Method for large well spacing in-situ conversion mining of shale oil and gas of medium and low maturity shale oil

A technology for shale oil and gas and shale oil, which is applied in the field of shale oil exploitation, can solve the problems that fracturing fractures cannot transmit hot steam, safety accidents, high temperature cracks in caprocks, etc., and achieves the effect of overcoming the problem of small well spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] This example provides a method for in-situ conversion and exploitation of shale oil and gas in shale oil with medium and low maturity with large well spacing. The organic carbon content (TOC, %) is 7%, and the vitrinite reflectance (RO, %) is 0.5;

[0080] Wherein, the method for in-situ conversion and exploitation of shale oil and gas with large well spacing of medium and low maturity shale oil includes:

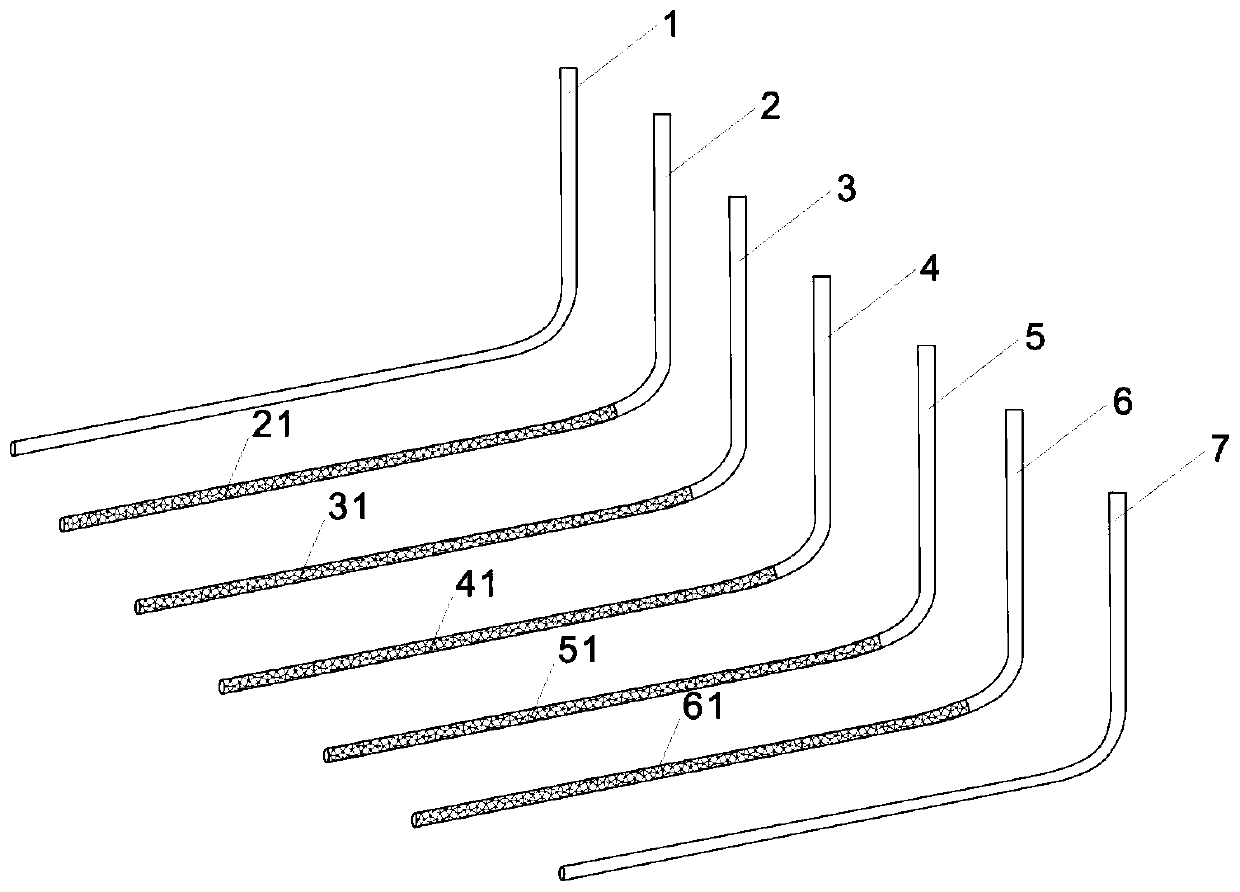

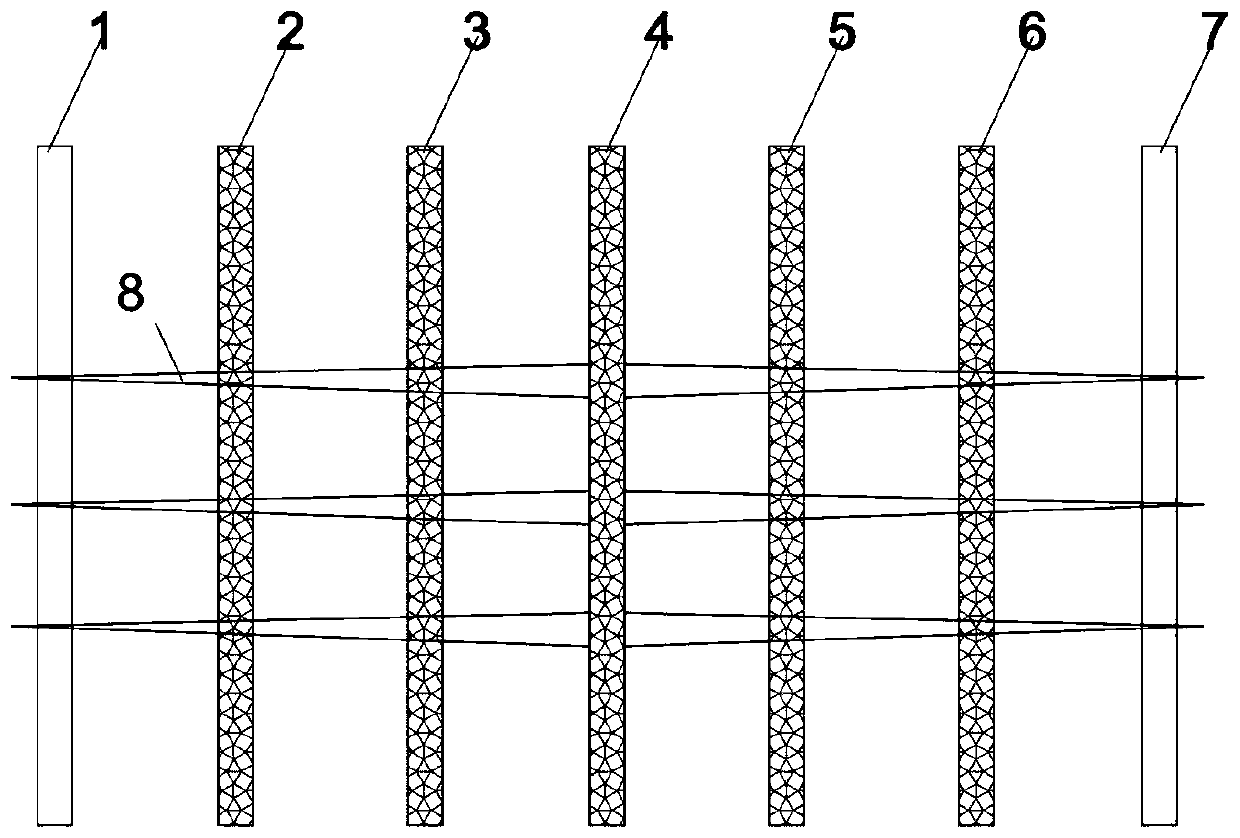

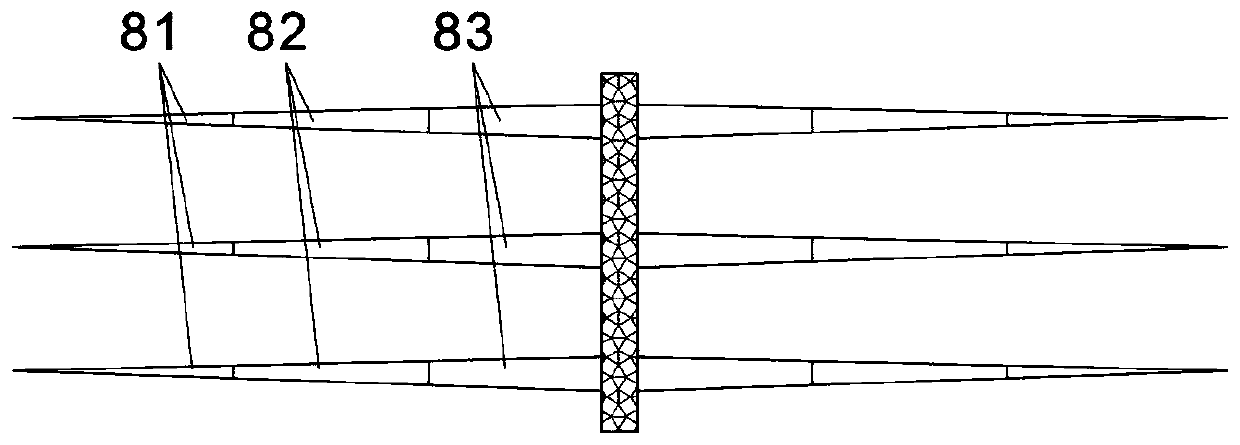

[0081] (1) In the above-mentioned low-medium maturity shale oil reservoirs, deploy 7 horizontal well groups with a well spacing of 15 meters and horizontal sections parallel to each other; the horizontal well located at the center of the horizontal well group is the central injection well 4. The two horizontal wells located at both ends of the central horizontal well group are the first production well 1 and the second production well 7; the wells between the first production well 1 and the second production well 7 and the central injection well 4 are respectively T...

Embodiment 2

[0095] This example provides a method for in-situ conversion and exploitation of shale oil and gas in shale oil with medium and low maturity with large well spacing. The organic carbon content (TOC, %) is 8%, and the vitrinite reflectance (RO, %) is 0.75;

[0096] Wherein, the method for in-situ conversion and exploitation of shale oil and gas with large well spacing of medium and low maturity shale oil includes:

[0097] (1) Deploy seven horizontal well groups with a well spacing of 35 meters in the above-mentioned low-medium maturity shale oil reservoirs, with horizontal sections parallel to each other; the horizontal well located at the center of the horizontal well group is the central injection well 4. The two horizontal wells located at both ends of the horizontal well group are the first production well 1 and the second production well 7; the wells between the first production well 1 and the second production well 7 and the central injection well 4 are respectively the ...

Embodiment 3

[0111] This example provides a method for in-situ conversion and exploitation of shale oil and gas in shale oil with medium and low maturity with large well spacing. The organic carbon content (TOC, %) is 10%, and the vitrinite reflectance (RO, %) is 1.0;

[0112] Wherein, the method for in-situ conversion and exploitation of shale oil and gas with large well spacing of medium and low maturity shale oil includes:

[0113] (1) Deploy seven horizontal well groups with a well spacing of 50 meters in the above-mentioned low-medium maturity shale oil reservoirs, with horizontal sections parallel to each other; the horizontal well located at the center of the horizontal well group is the central injection well 4. The two horizontal wells located at both ends of the horizontal well group are the first production well 1 and the second production well 7; the wells between the first production well 1 and the second production well 7 and the central injection well 4 are respectively the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com