Energy saving and environment protecting type full-automatic canned tea packaging machine

An energy-saving, environment-friendly and fully automatic technology, which is applied in packaging, transportation and packaging, and special packaging objects, etc., can solve the problems of inability to use canned tea packaging, low application rate, and inability to use tea packaging, etc., to achieve fully automated continuous production , The overall structure is compact and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

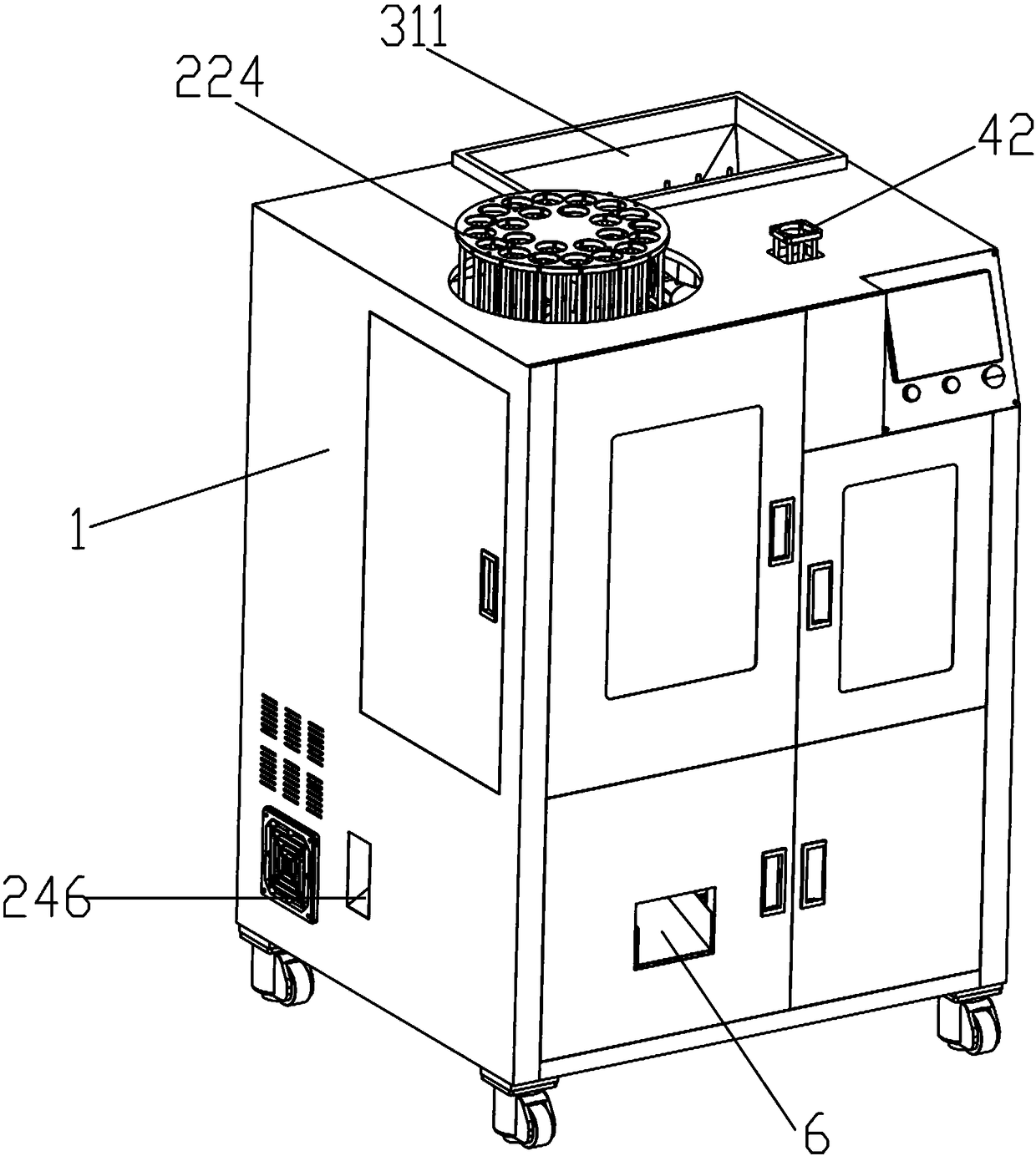

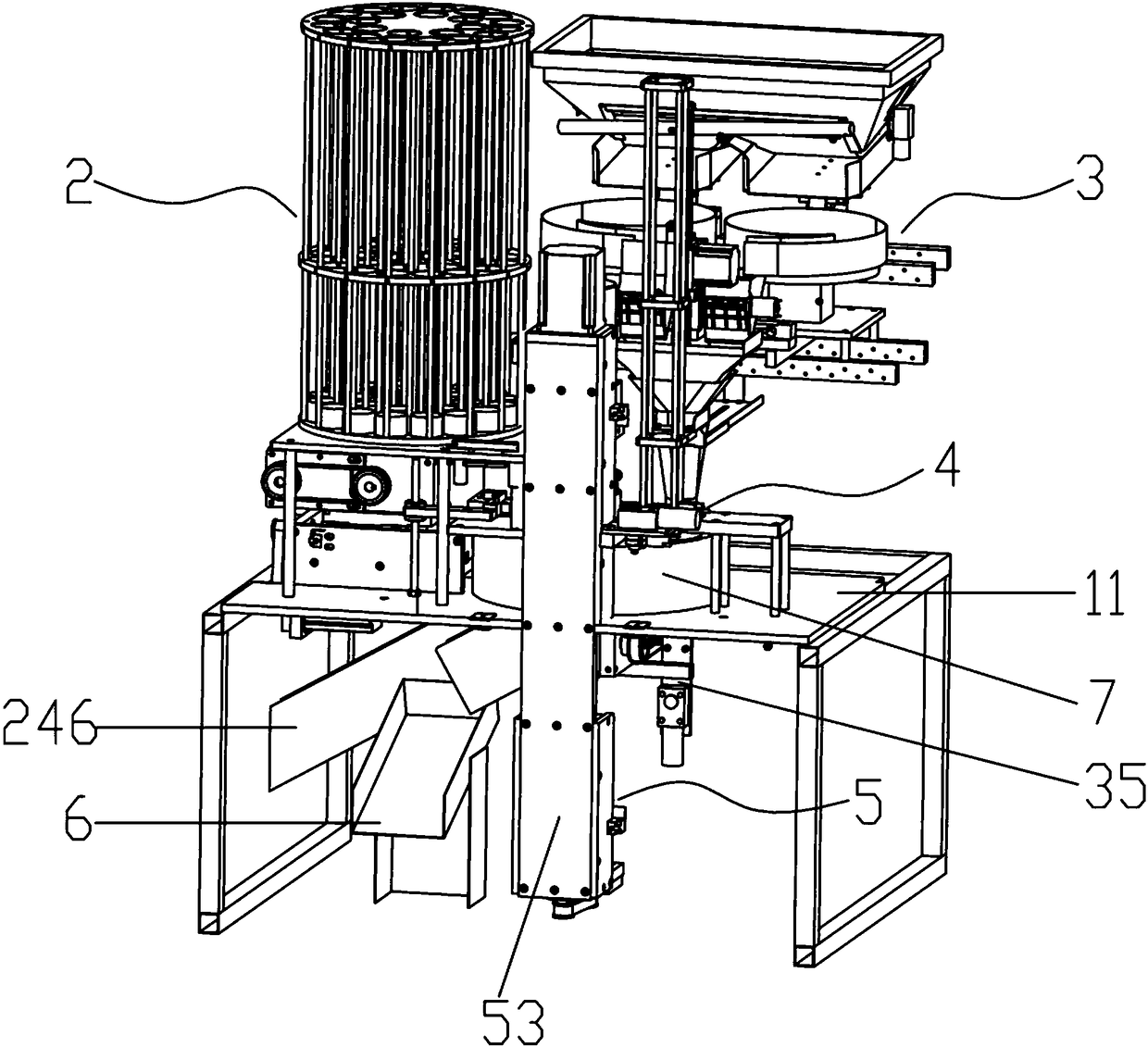

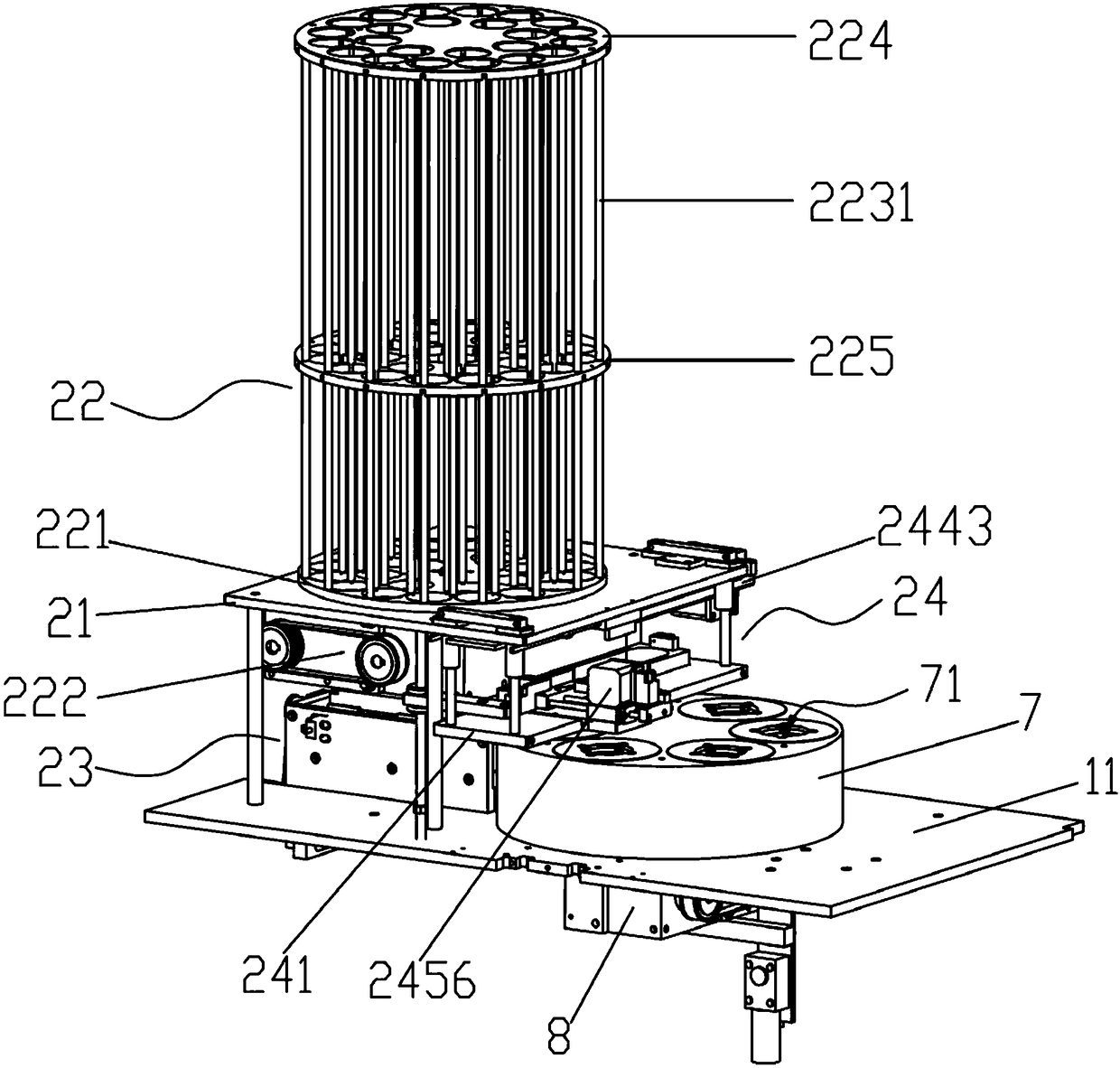

[0037] see Figures 1 to 15 , is an energy-saving and environment-friendly fully automatic canned tea packaging machine as the best embodiment of the present invention, which is used to pack tea into packaging cans and seal the cans. It includes a cabinet 1, and a worktable is horizontally arranged in the middle of the cabinet 1 11. A turntable 7 is provided on the worktable 11, and the lower end surface of the turntable 7 is slidingly connected with the upper end surface of the worktable 11. The first divider assembly 8 is installed under the workbench 11. The first divider assembly The output shaft of 8 passes through the worktable 11 and connects with the center of the turntable 7, and drives the turntable 7 to rotate intermittently. The output shaft corresponding to the first divider assembly 8 on the worktable 11 has a shaft hole 111, and the turntable 1 7 is provided with at least five tank cavities 71 evenly distributed around its central circumference, the tank cavitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com