Patents

Literature

125results about How to "Fully inflated" patented technology

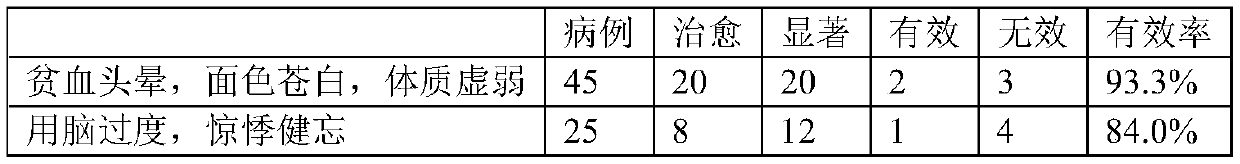

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

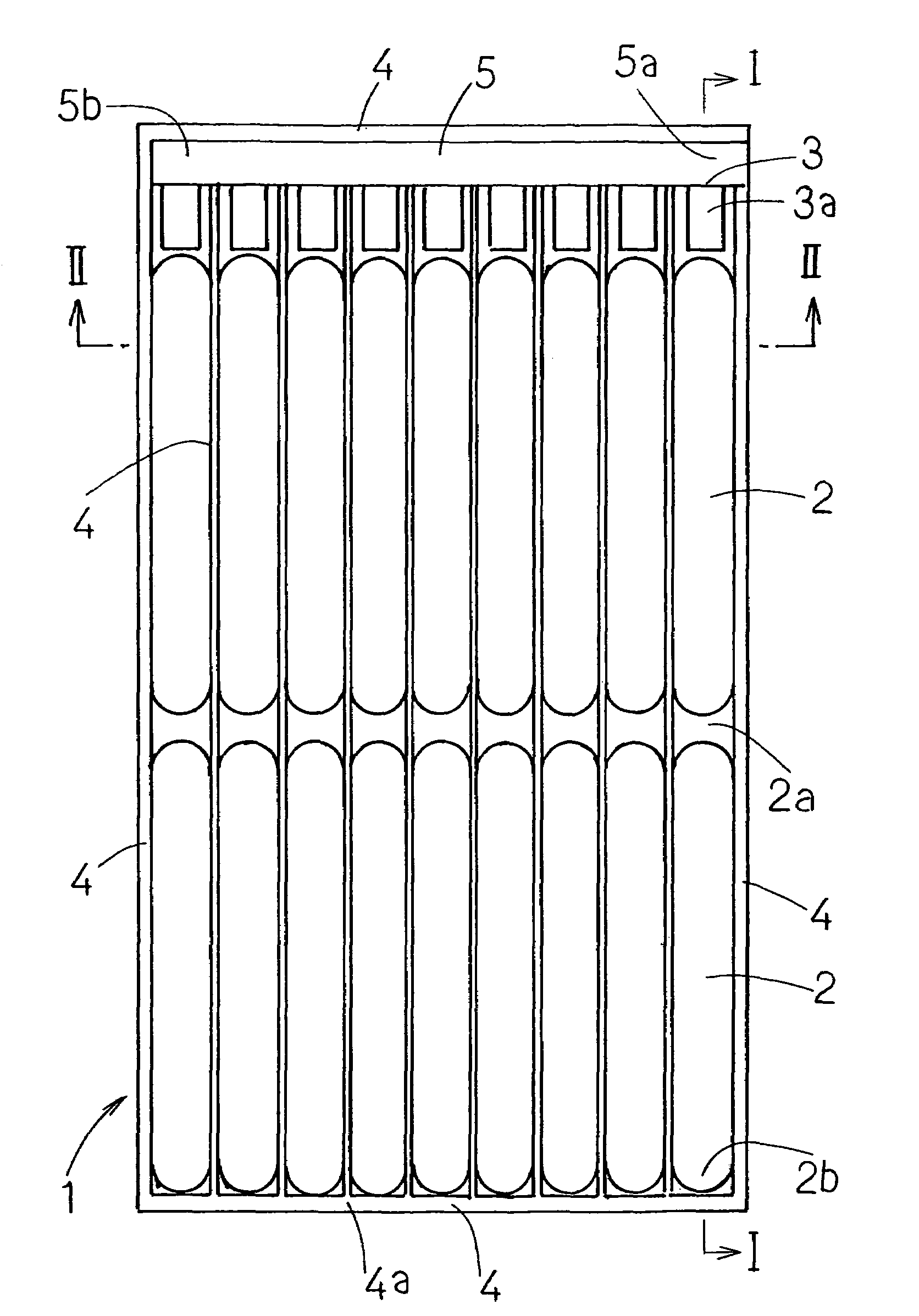

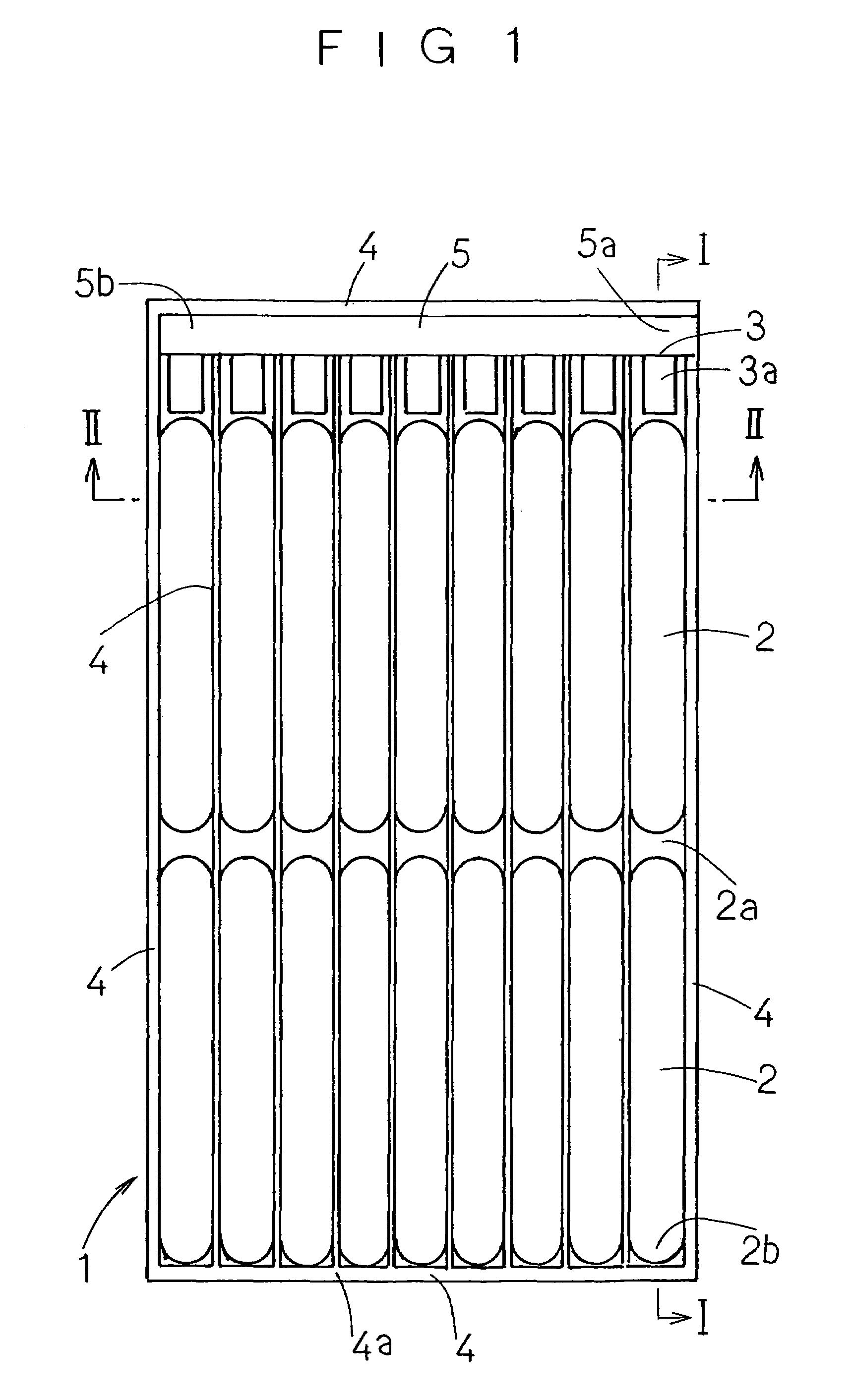

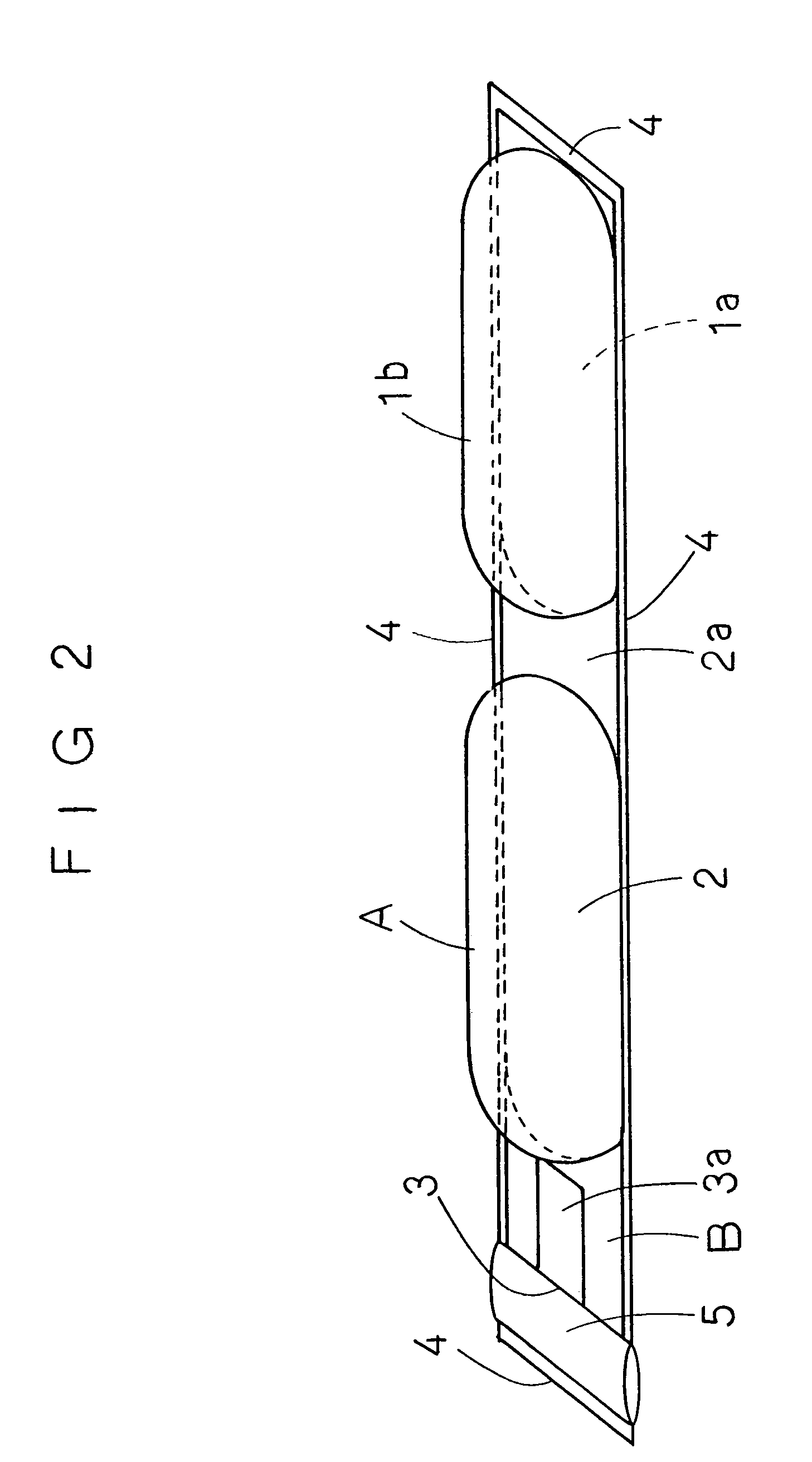

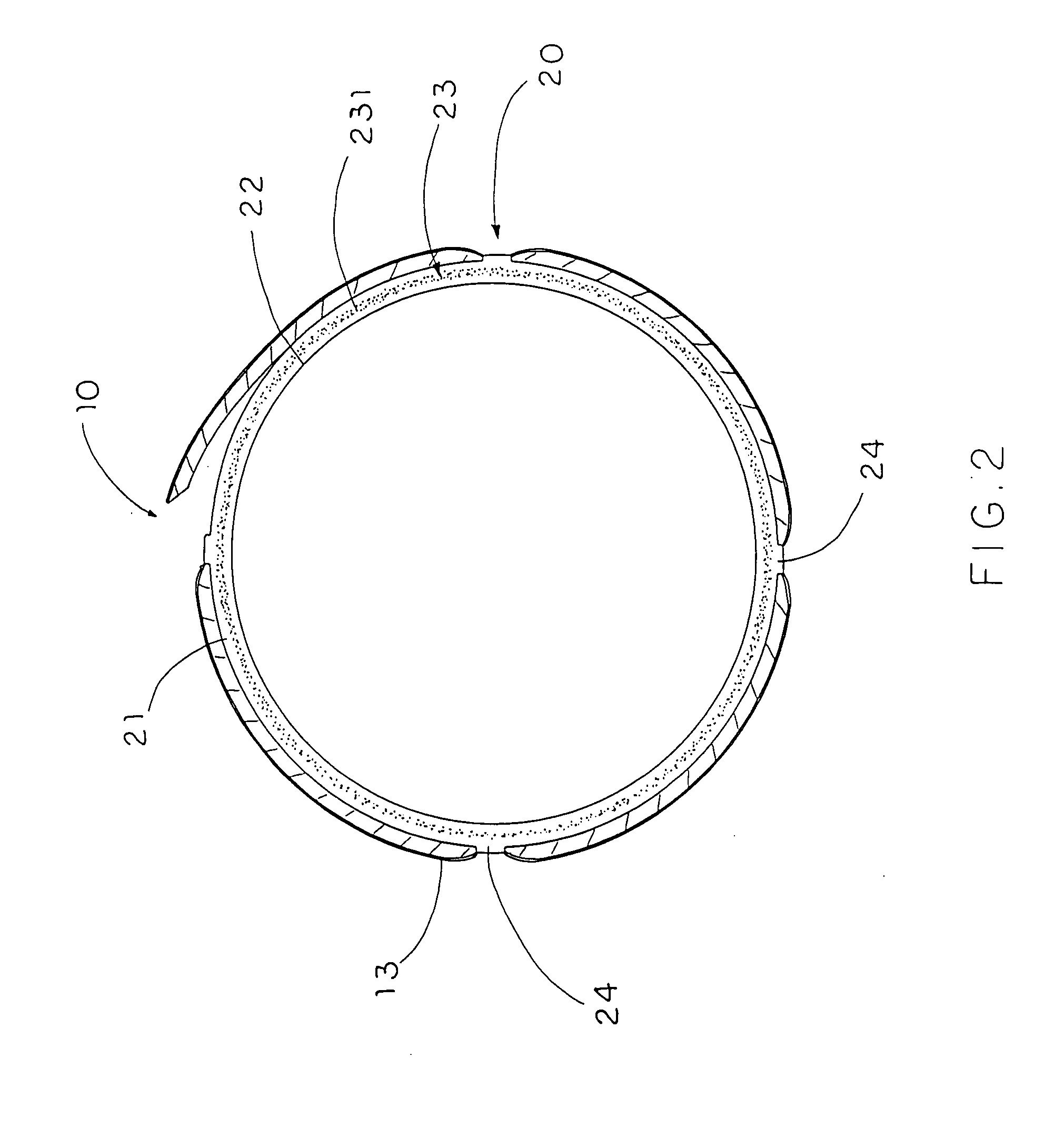

Air-filling cushioning material and method for manufacturing the same

ActiveUS7297387B2Fully inflatedReduce internal volumeWrappersPaper/cardboard articlesCushioningEngineering

The present invention provides an air-filling cushioning material which can sufficiently inflate cells and, in addition, which can hold the crease of the fold when being formed into a three-dimensional configuration. An air-filling cushioning material 1, in which a plurality of cells 2 having an air-fillable space are formed by adhering overlapped flexible sheets 1a, 1b at predetermined spots wherein one sheet 1a is flat while the other sheet 1b is molded beforehand into a configuration of the cells 2 in inflation at the position where the cells 2 are to be formed. Therefore, there is no such problem, as in the conventional case where the cells are formed by tucking the other sheet, the cells cannot inflate well. The cells 2 formed on the other sheet 1b can inflate sufficiently into a configuration as molded.

Owner:KASHIWARASEITAI CO LTD

Method for processing tobacco stem shreds

A method for processing tobacco stem shreds comprises the following steps of: washing stems by water, stem moistening, primary stem storage, stem evaporation, stem pressing, secondary stem storage, stem shred preparation through a recutting process, charging, warming and humidifying, stem shred drying, stem shred expanding, drying and shaping, winnowing, and perfuming and dampening. The strip-shaped stem shreds obtained by the invention have the characteristics of high filling value, soft hand feel, uniform particle phase, rich elasticity, and the like, and have less wood gas and miscellaneous gas, and strong the adsorbability on essence and spices; and the stem shreds are closer to leaf shreds in the physical characteristics, are uniformly distributed in cigarette products and play the role in reducing the cost and reducing harmful components in the smoke, and simultaneously, the production stability can be significantly improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Method for producing bamboo fibre artificial board without glue glued adhesion

InactiveCN101214678AEmission reductionReduce the degree of water condensationDomestic articlesFlat articlesPressure decreasePulp and paper industry

The present invention relates to a production method of self-bonding artificial bamboo fibre board, which includes the following technical processes: (1) bamboo particles, (2) high-temperature steam softening, (3) hot grinding, (4) drying, (5) the spraying of additive, (6) the spreading of material, (7) prepressing, (8) hot pressing, (9) the releasing of a board, (10) cooling, and (11) a finished product. Moreover, in the process of high-temperature steam softening, a softening method of gradually increasing temperature and pressure and momentarily decreasing pressure is applied; in the softening method, the bamboo particles with a water ratio less than 18 percent are loaded into a sealable pressure container, the temperature-increasing rate is controlled within 60 DEG C per hour, when the temperature is raised to 130 DEG C, the pressure is controlled at more than 0.4Mpa, and the temperature and the pressure are maintained for over one hour; later, a steam valve is opened, and the pressure is rapidly decreased to zero, and the pressure-decreasing period is controlled within three hundred and sixty seconds. Consequently, the condensation degree of condensed water can be decreased, the discharging quantity of the condensed water and the loss of carbohydrate and lignin degradation products in the discharging process can be reduced, the bamboo fibres can be sufficiently inflated and rapidly separated, the rate is increased, the concentration of free radical is increased, and the high-strength bonding requirement is satisfied.

Owner:张胜先

Method for abstracting and purifying betulin in birch bark

The invention relates to a method for extracting and purifying the betulin from birch bark. The invention comprises the following procedures, cutting the birch bark into the bark particles, heating, refluxing and extracting by aqueous ethanol solution, filtering, vacuum concentration of the filtrate, cooling, collecting and drying the separated crude betulin. The method of the invention can obtain the betulin with the purity of more than 90 percent, and has the advantages of simple process, lower cost and being suitable for the industrial production.

Owner:CHINA GATEWAY PHARMA DEV CO LTD

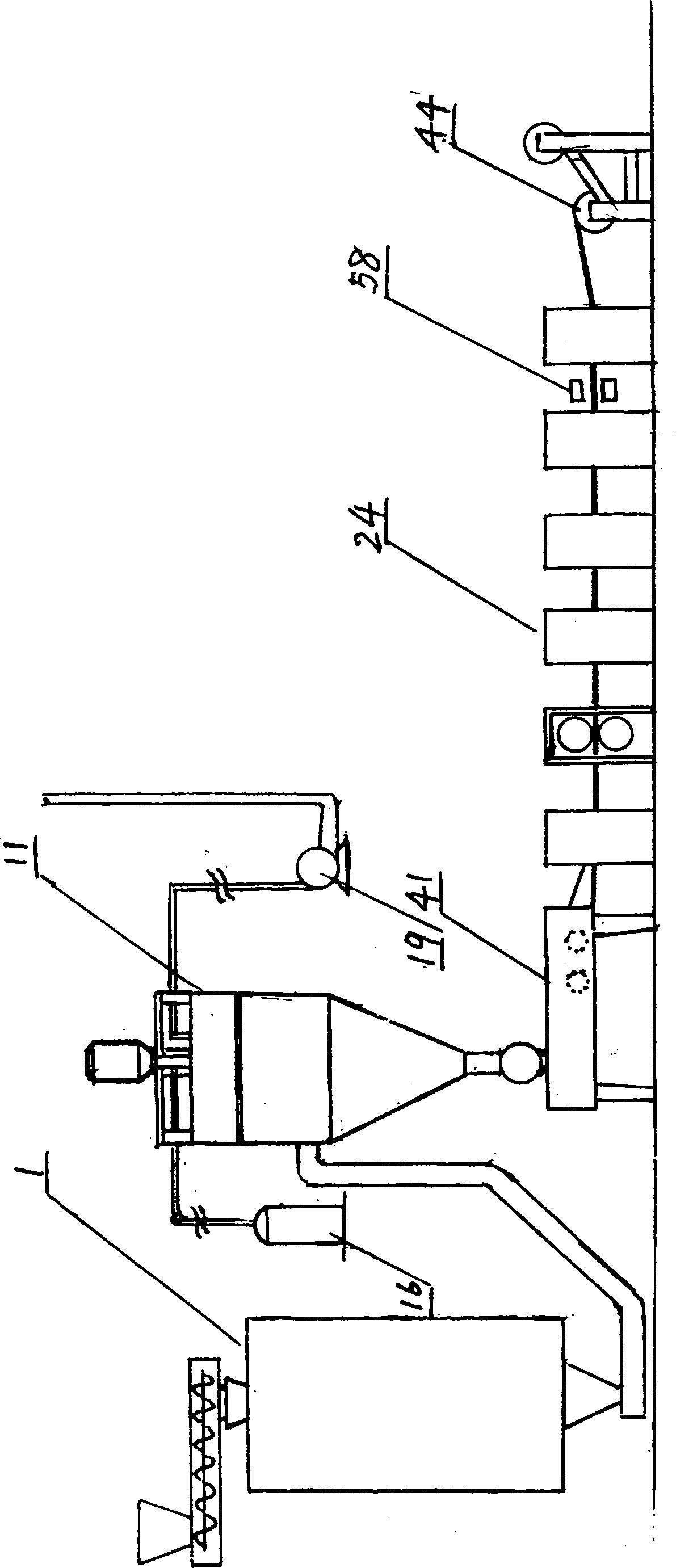

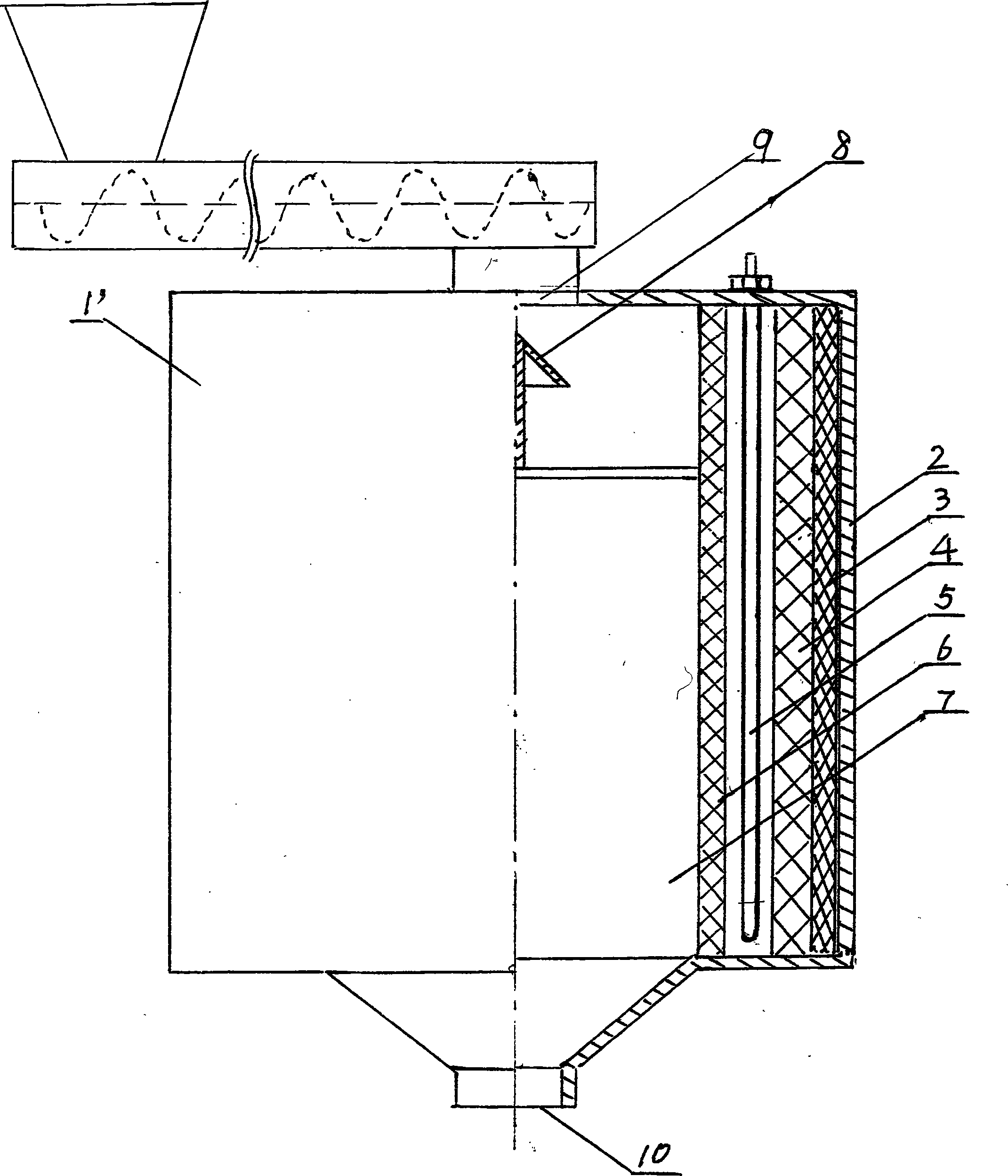

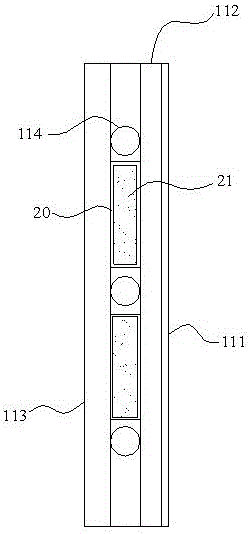

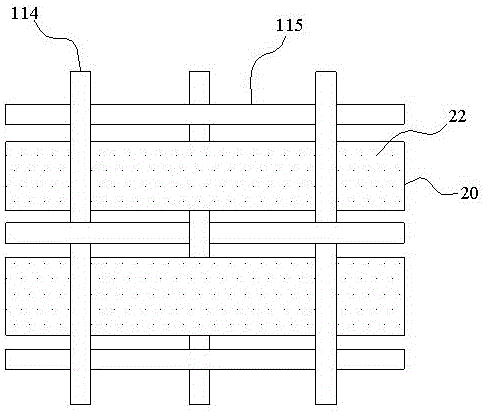

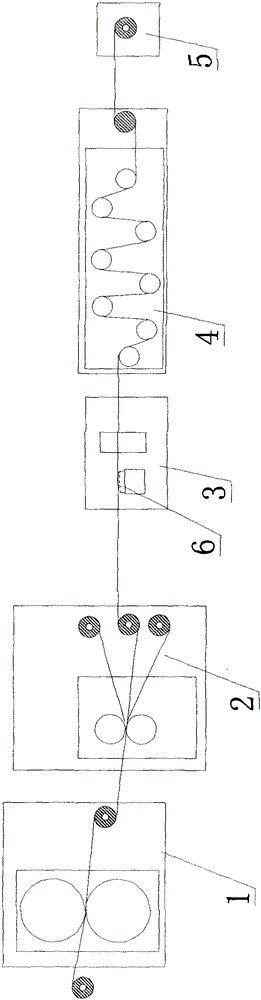

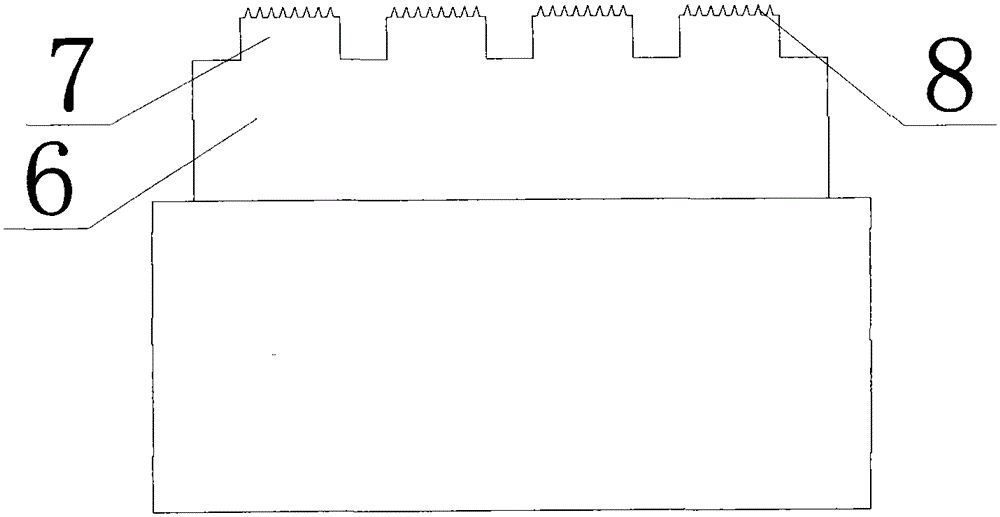

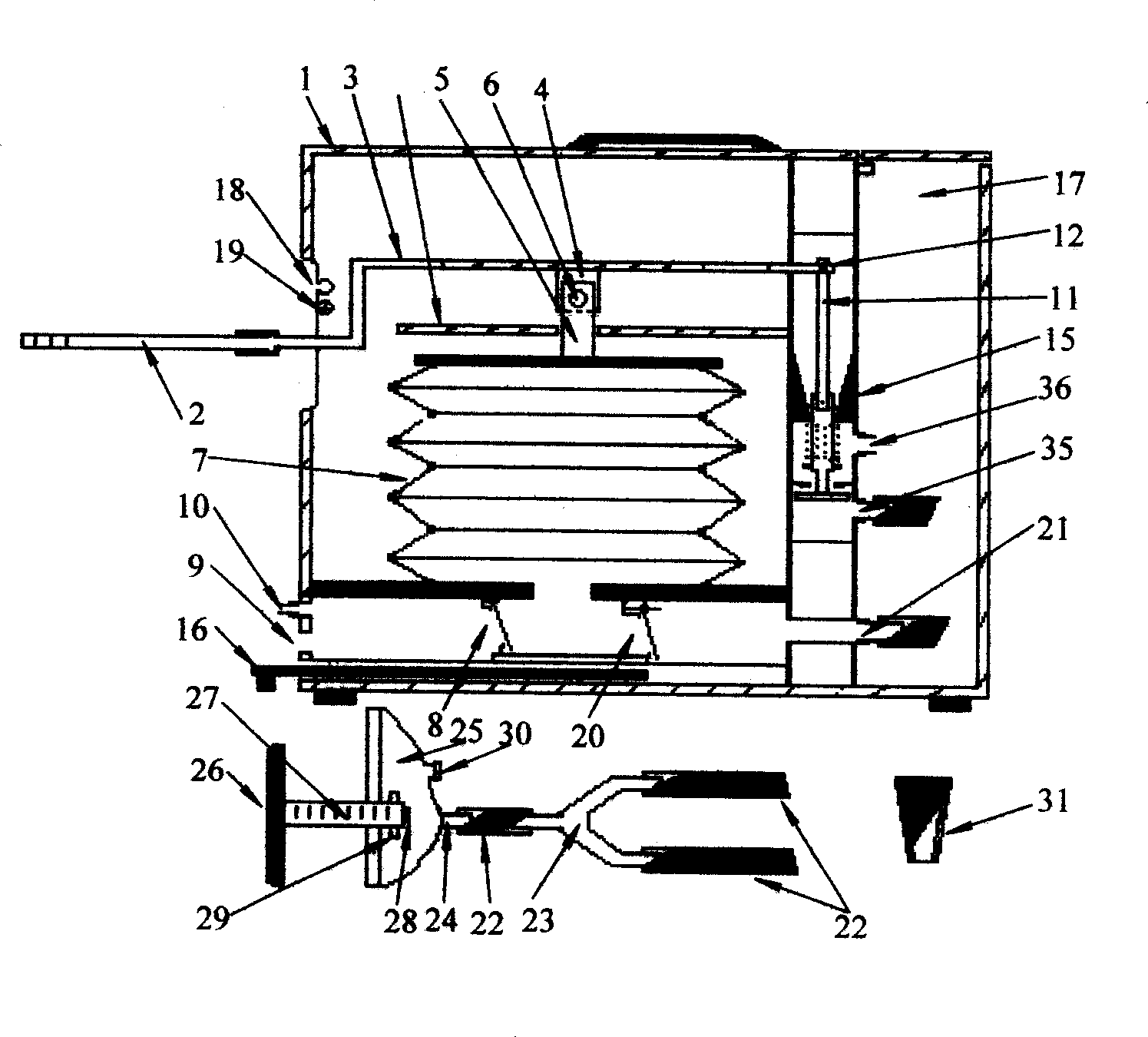

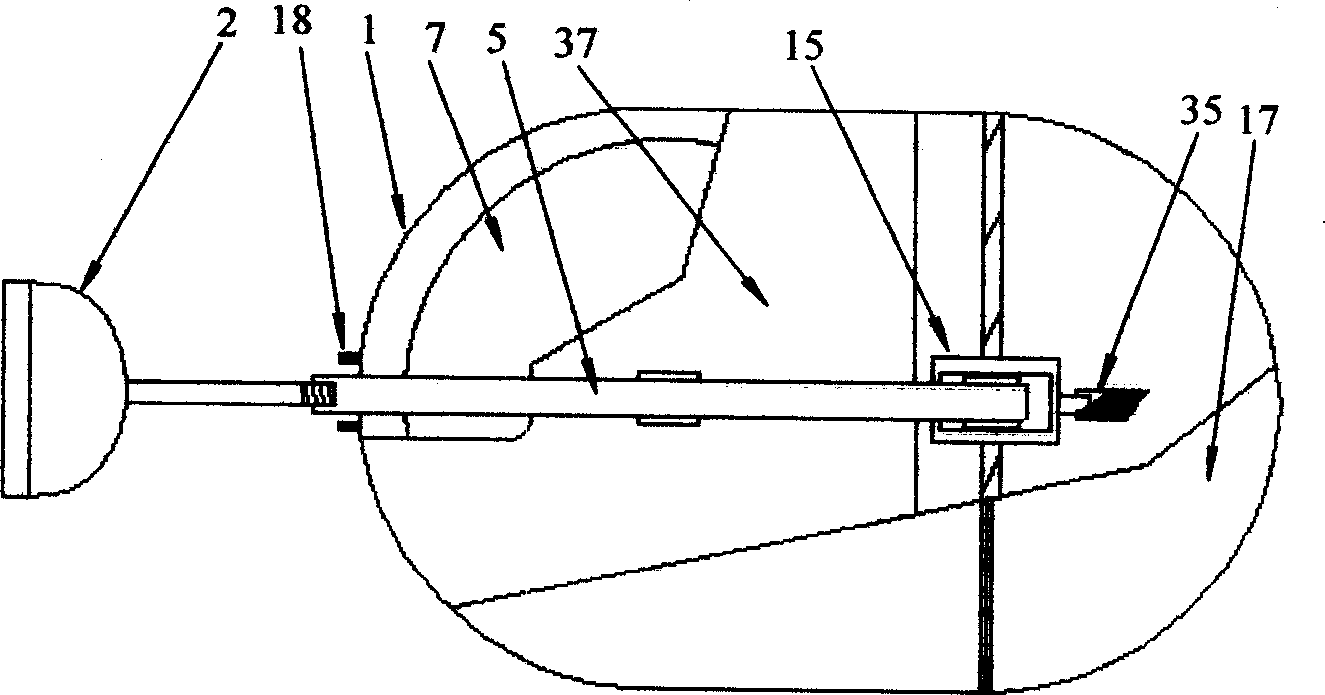

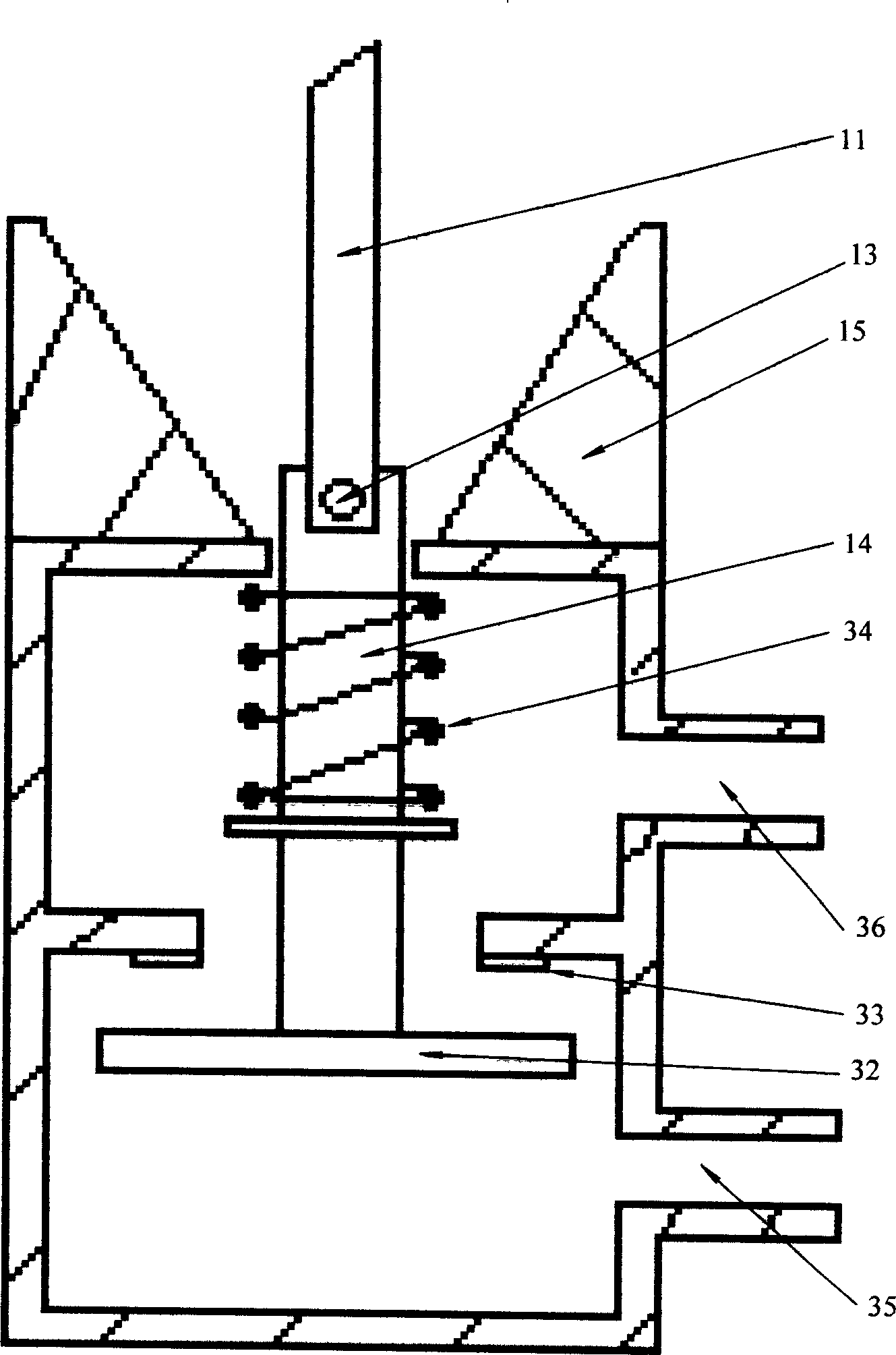

Production line of ultrathin flexible graphite paper

The invention relates to a production line of ultrathin flexible graphite paper, and relates to graphite paper production line equipment. The production line of the ultrathin flexible graphite paper comprises a graphite expansion apparatus, a desulphurization apparatus, a material-distributing apparatus, a calendaring apparatus and a paper-rolling apparatus. The expansion apparatus is a vertical expansion furnace. The desulphurization apparatus comprises a material-distributing groove and a material-distributing spine roller. The calendaring apparatus is composed of a plurality of calendaring machines in arrangement. The calendaring machines are provided with calendaring gap adjusting mechanisms. The production line of the ultrathin flexible graphite paper has the beneficial effects that high pure acidified graphite is used as a raw material; the vertical electrical heating expansion furnace is employed, so that pollutions can be prevented and the graphite is expanded into vermicular graphite; the cloth spindle roller with densely arranged spindle needles along a spiral line is used, so that the thickness of the cloth is uniform; and alternatively arranged calendaring machines with large and small diameter press rollers, middle convex press rollers and a laser thickness gauge closed-loop control system are used by the calendaring apparatus, so that calendaring gaps can be adjusted automatically. With comprehensive application of the above effective measures, high pure ultrathin flexible graphite paper is produced; applications are wide; and blanks of the ultrathin flexible graphite paper and production in China are filled.

Owner:QINGDAO JIUZHENGYUAN MACHINERY

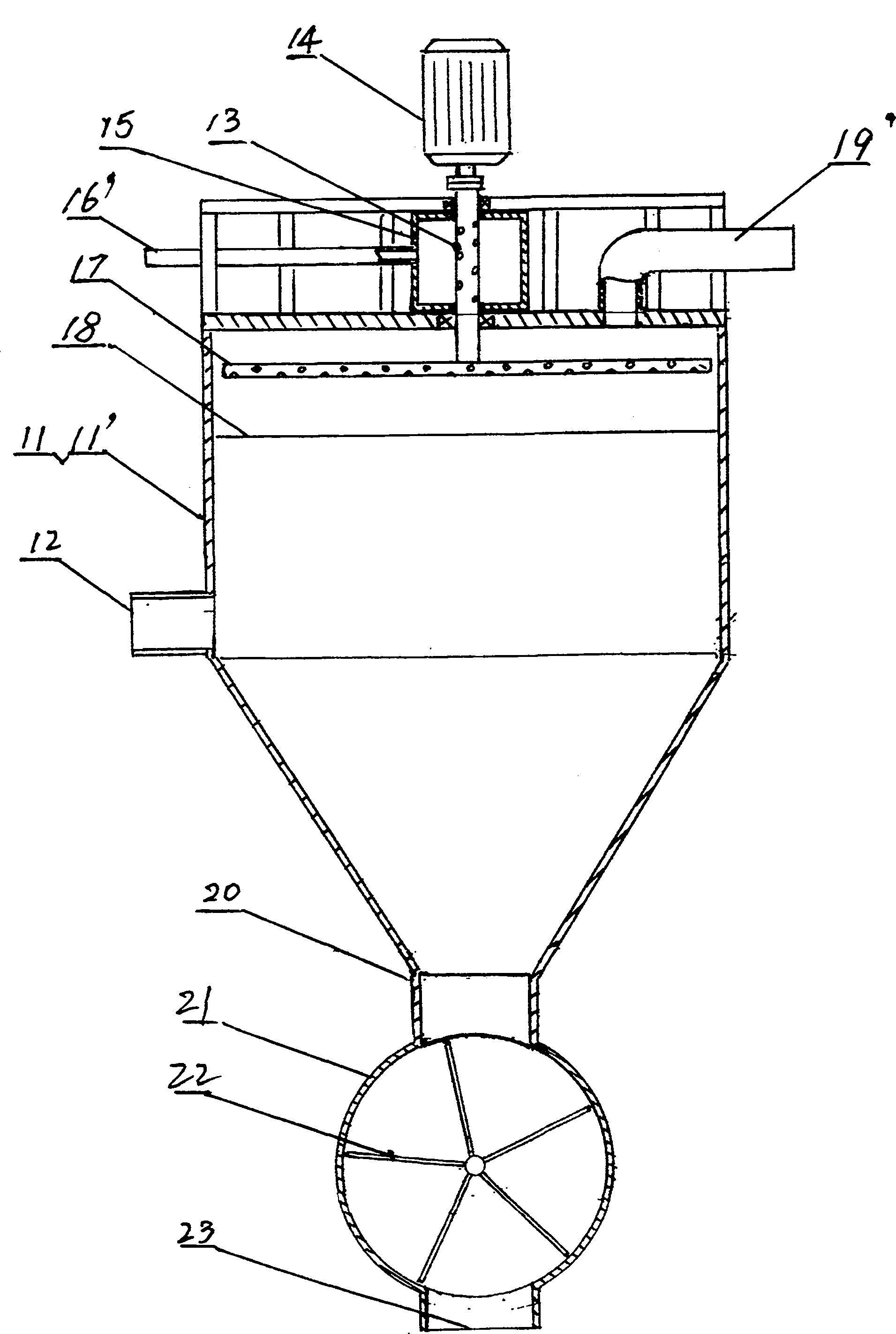

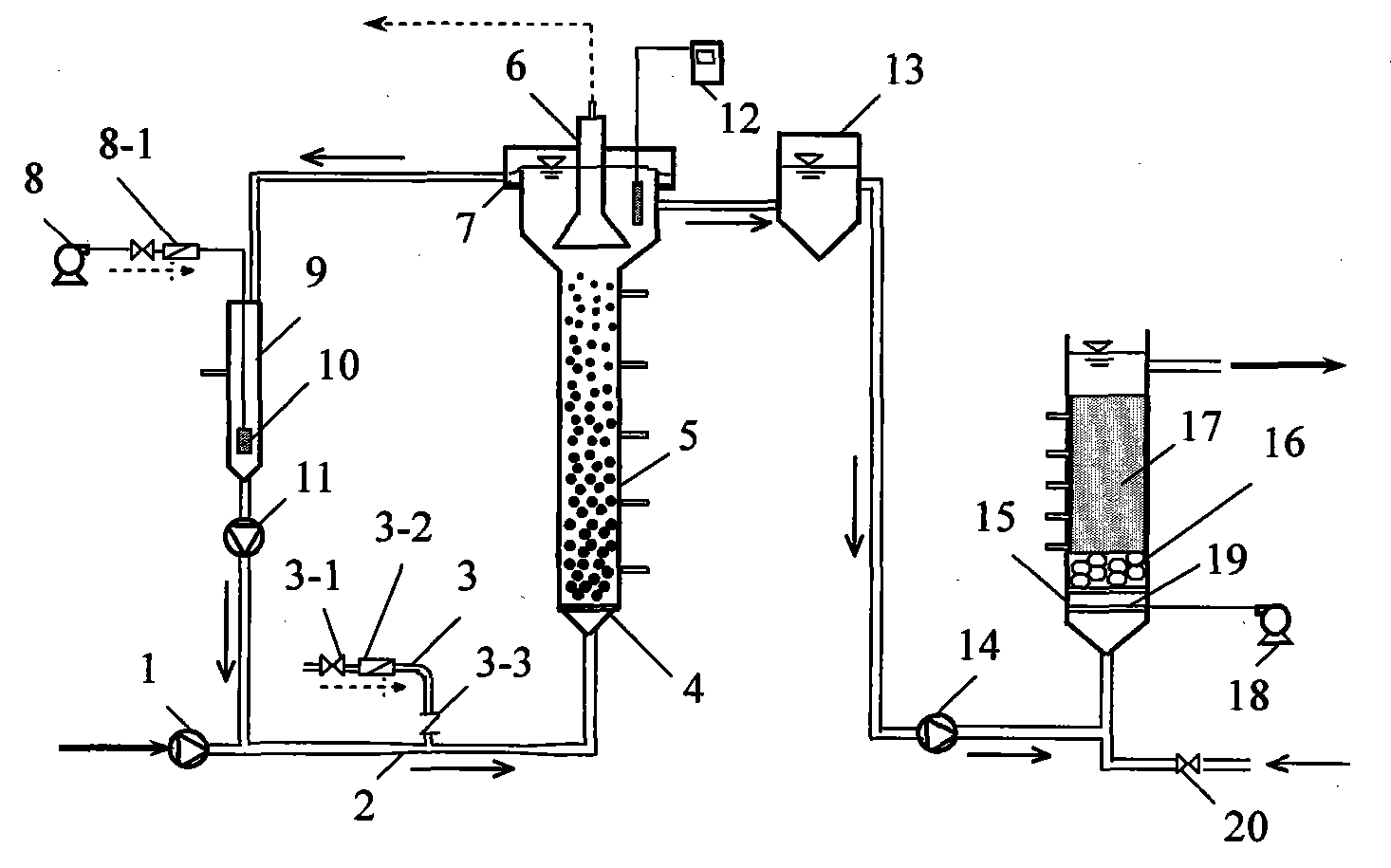

Sewage biochemical treatment equipment

InactiveCN101125706AIncrease the ascending velocityFully contactedSustainable biological treatmentWater/sewage treatment by flocculation/precipitationFiltrationDistributor

The invention provides a sewage biochemical processor, comprising a shell body, a water distributor, an aerator, filling materials, a supporting board and a mud-water-gas separating device that are arranged in the shell body, an inlet tube, an outlet tube and a mud discharging tube that are connected with the shell body and arranged outside the shell body, and gas gathering holes arranged at the top part of the shell body. The invention is characterized in that: the mud-water-gas separating device is formed by inclined boards or inclined tubes that are arranged on the upper part of the shell body in an inclined way and in parallel with each other, a drug feeder is arranged between the filling materials and the mud-water-gas separating device in the shell body and connected with a drug feeding tube arranged in a drug feeding device outside the shell body, and a return tube, the upper end and the lower end of which is communicated with the outlet tube and the inlet tube, is provided. The invention has reasonable and compact structure and compound filling materials that are in reasonable arrangement, thus, biochemical effects of biological oxidation, flocculation and absorption, etc. to the sewage and physical and chemical effects of filtration, micro-flocculation, sedimentation, etc. can be completed in the same tank body, thereby having the advantages of high treatment efficiency, rapid start, low cost, simple operation, easy maintenance and lower operating cost.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Oriental lily seed variable-temperature treatment method

InactiveCN102577697APromotes rapid germinationPromote germinationSeed and root treatmentHybrid seedGermination

The invention provides an oriental lily seed variable-temperature treatment method, which specifically comprises the following steps of: A) seed selection, B) matrix treatment, C) sub-packaging, D) room-temperature treatment, E) low-temperature treatment, F) detection and G) seedling training. The oriental lily seed variable-temperature treatment method has the advantages that the defects existing in the prior art are overcome, the rapid germination of seeds is promoted, the germination vigor and the germination rate of oriental lily seeds are improved, the germination tidiness of the seeds is improved, the step of seed sterilization is omitted, a better effect can be reached by adopting simple operations and the method is suitable for large-scale ball acceleration and germination of oriental lily hybrid seeds.

Owner:YUXI MINGZHU FLOWER

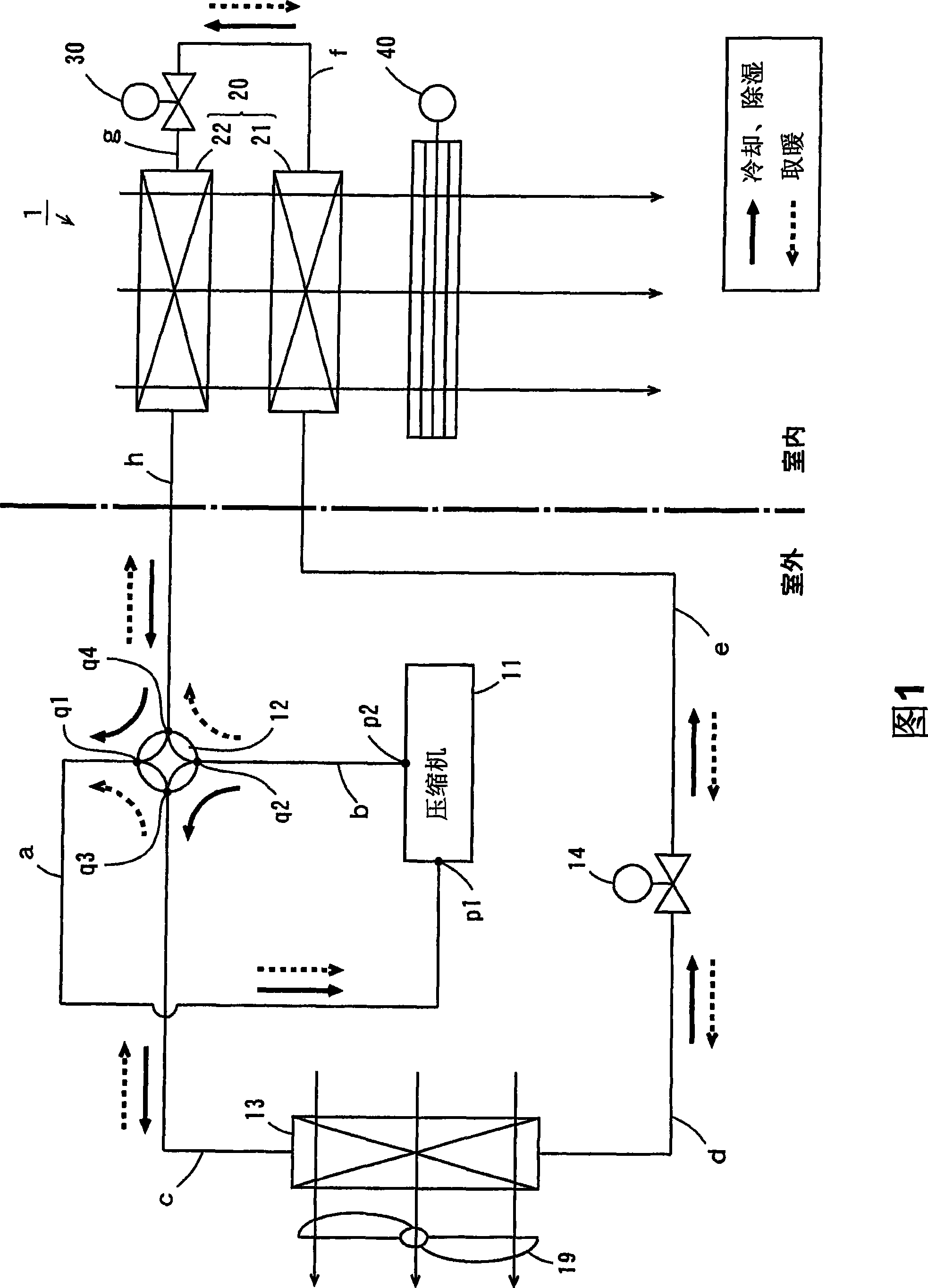

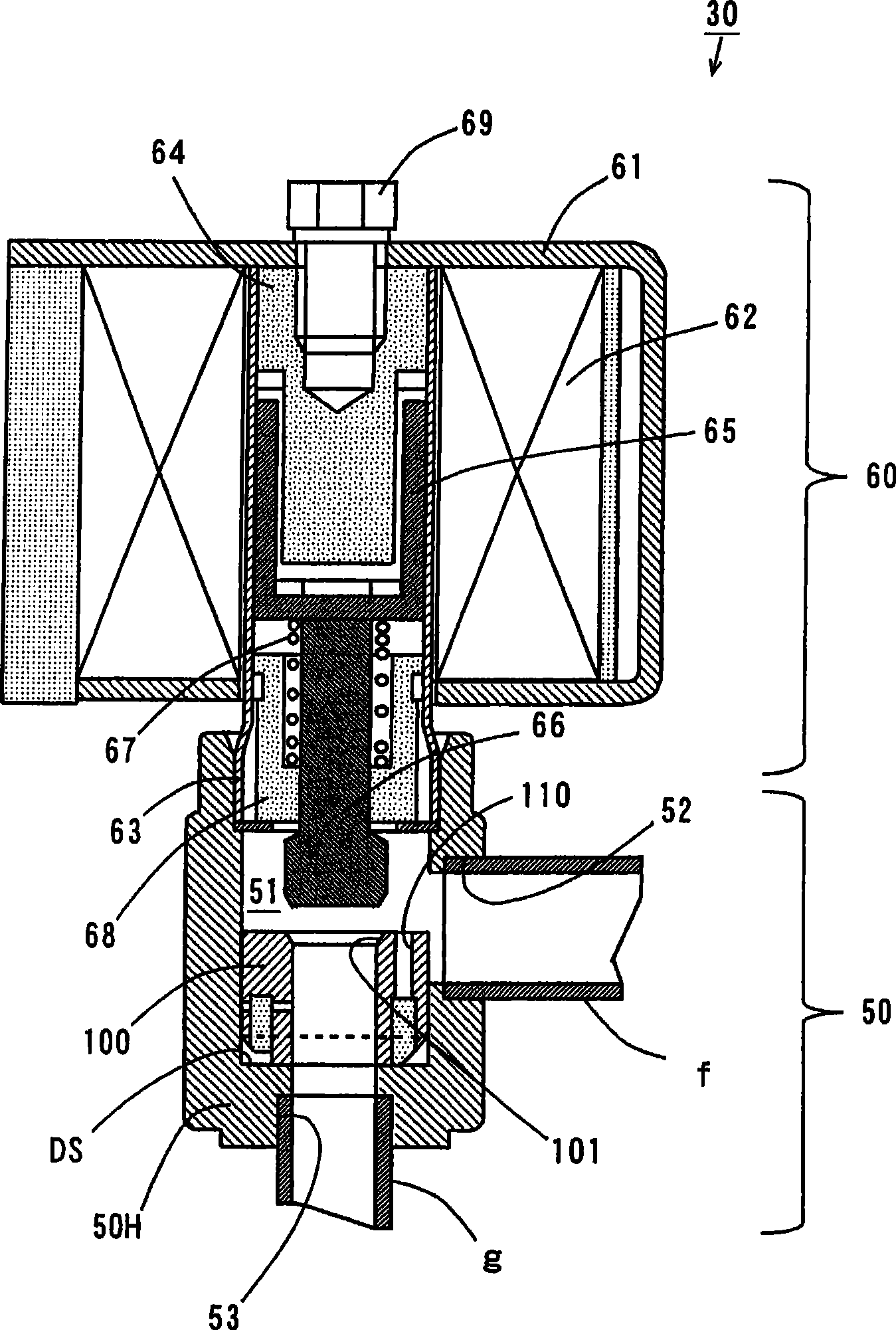

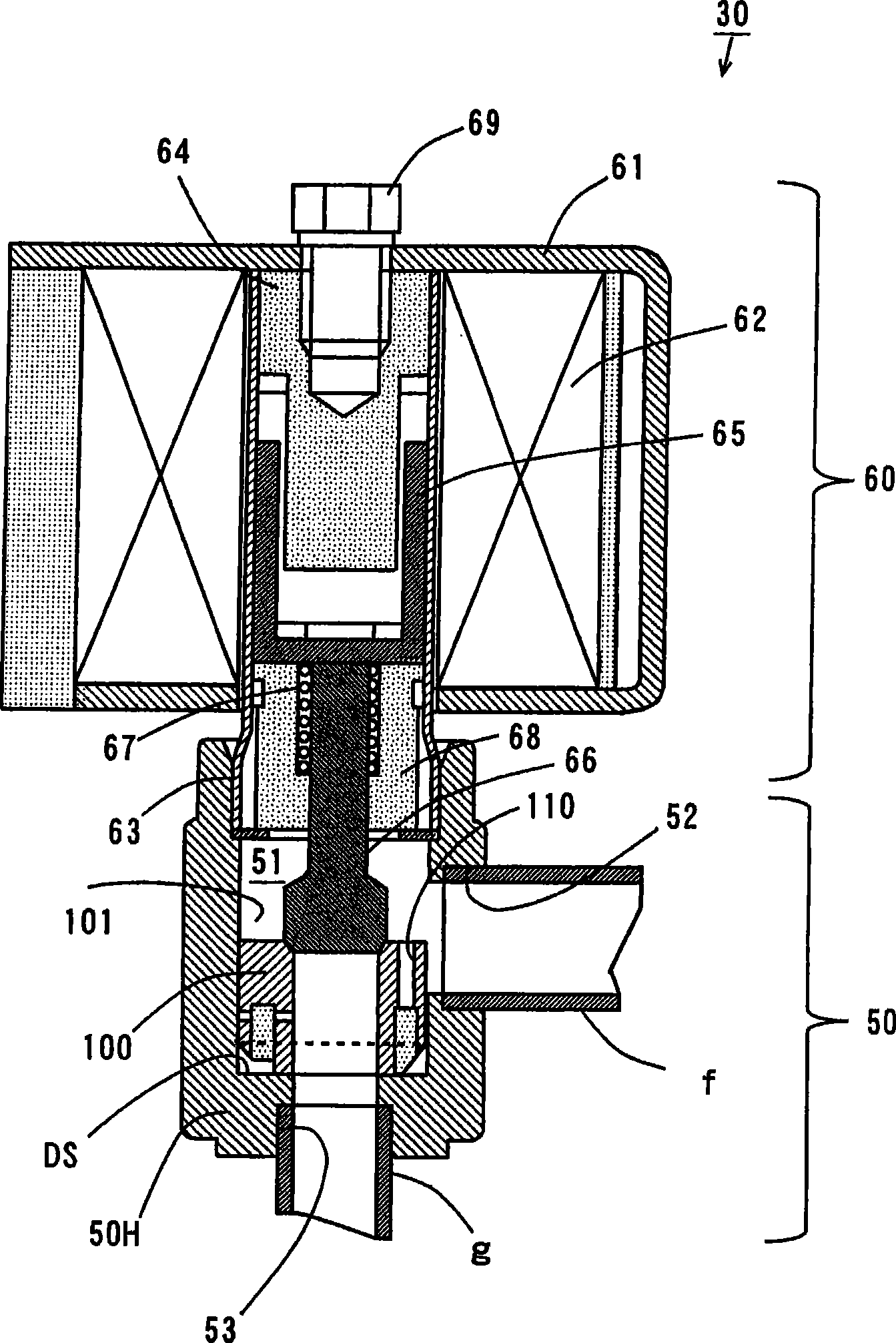

Valve device and air regulator equipped with the same

InactiveCN101441012AReduce flow soundSqueeze fullyOperating means/releasing devices for valvesCompression machines with non-reversible cycleInterior spaceEngineering

The invention provides a valve device and an air adjustor for the valve device. An indentation in the use of dry-type valve installed in the valve chamber in the upper parts of the valve seat within the department of weeks the Ministry of the edge of the formation of the valve seat. The components in the valve seat inside the walls of the upper part of the department of forming a vertical hole. The components in the valve seat inside the walls of the lower part of the department of the formation of the first and second filter port space. The vertical hole, as well as the first filter port connected space. The components in the seat bottom peripheral edge of the department of chamfering processing through the conical surface forming a ring. The components in the valve seat surface within weeks of the provisions of the location of the valve seat forming a part connected to the internal space and the second space filter through the port hole.

Owner:PANASONIC CORP

Plant filter base material

InactiveCN103285664AImprove filtration efficiencyImprove adsorption efficiencyOther chemical processesFiltration separationPlant fibrePlant stem

The invention discloses a plant filter base material which is prepared by the working procedures of crushing, screening, degreasing, washing, softening, cleaning, puffing and drying a mixture of plant stems and leaves, and the like. According to the filter base material disclosed by the invention, plants are puffed, so that the fiber structure of the plants is fluffy to form a plurality of small gaps, the flow resistance to filter media is reduced, and impurities in filtered substances are effectively intercepted. According to the filter base material, a surface barrier form of a traditional filter material is converted into a volume type echelon filter and deep adsorption form. Additionally, the filter base material disclosed by the invention is in a fluffy structure, so that various additives can be steadily stored in the structures and cell capsules of plant fibers so as to be processed into various gas and liquid filter materials. When the filter media pass through the filter materials, the plant fibers are extruded, so that the additives are slowly released to repair the filter media, and the adverse effect caused by excessive release of the additives can be avoided.

Owner:GANSU HENGTONG FILTER IND

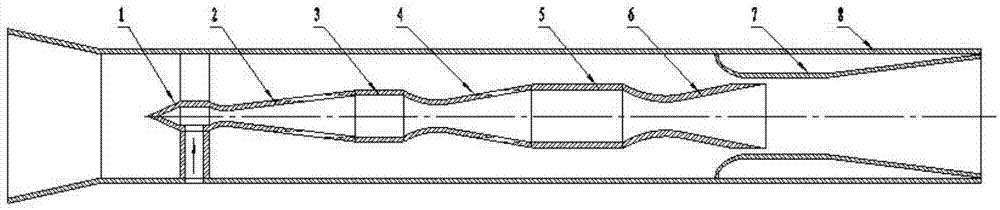

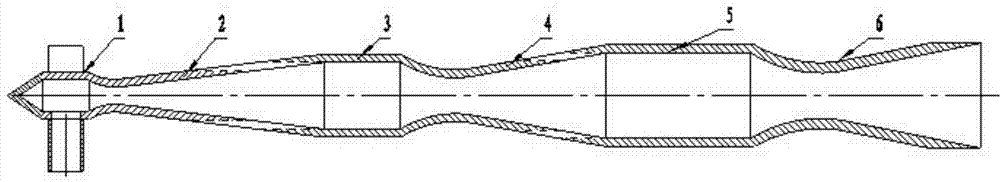

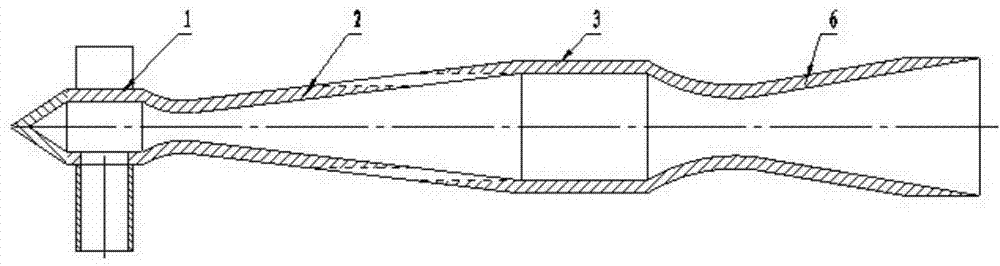

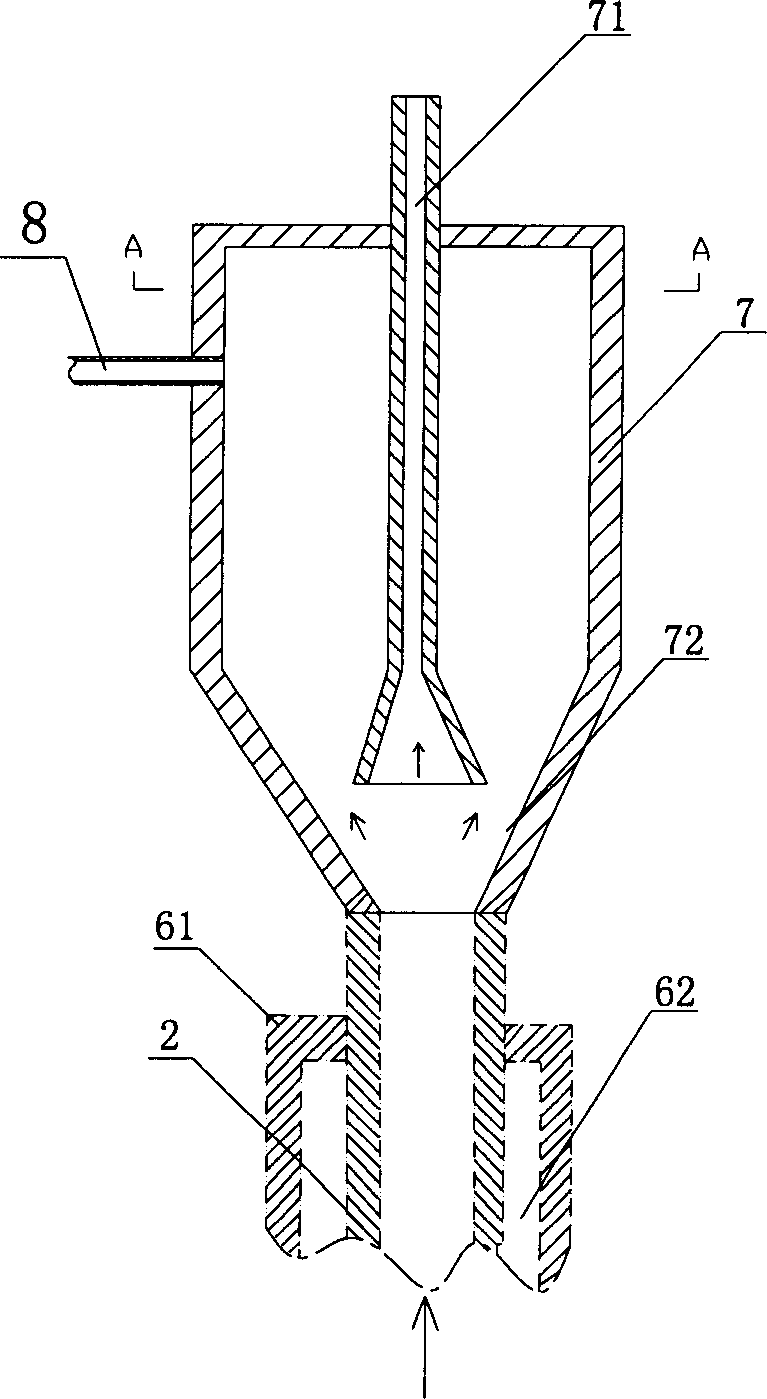

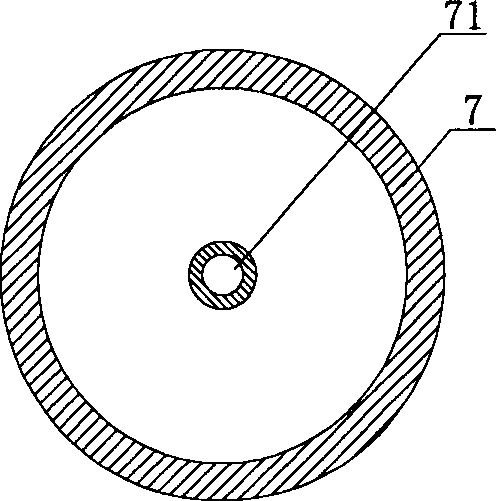

Supersonic ejector

ActiveCN104847708AThe airflow is well mixedEasy to processFlow mixersTransportation and packagingIntake pressureInjector

The invention discloses a supersonic ejector. The supersonic ejector comprises a gas inlet pressure chamber, a nozzle with injector, a supersonic diffusion section and a shell cylinder, the nozzle with injector is formed through connecting multiple stages of Laval nozzles with a tail nozzle in series through a mixing chamber after connecting the multiple stages of Laval nozzles in series through the mixing chamber, a forward gas inlet groove is opened in the peripheral wall of the expansion part of each Laval nozzle, the front end of the nozzle with injector is connected with the gas inlet pressure chamber, the outlet of the tail nozzle at the rear end is sleeved in the supersonic diffusion section, and the gas inlet pressure chamber, nozzle with injector and supersonic diffusion section are fixed in the shell cylinder in a mode that the central axes are the same with the central axis of the shell cylinder. The supersonic ejector fully uses the air pressure energy, the gas expands and compresses stage by stage, the mixing is complete, and the efficiency is high; the supersonic ejector uses a central symmetry structure, the manufacturing and processing are easy to perform, and the cost is low.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

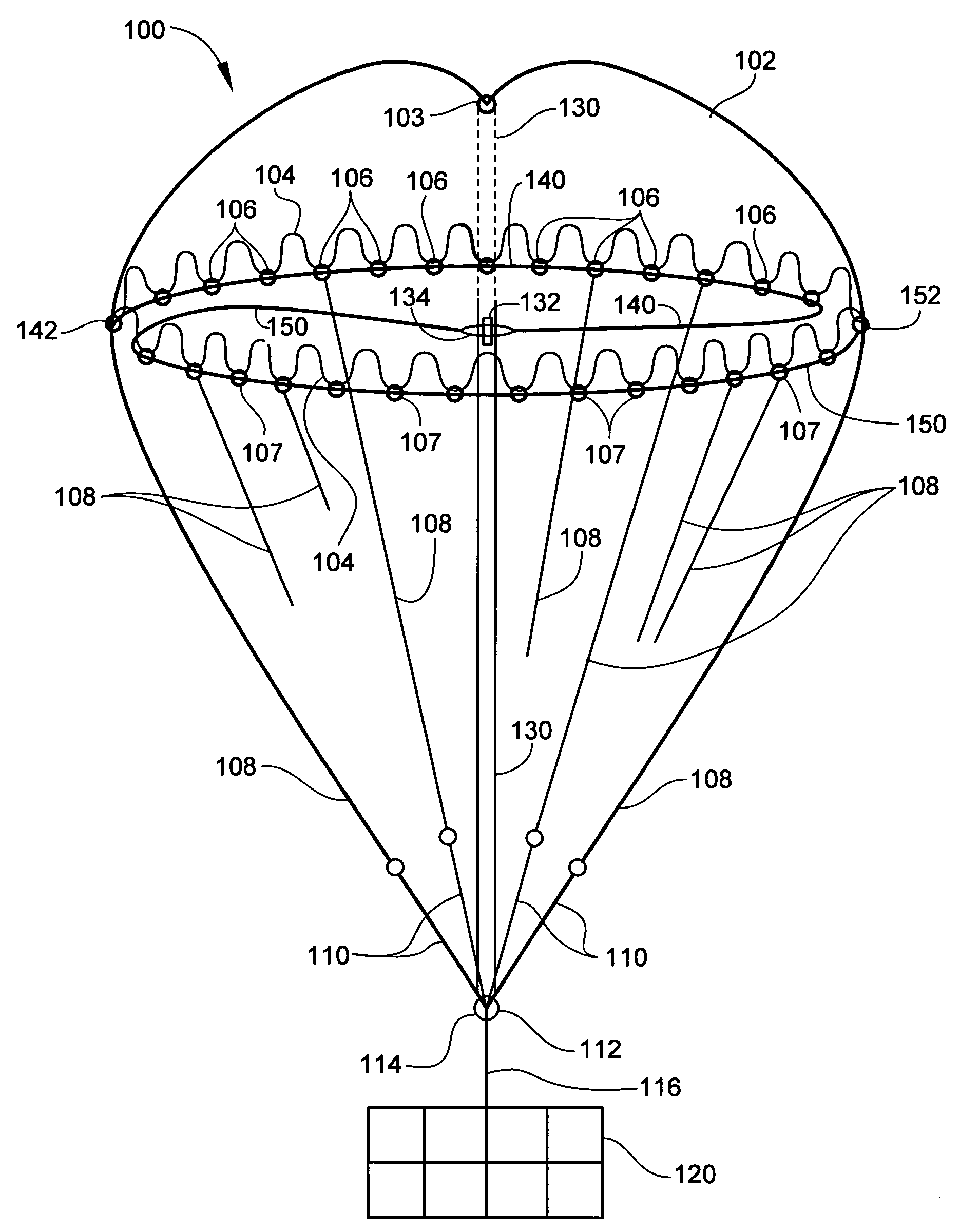

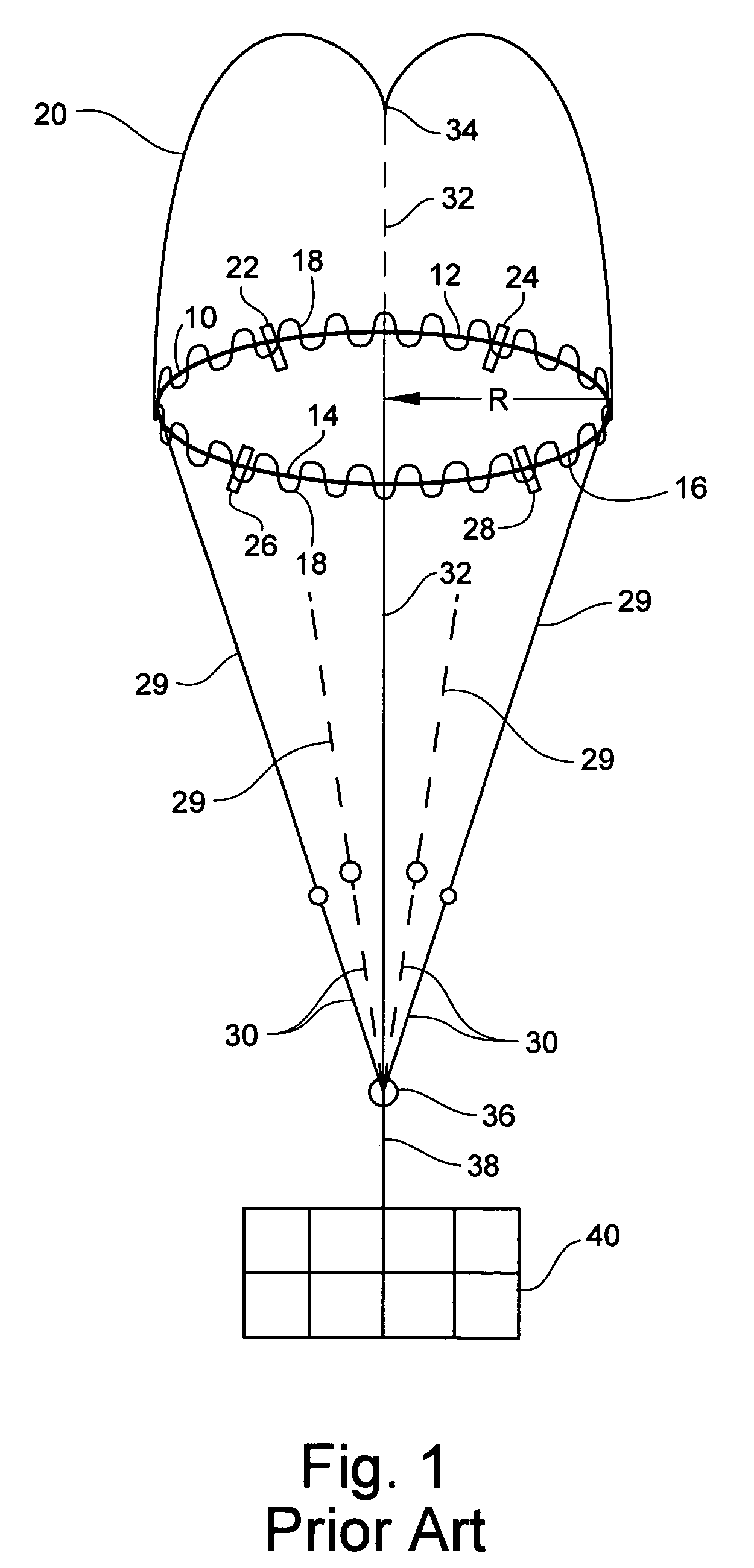

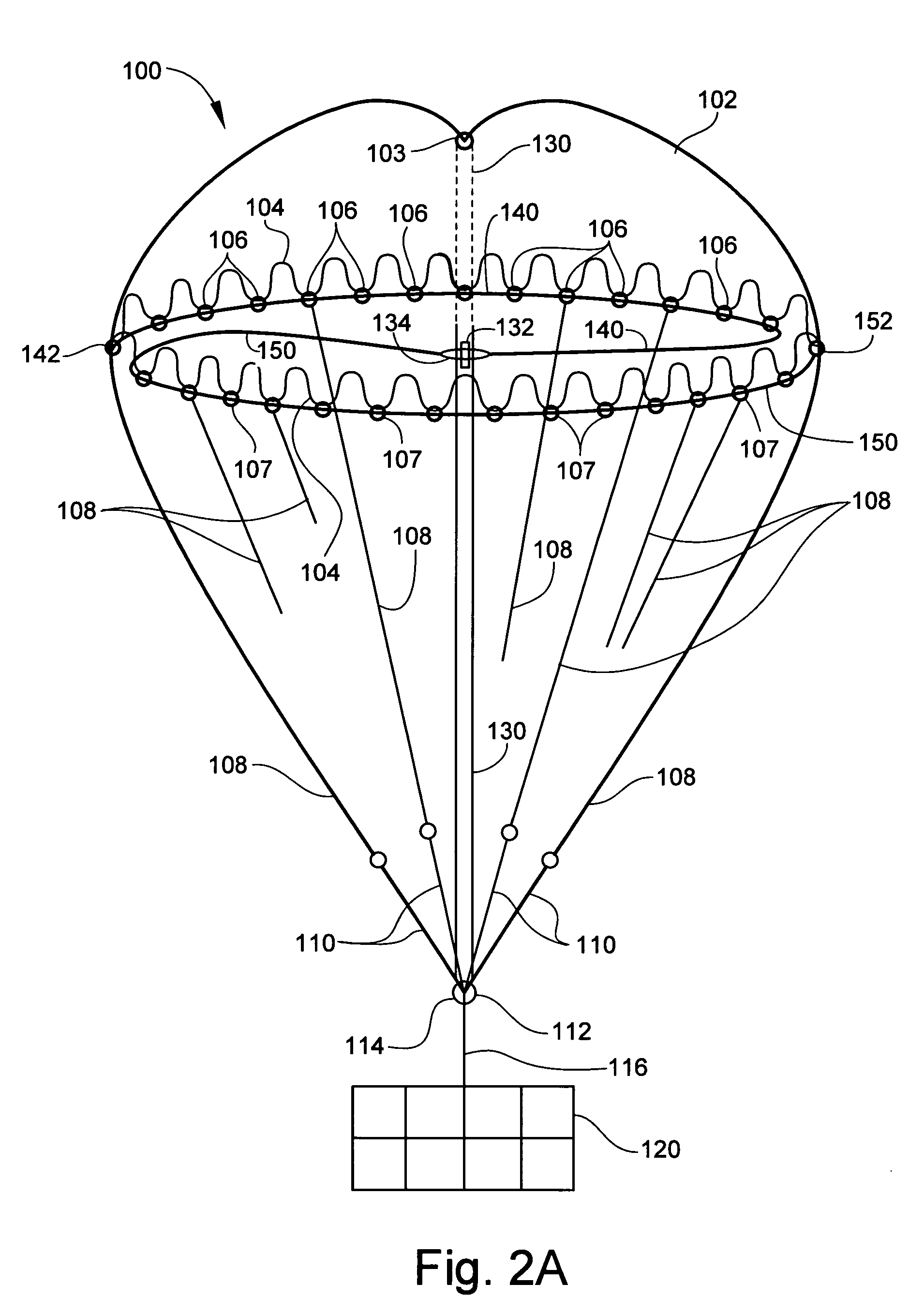

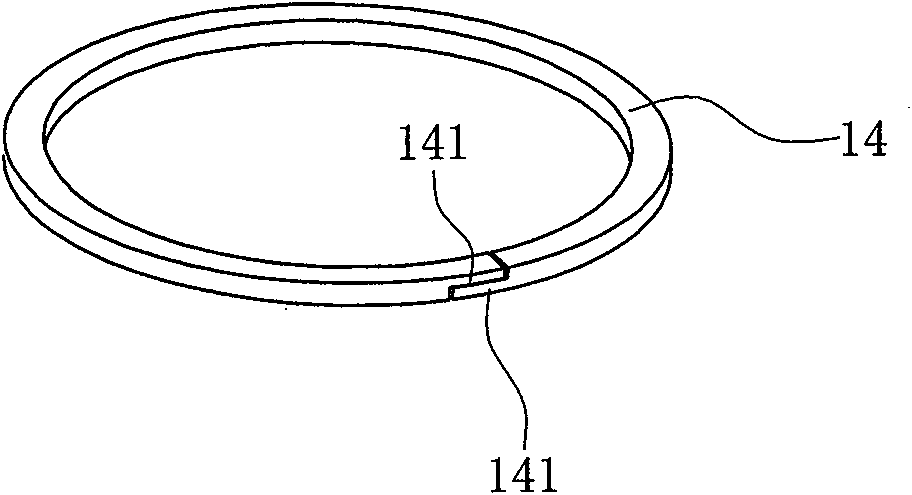

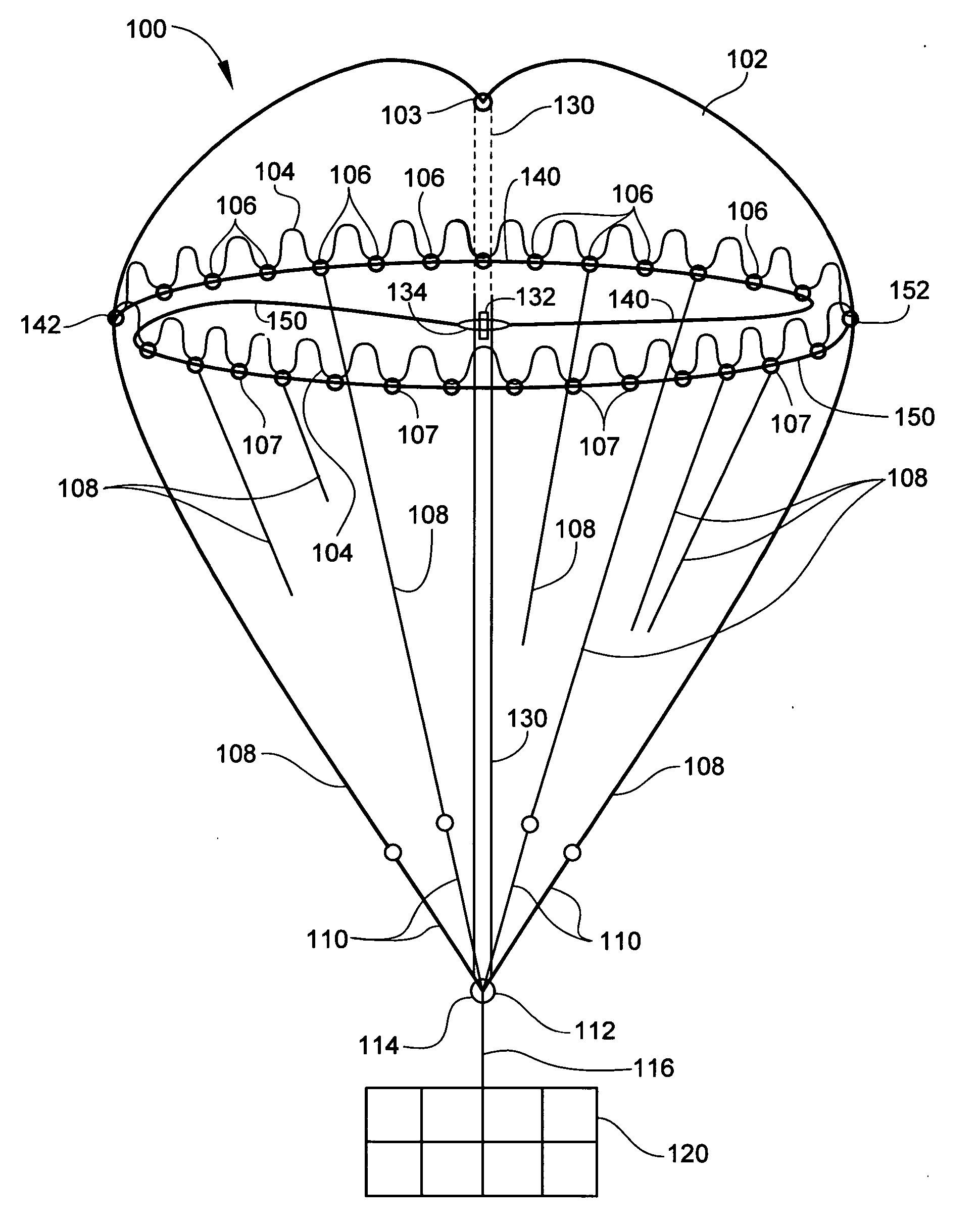

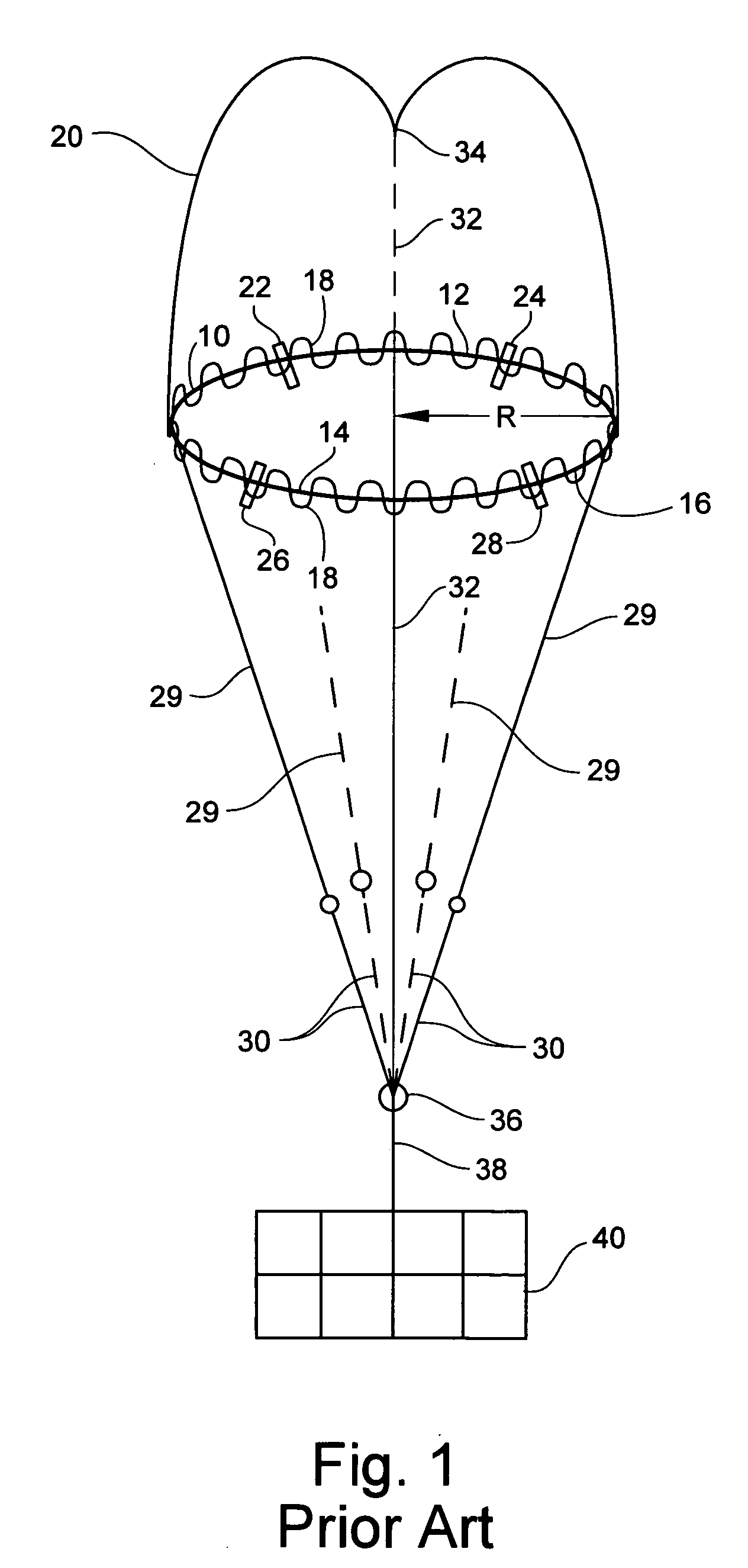

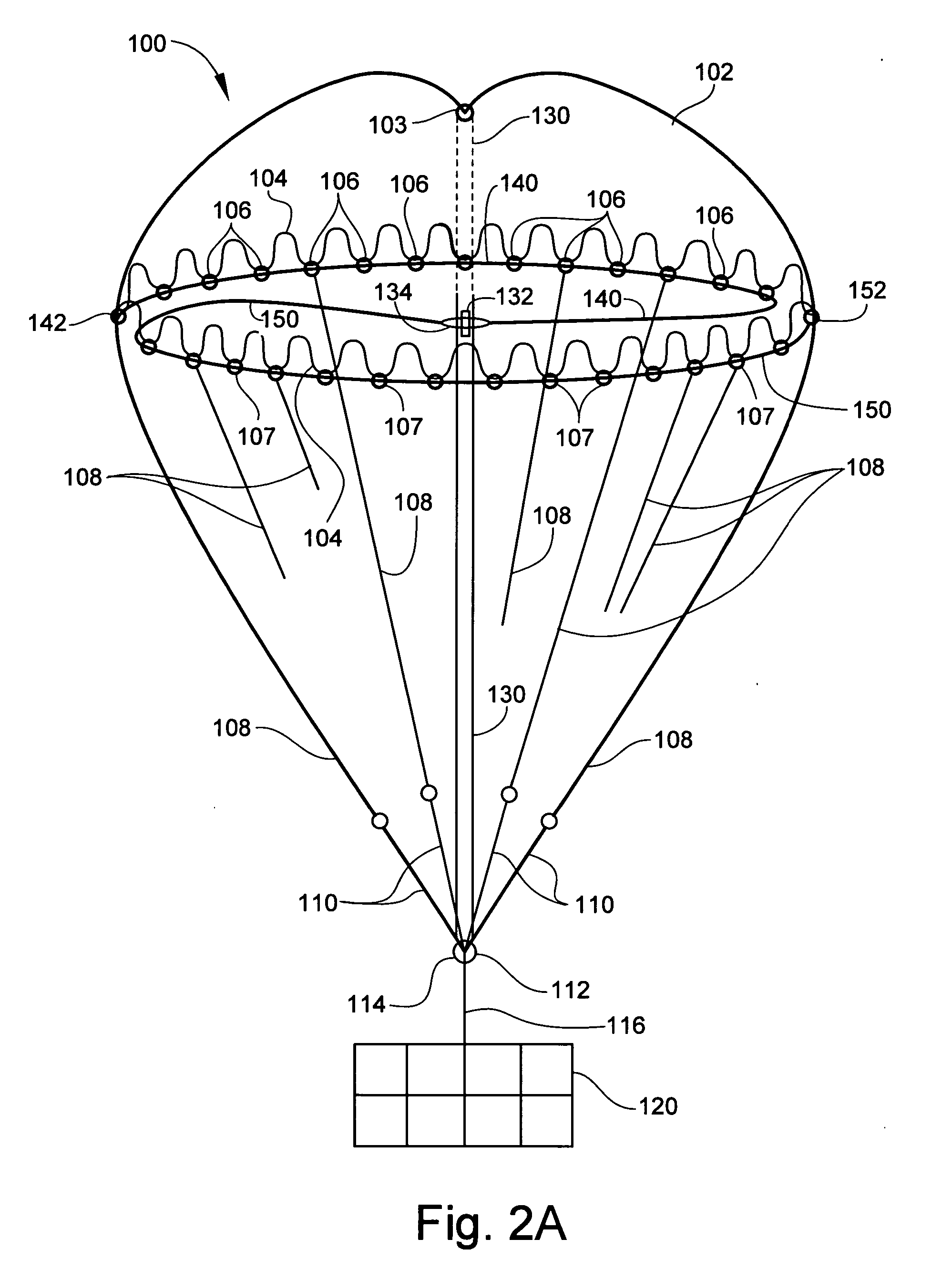

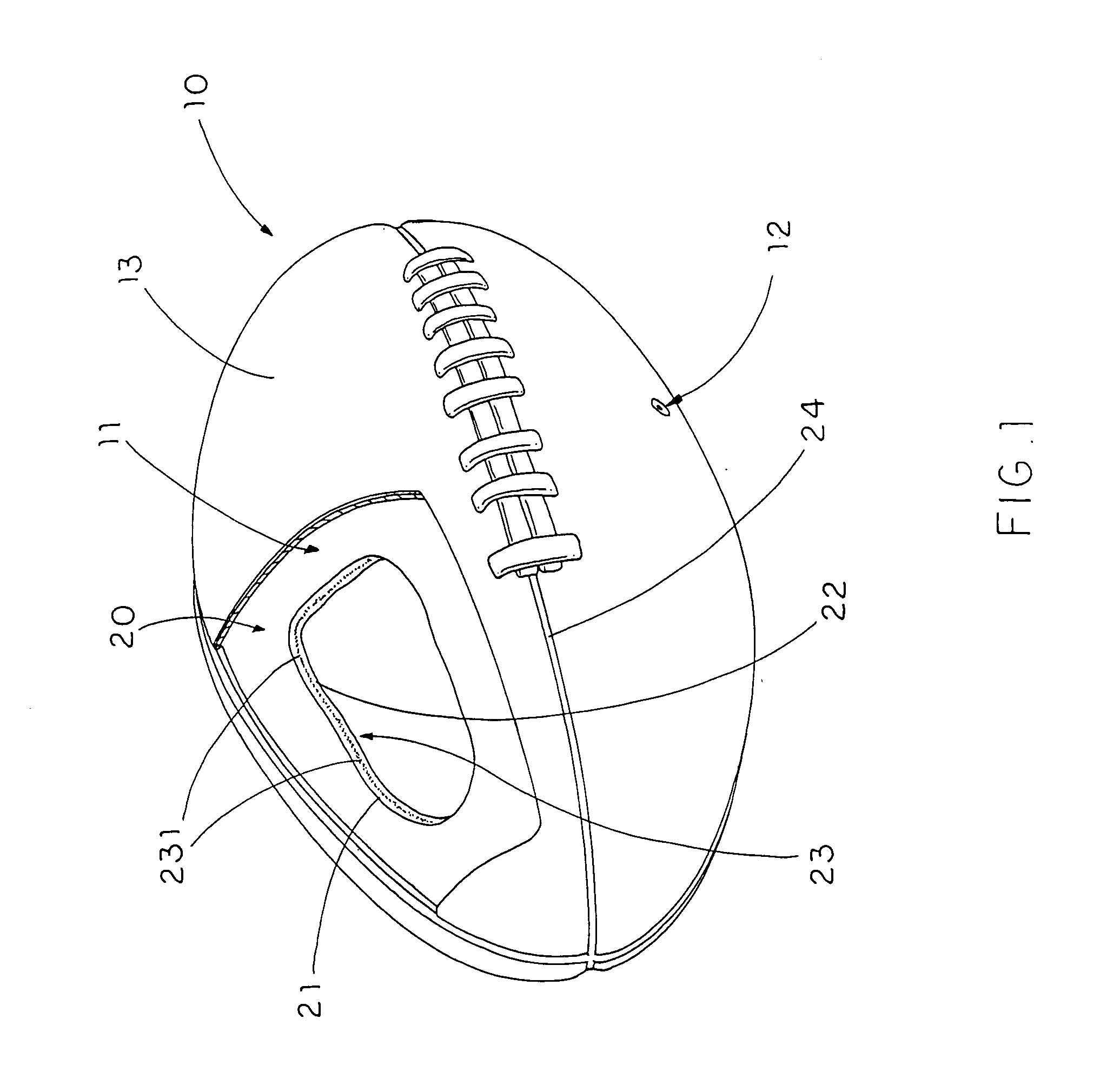

Parachute with skirt reefing system

InactiveUS7195205B1Fully inflatedParachutes testing apparatusNon-canopied parachutesEngineeringMechanical engineering

A parachute system has a canopy, suspension lines that extend from the canopy skirt to a confluence point, and a center line that is attached to and between the apex of the canopy and the confluence point. A single reefing line cutter is attached to the center line and is activated after a predetermined amount of time has elapsed. A first reefing line extends through a first group of reefing rings wherein one end of the first reefing line is attached to the single reefing line cutter and the opposite end is attached to the canopy skirt at a first predetermined location. A second reefing line extends through a second group of reefing rings that is opposite the first group of reefing rings. The second reefing line has one end attached to the single reefing line cutter and an opposite end attached to the canopy skirt at a second predetermined location that is across from the first predetermined location. The canopy opens to an initial circumference that is determined by the summation of the lengths of the first and second reefing lines. When the reefing line cutter is activated, the reefing line cutter releases the first and second reefing lines so as to allow full inflation of the canopy.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

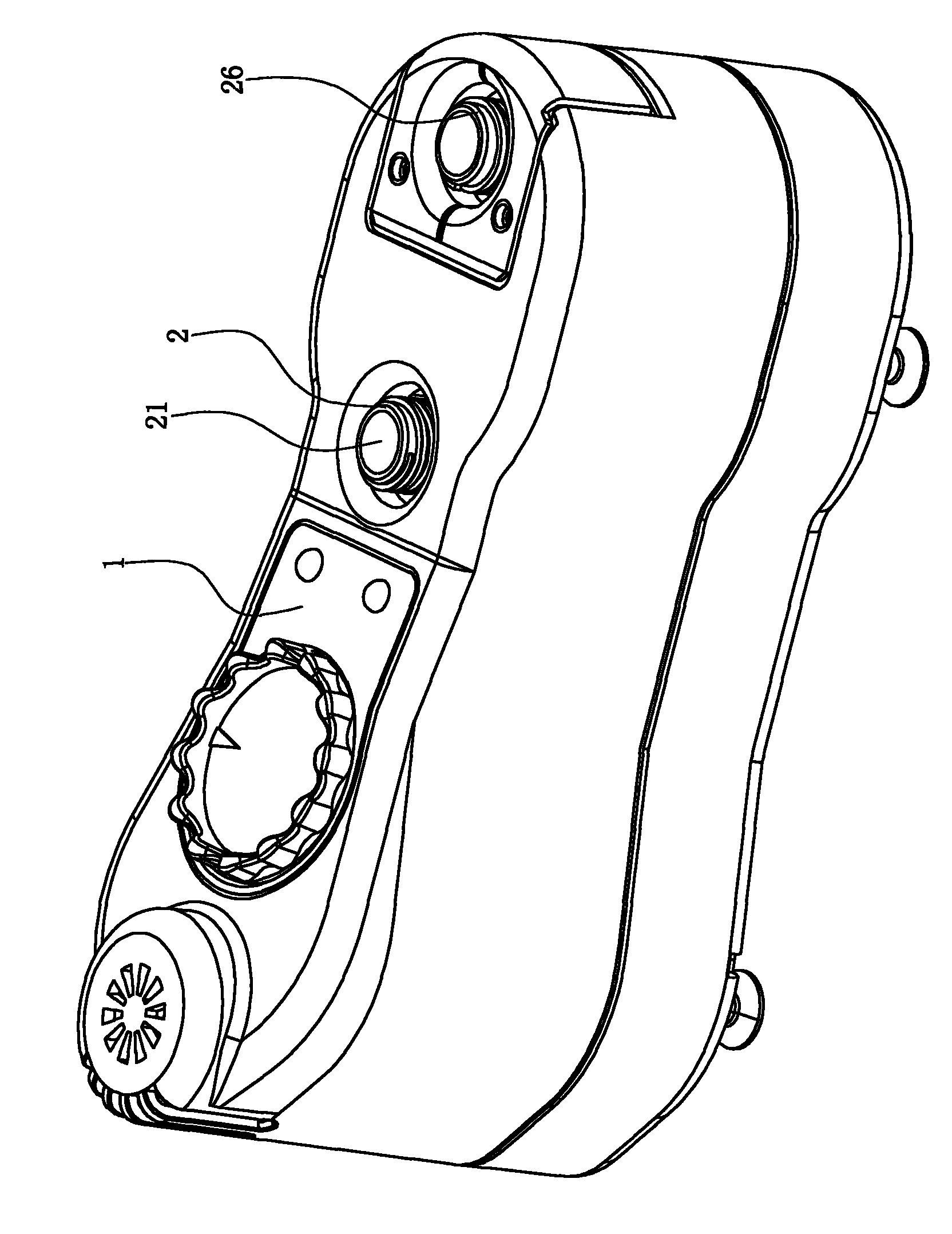

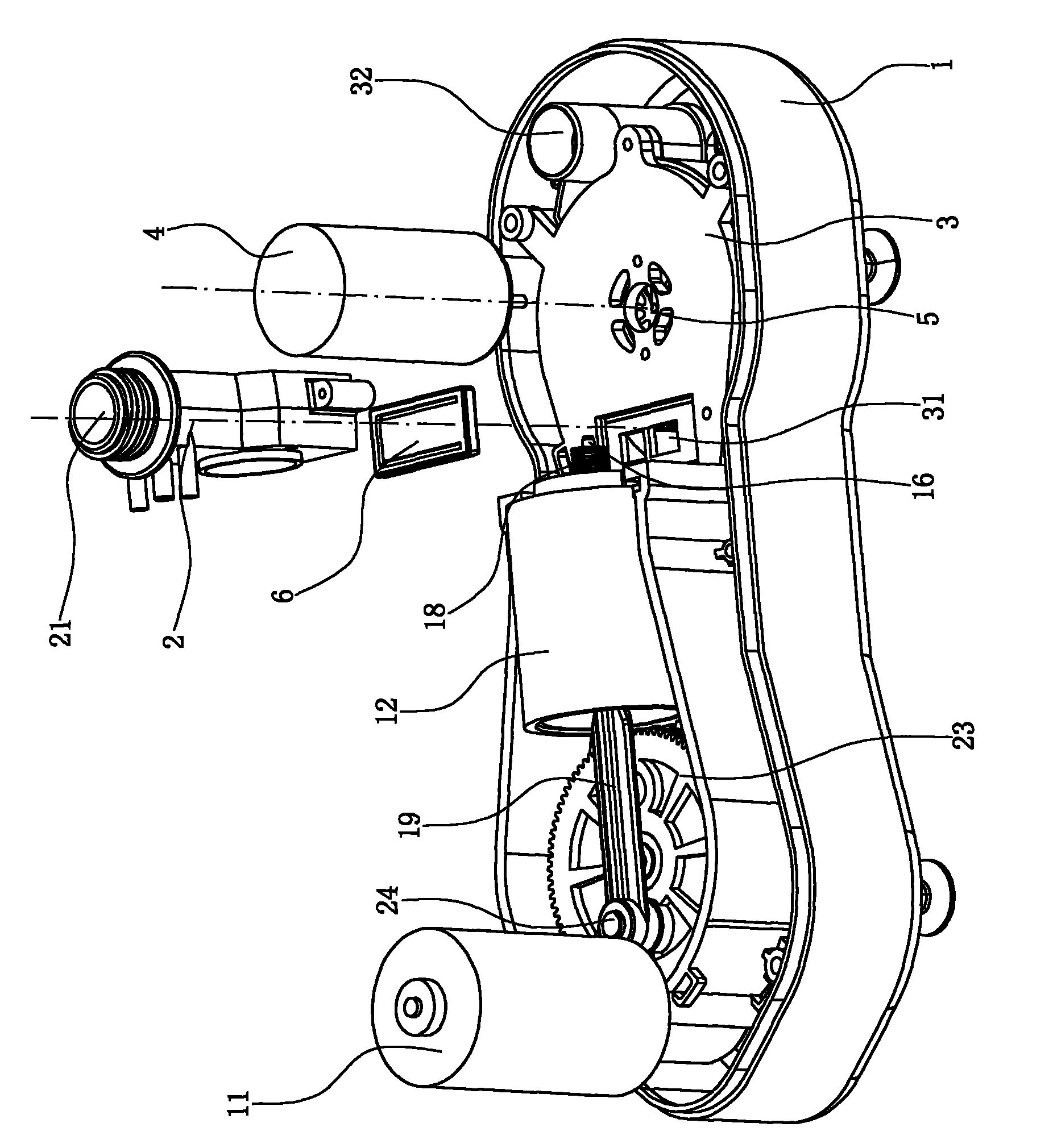

Electric air pump

ActiveCN101846054AImprove air tightnessImprove inflation efficiencyPositive displacement pump componentsPiston pumpsInlet channelAir pump

The invention relates to an electric air pump, which comprises a piston type inflating structure and a centrifugal inflating structure which are arranged in a casing, wherein the centrifugal inflating structure comprises a pump casing with an air outlet and an air inlet; a wind wheel is arranged in the pump casing; an air outlet of the piston type inflating structure and the air outlet of the pump casing are connected with a joint; and the joint is internally provided with an inflating hole communicated with the air outlet of the piston type inflating structure and the air outlet of the pump casing. The electric air pump is characterized in that a first unidirectional valve plate which only allows gas in the pump casing to be exhausted to the inflating hole is arranged at the air outlet of the pump casing; an air inlet channel communicated with the air inlet and the outside is arranged at the bottom of the pump casing; a valve port is arranged in the middle of the air inlet channel; a second unidirectional valve plate is arranged at the valve port and is internally provided with a magnet; and a reed switch capable of inducting the magnet only when the second unidirectional valve plate is positioned in a closed state is fixed outside the pump casing. The invention is the electric pump capable of automatically and stably switching the inflating mode according to the real-time pressure in the inflating equipment.

Owner:NINGBO BRAVO MFG OF INFLATORS & ACCESSORIES

Technique for producing starch stearate by semidry process

The invention discloses a technique for producing stearic acid starch ester by a semi-dry method, which comprises steps as follows: waxy corn starch is taken as a material and added in mixing equipment of a dry denaturizing starch reactor, the waxy corn starch is acidified by adding a hydrochloric acid solution and then neutralized to neutrality by adding a sodium hydroxide solution, the neutralized material is sprayed with a stearic acid water solution evenly, and the adding amount of the stearic acid is determined according to the required degree of substitution; after being evenly mixed, the material is pre-dried in pre-dry equipment of the dry denaturizing starch reactor; the pre-dried material is put in a main reactor of the dry denaturizing starch reactor, and esterification reaction is carried out within the temperature range of 145 DEG C to 155 DEG C; and then finished products can be obtained by washing and drying the esterized material. The stearic acid starch ester produced by the technique is low in pollution and friendly in reaction environment, and the organic solvent in products is low in content, the product is high in safety, and simultaneously, the product is high in quality stability and low in cost.

Owner:诸城兴贸玉米开发有限公司

Preparation method of calcium hydroxide with high porosity

The invention provides a preparation method of calcium hydroxide with the high porosity. The preparation method comprises the following steps: (1) high-temperature calcinations treatment; (2) breakingand screening of calcium oxide stone; (3) digestive reaction; (4) filtering and dewatering treatment; (5) baking and drying; and (6) screening and filtering treatment. The preparation method has thegreatest characteristics that by increasing the temperature of digestion water to be 85-100 DEG C greatly and increasing the material digestion temperature to be 145-155 DEG C, a material is sufficiently expanded under the high-temperature digestion state; and water in pores in powder is quickly evaporated, expanded and gasified, and by serving as a pore-forming agent, the porosity and the pore diameter of the interior of the powder are increased greatly. On the basis of the original high specific surface area, by increasing the pore diameter of the micropores in the powder, the worldwide problems that in the solid-liquid reaction process, liquid is difficult to infiltrate into the powder, and consequently the reaction speed is low, and reacting is not thorough are reduced.

Owner:南京格暠环保科技有限公司

Graphene modified filter bag and filtering material thereof

ActiveCN106512581AMake sure it's fully inflatedBring out fullyDispersed particle filtrationTransportation and packagingFiberGraphene

The invention relates to a graphene modified filter bag. The graphene modified filter bag includes a bag body, the bag body includes a dust facing layer, a middle layer and a base cloth layer in sequence from outside to inside, a woven mesh layer is arranged between the middle layer and the base cloth layer, the woven mesh layer includes warp strips and weft strips, the warp strips and the weft strips are intertwined and woven into a mesh shape, the warp strips are made by intertwining graphene fibers, the weft strips are made by intertwining polyurethane elastic fibers, strip-type liner sheets are arranged between the adjacent weft strips, the strip-type liner sheets are of a hollow structure, and anion powder are contained in the strip-type liner sheets. Due to the arrangement of the woven mesh layer, on one hand, the toughness of the bag body is improved, on the other hand, the shape restoring ability of the bag body is improved, that is, the bag body can restore its original shape after its surface wrinkles in filtering. The invention further provides a filtering material of the graphene modified filter bag.

Owner:ANHUI LITE ENVIRONMENTAL PROTECTION TECH

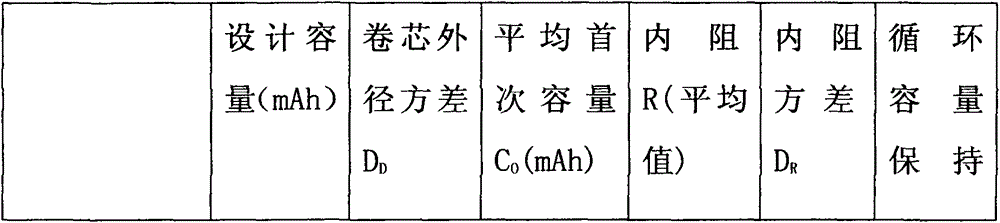

Preparation device and preparation process of power lithium ion battery pole piece

The invention belongs to a preparation device and preparation process of a power lithium ion battery pole piece. The preparation device comprises a twin-roller machine, wherein the twin-roller machine is provided with a winding device at a tail end, a splitting machine with a splitting winding device, a piece making machine, a baking oven with a post-baking winding device and a battery pole piece winding machine are sequentially arranged at the tail end of the twin-roller machine with the winding device at the tail end, and a transmission device is arranged in the baking oven with the post-baking winding device. The preparation device has the advantages that the battery pole piece before winding can be fully expanded and is uniform in thickness, the roll core is uniform in size after the battery is wound, the external diameter variance of the roll core is smaller than 0.01, and the internal resistance variance of a finished product is smaller than 1.0.

Owner:河南比得力高新能源科技有限公司

Mouth moie cap type forced aeration style artificial respirator

A forced inflation type artificial respirator with mouth-nose mask for rescuing the dangerous patient is composed of an operation unit for providing compressed air and O2, an inflation unit for filling air in lung via mouth and nose, and a waste air exhausting unit for exhausting waste air out of the lung. It uses the lever principle for saving labor.

Owner:韩英

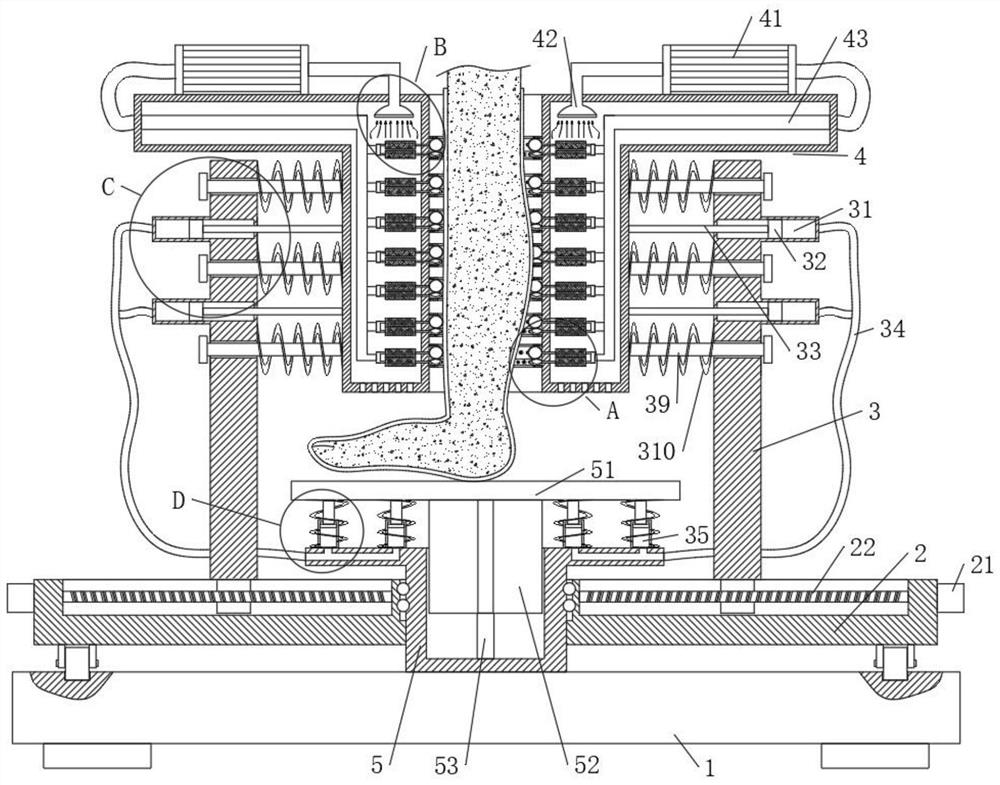

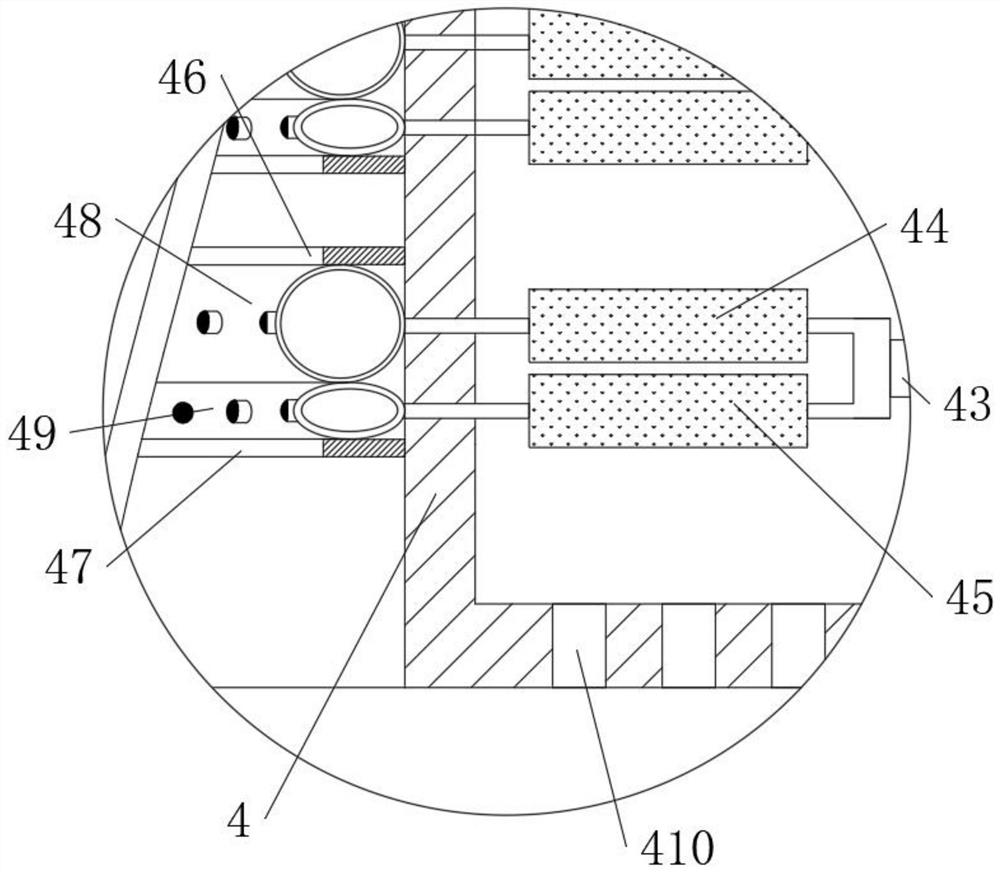

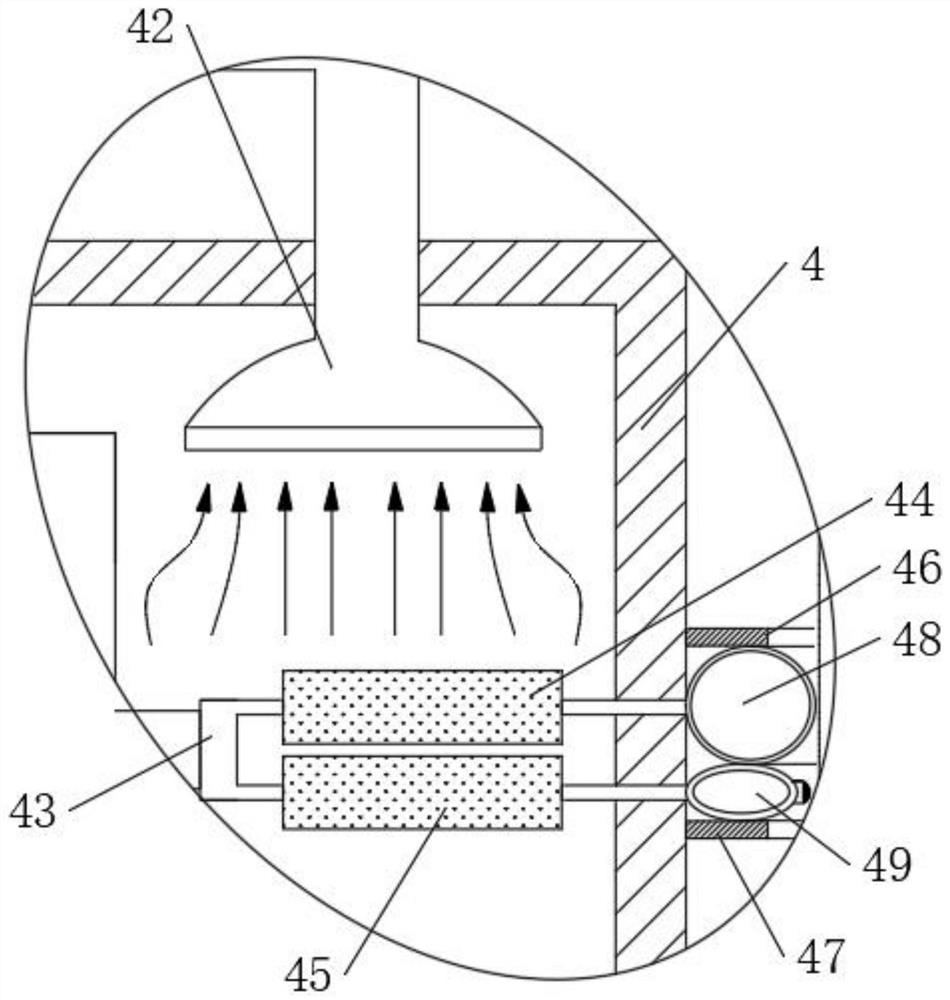

Varicosity massage device for surgery department

InactiveCN113181023AFully inflatedFully deflatedPneumatic massageSuction-kneading massageExternal energyMassage

The invention discloses a varicosity massage device for the surgery department, and relates to the technical field of medical instruments, the varicosity massage device comprises a base and two symmetrical clamping plates capable of moving on the base, the two clamping plates are elastically connected with box bodies used for being clamped outside the legs, the clamping faces of the box bodies and the legs are provided with a plurality of air bag sets, each air bag set is connected with an external energy device connected to the box body, and the external energy devices are used for inflating the multiple air bag sets. According to the massage device, the massage sequence from the far end to the near end is achieved, the massage effect on a patient with varicosity is improved, the air bag sets extrude and exhaust air in the oppositely-arranged air bags while conducting massage, therefore, after a single air bag is fully inflated, the effect of complete deflation is guaranteed, when two clamping plates 3 approach each other, air pressure is further conveyed to a second barrel through a second pipeline, and a second piston is jacked upwards to drive a second push rod to provide supporting force for a foot supporting plate.

Owner:钱进成

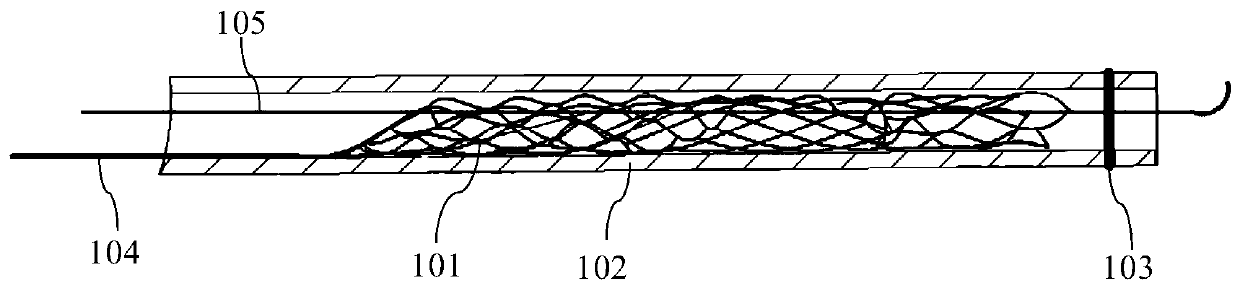

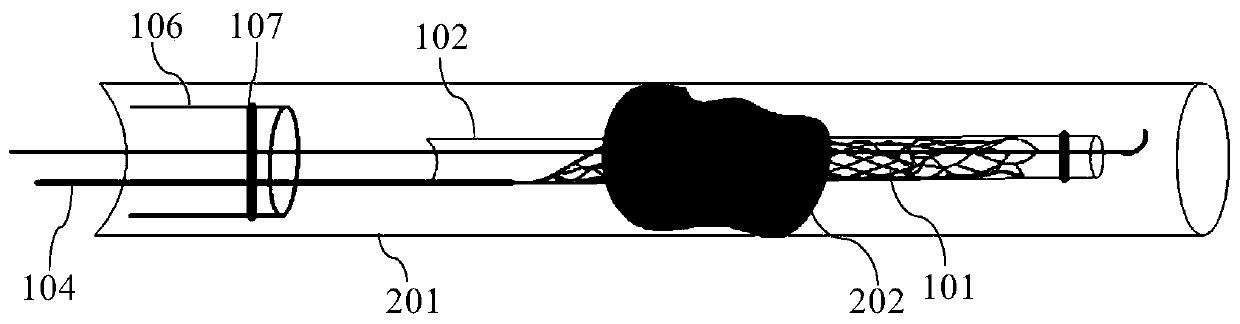

Thrombus taking device

Owner:LIFETECH SCI (SHENZHEN) CO LTD

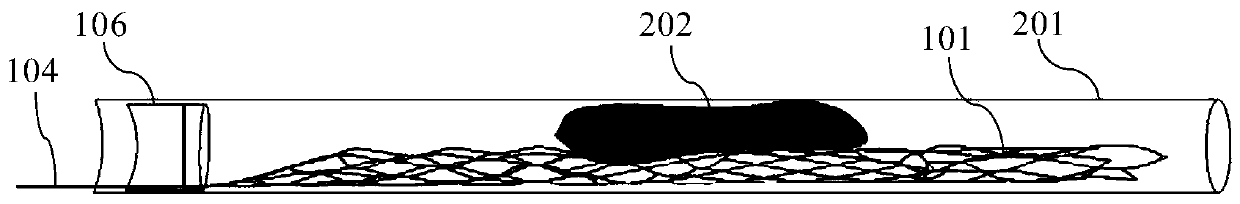

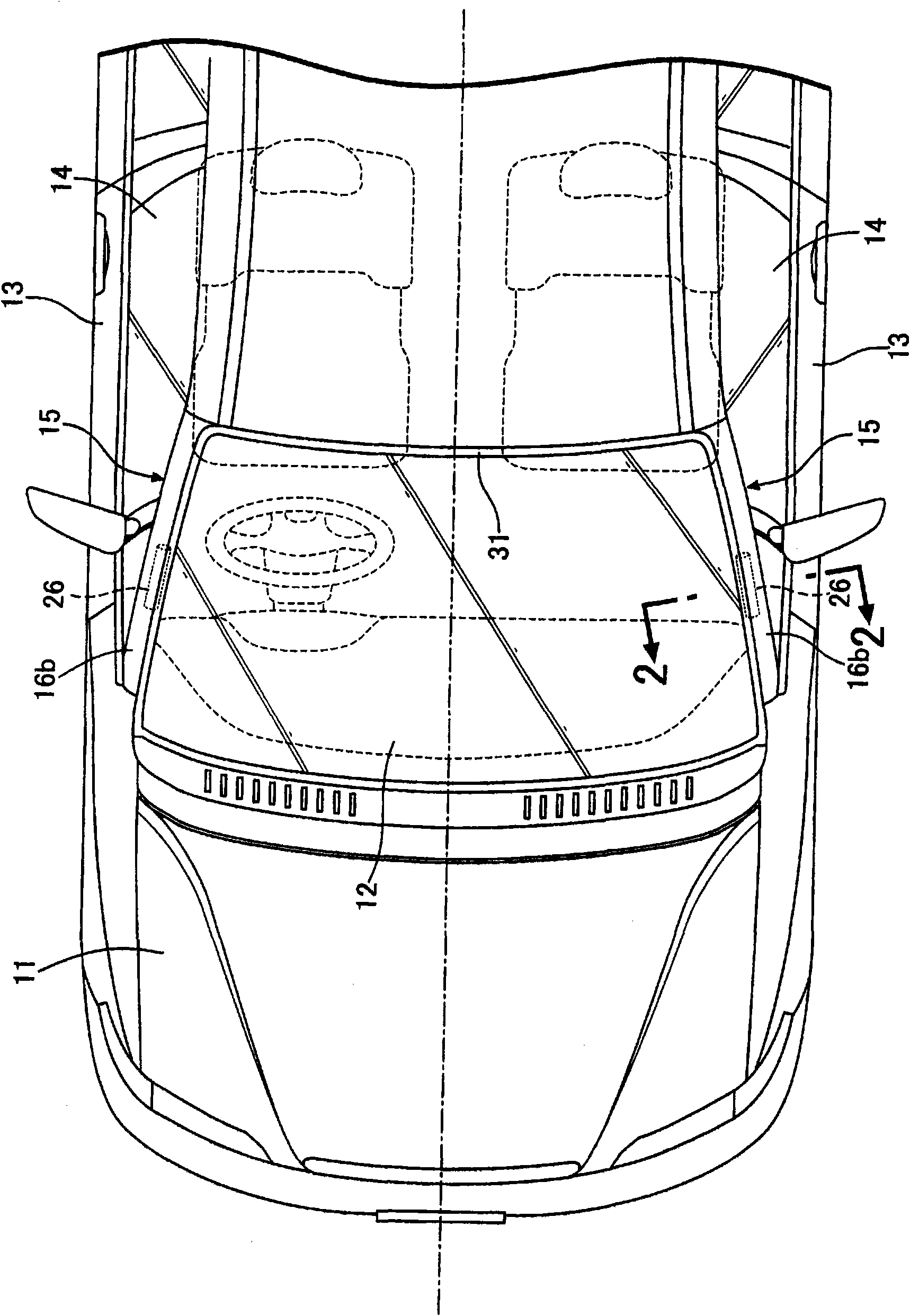

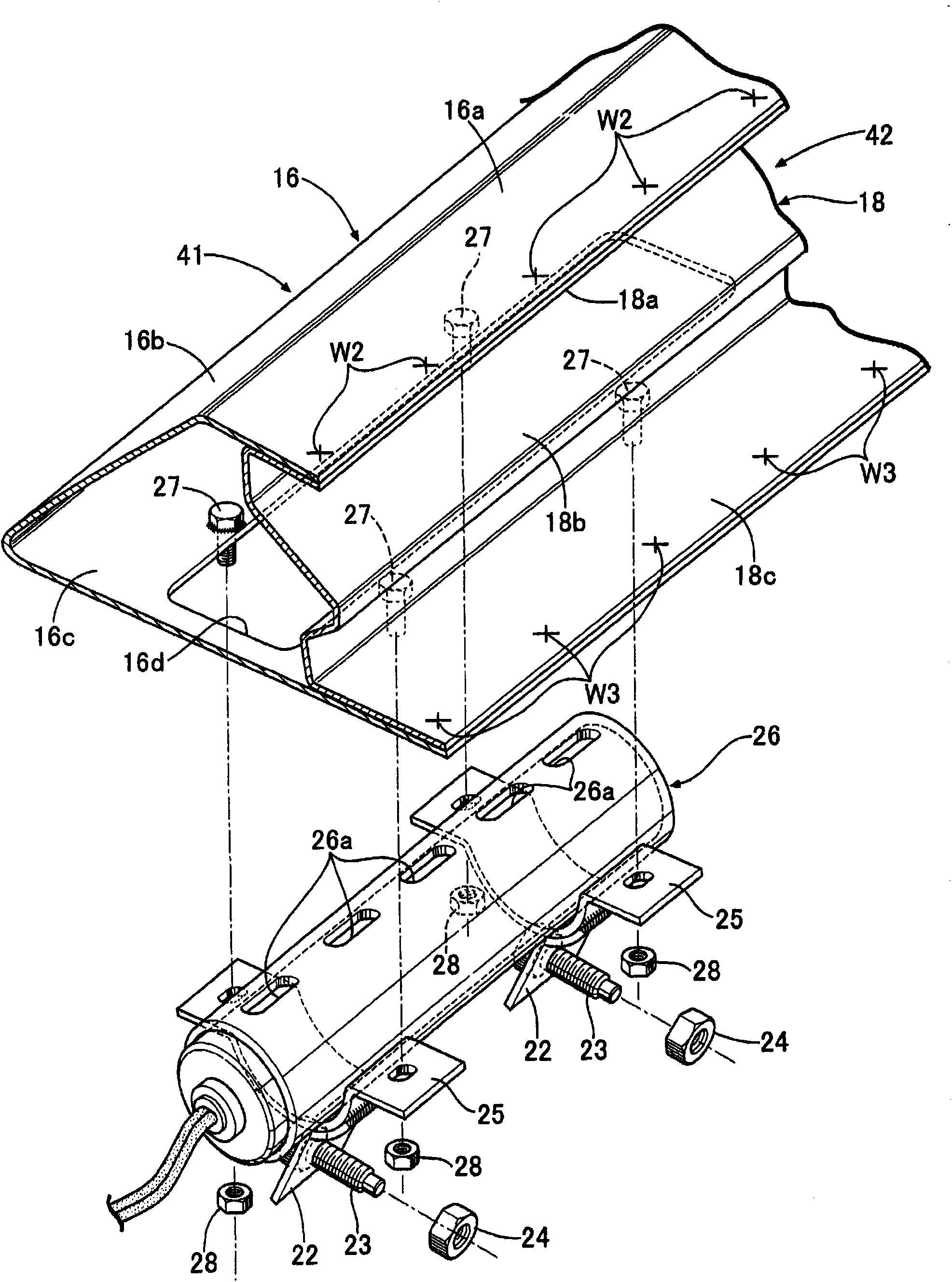

Pedestrian protection airbag device

ActiveCN101842272ASimple structureProtected from the impact of a collisionPedestrian/occupant safety arrangementSuperstructure subunitsInternal pressureEngineering

A pedestrian protection airbag device in which an airbag (34) having a closed cross-section is formed by inflating and expanding a front outer panel (16) and a front inner panel (18) of a front pillar (15) by high-pressure gas discharged from an inflator (26). This protects the head of a pedestrian from an impact due to collision of the head against the front pillar (15). Because the expanded airbag (34) exhibits its impact absorption performance when it plastically deforms, so long as the airbag (34) completes expansion until it retains the pedestrian, subsequent control of the inner pressure of the airbag (34) is not required. The construction simplifies specifications of the inflator (26) to reduce costs, and the airbag device can always exhibit effective impact absorption performance regardless of the vehicle speed at the time of collision and the body build of the pedestrian.

Owner:HONDA MOTOR CO LTD

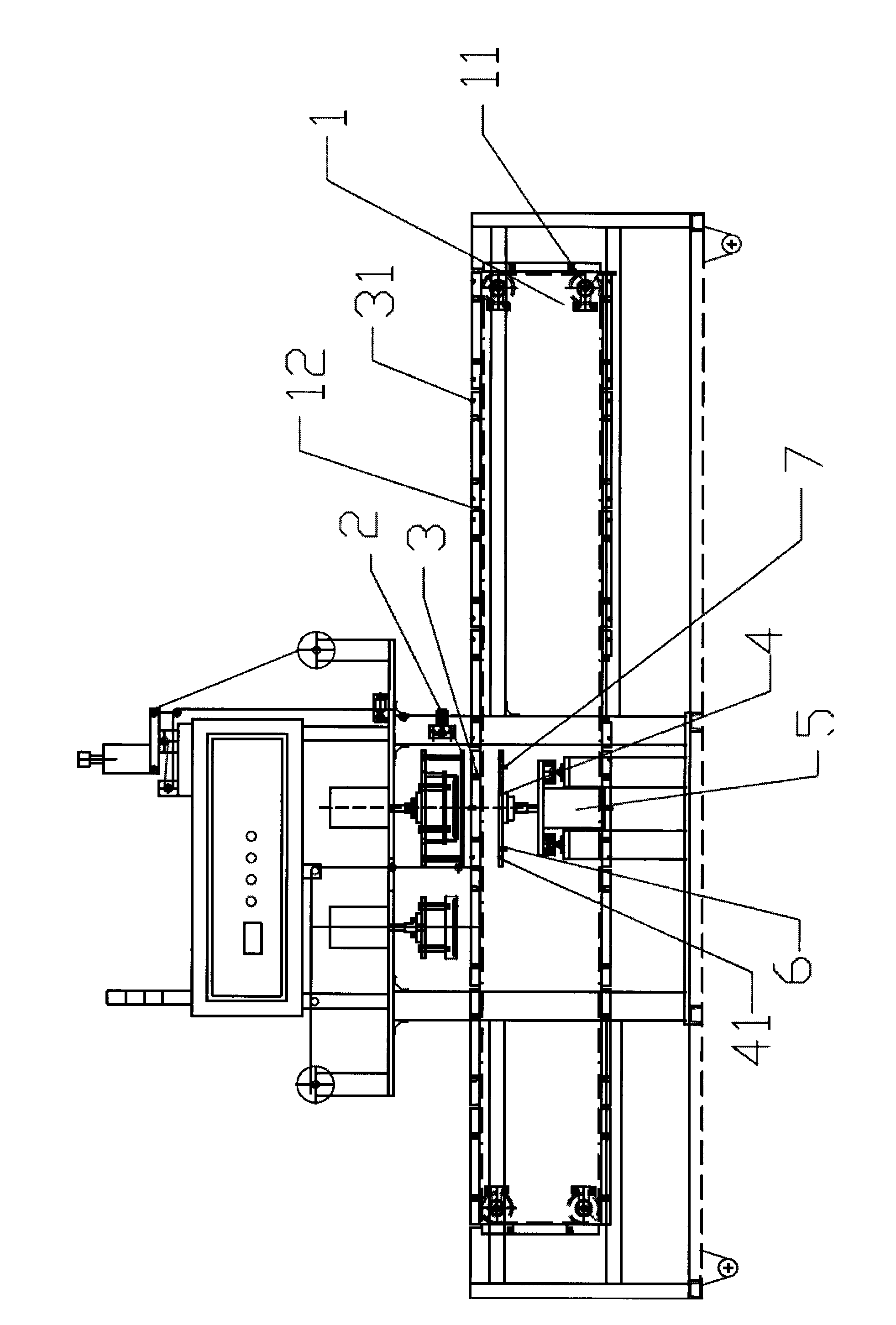

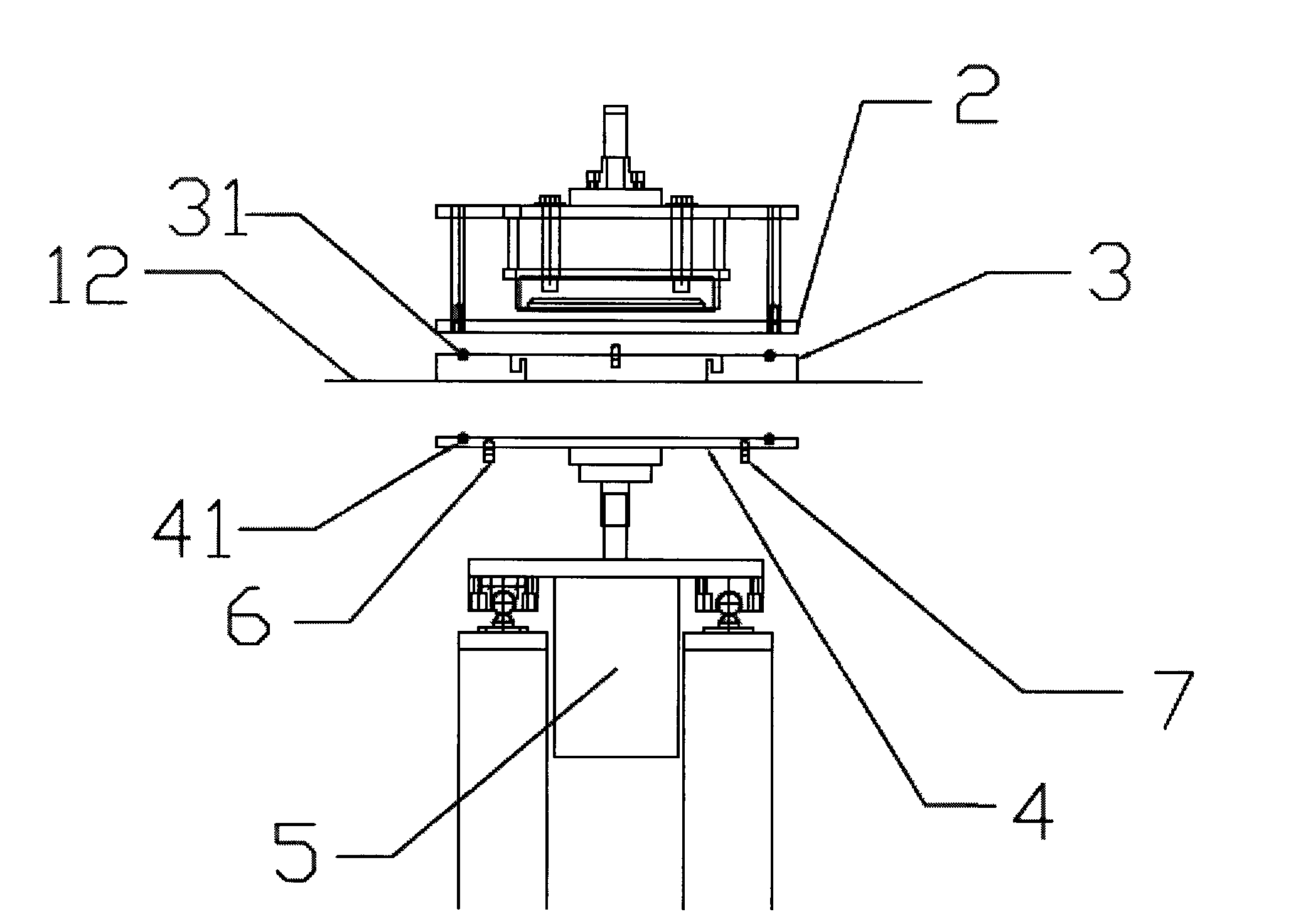

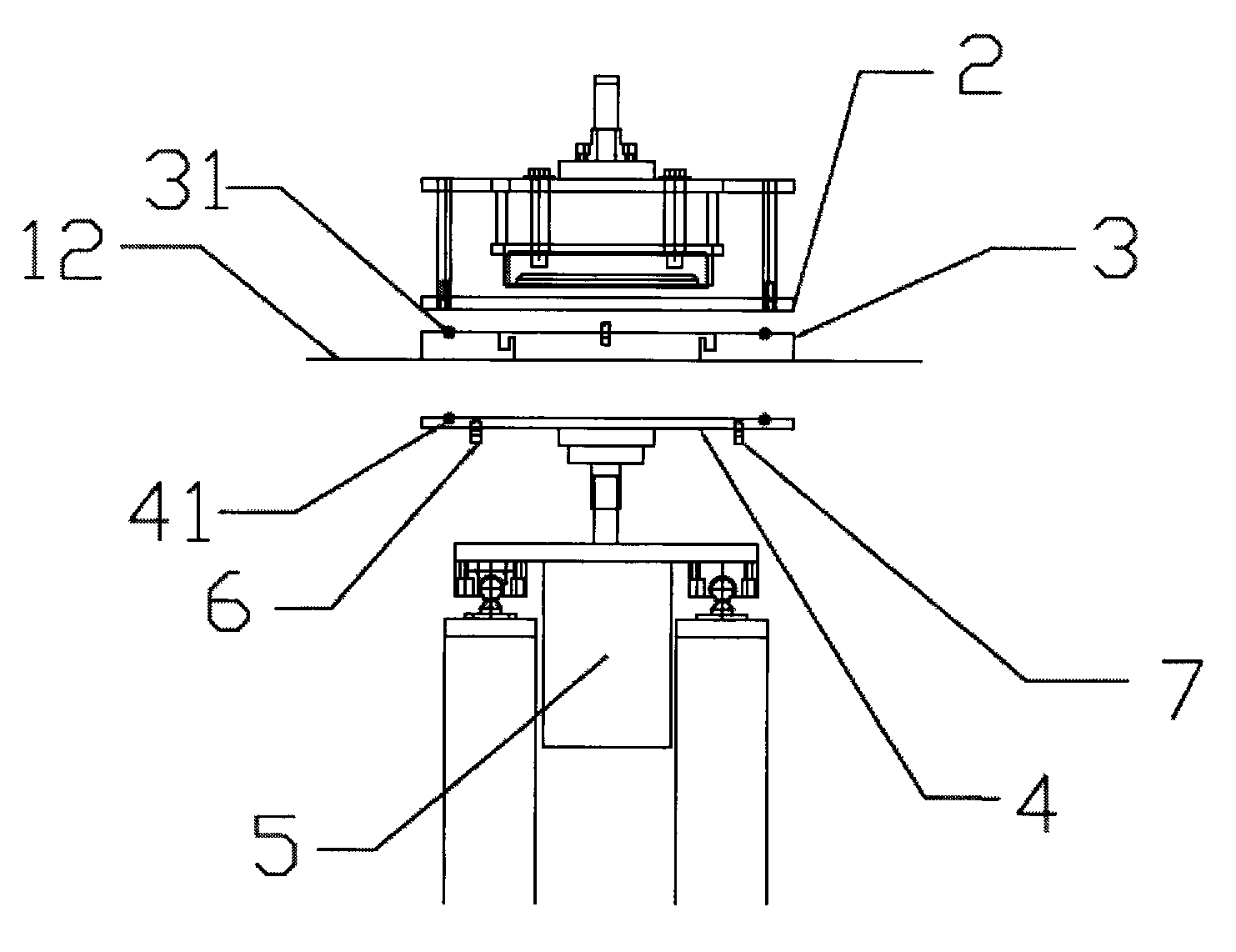

Continuous air conditioning packaging equipment

InactiveCN102219057AGood heat sealing performanceGood airtight environmentPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringAir conditioning

The invention discloses continuous air conditioning packaging equipment used for air conditioning package of a multi-grid packaging box. The continuous air conditioning packaging equipment comprises a conveyer which continuously moves, wherein the conveyer is composed of a conveyer belt which circulates around a turning roll; and an upper die is arranged above the conveyer belt, the conveyer belt is provided with a plurality of lower die cavity boards which are relatively independent and are used for placing the multi-grid packaging box in a penetrative manner, a lower die base plate is arranged below the conveyer belt and corresponds to the upper die, the lower die base plate is connected with a lower die lifting device which is fixed on the air conditioning packaging equipment, and the lower die base plate does lifting movement in a reciprocating way relative to the conveyer belt when being driven by the lower die lifting device. By adopting the continuous air conditioning packaging equipment disclosed by the invention, air conditioning package can be continuously carried out on the multi-grid packaging box, the closed environment in an air conditioning chamber is good, and air exhaust and aeration are more sufficient, thus the packaging quality is guaranteed, and the refreshing and quality guarantee period of an article in the multi-grid packaging box is prolonged.

Owner:苏州工业园区德森保鲜科技有限公司

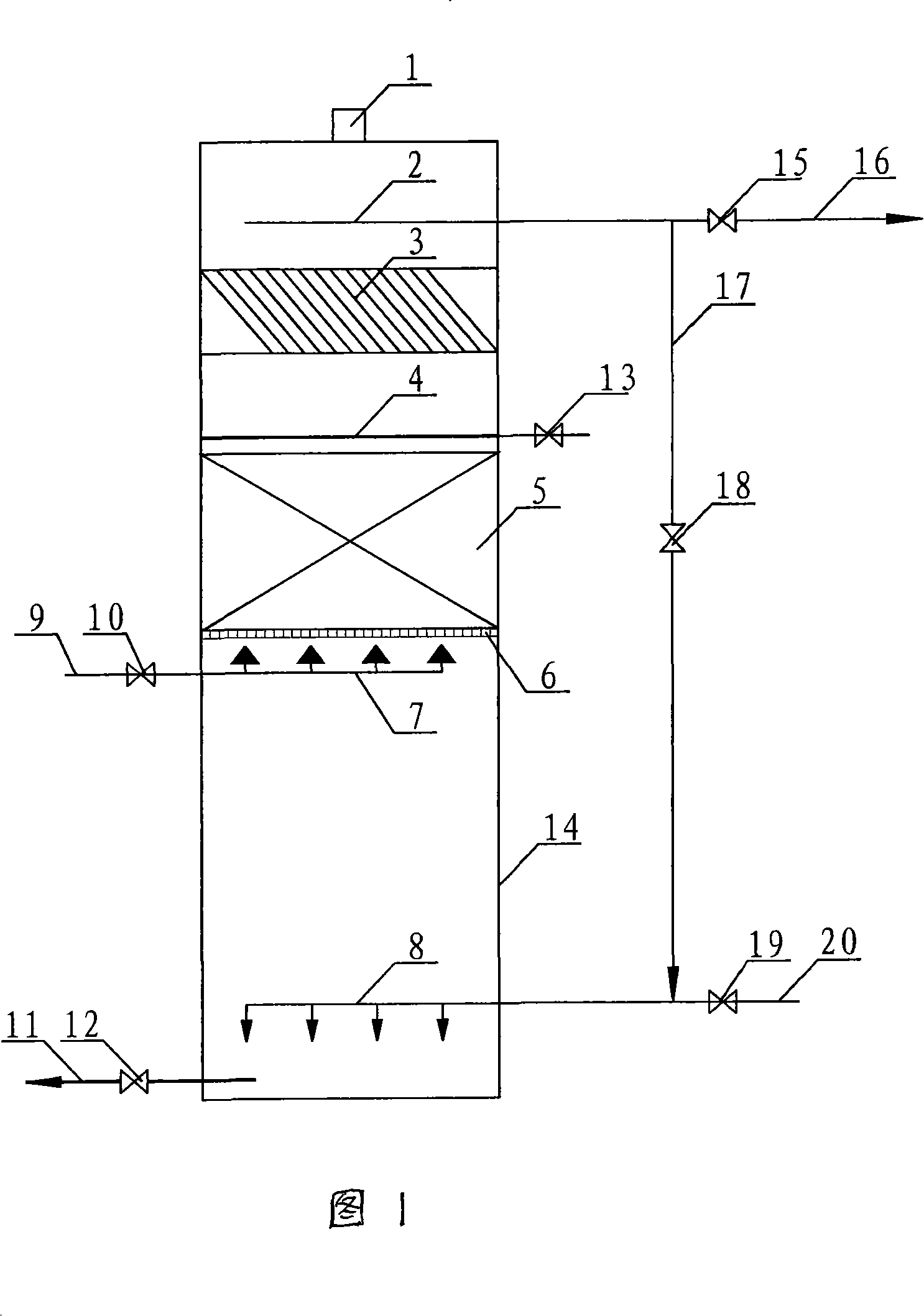

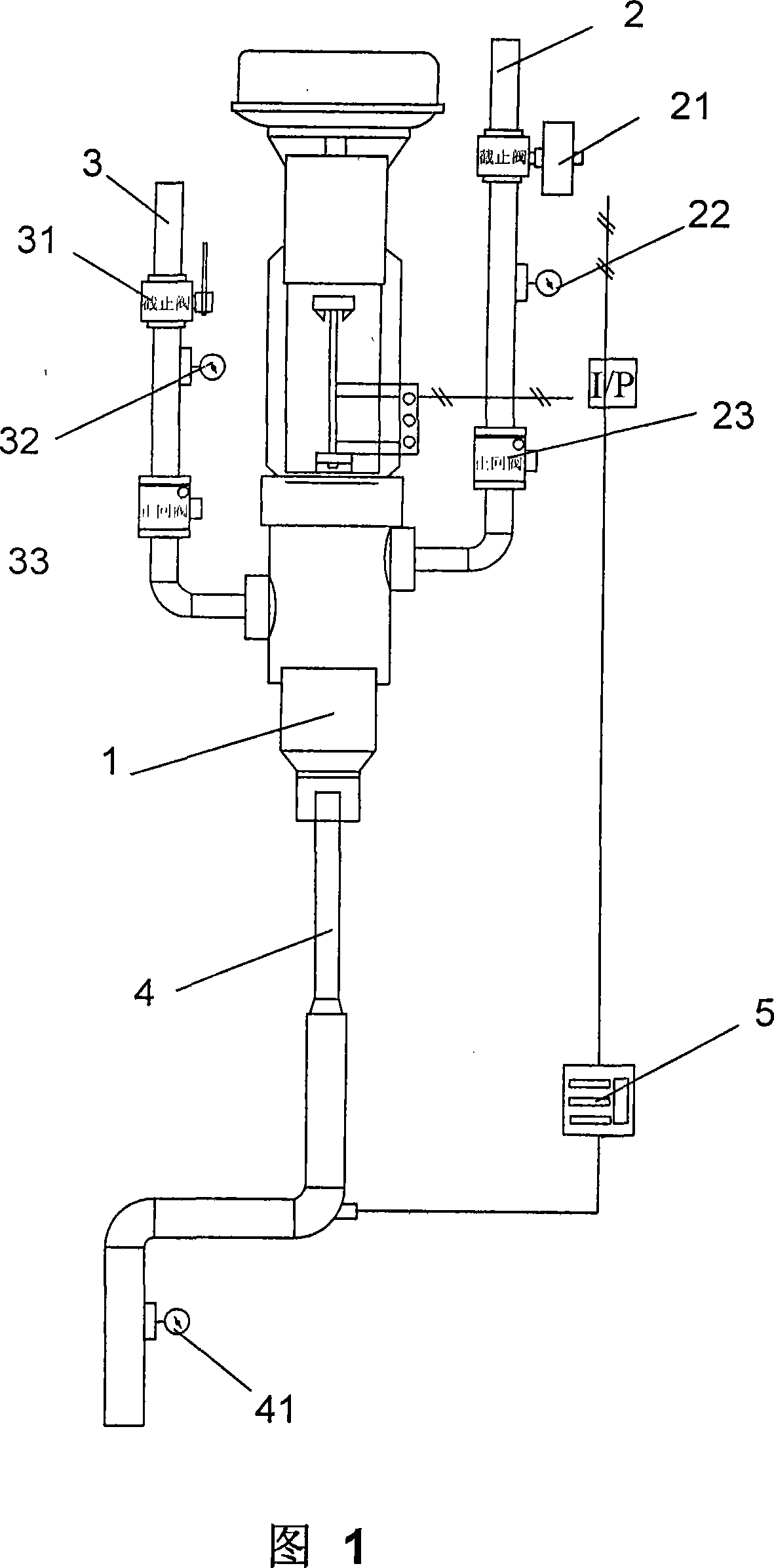

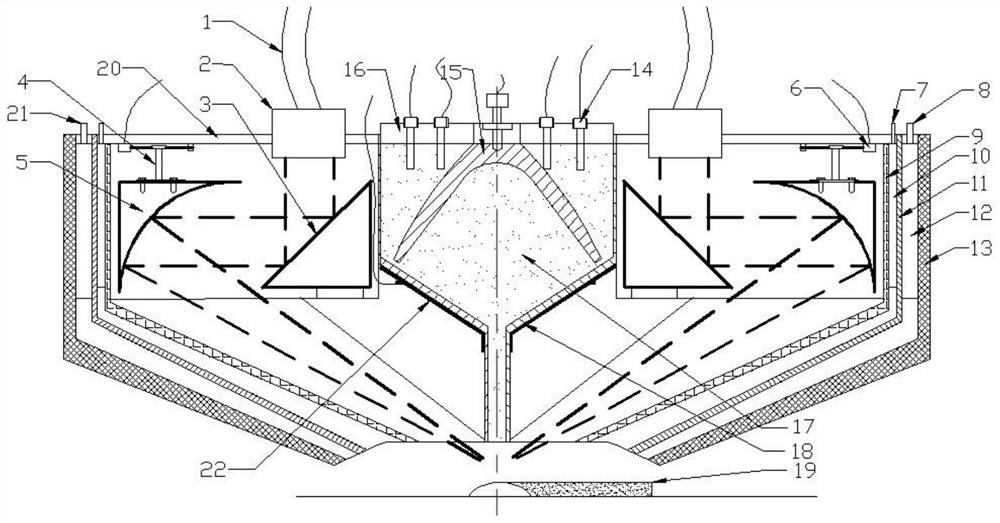

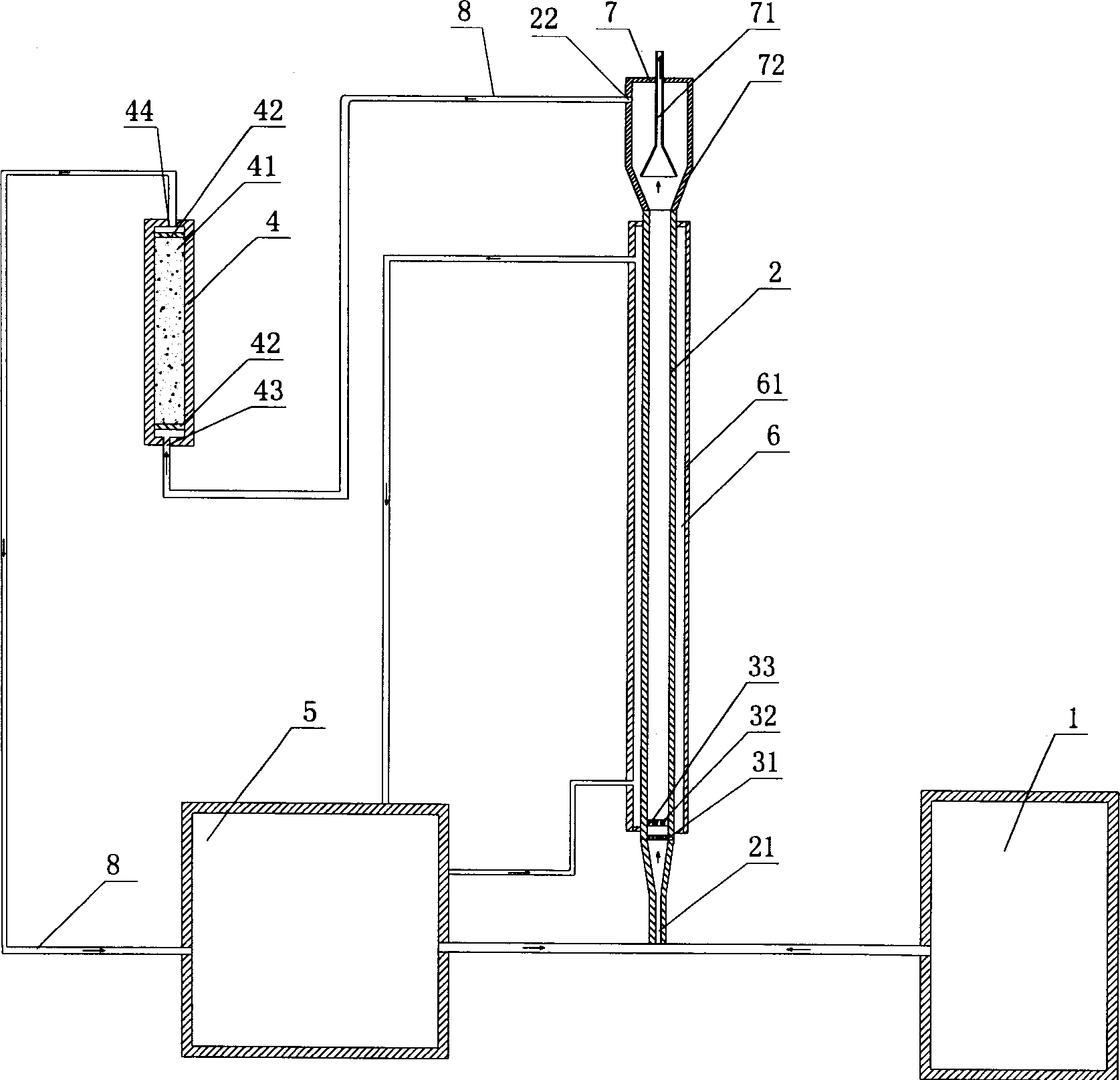

Sewage treating system for micro-aerobic expanded granular sludge bed-steel slag biological filter pond

InactiveCN103058459AReduce aeration energy consumptionFully inflatedTreatment using aerobic processesTreatment with aerobic and anaerobic processesActivated sludgeChemical oxygen demand

The invention discloses a sewage treating system with a compact structure and low operation cost for a micro-aerobic expanded granular sludge bed-steel slag biological filter pond. According to the sewage treatment system, the problems of great occupied area, high aeration energy consumption and high yield of residual sludge in an aerobic activated sludge method are solved. The sewage treating system is formed by combining a micro-aerobic expanded granular sludge bed reactor and a steel slag biological filter pond in series, wherein the micro-aerobic expanded granular sludge bed reactor adopts an oxygenating mode combining jet flow air suction with reflow water external aeration. Inflowing sewage enters the micro-aerobic expanded granular sludge bed reactor firstly to remove pollutants such as COD (Chemical Oxygen Demand), ammonia nitrogen and total nitrogen and then enters a biological aerated filter pond taking steel slag as filler to remove total phosphorus and further improve the quality of effluent. According to the sewage treating system, small area is occupied, energy consumption is saved and the yield of sludge is low; and the sewage treating system is suitable for treating municipal sewage.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Parachute with skirt reefing system

InactiveUS20070075189A1Fully inflatedParachutes testing apparatusNon-canopied parachutesEngineeringMechanical engineering

A parachute system has a canopy, suspension lines that extend from the canopy skirt to a confluence point, and a center line that is attached to and between the apex of the canopy and the confluence point. A single reefing line cutter is attached to the center line and is activated after a predetermined amount of time has elapsed. A first reefing line extends through a first group of reefing rings wherein one end of the first reefing line is attached to the single reefing line cutter and the opposite end is attached to the canopy skirt at a first predetermined location. A second reefing line extends through a second group of reefing rings that is opposite the first group of reefing rings. The second reefing line has one end attached to the single reefing line cutter and an opposite end attached to the canopy skirt at a second predetermined location that is across from the first predetermined location. The canopy opens to an initial circumference that is determined by the summation of the lengths of the first and second reefing lines. When the reefing line cutter is activated, the reefing line cutter releases the first and second reefing lines so as to allow full inflation of the canopy.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

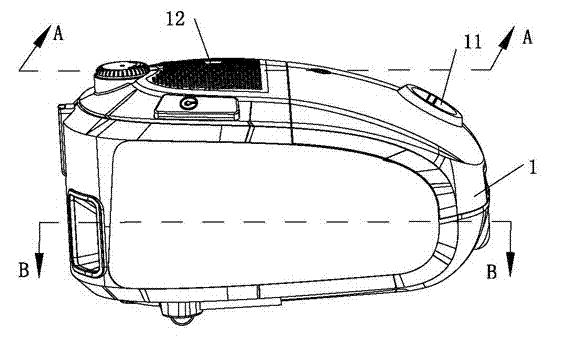

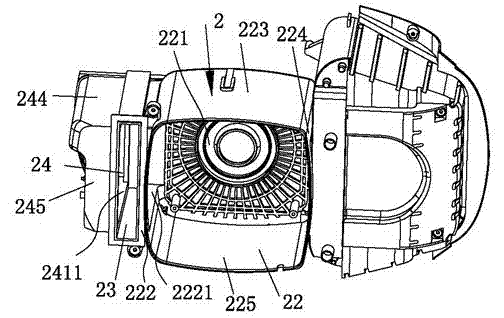

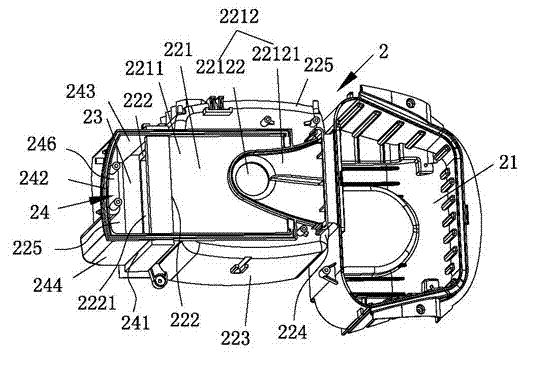

Silent dust collector

The invention discloses a silent dust collector, which comprises a shell, an inner cover and a motor component, wherein an air inlet and an air outlet are formed on the shell; the shell wraps the inner cover and the motor component; the inner cover is provided with an accommodating chamber used for accommodating the motor component; a motor air outlet and a motor air inlet which is communicated with the air inlet are formed on the motor component; the inner cover is provided with an expansion anechoic chamber communicated with the air outlet; the direction of the motor air outlet is opposite to the expansion anechoic chamber; the outer wall of the motor component, the side wall of the accommodating chamber and the bottom wall of the shell form two air outlet passages communicated with the motor air outlet and the expansion anechoic chamber in an enclosing way; the two air outlet passages are respectively poisoned on the two sides of the motor air outlet; and on a cross section vertical to the air outlet passages, the expansion anechoic chamber has a first width, the air outlet passages have the second widths, and the first width is larger than the sum of the second widths of the air outlet passages. Through the silent dust collector, noise can be effectively reduced.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

Process for corn starch sugar by enzyme method

ActiveCN101117647AStrong shear forceFully cookedFermentationGlucose productionFlocculationIon exchange

The present invention provides a process of corn starch sugar producing by an enzymatic technique. The process step mainly includes hydrolysis liquefaction, flash braise, saccharification, bleaching, ion exchange and enrichment of amylum material under the action of enzyme preparation; wherein the hydrolysis liquefaction uses a water heater as the braising and boiling reactor, and the water heater has an adjustable clearance for material entering into. In the process of the hydrolysis liquefaction, the pressure difference of the feeding amylum material and the discharged amylum material on the water heater can be controlled between 0.15-0.30MPa, and 0.20-0.25MPa are optimal; the single braising and boiling temperature is controlled between 110-130 DEG C, and 110-125 DEG C are optimal. The water heater adopted by the present invention can ensure a curtain pressure difference of the feeding material and the discharged material, can bring strong cut force, and can ensure zymolyte molecules sizes of the liquefaction liquid to be regular and proportioned. The present invention adopts high temperature braising and boiling, which can make the protein denaturation more rapid, more complete, and the flocculation better, and can facilitate the protein removing.

Owner:COFCO RONGS BIOTECH

Preparation process of three-penis wine

InactiveCN111019797AExtract impactExtract completelyAlcoholic beverage preparationBiotechnologyMedicinal herbs

The invention discloses a preparation process of three-penis wine. The preparation process comprises the following steps: S1, preparing the following medicinal materials in parts by mass: 0.2 part ofseal penis, 1 part of deer penis, 6 parts of penis canitis, 11.4 parts of ginseng, 10 parts of cinnamon, 20 parts of Chinese wolfberry, 20 parts of poria cocos, 30 parts of Chinese yam, 4 parts of Sichuan pepper and 4 parts of fennel, and crushing the medicinal materials into medicinal powder particles; S2, wetting and sealing the medicinal powder particles; S3, conveying the wetted medicine powder particles into a percolation device to be soaked; S4, carrying out percolation; S5, adding purified water into the percolation device, and carrying out circulating water washing; S6, blending wine,namely uniformly mixing an obtained percolate, sugar, yellow rice wine, old wine and purified water in proportion, standing and filtering. According to the preparation process of the three-penis wineprovided by the invention, effective components in the traditional Chinese medicine prescription can be more effectively extracted, and the medicinal effect of the traditional Chinese medicine prescription can be fully exerted.

Owner:烟台中亚至宝药业有限公司

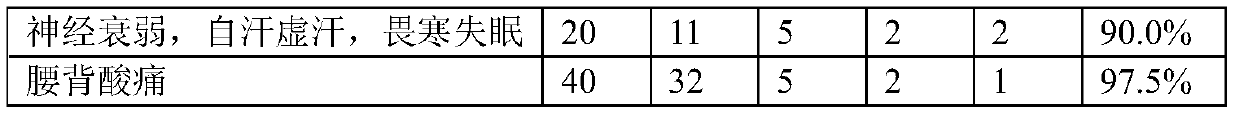

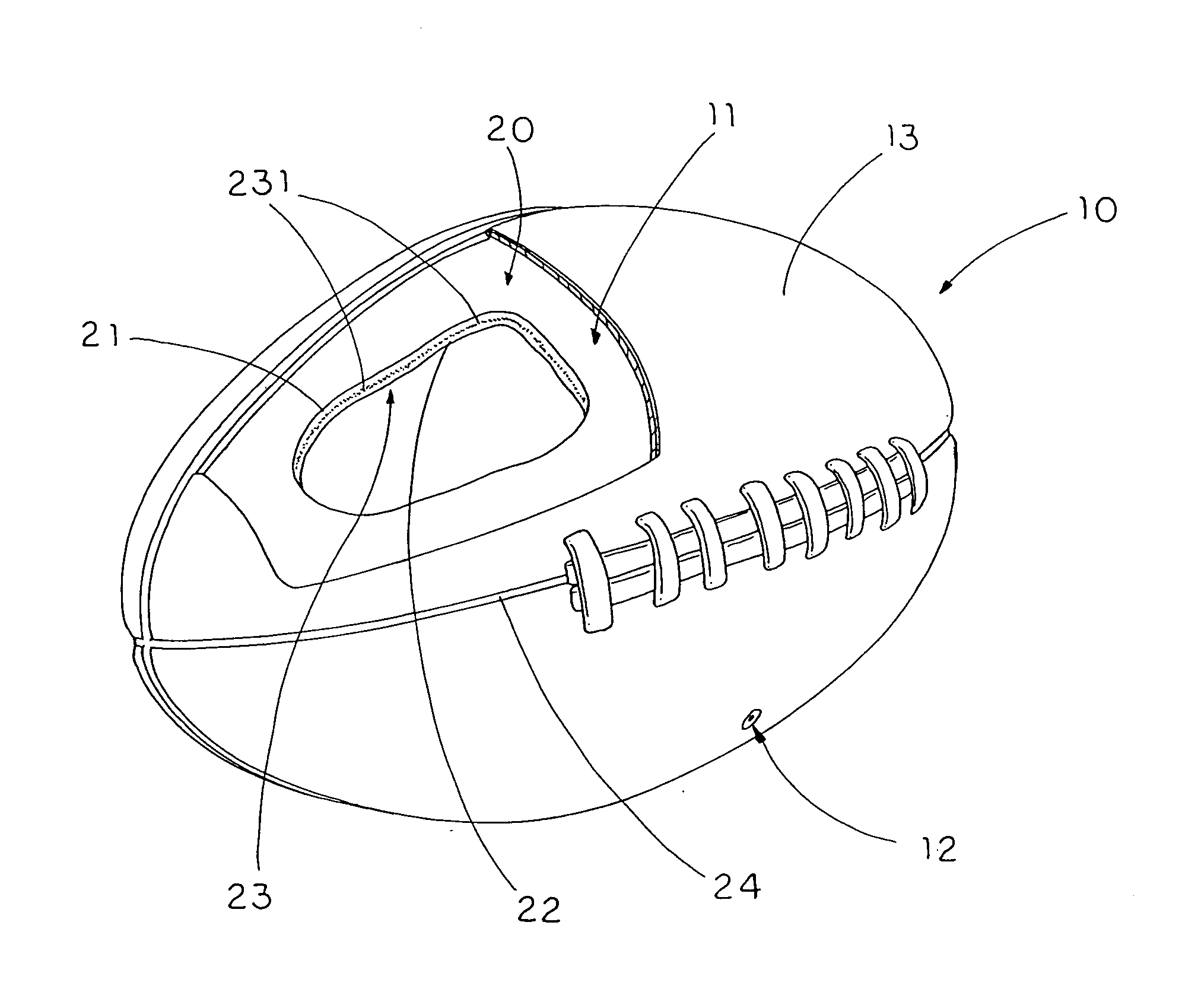

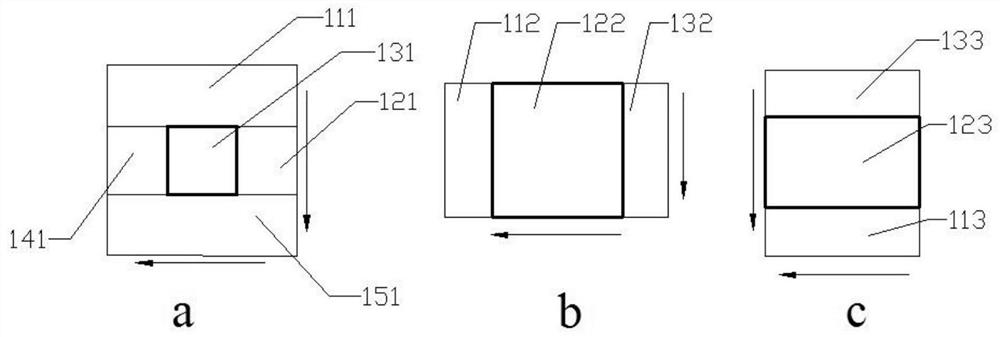

Padded sports ball

InactiveUS20090137352A1High strengthPreventing the inflatable ball bladder from being over inflatedHollow inflatable ballsHollow non-inflatable ballsEngineeringMechanical engineering

A sports ball includes a ball cover having a ball cavity and a valve hole, and an inflatable ball bladder. The inflatable ball bladder, which is disposed in the ball cavity of the ball cover and is adapted to be inflated through the valve hole to support the ball cover, includes an outer bladder portion layer, an inner bladder portion layer disposed in the outer bladder portion layer, and a webbing layer. The webbing layer is disposed between the inner and outer bladder portion layers, wherein the inner and outer bladder portion layers are treated to integrally embed the webbing layer therebetween to enhance the strength of the ball bladder such that the webbing layer allows the ball bladder to be fully inflated for evenly distributing air pressure therein to support the ball cover.

Owner:OU TSUNG MING

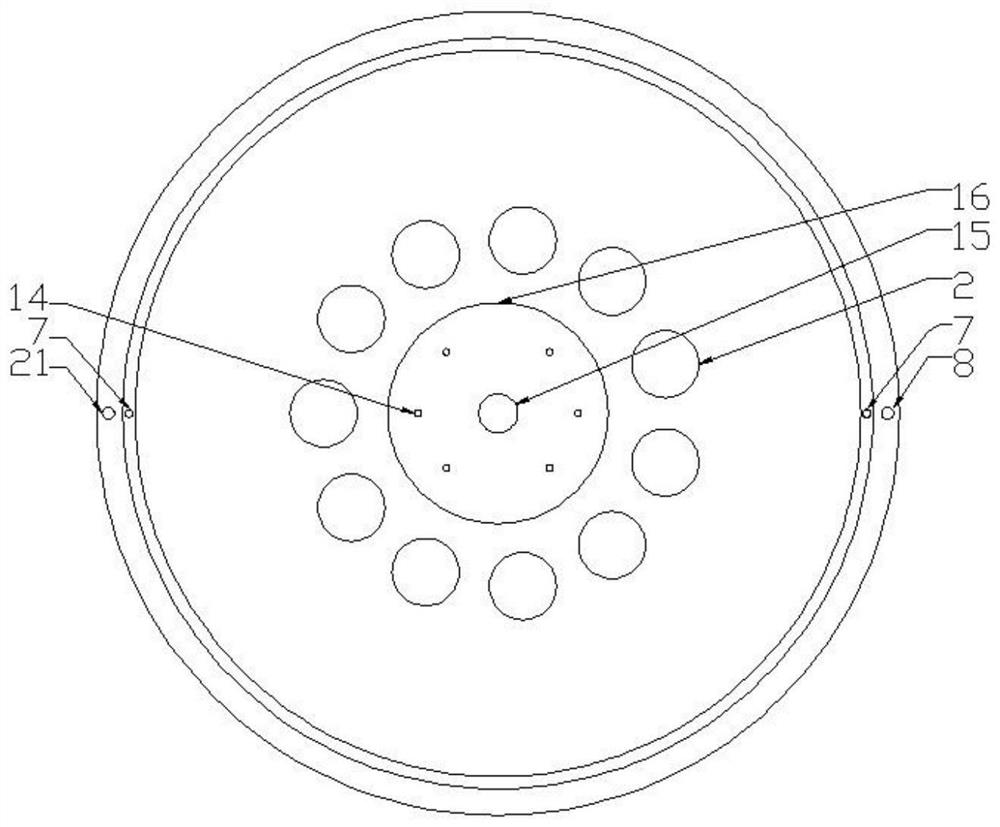

Coaxial multi-beam laser synthesis axis powder feeding ultrahigh-speed laser cladding head and cladding method thereof

ActiveCN112410779AImprove speed and efficiencySolve the problem of insufficient laser energyIncreasing energy efficiencyMetallic material coating processesErbium lasersMaterials science

The invention provides a coaxial multi-beam laser synthesis axis powder feeding ultrahigh-speed laser cladding head and a cladding method thereof. The laser cladding head comprises a laser cavity, a shielding gas cavity and a water cooling cavity which are sequentially and coaxially arranged from inside to outside, wherein a powder mixing cavity and a flying light path system are arranged in the laser cavity; an umbrella-shaped powder separator and a powder feeding nozzle are arranged in the powder mixing cavity; the umbrella-shaped powder separator is fixed to the center of a rear cover of the laser cladding head through the root; powder feeding needles are further arranged on the rear cover of the laser cladding head and are annularly arranged along the umbrella-shaped powder separator;the flying light path system is annularly arranged along the powder mixing cavity; and a light outlet of the laser cavity is formed in the periphery of the powder feeding nozzle and is annular. The laser cladding head has the beneficial effects that the laser spot area is large, the spot energy gradient distribution can be designed and adjusted, the functions of base material preheating and cladding layer remelting can be synchronously achieved, and therefore the requirement for high-speed laser cladding is met; and compared with a high-power laser device, cost is lower.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

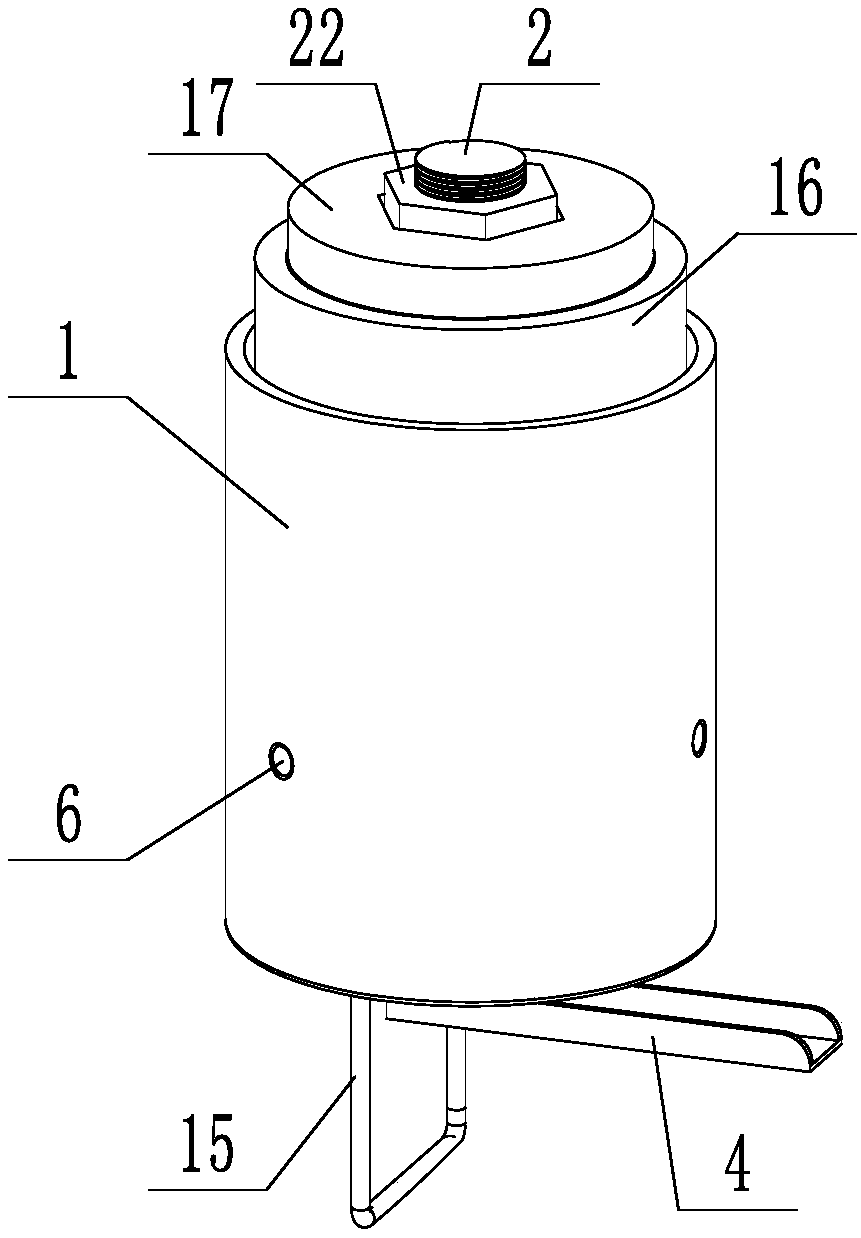

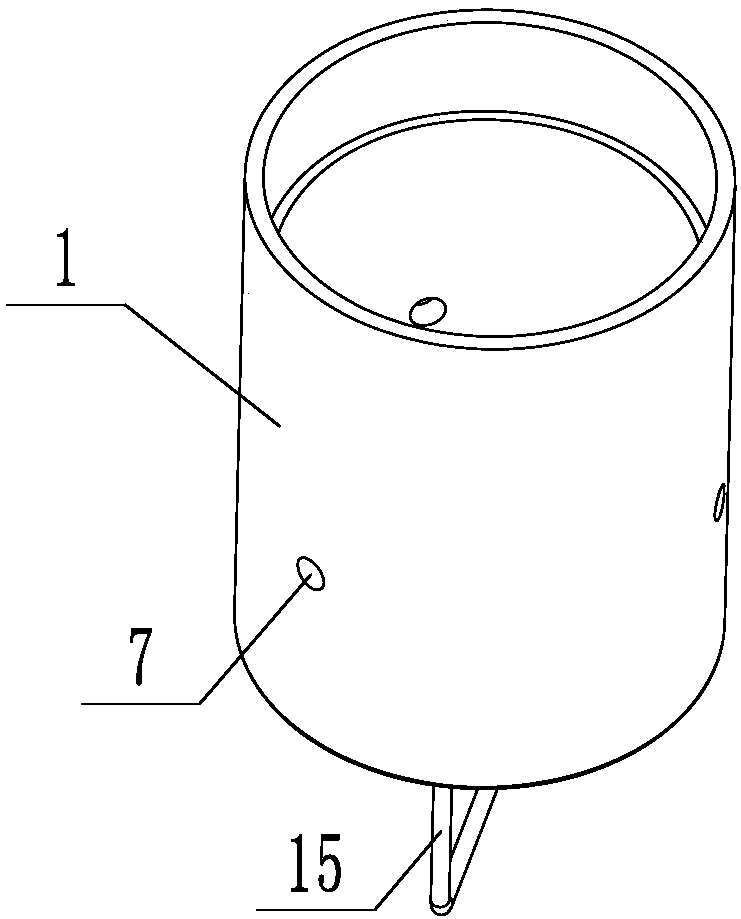

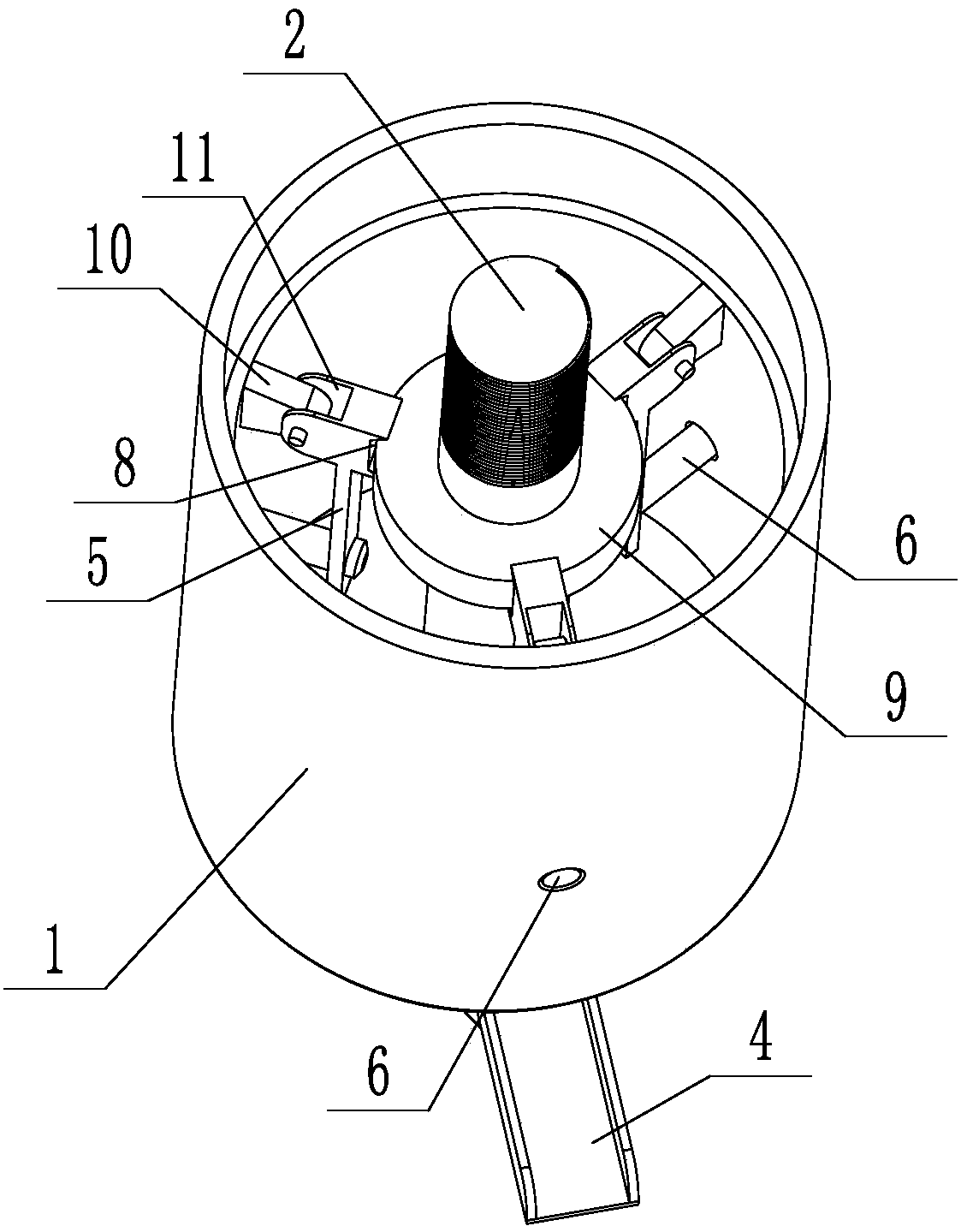

Solar water tank foamed positioning plug

The invention discloses a solar water tank foamed positioning plug which comprises a shell and a lifting rod positioned in the shell. An inner hole of the shell is a step hole, a baffle is arranged ata step, a sealing mechanism for sealing an inner container of a water tank is arranged above the baffle, a positioning mechanism for positioning the inner container is arranged below the baffle, andone end, extending out of the shell, of the lower end of the lifting rod is hinged to a driving handle. The inner container of the water tank and the shell of the water tank are fixed through the positioning mechanism and the sealing mechanism to prevent the inner container from swinging in the shell of the water tank, polyurethane hard foam after a foaming process is ensured to be uniform, and the water tank has good heat-insulating effect.

Owner:SHANDONG SANGLE SOLAR ENERGY

Integral treatment apparatus for urban sewage

InactiveCN1792878AEasy to cutAvoid affecting the adsorption effectTreatment with anaerobic digestion processesAmmoniacal nitrogenMunicipal sewage

A comprehensive treating system for city sewage is composed of an admission water tank, a reactor with water inlet on its bottom, water outlet on its top, screen plate at said water inlet and three-phase separator at its water outlet, an adsorptive column with zeolite as its filler and the screen plates at its water inlet and outlet, and a treating water tank. Its advantage is high effect to remove COD, ammoniacal nitrogen and P.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com