Patents

Literature

180results about How to "Avoid reheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

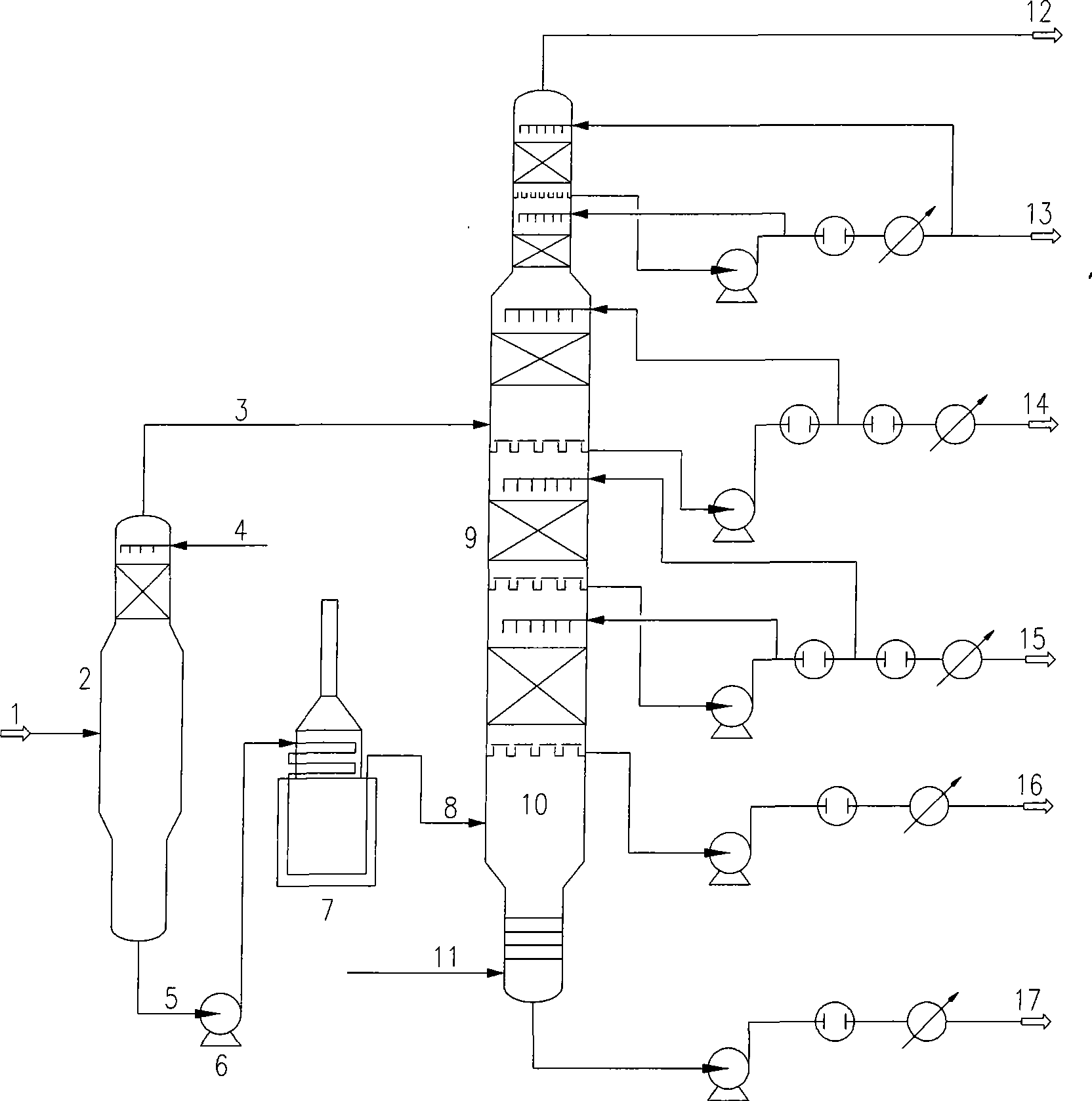

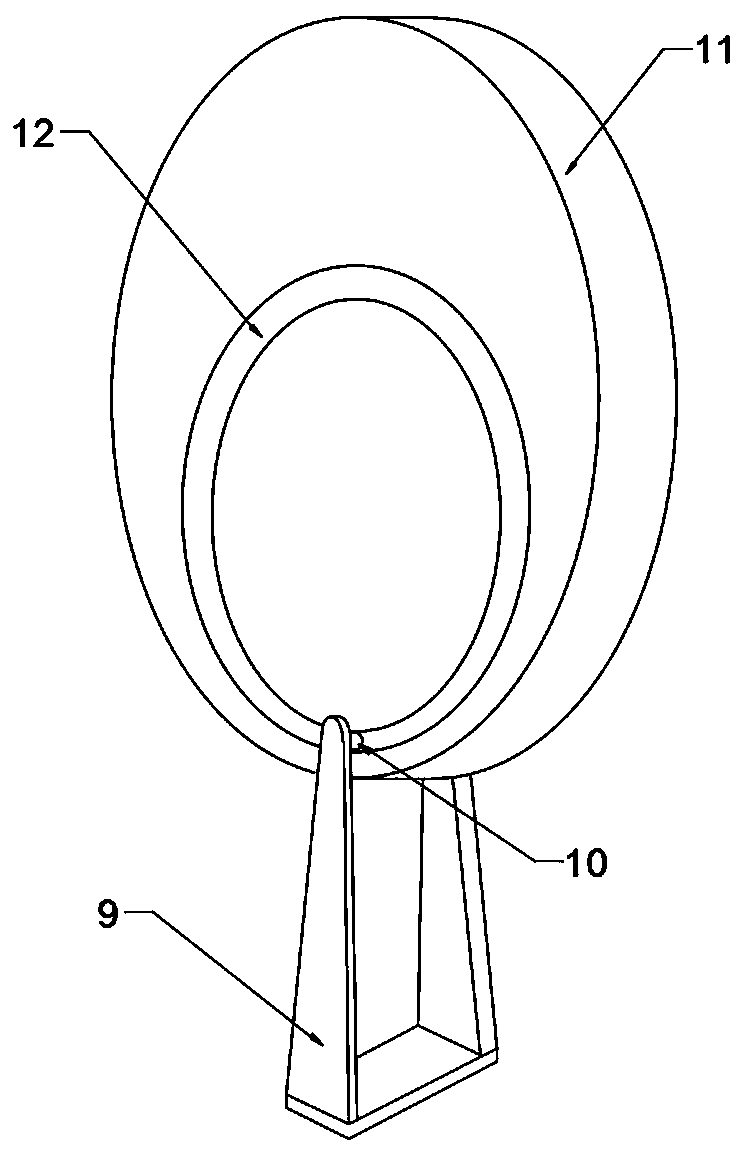

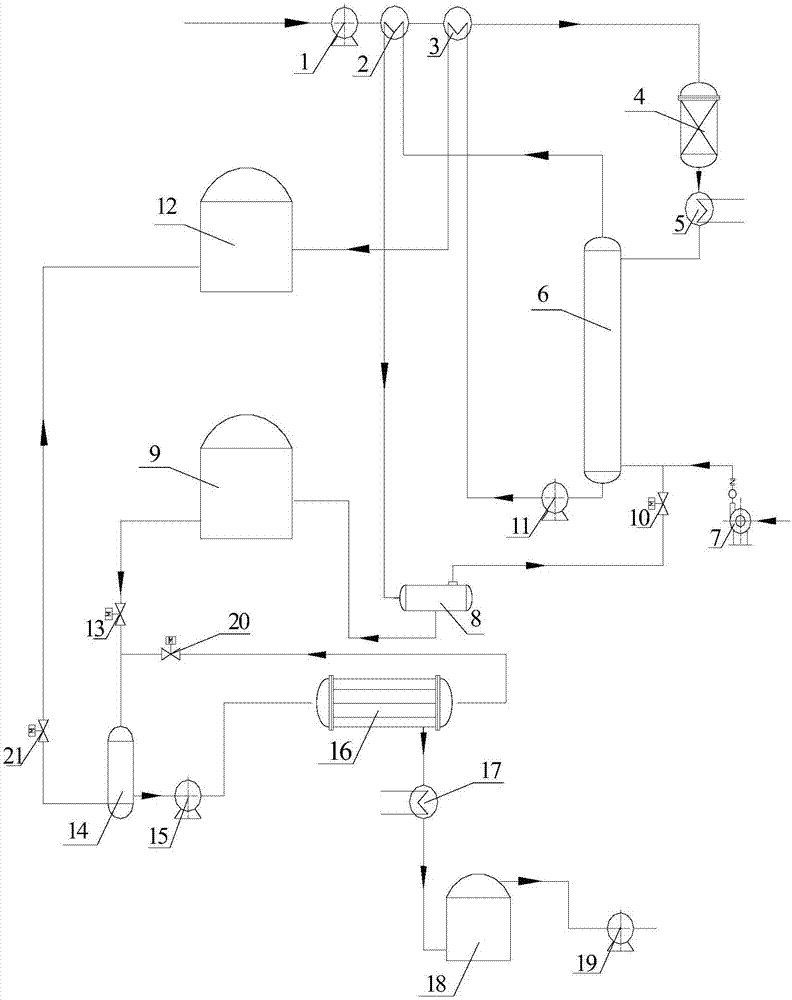

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

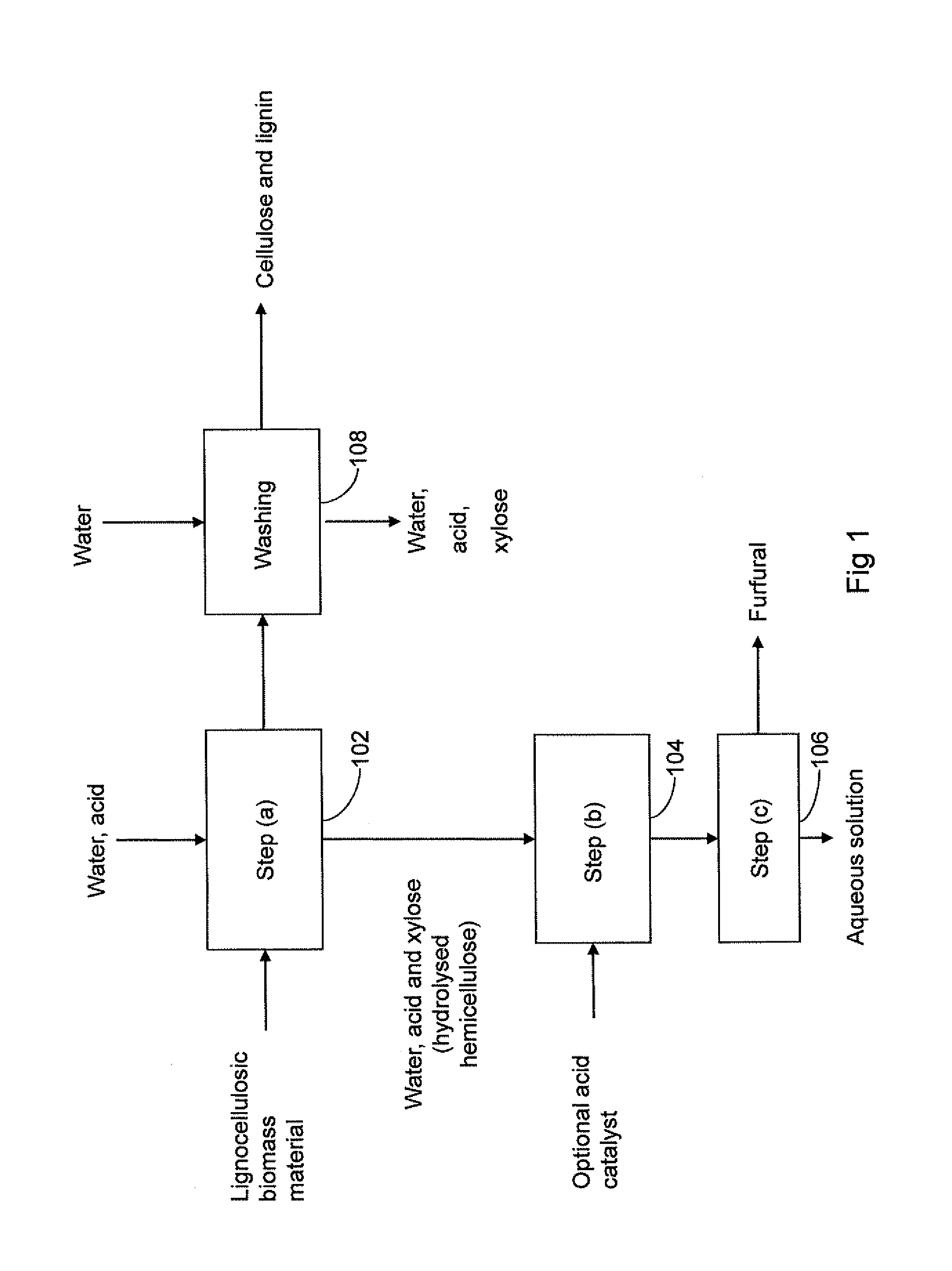

Method for producing furfural from lignocellulosic biomass material

InactiveUS20110144359A1The process is simple and effectiveEasy to useOrganic chemistryOrganic acidLignocellulosic biomass

A method for producing furfural from lignocellulosic biomass material is provided, comprising (a) contacting the lignocellulosic biomass material with a mixture comprising water and an organic acid at a temperature of at least 100° C. and a pressure of at most 10 bar (absolute) to obtain a first liquid stream comprising hydrolysed hemicellulose and a second stream comprising lignin and cellulose; (b) maintaining the first liquid stream comprising hydrolysed hemicellulose at a temperature of at least 130° C. to obtain a second liquid stream comprising furfural; and (c) separating the furfural obtained in step b) from the second liquid stream.

Owner:SHELL OIL CO

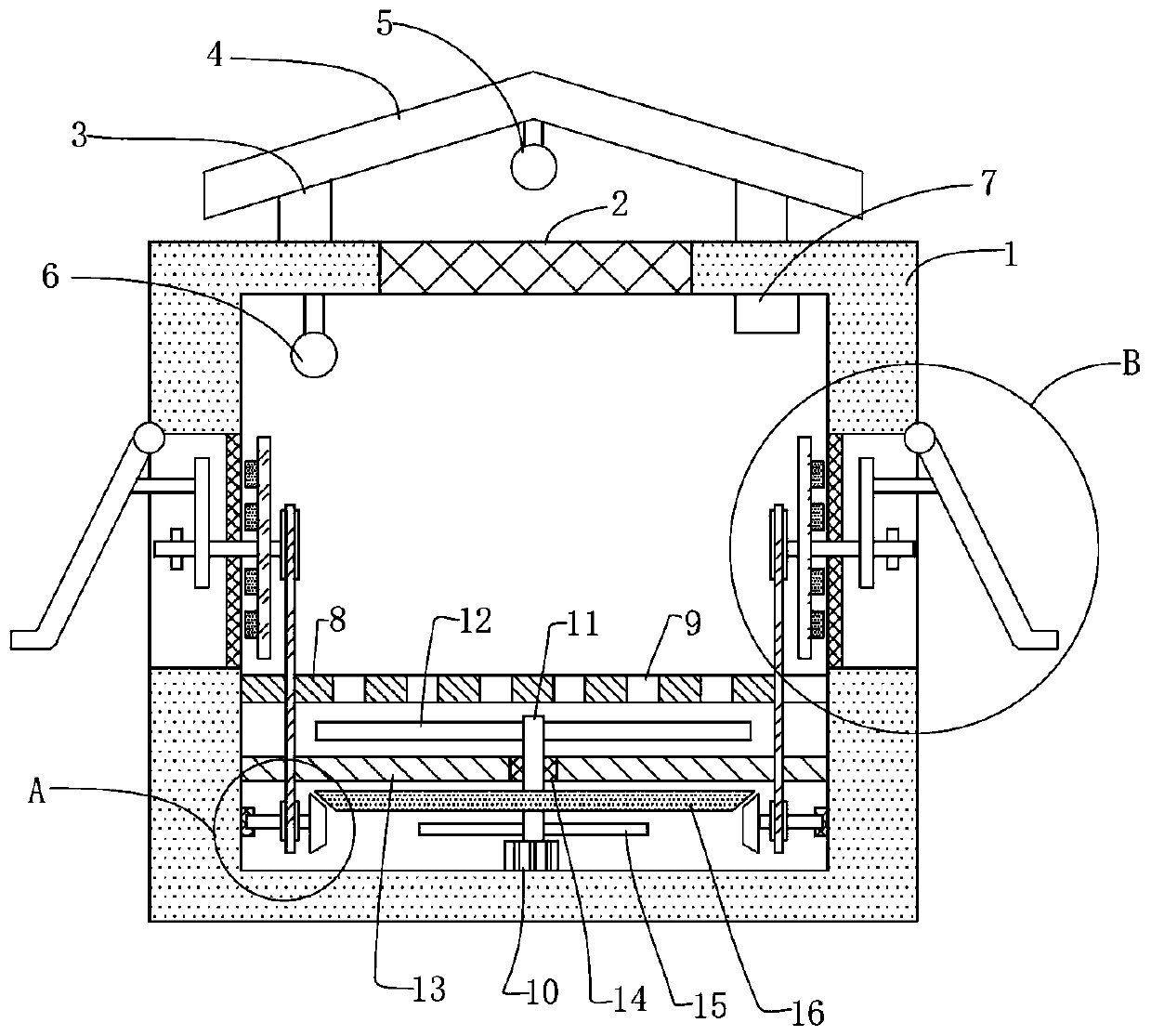

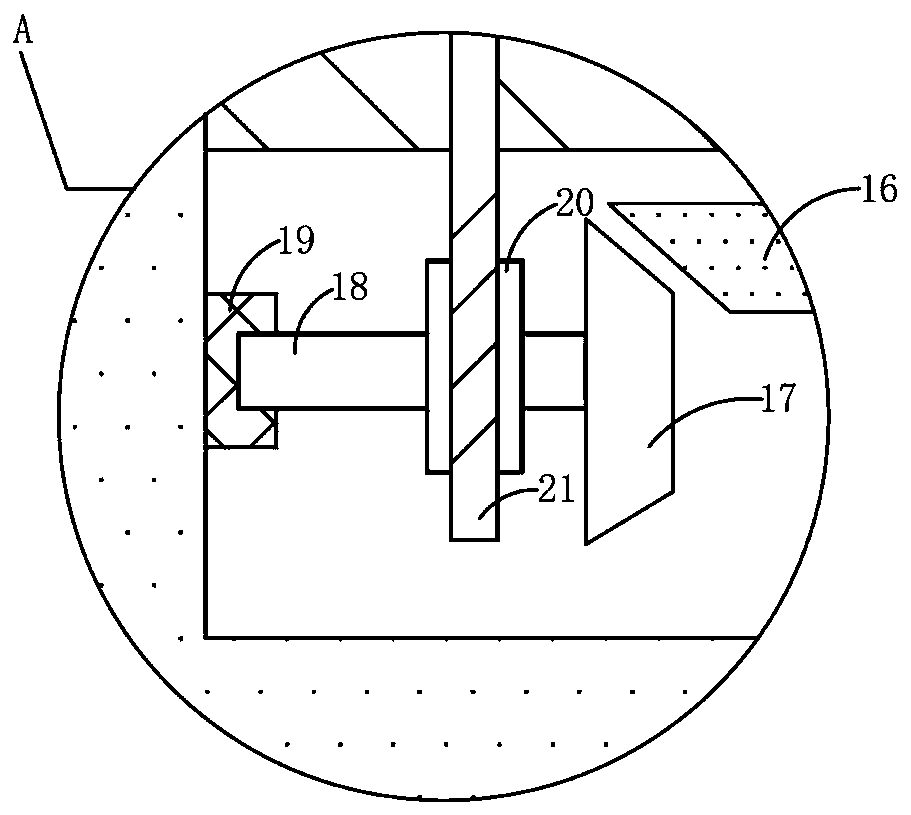

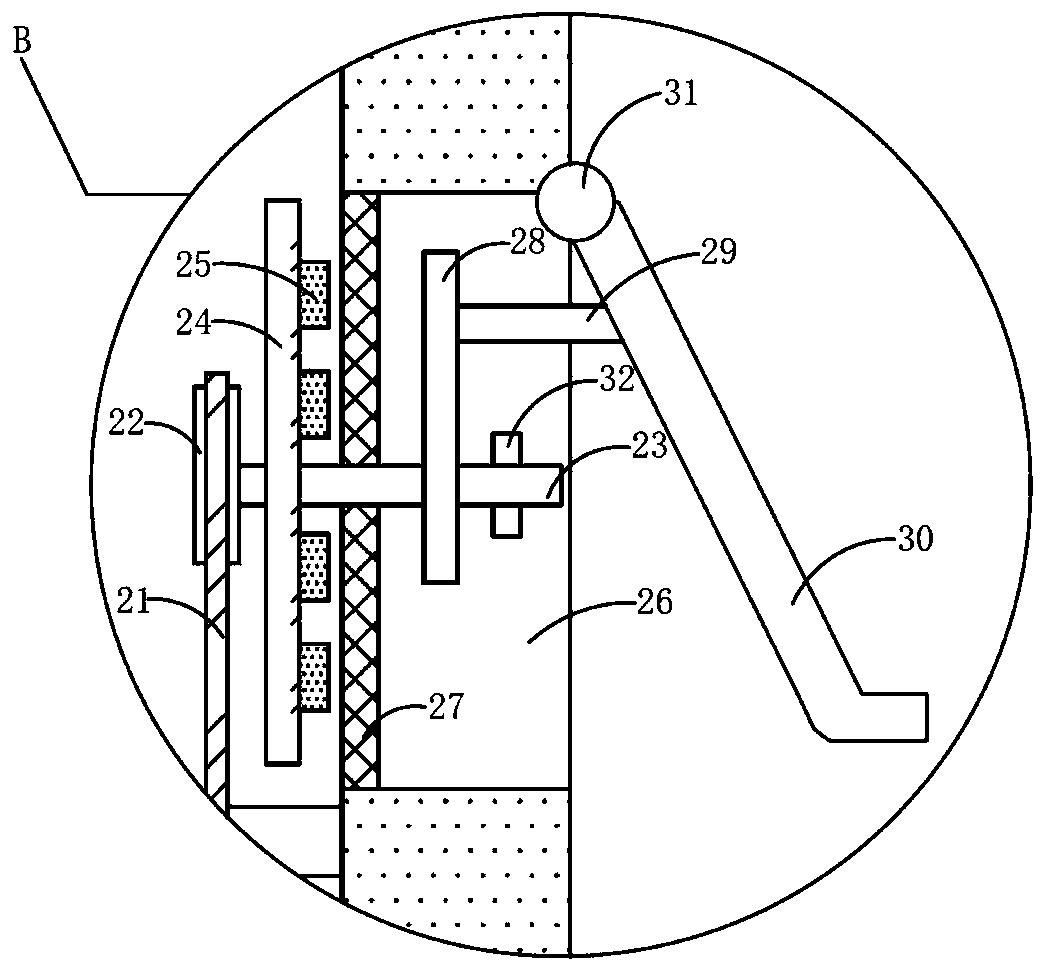

Air duct structure for power distribution cabinet and power distribution cabinet

ActiveCN110148893AImprove energy consumptionAvoid damageSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsBristleEngineering

The invention discloses an air duct structure for a power distribution cabinet and the power distribution cabinet. The cabinet comprises a cabinet body, and an upper ventilation net frame is arrangedon the cabinet body; a humidity detector is arranged at the side, close to the cabinet body, of a rainproof ceiling; main heat dissipation blades are fixedly arranged at one end, far away from the motor, of a main shaft; a cleaning rod is fixedly arranged on a lead screw in a penetrating mode, and brush bristles are arranged on the cleaning rod; a filter screen is arranged in a heat dissipation window, and a rain baffle is fixedly arranged on a push rod; and the rain baffle is arranged on the cabinet body in a hinged mode through a hinge. The invention provides the air duct structure for the power distribution cabinet. Two heat dissipation systems are arranged in the shell; a power structure can be automatically started at high temperature to assist in heat dissipation, and the rain baffleis movably arranged on the heat dissipation window of the cabinet body; the cabinet body can be automatically opened to strengthen ventilation in sunny days and can be automatically closed in rainy days to prevent rainwater from inclining into the cabinet body. The invention also discloses the power distribution cabinet with the above air duct structure, and the cabinet is good in using effect and quite worthy of popularization.

Owner:ANHUI QUEUE ELECTRIC

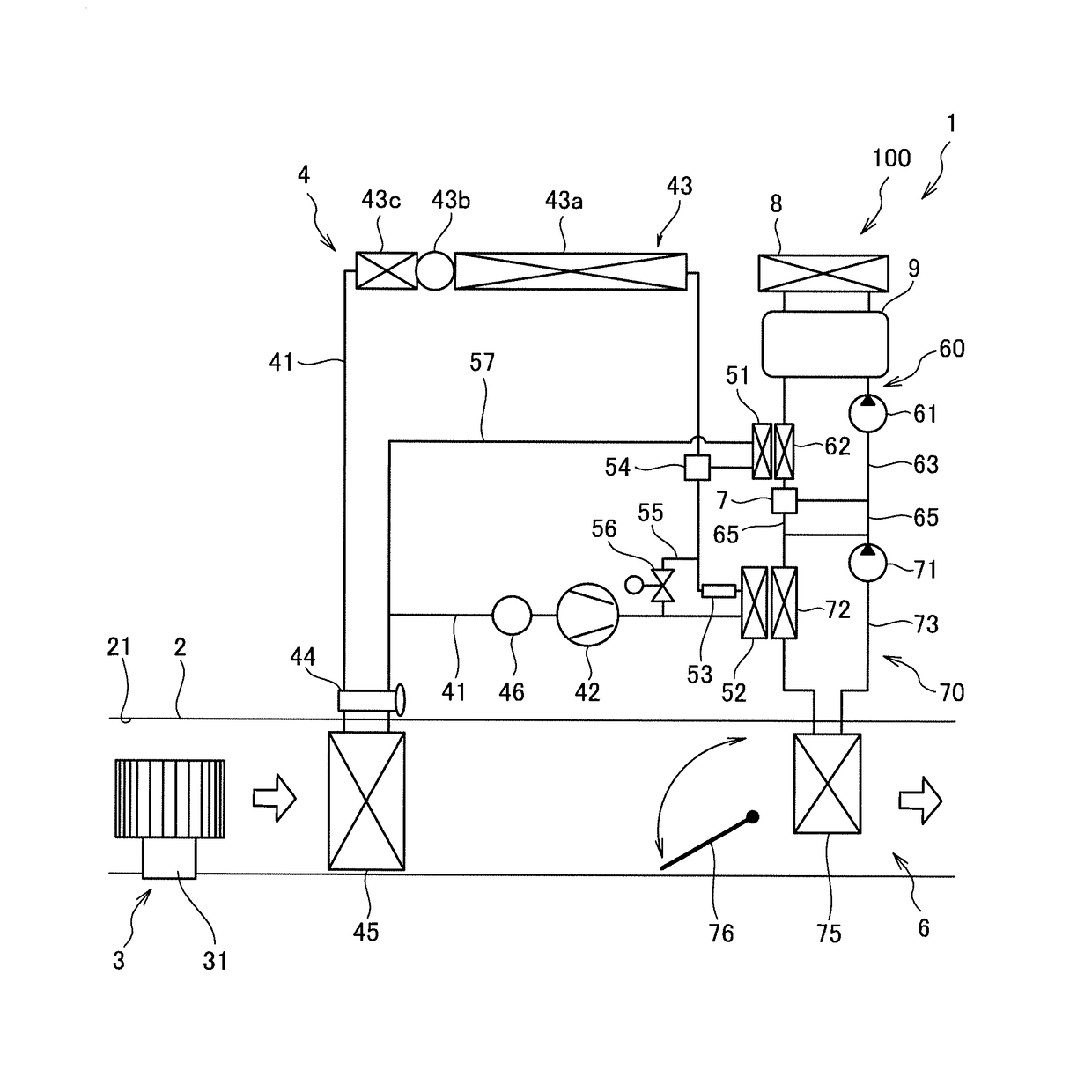

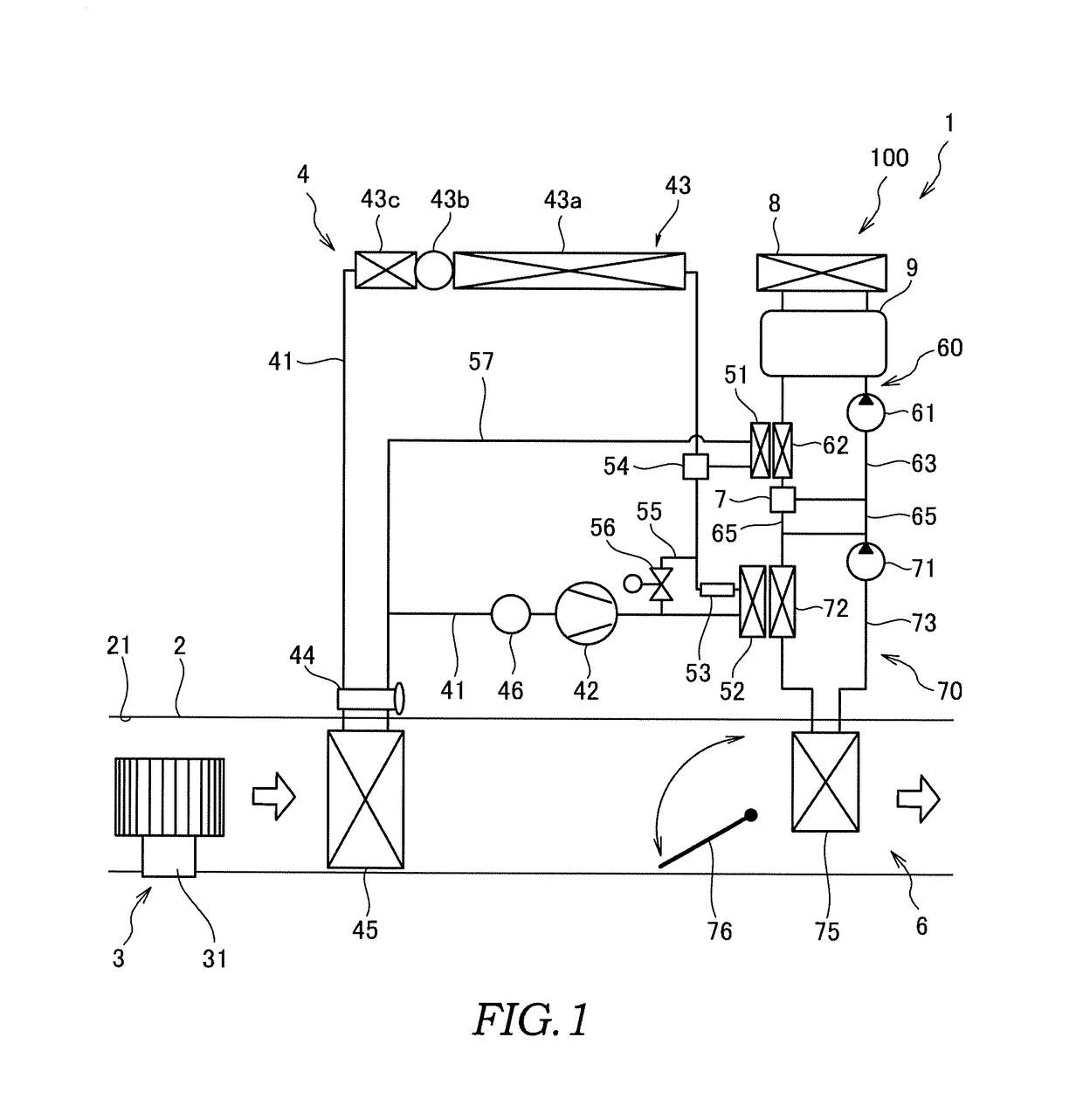

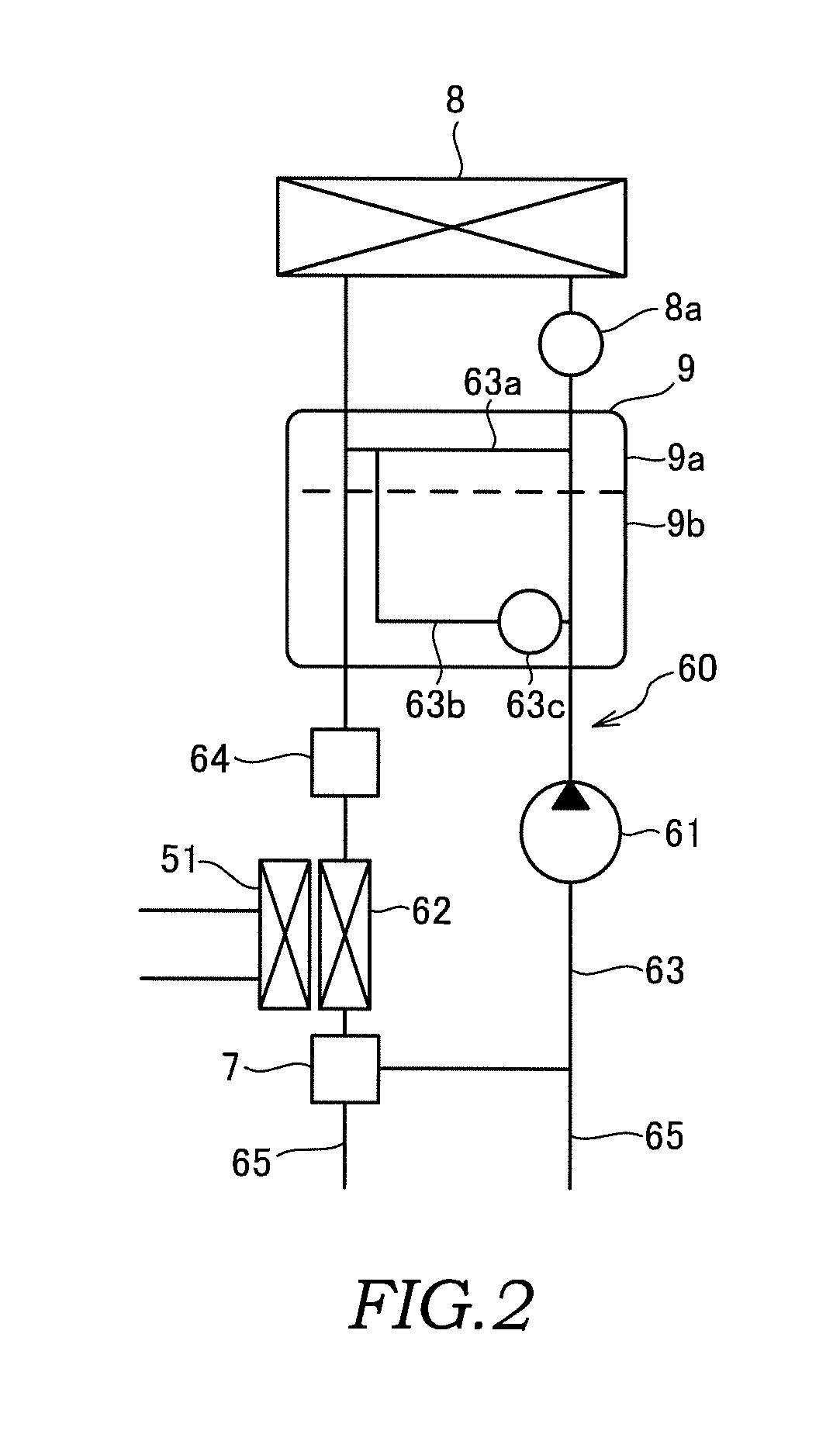

Vehicle air-conditioning device

ActiveUS20170326945A1Suppress deterioration of energy efficiencyAvoid reheatingAir-treating devicesVehicle heating/cooling devicesEngineeringWater circulation

A vehicle air-conditioning device includes: a first coolant-water circulation path in which coolant water passes through an engine ; a second coolant-water circulation path that is communicated with the first coolant-water circulation path and in which the coolant water passes through a vehicle-cabin radiator; a shutting off mechanism that shuts off, when switched to a shut-off state, the communication between the first coolant-water circulation path and the second coolant-water circulation path; and a refrigeration cycle. The refrigeration cycle has: a compressor for compressing cooling medium; a secondary evaporator in which the cooling medium absorbs heat from the coolant water in the first coolant-water circulation path; a secondary condenser that releases heat of the cooling medium that has absorbed the heat at the secondary evaporator to the coolant water in the second coolant-water circulation path; and a secondary expander that decompresses the cooling medium that has passed through the secondary condenser.

Owner:HIGHLY MARELLI JAPAN CORPORATION

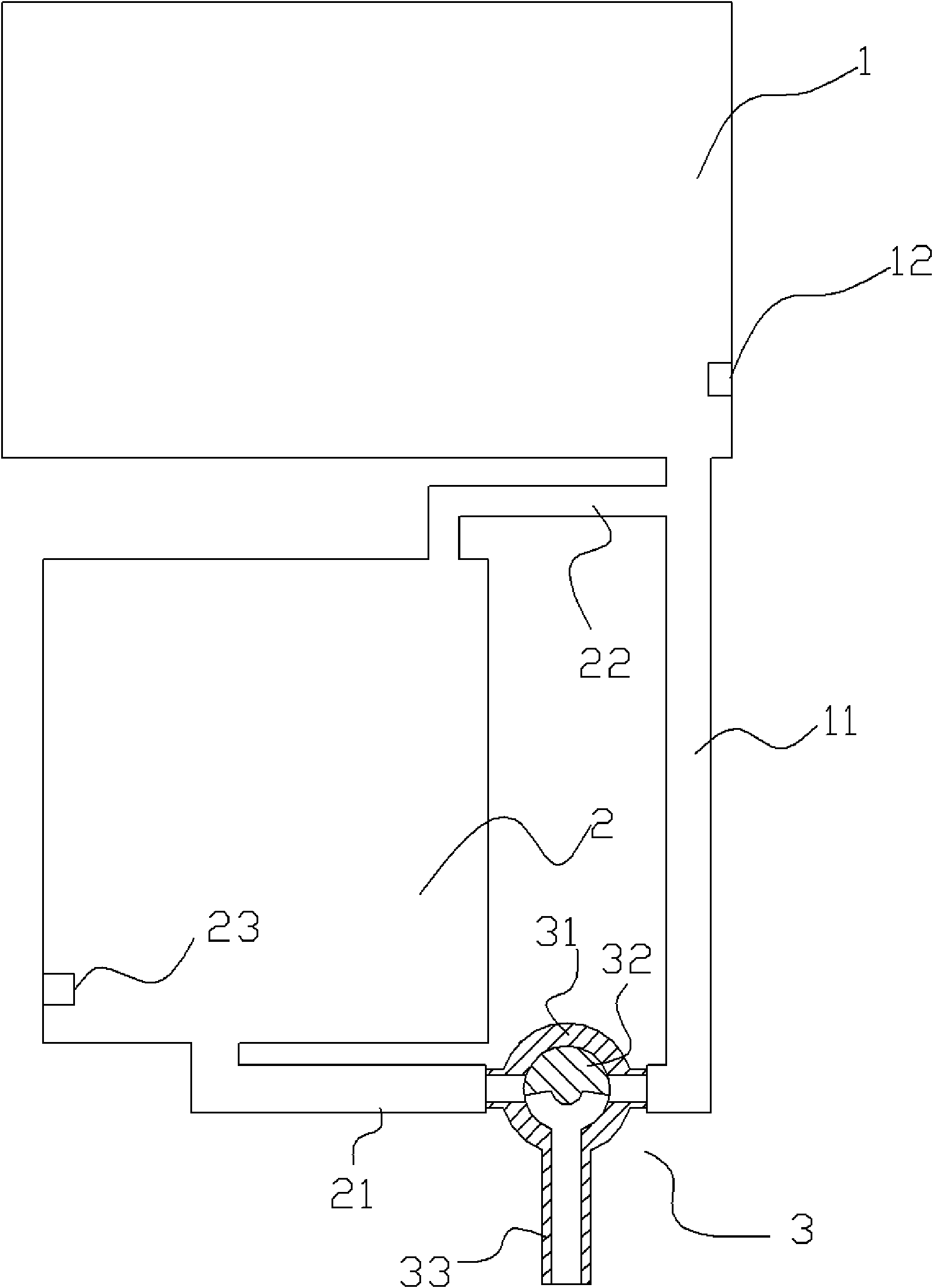

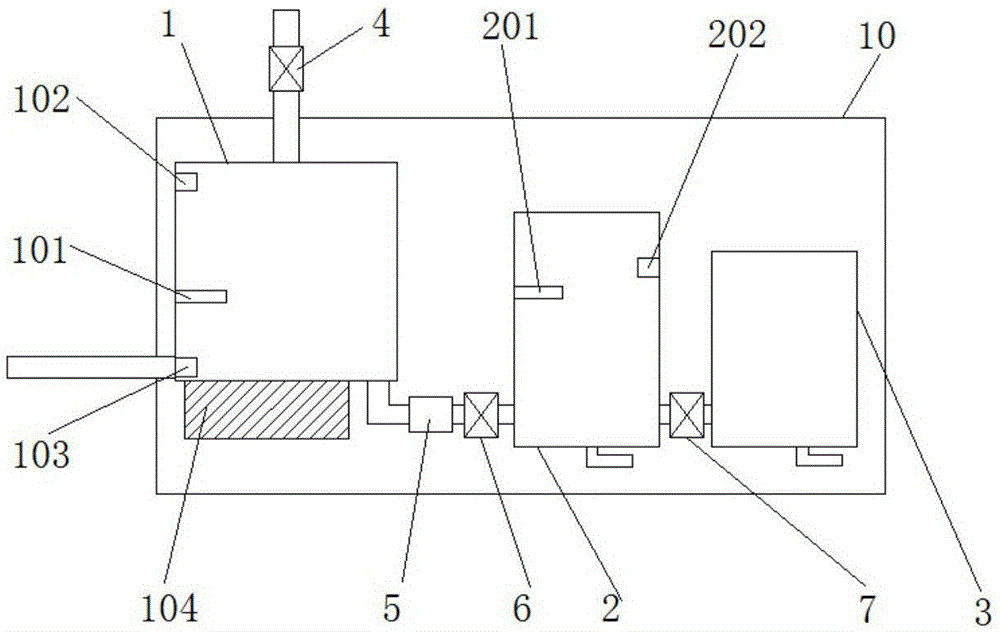

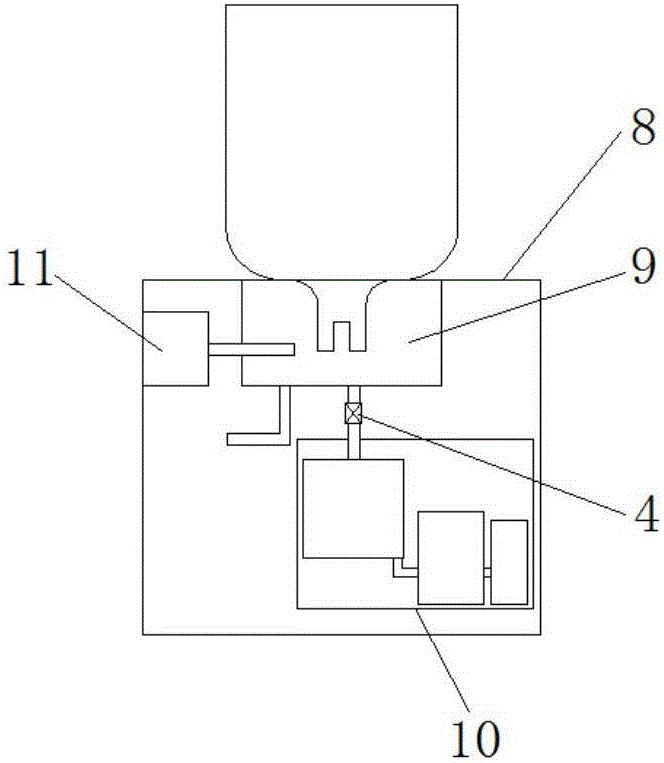

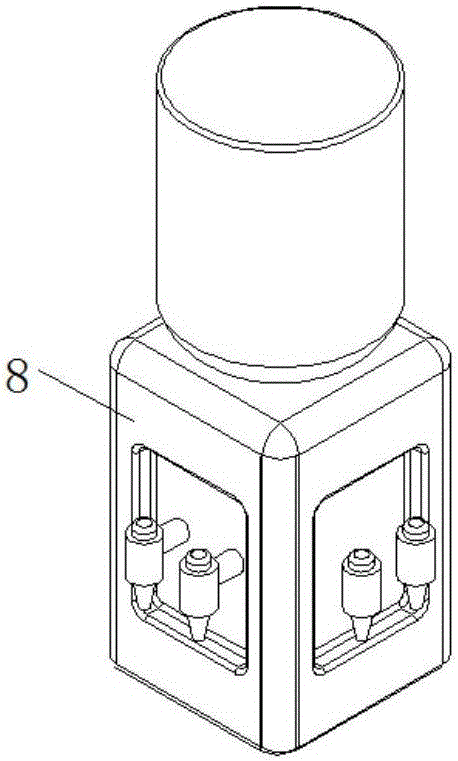

Drinking water attemperator and drinking water equipment composed thereof

InactiveCN101554292AAvoid reheatingReduce the hassle of matchingBeverage vesselsPotable waterEngineering

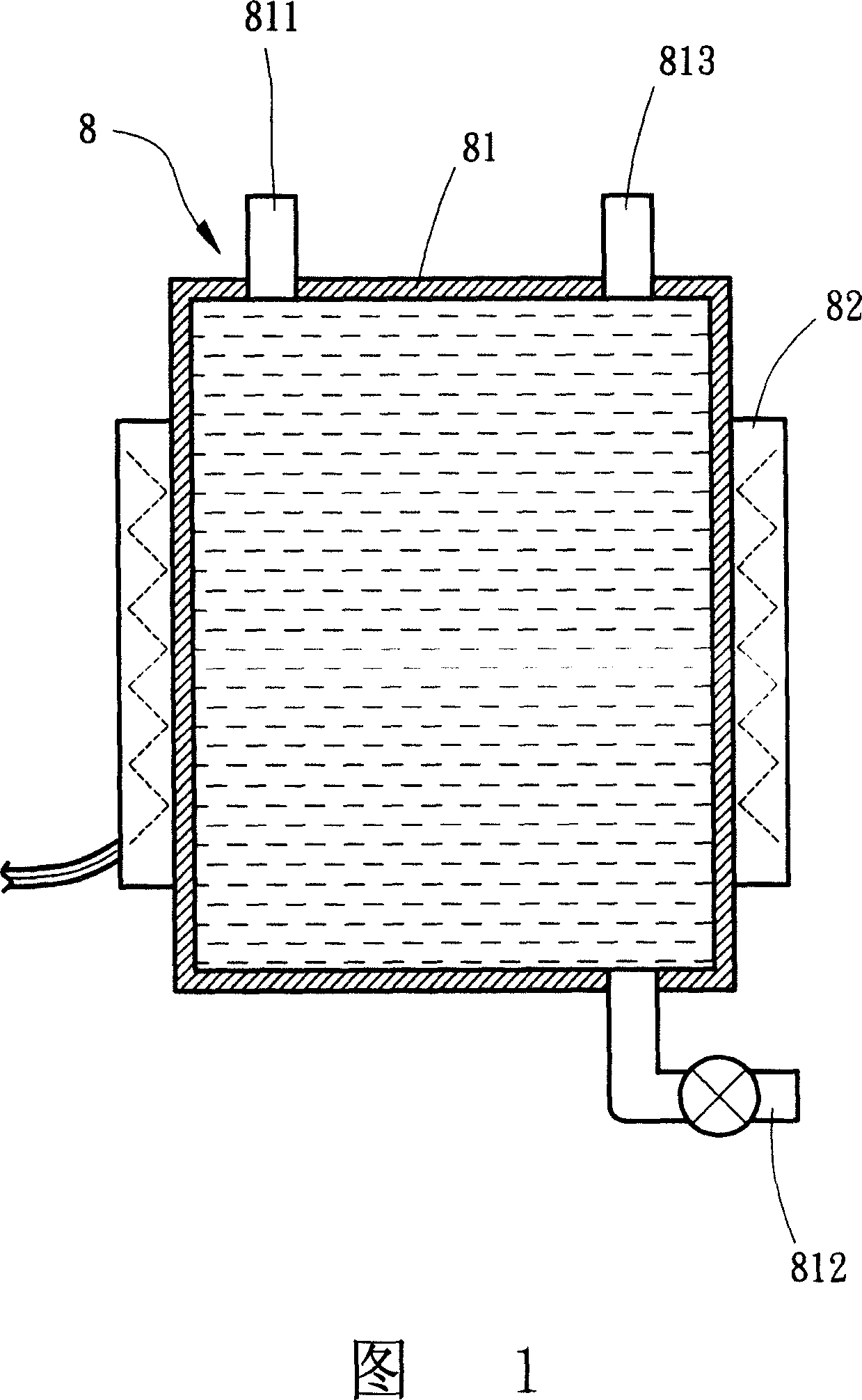

The invention discloses a drinking water temperature adjusting device which comprises a hot water supply pipe, a water valve connected with the hot water supply pipe, and a water outlet pipe connected with the water valve; the water valve is a mixed water valve which is connected with a cold water supply pipe; the hot water supply pipe is connected with a hot water tank; the cold water supply pipe is connected with a cold water tank; the mixed water valve comprises a valve seat used for connecting the hot water supply pipe, the cold water supply pipe and the water outlet pipe, and a valve plug arranged in the valve seat; and the valve plug adjusts the flow of the cold water supply pipe and the hot water supply pipe when deflecting in the valve seat, therefore, drinking water with different temperature is provided and flows out from the water outlet pipe. The drinking water temperature adjusting device is provided with a mixed water valve, thus being capable of realizing the temperature adjustment of drinking water; in addition the drinking water temperature adjusting device is also provided with a temperature sensor and a measuring cup, thus being capable of providing drinking water with specific quantity and specific temperature for users, and reducing the trouble of mixing cold water with hot water for users. The invention also discloses drinking water equipment which is provided with double heating boxes, can supply hot water continuously for users, prevent repetitive heating and effectively prevent the generation of nitrite.

Owner:DONGGUAN SAIKALYULA ELECTROMECHANICAL TECH DEV

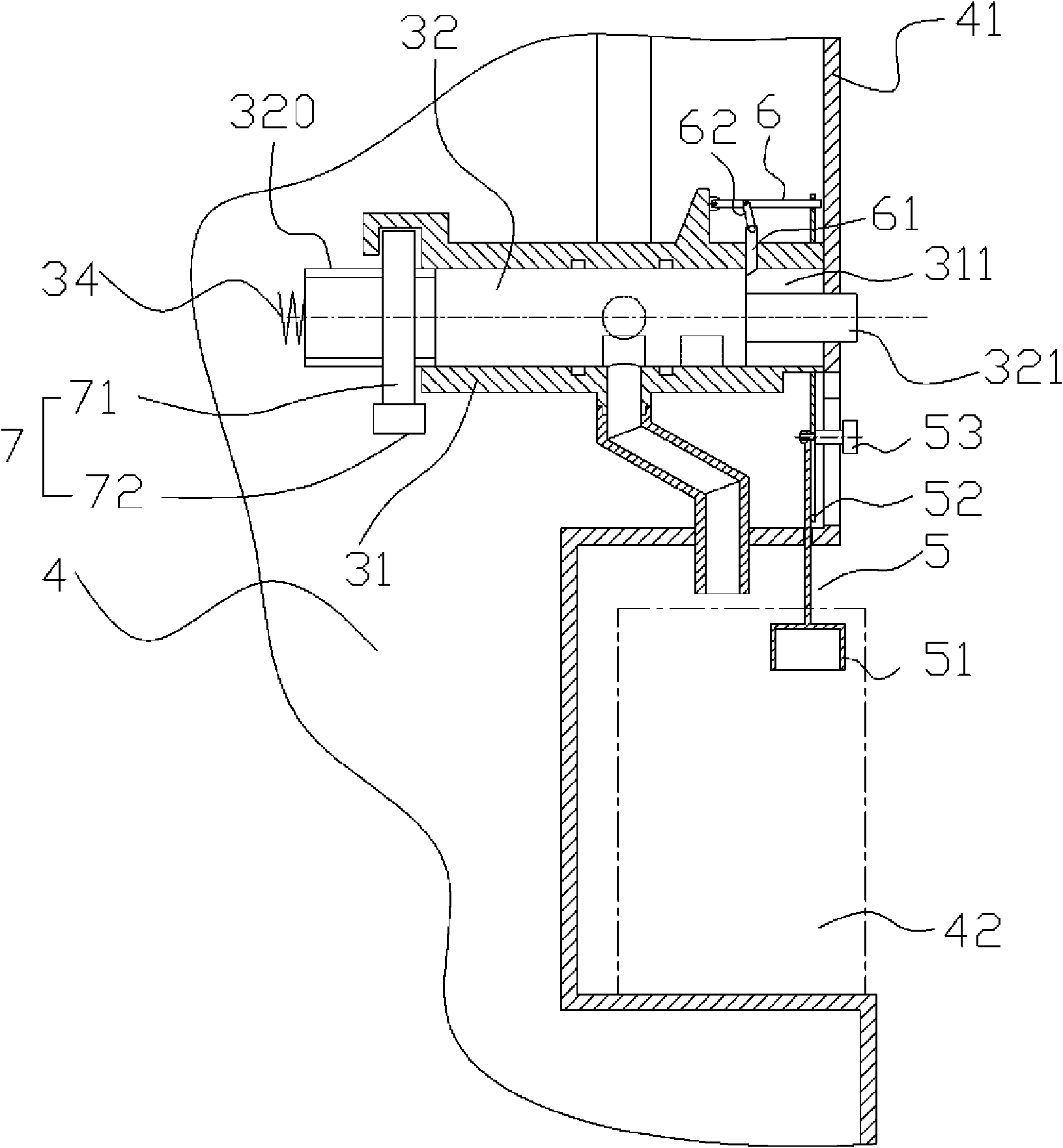

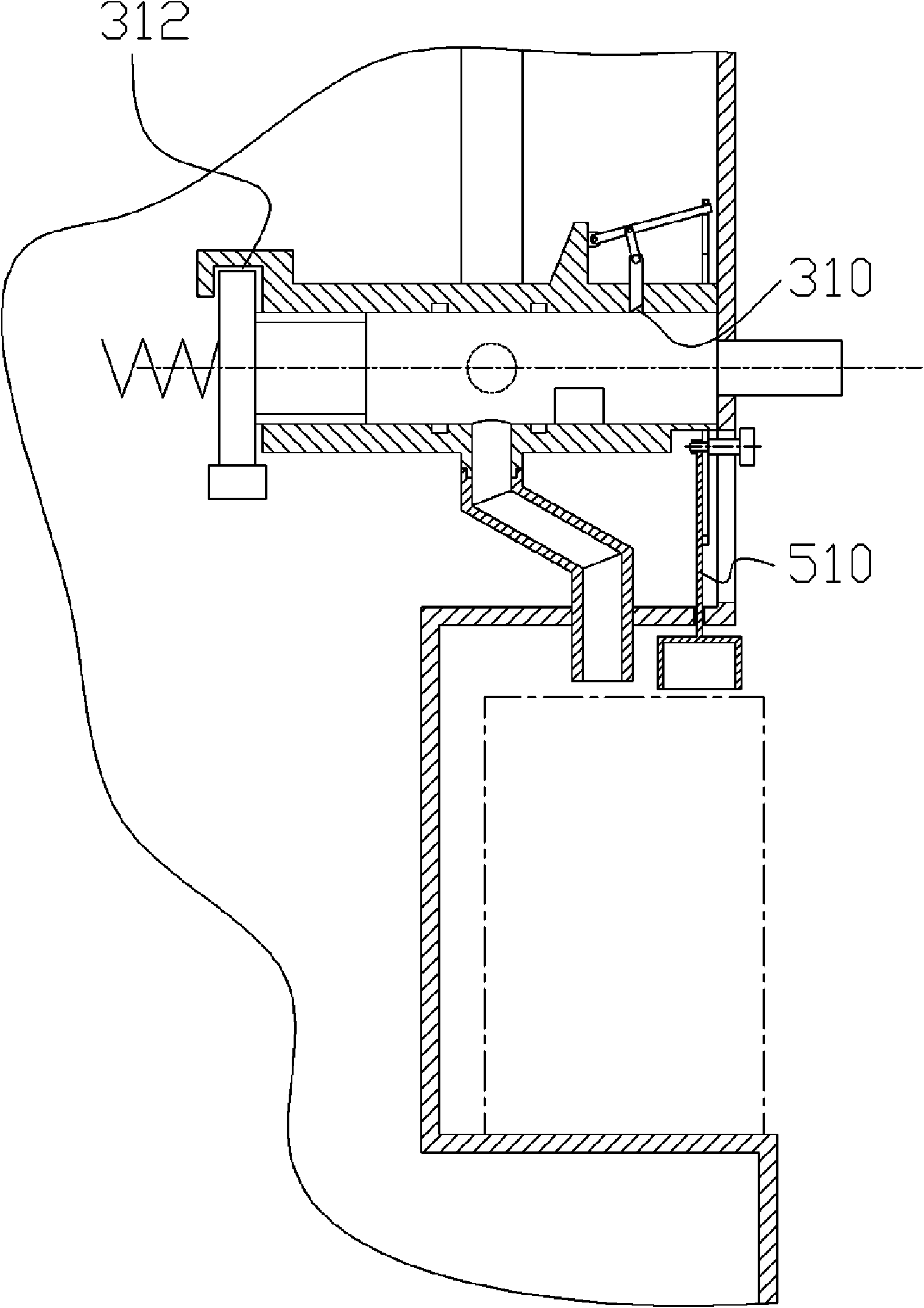

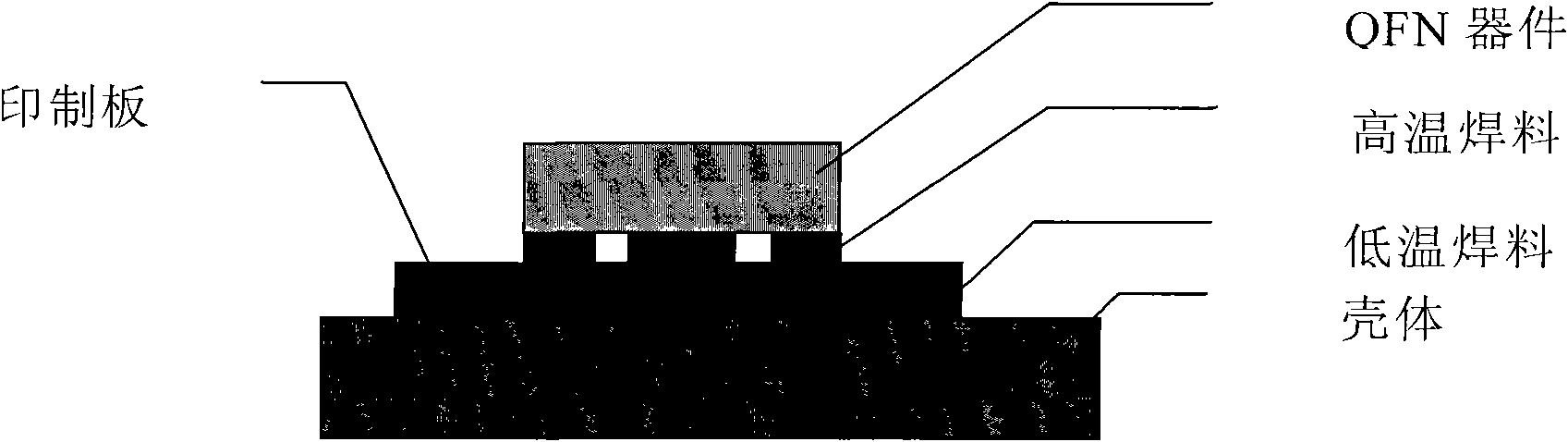

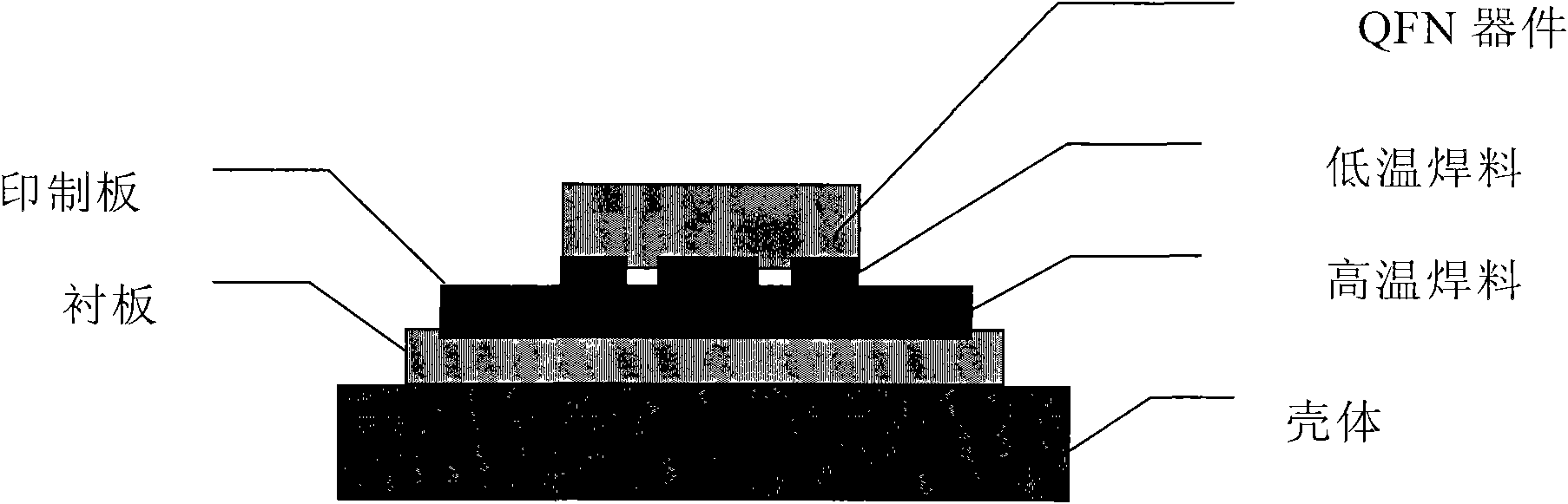

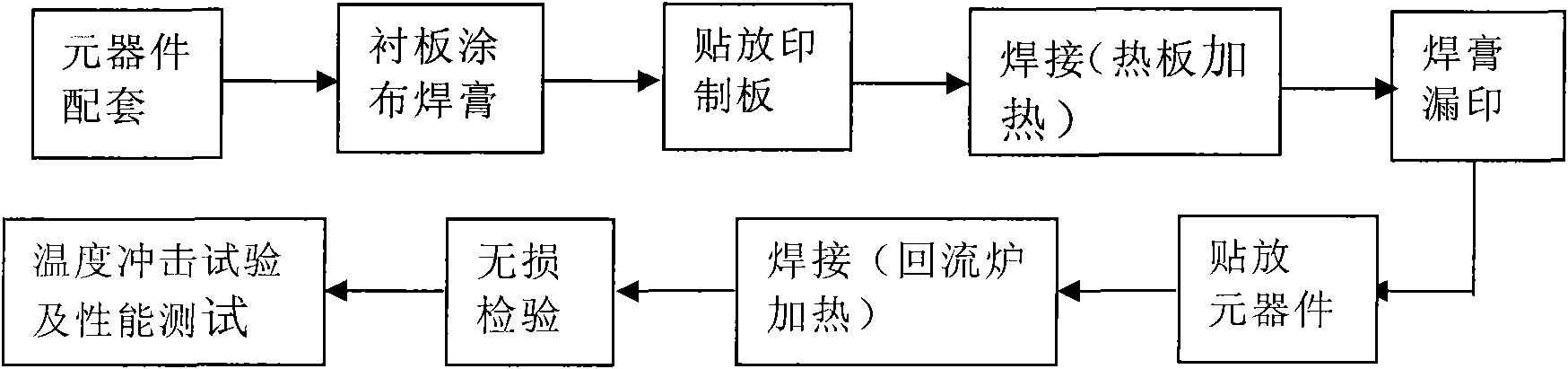

Method for enhancing welding reliability of high-frequency quad flat no lead (QFN) device

ActiveCN102083281AAvoid and reduce solder joint stressAvoid reheatingPrinted circuit assemblingElectrical and Electronics engineeringHigh frequency

The invention relates to a method for enhancing the welding reliability of a high-frequency quad flat no lead (QFN) device. The method comprises the following steps of: (1) uniformly coating a high-temperature solder with the smelting point of between 214 and 220 DEG C on a lining board and welding a printed board on the lining board; (2) coating a low-temperature solder with the smelting point of between 180 and 188 DEG C on a bonding pad of the printed board by using a bushing, sticking the QFN device and welding, wherein the opening size of the bushing is smaller than that of the bonding pad of the printed board; and (3) fastening the lining board in a shell. Through a welding method, secondary heating of the device is avoided, welding stress is reduced and good mechanical support is provided for the printed board assembly on the basis of ensuring that a printed board assembly is fully grounded; simultaneously, thermal stress produced by a component under a cold and heat exchange condition can be greatly reduced and the reliability of the QFN device is enhanced.

Owner:BEIJING RES INST OF TELEMETRY

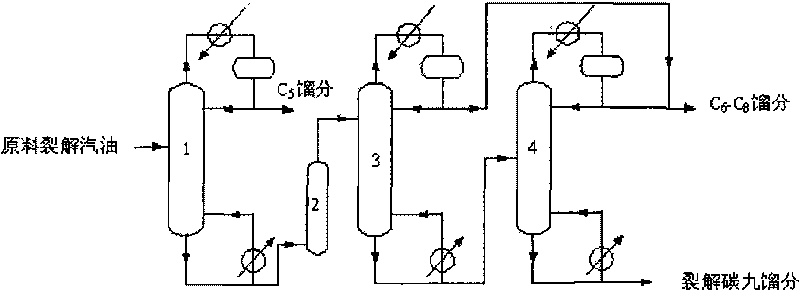

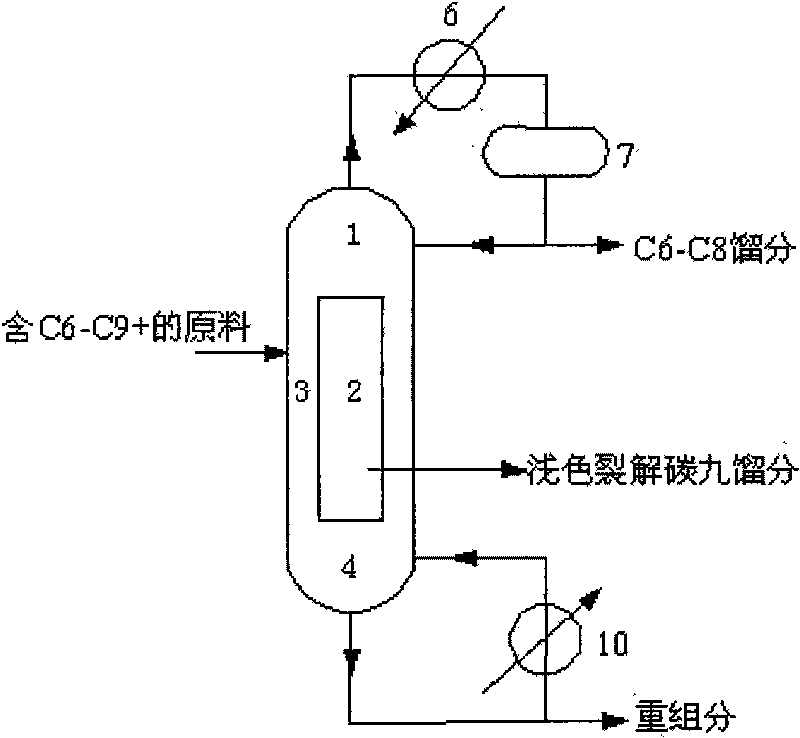

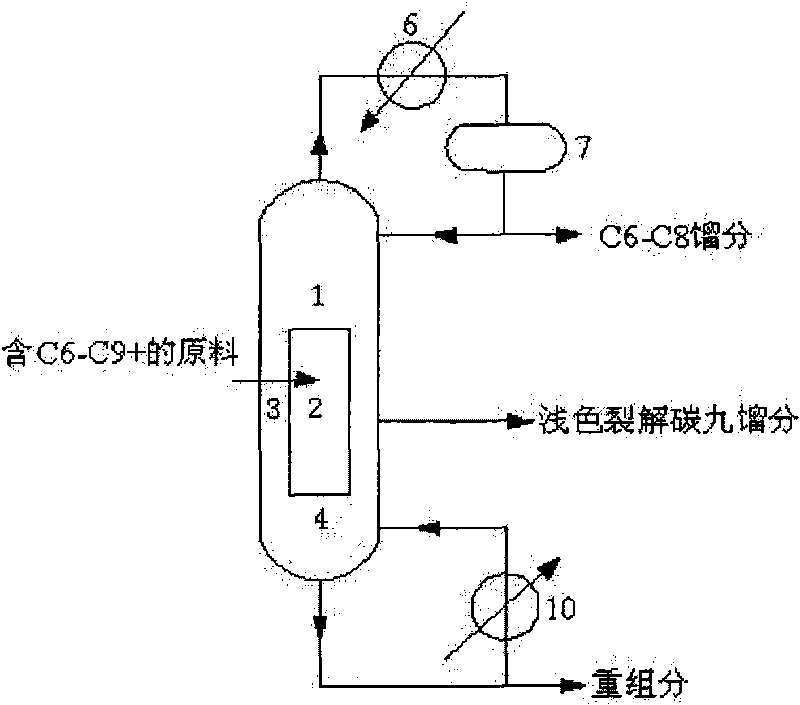

Device and method for separating light-colored C9 fraction of cracking

InactiveCN101717657AAvoid reheatingHigh activityHydrocarbon distillationFractional distillationReboilerEngineering

The invention discloses a device for separating a light-colored C9 fraction of cracking, which comprises a sleeve tower, a condenser, an overhead product accumulator tank and a tower bottom reboiler, wherein the inside of a rectifying tower is sleeved with an internal rectifying cylinder body, so the whole rectifying tower is divided into four parts, namely a public rectifying area, a public stripping area, the internal rectifying cylinder body and the external rectifying tower body, and the inside of the rectifying tower is provided with a tower plate or a filler; the part above the internal rectifying cylinder body is the public rectifying area, the top part of the public rectifying area is provided with an outlet for C6 to C8 fractions, and a raw material inlet or at least one outlet for the light-colored C9 product of the cracking are arranged in the internal rectifying cylinder body; and the part below the internal rectifying cylinder body is the public stripping area, and the bottom part of the public stripping area is provided with a heavy component outlet. The raw material is introduced from the middle upper part of the external rectifying tower body and is separated primarily in the external rectifying tower body, the separation of light components from medium components is completed in the upper part of the internal rectifying cylinder body, and the separation of heavy components from the medium components is completed in the lower part of the internal rectifying cylinder body. Compared with the traditional separation method, the method can save about 30 percent of energy and improve product yield.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

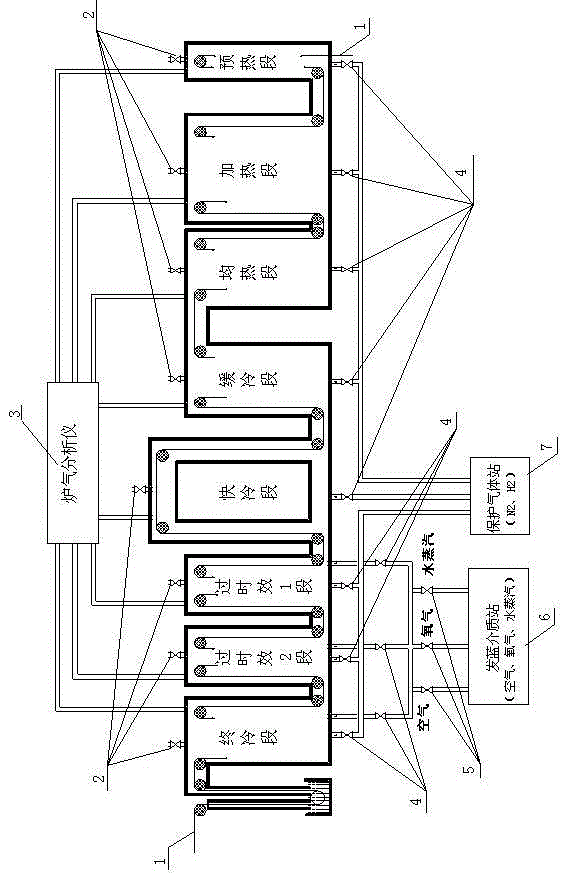

Vertical continuous annealing furnace bluing device and bluing technology thereof

InactiveCN103147084AAvoid reheatingBlue implementationSolid state diffusion coatingFurnace typesHearthBluing

The invention relates to a heat treatment device and heat treatment technology thereof and discloses a vertical continuous annealing furnace bluing device and bluing technology thereof. A bluing medium station is arranged and is communicated with a rapid cooling section, an overaging section and a final cooling section of a hearth through medium pipelines to control opening degree of a control adjusting valve and a relief valve. Oxygen content in the rapid cooling section and / or the overaging section and / or the final cooling section of the hearth is adjusted to be in a range of 0.03%-1.00%. An existing vertical continuous annealing furnace is used and a bluing device is added so that two processes of annealing and bluing of a bluing steel belt are finished by once in the vertical continuous annealing furnace, and therefore device investment and following heat treatment energy consumption are saved; continuous mass production is achieved, production cost is low, performance of a product is stable, surface bluing effect is good and production efficiency is high.

Owner:XINYU IRON & STEEL CO LTD

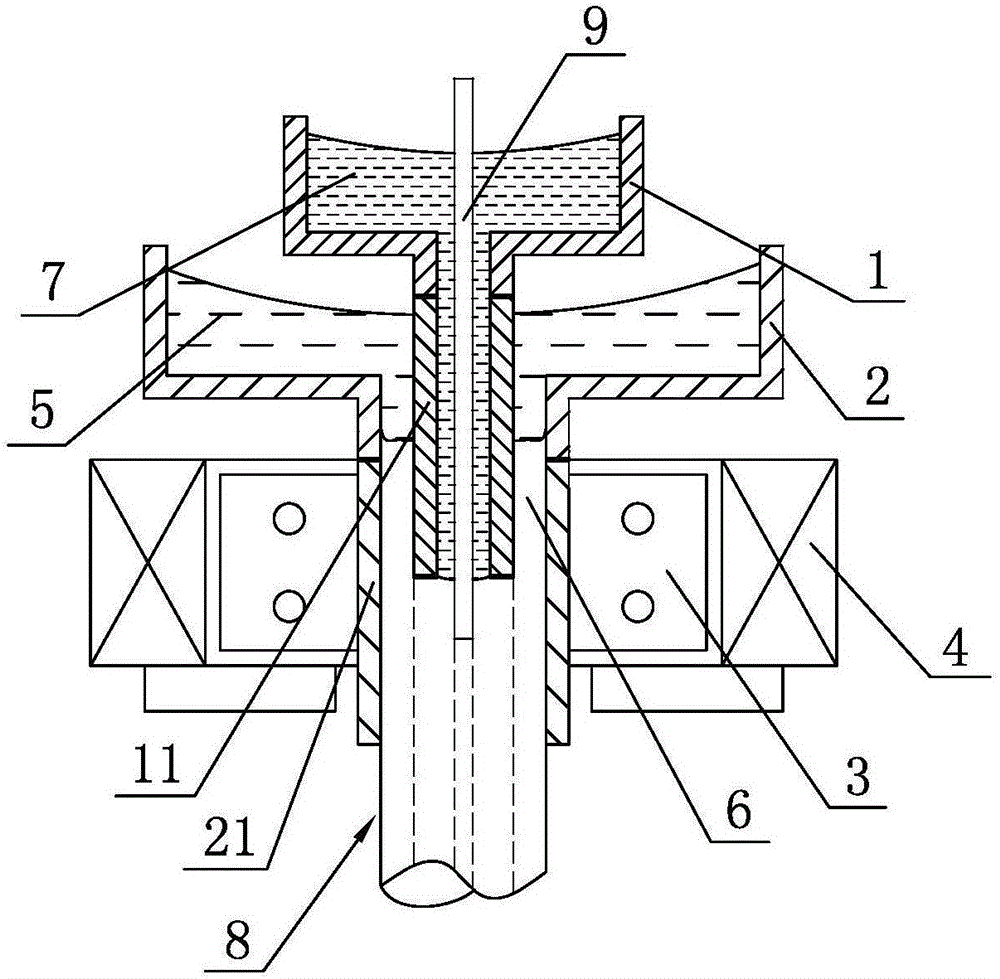

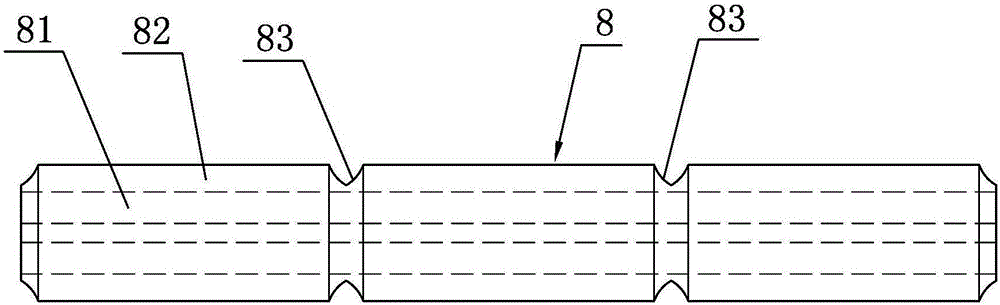

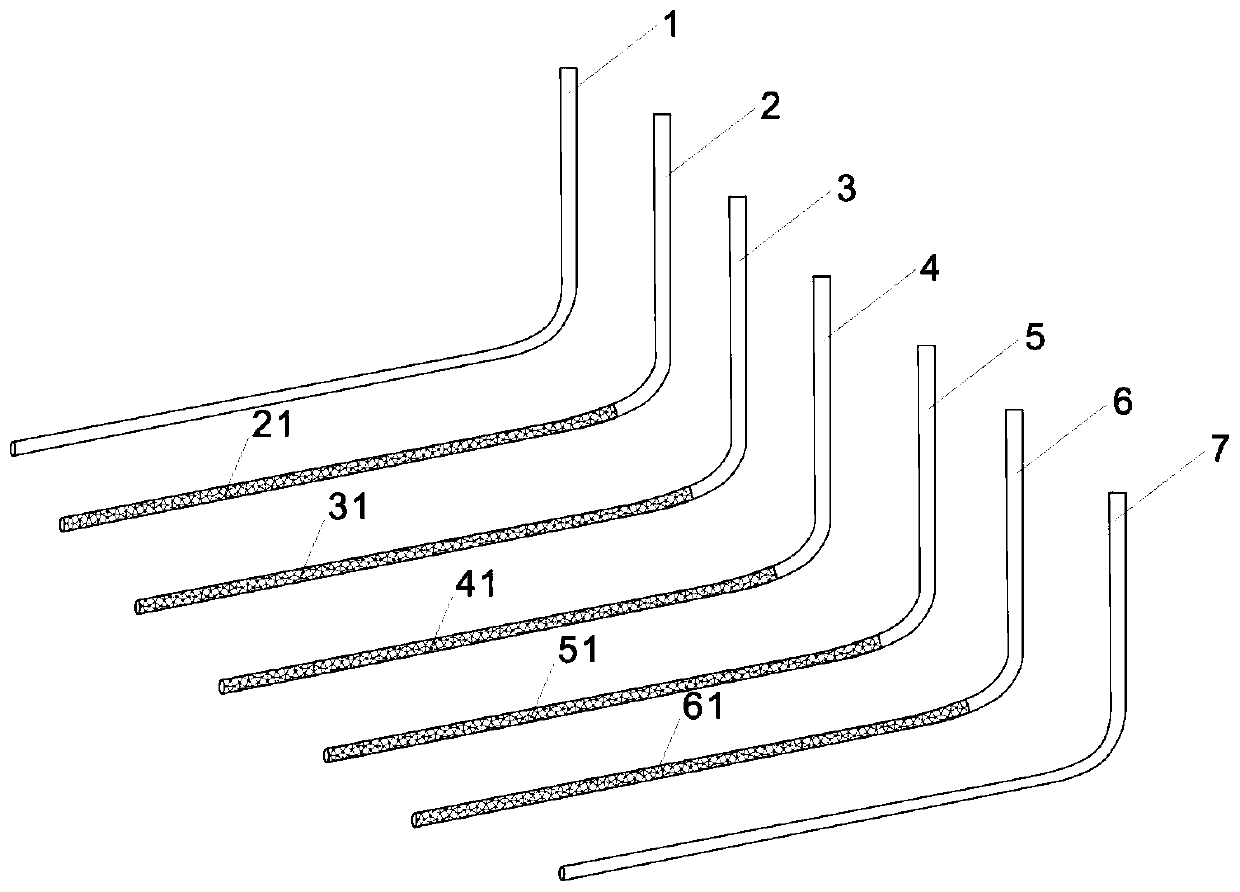

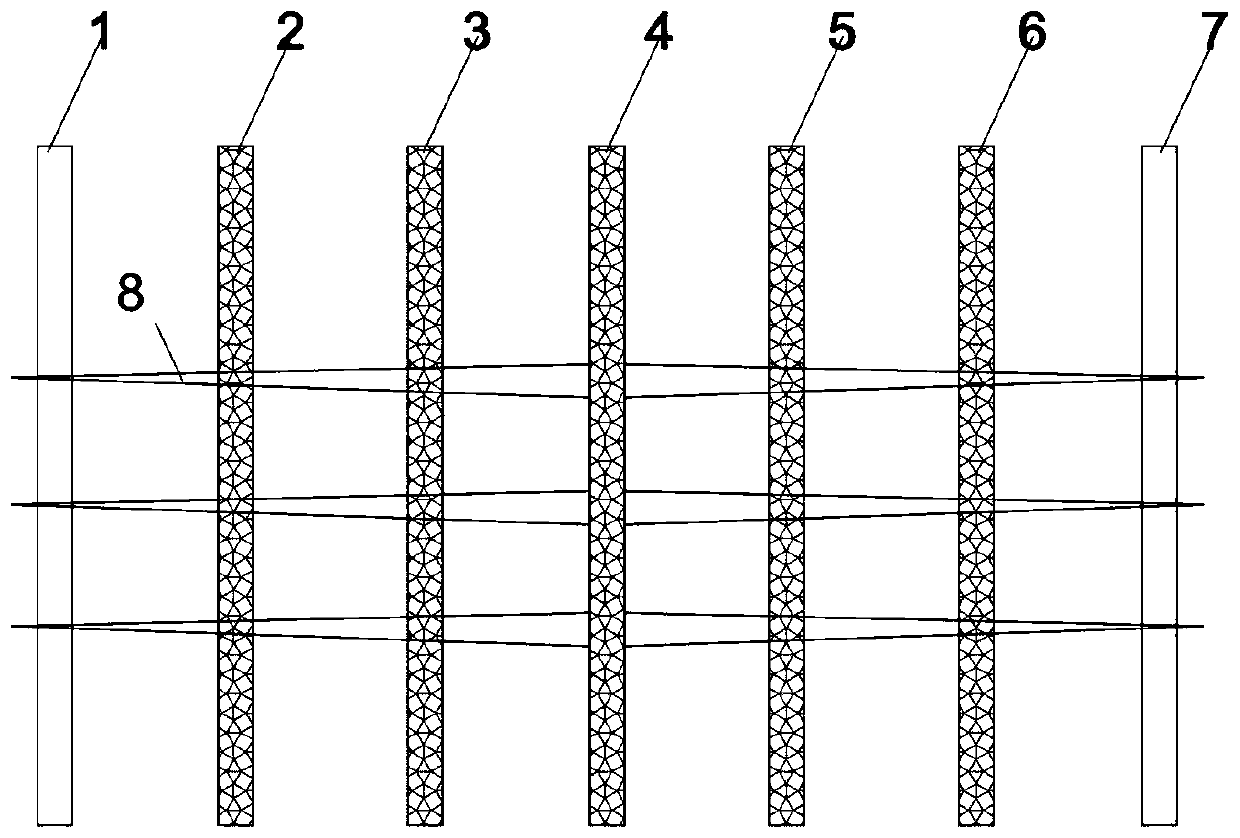

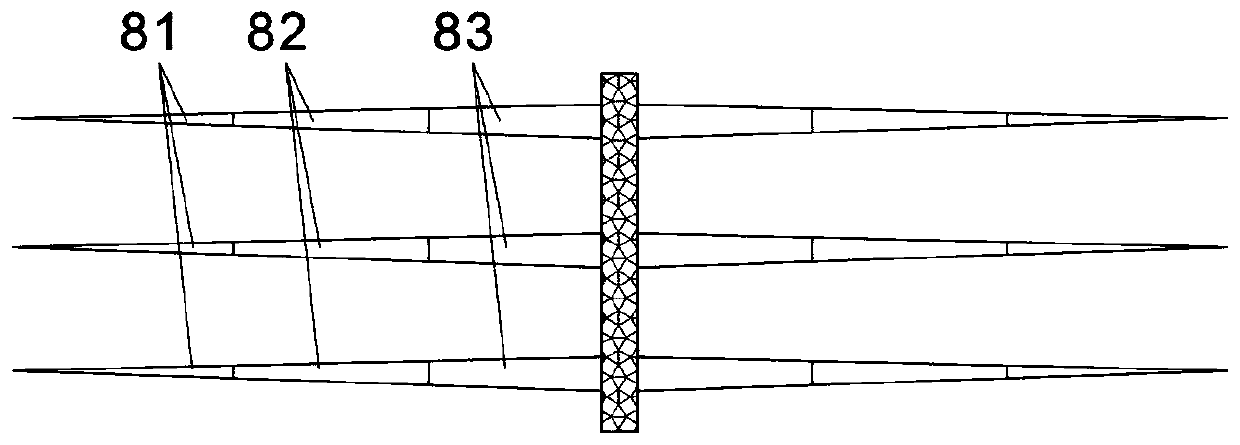

Continuous casting-cross-wedge rolling forming method for double-metal-layer composite hollow shaft without stub bars

The invention discloses a continuous casting-cross-wedge rolling forming method for a double-metal-layer composite hollow shaft without stub bars. The forming method is characterized in that coating-layer molten steel is added into a coating-layer pouring basket and solidified into a coating-layer metal pipe between a coating-layer casting pipe and a base-layer casting pipe. Base-layer molten steel is injected into the coating-layer metal pipe along an annular interspace between the base-layer casting pipe and a spacer rod and is solidified into a double-layer composite hollow bar material through cooling of a cooling crystallizer. The double-layer composite hollow bar material is subjected to secondary cooling, annular grooves are formed in the outer surface of the double-layer composite hollow bar material in an extruded mode, and a cutting machine cuts off the double-layer composite hollow bar material along the bottommost portions of the annular grooves in the radial direction. Finally, the double-layer composite hollow bar material is immediately placed to a cross-wedge rolling machine for rolling, and the double-metal-layer composite hollow shaft without the stub bars is obtained. The continuous casting-cross-wedge rolling forming method for the double-metal-layer composite hollow shaft without the stub bars has the advantages that the working procedure of the double-metal-layer composite hollow shaft is simplified, large-scale industrial production can be achieved, secondary heating of cross-wedge rolling is avoided, and the purposes of energy saving and consumption reducing are achieved.

Owner:NINGBO UNIV

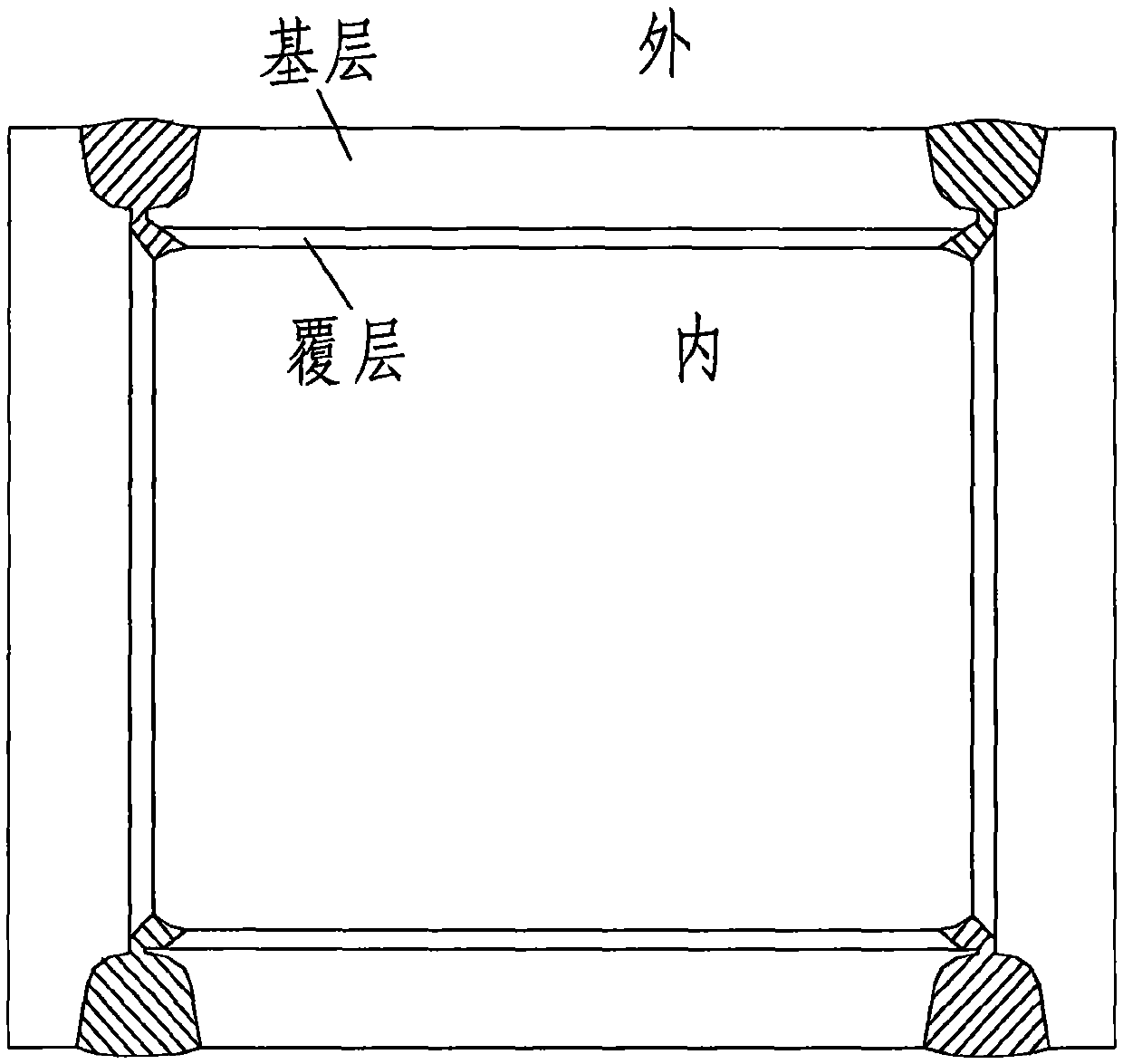

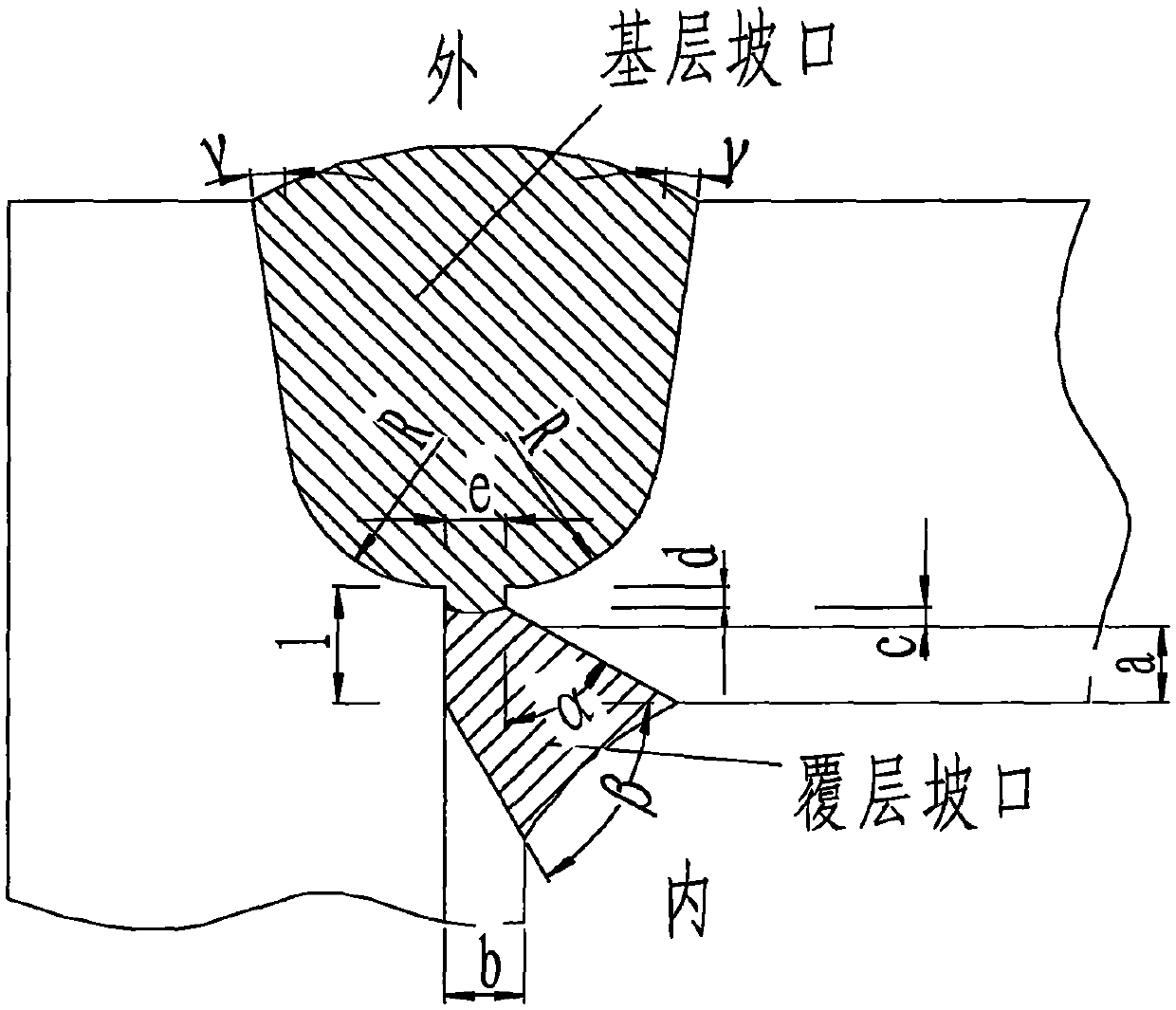

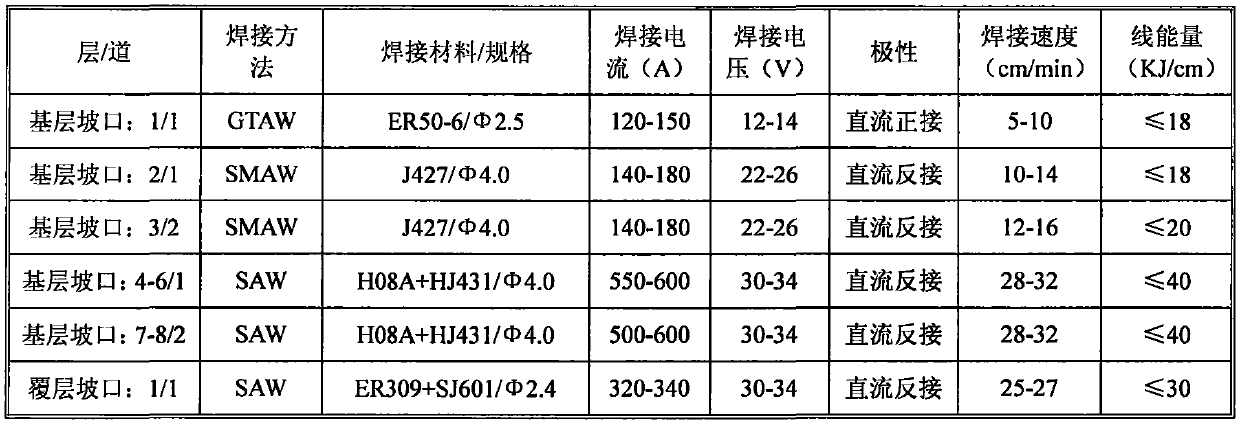

Welding technology for longitudinal joints of pipe-plug type channel of composite-plate type air cooler

ActiveCN105499749AImprove corrosion resistanceWelding shrinkage deformation is reducedArc welding apparatusMetal working apparatusShielded metal arc weldingEngineering

Disclosed is a welding technology for longitudinal joints of a pipe-plug type channel of a composite-plate type air cooler. An outer layer of the channel is a base layer, an inner layer of the channel is a coating, each of longitudinal channel joints is formed between each two adjacent perpendicular composite plates, a base layer groove is formed between the base layers, on the outer layer of each longitudinal channel joint, of each two corresponding composite plates, and a coating groove is formed between the coatings, on the inner layer of each longitudinal channel joint, of each two corresponding composite plates. The welding technology includes welding the base layer grooves and the coating grooves sequentially, wherein the base layer grooves are bottomed by argon arc welding and filled with two layers by shielded metal arc welding, the rest parts of the base layer grooves are covered by submerged arc welding, and then the inner coating grooves of the channel are welded on an inner-angle submerged arc welding machine. The welding technology has the advantages that welded joints are high in heat conductivity and small in linear expansion coefficient, channel welding shrinkage distortion amount is small, and welding material cost is reduced substantially; since the base layer grooves and the coating grooves are welded sequentially, the welded joints in the coating grooves can be protected from secondary heating, and corrosion resistance of the welded joints of the coating grooves is improved; production cost is reduced and production efficiency is improved.

Owner:LONGHUA TECHNOLOGY GROUP (LUOYANG) CO LTD

Method for large well spacing in-situ conversion mining of shale oil and gas of medium and low maturity shale oil

ActiveCN110005390AOvercoming the problem of small well spacing in in-situ miningAvoid closingFluid removalProduct gasShale oil and gas

The invention provides a method for large well spacing in-situ conversion mining of shale oil and gas of medium and low maturity shale oil. The method comprises the steps that a horizontal well groupwith at least three wells and with the well number being an odd number is deployed in a reservoir according to the well spacing of 15-50 meters; fracturing of the reservoir is performed, cracks are divided into three sections at equal intervals from a central injection well to production wells, and different types of propping agents are separately injected into the three sections in three stages;hot gas is injected into the central injection well and electrically heated, and is mined from the production wells; when temperatures between the central injection well and first-line round injectionwells reach a complete pyrolysis temperature, electric heating of the central injection well is stopped and normal temperature gas is injected into the central injection well; electric heating of thefirst-line round injection wells is started; when the temperatures between the first-line round injection wells and second-line round injection wells reach the complete pyrolysis temperature, injection of the normal temperature gas to the central injection well is stopped; electric heating of the first-line round injection wells is stopped, and normal temperature gas is injected into the first-line round injection wells; electric heating of the second-line round injection wells is started; and the cycle is repeated until reservoir temperatures between the production wells and adjacent last-line round injection wells reach the complete pyrolysis temperature.

Owner:PETROCHINA CO LTD

Repairing method of cracks on roll surface of back-up roll of rolling mill

ActiveCN103898518ASmall amount of grindingNo metallurgical cracksMetallic material coating processesAlloyHardness

The invention provides a repairing method of cracks on a roll surface of a back-up roll of a rolling mill. The repairing method comprises the following steps: (a) pre-treatment of cracks; (b) repairing, namely carrying out fusion covering on a to-be-repaired part through a laser by means of nickel base alloy powder; carrying out a vibration aging treatment, wherein the nickel base alloy powder comprises the following chemical components in percentage by mass: 0.5% of C, 18-20% of Cr, 2-3% of Mo, 0.5-1% of Mn, 2-3% of Si, 3.5-4.5% of Fe, 1.5-3% of W, 1.5-2% of Co, 2-3% of CeO and the balance of Ni; and carrying out fusion covering on rectangular spots in a laminated manner; and (c) post-treatment. The repairing method provided by the invention is used for repairing the cracks on the roll surface by adopting the laser cladding technology without pre-heating. Furthermore, subsequent grinding amount is small without metallurgical cracks, and the hardness can reach the operating requirement of a new roll [HRC (Rockwell Hardness) is over 60].

Owner:HANGZHOU DAYE LASER TECH

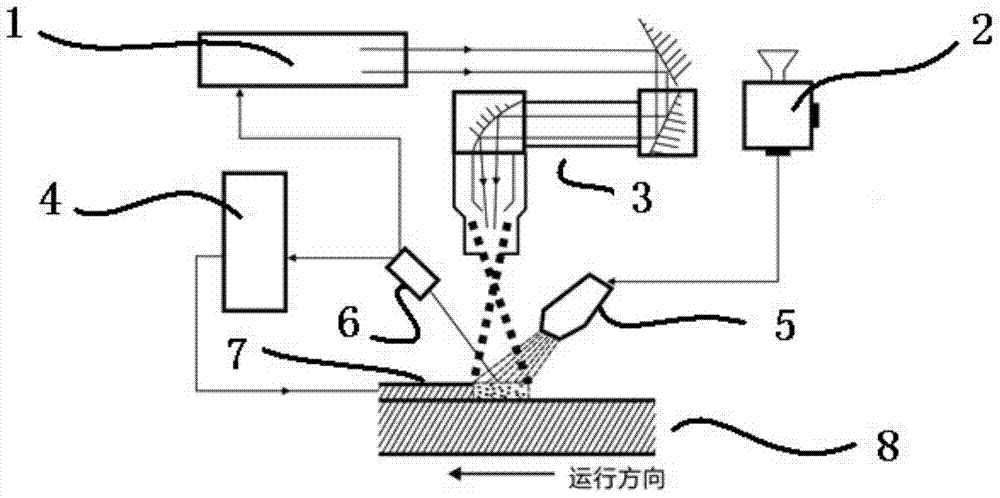

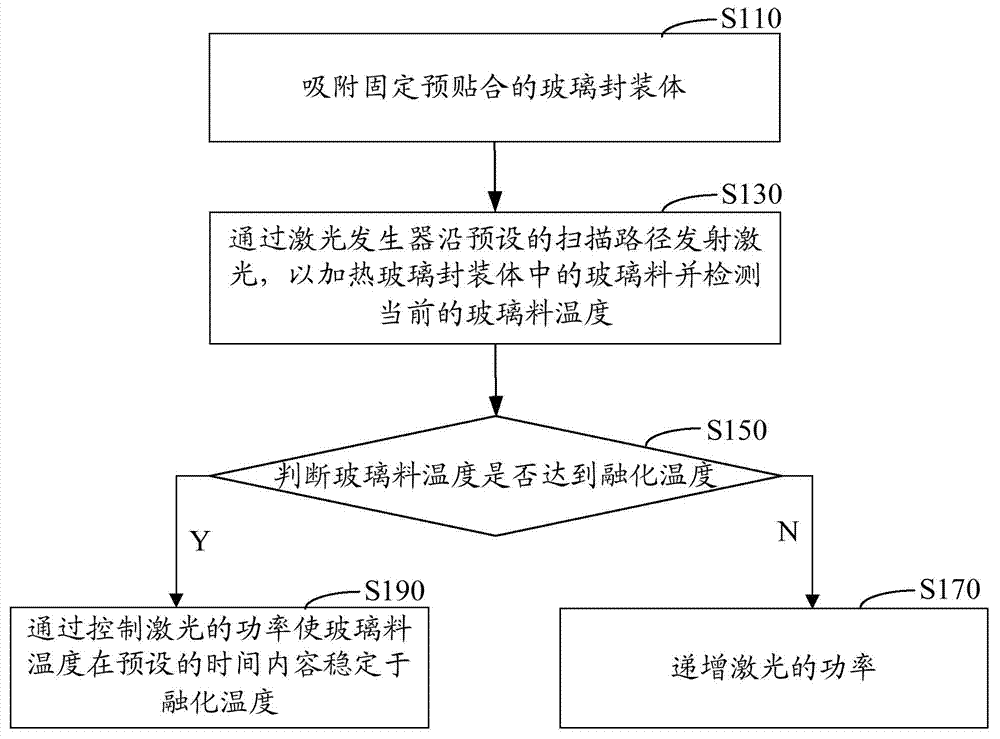

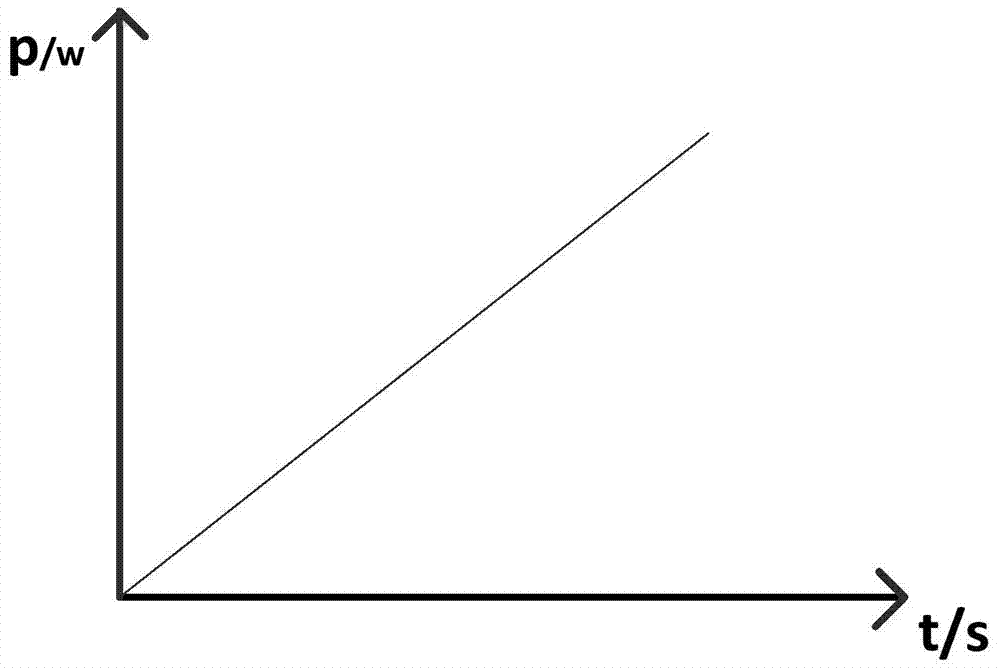

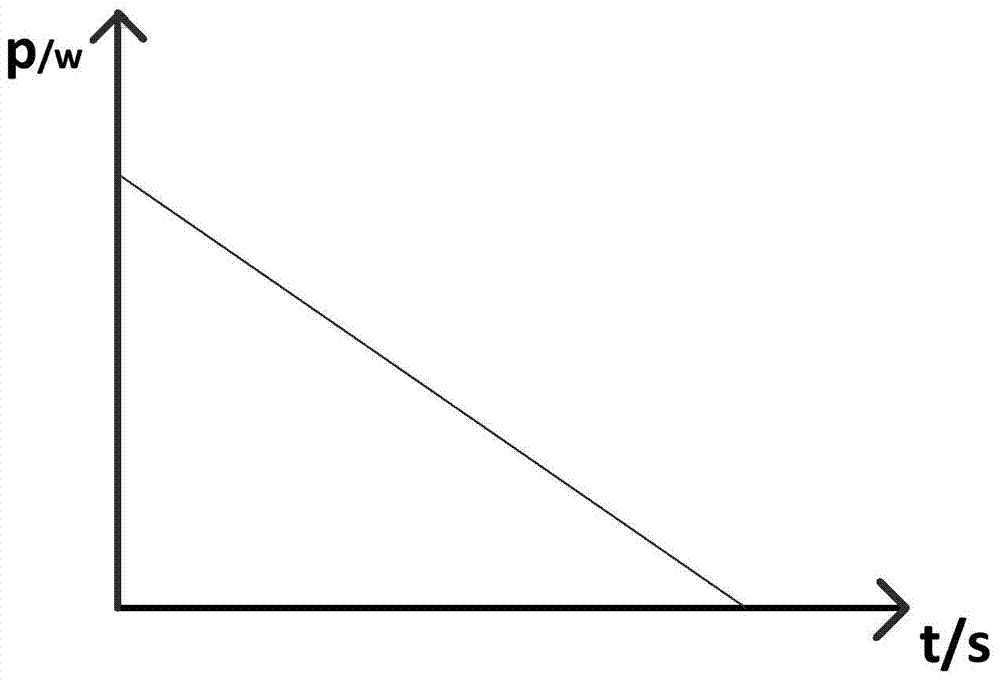

Laser quasi-synchronous scanning method and system

The invention provides a laser quasi-synchronous scanning method and a system. The method comprises: adsorbing and fixing a pre-attached glass package, emitting laser along a preset scanning path by a laser generator to heat the frit in the glass package, and detecting the current temperature of the frit; and judging whether the frit temperature reaches a melting temperature, if not, then progressively increasing the laser power. The system includes: an adsorption platform, the laser generator and a pyrometer. The adsorption platform is used for adsorbing and fixing the pre-attached glass package. The laser generator emits laser along the preset scanning path to heat the frit in the glass package, and the pyrometer detects the current temperature of the frit. The pyrometer judges whether the frit temperature reaches the melting temperature, and if not, the laser generator is controlled to progressively increase the laser power. By adopting the method and the system provided in the invention, excessive warping caused by too large stress generated by repeated heating can be avoided.

Owner:SHANGHAI UNIV +1

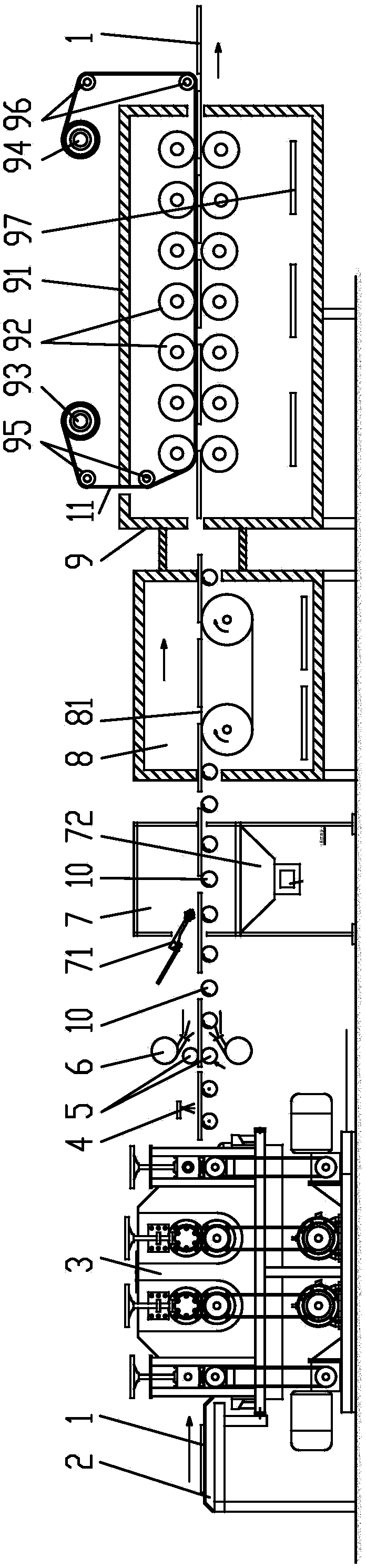

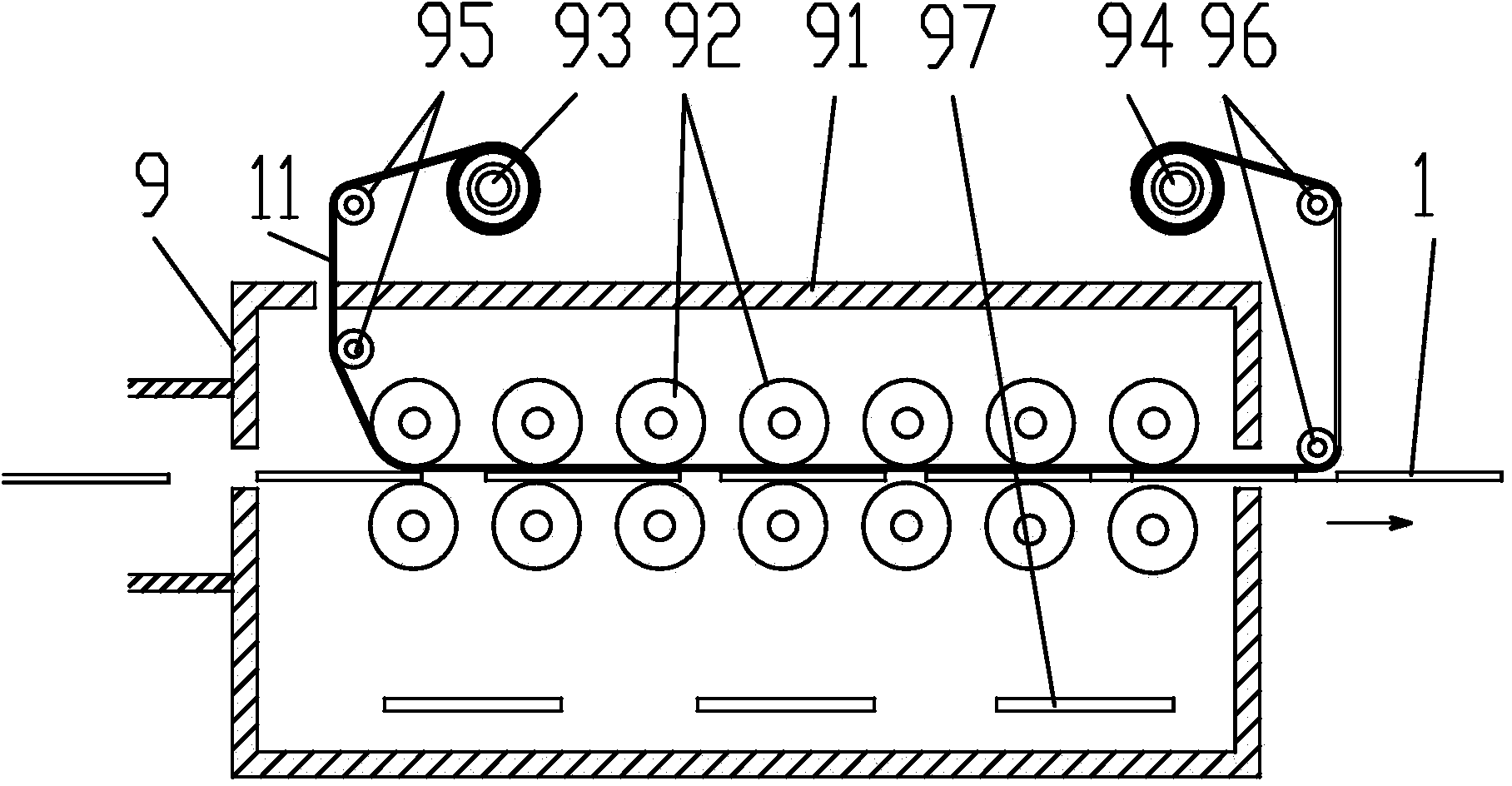

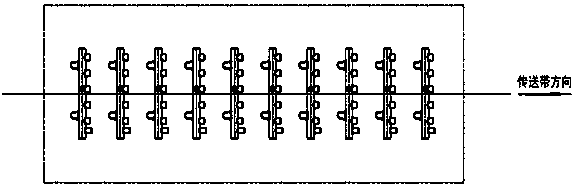

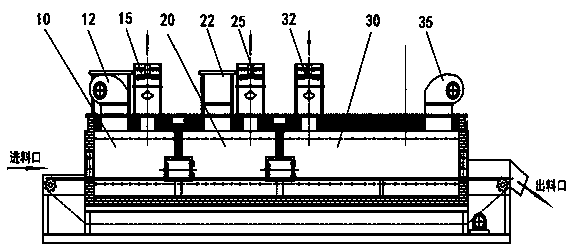

Production process and system applicable to steel plate heat transfer printing

InactiveCN103818138ARealize continuous thermal transfer operationSimple processTransfer printingDuplicating/marking methodsSheet steelEngineering

The invention discloses a production process and a system applicable to steel plate heat transfer printing. The production process and the system are applicable to continuous heat transfer printing operation of a single steel plate; a flat steel plate is fed into an operation system through a feeder to finish process steps through a washing and air-drying device, a powder spraying pretreatment device and a roll-type continuous heat transfer printing device in sequence. The process comprises the following steps: A, washing, degreasing and preprocessing the flat steel plate and air-drying the flat steel plate; B, carrying out powder spraying pretreatment on the upper surface of the flat steel plate, heating, curing and molding powder; and C, carrying out continuous heat transfer printing on the flat steel plate by using a heat transfer paper coil. Through the production process and the system, the continuous heat transfer printing of the single steel plate is realized; the continuous operation of the steel plate can be carried out; compared with a conventional platform type printing device, the production process and the system have the advantages that the transfer printing efficiency is greatly improved; the transfer printing effect is easily controlled; meanwhile, the flat steel plate does not need to be heated and cooled for multiple times; the energy is greatly saved.

Owner:殷殿荣 +1

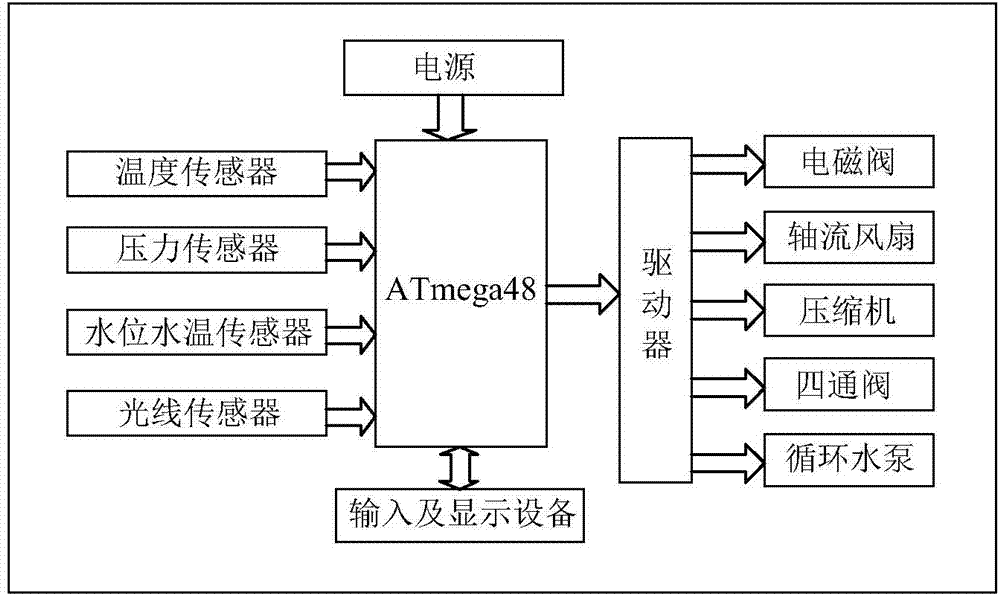

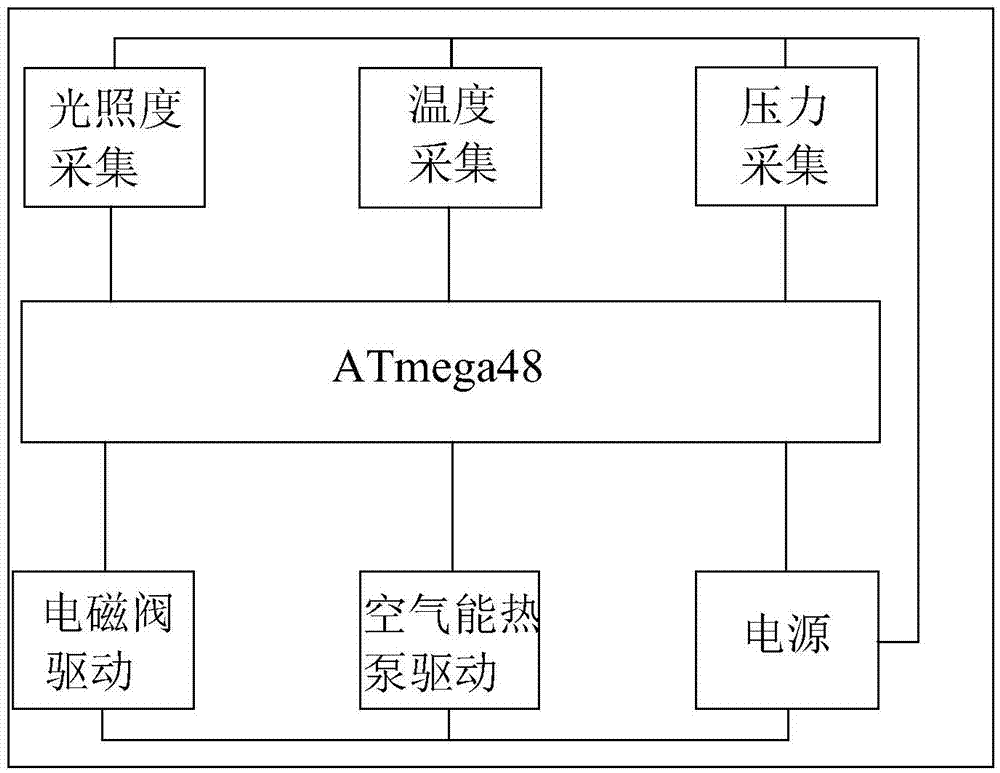

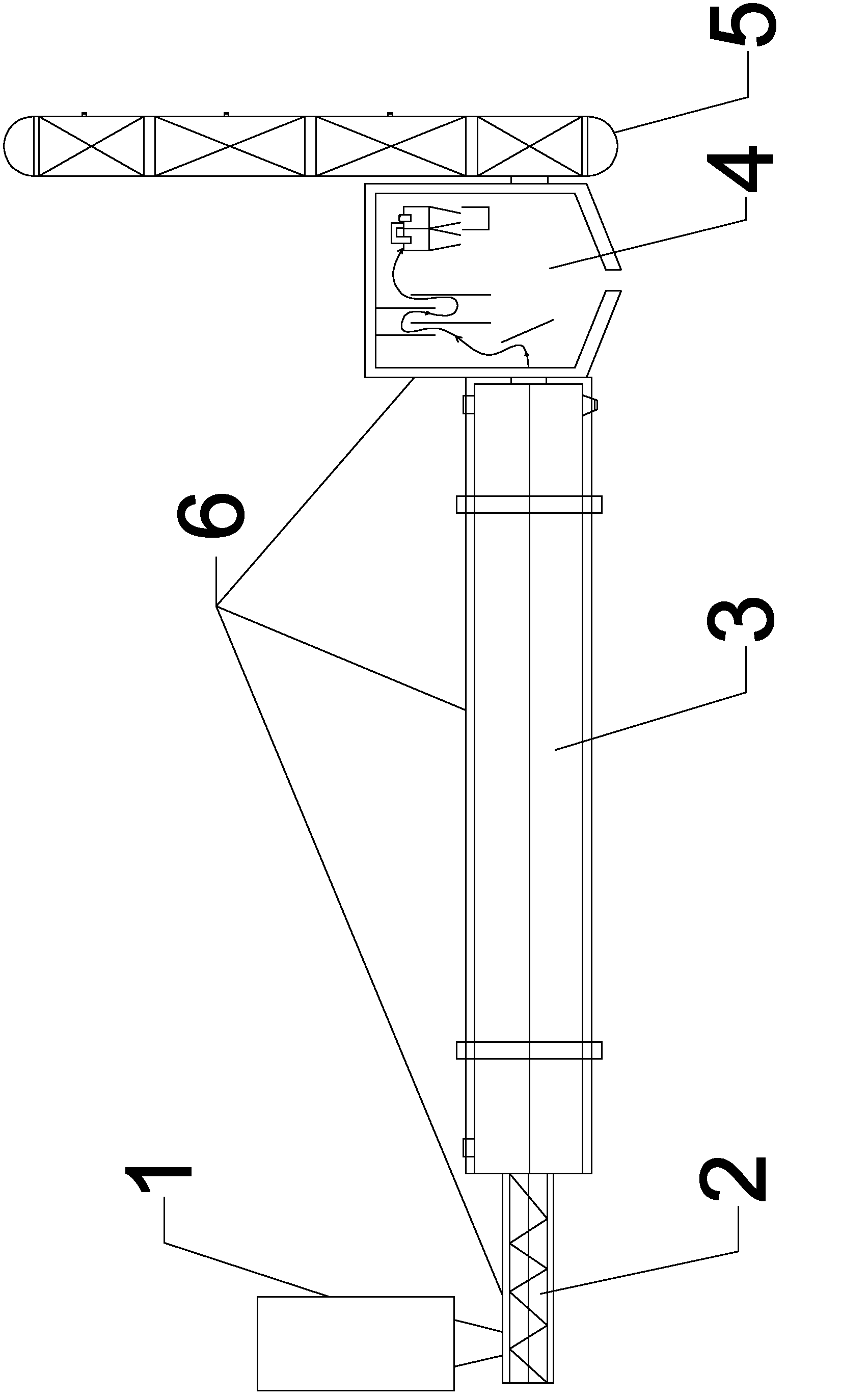

Solar and air energy full-intelligent control system

InactiveCN103884117AAvoid getting lostImprove comfortSolar heat devicesSolar thermal energy generationLine sensorEngineering

Owner:ZHUHAI BAIRUI ELECTRONICS TECH

Low-temperature pyrolysis device for coal

InactiveCN102618304AEfficient and stable productionAvoid reheatingIndirect heating destructive distillationSpecial form destructive distillationEngineeringTower

A low-temperature pyrolysis device for coal is characterized by comprising a feeder, a reactor, a dust remover and a separating tower according to the reaction sequence, wherein the feeder is used for providing raw coal for the reactor; the reactor is used for conducting pyrolysis on the raw coal; the dust remover is used for conducting dust removing treatment on volatile substances generated during the pyrolysis of the reactor, and is heated all the time during the working process; and the separating tower is used for separating the volatile substances treated with dust removing. The low-temperature pyrolysis device has the advantages that pipeline blockage can be reduced, so as to ensure stable and efficient low-temperature pyrolysis for the coal; and as the comparatively purer volatile substances treated by the dust remover are prevented from being heated again, the purposes of energy conservation, environmental protection and very high efficiency are realized.

Owner:苏忠

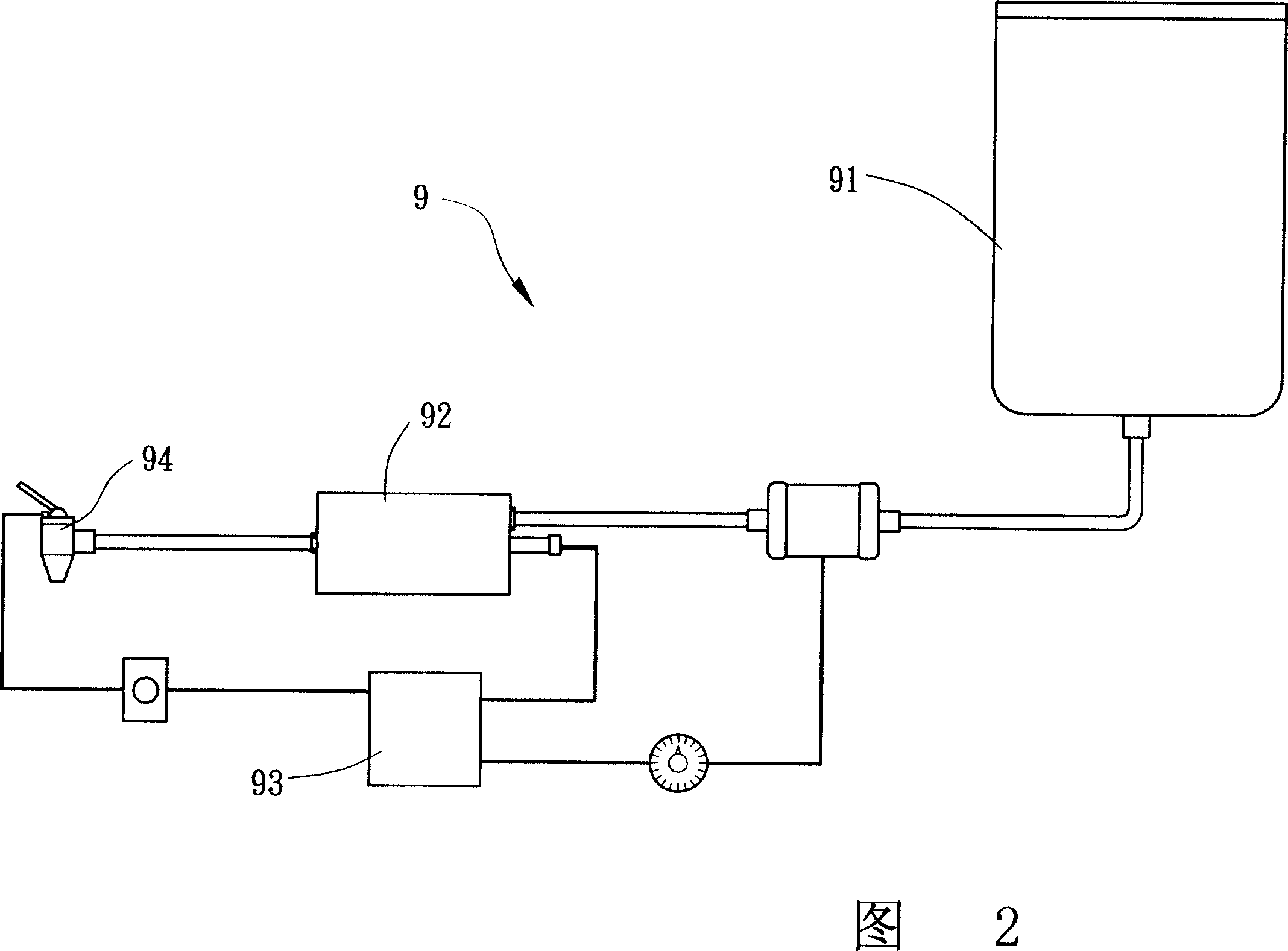

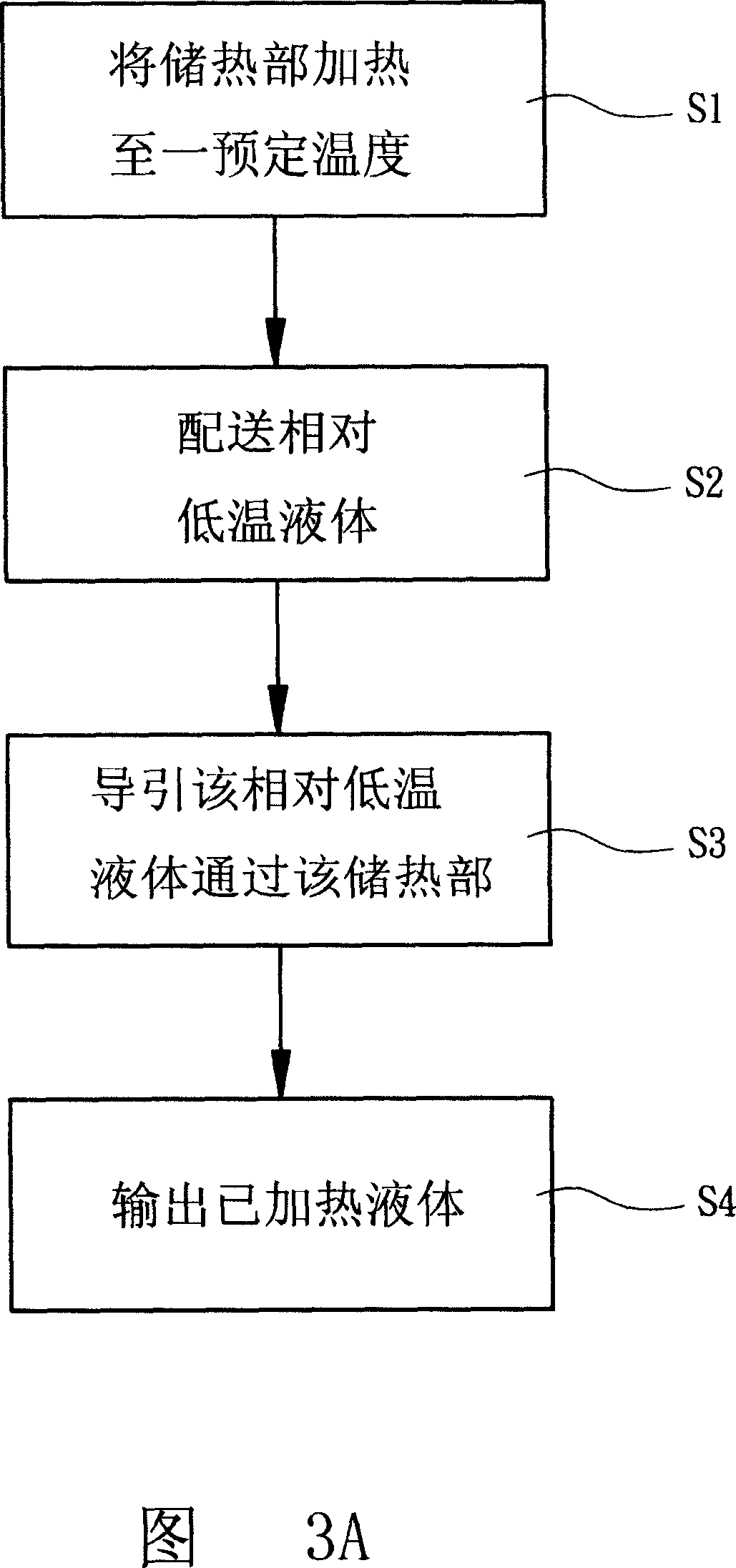

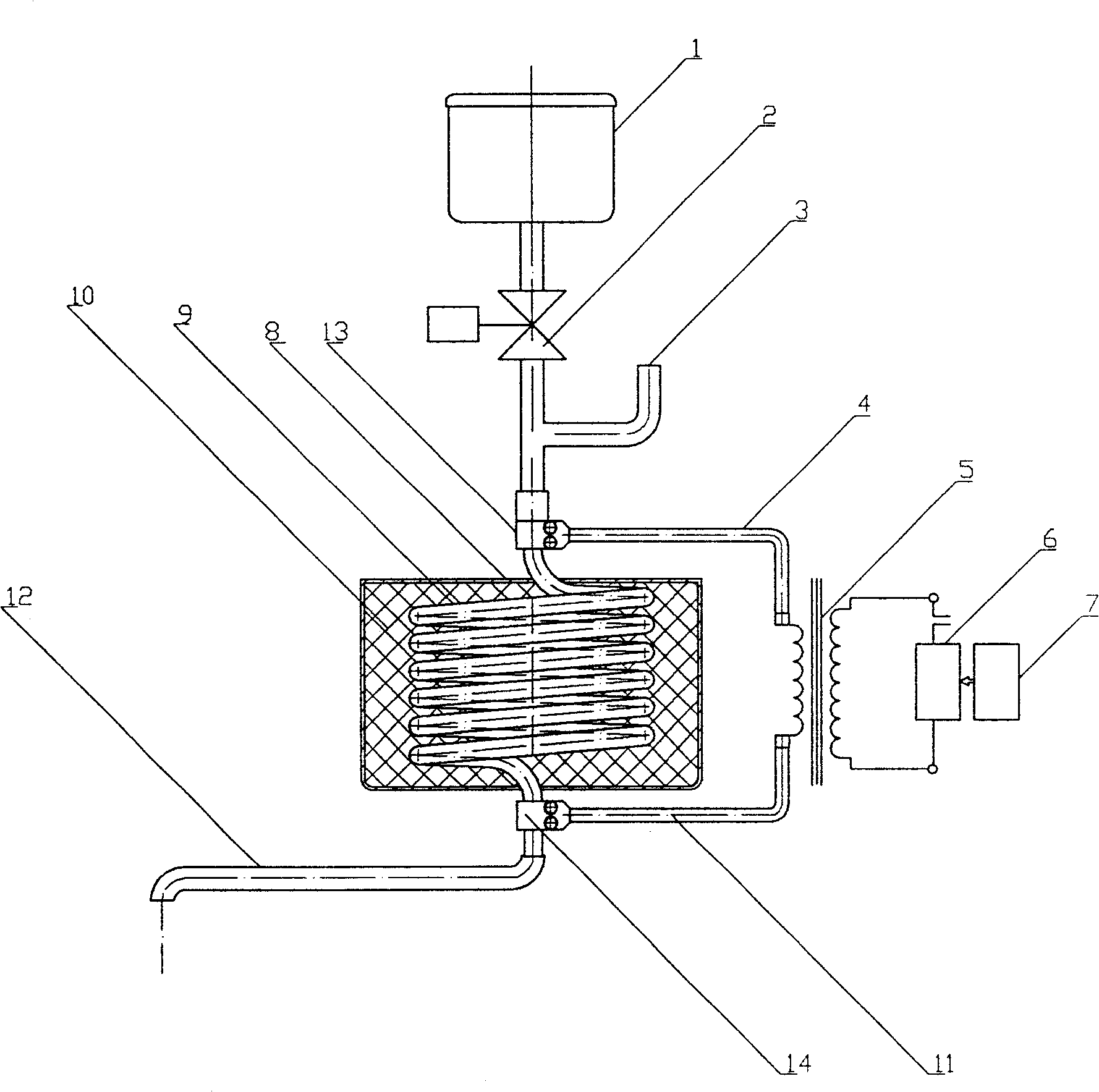

Beverage heating method and heater

InactiveCN101073475AAvoid reheatingReduce consumptionStorage heatersBeverage vesselsThermal energyEngineering

The invention is concerned with a kind of heating method for beverage. Heat the heating stored part to advanced temperature to store heat, send lower liquid through sending pipe and guide the liquid passing through the heating stored part to heat the low temperature liquid, and the low temperature liquid has been stored before sent, and at least, send the heated liquid out. This invention also opens the equipment to heat beverage. It relates to server unit of liquid, heating stored part, sending switch of liquid, control unit and sending pipe. The server unit of liquid connects with heating pipe through sending pipe, and heating pipe is inside of the heating stored part. The heating stored part stores heating at first to maintain the advanced temperature. The controller unit has at least one sensor of temperature to check the temperature of heating stored part. The sending switch of liquid controls the open and close of sending pipe, guides the low temperature liquid passing through the sending pipe to be heated.

Owner:YEN SUN TECH CORP

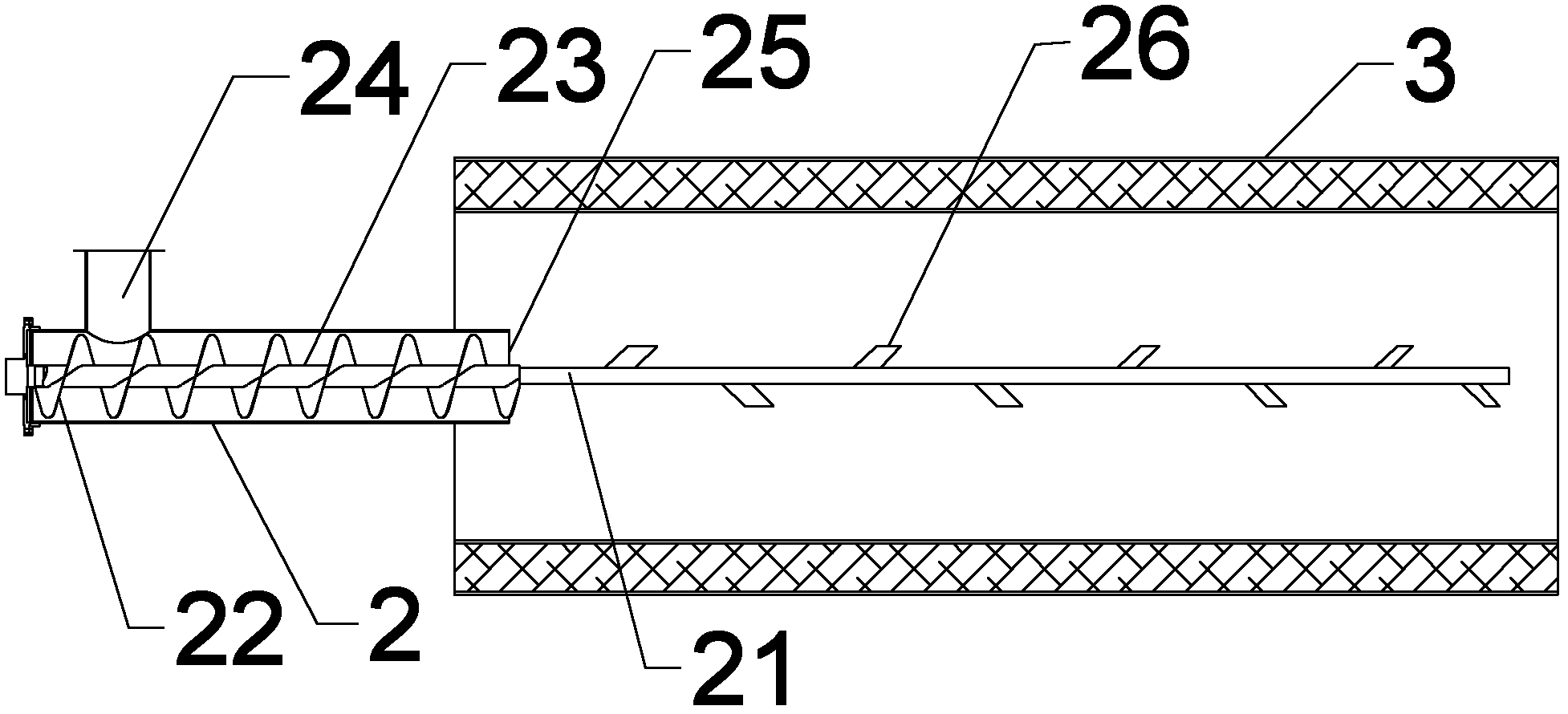

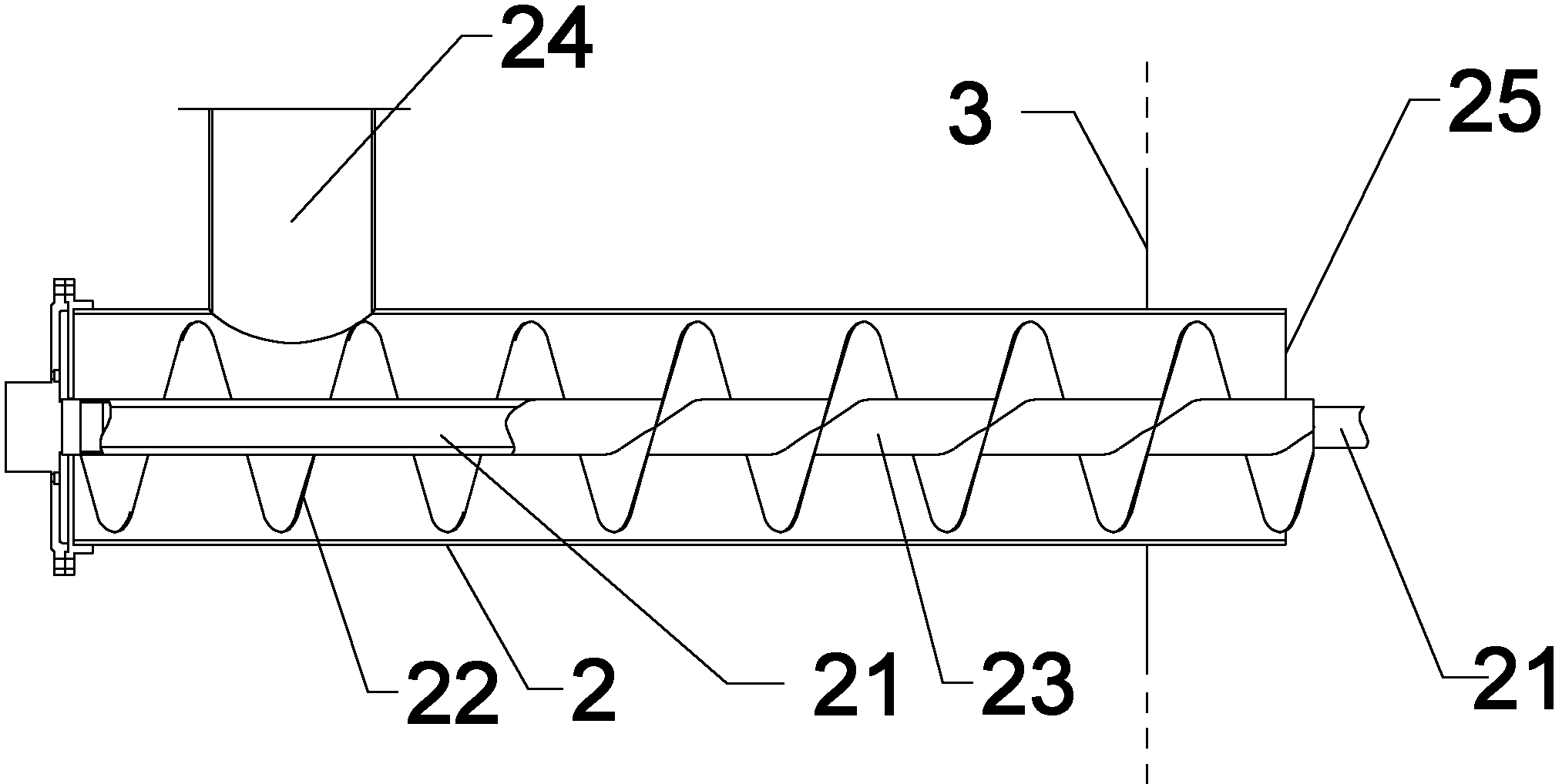

Processing method for supra-macromolecule polyethylene composite pipe

ActiveCN103587121AImprove wear resistanceGood self-lubricating performanceAntioxidantAging resistance

The invention discloses a processing method for a supra-macromolecule polyethylene composite pipe. The processing method comprises the following steps of (1) uniformly mixing supra-macromolecule polyethylene resin, graphite, polyethylene wax and an antioxidant which serve as raw materials, adding the uniformly mixed raw materials into a material barrel of a screw extruder, and manufacturing a pipe with the same shape as that of a neck mold with a certain shape through the neck mold on the screw extruder under the rotary extrusion action of a screw, wherein the pipe passes through a sizing device and a cooling device and is cooled to be hardened and sized by a water-oil cooling mode; continuously and uniformly leading out a product during cooling after a product plastic piece is extruded from the neck mold, cutting the cooled and sized product through a cutting device, and inspecting the cut product, wherein the qualified product is a supra-macromolecule polyethylene pipe; (2) cutting and posttreating the supra-macromolecule polyethylene pipe, and putting the post-treated supra-macromolecule polyethylene pipe into a steel pipe to obtain the supra-macromolecule polyethylene composite pipe. According to the processing method, the technology is simple; the supra-macromolecule polyethylene composite pipe is easy to produce and manufacture; the manufactured pipe is high in abrasion resistance, self-lubrication property and intensity, stable in chemical property and high in aging resistance.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

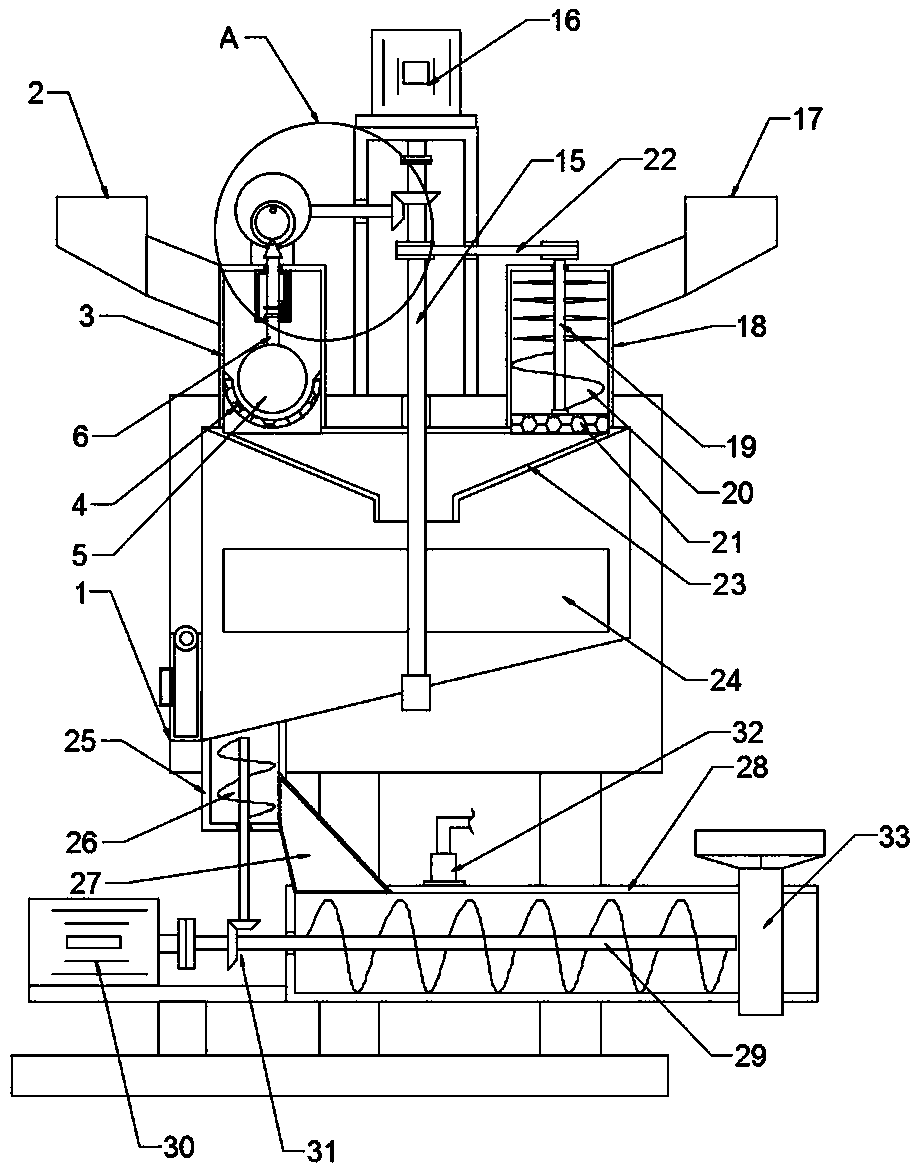

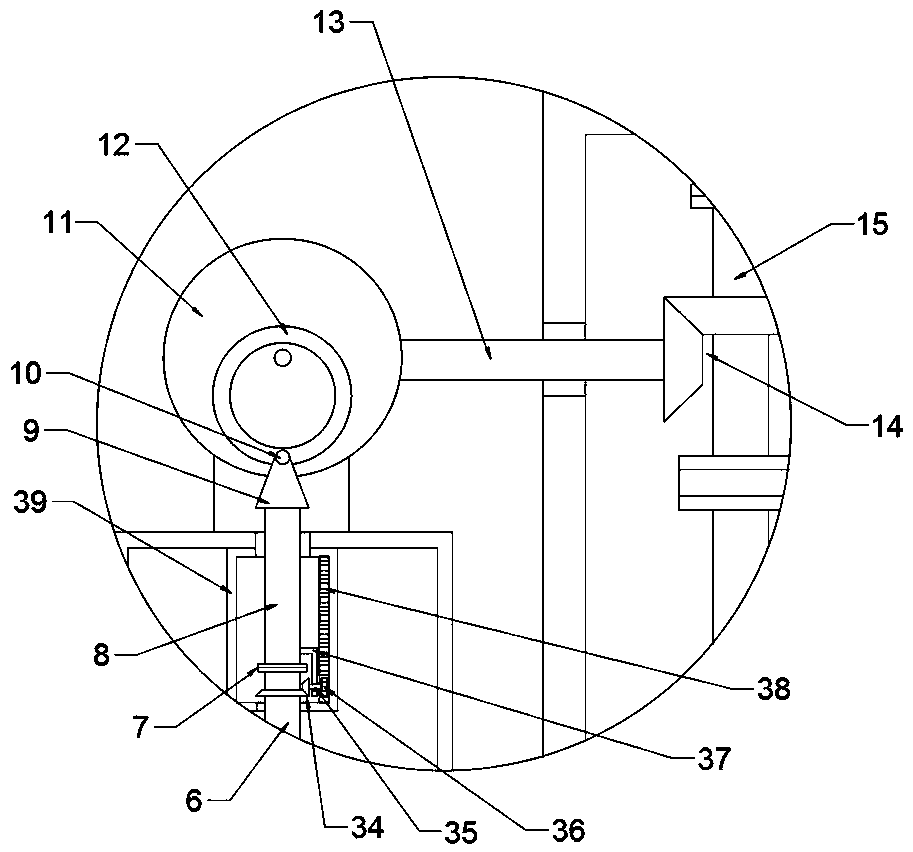

Fast water heater

InactiveCN101301167AAvoid reheatingImprove water qualityElectric heatingBeverage vesselsContactorHigher Power

The invention discloses a quick-heating water dispenser which is composed of a water tank, a solenoid valve, a three-way air-guide tube, a power transformer, an AC contactor, a temperature-control timer, a heat insulation case and a heating tube. A low voltage for power supply enables the heating tube in an instantaneous short circuit operating state, and the purified water flowing in the tube is heated quickly when instantaneous short circuit, thereby avoiding repeated heating of the water and improving the quality of the drinking water. The low voltage has an obvious effect on the electric safety of the electrical household appliance, and in contrast with the conventional water dispenser with high power consumption resulted from the repeated process of heating-cooling-reheating, and the water dispenser with a low voltage of the invention can realize energy saving.

Owner:邓梁

Method for sterilizing and filling liquid cereal product

A method for sterilizing and filling a liquid cereal product relates to a liquid cereal product. The invention provides the method for sterilizing and filling the liquid cereal product, which comprises the following steps: feeding liquid cereals from a material inlet, pumping the liquid cereals with a product pump into a preheating cooler for preheating; degassing the preheated liquid cereals, homogenizing the liquid cereals, and feeding the liquid cereals into a heater of an ultra-high-temperature sterilizer for primary heating; heating the homogenized and heated liquid cereals for the second time; heating the liquid cereals which is heated for the second time for the third time and keeping temperature; and after cooling the liquid cereals of which the temperature is kept with the cooler, cooling the liquid cereals in a preheating cooler of a sterilizer, reducing temperature with ice water, conveying the liquid cereals to an aseptic can, connecting the aseptic can to a filling machine, and performing aseptic filling on the liquid cereals. Because a sterilization temperature rise mode is changed to a four-section mode, namely preheating, primary heating, secondary heating and tertiary heating, the temperature difference between a medium and the material is kept constant and a scaling time can be effectively delayed to 4.6h.

Owner:XIAMEN HUIERKANG FOOD

Pig feed blending device for animal husbandry

ActiveCN110946299AFor subsequent mixingWell mixedFeeding-stuffGrain treatmentsAgricultural scienceAgricultural engineering

The invention discloses a pig feed blending device for animal husbandry. The device comprises a mixing box and a feed preprocessing device, wherein the feed preprocessing device comprises a breaking barrel used for grinding granulated feed, and a pulverization barrel used for pulverizing stalk feed; a grinding shell is arranged in the breaking barrel; a grinding ball is nested in the grinding shell; the upper end of the grinding ball is connected with a driving mechanism; and a pulverization blade roller is arranged in the pulverization barrel. The device is provided with the breaking barrel in which the grinding ball capable of vertically swirling and the grinding shell are arranged, and the pulverization barrel provided with the pulverization blade roller and a spiral lifting vane, and the granulated feed and the stalk fed are independently broken and pulverized so as to be convenient for subsequently mixing the feed. Meanwhile, a collection cover and a stirring plate are arranged, so that various types of feed are fully mixed. A material discharging barrel which communicates with a blanking pipe internally nested with a spiral blanking roller and also communicates with a hot water pipe is arranged, a purpose that the feed can be immediately used while the feed is blended is realized, the feed prevents from being repeatedly heated, and feed waste is avoided while energy is saved.

Owner:安徽省快乐农牧科技股份有限公司

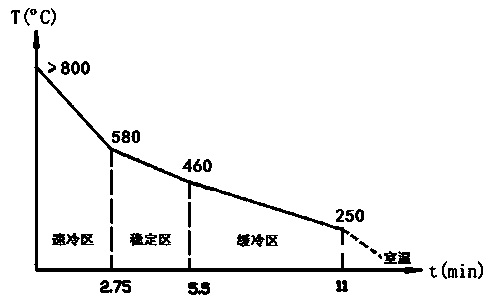

Controllable cooling method for high-pressure common rail

ActiveCN104178613AAvoid reheatingIncreased process stabilityFurnace typesHeat treatment furnacesLogistics managementIndustrial engineering

The invention relates to a controllable cooling method for a high-pressure common rail. The method is a thermal treatment method for a high-pressure common rail forge piece by utilizing forging waste heat, wherein the thermal treatment onto the high-pressure common rail forge piece is realized by virtue of controllable cooling in a quenching zone, a stable zone and a slow cooling zone; an inlet temperature of the high-pressure common rail forge piece is not lower than 800 DEG C and an outlet temperature of the high-pressure common rail forge piece is not higher than 250 DEG C. By virtue of the controllable cooling method disclosed by the invention, a thermal processing process and a physical metallurgical process for improving material performances are organically combined to avoid secondary heating of a thermal treatment process; and moreover, the process stability is high and the energy resource consumption is remarkably saved; not only is a reasonable metallographic texture guaranteed to enable the obtained high-pressure common rail to have good comprehensive mechanical performances, but also the energy consumption is remarkably lowered, the logistics cost is reduced, the producing and manufacturing period is shortened, and the production cost is greatly lowered.

Owner:SHANDONG JINMA INDAL GROUP

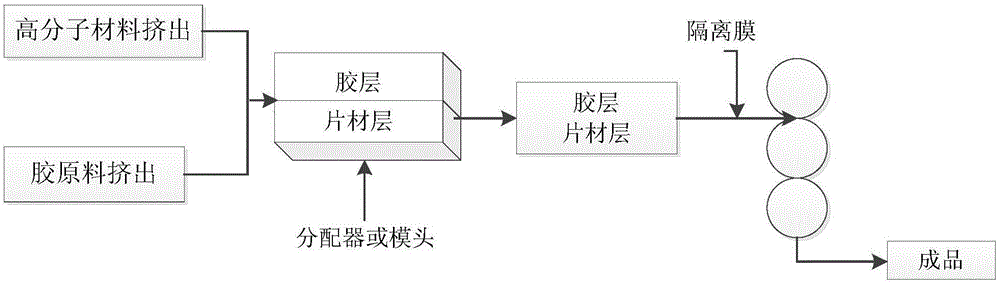

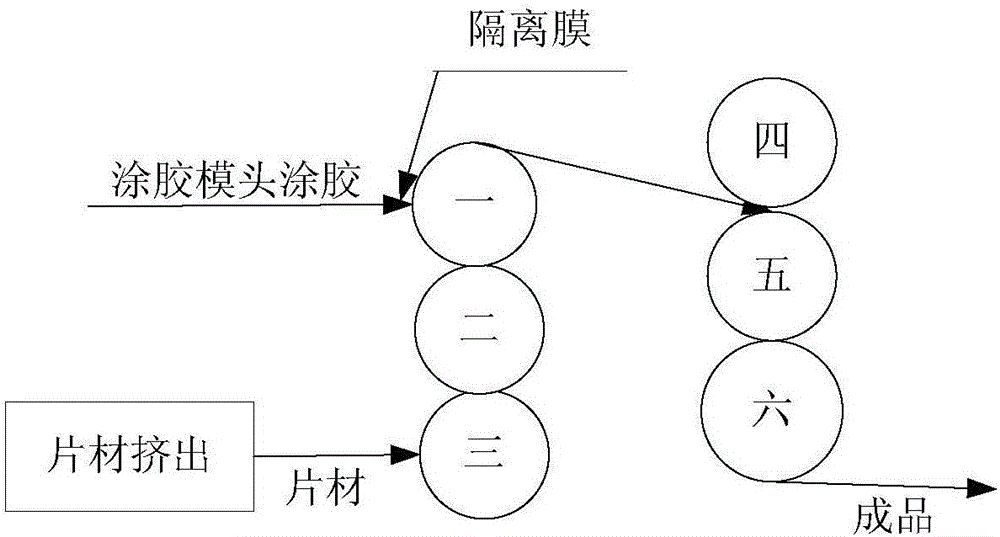

Integrated forming technology of macromolecular sheet production and gluing

InactiveCN106393750AAvoid reheatingReduce energy consumptionFlat articlesThermal stateContinuous production

The invention relates to gluing technologies of macromolecule co-mixing forming machines, and discloses an integrated forming technology of macromolecular sheet production and gluing. The technology comprises the steps of material mixing, extrusion of raw materials of macromolecules and glue, co-extrusion, direct coating of isolating membranes, and the like. According to the technology, sheet production and gluing are integrated, the production technology process is greatly simplified, a three-roll calendaring device, a traction and winding device and an unwinding device are decreased, a sheet and glue are compounded in the thermal state, the sheet and the glue are bonded more firmly and do not separate from each other, secondary heating of the glue is avoided, the energy consumption is reduced, the resources are saved, the labor cost is reduced, the controllability of the production steps is strengthened, the performance of a produced coiled material is higher, the continuous production can be achieved, and the stability is higher.

Owner:QINGDAO KEHUA M M M

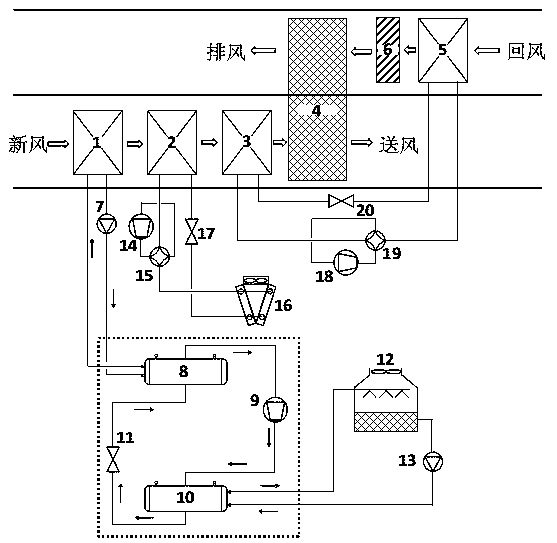

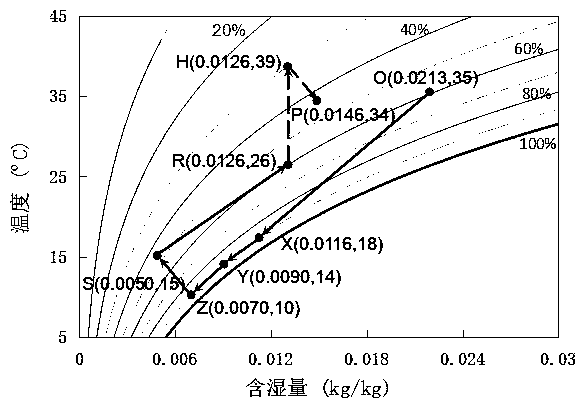

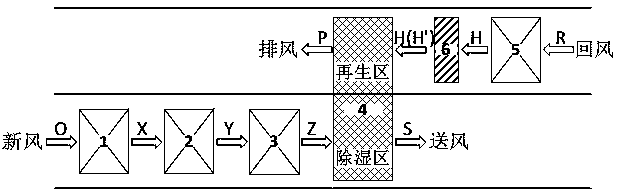

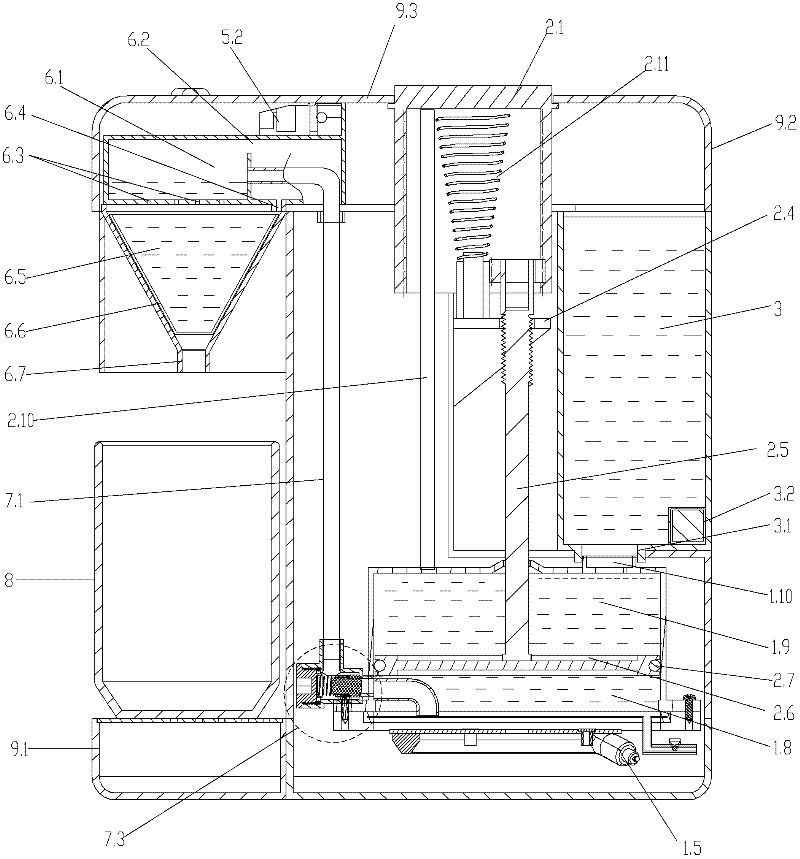

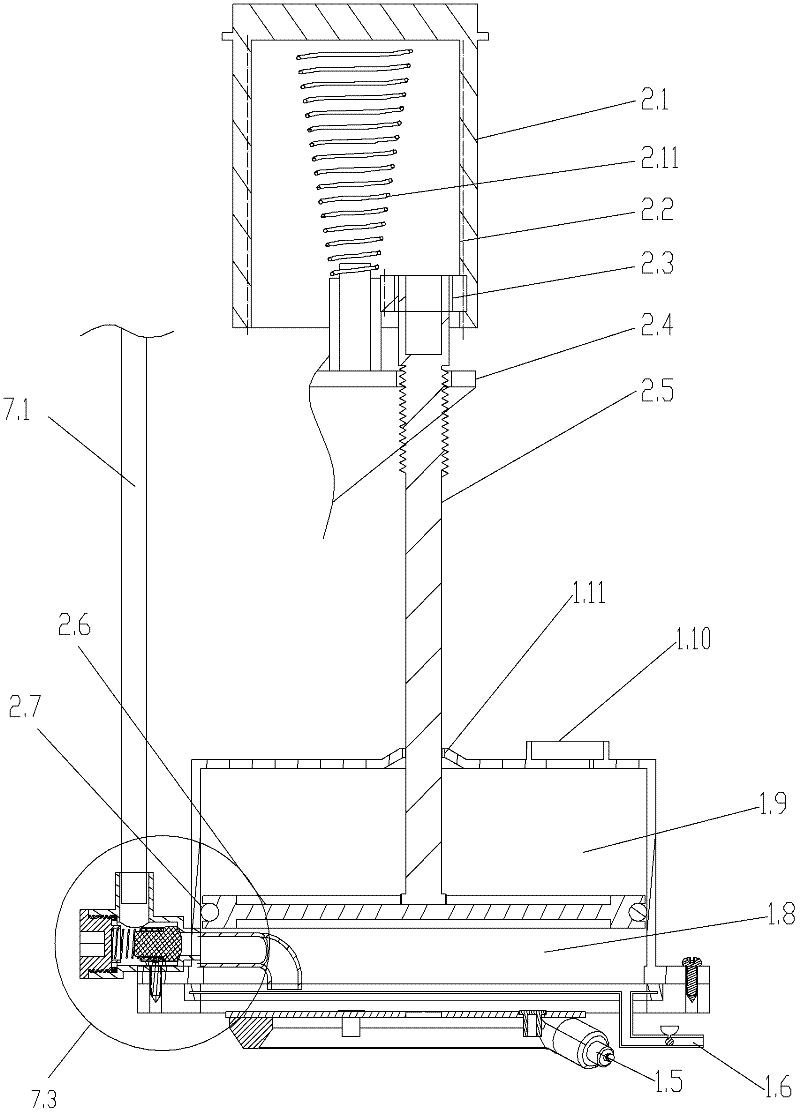

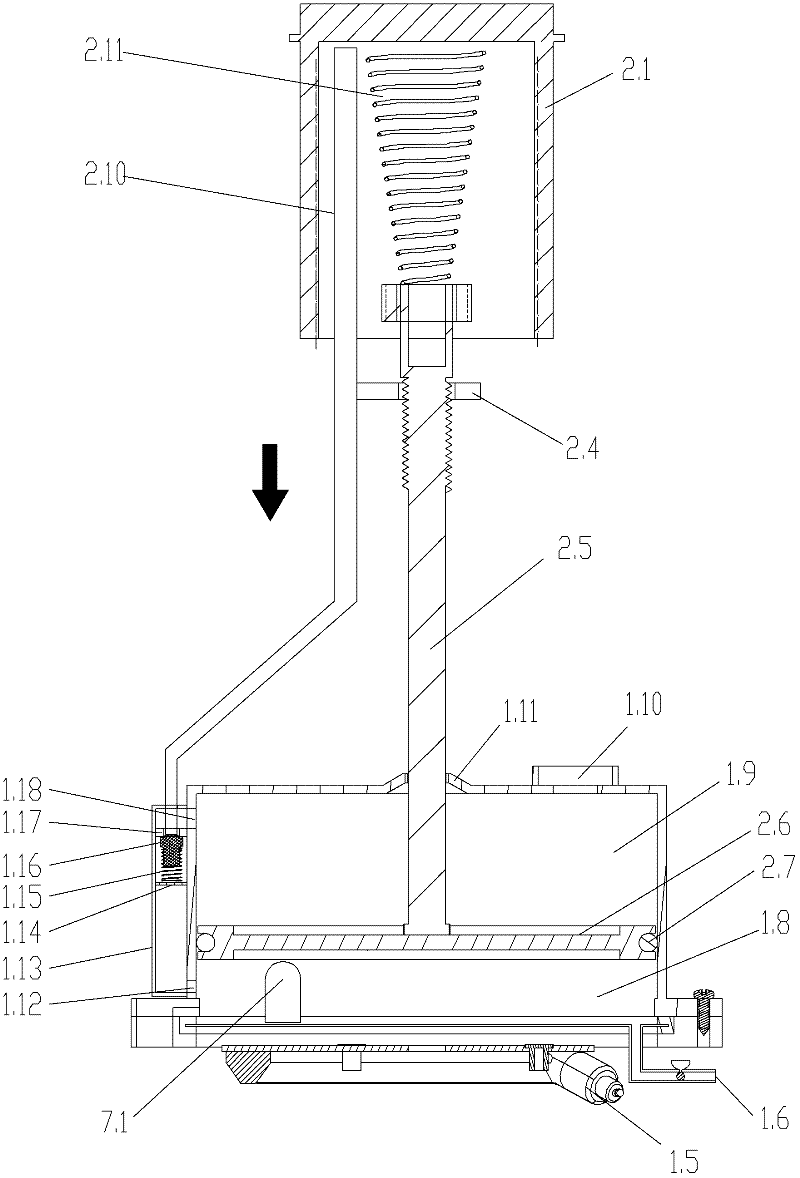

Pre-cooling type rotating wheel humidity adjusting fresh air processing device

ActiveCN110173776AAvoid reheatingIncrease temperatureAir treatment detailsLighting and heating apparatusCooling towerFresh air

The invention discloses a pre-cooling type rotating wheel humidity adjusting fresh air processing device. The fresh air processing device comprises a water cooling type water chilling unit, an air-cooled heat pump type unit, a sensible heat recovery unit and a rotating wheel type solid adsorption dehumidification device which are sequentially arranged; and the water cooling type water chilling unit comprises a water cooling type water chilling unit evaporator, a water cooling type water chilling unit compressor, a water cooling type water chilling unit condenser, a water cooling type water chilling unit throttle valve, a water cooling type water chilling unit fan coil and a cooling tower which are sequentially connected in the circulation direction of a refrigerant, wherein the water cooling type water chilling unit fan coil is connected to the chilled water outlet end and the chilled water inlet end of the water cooling type water chilling unit evaporator, and the cooling tower is connected to the cooling water outlet end and the cooling water inlet end of the water cooling type water chilling unit condenser. According to the fresh air processing device, regeneration air is preheated by utilizing discharged heat of the condenser in summer, so that the energy consumption caused by regenerated heat provided by an electric heater is reduced or avoided; and humidification air is pre-cooled by utilizing absorbed heat of the evaporator in winter, so that a return air cooling device is removed, and the energy efficiency of the fresh air processing device is improved.

Owner:SOUTHEAST UNIV

Production process of nanometer modified superhigh-molecular-weight polyethylene wear-resisting pipe

The invention discloses a production process of a nanometer modified superhigh-molecular-weight polyethylene wear-resisting pipe, comprising the steps of (1) preparing raw materials in mass percentage, uniformly mixing 74-90% of superhigh-molecular-weight polyethylene resin, 3-5% of nanometer laminated silicate, 2-8% of Si3N4, 3-10% of polyethylene wax and 2-3% of graphite; (2) adding material, performing reacting, extruding and molding; (3) cooling, shaping and drawing; (4) cutting; (5) post treating. The flowing property of the superhigh-molecular-weight polyethylene is improved due to the adding of nanometer laminated silicate and Si3N4, so that the mechanical property of the product is improved and the wear resistance of the product can be improved by more than 40%.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

Quick drink making machine

InactiveCN102362782AFast heatingSolve the defect that the amount of water to be heated cannot be freely setBeverage vesselsElectricityAgricultural engineering

The invention discloses a quick drink making machine which comprises a shell, a water tank arranged in the shell, a heating assembly, a filtering basket, a water manifold, a pressure valve and a volume control mechanism, wherein the heating assembly comprises heating pot body and a heater; the volume control mechanism comprises a water level adjustment plate, a transmission rod, a fixing frame arranged on the shell and an adjustment mechanism, wherein the water level adjustment plate is a piston type adjustment plate arranged in the heating pot body and can move up and down horizontally; the water level adjustment plate is connected with the lower end of the transmission rod, the transmission rod vertically penetrates out of the heating pot body, then is in threaded connection with the fixing frame, and penetrates out of the fixing frame and extends into the adjustment mechanism above the fixing frame, and the transmission rod is controlled by the adjustment mechanism to rotate. Based on a lower cost, the drink making machine can be used for realizing the purpose of setting the quality of water to be heated freely and boiling water quickly, and the defects that repeat heating of boiled water and power waste can be overcome, and users can be ensured to be supplyed with high-quality hot water.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

Drinking water supply device and water dispenser

PendingCN106473604AReduce power consumptionPrevent mixed (yin-yang-water) situationsBeverage vesselsPipingHigh energy

The invention provides a drinking water supply device and a water dispenser, and relates to the technical field of water dispensers. The drinking water supply device comprises a control circuit, and a heating tank, a hot water tank and a cold water tank which are sequentially connected serially and communicated, wherein a first electromagnetic valve is arranged on a water inlet pipe; a flow meter and a second electromagnetic valve are sequentially arranged between the heating tank and the hot water tank; a third electromagnetic valve is arranged between the hot water tank and the cold water tank; a heating tank temperature sensor, an upper heating tank liquid level sensor and a lower heating tank liquid level sensor are arranged inside the heating tank; a heating device for heating for the heating tank is arranged on the outer part of the heating tank; a hot water tank temperature sensor and a hot water tank liquid level sensor are arranged inside the hot water tank. The technical problems that the conventional drinking water supply device may produce repeatedly boiling water and mixed water of unboiled water and boiled water, which damages human health, causes high energy consumption and brings inconvenience to use, are solved; the drinking water supply device can ensure better drinking water quality and achieves a technical effect of convenience in use.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

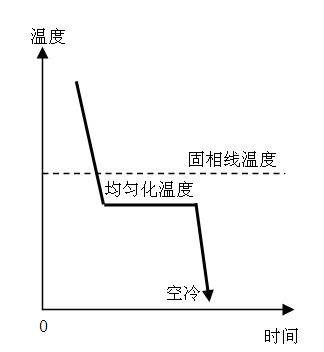

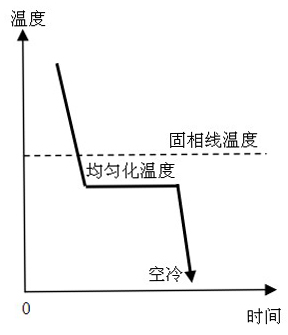

Homogenizing treatment method for strengthening Al-Zn-Mg-Cu series ultrahigh strength aluminum alloy

The invention provides a homogenizing treatment method for strengthening a Al-Zn-Mg-Cu series ultrahigh strength aluminum alloy, which comprises the following steps of: when the melt of the Al-Zn-Mg-Cu series ultrahigh strength aluminum alloy is subjected to metal mold casting, putting the alloy into a box-type resistance furnace for heat preservation after the temperature of the alloy is reduced to homogenizing treatment temperature below solidus temperature in a casting process, taking out and performing air cooling. The casting process and a heat treatment process are integrated, so that the problem caused by reheating and the improper control of heating rate is effectively solved, high supersaturation solid solubility can be achieved in short time, good organization foundations are laid for subsequent solid solution and ageing treatment, and the homogenizing heat preservation time is shortened at the same time.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

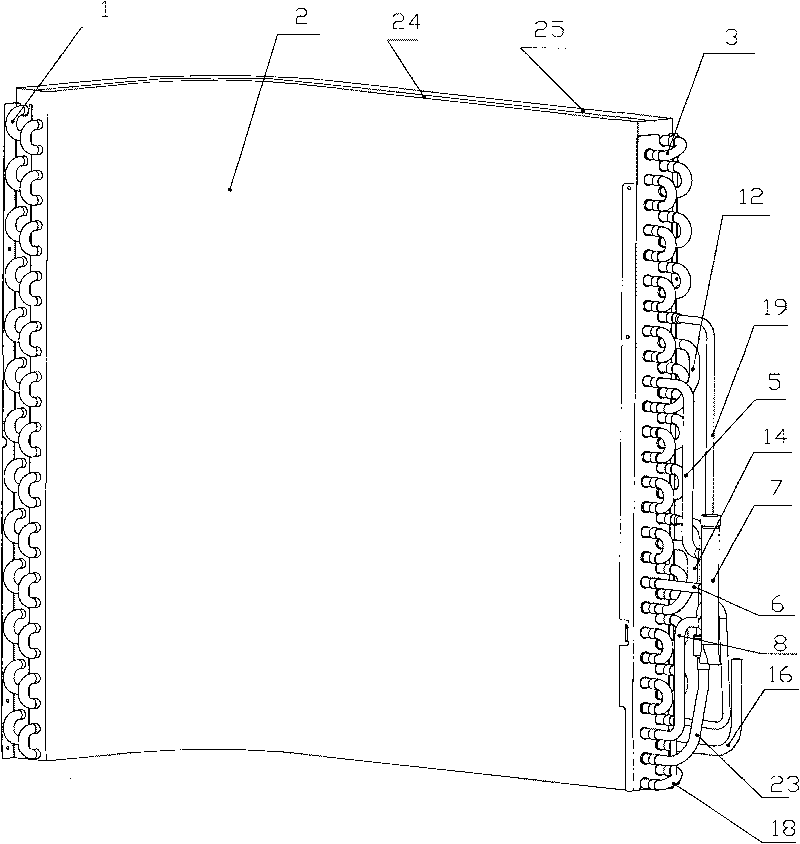

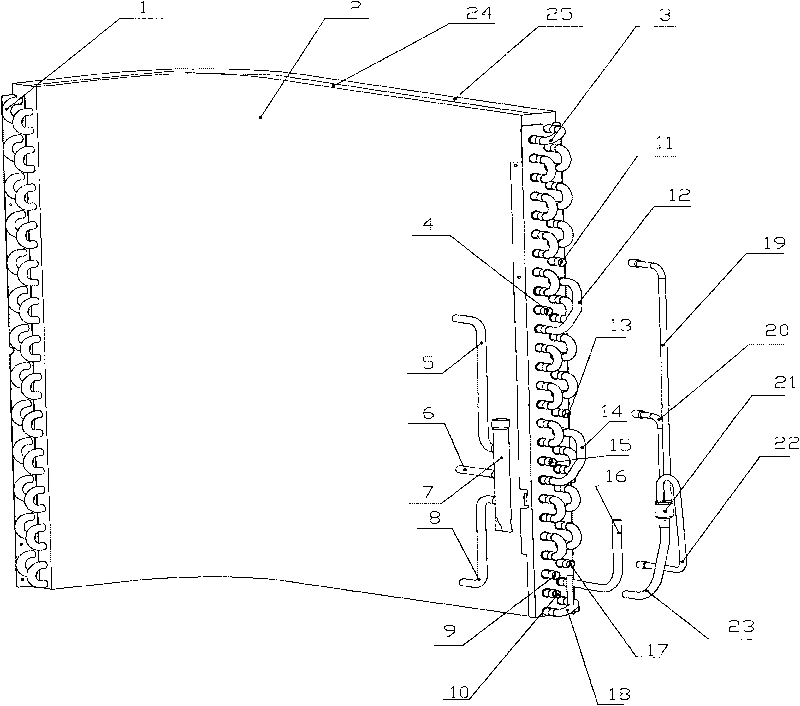

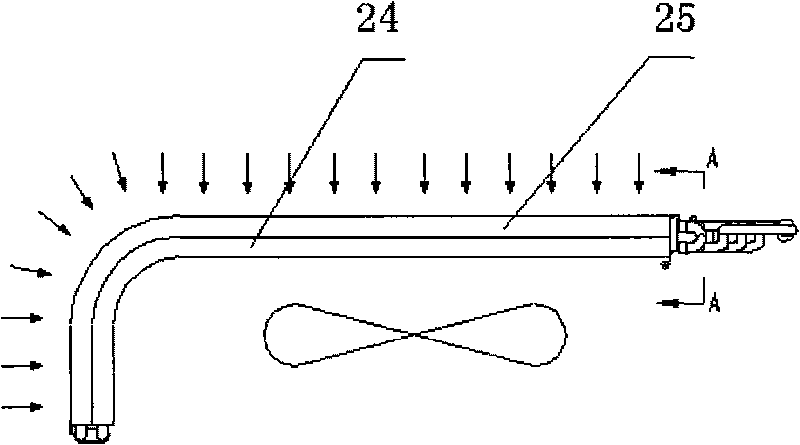

Heat exchanger of air conditioner with double rows of pipelines

InactiveCN101738012AImprove heat transfer coefficientAvoid reheatingEvaporators/condensersDouble rowRefrigerant

The invention relates to the technical field of the heat exchanger of an air conditioner, which provides a heat exchanger of an air conditioner with double rows of pipelines with a novel refrigerant procedure. The heat exchanger can enhance the efficiency of heat exchange simultaneously during refrigeration and heating. The heat exchanger divides a refrigerant into three paths to flow into the heat exchanger, all the three paths of refrigerants flow from the inner row of the heat exchanger and finally flow out from the outer row of the heat exchanger, a reversed U type layout is adopted, and full-range countercurrent heat exchange is realized; the design of a three-path refrigerant procedure considers the influence of gravity, adopts an unequal-range flow path and enhances the uniformity of the heat exchange of each path during refrigeration, thereby enhancing the heat exchange coefficient and the heat exchange quantity; and the invention adopts an unequal diameter design for a convergence pipe of the three paths, enhances the uniformity of the heat exchange of refrigeration, also distributes the flow rate of the refrigerant for heating finely and enhances the heat exchange coefficient and the heat exchange quantity of heating. The heat exchange efficiency of the heat exchanger is enhanced by about 10% in comparison with an original heat exchanger, and finally, the refrigeration energy efficiency (EER) and the heating energy efficiency (COP) of the complete machine are enhanced.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

Device and process for recycling methyl alcohol from gas field alcohol-containing sewage based on gas stripping process and vacuum membrane distillation process

ActiveCN106866368AShort processSimple processOrganic compound preparationWater contaminantsReboilerMembrane distillation

The invention relates to a device and a process for recycling methyl alcohol from gas field alcohol-containing sewage based on a gas stripping process and a vacuum membrane distillation process. A complex process route of performing gas stripping first to obtain a dilute methyl alcohol solution with fewer impurities and then concentrating the dilute methyl alcohol solution through vacuum membrane distillation is adopted. The device and the process have the beneficial effects that related equipment such as a complex rectifying tower, a reboiler and a reflux tank is not needed, so that equipment investment is greatly reduced; the integrated process does not generate methyl alcohol reflux, so that repeated heating of reflux and tower bottoms is avoided, raw materials are sufficiently heated by waste heat of a methyl alcohol product and tower bottom water; waste heat of raw materials heated at a gas-stripping section provides energy for phase change of vacuum membrane distillation, so that methyl alcohol recycling energy consumption is greatly reduced and economic benefits are improved; the problems that content of impurities of alcohol-containing sewage of the raw materials is relatively high and the solution pollutes the hydrophobic microporous membrane are avoided, and the service life of the membrane is prolonged; the gas stripping process and the vacuum membrane distillation composite process are integrated, so that recycling efficiency is improved, and content of methyl alcohol in alcohol-containing sewage is reduced.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com