Patents

Literature

67results about How to "Reduce carry out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

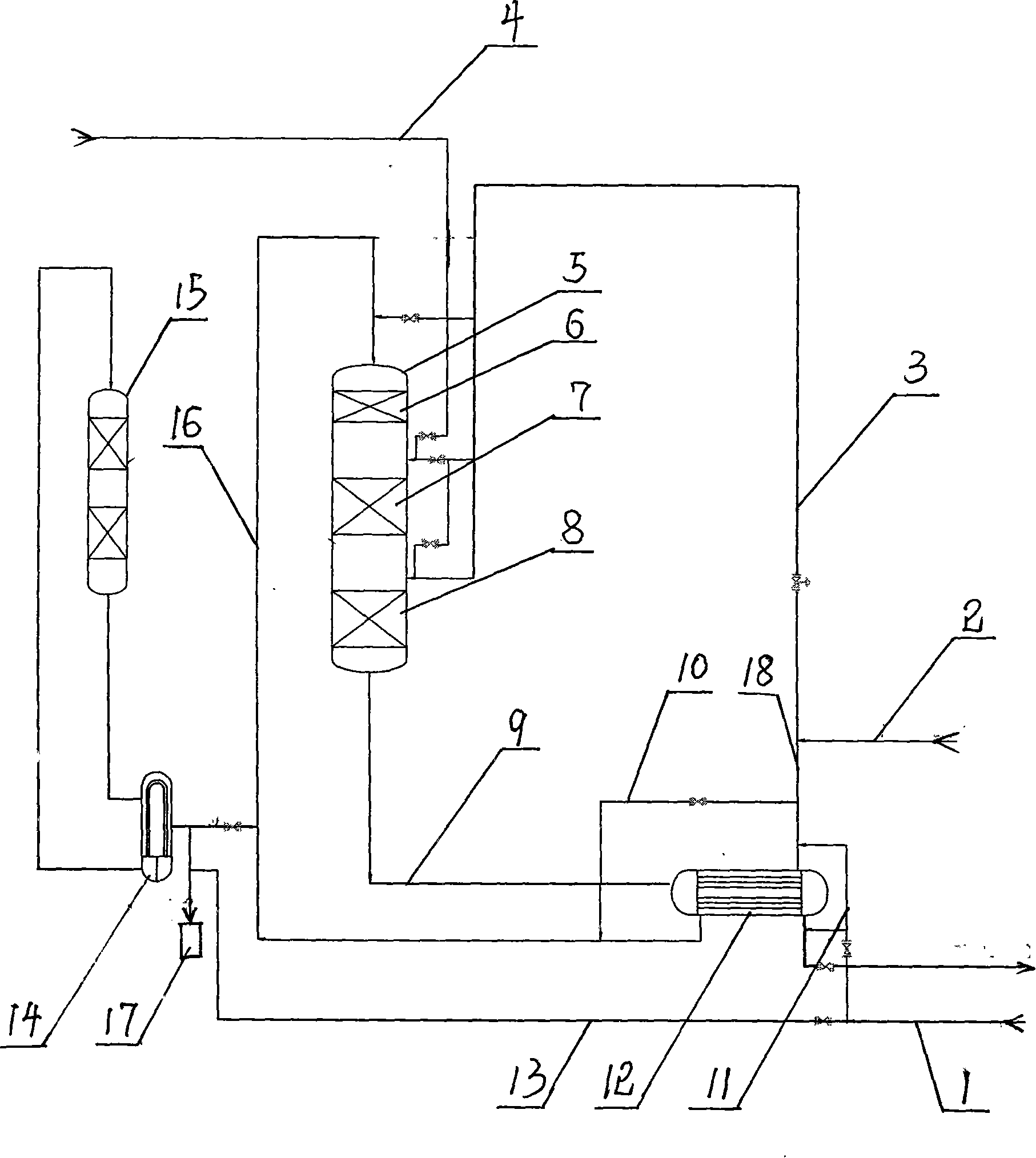

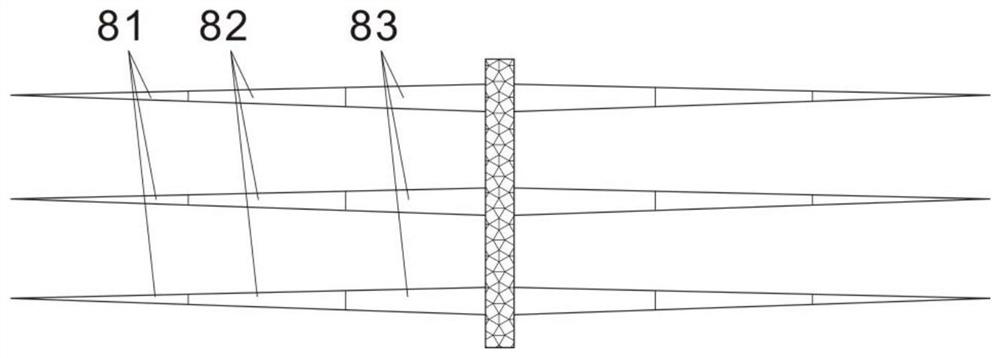

Technique for preparing gasoline by methanol

InactiveCN101104813AReduce carry outRealize large-scale industrial productionLiquid hydrocarbon mixture recoveryReaction temperatureGasoline

The invention relates to deep processing technology of methanol specific for producing gasoline with methanol, which solves the problems of hard controlling of the reaction temperature and inefficient extraction of the intermediate product of dimethyl ether in producing gasoline with methanol in prior art. The technology comprises the step of sending methanol vapor into the synthesis reactor which is equipped with at least three catalyst beds containing ZSM-5 catalysts to produce gasoline at a reaction temperature of 300-400DEG C and a pressure of 2.3-2.1MPa. The technology of the invention produces gasoline directly with raw materials which can produce dimethyl ether at the same time, making it possible to produce gasoline and dimethyl simultaneously with one raw material through different and respective producing technology. More importantly, the large-scale industrialized production becomes possible by efficiently controlling the temperature in the gasoline-synthesizing reactor through four different temperature-controlling methods.

Owner:全国煤化工设计技术中心

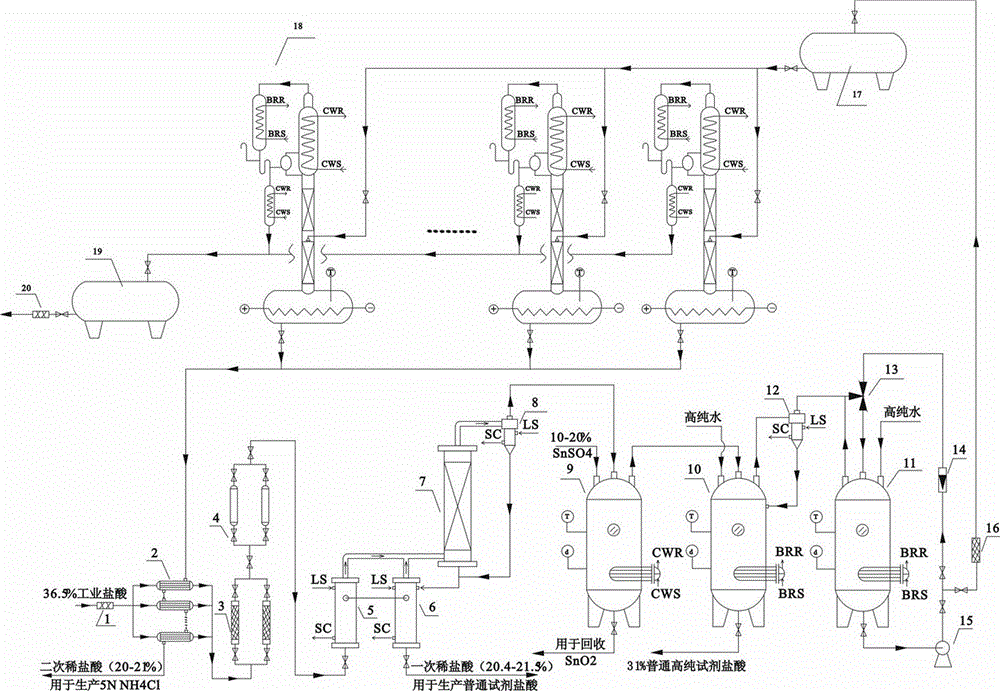

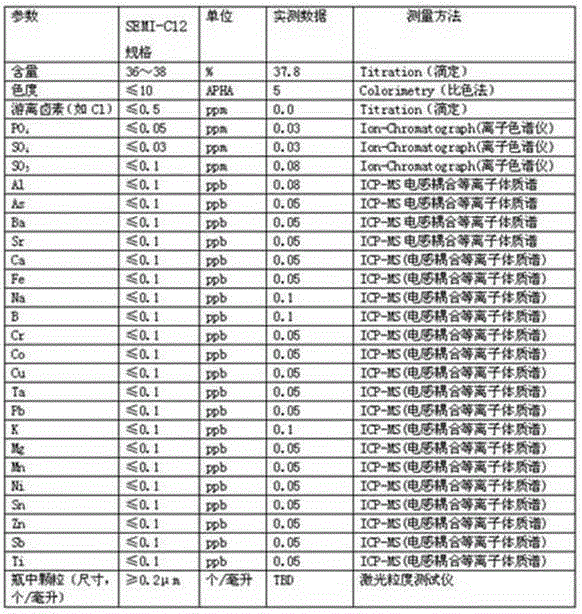

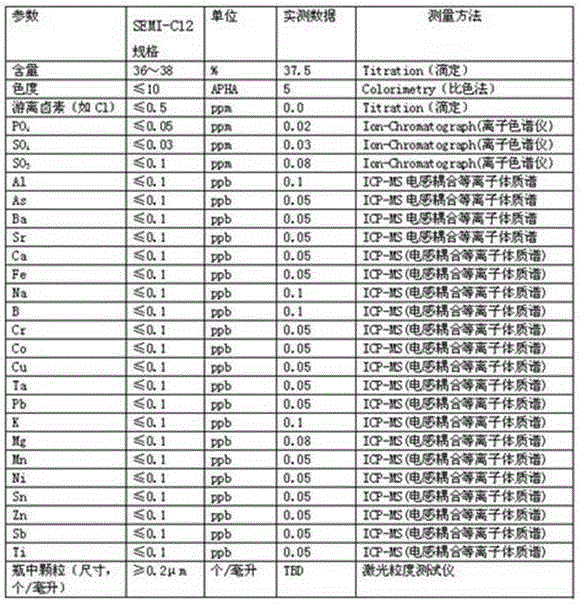

Method for preparing ultra-clean high-purity hydrochloric acid

ActiveCN103979497AReduce pollutionReduce oxidationChlorine/hydrogen-chloride purificationActivated carbonFiber

The invention discloses an industrial method for preparing ultra-clean high-purity reagent-grade hydrochloric acid from industrial hydrochloric acid through purification. The method comprises the following steps: filtering the industrial hydrochloric acid, dechlorinating activated carbon fibers, performing ion exchange through an anion exchange resin column, heating and evaporating; removing high-boiling-point substances out of gas-phase fractions through a super-pure polytetrafluoroethylene-dipped graphite packing tower, washing the gas-phase fractions in a stannous mono-sulfate solution, washing with high-purity water, then absorbing the high-purity water , thus obtaining the ultra-clean high-purity hydrochloric acid product. The method also can comprise a step of second distillation. The aim of realizing high-quality high-efficiency industrial batch production of ultra-clean high-purity reagent hydrochloric acid is reached.

Owner:XILONG SCI CO LTD

Process for hydrogenation of alkyl anthraquinone by using magnetically stabilized bed

ActiveCN1690035AReduce carry outImprove mass transfer efficiencyOrganic compound preparationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesReaction temperatureFixed bed

The alkyl anthraquinone hydrogenating reduction process is that inside magnetically stabilized bed reactor, alkyl anthraquinone solution, hydrogen and ferromagnetic hydrogenating catalyst are contacted at the conditions including reaction temperature of 25-150 deg.c, reaction pressure of 0.1-2.0 MPa, liquid spatial velocity of 3-40 / hr, hydrogen / liquid phase material feeding volume ratio of 5-300 and magnetic field strength of 1000 Oe. The ferromagnetic hydrogenating catalyst is selected from non-crystalline nickel alloy, Raney nickel or magnetic carrier loaded noble metal catalyst. Compared with fixed bed process, the process of the present invention has the advantages of lower bed pressure drop, higher mass transfer efficiency, less side reactions and less anthraquinone degrading amount. Compared with fluidized bed process, the process of the present invention has higher mass transfer efficiency and less catalyst carrying out.

Owner:CHINA PETROLEUM & CHEM CORP +1

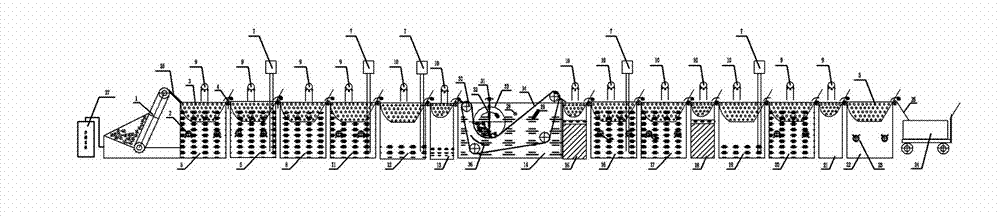

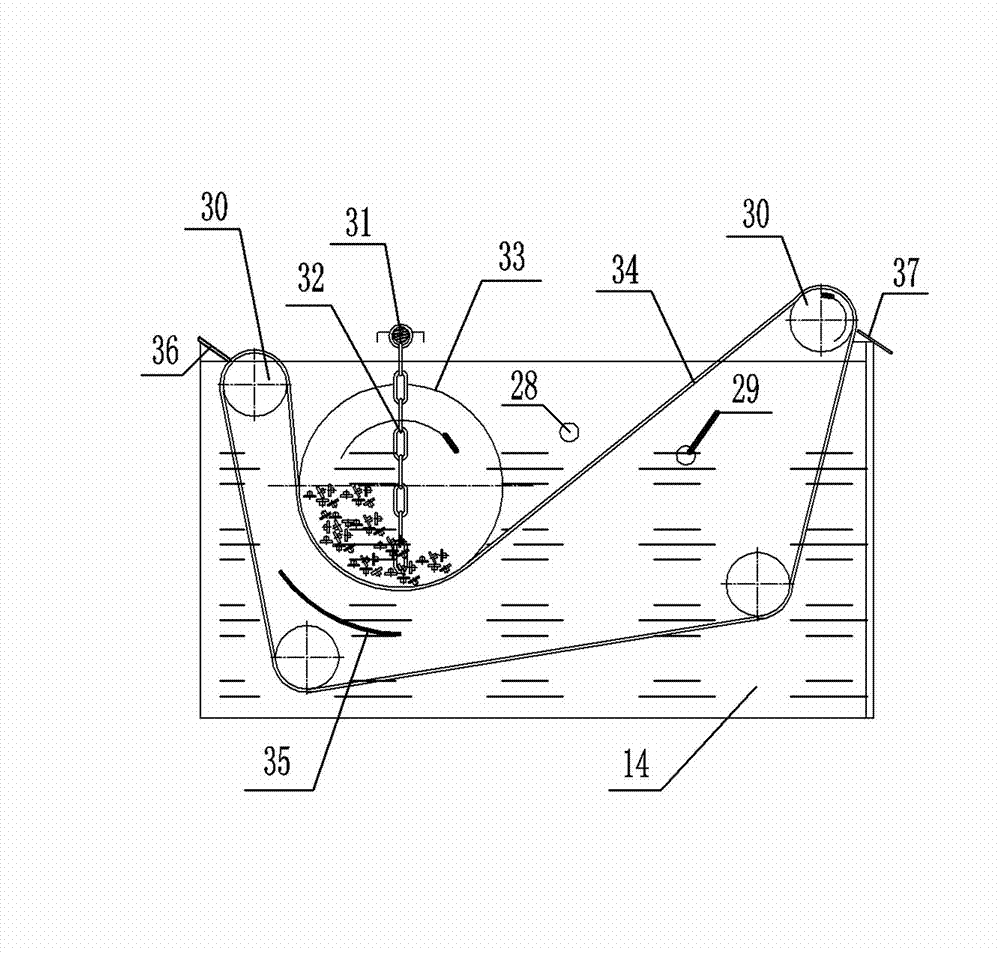

High-efficiency barrel plating washing system

InactiveCN103757654AReduce stressSave solutionElectrolysis componentsAutomatic controlTreatment burden

The invention discloses a high-efficiency barrel plating washing system which comprises a control system, a component lifting machine and a barrel plating washing tank group, wherein the barrel plating washing tank group sequentially comprises an alkali water washing tank, a hot water washing tank, a weak acid washing tank, a soaking washing tank, a primary spraying washing tank, a secondary spraying washing tank, a barrel plating tank body, an electroplating solution recycling tank, a dipping spraying tank, a passivation tank, a solution recycling tank, a spraying tank, a sealing tank, a blowing tank and a vibration drying tank; turning mechanisms are arranged at the upper ends of both two adjacent tanks; and except the barrel plating tank body, turning funnels are arranged at the upper parts of other tank bodies. When each procedure is accomplished, the funnels are turned for 45 degrees to vibrate to drain off water, so that the treatment burden to a next procedure is alleviated; and after barrel plating, a proper amount of deionized water is adopted for spraying and is recycled. The system is a full-automatic control system, the whole process of component washing, barrel plating, liquid level detection in tanks, conductivity detection and discharge of wastewater and the like is in closed loop control, the washing effect, the recycling of solutions and the water conservation and emission reduction of the whole process are sufficiently considered, and the system is a full-automatic barrel plating washing system with environment friendliness, energy conservation and emission reduction.

Owner:河南星光机械制造有限公司

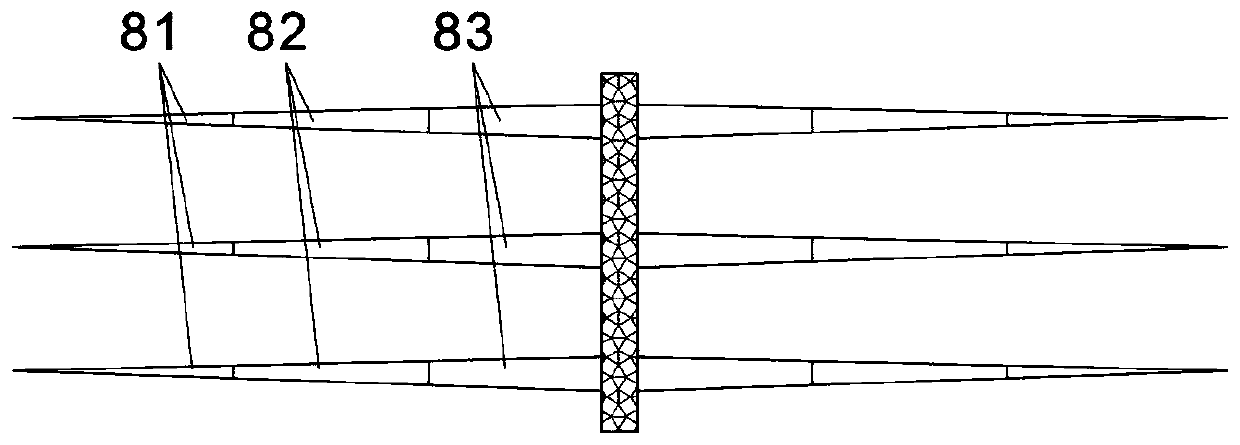

Method for large well spacing in-situ conversion mining of shale oil and gas of medium and low maturity shale oil

ActiveCN110005390AOvercoming the problem of small well spacing in in-situ miningAvoid closingFluid removalProduct gasShale oil and gas

The invention provides a method for large well spacing in-situ conversion mining of shale oil and gas of medium and low maturity shale oil. The method comprises the steps that a horizontal well groupwith at least three wells and with the well number being an odd number is deployed in a reservoir according to the well spacing of 15-50 meters; fracturing of the reservoir is performed, cracks are divided into three sections at equal intervals from a central injection well to production wells, and different types of propping agents are separately injected into the three sections in three stages;hot gas is injected into the central injection well and electrically heated, and is mined from the production wells; when temperatures between the central injection well and first-line round injectionwells reach a complete pyrolysis temperature, electric heating of the central injection well is stopped and normal temperature gas is injected into the central injection well; electric heating of thefirst-line round injection wells is started; when the temperatures between the first-line round injection wells and second-line round injection wells reach the complete pyrolysis temperature, injection of the normal temperature gas to the central injection well is stopped; electric heating of the first-line round injection wells is stopped, and normal temperature gas is injected into the first-line round injection wells; electric heating of the second-line round injection wells is started; and the cycle is repeated until reservoir temperatures between the production wells and adjacent last-line round injection wells reach the complete pyrolysis temperature.

Owner:PETROCHINA CO LTD

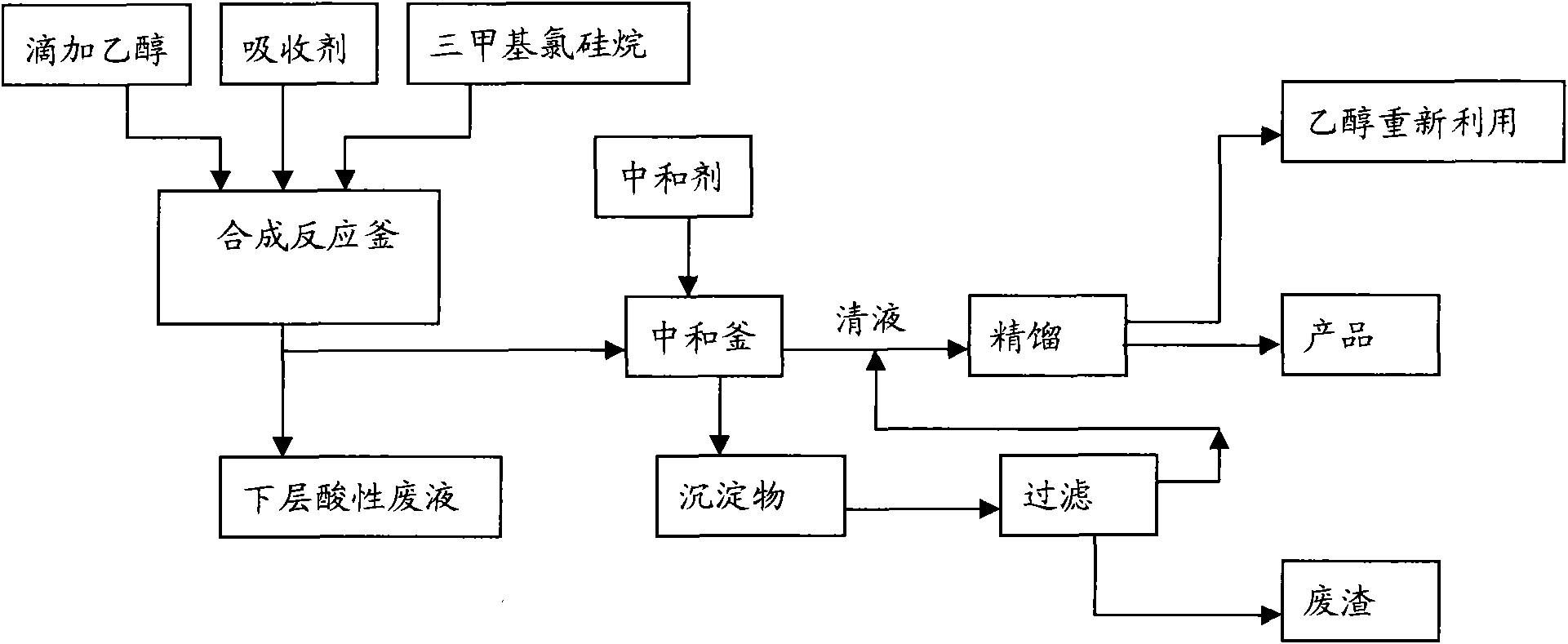

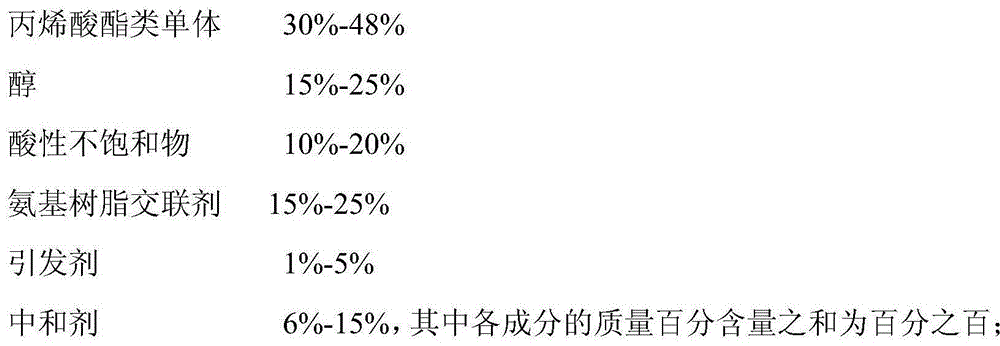

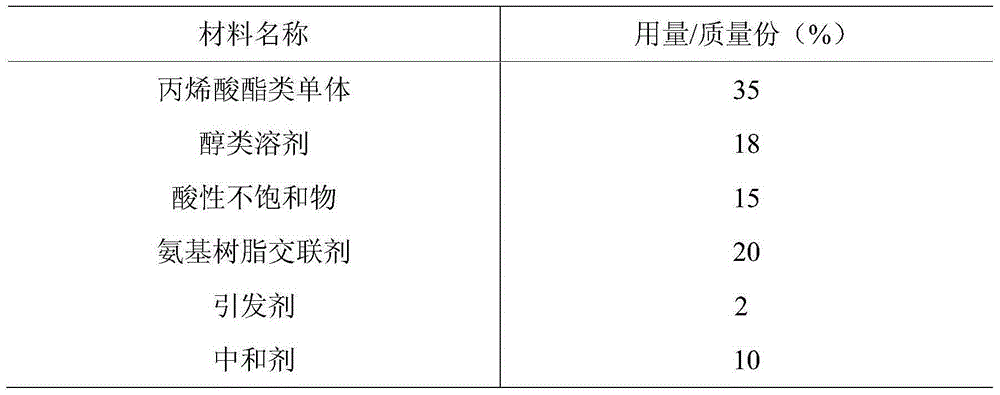

Preparation method for trimethylethoxysilane

InactiveCN101613367AReduce carry outImprove responseSilicon organic compoundsTrimethylsilyl chlorideReaction temperature

The invention discloses a preparation method for trimethylethoxysilane, which comprises the following steps: (1) adding trimethyl chlorosilane into a reaction kettle, and then adding an absorbent capable of absorbing chlorine hydride by stirring, wherein the addition of the absorbent is 20 to 70 percent of the weight of the trimethyl chlorosilane; (2) dripping ethanol in the stirring process, controlling the dripping speed to enable the reaction temperature to less than or equal to 80 DEG C, and continuously stirring the mixture for 1 to 4 hours, wherein in the reaction, the addition of the ethanol is 1.10 to 1.20 times of the theoretically calculated molar mass; (3) after the reaction is completed, stopping stirring, standing the mixture for 5 to 30 minutes, performing natural layering on the product, and performing layering and separation to obtain a crude product of the trimethylethoxysilane in the upper layer. The method adopts the absorbent capable of absorbing the chlorine hydride, so that the reaction is performed smoothly under the condition of normal temperature, and the reaction is simplified and saves energy. The process is simplified, has high product yield, and reduces the extraction of a large amount of salt and volatilization loss so as to reduce the production cost greatly.

Owner:吉林新亚强生物化工有限公司

Aluminium paste anode electrophoresis tank liquid and aluminium paste anode electrophoresis technology

InactiveCN105153782ALow solidsImprove stabilityElectrophoretic coatingsPaints for electrolytic applicationsElectrophoresisHardness

A provided aluminium paste anode electrophoresis tank liquid is composed of anode electrophoresis paint, aluminium paste, an aluminium paste auxiliary agent, a solvent and deionized water. A provided aluminium paste anode electrophoresis technology comprises the following steps: (1) pretreating a base material; (2) putting the pretreated base material in the aluminium paste anode electrophoresis tank liquid for electrophoresis, and controlling all technological parameters; (3) washing by using pure water; and (4) solidifying and drying. Various technological problems in the prior art are broken through, the developed liquid and technology are suitable for aluminium paste anode electrophoresis, an electrophoresis film with the thickness of 15-30 mu m is obtained, and the film is uniform in thickness, high in hardness, good in adhesive force, good in wear resistance, flat in appearance, slivery white and strong in metal texture, and possesses both corrosion resistance and decorative property.

Owner:东莞市霖辉金属表面处理材料有限公司

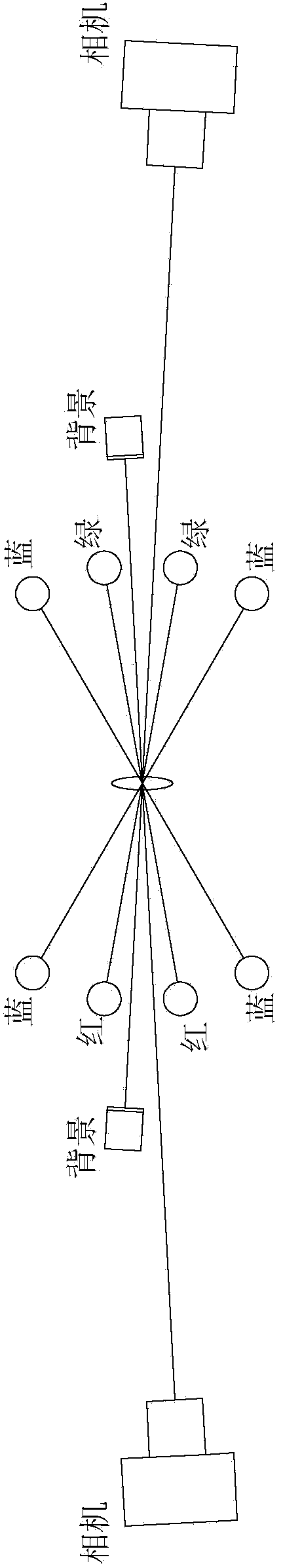

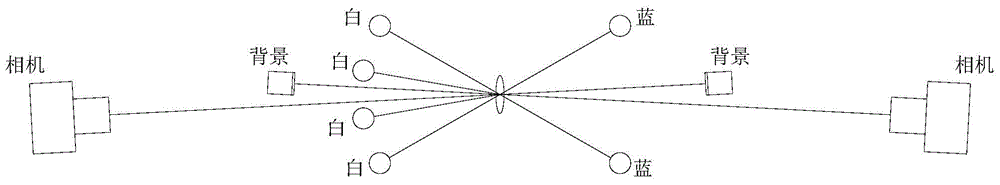

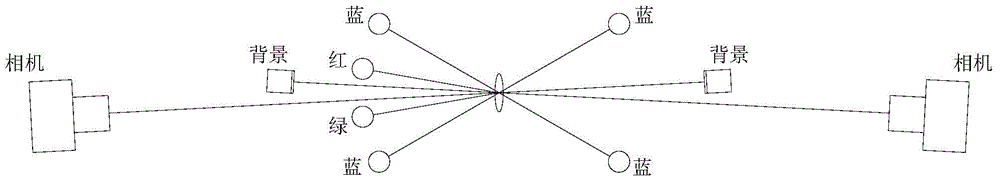

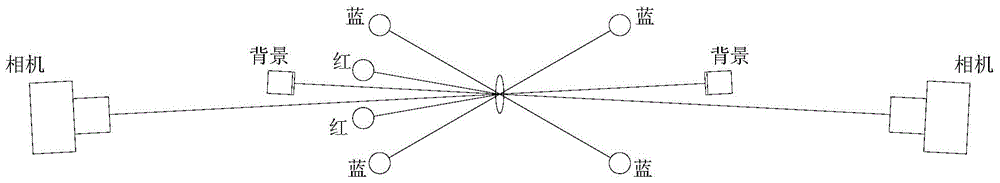

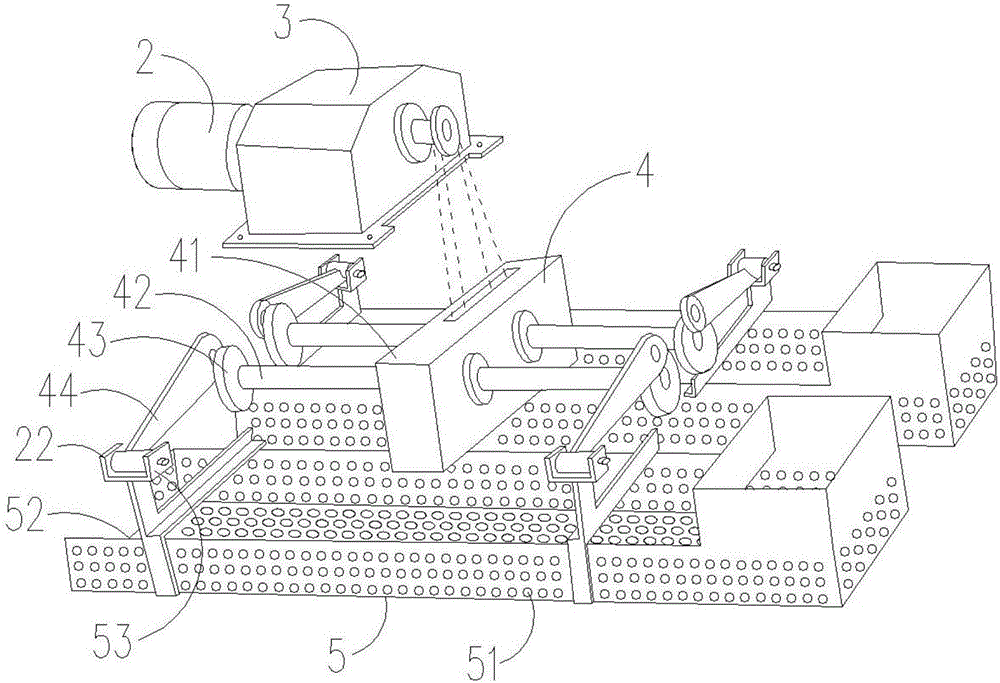

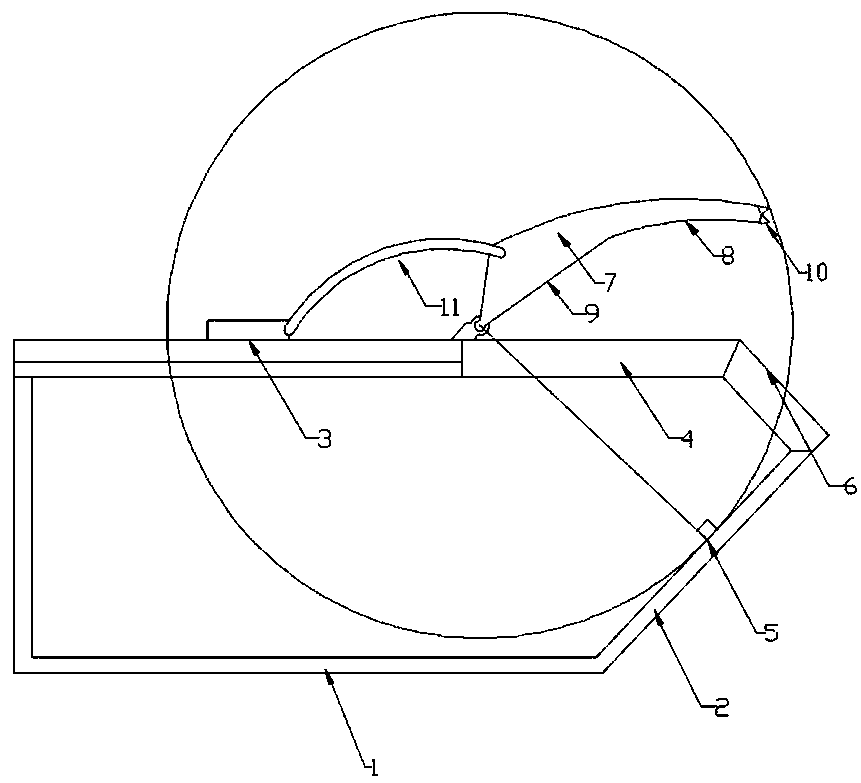

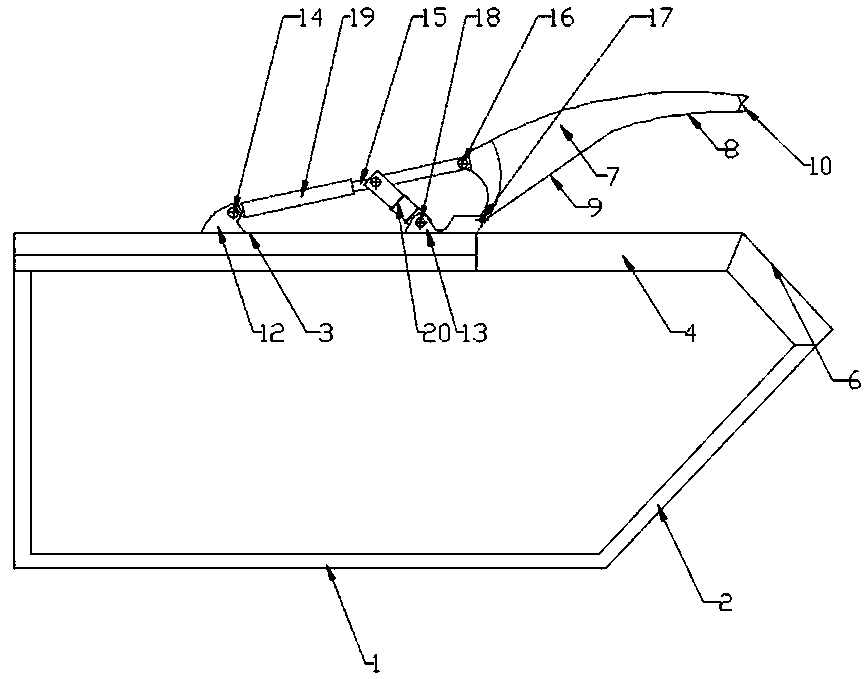

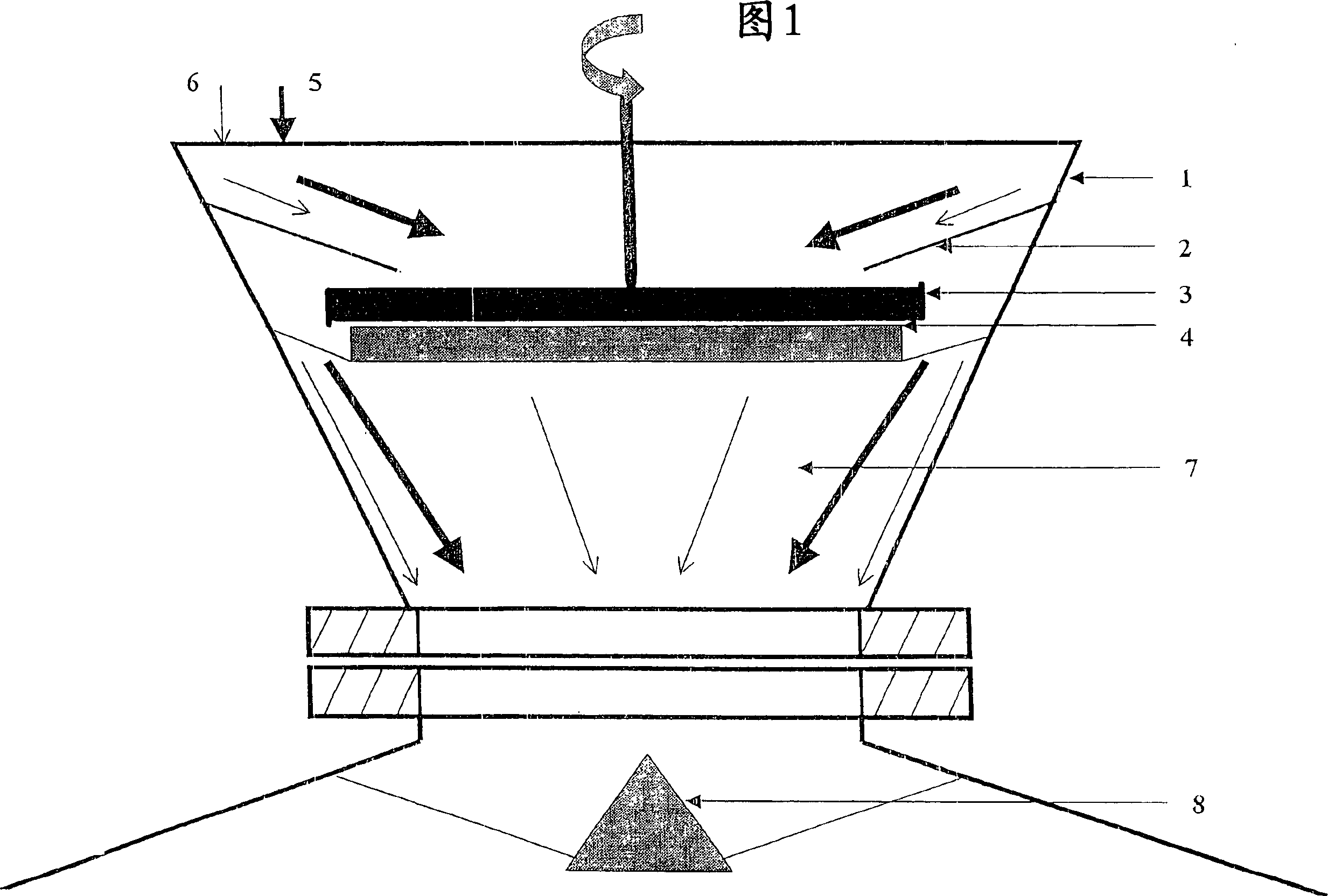

Detecting and sorting method and device for rice material

The invention provides a detecting and sorting method for a rice material, which is applied to sorting of transparent rice, ventral white rice, light yellow rice, deep yellow rice and deep color foreign matters. The method comprises the following steps: arranging blue light sources on two sides of the rice material to be sorted respectively, arranging a red light source on one side and a green light source on the other side, arranging cameras for receiving light source signals on two sides of the rice material, detecting reflected and transmitted blue light signals and transmitted green light signals by using the camera on the red light source side, and detecting reflected and transmitted blue light signals and transmitted red light signals by using the camera on the green light source side; configuring a sorting mode according to the grading requirement of sorting yellow rice or classifying transparent rice and ventral white rice or sorting yellow and white rice. The invention further provides a device for use in the detecting and sorting method for the rice material. The method and the device have the advantages that the bringing-out of ventral white rice is reduced, three different requirements of sorting yellow and transparent rice, classifying ventral white rice and sorting yellow and white rice by using the same scheme are met, the sorting adaptability is enhanced, and greater economic benefit is achieved.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

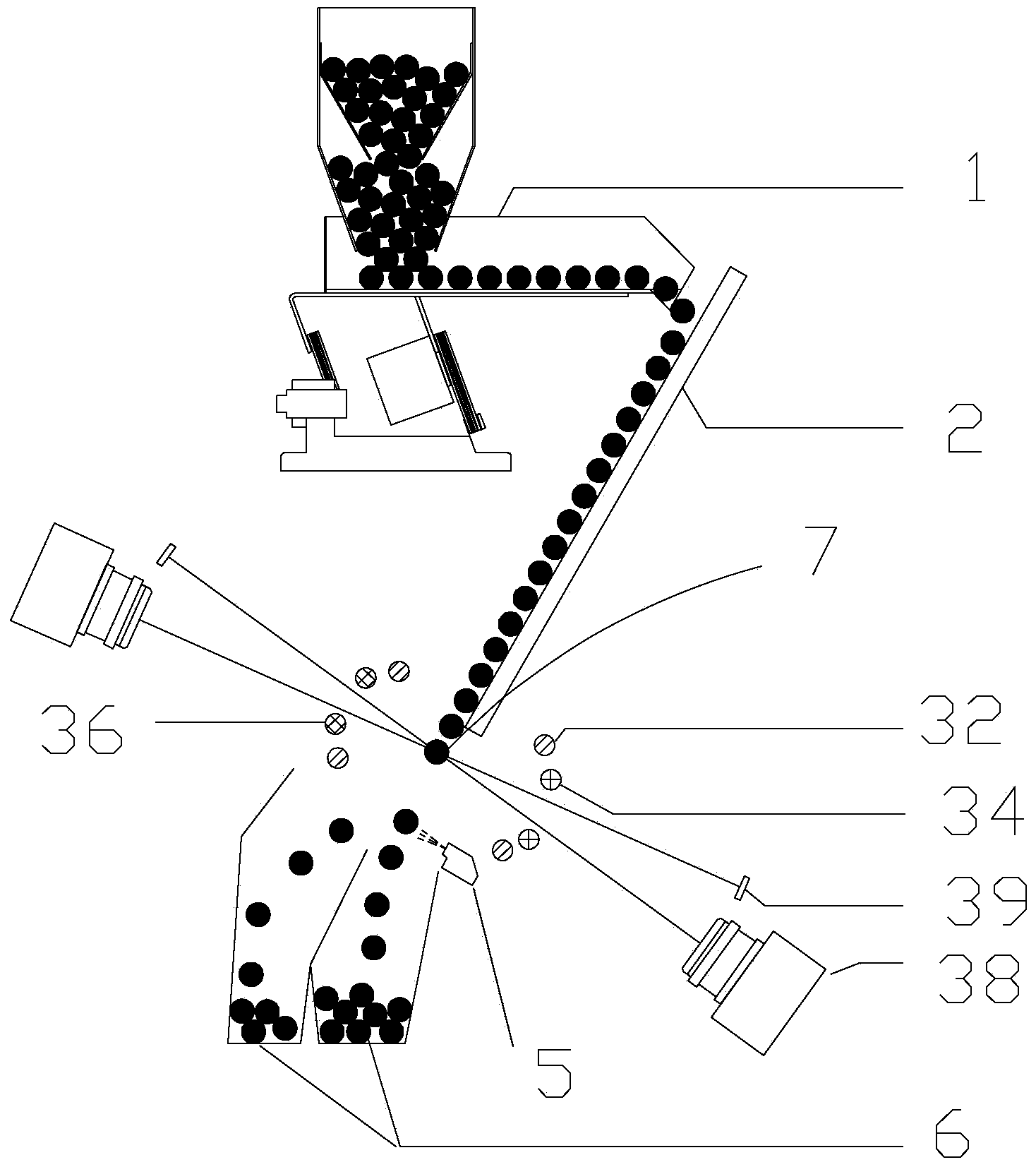

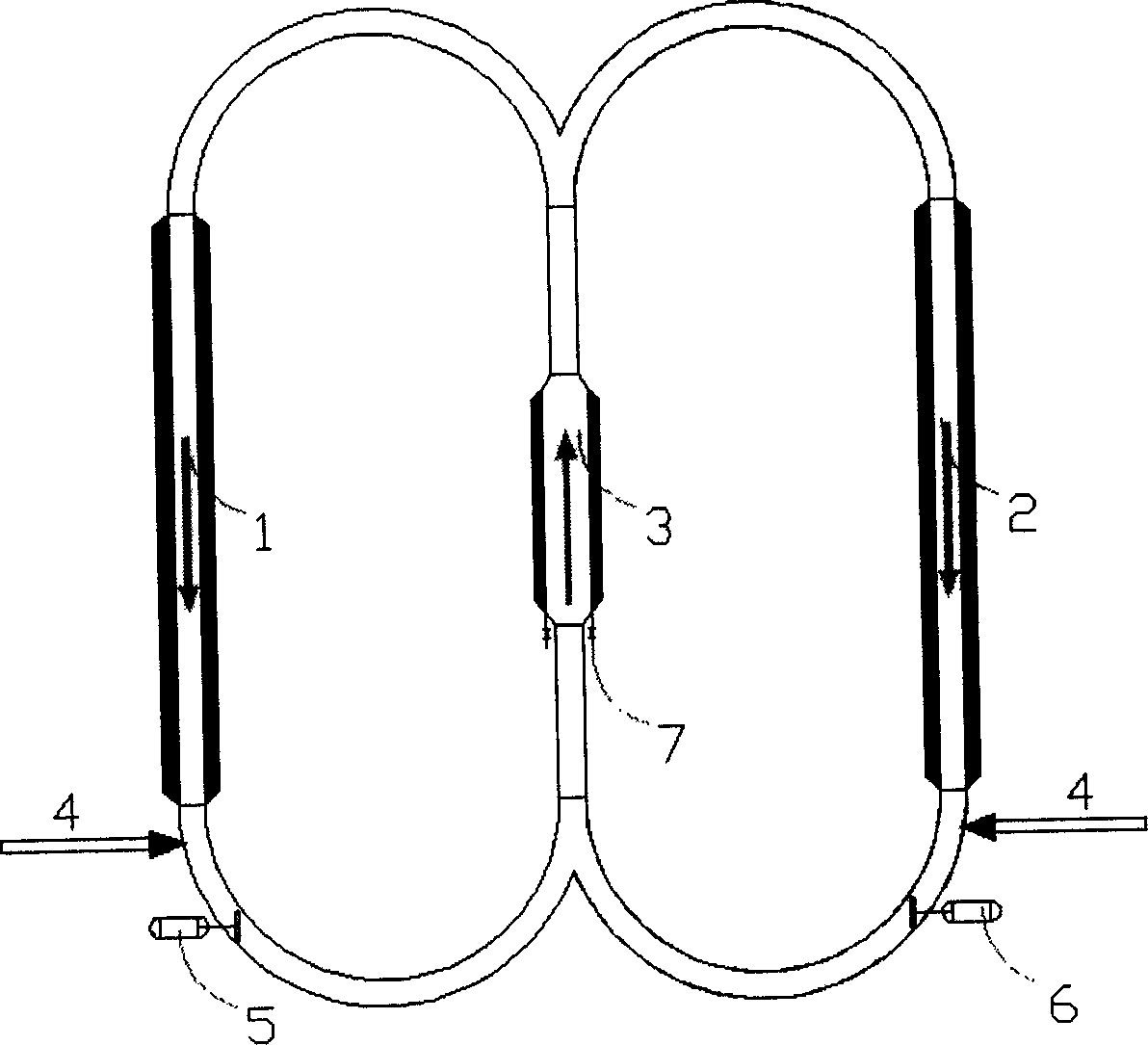

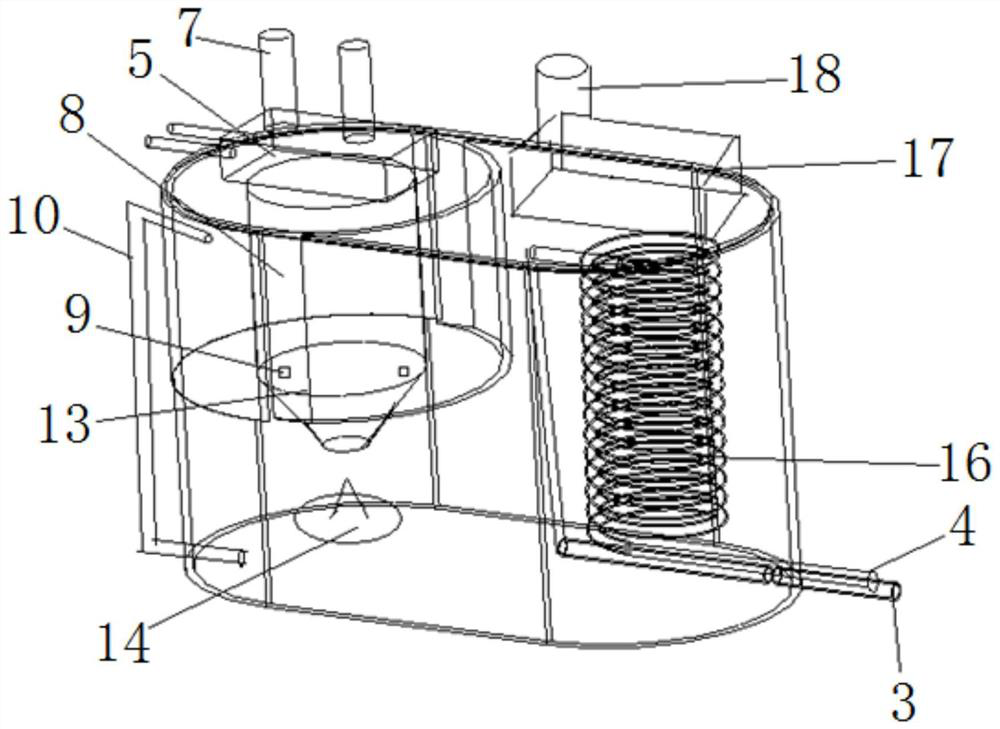

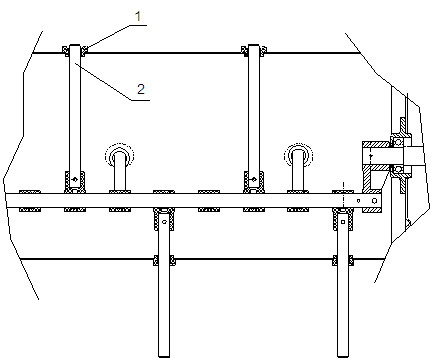

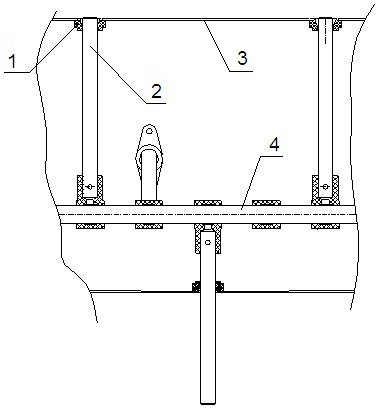

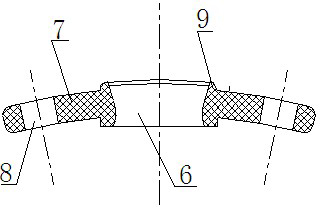

Olefin polymerizing reactor

An olefine polymerization reactor consists of circular reaction pipeline, axial flow pump or centrifugal pump, feeder unit, discharger, heat exchanger, at least one enlarging section with discharger is arranged at ascending straight pipe, the internal diameter of enlarging section is at least as 2 times as that of enlarging section. It has higher circulation sizing concentration, more space-time recovery rate, less consumption, single granular diameter distribution and better quality. It can be used for polyvinyl and polypropylene production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Detection sorting device and method for rice material

The invention provides a detection sorting device for a rice material. The detection sorting device is applied to sorting of transparent rice, white belly rice, pale yellow rice, deep yellow rice, and dark color foreign matter. The detection sorting device comprises a light source including the blue light spectrum and a blue light source which are arranged on the two sides of the rice material to be sorted respectively, and cameras for receiving light source signals are arranged on the two sides of the rice material respectively. The camera at the side with the light source including the blue light spectrum is used for detecting reflected and transmitted light source signals and blue light signals, wherein the light source signals and the blue light signals include the blue light spectrum. The camera on the side with the blue light source is used for detecting reflected and transmitted blue light signals and while signals. Sorting modes are configured according to the requirement for sorting the yellow rice, the requirement for classifying the transparent rice and the white belly rice and the requirement for commonly sorting the yellow rice and white rice. The invention further provides a sorting method. The detection sorting device and method for the rice material have the advantages that brought-out white belly rice is reduced, the pale yellow selecting performance is improved, the three different demands for sorting the yellow rice, the requirement for classifying the transparent rice and the white belly rice and the requirement for commonly sorting the yellow rice and white rice are met at the same time, the sorting adaptability is improved, and larger economic benefits are achieved.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

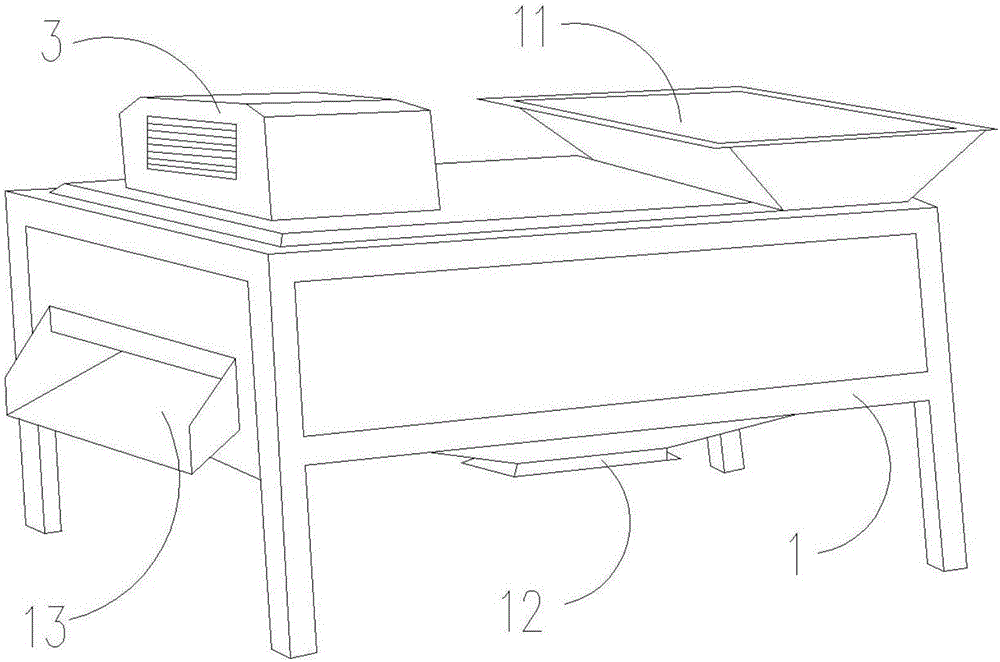

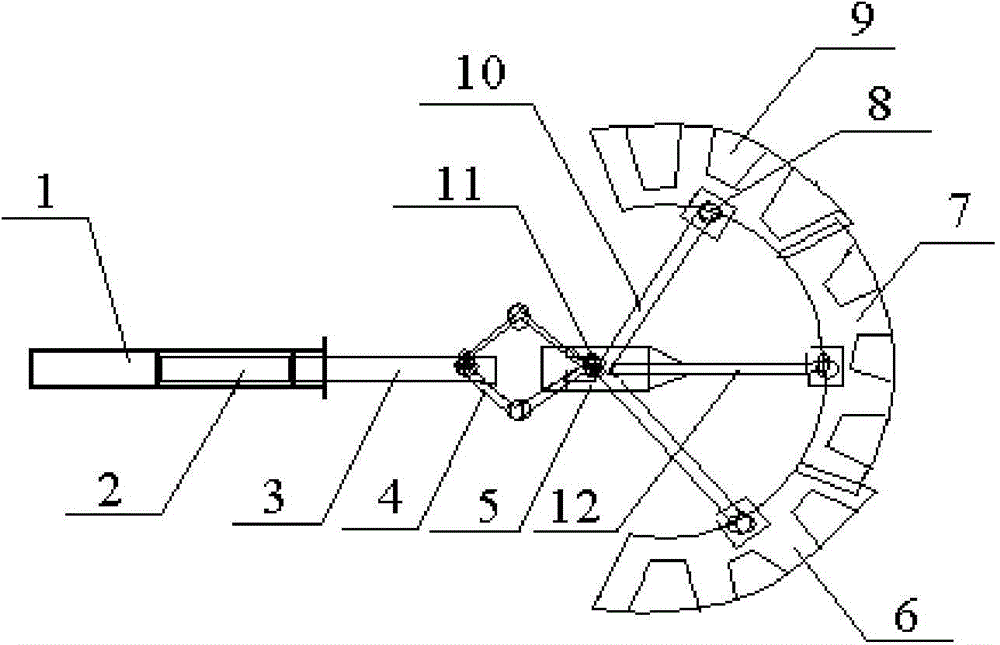

Grape destemer

ActiveCN106108074AImprove the whole grain rateLess stemsFood treatmentDried fruitsAgricultural engineering

A grape destemer is composed of a rack, a motor, a gearbox, a transmission device and a screen basket. The motor, the gearbox and the transmission device are fixedly mounted on the rack, and the screen basket is hoisted in the rack. The motor is in transmission connection with the input end of the gearbox, the output end of the gearbox is in transmission connection with the transmission device, and a rocker arm of the transmission device is in transmission connection with the screen basket. A feed port is formed in the upper portion of the rack and located over the right end of the screen basket. A discharge port is formed in the bottom of the rack and located under the screen basket; a stem discharge opening is formed in the side of the rack and rightly faces the leftmost side of the screen basket. The grape destemer has the advantages that picked grape grains are high in complete grain rate, few fruit stems are brought out, and mixing of green fruits and dry fruits is avoided reasonably and effectively; the equipment technology of the grain stem removing process in the wine making process is remarkably improved, the production quality of wine is improved, the raw material use rate of the wine is increased, and the production equipment investment cost is reduced.

Owner:宁夏圆润葡萄酒有限公司

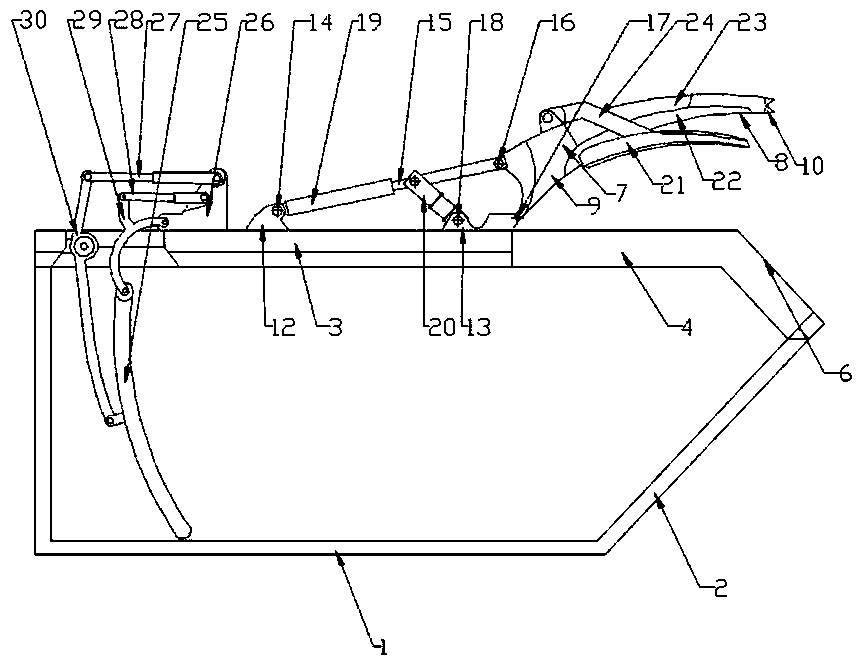

Compression garbage truck with top-mounted pushing mechanisms

InactiveCN109625716AGuaranteed tightnessGuaranteed filling efficiencyRefuse receptaclesRefuse vehiclesTruckEngineering

The invention relates to a compression garbage truck with top-mounted pushing mechanisms. The compression garbage truck comprises a dustbin located on a truck chassis and a garbage compression mechanism connected to the dustbin. A garbage guide-in opening is formed in the top of the dustbin, and a garbage guide-in face is arranged on the wall face of the bottom of the dustbin. The garbage compression mechanism comprises a garbage compression plate. A sealing portion is arranged at the other end of the garbage compression plate. The rotating position between the garbage compression plate and the outer wall of the top of the dustbin serves as a rotating site A, and the rotating site A is located at the garbage guide-in opening in the horizontal direction. The pushing mechanisms used for driving the garbage compression plate to rotate relative to the rotating site A are further arranged on the dustbin on the opening on the outer wall of the top of the dustbin. The garbage compression plate moves into the dustbin through the garbage guide-in opening, and when the garbage compression plate rotates, the arc formed by the rotating path of the sealing portion is tangent to the surface of the garbage guide-in face. The garbage compression plate is of an inward concaved structure in the longitudinal direction, and the inward concaved face of the garbage compression plate backs on to thelinear pushing mechanism.

Owner:NANJING HUANLV NEW ENERGY VEHICLE CO LTD

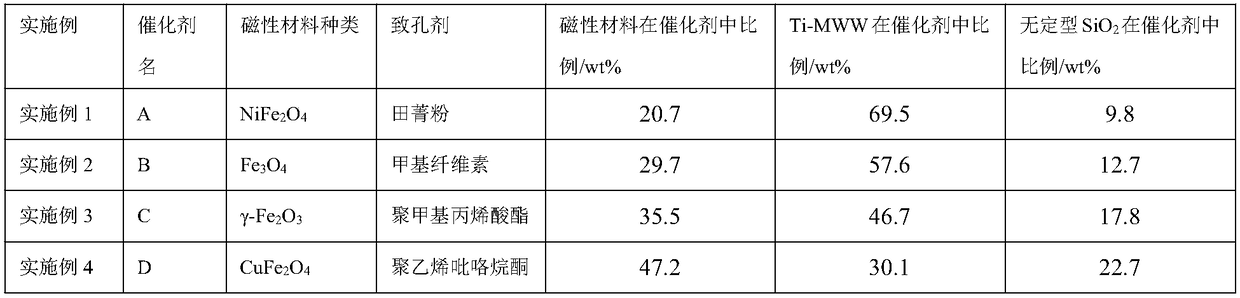

Preparation method and application of magnetic Ti-MWW molecular sieve microsphere catalyst

ActiveCN108126740AReduce carry outReduce consumptionOrganic chemistryMolecular sieve catalystsMolecular sieveMicrosphere

The invention discloses a preparation method and application of a magnetic Ti-MWW molecular sieve microsphere catalyst. The preparation method comprises the following steps: mixing a SiO2-coated inorganic magnetic particle material with silica sol, a Ti-MWW molecular sieve and deionized water into a slurry with the concentration of 25-50wt%, moulding through spray drying to obtain magnetic microspheres with the sizes of 30-100 microns, and then calcining at 450-650 DEG C for 2-12 hours to obtain the magnetic Ti-MWW molecular sieve microsphere catalyst, wherein the inorganic magnetic particle material is any one of Fe3O4, gamma-Fe2O3, NiFe2O4 and CuFe2O4 and accounts for 20-50wt% of the microsphere content. The magnetic catalyst particles can be suspended in a magnetically stabilized bed reactor and can catalyze an epoxidation reaction of propylene to produce propylene oxide, and a result shows that the product selectivity, the yield and the effective H2O2 utilization rate are very high.

Owner:CHINA CATALYST HLDG CO LTD

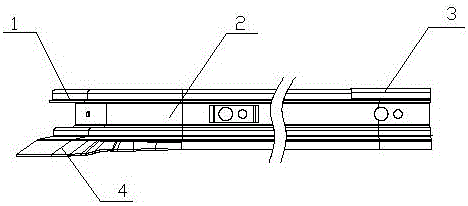

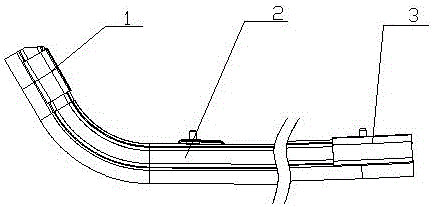

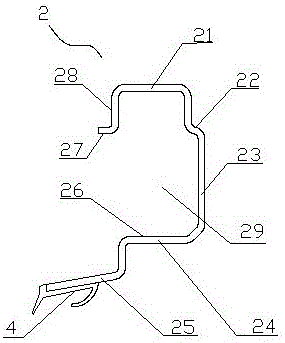

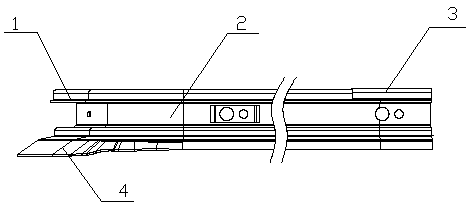

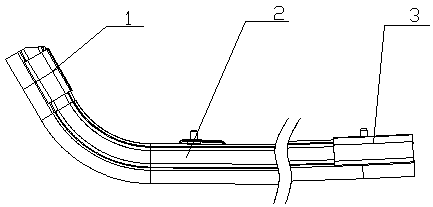

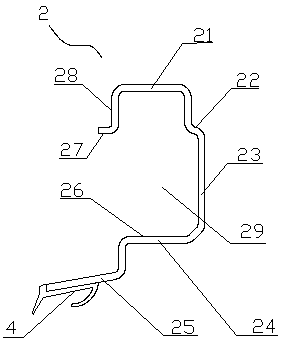

Automobile sliding door guide rail and machining process

ActiveCN106522714AImprove corrosion resistanceStrong anti-corrosion abilityWing suspension devicesDoorsTectorial membraneElectrophoresis

The invention relates to an automobile system, and particularly discloses an automobile sliding door guide rail and a machining process. The machining process for the automobile sliding door guide rail comprises the processes of pre-forming, saw-cutting, forming, performing electrophoresis, installing accessories and the like; adhering a protective film to a weight bearing surface of the guide rail before an electrophoresis operation is performed, and removing the protective film after the electrophoresis is completed. The technical problem to be solved by the invention is about provision of the machining process for the automobile sliding door guide rail; the electrophoresis operation is performed on the surface of the guide rail so that the surface of the guide rail is coated with an electrophoresis coating layer; therefore, the appearance of the guide rail is attractive; moreover, the corrosion resistance is good; the use performance is high.

Owner:ZHEJIANG XINGYU AUTO PARTS CO LTD

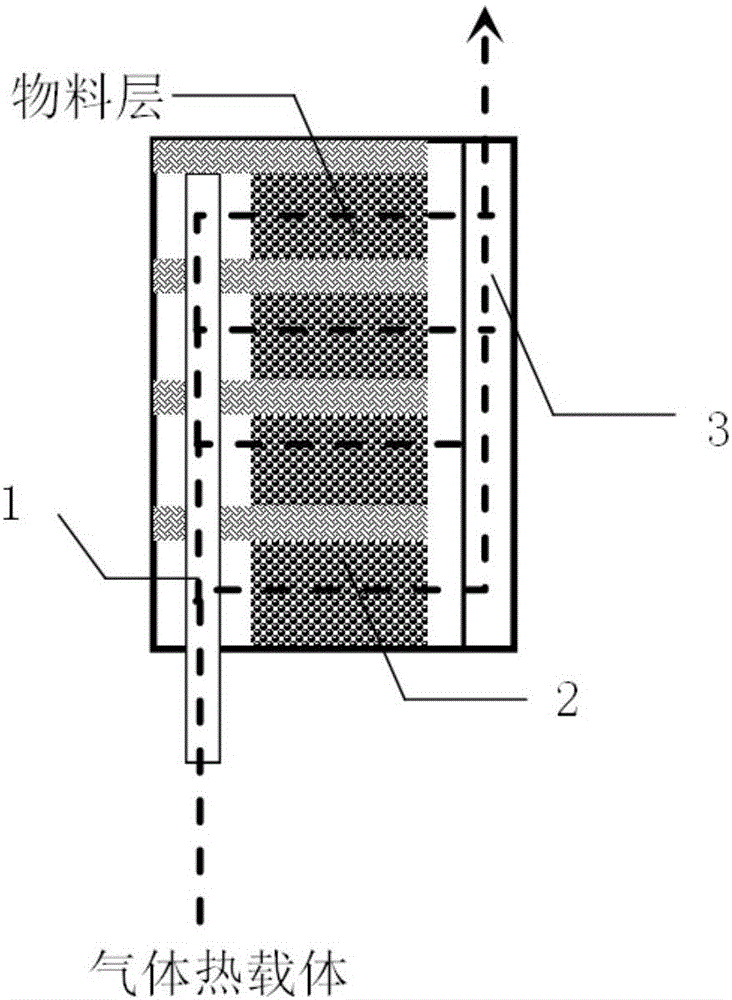

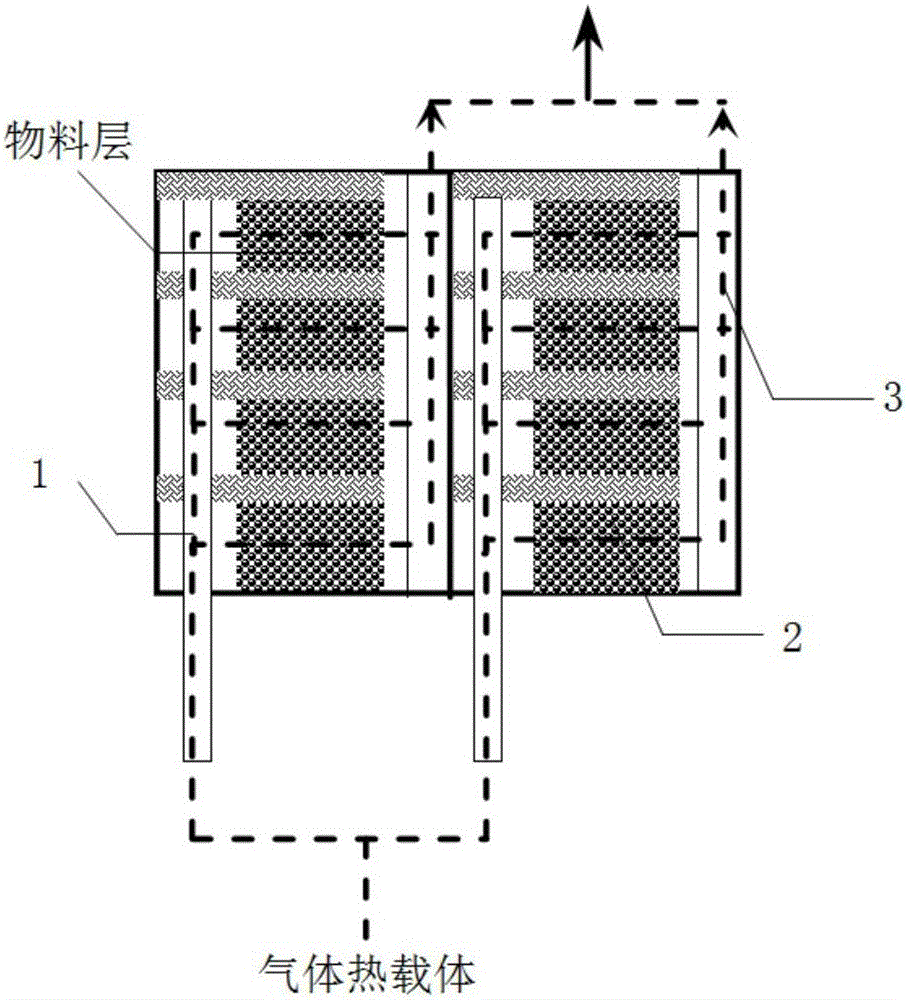

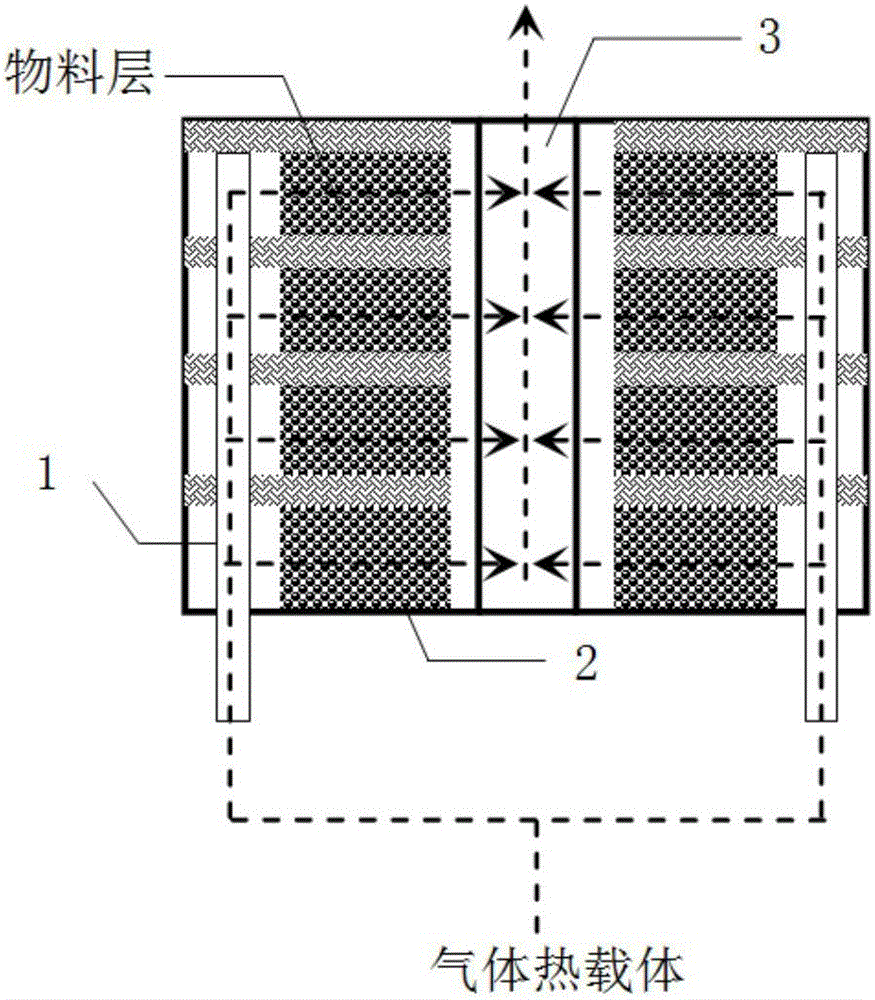

Pyrolysis method for low-rank coal or oil shale with higher tar yield

InactiveCN105018116AHigh yieldReduce resistanceDirect heating destructive distillationSpecial form destructive distillationHeat carrierCombustion chamber

The invention relates to a pyrolysis method for low-rank coal or oil shale with higher tar yield, and is suitable for a heat upgrading process of a low-rank coal moving bed with the purpose of obtaining high-yield tar. The method is a gas heat carrier technology, high-temperature gas flows to the cold end of a collection chamber from a combustion chamber at the hot end of a carbonization chamber by traversing a coal material, quick gas-solid heat exchange between hot carrier gas and the coal material is performed, and the coal material is heated to perform low-temperature pyrolysis. A gas-oil mixture generated by pyrolysis, together with the hot carrier gas, is introduced by the collection chamber at the cold end of the carbonization chamber. The pyrolysis method is characterized in that oil gas and a hot carrier generated by pyrolysis quickly pass through the coal material with the average radial temperature gradient of 600 DEG C / m, and flow to a low-temperature area from a high-temperature area, so that obvious secondary splitting is avoided in time. On the other hand, the method adopts the gas hot carrier to radially penetrate a coal layer, and heat is transferred to the internal coal material at a short transverse distance by the hot carrier, so that the material layer resistance can be obviously reduced, pulverization and semi-coke bringing is reduced, and the heat transfer efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Developing spray nozzle structure and method for spraying developing solution

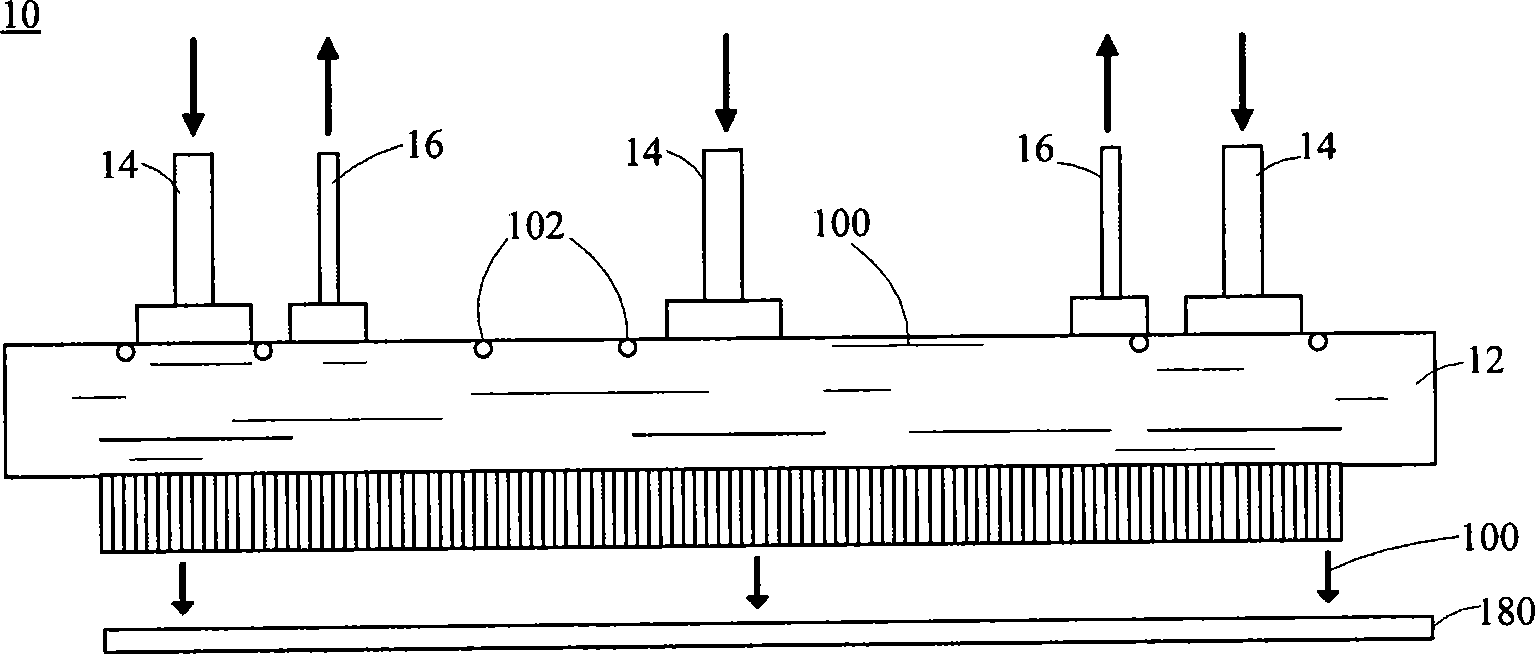

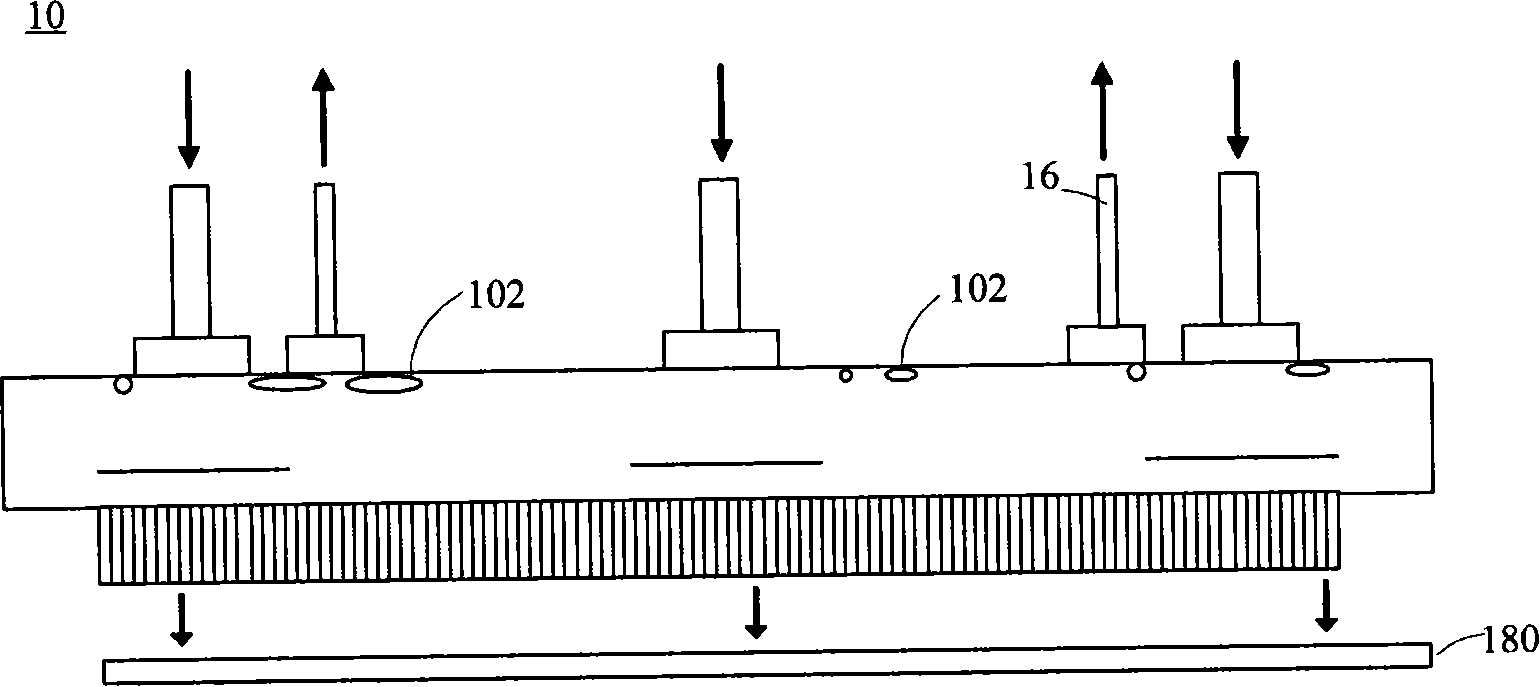

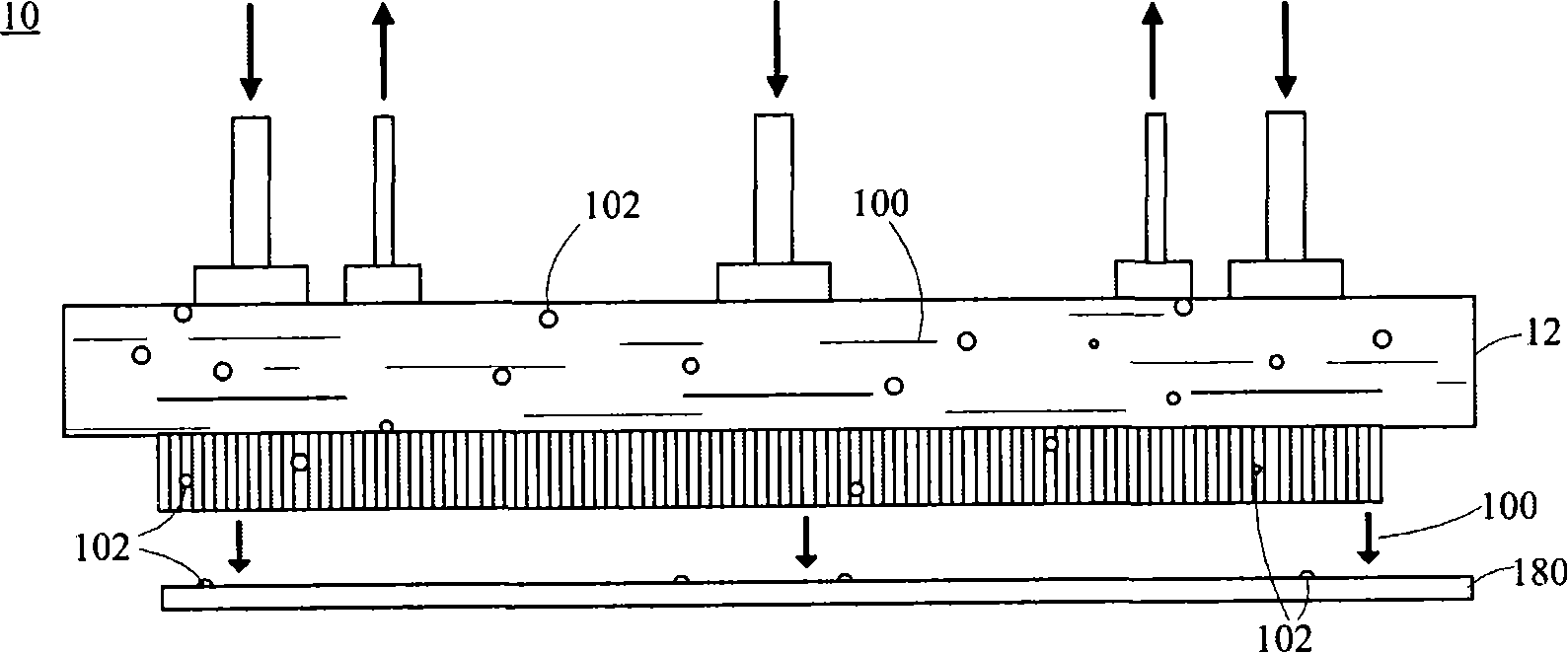

InactiveCN101251721AReduce carry outImprove processing efficiencySemiconductor/solid-state device manufacturingPhotosensitive material processingSpray nozzleEngineering

The invention provides a developing nozzle structure and a method for spray coating developing solution. The developing nozzle structure comprises a nozzle cavity and a valve system, wherein, the nozzle cavity is provided with a first chamber, a second chamber which is positioned under the first chamber, an injection pipe which supplies the developing solution and injects the developing solution into the second chamber, and a spray coating pipe which is communicated with the second chamber and positioned under the second chamber; the valve system is arranged between the first chamber and the second chamber; when the valve system is opened, air bubbles in the developing solution enter into and concentrate in the first chamber; when the valve system is closed, the air bubbles in the first chamber are isolated from the developing solution in the second chamber, and the developing solution in the second chamber is sprayed out through the spray coating pipe. In this way, the air bubbles which are brought out to a panel along with the developing solution are greatly reduced, thereby the technological efficiency can be improved.

Owner:AU OPTRONICS CORP

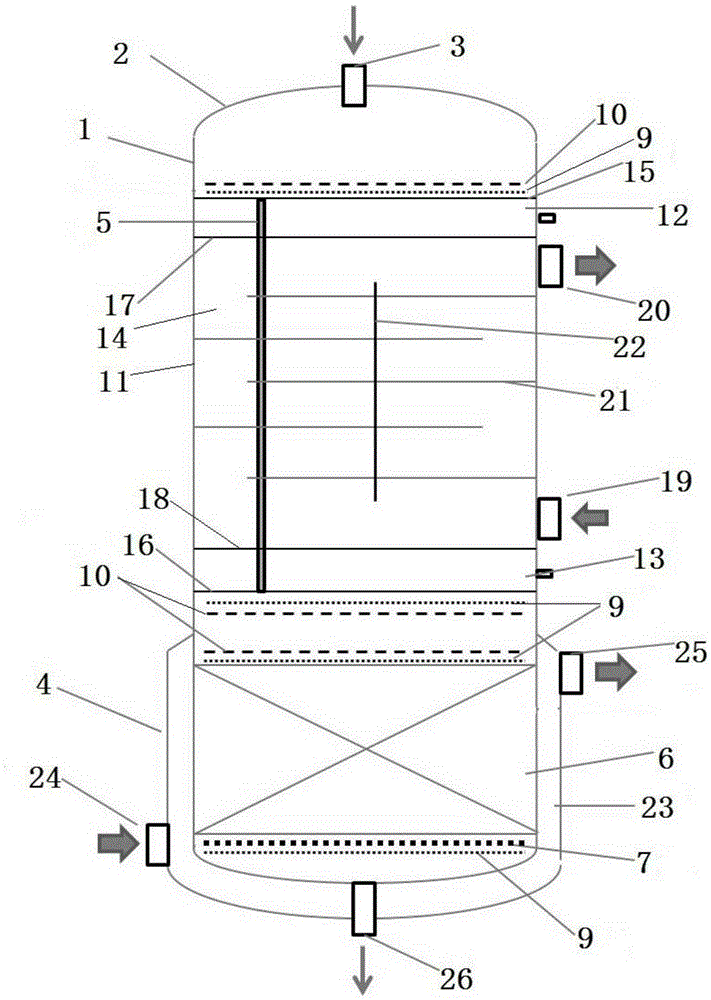

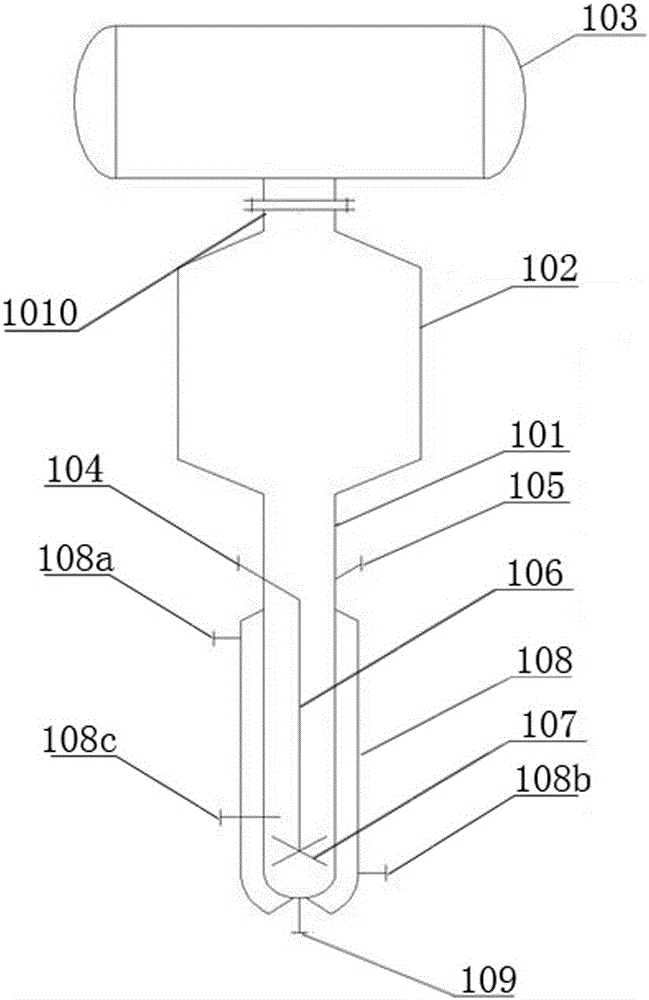

Phosgene production device and method

InactiveCN105347343AGuarantee product qualityEnsure production safetyPhosgeneCarbon monoxide detectorFixed bed

The present invention discloses a phosgene production device and method. The phosgene production device is a dividing wall type heat exchange type spring supported catalyst two-stage reaction synthesis device, and is used for phosgene production by reaction of chlorine and carbon monoxide in the role of a catalyst. The phosgene production device comprises a reactor casing, the reactor casing is internally provided with a primary reactor and a secondary reactor, the lower end of the primary reactor is connected with the secondary reactor by a connecting section, a multitubular-type reaction tube bundle is vertically arranged within the primary reactor, and comprises a plurality of reaction tubes; a secondary reactor casing is internally provided with a reaction zone main body, the reaction tubes and the secondary reactor reaction zone main body are partly filled with a fixed bed catalyst; the reactor casing is internally provided with a protective detection chambers, the protective detection chamber is internally provided with phosgene, chlorine and carbon monoxide detectors for detecting gas leakage. A gas detection warning instrument is arranged outside the reactor casing. The phosgene production device and method has the advantages of complete reaction, reduction of catalyst content in the finished product, lower cost, more security and the like.

Owner:LIAOCHENG LUXI POLYCARBONATE CO LTD

Novel dross removal head

The invention provides a novel dross removal head. The novel dross removal head comprises a base, movable dross removal plates, a fixed dross removal plate and a hydraulic cylinder. The hydraulic cylinder is located in a stretchable arm and connected with a push-pull rod, the base is connected with the push-pull rod through hinged rods, the movable dross removal plates and the fixed dross removal plate are arranged on the base, the movable dross removal plates are connected with the base through movable supporting arms, the fixed dross removal plate is connected with the base through a fixed supporting arm, the movable dross removal plates and the fixed dross removal plate are connected with the movable supporting arms and the fixed supporting arm through wedge pieces, the hinged rods, the movable supporting arms, the fixed supporting arm and the base are connected together through a main shaft, and the movable dross removal plates and fixed dross removal plate are provided with grooves. The novel dross removal head is reasonable in structure, simple in design and convenient to operate; the working efficiency is improved, time is shortened, heat losses of solutions in the process and the solutions taken out during dross removing are reduced, the frequency is increased, yield is increased, cost is reduced, energy resources are saved, and the service life is prolonged.

Owner:天津吉泰空调通风设备有限公司

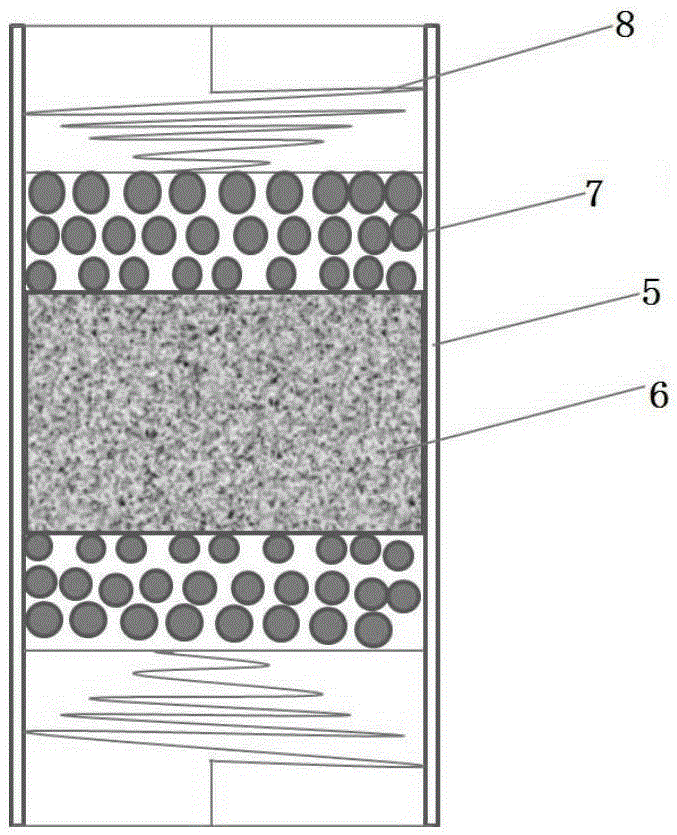

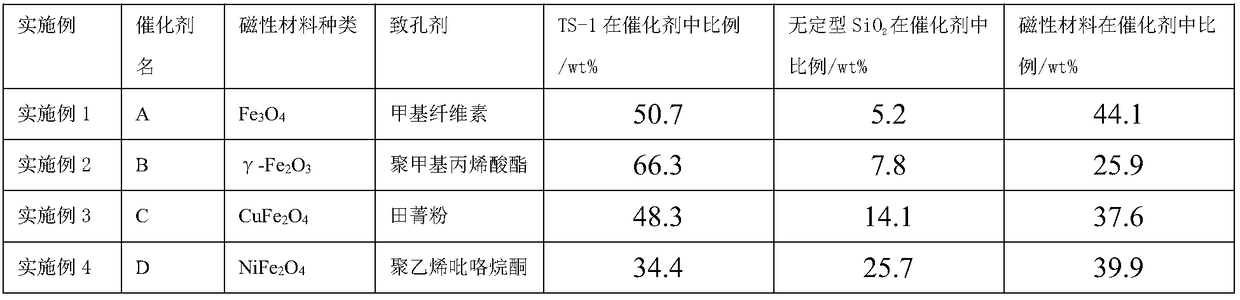

Preparation method of TS-1 molecular sieve microspherical catalyst with magnetism and application

ActiveCN108187738AReduce carry outReduce consumptionOrganic chemistryMolecular sieve catalystsIonMolecular sieve

The invention discloses a preparation method of a magnetic composite TS-1 molecular sieve catalyst and application. The method comprises the following steps: mixing a SiO2 coated inorganic magnetic particle material with silica sol, a TS-1 molecular sieve and deionized water into 25 to 50wt percent slurry, and performing spray drying molding, so as to obtain a 30 to 100 micrometer magnetic microsphere, and then calcining for 2 to 12h at 450 to 650 DEG C, so as to obtain the magnetic TS-1 molecular sieve catalyst. The inorganic magnetic particle material adopts any of Fe3O4, gama-Fe2O3, NiFe2O4and CuFe2O4; the content of the inorganic magnetic particle material is 20 to 50wt percent of that of the microsphere; the content of the amorphous SiO2 is 5 to 30wt percent of that of the microsphere. The magnetic catalyst microsphere can suspend in a magnetically stabilized bed reactor, and catalyze propylene epoxidation reaction to produce propylene epoxide, and results show that the magneticcatalyst microsphere has good product selectivity, yield and effective utilization of H2O2.

Owner:CHINA CATALYST HLDG CO LTD

A processing technology of sliding door guide rail of automobile

ActiveCN106522714BStrong anti-corrosion abilityEvenly distributedWing suspension devicesDoorsElectrophoresisEngineering

The invention relates to an automobile system, and particularly discloses an automobile sliding door guide rail and a machining process. The machining process for the automobile sliding door guide rail comprises the processes of pre-forming, saw-cutting, forming, performing electrophoresis, installing accessories and the like; adhering a protective film to a weight bearing surface of the guide rail before an electrophoresis operation is performed, and removing the protective film after the electrophoresis is completed. The technical problem to be solved by the invention is about provision of the machining process for the automobile sliding door guide rail; the electrophoresis operation is performed on the surface of the guide rail so that the surface of the guide rail is coated with an electrophoresis coating layer; therefore, the appearance of the guide rail is attractive; moreover, the corrosion resistance is good; the use performance is high.

Owner:ZHEJIANG XINGYU AUTO PARTS CO LTD

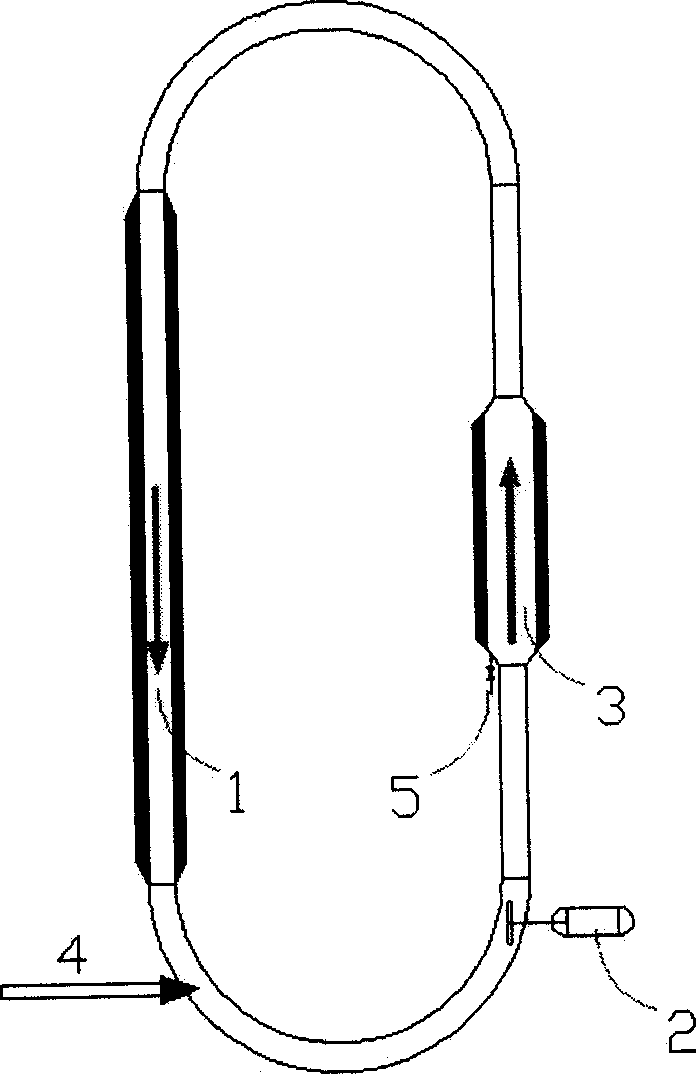

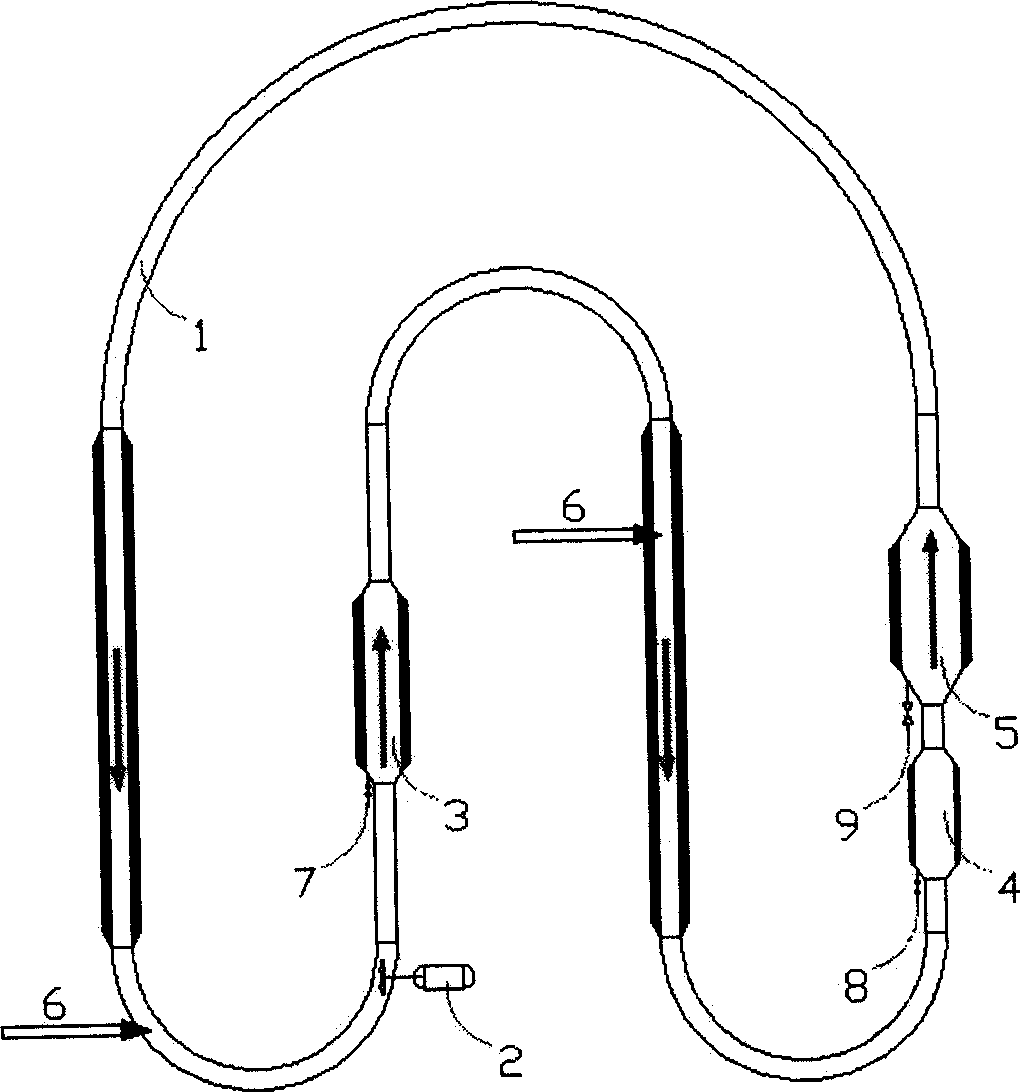

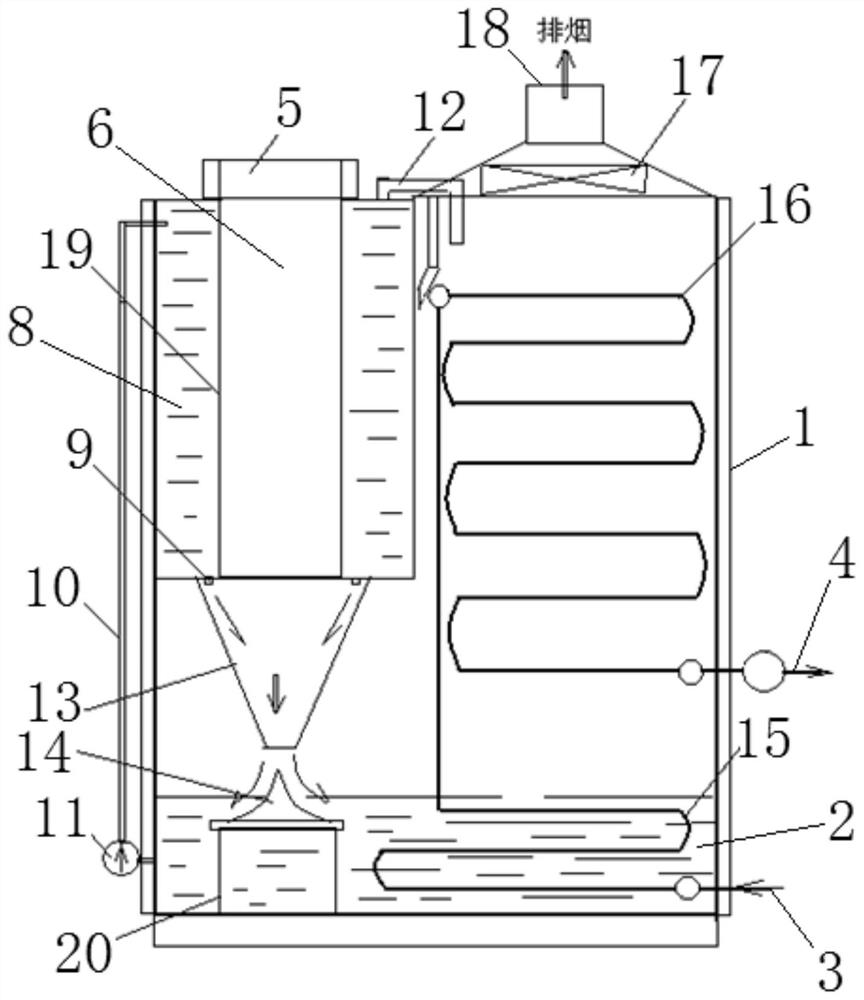

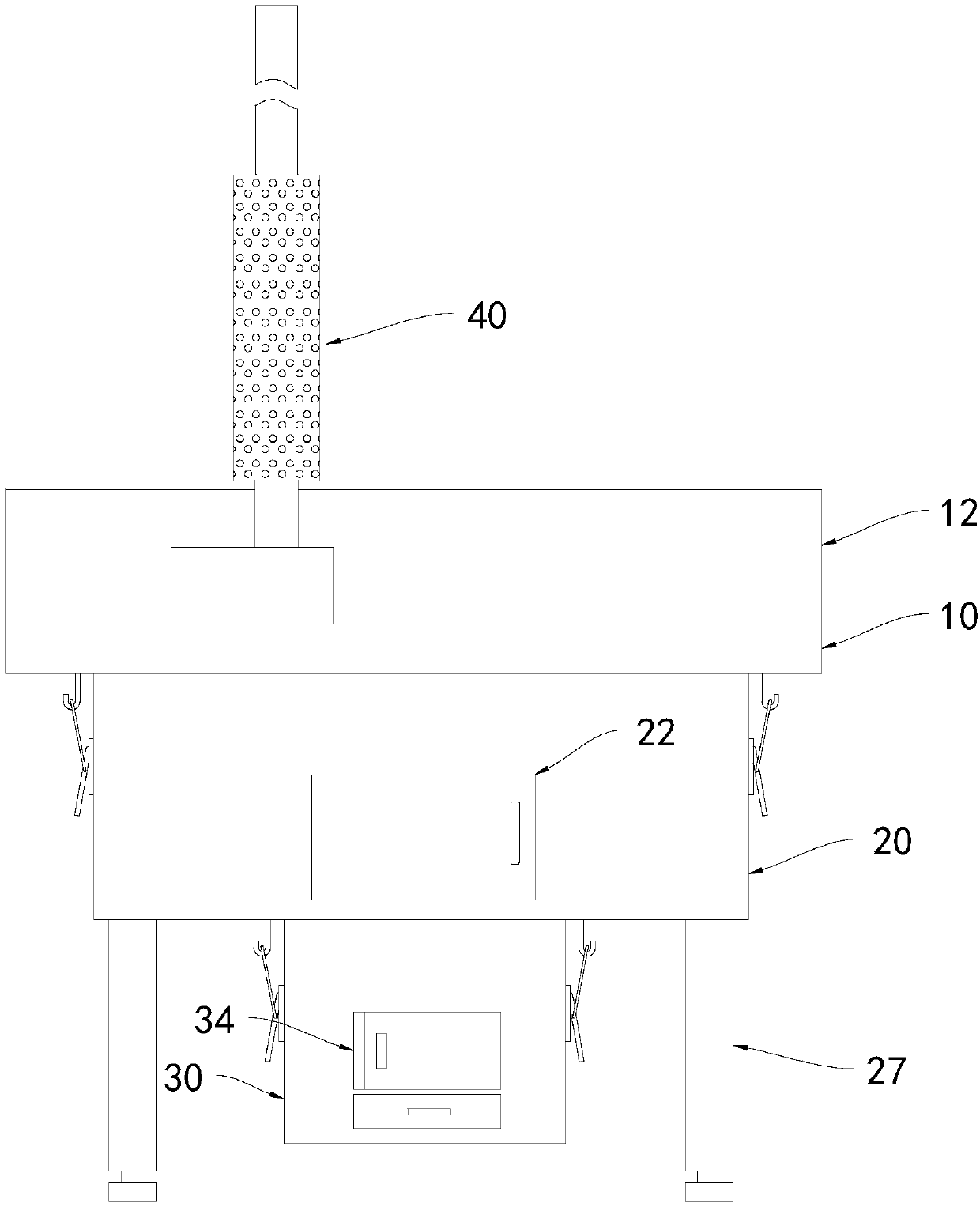

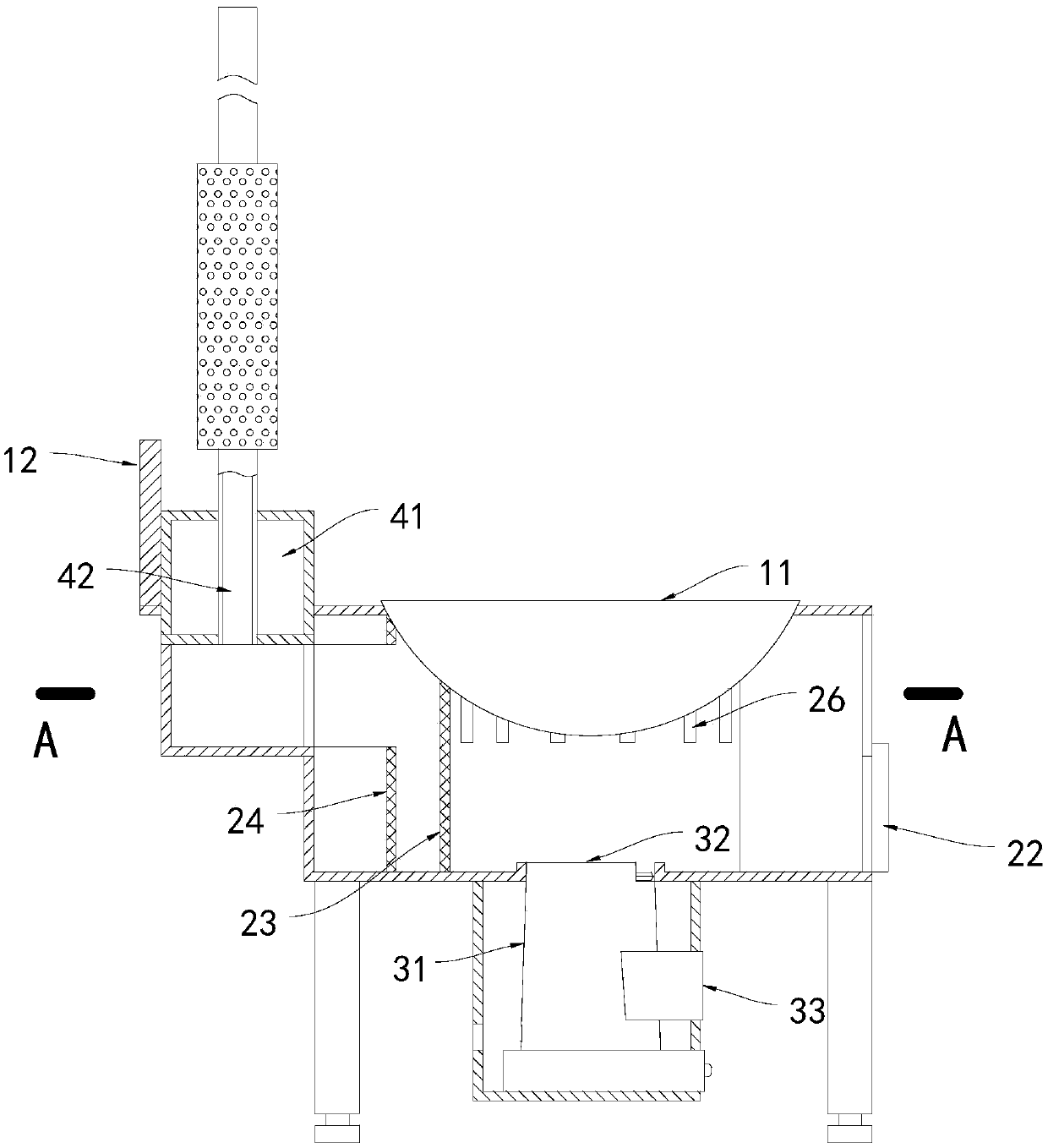

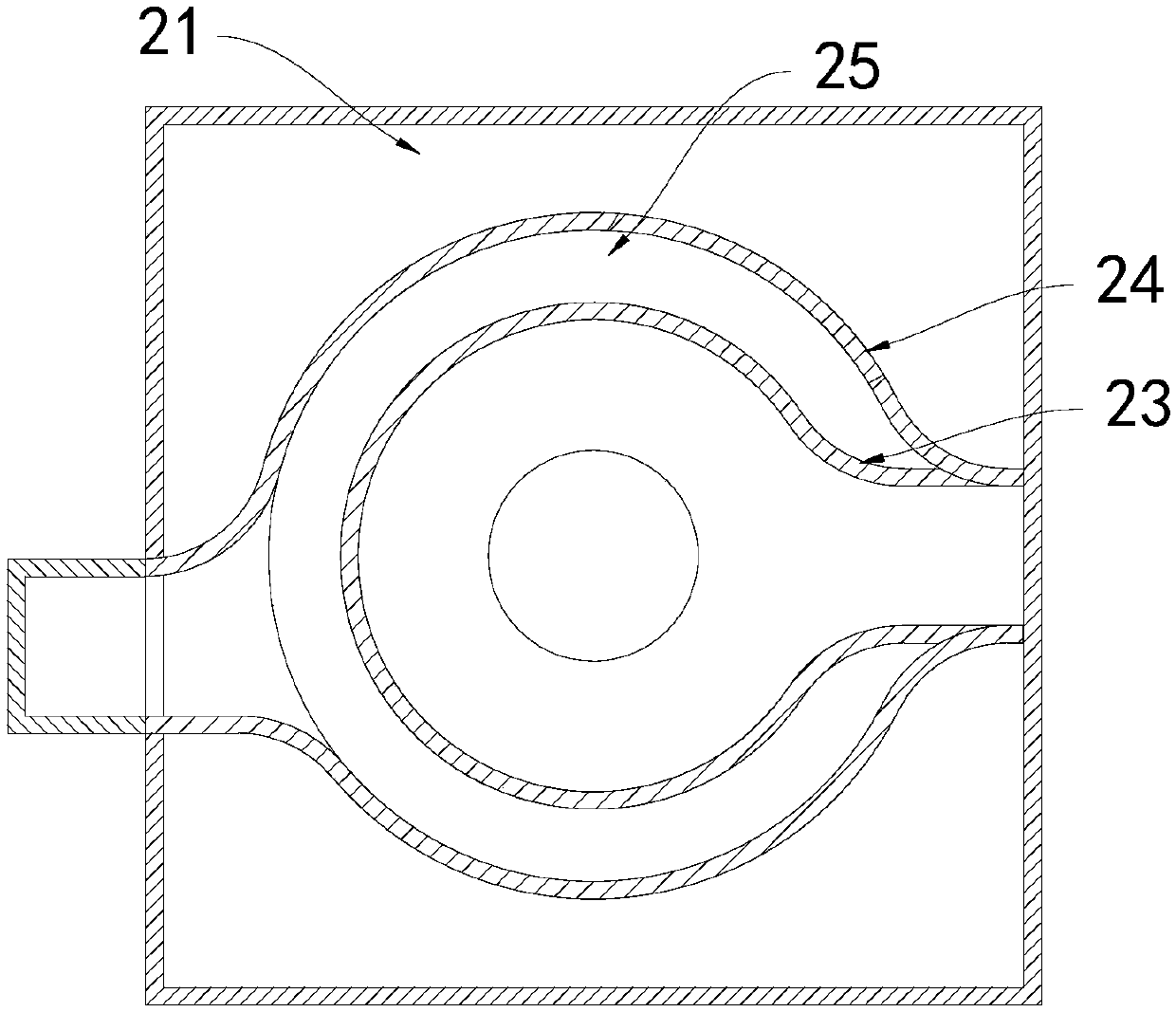

Vertical U-shaped gasification heating equipment

ActiveCN111780410AImprove heat transfer effectEffectively adjust working conditionsChemical industryStorage heatersIndustrial gasThermodynamics

The invention relates to vertical U-shaped gasification heating equipment. The equipment comprises a shell, a bottom water pool arranged in the shell and a heat source unit and a heated unit arrangedin the shell side by side, wherein the bottoms of the heat source unit and the heated unit are located in the bottom water pool, the heat source unit comprises a combustion mechanism and an injectionguide mechanism which are arranged up and down respectively, a fluid inlet and a fluid outlet are formed in the side face of the shell, the heated unit communicates with the fluid inlet and the fluidoutlet, and a smoke exhaust unit is arranged above the heated unit. Compared with the prior art, the equipment can be used for heating industrial gas or industrial liquid, is wide in application range, increases a heat exchange rate, improves an energy utilization rate, and has a peak regulation effect, so that the equipment is higher in working usability, economical and convenient.

Owner:SHANGHAI UNIV OF ENG SCI

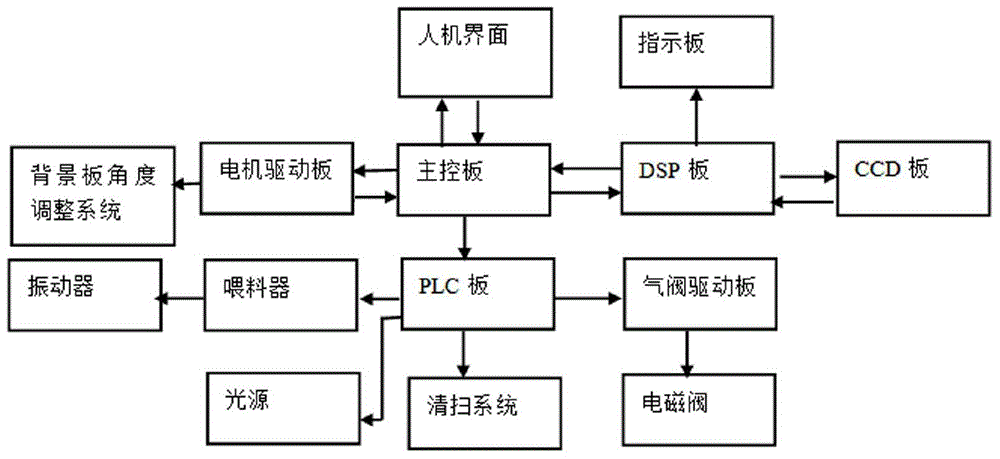

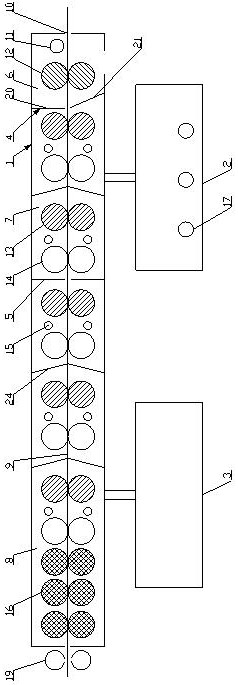

Cereal color sorting control system

InactiveCN104133395AEconomically flexibleRealize real-time controlProgramme control in sequence/logic controllersControl systemTime control

The invention discloses a cereal color sorting control system. The cereal color sorting control system is characterized by comprising a main control board, wherein the main control board is connected with a human-computer interface, a DSP board, a motor driver board and a PLC board; the DSP board is connected with a CCD board and an indicator board; the motor driver board is connected with a background board angle adjusting system; the PLC board is connected with a feeder, a light source, a sweeping system, an air valve driver board and the motor driver board; the feeder is connected with a vibrator, and the air driver board is connected with an electromagnetic valve. Compared with the prior art, the cereal color sorting control system has the advantages that stability, reliability, economy and flexibility are achieved, the small, exquisite and complete control system is formed through expansion of an output port of a single chip microcomputer of the main control board, real-time control and adjustment of all working parts are achieved, the color sorting rate is improved, and the bring-out rate is reduced; the control system can be conveniently transplanted into other systems.

Owner:JIAMUSI UNIVERSITY

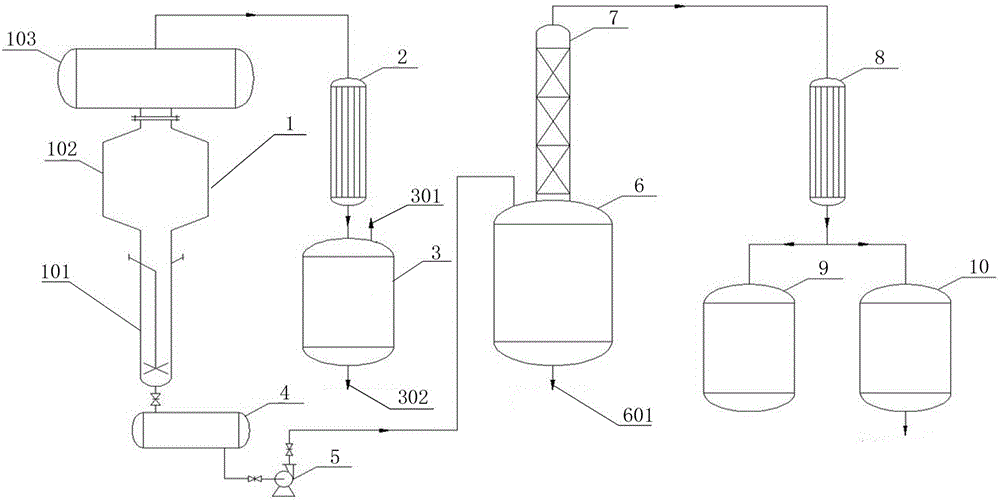

Reaction unit for synthetic production of sebaconitrile and synthetic technique of sebaconitrile

InactiveCN106824038AReduce usageReduce flow ratePhysical/chemical process catalystsChemical/physical/physico-chemical stationary reactorsVapor–liquid separatorDistillation

A reaction unit for synthetic production of sebaconitrile comprises an ammoniating kettle, an ammonia cooler, a gas-liquid separator, a crude sebaconitrile receiving tank, a crude sebaconitrile conveying pump, a crude sebaconitrile distillation kettle, a crude sebaconitrile distillation column, a fine sebaconitrile cooler, a fine sebaconitrile receiving tank, a high-low boiling receiving tank and an evacuating system; the ammoniating kettle in the reaction unit allows full contact of reaction materials and allow reaction condition parameters, such as temperature and pressure, to be well adjusted, full ammoniating of the materials is guaranteed, the synthetic technique allows the materials to be fully and reasonably utilized in maximum extent, and the yield and purity of the finished sebaconitrile are guaranteed; the reaction unit for synthetic production of sebaconitrile is reasonable in layout, the technique is highly operable, the temperatures of the parts in the reaction unit, such as the ammoniating kettle and the crude sebaconitrile distillation kettle, are easy to adjust, the parts are convenient to operate, and the reaction unit has high overall recycling rate of materials, and has high production precision and quality.

Owner:PUYANG SHENGYUAN ENERGY TECH

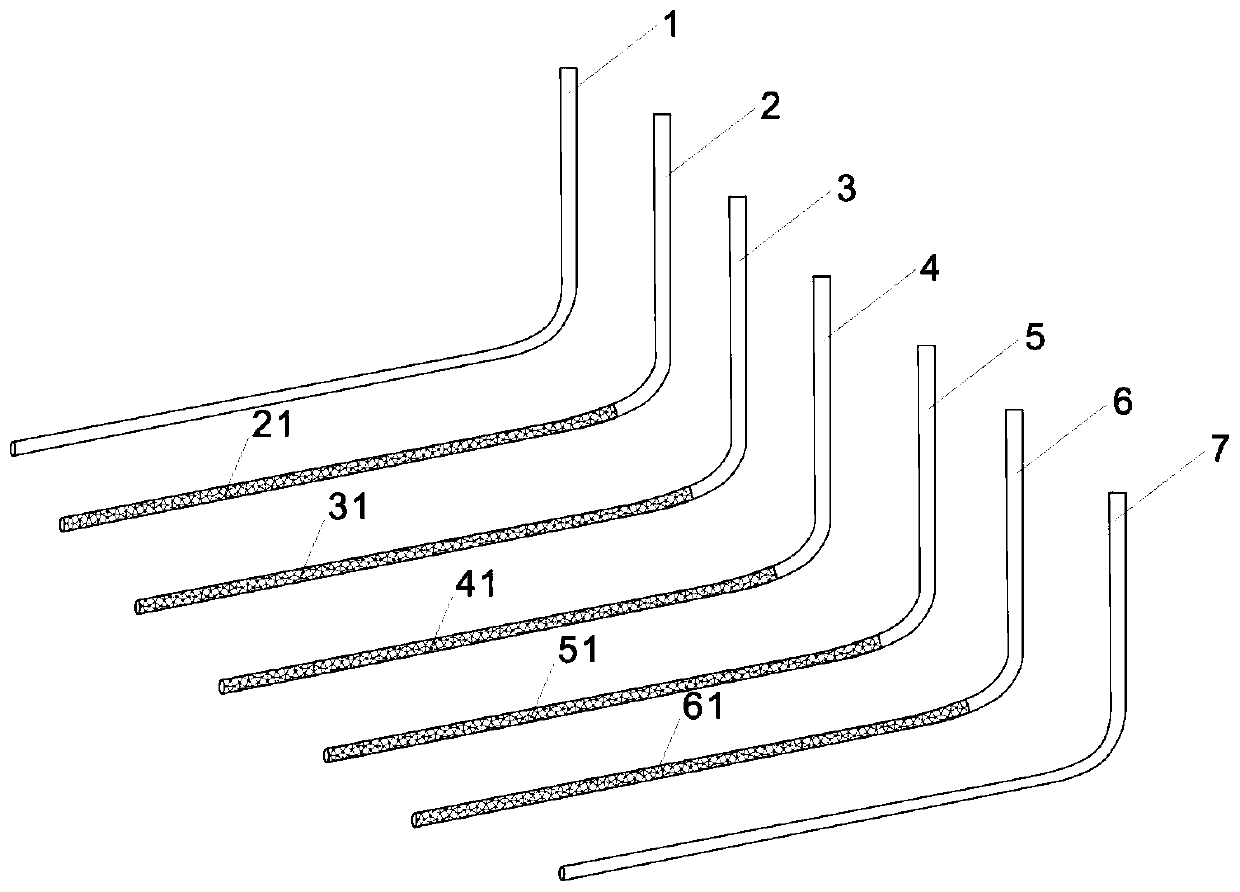

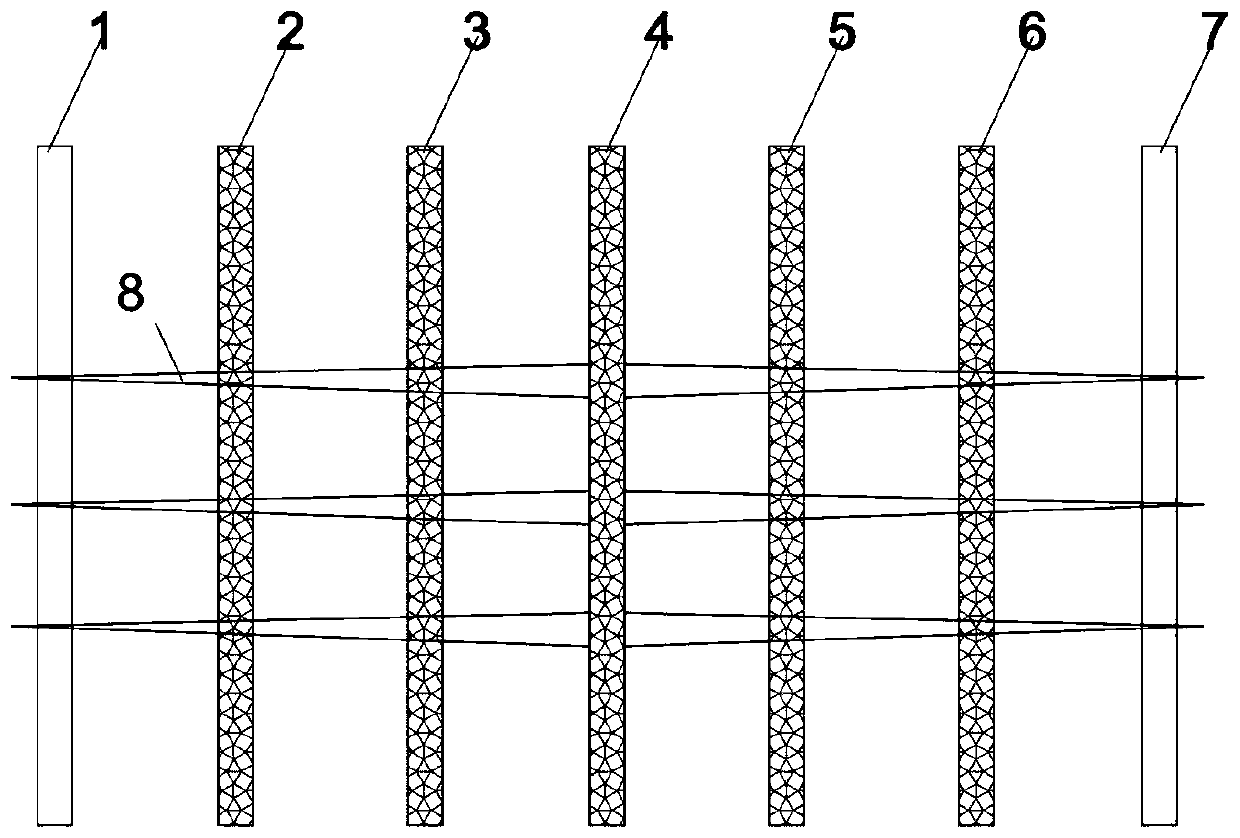

Method for installing telescopic shifting finger sleeve of harvester cutting table drum and telescopic shifting finger device

The invention discloses a method for installing a telescopic shifting finger sleeve of a harvester cutting table drum and a telescopic shifting finger device. The telescopic shifting finger sleeve is sleeved on a telescopic shifting finger and installed on the harvester cutting table drum at the same time, and the telescopic shifting finger sleeve is installed on the wall of the harvester cutting table drum from the inner surface of the harvester cutting table drum. The telescopic shifting finger device comprises the harvester cutting table drum, the telescopic shifting finger, the telescopic shifting finger sleeve and a telescopic shifting finger driving mechanism; the telescopic shifting finger and the telescopic shifting finger driving mechanism are installed in the harvester cutting table drum, and the telescopic shifting finger stretches and retracts under the drive of the telescopic shifting finger driving mechanism during rotating together with the harvester cutting table drum; and the telescopic shifting finger sleeve is a lantern ring with a fixed lug, the upper part of the lantern ring is provided with a seam allowance, the outside diameter of the seam allowance is matched with the size of a hole, which is used for installing the telescopic shifting finger sleeve, of the harvester cutting table drum, the telescopic shifting finger sleeve is installed in the hole from the inner surface, and the outer end face of the seam allowance of the installed telescopic shifting finger sleeve is 0.5 to 1 millimeter higher than that of the cutting table drum.

Owner:株洲联合收割机有限公司

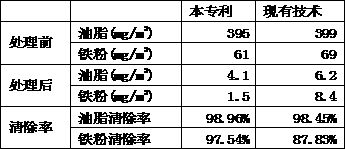

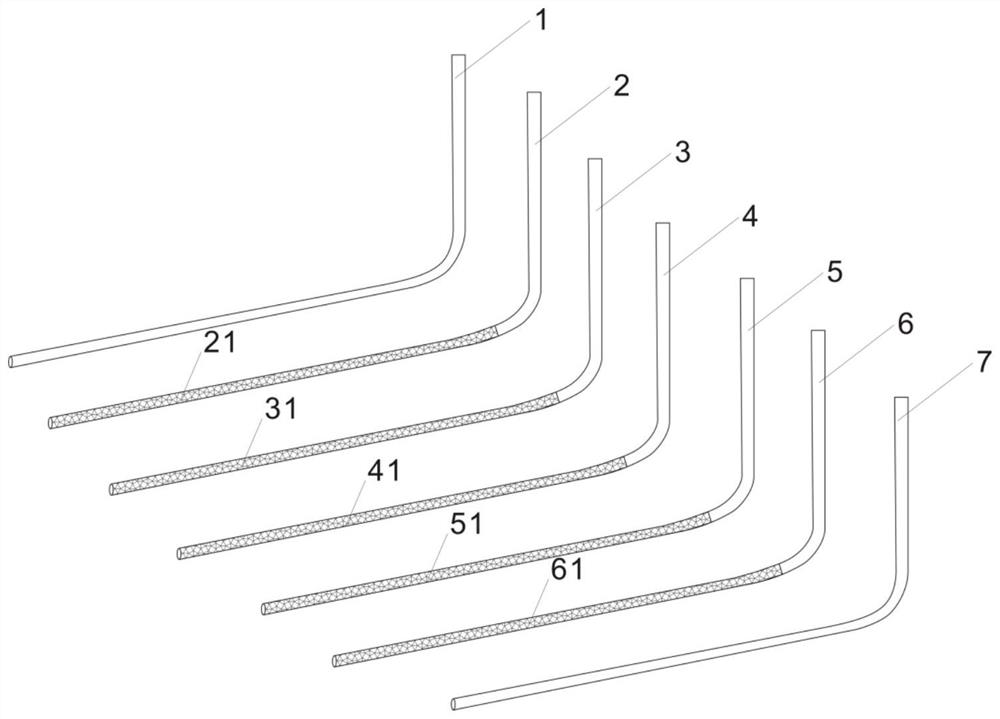

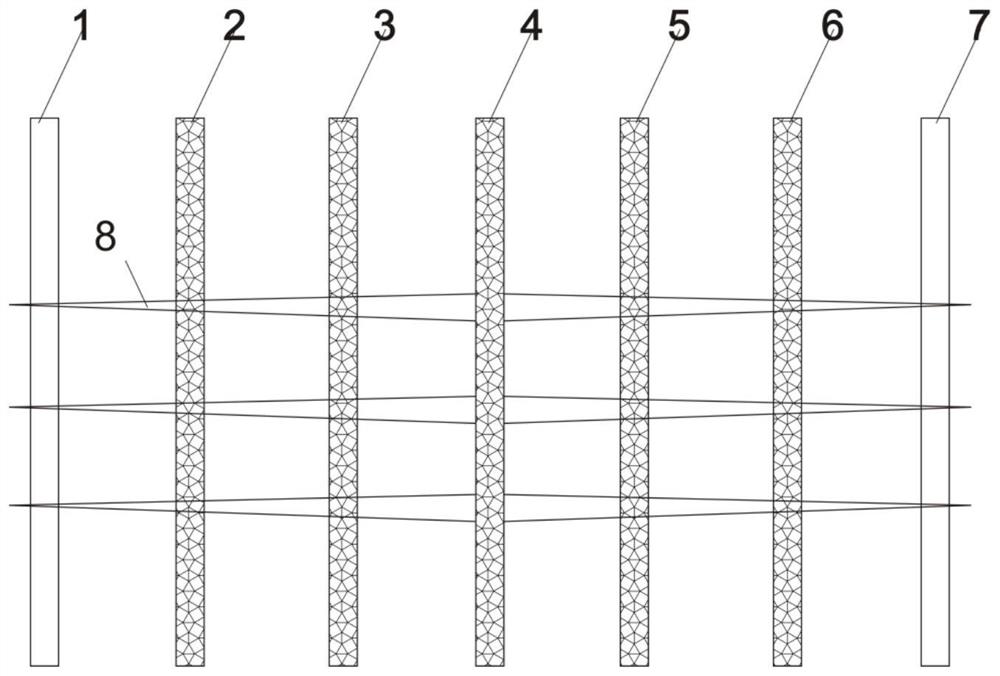

Steel belt cleaning device

PendingCN112371574AEasy to cleanReduce carry outDrying gas arrangementsCleaning using toolsProcess engineeringSteel belt

The invention discloses a steel belt cleaning device, and belongs to the technical field of drainage pipes. The steel belt cleaning device comprises a cleaning bin, an air cooling structure, a degreasing agent circulating pool and a clear water circulating pool; the interior of the cleaning bin is sequentially divided into a scrap iron cleaning chamber, a degreasing chamber and a cleaning chamberfrom front to back; the degreasing chamber is located above the degreasing agent circulating pool and connected with the degreasing agent circulating pool through a water return pipeline; the cleaningchamber is positioned above the clear water circulating pool and is connected with the clear water circulating pool through a water return pipeline; a rough surface rubber roller pair and a magneticrod are arranged in the scrap iron cleaning chamber; at least two sets of cleaning units are sequentially arranged in the degreasing chamber from front to back; at least two sets of cleaning units andat least one set of extrusion rubber roller pair are sequentially arranged in the cleaning chamber from front to back; each cleaning unit comprises a conveying rubber roller pair, a brush roller pairand a spraying structure, wherein the conveying rubber roller pair and the brush roller pair are arranged side by side front and back, and the spraying structure is arranged between the conveying rubber roller pair and the brush roller pair; a scraper pair is arranged or not arranged behind each cleaning unit; and the degreasing chamber and the cleaning chamber are each internally provided with at least one scraper pair.

Owner:HUBEI TUNCANG PIPE TECH DEV CO LTD

Method for in-situ transformation and exploitation of shale oil and gas in medium and low maturity shale oil with large well spacing

ActiveCN110005390BOvercoming the problem of small well spacing in in-situ miningAvoid closingFluid removalThermodynamicsHorizontal wells

The invention provides a method for in-situ conversion and exploitation of shale oil and gas with medium and low maturity shale oil with large well spacing, comprising deploying at least 3 horizontal wells with an odd number of wells at a well spacing of 15-50 meters in the reservoir group; fracturing the reservoir, dividing the fractures into three sections at equal intervals from the central injection well to the production well, and injecting different types of proppant into the three sections in three stages; injecting hot gas into the central injection well and electrically heating it, Produced from the production well; when the temperature between the central injection well and the first-line wheel injection well reaches the complete pyrolysis temperature, the central injection well stops electric heating and injects normal temperature gas into it; the first-line wheel injection well turns on electric heating; when the first-line and second-line wheel injection wells After the temperature between the wells reaches the complete pyrolysis temperature, the center injection well stops injecting normal temperature gas; the first wheel injection well stops electric heating, and injects normal temperature gas into it; The temperature of the reservoir between the injection wells adjacent to the last line reaches the complete pyrolysis temperature.

Owner:PETROCHINA CO LTD

Water-soluble inorganic quenching agent and production process thereof

The invention relates to a novel water-based inorganic quenching agent which is characterized by being prepared from the following components in percentage by weight: 0.1 to 10 percent of glycerol, 0.1 to 10 percent of diethanol amine, 0.1 to 10 percent of triethanolamine, 0.1 to 10 percent of sodium benzoate, 0.1 to 10 percent of sodium formate, 0.005 to 1 percent of sodium hydroxide and the balance of water. The quenching agent provided by the invention is high in cooling speed in a high-temperature stage and relatively low in cooling speed in a low-temperature stage, so that the quenching agent can satisfy the hardenability of a material and also prevent relatively high internal stress from being generated in a workpiece; therefore, the performance of the workpiece is improved; and furthermore, the quenching agent is safe, environmentally friendly, colorless, tasteless, sediment-free, non-combustible, pollution-free, inverse solving-free and low in use cost, and little quenching agent can be brought out.

Owner:李广东

Combined type all-closed smoke dust removal energy-saving firewood stove

PendingCN109579056AWon't pile upAvoid accumulationLighting and heating apparatusStove/ranges for heating waterFirewoodCombustion chamber

The invention discloses a combined type all-closed smoke dust removal energy-saving firewood stove. The combined type all-closed smoke dust removal energy-saving firewood stove comprises a stove bodyand a table board, wherein the table board is arranged at the upper end of the stove body. A stove combustion chamber is formed in the stove body. An oxygen supplementation box is arranged below the stove body and internally provided with an oxygen adding furnace. The upper end of the oxygen adding furnace is provided with a gas outlet communicating with the stove combustion chamber. A movable grate is arranged at the gas outlet. Carrying blocks for supporting the grate are arranged on the furnace wall of the oxygen adding furnace. A gas inlet is formed in the front face of the lower end of the oxygen adding furnace. A control damper is arranged at the gas inlet. The furnace wall of the oxygen adding furnace is hollow. The outer wall of the oxygen adding furnace is provided with a subsidiary hole. The inner wall of the oxygen adding furnace is provided with breeze holes. The table board is detachably connected with the stove body, and the stove body is detachably connected with the oxygen supplementation box. The edge of the stove body is provided with a dismountable water-cooling type funnel. The combined type all-closed smoke dust removal energy-saving firewood stove has the beneficial effects that ignition can be achieved easily, oxygen adding, ash discharging and carbon discharging are higher in efficiency, and transportation is convenient to conduct; and in addition, the combined type all-closed smoke dust removal energy-saving firewood stove has the beneficial effects that energy is saved, little smoke dust is generated, heating is conducted uniformly, and the heightcan be adjusted.

Owner:胡肖成

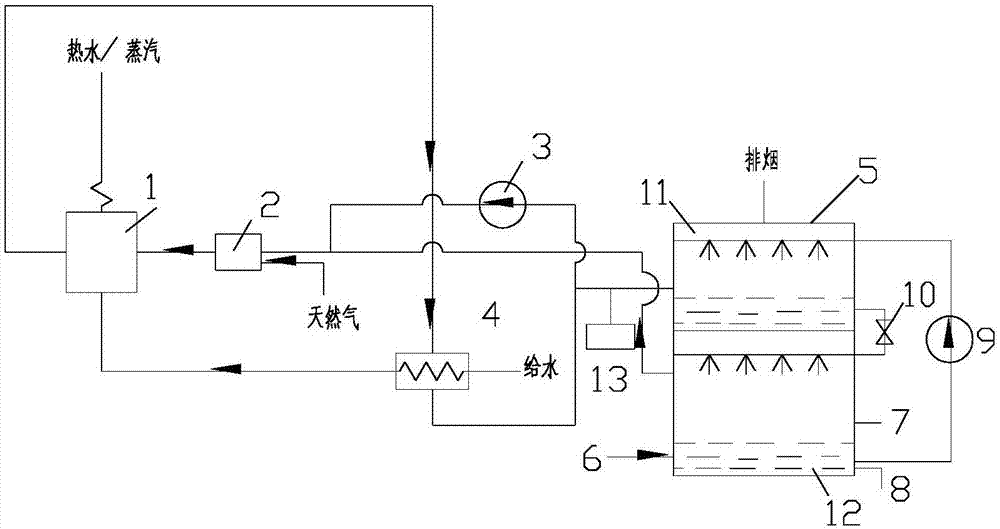

Contact heat exchange desulfurization and denitrification integrated natural gas condensation boiler

PendingCN107490191AAvoid pollutionImprove heat transfer efficiencyEmission preventionAir heatersWater vaporAir heater

The invention discloses a contact heat exchange desulfurization and denitrification integrated natural gas condensation boiler. A smoke outlet of a combustor communicates with a smoke inlet of a boiler body; a water outlet of a smoke water feeding heat exchanger communicates with a water inlet of the boiler body; a smoke inlet of the smoke water feeding heat exchanger communicates with a smoke outlet of the boiler body; a smoke inlet of a contact condensation smoke cooler communicates with the smoke outlet of the smoke water feeding heat exchanger through a first pipeline; an ozone adding port is formed in the first pipeline, and communicates with an ozone adding device; a wet air outlet of a contact air heater communicates with a combustion assistance gas inlet of the combustor; and a condensation absorbing liquid inlet of the contact air heater communicates with a condensation absorbing liquid outlet of the contact condensation smoke cooler. The desulfurization and denitrification natural gas condensation boiler is simple in structure, environment-friendly, high in efficiency, lower in investment cost and higher in utilization rate of latent heat of water vapor in discharged smoke.

Owner:XI AN JIAOTONG UNIV

Method and device for preventing coarse coal-gas from fluctuating in fixed bed type reactor

InactiveCN1640995APrevent backflowHigh speedGasifier feeding meansCombined combustion mitigationFixed bedSolid fuel

Process for preventing crude gas fluctuations in fixed bed reactors comprises charging the reactor from a supply container placed under a reactor pressure with a charge consisting of solid carbon-containing waste materials mixed with carbon-containing fuels. The charge is guided on a discharge unit to form a natural material closure. The discharge is cooled and operated discontinuously or continuously operated. - An INDEPENDENT CLAIM is also included for a device for carrying out the process. Preferred Features: During operation of the discharge unit, the inhomogeneous solid mixture is removed through a gap of corresponding size between the inner wall of the supply container and cooled discharge unit.

Owner:SUSTEC SCHWARZE PUMPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com