Continuous casting-cross-wedge rolling forming method for double-metal-layer composite hollow shaft without stub bars

A double-metal layer and hollow shaft technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of unfavorable automatic production and low work efficiency, and achieve large-scale industrial production, easy operation, and crystal grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

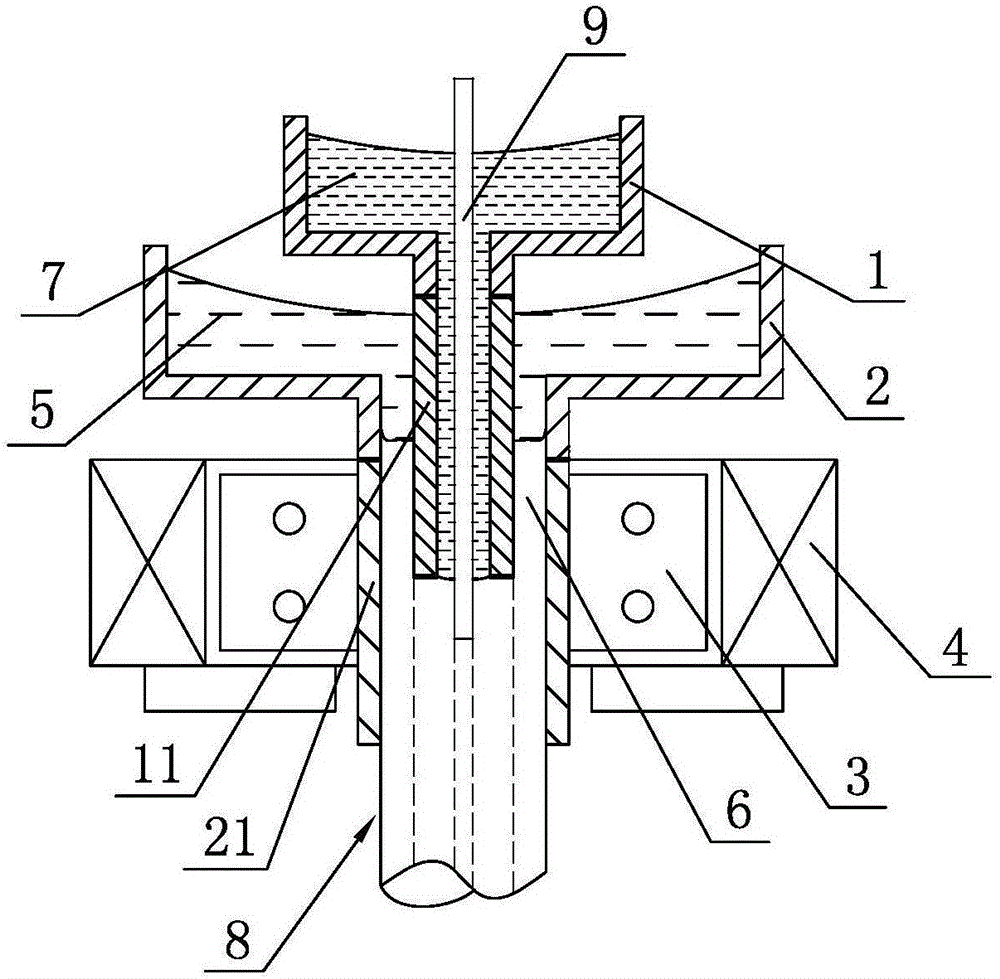

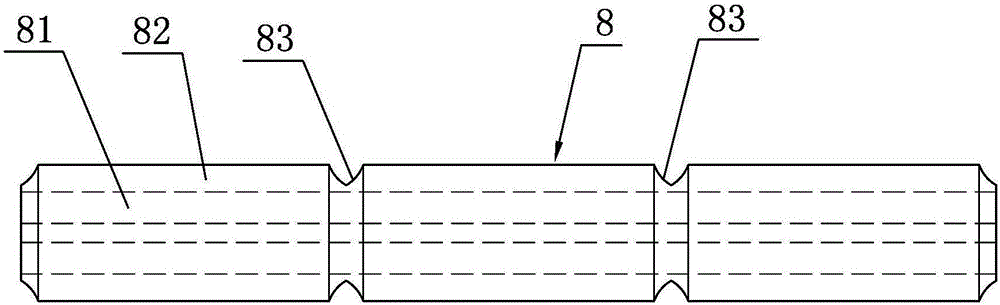

[0024] Embodiment 1: A continuous casting-cross-wedge rolling forming method of double-metal layer composite hollow shaft without head, the continuous casting device used in this method includes base tundish 1, cladding tundish 2, spacer rod 9, Cooling the crystallizer 3 and the electromagnetic stirrer 4, the lower end of the base tundish 1 is fixedly provided with a base pouring pipe 11, the lower end of the cladding tundish 2 is fixedly provided with a cladding pouring pipe 21, and the base pouring pipe 11 is coaxially arranged on the cladding In the pouring tube 21, the spacer rod 9 is coaxially arranged in the base pouring tube 11 and passes through the base pouring tube 11 downwards, the cooling crystallizer 3 is coaxially fixed on the coating pouring tube 21, and the electromagnetic stirrer 4 is coaxially installed on the pouring tube 21. On cooling crystallizer 3, the concrete processing step of this method is:

[0025] (1) Add the cladding molten steel 5 made of Q235 i...

Embodiment 2

[0032] Embodiment 2: A continuous casting-cross-wedge rolling forming method of double-metal layer composite hollow shaft without tip, the continuous casting device used in this method includes base tundish 1, cladding tundish 2, spacer rod 9, Cooling the crystallizer 3 and the electromagnetic stirrer 4, the lower end of the base tundish 1 is fixedly provided with a base pouring pipe 11, the lower end of the cladding tundish 2 is fixedly provided with a cladding pouring pipe 21, and the base pouring pipe 11 is coaxially arranged on the cladding In the pouring tube 21, the spacer rod 9 is coaxially arranged in the base pouring tube 11 and passes through the base pouring tube 11 downwards, the cooling crystallizer 3 is coaxially fixed on the coating pouring tube 21, and the electromagnetic stirrer 4 is coaxially installed on the pouring tube 21. On cooling crystallizer 3, the concrete processing step of this method is:

[0033] (1) Add the cladding molten steel 5 made of 45# ste...

Embodiment 3

[0040] Embodiment 3: A continuous casting-cross-wedge rolling forming method of double-metal layer composite hollow shaft without head, the continuous casting device used in this method includes base tundish 1, cladding tundish 2, spacer rod 9, Cooling the crystallizer 3 and the electromagnetic stirrer 4, the lower end of the base tundish 1 is fixedly provided with a base pouring pipe 11, the lower end of the cladding tundish 2 is fixedly provided with a cladding pouring pipe 21, and the base pouring pipe 11 is coaxially arranged on the cladding In the pouring tube 21, the spacer rod 9 is coaxially arranged in the base pouring tube 11 and passes through the base pouring tube 11 downwards, the cooling crystallizer 3 is coaxially fixed on the coating pouring tube 21, and the electromagnetic stirrer 4 is coaxially installed on the pouring tube 21. On cooling crystallizer 3, the concrete processing step of this method is:

[0041] (1) Add the cladding molten steel 5 of the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com