Patents

Literature

305results about How to "Guaranteed packaging quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

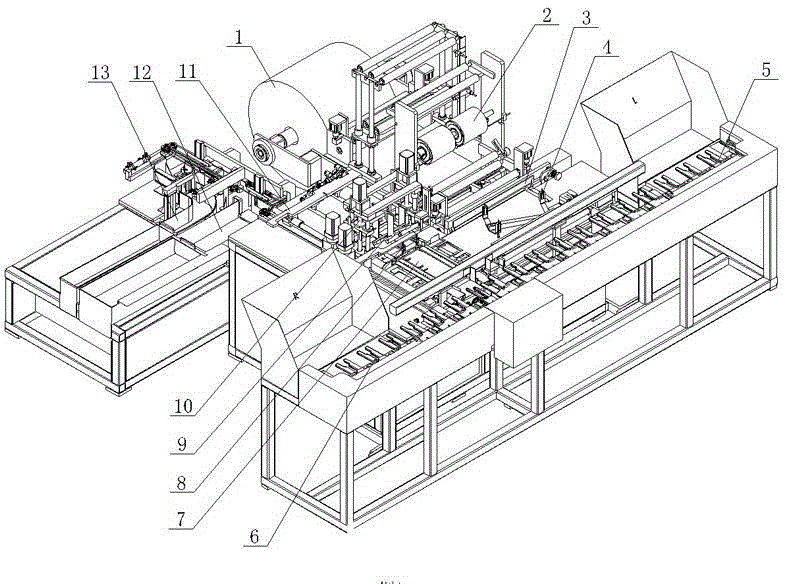

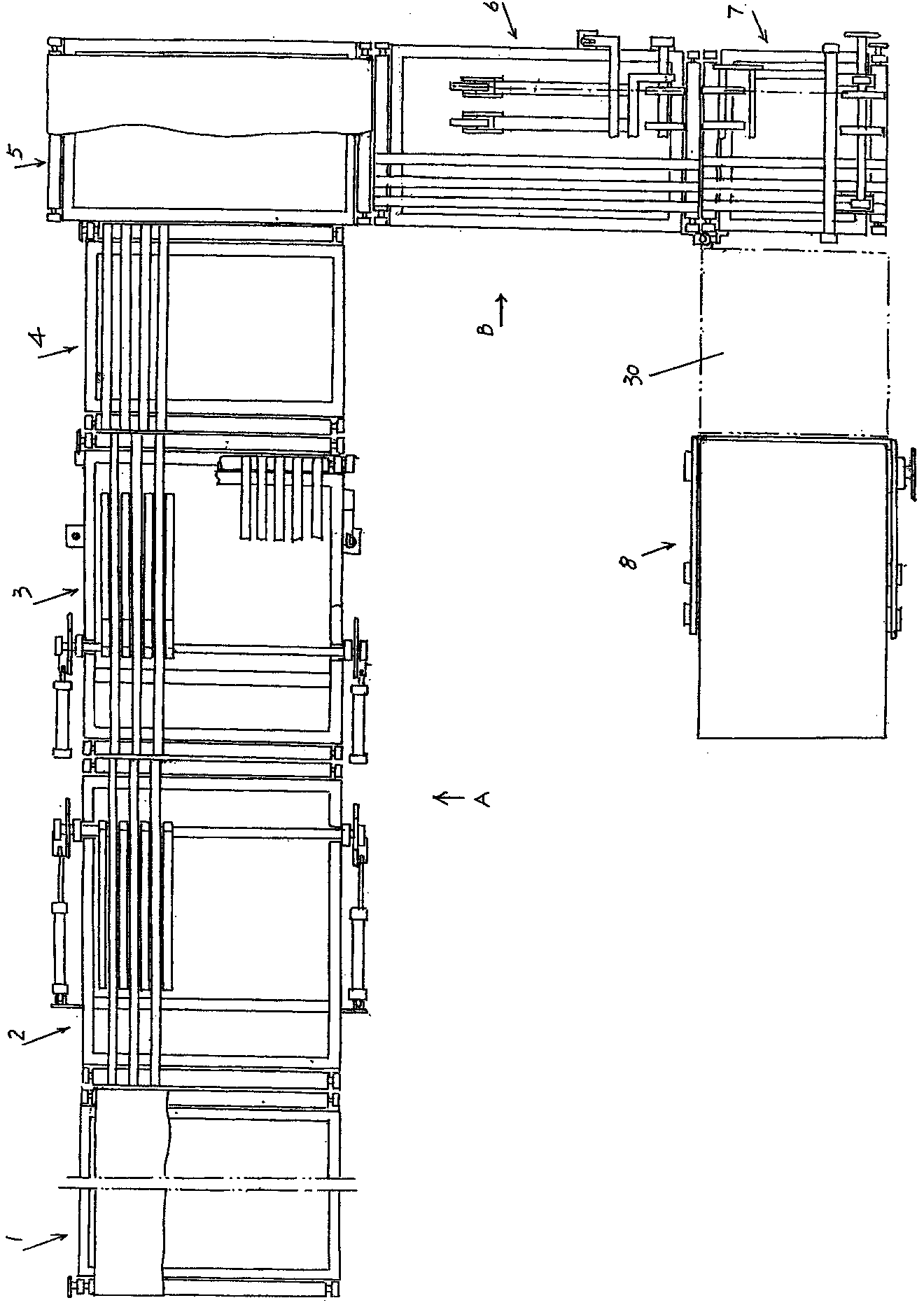

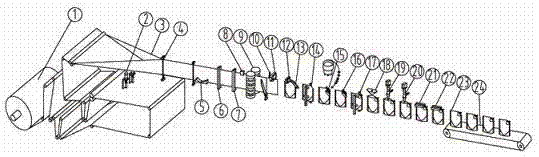

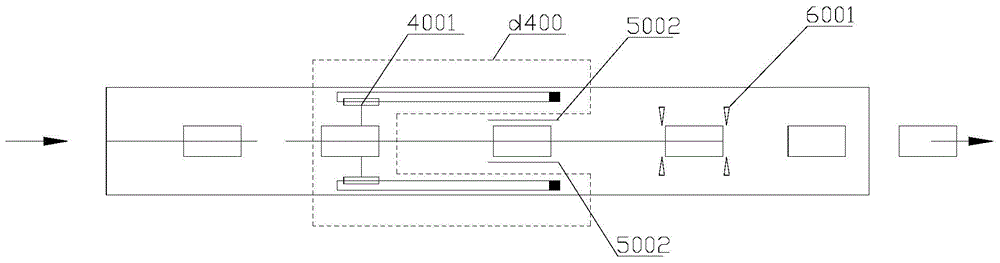

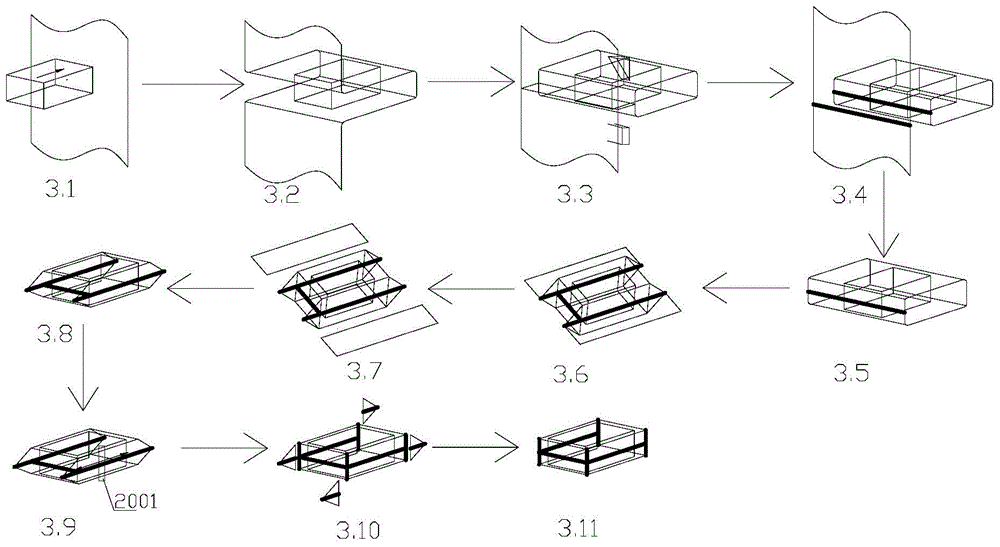

Medical glove lining paper packaging machine

ActiveCN104859881ARealize fully automatic productionEasy to useWrapper folding/bending apparatusWrappingPulp and paper industryMoving parts

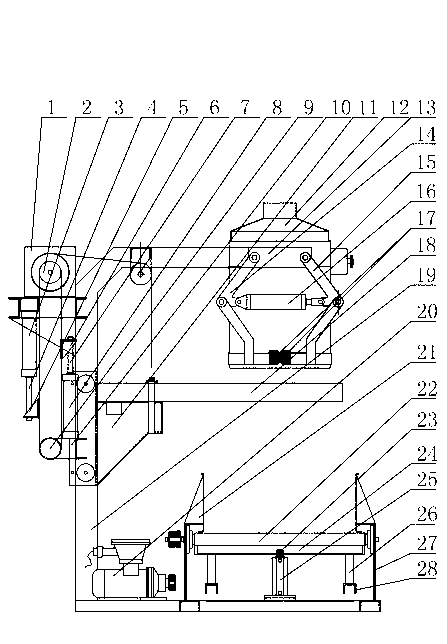

The invention discloses a medical glove lining paper packaging machine which is sequentially provided with an unwinding part, a folding part, a cutter part, a transverse paper moving part, a left and right glove conveying part, a glove clamping part, a left and right folding part, a longitudinal paper moving part, a forward and backward folding part, a middle folding part, a finished product conveying part, and a long packet material receiving part or a short packet material receiving part or a long and short packet material receiving part. The machine is specially used for full-automatic production of medical glove lining paper packages, is simple and reasonable in structure, and is high in production efficiency. In the production process, left hand gloves and right hand gloves are conveyed separately, so that it is guaranteed that the phenomenon that two left hand gloves or two right hand gloves are arranged in the same package does not occur; meanwhile, empty packaging and half packaging are prevented, and packaging quality is guaranteed; an air blowing device is arranged so that the gloves can be sleeved more easily, and speed is increased; the produced medical glove lining paper packages are provided with folded parts, and it is guaranteed that the gloves are convenient to use, hygienic and absolutely safe; after medical glove lining paper is packaged, the lining paper is automatically collected and sorted in long packets or short packets according to free choices, and the lining paper can be used conveniently by users.

Owner:ZHEJIANG HONGCHANG MACHINERY

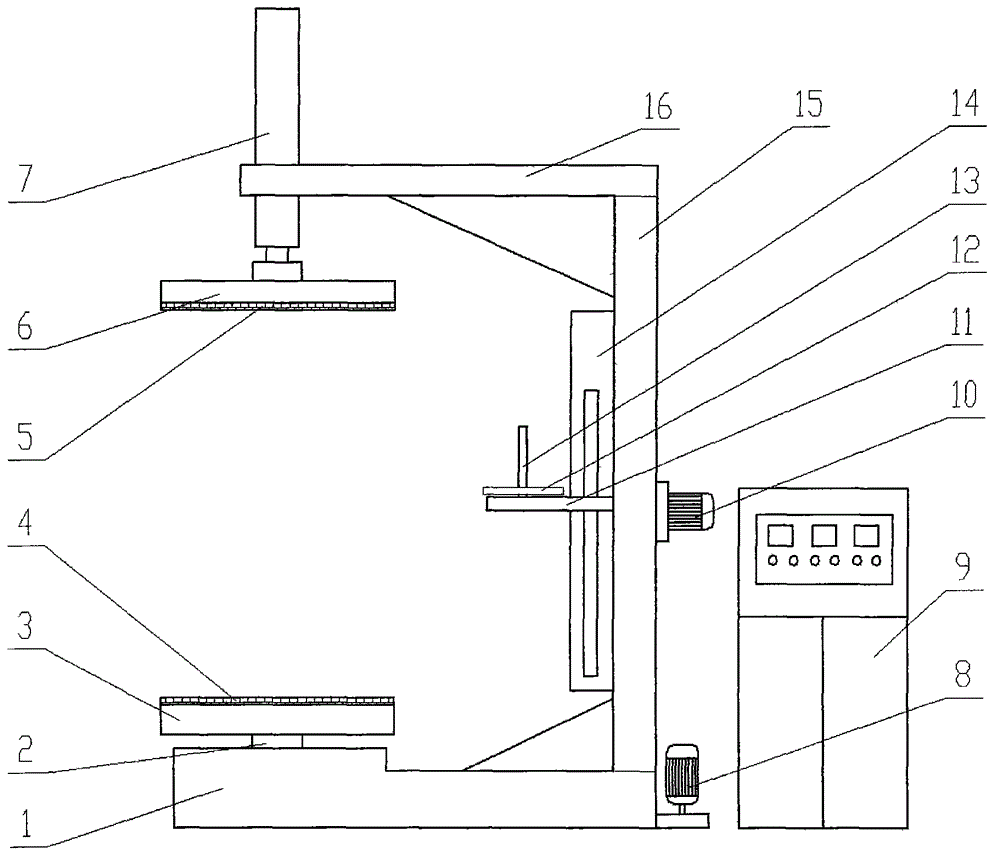

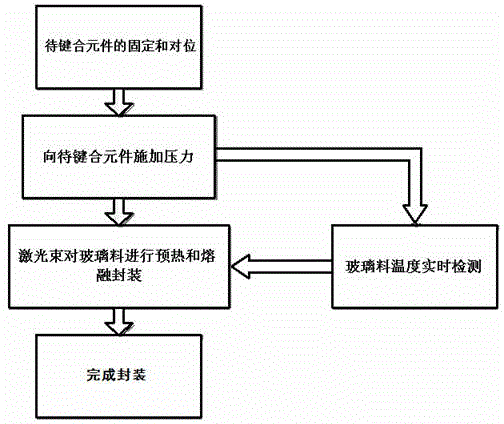

Packaging machine

InactiveCN104477432ASimple structureEasy to packPackaging automatic controlWrapping with article rotationSteel barEngineering

The invention discloses a winding packaging machine which comprises a base, a vertical column, a beam, a lifting mechanism and a control cabinet. One end of the base is fixedly connected with the vertical column through a diagonal draw steel bar, the beam is fixedly connected at the upper end of the vertical column through a diagonal draw steel bar, the lifting mechanism is mounted on the vertical column, a turntable motor is arranged at the rear end of the base, a spindle and a driving turntable are connected on the turntable motor, a lower turntable rubber mat is mounted on the turntable, the lifting mechanism and a lifting motor are mounted on the vertical column, a lifting table is mounted on the lifting mechanism, a tray and a rotating shaft are connected on the lifting table, a cylinder is mounted at one end of the beam, a servo pressure plate is connected on the cylinder, and an upper turntable rubber mat is mounted on the pressure plate. The packaging machine is simple in structure, wide in packaging product range and fine in packaging effect, and products can be effectively prevented from being scratched in packaging.

Owner:TONGXIANG GUANGYU PLASTIC PROD

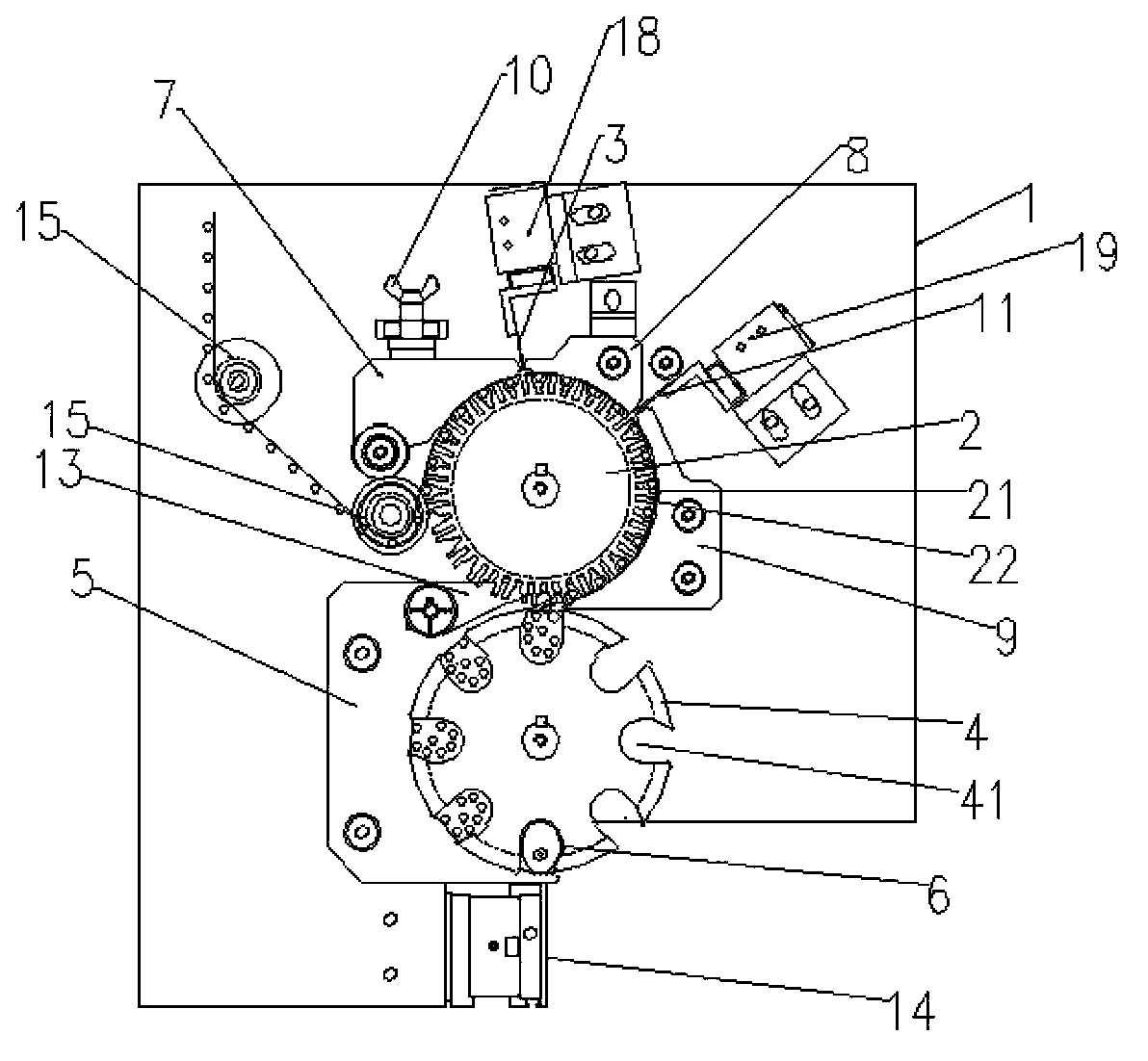

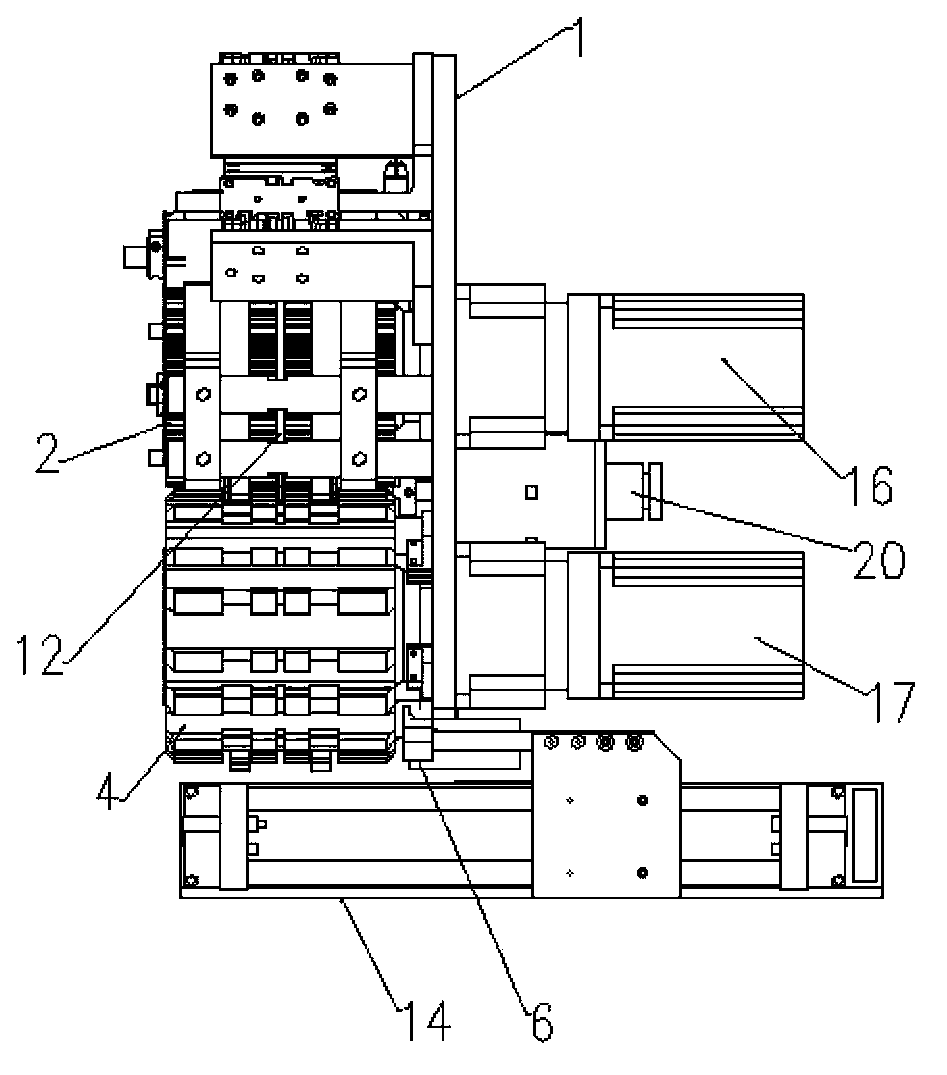

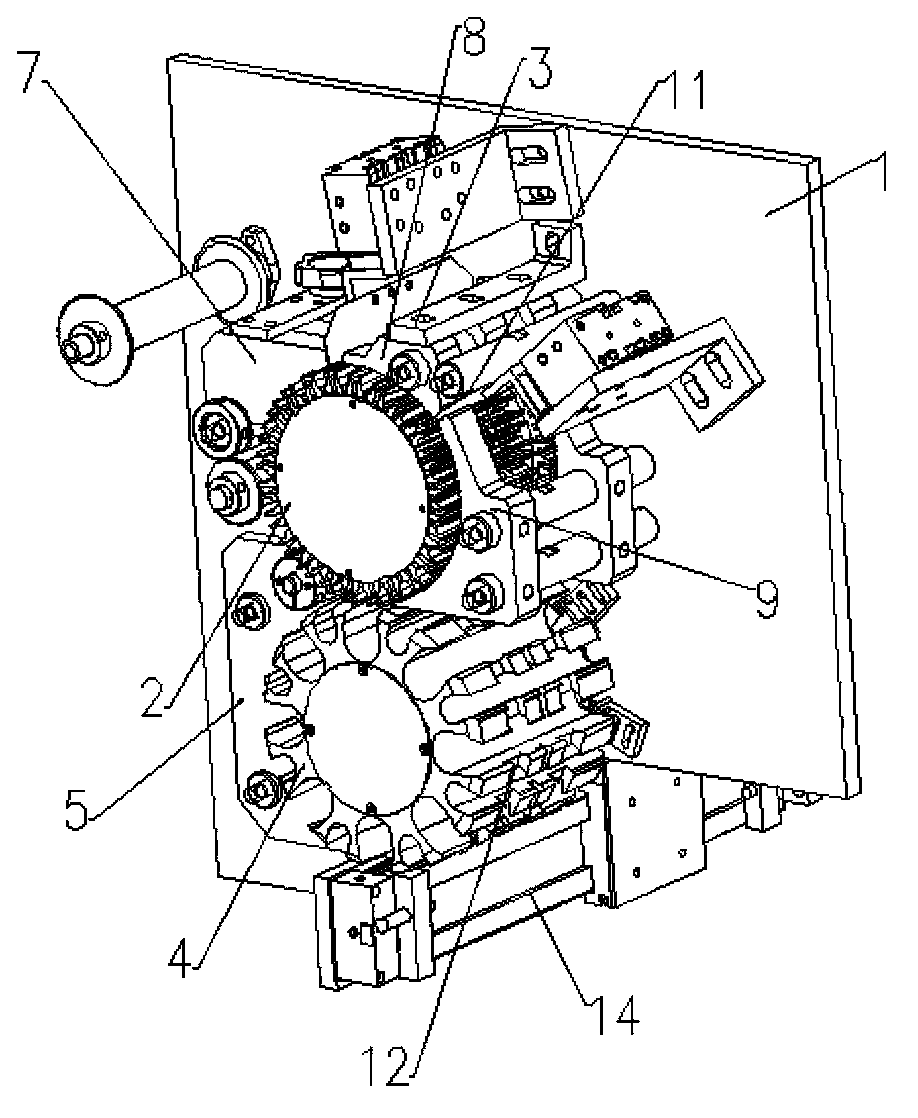

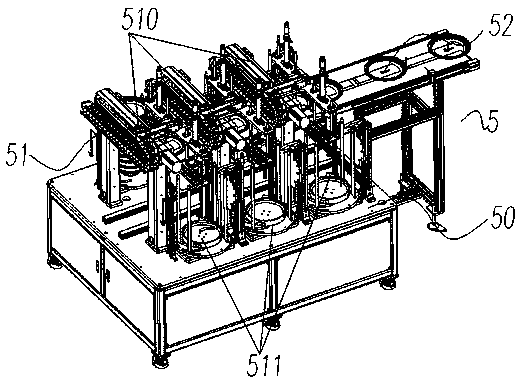

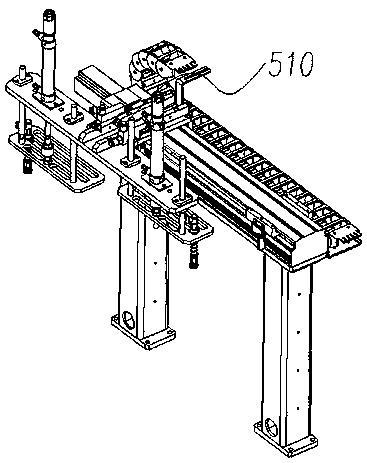

Full automatic packing machine for button cells

The invention discloses a full automatic packing machine for button cells, which comprises a machine frame, a bottom board and a vibrating disk, wherein the bottom board is arranged on the machine frame; and a blanking mechanism for automatically putting the button cells and uniformly placing the button cells in a packing box, a displacement mechanism for pushing a product tool for placing the packing box to carry out fore-and-aft movement, a box transferring mechanism for transferring an empty packing box and a packing box filled with cells, a loading mechanism for automatically filling up the empty packing box and a finished product discharging mechanism for automatically discharging the packing box filled with cells are further arranged on the machine frame. The full automatic packing machine for the button cells has the advantages of being full automatic in work, high in production efficiency and low in cost, and the market competitive power is improved.

Owner:DONGGUAN CITY TIANXIANG AUTOMATION EQUIP

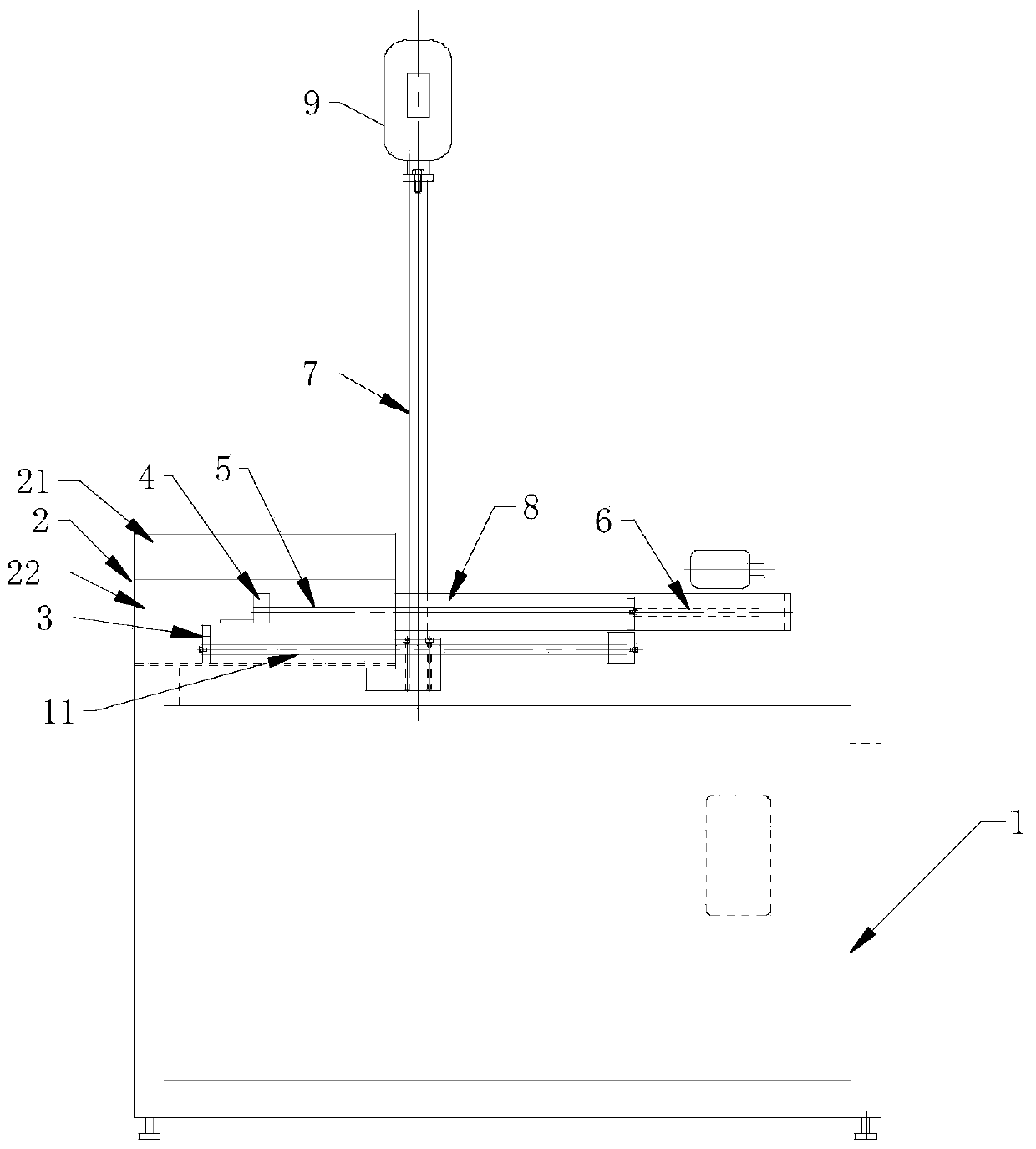

Quilt folding machine

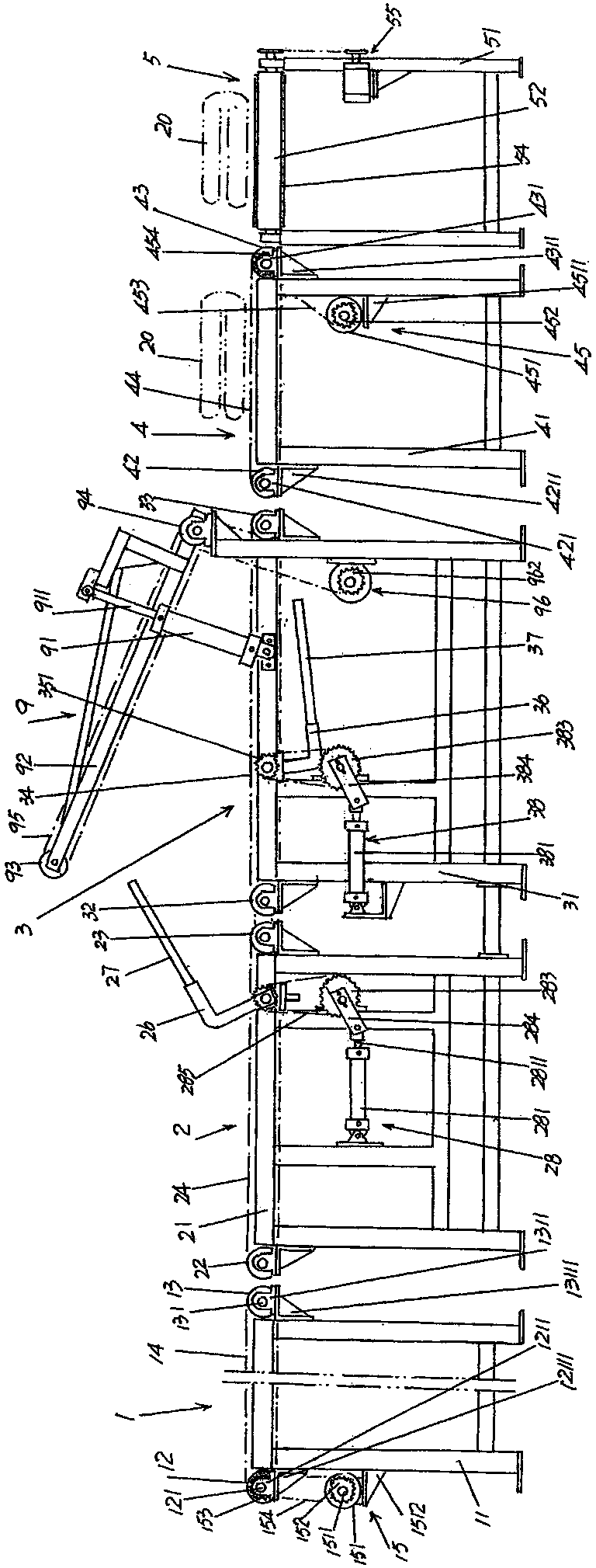

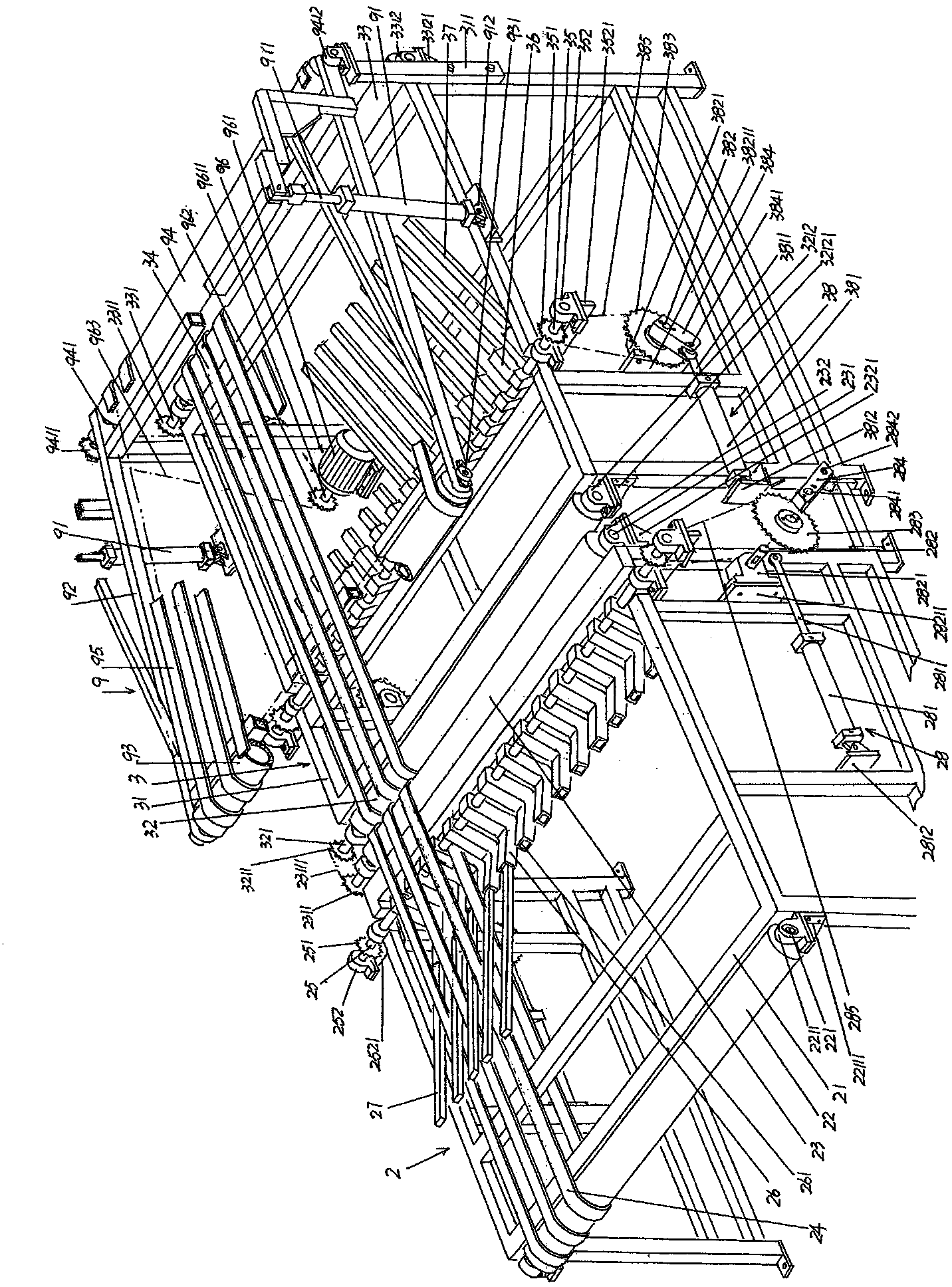

ActiveCN104108497ARealize automatic foldingReduce human inputFolding thin materialsPackagingEngineeringAssembly line

The invention relates to a quilt folding machine, and belongs to the technical field of packaging machines. The quilt folding machine comprises a quilt tiling guiding-in mechanism, a front longitudinal quilt folding mechanism, a back longitudinal quilt folding mechanism, a folded quilt transferring mechanism, a folded quilt conveying mechanism, a transverse quilt folding mechanism and a folded quilt output mechanism; wherein the back longitudinal quilt folding mechanism is located between the quilt tiling guiding-in mechanism and the front longitudinal quilt folding mechanism, the folded quilt transferring mechanism corresponds to the front longitudinal quilt folding mechanism, the folded quilt conveying mechanism corresponds to the folded quilt transferring mechanism, the transverse quilt folding mechanism corresponds to the folded quilt conveying mechanism, the folded quilt output mechanism is located between the transverse quilt folding mechanism and a bagging mechanism and used for conveying a folded quilt folded and shaped by the transverse quilt folding mechanism to the bagging mechanism, and the folded quilt coming from the folded quilt output mechanism is guided into a packaging bag through the bagging mechanism. The quilt folding machine has the advantages that manual folding is not needed so that manual input can be remarkably reduced, and labor resources can be saved; as the quilt can be automatically folded so that the folding efficiency can be high and can adapt to the production efficiency of a quilt manufacturing assembly line; as mechanical automatic folding is achieved, the stable folding effect is achieved to guarantee the packaging quality.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

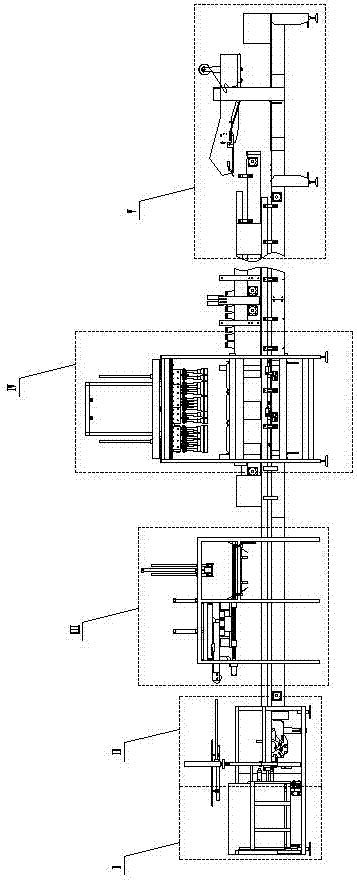

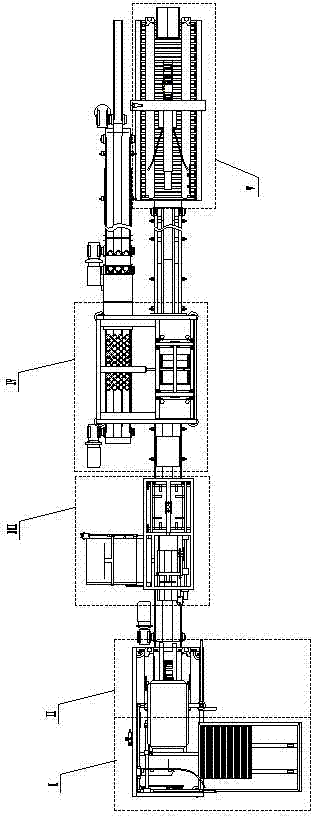

Full-automatic unpacking, packing and sealing all-in-one machine

ActiveCN107200159AImprove labor efficiencyGuaranteed packaging qualityWrapper twisting/gatheringPackaging bottlesCartonEngineering

The invention discloses a full-automatic unpacking, packing and sealing all-in-one machine. The full-automatic unpacking, packing and sealing all-in-one machine comprises an unpacking device, a bottom sealing device, a packing device and a carton top sealing device. The full-automatic unpacking, packing and sealing all-in-one machine further comprises a carton conveying device. The unpacking device comprises an unpacking frame, a carton bracket is mounted on the unpacking frame, a carton pulling frame is connected to the unpacking frame, and a plurality of carton pulling suction cups are mounted on the carton pulling frame. An ejection rod is mounted on the unpacking frame. Small edge unfolding shift levers and big edge unfolding shift levers are mounted on the unpacking frame. The bottom sealing device comprises a bottom sealing tape machine and a top pressing plate. The packing device comprises a packing frame, a top sliding plate is mounted on the packing frame, a bottle clamping plate is connected to the top sliding plate, and a bottle clamping device is mounted on the bottle clamping plate. The carton top sealing device comprises a sealing frame, a small edge swing arm is hinged to the sealing frame, an arc-shaped small edge folding plate and a big edge folding plate are further mounted on the sealing frame, and a top sealing tape machine is mounted on the sealing frame. By adoption of the full-automatic unpacking, packing and sealing all-in-one machine, multiple procedures including unpacking, bottom sealing, plate insertion, packing and sealing are achieved automatically; and the full-automatic unpacking, packing and sealing all-in-one machine has the advantages of being capable of improving labor efficiency and ensuring packaging quality.

Owner:潍坊现代科技发展有限公司

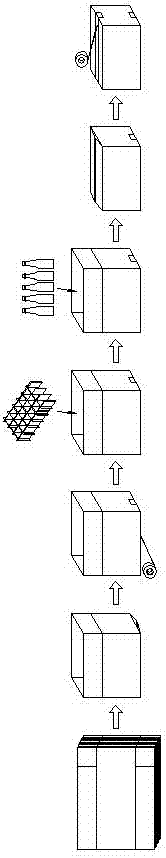

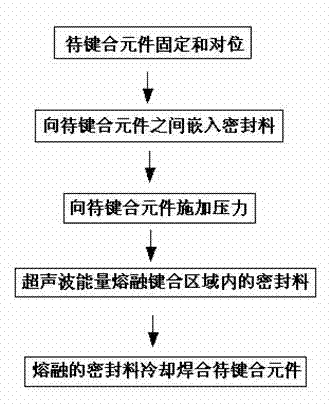

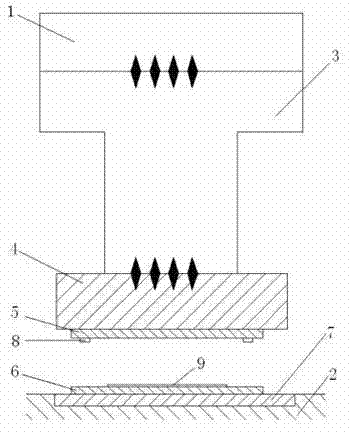

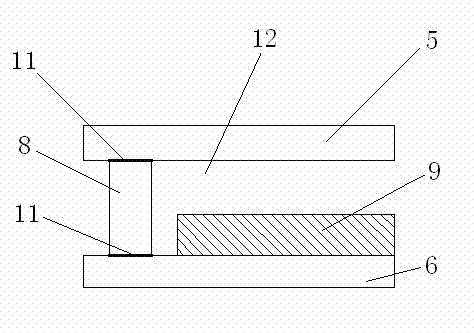

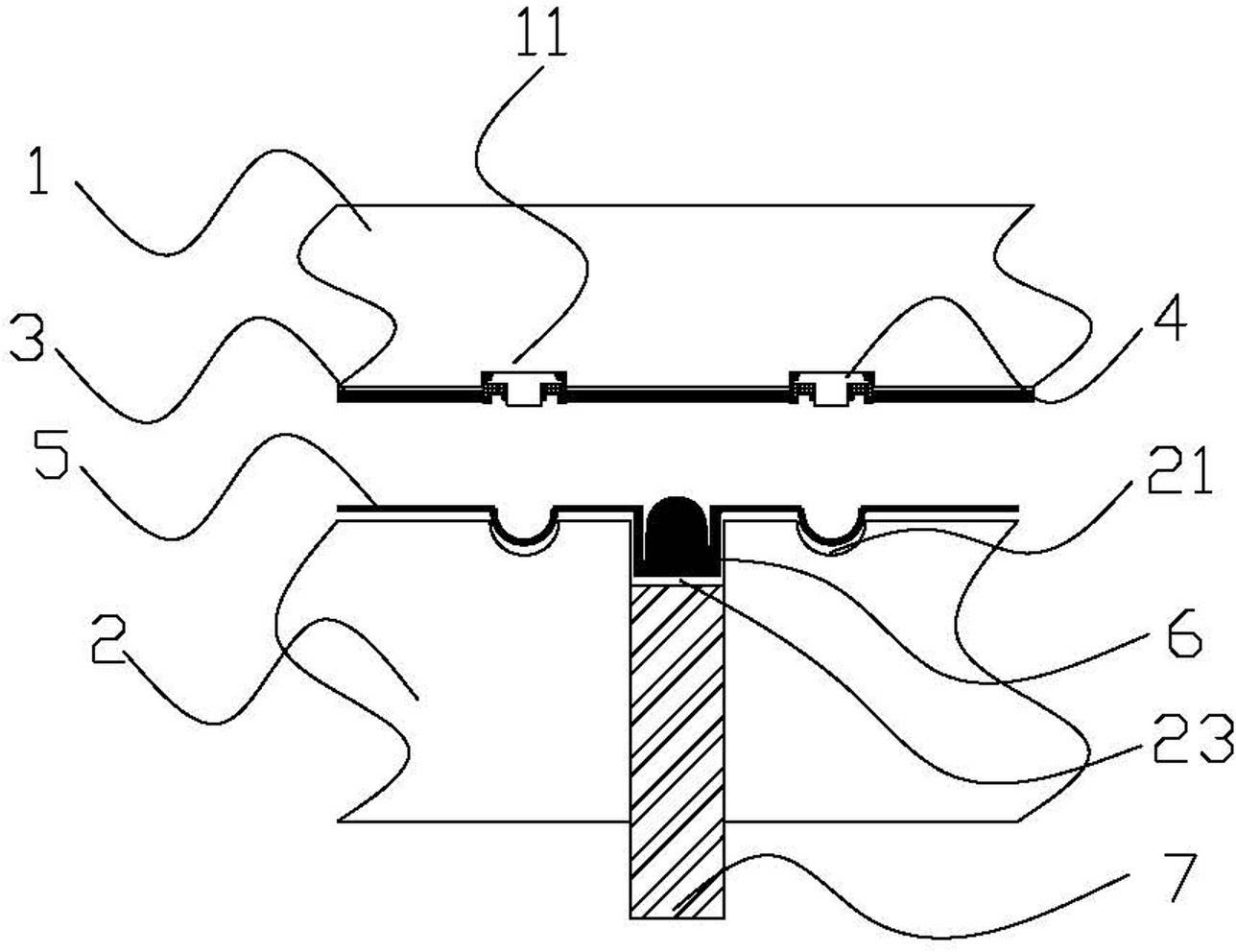

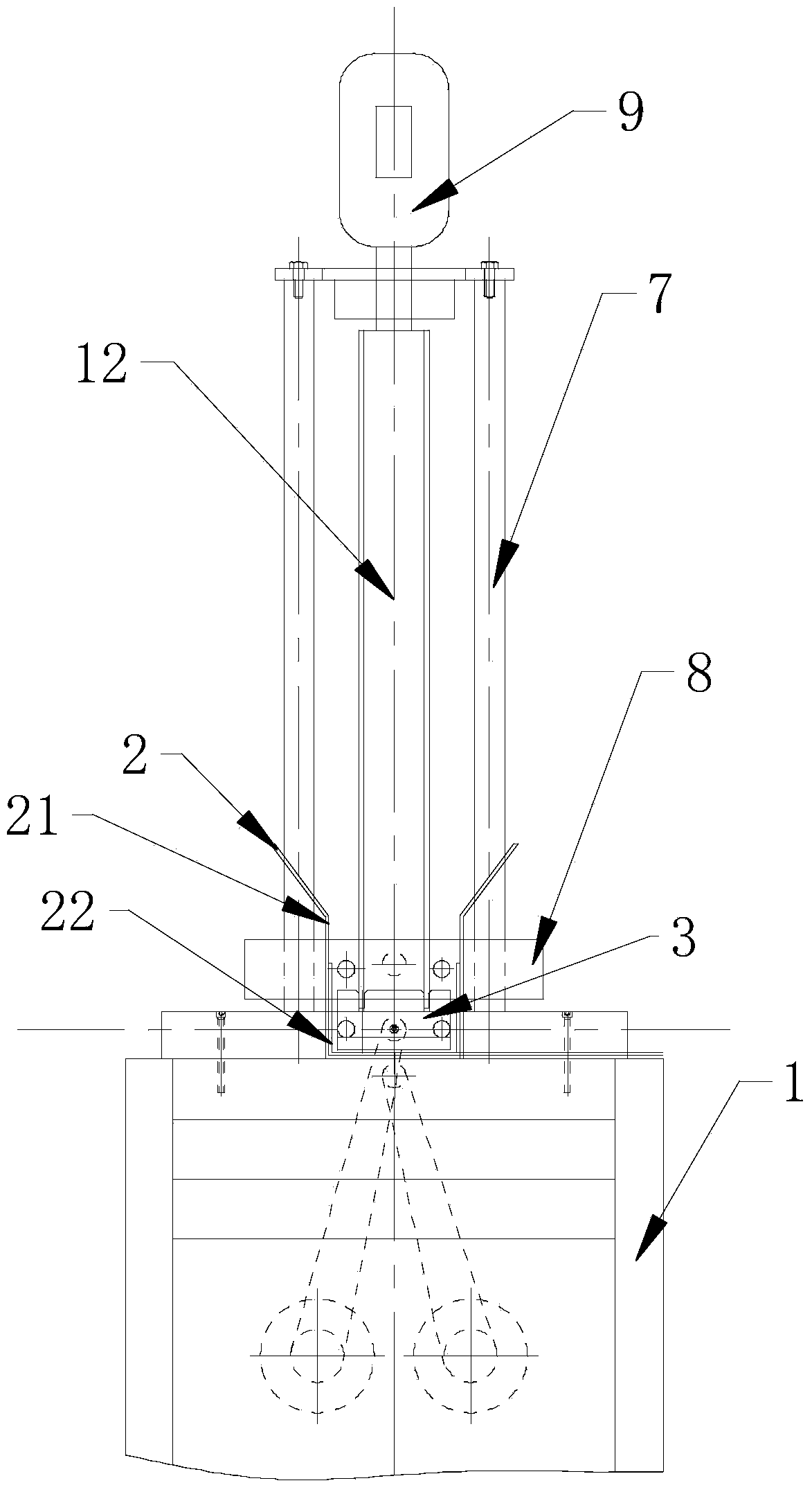

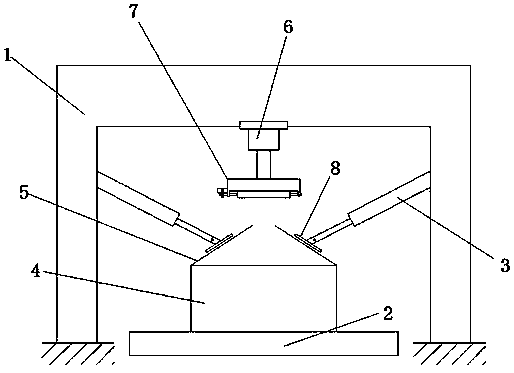

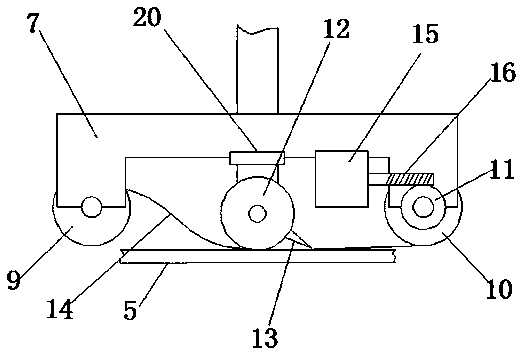

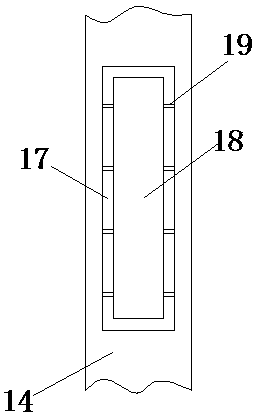

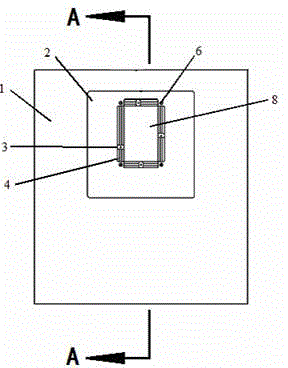

Ultrasonic bonding method and special ultrasonic welding machine used for optoelectronic device packaging

ActiveCN102225839ASolve the problem of hermetic packaging processImprove residual stress distribution stateSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationEngineering

The present invention discloses an ultrasonic bonding method and a special ultrasonic welding machine used for optoelectronic device packaging. The ultrasonic bonding method provided by the invention comprises the following steps of: fixing and precisely positioning the component to be welded, and applying an initial clamping force on the component to be welded, so that a glass sealing material is clamped by the component to be welded; and transferring the high-frequency vibration energy generated by an ultrasonic welding machine to the bonding surfaces through an energy guiding component, thus realizing the indeformable rapid welding package of the component to be welded. The special ultrasonic welding machine provided by the invention comprises an ultrasonic generator, a clamping component, the energy guiding component and a temperature control device. The ultrasonic bonding method and the special ultrasonic welding machine provided by the invention can accurately and precisely utilize energy, achieve the hermetic package of the component to be welded through energy transfer and transformation, significantly improve the residual stress distribution of the semiconductor optoelectronic device packaging layer, reduce stress concentration, guarantee the packaging quality of the semiconductor optoelectronic device and prolong the service life of the optoelectronic device, and canbe widely applied in the packaging of OLEDs (organic light emitting diodes), solar cells and other semiconductor optoelectronic devices.

Owner:SHANGHAI UNIV

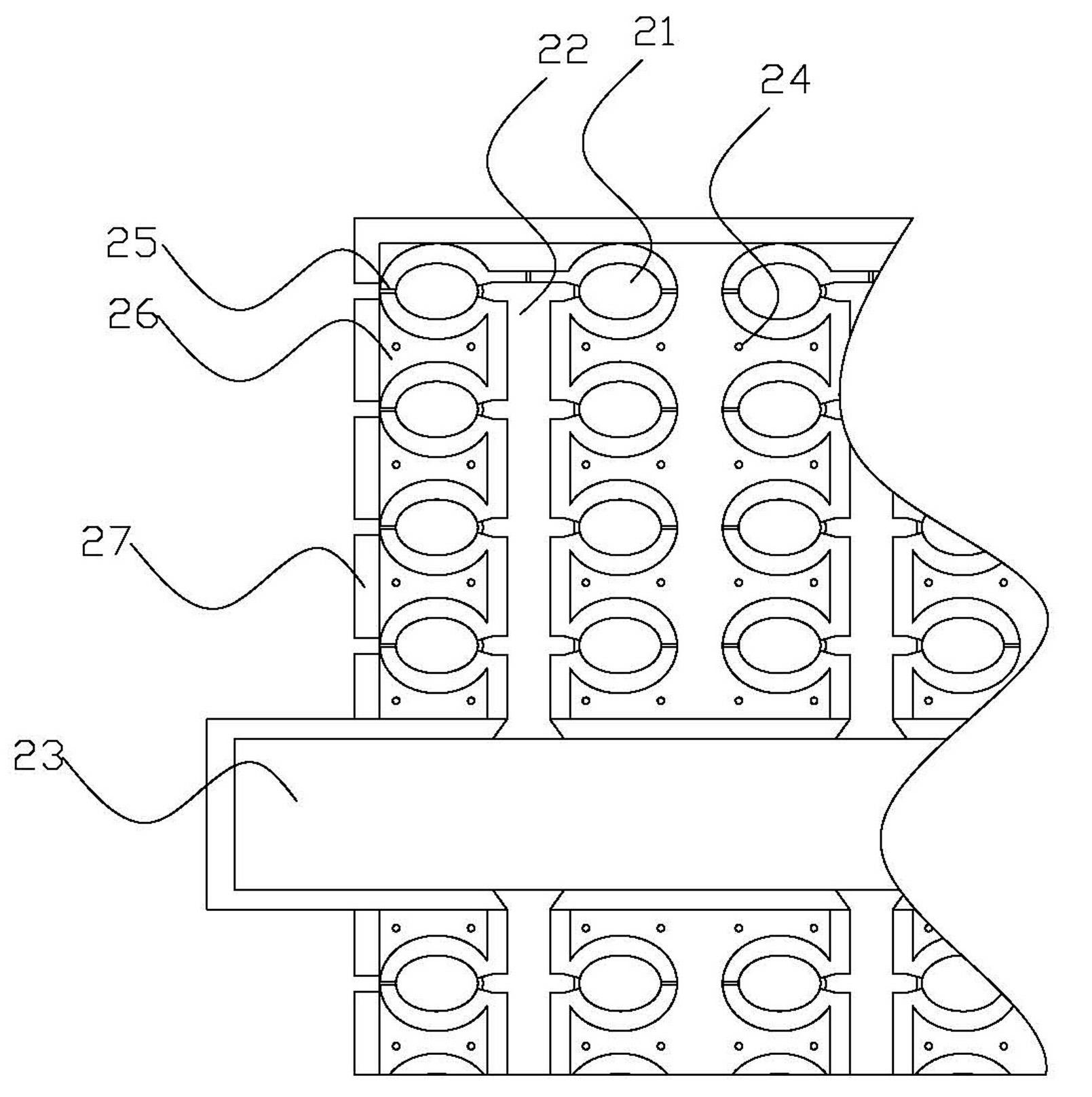

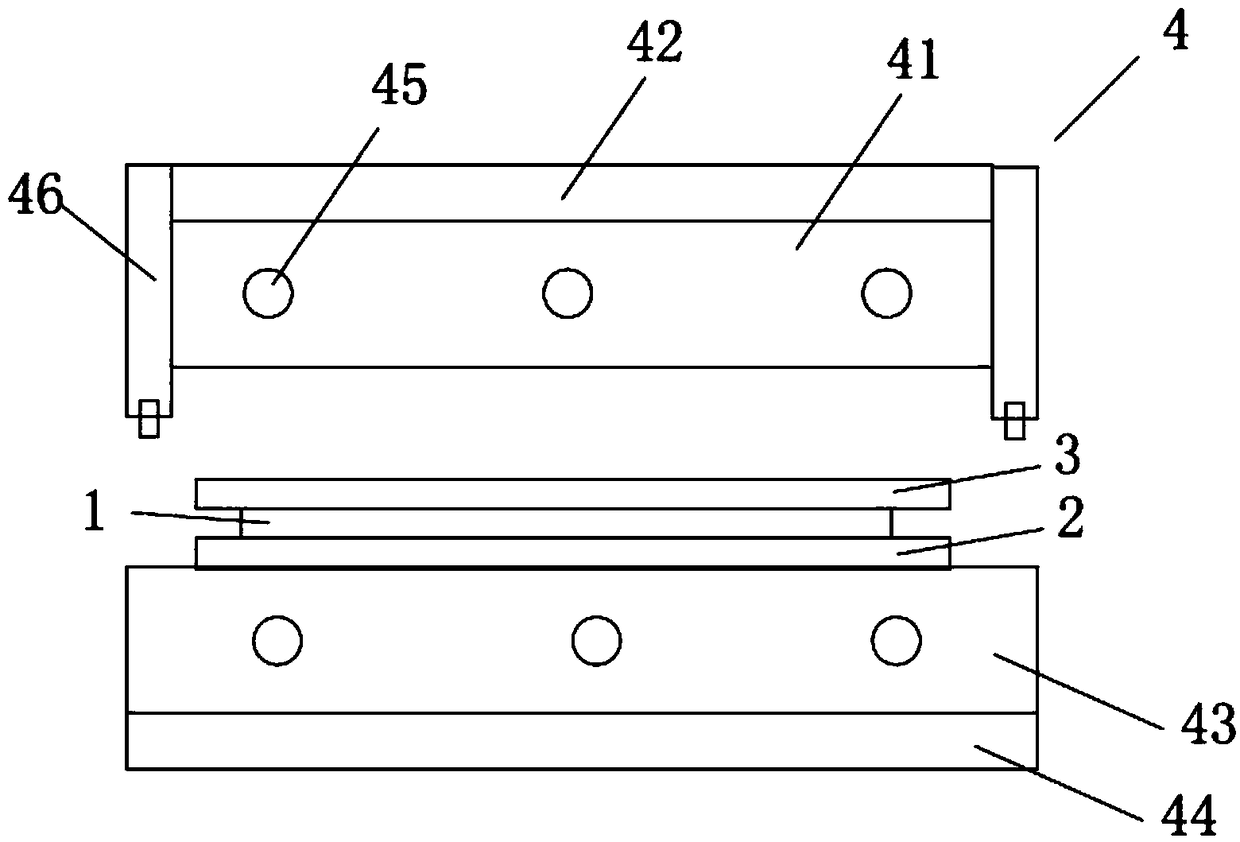

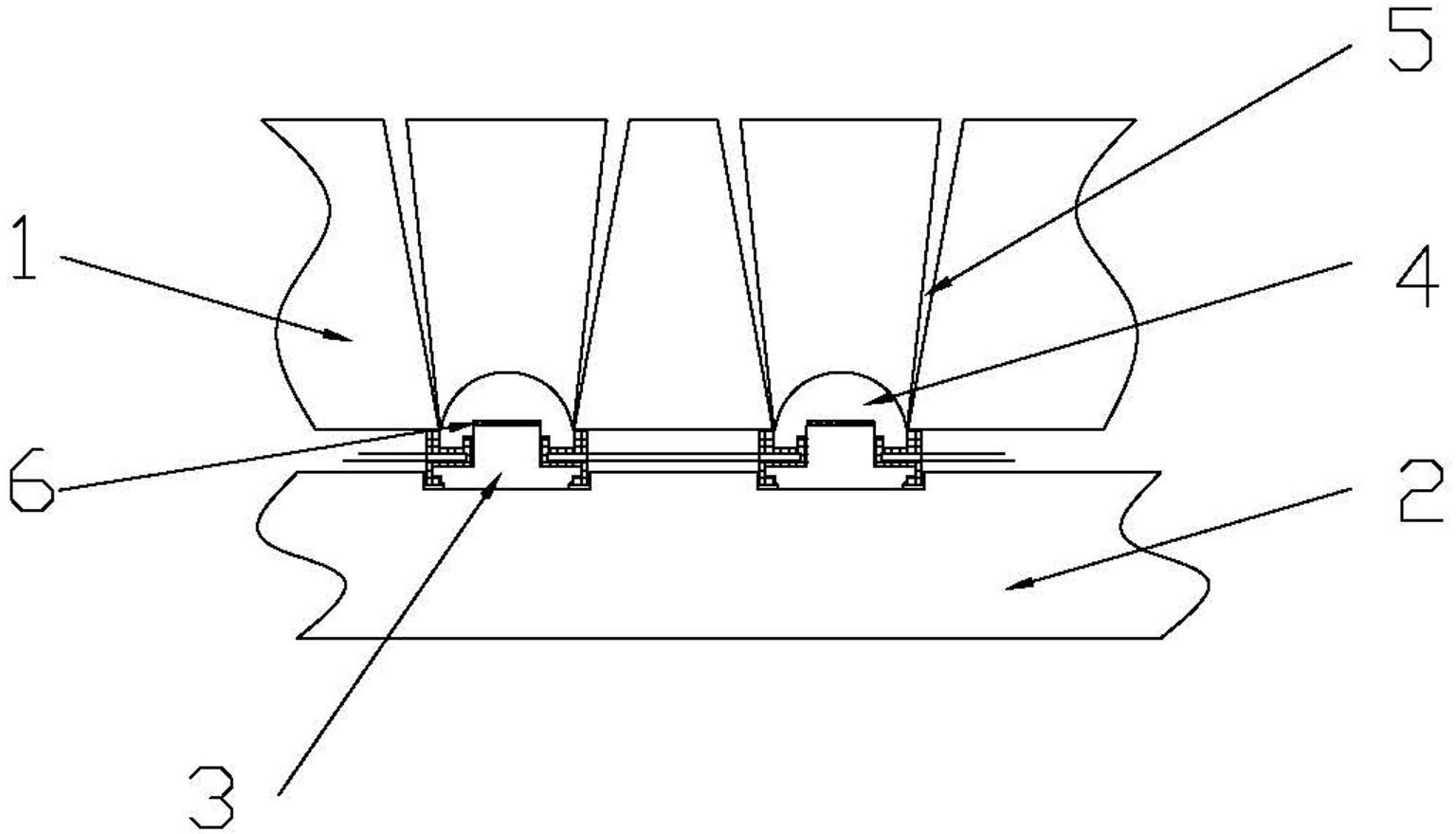

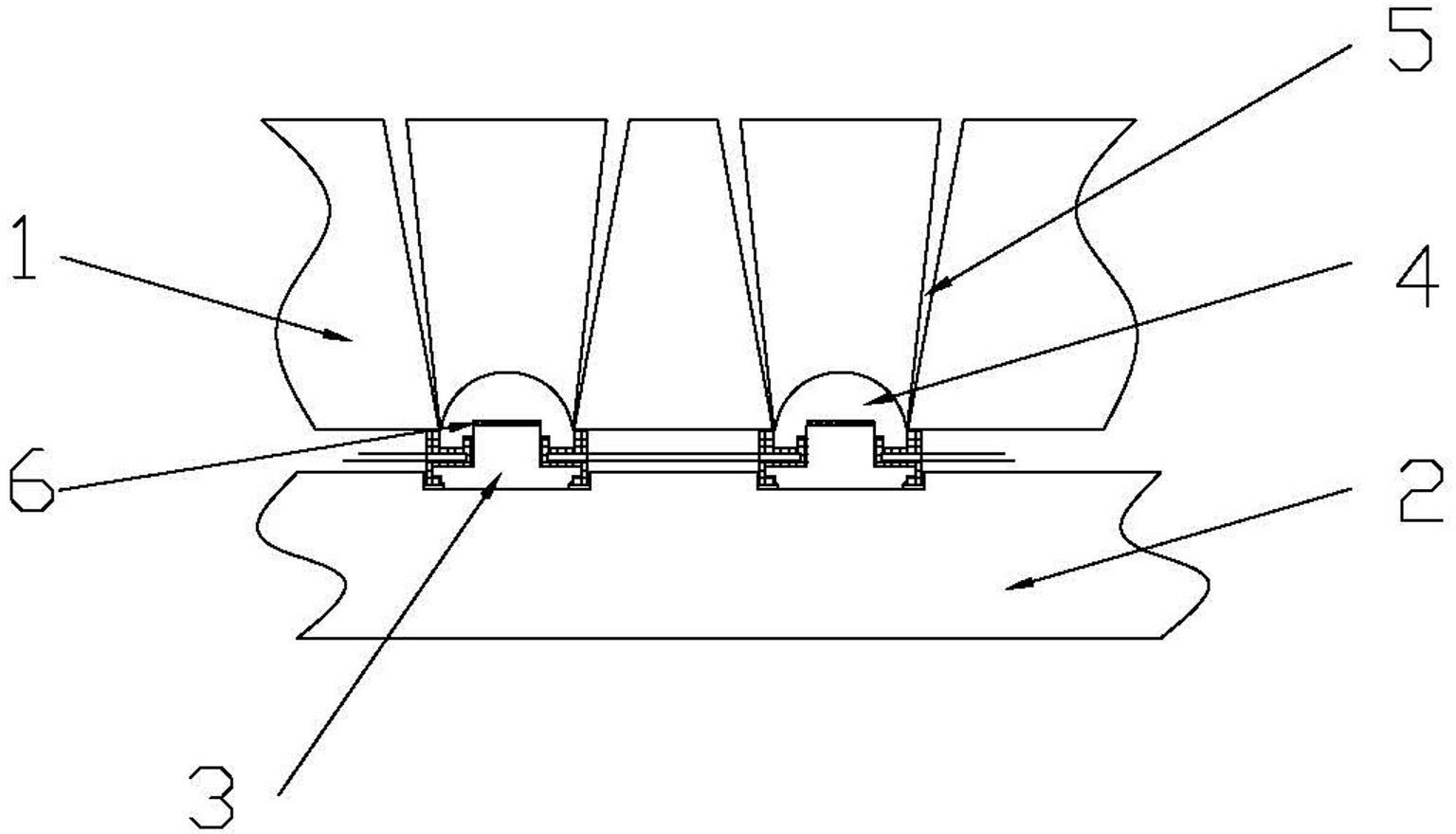

Method and mold for packaging high-power LED (light emitting diode) liquid silicon rubber

InactiveCN102157634ASimple processIncrease productivitySemiconductor devicesInlet channelEngineering

The invention relates to a method and mold for packaging high-power LED (light emitting diode) liquid silicon rubber. The method comprises the following steps: 1) preparing an upper mold, a lower mold and a middle partition board, and installing the upper mold and the lower mold at a working region for later use; 2) placing a support in a charging box, and then placing the charging box at a feed inlet; 3) delivering the support to a positioning groove of the upper mold, then sleeving the middle partition plate for positioning, laying a thin film layer at the surface of the lower mold, and then injecting a glue into a glue storage groove; 4) combining the upper mold and the lower mold, and vacuumizing; 5) rising a piston at the bottom of the glue storage groove, pushing the glue into a glue inlet channel, and injecting the glue into a cavity which is formed by a stand-by support and the lower mold through the glue inlet channel, thus the injected glue is formed and solidified; and 6) separating the upper mold from the lower mold, pulling away the thin film, delivering the support to a machine discharge hole, and pushing the support out of a discharging box. The packaging method has the advantages of simple and reasonable working procedure and high production efficiency; automatic glue injection is adopted, the speed is rapid, the glue amount is consistent, and the package quality is good; and in addition, high temperature solidification is adopted, and the time is short.

Owner:MLS

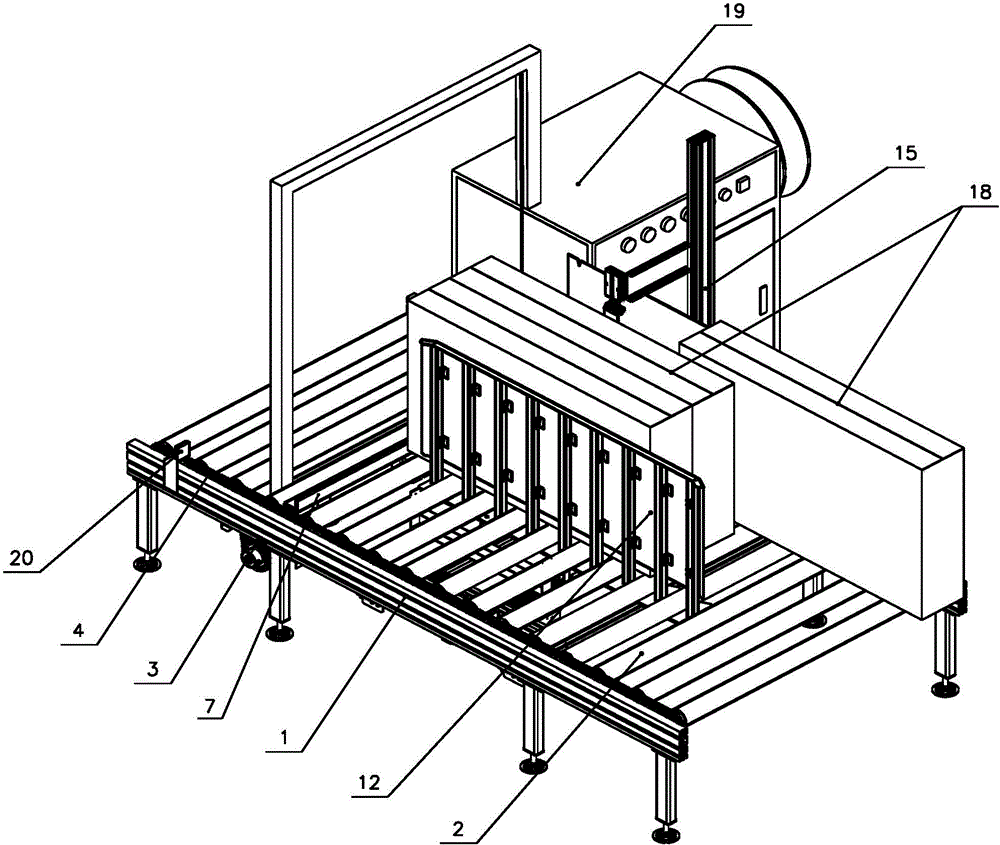

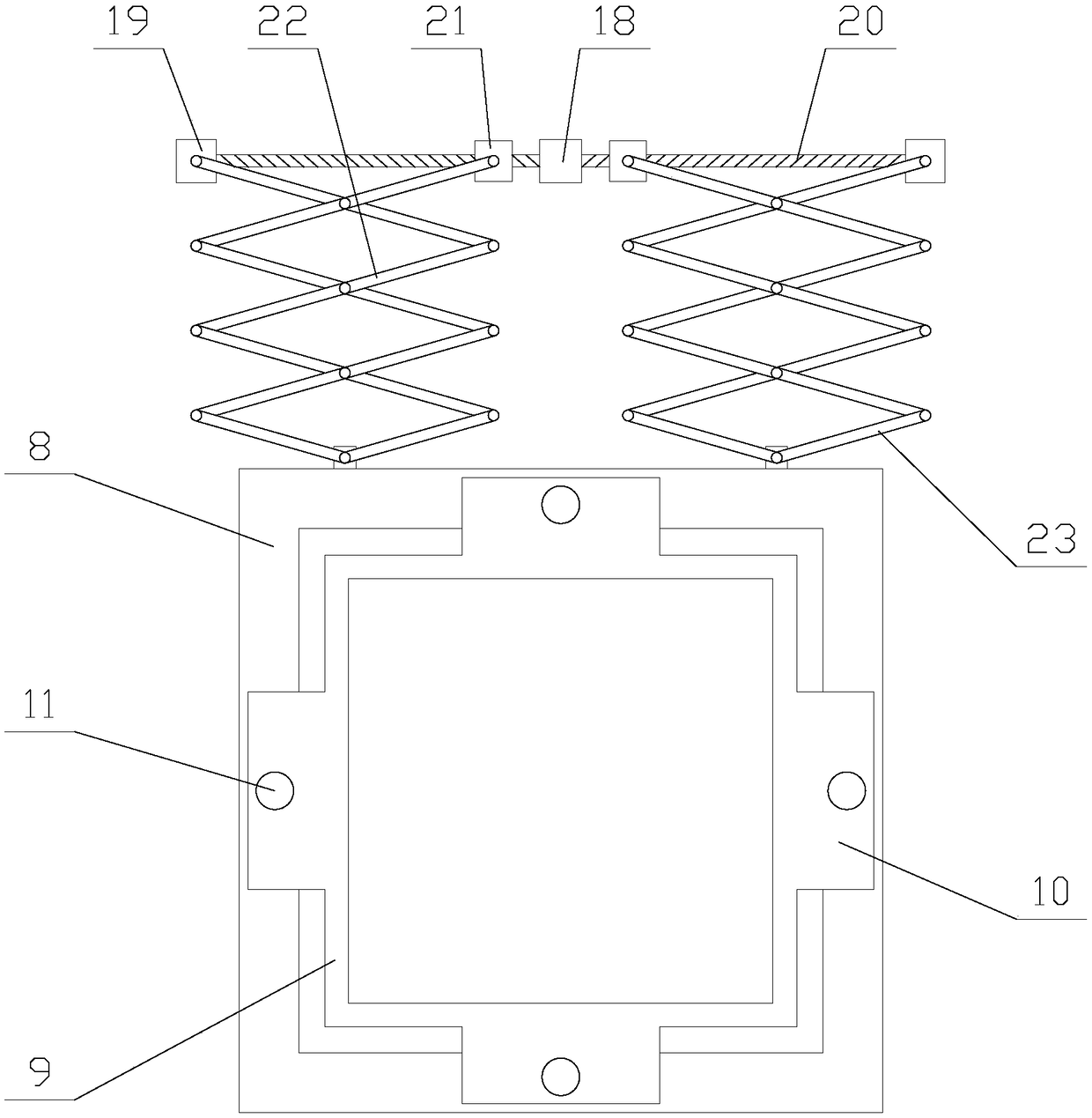

Device for arranging and binding packaging boxes automatically

ActiveCN104554890AGuaranteed packaging qualitySimple structurePackagingConveyor partsEngineeringMechanical engineering

The invention discloses a device for arranging and binding packaging boxes automatically. The device mainly comprises a rack, a binding machine, a stopping mechanism for stopping the packaging boxes from being delivered continuously, a translation mechanism for moving and arranging the packaging boxes laterally and an anti-falling mechanism for preventing the packaging boxes from falling. A delivery mechanism is arranged on the rack, and the binding machine is arranged at the tail end of the delivery mechanism. The translation mechanism, the stopping mechanism and the binding machine are arranged along the delivery direction of the delivery mechanism successively. Compared with prior equipment, the device has the advantages that the structure is simple, the cost is low, the packaging boxes can be advanced stably, stopped at fixed points and arranged in groups, the plate product packaging quality can be guaranteed, production and transportation requirements can be met, the cost can be saved, and the production efficiency can be improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

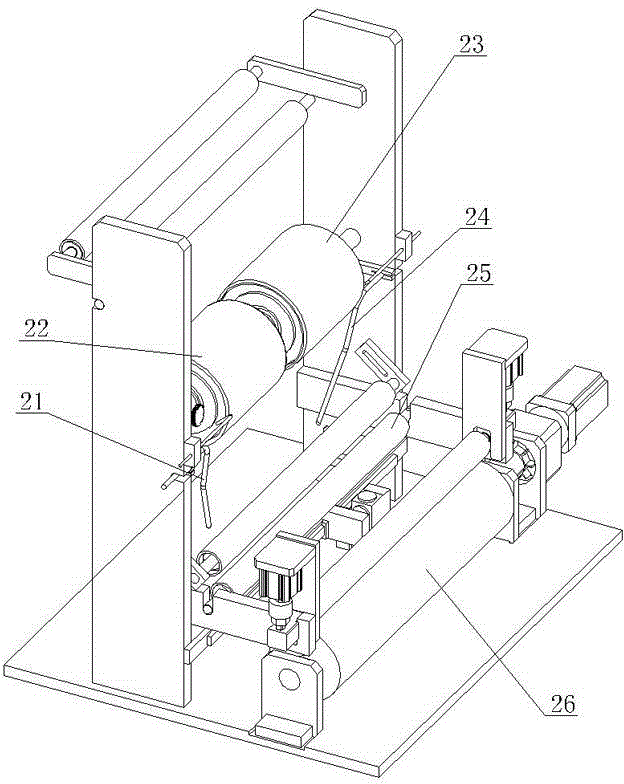

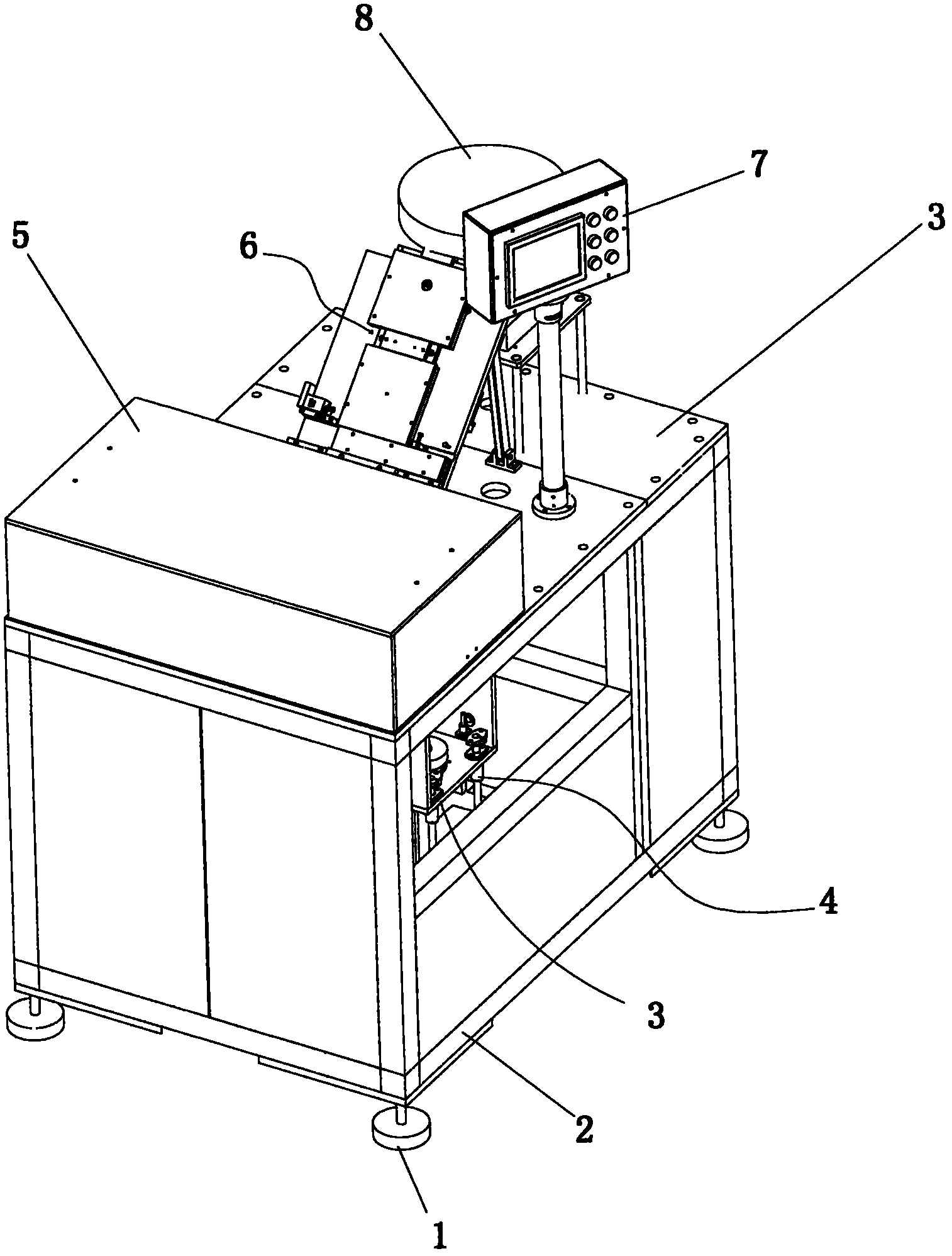

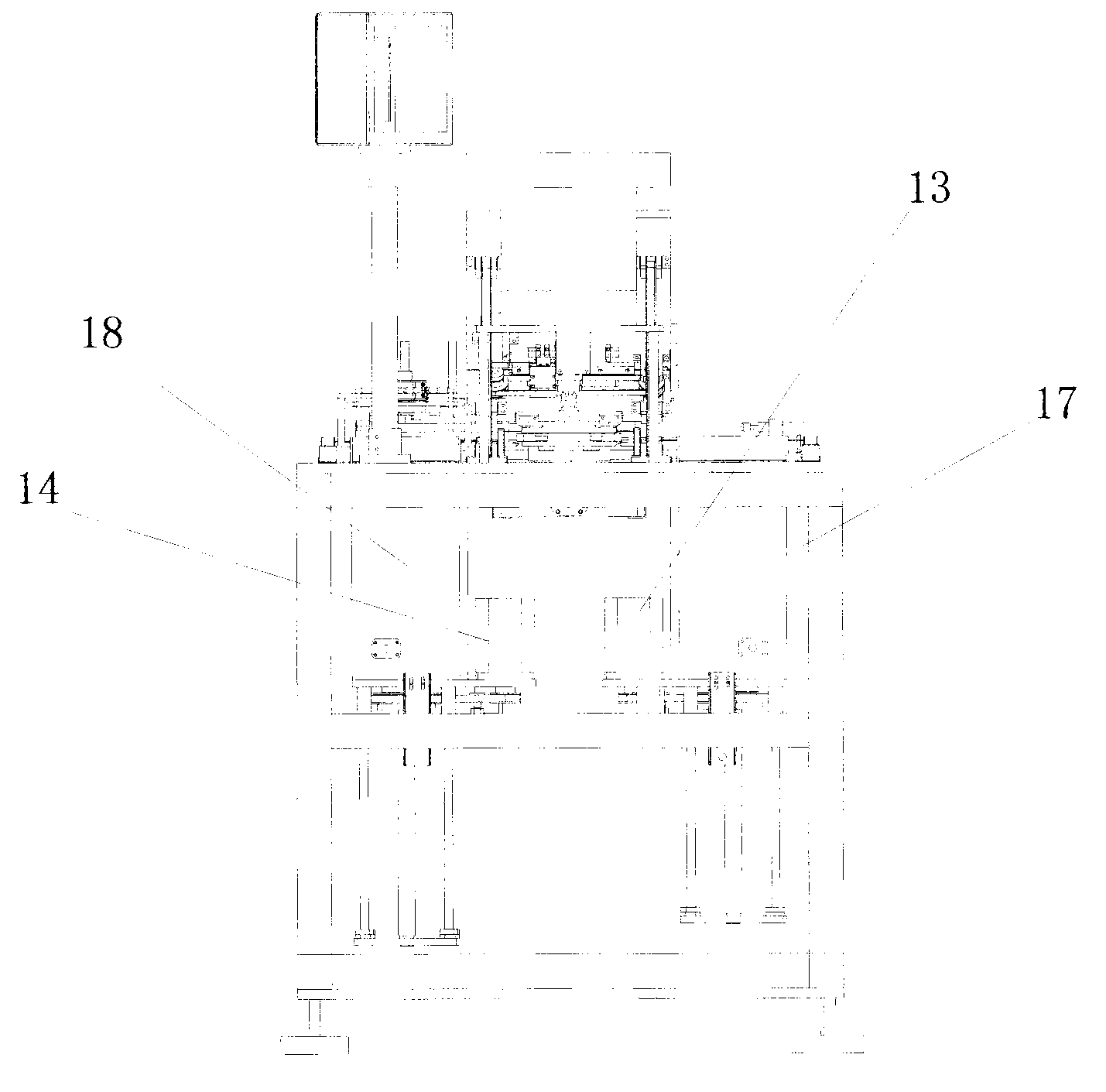

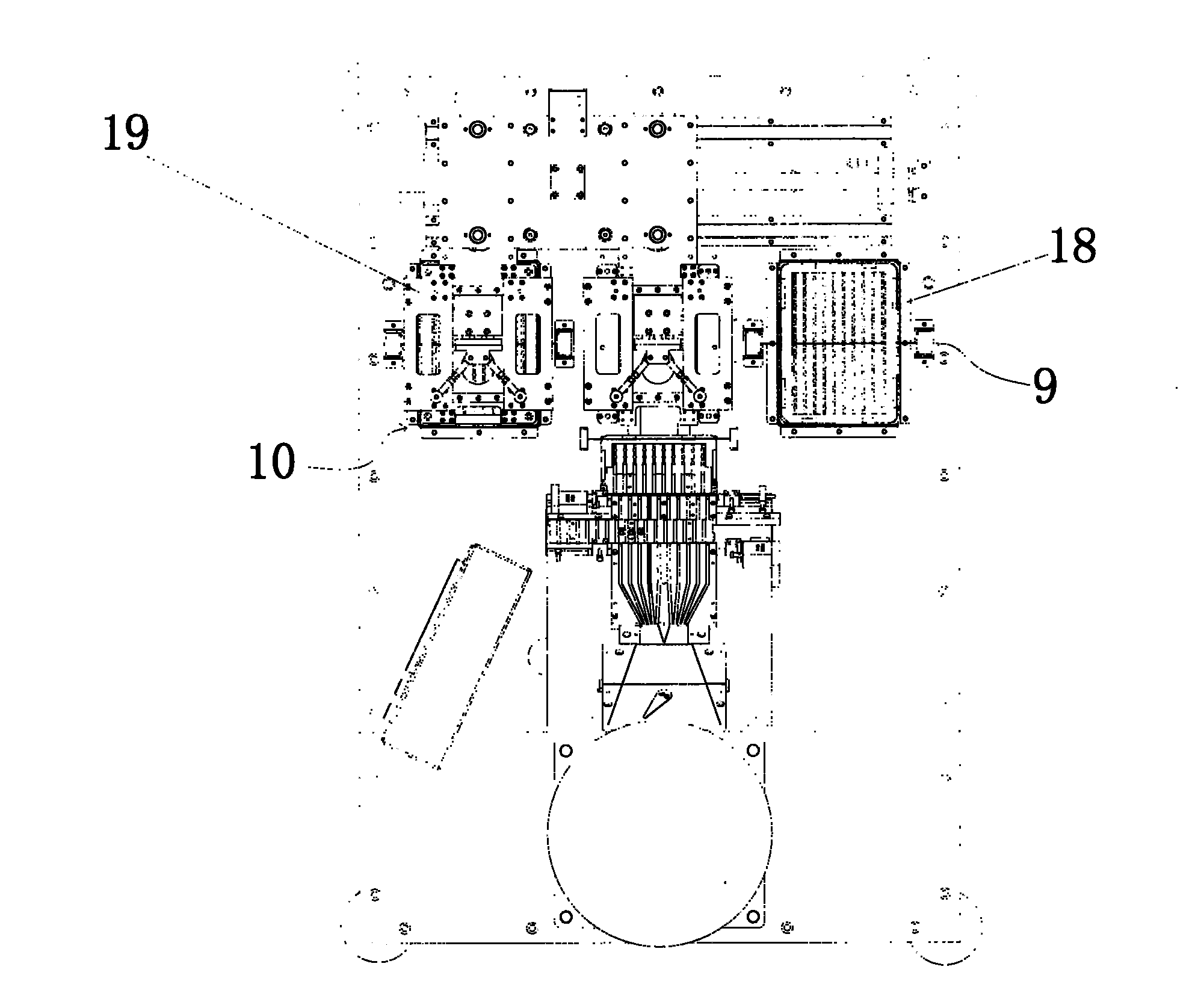

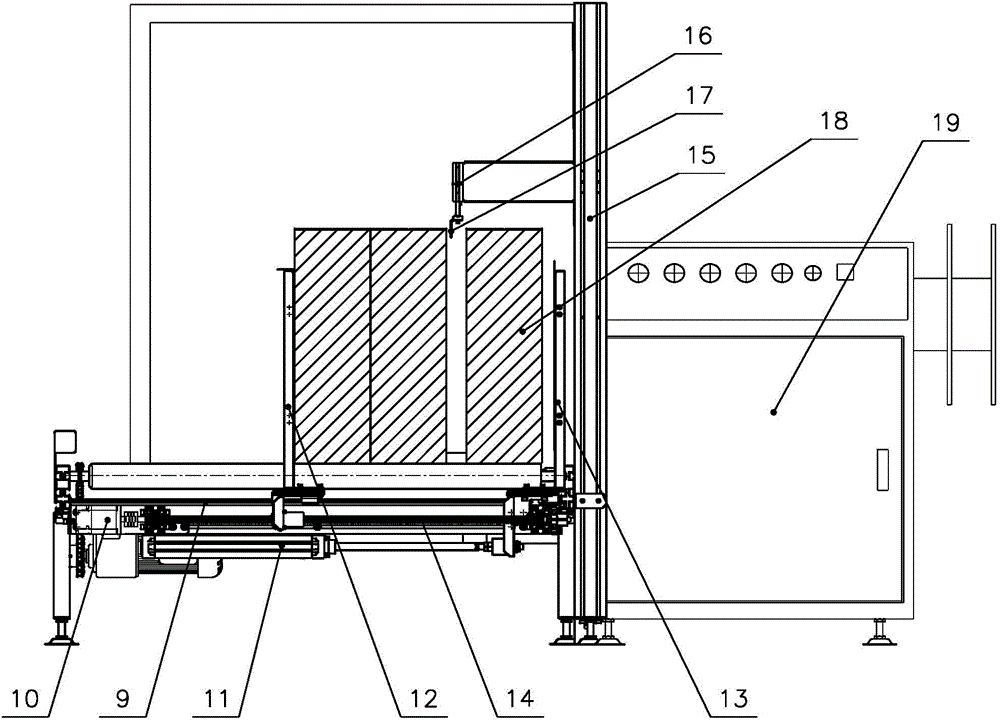

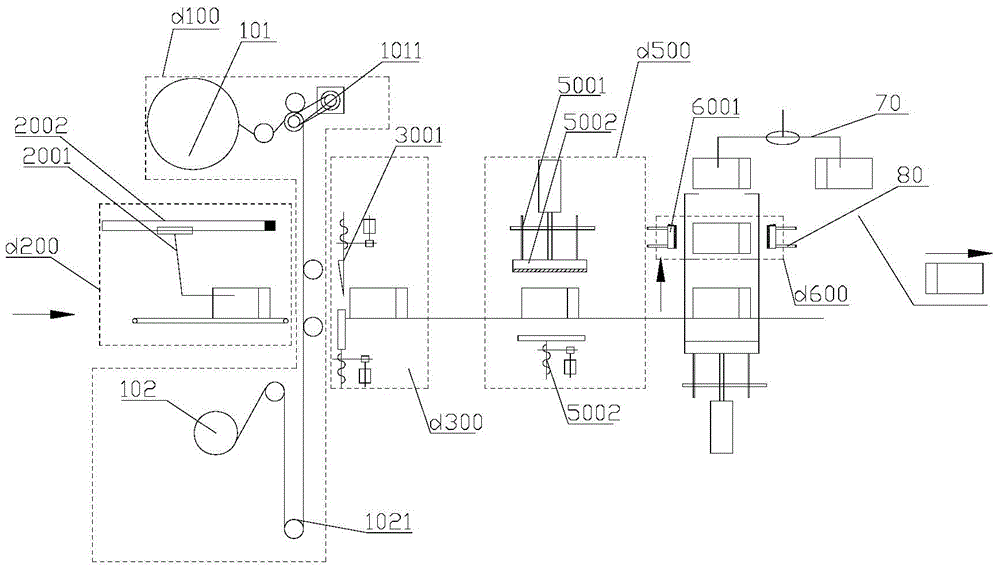

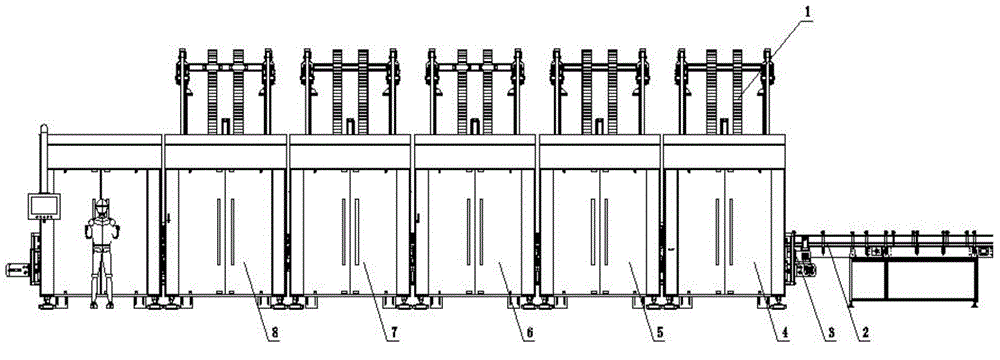

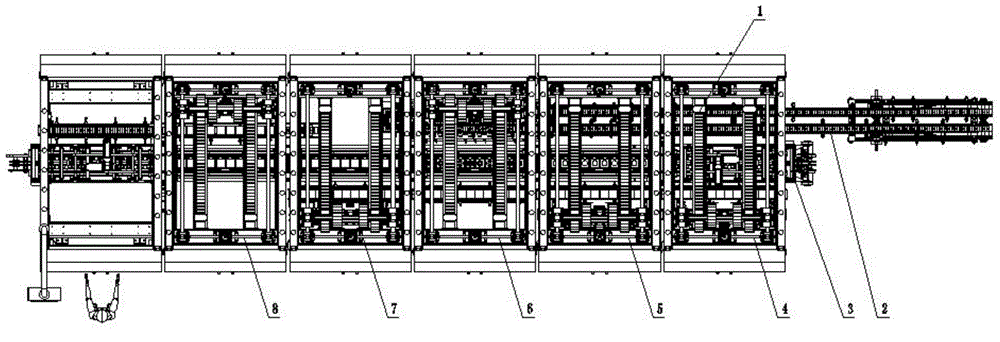

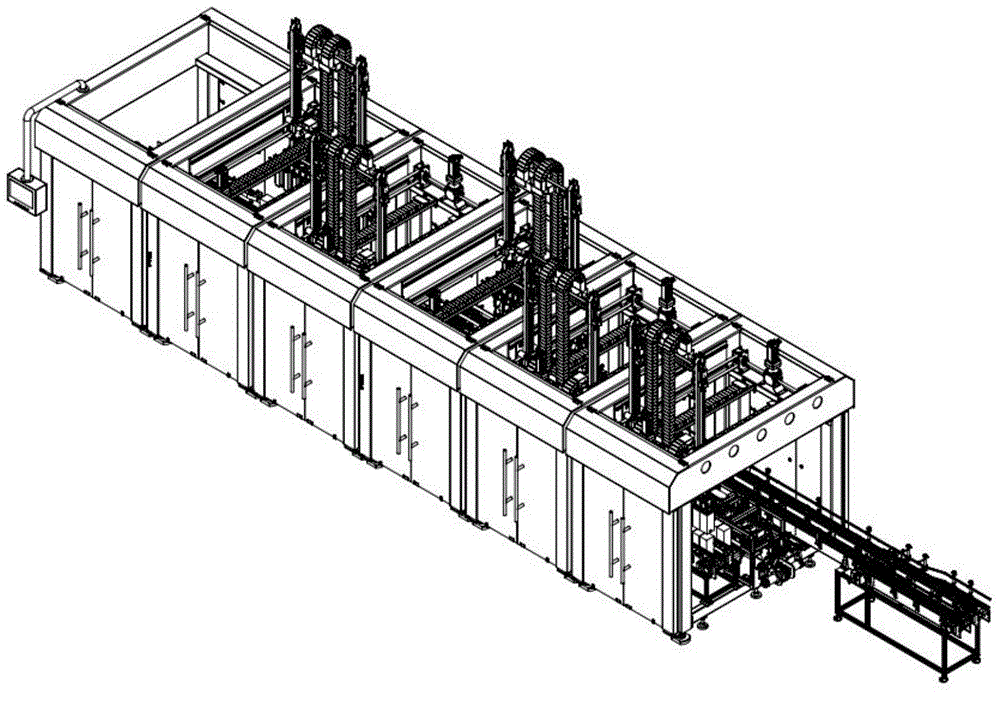

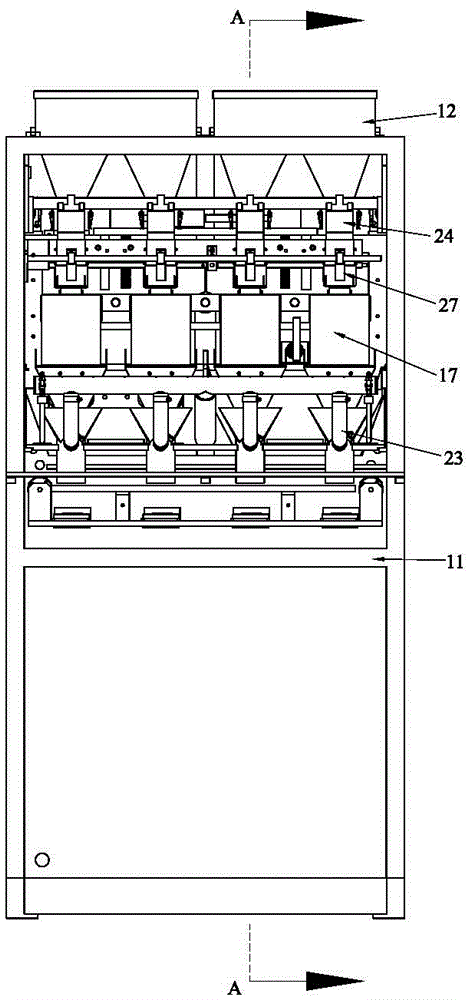

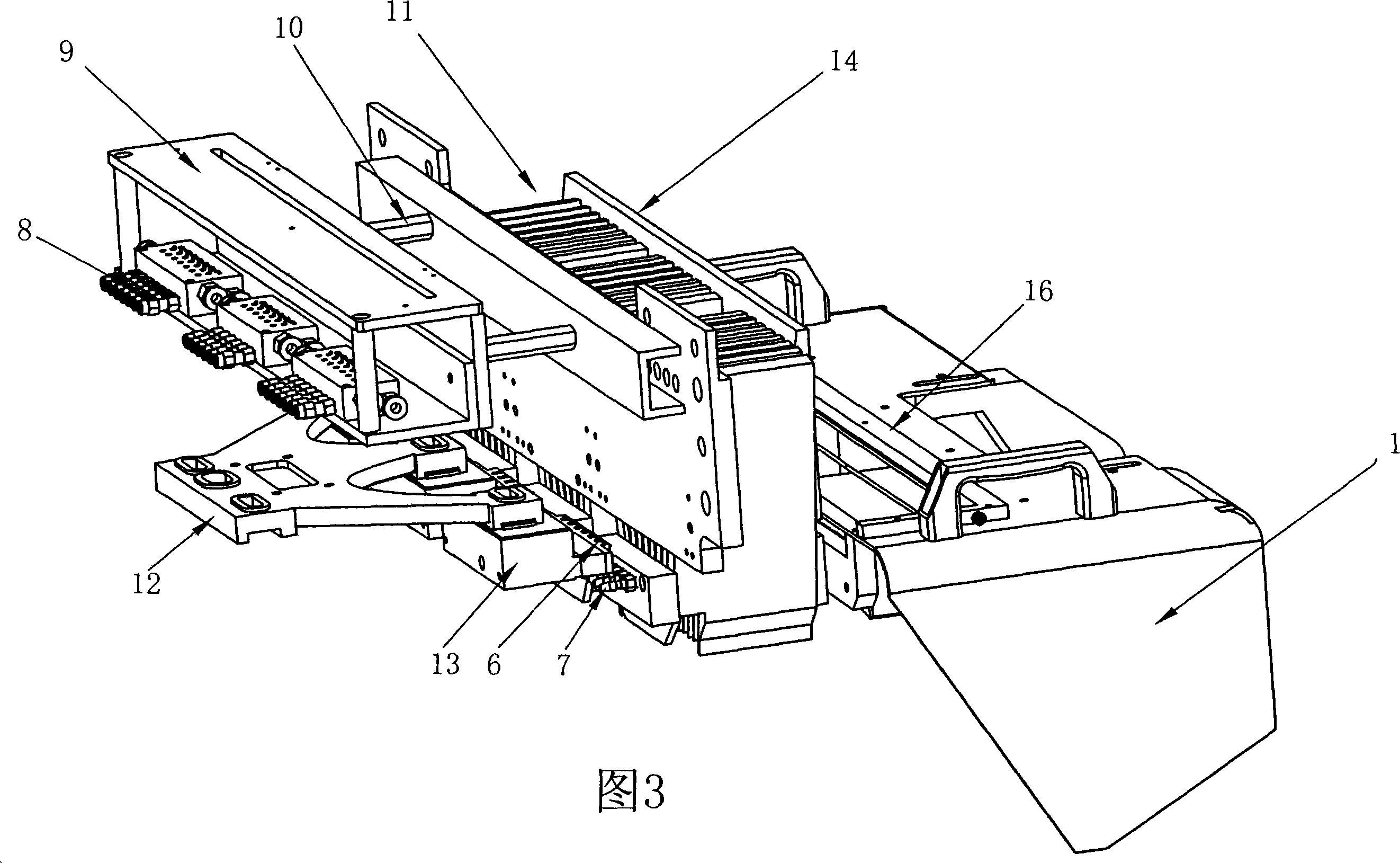

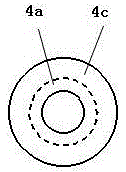

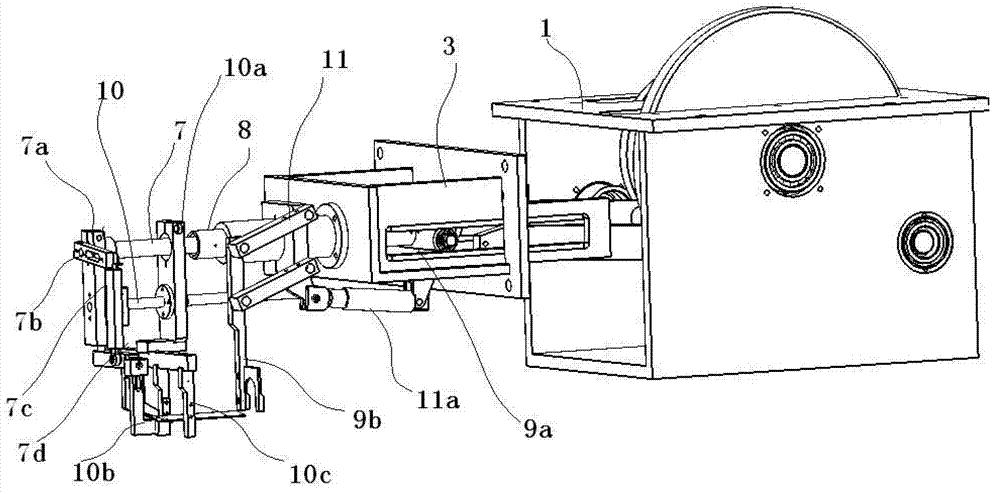

Glove automatically packaging machine and method

ActiveCN103466133AHigh degree of automationGuaranteed packaging qualityPackagingEngineeringPacking method

The invention discloses a glove automatically packaging machine. The glove automatically packaging machine comprises a frame, a feeding box, a material pushing board, an inner box body driving mechanism and an auxiliary pushing and pressing unit, wherein the feeding box is fixed onto the frame and comprises an outer box body and an inner box body mounted inside the outer box body, the outer box body is provided with an upward opening to facilitate glove feeding, and the front ends of the outer box body and the inner box body are opened to facilitate glove discharging; the material pushing board is slidingly mounted inside the inner box body and driven by a material pushing board power device; the inner box body driving unit is mounted on the frame and connected with the inner box body to drive the inner box body to slide inside the outer box body; the auxiliary pushing and pressing unit is mounted on the frame and used for pressing gloves inside the inner box body and assisting the material pushing board to push the gloves into packaging boxes. The glove automatically packaging machine can automatically send folded gloves into the packaging boxes, thereby greatly improving the packaging efficiency and saving manpower and costs. Besides, the invention also discloses a packaging method of the glove automatically packaging machine.

Owner:张家港宝翔机械有限公司

Device used for carton folding and packaging

PendingCN107738779AImplement encapsulationPrecise alignmentWrapper twisting/gatheringAdhesive beltClassical mechanics

The invention relates to the technical field of packaging box production, in particular to a device used for carton folding and packaging. The device comprises a mounting support, a conveying belt isarranged at the bottom of the mounting support, a carton is placed on the conveying belt, the side wall of the mounting support is fixedly connected with a pair of first electric cylinders, the ends of power rods of the first electric cylinders are connected with a movable plate, the movable plate is in contact with a cover plate on the carton, the top of the mounting support is fixedly connectedwith a second electric cylinder, the end of a power rod of the second electric cylinder is fixedly connected with a pressing plate, the side, away from the second electric cylinder, of the pressing plate is provided with a first roller and a second roller, the first roller and the second roller are connected with adhesive tape in a winding manner, strip through holes are evenly formed in the adhesive tape, and according to the device used for carton folding and packaging, a bonding strip can be automatically pasted on the middle gap. Carton packaging is achieved, compared with an existing manual adhesive tape bonding manner, the efficiency is higher, manual operation is not needed, the packaging cost is reduced, the adhesive tape is accurately aligned with the middle gap of the carton, andthe packaging quality is ensured.

Owner:阜宁县华强纸品有限公司

Horizontal type oblique nozzle bag full-automatic packaging technology

ActiveCN102501995AIncrease productivityGuaranteed packaging qualityPackaging automatic controlSuccessive articlesUltimate tensile strengthFine chemical

The invention relates to a horizontal type oblique nozzle bag full-automatic packaging technology. The horizontal type oblique nose bag full-automatic packaging which is designed and manufactured by adopting the process flow can automatically complete packaging technological processes of making a heat-seal multi-layer composite membrane packaging bag, shearing an angle, adding an oblique nozzle, filling, sealing and the like. The horizontal type oblique nozzle bag full-automatic packaging technology process disclosed by the invention comprises the following steps of: forming a packaging film, bagging, shearing into a bag, adding an oblique nozzle, opening the bag, filling, sealing and the like. The horizontal type oblique nozzle bag full-automatic packaging machine which is designed and manufactured by adopting the technology provided by the invention has the advantages of smooth and beautiful suction nozzle sealing, high sealing strength, no leakage and high production efficiency, is applicable to medium and large heat-seal multi-layer composite membrane packaging bags, can be used for packaging various products such as powder, granules, liquid and the like and can be widely applied to industries such as foods, medicines, cosmetics, articles for daily use, fine chemical engineering and the like.

Owner:上海欧朔智能包装科技有限公司

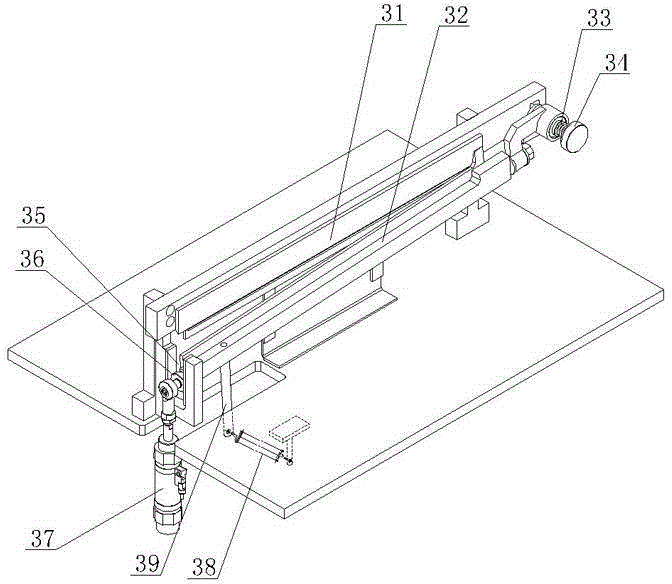

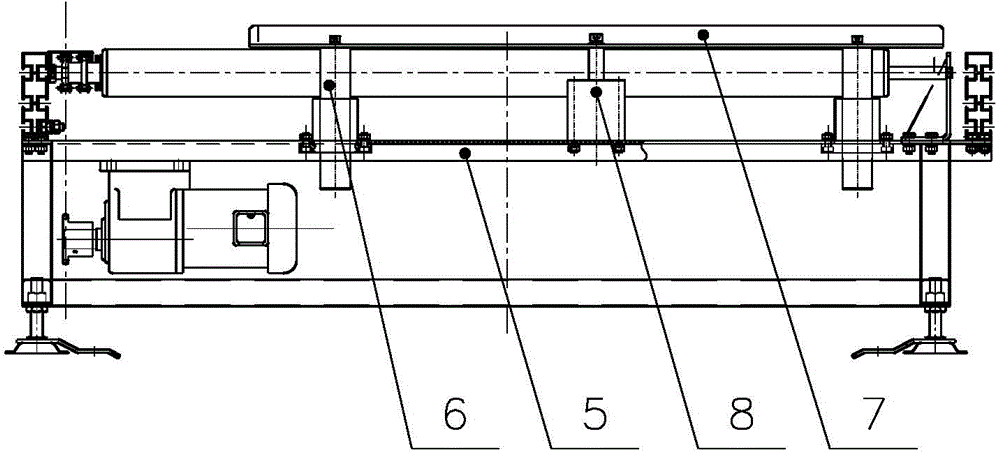

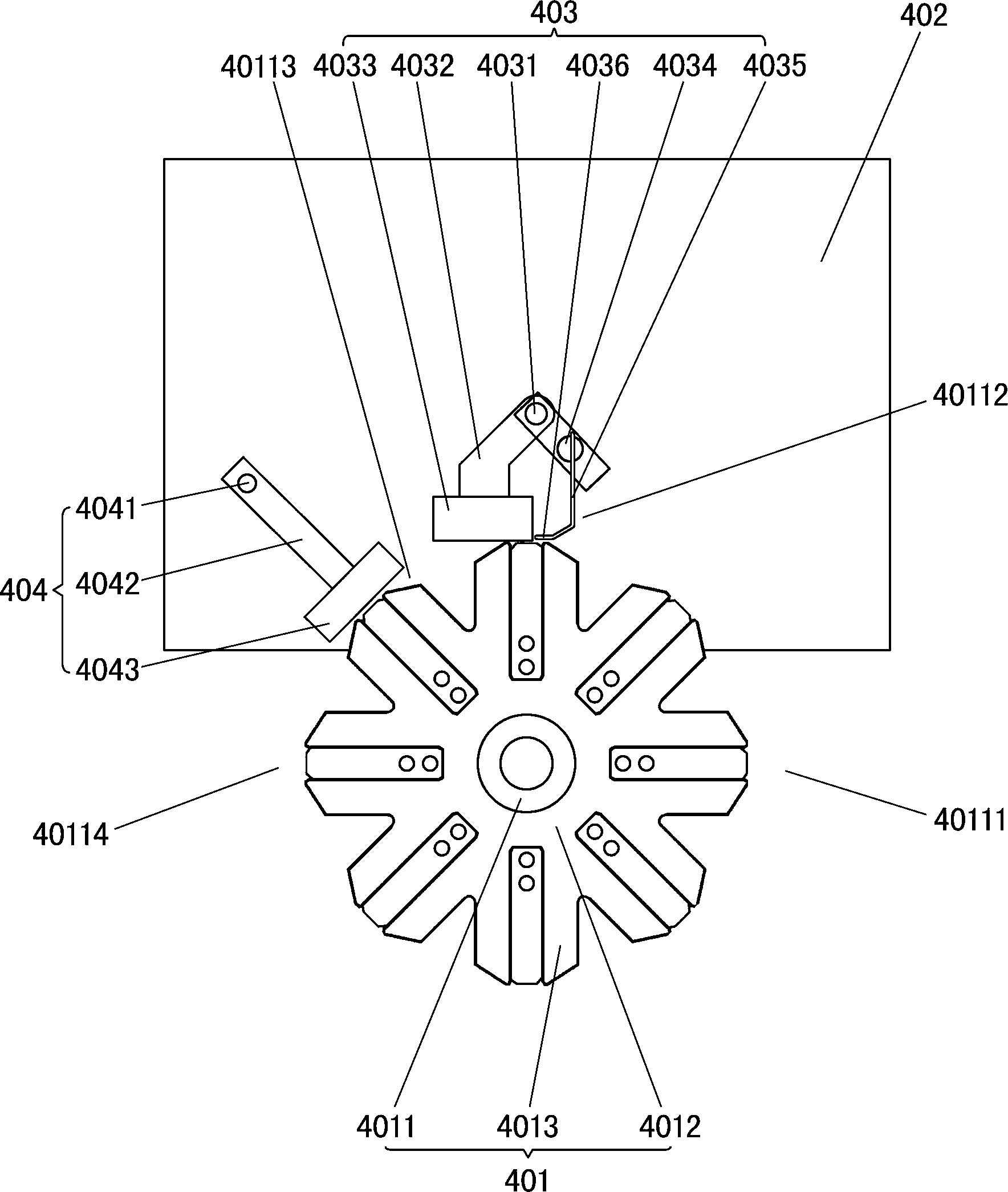

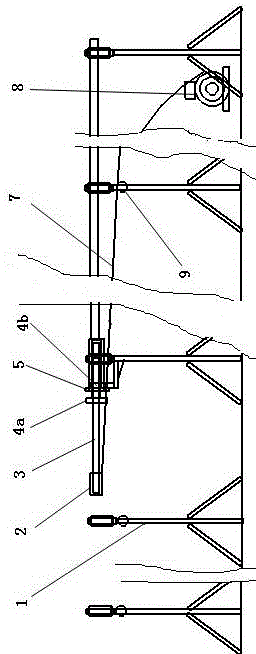

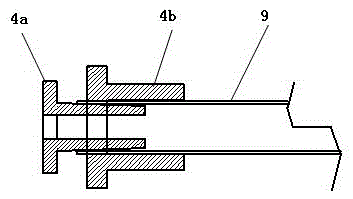

Slitting and feeding device for row straw

The invention discloses a slitting and feeding device for a row straw. A pineapple head and a collector are rotatably positioned on a rack; the outer side of the circumference of the pineapple head is provided with a plurality of straw containing slots and cutter slots at an interval; the outer side of the circumference of the collector is provided with a plurality of straw collection slots; the opening of the straw containing slot between the feeding end and the discharging end of the pineapple head can be covered by a material blocking device; a first cutter can extend into the cutter slot of the pineapple head to cut off the row straw; the cut-off row straws on the discharging side of the pineapple head can be sent into the straw collection slots of the collector by a material guide device; a push rod is positioned on the rack; the straws in the straw collection slots of the collector can be pushed out of the straw collection slots by the push rod; the pineapple head, the collector, the first cutter and the push rod are respectively driven by a first driving device, a second driving device, a third driving device and a fourth driving device to move; the first driving device, the second driving device, the third driving device and the fourth driving device are controlled by a controller to act. According to the slitting and feeding device for the row straw, which is disclosed by the invention, the straw can be fully-automatically slit and conveyed, manpower is saved, slitting can be accurately carried out, and the packaging quality is guaranteed.

Owner:KUSN FASTEC MACHINERY

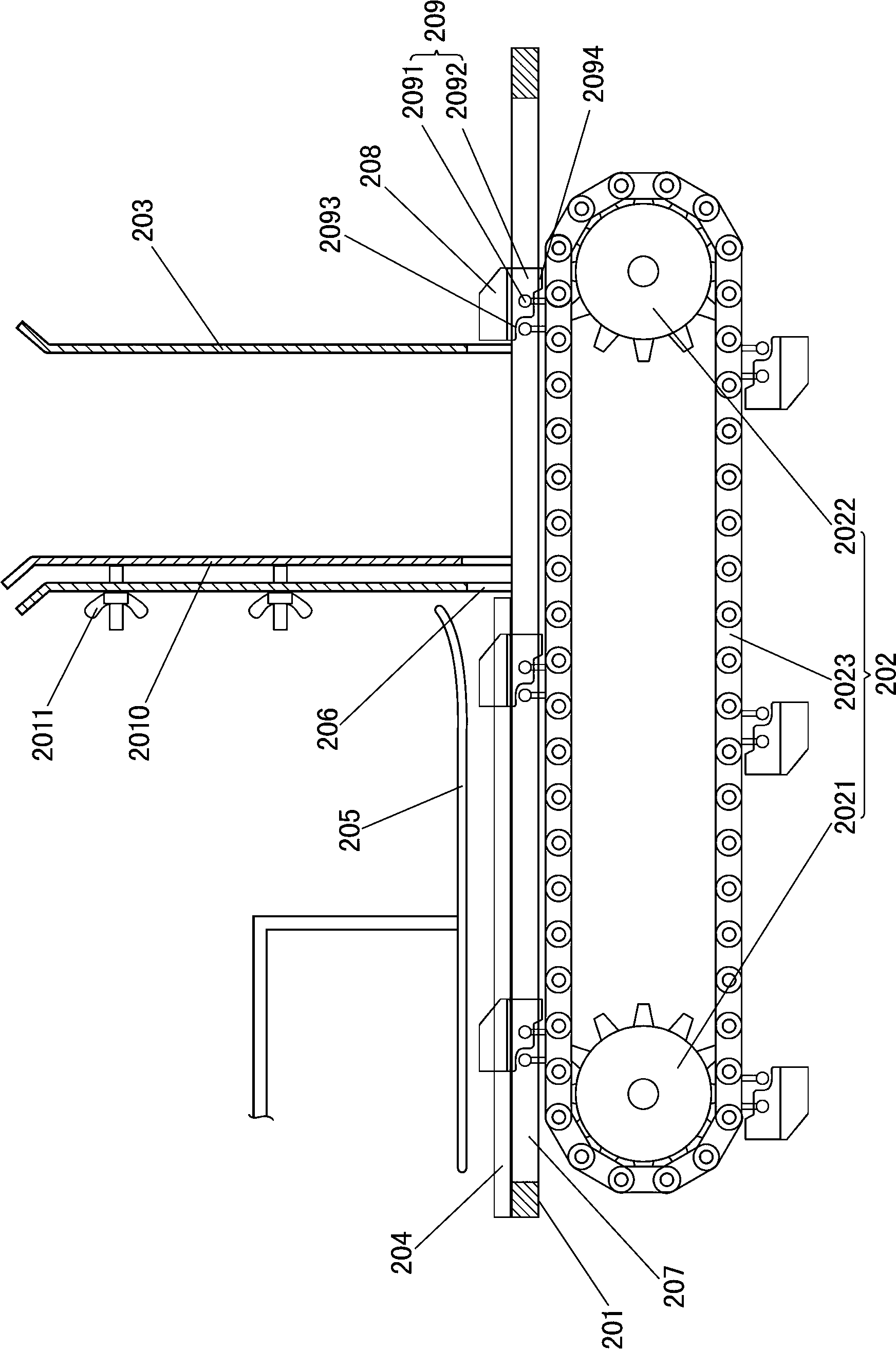

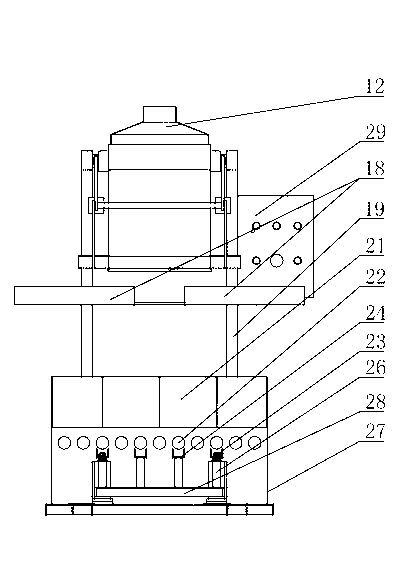

Thermal shrink film packaging machine for drug package box

ActiveCN103010504AAvoid destructionGuaranteed packaging qualityWrappers shrinkageConveyor wrappingEngineeringPackaging machine

The invention relates to a thermal shrink film packaging machine for a drug package box. The thermal shrink film packaging machine is specifically and structurally characterized in that a conveying mechanism is provided with a first conveying mechanism, a second conveying mechanism and a third conveying mechanism in a separated manner; and a box supply mechanism, a film rolling mechanism, a folding and sealing mechanism, a film cylinder double-end folding mechanism and a film cylinder double-end thermal sealing mechanism are respectively arranged. The first conveying mechanism and the second conveying mechanism are chain conveying mechanisms, and are respectively combined with the box supplying mechanism and the film cylinder double-end folding mechanism; the second conveying mechanism is a division rotary table, and is combined with the folding and sealing mechanism; the division rotary table is jointed with the front and back chain conveying mechanisms; and the division rotary table turns over the drug package box. Therefore, the thermal shrink film packaging machine has no need of additionally arranging the other complex switchover and turnover mechanism, so that the structure of the entire thermal shrink film packaging machine is simple and compact, and the manufacturing cost is lower.

Owner:GUANGDONG T&K PHARMA

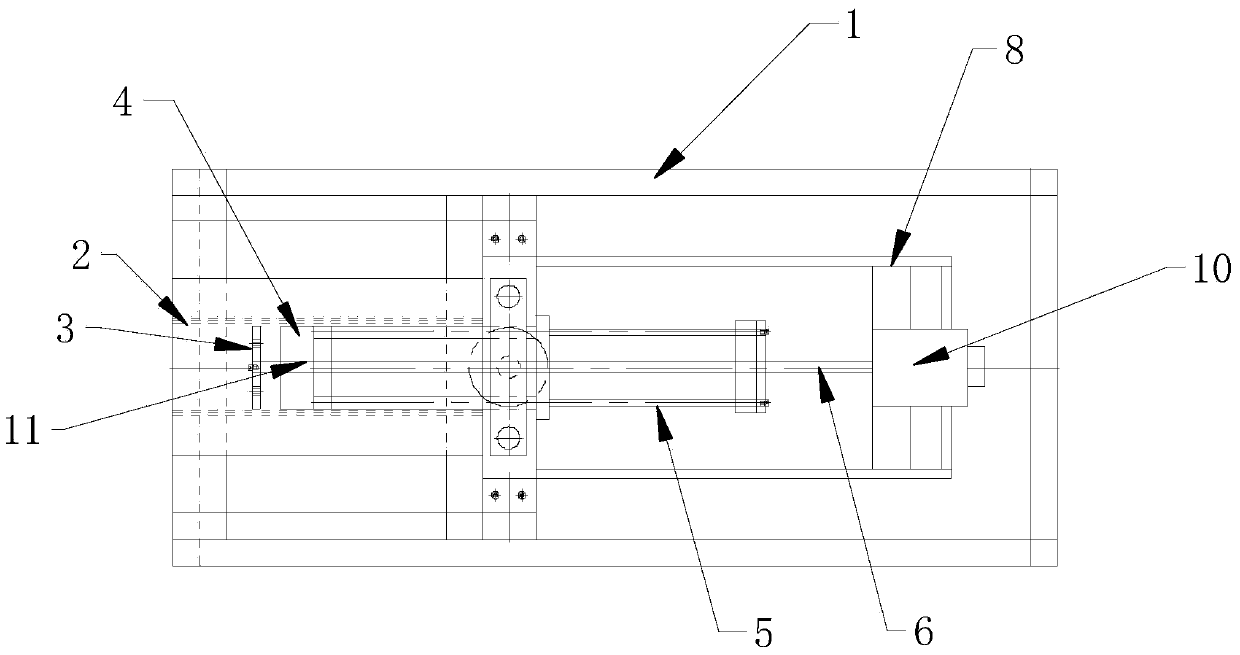

Bar beating and aligning device

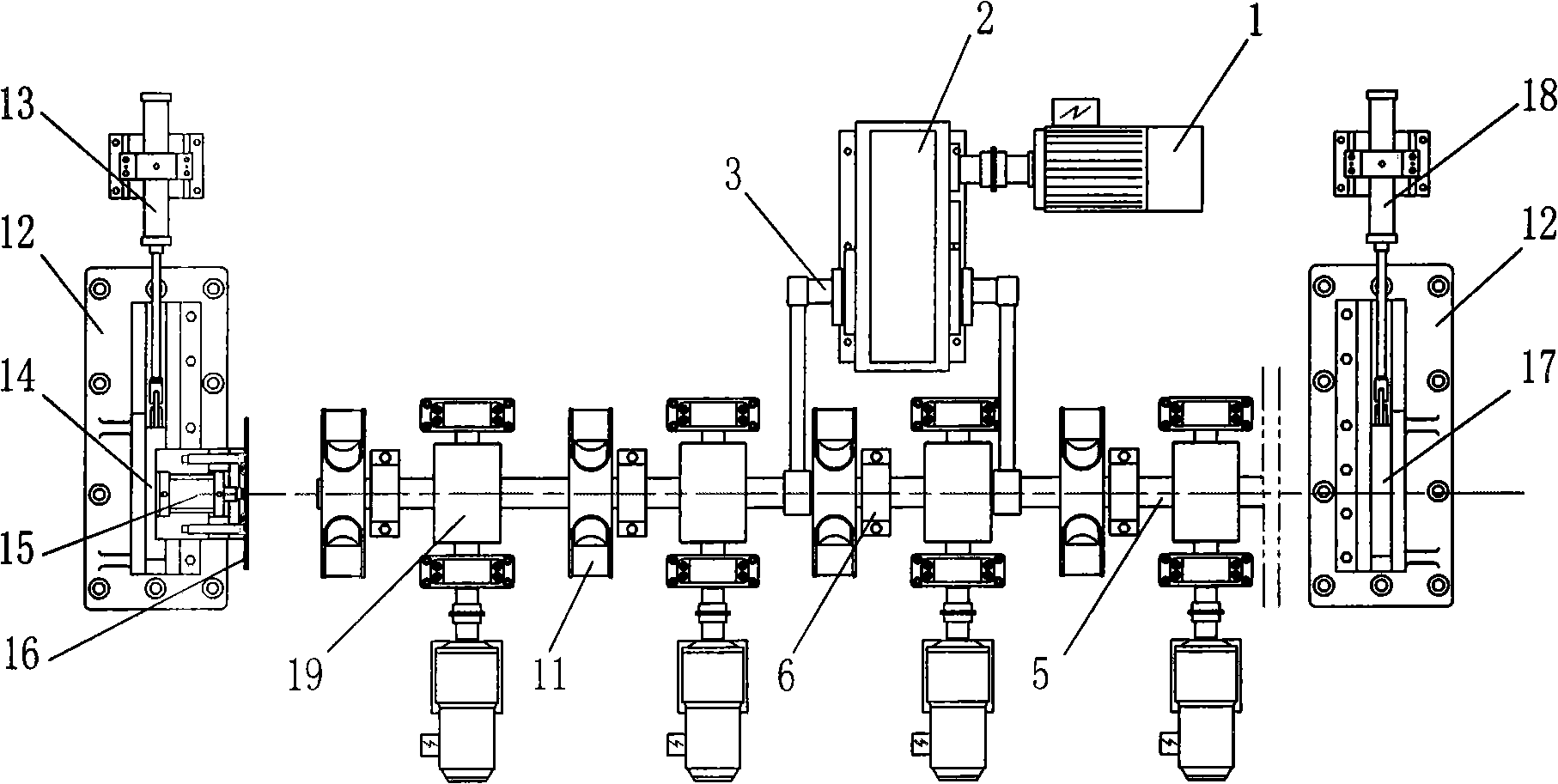

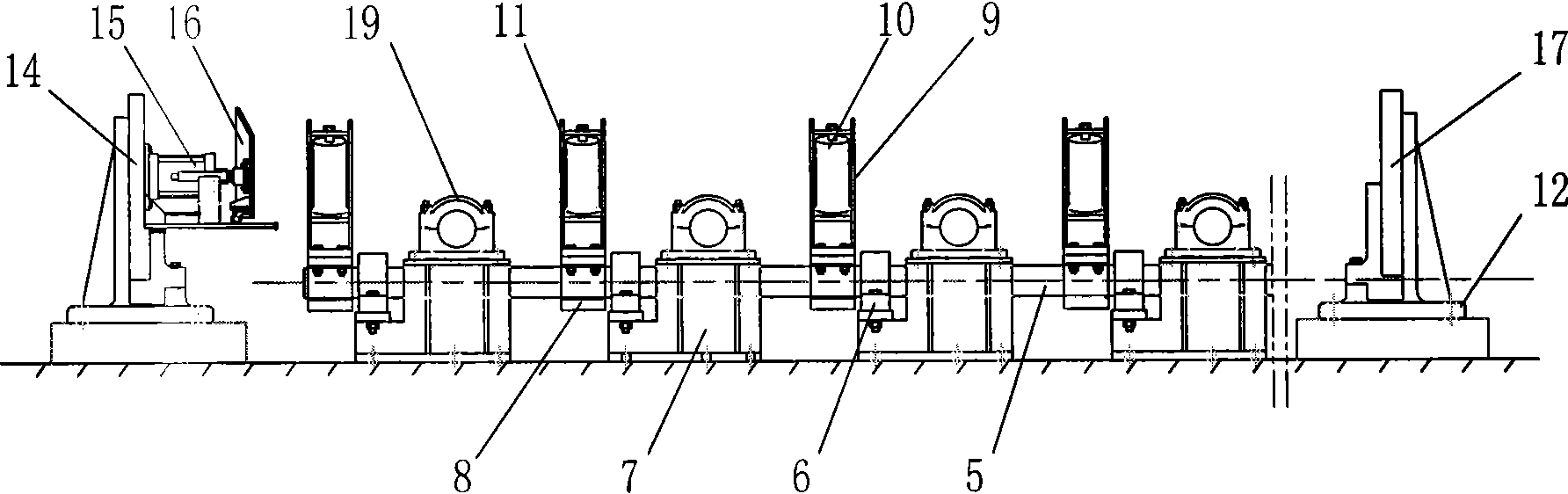

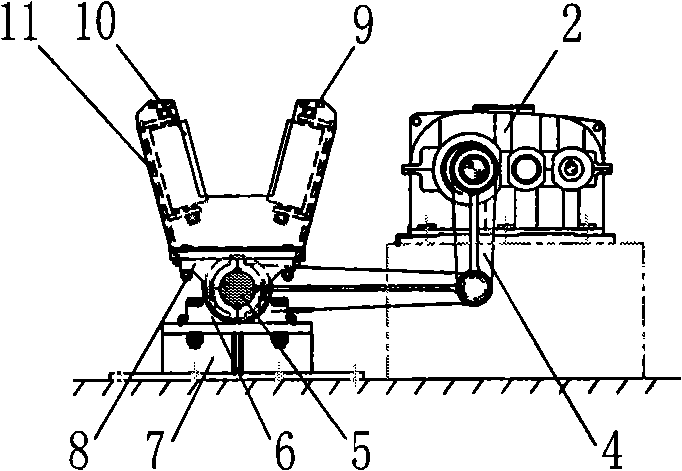

The invention discloses a bar beating and aligning device which comprises at least one collecting basket, an aligning mechanism and a beating mechanism correspondingly arranged at both sides of the collecting basket, wherein the collecting basket includes a vibration frame body (11) of which a cross section is of a groove shape and a ledge is outwardly oblique and a brake support (8) connected therewith, freedom rollers (10) are respectively arranged on two inner walls of the groove of the vibration frame body (11); a fixed base (12) of the aligning mechanism and a fixed base (12) of the beating mechanism are respectively provided with chutes, at least one vibration mechanism for shaking the collecting basket is arranged between the aligning mechanism and the beating mechanism and comprises a speed reducer (2) and a crank lever mechanism (4), wherein the speed reducer (2) is provided with an eccentric output shaft (3), and the crank lever mechanism (4) is connected with one or two ends of the eccentric output shaft. The bar beating and aligning device of the invention can ensure that fixed-length bars to be bound are beaten and aligned in reduplicating shake, be suitable for beating different-length bars to be bound into set length and have the advantages of high beating efficiency, good beating quality, and convenient operation.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

Tightened bag compacting mechanism for loose powdered materials with low bulk density

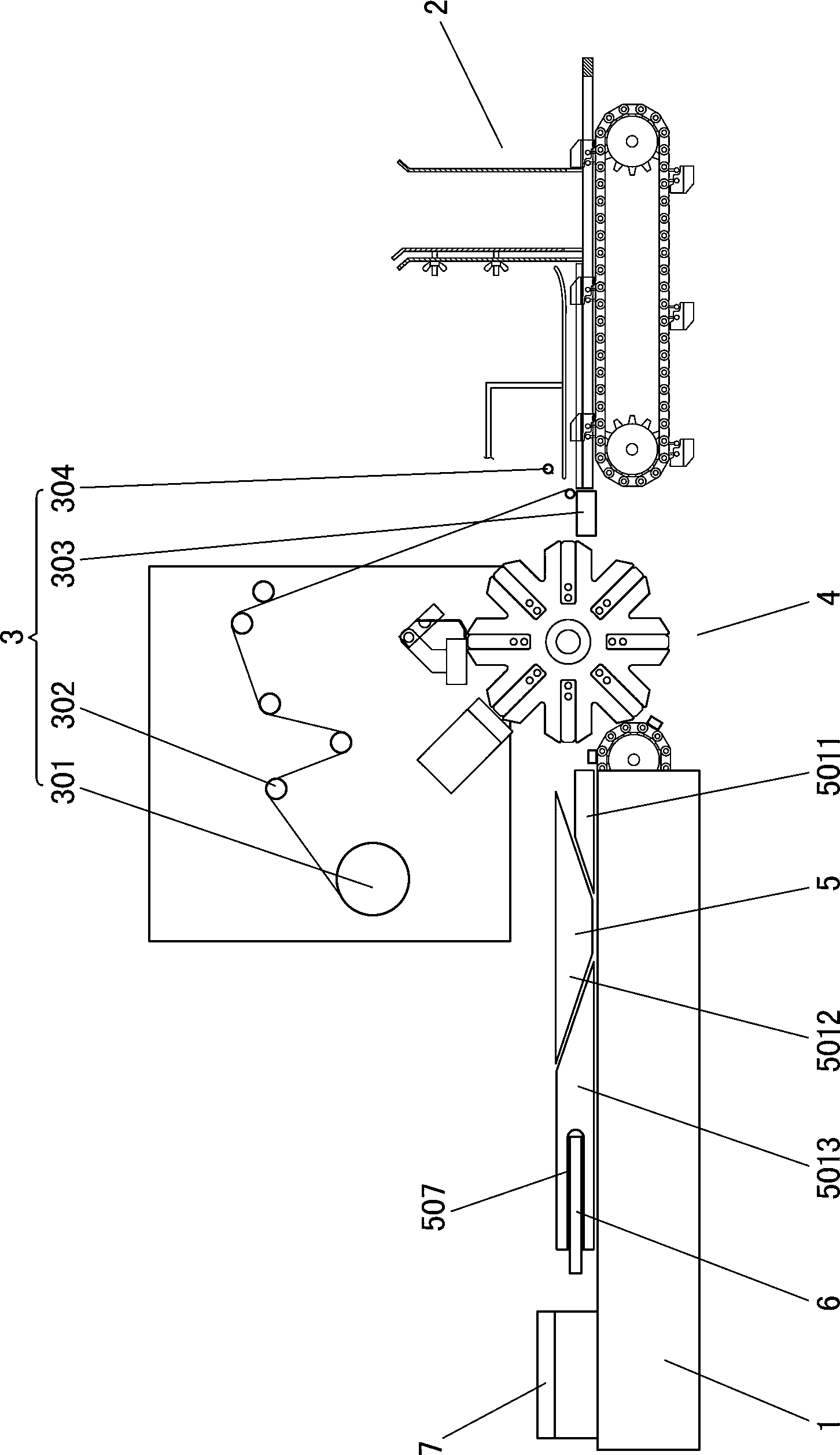

ActiveCN103183134AGuaranteed packaging qualityReduce labor intensitySolid materialSprocketEngineering

The invention relates to a tightened bag compacting mechanism for loose powdered materials with low bulk density. The tightened bag compacting mechanism comprises a rack; a tightened bag conveying mechanism is arranged at the bottom part of the rack; a chain wheel lifting mechanism is arranged on one side of the rack; a bag clamping mechanism is arranged on an upper rack arm at the top part of the rack and is positioned on the tightened bag conveying mechanism; a first power device is arranged on the sidewall of the rack through a sliding mechanism; and a pair of compacting plates is arranged at the output end of the first power device through a hinge mechanism and is positioned between the bag clamping mechanism and the tightened bag conveying mechanism. The tightened bag compacting mechanism is compact and reasonable; can be used for tightening packaging bags with the materials by virtue of the bag clamping mechanism, the tightened bag conveying mechanism and the chain wheel lifting mechanism, has a good bag tightening effect, facilitates the next operation of sealing of the packaging bags, ensures the packaging quality of the packaging bags, improves production efficiency, and reduces the working intensity of workers.

Owner:M & J MACHINERY ENGINEER

Thin film corner cutting packing process and packing machine

InactiveCN104590636AIncrease production capacityReduce process stepsPackagingElectrical and Electronics engineeringPackaging machine

The invention discloses thin film corner cutting packing process and a packing machine which are used for packing a rectangular object to-be-packed through a single layer of film. The object to-be-packed is provided with two opposite side faces, and four continuous peripheral faces are arranged between the two side faces. The process comprises the following steps: S100, wrapping the thin film on the four peripheral faces of the object to-be-packed; S200, spreading the thin film on the two side faces along the middles of the respective faces; S300, cutting off the spread thin film; S400, cutting off the thin film corners at the connecting positions of the four peripheral faces. The packing machine comprises a supporting and spreading conveying unit, a push unit, a primary hot cutting unit, a film spreading unit, a secondary hot cutting unit and a corner cutting unit, wherein the push unit, the primary hot cutting unit, the film spreading unit, the secondary hot cutting unit and the corner cutting unit are arranged in sequence. The packing machine is suitable for the thin film corner cutting packing process. The thin film corner cutting packing process and the packing machine are high in packing efficiency and good in quality and generality.

Owner:游顺球

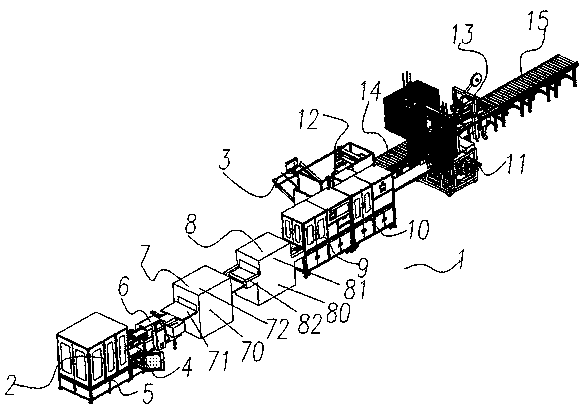

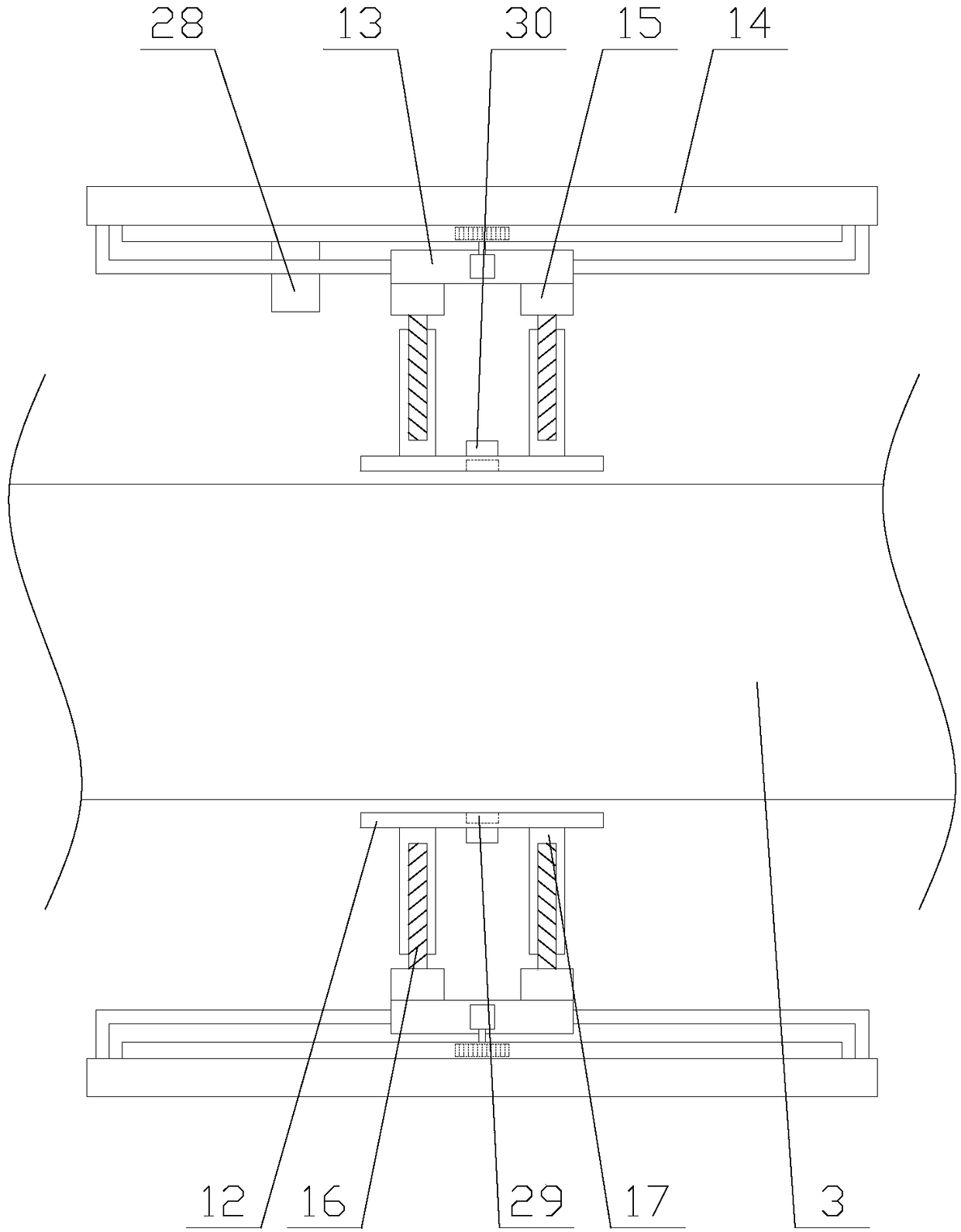

Gift box type white spirit automatic packing system

ActiveCN104986372AImprove packaging efficiencyGuaranteed packaging qualityPackaging bottlesModular designEngineering

The invention relates to a gift box type white spirit automatic packing system. The gift box type white spirit automatic packing system comprises a splitting module, a white spirit support feeding module, a bottle feeding module, a box cover buckling module and a gift box discharging module which are arranged in sequence. A double-servo moving mechanism is arranged at the top end of a door type frame of the splitting module, the white spirit support feeding module, the bottle feeding module, the box cover buckling module and the gift box discharging module. A circulation feeding mechanism is coaxially arranged in the middle of the inner sides of the splitting module, the white spirit support feeding module, the bottle feeding module, the box cover buckling module and the gift box discharging module in the horizontal transverse direction. The circulation feeding mechanism is controlled by a system program for circulation running for conveying of a support bottom. Conveying belts are horizontally arranged on the two longitudinal sides of the circulation feeding mechanism respectively, and the conveying belts on the two sides are used for conveying bottles and gift boxes respectively. According to the system, the modular design production is adopted, and the number of the modules is increased and reduced according to different technical processes. The system is widely applied to white spirit package and production, the packaging efficiency is improved, and the packaging quality of products is guaranteed.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

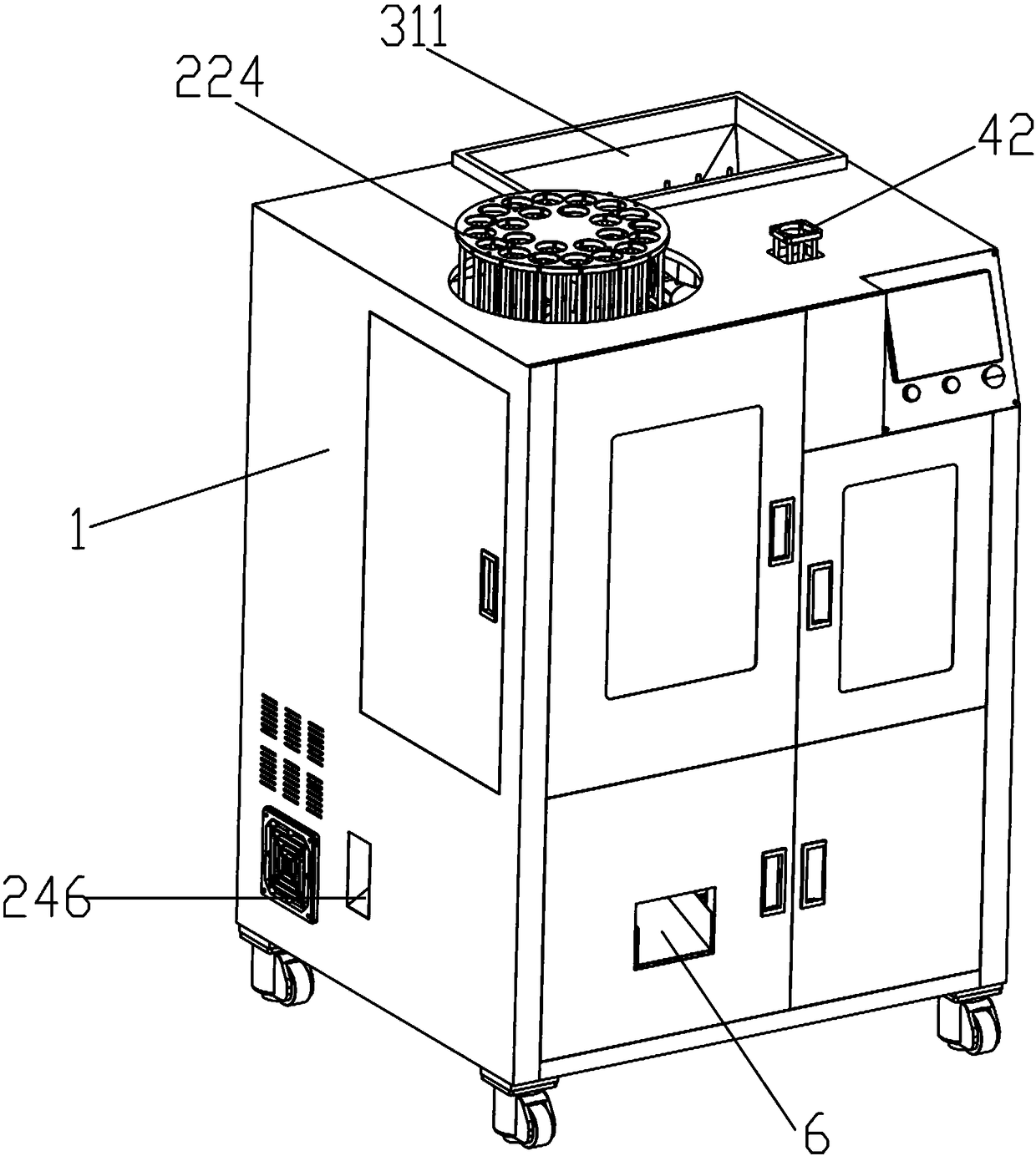

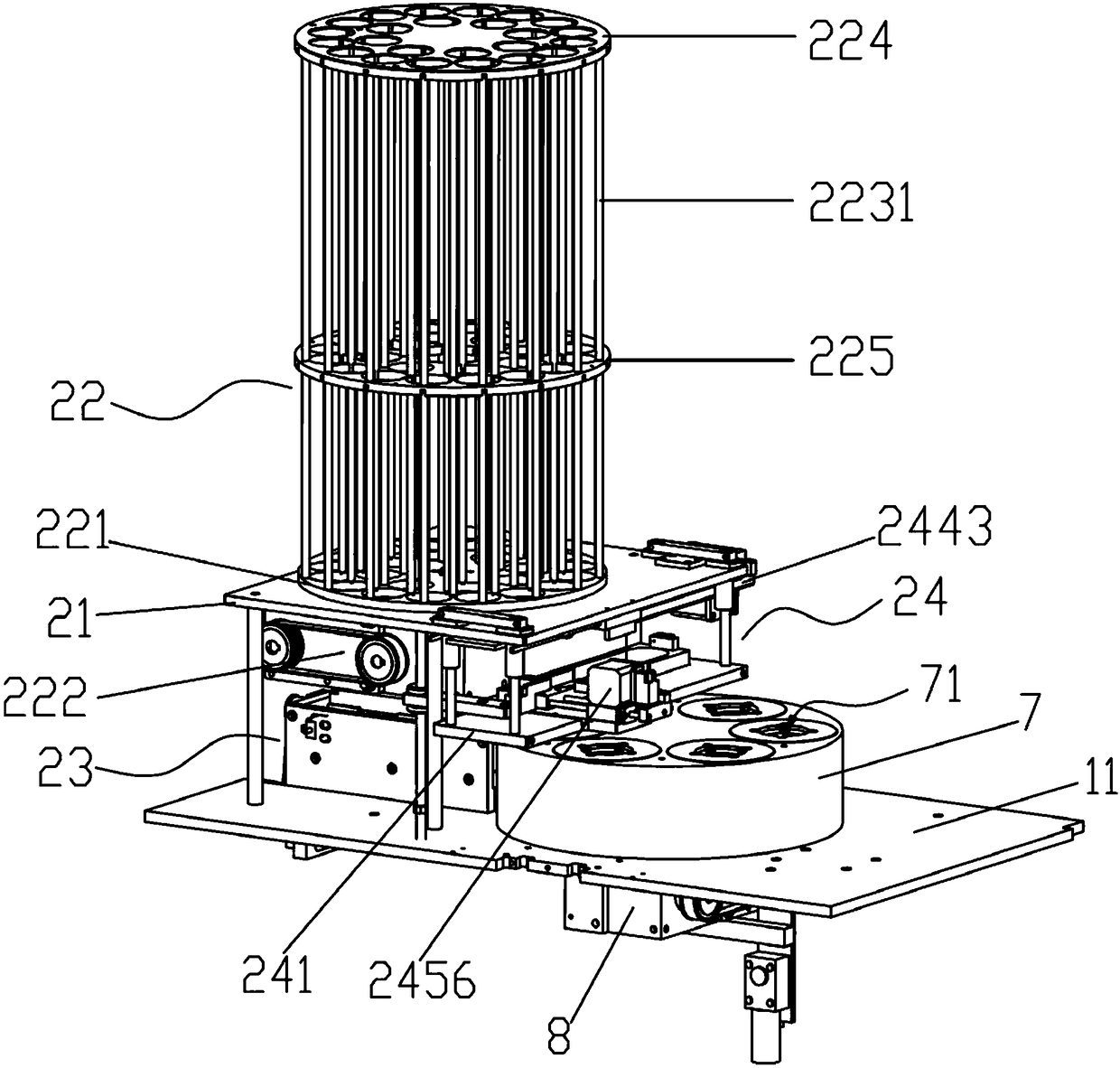

Energy saving and environment protecting type full-automatic canned tea packaging machine

ActiveCN108557165ARealize fully automated continuous productionGuaranteed packaging qualityPackaging by pressurising/gasifyingNitrogenEnergy analysis

The invention provides an energy saving and environment protecting type full-automatic canned tea packaging machine. A machine cabinet is included, and a work table board is horizontally arranged on the middle portion of the machine cabinet, and is provided with a first rotating disk; a first divider assembly is installed below the work table board; after penetrating the work table board, an output rotating shaft of the first divider assembly is connected with the center of the first rotating disk; the first rotating disk is provided with at least five can containing cavities uniformly distributed around the periphery of the center of the first rotating disk, and the can containing cavities penetrate the upper and lower surfaces of the first rotating disk; a can body feeding device, a teaweighing feeding device, a can cover feeding device, a vacuumizing nitrogen filling can sealing device and a finished product discharging hopper are arranged in the machine cabinet, and the can body feeding device, the tea weighing feeding device, the can cover feeding device, the vacuumizing nitrogen filling can sealing device and the finished product discharging hopper are sequentially distributed beside the first rotating disk in the rotating direction of the first rotating disk, and correspondingly arranged with the can containing cavities; the finished product discharging hopper is located below the work table board; and the work table board is provided with finished product can discharging holes corresponding to the can containing cavities on the finished product discharging hopper and the first rotating disk.

Owner:福建元弘自动化科技有限公司

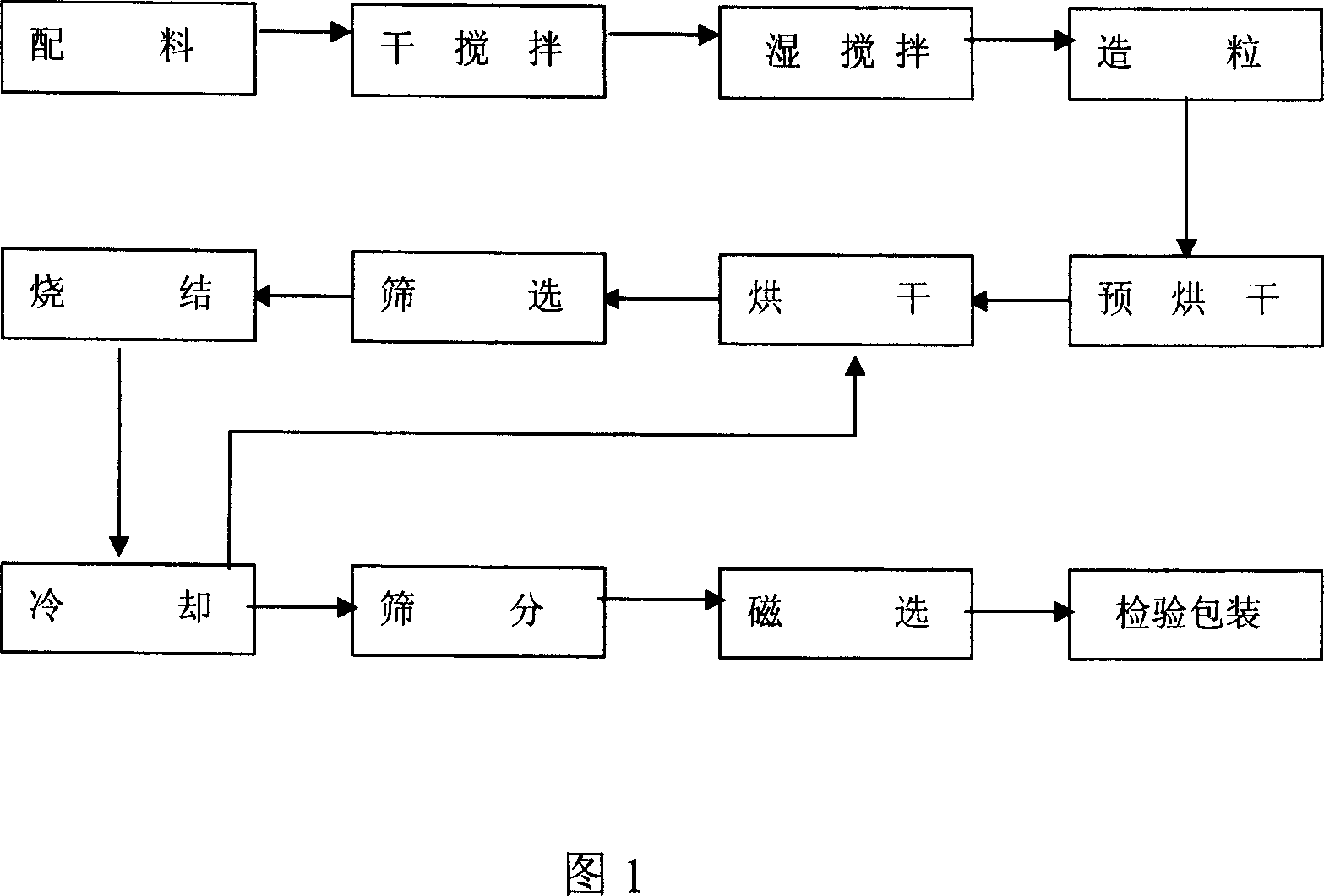

Sintered flux production process

ActiveCN1962156AEliminate dead endsGuaranteed uniformityWelding/cutting media/materialsSoldering mediaAnti adhesiveWork in process

The invention relates to a method for producing sinter solder, which comprises preparing material, mixing, making particles, pre-drying, drying, selecting, sintering, cooling, selecting, magnetic selecting, checking, and packing, wherein the invention uses dry-wet mixing separating technique, to eliminate the dead corner and confirm the uniform product, with stable product quality. And it uses vibration fluidize drying technique to reduce block ratio in drying process under 5%. And it coats anti-adhesive coat on the contact with material. The invention uses left heat recycle technique, to recycle the heat when cooling solder into former processes to dry the semi product. And the energy consumed by roller drier is from the left heat.

Owner:BAOJI PETROLEUM STEEL PIPE

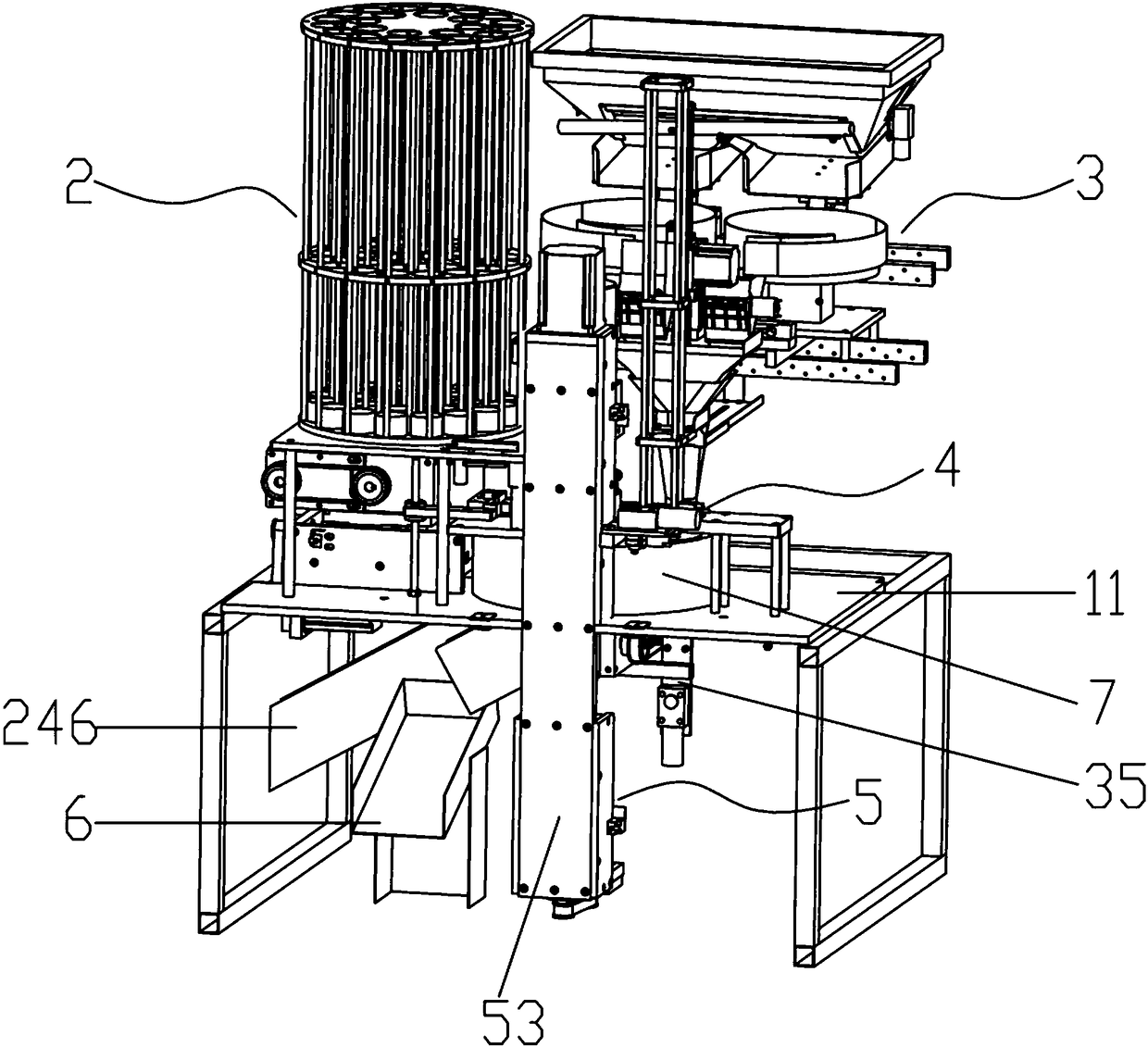

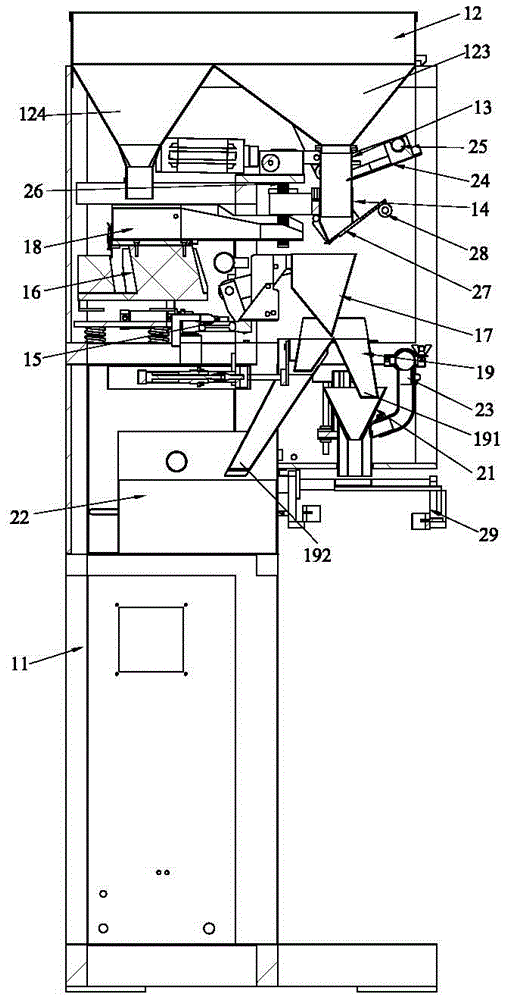

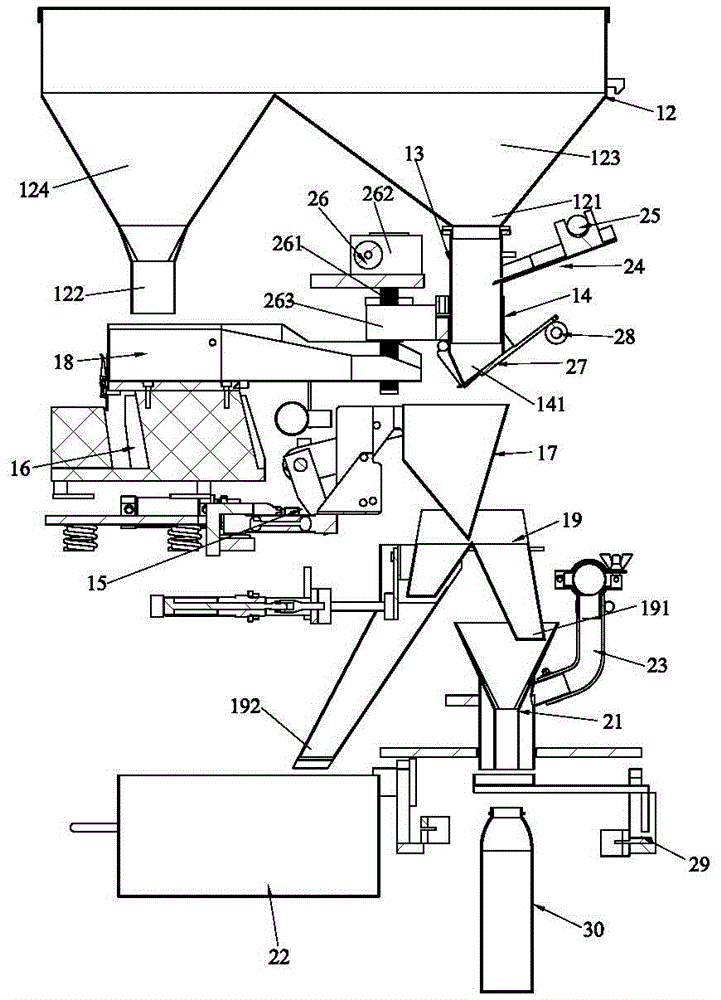

Fragile particle weighing filling machine

InactiveCN105620795AEasy to replaceGuaranteed packaging qualitySolid materialParticle materialMeasuring cup

The invention discloses a fragile particle weighing filling machine. The fragile particle weighing filling machine comprises a frame, a storage hopper, a measuring cup, a cup sleeve, a weighing sensor, a vibrator, a weighing hopper, a feeding hopper, a shunting hopper, a filling hopper, a recycling hopper and a dust collecting mechanism, wherein the storage hopper is arranged on the frame and comprises a first outlet and a second outlet; the measuring cup is fixedly connected with the storage hopper; a movable quantifying door is arranged at the side surface of the measuring cup; the quantifying door is driven to be inserted into the measuring cup back and forth by a first driving mechanism; the cup sleeve can sleeve the lower end of the measuring cup in a way of moving up and down; the cup sleeve is driven to move up and down by a second driving mechanism. By utilizing all components and mechanisms in a cooperation way, the fragile particle weighing filling machine is capable of automatically weighing a fragile particle material and filling the fragile particle material into a bottle and guaranteeing that the powder percent of the filled fragile particle material is smaller than 15%; the components in contact with the material are easy to dismount, replace and wash; meanwhile, the fragile particle weighing filling machine also has a dust treatment function to guarantee the packaging quality of the material and is capable of providing convenience for packaging operation.

Owner:GUANGZHOU V PACK IND CO LTD

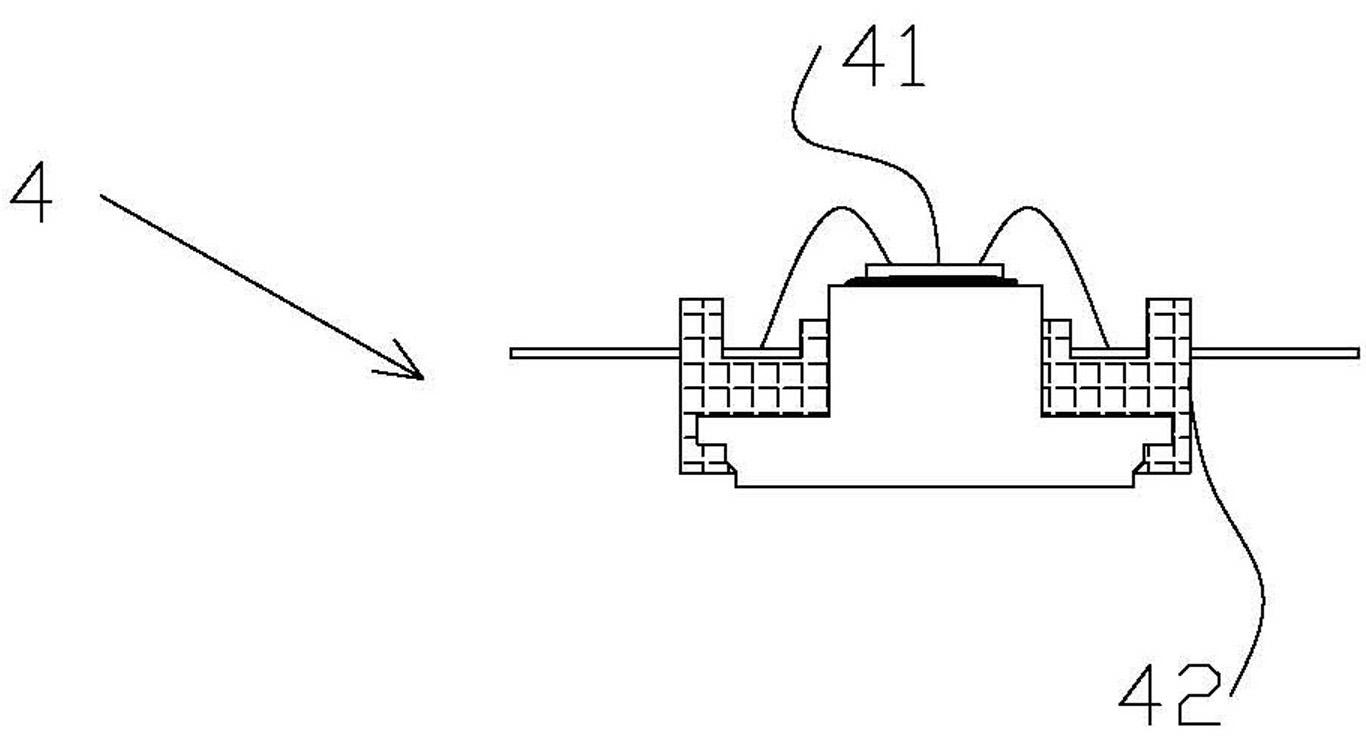

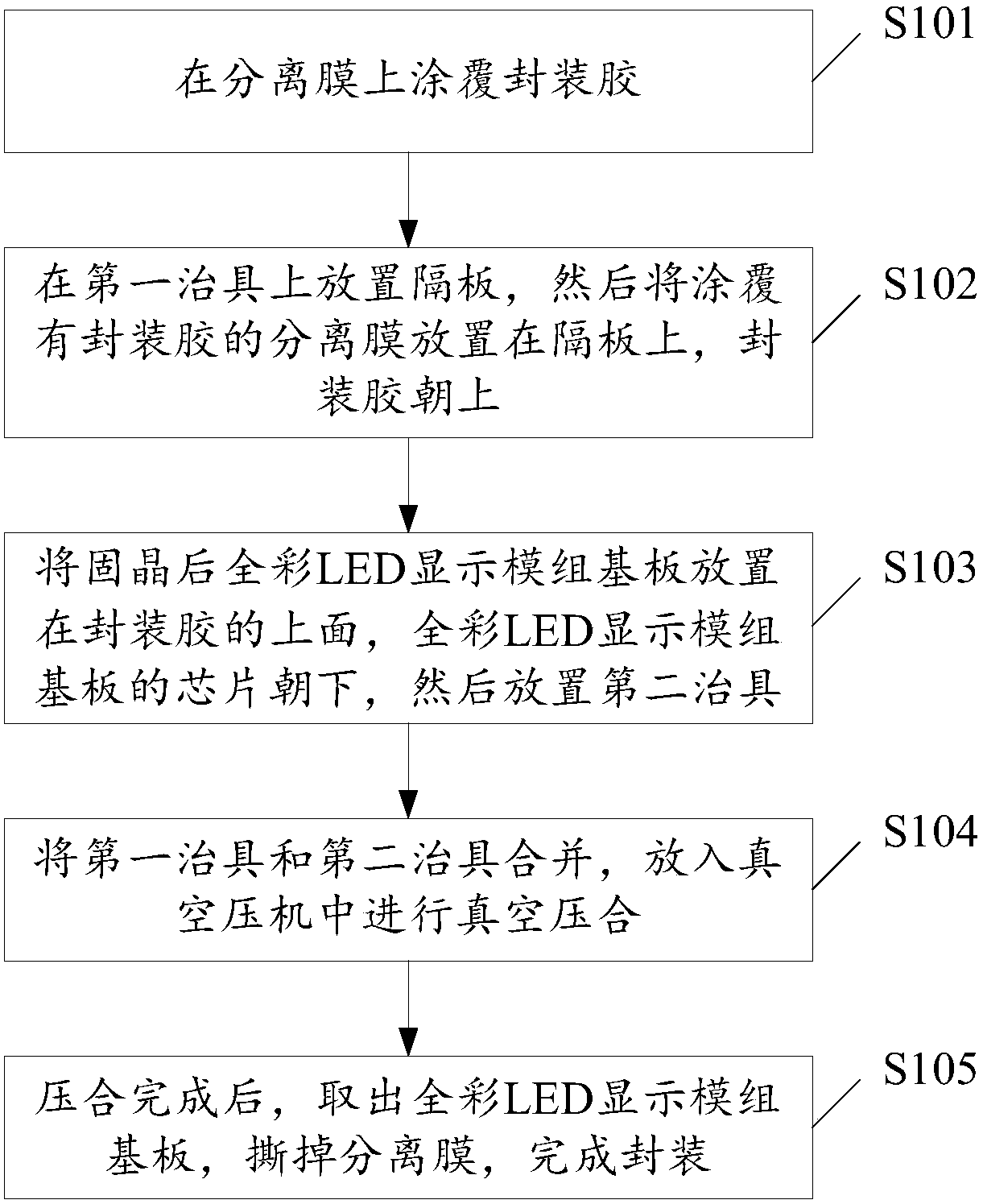

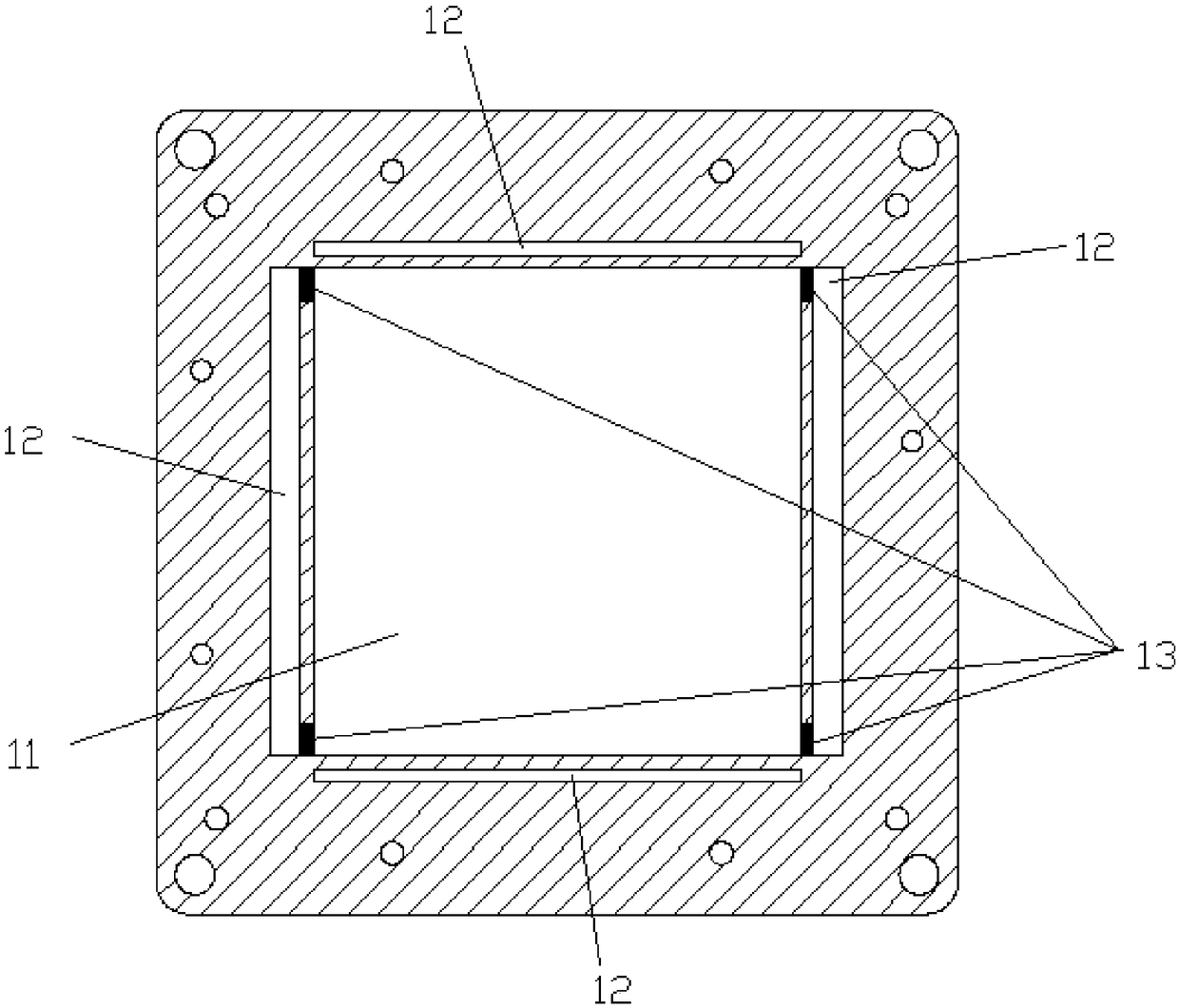

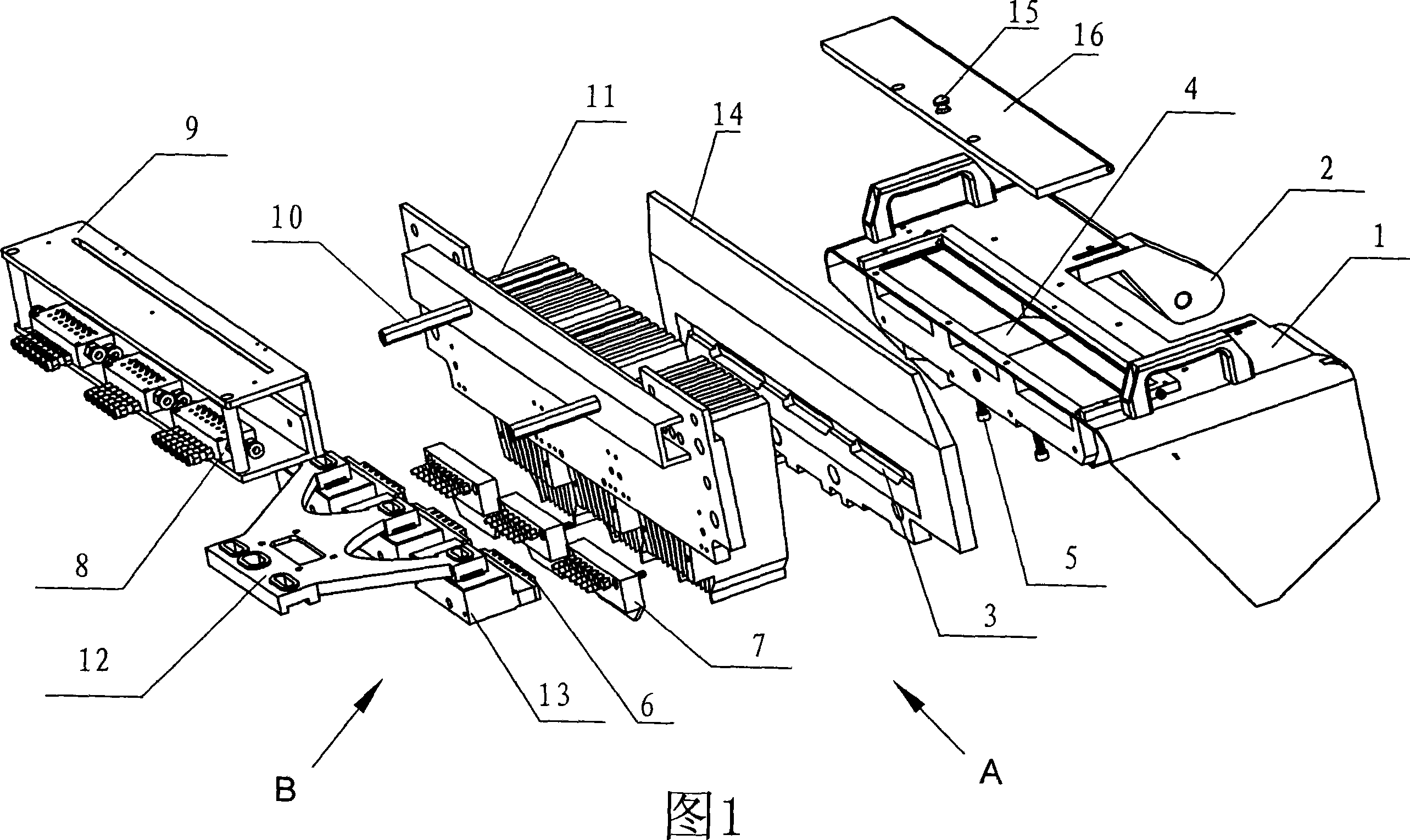

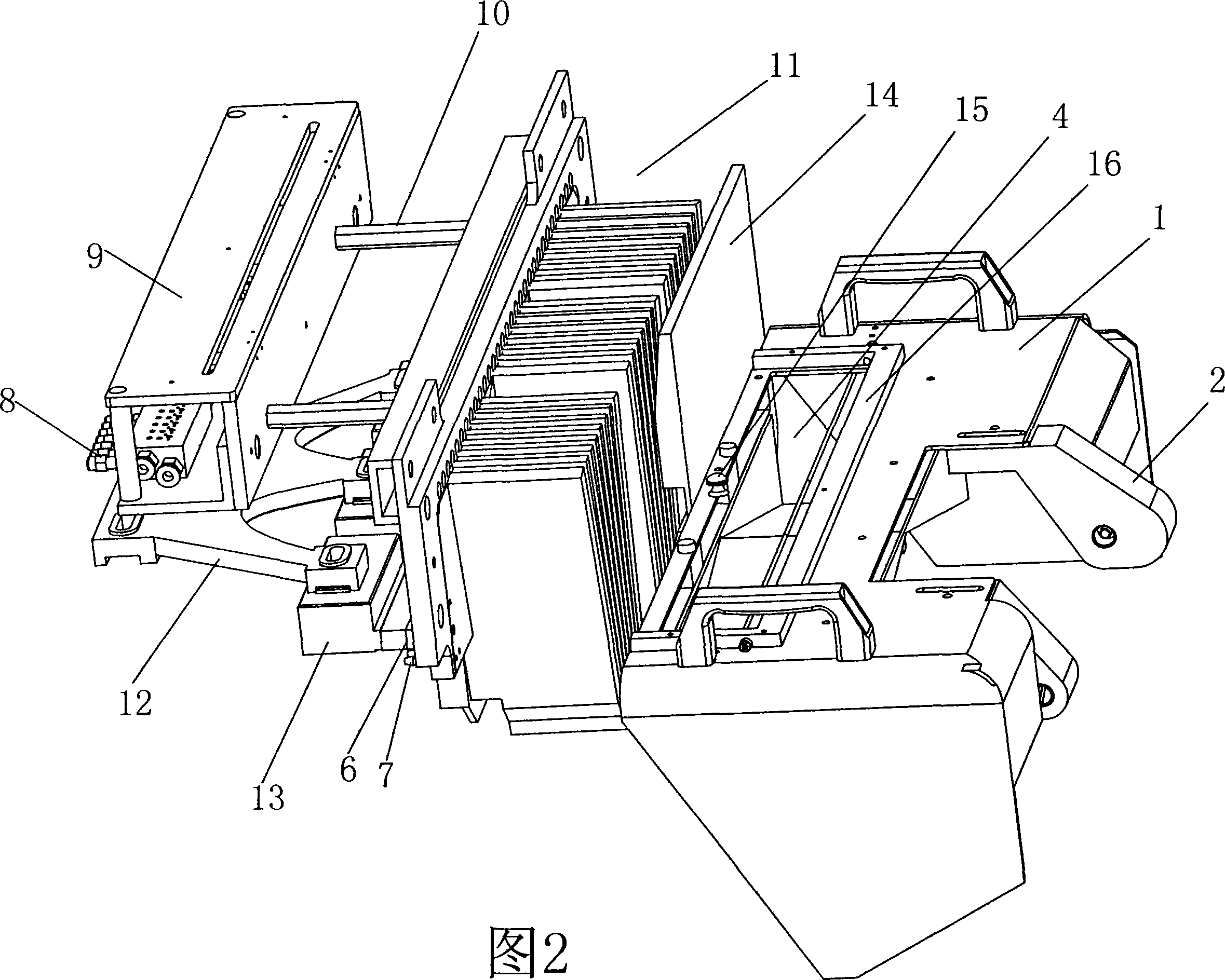

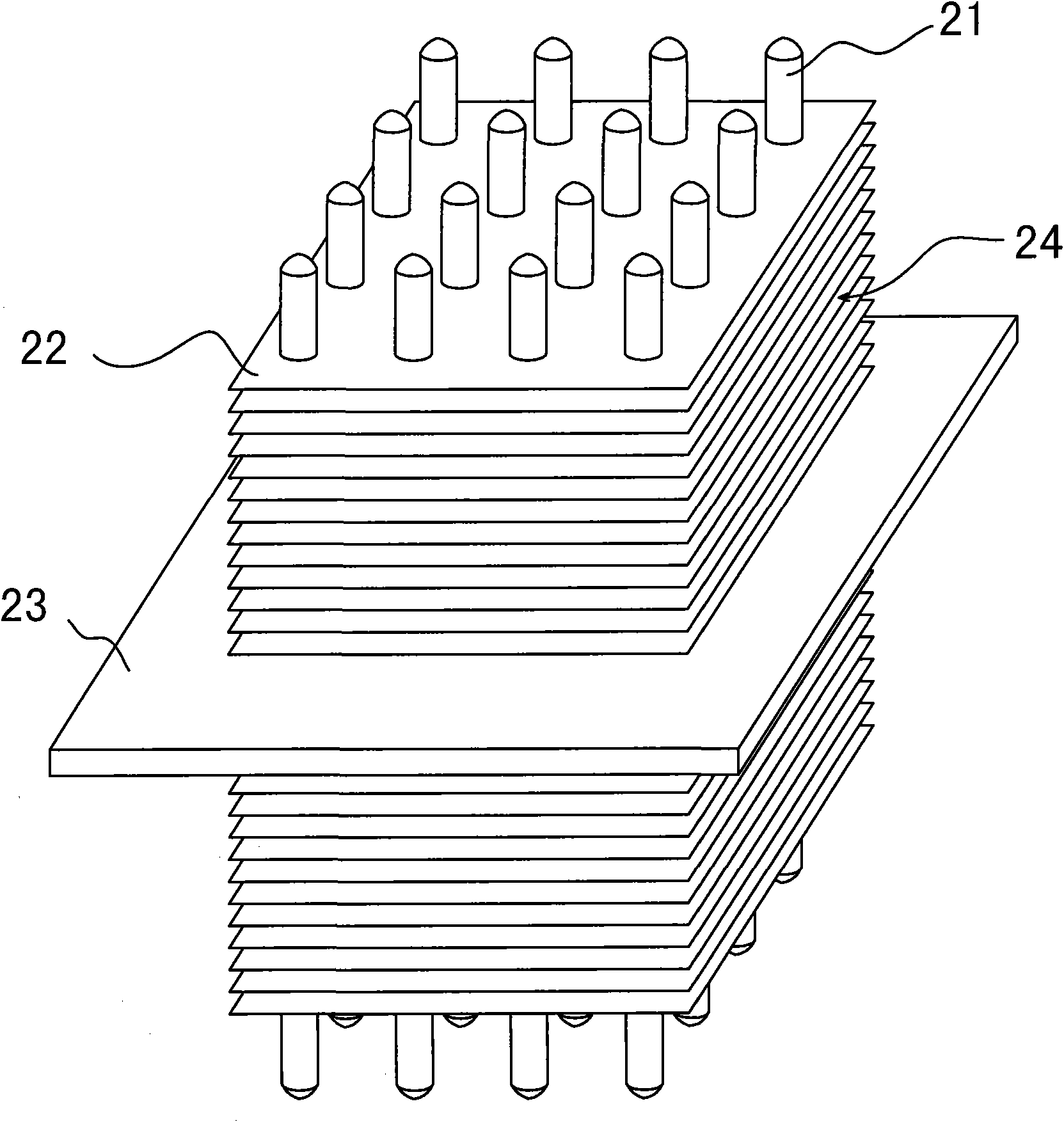

Full-color LED display module, packaging method and display screen of full-color LED display module

InactiveCN108448012ATo achieve a variety of choicesImproved size adaptabilitySolid-state devicesSemiconductor/solid-state device manufacturingLED displayEngineering

The invention discloses a packaging method of a full-color LED display module. The method comprises the steps of 1, coating the package resin on a separation film; 2, placing a separation plate on a first jig, and placing the separation film coated with the package resin on the separation plate, wherein the side of the separation film with the package resin is placed upwards; 3, placing the solid-crystal full-color LED display module substrate on the package resin, placing the chip of a full-color LED display module substrate to be downwards, and then placing a second jig; 4, combining the first jig and the second jig, and putting the first jig and the second jig into a vacuum air compressor for vacuum lamination; 5, after the lamination is completed, taking out the full-color LED displaymodule substrate, tearing off the separation film, and finishing the packaging operation. Correspondingly, the invention further provides a full-color LED display module and a display screen of the full-color LED display module. By the adoption of the method, the diversified selection of packaging sizes and packaging materials can be realized. The packaging quality is good, and the foaming is avoided. The requirement on packaging equipment is low.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

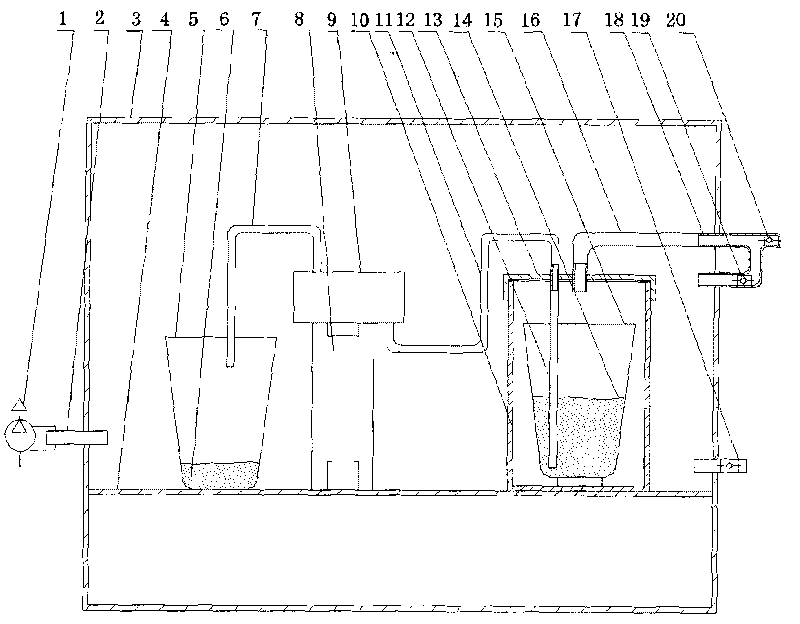

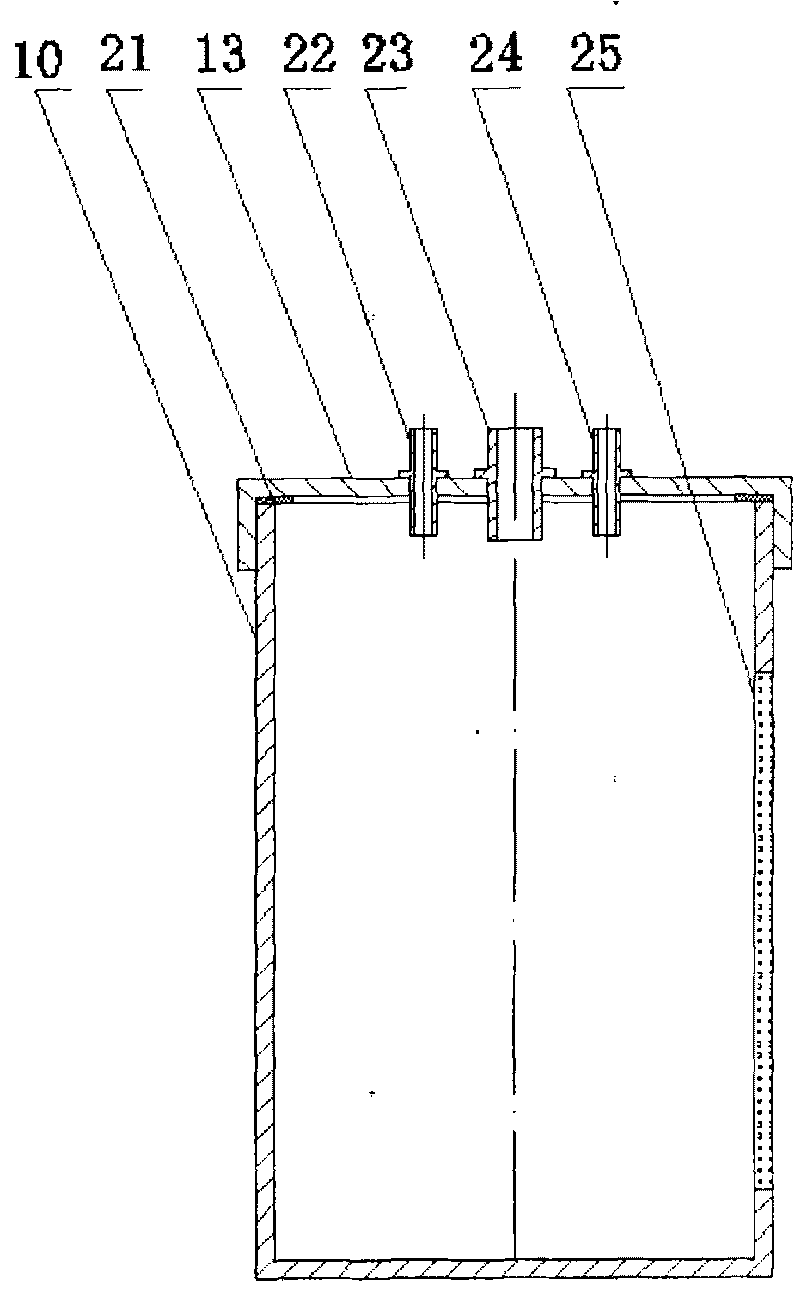

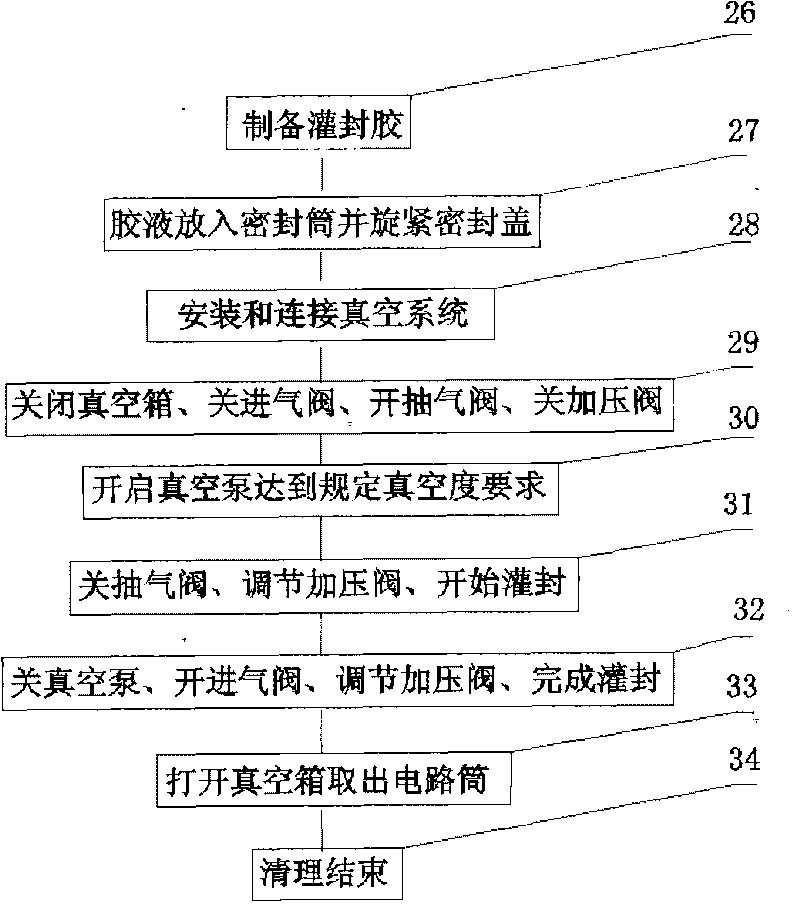

Resin adhesive vacuum encapsulation device and process thereof

InactiveCN101764070AControl flow speedControlling the potting processSemiconductor/solid-state device manufacturingVacuum pumpingDifferential pressure

The invention relates to a resin adhesive vacuum encapsulation device and a process thereof, which belong to the resin adhesive vacuum encapsulation technical field. The encapsulation device comprises a vacuum drying box, a vacuum pump, a sealing tube, a circuit tube, an overflow adhesive cup, connecting pipelines and valves and the like, which wholly form a complete set of differential-pressure vacuum encapsulation system with encapsulating adhesive automatic flowing for vacuum pumping and atmospheric pressure pushing. The differential-pressure encapsulation device has reasonable design and simple and practical structure, and is worth applying and promoting. The encapsulation process includes the following steps of preparing vacuum encapsulation adhesive, assembling the encapsulation device, operating a valve system of the device for a vacuum-pumping process, encapsulating a circuit, and finishing the encapsulation process. The encapsulation process is adopted to form a differential-pressure encapsulation circuit process with automatic flowing of resin adhesive, the encapsulation device is adopted, the resin adhesive is improved, and the whole structure of the circuit is enhanced, and the impact resistance and the vibration resistance and other harsh environment resistance and the insulation performance for the electronic device and components are increased. The encapsulation process of the invention is applied to engineering test under various harsh environments and complex conditions, and has good practical effect.

Owner:ZHONGBEI UNIV

High-power light emitting diode (LED) liquid silicone rubber encapsulation method and encapsulation mould

ActiveCN102185044ASimple processReduce processSemiconductor/solid-state device manufacturingSemiconductor devicesCooking & bakingPolymer science

The invention discloses a high-power light emitting diode (LED) liquid silicone rubber encapsulation method and a high-power LED liquid silicone rubber encapsulation mould. The method comprises the following steps of: 1) preparing an upper mould and a lower mould, and arranging the upper mould in a working area for later use, wherein the upper mould is provided with an inwards-sunken cavity and amaterial inlet; the shape of the inwards-sunken cavity corresponds to the upper shape of a to-be-encapsulated LED bracket chip; the material inlet injects rubber into the cavity; and the lower mould is provided with a positioner of which the shape corresponds to the lower shape of a to-be-encapsulated LED bracket; 2) arranging the LED bracket into the lower mould for preheating; 3) conveying the lower mould with the LED bracket to the working area; 4) aligning the upper and lower moulds, and performing mould matching, wherein the upper mould tightly presses the LED bracket; 5) injecting the rubber into an inner cavity formed by the LED bracket and the upper mould, and performing heating baking to mold and cure the injected rubber solution; and 6) separating the upper mould from the lower mould, conveying the lower mould back into a transition area, and taking the bracket out. In the encapsulation method, a process is simple and rational, and production efficiency is high; the rubber is injected automatically uniformly at high speed, encapsulation quality is high, and curing time is short.

Owner:MLS

Empty cigarette detecting and eliminating device

InactiveCN101020506APrecise positioningAvoid cloggingPackaging cigarettePackaging cigarsEngineeringSmoke

The empty cigarette detecting and eliminating device for detecting cigarettes in the model box and eliminating empty cigarette consists of one detecting unit and one eliminating unit. The detecting unit consists of sensor mounted inside the lower cigarette passage and outside the back protecting board. The eliminating unit consists of one eliminating valve, one eliminating nozzle and one eliminating channel. The present invention can reduce waste, and raise packing quality and speed.

Owner:NANJING DASHU INTELLIGENT SCI & TECH CO LTD

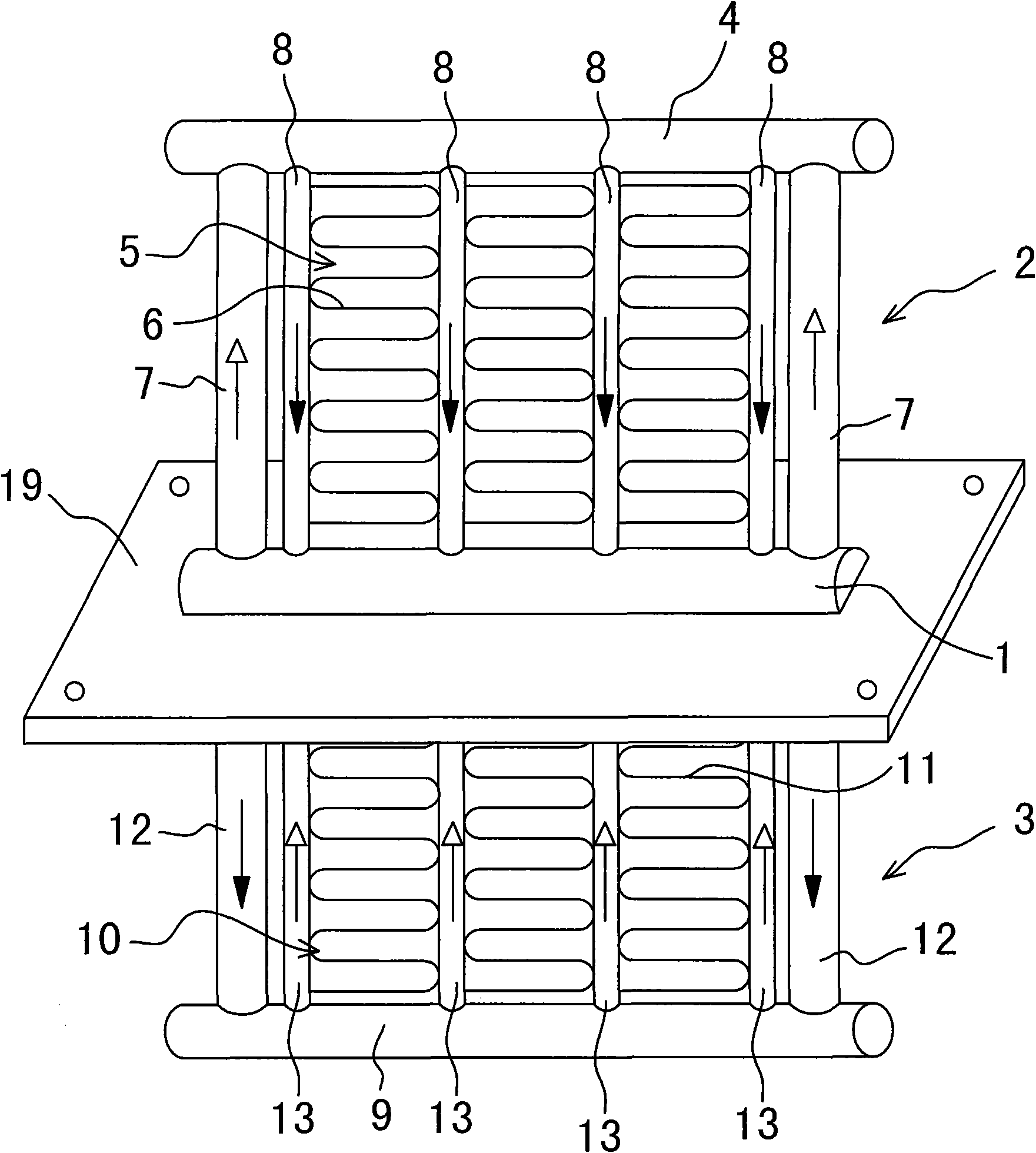

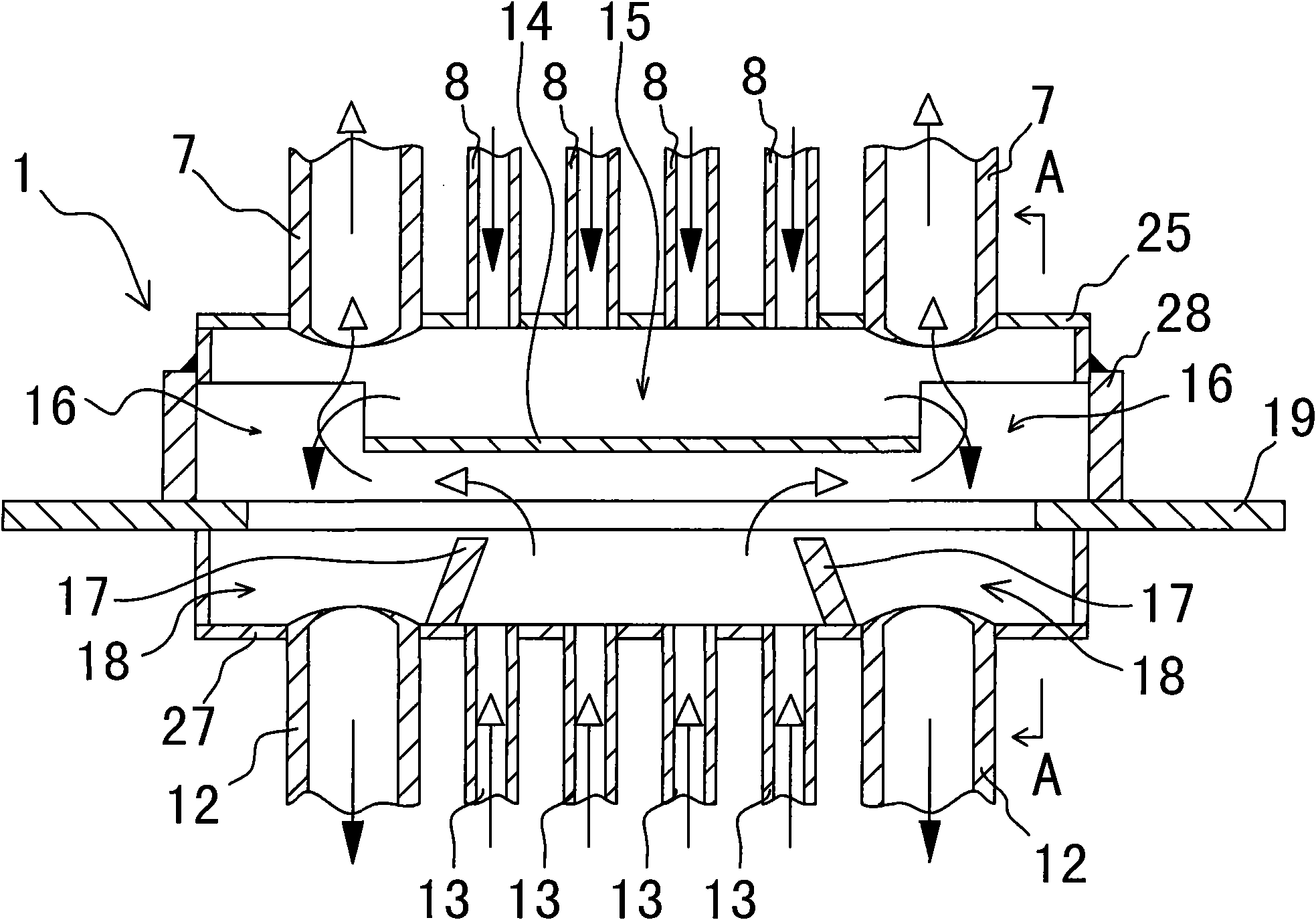

Heat exchanger for flat heat pipe

InactiveCN101556121AShort heat exchange ductIncrease the cross-sectional areaIndirect heat exchangersHeat exchanger casingsHeat pipe heat exchangerEngineering

The invention relates to a heat exchanger for a flat heat pipe, which is characterized in that the heat exchanger consists of a middle gas-liquid separation chamber, a condensation unit and an evaporation unit; the condensation unit consists of a gas collecting pipe, a condensation flat pipe group, a heat exchange plate and a gas conveying pipe; the condensation flat pipe group consists of a plurality of metal flat pipes which are connected between the gas collecting pipe and the top part of the middle gas-liquid separation chamber; the evaporation unit consists of a liquid collecting pipe, an evaporation flat pipe group, the heat exchange plate and a liquid conveying pipe; transverse baffle plates are arranged in the middle gas-liquid separation chamber and corresponding to the lower parts of pipe ends of all the metal flat pipes of the condensation flat pipe group, thereby forming a liquid guide channel by separation in the middle gas-liquid separation chamber; the periphery of the pipe end of the liquid conveying pipe arranged at the bottom part in the middle gas-liquid separation chamber is separated by a vertical baffle plate for forming a liquid storage cavity; a channel port of the liquid guide channel and the liquid storage cavity are relatively arranged at the upper and the lower parts; the condensation unit and the evaporation unit are communicated by the middle gas-liquid separation chamber and sealed to the outside as a whole, and working medium liquid is filled therein. The heat exchanger is a heat pipe structure as a whole, the packaging is more convenient, liquid and gas are further parallel, and the heat exchange efficiency is high.

Owner:苏州森光换热器有限公司

Sleeving equipment and sleeving method of profile steel and thermal shrinkage corrosion resisting jacket

ActiveCN105643254AGuaranteed packaging qualityEasy to fixMetal working apparatusMaterials scienceTractor

The invention discloses sleeving equipment and a sleeving method of profile steel and a thermal shrinkage corrosion resisting jacket, and belongs to the field of corrosion resistance. The sleeving equipment comprises inner and outer layers of clamping pipes for clamping and fixing a jacket opening of the thermal shrinkage corrosion resisting jacket, multiple Y-shaped brackets for supporting the profile steel or the thermal shrinkage corrosion resisting jacket, and a tractor for towing the profile steel to move; the tractor is used for pulling theprofile steel to insert in a pipe port of an inner-layer clamping pipe in the inner and outer layers of clamping pipes for clamping the thermal shrinkage corrosion resisting jacket; then, a heat source is used for heating the thermal shrinkage corrosion resisting jacket; and the thermal shrinkage corrosion resisting jacket tightly wraps the profile steel. According to the sleeving equipment,operators can be liberatedfrom highlabor intensity, the sleeving speed of the profile steel and the thermal shrinkage corrosion resisting jacketcan be accelerated, andthe sleeving quality of the thermal shrinkage corrosion resisting jacket and the production safety can be guaranteed.

Owner:ANYANG LONGTENG SPECIAL STEEL MFG

Material-pushing and box-packing device

ActiveCN103086006AGuaranteed packing qualityImprove packing efficiencyPackaging bottlesSprocketEngineering

The invention discloses a material-pushing and box-packing device. The material-pushing and box-packing device comprises a cam box, a guide rail box body and an execution mechanism, wherein the cam box comprises a large cam and a small cam which are coaxially connected; and a chain wheel and an input shaft which are arranged on one side of the cam box are used for transmitting power to the large cam and the small cam; the guide rail box body is fixed on the cam box; and the execution mechanism comprises a placement mechanism for pushing a product into a paper box and a U-shaped block for clamping an opening of the paper box. By the material-pushing and box-packing device, a specification and the product are simultaneously pushed into the box, and the U-shaped block can prevent the product from returning together with a product warehouse-entry pushing block, so that the box-packing quality is guaranteed; and a cam mechanism can rotate at a high speed so that the box-packing efficiency is greatly increased.

Owner:SHANGHAI KINGSUN PACKING MACHINERY

Full-automatic detection and packaging system for circular dinner plate and detection and packaging method

PendingCN110861811AImprove securityImprove efficiencyPackaging automatic controlPackaging machinesProcess engineeringManufacturing line

The invention discloses a full-automatic detection and packaging system for a circular dinner plate. The full-automatic detection and packaging system comprises a circular dinner plate full-automaticdetection packaging production line and a boxing packaging production line, wherein the circular dinner plate full-automatic detection packaging production line comprises a control box, a circular dinner plate splitting and feeding device, a weighing device, a dust removal device, a disinfection device, a visual detection device, an automatic stacking device and a packaging bag automatic packing device. The invention further discloses a detection and packaging method. According to the full-automatic detection and packaging system, the procedures of automatic sorting separation feeding, weighing detection, dust removal treatment, disinfection treatment, appearance detection, unqualified and qualified product sorting and qualified product automatic bagging packaging and boxing are integrated, the detection packaging efficiency and the product detection qualification rate are improved, the labor intensity of workers is reduced, the hygiene standards of products is improved, and the follow-up use of the products can be ensured; and the system can be used for detecting and packaging of the products with various specifications, the applicability is high, and the requirements of existingautomation and high-precision detection and packaging can be met.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST +1

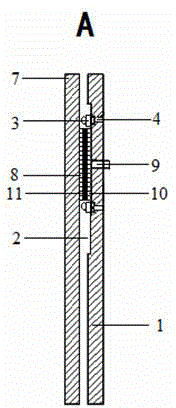

Laser bonding temperature acquisition system for photoelectric device packaging and method for photoelectric device packaging

ActiveCN102865939AEasy to measureSimple structureThermometers using electric/magnetic elementsSolid-state devicesLaser bondingEngineering

The invention discloses a laser bonding temperature acquisition system for photoelectric device packaging, which comprises a temperature sensor and locating elements thereof, wherein the locatingelements comprise a fixed-position locating element and a variable-position locating element; the temperature sensor, which is used for fixed point temperature measurement, of the fixed-position locating element is fixed onto a corresponding position corresponding to a glass sealing strip, and is used for testing fixed point temperature of the glass sealing strip; a movable part of the variable-position locating element is fixedly connected with other temperature sensors, so that the temperature sensors are limited to move along the periphery of the glass sealing strip; and temperature testing on different points of the glass sealing strip is realized through controlling positions of test points of the temperature sensor. The invention discloses a method for photoelectric device packaging, and through carrying out real-time fixed point temperature acquisition and real-time non-fixed point temperature acquisition on temperature of the glass sealing strip, the output power, the laser beam movement speed and the direction of a laser are controlled. According to the invention, the temperatures at different positions of glass material bonding parts can be simply and conveniently measured in real time, the structure is simple, and the efficiency is high.

Owner:SHANGHAI UNIV

Edible oil filling equipment capable of preventing oil leakage

InactiveCN108640071AExactly fall intoLoading and unloadingSafety device in filling machineryResidual oilEngineering

The invention relates to edible oil filling equipment capable of preventing oil leakage. The edible oil filling equipment comprises a base, a main body, a conveying belt, a material box, a controllerand two adjusting mechanisms; the main body is provided with a concave opening, a lifting mechanism, a filling opening and a conveying pipe; an anti-leakage mechanism comprises a stretchable assembly,a dual-rectangular-shaped frame and an anti-leakage box, side plates are arranged on the four sides of the anti-leakage box, through holes are formed in the side plates, and protruding rods are arranged on the four sides of the dual-rectangular-shaped frame; and each adjusting mechanism comprises a vertical plate, a fixing plate, an excursion plate, two excursion assemblies and two fixing assemblies, and each fixing assembly comprises a first motor, a first driving shaft and a sleeve. According to the edible oil filling equipment capable of preventing oil leakage, the anti-leakage box receives residual oil drops falling from the filling opening through the anti-leakage mechanism, the oil drops are prevented from influencing cleanliness of the conveying belt and a bottle body, and the packaging quality is guaranteed; and in addition, the adjusting mechanisms are used for adjusting the position of the bottle body, a bottle opening aligns at the filling opening, edible oil can conveniently and accurately fall into the bottle body, filling is completed, and the equipment practicability is improved.

Owner:南安市执力信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com