Patents

Literature

103 results about "Reaction sequence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanocoated primary particles and method for their manufacture

InactiveUS6913827B2Granule coatingSemiconductor/solid-state device detailsConformal coatingElectronic packaging

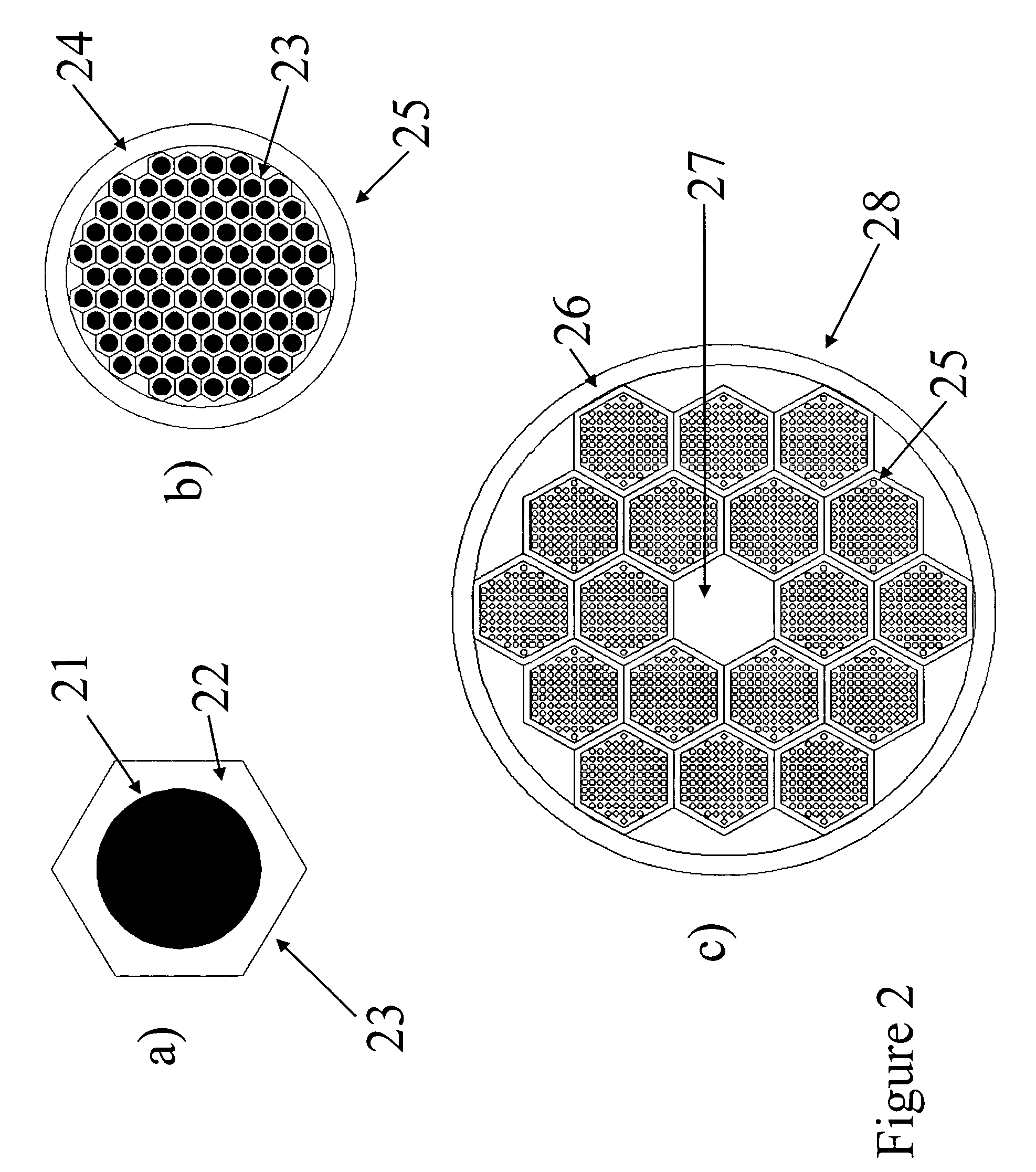

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:UNIV OF COLORADO THE REGENTS OF

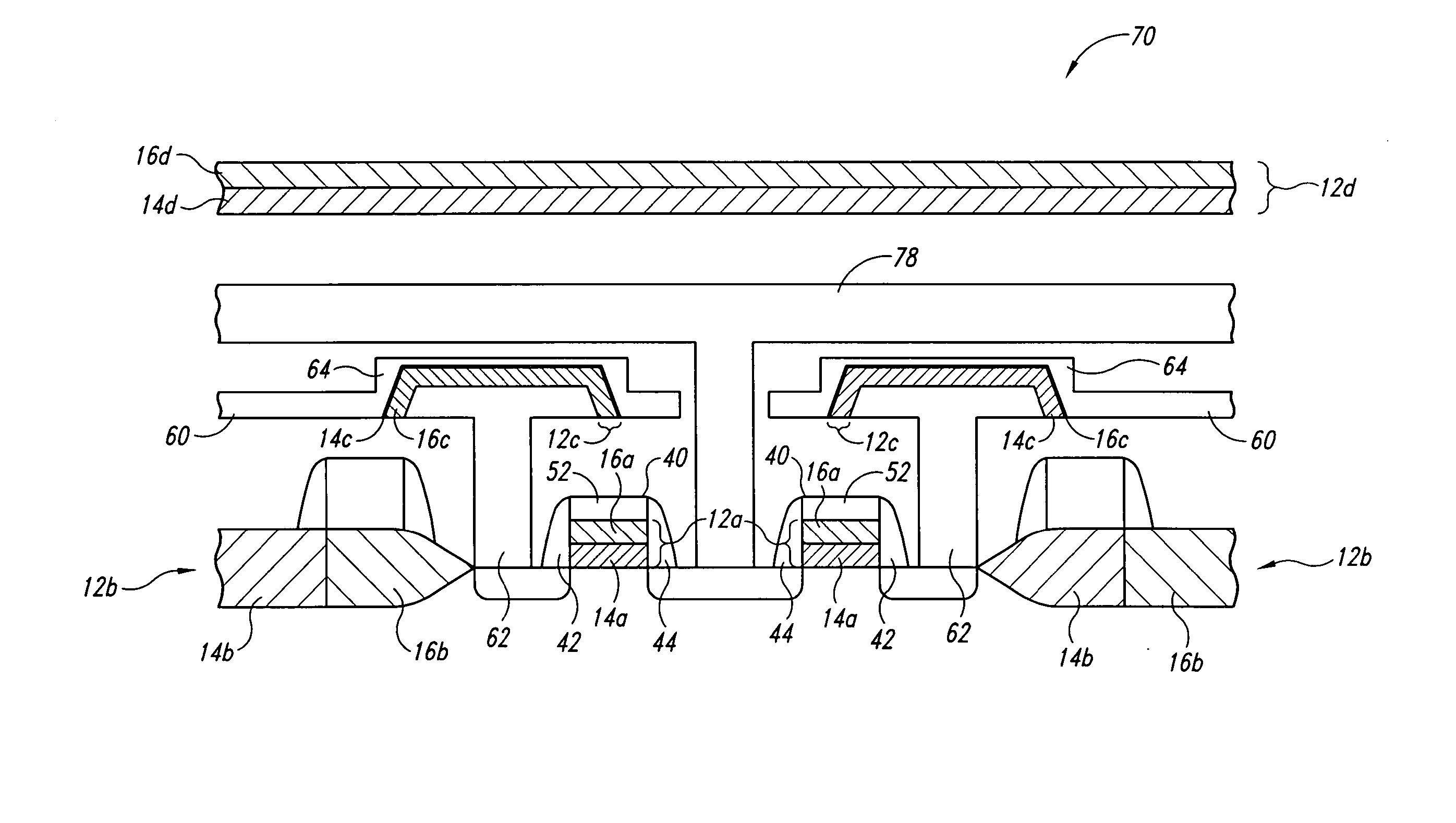

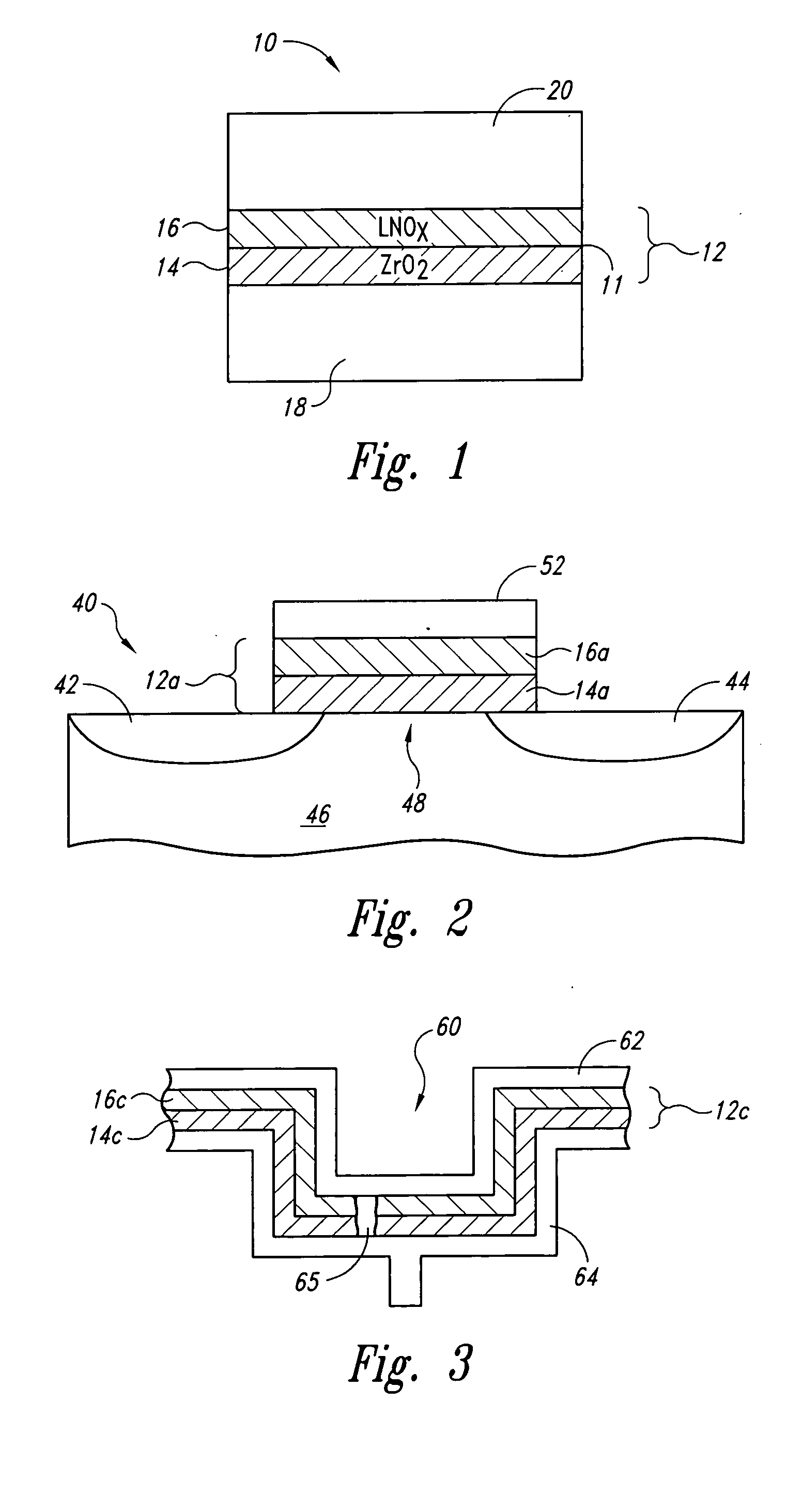

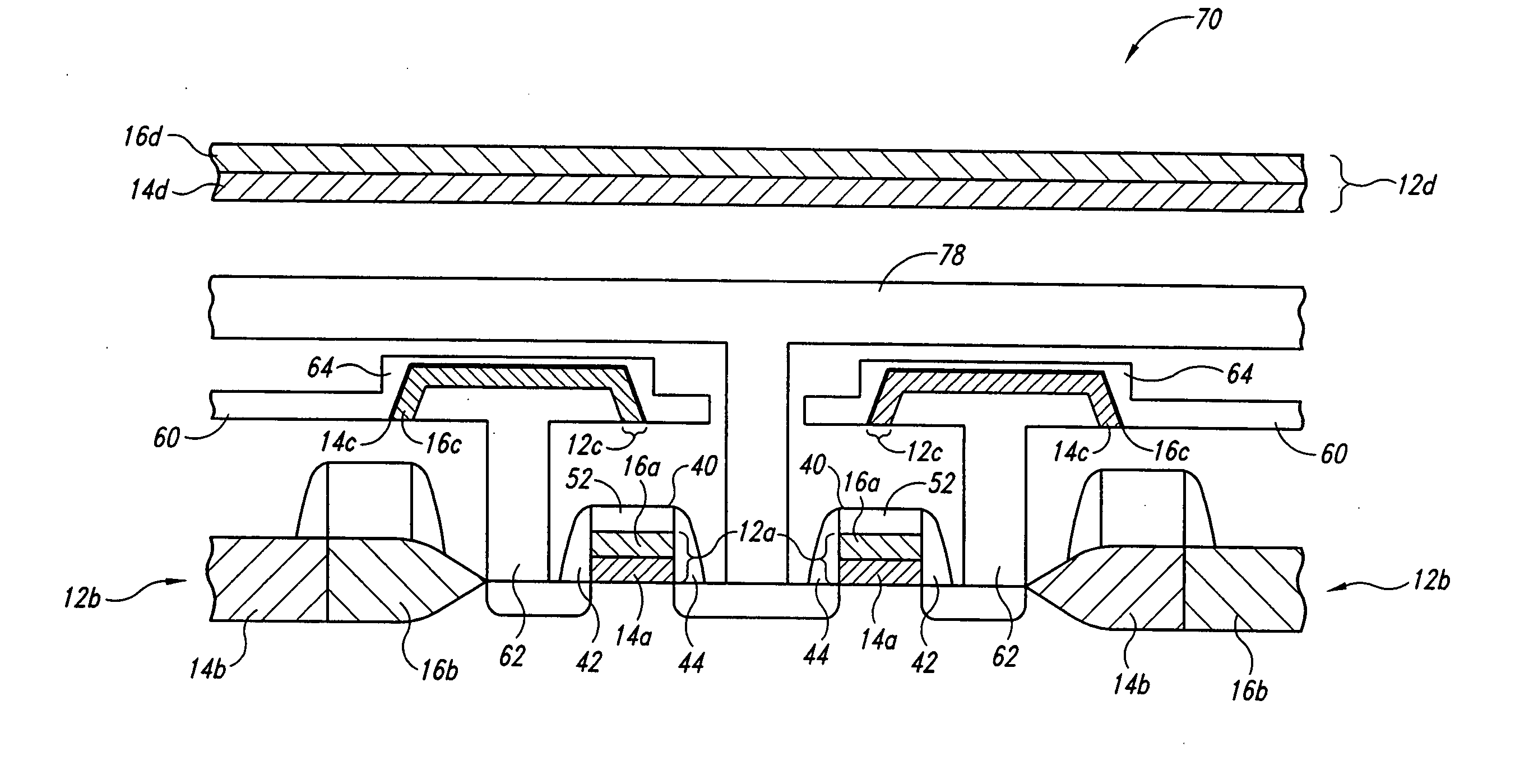

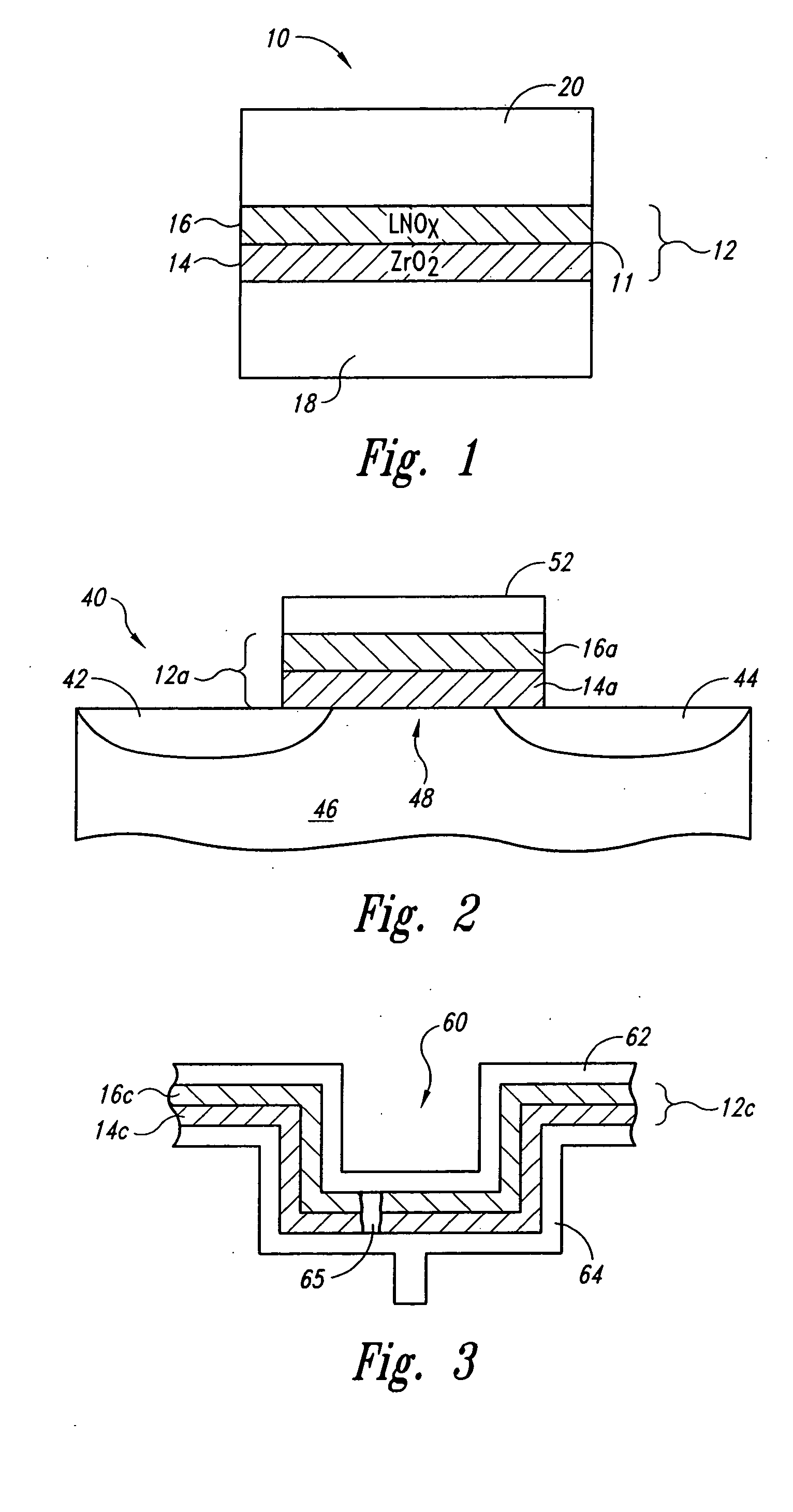

Lanthanide oxide/zirconium oxide atomic layer deposited nanolaminate gate dielectrics

The invention provides a laminated dielectric layer for semiconductor devices formed by a combination of ZrO2 and a lanthanide oxide on a semiconductor substrate and methods of making the same. In certain methods, the ZrO2 is deposited by multiple cycles of reaction sequence atomic layer deposition (RS-ALD) that includes depositing a ZrI4 precursor onto the surface of the substrate in a first pulse followed by exposure to H2O / H2O2 in a second pulse, thereby forming a thin ZrO2 layer on the surface. After depositing the ZrO2 layer, the lanthanide oxide layer is deposited by electron beam evaporation. The composite laminate zirconium oxide / lanthanide oxide dielectric layer has a relatively high dielectric constant and can be formed in layers of nanometer dimensions. It is useful for a variety of semiconductor applications, particularly for DRAM gate dielectric layers and DRAM capacitors.

Owner:MICRON TECH INC

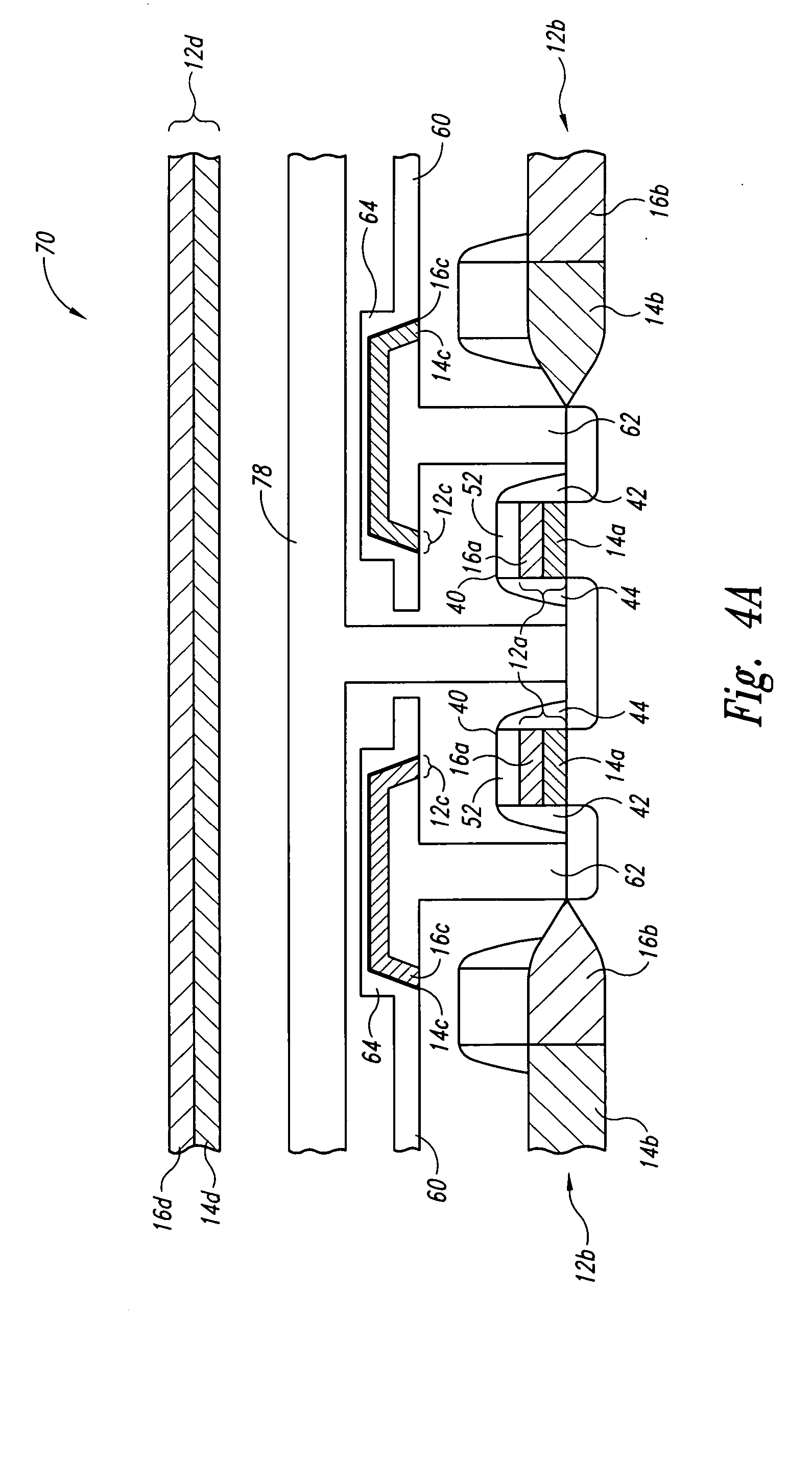

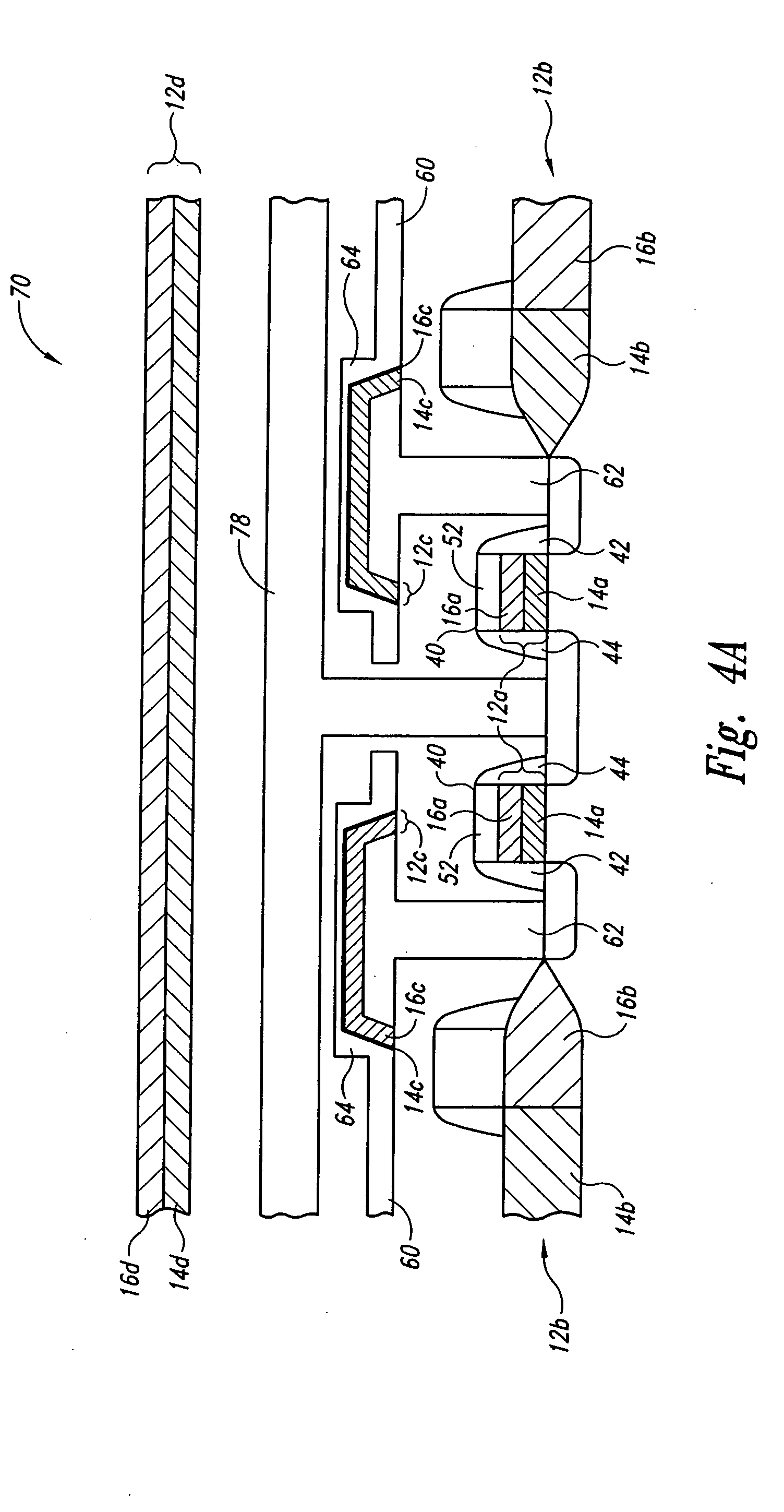

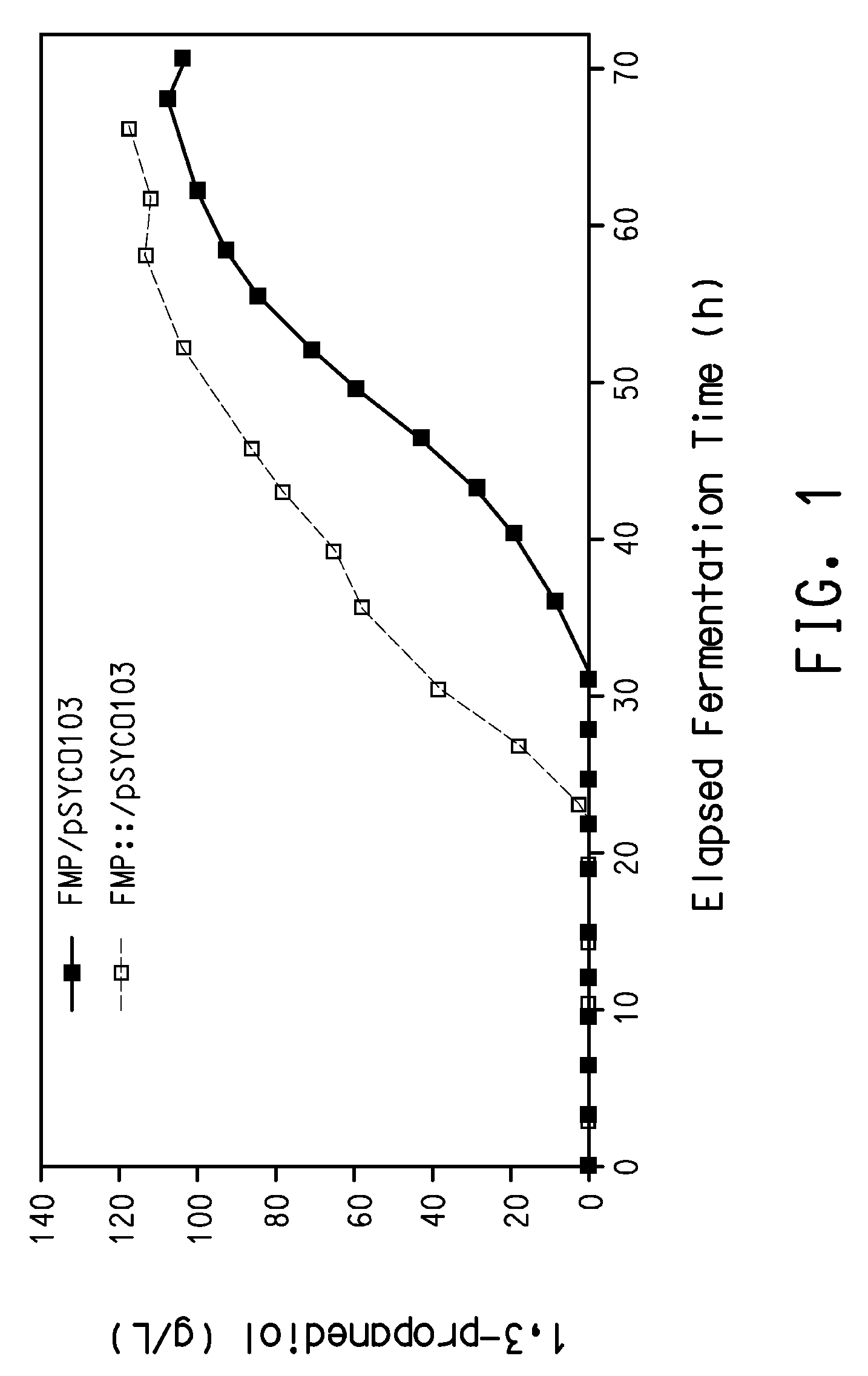

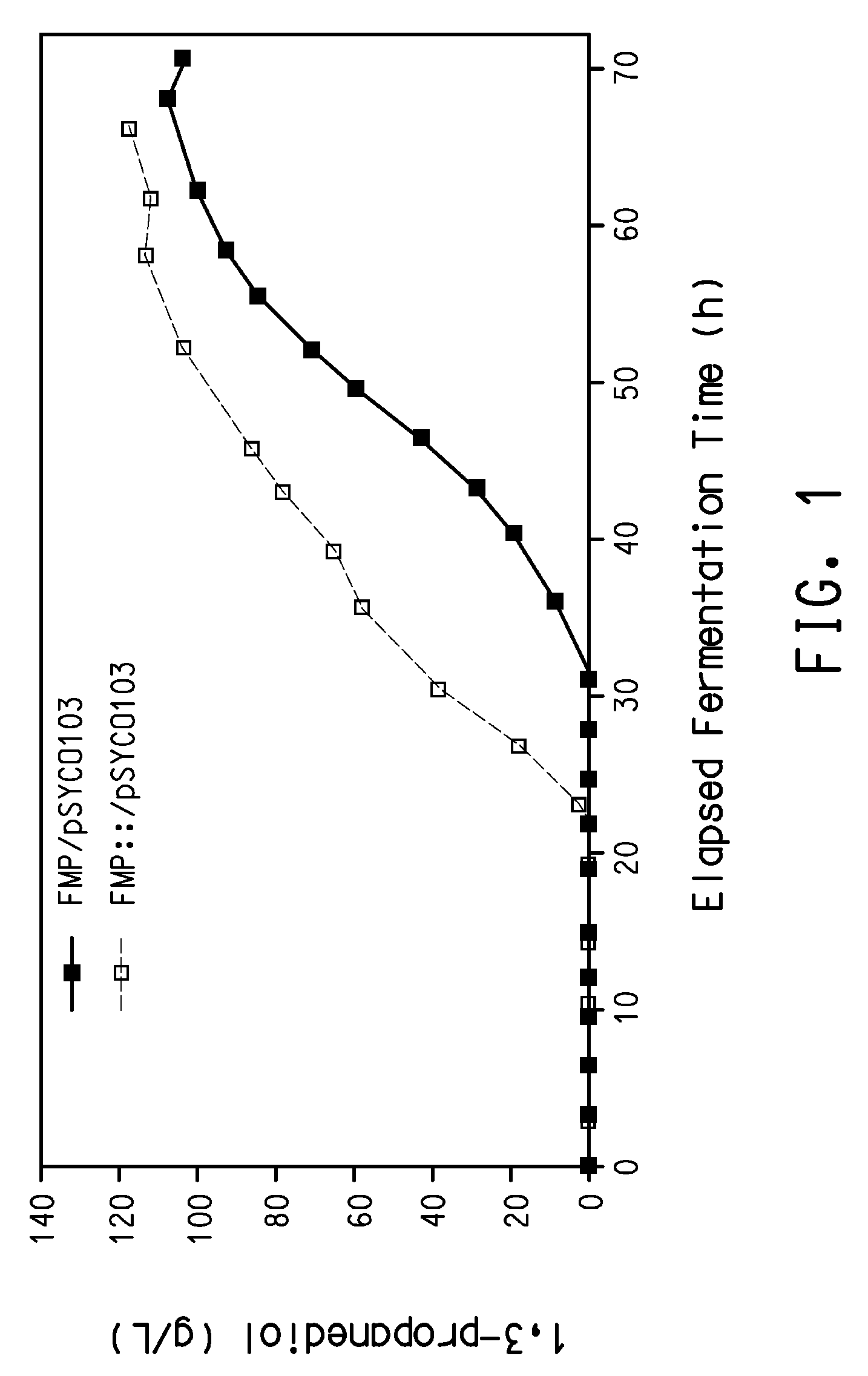

Process for the biological production of 1,3-propanediol with high yield

The present invention provides a microorganism useful for biologically producing 1,3-propanediol from a fermentable carbon source at higher yield than was previously known. The complexity of the cofactor requirements necessitates the use of a whole cell catalyst for an industrial process that utilizes this reaction sequence to produce 1,3-propanediol. The invention provides a microorganism with disruptions in specified genes and alterations in the expression levels of specified genes that is useful in a higher yielding process to produce 1,3-propanediol.

Owner:NUTRITION & BIOSCIENCES USA 4 INC +1

Lanthanide oxide/zirconium oxide atomic layer deposited nanolaminate gate dielectrics

The invention provides a laminated dielectric layer for semiconductor devices formed by a combination of ZrO2 and a lanthanide oxide on a semiconductor substrate and methods of making the same. In certain methods, the ZrO2 is deposited by multiple cycles of reaction sequence atomic layer deposition (RS-ALD) that includes depositing a ZrI4 precursor onto the surface of the substrate in a first pulse followed by exposure to H2O / H2O2 in a second pulse, thereby forming a thin ZrO2 layer on the surface. After depositing the ZrO2 layer, the lanthanide oxide layer is deposited by electron beam evaporation. The composite laminate zirconium oxide / lanthanide oxide dielectric layer has a relatively high dielectric constant and can be formed in layers of nanometer dimensions. It is useful for a variety of semiconductor applications, particularly for DRAM gate dielectric layers and DRAM capacitors.

Owner:AHN KIE +1

Coated particles and sunscreen and cosmetic products containing same

InactiveUS20070280895A1Increasing bed volumeEqually distributedCosmetic preparationsToilet preparationsMetallic materialsConformal coating

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:WEIMER ALAN W +1

Process for producing a homogeneous polyethylene material in the presence of a catalyst

InactiveUS6455642B1Reduce partHigh molecular weightChemical/physical/physico-chemical processesPolymer scienceGas phase

The present invention concerns a process for producing homogeneous polyethylene materials and processes for making high density, medium density and low density films therefrom. The process involves producing a polyethylene composition in a multistage reaction sequence of successive polymerization stages in the presence of an ethylene-polymerizing catalyst system. According to the invention, the process is carried out using an unsupported catalyst having magnesium and titanium as active constituents, in at least one loop polymerization stage and at least one gas phase polymerization stage and, operated with different amounts of hydrogen and comonomers to produce a high molecular weight portion in one of the polymerization stages and a low molecular weight portion in another so as to provide a polyethylene composition with the low molecular weight part having a MFR2 of 250 g / 10 min or more. With this process it is possible to obtain homogeneous bimodal polyethylene material.

Owner:BOREALIS TECH OY

Process for the biological production of 1,3-propanediol with high yield

Owner:NUTRITION & BIOSCIENCES USA 4 INC

Establishing method of paper-based photoinduced electrochemical biological sensor with high flux

InactiveCN107064118AImprove conductivityHigh detection sensitivityMaterial analysis by observing effect on chemical indicatorMaterial analysis by electric/magnetic meansFiberElectrochemical biosensor

The invention discloses a photoinduced electrochemical biological sensor with advantages of simple operation and high flux, which is successfully applied to simultaneously detect three types of cancer cells. The photoinduced electrochemical biological sensor is characterized in that a layer of gold nanoparticles is modified onto the surface of paper fiber through gold nanometer self-catalytic reduction; then, preparing cadmium sulfide-graphene-zinc oxide bar ternary composite materials at the surface of a paper working electrode which are modified by long gold, and using as photo-electrodes; using chemical light emitting to replace the traditional xenon lamp; by controlling the chemical light emitting reaction sequence, sequentially exciting photo-electrodes; sequentially detecting three photo-current peaks, so as to simultaneously detect the three types of cancer cells.

Owner:UNIV OF JINAN

Process for the biological production of 1,3-propanediol with high yield

The present invention provides a microorganism useful for biologically producing 1,3-propanediol from a fermentable carbon source at higher yield than was previously known. The complexity of the cofactor requirements necessitates the use of a whole cell catalyst for an industrial process that utilizes this reaction sequence to produce 1,3-propanediol. The invention provides a microorganism with disruptions in specified genes and alterations in the expression levels of specified genes that is useful in a higher yielding process to produce 1,3-propanediol.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

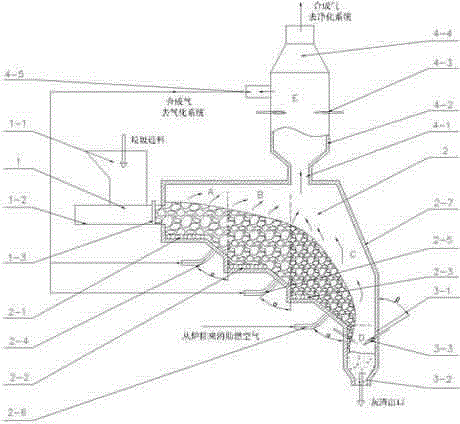

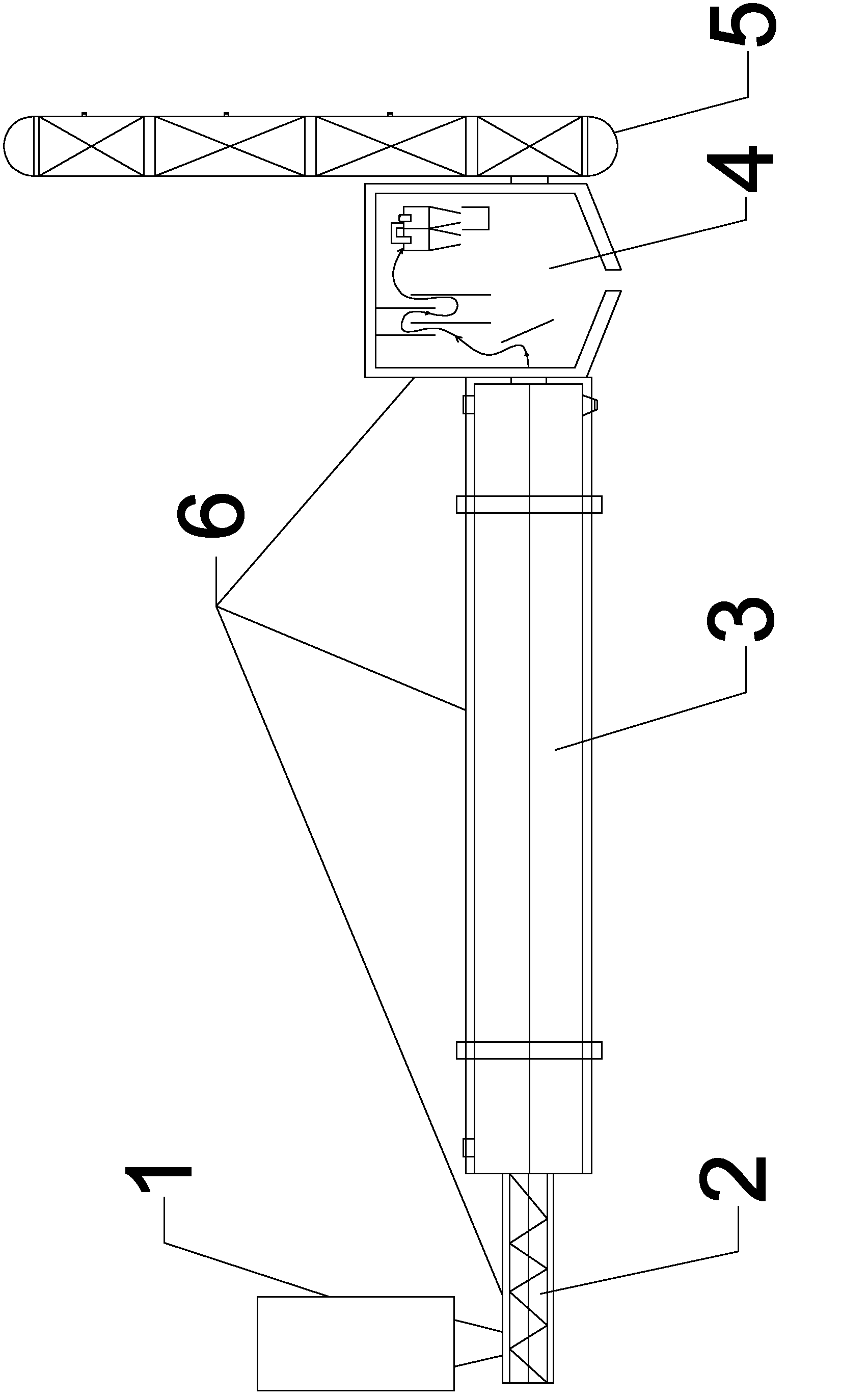

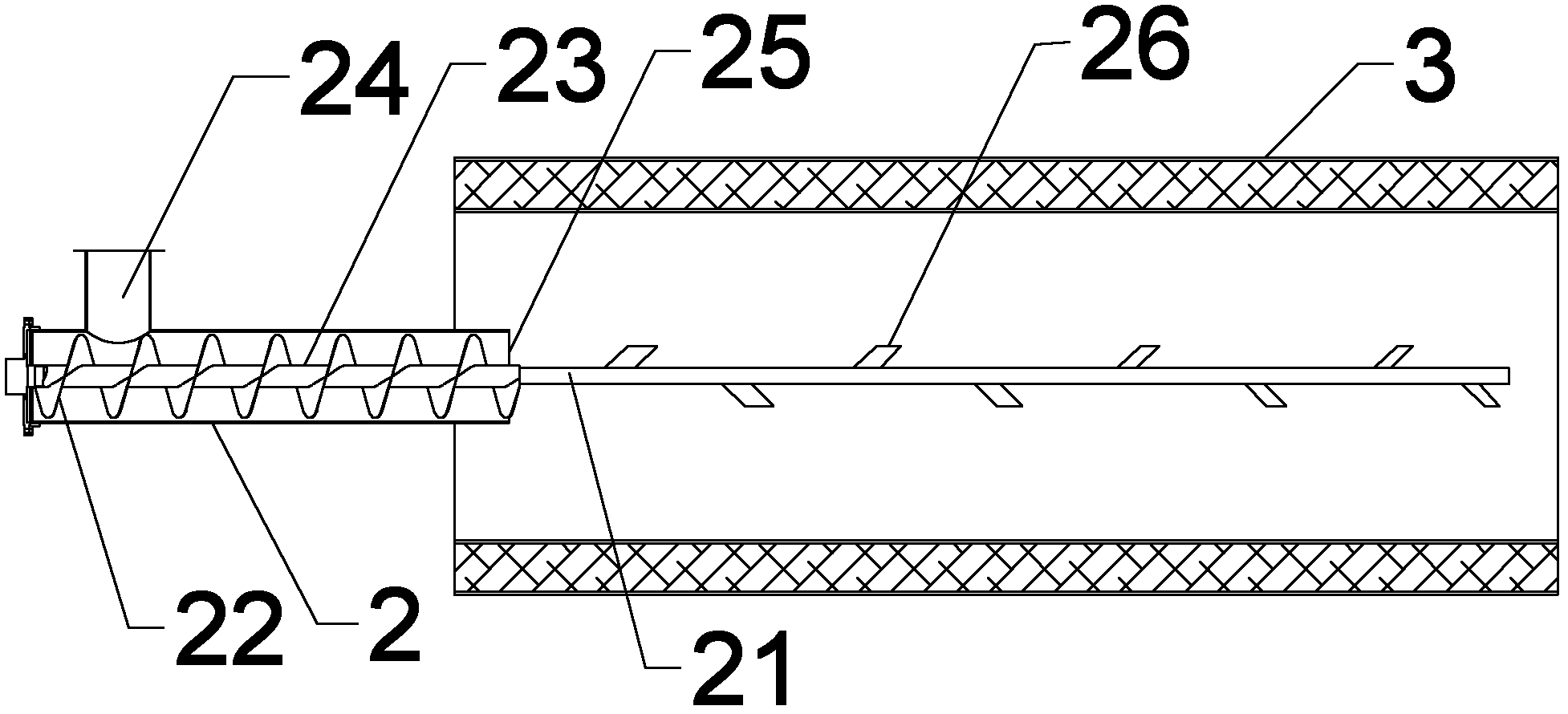

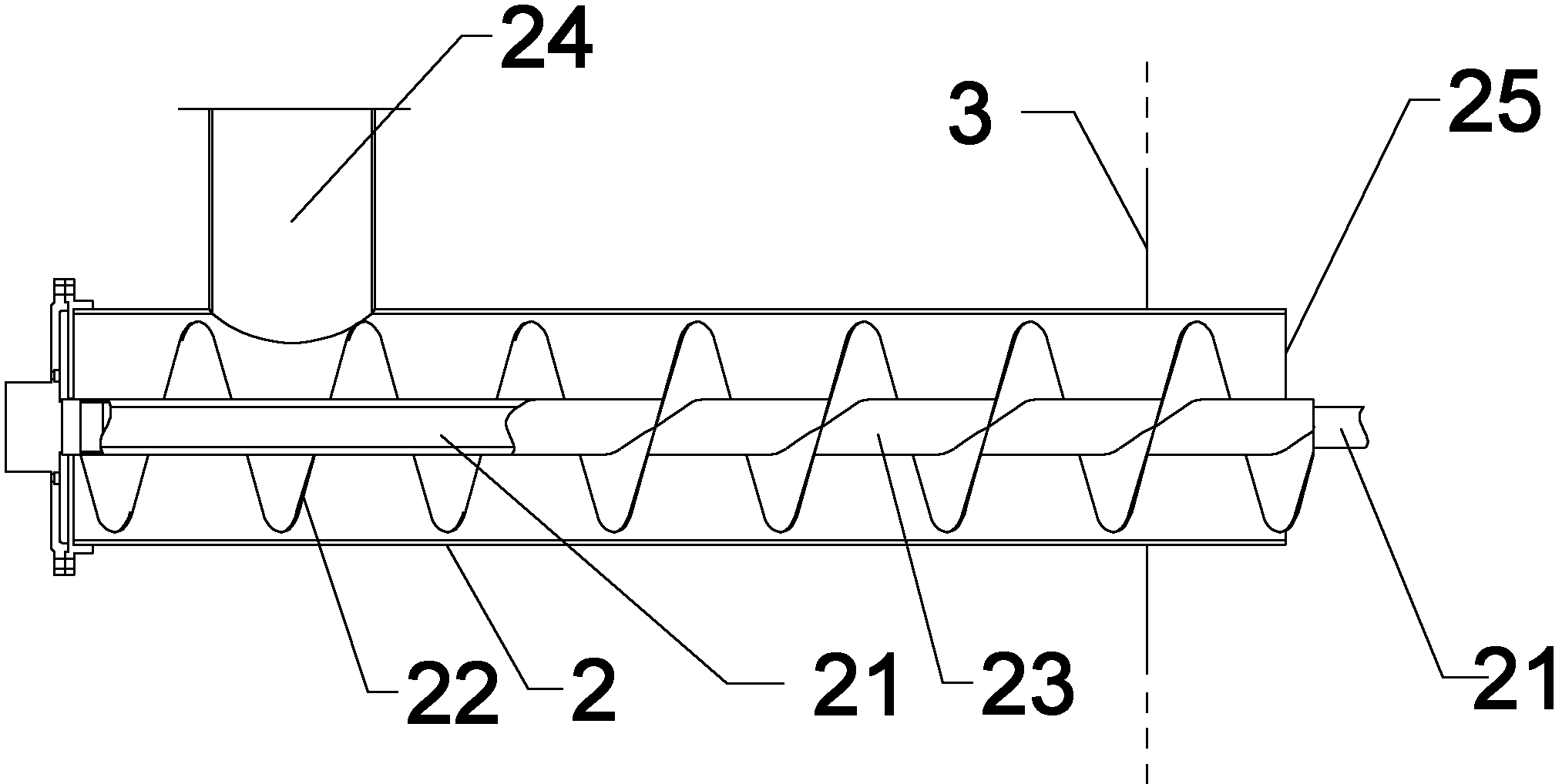

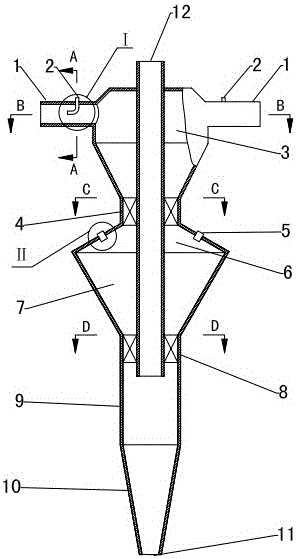

Plasma auxiliary-heating melting and gasifying reactor

ActiveCN104449875ASolve the emission problemFix issues that require reprocessingGasification processes detailsCombustible gas productionOperational costsReaction sequence

The invention relates to a plasma auxiliary-heating melting and gasifying reactor. The plasma auxiliary-heating melting and gasifying reactor comprises a feeder and a reaction chamber, wherein the feeder is connected with the reaction chamber; the reaction chamber sequentially comprises a drying area, a pyrolysis and gasification area, a burn-out area and an ash melting area according to a reaction sequence along a horizontal direction; the drying area is connected with the feeder through a charge port; the bottom of the pyrolysis and gasification area is lower than that of the drying area; the bottom of the burn-out area is lower than that of the pyrolysis and gasification area; the bottom of the ash melting area is lower than that of the burn-out area; the top of the burn-out area is connected with a synthesis gas reforming area through a throat opening; plasma torches are arranged in both the ash melting area and the synthesis gas reforming area. According to the plasma auxiliary-heating melting and gasifying reactor disclosed by the invention, the plasma torches are used as a high-quality external heat source for melting the ash generated after pyrolysis and gasification for household garbage, and the gasified synthesis gas is reformed, thus removing all harmful substances which are possibly generated by the household garbage in pyrolysis and gasification processes, reducing the one-time investment cost and operation cost of garbage plasma gasification, and enabling the synthesis gas to be purer.

Owner:中国东方电气集团有限公司

Medical polyacrylate pressure-sensitive adhesive with high adhesion performance

ActiveCN105219316AGood adhesionHigh molecular weightEster polymer adhesivesCross-linkPolymer science

The invention relates to a medical polyacrylate pressure-sensitive adhesive with high adhesion performance. The medical polyacrylate pressure-sensitive adhesive comprises soft monomers, hard monomers, functional monomers, initiators, cross-linking agents and solvents. The glass-transition temperature of the soft monomers ranges from -65 DEG C to -60 DEG C. The cross-linking agents are isocyanate-group-containing compounds generated through the reaction between polyisocyanates and polyhydroxy compounds. The weight-average molecular weight of the pressure-sensitive adhesive ranges from 80*10<4> g / mol to 140*10<4> g / mol. The molecular weight distribution of the pressure-sensitive adhesive ranges from 10 to 25. In the preparing process of the pressure-sensitive adhesive, temperature and the reaction sequence and the adding quantity of the reaction materials are gradually controlled, and the product with the high molecular weight and the wide molecular weight distribution is obtained. The product can be used for the medical and health field.

Owner:四川厚生天佐药业有限公司

Manufacture of high temperature superconductor coils

ActiveUS20090325809A1High currentLine/current collector detailsSuperconductors/hyperconductorsHigh current densityReaction temperature

A method for successfully heat treating magnet coils of braided Bi2Sr2Ca1Cu2Ox (Bi-2212) strand. The Bi-2212 coil is fabricated using standard round wire powder-in-tube techniques, and braided with a ceramic-glass braid with integrated carbonaceous binder. The coil is heated in an atmosphere controlled furnace below the high current density phase reaction sequence to burn off the carbonaceous binder and evacuated to remove unwanted gases from the inner windings. The oxygen environment is then reintroduced and the coil is heat treated to the high Jc reaction temperature and then processed as normal. As the local atmosphere around the surface of the wire, particularly the concentration of oxygen, is critical to a successful reaction sequence, high current Bi-2212 coils can thereby be obtained.

Owner:OXFORD SUPERCONDUCTING TECH

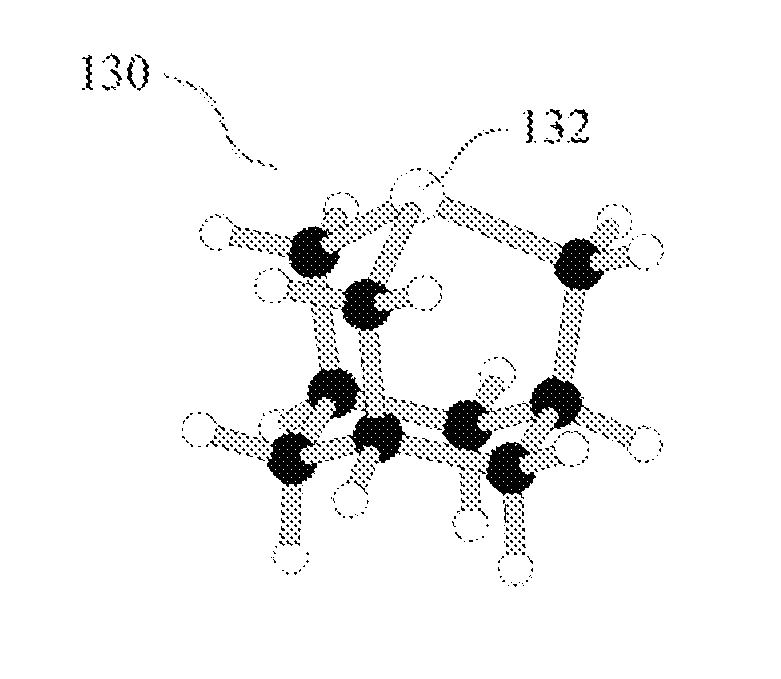

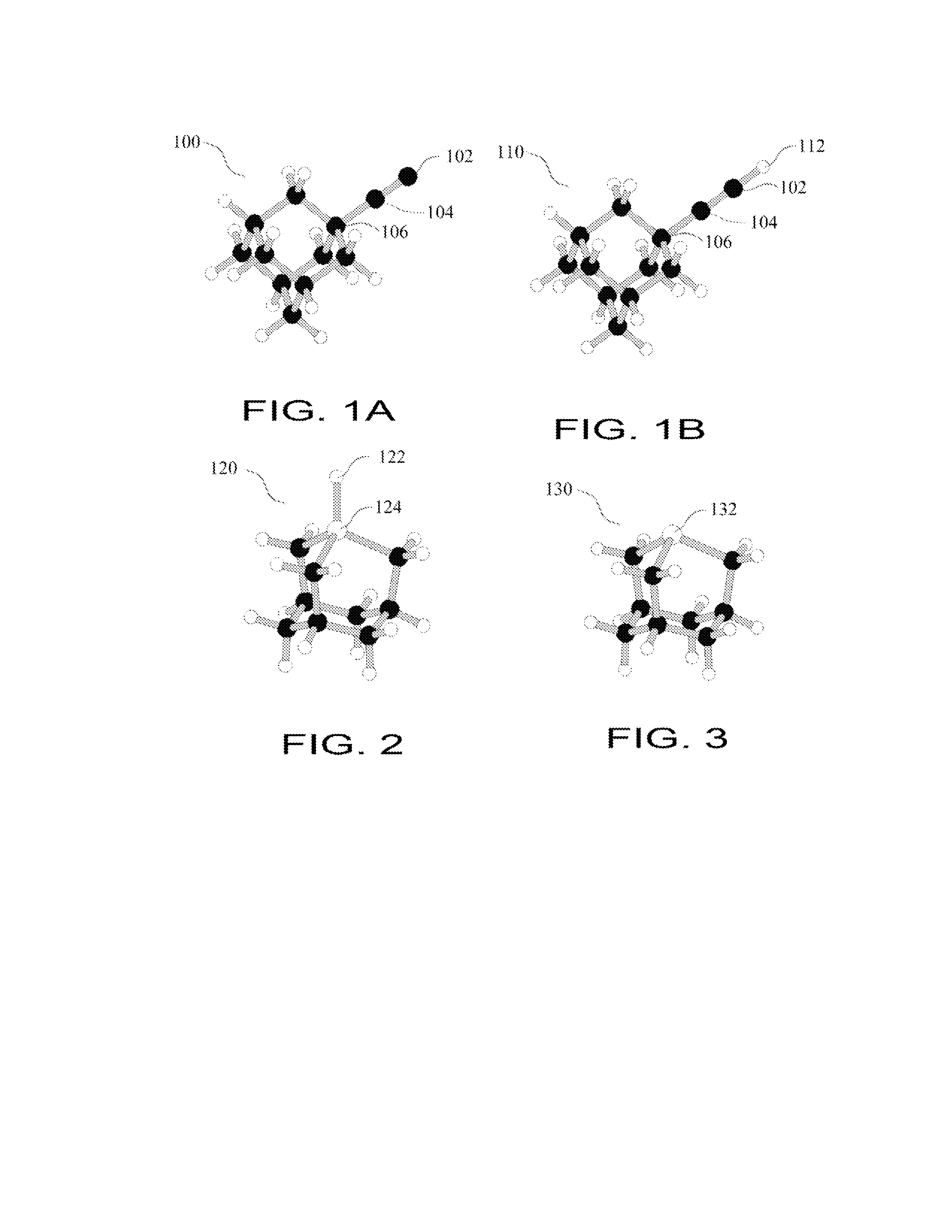

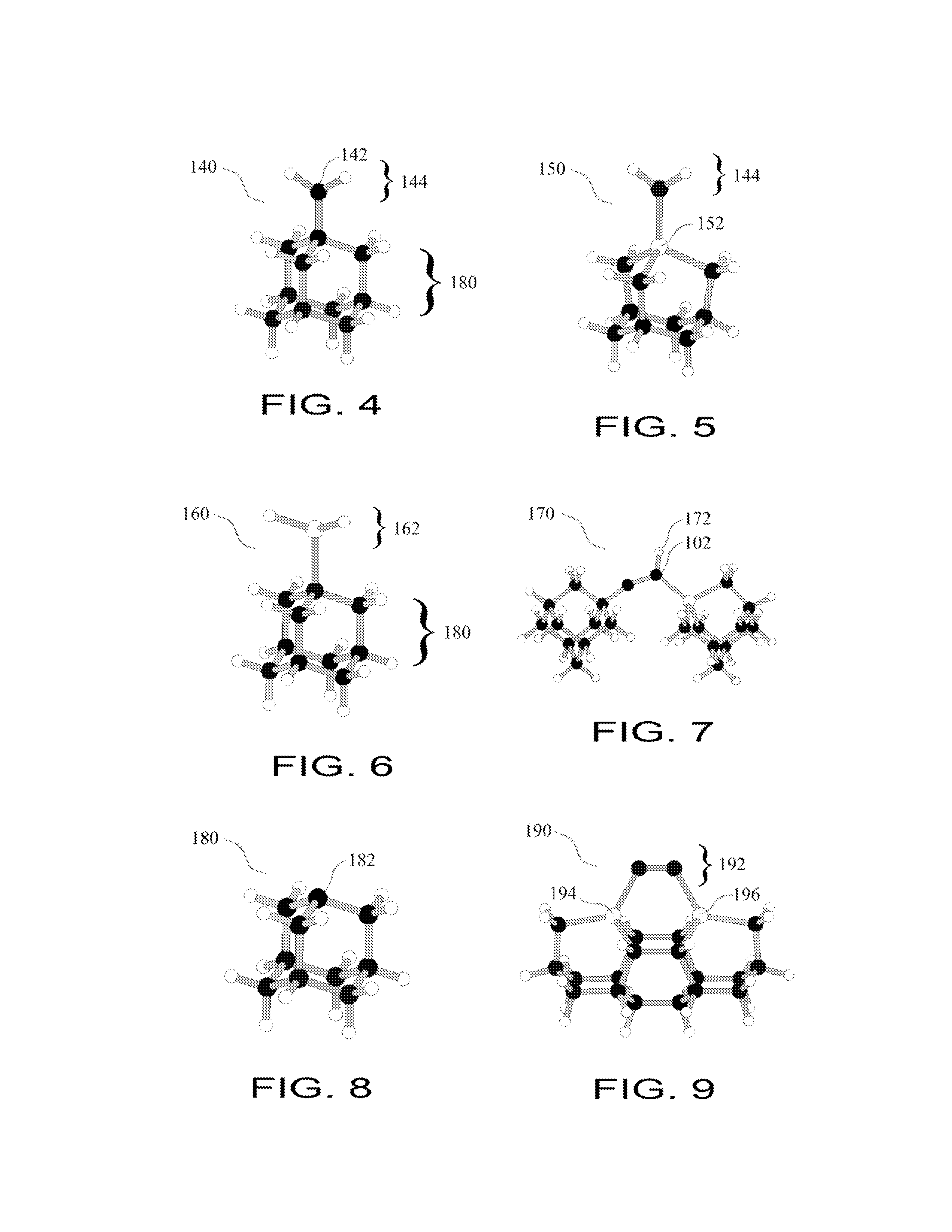

Methods, Systems and Workpieces Using Mechanosynthesis

InactiveUS20130178627A1SamplingGroup 8/9/10/18 element organic compoundsMechanosynthesisReaction sequence

Methods and systems for building three-dimensional workpieces are described using a plurality of mechanosynthetic reactions. These methods may employ engineered reliability in reactions and process conditions and may use simulated or otherwise vetted reaction sequences, to allow workpieces requiring many reactions to be built with acceptable reliability. These many reactions may be the repetition of one or a small number of reactions, or many diverse reactions, or a combination thereof.

Owner:CBN NANO TECH INC

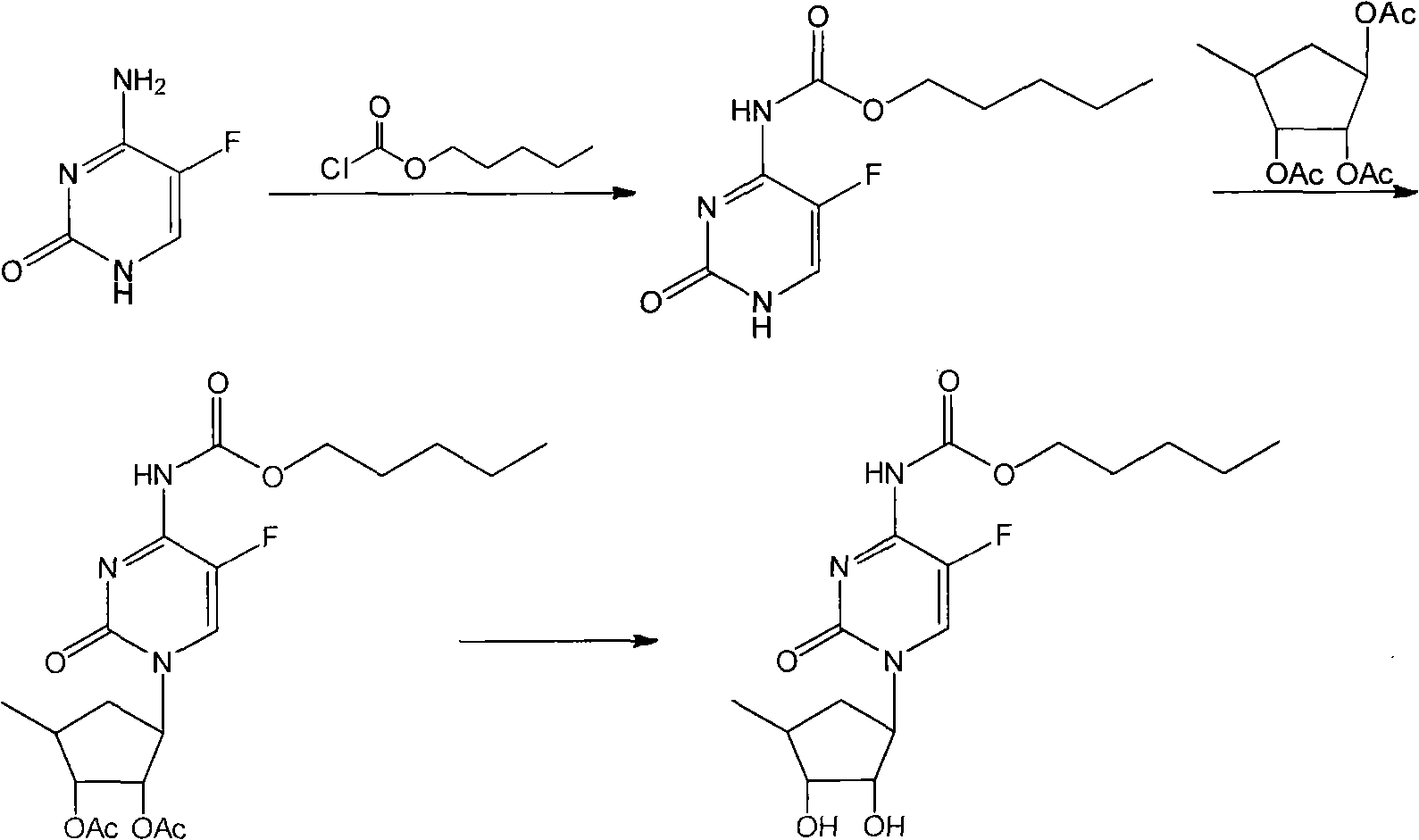

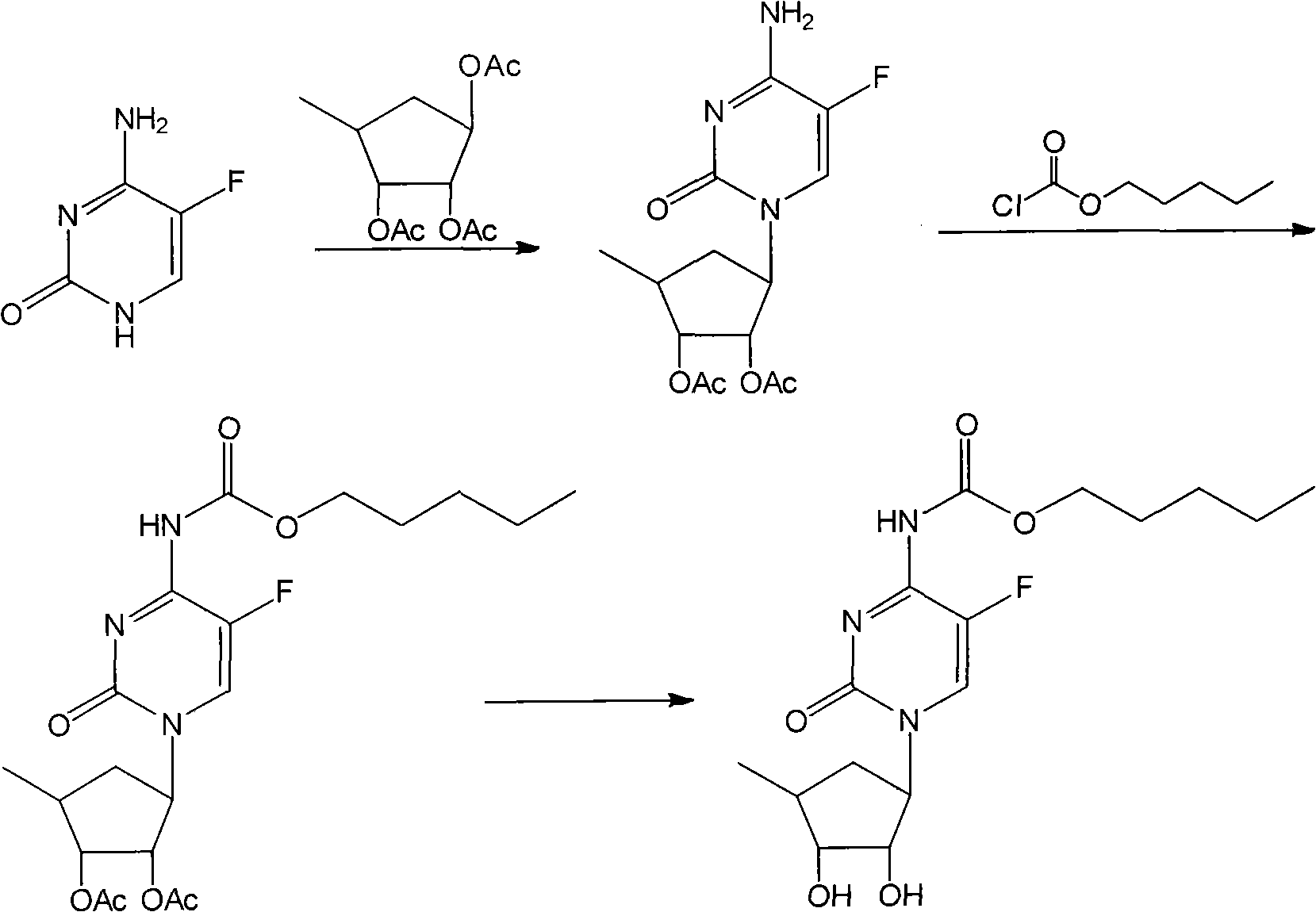

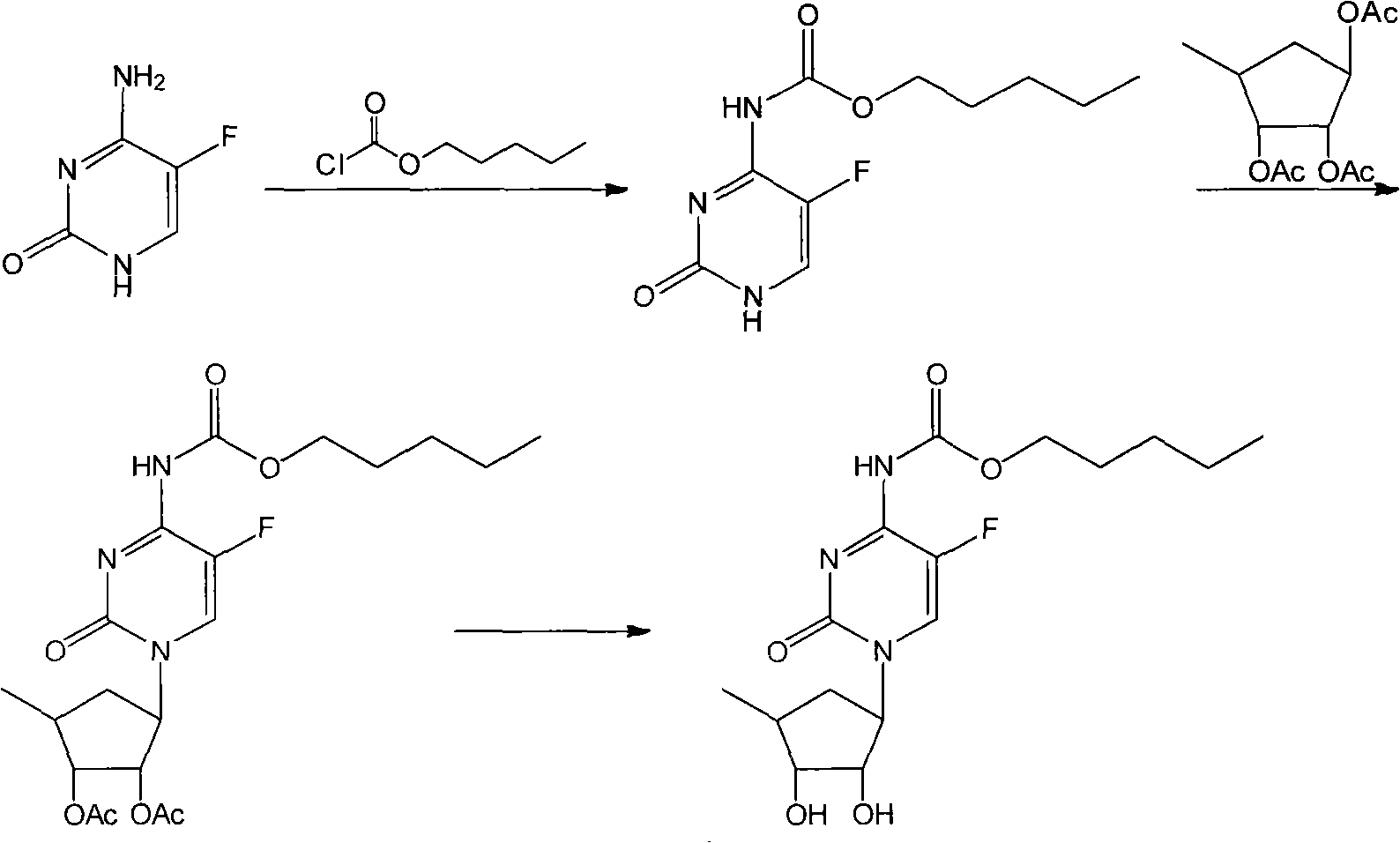

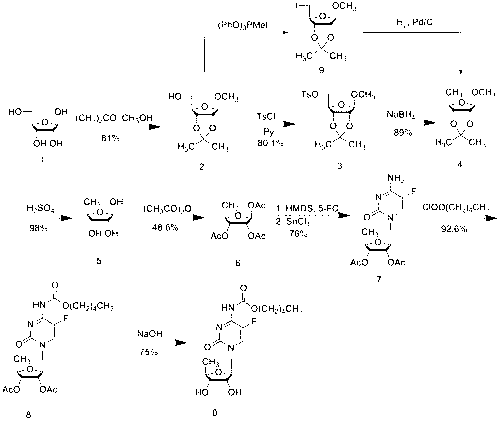

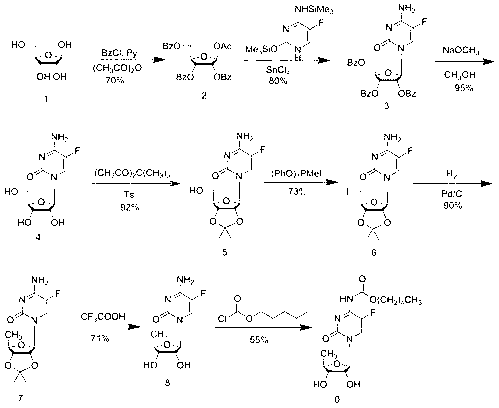

New method for continuously operating to synthesize capecitabine

InactiveCN101812104AReduce lossesReduced Distillation RecoverySugar derivativesSugar derivatives preparationReaction sequenceHydrolysis

The invention relates to a new method for continuously operating to synthesize capecitabine, which is characterized in that 5-flucytosine is subjected to acylation, condensation and hydrolysis to synthesize the capecitabine. The invention has the advantages of reasonable reaction sequence, continuous operation of three steps, operation simplification, high yield, low cost and less pollution.

Owner:江苏吴中苏药医药开发有限责任公司

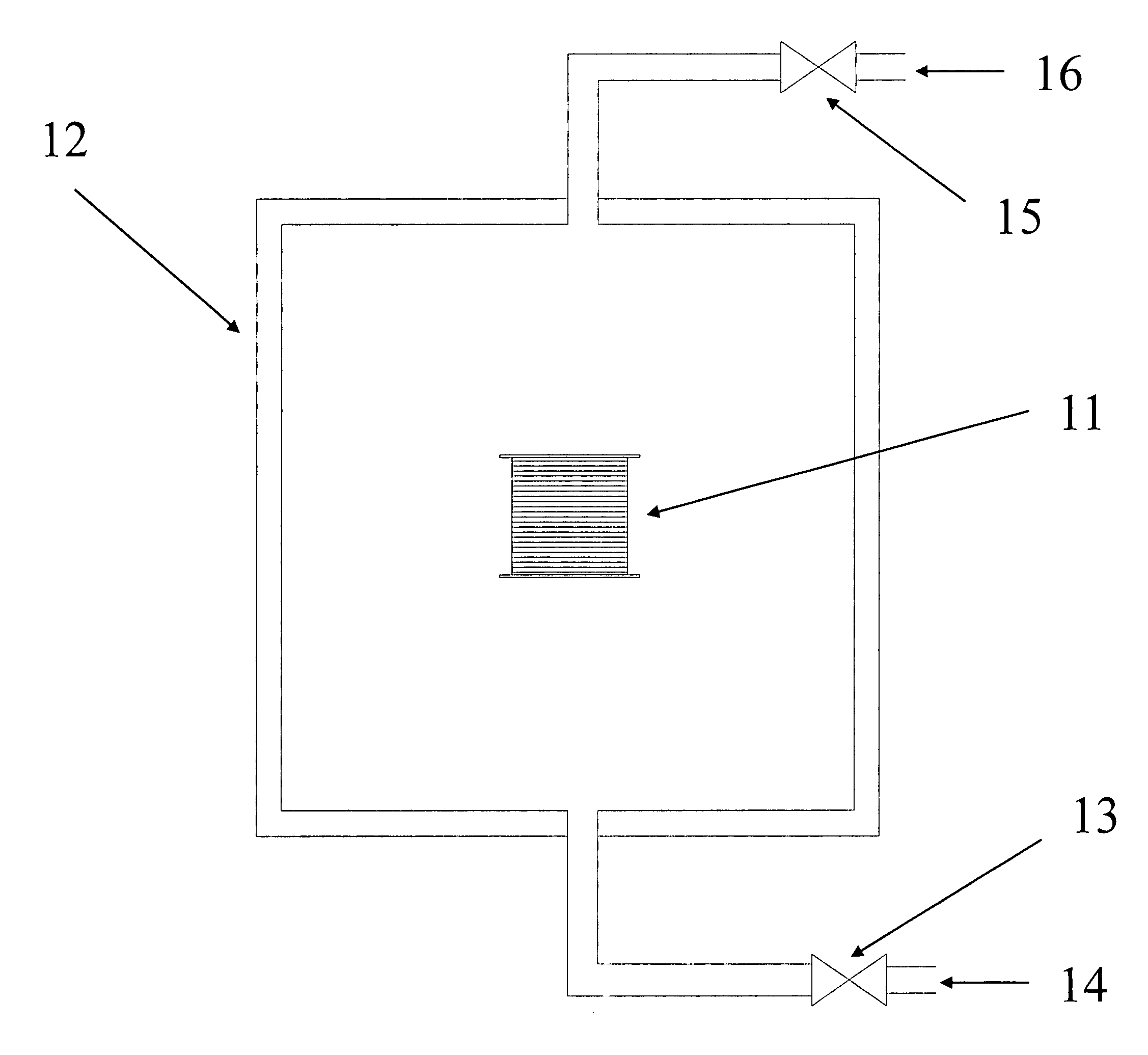

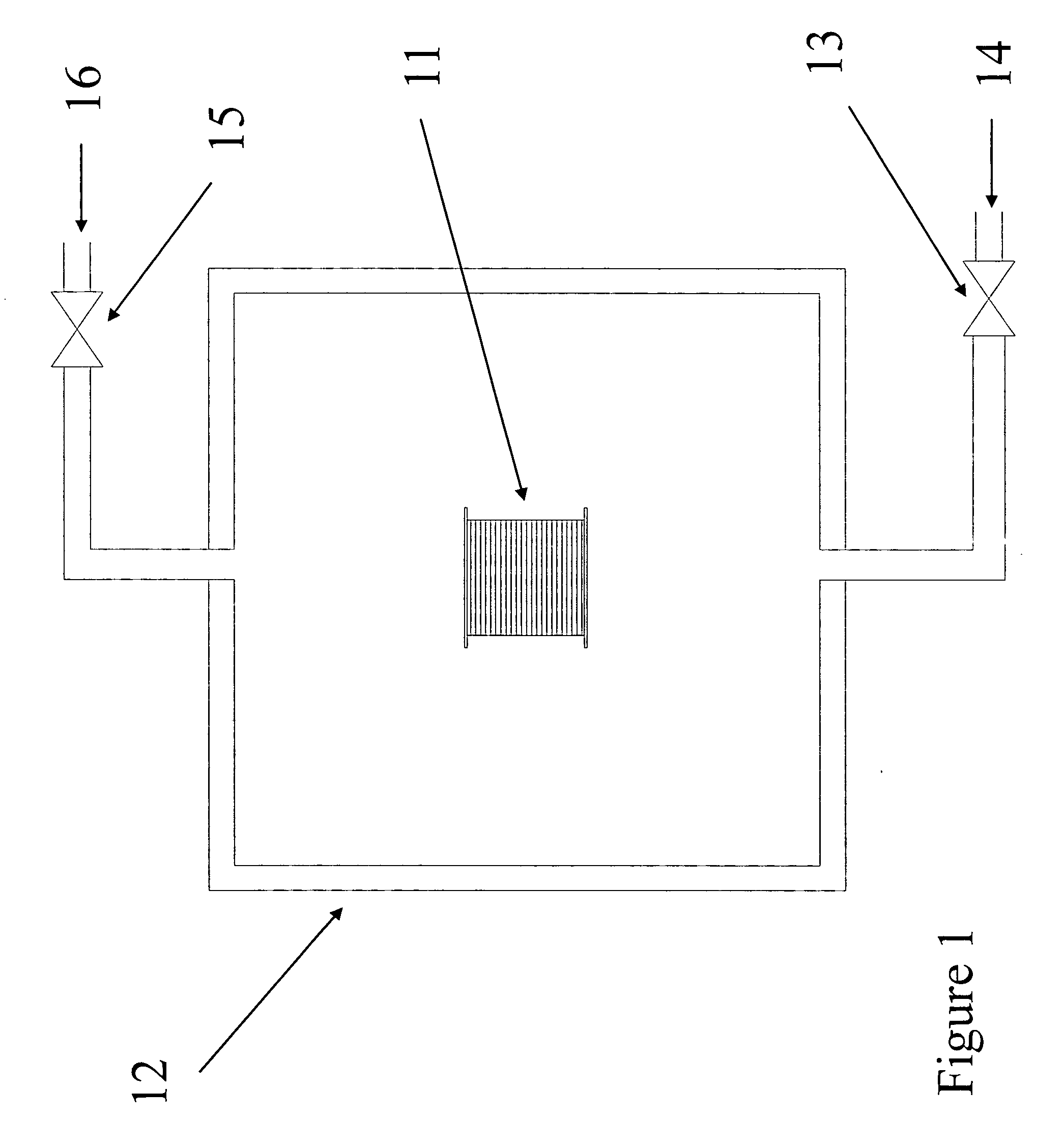

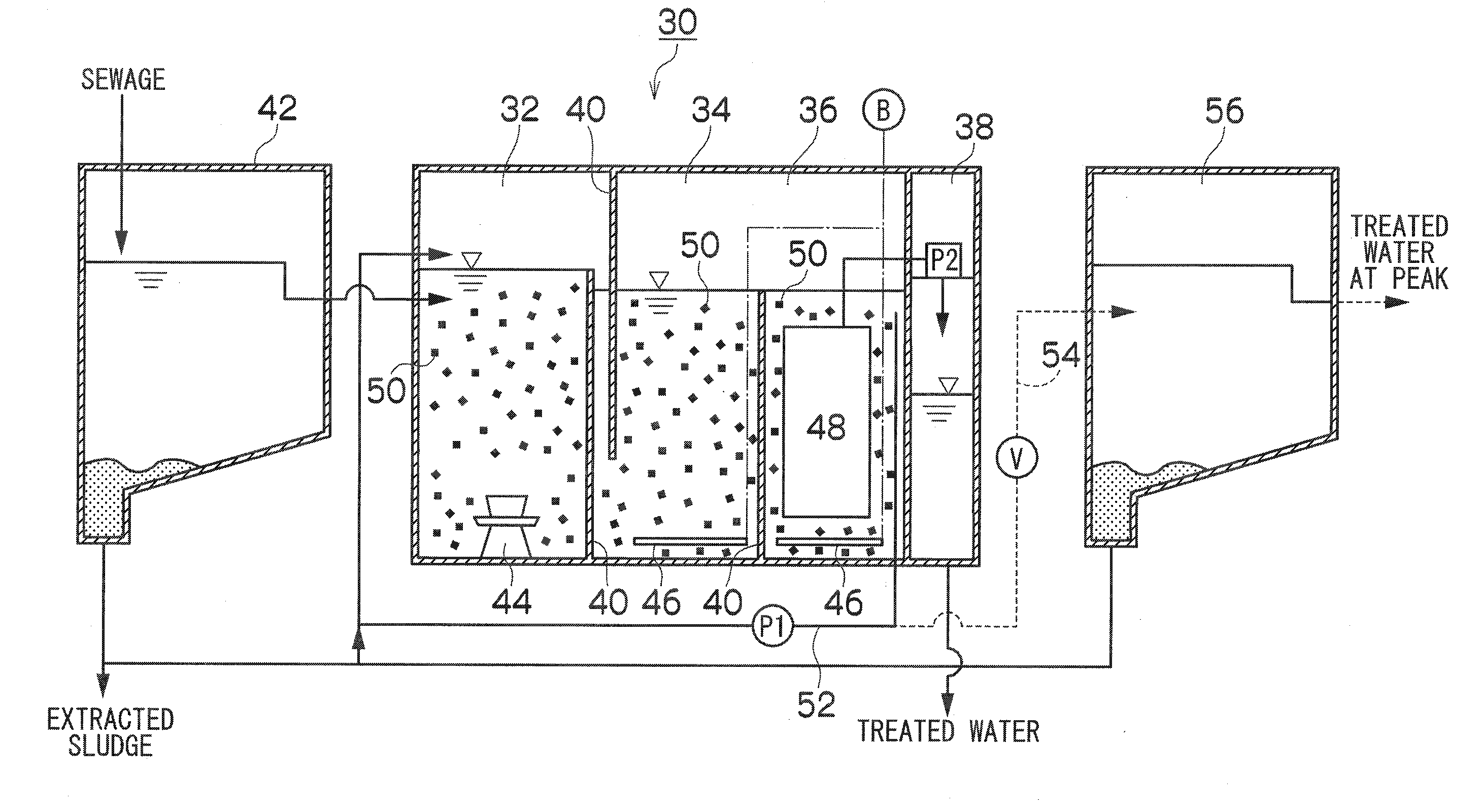

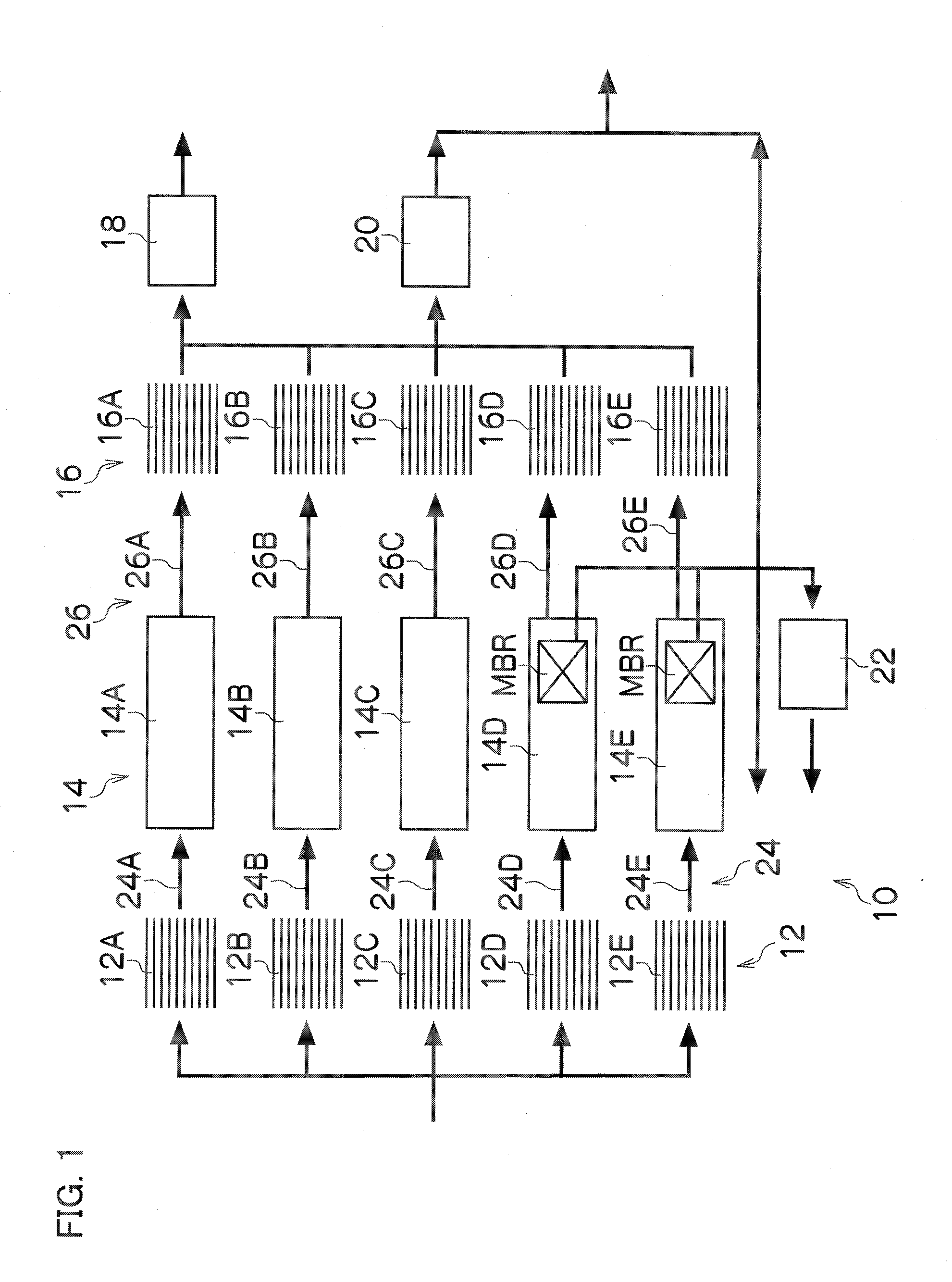

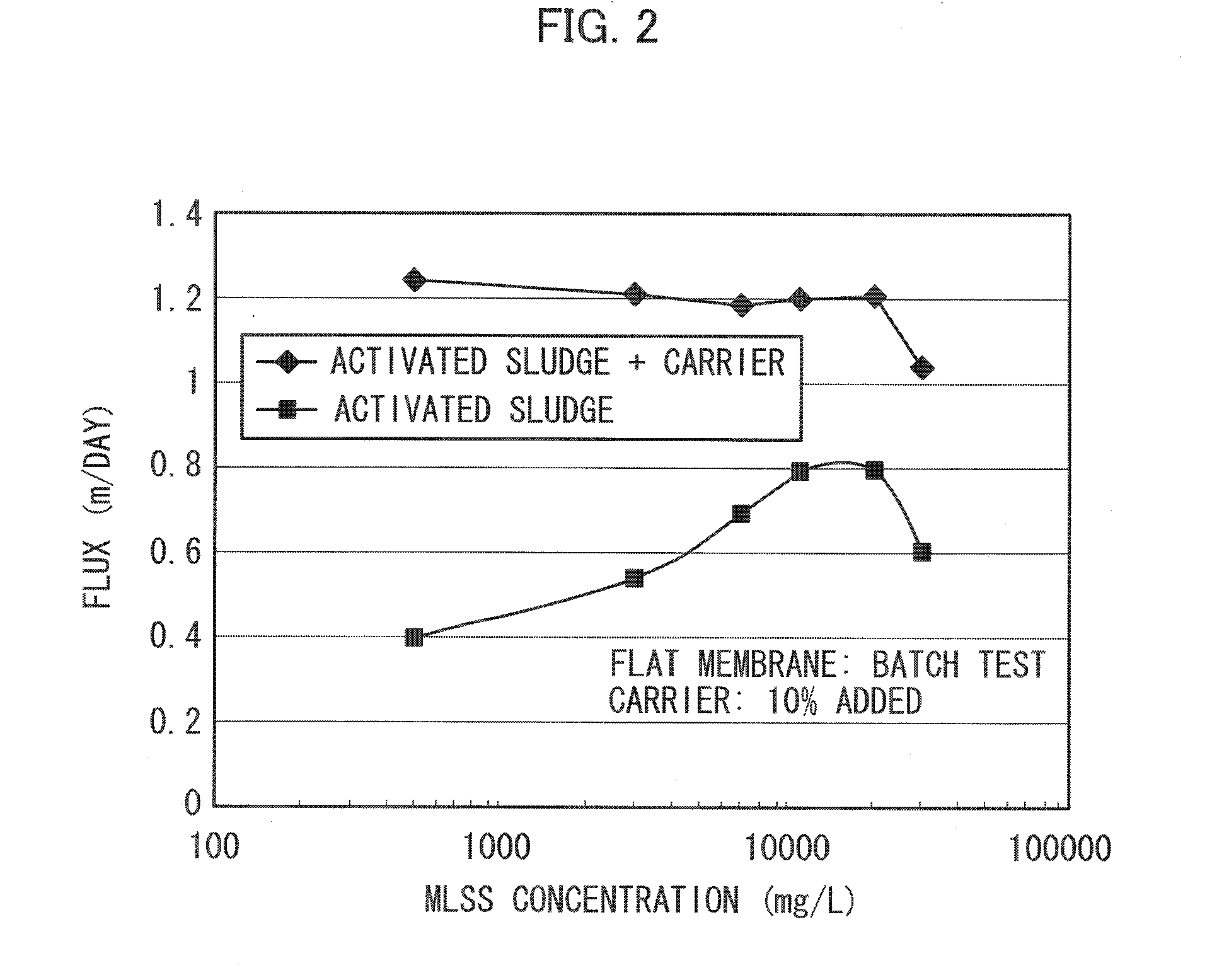

Wastewater treatment system and wastewater treatment process

InactiveUS20110174709A1Semi-permeable membranesOther chemical processesActivated sludgeReaction sequence

The wastewater treatment system according to the present invention includes a plurality of reaction sequences including a first sedimentation tank, a reaction tank, a final sedimentation tank, a first channel which connects the first sedimentation tank and the reaction tank and a second channel which connects the reaction tank and the final sedimentation tank. In one reaction sequence of the plurality of reaction sequences, the reaction tank has a membrane separation tank including a carrier, a membrane unit, and activated sludge and in which an MLSS concentration of the activated sludge is in a range of 500 mg / L to 7000 mg / L, and wastewater is supplied to the reaction tank via the first channel, and wastewater in a quantity exceeding a treatment capacity of the reaction tank is supplied to the final sedimentation tank via the second channel.

Owner:HITACHI PLANT TECH LTD

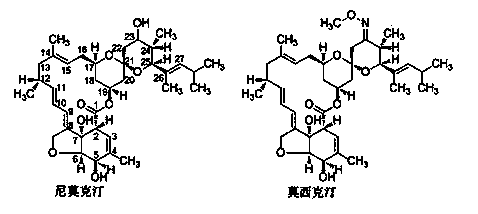

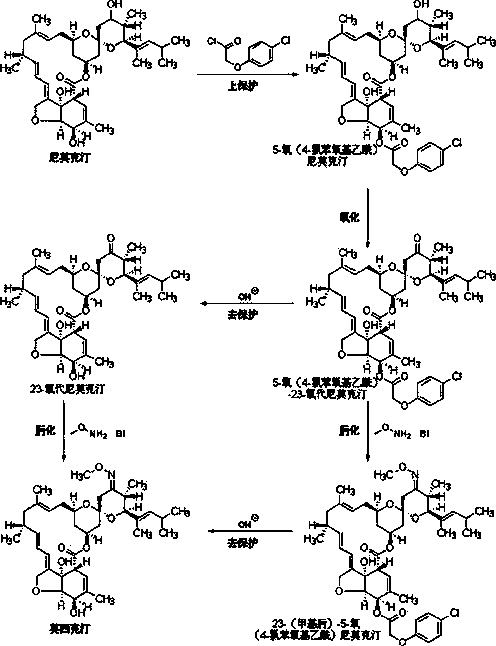

Method of chemically synthesizing moxidectin

ActiveCN104017001ALow purity requirementLower reaction costOrganic chemistryChemical synthesisChlorobenzene

The invention relates to a method of chemically synthesizing moxidectin and belongs to the field of medicinal chemistry. The method comprises the following step: carrying out a reaction on nemadectin as a raw material and 4-chlorophenoxyacetyl chloride as an upper protective agent, and preparing moxidectin through a reaction of four steps: upper protection, oxidization, oximation and deprotection, wherein the reaction sequence of oximation and deprotection can be interchanged without affecting the final reaction product. In the reaction process, the products in upper protection, oxidization and oximation can be recrystallized and extracted through methanol and the like, so that the requirements on the purity of the raw material is reduced, the operating flow is simplified and the reaction cost is lowered.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

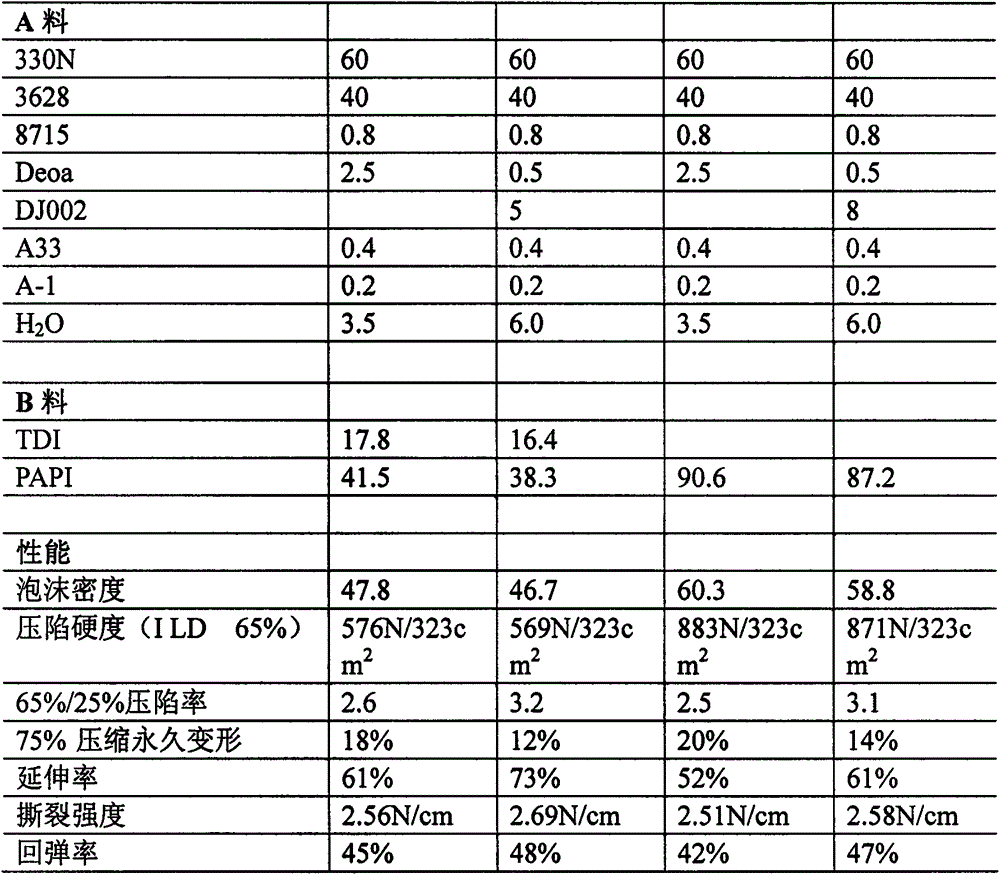

High-resilience foam material containing rich PAPI (polyaryl polymethylene isocyanate) polyurethane

The invention relates to a high-resilience foam material containing rich PAPI (polyaryl polymethylene isocyanate) polyurethane, which is composed of a component A and a component B in a weight ratio of 100:(50-70). The component A is composed of 33-60% of polyether 330N, 33-60% of polymer polyalcohol, 0.5-1.5% of silicon oil, 0.2-0.8% of catalyst A33, 0.2-0.8% of catalyst A-1, 0.5-3.0% of diethanolamine, 3-10% of polyalcohol assistant and 2.5-6% of water. The component B is composed of 0-40% of toluene diisocyanate and 60-100% of polymethylene polyphenyl isocyanate. By using the raw materials containing multiple active hydrogens as an initiator and the polyalcohol prepared by polymerization reaction between the epoxypropane and epoxyethane at high temperature as a modifier, the foaming reaction sequence of the MDI (methylenediphenyl diisocyanate) base (PAPI) foam is regulated, so that the prepared foam mainly composed of MDI base (PAPI) has the advantages of high resilience, high foaming ratio, high elongation percentage and high tearing strength, and more importantly, has favorable tactile sensation.

Owner:ZHOUSHAN YINDAI AUTO PARTS

Process for producing homogeneous polyethylene material

InactiveCN1311801AImprove mechanical propertiesGood lookingChemical/physical/physico-chemical processesPolymer scienceGas phase

Owner:ボレアリステクノロジーオイ +1

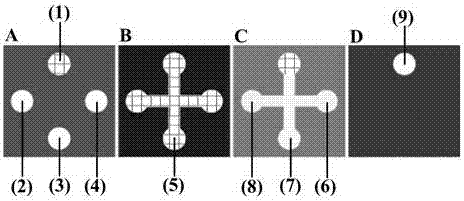

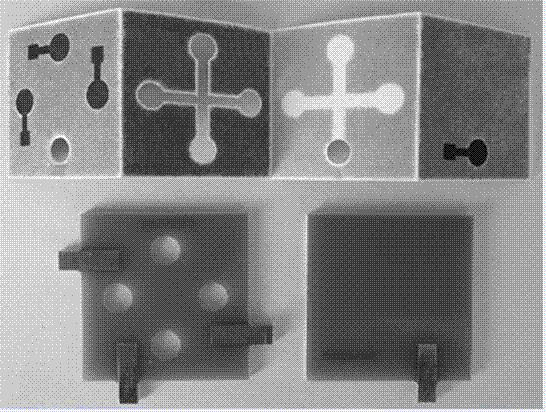

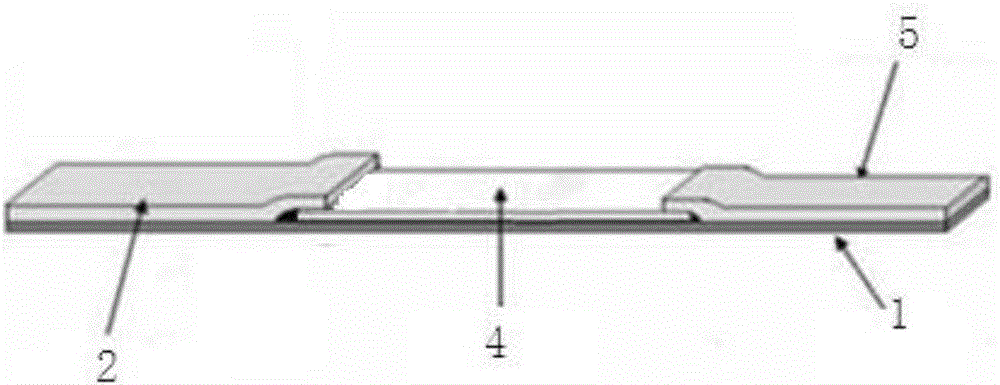

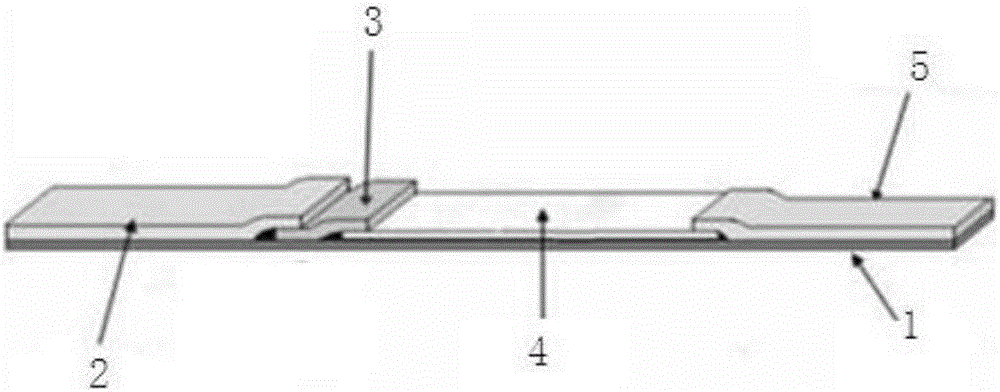

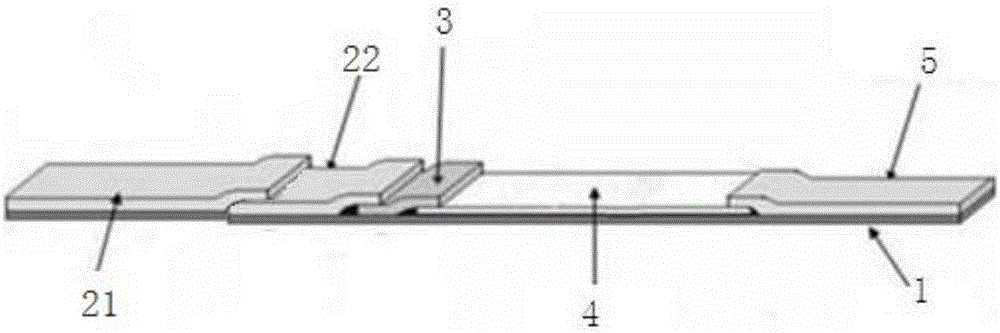

Lateral chromatographic test paper for chemical detection and detection method of lateral chromatographic test paper

PendingCN106645133ASolve problems that cannot coexistHigh sensitivityMaterial analysis by observing effect on chemical indicatorPolyesterGlass fiber

The invention provides lateral chromatographic test paper for chemical detection. The test paper is assembled according to a lateral chromatographic structure based on a reaction sequence of the chemical detection. The test paper comprises a detection reaction condition preparation area, a detection color development area and a water absorption area which are successively arranged on a bottom plate, wherein the detection reaction condition preparation area is qualitative filter paper, quantitative filter paper, glass cellulose membrane, water absorption paper or polyester cellulose membrane test paper loaded with a reaction reagent, and the detection color development area is qualitative filter paper, quantitative filter paper, glass cellulose membrane, water absorption paper or polyester cellulose membrane. The test paper is uniform in color development, capable of solving the problem in the existing detection method that various reaction reagents cannot coexist on a piece of paper and breaking the limitation of the chemical detection test paper, and is more reliable in detection result.

Owner:CHENGDU HEYU TECH CO LTD

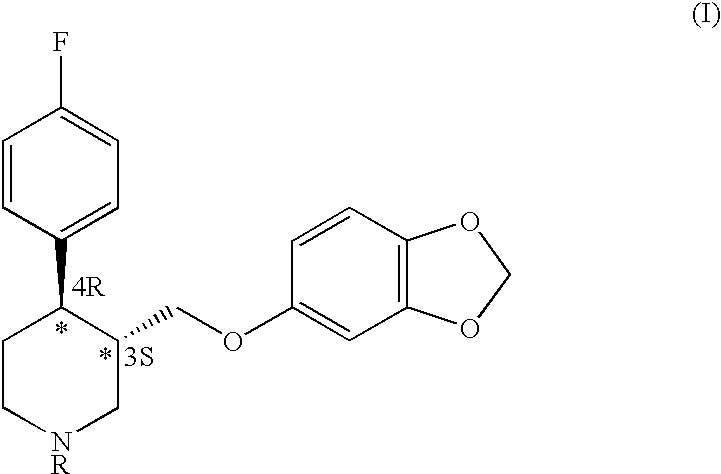

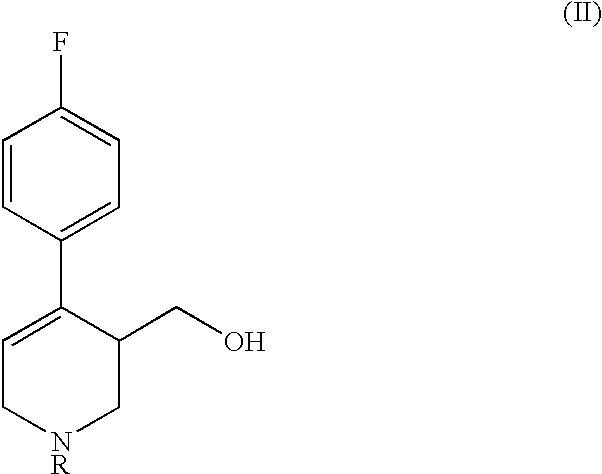

Process for the production of paroxetine

A process for the production of paroxetine is described, wherein N-substituted derivatives of 4-(p-fluorophenyl)-3-hydroxymethyl-1,2,3,6-tetrahydropyridine are treated according to the following sequence of reactions: (a) hydrogenation catalyzed by transition metal complexes with chiral diphosphinic ligands; (b) -OH derivatisation and nucleophilic substitution, the substituent being sesamol; (c) N-dealkylation. The process is highly stereospecific and brings about the formation of intermediates enriched with the desired isomeric components, which are converted into paroxetine in quantitative yields.

Owner:APOTECNIA

Low-temperature pyrolysis device for coal

InactiveCN102618304AEfficient and stable productionAvoid reheatingIndirect heating destructive distillationSpecial form destructive distillationEngineeringTower

A low-temperature pyrolysis device for coal is characterized by comprising a feeder, a reactor, a dust remover and a separating tower according to the reaction sequence, wherein the feeder is used for providing raw coal for the reactor; the reactor is used for conducting pyrolysis on the raw coal; the dust remover is used for conducting dust removing treatment on volatile substances generated during the pyrolysis of the reactor, and is heated all the time during the working process; and the separating tower is used for separating the volatile substances treated with dust removing. The low-temperature pyrolysis device has the advantages that pipeline blockage can be reduced, so as to ensure stable and efficient low-temperature pyrolysis for the coal; and as the comparatively purer volatile substances treated by the dust remover are prevented from being heated again, the purposes of energy conservation, environmental protection and very high efficiency are realized.

Owner:苏忠

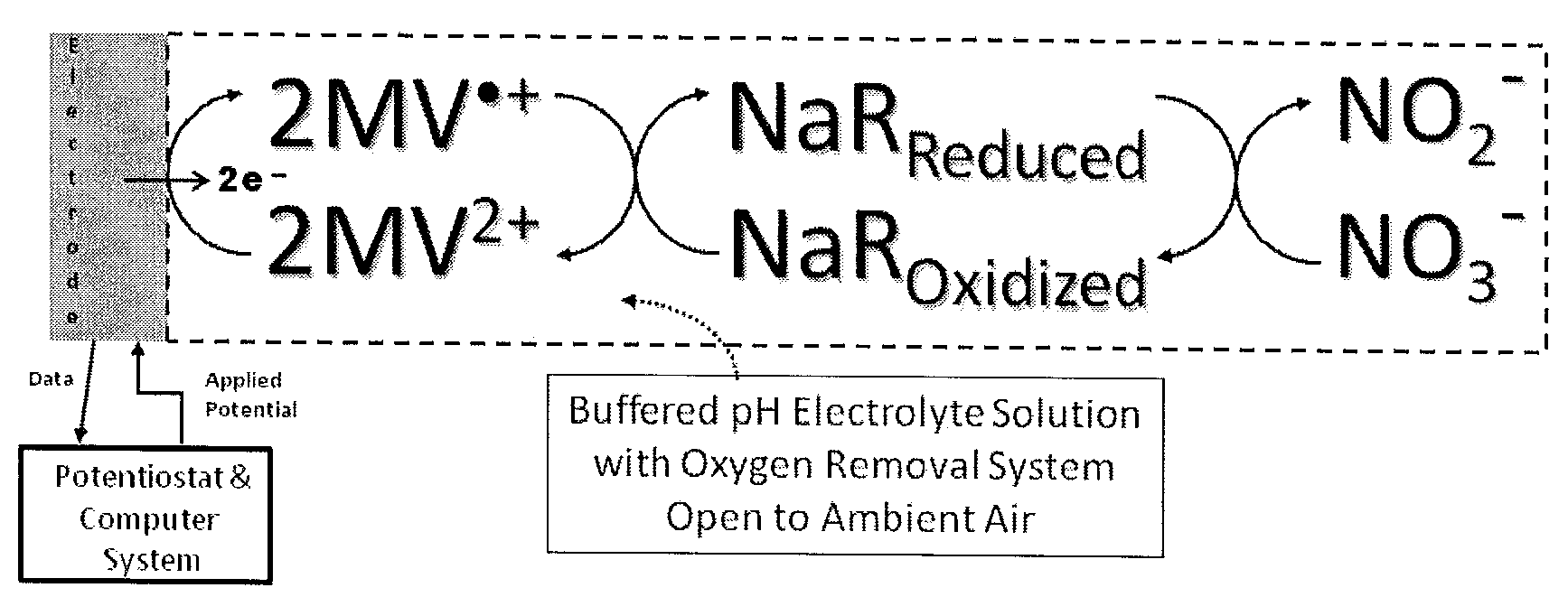

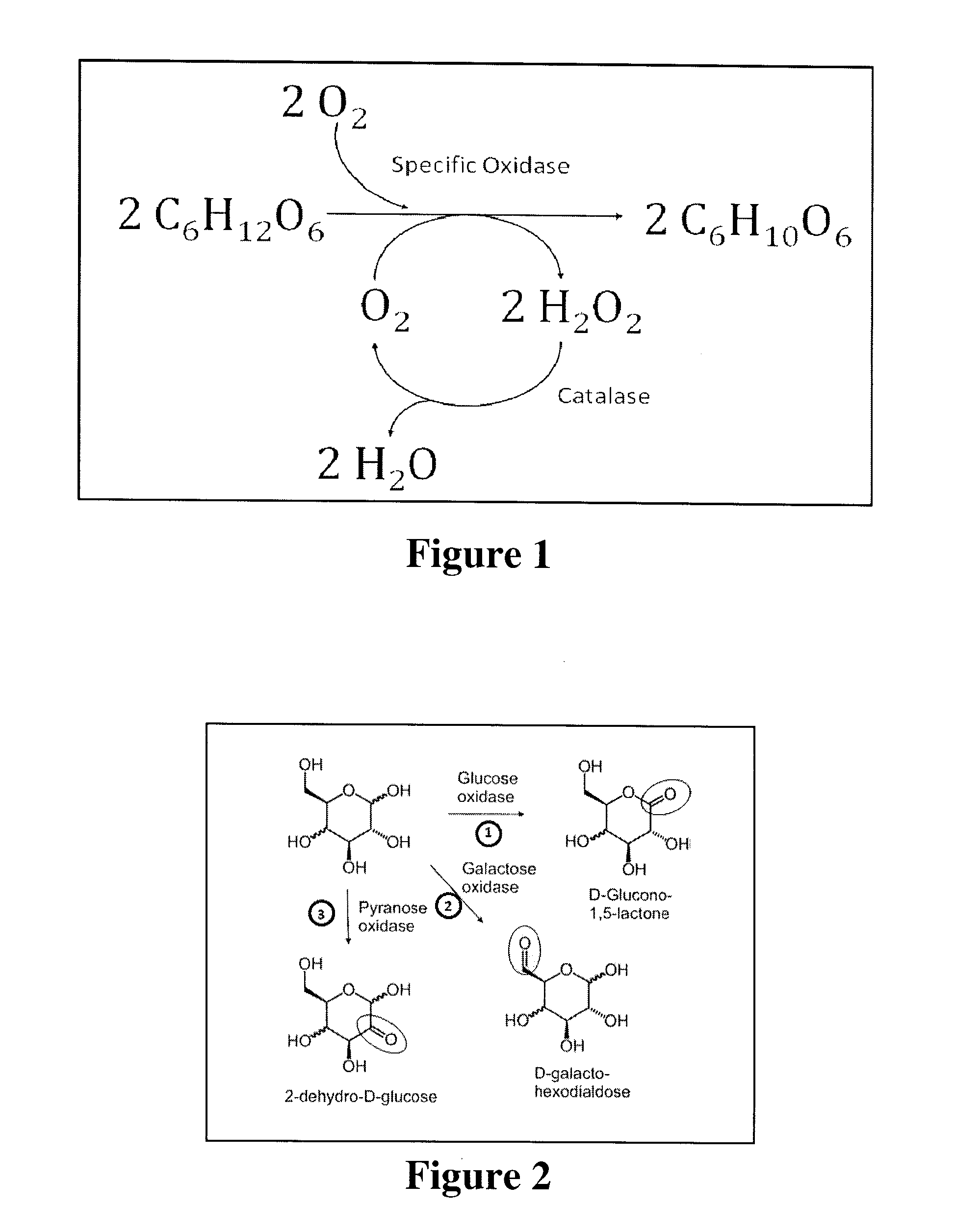

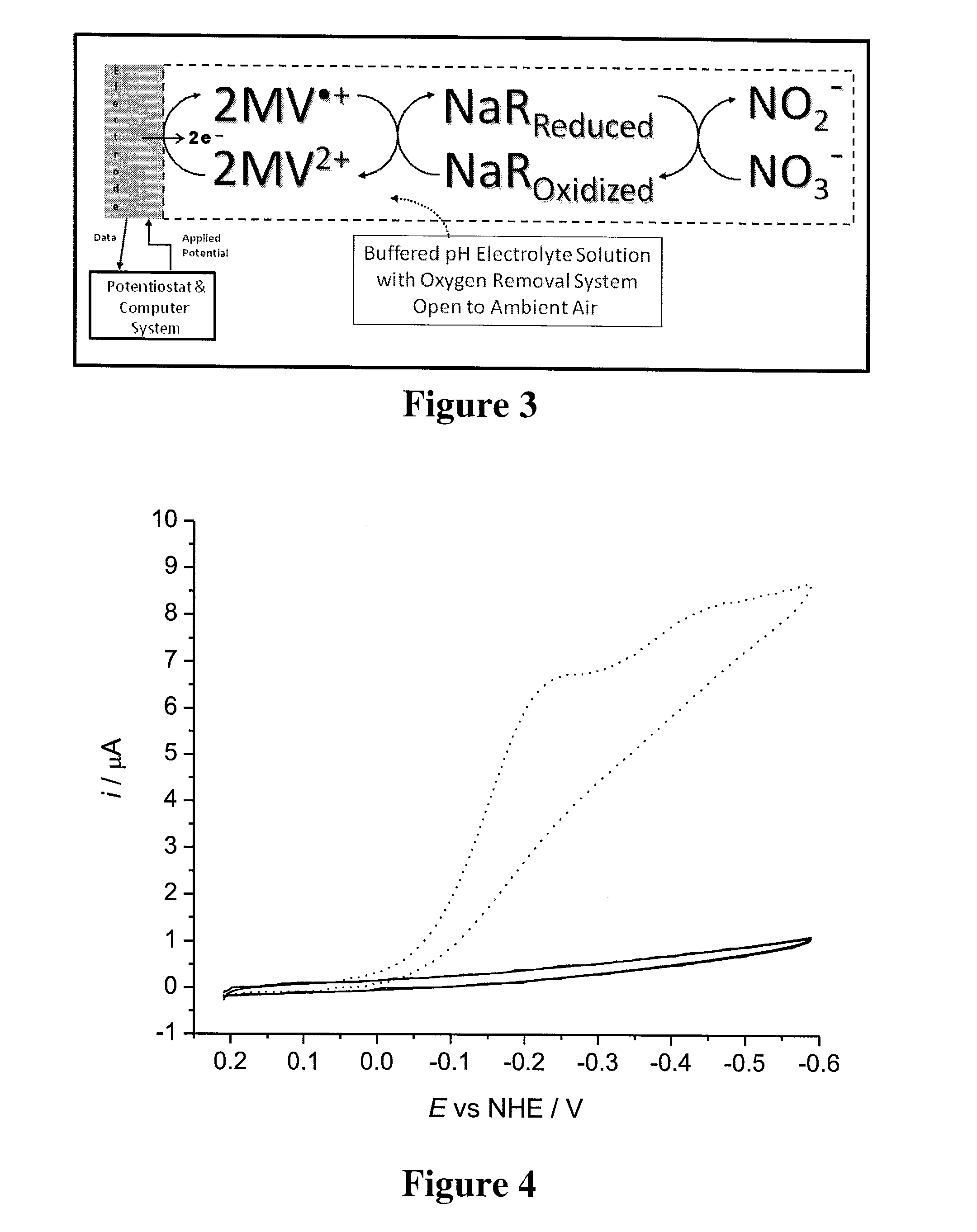

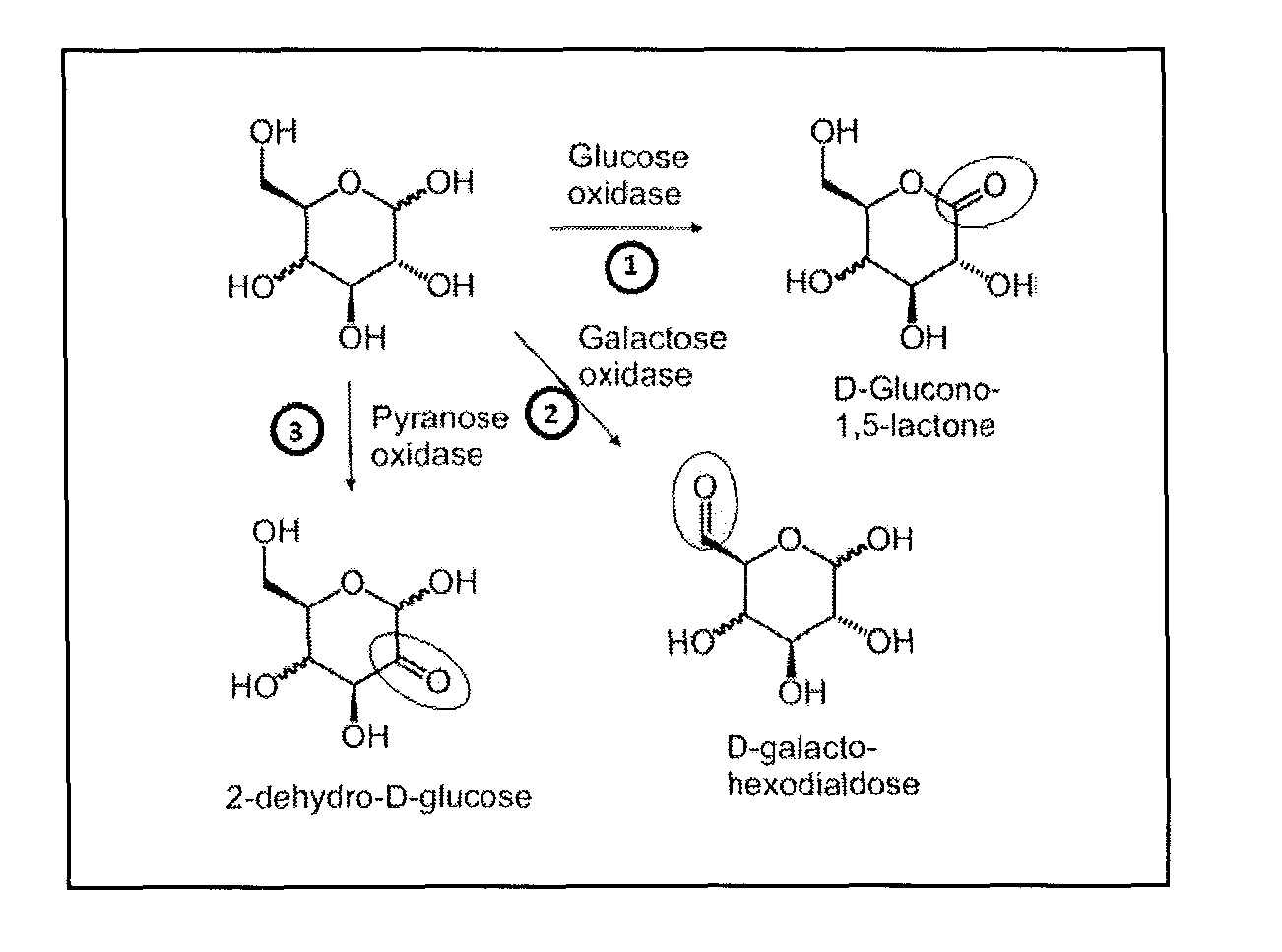

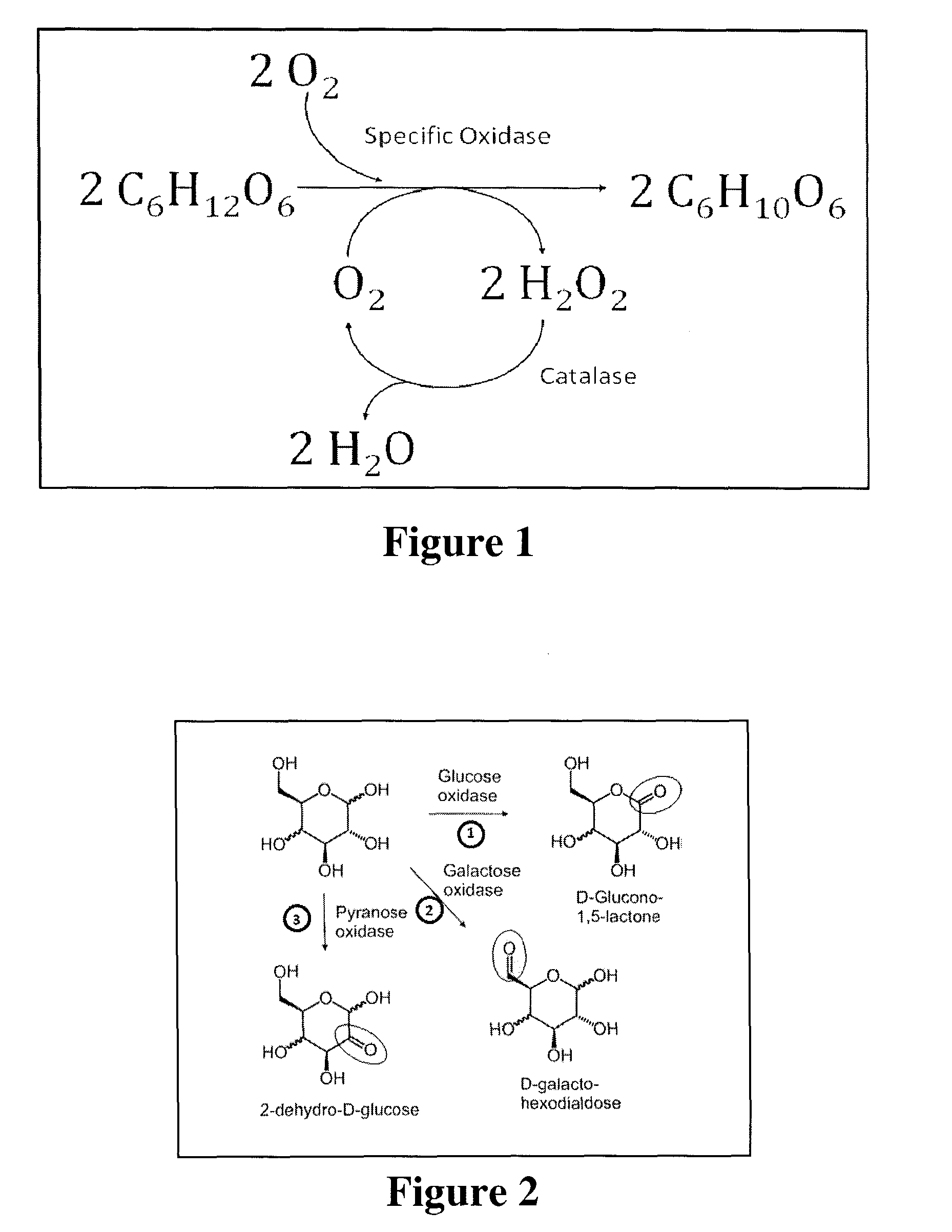

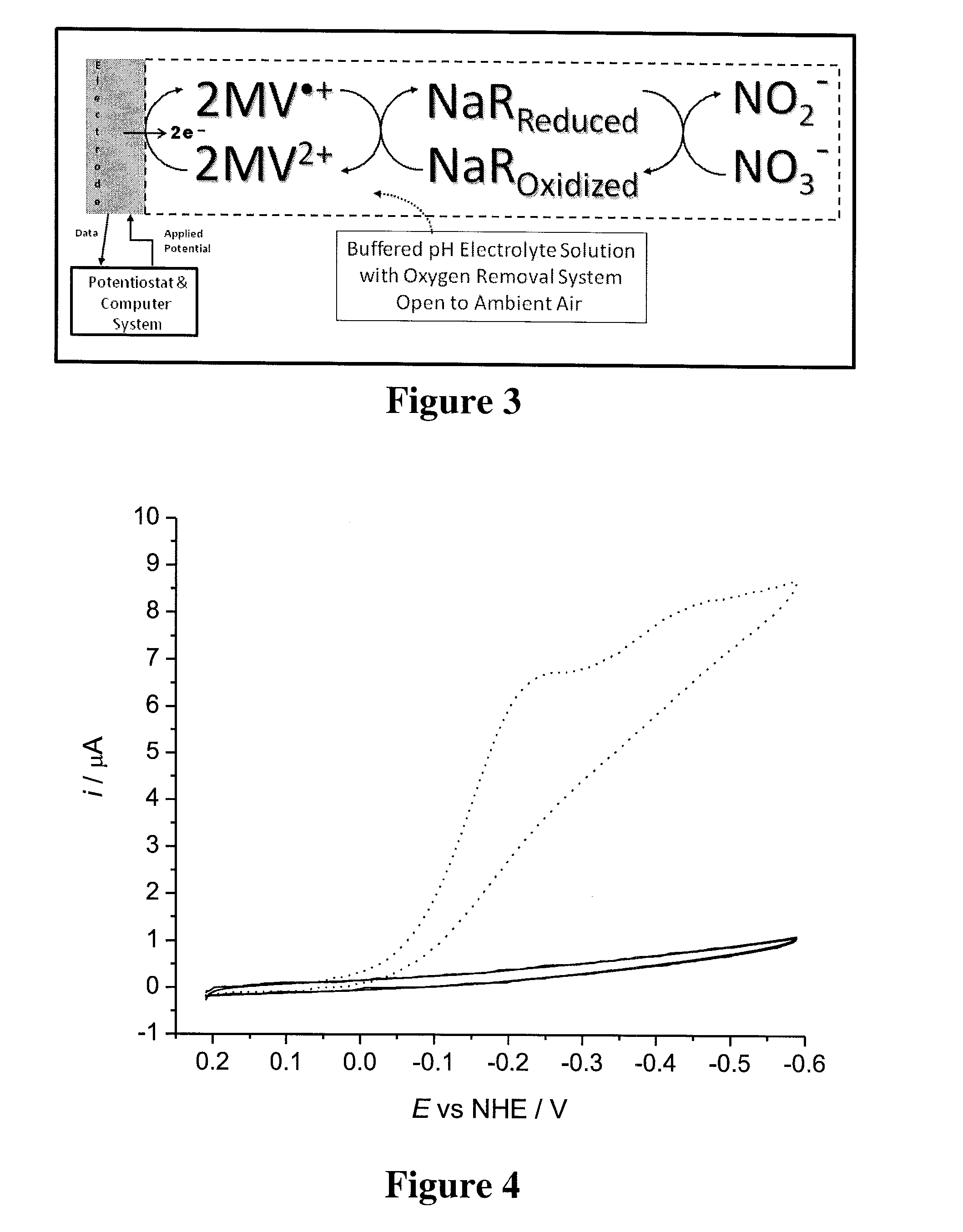

Systems and Methods for Enzymatic Oxygen Removal

ActiveUS20120211372A1Microbiological testing/measurementVolume/mass flow measurementElectrochemical responseOxidative enzyme

Systems and methods for oxygen removal from aqueous solutions are presented in which a bi-enzymatic reaction sequence recycles and depletes oxygen to extinction, preferably using an oxidase and a catalase as biocatalysts and a carbohydrate as co-substrate. Contemplated systems and methods are particularly advantageous in conjunction with electrochemical reaction systems in which oxygen would adversely interfere with the reaction system.

Owner:SILVER BEAR INC

Preparation method of water-repellent and oil-repellent antistatic finishing agent

ActiveCN103590249AConduct static electricity in timeGood water and oil repellencyFibre treatmentMethacrylateEnd-group

The invention relates to a preparation method of a water-repellent and oil-repellent antistatic finishing agent. The water-repellent and oil-repellent antistatic finishing agent is prepared from methyl methacrylate, n-butyl acrylate, perfluoro-n-butyl ethyl methacrylate, 3-propyl-2-enoyl acyloxy propane-1- sodium sulfonate, sodium dodecyl benzene sulfonate, fatty alcohol-poly-oxyethylene ether AEO-9, and n-butyllithium. A polymer with a fluorocarbon group on the side group and an antistatic group on the end group or close to the end group can be obtained by controlling the reaction sequence, time and equivalent ratios of reaction monomers to directionally influence the structure of the polymer to a certain extent. The finishing agent containing the polymer as main component has excellent water-repellent, oil-repellent and antistatic properties.

Owner:上海天伟质量检测技术服务有限公司 +2

Absorption-separation integrated cyclone reactor for desulfurizing sulfur-containing gas

ActiveCN105107355AIncrease contact areaIncrease mass transfer rateDispersed particle separationCycloneProcess engineering

The invention relates to an absorption-separation integrated cyclone reactor for desulfurizing sulfur-containing gas and belongs to the field of cyclone reactors for desulfurizing sulfur-containing gas. The cyclone reactor is characterized in that the outlet end of a mixing chamber (3) is sequentially communicated with a reaction mechanism and a separation mechanism in a reaction sequence; air inlet pipes are tangentially arranged at the upper part of the mixing chamber (3); first atomizing nozzles (2) are inserted onto the air inlet pipes; first level guide blades (4) are arranged between the mixing chamber (3) and the reaction mechanism; second level guide blades (8) are arranged between the reaction mechanism and the separation mechanism; each of the mixing chamber (3), the reaction mechanism and the separation mechanism comprises a cavity with a gradually varied inner diameter. The device provided by the invention integrates desulfurization and separation of sulfur containing gas and an absorption liquid. The gas-liquid contact area is increased and the gas-liquid transfer speed is accelerated by virtue of a high turbulence level of a swirling flow field, so that hydrogen sulfide in the sulfur containing gas is quickly absorbed, the reaction efficiency is effectively enhanced, and the reaction space is saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

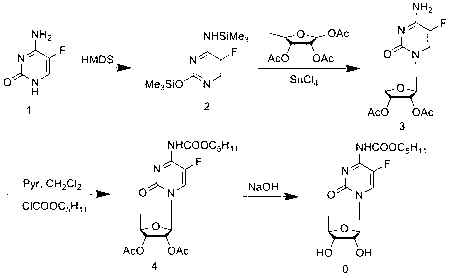

Novel technology for synthesis of capecitabine

InactiveCN103288905ASuitable for industrialized mass productionHigh yieldSugar derivativesSugar derivatives preparationSodium methoxideMeth-

The invention relates to a novel technology for synthesis of capecitabine. The technology is characterized in that: 5-fluorocytosine protected by trimethyl silicon is taken as raw material; and the capecitabine is obtained after condensation, esterification and deacetylation. The Reaction sequence is more economically reasonable, the synthetic route is short, the cost is low, the operation is simplified, the yield is high, the synthetic period is short, the quality of intermediates can be controlled, solvents used in reaction are few, pollution to the environment is little, and the technology is suitable for industrial production. Comparing the technology with the prior art for capecitabine production, trimethylsilyl trifluoromethanesulfonate (TMSOTf) which replaces a heavy metal agent stannic chloride is used as a condensing agent for glycosylation (condensation), and a sodium methoxide / methanol system replaces an ammonia gas / methanol system for deacetylation, so that the production yield is increased, and heavy metal residues of the products and the environmental pollution are reduced. The overall yield of the technology of the invention reaches 59%, the purity of the production is high and meets the standards of the United States Pharmacopeia.

Owner:北京博时安泰科技发展有限公司

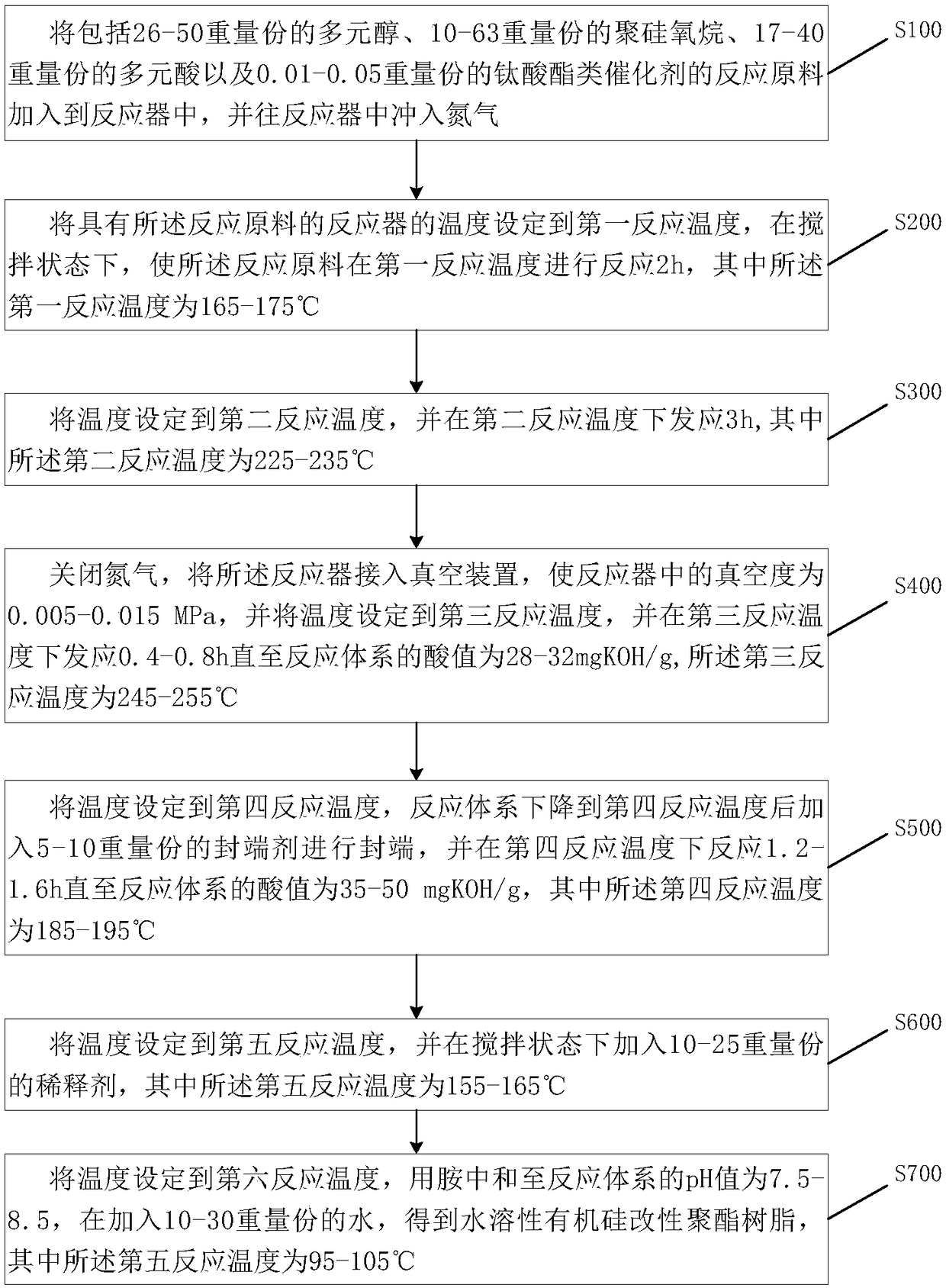

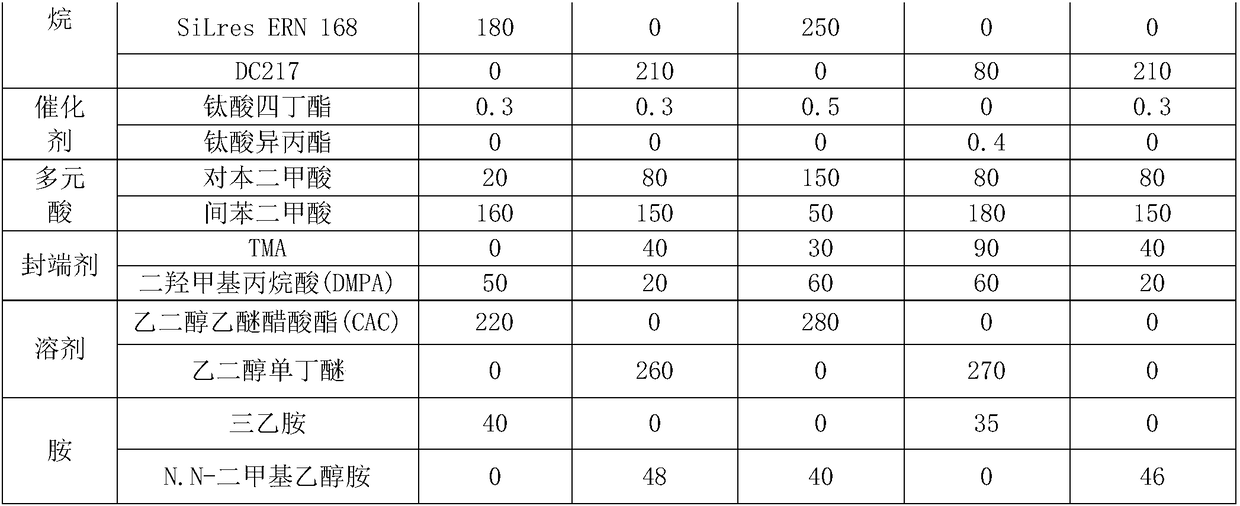

Water-soluble organic silicon modified polyester resin and water-soluble coating

The invention provides a water-soluble organic silicon modified polyester resin. A preparation method of the water-soluble organic silicon modified polyester resin comprises the following steps: putting reaction raw materials, namely 26-50 parts by weight of polyhydric alcohols, 10-63 parts by weight of polysiloxane, 17-40 parts by weight of polyatomic acids and 0.01-0.05 part by weight of a titanate catalyst, into a reactor, and introducing nitrogen into the reactor; after a reaction is completed, carrying out end sealing with 5-10 parts by weight of an end sealing agent, further adding 10-25parts by weight of a diluent to carry out a reaction, and controlling conditions such as reaction temperatures and reaction sequences in each step, thereby obtaining the water-soluble organic siliconmodified polyester resin. The invention further provides a water-soluble coating. The water-soluble organic silicon modified polyester resin provided by the invention has good glossiness, transparency and adhesive force, and in addition has good water solubility and thermal resistance.

Owner:FOSHAN POLIMA ADVANCED TECH & SUPPLIES CO LTD

Systems and methods for enzymatic oxygen removal

ActiveUS9187779B2Microbiological testing/measurementVolume/mass flow measurementElectrochemical responseCo substrate

Systems and methods for oxygen removal from aqueous solutions are presented in which a bi-enzymatic reaction sequence recycles and depletes oxygen to extinction, preferably using an oxidase and a catalase as biocatalysts and a carbohydrate as co-substrate. Contemplated systems and methods are particularly advantageous in conjunction with electrochemical reaction systems in which oxygen would adversely interfere with the reaction system.

Owner:SILVER BEAR INC

Treatment method for tank bottom oil sludge

PendingCN108706843AEasy to separateReduce pollutionSludge treatmentSpecific water treatment objectivesAlkaline waterOil sludge

The invention provides a treatment method for tank bottom oil sludge. The method comprises the following steps: step one, performing water adding and mixing treatment on the oil sludge, enabling the solid content of the oil sludge to reach 4-15%; step two, adding sodium hydroxide solution to adjust a pH value to be 7.5-9; step three, adding a non-ionic surfactant and stirring in a high speed; andstep four, pumping into a clarification tank for precipitation separation. The provided treatment method for the tank bottom oil sludge is simple in reaction condition, convenient in operation, and capable of combining a demulsifying agent, the surfactant and an alkaline water washing technology in a specific reaction sequence and the reaction condition, realizing the rapid separation of the oil sludge, enabling a deoiling rate to reach 95% or more, and reducing the pollution of the oil sludge to the environment.

Owner:中科海创环境科技(大连)有限公司

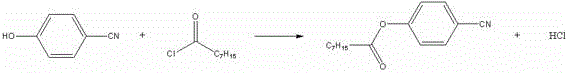

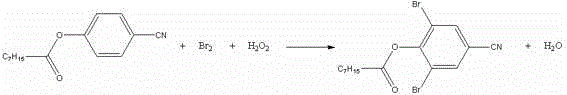

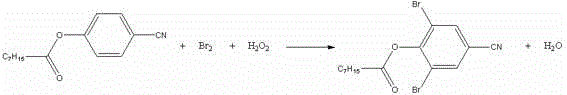

Preparation process for bromoxynil octanoate

InactiveCN104926692AReduce recyclingWeaken the centrifugationCarboxylic acid nitrile preparationOrganic compound preparationBromoxynil octanoateReaction sequence

The invention discloses a preparation process for bromoxynil octanoate. The preparation process is characterized in that octanoyl chloride, 4-cyanophenol, 50% hydrogen peroxide and bromine are used as reaction raw materials and the preparation process comprises an esterification reaction step and a bromination reaction step according to a reaction sequence. The preparation process has the advantages as follows: the steps of bromination mother liquor recovery, centrifugation and drying are eliminated, dry powder feeding is avoided, the occurrence rate of contamination accidents is reduced, the yield is increased, material consumption is reduced, equipment investment is reduced and the production cost is reduced.

Owner:JIANGSU HEBEN BIOCHEM

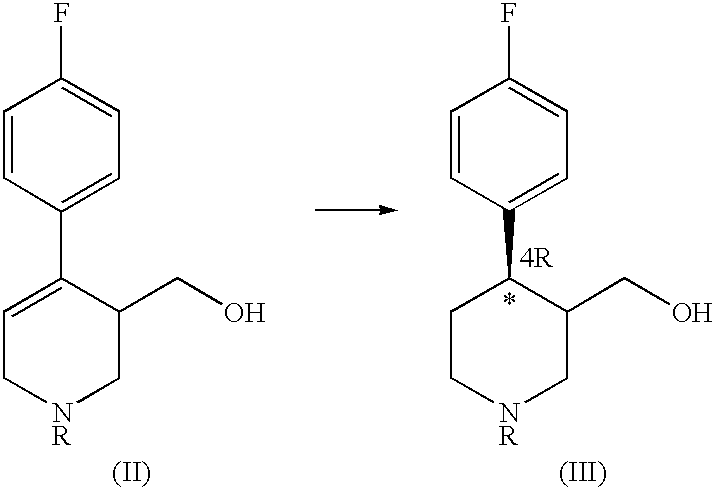

Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile

This invention relates to a process for preparing 4-[(1,6-dihydro-6-oxo-2-pyrimidinyl)-amino]benzonitrile (I) starting from a 4-oxo-1,6-dihydro-pyrimidinylcarboxylic acid ester (II) or starting from a guanidine derivative which is reacted with an alkoxy-methylene malonic acid ester to an ester (II) which is converted to (I), which reaction sequence may be a one-pot procedure.

Owner:JANSSEN SCI IRELAND UC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile](https://images-eureka.patsnap.com/patent_img/cb33c92c-4f26-40d7-b7bb-958a7b2a7dae/US20080171878A1-20080717-C00001.png)

![Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile](https://images-eureka.patsnap.com/patent_img/cb33c92c-4f26-40d7-b7bb-958a7b2a7dae/US20080171878A1-20080717-C00002.png)

![Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile Process for Preparing 4-[(1,6-Dihydro-6-Oxo-2-Pyrimidinyl)Amino]Benzonitrile](https://images-eureka.patsnap.com/patent_img/cb33c92c-4f26-40d7-b7bb-958a7b2a7dae/US20080171878A1-20080717-C00003.png)