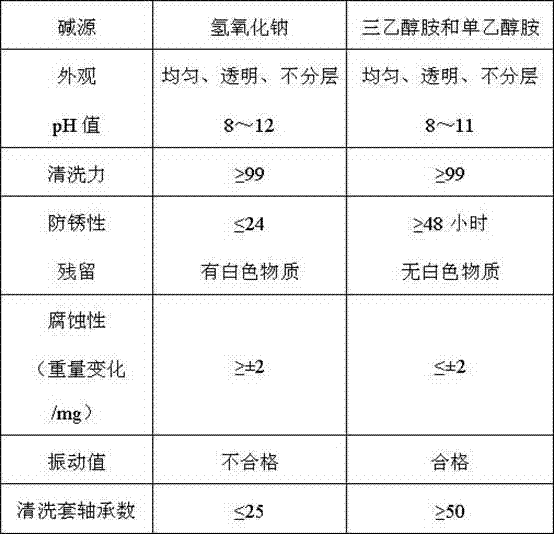

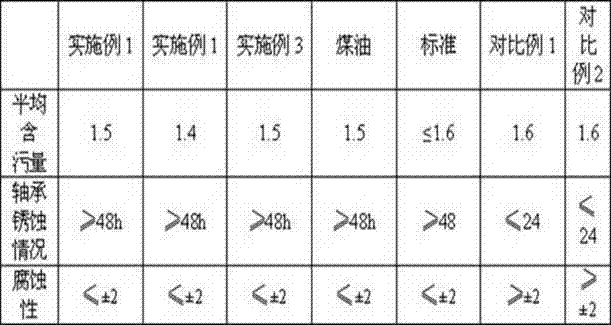

Metallic bearing water-based detergent and rinsing agent used together with the same, and method for producing the same

InactiveCN101195790AAvoid corrosionImprove rust resistanceOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedPhosphoric Acid Esters

The invention relates to metal bearing water-based cleaning agent, rinsing agent matched with the water-based cleaning agent, and the preparation method thereof. Petroleum sodium sulfonate, triethanol amine oleate, fatty alcohol-polyoxyethylene ether, emulgator, and cocoanut oil diethanolamine phosphoric acid ester are mixed with tiethanolamine and ethanolamine according to the weight percentage, are stirred uniformly at room temperature, then are mixed with other raw materials and water, then antibubbling agent AF9020 is added, and therefore the brown yellow and transparent concentrated cleaning agent is formed; nitrous acid dicyclohexylamine, oleic acid triethanolamine and petroleum sodium sulfonate are respectively dissolved into the mixed solvent of tiethanolamine and mono ethanolamine, then benzotriazole is dissolved into water to mix the two solvent, to form the brown yellow and transparent concentrated rinsing agent; the cleaning agent and the rinsing agent are mixed into 5 percent treatment fluid and 1 percent of treatment fluid, then the treatment fluid is cleaned for 30 seconds to 1 minute under ultrasonic wave, rinsed for 30 seconds, and then hot air seasoning, drying and 48 h rust preventing are performed. The invention can replace gasoline cleaning agent, kerosene cleaning agent, and universal water-based cleaning agent, the used raw material is easy to be acquired, the production cost is low, and the invention without parkerizing process can effectively prevent the environmental pollution.

Owner:白马轴承技术(洛阳)有限公司

Environment-friendly water-based synthetic metal machining liquid

InactiveCN104293471AImprove the lubrication effectImprove anti-corrosion performanceAdditivesWater basedVegetable oil

The invention discloses an environment-friendly water-based synthetic metal machining liquid which is prepared from the following raw materials in parts by weight: 10-25 parts of triethanolamine sebacate, 5-13 parts of benzotriazole, 5-10 parts of sodium benzoate, 3-10 parts of dodecenylsuccinic acid, 5-13 parts of laurate alcohol ester, 5-10 parts of triethanolamine oleate, 5-15 parts of borate, 8-20 parts of a polyether nonionic surfactant, 5-8 parts of triethanolamine, 3-5 parts of ethylene diamine tetraacetic acid, 5-10 parts of borax, 2-5 parts of a chelating agent, 0.5-3 parts of a bactericide, 2-6 parts of a defoaming agent and 120-180 parts of water. The environment-friendly water-based synthetic metal machining liquid disclosed by the invention further has good cooling property, lubricity, anti-rust property and cleaning property, is stable in product quality, long in service period, free of mineral oil and vegetable oil as well as additives which are harmful to human bodies and pollute the environment and easily biodegraded, belongs to an environment-friendly product and has a relatively good application prospect.

Owner:CHAOHU GUANGFENG METAL PROD

Water-base lubricant and preparation method thereof

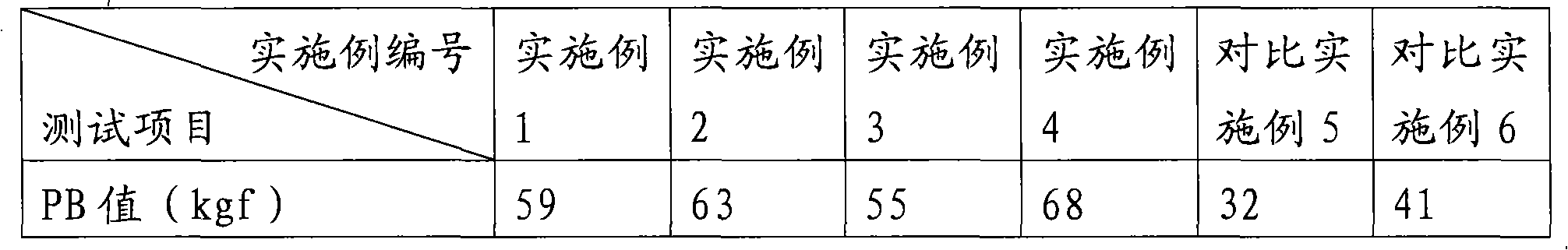

ActiveCN101591584AIncreased maximum no-seize loadImprove the lubrication effectBase-materialsTriethanolamine oleateWater based

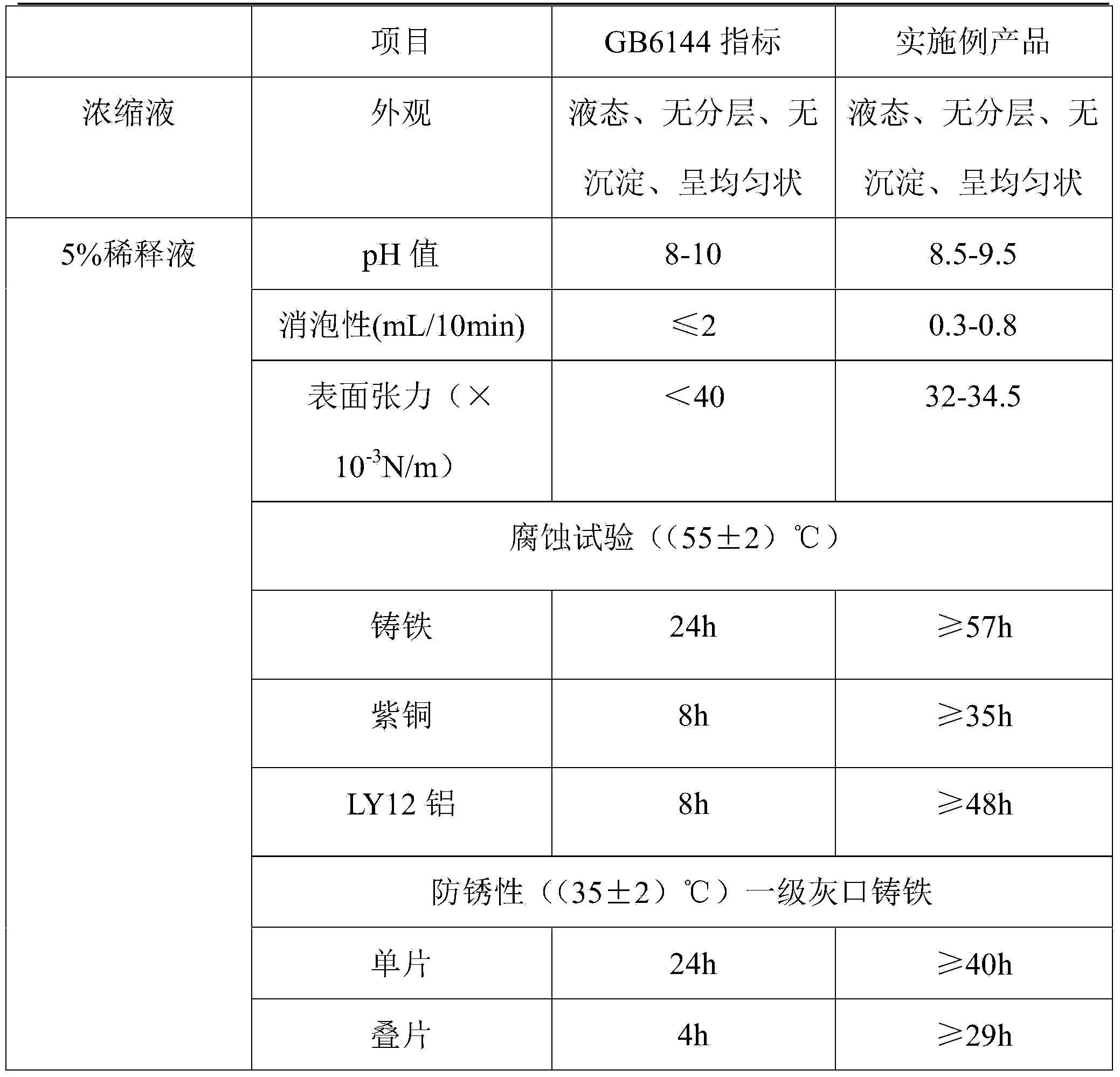

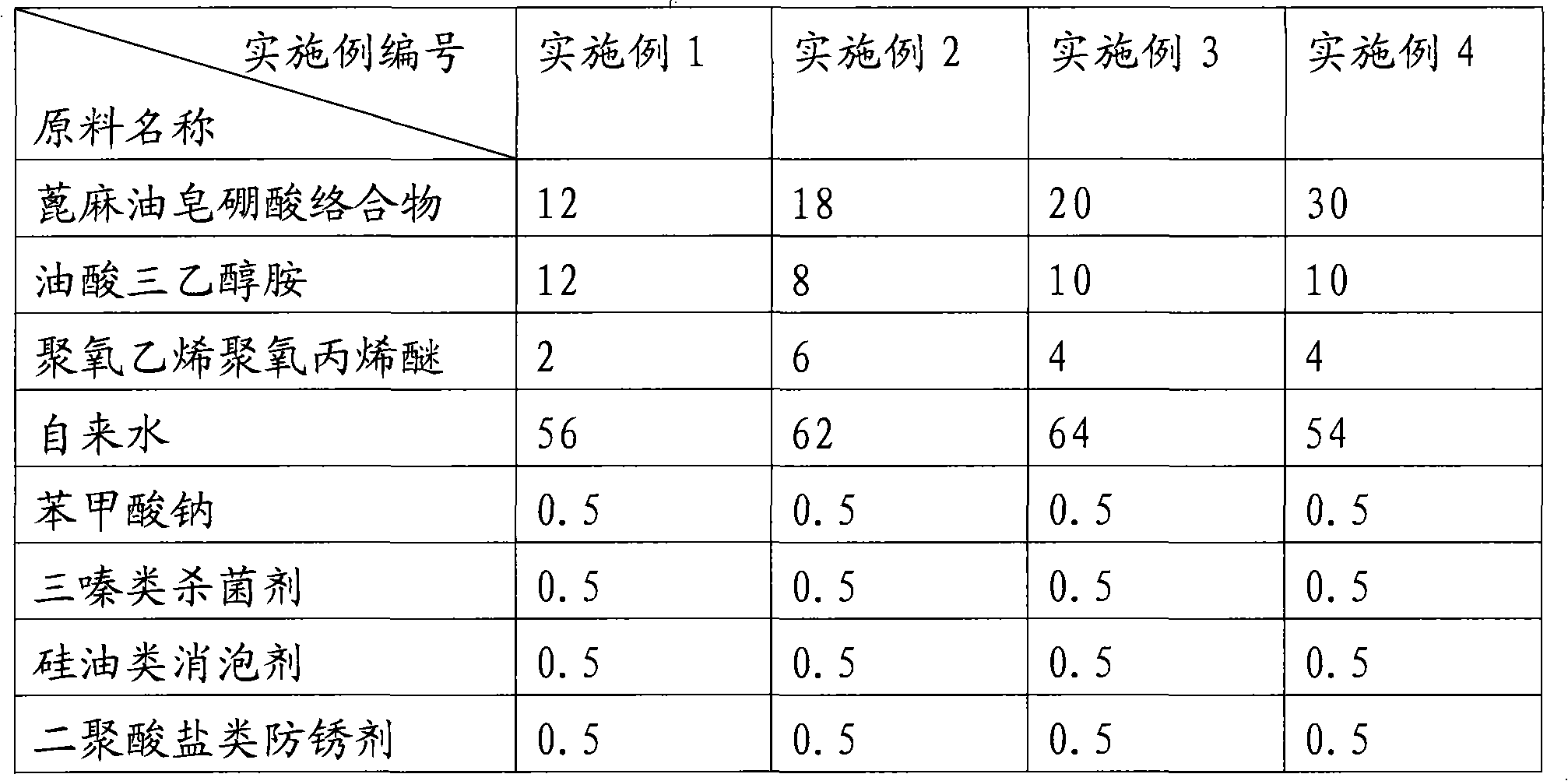

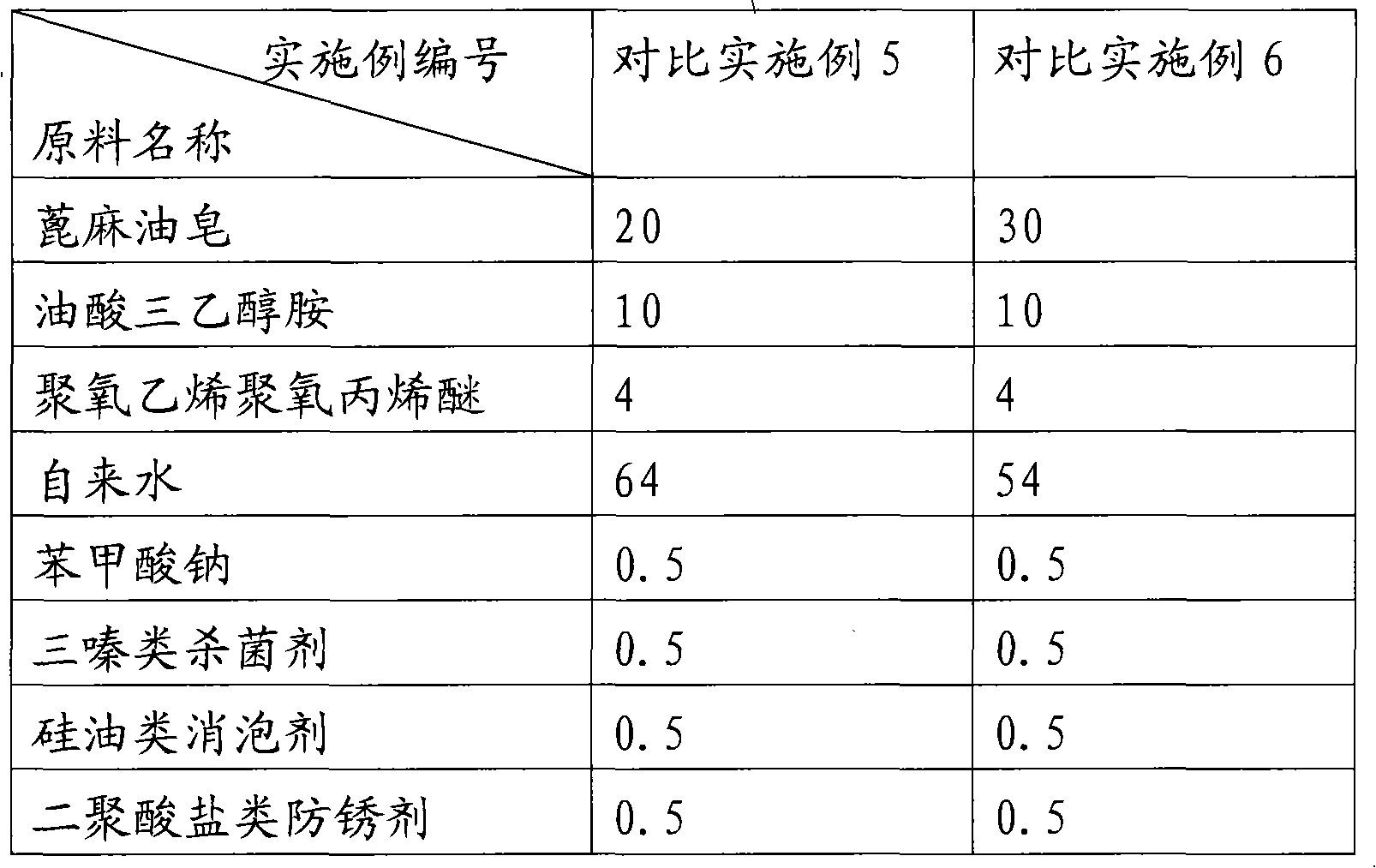

The invention discloses a water-base lubricant and a preparation method thereof. The water-base lubricant comprises the following compositions: monopol soap boric acid complex, triethanol amine oleate, viscosity modifier and water. Compared with the prior art, the water-base lubricant prepared by combining the monopol soap boric acid complex instead of monopol soap and the triethanol amine oleate greatly improves the maximum non-seizure load so as to improve the lubricating performance. The water-base lubricant is applicable to lubrication of gears and other mechanical components.

Owner:KASONG SCI & TECH

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

Grinding fluid for metal processing and preparation method thereof

InactiveCN109536263AWith carrying capacityImprove permeabilityLubricant compositionChemical reactionHigh pressure

The invention relates to the field of metal cutting additives, in particular to a grinding fluid for metal processing and a preparation method thereof. According to a technical scheme adopted by the invention, the grinding fluid for metal processing is composed of the following components by weight percentage: 5-15% of a PH value stabilizer, 3-5% of a surfactant, 5-10% of a water-borne lubricant,5-15% of an antirust agent, 4-8% of a coupling agent, 0.2-1% of a bactericide, 0.1-1% of a defoamer, 1-3% of a corrosion inhibitor, 0.2-0.4% of a settling agent, and the balance deionized water. The invention has the advantages that: the grinding fluid for metal processing adopts triethanolamine oleate as the surfactant, has good permeability and wettability, is conducive to entering a high temperature and high pressure working face, and at the same time is also a lubricant, the molecule has strong polar groups, can achieve strong adsorption with the metal surface, and chemical reaction can becarried out to form a firm physical absorption film and chemical reaction film with certain carrying capacity.

Owner:上海加美实业有限公司

Environmental-friendly water-based detergent for soldering tin residue and preparation and use method of environmental-friendly water-based detergent

PendingCN107312662AImprove penetrating decontamination performanceImprove solubilityNon-ionic surface-active compoundsPolymeric surface-active compoundsWater basedEnvironmental resistance

The invention provides an environmental-friendly water-based detergent for soldering tin residues and a preparation and use method of the environmental-friendly water-based detergent, and relates to the field of water-based detergent preparation. The environmental-friendly water-based detergent is prepared from the following raw materials in parts by weight: 10-20 parts of tetrahydrofuran, 5-15 parts of ethylene glycol monoethyl ether, 7-15 parts of a surfactant, 1-13 parts of a saponifying agent, 1-5 parts of ethylene diamine tetraacetic acid tetrasodium, 2-4 parts of sodium borate, 1-5 parts of oleic acid triethanolamine, 1-5 parts of sodium citrate, 2-4 parts of glycerin monostearate, 5-8 parts of zinc stearate, 0.1-0.5 part of a defoaming agent, 0.5-2.5 parts of a corrosion inhibitor, 3-5 parts of carboxymethyl chitosan and 90-130 parts of deionized water. The environmental-friendly water-based detergent for soldering tin residues, which is provided by the invention, is capable of forcefully cleaning residues at soldering points of products after tin soldering, the soldering points are kept bright after cleaning, and cleaned parts are free of residue substance or whiting.

Owner:中山翰华锡业有限公司

Copper wire drawing lubricating fluid and preparation method thereof

InactiveCN103614221AImprove cooling effectExtended service lifeAdditivesManufacturing technologyPhosphate

The invention discloses a copper wire drawing lubricating fluid and a preparation method thereof. The lubricating fluid and the preparation method are characterized in that: the lubricating fluid is prepared from following raw materials by weight: 15-25 parts of palm oil, 2-3 parts of sodium petroleum sulfonate, 30-35 parts of polyethylene glycol, 1-2 parts of sulfurized calcium alkyl phenolate, 1-2 parts of a sodium naphthenate, 2-3 parts of a water soluble phosphate ester, 1-2 parts of sodium benzoate, 2-3 parts of triethanolamine oleate, 0.2-0.4 part of diamond nanoparticles, 10-14 parts of an antiwear agent and 1000 parts of water; nano aluminium nitride powder is added into the antiwear agent, thus promoting heat dissipation, enhancing cooling effects, enhancing film-forming property and prolonging the service lifetime; the service cycle of the lubricating fluid is long; and copper wires after wire drawing processes have significant characteristics of shining surfaces, capability of being stored for a long time, difficult surface oxidation, simple manufacturing technology, low technical requirements, and the like.

Owner:全威(铜陵)铜业科技有限公司

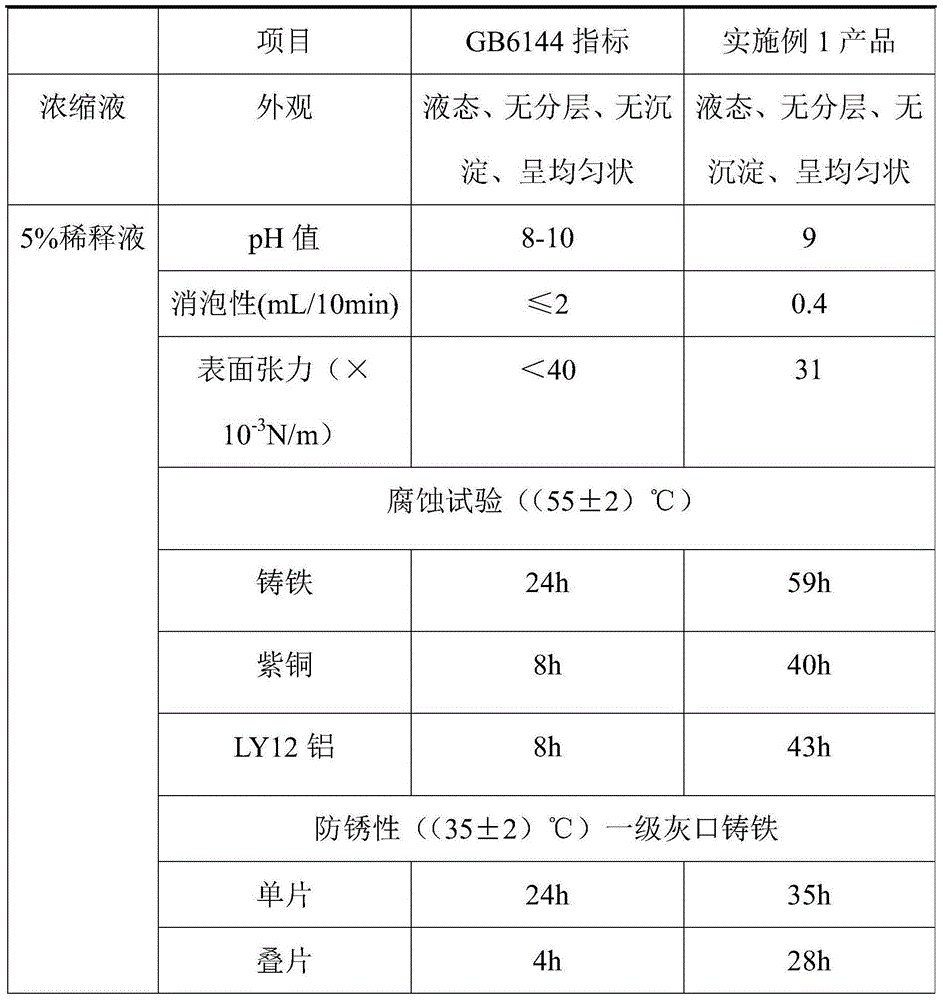

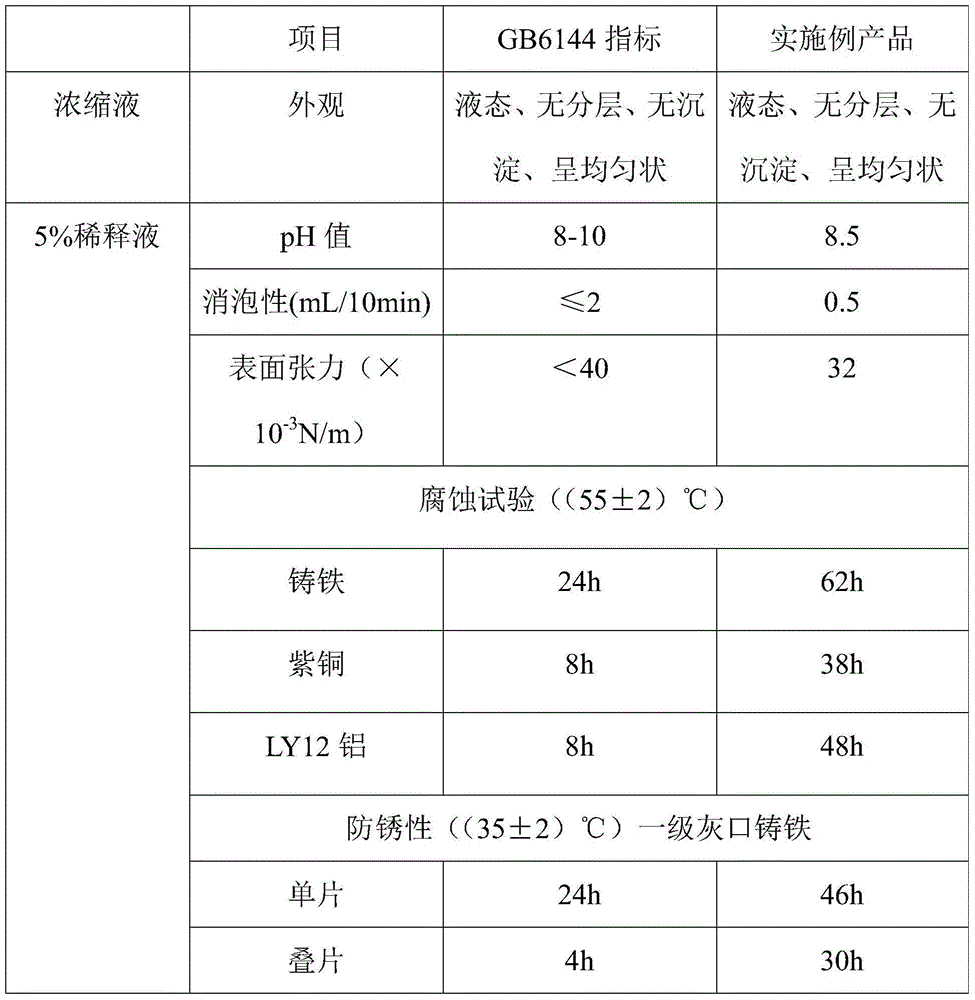

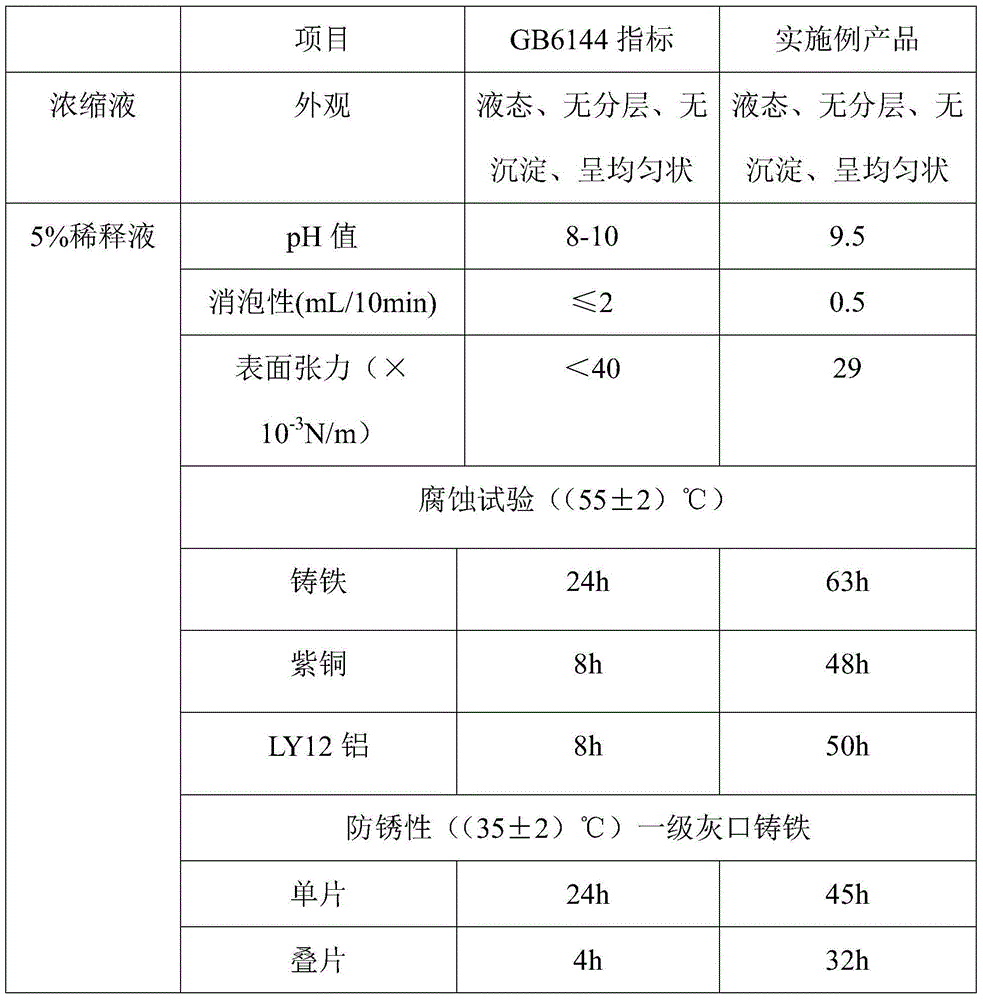

Multifunctional fully-synthetic cutting fluid and preparation method thereof

The invention discloses multifunctional fully-synthetic cutting fluid and a preparation method thereof. The multifunctional fully-synthetic cutting fluid is prepared from modified vegetable oil, organic carboxylic acid amide, borate, ethanolamine, a polyether activating agent, a non-ferrous metal corrosion inhibitor, triethanolamine oleate, ethanolamine citrate, triethanolamine phosphate, emulsified silicone oil and the like. According to the multifunctional fully-synthetic cutting fluid and the preparation method thereof, an easily-biodegradable special additive combination is adopted, so that the problem that similar products on the market are generally poor in lubricity and rust resistance is solved; a formula does not contain nitrite, benzene and phenol substances, so that waste liquid is easy to process, the destruction to the environment can not be caused, and the environmental friendliness is good; and the multifunctional fully-synthetic cutting fluid can be applied to medium / heavy-load cutting processing and is applicable to automated production equipment, such as numerically-controlled machine tools, processing centers and the like.

Owner:水泽节(山东)环保科技有限公司

High-performance metal cutting fluid

InactiveCN104403772AEasy to cleanImprove anti-corrosion performanceLubricant compositionPhosphateChemistry

The invention discloses a high-performance metal cutting fluid including following raw materials, by weight: 3-15 parts of an oleamide-based nonionic surfactant, 5-12 parts of twain, 10-25 parts of dodecyl aminopropionic acid, 5-10 parts of a betaine-typed ampholytic surfactant, 10-20 parts of sodium alkyl benzene sulfonate, 1-10 parts of sophorolipid, 10-25 parts of a water-soluble lubricant, 5-18 parts of triethanolamine oleate, 5-15 parts of sodium borate, 1-5 parts of benzotriazole, 5-20 parts of cyclohexanehexol phosphate, 8-25 parts of an organic borate, 5-15 parts of a molybdate, 3-8 parts of copper citrate, 3-10 parts of a chelating agent, 3-10 parts of sodium citrate, 4-15 parts of citric acid and 80-150 parts of water. The high-performance metal cutting fluid is excellent in cleaning performance, corrosion-resistant performance, cooling performance, lubricating performance and anti-hard-water performance, is stable when being stored and is suitable for various materials.

Owner:CHAOHU GUANGFENG METAL PROD

Normal temperature metal cleaner and technique of preparing the same

ActiveCN101333664AEasy to prepareImprove decontamination abilityTriethanolamine oleateRoom temperature

The invention relates to a normal temperature metal cleaner as well as a preparation process thereof. The cleaner comprises the following components by weight: 6 to 8 parts of amphoteric surfactant; 0.2 to 0.4 parts of potassium permanganate; 1 to 2 parts of emulsifying agent; 4 to 8 parts of oxalic acid; 10 to 20 parts of acid fog inhibitor; 5 to 10 parts of triethanolamine oleate; 2 to 4 parts of surface conditioning agent; 3 to 6 parts of pickling inhibitor; 50 to 100 parts of hydrochloric acid with concentration of 31 to 36 percent; and 20 to 40 parts of water. Compared with the prior art, the normal temperature metal cleaner and the preparation process thereof have the advantages of: 1. convenience: the product is applied to the cleaning of various metallic products, and is simple and convenient in operation. 2. High efficiency: the operation process is simple, and the cleaning efficiency is greatly improved. 3. Economy: surfaces of various metal workpieces can be effectively cleaned and treated, the consumption of cleaner is low, and the production speed is expedited for users. 4. Environmental protection: the cleaner has no acid mist and is safe for human body.

Owner:万晓茂

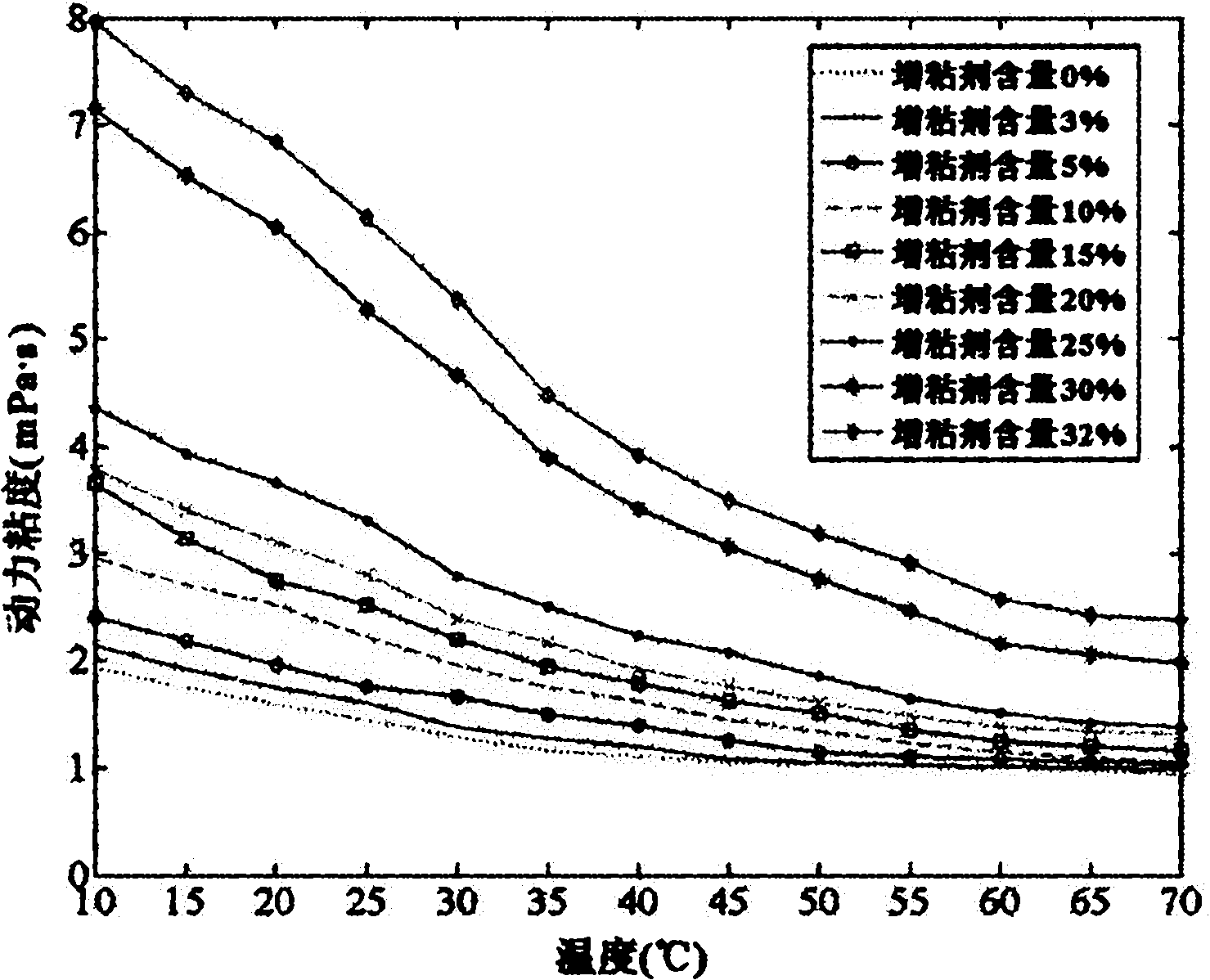

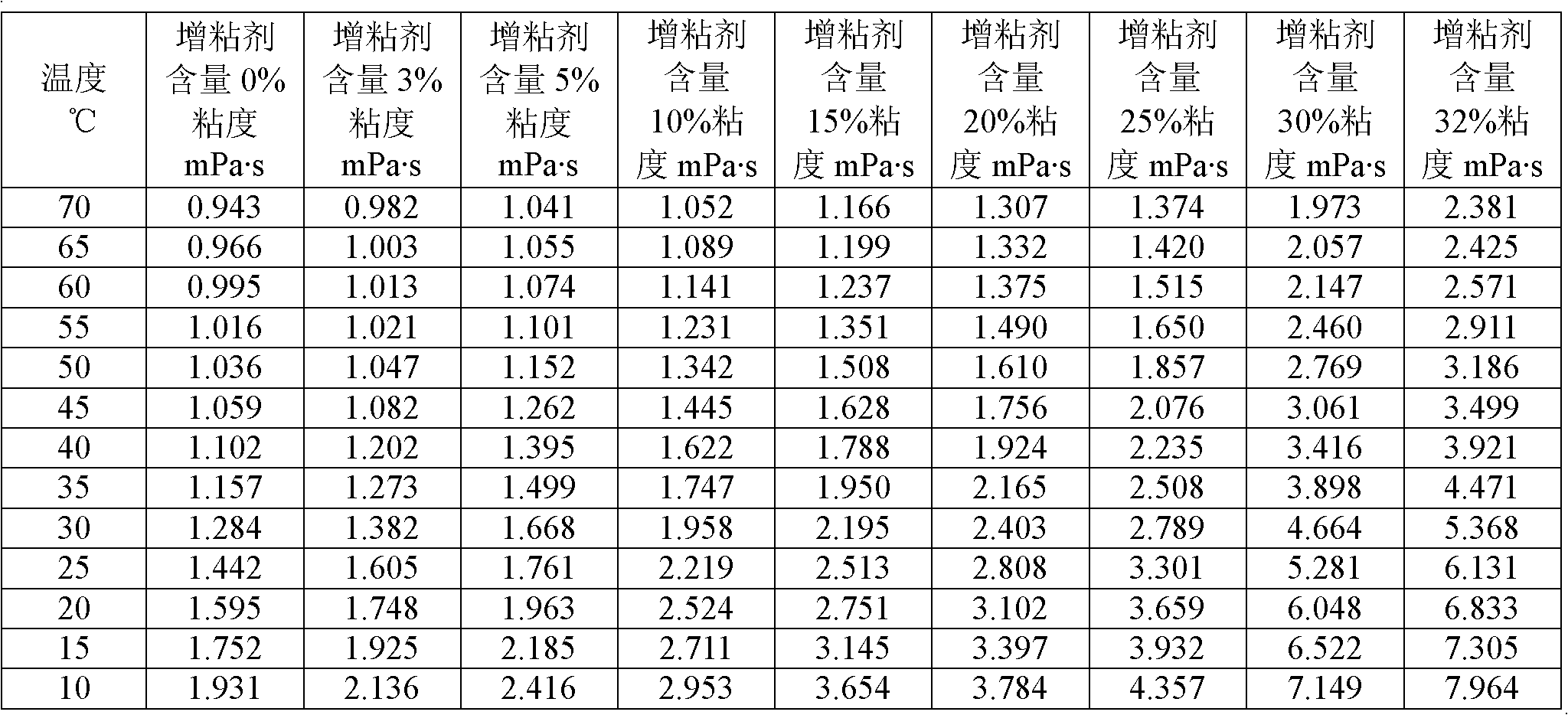

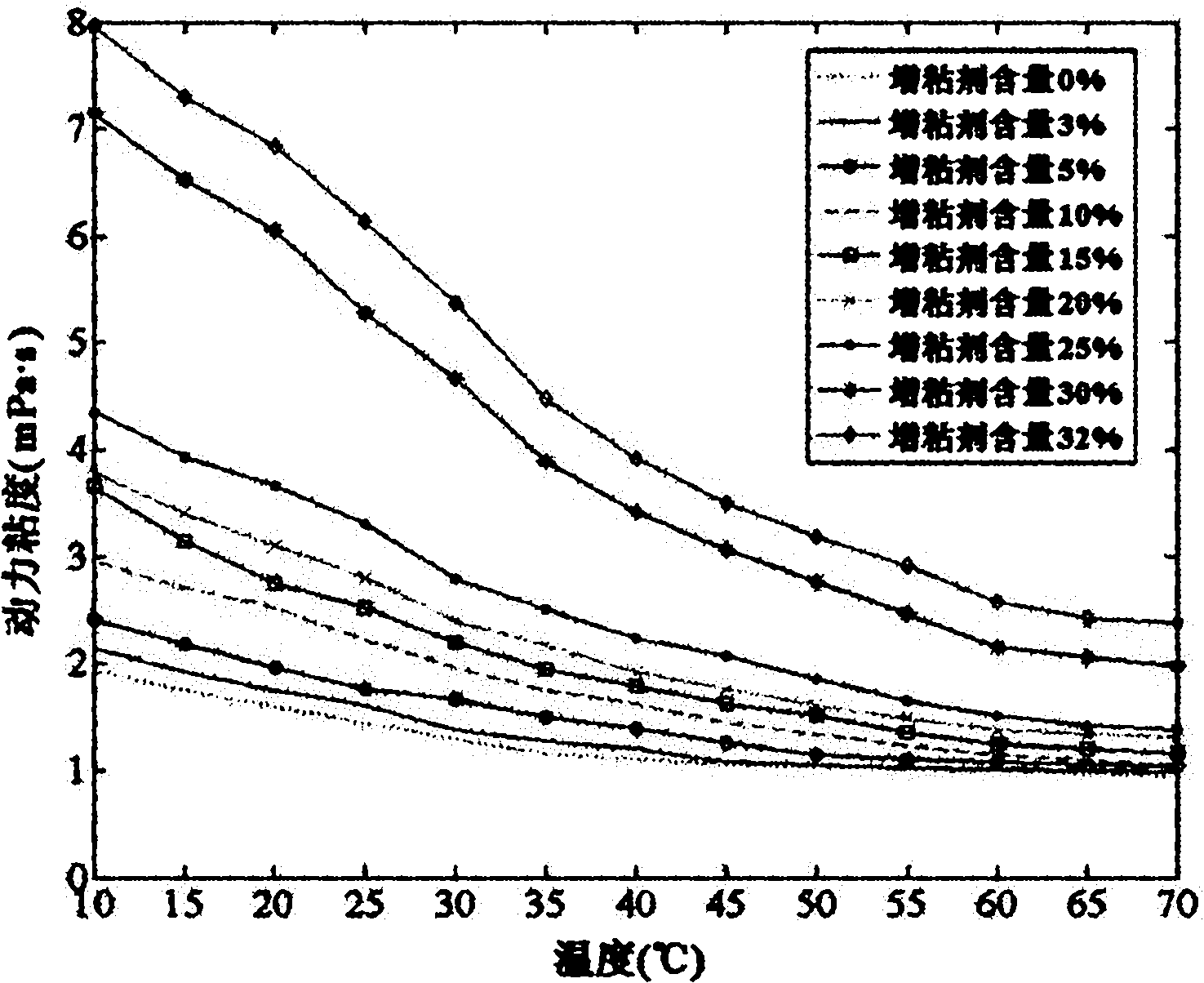

Viscosity-controllable aqueous lubricating liquid and application

ActiveCN102010780AExcellent Features - Flame RetardancyPromote degradationLubricant compositionTriethanolamine oleateAlcohol

The invention relates to viscosity-controllable aqueous lubricating liquid and application. The viscosity-controllable aqueous lubricating liquid consists of triethanolamine borate, triethanolamine oleate, triethanolamine sebacic acid, an alcohol viscosifier, an organic silicon defoaming agent and water. The viscosity range is from 0.9 Pa.s to 8 Pa.s. The main component of the water-based lubricating liquid is water, so excellent characteristic, such as fire resistance, of the water and high specific heat are preserved; each component of the aqueous lubricating liquid has low price, no toxicity and high degradability and meets the requirements of environmentally-friendly lubricants; tests show that the aqueous lubricating liquid has high rust resistance; an anti-rusting agent component ofthe aqueous lubricating liquid comprises a polar group with a large adsorption force, so the aqueous lubricating liquid has anti-friction and anti-wear effects on a friction pair and prolongs the service life of equipment; and the viscosity of the lubricating liquid can be adjusted by changing the viscosifier content according to specific engineering requirements, so that the higher rigidity, bearing capacity and heat stability of a processing equipment main shaft and a hydrostatic guideway system are guaranteed.

Owner:TIANJIN UNIV

Water base cutting fluid for cutting silicon wafers

InactiveCN102363738AReduce surface tensionImprove liquidityLubricant compositionWater basedTriethanolamine oleate

The invention provides a water base cutting fluid for cutting silicon wafers, which consists of glycol, triethanolamine oleate, non-ionic surface active agents, extreme pressure antiwear agents and water. The water base cutting fluid has the advantages that the surface tension of the cutting fluid is greatly reduced, the flowability and the permeability of the cutting fluid are greatly improved, the wettability of the cutting fluid on grinding materials is greatly improved, the dispersibility of the grinding materials is improved, the damage to the silicon wafers brought by aggregation and agglomeration of the grinding materials is avoided, the increase of the silicon wafer cutting yield is facilitated, and the silicon wafer cutting yield can reach 98 percent; and protective films can be formed on the surfaces of the silicon wafers, so the silicon wafers are easier to clean, and the lubricating effect, the abrasion performance and the cooling performance of the cutting fluid are improved.

Owner:ZHENJIANG GANGNAN ELECTRIC

Micro-emulsion cutting fluid for aluminum alloy, and preparation method of micro-emulsion cutting fluid

The invention discloses a micro-emulsion cutting fluid for aluminum alloy and a preparation method of the micro-emulsion cutting fluid. The micro-emulsion cutting fluid comprises the following raw materials in parts by weight: 12-16 parts of paraffin-based oil, 3-5 parts of star anise oil, 4-7 parts of eucalyptus oil, 5-7 parts of sorbitan fatty acid, 3-4 parts of triethanolamine oleate, 3-4 parts of petroleum sodium sulfonate, 7-8 parts of sorbitan monooleate, 3-4 parts of monoethanolamine, 6-7 parts of zinc sulfate, 4-7 parts of sodium oleate, 6-8 parts of dimethicone, 2-4 parts of sodium molybdate, 4-7 parts of octylphenol polyoxyethylene ether, 4-7 parts of chlorinated paraffin, 4-5 parts of ricinoleic acid, 0.5-1.5 parts of dodecanol, 1.2-1.5 parts of imidazolidinyl urea, 10-15 parts of additives and 15-25 parts of deionized water. The micro-emulsion cutting fluid for aluminum alloy also has the outstanding performances on the aspects of corrosion inhibition property, corrosion resistance, lubrication, rust resistance, defoaming property, service life and the like.

Owner:江苏悠谷未来科技有限公司

Environmental-protection range hood detergent and preparation method thereof

InactiveCN105255597AEfficient removalEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsLinear alkylbenzeneFatty alcohol

The invention discloses environmental-protection range hood detergent and a preparation method thereof. The environmental-protection range hood detergent is prepared from, by mass, 1-3 parts of sodium dodecyl benzene sulfonate, 1-2 parts of fatty alcohol polyoxylethylene ether sodium sulphate, 2-5 parts of linear alkylbenzene sulphonic acid, 0.5-1.5 parts of hydroxyethyl dodecyl alcohol, 0.1-0.8 part of triethanolamine, 3-8 parts of polyatomic alcohol, 2-6 parts of sodium carbonate, 1-5 parts of potassium sorbate, 0.5-1.3 parts of triethanolamine oleate, 0.8-1.6 parts of EDTA-disodium, 0.6-1.5 parts of emulgator, 0.5-1.2 parts of stabilizers and 50-70 parts of distilled water. According to the obtained environmental-protection range hood detergent, the safety to the human body is achieved, the toxicity to the human body does not exist, skins are not stimulated in the cleaning process, the greasy stains on a range hood and various cooking utensils can be cleaned away rapidly, simply and conveniently, and the detergent and the cleaning method do not damage the utensils.

Owner:李康

Anti-rust oil and preparation method thereof

ActiveCN103254978ANot easy to change colorNot easily oxidizedLubricant compositionButanedioic acidButylated hydroxytoluene

The invention discloses anti-rust oil, which consists of the following raw materials in parts by weight: 50-60 parts of kerosene, 10-20 parts of light diesel oil, 1-2 parts of barium petroleum sulfonate, 2-3 parts of triethanolamine oleate, 2-3 parts of stearic acid, 4-5 parts of dioctyl phthalate, 1-3 parts of zinc dialkyl dithiophosphate, 1-2 parts of 2,6-butylated hydroxytoluene, 3-4 parts of alkenyl butanedioic acid, 2-3 parts of coalescing agent, 1-2 parts of 2-aminoethyl heptade-alkenyl imidazoline and 0.2-0.3 part of dimethicone. The anti-rust oil prepared by the invention is difficult to discolor and oxidize, cannot influence the appearance of a workpiece and has hig comprehensive performance, high salt mist resistance, high damp-heat resistance, high aging resistance and high cleanability; by the coalescing agent, the surface tension of an oil film is improved, so that the oil film can be uniformly sprayed; the spreading performance on the surface of a metal workpiece is high; the formed oil film is uniform and stable; and the metal retaining protection effect is enhanced.

Owner:马鞍山采石矶涂料有限公司

Environmentally-friendly metal polishing agent and preparation method thereof

ActiveCN103451658AImprove antioxidant capacityImprove corrosion resistanceVegetable oilPolyethylene glycol

The invention relates to an environmentally-friendly metal polishing agent and a preparation method thereof, belonging to the technical field of metal surface treatment. The environmentally-friendly metal polishing agent comprises the following raw materials in parts by weight: 2-10 parts of vegetable oleic acid, 5-8 parts of coconut oil-based glucoside, 5-10 parts of sodium dodecylbenzene sulfonate, 20-30 parts of mineral oil, 8-13 parts of imidazoline quaternary ammonium salt, 2-5 parts of oleic acid triethanolamine, 50-80 parts of silicon micro-powder, 5-10 parts of polyethylene glycol, 15-20 parts of crystalline layered sodium disilicate and 80-100 parts of deionized water. The environmentally-friendly metal polishing agent can be used for effectively clearing away oil stains and rusty spots on the surfaces of metals, so that the surfaces of the metals are kept glossy and bright; and the raw materials do not comprise fluorine-containing or phosphorus-containing compounds, so that the environmentally-friendly metal polishing agent is safe and has environmentally-friendly effect; and meanwhile, as the raw materials comprise the mineral oil and the imidazoline quaternary ammonium salt, the surface smoothness of the metals can be effectively improved, and a layer of protective film is formed on the surfaces of the metals and has strong covering power, so that the oxidation resistance and the corrosion resistance of the metals are greatly improved.

Owner:江苏悠谷未来科技有限公司

Environmentally friendly multifunctional metal cleaning agent

The invention relates to environmentally friendly multifunctional metal cleaning agent, especially applicable to cleaning of metal workpieces of bearing, tractor, automobile, construction machine, aviation machine, textile machine and chemical machine. The environmentally friendly multifunctional metal cleaning agent provided by the invention can effectively remove oil on non-ferrous metal and ferrous metal, is antirust and has no pollution to the environment. The invention is prepared by the following raw materials: 0.5-2% of peregal, 1-10% of 6501, 1-5% of triethanolamine oleate, 1-10% of sodium nitrite, 1-10% of triethanolamine, 5-8% of triethanolamine, 10-12% of C8-9 alkylphenol polyoxyethylene ether, 8-10% of C12 fatty alcohol-polyoxyethylene ether, 6-9% of 12 fatty alcohol-polyoxyethylene ether, 8-10% of polyether and 50-70% of water.

Owner:黄远婕

Environmentally-friendly interprocess aqueous antirust liquid and preparation method thereof

An environmentally-friendly interprocess aqueous antirust liquid is composed of 3-14 parts by weight of triethanolamine oleate, 1-8 parts by weight of an inorganic corrosion inhibitor, 0.1-2 parts by weight of sodium benzoate, 1-10 parts by weight of glycerin, and 70-95 parts by weight of deionized water; and the inorganic corrosion inhibitor is one of sodium tungstate of sodium molybdate, or a sodium tungstate and sodium molybdate combination. Triethanolamine oleate and sodium benzoate in the above formula are organic corrosion inhibitors, and the aqueous solutions of the organic corrosion inhibitors and the aqueous solution of the inorganic corrosion inhibitor sodium tungstate and / or sodium molybdate have certain corrosion inhibition and antirust functions to steel. The compounding of the inorganic corrosion inhibitor and the organic corrosion inhibitors promotes and reinforces respectively corrosion inhibition and antirust performances of the inorganic corrosion inhibitor and the organic corrosion inhibitors. Sodium benzoate in the formula used as the organic corrosion inhibitor also has certain sterilization and anticorrosion effects; and glycerin in the formula used as an assistant is mainly used for adjusting the surface tension of the antirust liquid in order to improve the wetting property of the antirust liquid to the surface of a metal substrate.

Owner:马鞍山采石矶涂料有限公司 +1

Graphene oxide-containing water-based metal cutting fluid and preparation method thereof

InactiveCN106590906AImprove the lubrication effectImprove anti-wear performanceAdditivesWater basedLubrication

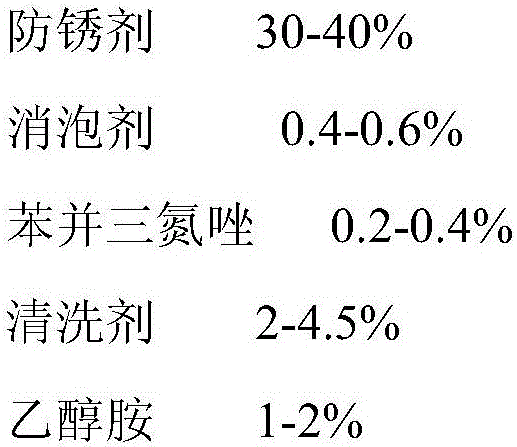

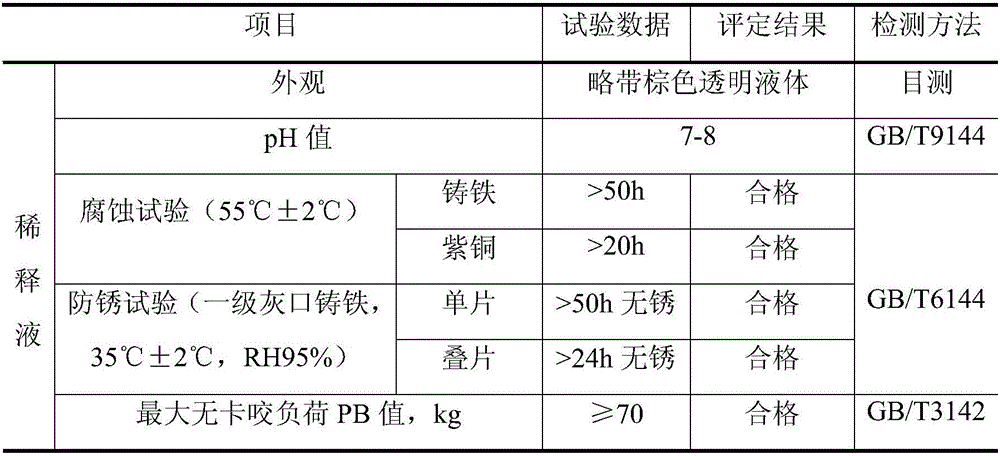

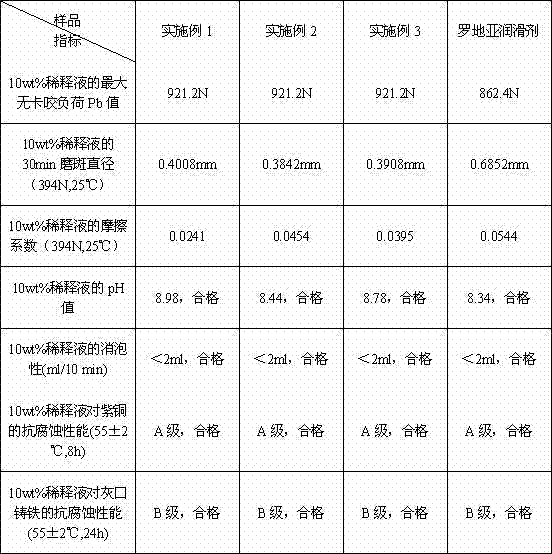

The invention discloses graphene oxide-containing water-based metal cutting fluid and a preparation method thereof. The graphene oxide containing water-based metal cutting fluid consists of a lubricating additive, an anti-rusting agent, a defoaming agent, benzotriazole, triethanolamine oleate, ethanol amine and water. The contents of the raw materials are as follows in percentage by weight: 0.5-5% of the lubricating additive, 30-40% of the anti-rusting agent, 0.4-0.6% of the defoaming agent, 0.2-0.4% of the benzotriazole, 2-4.5% of a detergent, 1-2% of ethanol amine and the balance water, wherein the lubricating additive is a graphene oxide dispersion liquid. The graphene oxide-containing water-based metal cutting fluid has the beneficial effects that due to addition of a graphene oxide additive, not only are properties of the cutting fluid improved, such as the lubrication property, the anti-wearing property and the cooling property, but also graphene oxide has slight environment influence and is beneficial to environmental protection.

Owner:SHANGHAI INST OF TECH

Automobile radial tire steel cord wet-pulling lubricating agent

InactiveCN102559351AImprove performanceImprove corrosion resistanceLubricant compositionPhosphoric acidMaterials science

The invention relates to automobile radial tire steel cord wet-pulling lubricating agent, comprising the following components in percent by weight: 13-30% of oiliness solvent, 1-8% of extreme-pressure antiwear agent, 0.5-5% of emulsifier, 3-10% of pH regulator, 2-7% of cosolvent, 3-14% of antirusting agent, 1.1-4% of complexing agent, 0.1-5% of bactericide, 0.1-2% of defoaming agent and balance of water, wherein the oiliness solvent is a mixture of triethanolamine oleate soap, triethanolamine oleate ester, oleic diethanolamide and castor oil; and the extreme-pressure antiwear agent is a mixture of tri-n-butyl phosphate and zinc dialkyl dithiophosphates. The lubricating agent has good extreme-pressure antiwear performance, and service life of a mould can be effectively prolonged; and all the components of the lubricating agent can be effectively biologically degraded, thus the lubricating agent is environmentally friendly.

Owner:WUHAN UNIV

Environment-friendly emulsified cutting fluid and method for preparing same

ActiveCN102604728ANo pollution in the processStable processingAdditivesSODIUM METAPHOSPHATECarboxylic acid

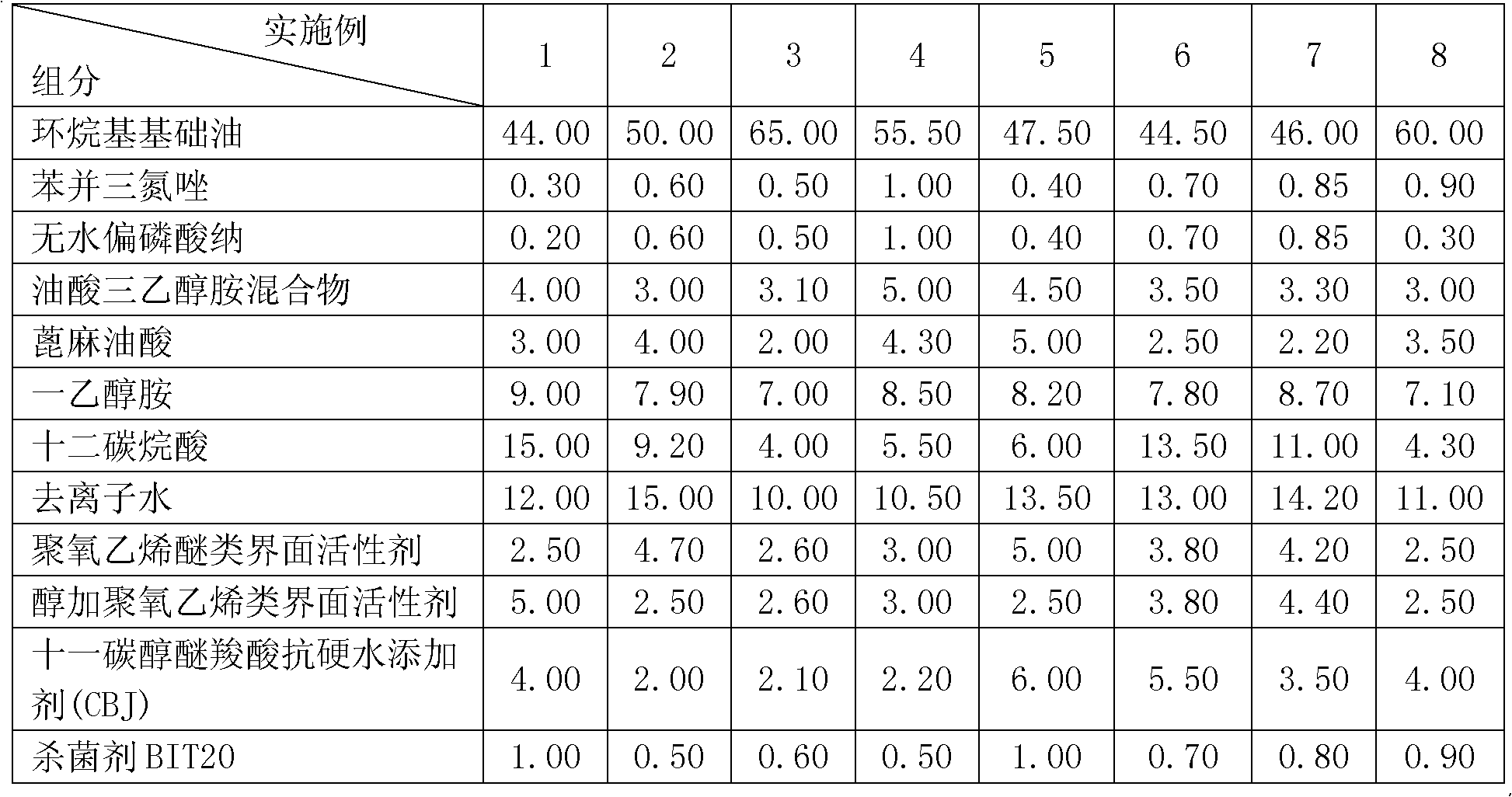

The invention discloses an environment-friendly emulsified cutting fluid and a method for preparing the environment-friendly emulsified cutting fluid. The environment-friendly emulsified cutting fluid is prepared by mixing naphthenic base oil, benzotriazole, anhydrous sodium metaphosphate, triethanol amine oleate mixture, ricinoleic acid, monoethanolamine, dodecanoic acid, deionized water, polyethenoxy ether surfactant, alcohol-polyoxyethylene surfactant, undecylenic alcohol ether carboxylic acid hard-water resisting additive and fungicide BIT20 uniformly according to a certain proportion and sequence under a certain temperature condition. The environment-friendly emulsified cutting fluid prepared by adopting the method can meet the requirement for cooling performance during processing, can not release irritating odor during processing and can not pollute the working environment of the operators. The waste generated after using the environment-friendly emulsified cutting fluid can be degraded biologically with the passing of time without causing pollution to the environment and the ambient around the processing machines of the client, thus the operating environment can be kept clean.

Owner:苏州铱诺化学材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com