Reaction unit for synthetic production of sebaconitrile and synthetic technique of sebaconitrile

A technology of sebaconitrile and crude nitrile, which is applied in the field of reaction devices for the synthesis and production of sebaconitrile, which can solve problems such as complex operation steps such as temperature adjustment, difficulty in ensuring the production accuracy of finished products, and difficulty in accurately grasping operating temperature, etc., and achieves enhanced human reliability. Operability, convenient reaction progress, good effect of temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

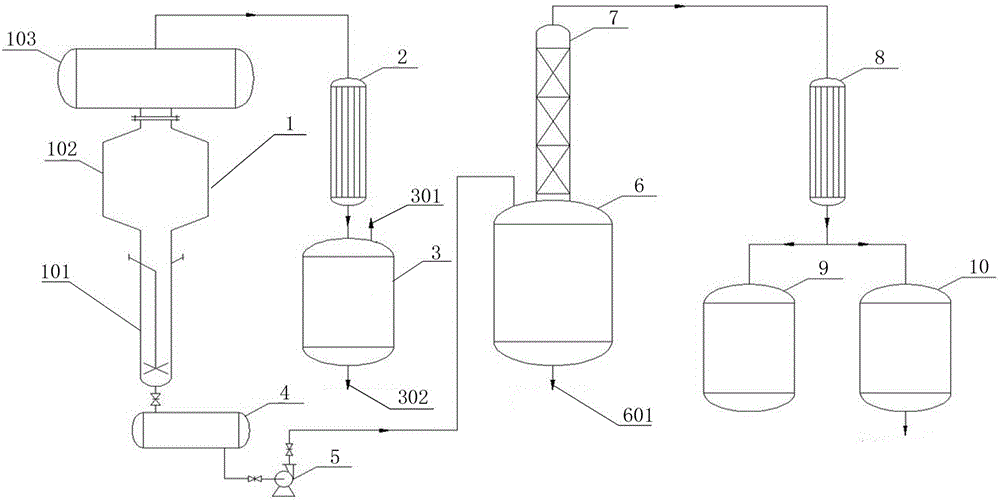

[0031] A reaction device for the synthesis and production of sebaconitrile, mainly comprising an ammoniation kettle 1, an ammonia gas cooler 2, a gas-liquid separator 3, a crude nitrile receiving tank 4, a crude nitrile delivery pump 5, a crude nitrile distillation tank 6, a crude nitrile Distillation tower 7, refined nitrile cooler 8, refined nitrile receiving tank 9, high and low boiling receiving tank 10, vacuum system and cooling system provided on multiple devices.

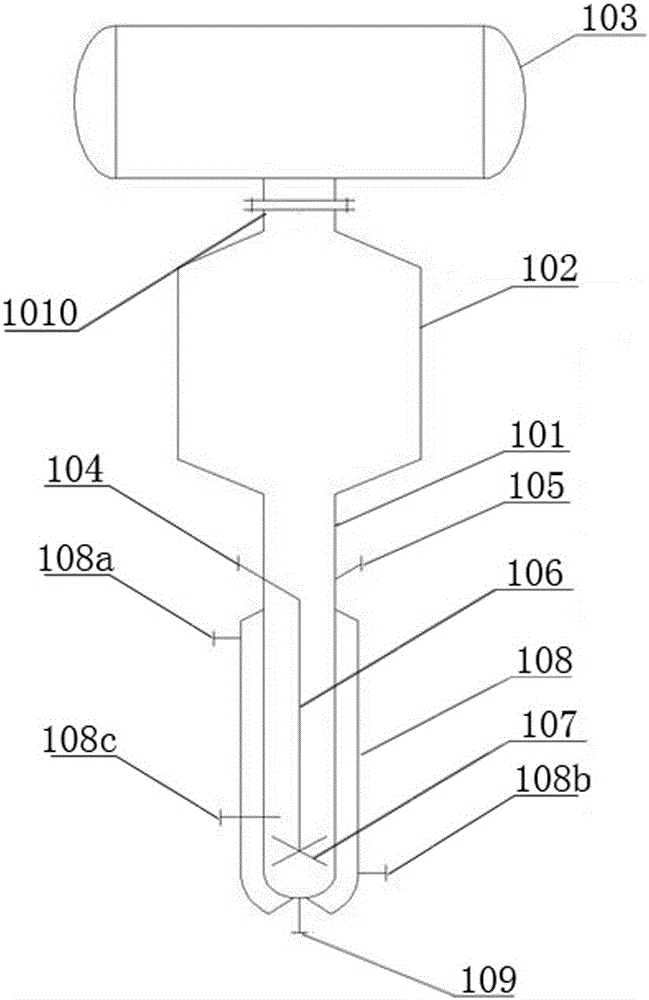

[0032] The core equipment wherein is the ammoniation kettle 1, and the ammoniation kettle comprises a cylindrical shell 101, an enlarged buffer 102 connected to the top of the cylindrical body 101 and an upper separator 103 arranged on the top of the enlarged buffer 102, and the cylinder 101 Ammonia gas inlet 104 and material inlet 105 are provided on the side wall, wherein amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com