Transformer automatic machining production device

A production device and transformer technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high defective rate, low degree of automation, low continuous production efficiency of transformer production process, etc., to reduce labor costs , Improve the degree of automation, and realize the effect of fully automated continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

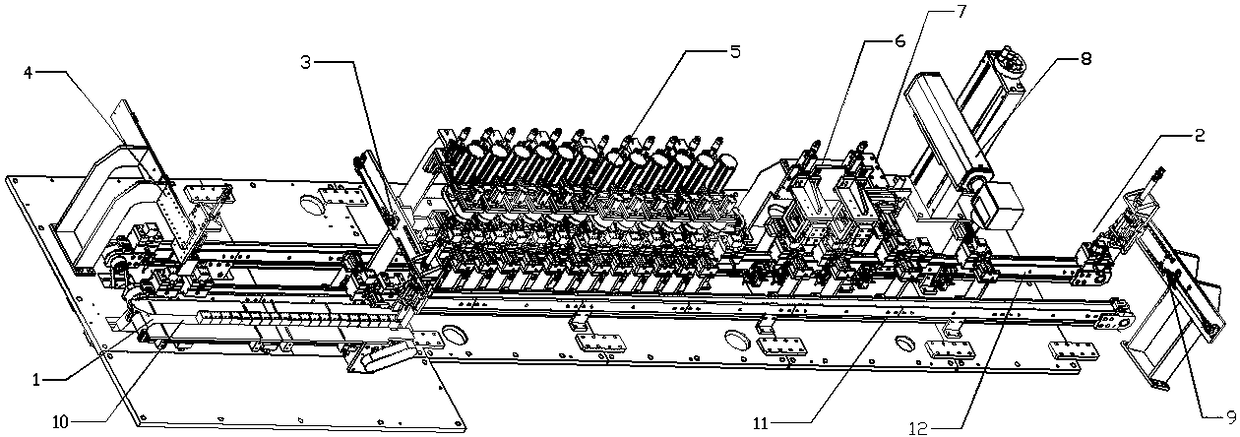

[0054] An automatic processing and production device for transformers includes a shaping section and a testing section.

[0055] The shaping section includes a first transmission mechanism, a first transfer mechanism, a foot cutting mechanism 5 , a foot trimming mechanism 6 , an overturning mechanism 7 and a coding mechanism 8 .

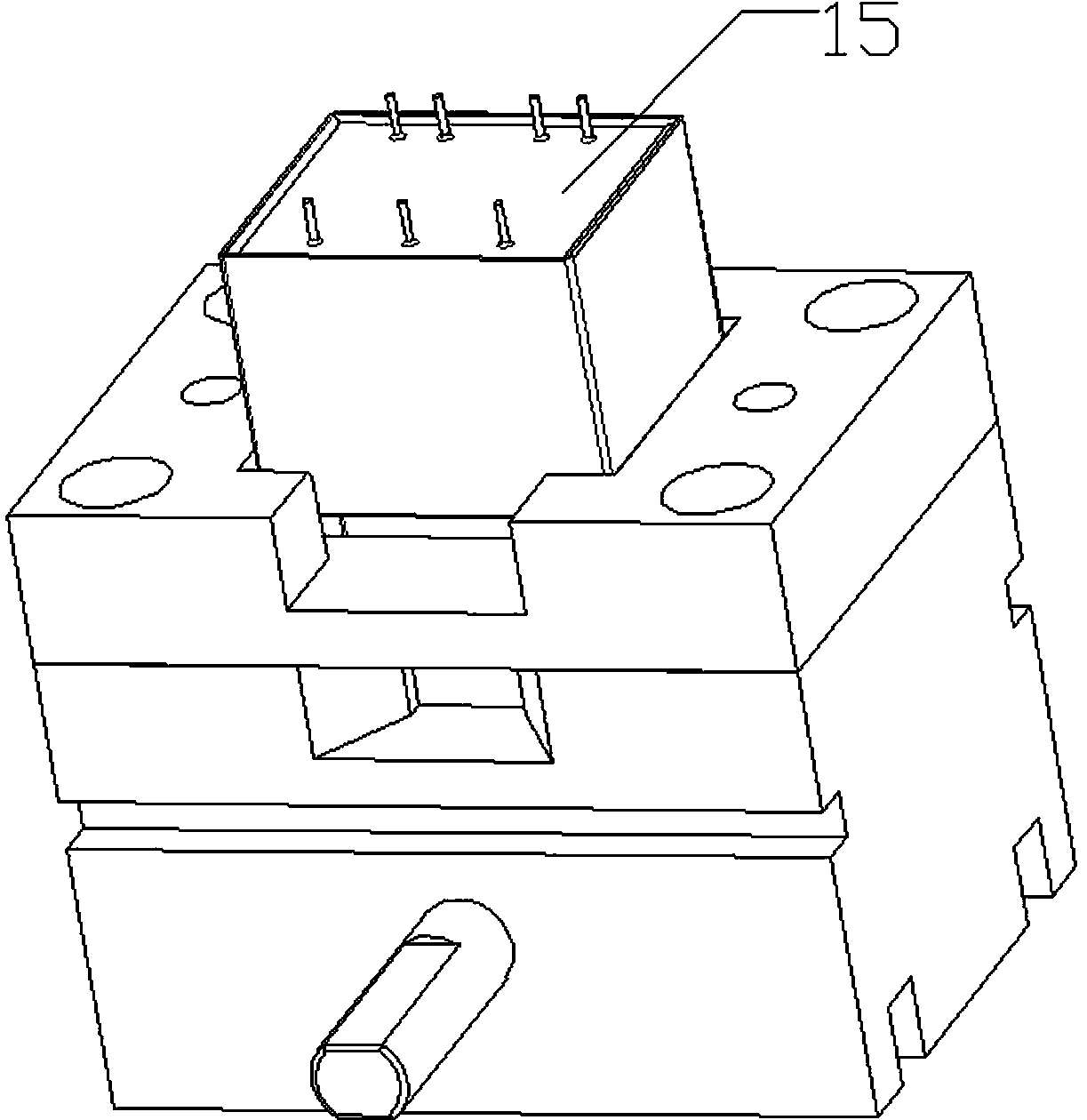

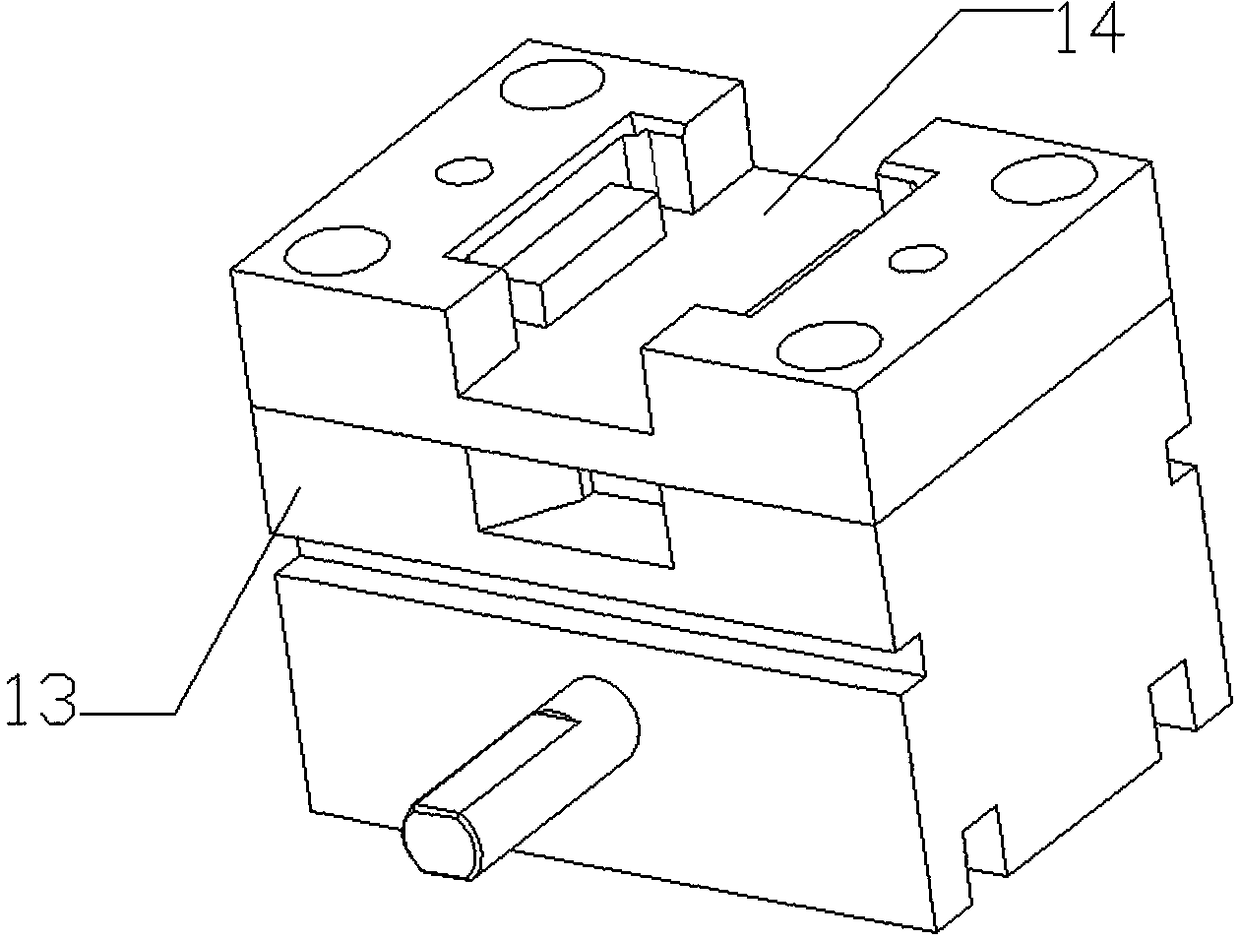

[0056] The first conveying mechanism comprises a transformer bracket 13, a first entrance 1, a first conveyor belt 10, a second conveyor belt 11, a third conveyor belt 12 and a first outlet 2; the transformer 15 is placed on the upper part of the transformer bracket 13 in slot 14. The first conveyor belt 10, the second conveyor belt 11 and the third conveyor belt 12 are parallel to each other. The first inlet 1 is located at the front end of the first conveyor belt 10 , and the first outlet 2 is located at the end of the third conveyor belt 12 .

[0057] The first transfer mechanism includes a first manipulator 3 , a second manipulator 4 and a thir...

Embodiment 2

[0070] The difference between this embodiment and Embodiment 1 is that the first manipulator 3 includes a bracket 21 , a horizontal rail 22 , a vertical rail 23 and a small clamp 25 . Both the second manipulator 4 and the third manipulator 9 include a bracket 21 , a horizontal rail 22 , a vertical rail 23 and a large clamp 24 . The sixth manipulator 45 includes a support 21 , a horizontal rail 22 , a vertical rail 23 and a large clamp 24 . Both the fourth manipulator 43 and the fifth manipulator 44 include a bracket 21 , a horizontal rail 22 , a vertical rail 23 and a small clamp 25 . The seventh manipulator 35 includes a bracket 21 , a horizontal rail 22 , a vertical rail 23 and a small clamp 25 .

Embodiment 3

[0072] The difference between this embodiment and Embodiment 1 is that: the foot-cutting mechanism 5 includes several foot-cutting units, and the foot-cutting units include a foot-cutting motor 16 and a foot-cutting cutter 17 . The foot-shearing mechanism 5 includes a front-section foot-shearing unit and a rear-section foot-shearing unit. The front-section foot-shearing unit and the rear-section foot-shearing unit are on two parallel lines, and the distance between them is the distance between two rows of wires of the transformer 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com