Continuous air conditioning packaging equipment

A modified atmosphere packaging and equipment technology, which is applied in packaging, pressurized/gasification packaging, transportation packaging, etc., can solve the problems of incomplete gas replacement, poor heat sealing effect of the middle partition, inconsistent air pressure, etc. Fresh-keeping shelf life, full pumping and inflation, and the effect of ensuring packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

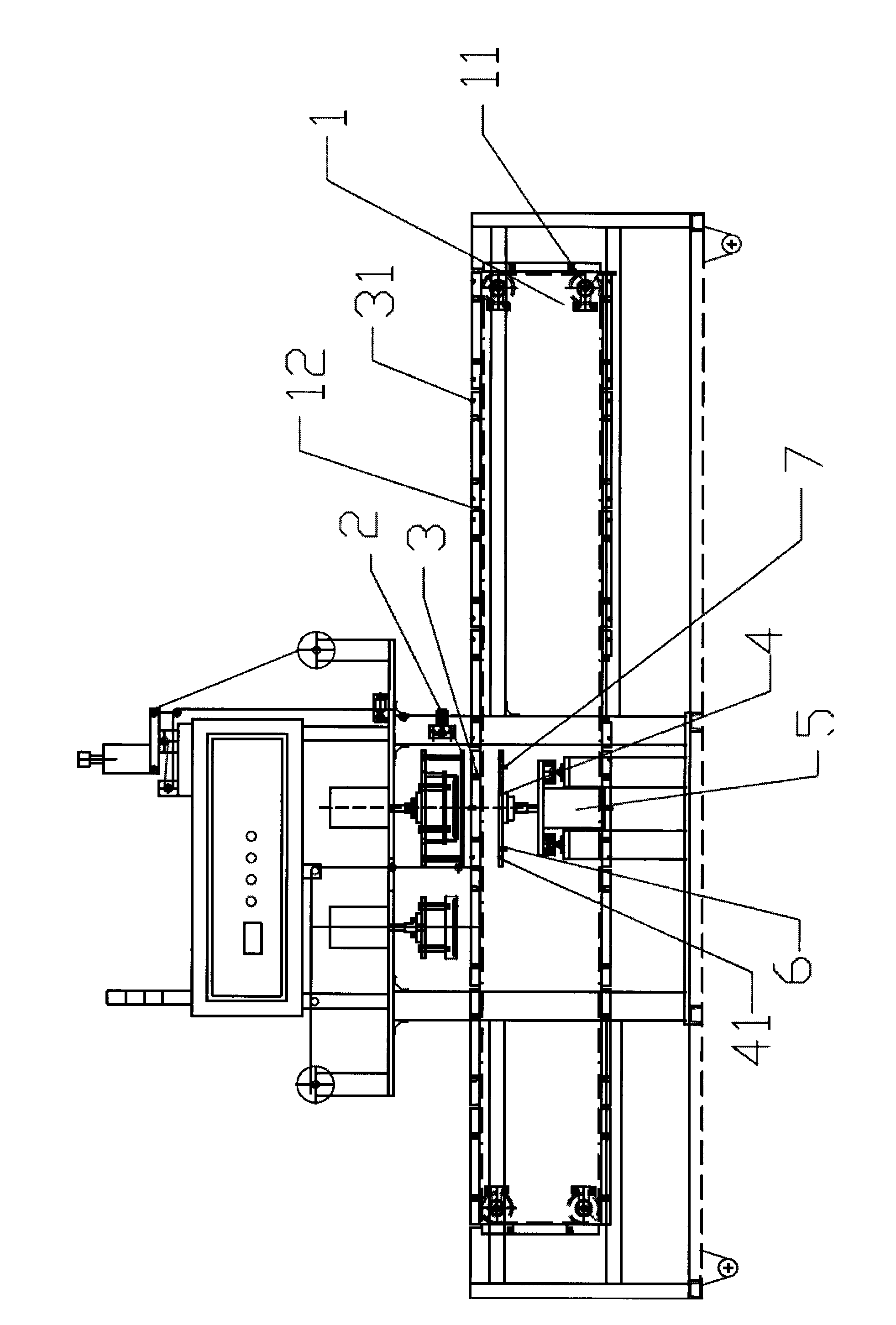

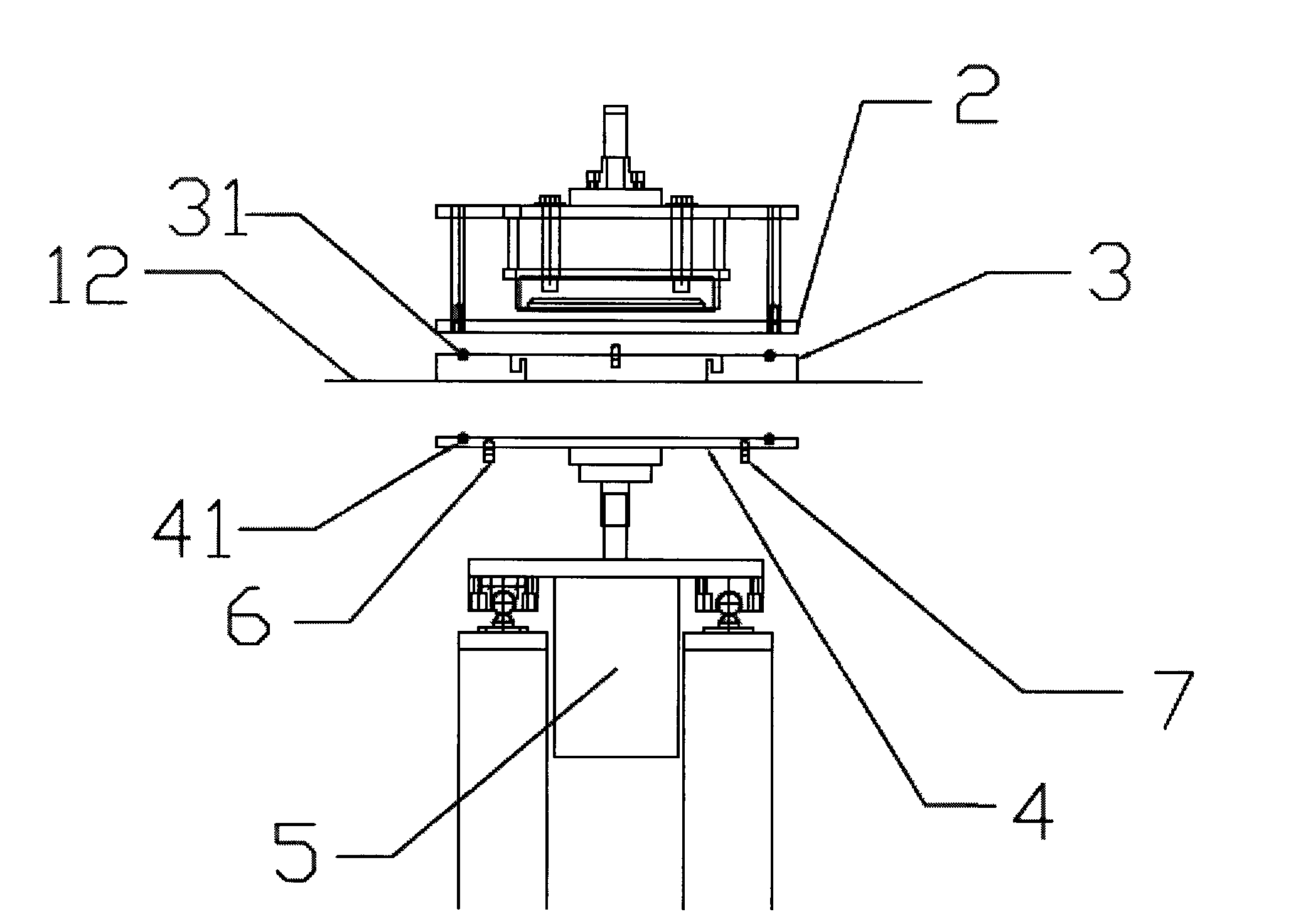

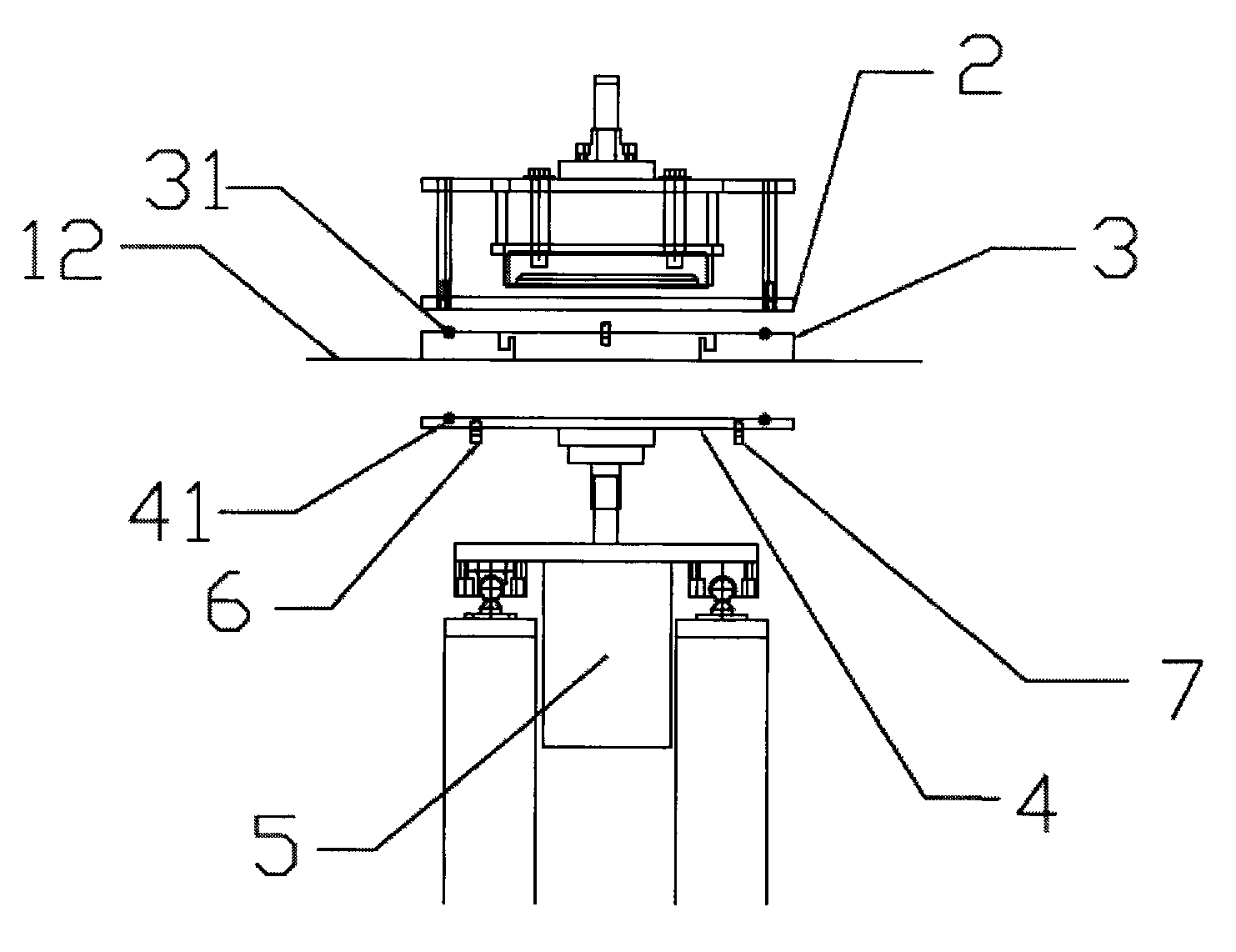

[0017] A continuous modified atmosphere packaging equipment of this embodiment is used for the modified atmosphere packaging of multi-compartment packaging boxes, such as figure 1 with figure 2 Shown, comprise a continuous motion conveyor 1, the conveyor is made up of a conveyor belt 12 that goes around the loop of the steering roller 11; the top of the conveyor belt 12 is provided with an upper mold 2, and the structure and function of the upper mold 2 are consistent with those of the prior art. I won't repeat them here. The conveyor belt 12 is threaded with a plurality of relatively independent lower mold cavity plates 3, and the bottom of the conveyor belt 12 is provided with a lower mold bottom plate 4 corresponding to the upper mold 2. The cylinder 5 and the bottom plate of the lower mold 4 are driven by the cylinder 5 to move up and down reciprocally relative to the conveyor belt 12 . The lower mold cavity plate 3 is provided with an upper mold sealing ring 31 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com