Sleeving equipment and sleeving method of profile steel and thermal shrinkage corrosion resisting jacket

A technology of heat shrinkage and sheathing, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as safety hazards and low production efficiency, and achieve the effects of ensuring safe production, reducing energy consumption, and ensuring the quality of suits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

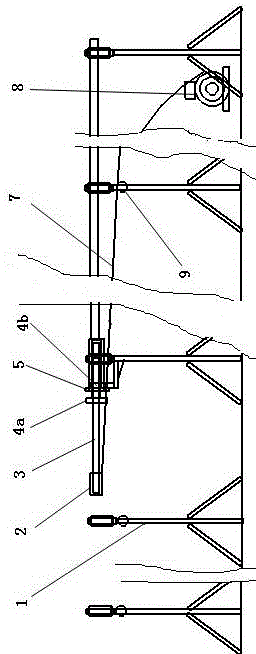

[0031] The technical solution of the present invention is a set of equipment for heat-shrinkable anti-corrosion sheath of section steel, figure 1 It is a structural schematic diagram when implementing the present invention. The set equipment includes clamping and fixing the inner and outer layers of the heat-shrinkable anti-corrosion sheath 9, clamping pipe fittings 4, supporting steel 3 or multiple "Y"-shaped brackets 1 for the heat-shrinkable anti-corrosion sheath 9, and a tractor for pulling the steel 3 to move 7. In the embodiment, the tractor 7 utilizes a small winch.

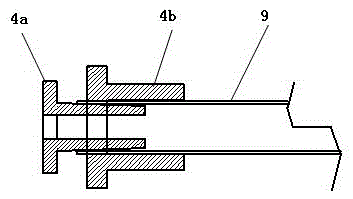

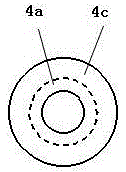

[0032] figure 2 It is a schematic diagram of clamping the heat-shrinkable anti-corrosion sheath by the inner and outer layer clamping pipe fittings. In the inner layer clamping pipe fitting 4a and the outer layer clamping pipe fitting 4b of the inner and outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com