Metal bearing water-based cleaning agent and preparation method and application thereof

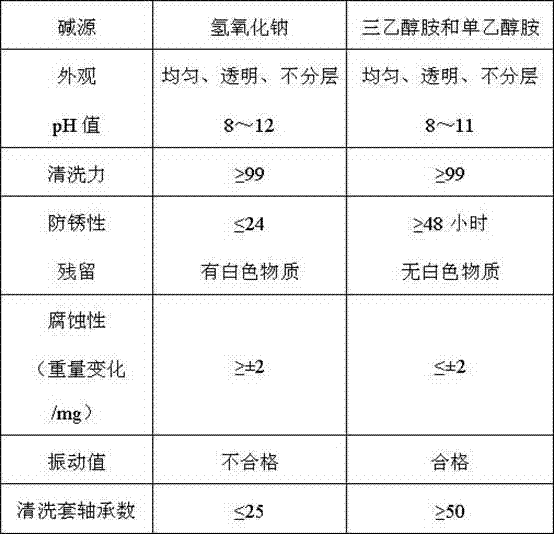

A water-based cleaning agent and bearing technology, applied in the field of metal cleaning agents, can solve the problems of precipitation, strong irritation, and reduced cleaning effect, and achieve the effect of easy-to-obtain raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

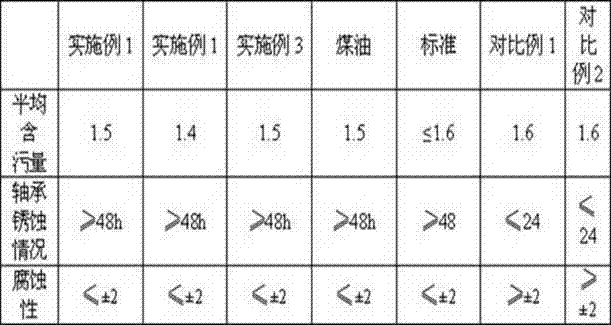

Examples

Embodiment 1

[0037] 1. Take 10 parts of triethanolamine oleate, 12 parts of triethanolamine, and 16 parts of monoethanolamine, then add 0.2 parts of benzotriazole, stir to dissolve, then add 1 part of sodium tetradecylsulfonate, stir evenly, and Add 3 parts of coconut oil polyoxyethylene ether-9 (AEO-9), 2 parts of nonylphenol polyoxyethylene ether-10 (OP-10), 3 parts of lauric acid diethanolamide, and stir well to form an oil phase .

[0038] 2. Take 51.8 parts of pure water, add 1 part of disodium edetate, stir and dissolve to form a water phase.

[0039] 3. Add the oil phase to the water phase, stir quickly and evenly, and let it stand for 12 hours to form a uniform brown clear liquid.

[0040] 4. Packaging.

Embodiment 2

[0042] 1. Take 18 parts of triethanolamine oleate, 14 parts of triethanolamine, and 10 parts of monoethanolamine, then add 0.3 parts of benzotriazole, stir to dissolve, then add 0.5 parts of sodium cetyl sulfonate, stir evenly, and then add 3 parts of lauryl polyoxyethylene ether-9 (AEO-9), 3 parts of octylphenol polyoxyethylene ether-10 (OP-10), 5 parts of lauric acid diethanolamide (6503), stir quickly to form oily phase.

[0043] 2. Take 45 parts of pure water, add 1.2 parts of disodium ethylenediamine tetraacetate, stir and dissolve to form a water phase.

[0044] 3. Add the oil phase to the water phase, stir quickly and evenly, and let it stand for 12 hours to form a uniform brown clear liquid.

[0045] 4. Packaging.

Embodiment 3

[0047] 1. Take 20 parts of triethanolamine oleate, 15 parts of triethanolamine, and 11 parts of monoethanolamine, then add 0.05 parts of benzotriazole, stir to dissolve, then add 1 part of sodium octadecylsulfonate, stir evenly, and add 2 parts cetyl alcohol polyoxyethylene ether-9 (AEO-9), 4 parts laurylphenol polyoxyethylene ether-10 (OP-10), 6 parts saturated oleic acid diethanolamide (6503), stir well , forming an oil phase.

[0048] 2. Take 39.95 parts of pure water, add 1 part of disodium ethylenediamine tetraacetate, stir and dissolve to form a water phase.

[0049] 3. Add the oil phase to the water phase, stir evenly, and let stand for 12 hours.

[0050] 4. Packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com