Preparation method of environmentally-friendly storage battery

A battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as loss of use value of land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

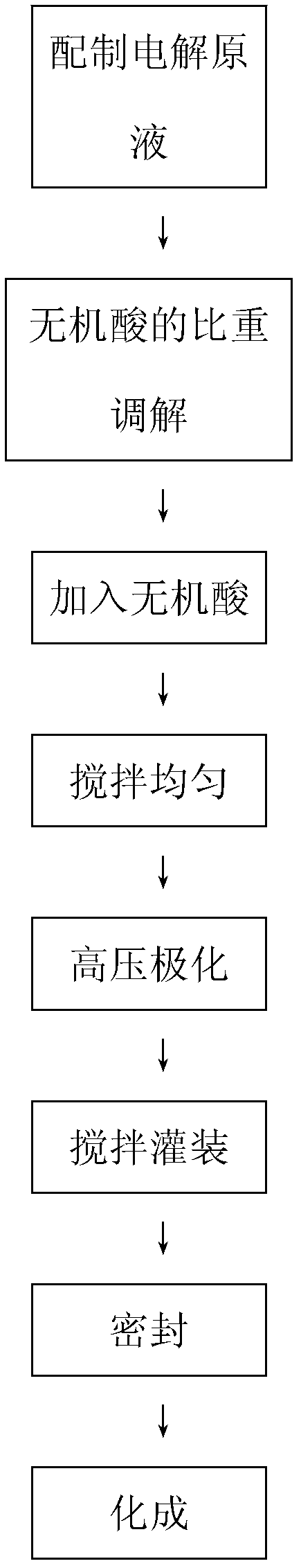

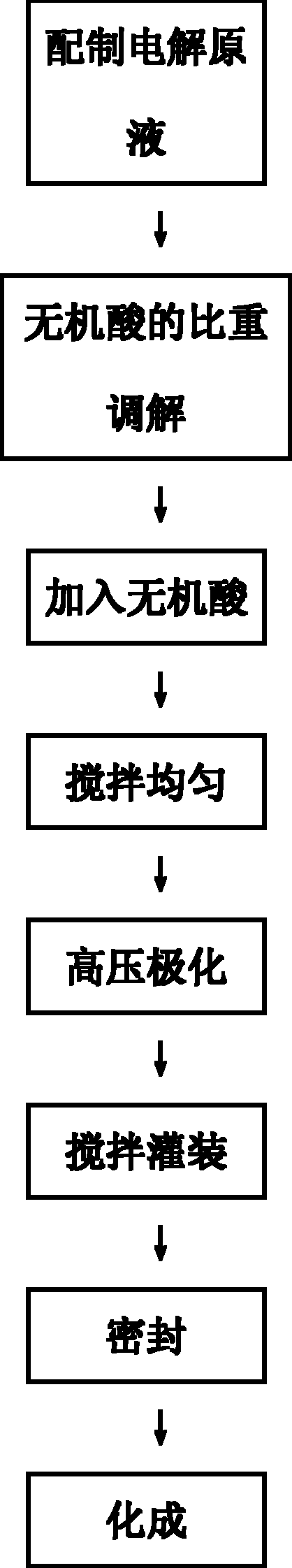

[0019] With reference to accompanying drawing, the present invention comprises the following steps:

[0020] 1. Configure the electrolytic stock solution. The composition of the electrolytic stock solution is:

[0021] A. Contains 31-37.9% pure silicon dioxide (SiO 2 ) of sodium silicate (Na 2 OSoO 2 ) 12~15%;

[0022] B. Sodium sulfate (Na 2 SO 4 ) 11~16%;

[0023] C. Sodium carbonate (Na 2 CO 3 )8.87~10%;

[0024] D. Poly-3-chlorobutene 0.014~0.028%;

[0025] E. Polyaminosiloxane 0.38~1.18%;

[0026] F. The balance is water. The above is volume percentage;

[0027] 2. Dilute the prepared electrolytic stock solution and water with a volume ratio of 1:30-50 and add water. The specific gravity of the diluted liquid is 0.87-1.1 g / cm 3 , the pH value is 8.5-9.1;

[0028] 3. Adjust the specific gravity of the inorganic acid to 1.356-1 g / cm 3 , mixing and stirring the diluted liquid and the inorganic acid at a volume ratio of 3.8 to 4:1;

[0029] 4. Place the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com