Water-soluble organic silicon modified polyester resin and water-soluble coating

A technology for modifying polyester and silicone, applied in the field of polyester technology, can solve the problems of turbidity, low transparency and limited application range, and achieve the effects of good gloss, good water solubility and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

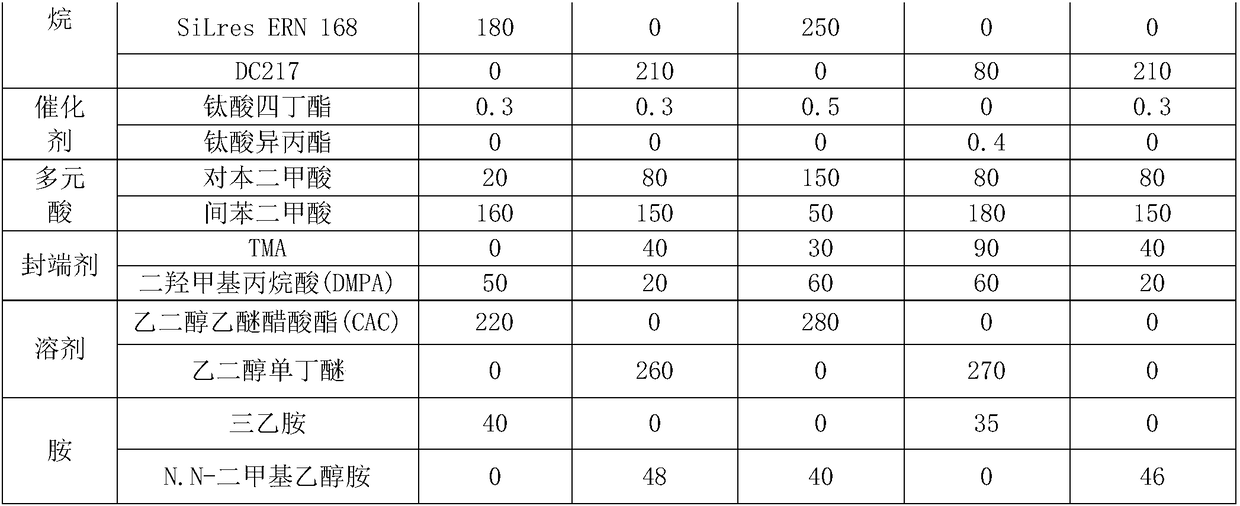

Examples

preparation example Construction

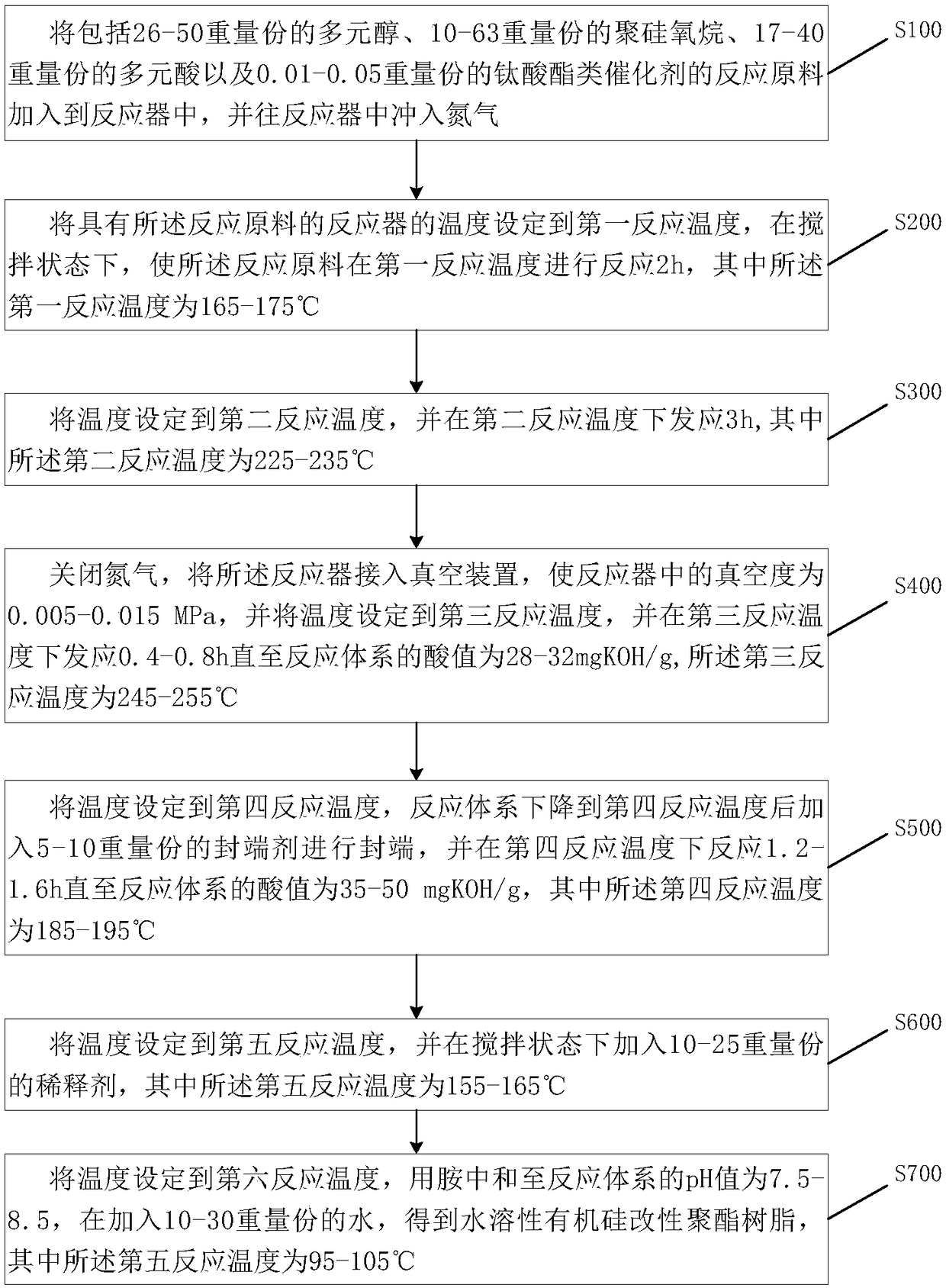

[0024] The invention provides a water-soluble organosilicon-modified polyester resin. The preparation method of the water-soluble organosilicon-modified polyester resin comprises 26-50 parts by weight of polyhydric alcohol, 10-63 parts by weight of polysiloxane Alkanes, 17-40 parts by weight of polybasic acid and 0.01-0.05 parts by weight of titanate catalyst are added to the reactor, and nitrogen is flushed into the reactor; after the reaction is completed, 5-10 parts by weight of The capping agent is capped, and after adding 10-25 parts by weight of diluent to react, the water-soluble organosilicon-modified polyester resin of the present invention can be controlled by controlling the reaction temperature, reaction sequence, etc. of each step under the process method provided by the present invention. Conditions make the water-soluble silicone-modified polyester resin have better gloss, transparency, adhesion, and better water-solubility and heat resistance.

[0025] see fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com