Door frame cover board and processing method thereof

It is a technology for setting boards and door frames, which is applied in the direction of window/door frames, wood processing equipment, manufacturing tools, etc. It can solve the problems of polluting the indoor environment and achieve the effects of convenient processing, no hidden danger of indoor environmental pollution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

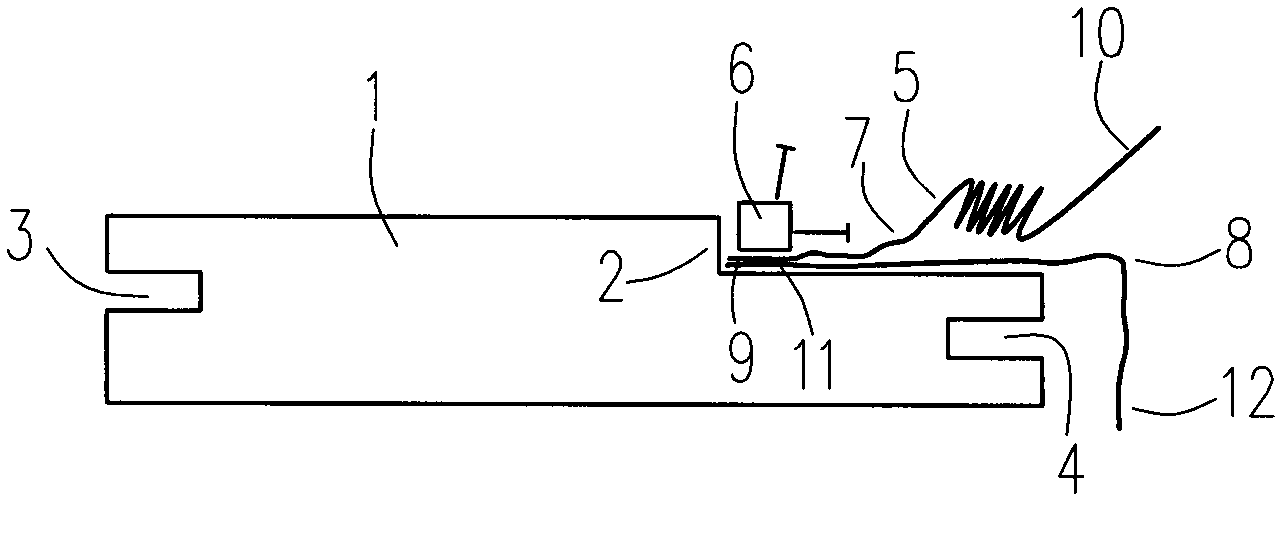

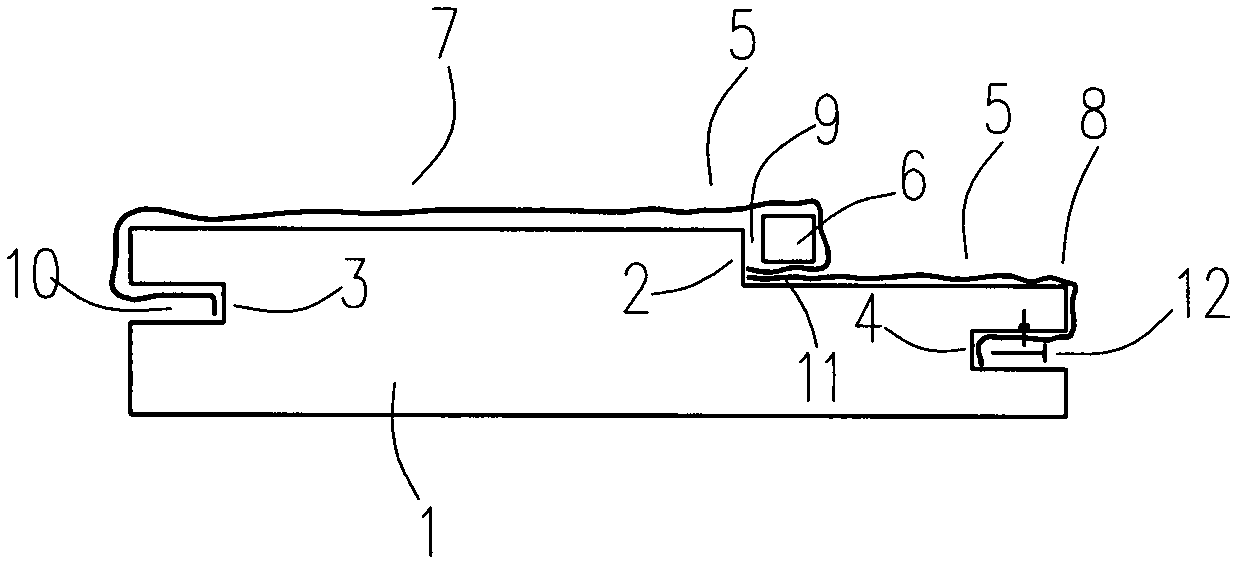

[0013] Such as image 3 As shown, the cover plate body 1 is provided, and the cover plate body 1 is provided with an L-shaped slot for installing the door leaf 2, a first decorative board installation groove 3, a second decorative board installation groove 4, and a leather surface layer 5, Edge-sealing wood strip 6, the leather surface layer 5 includes a first surface layer 7 and a second surface layer 8, the first surface layer 7 is provided with a first side 9 and a second side 10, and the second surface layer 8 is provided with a first side The three sides 11 and the fourth side 12, the first side 9 and the third side 11 are fixed to the L-shaped notch 2 by the edge-sealing wood strip 6 and fastening nails, and the second side 10 is fixed to the first decoration by the fastening nails In the board installation groove 3, the fourth side 12 is fixed in the second decoration board installation groove 4 by fastening nails.

[0014] The principle is: the first surface layer 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com