Recovery treatment system and method for oil field waste filtered substance

A technology for recycling and filtering materials, applied in separation methods, chemical instruments and methods, filtration and separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

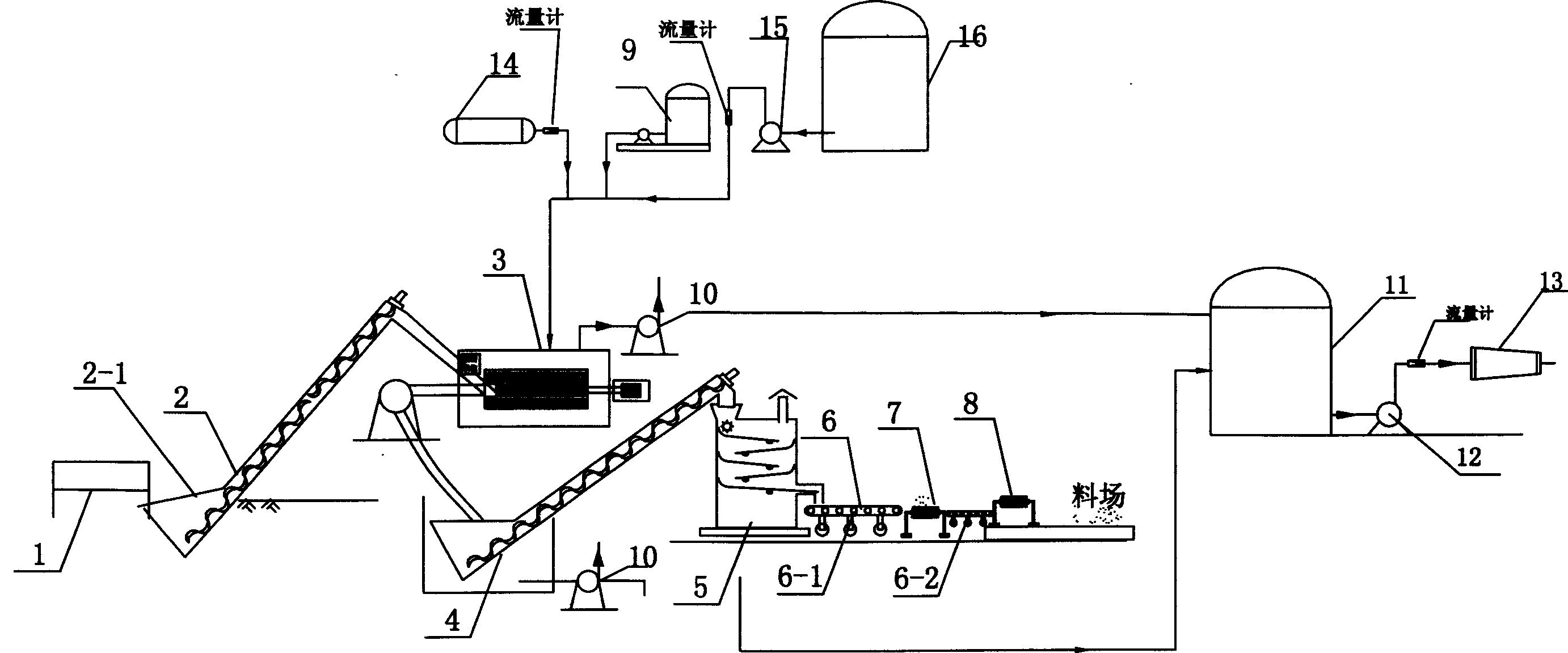

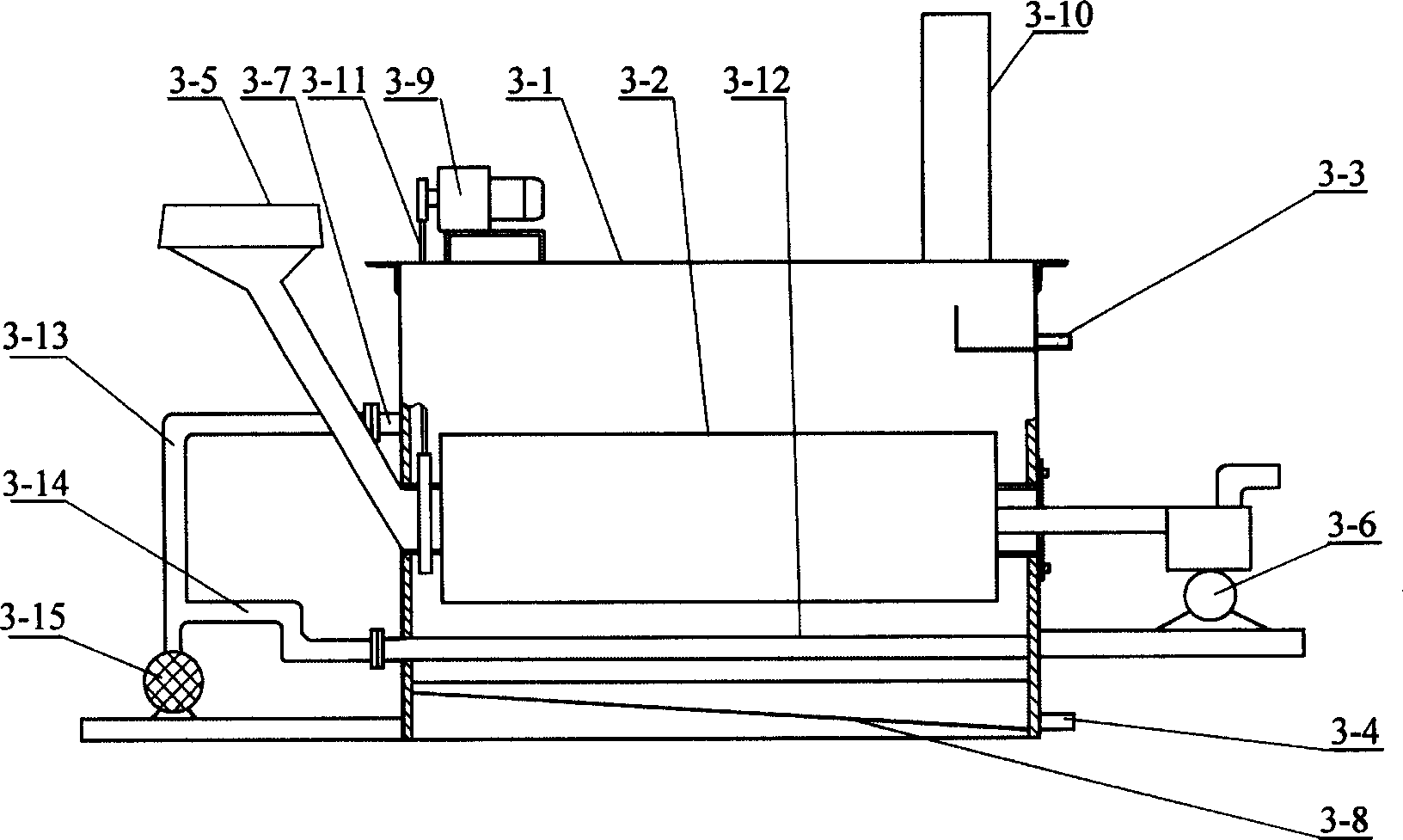

[0005] In this embodiment, the oilfield waste filter material recycling system includes the following devices: the coarse screening machine 1 is connected to the lower end of the screw elevator 2, and the upper end of the screw elevator 2 is arranged on the upper end of the filter material cleaning treatment device 3 feeding port, and the filter material The outlet of the cleaning treatment device 3 is arranged above the hopper of the spiral lifting separator 4, the upper end of the spiral lifting separator 4 is connected with the inlet of the drying box 5, and the outlet of the drying box 5 is connected with one end of the transmission belt 6, and the transmission belt 6 The other end of the magnetic separator is connected to one end of the magnetic separator 7, and the other end of the magnetic separator 7 is connected to the multi-layer electric screening machine 8 through the transmission belt 6. The filter material cleaning treatment device 3 is connected with the dosing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com