Operation method of steel pipe hydraulic-type lifting blanking device

An operation method and hydraulic cylinder technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems affecting product quality and service life, damage to the plastic-coated layer on the surface of the steel pipe, and easy damage to the plastic-coated layer, so as to reduce labor Manual operation, reduced labor intensity, and the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

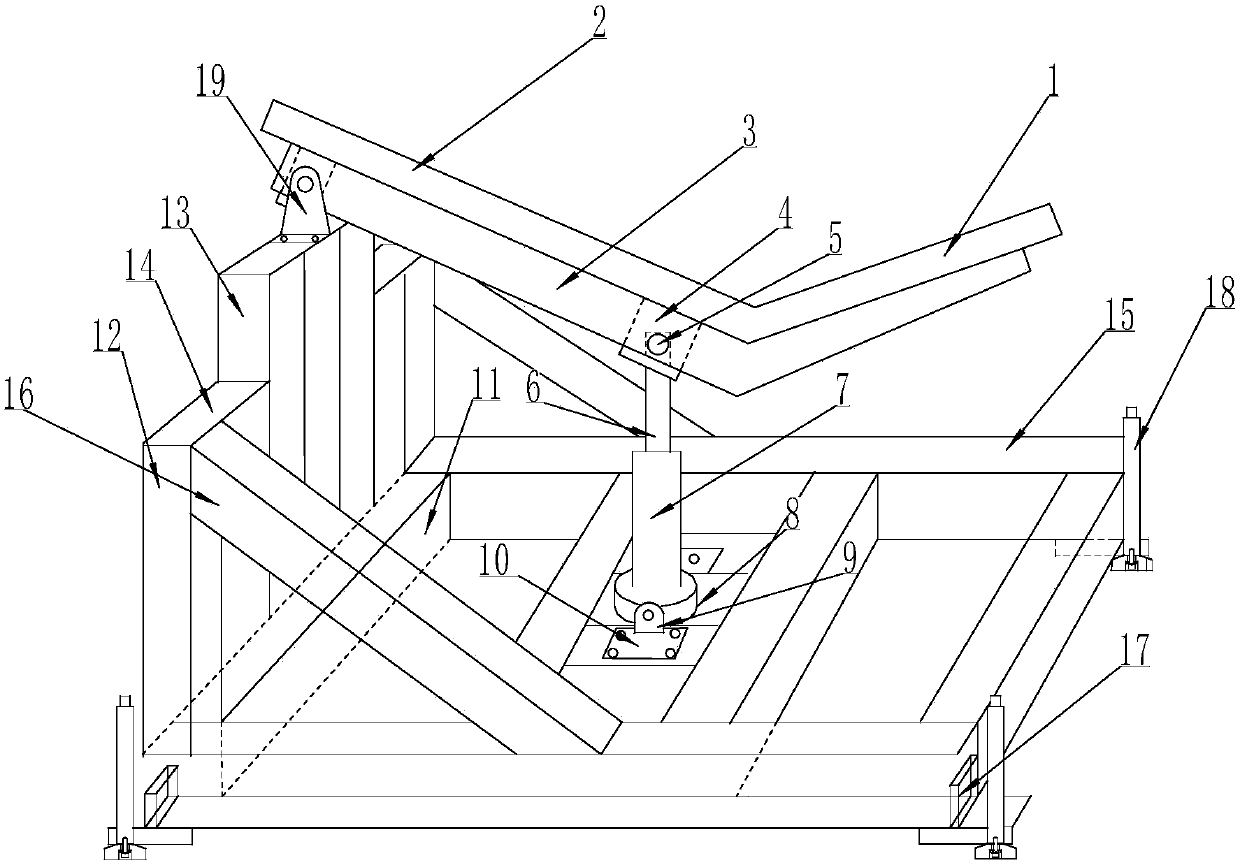

[0016] The structure of the base is: a pair of parallel base long rods 15 are vertically arranged at the two ends of four parallel base short rods 11, and two base long rods 15 and two base short rods 11 at the two ends of the base long rods 15 form a rectangular frame. , the bottom of the four corners of the rectangular frame is provided with an inverted T-shaped fixing seat 17, and one side of the horizontal plate of the fixing seat 17 is provided with holes, and the anchor screws 18 pass through the holes on the fixing seat 17, and the two sides of the rectangular frame are Two base short vertical bars 12 are vertically set above the two angles, two base long vertical bars 13 are vertically set on the base short bar 11 between the two base short vertical bars 12, two base short vertical bars 12 and two bases The long vertical bars 13 are parallel to each other, the base cross bar 14 is set between the base short vertical bar 12 upper ends and the base long vertical bar 13, t...

Embodiment 2

[0021] An operation method of a steel pipe hydraulic cylinder type lifting and unloading device, the base is adjusted to be parallel to the horizontal plane through the anchor screw 18, and the height of the base is adjusted through the anchor screw 18 at the same time, and the distance between the long arm 2 and the short arm 1 is adjusted according to the diameter of the steel pipe angle, the piston rod 6 on the hydraulic cylinder 7 drives the lifting arm to rotate along the pin shaft 5 at the upper end of the lifting arm, and the piston rod 6 on the hydraulic cylinder 7 drives the lifting arm to descend, thereby adjusting the lifting arm to a suitable height. The shelf rolls slowly along the short arm 1 to the bend of the lifting arm. After the steel pipe stops, the piston rod 6 on the hydraulic cylinder 7 drives the lifting arm up. When the vertex of the angle between the long arm 2 and the short arm 1 When the horizontal line was higher than the horizontal line of the uppe...

Embodiment 3

[0023] The included angle between the short arm 1 and the long arm 2 is 120-150°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com