Patents

Literature

284results about How to "Avoid heavy pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

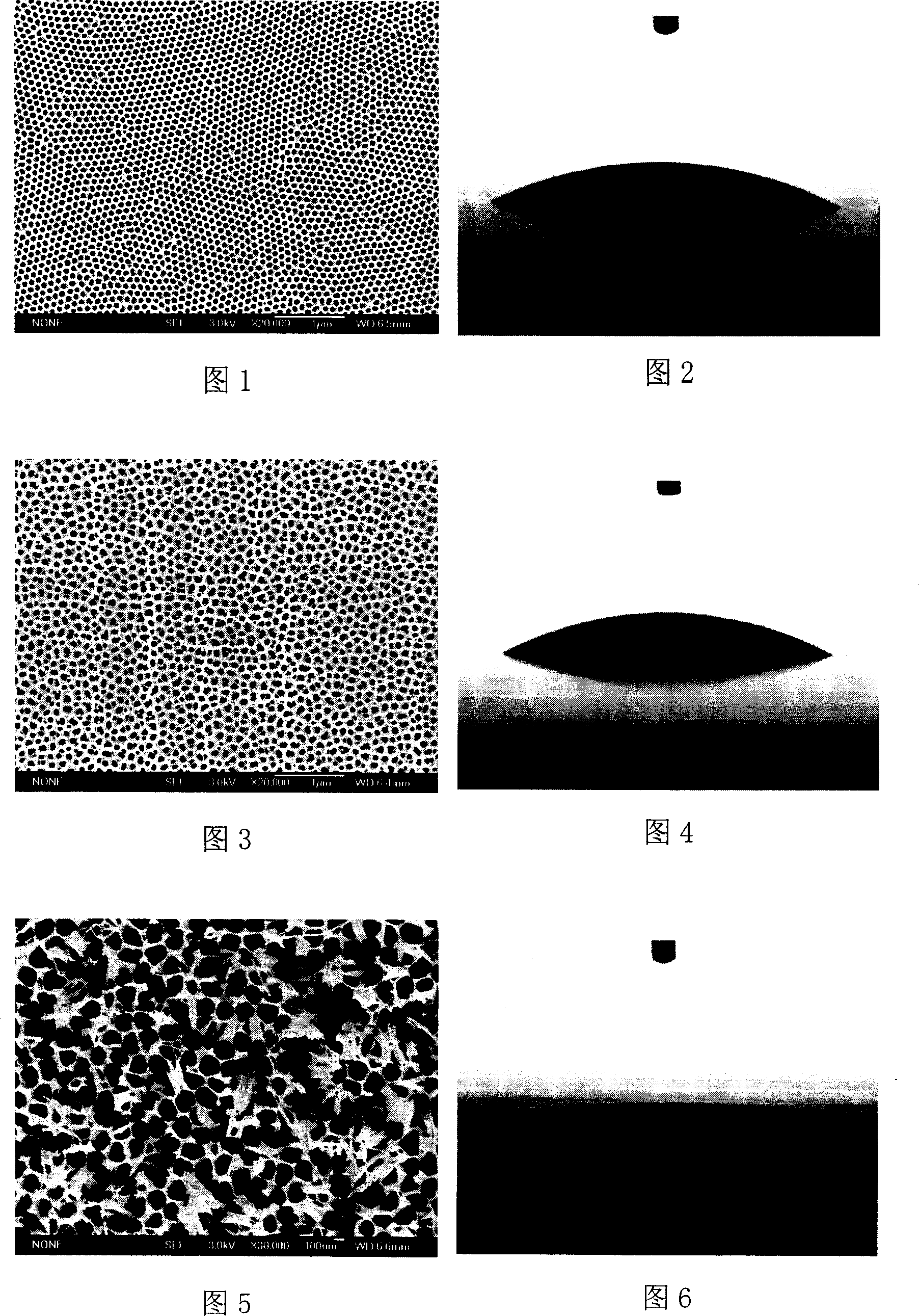

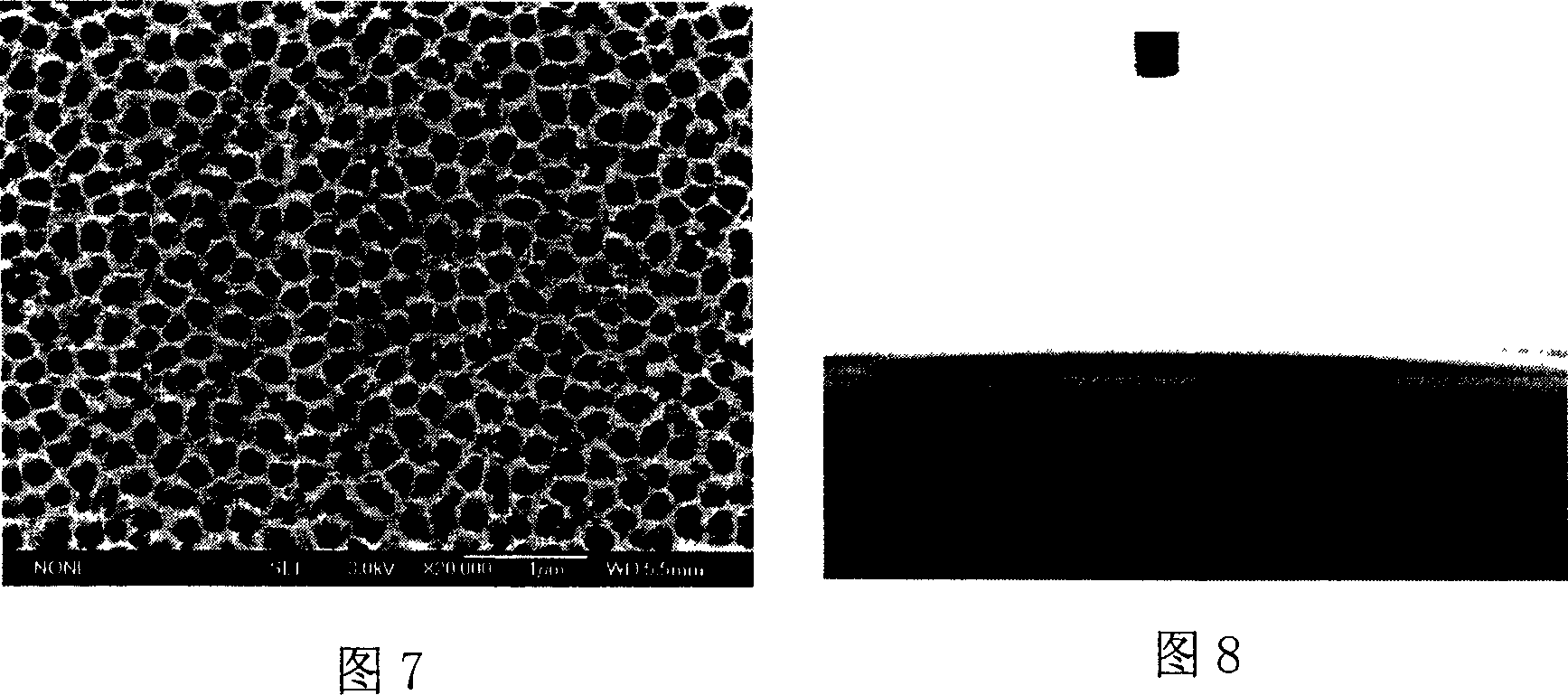

Process for preparing highly-hydrophilic alumina film material

InactiveCN101007645AImprove stabilityShape is easy to controlAluminium oxide/hydroxide preparationPhosphoric acidElectrochemistry

The invention discloses a making method of high-hydrophilicity alumina film, which comprises the following steps: adopting electrochemical polished aluminium foil as anode and platinum piece as cathode; selecting one of sulfuric acid, oxalic acid phosphoric acid with water or poor water (the composite solution of oxalic alcohol and water) as electrolyte solution; using electrochemical oxidizing method to strip aluminium base; removing damping layer; obtaining the product with different shapes and areas.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

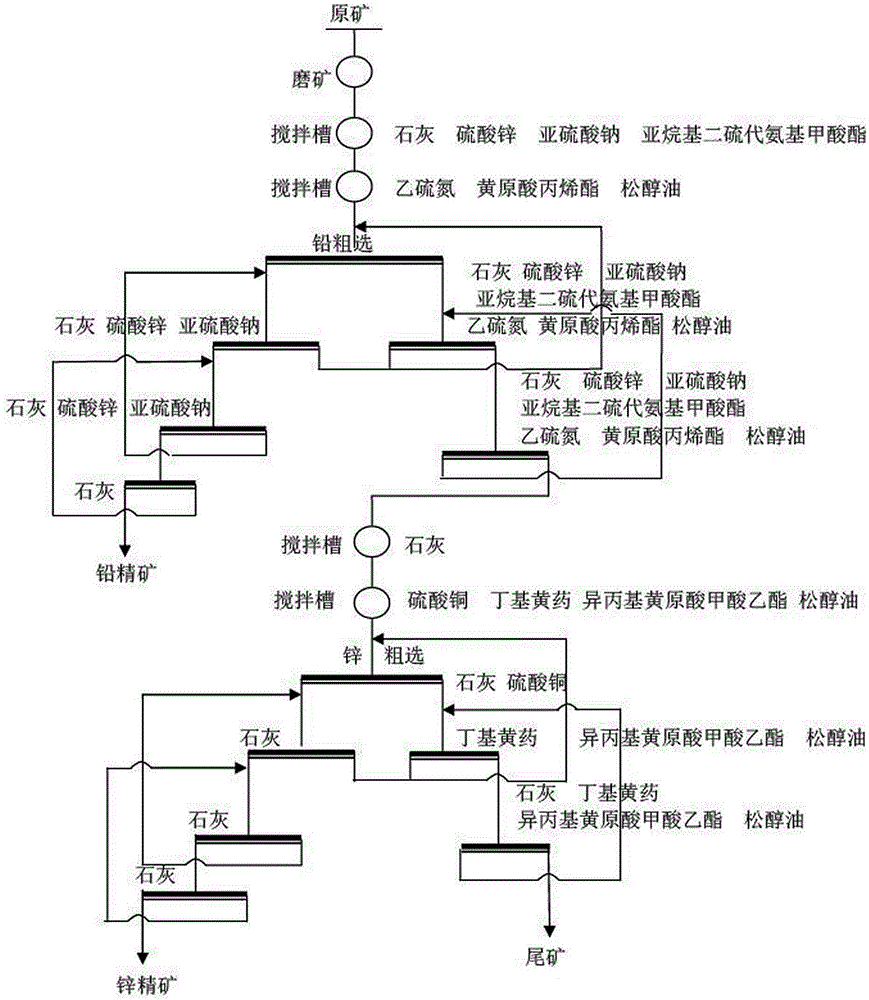

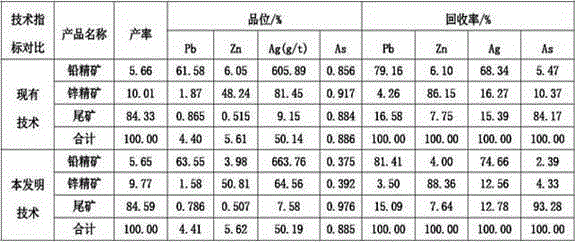

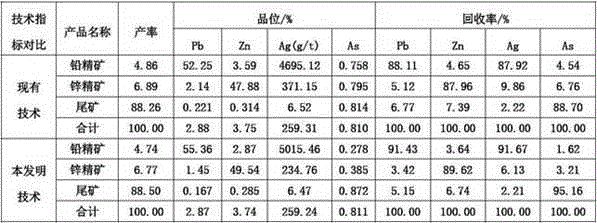

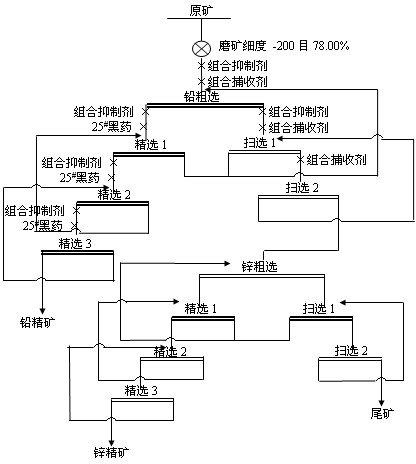

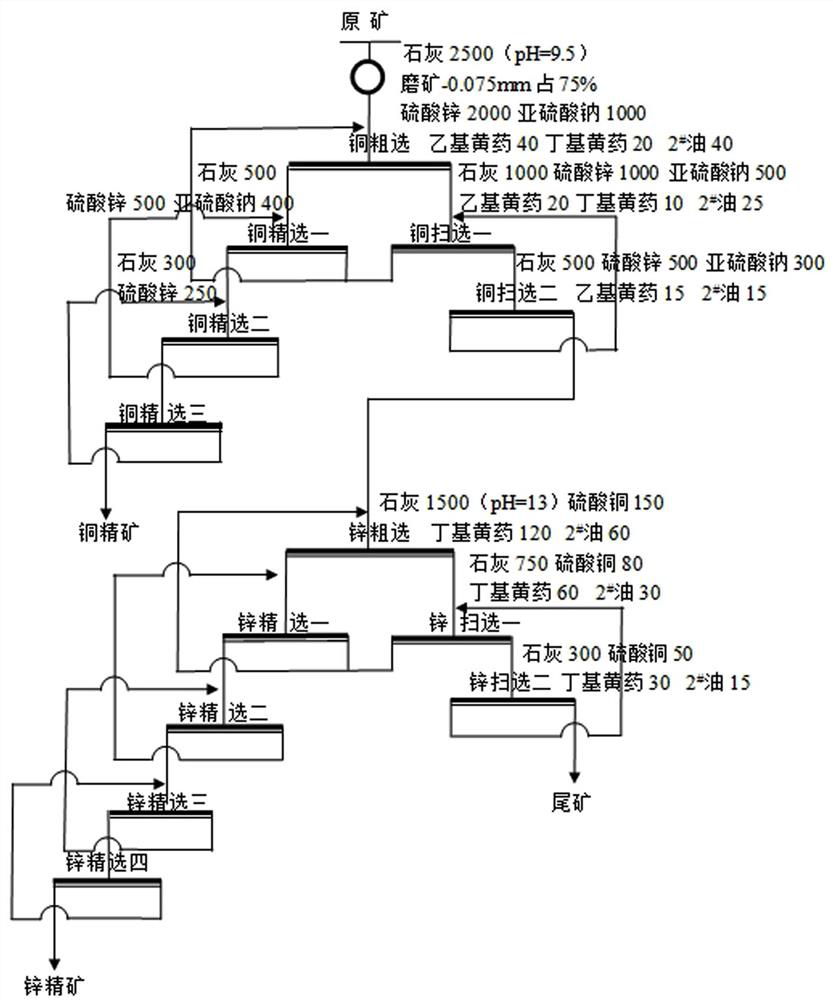

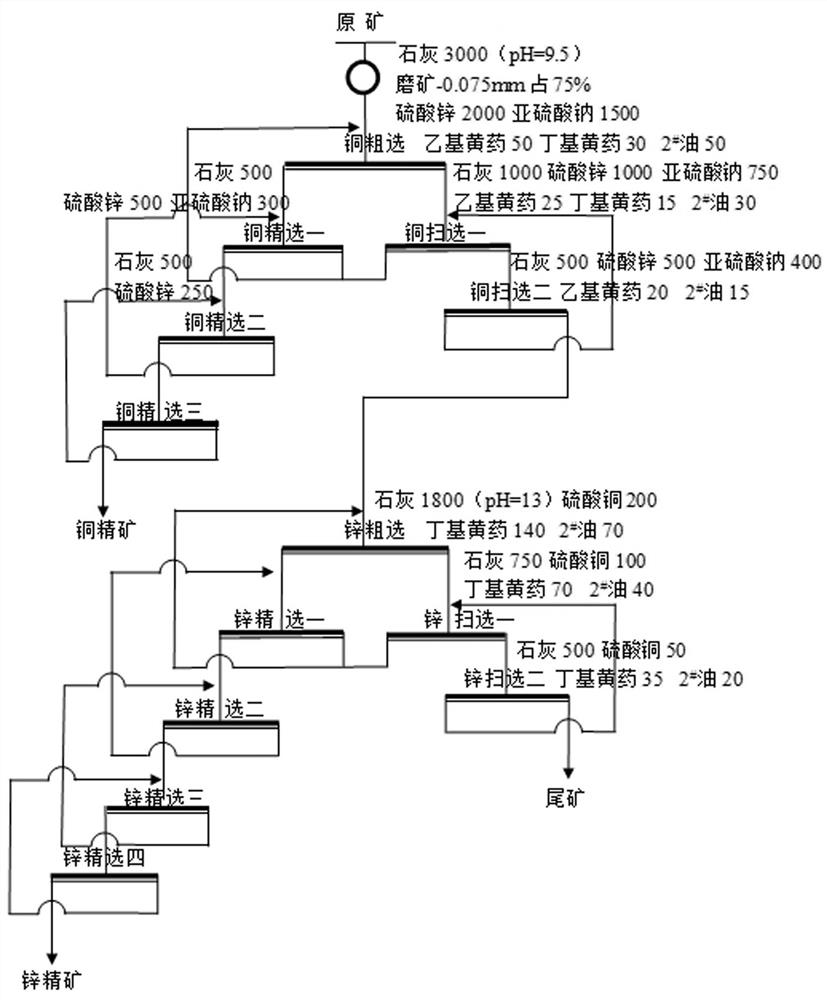

Beneficiation method for complex sulphide lead-zinc ore containing arsenic

The invention discloses a beneficiation method for complex sulphide lead-zinc ore containing arsenic. The beneficiation method is characterized by comprising the steps that raw ore is added into a ball mill to be milled, lime, zinc sulfate, sodium sulfite and p-xylylenebis(n,n- diethyldithiocarbamate) are added after the milled raw ore enters a first stirring tank, and diethyldithiocarbamate, isoamylxanthate and terpenic oil are added into a second stirring tank; a combined inhibitor and a combined collector are added before first-time scavenging and second-time scavenging of lead floatation; the combined inhibitor and the combined collector are added before first-time lead concentration, second-time lead concentration and third-time lead concentration; zinc floatation is conducted on tailings obtained after lead floatation; the combined inhibitor and the combined collector are added before first-time scavenging and second-time scavenging of zinc floatation; and lime is added before each time zinc concentration is conducted. By the adoption of the beneficiation method, lead-zinc concentrate products qualified in arsenic content are obtained, the grade and yield of lead and zinc in lead concentrate can be increased, and the grade and yield of zinc in zinc concentrate can also be increased; highly toxic products such as sodium cyanide or oxidizing agents do not need to be added, serious pollution to the environment is avoided, and clean, environment-friendly and safe production is achieved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

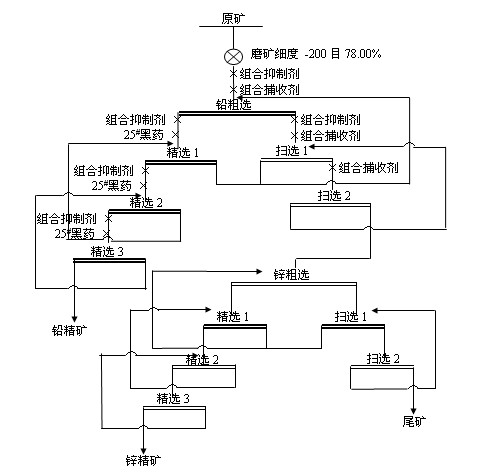

Beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore

The invention relates to a beneficiation method for difficultly selecting lead-zinc ore, in particular to a beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore. The beneficiation method comprises the steps of: (1) ore grinding: grinding raw ore into the ore with the material particle size being smaller than 0.074mm and being 72%-84% of the whole raw ore;(2) differential flotation of lead; and (3) differential flotation of zinc in float lead tailings. Particularly, the method adds a combined inhibitor and a combined collector in the beneficiation process to replace highly-toxic sodium cyanide selecting lead-zinc ore, so that the environmental pollution is reduced. In addition, the method is used for increasing the recovery ratio of lead-zinc concentrate, increasing the recovery ratio of precious metals including gold and silver, and increasing the economic benefit of enterprises.

Owner:HUNAN RES INST FOR NONFERROUS METALS

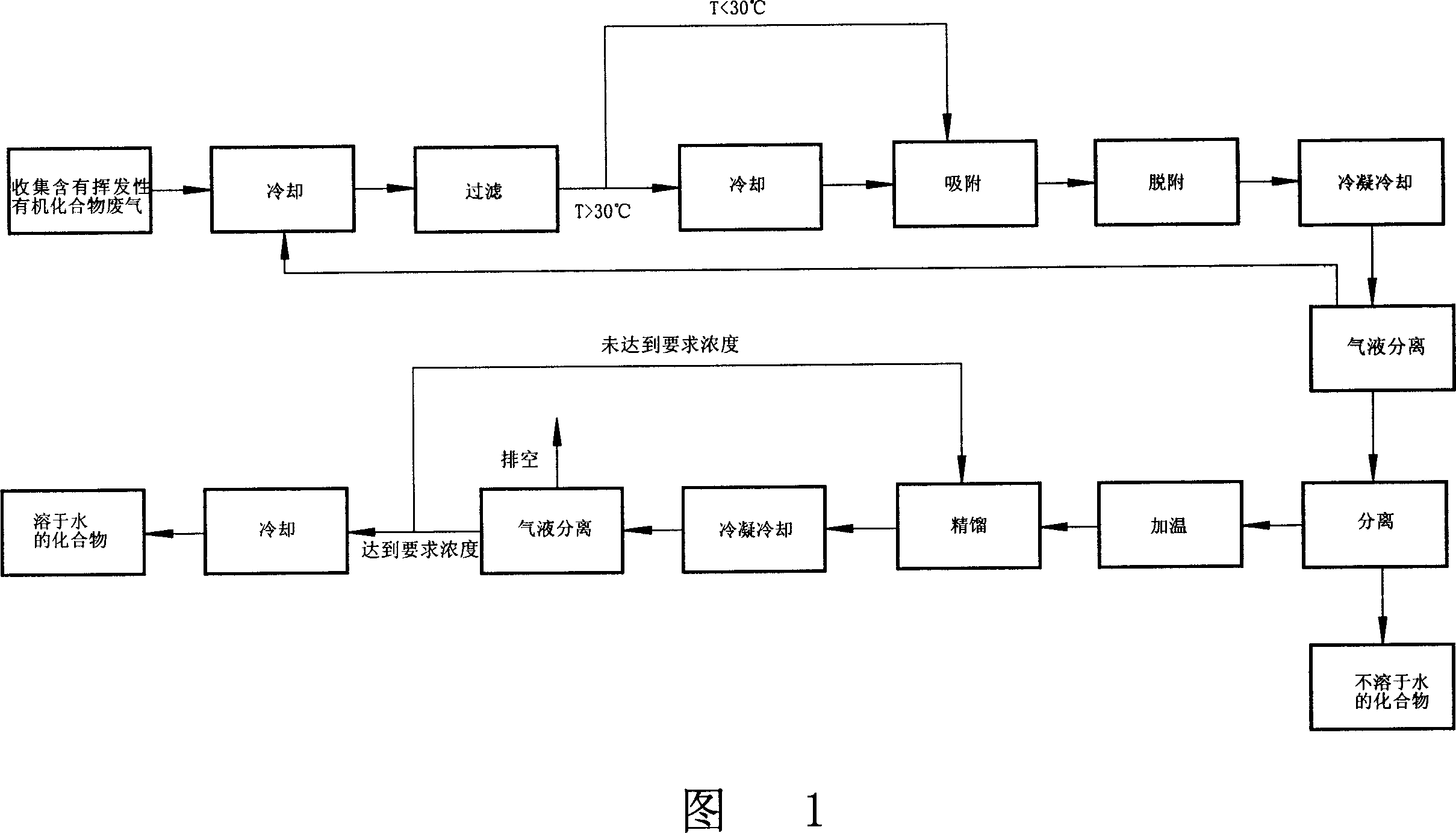

Process of purifying and recovering waste gas containing volatile organic compound and its application

ActiveCN1986028ASolve pollutionAvoid heavy pollutionDispersed particle separationVapor condensationRecovery methodVapor–liquid separator

The present invention relates to purification, recovery and application of waste gas containing volatile organic compound, and the process includes collecting waste gas containing volatile organic compound, cooling the waste gas and filtering in the filter, measuring the temperature of the filtered waste gas and further cooling to below 30 deg.c, adsorbing cooled waste gas in the adsorber, desorbing the adsorbed waste gas with water vapor, condensating and cooling the desorbed gas-liquid mixture in the condensate cooler, gas-liquid separating the condensated and cooled mixture in the gas-liquid separator, mixing the separated gas and the collected waste gas and feeding the gas mixture into the cooler, and recovering water insoluble volatile organic compound and water soluble volatile organic compound separately. The process is used to eliminate air pollution of printing machine, dyeing machine and reaction kettle while creating great economic benefit.

Owner:何金星

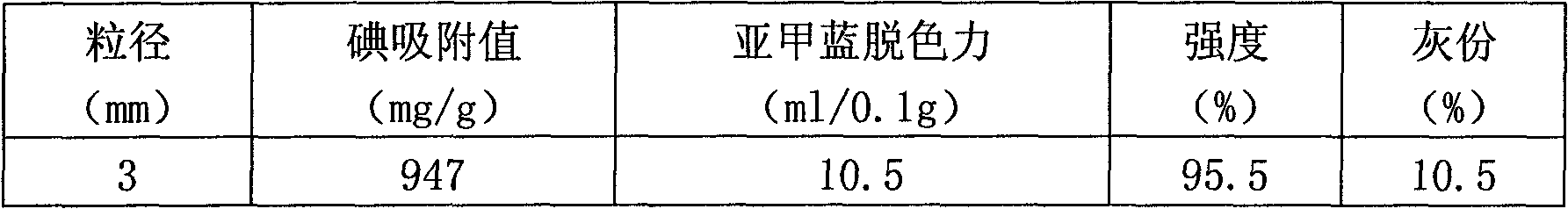

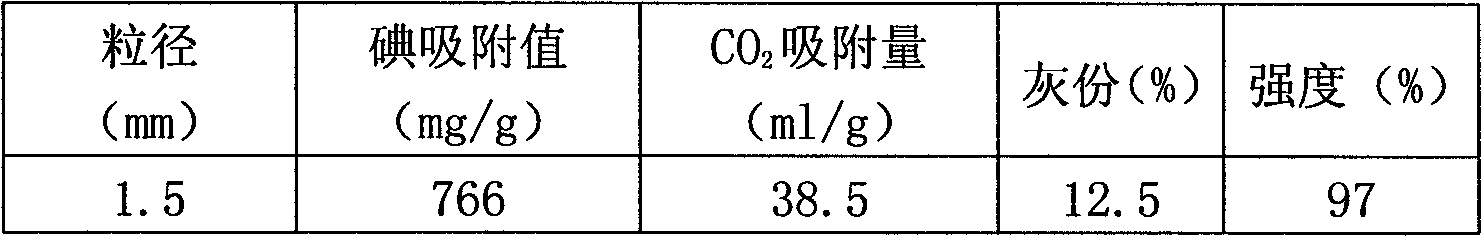

Production method for activated carbon

The invention discloses a production method for activated carbon. The production method comprises the following steps of: adding binding agents such as polyphosphates, active silicic acid and the like to raw materials such as pulverized coal and the like, and obtaining a finished product after kneading, extruding, drying and activating the mixture. According to the production method, as the binding agents formed by matching one or several compounds are used for replacing coal tar, the serious pollution caused by using the coal tar as the binding agent can be avoided, and plenty of coal tar with the high cost is saved, and the production cost is reduced. The obtained activated carbon has high strength, very few floating dust and very high adsorptive capacity and can be used for water treatment, deodorization, decolorization, a catalyst carrier, the desorption of CO2 and N2 gasses in pressure swing adsorption, gas phase adsorption, solvent recovery, a carbon catalyst and the like.

Owner:淮北市大华环保科技有限公司

Electrolyte and method for electrolyzing and refining crude lead

InactiveCN104746098AAvoid serious harmAvoid heavy pollutionPhotography auxillary processesHydrometallurgyMethanesulfonic acid

The invention relates to electrolyte and a method for electrolyzing and refining crude lead, and belongs to the technical field of wet-process metallurgy. The electrolyte electrolyzing and refining crude lead is of a methylsulphonic acid solution system comprising methyl lead sulfonate and free methyl sulfonic acid, wherein the concentration of Pb<2+> is 50-200g / L, and the concentration of the free methyl sulfonic acid is 50-160g / L. The method comprises the following steps: placing a solution system electrolyte comprising the methyl lead sulfonate and free methyl sulfonic acid, a to-be-refined crude lead anode plate and a cathode plate into an electrolytic cell, then, applying direct-current power, adding an additive comprising one or a mixture of animal glue, lignosulfonate, aloin and beta-naphthol into the electrolyte to electrolyze for 2-7 days so as to generate cathode lead and anode mud, obtaining national-standard 1# lead ingot after melting and casting cathode lead, performing washing and filter pressing on the anode mud, and then feeding the anode mud to a noble metal extracting process. According to the method, a brand-new methanesulfonic acid solution system is adopted as an electrolyte for electrolysis, so that the method has the characteristic of being remarkable in environment-friendly advantage.

Owner:KUNMING UNIV OF SCI & TECH

Modified stalk material and its application

InactiveCN1412092AHigh strengthEnvironmental pollutionFlexible coversWrappersPhanerochaete chryosporiumChemistry

The present invention relates to a modified straw material, its production method and application. The production method of the modified straw material includes the following steps: 1. steam-blastingstraw to obtain steam-blasted straw; 2. inoculating the steam-blasted straw with culture liquor to make solid fermentation treatment to degrade lignin; 3. mixing the steam-blasted straw and air-driedstraw, making their mixture undergo the processes of thermosetting treatment and forming treatment so as to obtain the invented modified straw material which can be made into plate material or light packaging material instead of wood material, so that it possesses extensive application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing mine fill by utilizing Bayer process red mud

InactiveCN103130434AAvoid heavy pollutionImprove early strengthSolid waste managementEnvironmental resistanceResource utilization

Provided is a method for preparing mine fill by utilizing Bayer process red mud. The method belongs to the technical fields of construction materials and solid waste resource utilization. The technical scheme of the method for preparing the mine fill is that the Bayer process red mud, coal ash, lime and gypsum are adopted to serve as raw materials and are evenly mixed according to a certain weight percentage to form the mine fill. The method for preparing the mine fill by utilizing the Bayer process red mud has the advantages that due to the fact that after the Bayer process red mud is hydrated, large amount of ettringite is produced and has high strength in an early period, the ettringite has an function of micro-expansion without shrinkage, and a goaf of a mine can be filled. Compared with cement used for the fill, cost can be saved by more than 60%. The method for preparing the mine fill by utilizing the Bayer process red mud facilitates saving of land source, avoids causing severe pollution to peripheral water bodies, atmosphere and soil, and facilitates environment protection.

Owner:HENAN POLYTECHNIC UNIV

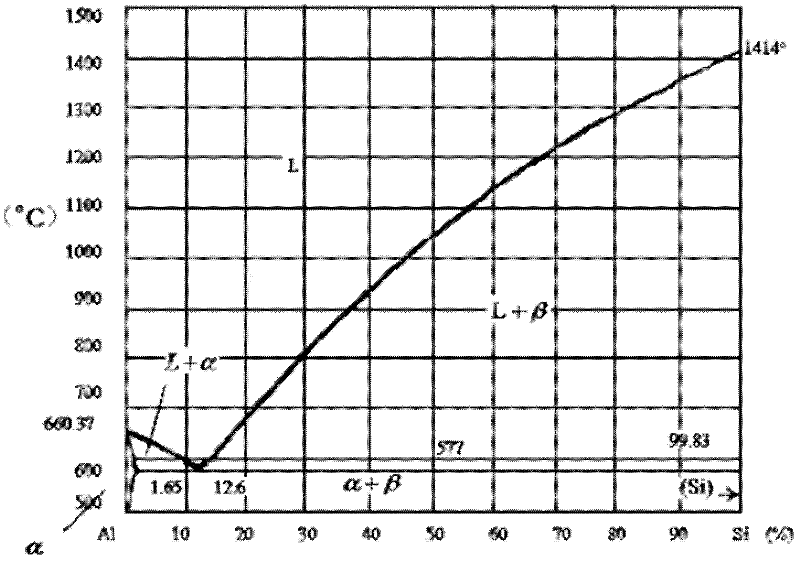

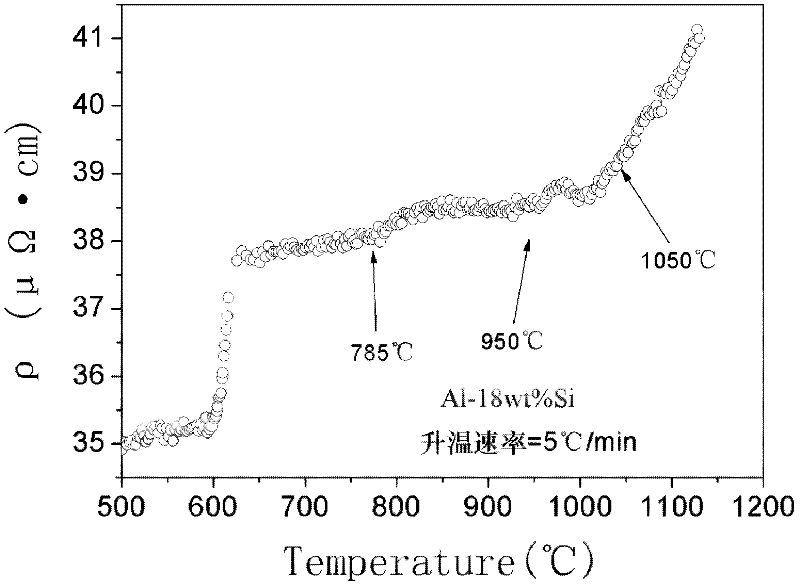

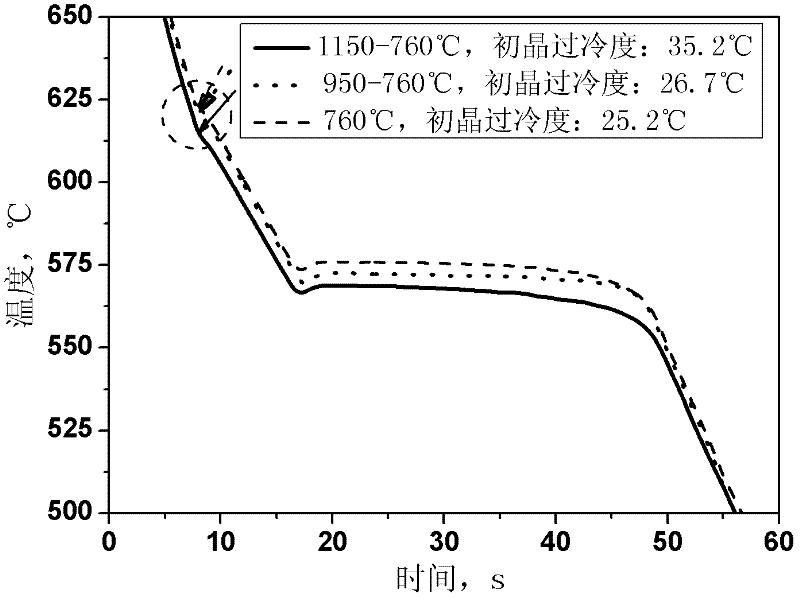

Method for refining hypereutectic aluminum-silicon alloy primary crystal silicon tissues

The invention discloses a method for refining hypereutectic aluminum silicon-alloy primary crystal silicon tissues, which is characterized in that high-temperature alloy melt bodies after being subjected to qualitative change and structural state change and low-temperature alloy melt bodies in the specific semi-solid temperature region are mixed and melt according to the mass ratio of 1 / 1 to 2 / 1, the mixed alloy melt bodies are obtained, the temperature of the mixed alloy melt bodies is reduced to 720 to 750 DEG C under the protection of covering agents, and hypereutectic aluminum-silicon alloy castings are obtained after casting and temperature-reduction solidification. The method has the advantages that the addition of leavening agents is not needed, the serious pollution on production and social environments caused by the use of the ordinary leavening agents is avoided, the average dimension of primary crystal silicons can be refined from about 50mum to 11-13mum under the faster cooling condition (8 to 10 DEG C / s) of the ordinary casting, in addition, the distribution tends to be uniform, and silicon crystal grain corners are passivated.

Owner:HEFEI UNIV OF TECH

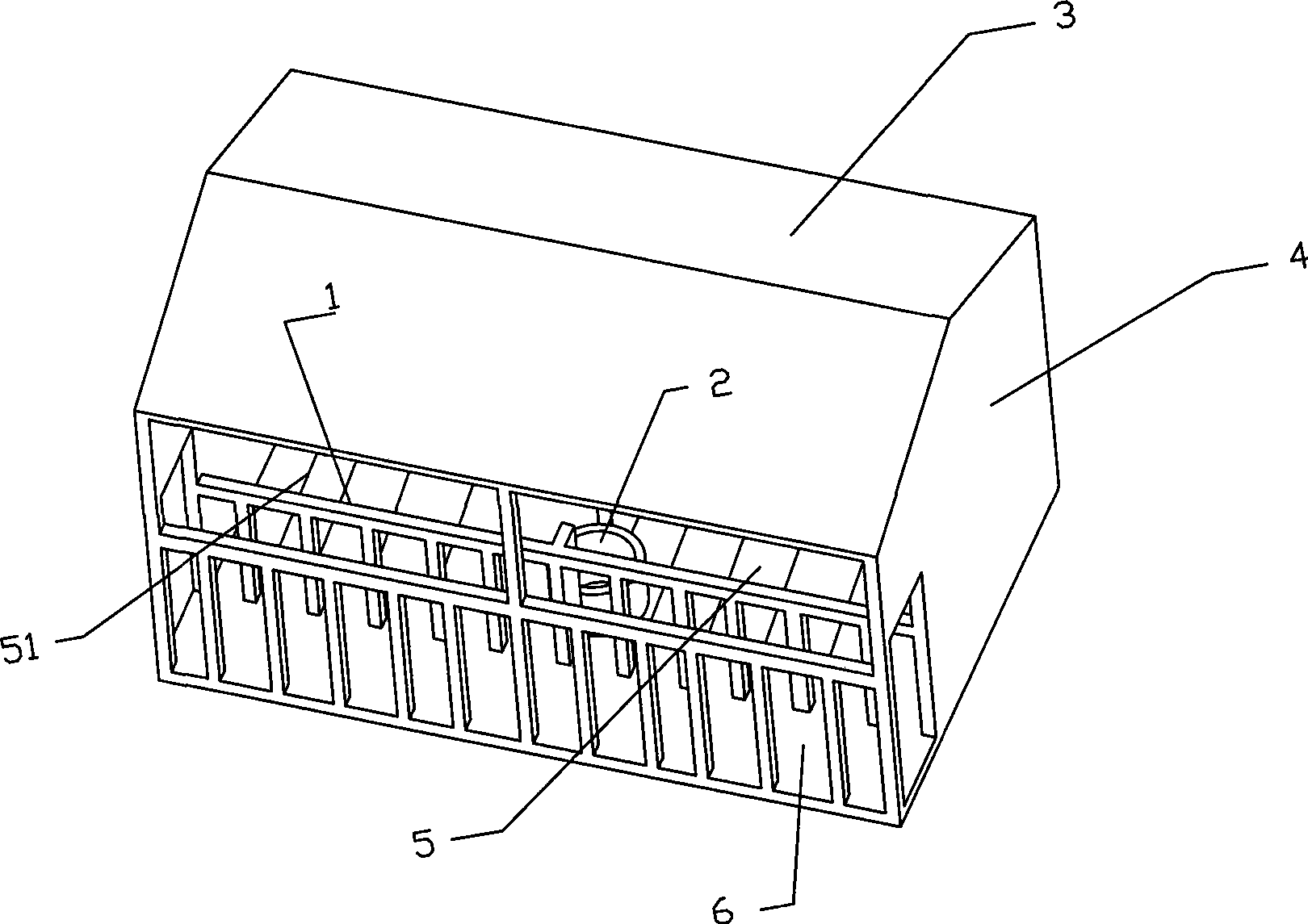

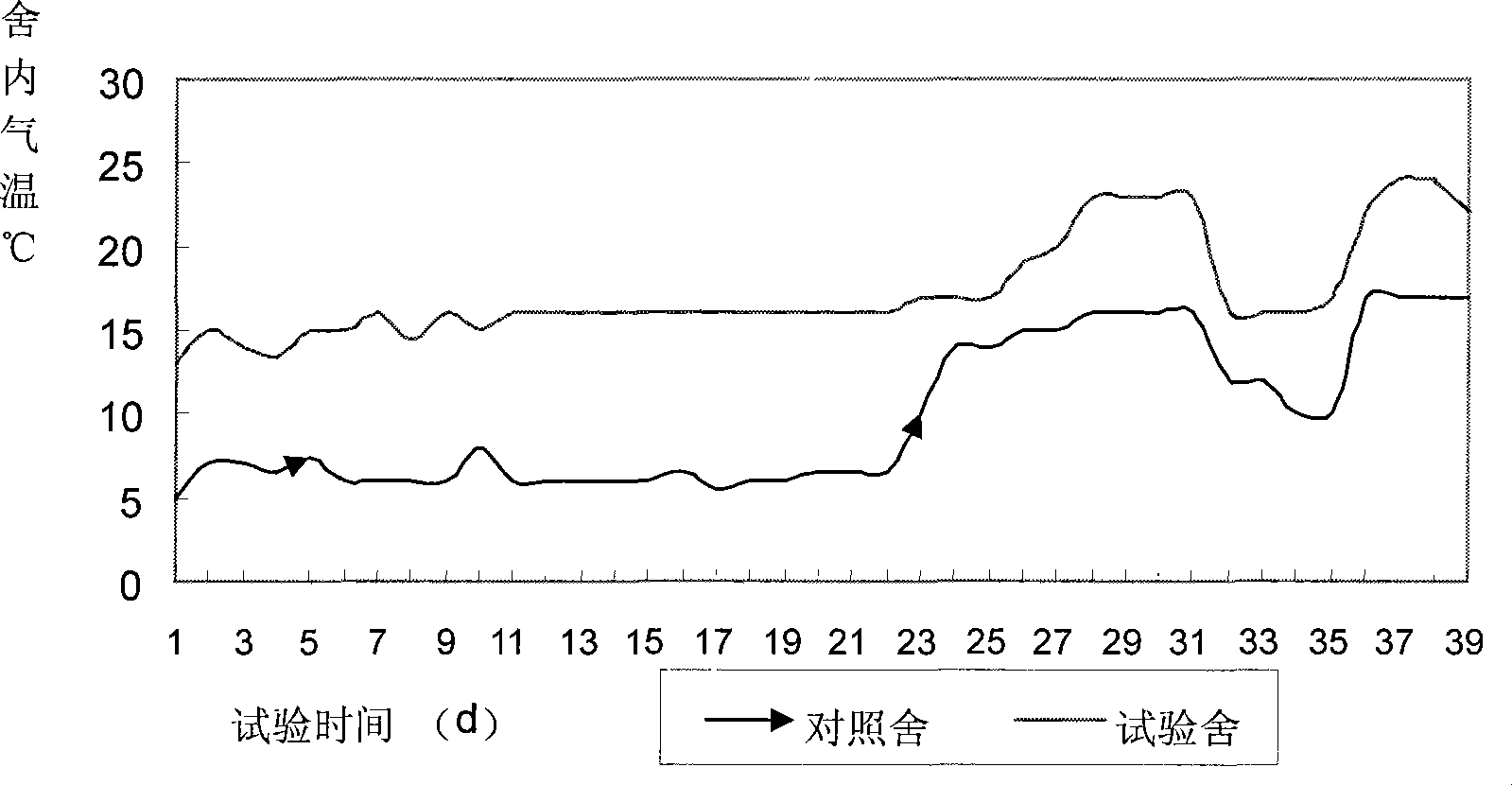

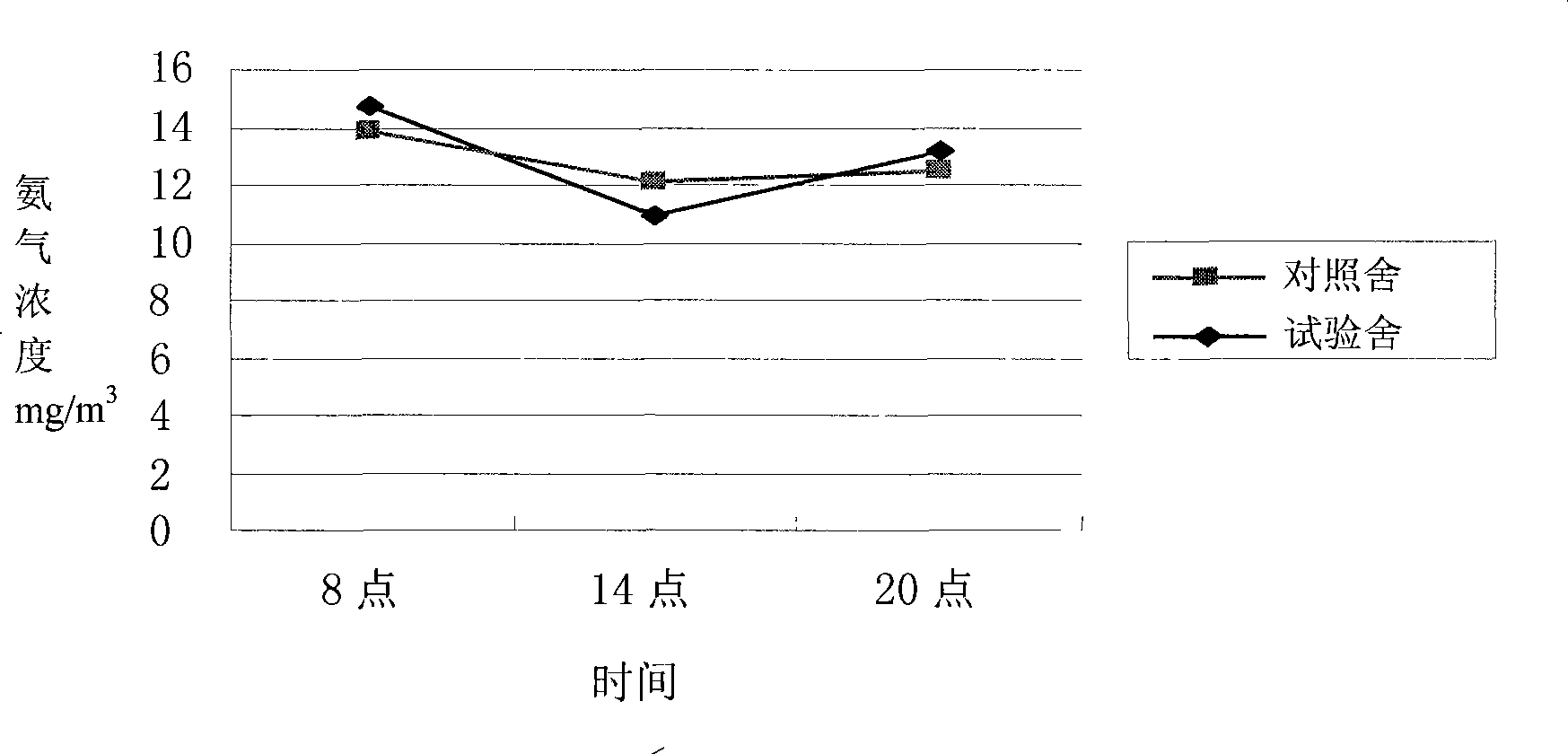

Alternate cultivation ecology pig culturing method and detachable piggery

InactiveCN101449669AIncrease profitTake advantage ofAnimal housingHorticultureLivestock breedingEcological safety

The invention provides a method of ecological cultivating pigs in shift planting and cultivation, comprising: adopting a detachable piggery for cultivating finishing pigs, removing the piggery after finishing pigs delivers, performing composting on the spot for the shit generated in the cultivating process, performing herbage or crop cultivation on the original ground, so the cultivation of the finishing pigs and the herbage or the crop is alternatively processed. The invention has the beneficial effects that: (1) building the piggery does not damage a plow layer of the ground, the second plowing can be performed at any time after removing, partial idle ground can be fully made use to develop livestock breeding, ground availability is increased, conflicts of cultivation fight for ground and supply and demand of organtic fertilizer are released; (2) cultivation shit are completely utilized as cultivation source, without environmental protection government and environmental pollution, meanwhile fertilizer amount for planting the crop is reduced; (3) compared with fixed cultivation in prior art, the invention has the advantages of ground saving, energy saving, low cost and ecological safety and the like.

Owner:ZHEJIANG UNIV

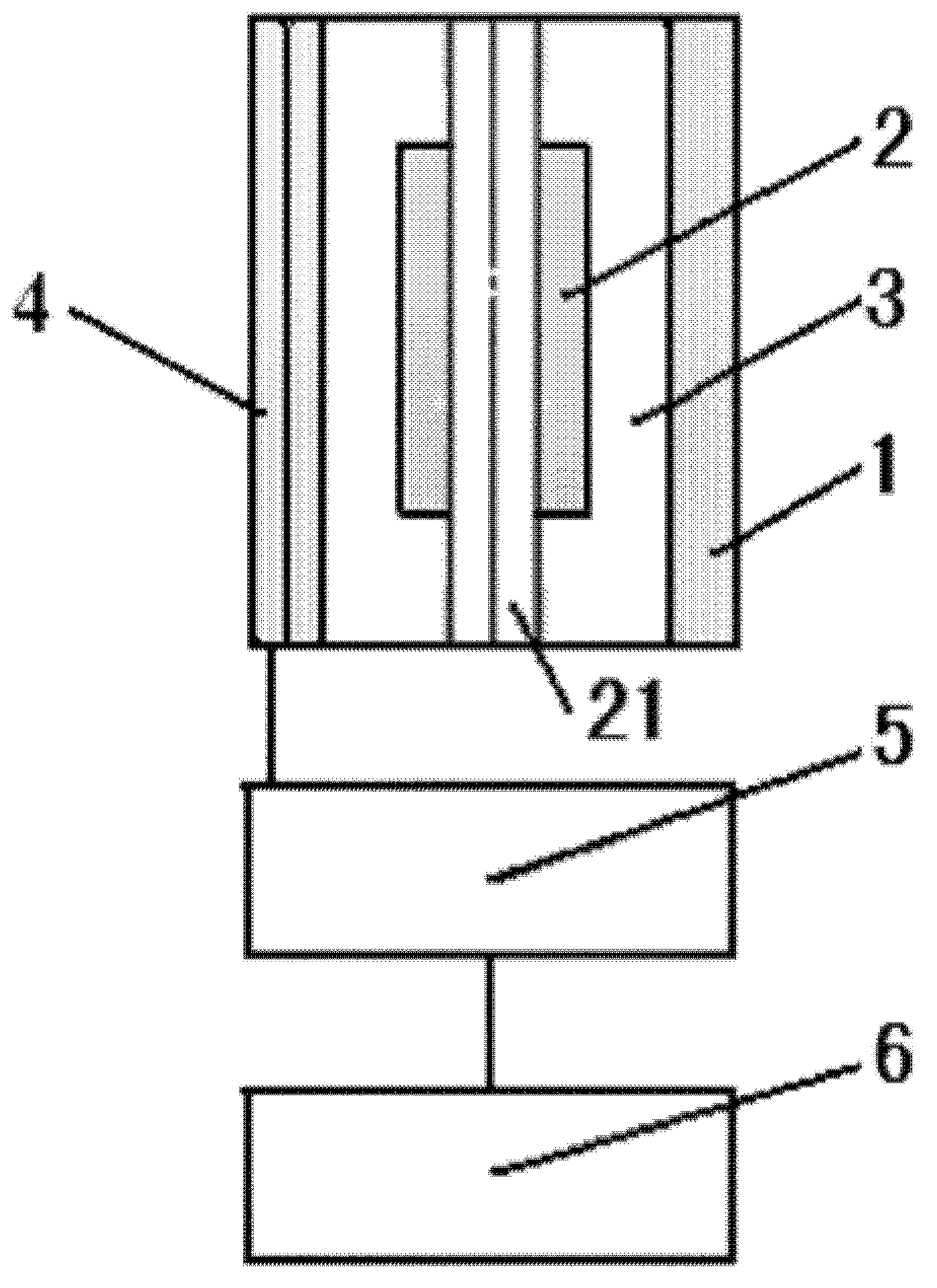

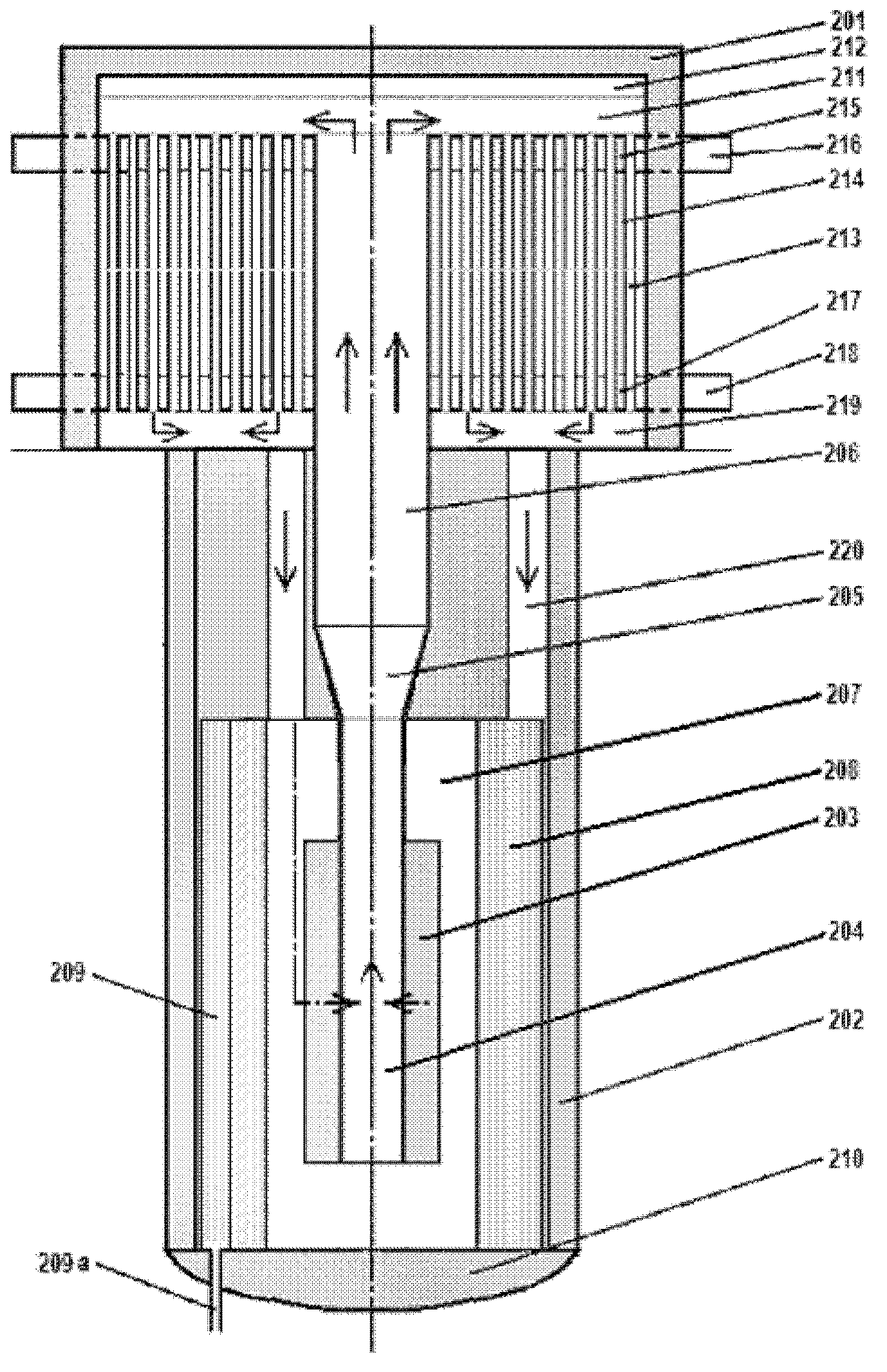

Universal uranium-thorium conversion-proliferation reactor device and method for producing nuclear fuel uranium-233

InactiveCN103077759AAvoid heavy pollutionNuclear energy generationReactors manufactureFertilizerGraphite

The invention discloses a universal uranium-thorium conversion-proliferation reactor device and a method for producing a nuclear fuel uranium-233. The universal uranium-thorium conversion-proliferation reactor device comprises a fused salt proliferation layer, a reactor core, a graphite reflecting layer, an instant separator, a disintegration separator and a fluoride fused salt fuel preparation device, wherein the fused salt proliferation layer is a hollow structure, and thorium is taken as a nuclear fertilizer; the reactor core takes uranium as a nuclear fuel and is located in the middle of the fused salt proliferation layer, and a high-temperature fused salt runner is formed in the center of the reactor core; the graphite reflecting layer and the reactor core are located between the fused salt proliferation layer and the reactor core; the instant separator is the separator for the nuclear fuel thorium and Pa-233 after irradiation and located on one side of the graphite reflecting layer; Pa-233 is stored in the disintegration separator, and the disintegration separator is connected with the instant separator; and the fluoride fused salt fuel preparation device is connected with the disintegration separator.

Owner:吕应中

High hardness and low friction Cr/CrCN gradient coating technology applicable to surface of profiled reed

InactiveCN101608299AAvoid heavy pollutionImprove performanceVacuum evaporation coatingSputtering coatingStructure and functionHardness

The invention disclose a high hardness and low friction coefficient Cr / CrCN gradient coating technology applicable to the surface of profiled reed for a high speed loom. The technology includes the steps of preplating, bias back wash cleaning and depositing Cr / CrCN wearproof gradient coating on the surface of the profiled reed with complex contour, large tip edge arc angle and small thickness. The Cr / CrCN gradient coating deposited by the invention has hardness as high as 2400HV and friction coefficient as low as 0.11, not only has high hardness and low friction coefficient but also has good coating uniformity and favourable toughness, and coordination of structure and function of the profiled reed top coating can be realized, thus effectively improving the properties and service life of the coating and the whole parts of the profiled reed base body.

Owner:SICHUAN UNIV

Magnesium-forsterite synthetic sand and preparation method thereof

ActiveCN102633515AReduce manufacturing costSolve the problem of poor high temperature performance when used aloneBeneficiationPowder

The invention relates to a magnesium-forsterite synthetic sand and a preparation method thereof. The magnesium-forsterite synthetic sand is prepared from the following raw materials in percentage by weight: 30-50% of waste magnesite fine powder, 20-30% of magnesite concentrate tailing powder, 0-20% of active light-burned magnesia powder and 30-50% of boric sludge. The preparation method comprisesthe following steps: sufficiently mixing and rolling waste magnesite fine powder, magnesite concentrate tailing powder, boric sludge, light-burned magnesia and water which accounts for 20 wt% of the raw materials in a wet pan; compacting, and balling to obtain ball billets with the diameters of 40-60mm; and naturally drying until the water content is less than 0.5%, adding into a magnesia shaft kiln, and calcining at 1550-1650 DEG C to obtain the magnesium-forsterite synthetic sand. The invention solves the problem of poor high temperature property of the independently used forsterite, and comprehensively utilizes the waste magnesite fine powder, magnesite concentrate tailing powder and boric sludge, thereby changing wastes into valuable substances and lowering the production cost of the magnesium-forsterite synthetic sand.

Owner:LIAONING ZHONGMEI HLDG

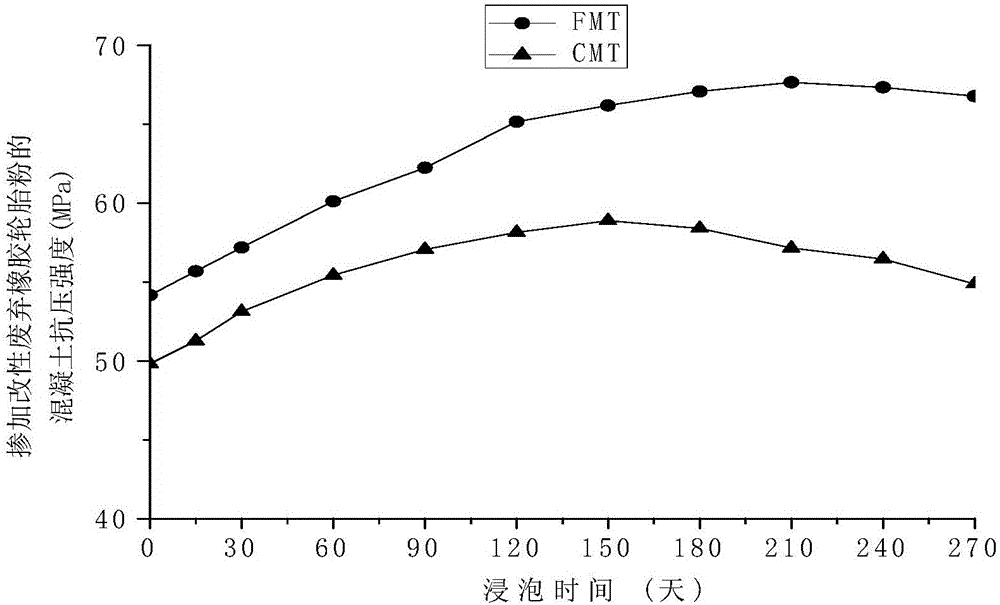

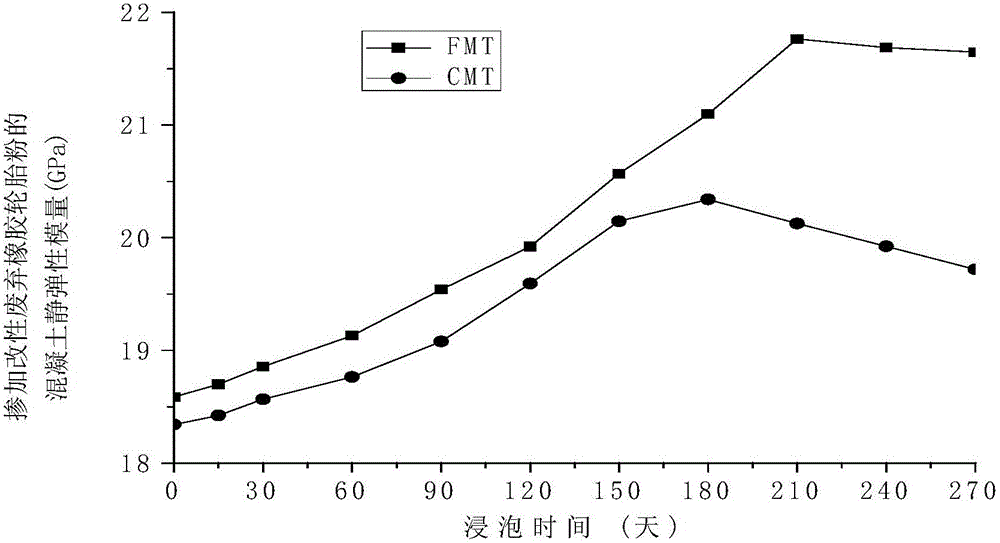

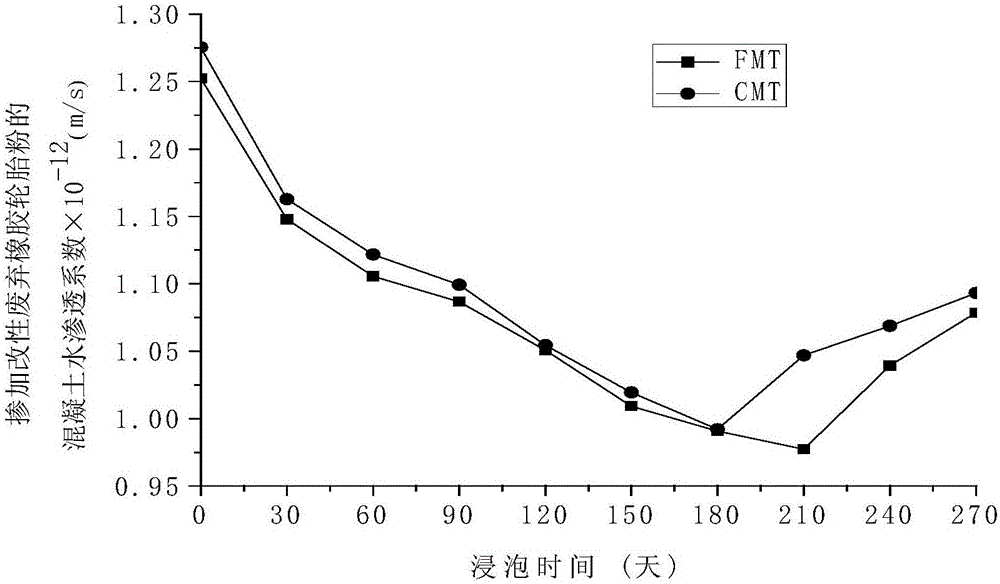

Preparation method of structural concrete capable of preventing erosion by sulfate mediums

ActiveCN105777003AImprove mechanical propertiesImprove compactnessSolid waste managementCeramic shaping apparatusSulfateCrushed stone

The invention discloses a preparation method of structural concrete capable of preventing erosion by sulfate mediums. The preparation method mainly comprises the following steps: crushing abandoned rubber tires into granules, screening the granules, and then grinding the screened granules so as to obtain abandoned rubber tire powder; performing surface chemical oxidation modification on the abandoned rubber tire powder with treatment fluid prepared from sodium bichromate, concentrated sulfuric acid and distilled water; stirring the abandoned rubber tire powder after the surface chemical oxidation modification, with cement, mineral admixture, broken stones, sand and water so as to obtain concrete mixed with abandoned rubber tire powder of surface chemical oxidation modification; finally performing conventional maintenance and CO2 gas maintenance. According to the preparation method, the technology is simple, the cost is reduced, through addition of the modified abandoned rubber tire powder and the CO2 gas maintenance, the capacity of the structural concrete resisting to the erosion of the sulfate mediums is improved, and the structural concrete has excellent mechanical properties.

Owner:HOHAI UNIV

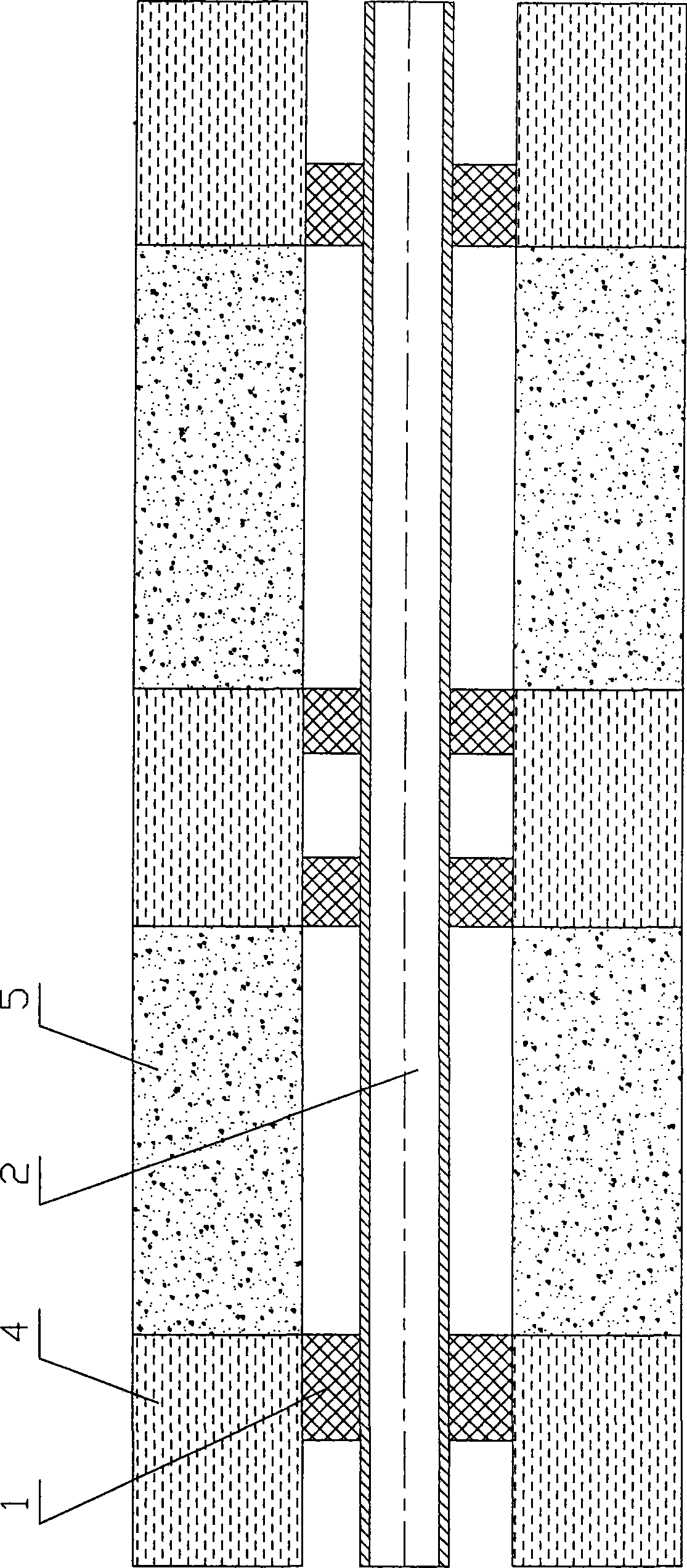

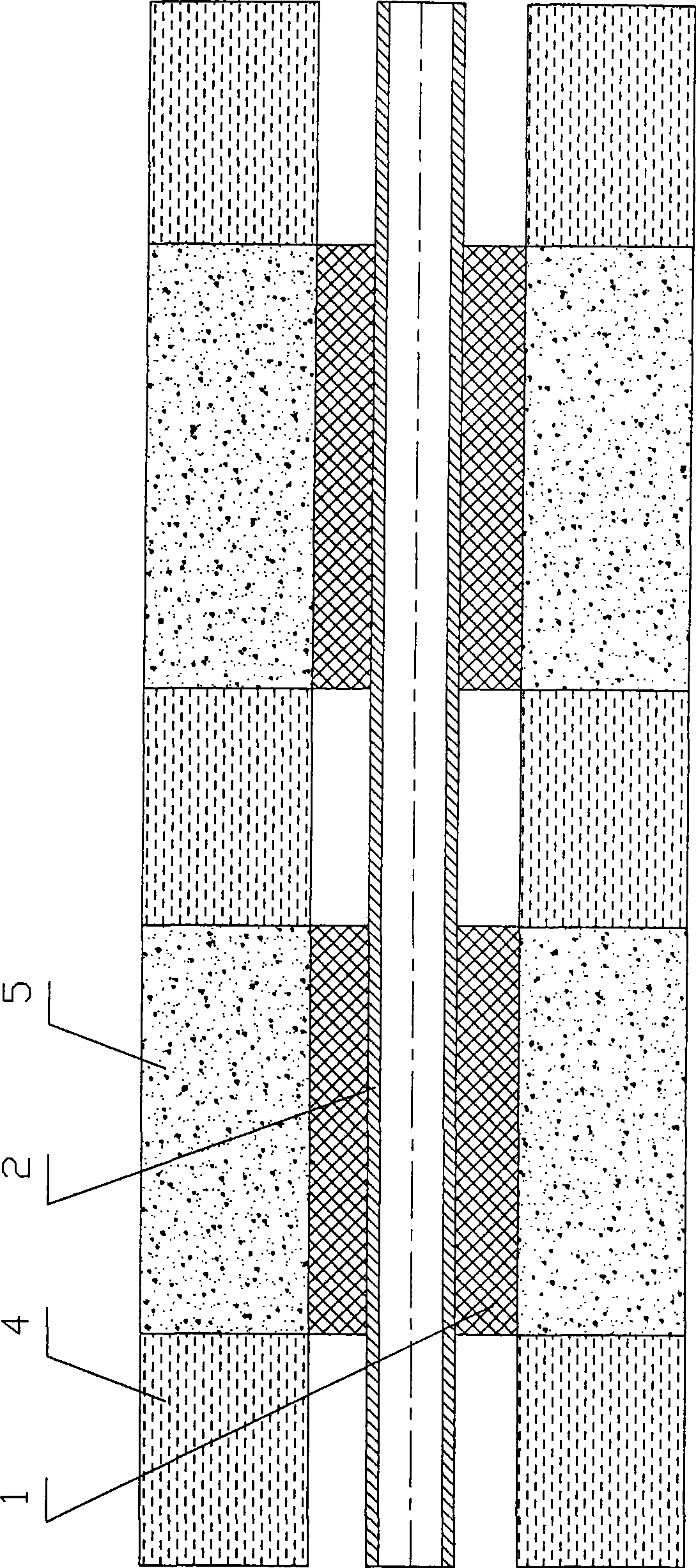

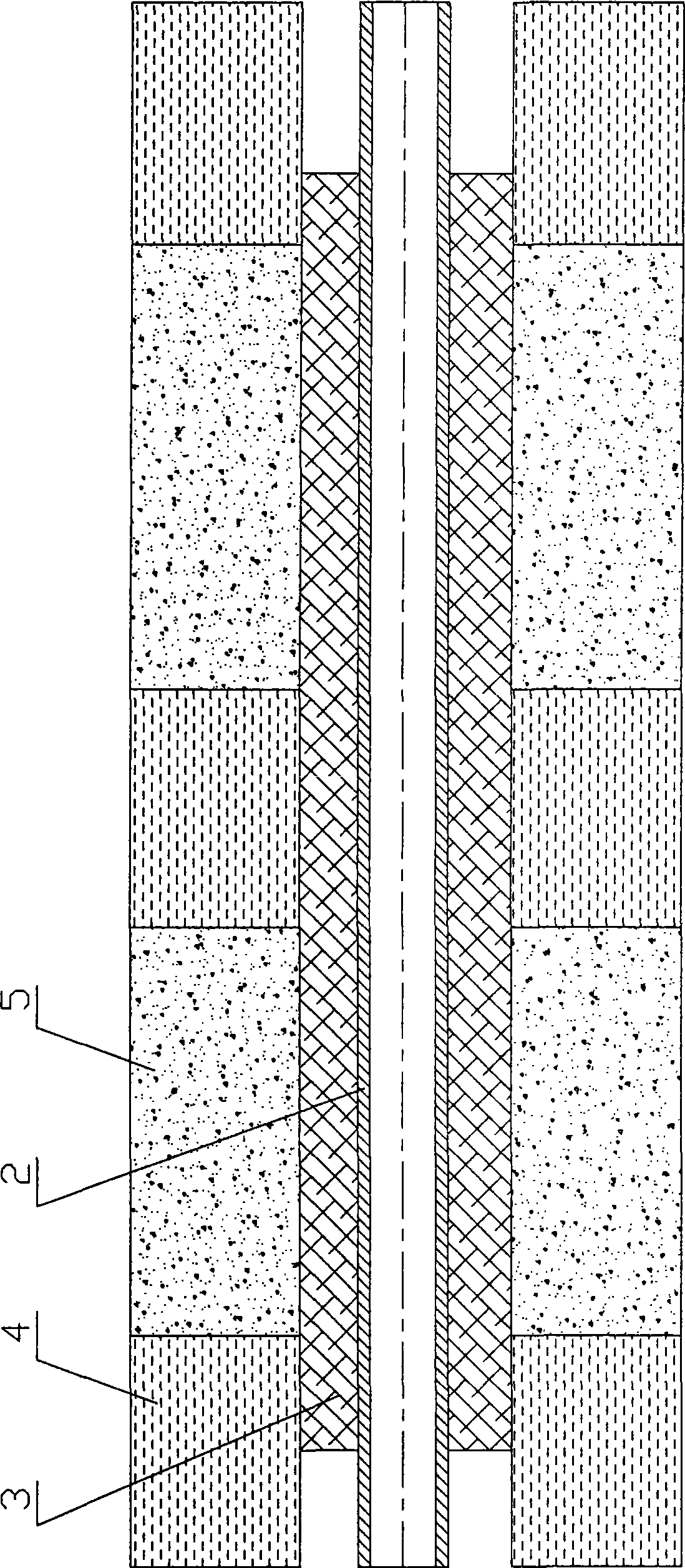

Oil and gas well cementation and completion method

InactiveCN101387193AAvoid heavy pollutionAvoid interactionFluid removalSealing/packingWell drillingWell cementing

The invention relates to a well cementing and completion method for an oil-gas well used for the well-completion operation of petroleum, which comprises the following steps: after the under-balanced drilling operation is completed, a certain number of and adequate types of packers are arranged on a well-completion pipe column (2) according to the measured position of an oil-gas layer and the predetermined interlayer isolation proposal; the position of the oil-gas layer (5) is accurately clamped through an underground control valve or other no-killing trip device, and the well-completion pipe column is landed; when the well-completion pipe column is landed to the predetermined position, the packers (1) are sealed (the packers or oil-expanded packers are filled with cement slurry) or long packer rubber packers (3) are filled with the cement slurry, and interlayer isolation between the oil-gas layer (5) and a non oil-gas layer (4) can be realized under the underbalance condition; and a perforating hole of the oil-gas layer is aligned, so as to communicate a wellbore and the oil-gas layer and perform mining or implement strengthening mining measures. By adoption of the method for well cementing and completion, severe pollution of the overbalance pressure on the oil-gas layer can be avoided during the well cementing process of a lower sleeve after under-balanced drilling.

Owner:WESTERN DRILLING KELAMAYI DRILLING TECH INST

Method for recycling cast waste sand

InactiveCN101869965AImprove performanceEasy to useMould handling/dressing devicesEcological environmentIron(II) chloride

The invention provides a method for recycling cast waste sand, which is characterized in that: adding calcium chloride or ferrous chloride into the waste sand in a molar ratio of sodium in waste sand to the calcium chloride or ferrous chloride of 2:0.8-1.5 and uniformly mixing the materials to recycle the waste sand. The method can be used for harmless treatment of cast waste sand, namely water-glass sand, to make the cast waste sand a stable and reliable building material that can be used in a large amount. Thus, not only the serious pollution caused by the burying and discarding of the conventional cast waste sand to the ecological environment and great waste of finite resources are prevented, but also the elimination of finite land occupation and the change of the cast waste sand into the building material are realized. The sodium oxide (Na2O) content of recycled waste sand provided by the invention is lower than 1 percent; the recycling cost is low; the selling price is 2 to 3 times the recycling cost; and real 'zero' discharge is realized.

Owner:余钟泉 +1

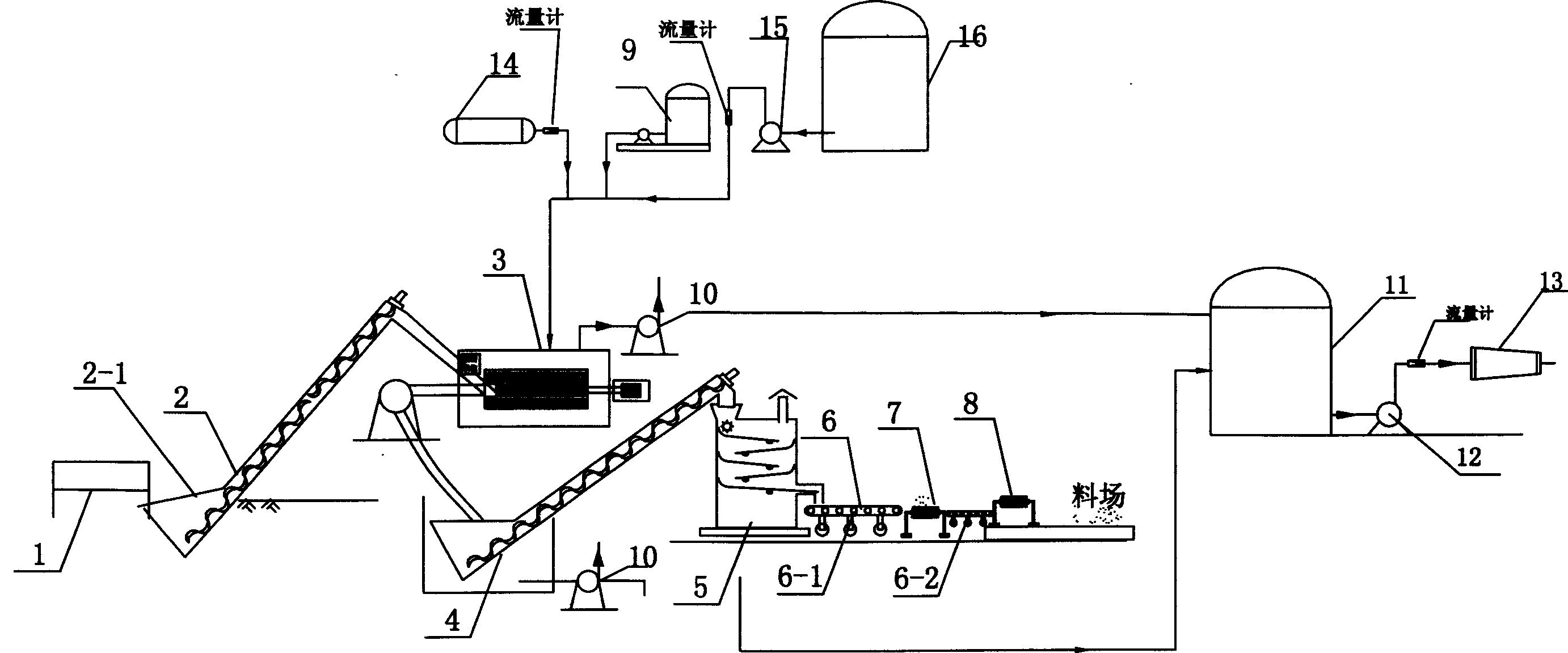

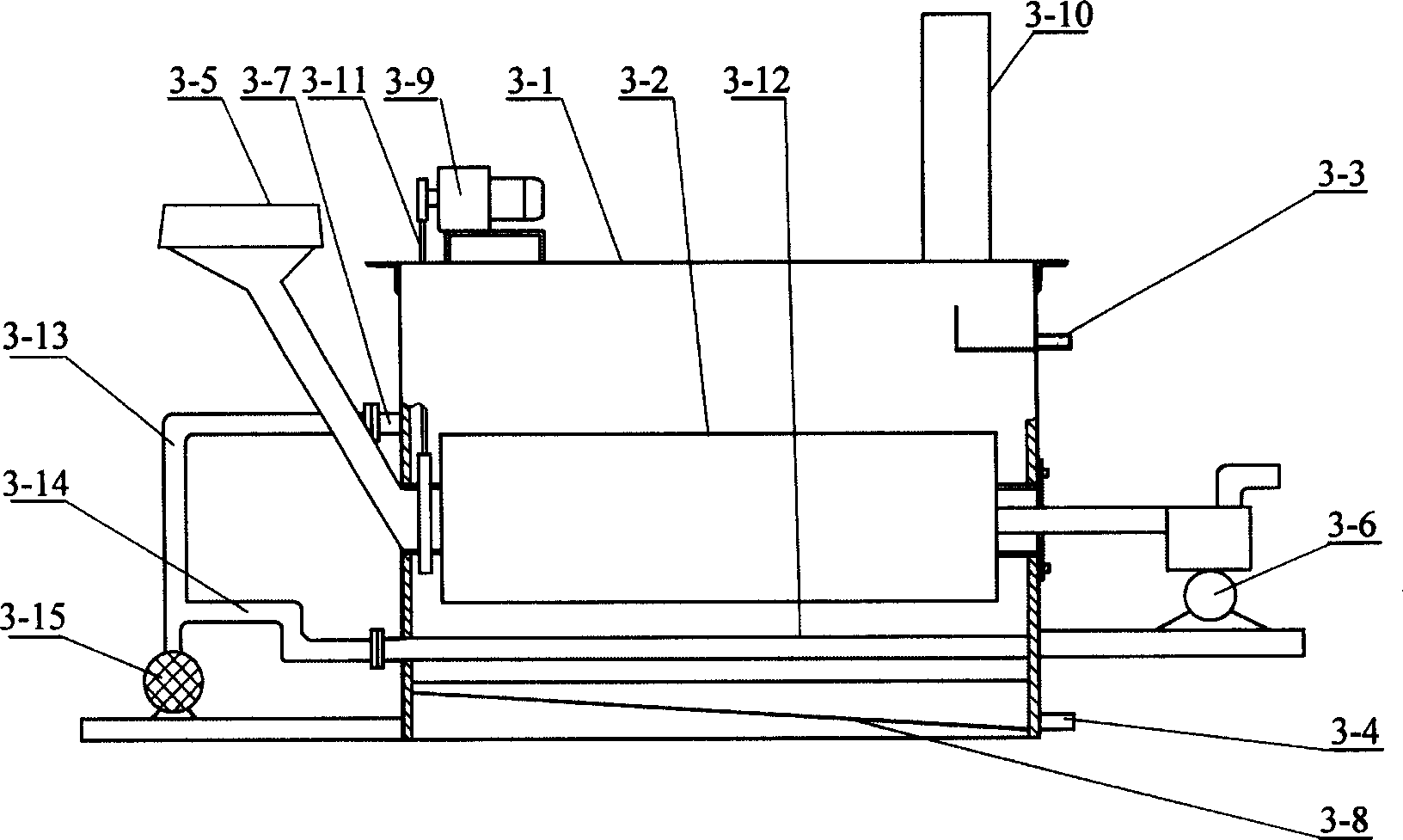

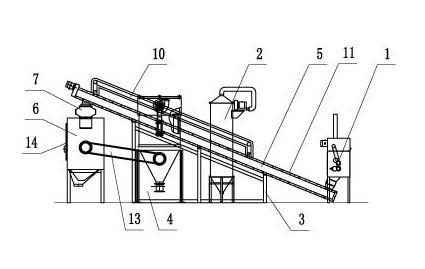

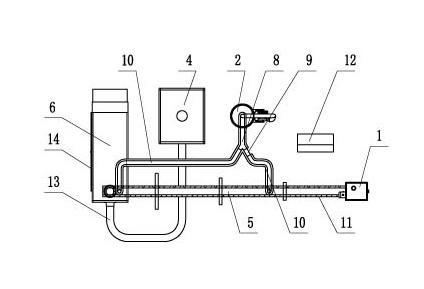

Recovery treatment system and method for oil field waste filtered substance

ActiveCN1569307ASolve the emission problemSolve protection problemsFilter regenerationTransmission beltFilter material

The invention is a reclaiming system and method for oil field waste filter material. The oil waste will contaminate environment and wastes resources. The system is: a coarse sifter is connected to a spiral elevator, the outlet of the filter rinsing process device is arranged above the spiral elevating separator, the drying box is connected to the transmission belt, and the magnetism separator is connected to the transmission belt and multi-layer electric sifter. The method is: the waste material passes through the coarse sifter, spiral elevator, filter rinsing device, the material is rinsed in the device and then it is elevated by the elevating separator, enters the drying box.

Owner:DAQING OILFIELD CO LTD +1

Ammonia recovery method for gas mixture in hydrogen cyanide production

ActiveCN101264901AAvoid lossReduce manufacturing costHydrogen cyanide preparation/purification/separationAmmonia preparation/separationRecovery methodDesorption

The invention discloses an ammonia recovery method from the mixing gas produced in the process of hydrogen cyanide production, comprising ammonia absorption process, decyanation process, desorption process and rectifying process for solving the technical problem. The invention is characterized in that decyanation process is set separately to recovery hydrogen cyanide gas, avoiding the loss of hydrogen cyanide caused by a large amount of acid gas like hydrocyanic acid contained in the ammonium phosphate solution directly steamed in Versum method, reducing production cost of hydrogen cyanide, reducing the emission of the harmful acid gas like hydrogen cyanide, and avoiding the serious pollution of peripheral enviroment. Besides, the ammonium phosphate solution contains a much smaller amout of hydrocyanic acid after hydrogen cyanide is recovered, which can not influence production process and make the production process more safety.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

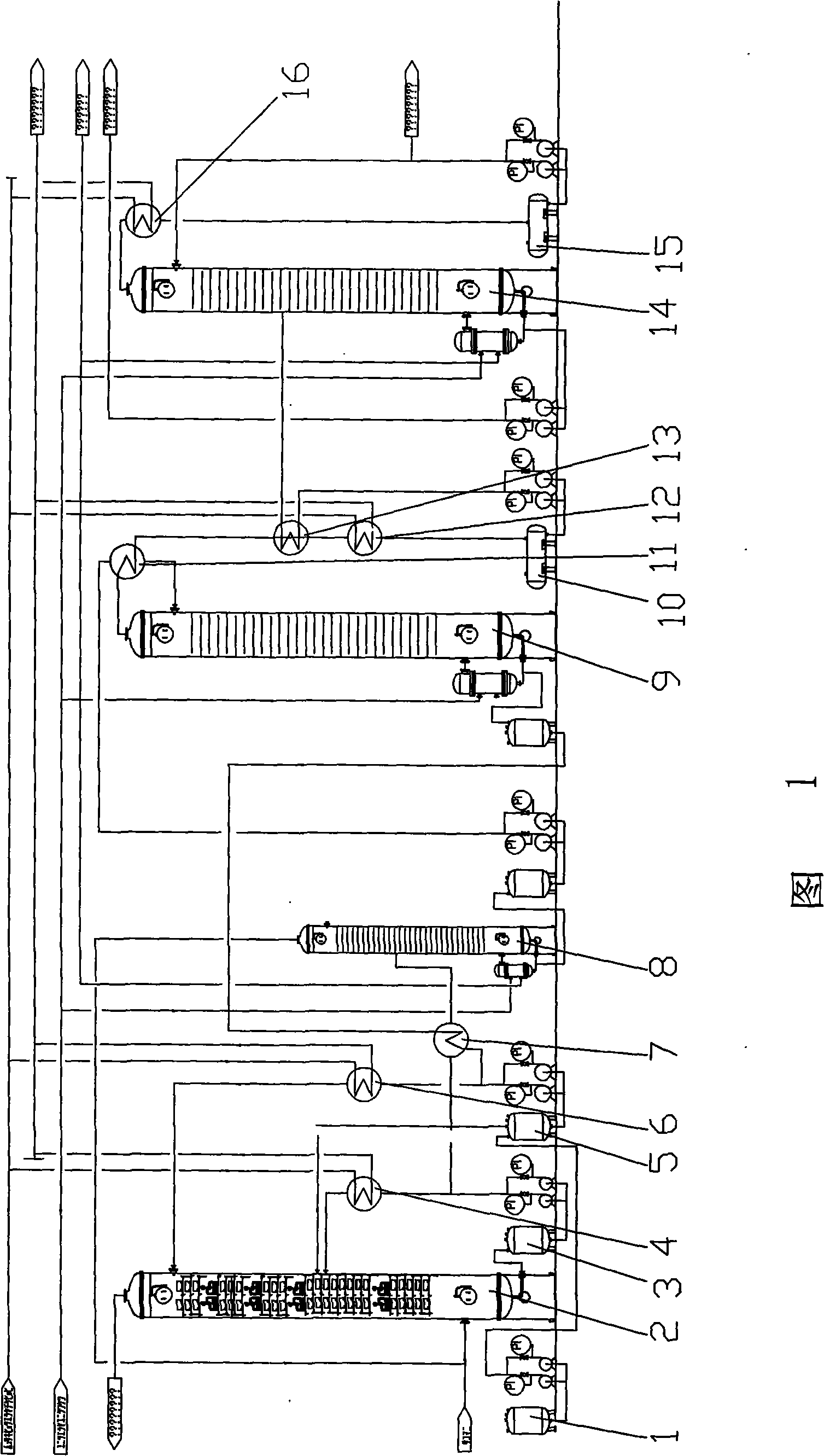

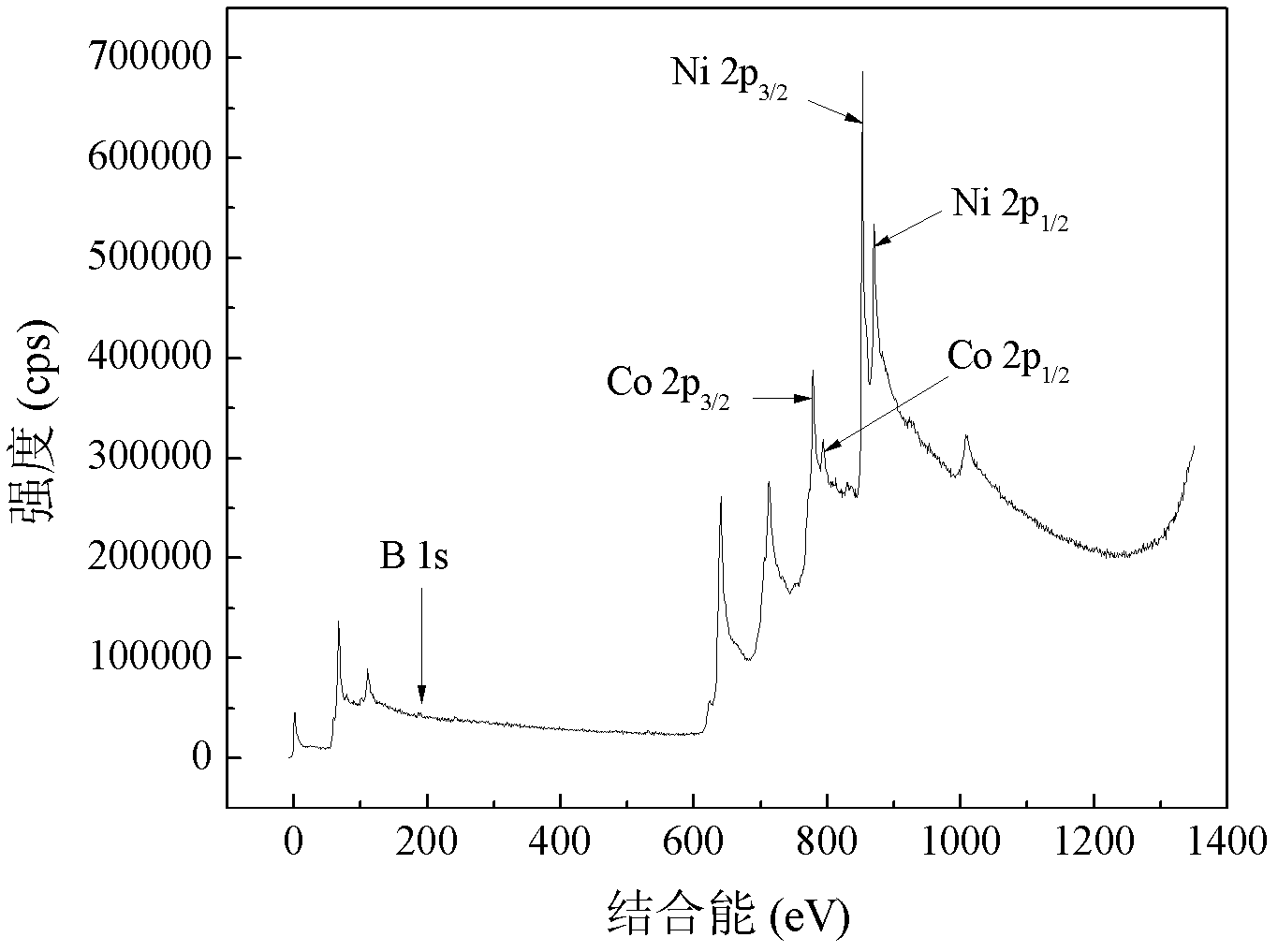

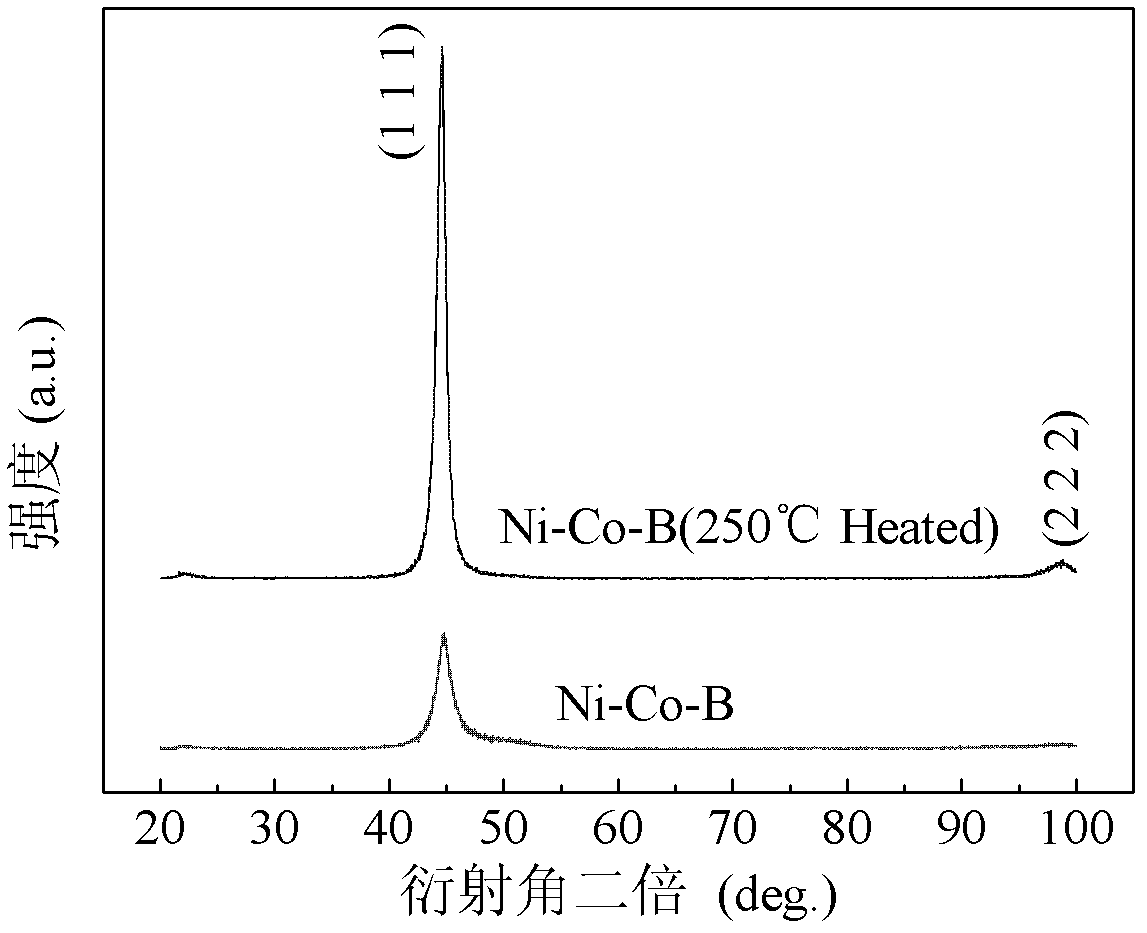

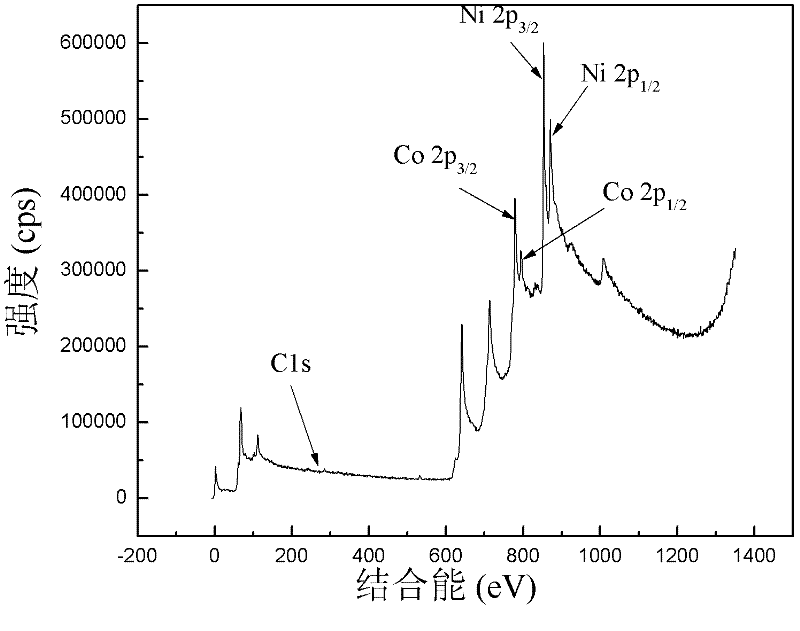

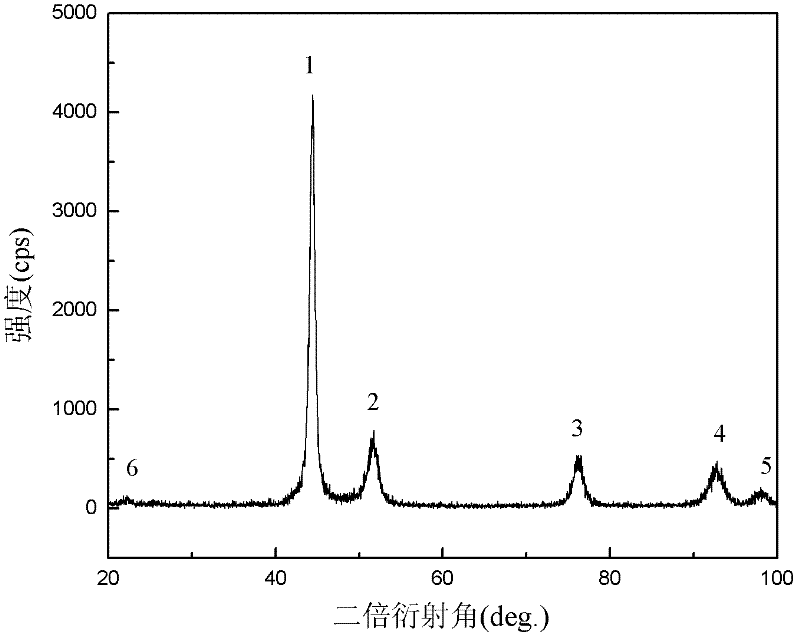

Electric deposition preparation method of Ni-Co-B alloy substituted hard chromium plating

The invention provides an electric deposition preparation method of a Ni-Co-B alloy substituted hard chromium plating, relating to a preparation method of the Ni-Co-B alloy substituted hard chromium plating. The method 1 comprises the following steps of: taking nickel salt, cobalt salt, nickel chloride, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. The method 2 comprises the following steps of: taking nickel chloride, cobalt salt, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. In the invention, a Ni-Co-B alloy plating with uniform brightness, hardness of 770-800HV50 as well as good corrosion resistance and bonding force is obtained at a deposition rate higher than 60mu m / h. In the plating process, the cathode current efficiency is higher than 96%; and after the plating is subjected to heat treatment at 150-400 DEG C for 1-3 hours, the hardness of the plating can be increased to 1055-1108HV50.

Owner:HARBIN INST OF TECH +1

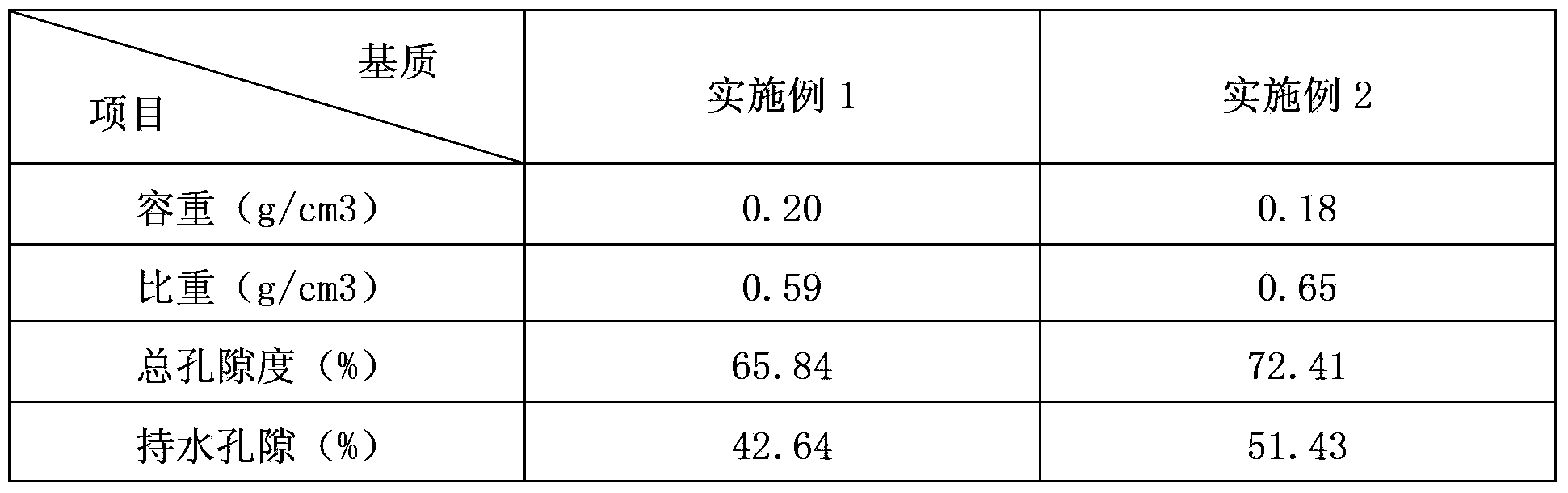

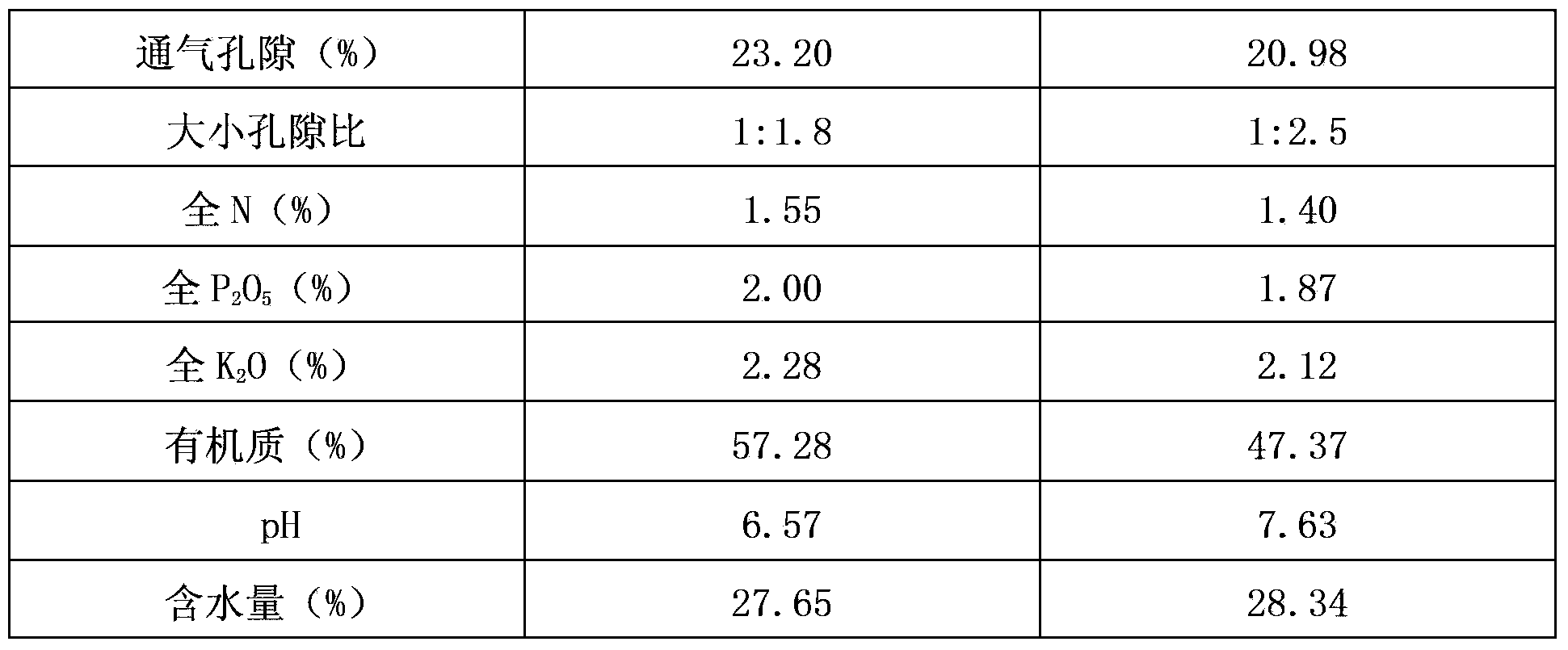

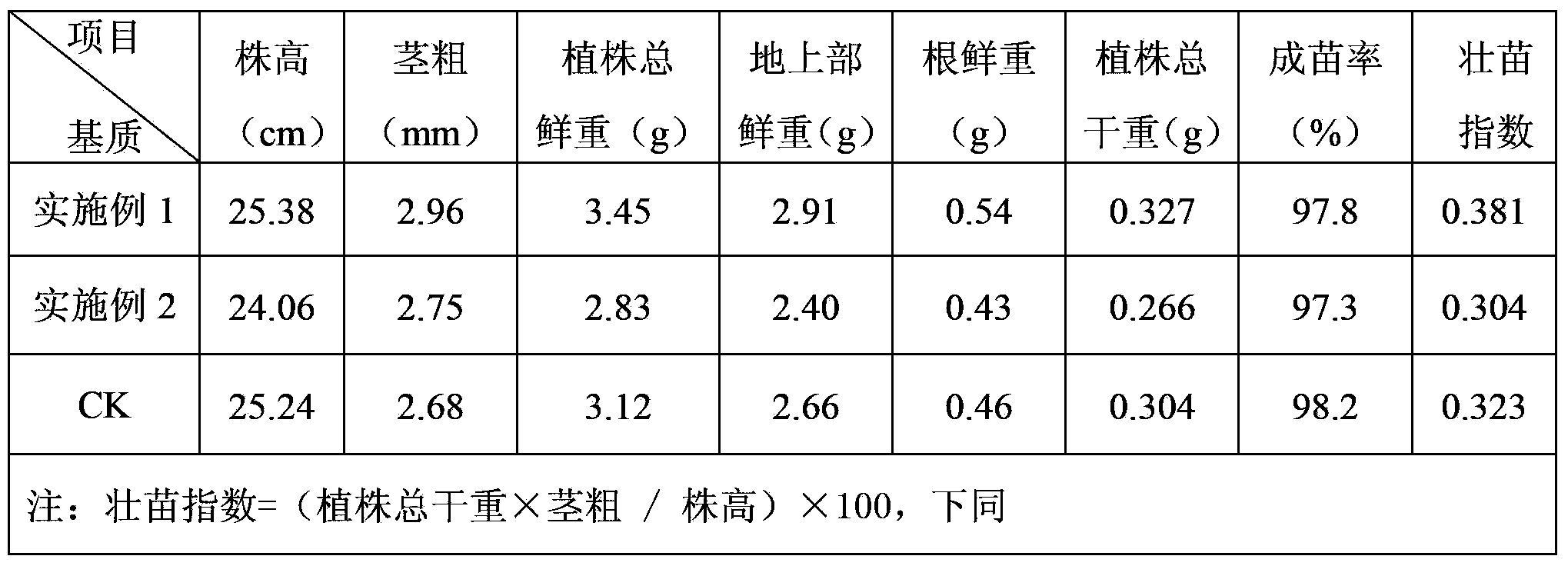

Method for producing solanaceous vegetable seedling growing substrate by utilizing salvaged material of cassava processing

ActiveCN103396182AImprove survival rateImprove stress resistanceBio-organic fraction processingOrganic fertiliser preparationBiotechnologyResource utilization

The invention discloses a method for producing a solanaceous vegetable seedling growing substrate by utilizing a salvaged material of cassava processing. Cassava peels and starch residues are used as main raw materials, chicken manure and seed tung tree bran or chicken manure and shell powder are used as auxiliary materials, and the excellent solanaceous vegetable seedling growing substrate is produced through fermentation. The substrate is light and loose, has the advantages of good permeability, good water holding and fertilizer retaining abilities, and balanced, scientific and reasonable nutrient supply, can meet the balance demand of solanaceous vegetable crop seedlings on nutrients during a whole growth period, and effectively improves the survival rate, the stress resistance and the growing seedling quality of the solanaceous vegetable growing seedlings. The method realizes harmless treatment and resource utilization of the salvaged material of cassava processing, avoids great waste of resources and serious pollution of the environment, provides a new way for comprehensive utilization of the agricultural salvaged material, reduces the substrate production cost, reduces excessive exploitation of peat resources, protects the natural environment, and has wide application value.

Owner:广西泥微生物科技有限公司

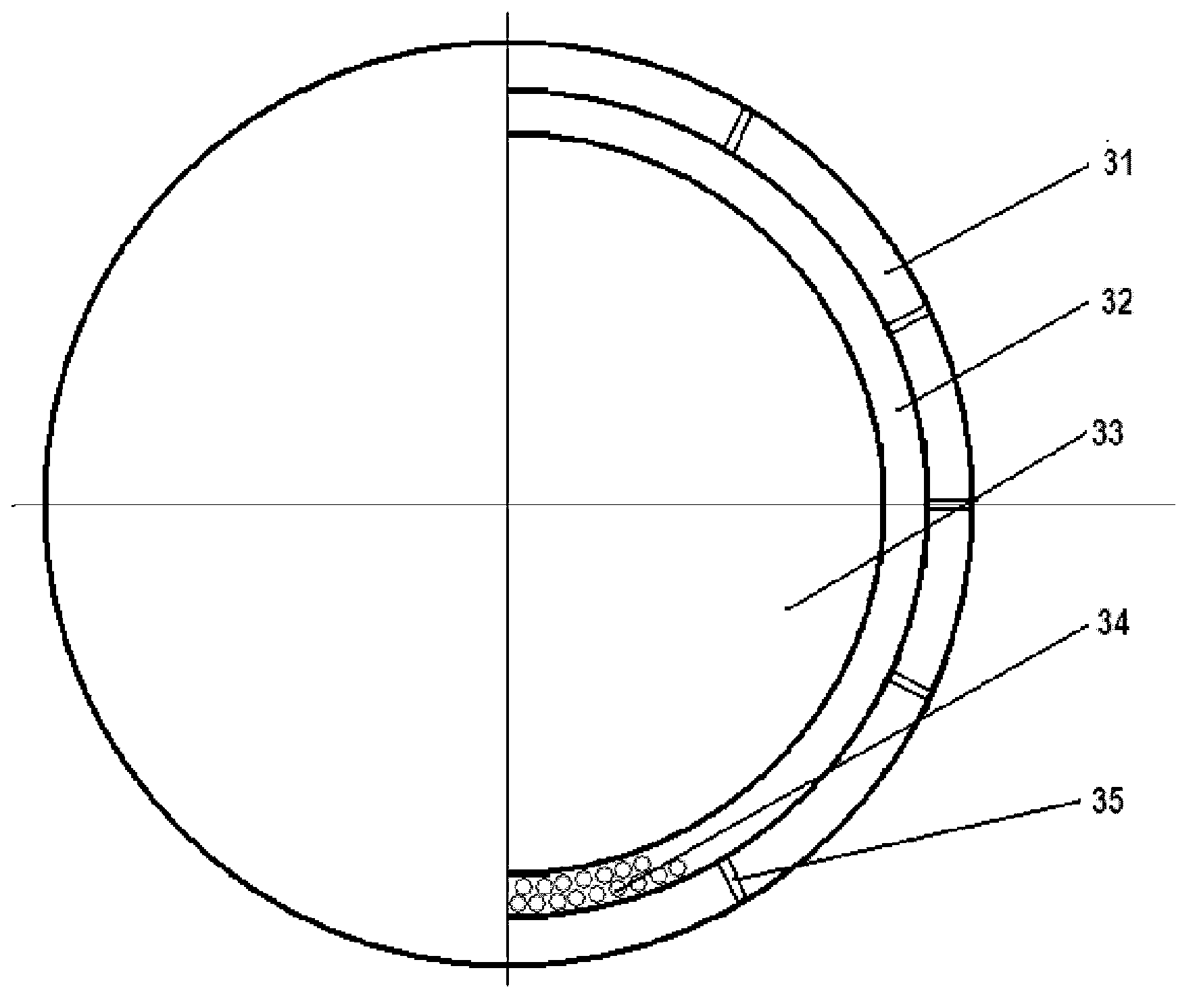

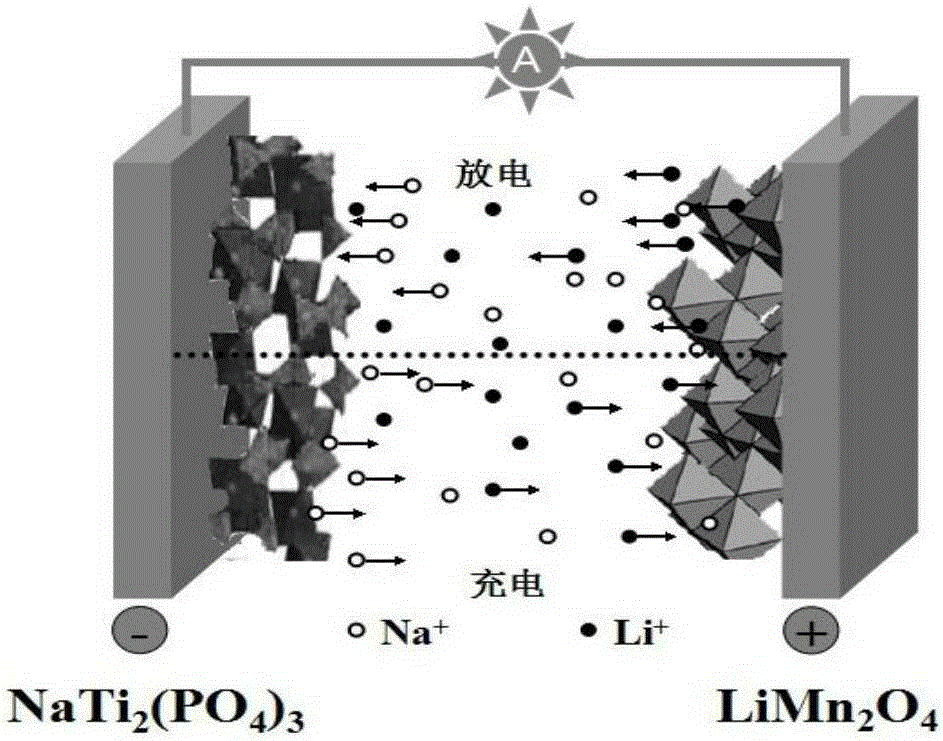

Aqueous ion-exchange cell

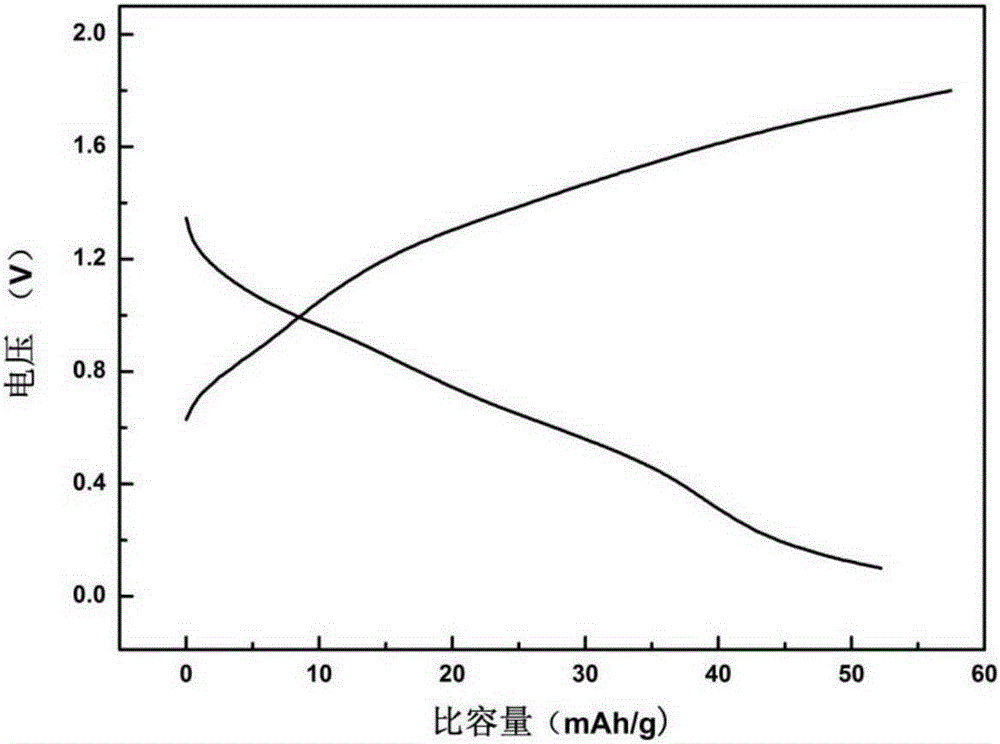

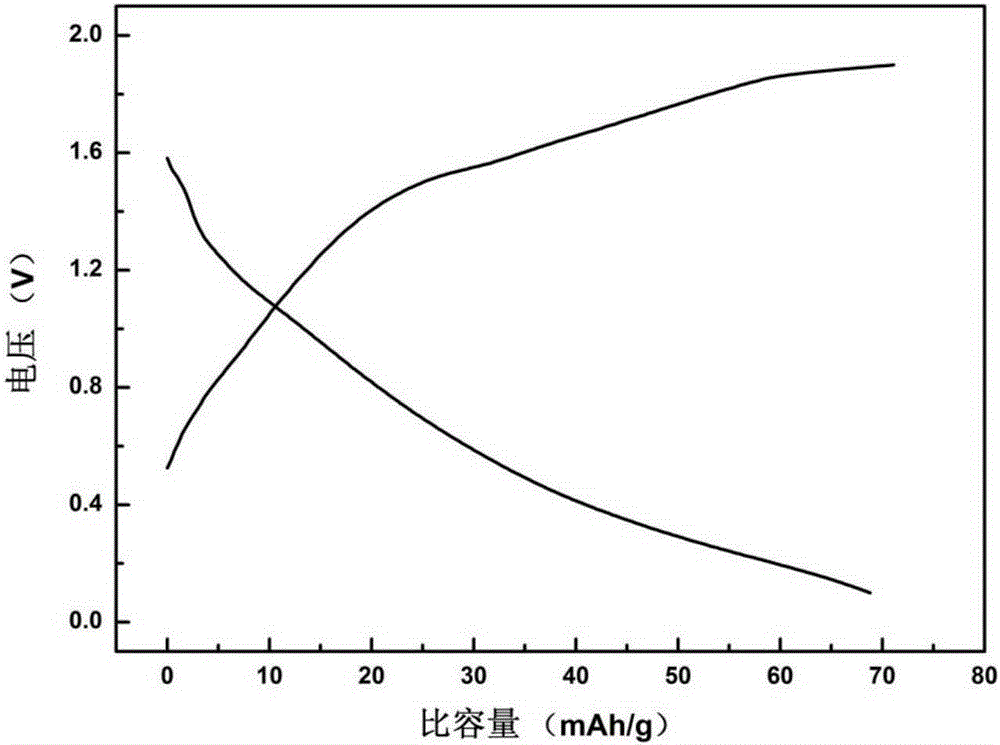

InactiveCN105322241AAvoid heavy pollutionRealize the goal of green environmental protection and safetyCell electrodesSecondary cellsAdhesiveHigh energy

The invention discloses an aqueous ion-exchange cell, which comprises a positive film, a negative film, a diaphragm and an electrolyte, wherein the negative film comprises a negative active material, a conductive material and an adhesive; the negative active material is NaTi<2>(PO<4>)<3>; and the negative active material accounts for 65%-85% of the total weight of the negative film. Compared with the prior art, the aqueous ion-exchange cell has the advantages of high power density, high energy density and long cycle lifetime, and is green and safe; the used electrolyte is a saline solution which is safe, nontoxic and cheap and contains sodium and lithium; the problems that a conventional organic electrolyte is flammable and combustible, and pollutes the environmentare solved; the targets of environmental protection and safety are achieved; the raw material cost is reduced; and the aqueous ion-exchange cell is a sustainable cell system.

Owner:ANHUI NORMAL UNIV

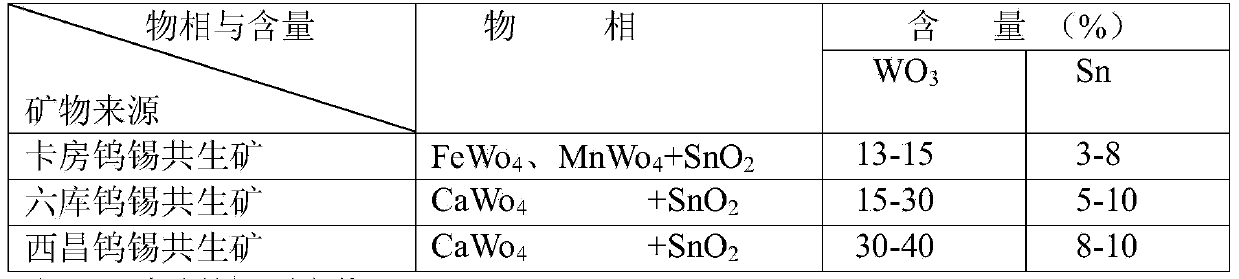

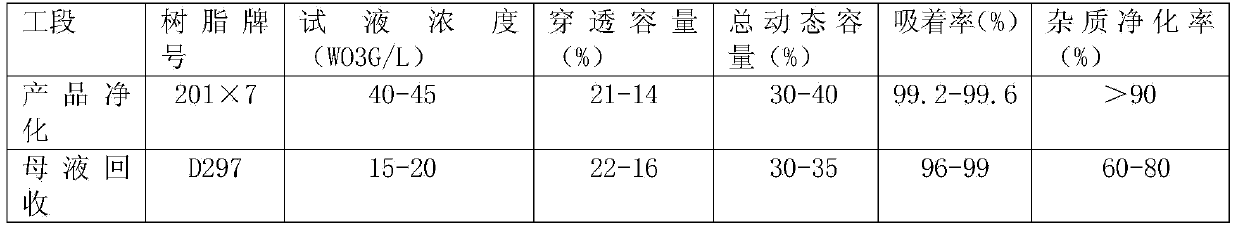

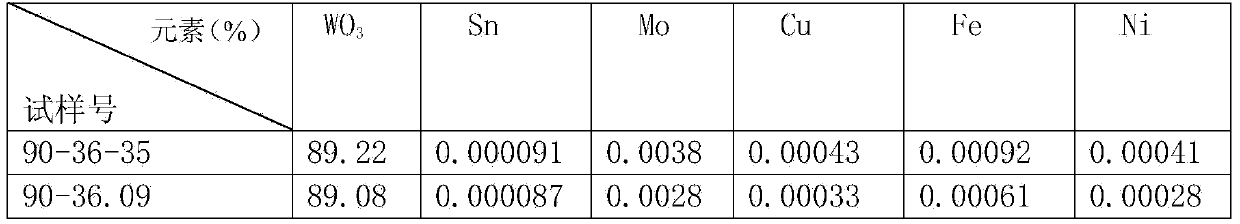

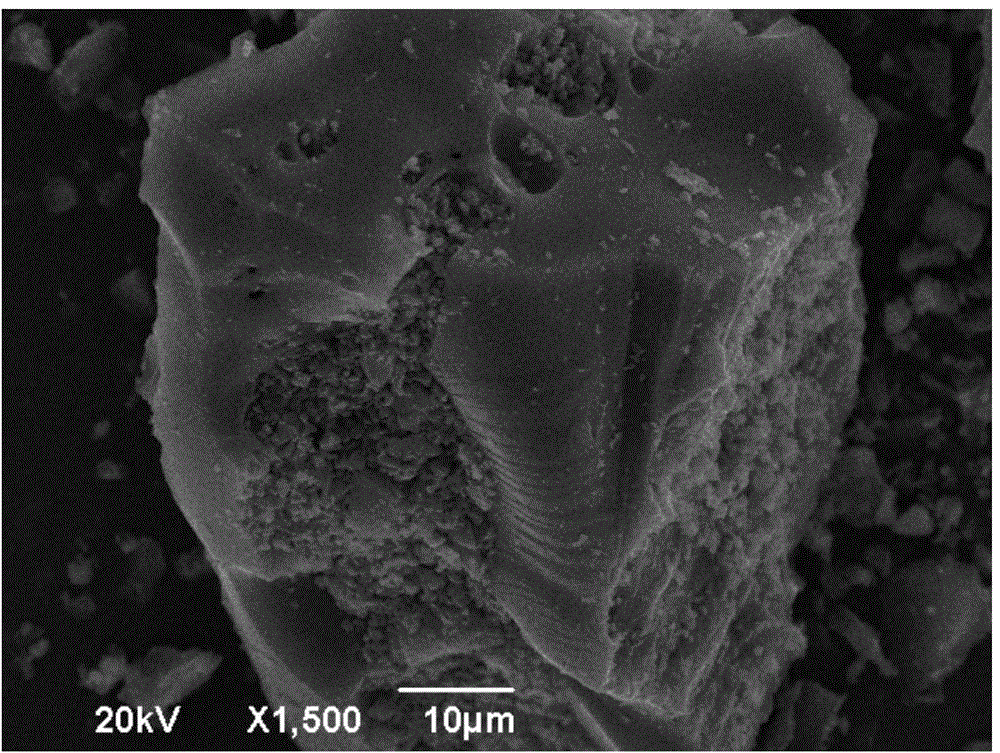

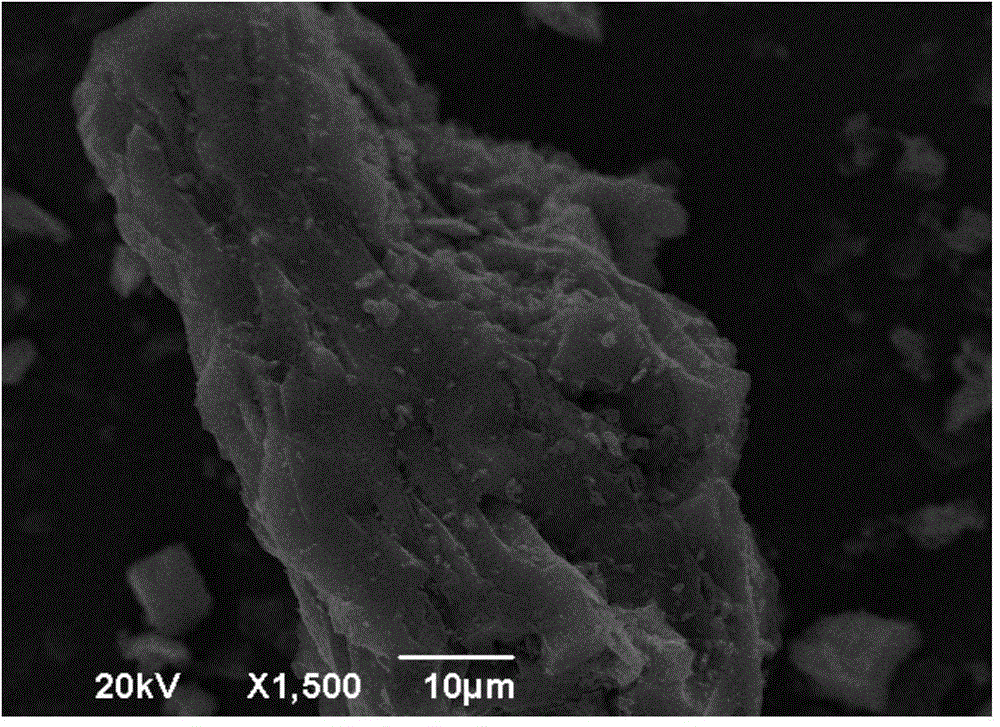

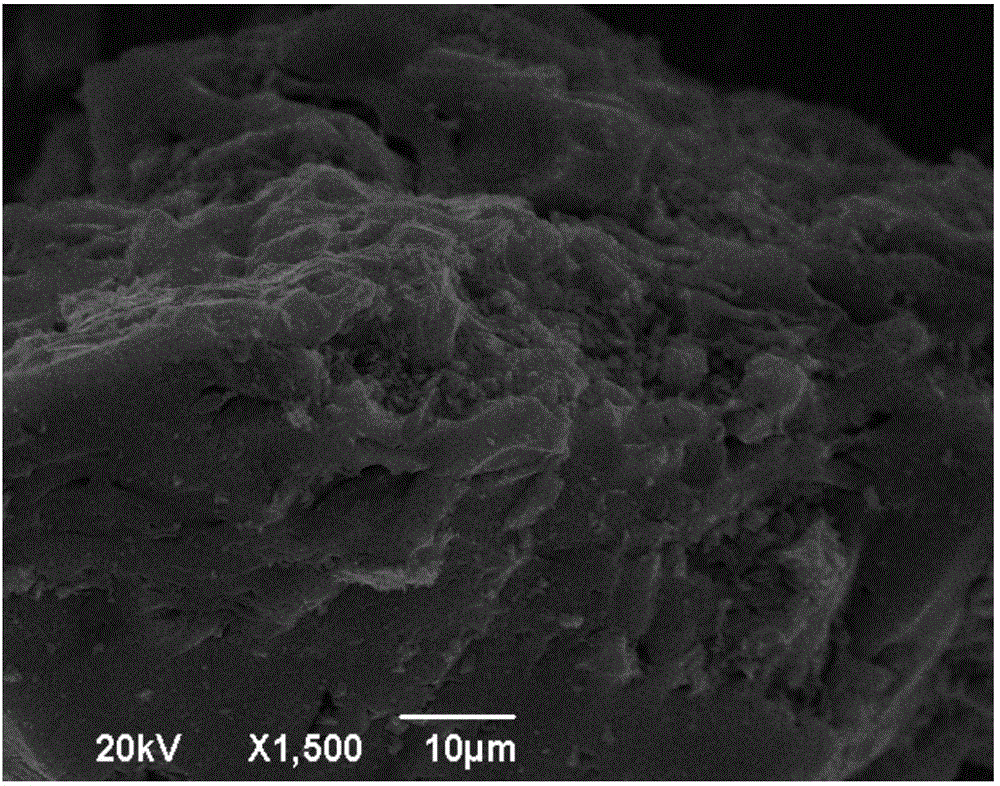

Method for producing tungsten and tin chemical products through chemical metallurgical separation of tungsten-tin paragenic ore

InactiveCN103725879AGuaranteed high oxidationGuaranteed stabilityProcess efficiency improvementLiquid wasteTin dioxide

The invention belongs to the field of chemical metallurgical technology, and particularly relates to a method for producing tungsten and tin chemical products directly from tungsten-tin paragenic ore by use of the chemical metallurgical technology. The method comprises the steps of grinding the tungsten-tin paragenic ore serving as a raw material, and performing acidolysis by use of nitric acid to obtain tungsten-tin mixed slag; dissolving the tungsten-tin mixed slag with ammonia water to obtain ammonium tungstate and tin slag; after the ammonium tungstate enters the solution, performing ion-exchange purification with anion gel resin and desorption with ammonium chloride or ammonia water to obtain high-purity ammonium paratungstate; with lignite as a reducing agent and a non-metal mineral as a stabilizer, performing reduction stabilization of the tin slag, and leaching out the tin with sulfuric acid; performing liquid-phase oxidation and dehydration drying to obtain tin dioxide; performing corresponding after-treatment on the waste gas and waste liquid generated in the preparation process. The method provided by the invention can be used for effectively producing tungsten and tin chemical products at the same time, avoids resource waste and can guarantee the quality of the tin products and relatively low cost as well as the quality of the tungsten products.

Owner:戴元宁

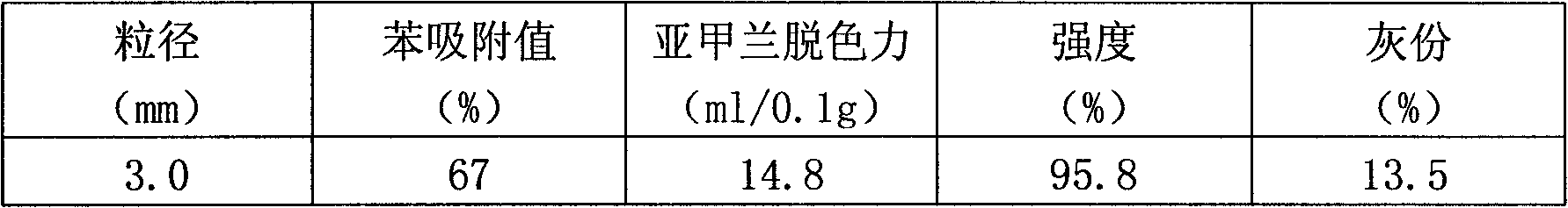

Method for preparing adsorbent by using semi-coke modification

InactiveCN104525113AAvoid heavy pollutionSimple preparation processOther chemical processesWater contaminantsMuffle furnaceActivated carbon

The invention discloses a method for preparing an adsorbent by using semi-coke modification. The method is characterized by comprising the following steps: grinding and screening semi-coke, thereby obtaining 80-200-mesh semi-coke powder; adding the semi-coke powder into an aqueous solution of nitric acid, carrying out stirring reaction at the temperature of 50-95 DEG C for 6-24 hours, filtering, drying, adding the powder into a muffle furnace, activating at the temperature of 300-500 DEG C for 10-60 minutes, grinding the activated product to 180-200 meshes, thereby obtaining the target product adsorbent. The adsorbent prepared by the invention has excellent adsorptive property, particularly has an excellent adsorption effect on phenolic substances in wastewater and has equivalent adsorptive property to that of commercial grade activated carbon. Moreover, the used semi-coke refers to industrial waste semi-coke, the wastes are changed into valuable materials, the process is simple, and the product application is wide.

Owner:HEFEI UNIV OF TECH

Circuit board manufacturing method without tin plating, tin retreating and capable of saving copper and nickle

InactiveCN101489355AAvoid heavy pollutionSave potionConductive material chemical/electrolytical removalTinningElectricity

A method for manufacturing circuit board which is free of tin plating and tin removing and can save the using amounts of copper and nickel comprises the following steps: a. coating plating-resistant covering film on the circuit board after copper deposition or the first time of copper plating, then adhibiting the positive film of all metal holes and hole rings in the circuit pattern on the covering film for forming a primary circuit after exposing and developing; b. electroplating copper and nickel on the hole wall and hole ring of all metal holes, then removing the covering film; c. coating etching-resistant covering film on the circuit board after film removing, adhibiting the negative film of circuit pattern on the etching-resistant covering film, and forming the secondary circuit after exposing and developing; d. etching the circuit pattern, then removing film and checking erosion; and e. forming the finished product of circuit board through executing the steps of resistance welding, exposing, developing, printing component symbol or tin spraying or executing oxidation prevention procession. The method of the invention can reduce environment pollution and realize clean production through eliminating electrotinning and tin removing technique, effectively saves metal, water, electricity and chemical material and reduces production cost of enterprise through selectively electroplating copper and nickel.

Owner:陈国富

Method for leaching lead by wet method through copper anode slime silver-extracted sediment

ActiveCN104878210AHigh activityImprove leaching effectProcess efficiency improvementPregnant leach solutionMicrowave

The invention belongs to the technical field of wet metallurgy, and specifically relates to a method leaching lead by the wet method through copper anode slime silver-extracted sediment. The method is that 100 to 350g / L by concentration of sodium hydroxide solution is added to the silver-extracted sediment to perform size mixing; the weight concentration of the size is controlled to be 10 to 40%; after size mixing, the size is fed into a microwave reaction furnace to perform leaching reaction for 5 to 25 minutes under the normal pressure; then the size is discharged and subjected to solid-liquid separation so as to obtain the lead-containing leaching liquid. With the adoption of the method, lead in the silver-extracted sediment can be efficiently and quickly leached, overcomes the shortages of small leaching rate, long process and heavy environmental pollution in the traditional process can be overcome, and has the advantages of being simple in process, small in cost, quick to leach, environmentally friendly, small in treatment time, and high in comprehensive recovering benefit; the leaching rate of lead is 93 to 98%.

Owner:NORTHEASTERN UNIV LIAONING

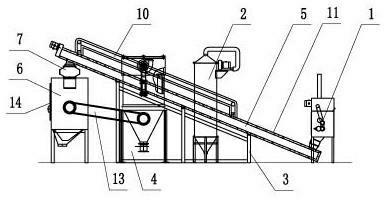

Recycling and processing equipment of waste and old fluorescent lamp

InactiveCN102145344ASolve pollutionAvoid heavy pollutionSolid waste disposalBaghouseMetallic materials

The invention relates to recycling and processing equipment of a waste and old fluorescent lamp, belonging to the technical field of the recycling and processing of fluorescent lamps. The equipment comprises a smashing device, a separating device, a support, a bag-type dust remover, a screw conveyer, an air separation device, an air close discharging valve and an electric control device. The smashing device and the air separation device are respectively installed at two ends of the support and connected through the screw conveyer installed at the top of the support. The separating device and the bag-type dust remover are installed at one side of the support, wherein the separating device is connected with the screw conveyer through two mercury vapor recycling pipelines, and the bag-type dust remover is connected with the air separation device through a fluorescent powder recycling pipeline. Through the process that the waste and old fluorescent lamp is smashed and heated in a sealed environment, mercury vapor is absorbed by active carbon and then delivered to a special factory for recycling and purifying; and meanwhile, the glass, fluorescent powder and metal material of the waste and old fluorescent lamp are recycled, the recycling and processing equipment of the waste and old fluorescent lamp can be used for solving the problems that the environment is polluted by mercury in the traditional waste and old fluorescent lamp and waste and old materials are not recycled and utilized.

Owner:荆州市大明灯业有限公司

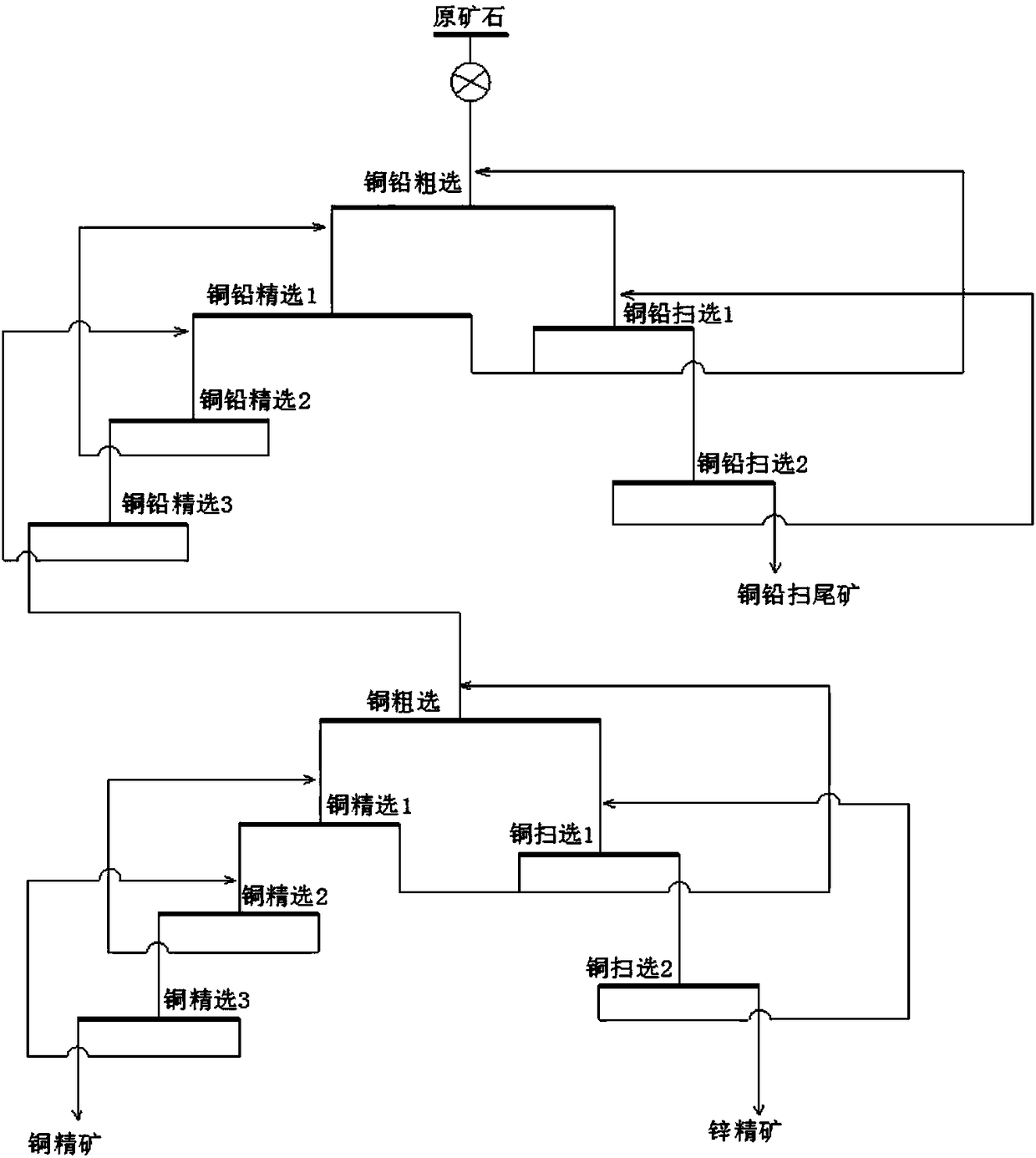

Beneficiation method for copper-lead sulphide ore

ActiveCN108405189APromote separationImprove recovery rate and gradeFlotationCitrate sodiumCalcium hypochlorite

The invention discloses a beneficiation method for copper-lead sulphide ore, and belongs to the technical field of beneficiation. The method comprises raw ore grinding, copper-lead mixing flotation and copper-lead separation. Copper-lead mixing flotation comprises primary copper-lead roughing, tertiary copper-lead fine selecting and secondary copper-lead scavenging. Copper-lead separation comprises primary copper roughing, tertiary copper fine selecting and secondary copper scavenging. Lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulphide, dimethyl dicarbonate, sodium pyrophosphate, sodium citrate, ethionine ester, ethyl thio carbamate, sodium n-butylxanthate, aniline aerofloat, diphenyl amino phosphorodithioic acid and sodium carbonate are added in the copper-lead roughing and copper-lead scavenging processes. Lime, water glass, sodium phosphate starch, carboxymethyl starch, phthalic acid, thiosalicylic acid, ethionine ester and sodium ethylxanthate are added in the copper roughing and copper scavenging processes. The beneficiation method solves the problem that in the process of beneficiation of the copper-lead sulphide ore through a traditional flotation method, the copper and lead recycling rate is low.

Owner:广西华洋矿源材料有限公司

Electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating

The invention discloses an electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating, which relates to the preparation method of Ni-Co-C alloy substitute hard chromium plating. The method one comprises the steps of: taking nickel salt, cobalt salt, NiC12.6H2O, boric acid, ammonium citrate, a carbon-containing compound, an N13# rapid high-leveling nickel plating glossing agent A and a stress relieving agent; preparing plating solution; and carrying out electroplating on a plated part. The method two comprises the steps of: taking NiC12.6H2O, cobalt salt, boric acid, ammonium citrate, a carbon-containing compound, an N13# rapid high-leveling nickel plating glossing agent A and a stress relieving agent; preparing plating solution; and carrying out electroplating on a plated part. In the invention, the Ni-Co-C alloy plating with uniform brightness, hardness of 690-770HV50 and favorable corrosion resistance is obtained at a deposition speed of 32 microns per hour; in the electroplating process, the cathode current efficiency is higher than 60%; and the hardness of the plating can be improved to 1000-1100HV50 after undergoing heat treatment for 1-3h at a temperature between 150-400DEG C.

Owner:HARBIN INST OF TECH +1

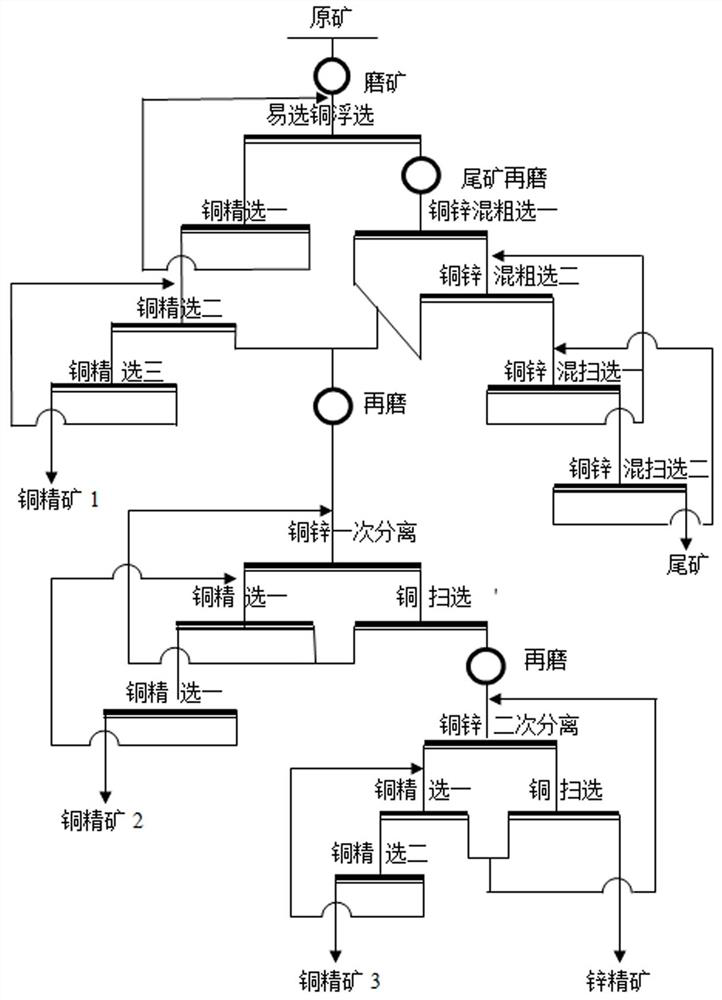

Beneficiation method for complex copper-zinc sulfide ore

The invention relates to the technical field of beneficiation, in particular to a beneficiation method for separating copper and zinc from copper-zinc sulfide ore. The invention discloses a beneficiation method for complex copper-zinc sulfide ore. The beneficiation process comprises the steps of an ore grinding method, a using method of a combined inhibitor in flotation and a using method of a combined collecting agent. The method, based on the principle of clean and environment-friendly production, aims to improve the recovery rate of copper, zinc and associated gold, reduce the problem of serious mutual content of copper and zinc concentrates and improve economic benefits. The beneficiation method is feasible in technology and copper-zinc minerals are separated in an environment-friendlymanner, wherein valuable metal complex copper-zinc sulphide ore is comprehensively recycled, use of sodium cyanide or an oxidizing agent in beneficiation can be omitted, the copper-zinc recycling rate is effectively increased, the precious metal gold recycling rate is increased, meanwhile, mutual content of concentrate impurities is reduced, economic benefits of enterprises are increased, and economic benefits of enterprises are increased. Meanwhile, environmental pollution caused by ore dressing tailing discharge is reduced, and industrial clean, environment-friendly and safe production is achieved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com