Welding technology for longitudinal joints of pipe-plug type channel of composite-plate type air cooler

A welding process and composite plate technology, applied in welding equipment, manufacturing tools, metal processing and other directions, can solve the problems of low welding efficiency of electrode arc welding, affecting the corrosion resistance of cladding, large shrinkage and deformation of the tube box, etc., to avoid Effects of secondary heating, improved flaw detection efficiency, improved welding quality and corrosion resistance of clad groove welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

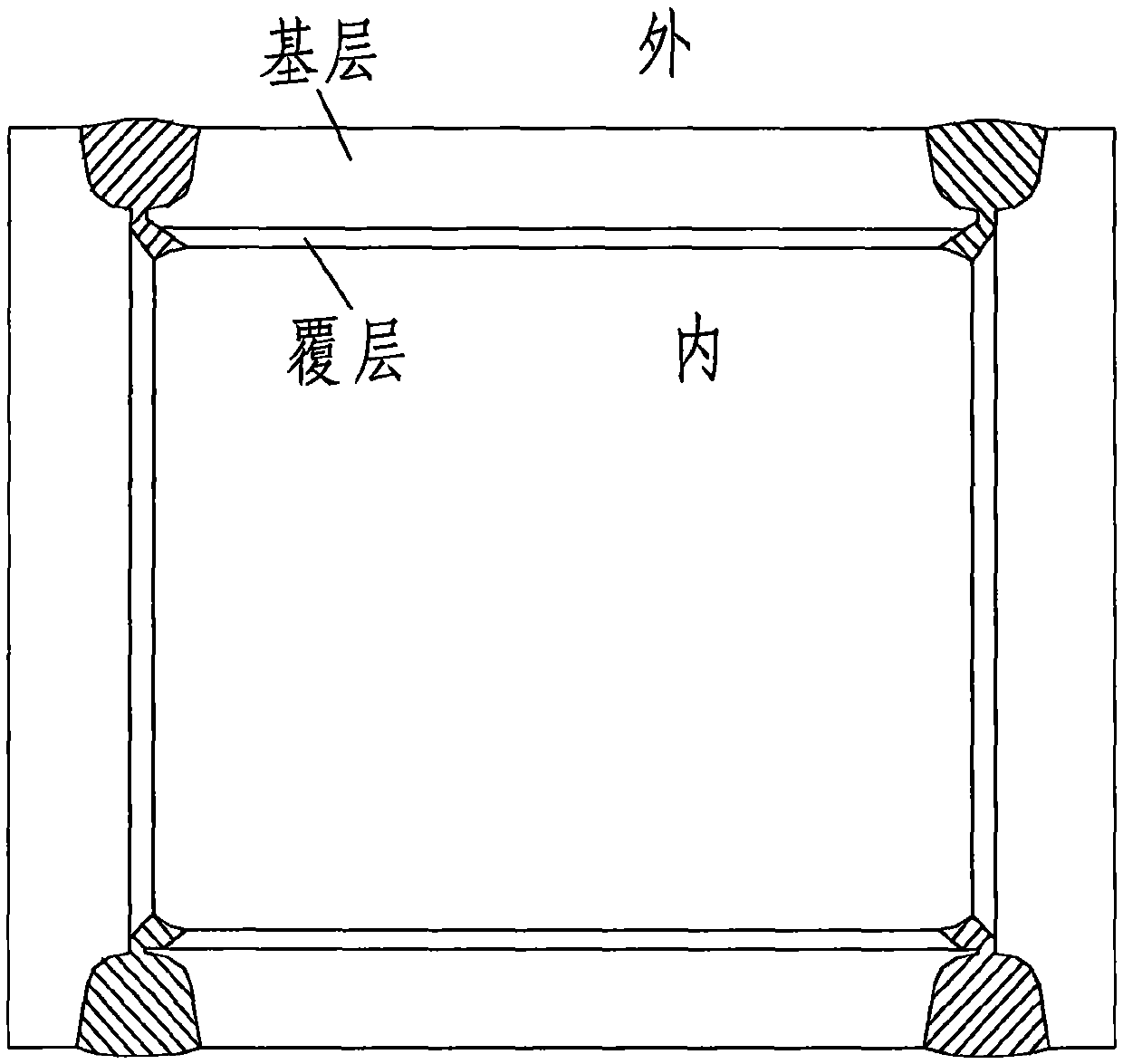

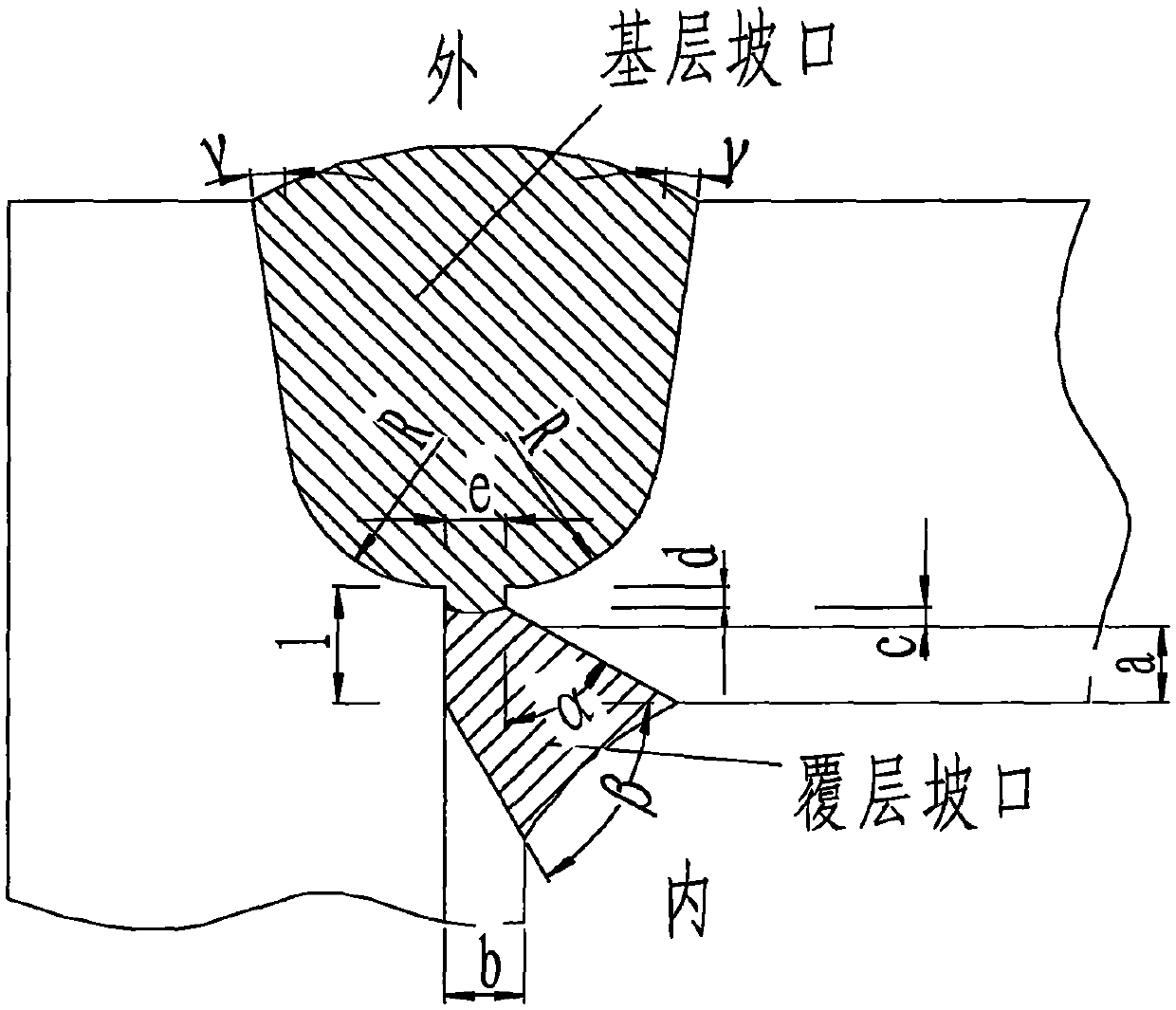

[0029] The material of the composite plate of the composite board pipe box is Q245R+S30408, the thickness is δ22+4mm, the section of the pipe box is square, the outer layer of the pipe box is the base layer, the thickness of the base layer is 22mm, the inner layer is the cladding layer, and the thickness of the cladding layer is 4mm. The longitudinal joints of the pipe box are formed between the two composite plates perpendicular to each other on the box, and the four corners of the pipe box form four longitudinal seams of the pipe box. The mouth is U-shaped or inverted U-shaped, and the cladding groove formed between the cladding layers of the two composite panels in the longitudinal joint of the pipe box is inclined V-shaped or inverted V-shaped;

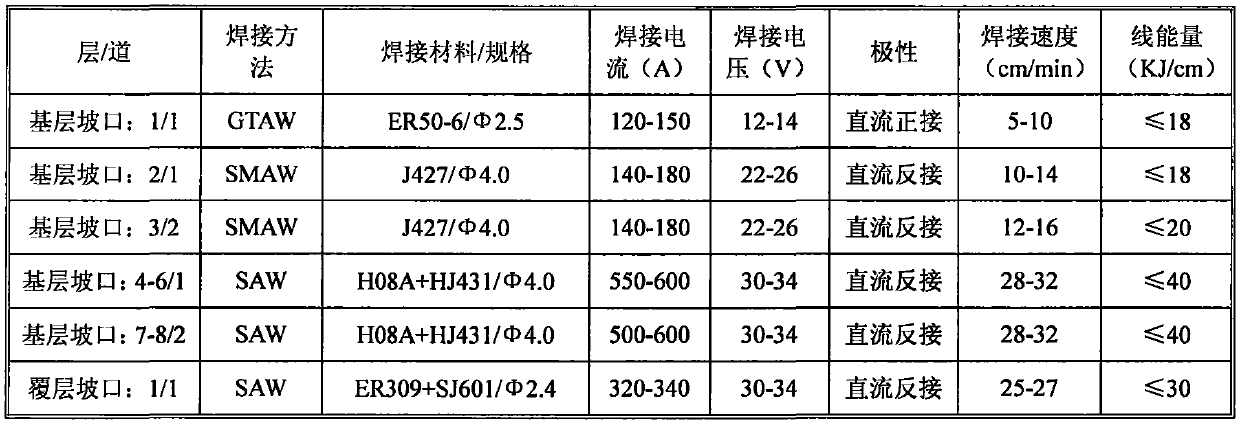

[0030] When welding, first weld the groove of the base layer, and then weld the groove of the cladding layer. First use argon arc welding to make a primer on the groove of the base layer, then fill the 2 layers with electrode arc w...

Embodiment 2

[0043] The material of the composite plate of the composite board pipe box is Q245R+S30408, the thickness is δ20+3mm, the section of the pipe box is square, the outer layer of the pipe box is the base layer, the thickness of the base layer is 20mm, the inner layer is the cladding layer, and the thickness of the cladding layer is 3mm. The longitudinal joints of the pipe box are formed between the two composite plates perpendicular to each other on the box, and the four corners of the pipe box form four longitudinal seams of the pipe box. The mouth is U-shaped or inverted U-shaped, and the cladding groove formed between the cladding layers of the two composite panels in the longitudinal joint of the pipe box is inclined V-shaped or inverted V-shaped;

[0044] When welding, first weld the groove of the base layer, and then weld the groove of the cladding layer. First use argon arc welding to make a primer on the groove of the base layer, then fill the 2 layers with electrode arc w...

Embodiment 3

[0058] The material of the composite plate of the composite board pipe box is Q345R+S30408, the thickness is δ22+4mm, the section of the pipe box is square, the outer layer of the pipe box is the base layer, the thickness of the base layer is 22mm, the inner layer is the cladding layer, and the thickness of the cladding layer is 4mm. The longitudinal joints of the pipe box are formed between the two composite plates perpendicular to each other on the box, and the four corners of the pipe box form four longitudinal seams of the pipe box. The mouth is U-shaped or inverted U-shaped, and the cladding groove formed between the cladding layers of the two composite panels in the longitudinal joint of the pipe box is inclined V-shaped or inverted V-shaped;

[0059] When welding, first weld the groove of the base layer, and then weld the groove of the cladding layer. First use argon arc welding to make a primer on the groove of the base layer, then fill the 2 layers with electrode arc w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com