Quick drink making machine

A fast and beverage technology, applied in the field of devices for brewing beverages, can solve the problems of high manufacturing cost, discontinuous and intermittent, poor soaking effect, etc., and achieve the effects of avoiding repeated heating, increasing heating speed, and overcoming waste of electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

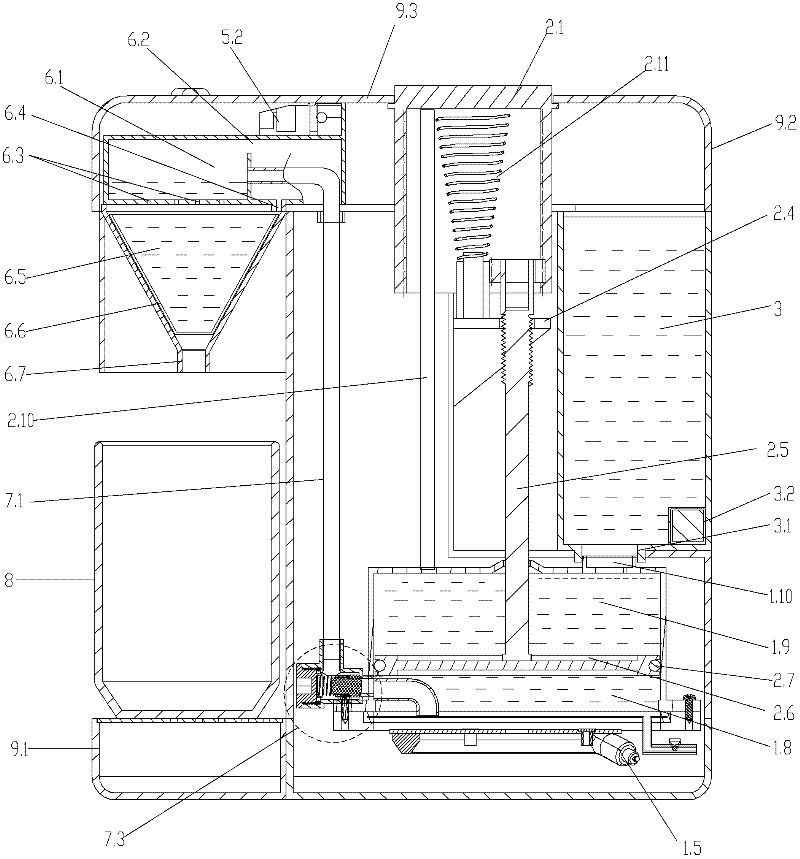

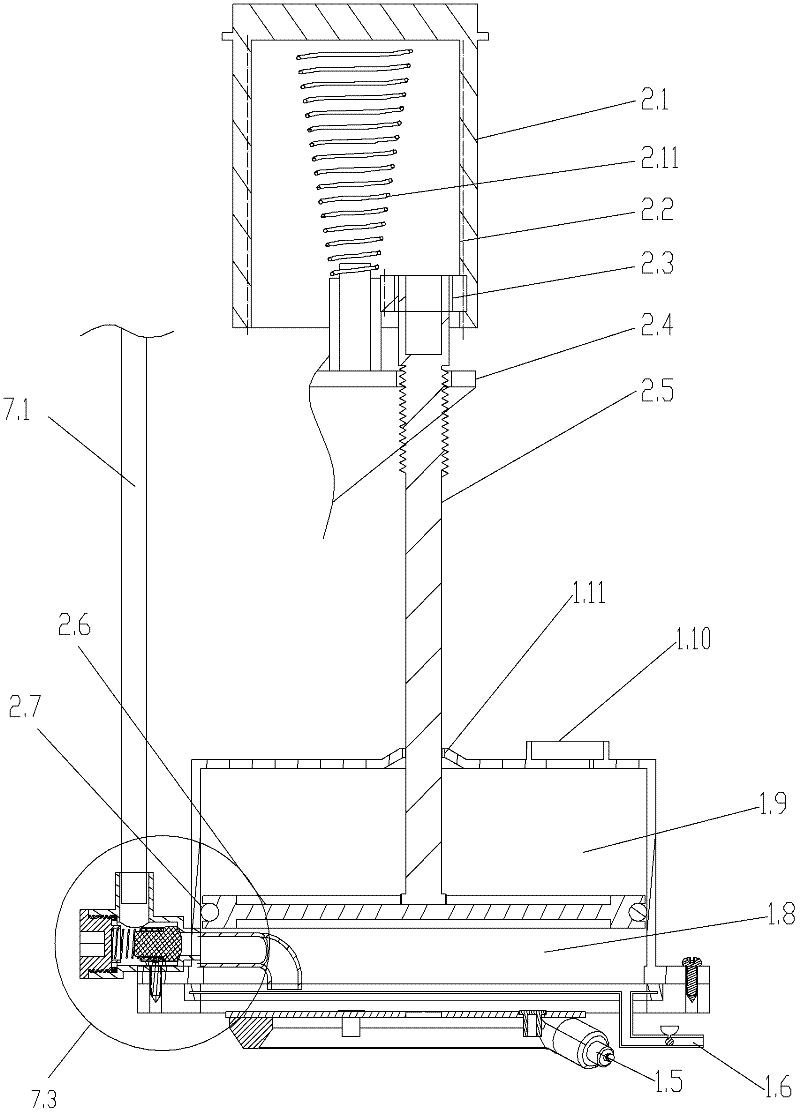

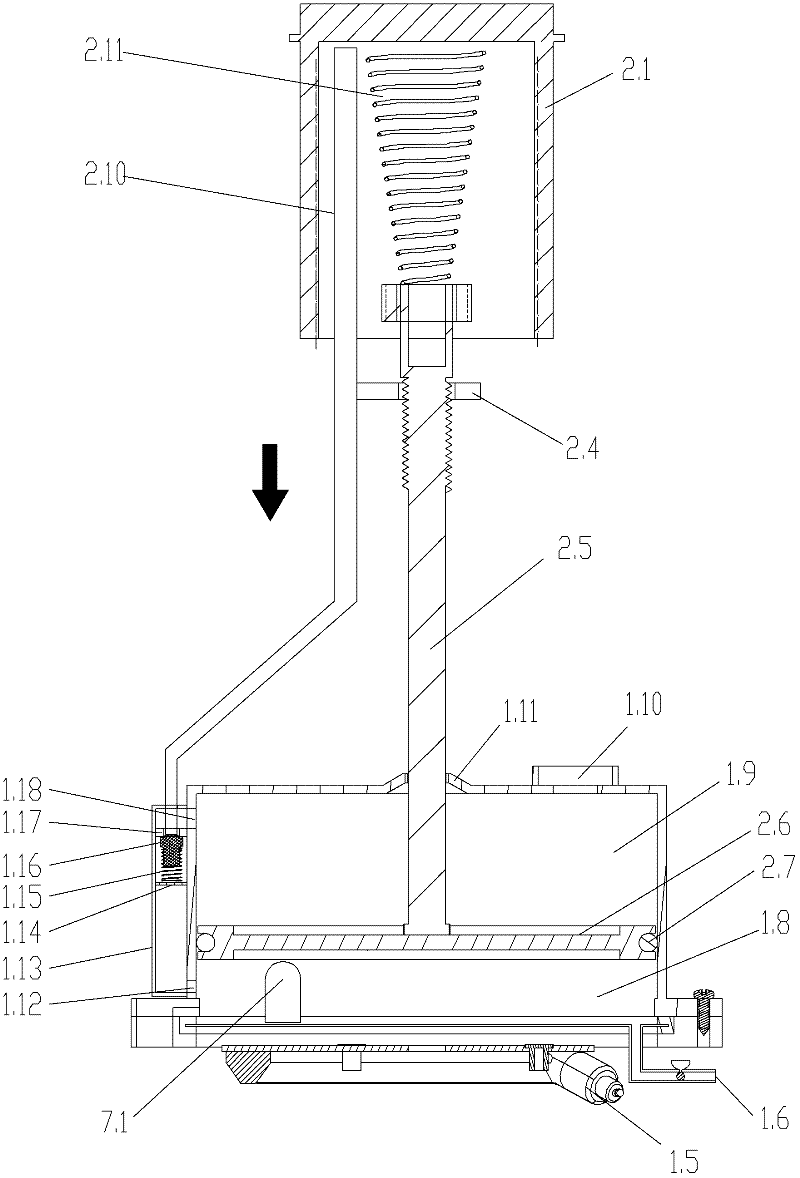

[0028] Figure 1 to Figure 4 The beverage rapid brewing machine shown is one of the embodiments of the present invention. The beverage rapid brewing machine includes a shell 9, a water tank 3 located in the brewing machine shell, a heating assembly, a filter basket, a water guide pipe 7.1, a pressure valve 7.3, a capacity control mechanism and a temperature controller 5.2. Wherein, the shell in this embodiment is composed of a base 9.1, a housing 9.2 and a top cover 9.3, and the heating assembly is composed of a heating pot and a heater.

[0029] Such as figure 2As shown, the capacity control mechanism is composed of an adjustment mechanism, a fixed frame 2.4, a transfer rod 2.5, a water level adjustment plate 2.6 and a sealing ring 2.7; In order to partition the heating pot body into an upper chamber 1.9 and a lower chamber 1.8, and change the volume of the upper and lower chambers; the water level adjustment plate 2.6 is connected to the lower end of the transfer rod 2.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com