Patents

Literature

242results about How to "Exactly fall into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-automatic noodle cooking machine and application method thereof

ActiveCN103750082AReasonable structureDesign scienceCooking vesselsDough extruding machinesEngineeringMechanical engineering

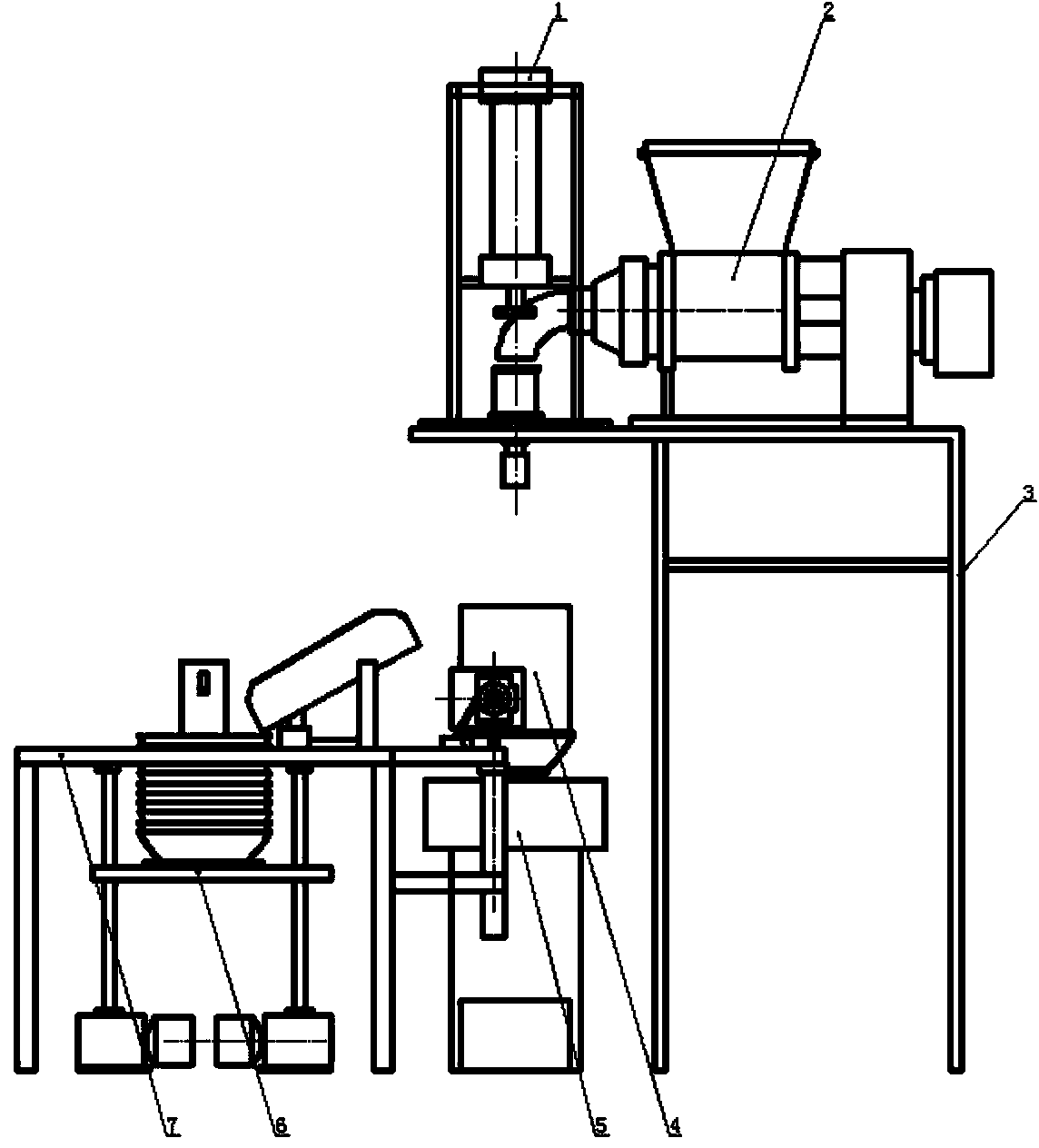

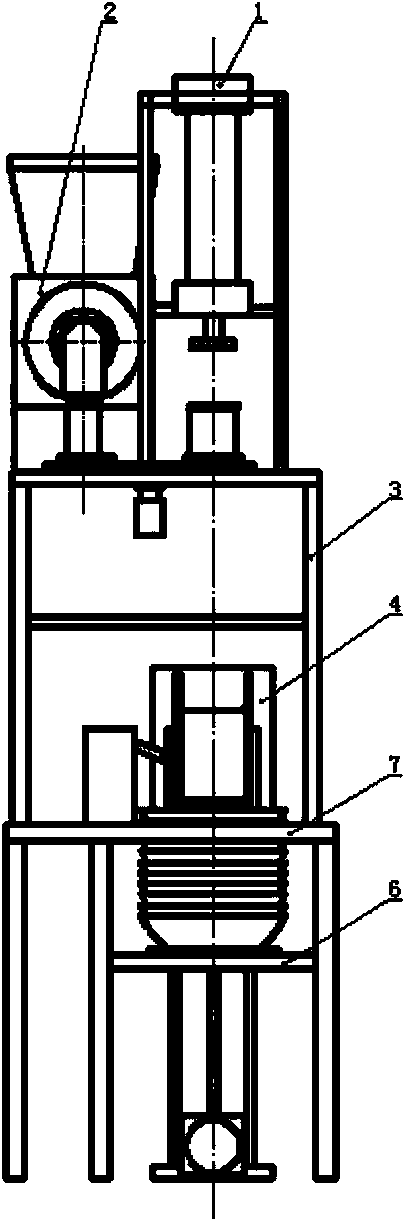

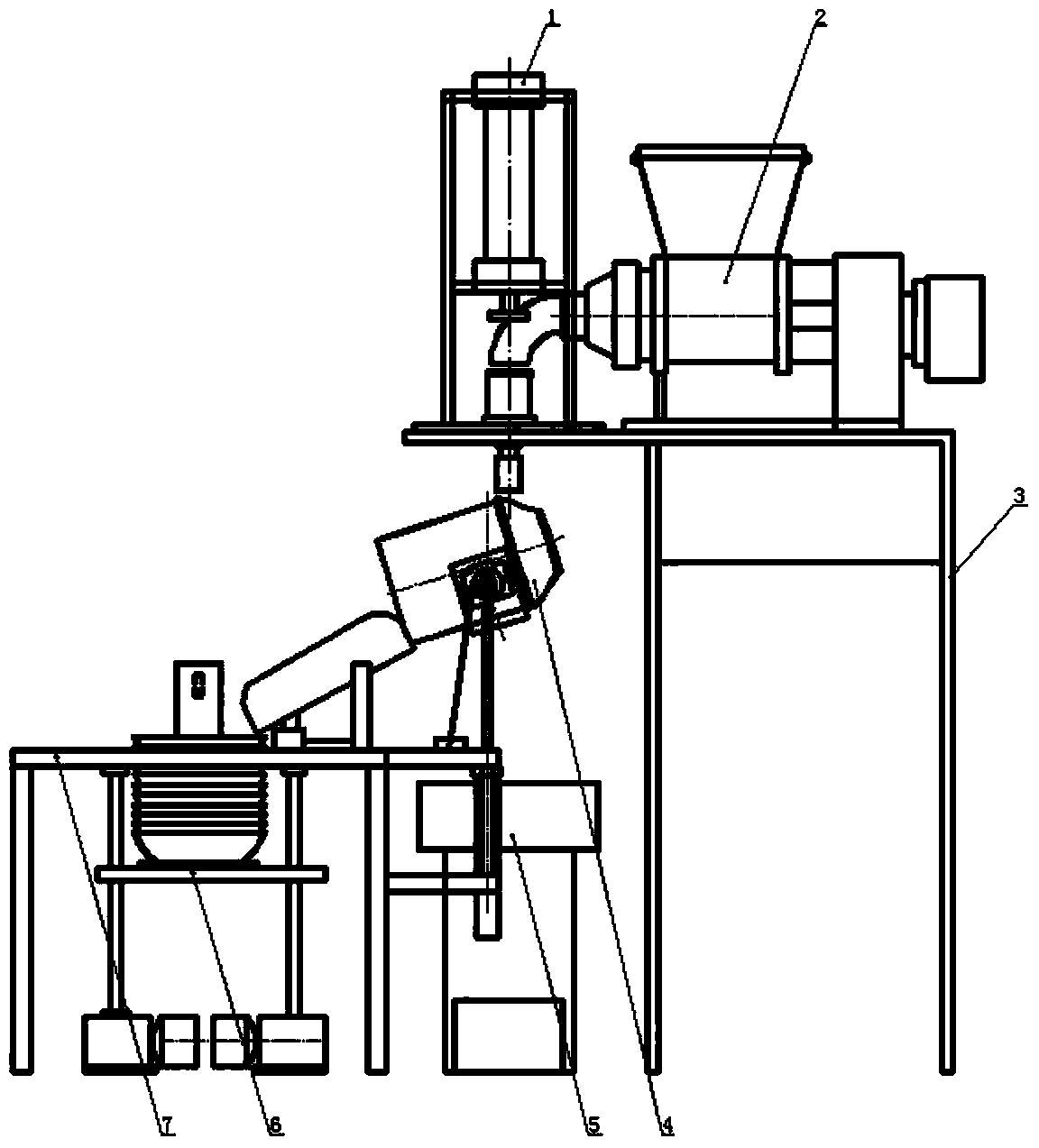

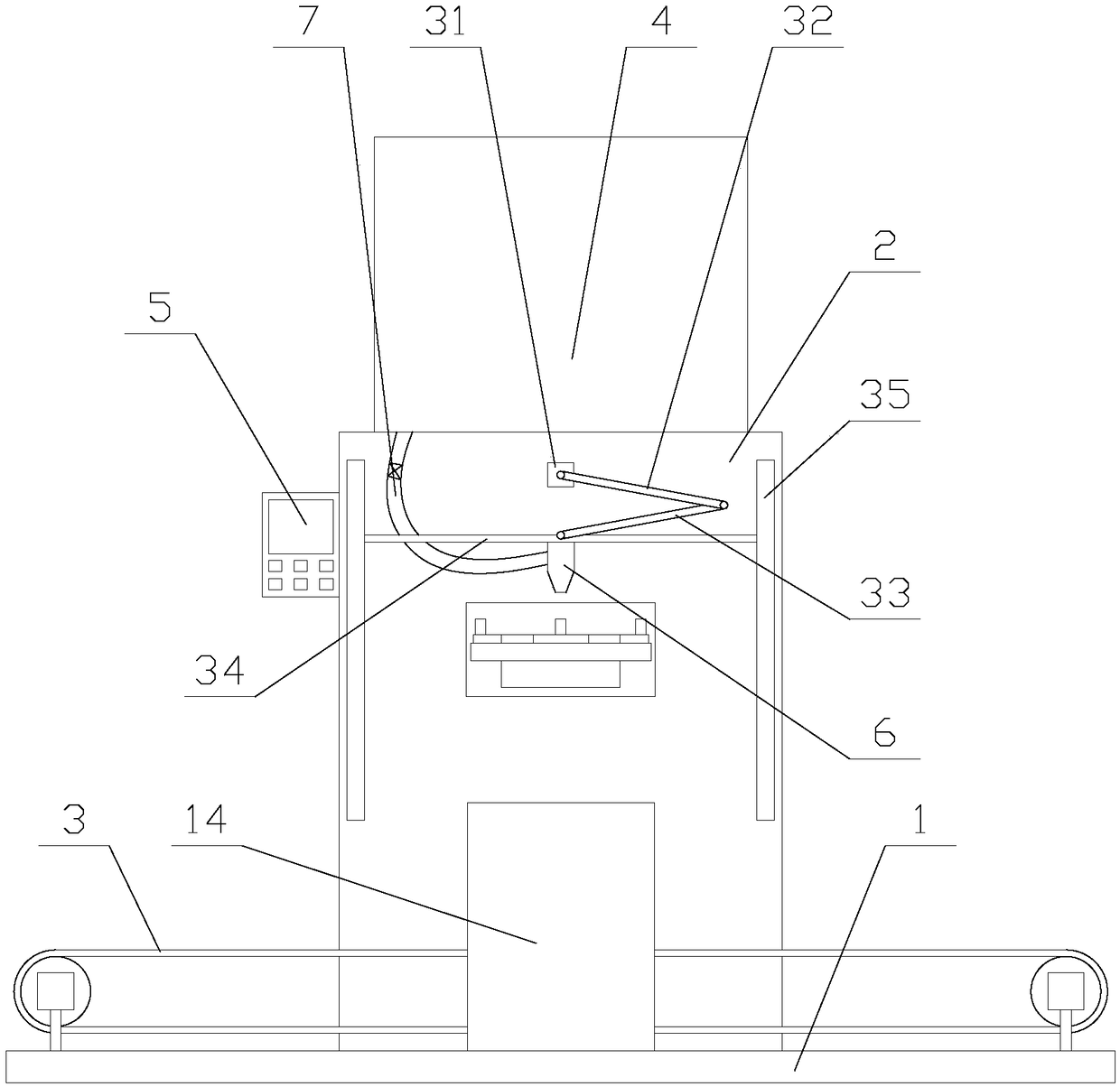

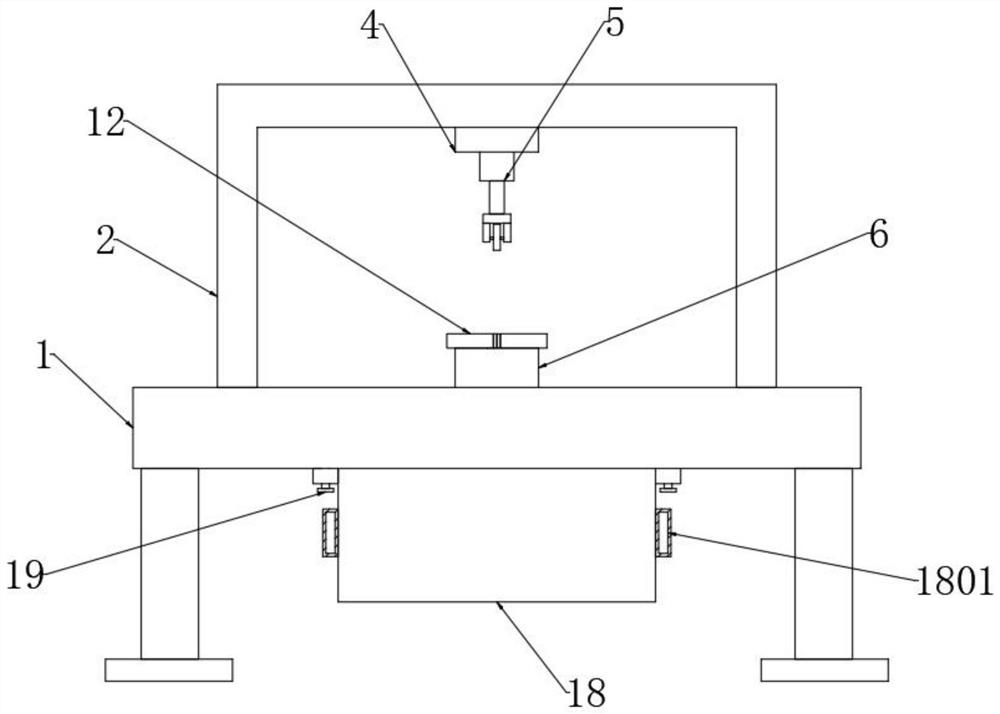

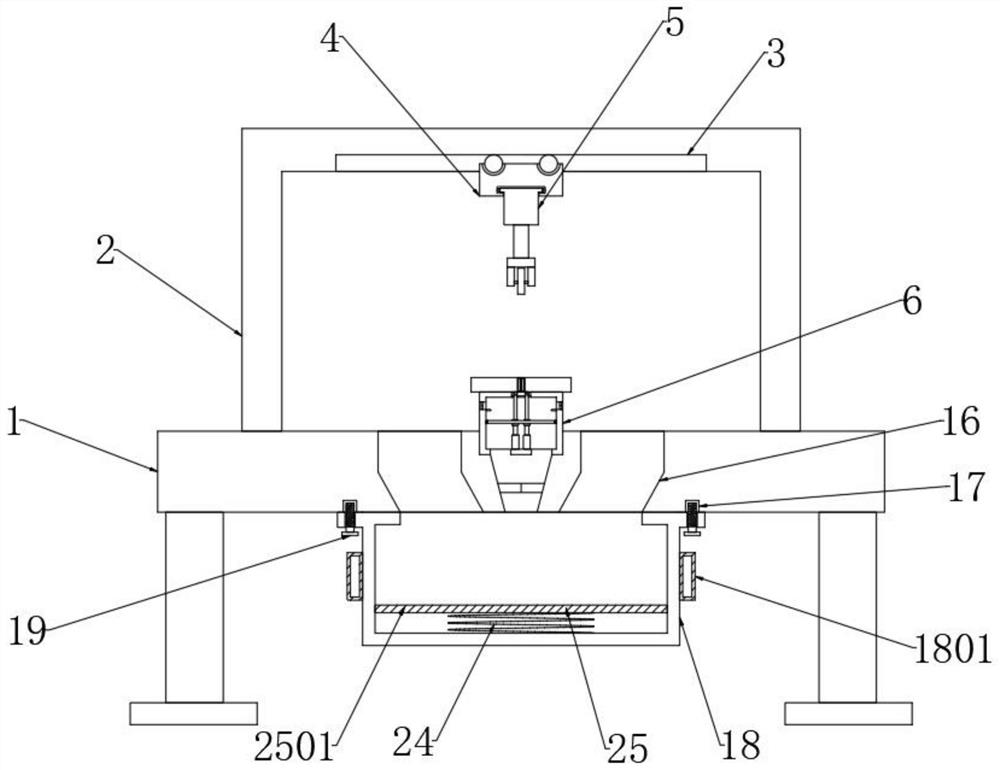

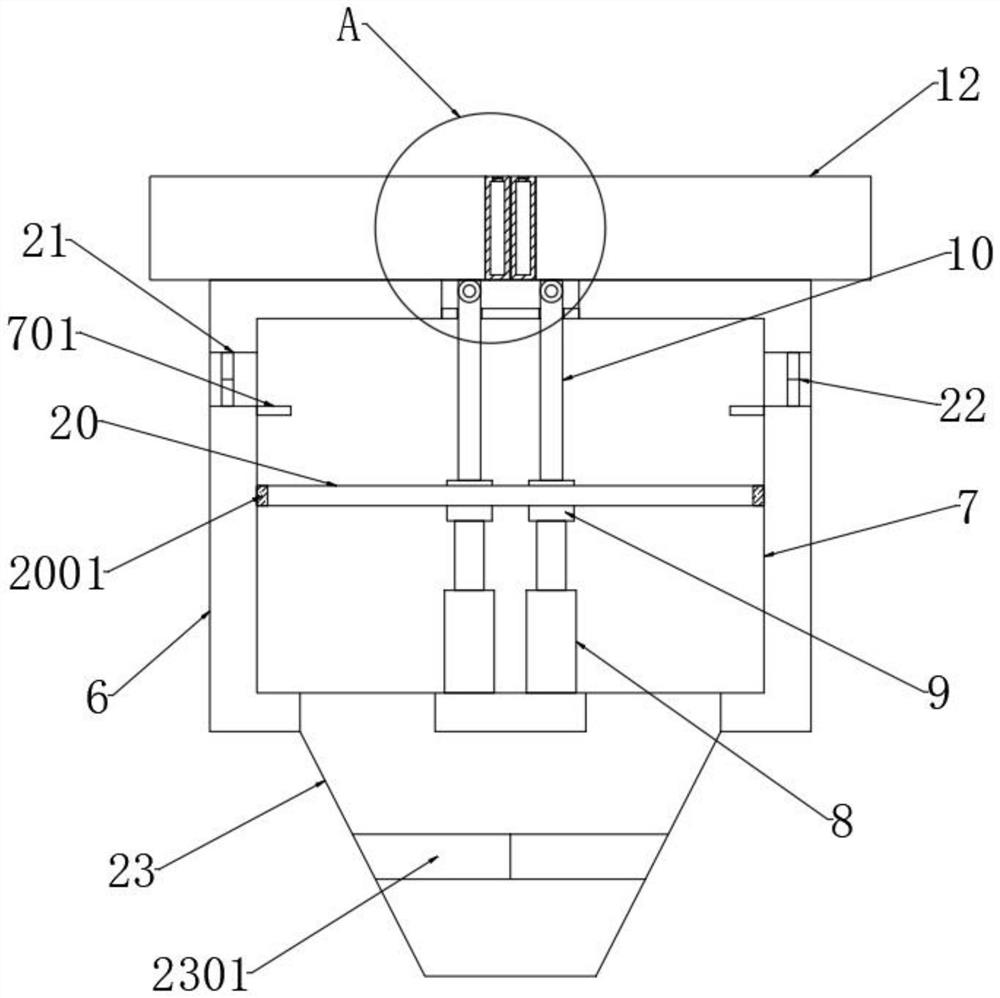

The invention relates to a full-automatic noodle cooking machine and an application method thereof. The full-automatic noodle cooking machine comprises a dough kneading device, a dough pressing device, a hopper, a noodle cooking furnace, a worktable and a hoisting supporting frame, wherein the dough kneading device and the dough pressing device are mounted on the bracket; the dough kneading device, the dough pressing device, the hopper, the noodle cooking furnace and the worktable are sequentially mounted; the hoisting supporting frame is mounted in the middle below the workable; the hoisting supporting frame is used for supporting a plurality of noodle bowls for containing noodles and is driven by a worm and worm rod structure to be hoisted. The whole process is finished by a full-automatic machine and a worker only needs to set the time of each step through a controller; the worker does not need to contact noodles from the step of putting flour to the step of forming the noodles, so that a noodle processing process is safe and sanitary and the food health is guaranteed.

Owner:于敬伟

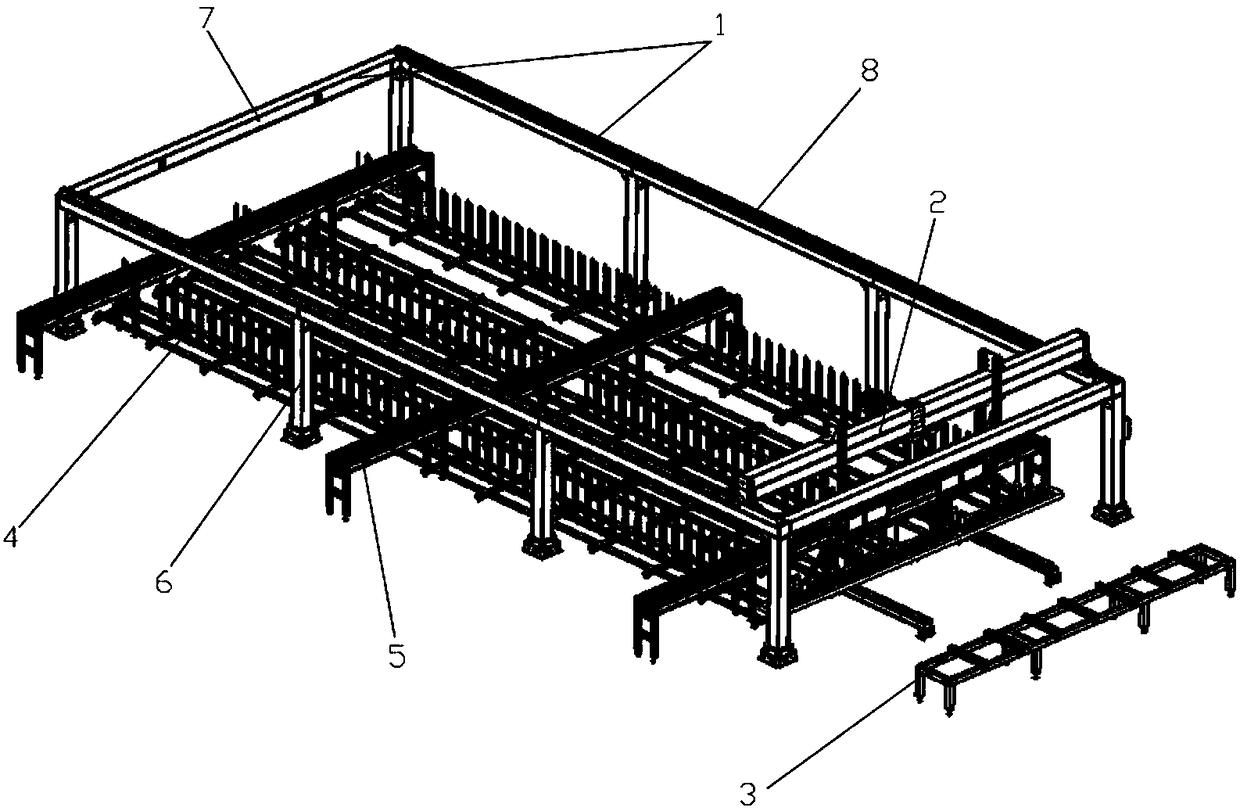

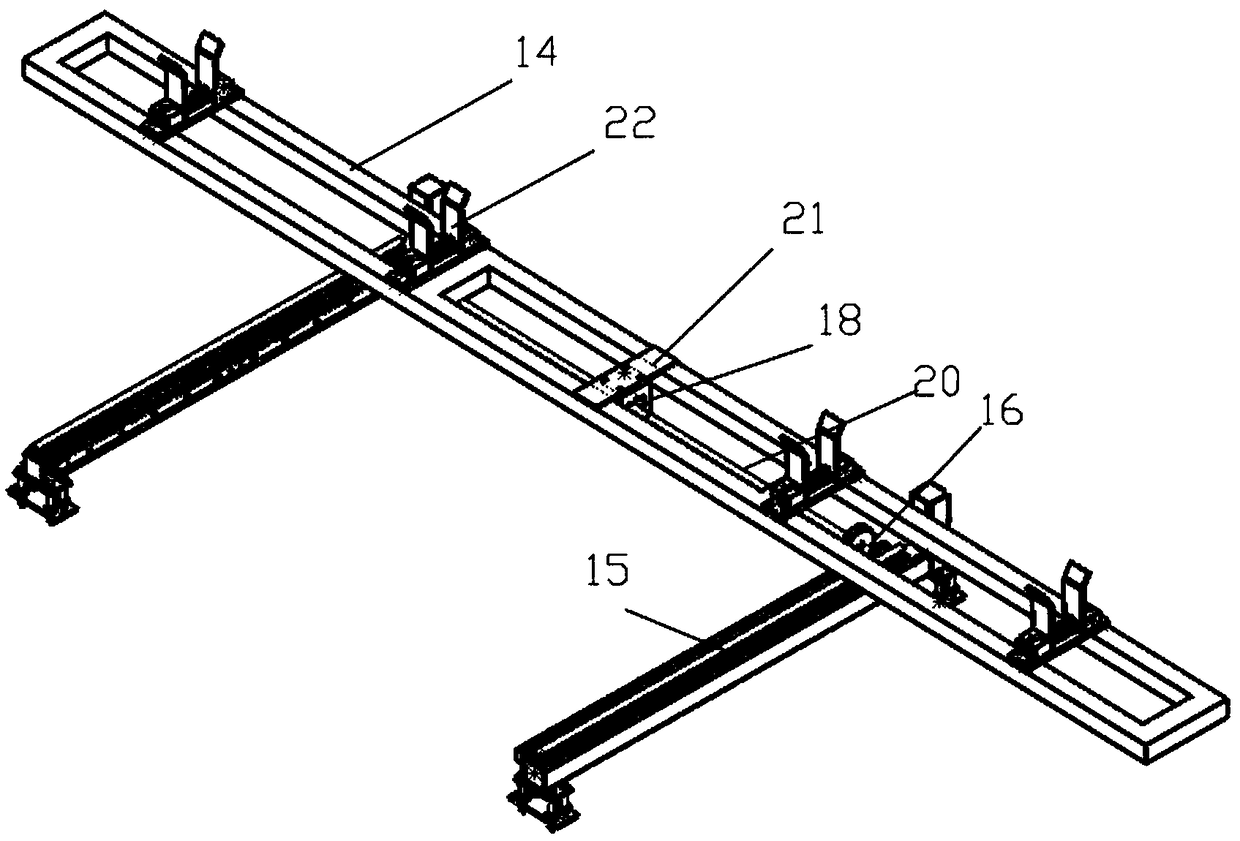

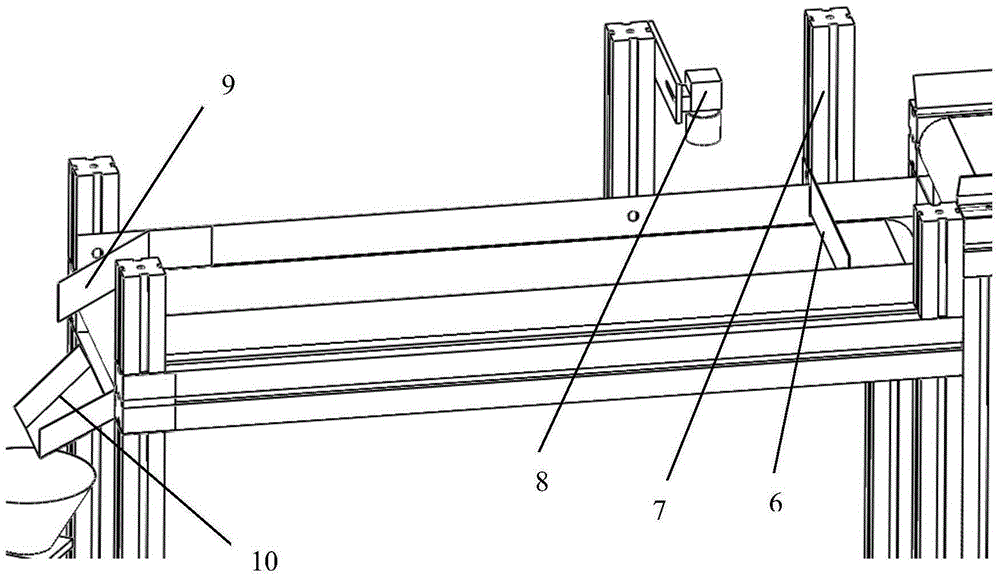

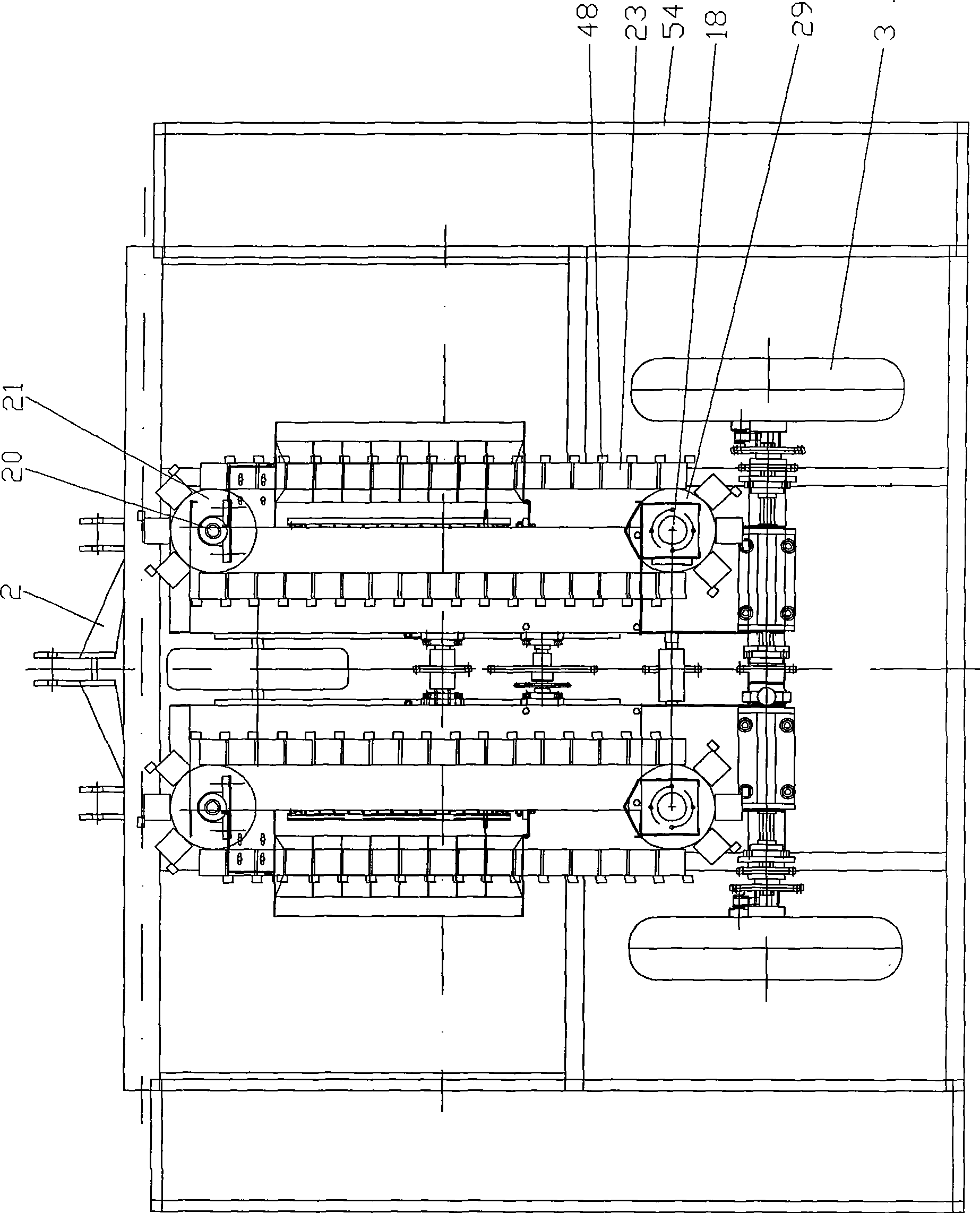

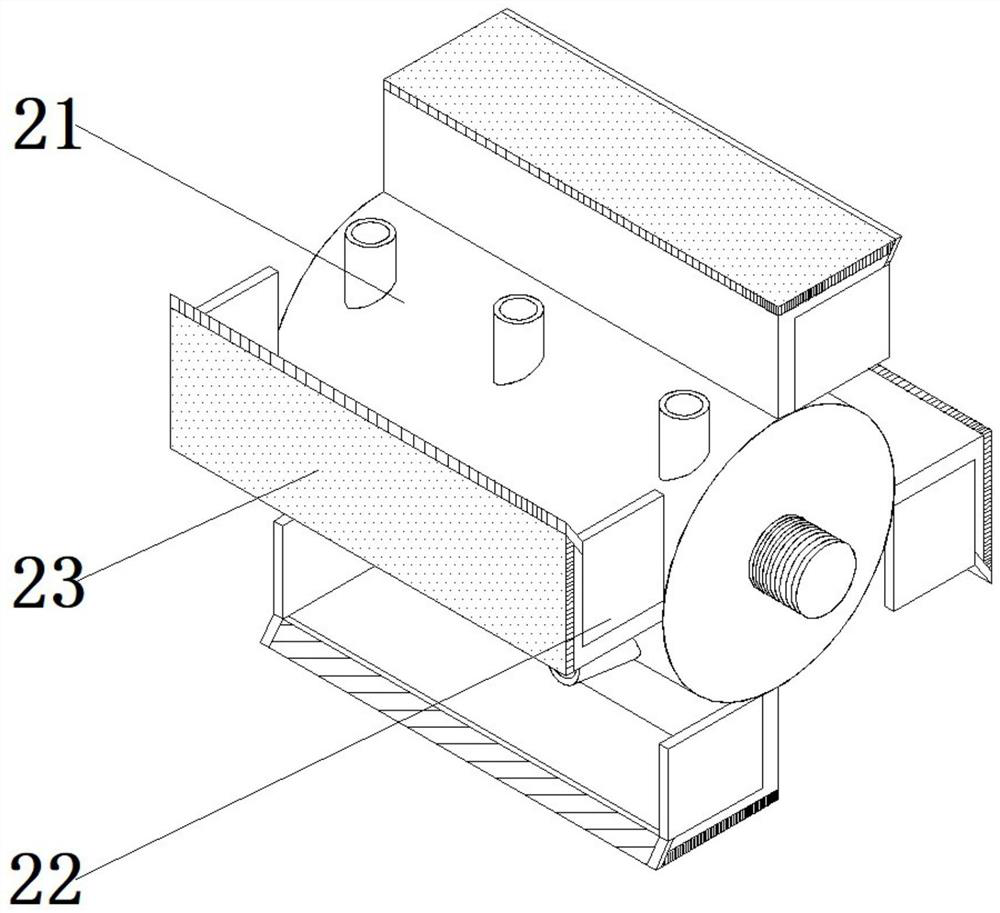

Copper bar automatic plane warehouse and copper bar integrated production line

PendingCN108249119ASmooth transferRealize automatic loading and unloading functionOther manufacturing equipments/toolsMechanical conveyorsProduction lineEngineering

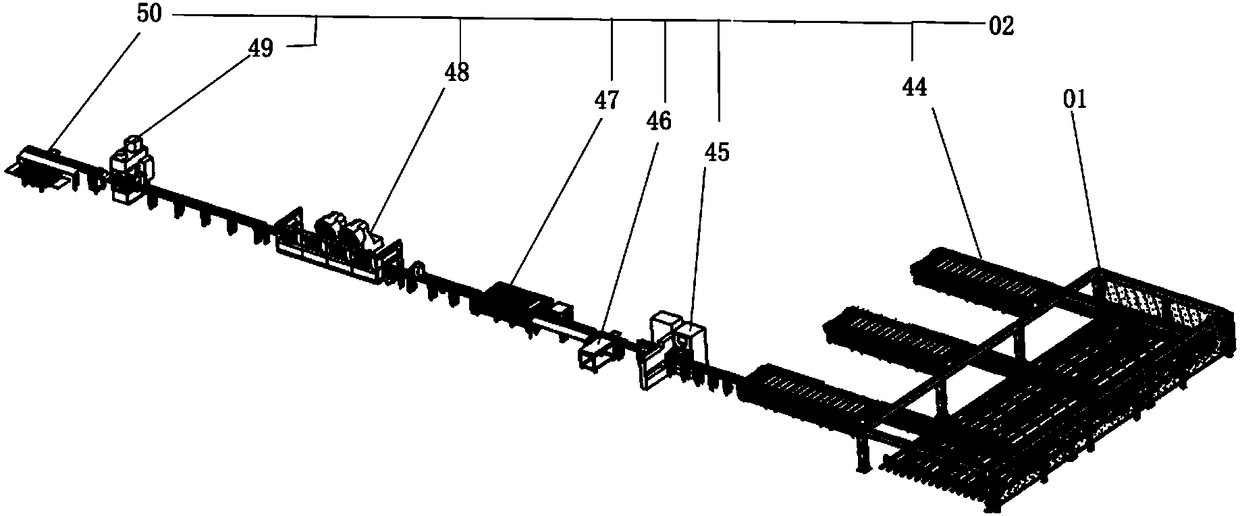

The invention relates to a copper bar production technology, in particular to copper bar automatic plane warehouse and copper bar integrated production line which achieves automatic storage, automaticfeeding, automatic production and automatic discharge for copper bars. The production line comprises a copper bar automatic plane warehouse and a copper bar automatic production line. A copper bar warehouse outer frame comprises stand columns, a beam and a linear guide rail, the stand columns are installed on the ground, the beam is connected with the stand columns on the two sides, the linear guide rail is installed on the stand column, each copper bar warehouse location comprises a copper bar warehouse location frame and multiple limiting columns, the copper bar warehouse location is arranged inside the copper bar warehouse outer frame, the multiple limiting columns are installed on the copper bar warehouse location frame, a copper bar discharge conveying line is also arranged in the copper bar warehouse outer frame and penetrates through multiple copper bar warehouse locations, the copper bar discharge conveying line comprises a copper bar discharge conveying frame, a copper bar discharge motor and a conveying belt wheel, and the copper bar discharge motor is installed on the copper bar discharge conveying frame and is in linkage with the conveying belt wheel.

Owner:JIANGSU SENLAN INTELLIGENCE SYST CO LTD

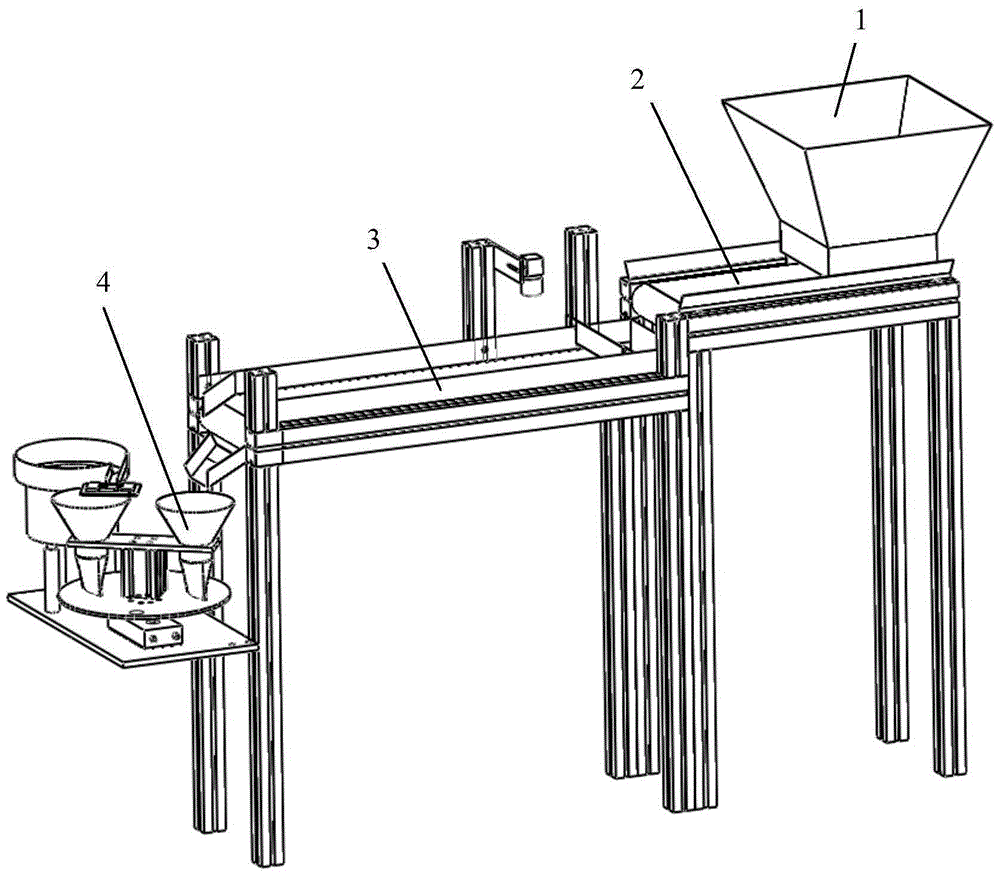

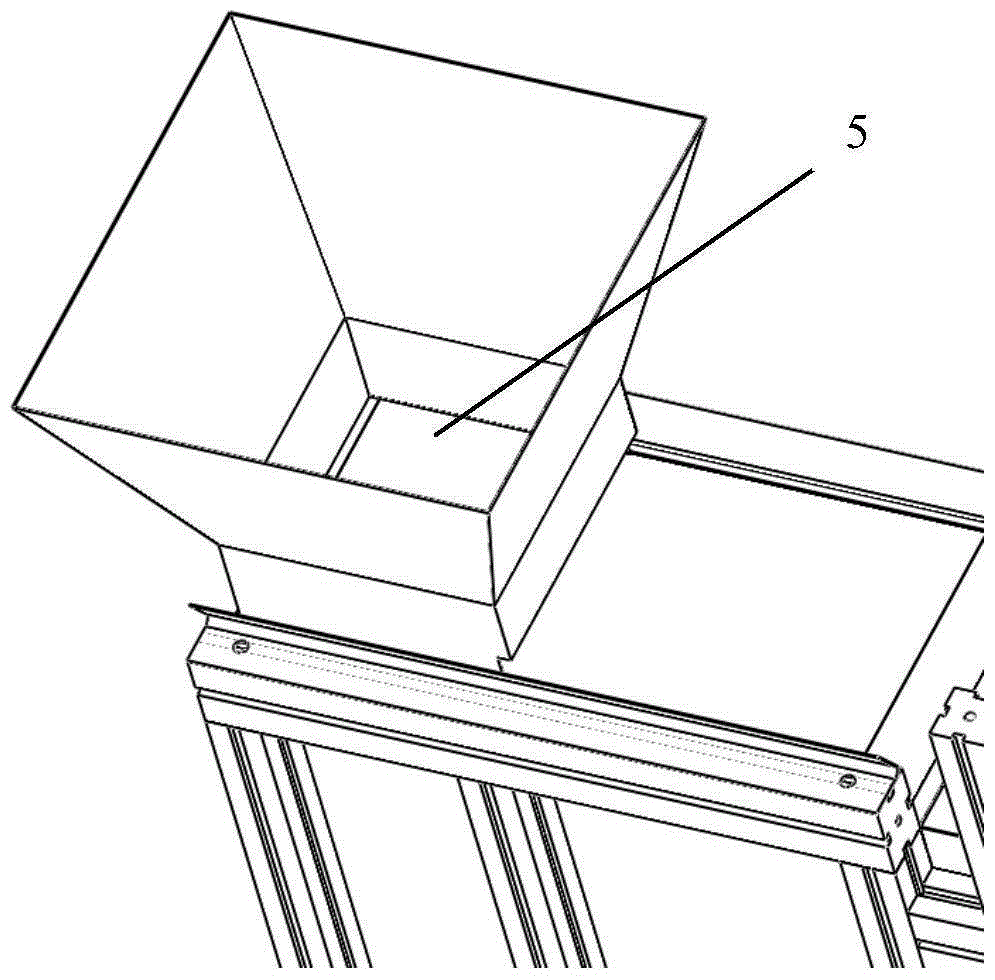

Counting machine, working method of counting machine and packing production line adopting counting machine

InactiveCN105292623AIncrease productivitySmooth movementPackaging automatic controlEngineeringImaging processing

The invention relates to a counting machine, a working method of the counting machine and a packing production line adopting the counting machine. The counting machine comprises a CCD sensor arranged above a working surface of a conveying belt, wherein the CCD sensor is connected with a computer for counting; the computer adopts an image processing method to count images, to be counted, transmitted by the CCD; a material receiving and replenishing mechanism capable of receiving and replenishing materials is arranged at one side of the tail end of the conveying belt, and comprises a material receiving hopper and a vibration disc with the materials; the vibration disc is controlled by the computer; when the vibration disc vibrates, the materials inside can be vibrated out in the set direction and replenished into the material receiving hopper; the CCD sensor is used for detecting the material passing through the conveying belt; the computer is used for counting; and the computer is used for controlling the vibration disc to replenish the materials to packing bags according to set full loading material numbers of all the packing bags.

Owner:常州常创电气科技有限公司

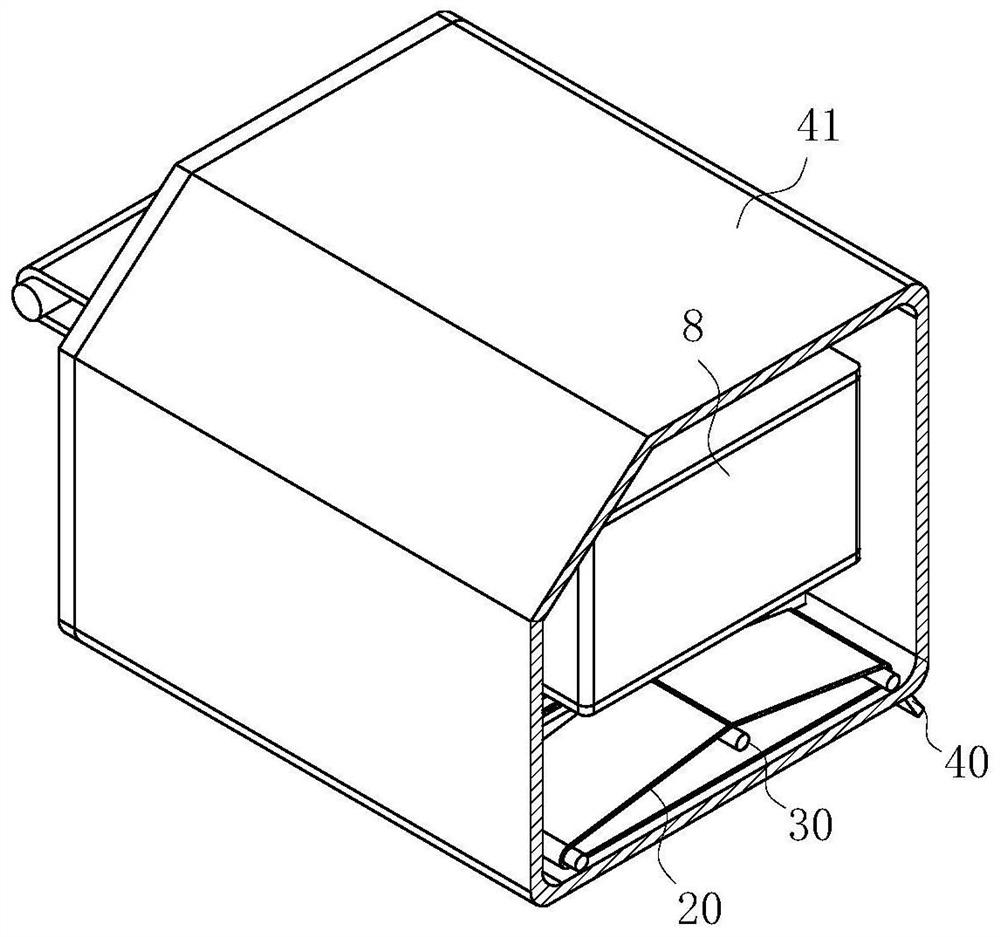

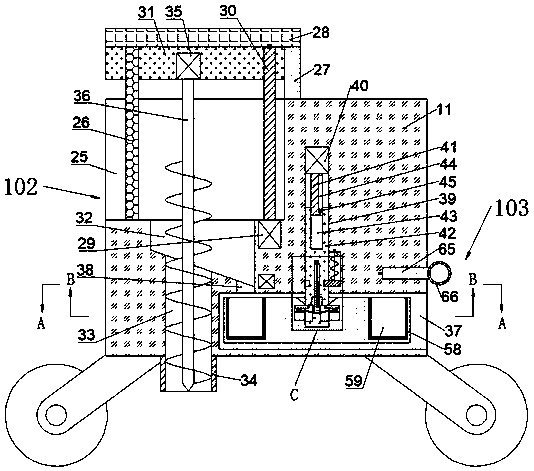

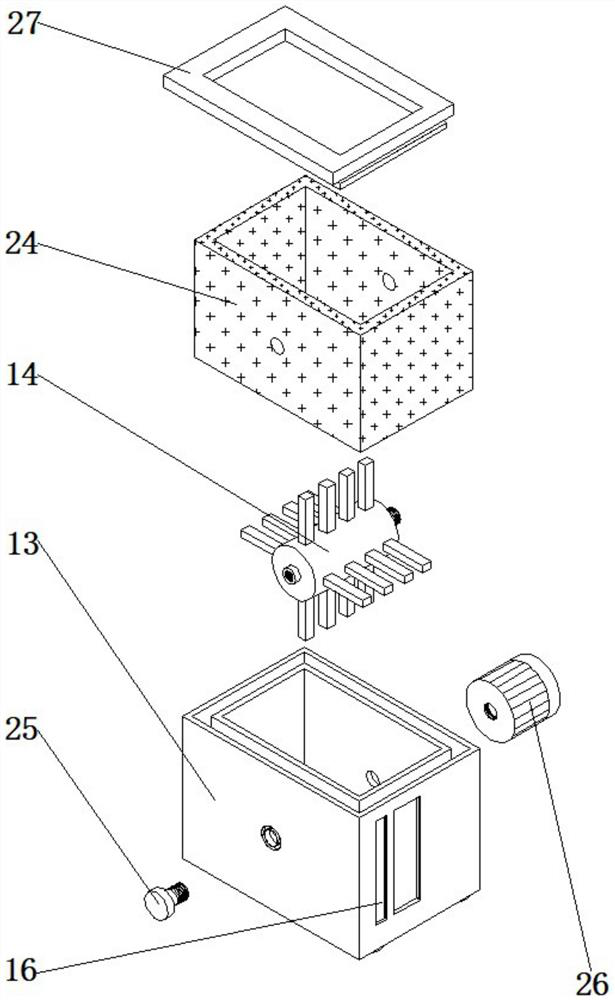

Mathematical probability demonstration device

InactiveCN107146502AHigh degree of automationLabor savingEducational modelsEngineeringMathematical probability

The invention provides a mathematical probability demonstration device, which comprises a transparent box body and an iron coin capable of being attracted by a magnet, and is characterized in that the box body is internally provided with a baffle plate which guides the iron coin to fall, an iron coin accommodating cavity provided for the iron coin to drop is arranged between the baffle plate and the box body, the bottom of the iron coin accommodating cavity is provided with a horizontal conveying mechanism, one side of the iron coin accommodating cavity is provided with a coin falling crack adapting to the thickness of the iron coin, the outlet side of the coin falling crack is provided with a coin storage box, the coin storage box is provided with a coin storage crack at the position corresponding to the outlet of the coil falling crack, one side of the coin storage crack is provided with an electromagnet fixed on the coin storage box, and the coin storage box is fixed on a lifting mechanism. The mathematical probability demonstration device is simple in structure, demonstration is performed through cyclic throw statistics for one iron coin, the whole process does not need manual assistance, the automation degree is high, a teacher can be enabled to perform the demonstration while giving instruction without mutual influence, and the teaching efficiency can be greatly improved.

Owner:SHANDONG JIAOTONG UNIV

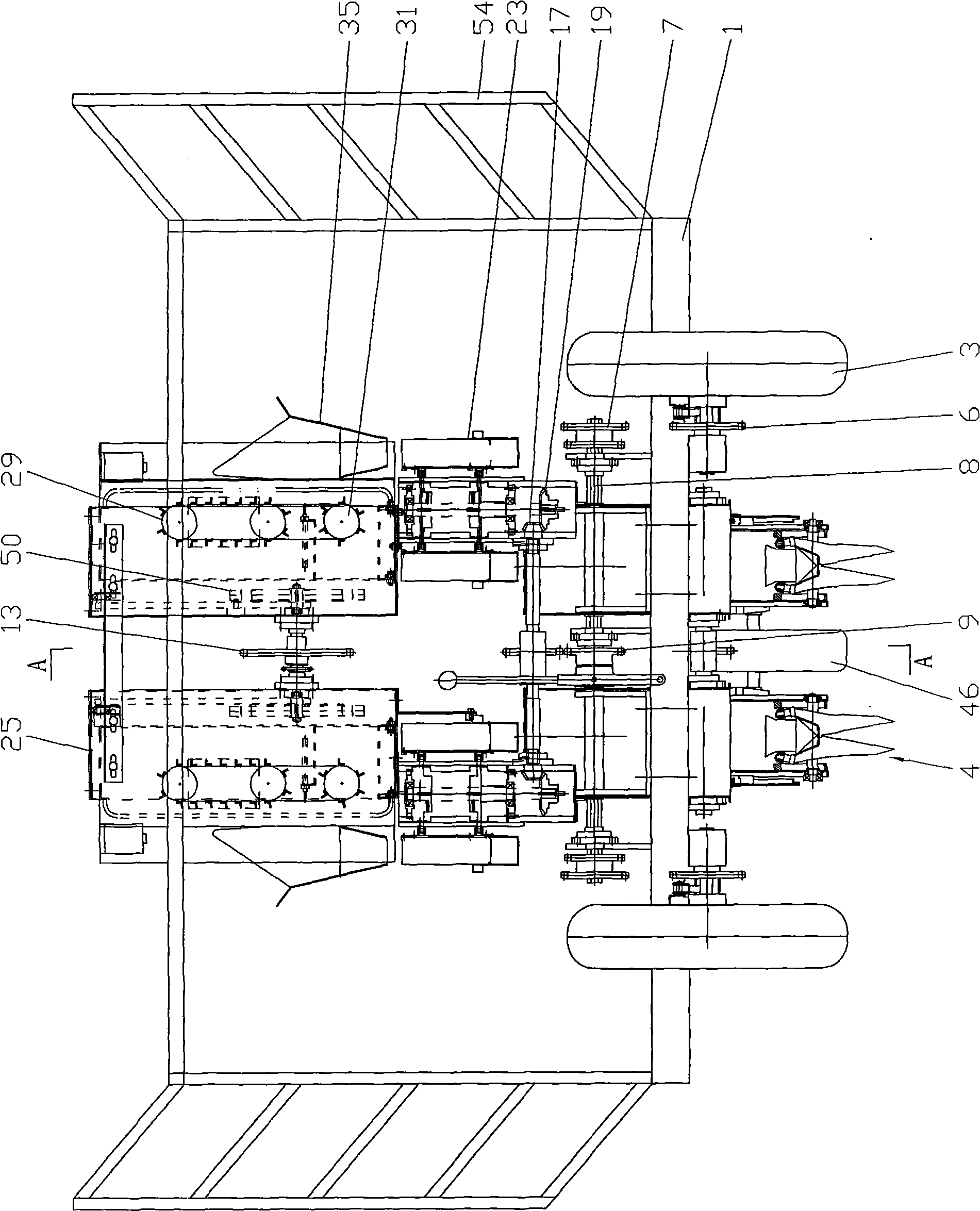

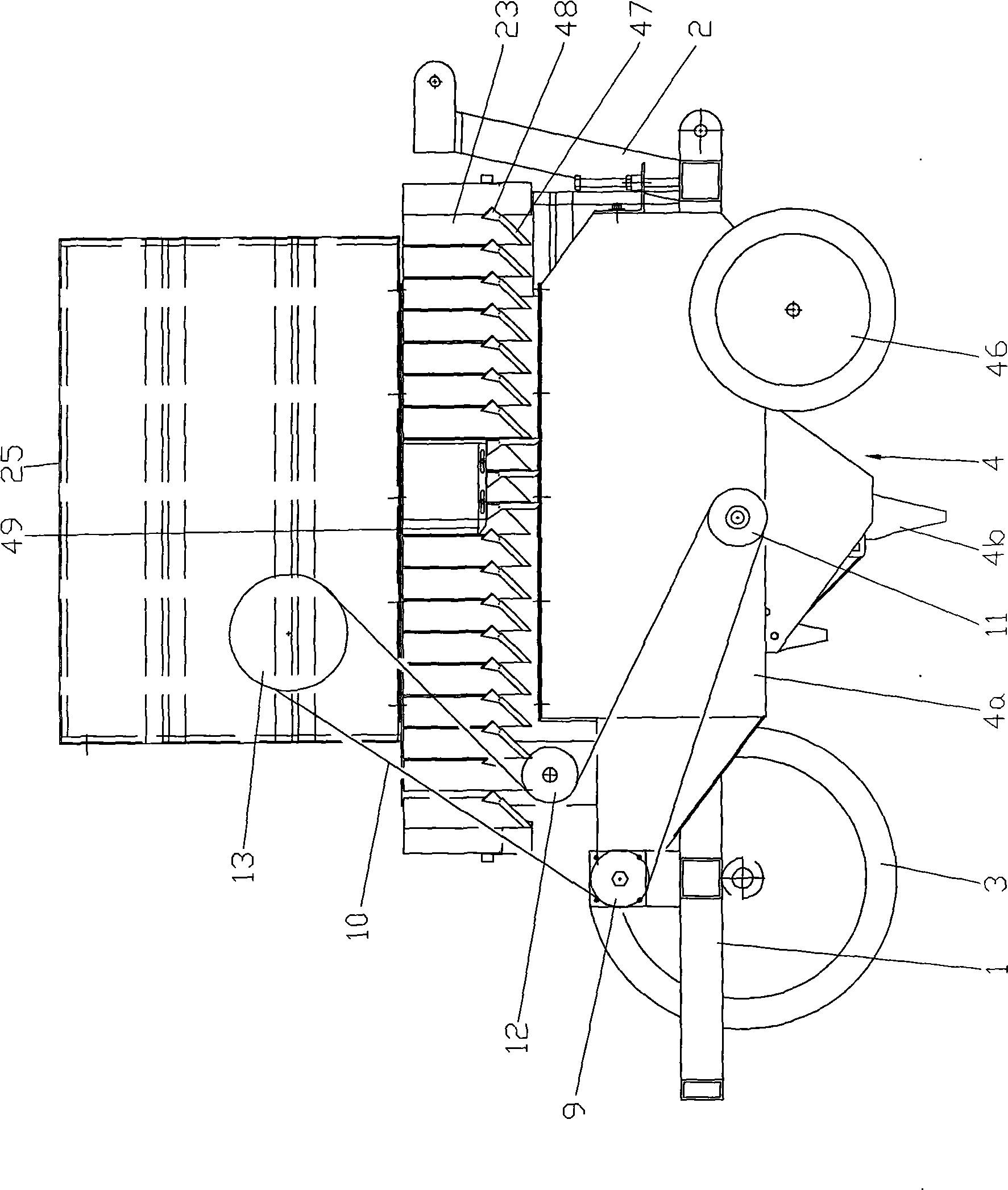

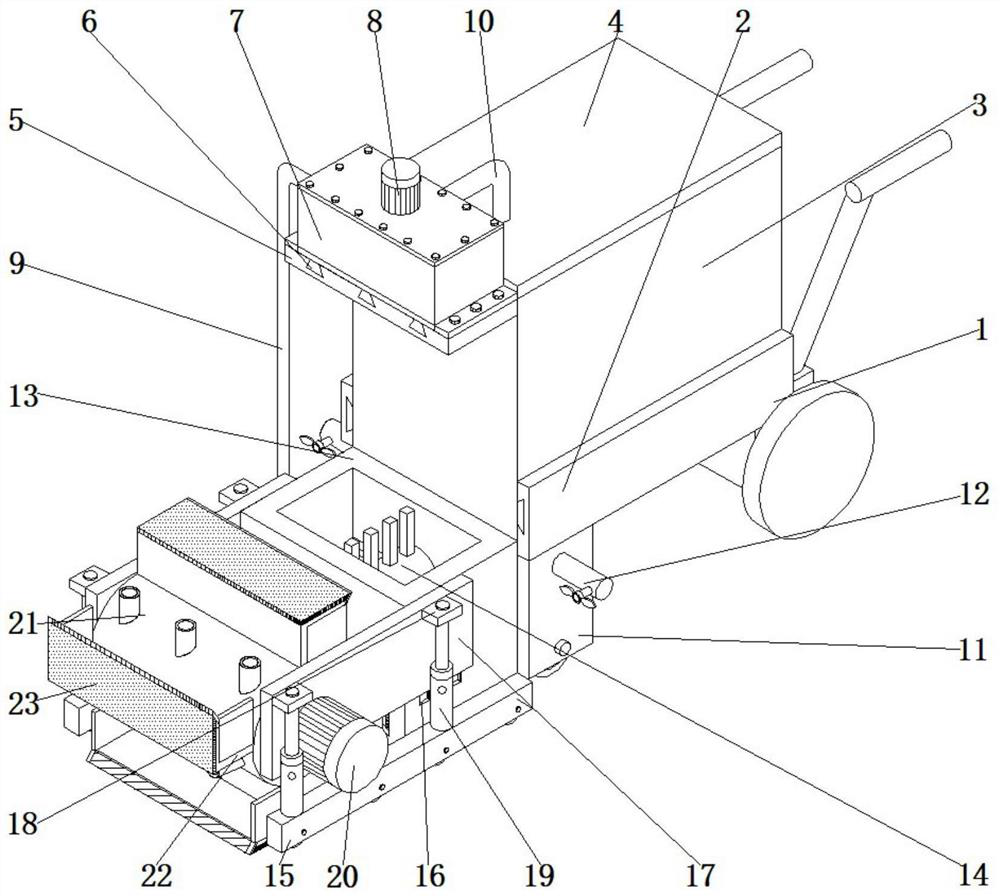

Automatic dry land transplanter

An automatic dry land transplanter is provided. An axletree of a road wheel is sleeved with a first chain wheel which is connected with a second chain wheel via chains. The second chain wheels on both sides are sleeved on both ends of a same chain wheel. The axletree is provided with a third chain wheel in middle; the third chain wheel is connected with the fourth, fifth and sixth chain wheels via the main chain at the same time. The fourth chain wheel drives a mechanical hand via the chain, the fifth one driving a seedling grafter via the chain and the chain-drive mechanism; the sixth one drives an active seedling disc bracket via the chain, the heart piece drive mechanism and the lever. The invention is simple in structure, easy to assemble, low in cost, convenient to operate and reliable in operation, which can reduce labor intensity of operators efficiently and improve precision and transplanting efficiency of transplantation greatly. 50 mou above is transplated each day with transplating efficiency which is 100 to 167 fold of that of manual transplating.

Owner:陈燕

Moisture-proof communication cabinet

InactiveCN110868645AAvoid internal moisture problemsExactly fall intoSelection arrangementsCold airMechanical engineering

The invention discloses a moisture-proof communication cabinet. Box body, heat dissipation openings are formed in the two sides of the box body; a heat conduction metal block penetrates through the inner wall of the box body and is positioned above the heat dissipation opening; an external heat conduction sheet a is arranged at the end, located on the outer side of the box body and located above the heat dissipation opening, of the heat conduction metal block, an internal heat conduction sheet b is arranged at the end, located on the inner side of the box body and located on the heat dissipation opening, of the heat conduction metal block, and the external heat conduction sheet a and the internal heat conduction sheet b are coated with heat conduction layers; cold air flow entering the boxbody from the outside impacts the outer surface of the internal heat conduction sheet b and is liquefied to fall into the drainage groove to flow out of the box body, and the problem that the interior of the box body is wet due to the fact that the cold air flow is liquefied when the external cold air flow is directly blown into the box body can be effectively solved.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

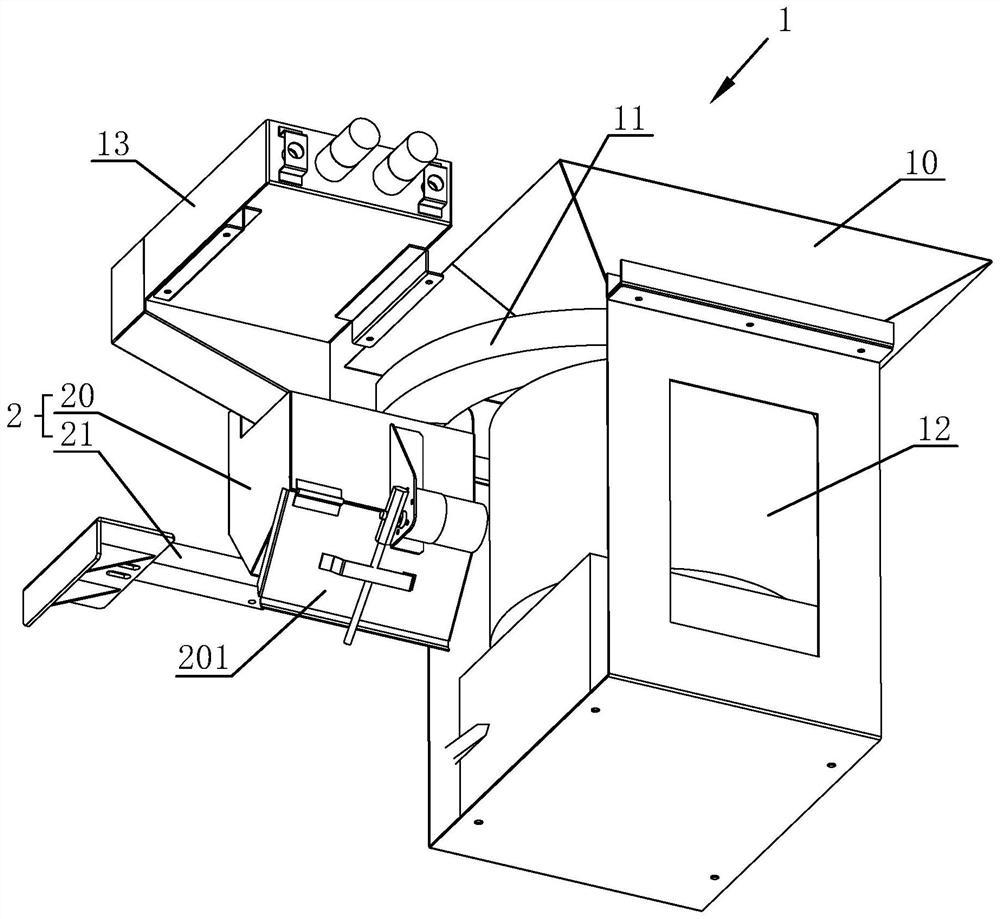

High-pressure water sand-spraying deflashing machine

InactiveCN101143475AStable and orderly deliveryGuaranteed stabilityBlast gunsSedimentation separationAutomatic controlEngineering

The invention relates to a cleaning equipment for a IC molding strip flash, to be more precise, relates to a flash machine with a IC strip high pressure water sand-blast. The invention comprises a charging device, a material pushing and storage device, a transmission part, a spewing system, a baiting device and an automatic control system. The spewing system comprises a sand-collection sand-and-water separation bin, a plurality of sand-and-water spray heads, a plurality of water spray heads, a dried device and a high-pressure pump. The invention is characterized in that the charging device pushes the IC strip into the pushing and storage device through a vacuum grasp manner. The transmission part drives the strips to progress through a drive shaft in an upper and a lower rows. Through a blanking part, the baiting device drives the strip to fall to the location with its own body weight. The invention has the characteristics of easy control of charging and baiting, good processing quality and high efficiency.

Owner:GRAND TECH SHENZHEN

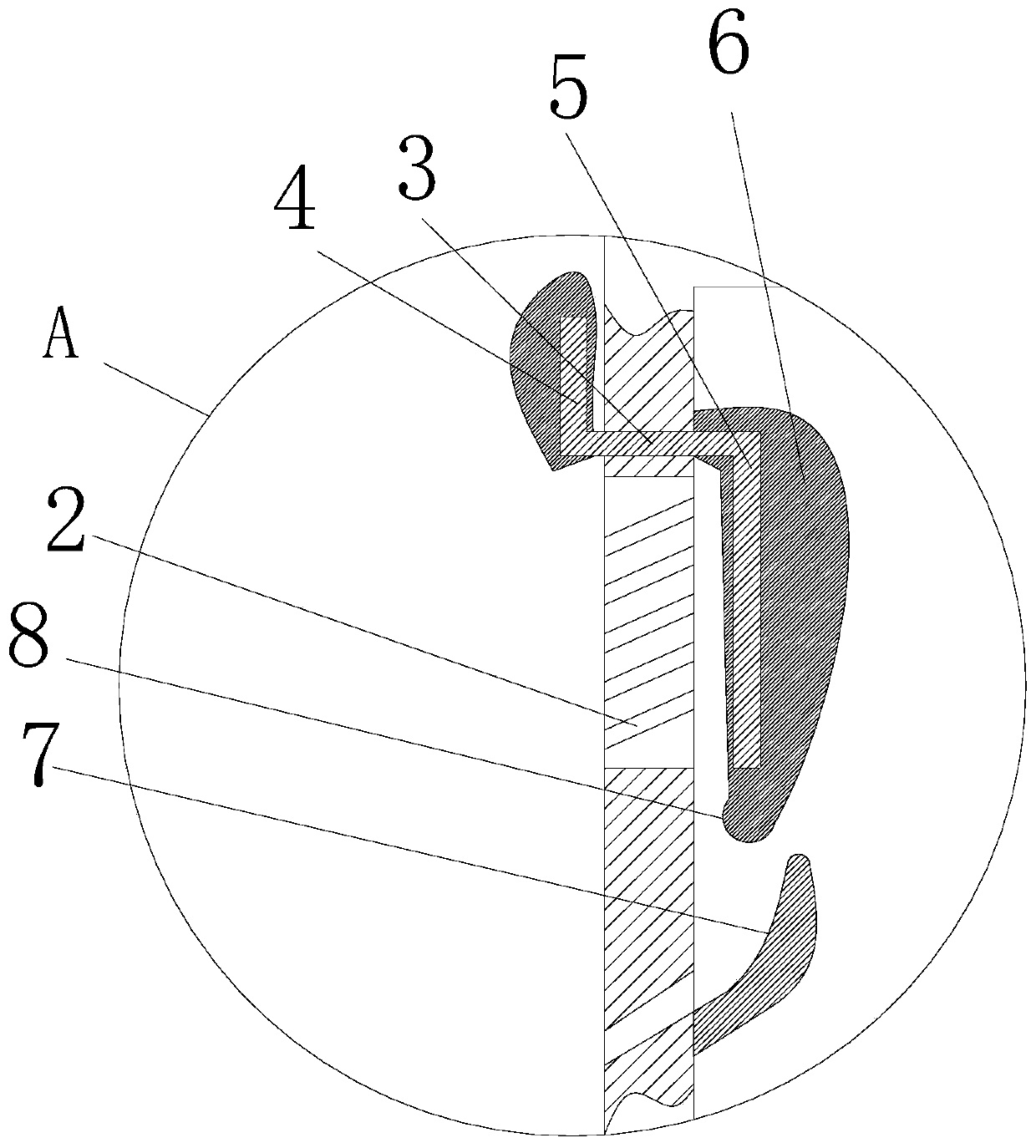

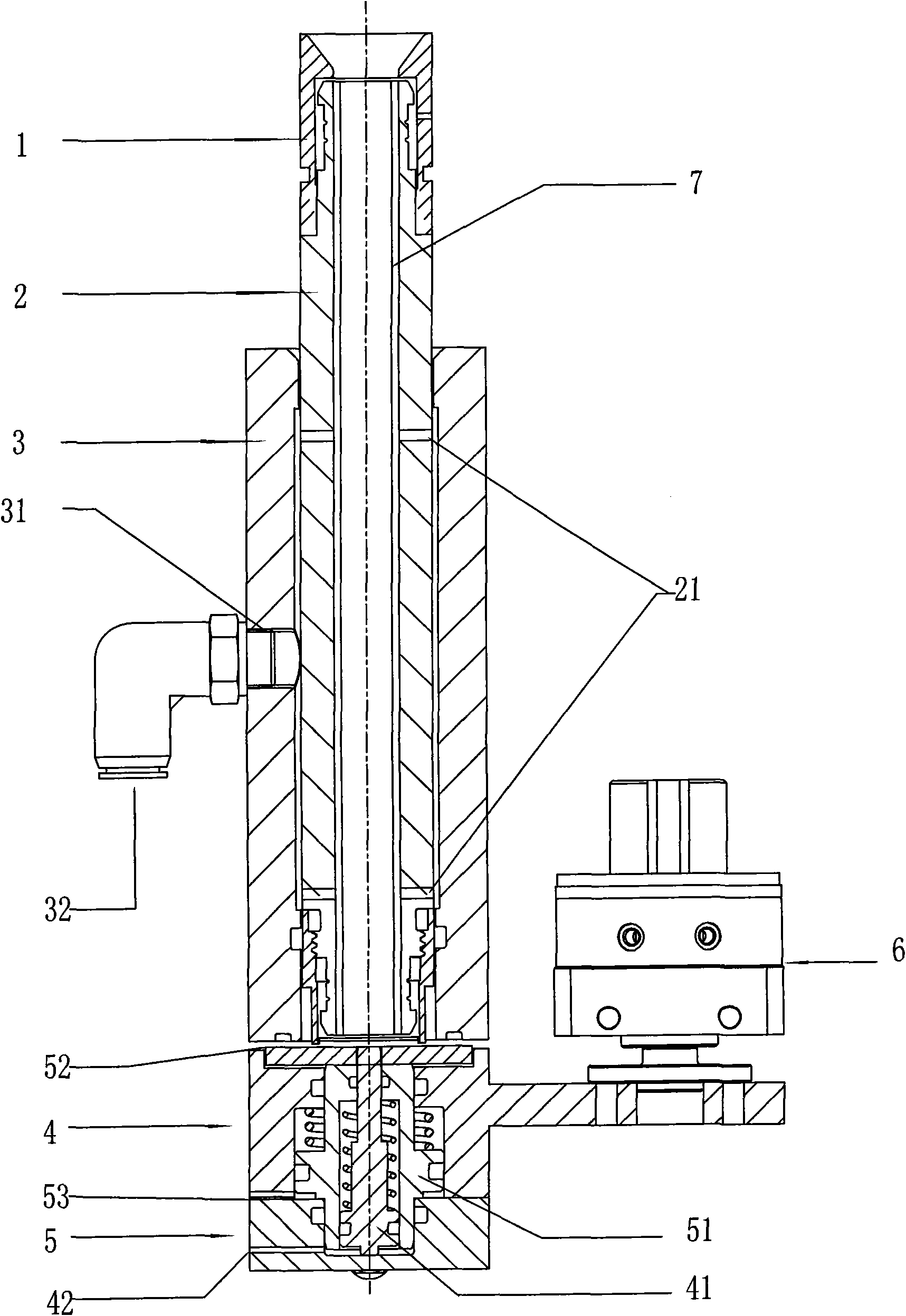

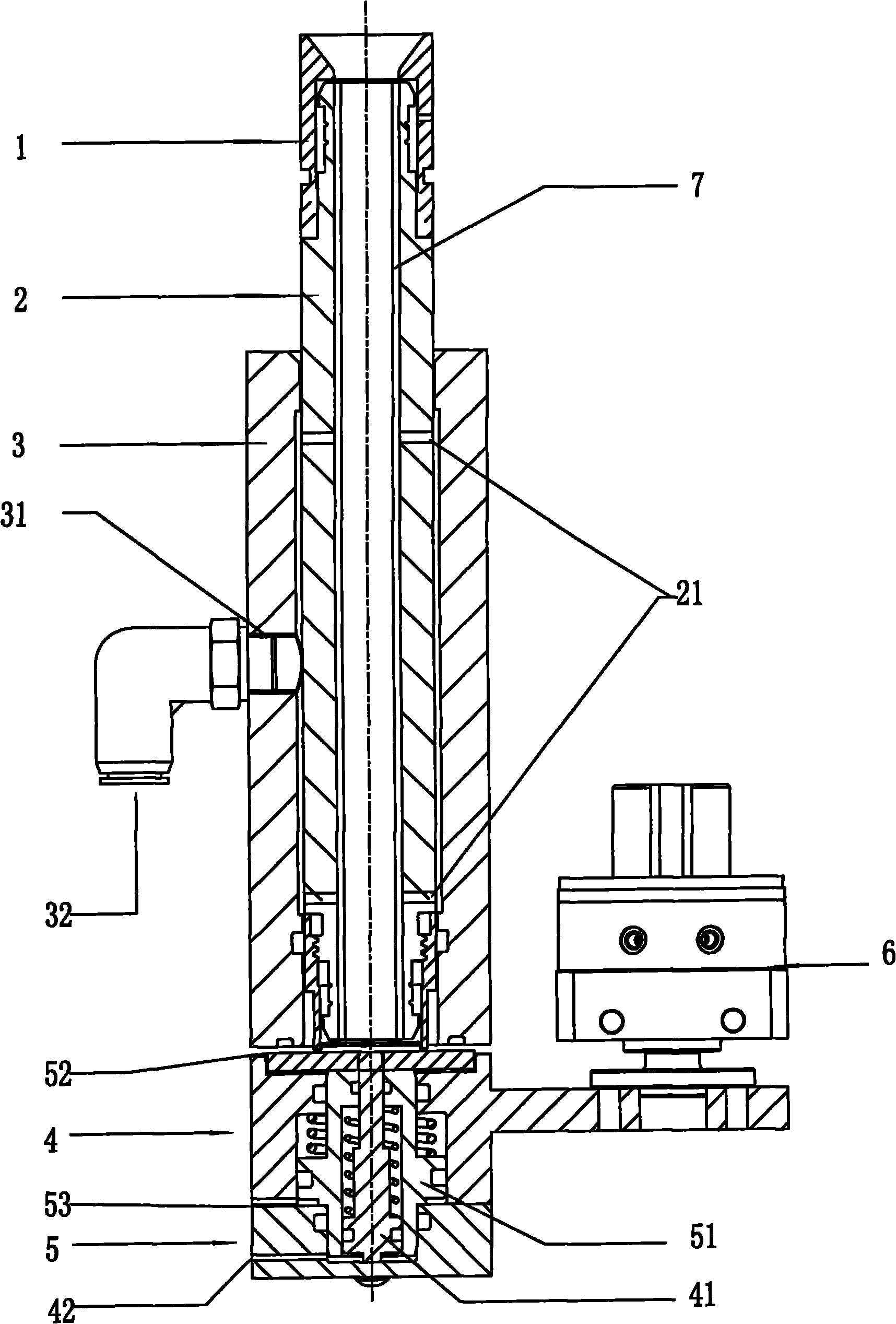

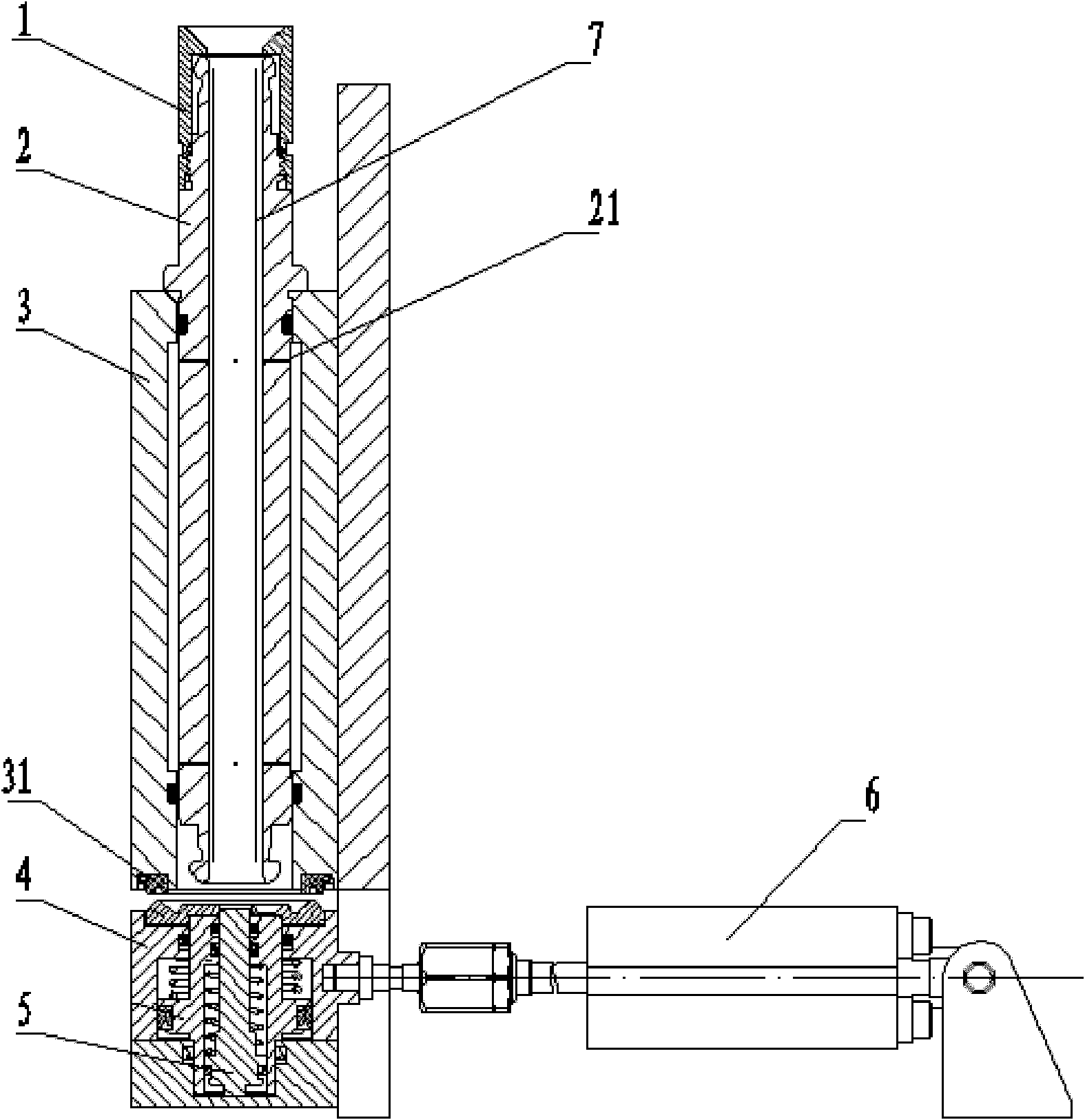

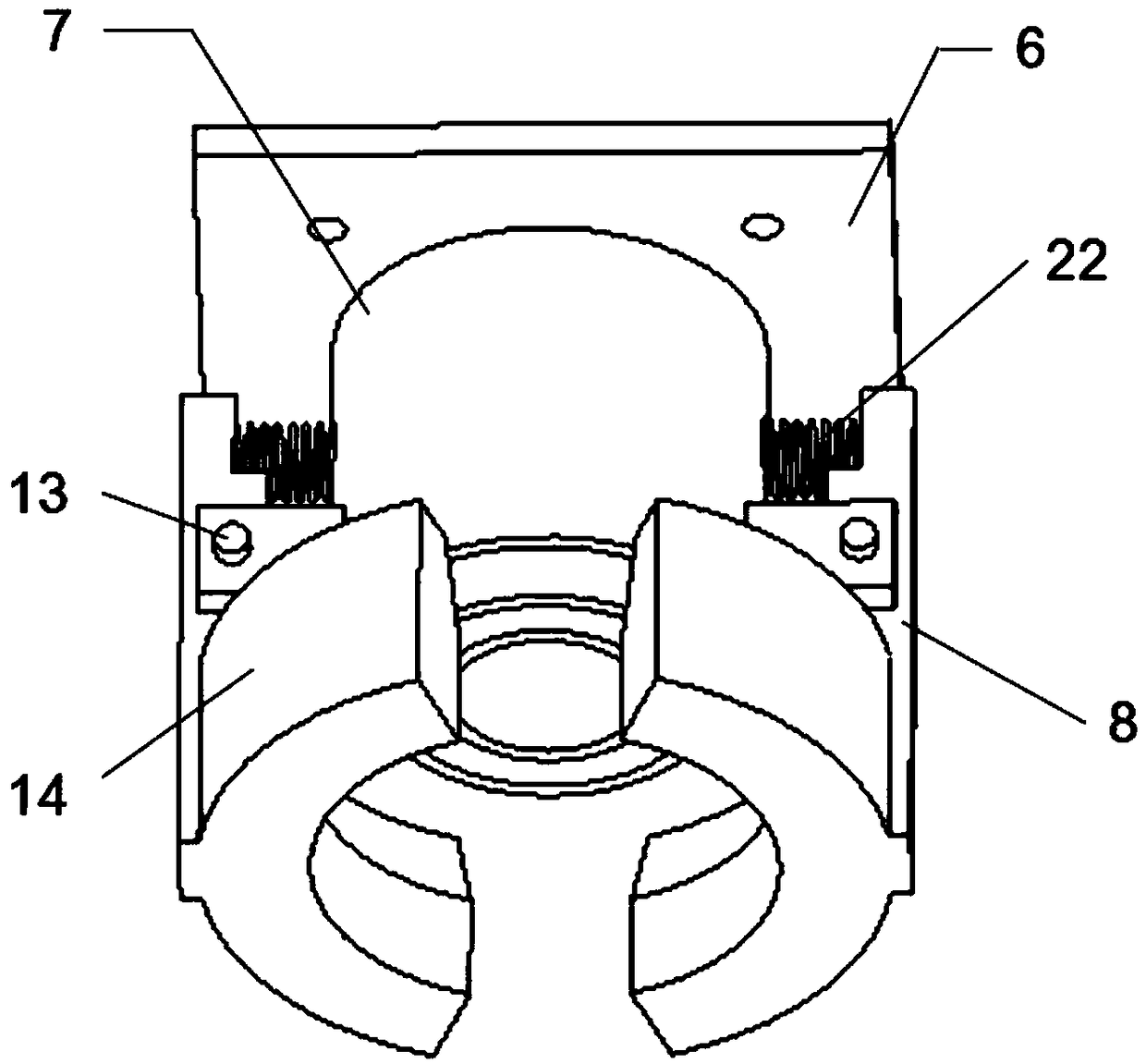

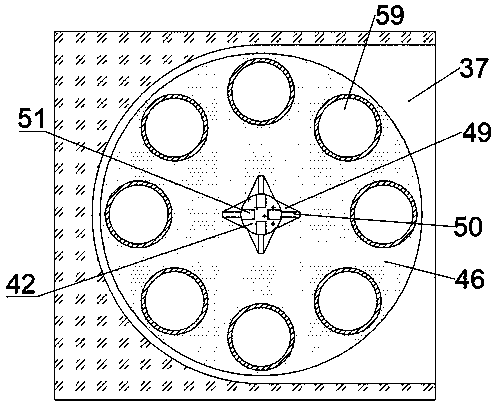

Filter stick suction resistance on-line measuring device

ActiveCN101943651AExactly fall intoWon't hurtPermeability/surface area analysisMeasurement deviceHollow cylinder

The invention relates to a filter stick suction resistance on-line measuring device which comprises a control system, an air channel system, a differential pressure transmitter, a vacuum flow sucker and a suction resistance measuring mechanism, wherein the suction resistance measuring mechanism is composed of a measuring head and an auxiliary cylinder; the measuring head is fixed in the falling position of the filter stick; the center of the measuring head and the falling center of the filter stick are positioned on one straight line; the measuring head is composed of a measuring seat and a measuring tube fixed in the measuring seat; the measuring seat is provided with a through hole which is connected with an air channel; the measuring tube is a hollow cylinder of which the inner wall is sheathed with a latex sleeve; the measuring tube is provided with a latex sleeve air inlet; the auxiliary cylinder is arranged below the measuring head and composed of two single-acting cylinders which are combined together; and an oscillating cylinder drives the whole auxiliary cylinder to rotate and reset. The invention has the advantages of reasonable design, simple operation, stable and reliable operation, high precision for measuring suction resistance differential pressure, and accurate measured data, and can realize real-time detection, analysis and control.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

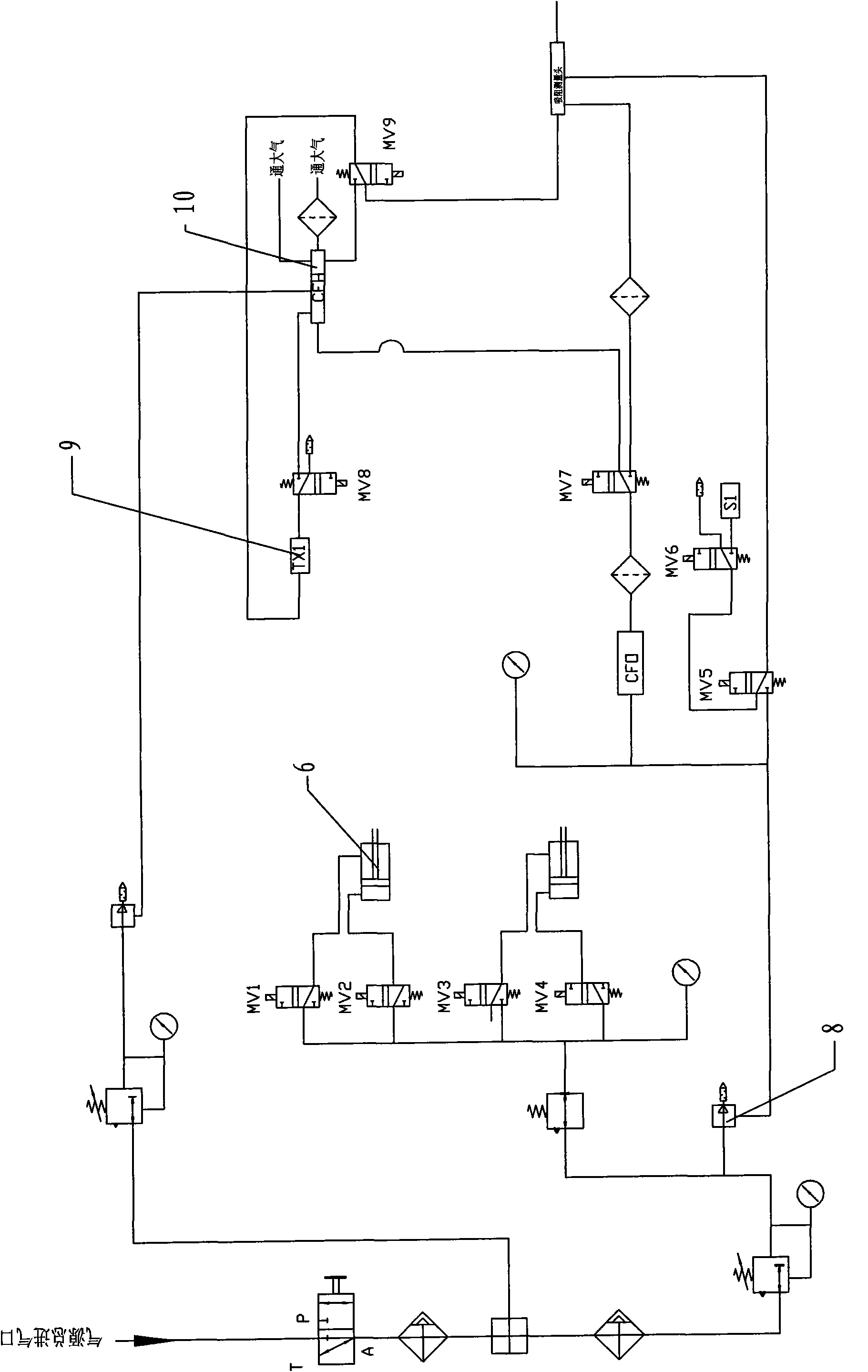

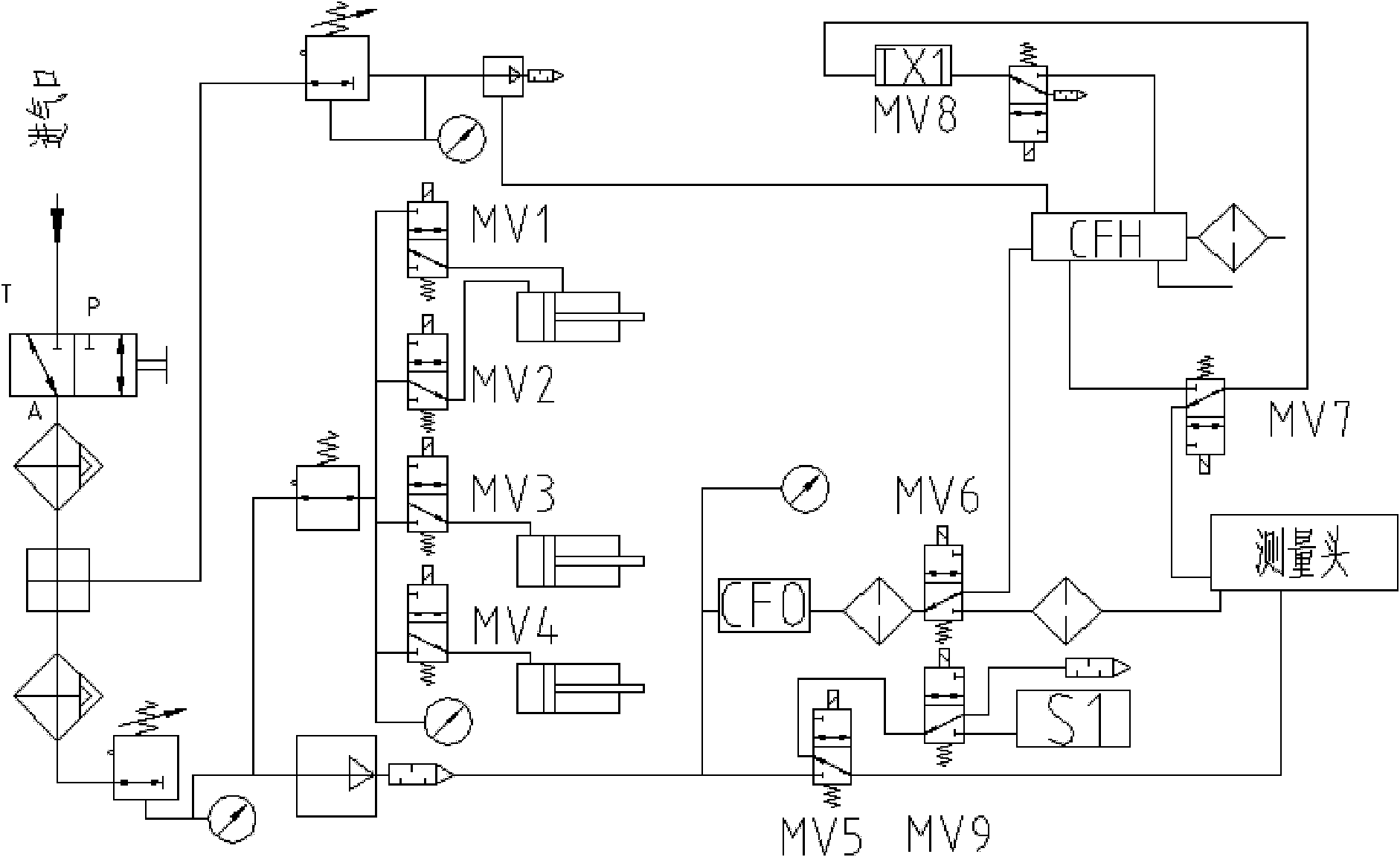

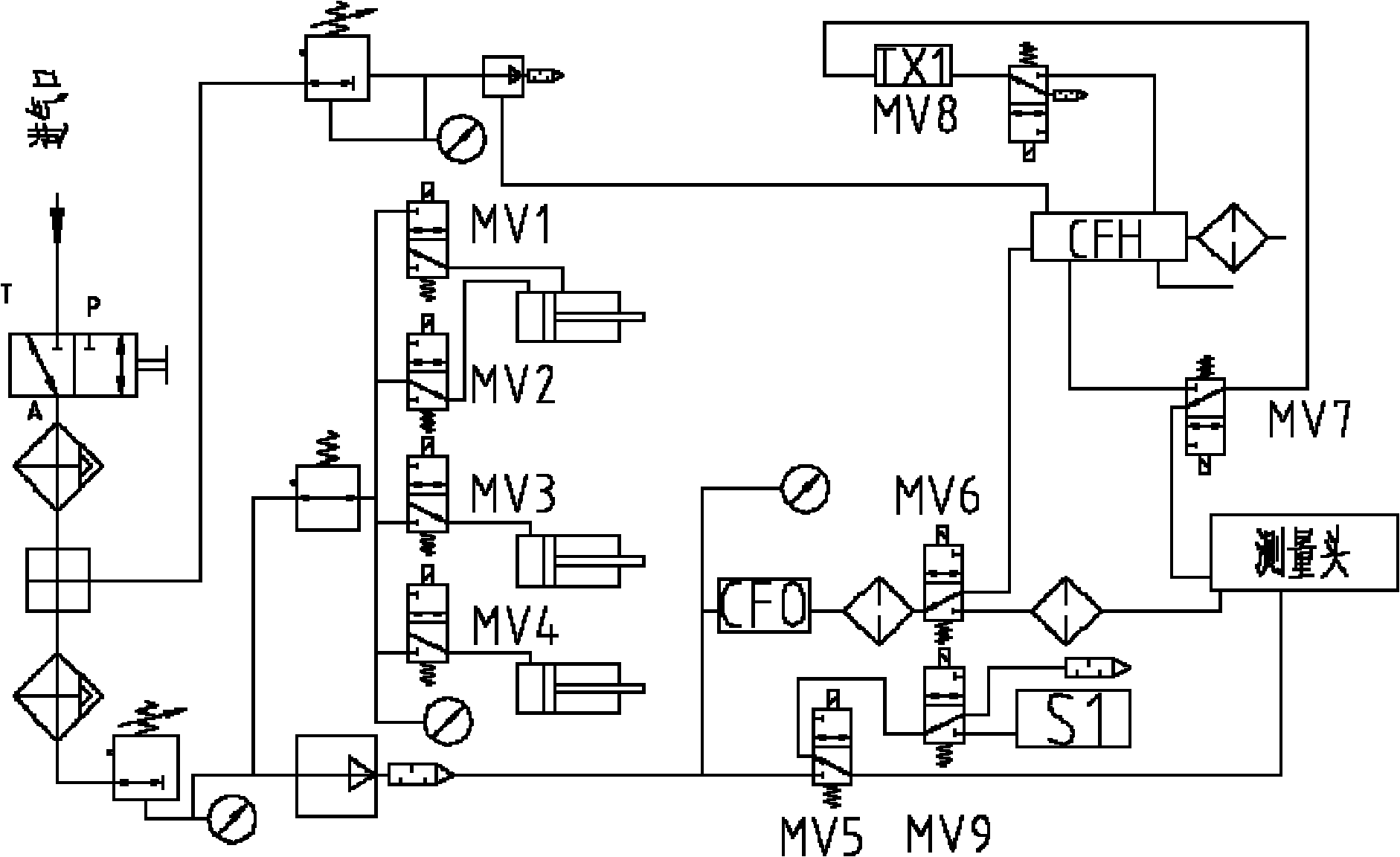

Device and method for measuring suction resistance of filter stick or cigarette

The invention discloses a device and a method for measuring suction resistance of a filter stick or cigarette. The device comprises a control system, an air circuit system, a first pressure difference converter, a vacuum flow sucker and a suction resistance meter, wherein the control system further comprises a digital output module and an analog input module; the air circuit system further comprises a first solenoid valve, a second solenoid valve, a third solenoid valve, a fourth solenoid valve, a fifth solenoid valve and a sixth solenoid valve; the suction resistance meter further comprises a metering head, an auxiliary cylinder and a linear cylinder; the metering head further comprises a metering base, a metering tube and a latex sleeve; and the auxiliary cylinder comprises a first cylinder and a second cylinder. By using the technical scheme in the invention, the suction resistance of the filter stick or cigarette can be detected, analyzed and controlled at real time, the positioning accuracy is high and the measured data is accurate.

Owner:ZHENGZHOU HAIYI TECH

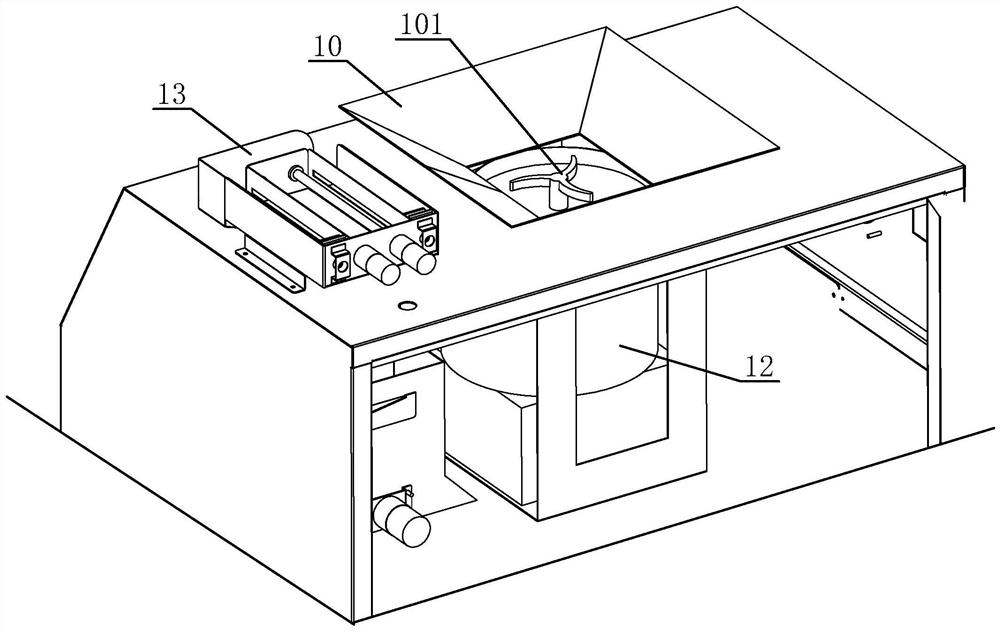

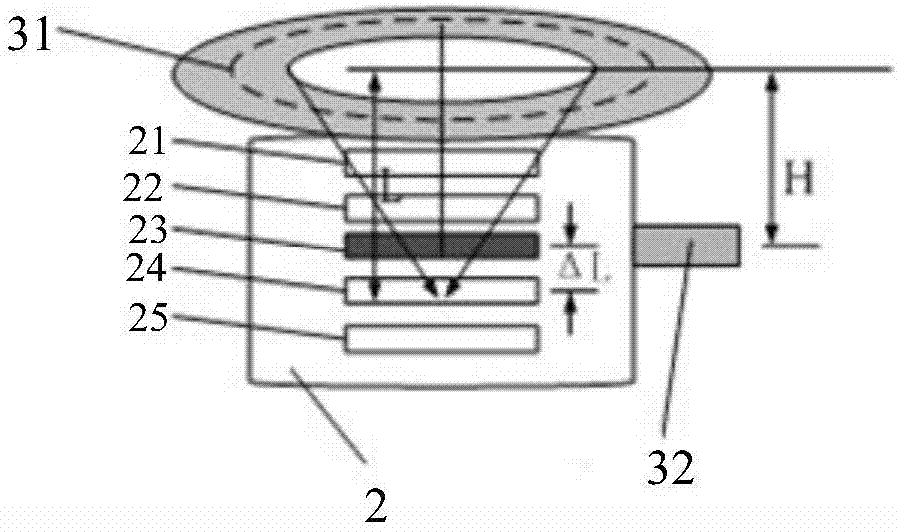

Movable photoelectric separation robot for coal and gangue

The invention belongs to the technical field of coal separation, and particularly relates to a movable photoelectric separation robot for coal and gangue. The robot comprises a vibration feeding module, a conveying module, a dual-energy X-ray identification and decision module and a coal and gangue separation module; a dual-energy X-ray source is fixedly installed in an installation box and is located above a conveying belt; an X-ray flat panel detector is installed under an empty belt of the conveying module and is right corresponding to the dual-energy X-ray source; a measurement and controlinstrument is in electric signal connection with the dual-energy X-ray source; a power supply device is used for supplying power to the measurement and control instrument, the dual-energy X-ray source and the X-ray flat panel detector. The intelligent and efficient coal and gangue separation equipment based on dual-energy X-ray transmission coal separation can achieve real-time and intelligent separation of coal and gangue underground, and compared with an underground jigger, a dense medium cyclone and the like, the equipment has the advantages that the coal separation technology is optimized, the coal and gangue separation rate is increased, the occupied area of a chamber is reduced, and the coal quality is improved.

Owner:ANHUI UNIV OF SCI & TECH

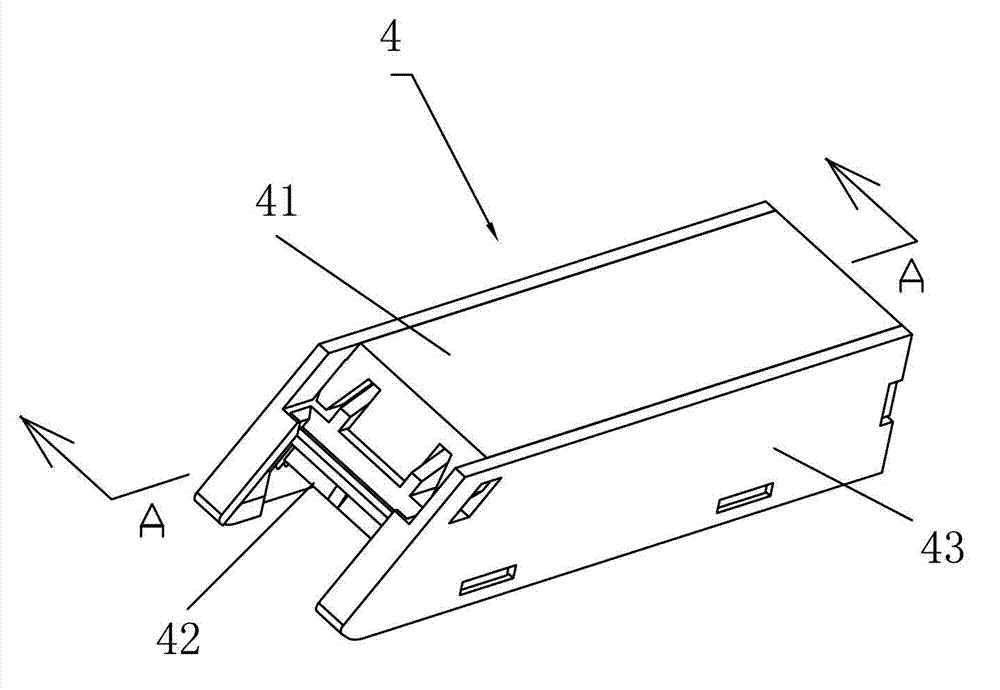

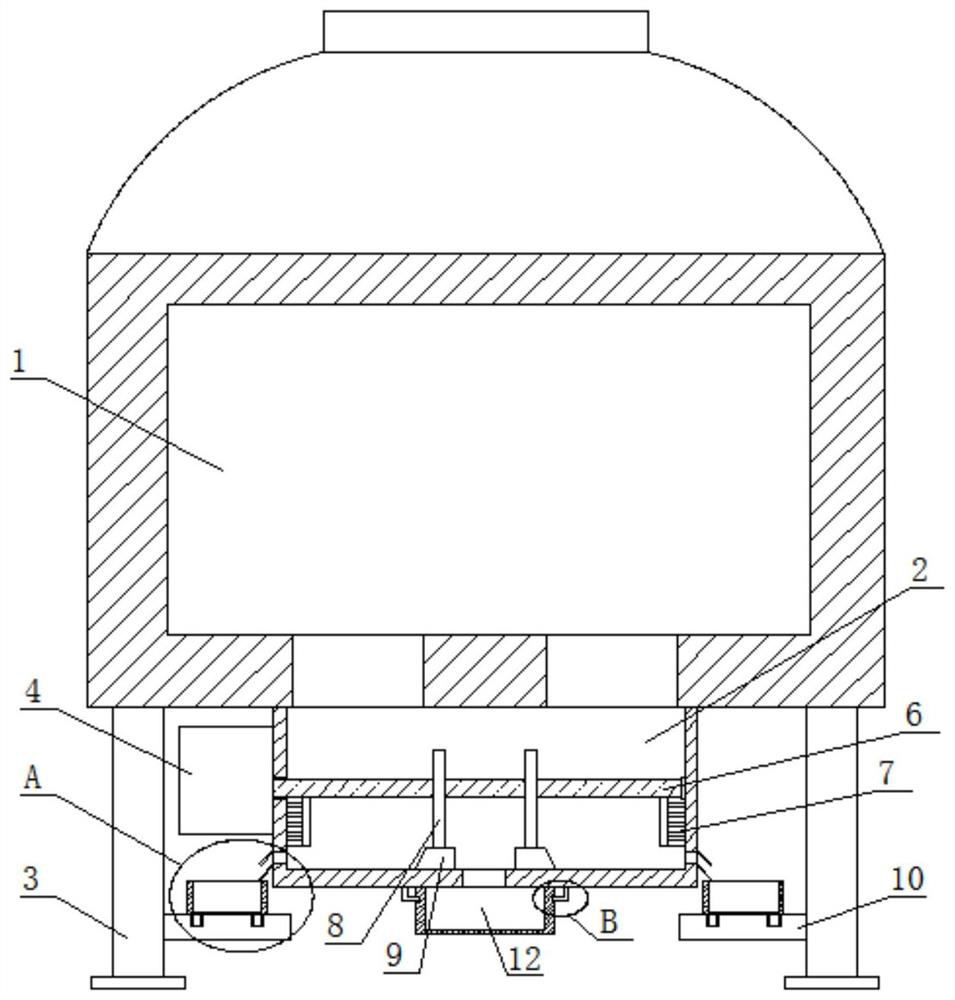

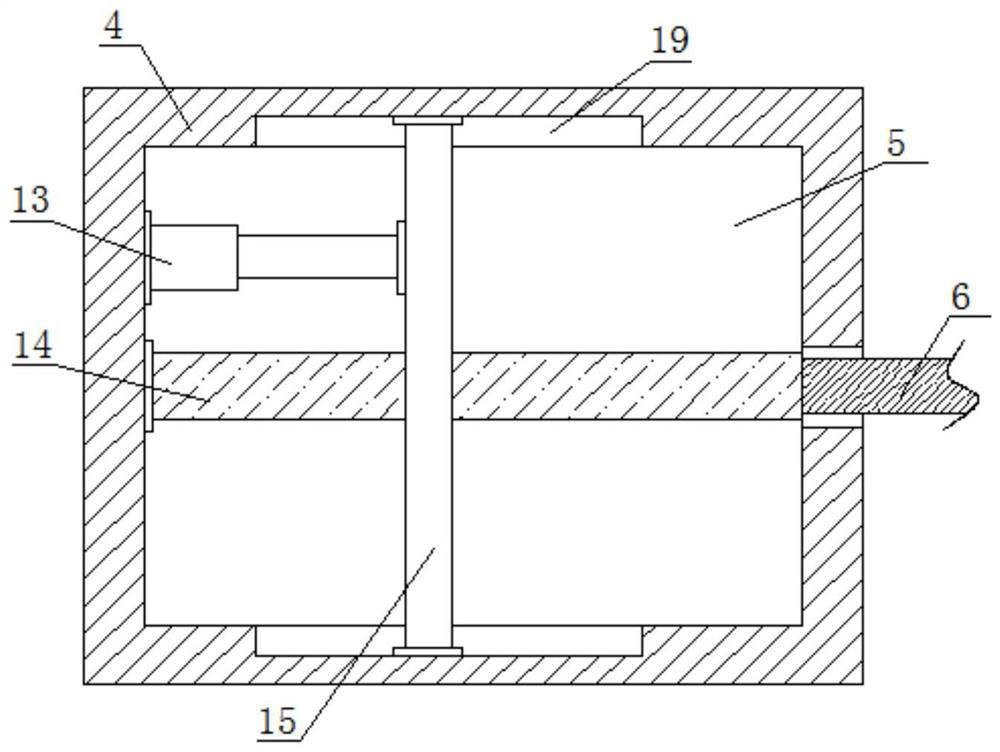

Battery replacement charging system of unmanned aerial vehicle

ActiveCN108528745AImprove fault toleranceReduced precision requirementsCharging stationsCurrent conducting connectionsUncrewed vehicleEngineering

The invention discloses a battery replacement charging system, and belongs to the technical field of machinery. The battery replacement charging system of an unmanned aerial vehicle comprises a detachable battery and a detachable battery replacement charging device. The system has the advantages that the use efficiency of the unmanned aerial vehicle is improved, the overall battery life of the unmanned aerial vehicle is prolonged, the application range is wide, the development period is short, the difficulty is moderate, and the cost is low.

Owner:JIANGNAN UNIV

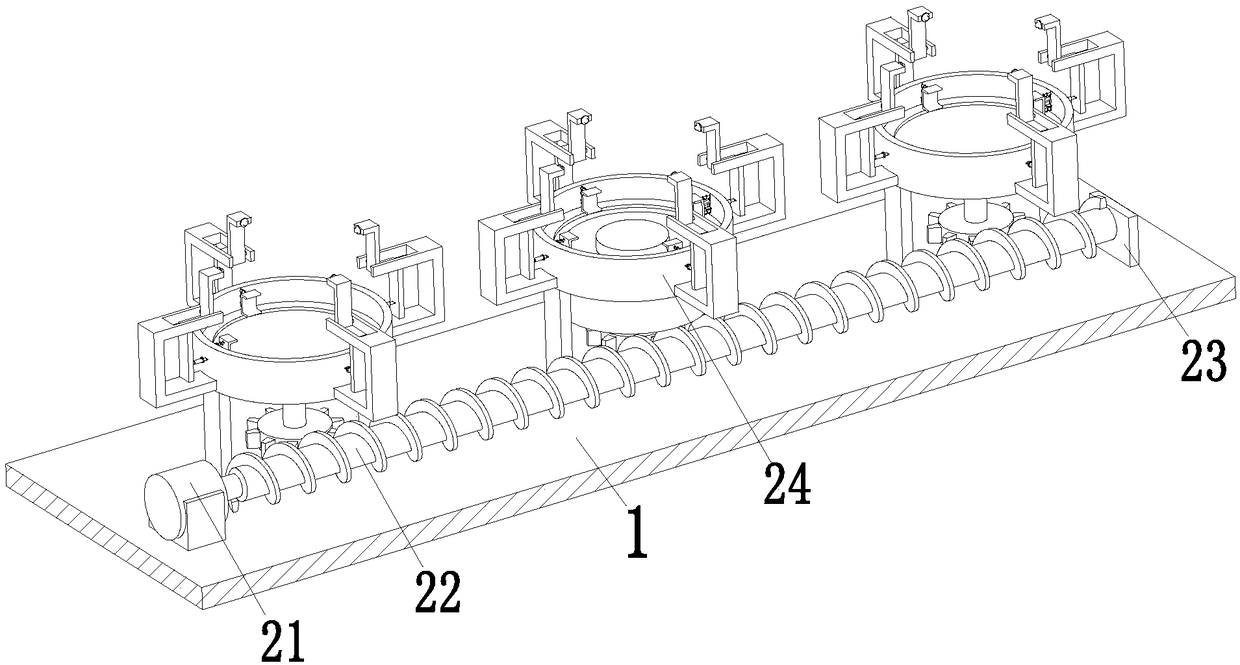

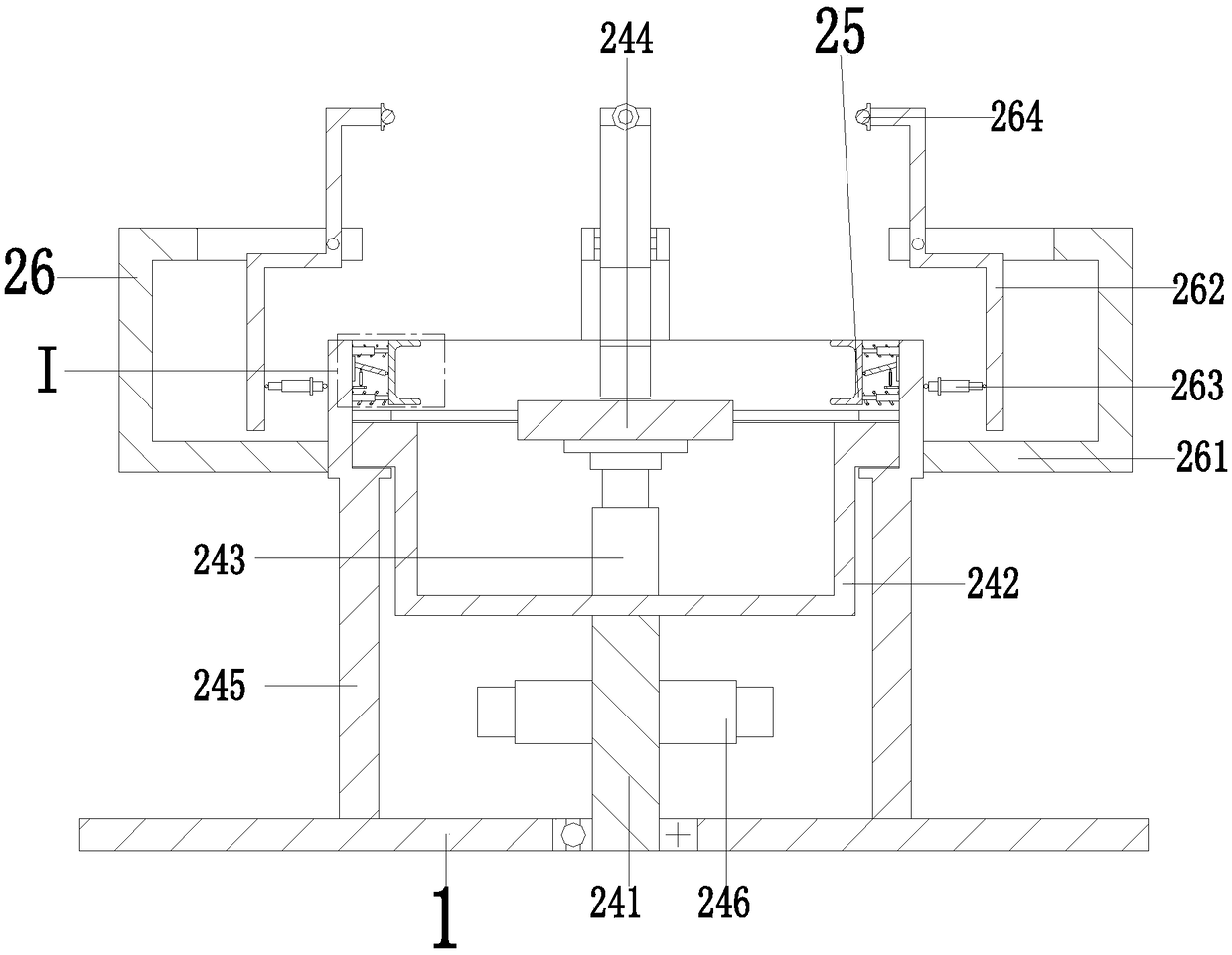

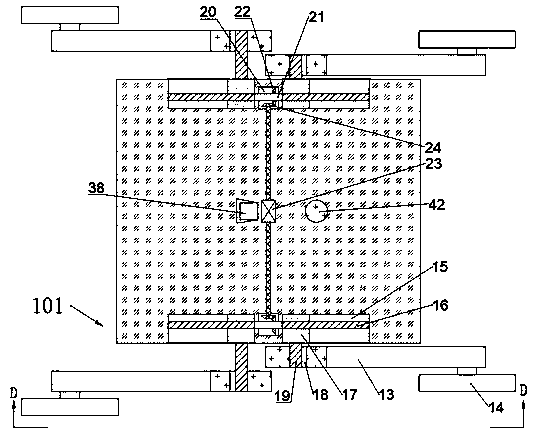

Semiconductor integrated circuit wafer processing production line and production and processing method thereof

ActiveCN108995060AUnified specificationsNo labor intensityEdge grinding machinesWorking accessoriesIntegrated circuitEngineering

The invention relates to a semiconductor integrated circuit wafer processing production line and a production and processing method thereof. The semiconductor integrated circuit wafer processing production line comprises a bottom plate, wherein edge grinding devices are installed at the middle part of the upper end of the bottom plate, movable electric sliders are symmetrically installed on the front and rear sides of the bottom plate, lifting adjusting cylinders are installed on the movable electric sliders, the top ends of the lifting adjusting cylinders are installed on a lifting driven plate through flanges, a slicing device is installed on the lifting driven plate, and the slicing device is positioned directly above the edge grinding devices. According to the semiconductor integratedcircuit wafer processing production line and the production and processing method thereof, the problems in the prior silicon crystal rod slicing and edging process that cut wafers need to be manuallytransported to a designated position for edging processing, the processing of the silicon crystal rod slicing is not accurately controlled manually, the wafers are prone to being injured by mistake inthe conveying process, the wafers cannot be normally used due to mutual collision during the wafers conveying process, the edging of the wafers takes a long time manually with the aid of the prior instrument and multiple wafers cannot be processed at the same time are solved.

Owner:WENZHOU YIWO MASCH TECH CO LTD

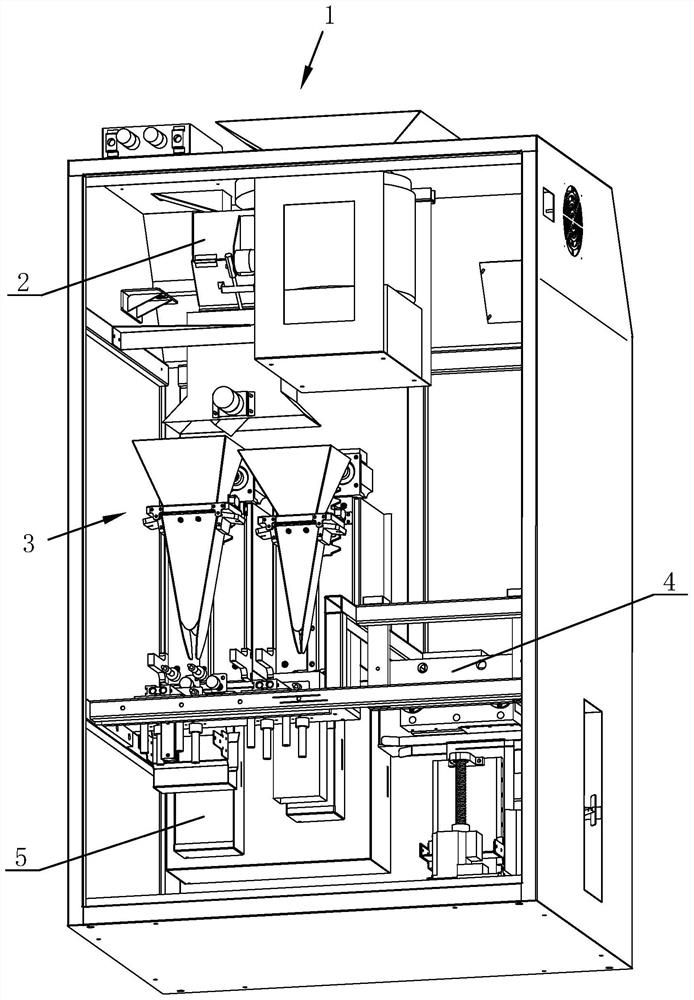

Automatic tea leaf subpackaging and packaging machine

InactiveCN112777012AReduce labor intensityReduce labor inputWrapper twisting/gatheringSolid materialComputer control systemHeat sealer

The invention discloses an automatic tea sub-packaging and packaging machine which can automatically carry out feeding, weighing, bagging and sealing on bulk tea and send out packaged finished products and can also package materials of two specifications at the same time through a weighing and sub-packaging structure. According to the key points of the technical scheme, the automatic tea sub-packaging and packaging machine comprises a feeding mechanism, a weighing mechanism, a bagging mechanism, a heat sealing mechanism, a discharging mechanism and a computer control system, and the feeding mechanism comprises a feeding hopper and an inclined feeding channel; the weighing mechanism comprises a weighing hopper and a pressure sensor; the bagging mechanism comprises a sub-packaging structure, two filling hoppers, a bag opening structure and a tray, the sub-packaging structure comprises sub-packaging hoppers, swing pieces are arranged in the sub-packaging hoppers, the swing pieces are used for switching channels in the sub-packaging hoppers, openings in the upper portions of the two filling hoppers directly face the two channels formed by swinging of the swing pieces respectively, and the bag opening structure adopts suction cups which are oppositely arranged; and at least one sucking disc can move up and down and stretch back and forth, the tray is located below the bag opening structure, and a swing rod is arranged in the discharging mechanism.

Owner:湖州曼智科技发展有限公司

Soil sampler capable of automatically storing soil sample

The invention discloses a soil sampler capable of automatically storing a soil sample. The soil sampler comprises a sampler body, a walking device is arranged on the sampler body; a sampling device isarranged on the sampler body; the sampling device comprises a lifting cavity which is formed in the upper end surface of the sampler body and is provided with an upward opening; a second limiting rodis fixedly arranged on the lower wall of the lifting cavity; a supporting rod is fixedly arranged on the upper end surface of the sampler body; a fixing plate is fixedly arranged at the upper ends ofthe second limiting rods and the upper ends of the supporting rods; a lifting plate capable of sliding up and down is arranged on the second limiting rod; a storage device is arranged in the samplerbody; the storage device is used for storing a soil sample; effective soil parts can be selectively taken and used during soil exploration sampling, soil samples are stored in the storage tank, the sampler can store and collect various soil samples through rotation of the disc, when the storage tank is replaced, the position of the disc can be automatically found again, the disc is lifted, and itis guaranteed that the soil samples can accurately fall into the storage tank.

Owner:聊城市科源环保检测服务中心(普通合伙)

System and method for pressing walnuts into cracks based on precise self-positioning

InactiveCN106666763ASave energySave manpower and material resourcesHuskingHullingMaterial resourcesEngineering

The invention discloses a system and method for pressing walnuts into cracks based on precise self-positioning. The system comprises a driving mechanism, a transmission mechanism and a pressing mechanism. The driving mechanism generates driving force and pushes the transmission mechanism to reciprocate; the pressing mechanism comprises falling blocks and pressing blocks opposite to the falling blocks, gaps are formed between the falling blocks and the pressing blocks, and the gaps are gradually reduced so as to position falling walnuts; the transmission mechanism pushes the falling blocks and the pressing blocks, and the gaps between the pressing blocks and the falling blocks are changed so as to press walnuts falling into the gaps between the pressing blocks and the falling blocks so that cracks can be generated. By means of the system, the pre-shell-breaking process is added on the premise of effectively reducing the consumption of manpower and material resources and improving the production efficiency, and the completeness of kernels is fully guaranteed. Besides, through mechanism optimization, the working stability of the system is improved while mechanism simplification is achieved, the total cost of the system is reduced, and a significant production effect is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Automatic permanent magnet product dividing and box packing equipment

PendingCN108583995AGuaranteed accuracySave the area occupied by the stationPackaging automatic controlEngineeringMechanical engineering

The invention discloses automatic permanent magnet product dividing and box packing equipment which comprises a rack, a conveyor belt, a loading device and a loading box, wherein the loading device comprises a storage groove, a first push block and an air claw; the storage groove and the conveyor belt are perpendicularly and fixedly arranged on the rack; the first push block is positioned on the second side close to the second end of the conveyor belt and is in sliding fit with the rack; the air claw is in sliding fit with the rack, can move up and down and can move horizontally in the lengthdirection of the storage groove; and the air claw is driven by a third air cylinder. The automatic permanent magnet product dividing and box packing equipment is suitable for box packing operation ofpermanent magnet products with multiple specifications, realizes general utilization of the products with multiple specifications, is integrally designed, reduces the equipment station occupied area,can reduce the investment cost compared with the original equipment with the single specification, can automatically adjust the key sizes including box packing position, quantity and the like according to the product specification requirement, greatly improves the working efficiency, ensures the precision of the box packing quantity, and lowers the strength of manual labor.

Owner:京磁材料科技股份有限公司

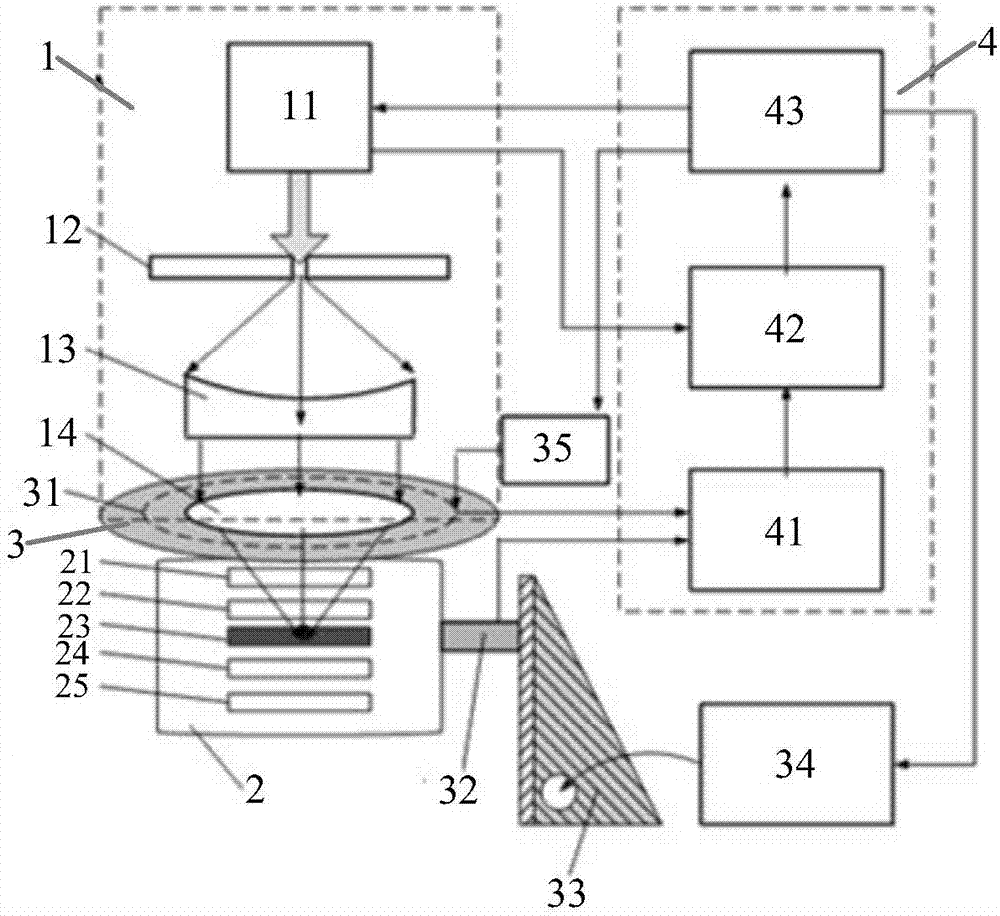

Photoacousticblood glucose detection method and device for automatically positioning vessels

ActiveCN107157491AImprove accuracyExactly fall intoDiagnostic signal processingSensorsAudio power amplifierGlucose detection

The invention provides a photoacousticblood glucose detection method and device for automatically positioning vessels. The device comprises an excitation light source device, a sample device, a detection device and a signal processing device. Theexcitation light source device comprises a laser, a diaphragm, a collimating lens and a focusing lens, wherein the detection device comprises a backwardultrasonic detector, a lateralultrasonic detector, a scanning mobile platform, a mobile platformcontroller and a miniaturefocusing controller; the signal processing device comprises a signal amplifier, a signal acquisition card and a computer which are electrically connected in sequence. The lateralultrasonic detector is fixed on the scanning mobile platform and moves with the scanning mobile platform, and the scanning mobile platform is connected with thecomputer through the mobile platform controller. The input terminal of the signal amplifier is respectively connected with thebackwardultrasonic detector and the lateralultrasonic detector, and the signal acquisition card is connected with the laser. The device and the method realize photoacoustic detection on blood sugar concentration in vessels, and greatly improve the accuracy.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Edible oil filling equipment capable of preventing oil leakage

InactiveCN108640071AExactly fall intoLoading and unloadingSafety device in filling machineryResidual oilEngineering

The invention relates to edible oil filling equipment capable of preventing oil leakage. The edible oil filling equipment comprises a base, a main body, a conveying belt, a material box, a controllerand two adjusting mechanisms; the main body is provided with a concave opening, a lifting mechanism, a filling opening and a conveying pipe; an anti-leakage mechanism comprises a stretchable assembly,a dual-rectangular-shaped frame and an anti-leakage box, side plates are arranged on the four sides of the anti-leakage box, through holes are formed in the side plates, and protruding rods are arranged on the four sides of the dual-rectangular-shaped frame; and each adjusting mechanism comprises a vertical plate, a fixing plate, an excursion plate, two excursion assemblies and two fixing assemblies, and each fixing assembly comprises a first motor, a first driving shaft and a sleeve. According to the edible oil filling equipment capable of preventing oil leakage, the anti-leakage box receives residual oil drops falling from the filling opening through the anti-leakage mechanism, the oil drops are prevented from influencing cleanliness of the conveying belt and a bottle body, and the packaging quality is guaranteed; and in addition, the adjusting mechanisms are used for adjusting the position of the bottle body, a bottle opening aligns at the filling opening, edible oil can conveniently and accurately fall into the bottle body, filling is completed, and the equipment practicability is improved.

Owner:南安市执力信息科技有限公司

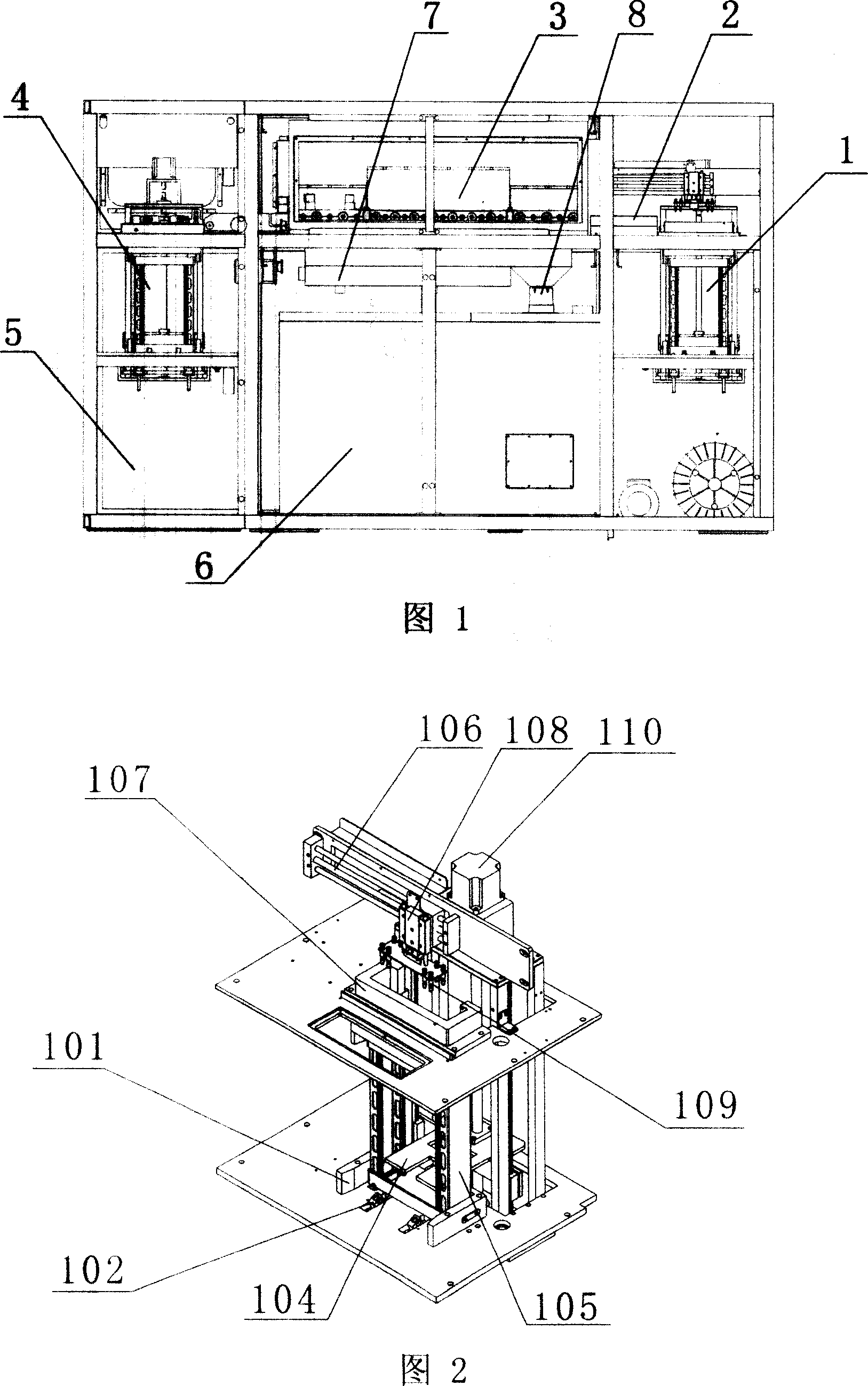

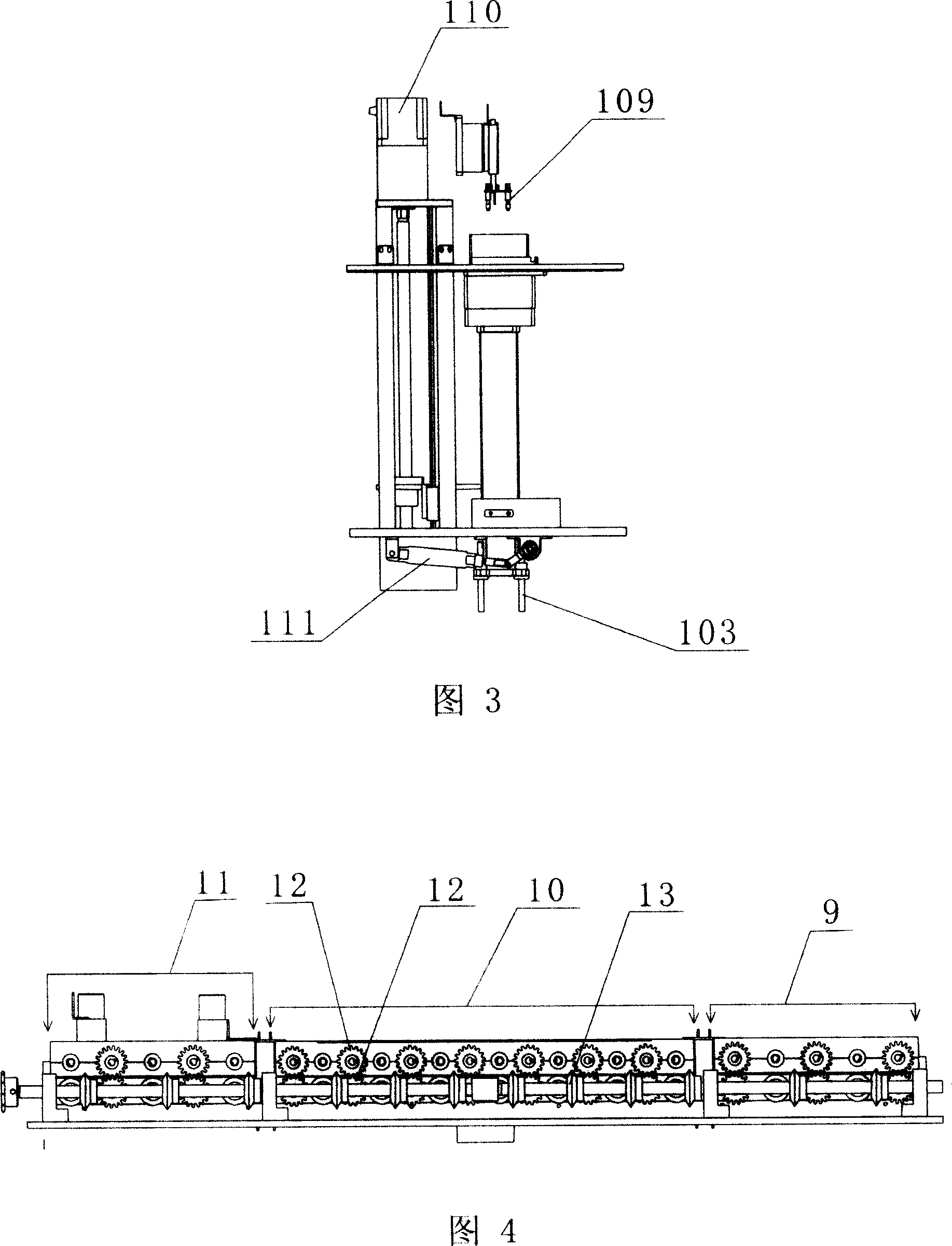

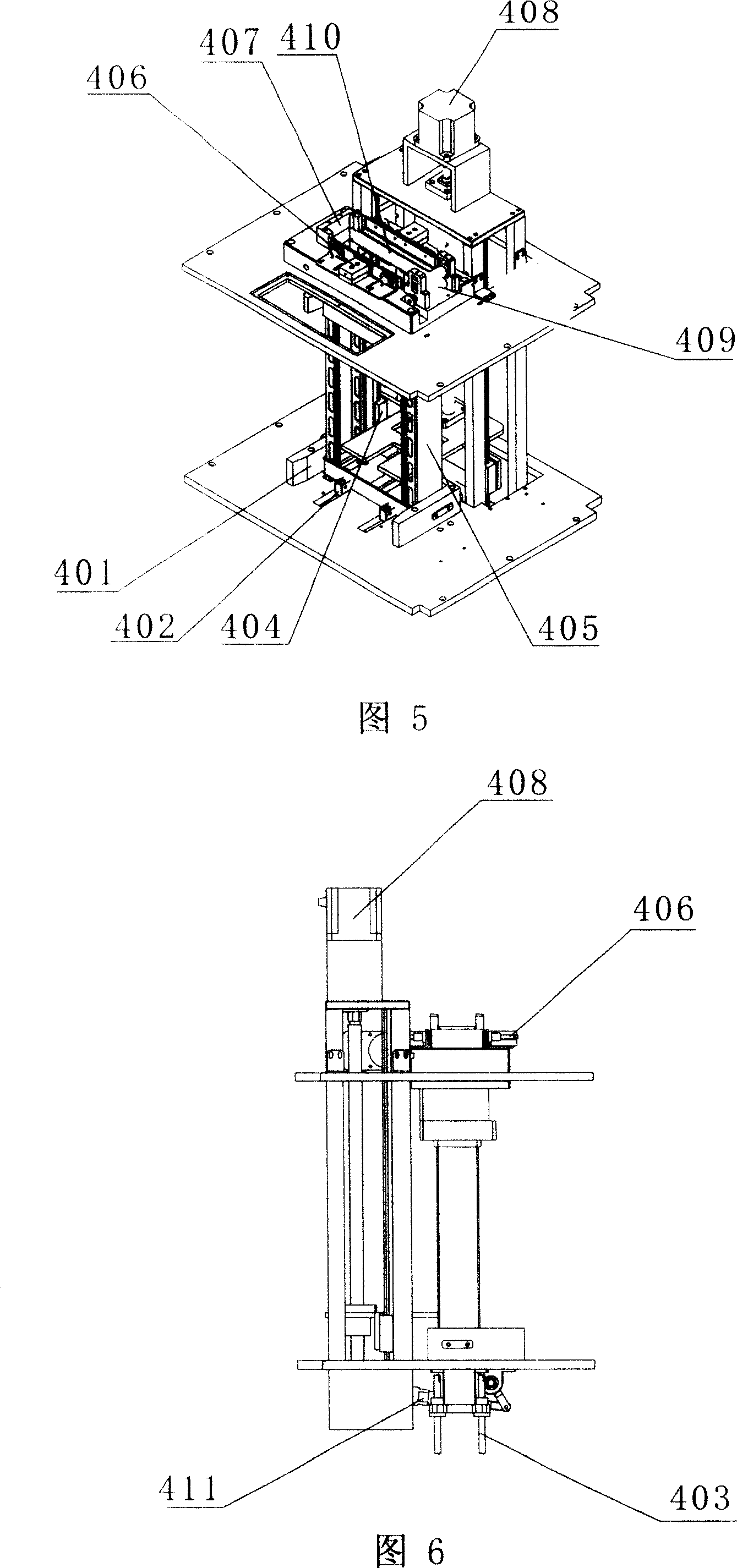

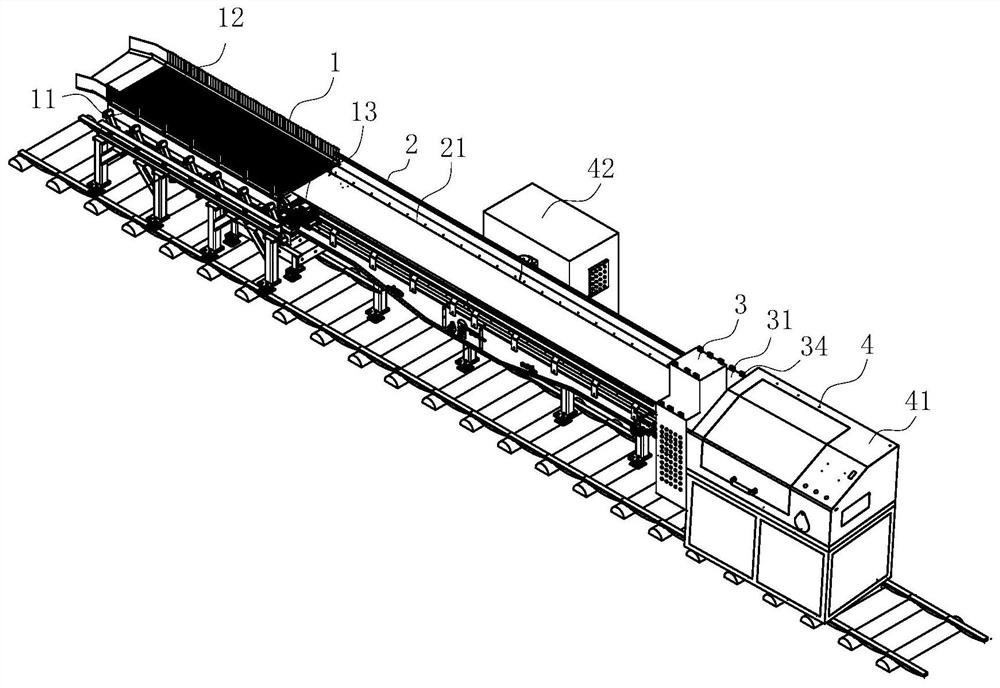

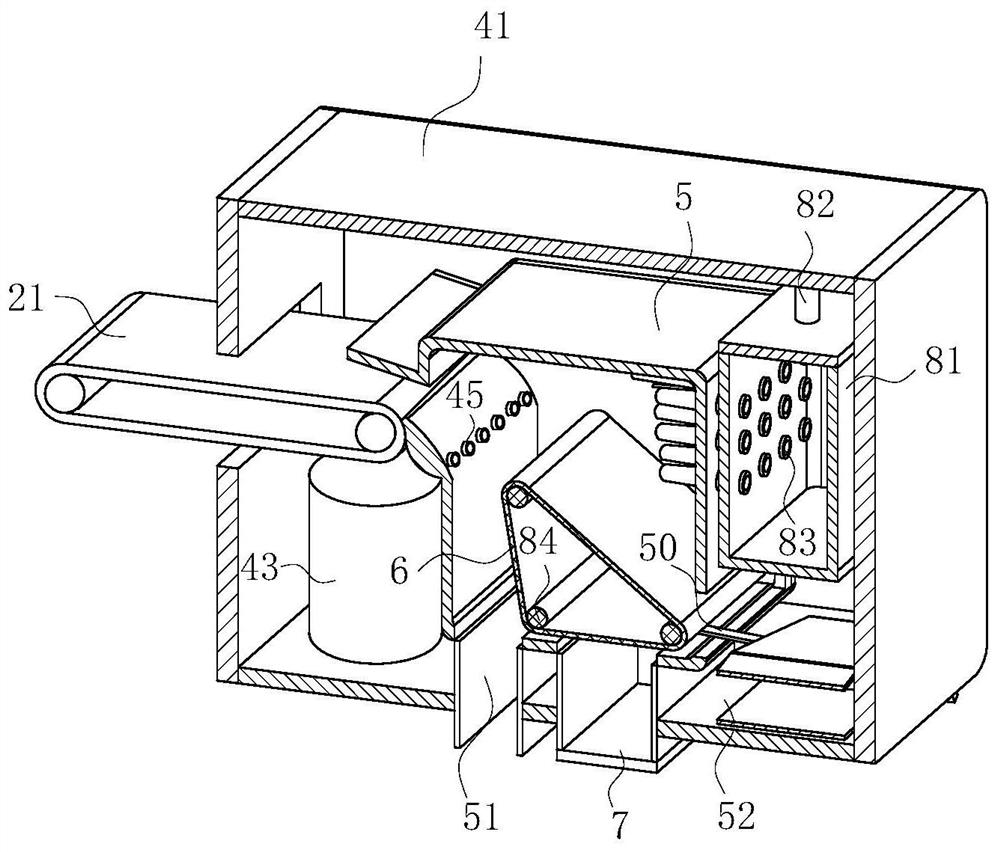

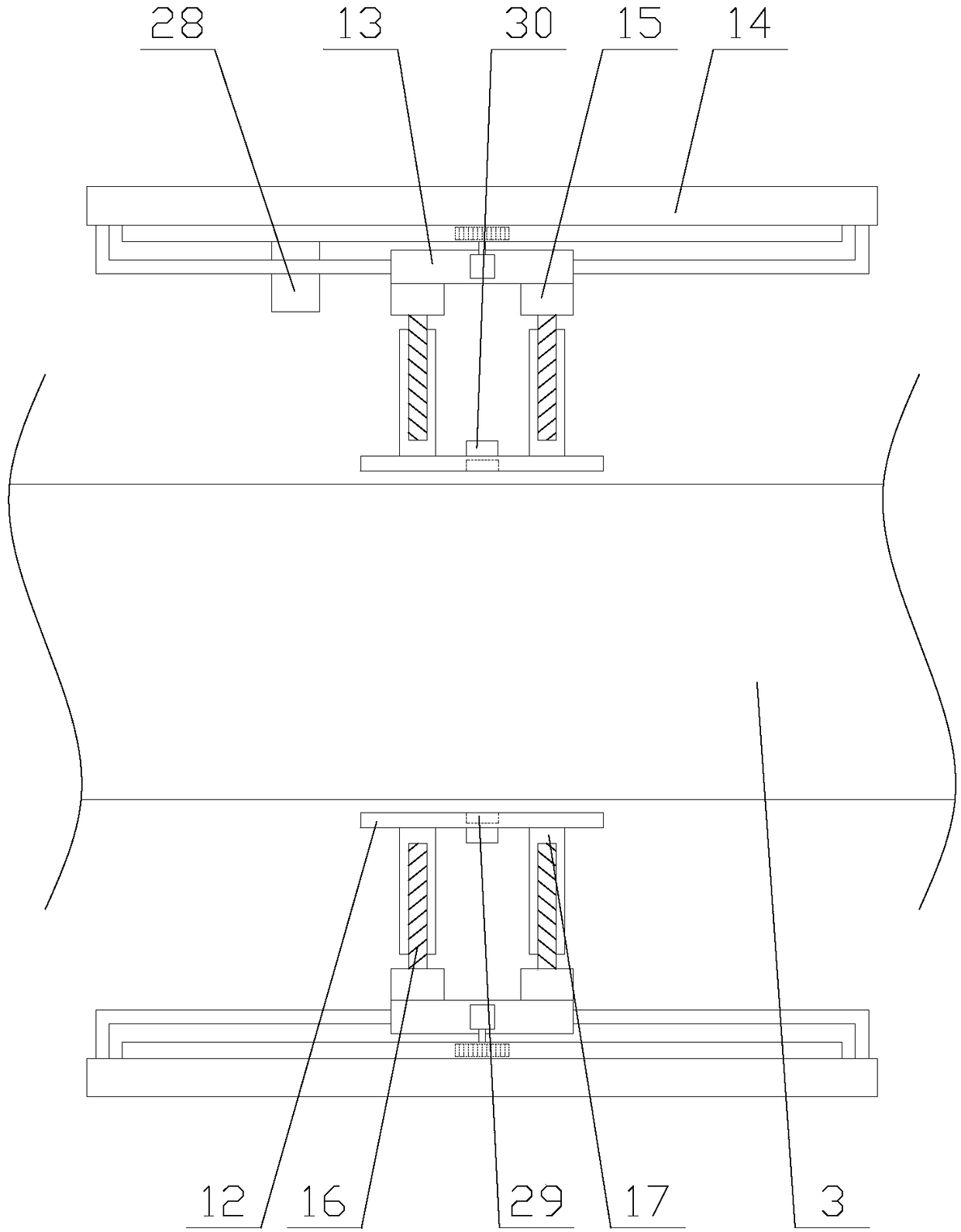

Horizontal cut tobacco boxing system and boxing method

ActiveCN108910131AHigh densityImprove work efficiencyPackagingTransfer mechanismAgricultural engineering

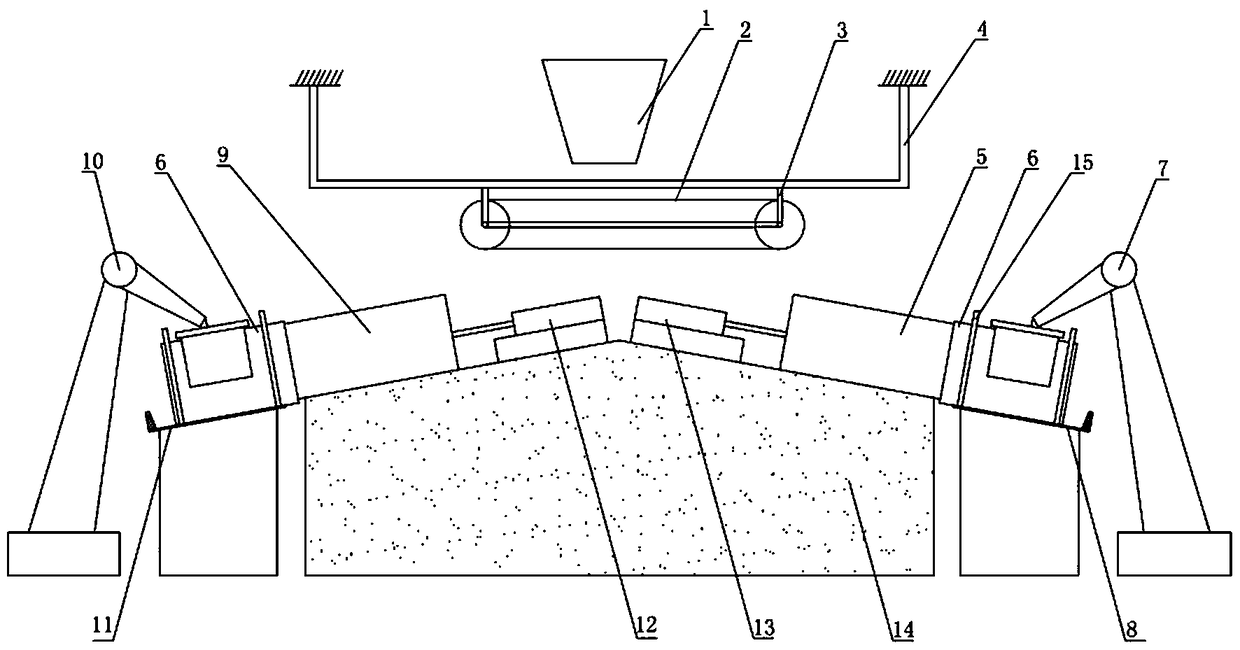

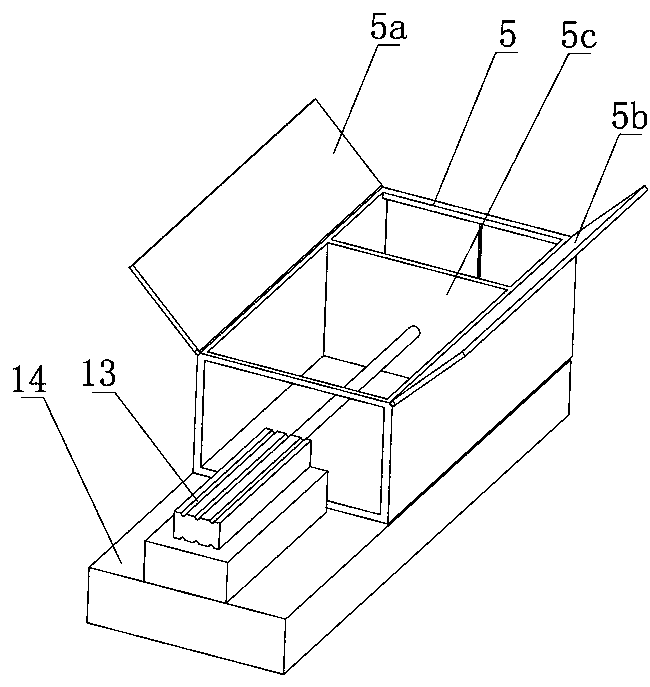

The invention discloses a horizontal cut tobacco boxing system and boxing method. The horizontal cut tobacco boxing system comprises a quantitative feeding mechanism, a pre-pressing mechanism, a transfer mechanism and a tobacco box. The quantitative feeding mechanism is located above the pre-pressing mechanism and paves tobaccos quantitatively in a reciprocating mode in the pre-pressing mechanism;the transfer mechanism is arranged on the right side of the pre-pressing mechanism which is arranged on the bottom right side of the quantitative feeding mechanism; left and right symmetrical reversepre-pressing mechanisms same in structure with the pre-pressing mechanism are arranged on the bottom left side of the quantitative feeding mechanism; and left and right symmetrical reverse transfer mechanisms same in structure with the transfer mechanism are arranged on the left sides of the reverse pre-pressing mechanisms. The horizontal cut tobacco boxing system disclosed by the invention can improve the boxing uniformity and the boxing density of tobacco materials in the box and reduce the occupied area and the transportation cost, is low in demand on site, suitable for boxing and distributing of the tobacco materials such as cut tobaccos, tobacco sheets, expanded cut tobaccos, tobacco slices and cut stems and wide in application range. Meanwhile, a vertical boxing mode is replaced bya horizontal boxing mode, so that the demand on the size of the boxing equipment and the plant design is reduced, and the equipment cost is lowered indirectly.

Owner:CHINA TOBACCO HENAN IND

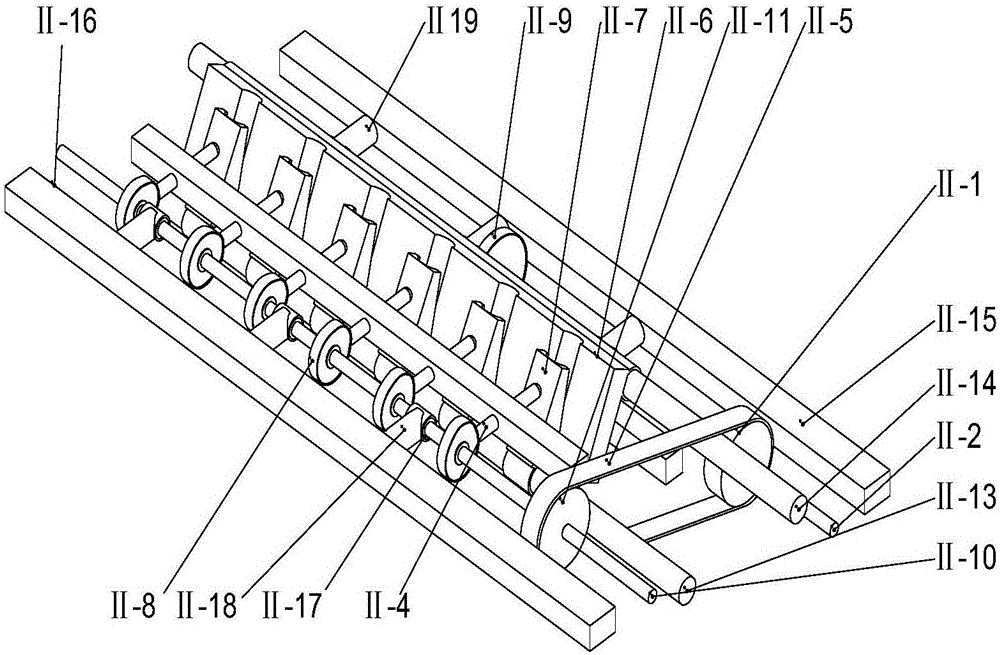

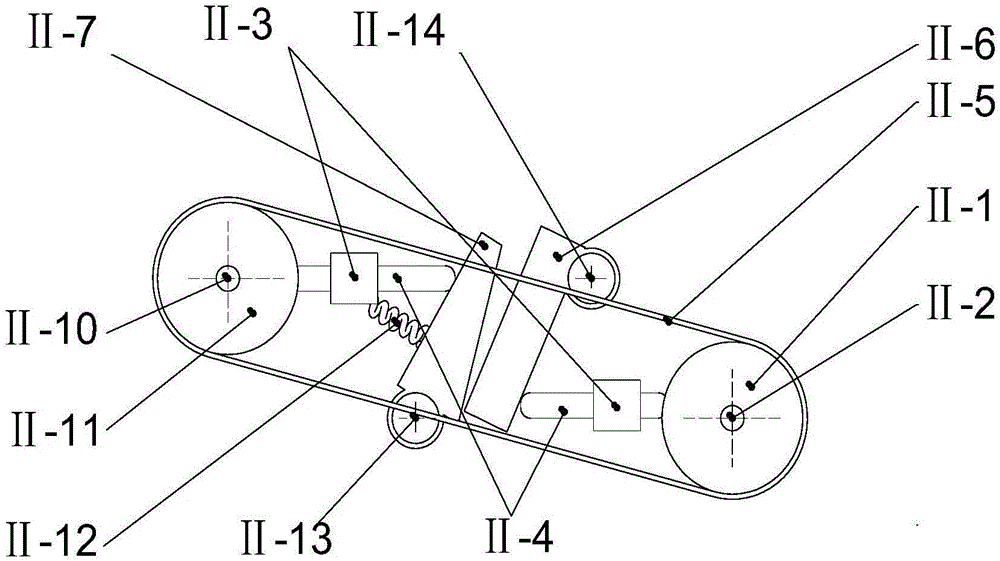

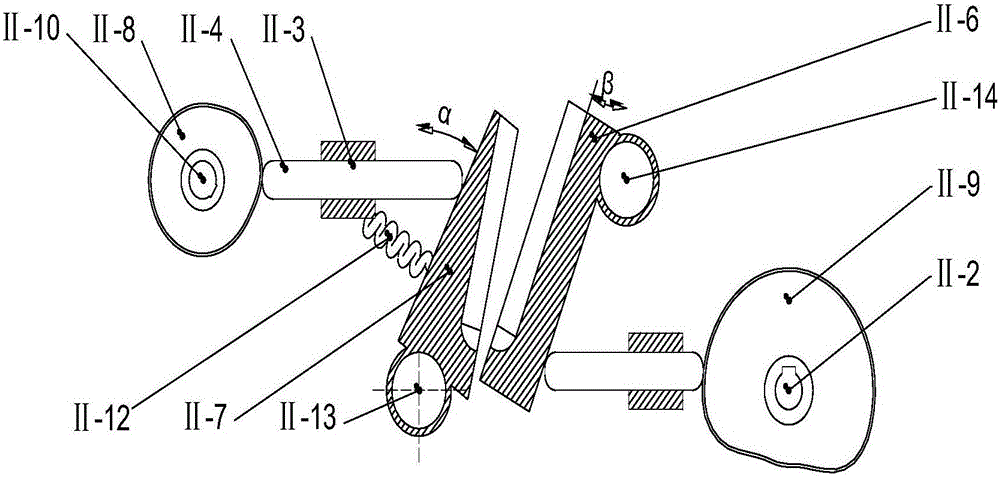

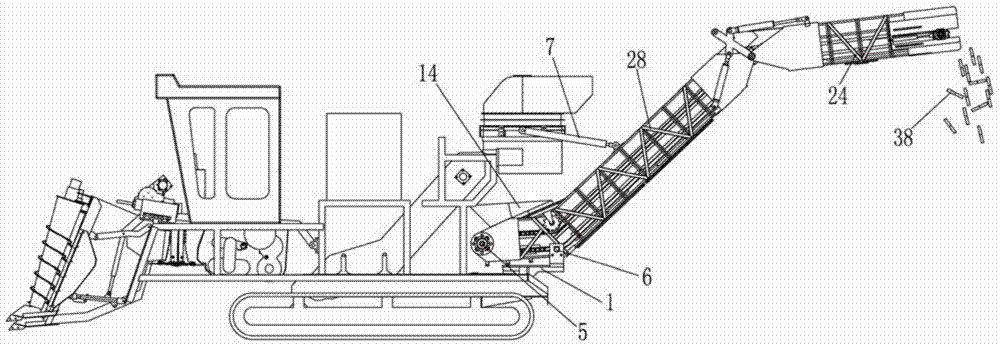

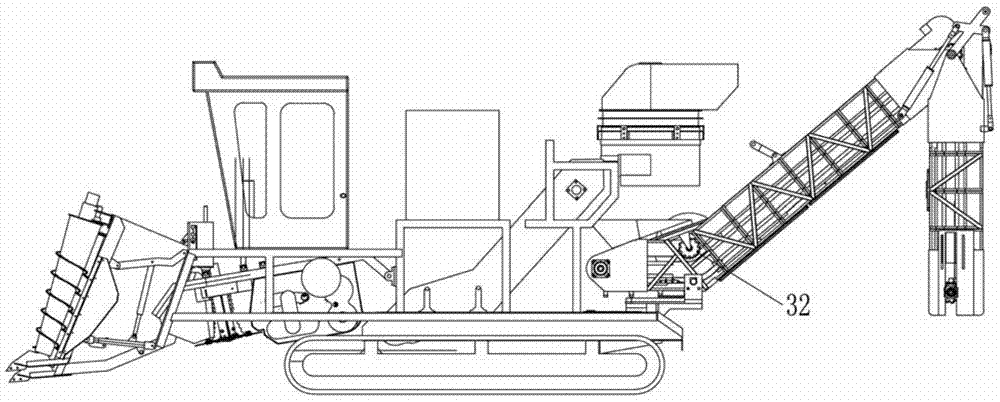

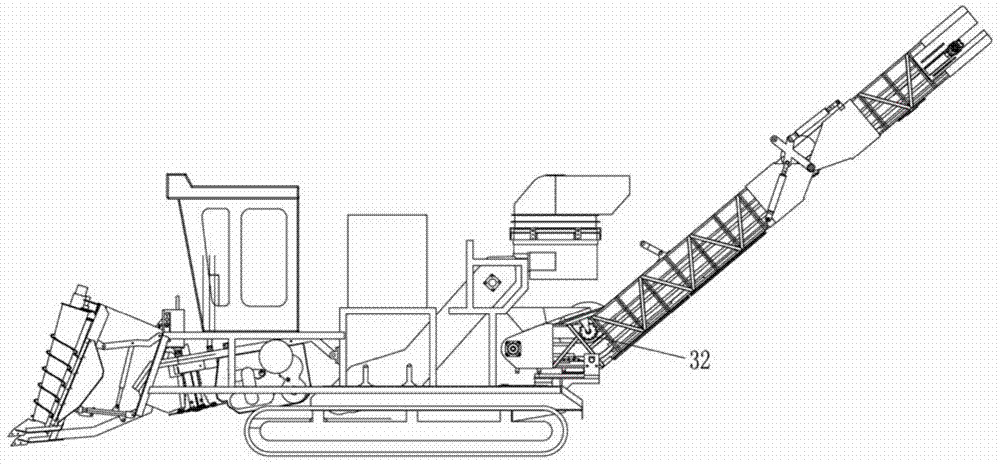

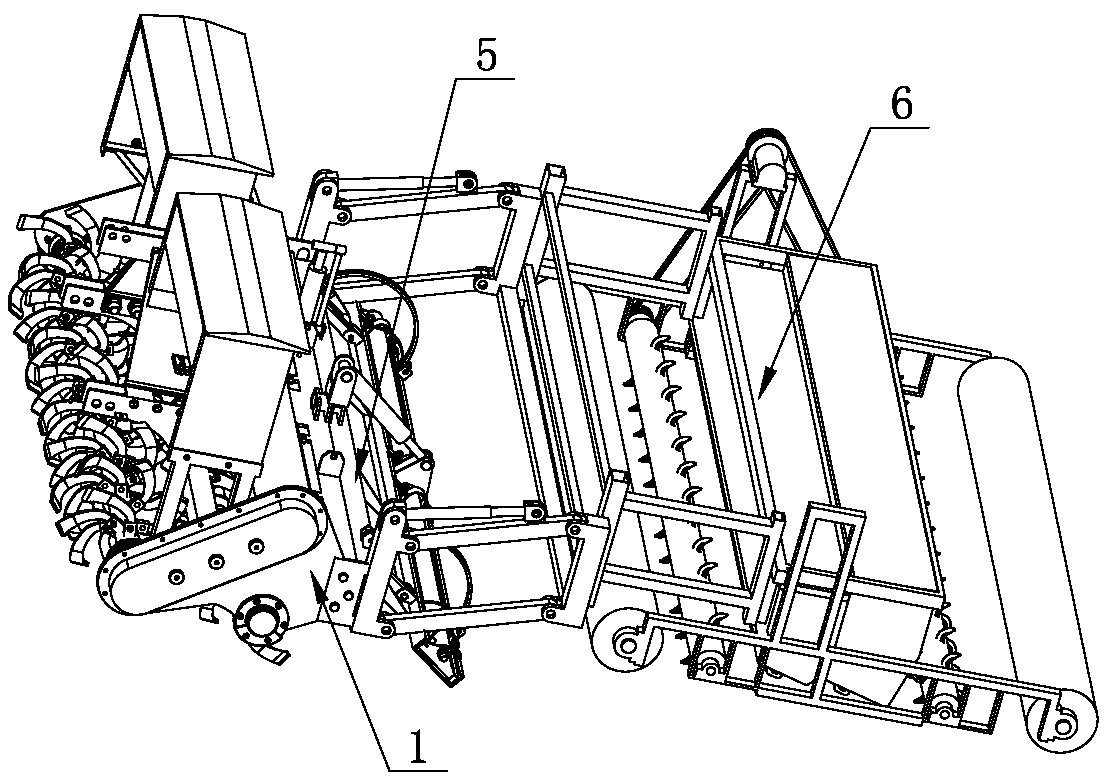

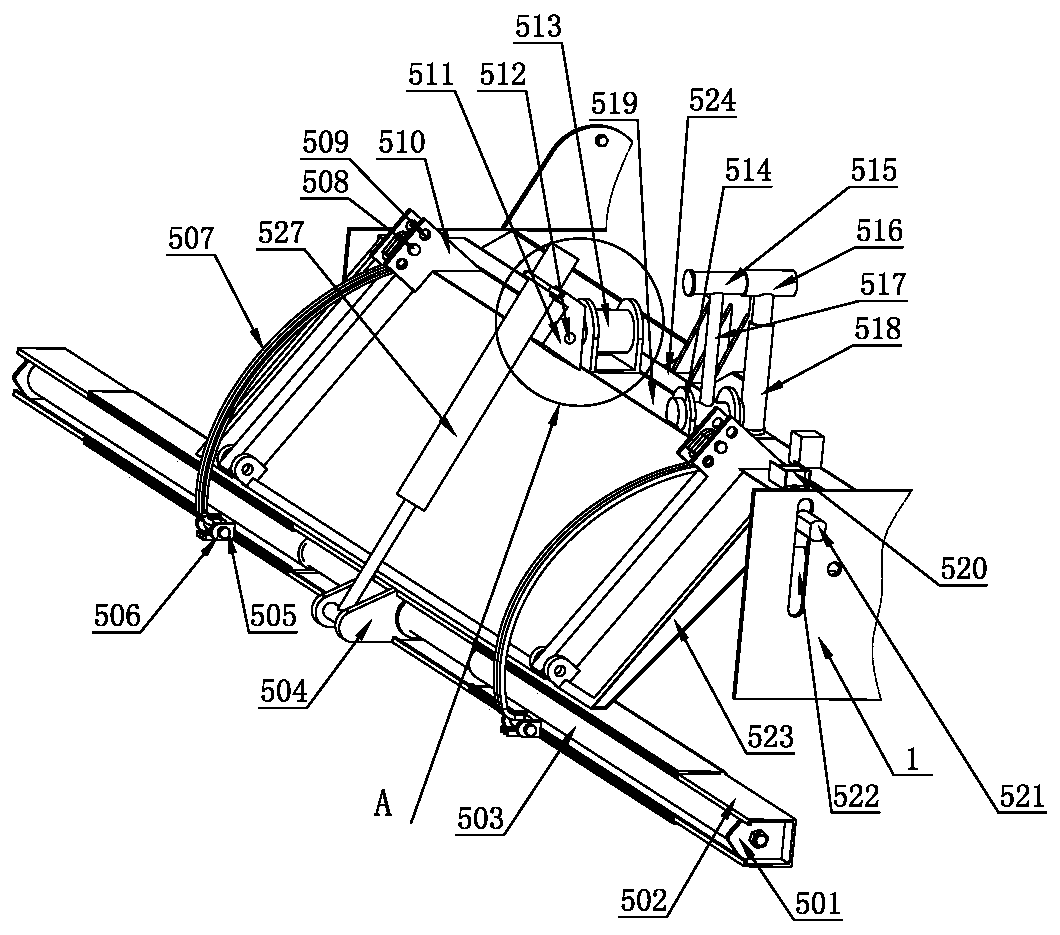

Foldable scraper blade type conveying arm for cutting type sugarcane harvester

The invention discloses a foldable scraper blade type conveying arm for a cutting type sugarcane harvester. The foldable scraper blade type conveying arm for the cutting type sugarcane harvester comprises an upper arm section, a lower arm section, a folding driving portion and a chain scraper blade mechanism, wherein one end of the upper arm section is hinged to a first driven chain wheel shaft; the other end of the upper arm section is provided with a driving chain wheel shaft; one end of the lower arm section is hinged to the first driven chain wheel shaft; the other end of the lower arm section is provided with a second driven chain wheel shaft and is hinged to a horizontal angular rotating plate through a first hinge pin; the lower arm section is connected with the cutting type sugarcane harvester through a first hydraulic cylinder; the upper arm section and the lower arm section are driven through the folding driving portion and can be folded or unfolded; bottom plates for supporting materials are respectively arranged on the upper arm section and the lower arm section; two chains of the chain scraper blade mechanism are wound on chain wheels at two ends of the first driven chain wheel shaft, two ends of the second driven chain wheel shaft and two ends of the driving chain wheel shaft; and a scraper blade for scraping materials on the bottom plates is arranged between the two chains. The foldable scraper blade type conveying arm can accurately convey sugarcane sections, and can be folded in a conveying process.

Owner:SOUTH CHINA AGRI UNIV

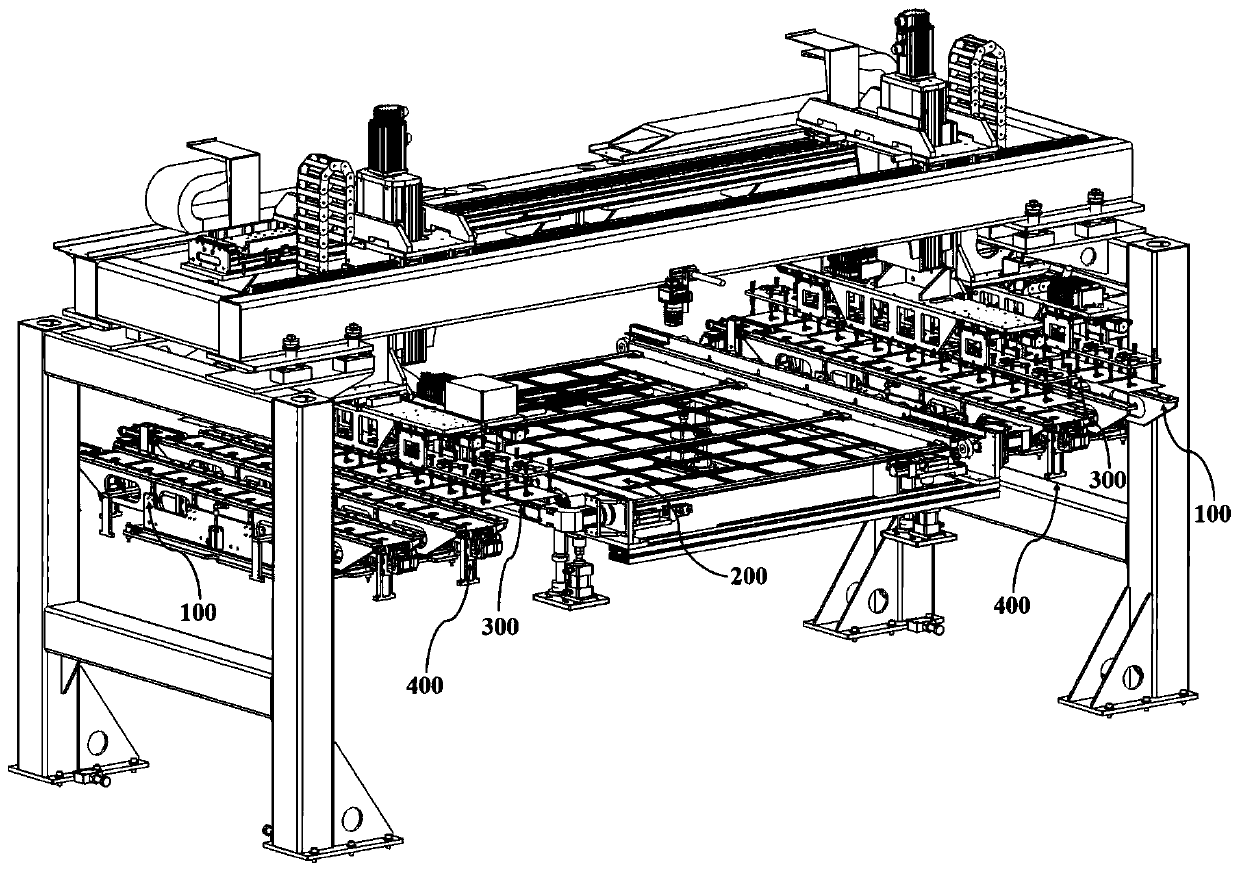

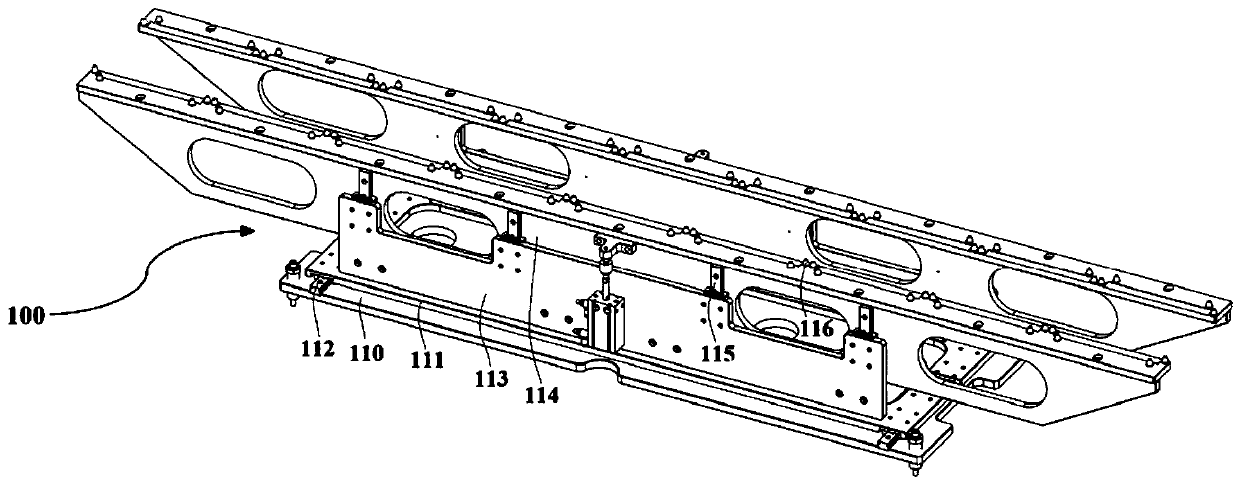

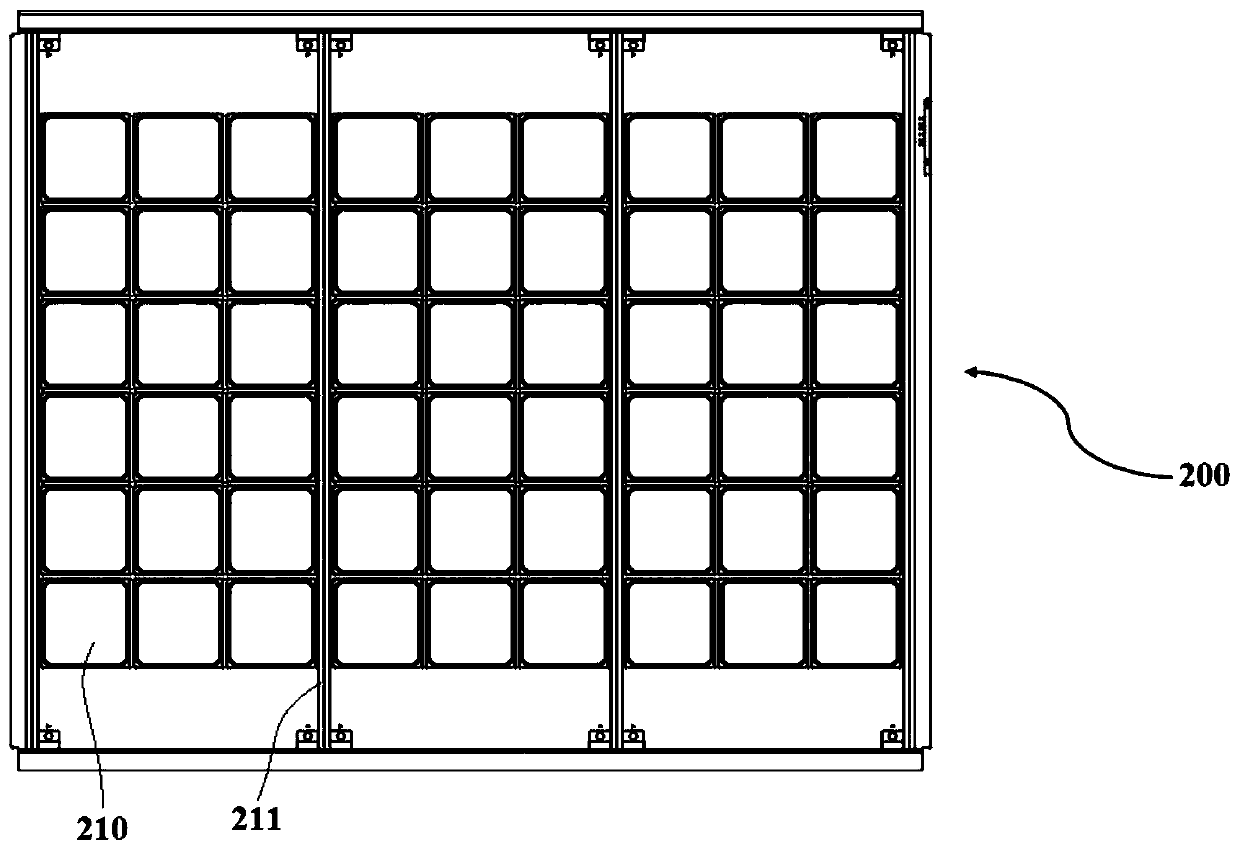

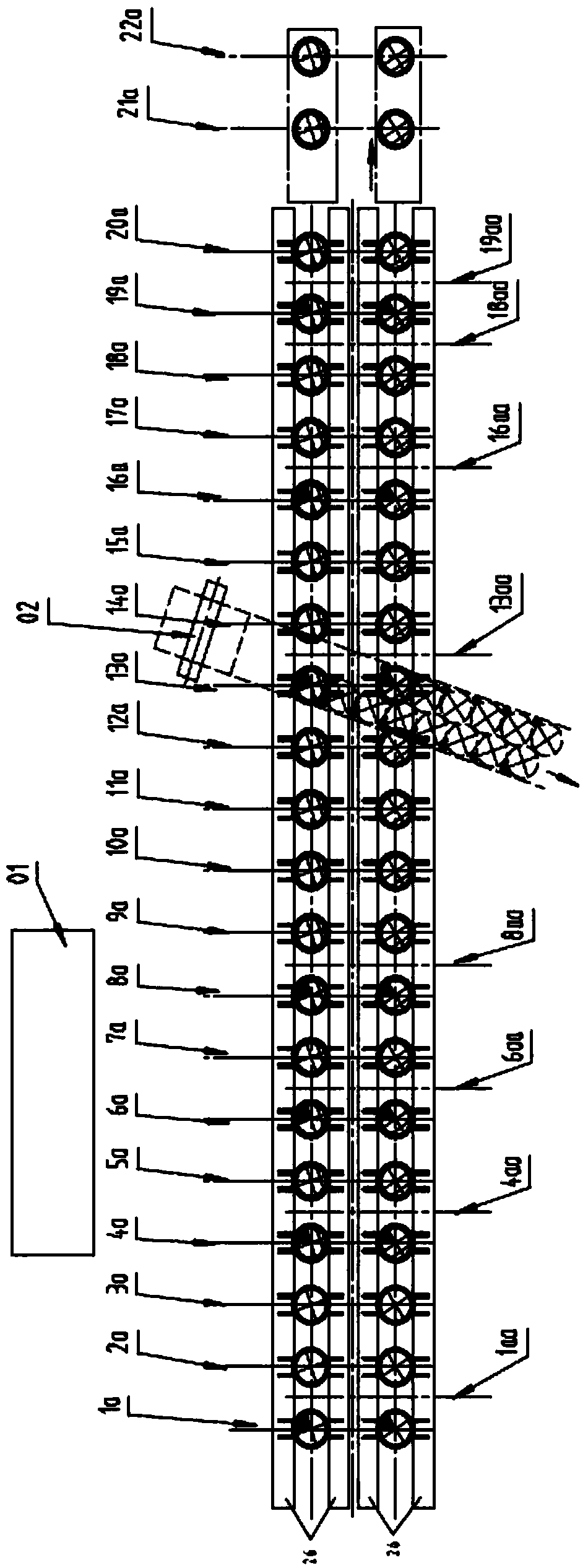

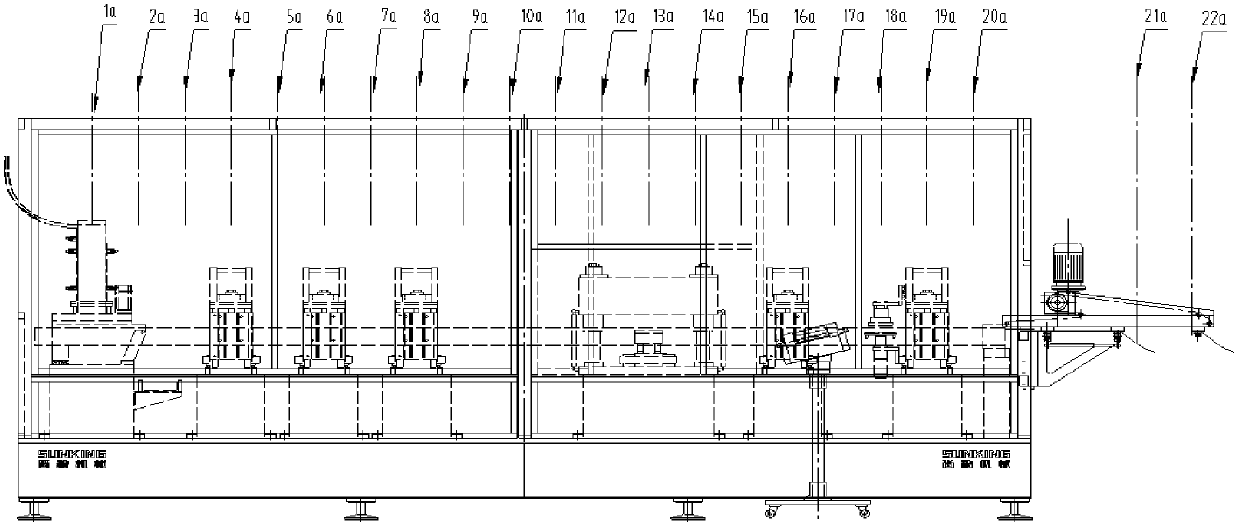

Silicon wafer feeding and discharging transmission system

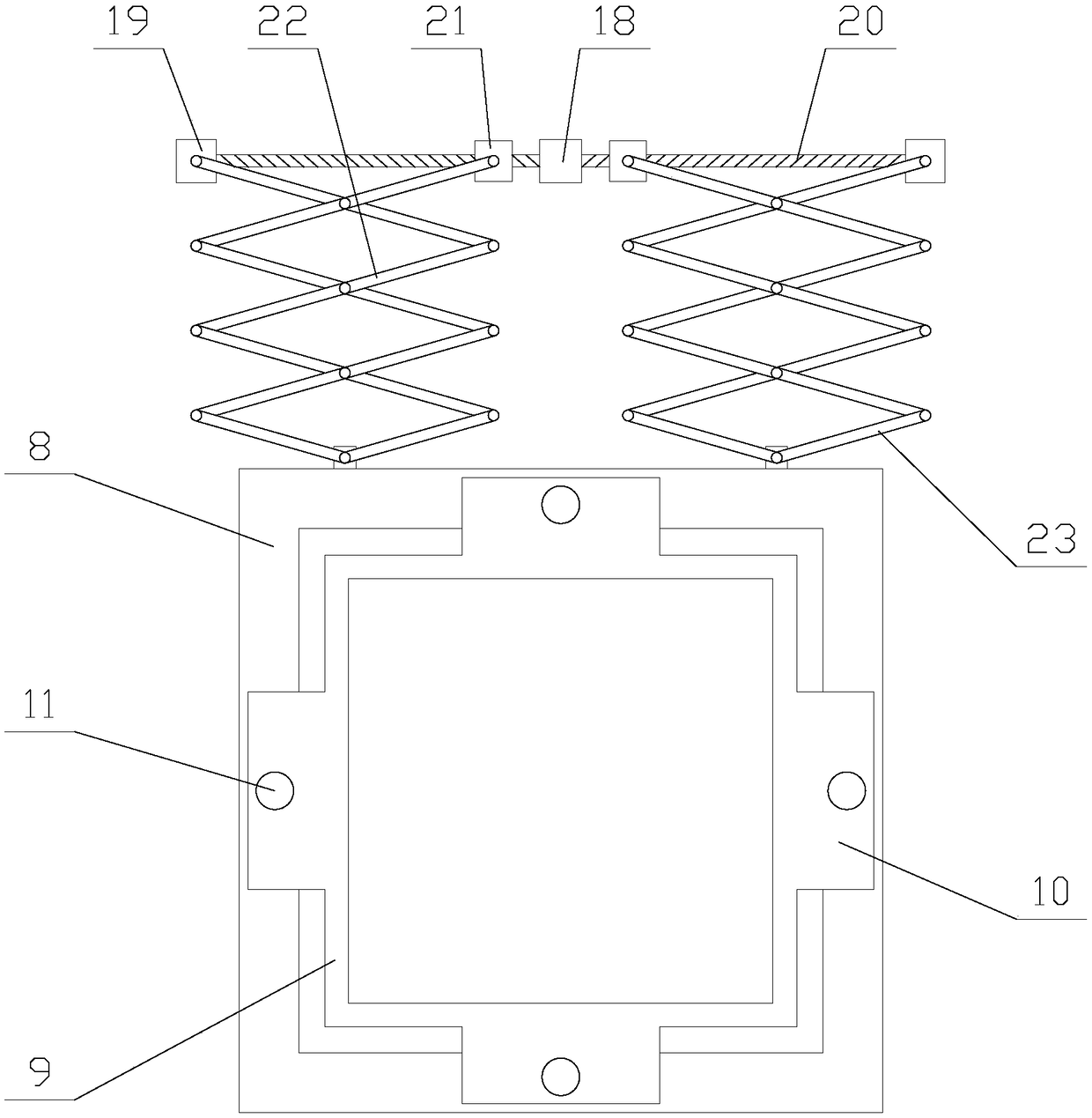

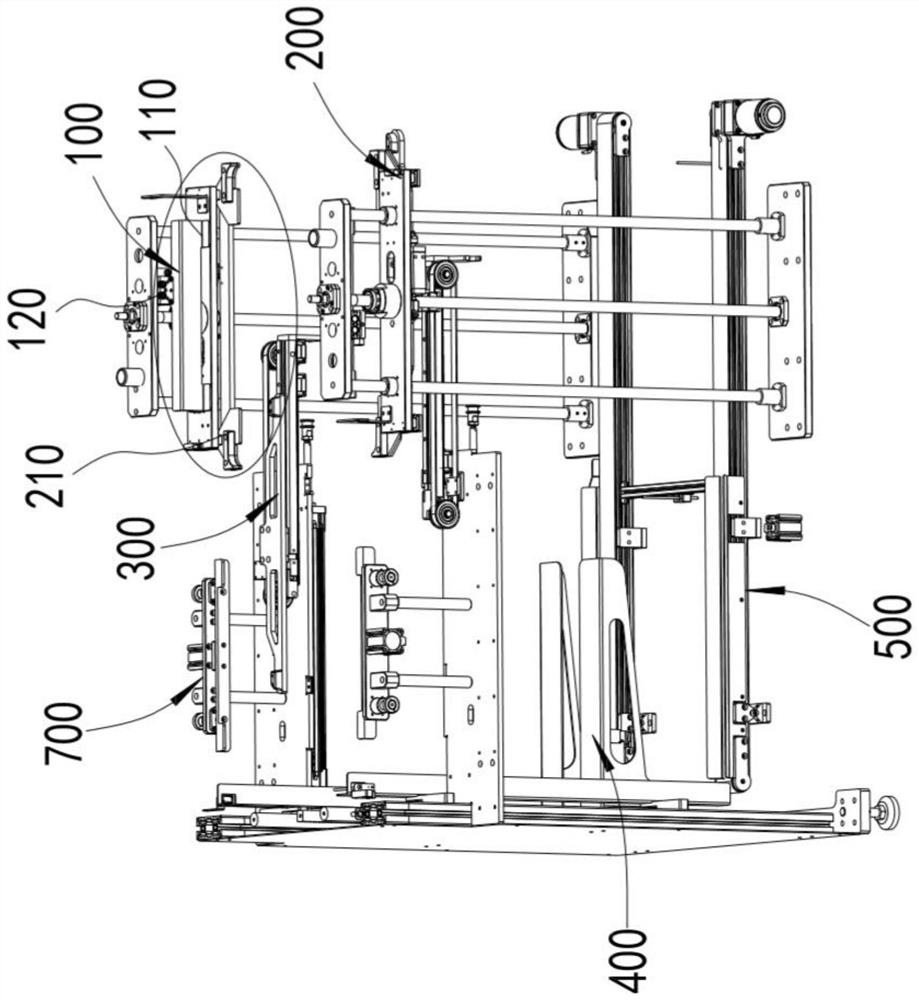

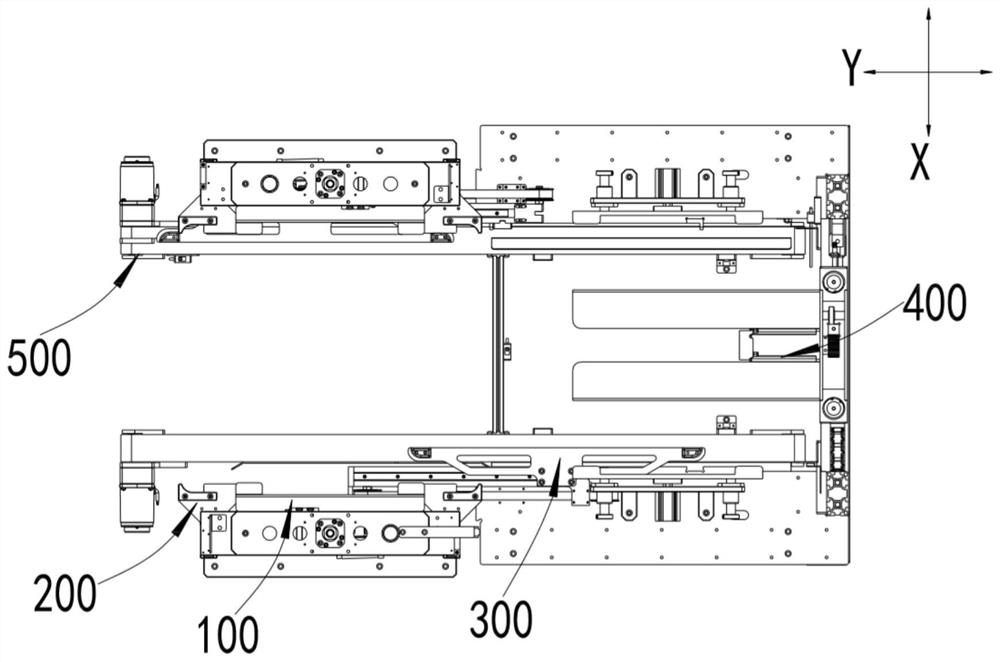

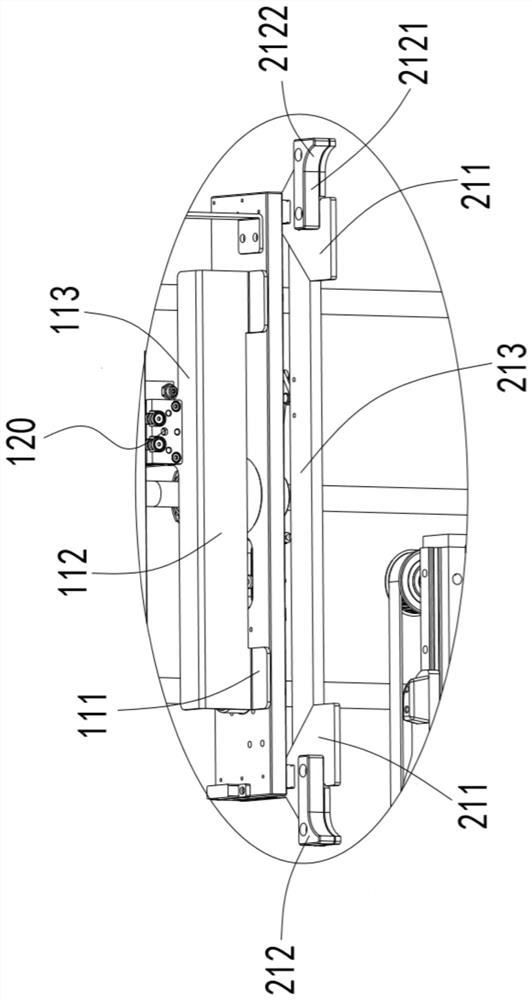

PendingCN111312641AImprove transmission efficiencyRealize accurate dockingSemiconductor/solid-state device manufacturingConveyor partsSilicon chipTransmission system

The invention discloses a silicon wafer feeding and discharging transmission system, and belongs to the technical field of solar cells. The feeding and discharging transmission system comprises a silicon wafer positioning mechanism, a silicon wafer carrier, a silicon wafer variable-pitch carrying mechanism and a belt conveying mechanism, wherein the silicon wafer variable-pitch carrying mechanismis used for carrying silicon wafers from the silicon wafer positioning mechanism to the silicon wafer carrier or carrying the silicon wafers from the silicon wafer carrier to the belt conveying mechanism, and the silicon wafer variable-pitch carrying mechanism is used for carrying out variable-pitch adjustment on the silicon wafer so that the silicon wafer can be matched with the silicon wafer positioning mechanism and the silicon wafer pocket on the silicon wafer carrier respectively. The silicon wafer variable-pitch carrying mechanism can carry out variable-pitch adjustment on silicon wafersso as to adapt to the silicon wafer positioning mechanism and the silicon wafer pockets on the silicon wafer carrier, the transmission efficiency is greatly improved and accurate butt joint of feeding and discharging of the silicon wafers is achieved.

Owner:SUZHOU MAXWELL TECH CO LTD

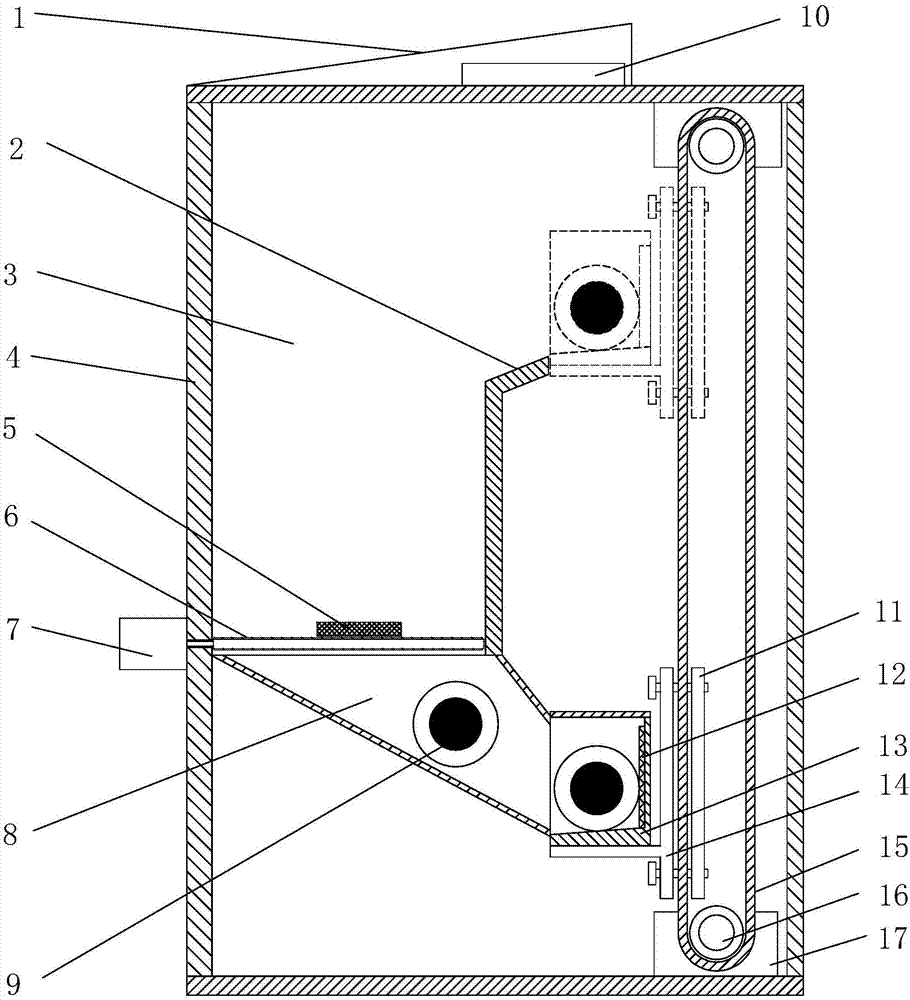

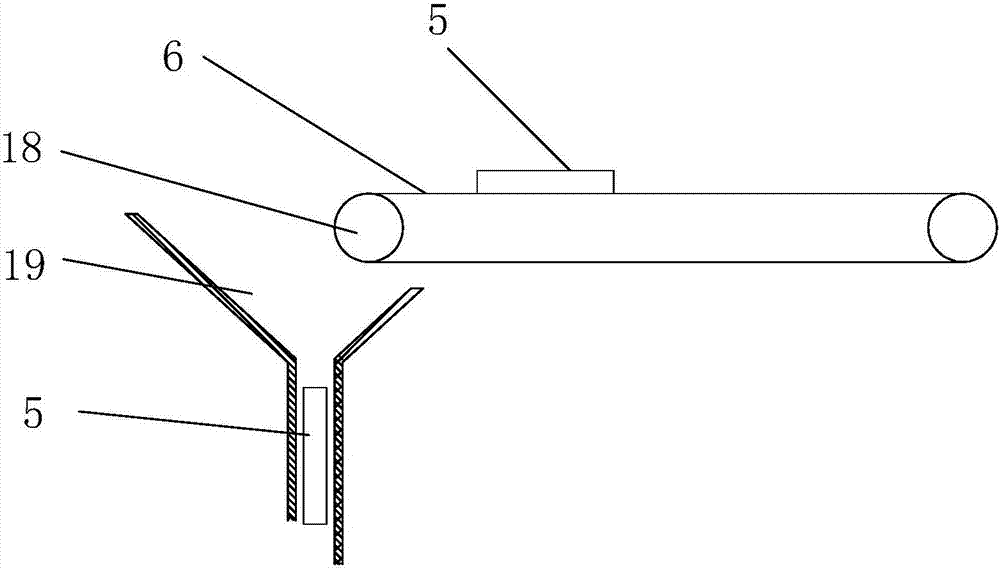

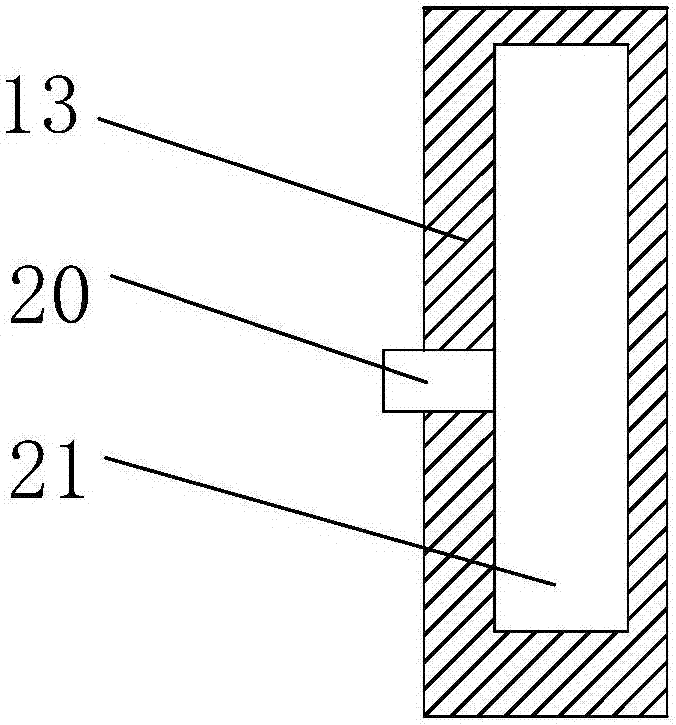

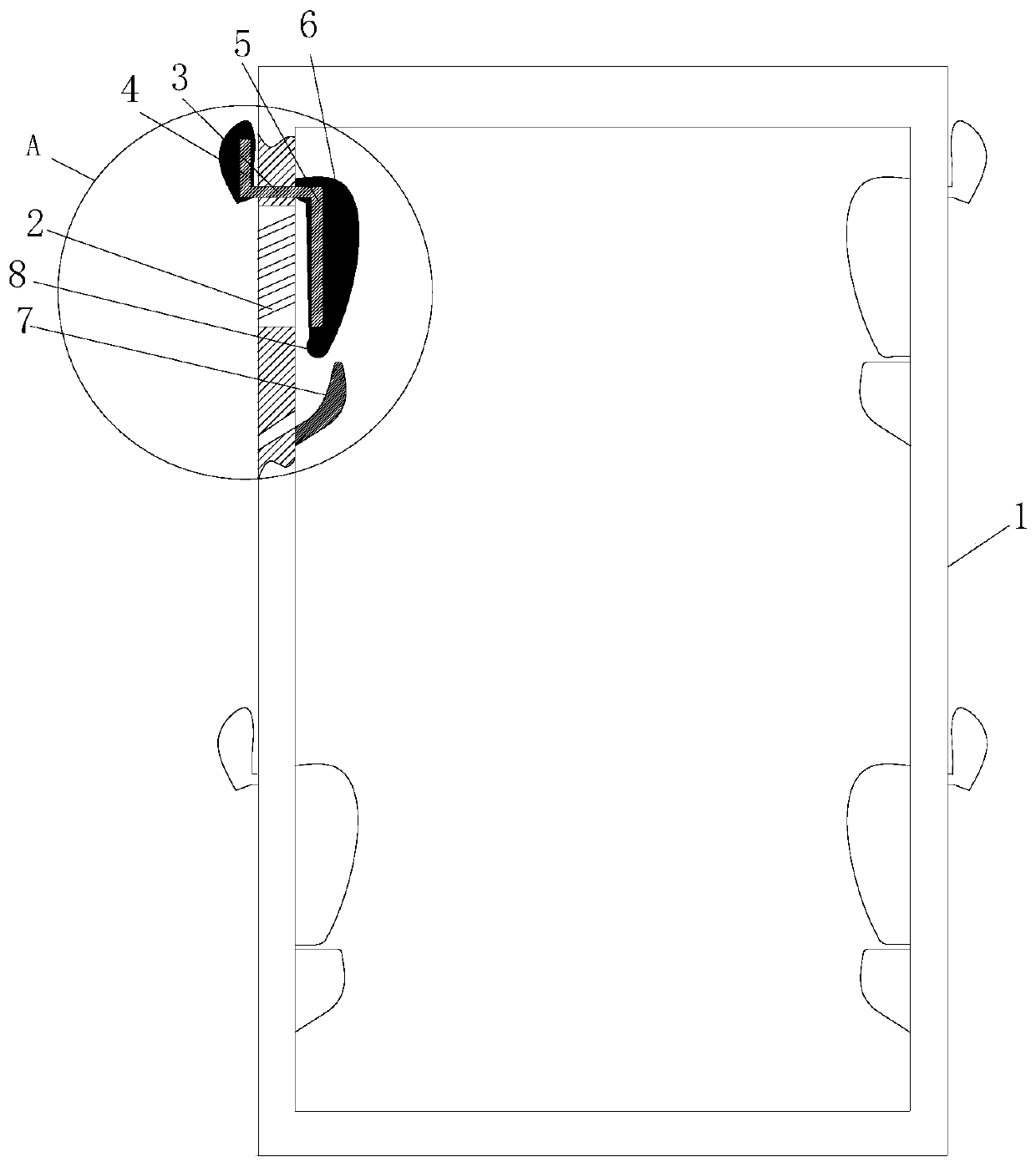

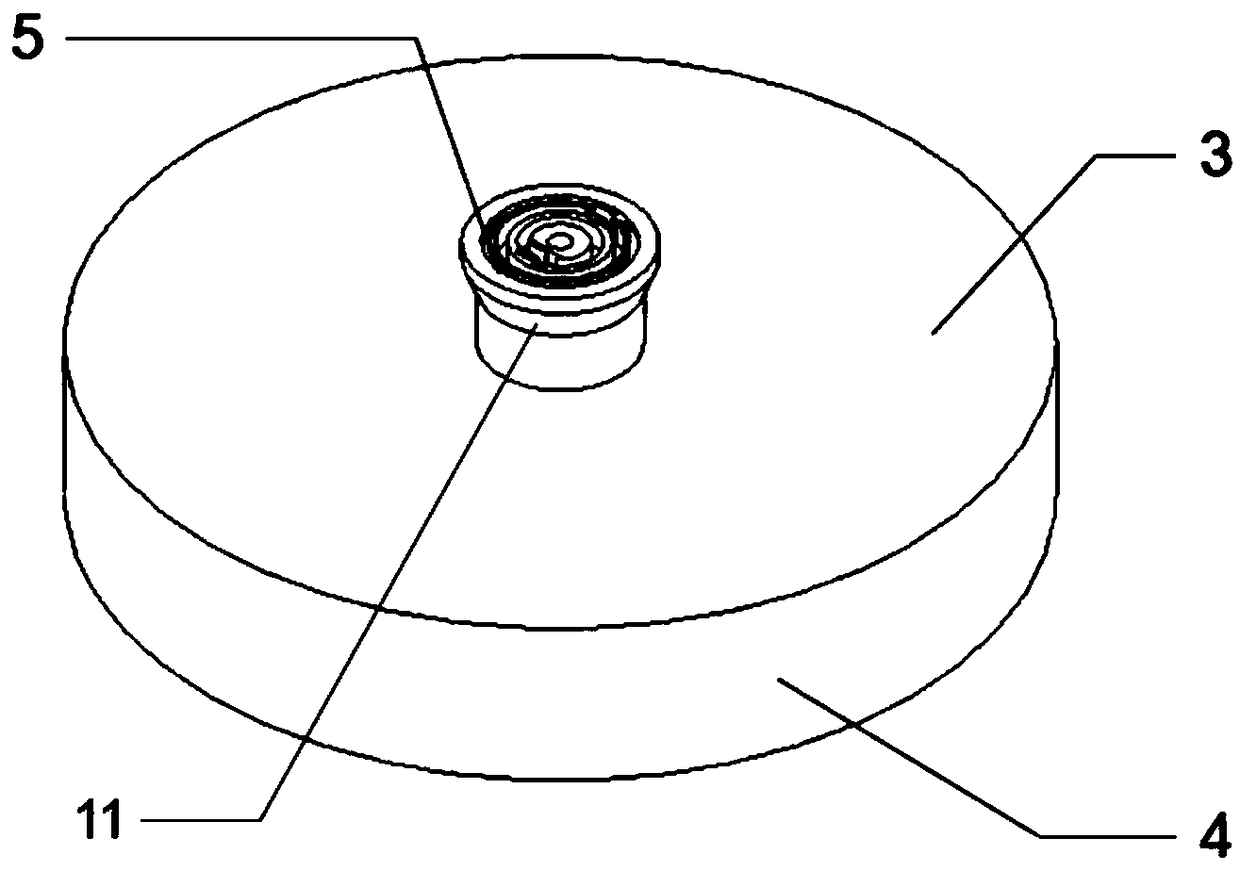

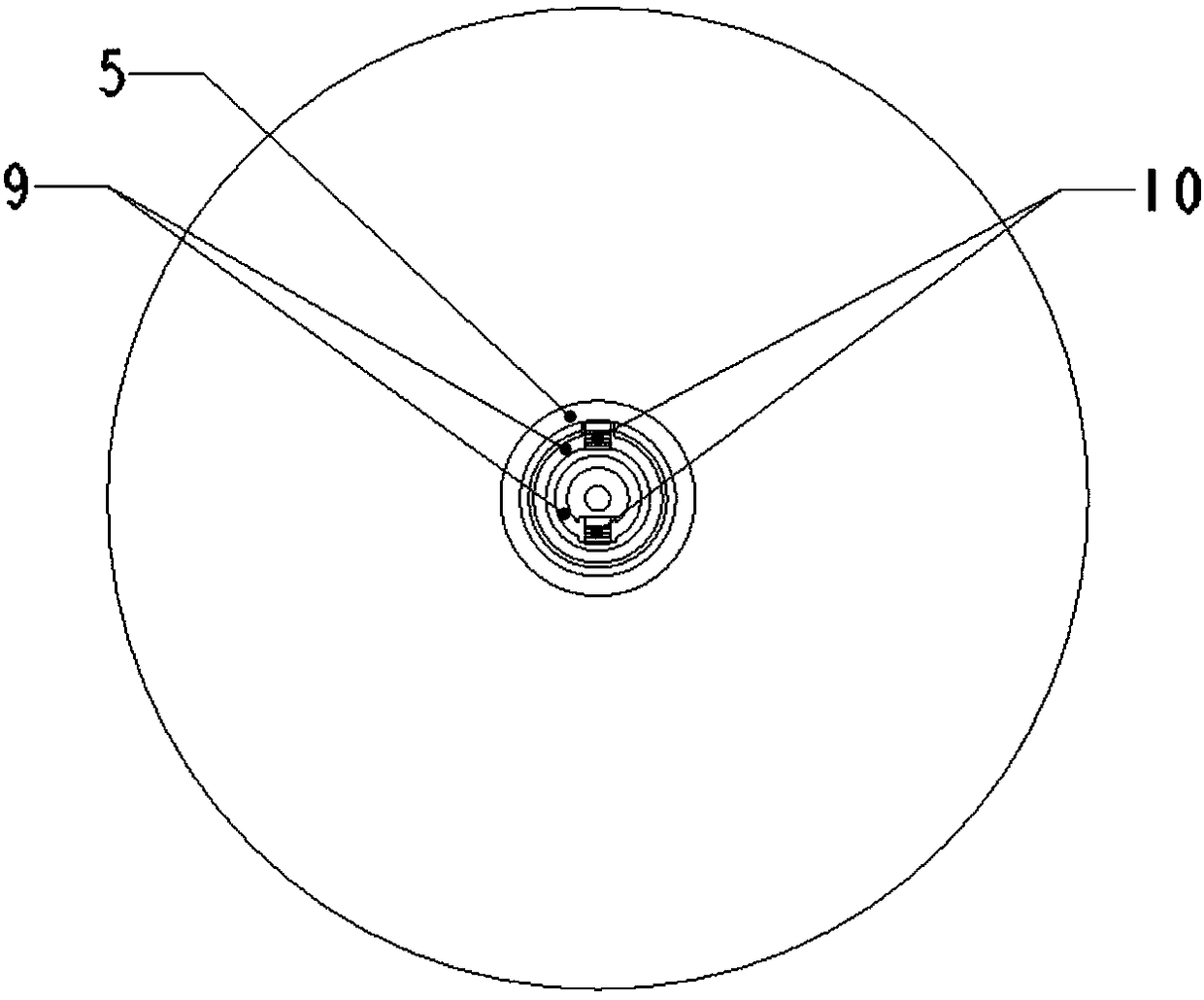

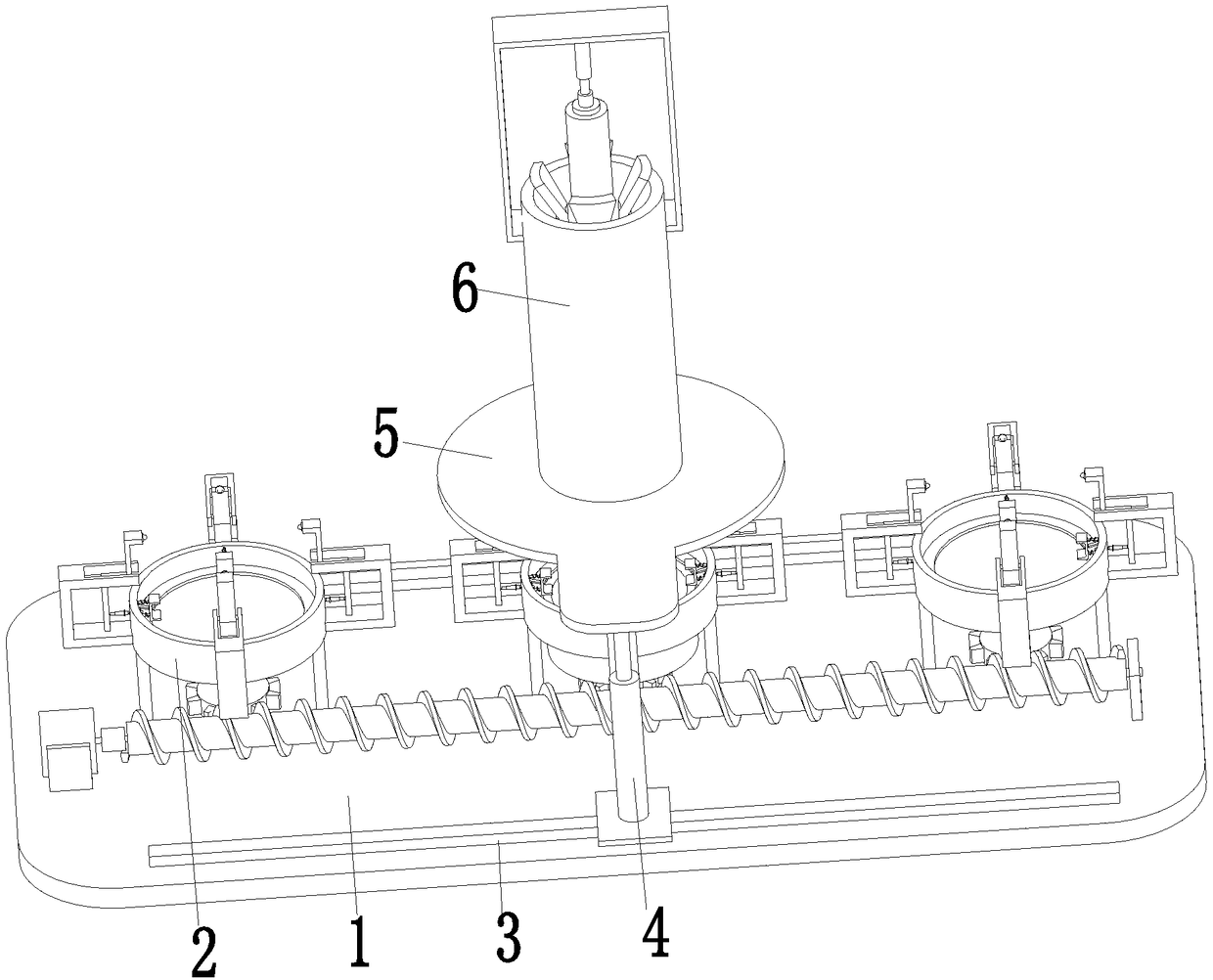

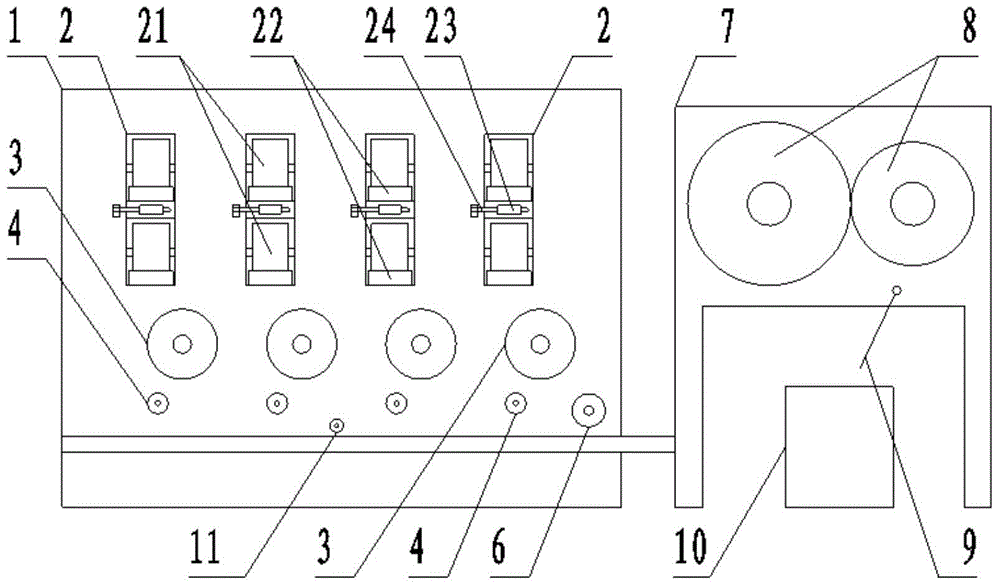

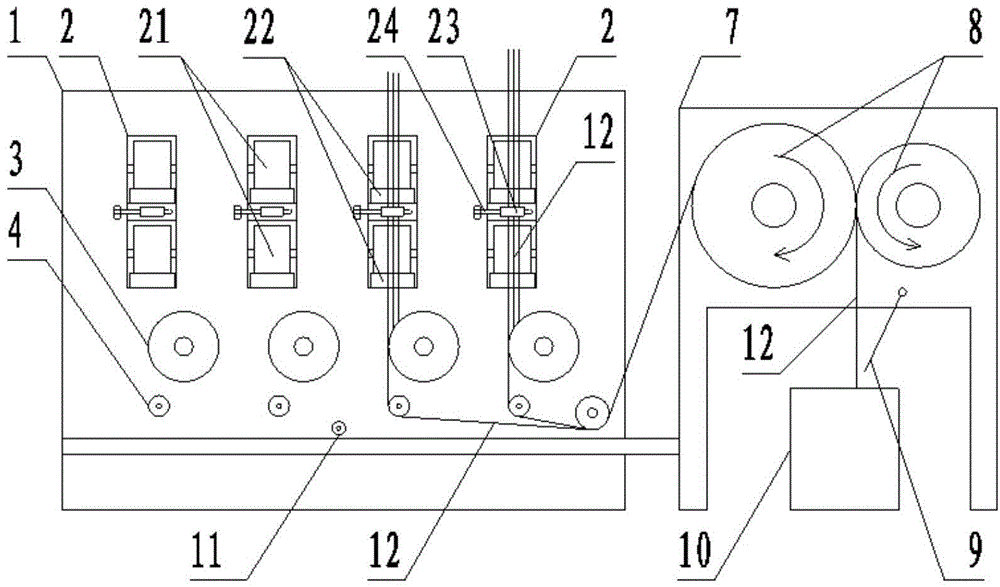

Automatic fiber collecting device

The invention discloses an automatic fiber collecting device. The automatic fiber collecting device comprises a rack (1), and a plurality of lubricating devices (2) are arranged at the upper end of the rack (1); a limiting wheel (3) is arranged below each lubricating device (2), and a guiding wheel (4) is arranged below each limiting wheel (3); a liquid collecting groove (5) is formed in the position below the guiding wheels (4), and a tensioning wheel (6) is arranged above the right end of the liquid collecting groove (5); a gear frame (7) is arranged at the right side of the rack (1), two gears meshed with each other are arranged on the gear frame (7), a baffle (9) is arranged below the meshed portion of the two gears (8), and a circular bucket (10) is arranged below the baffle (9). The automatic fiber collecting device not only can improve the fiber collecting efficiency, but also has the advantages of being capable of preventing fiber from being abraded and preventing workshop environment from being polluted.

Owner:湖州港湖塑料贸易有限公司

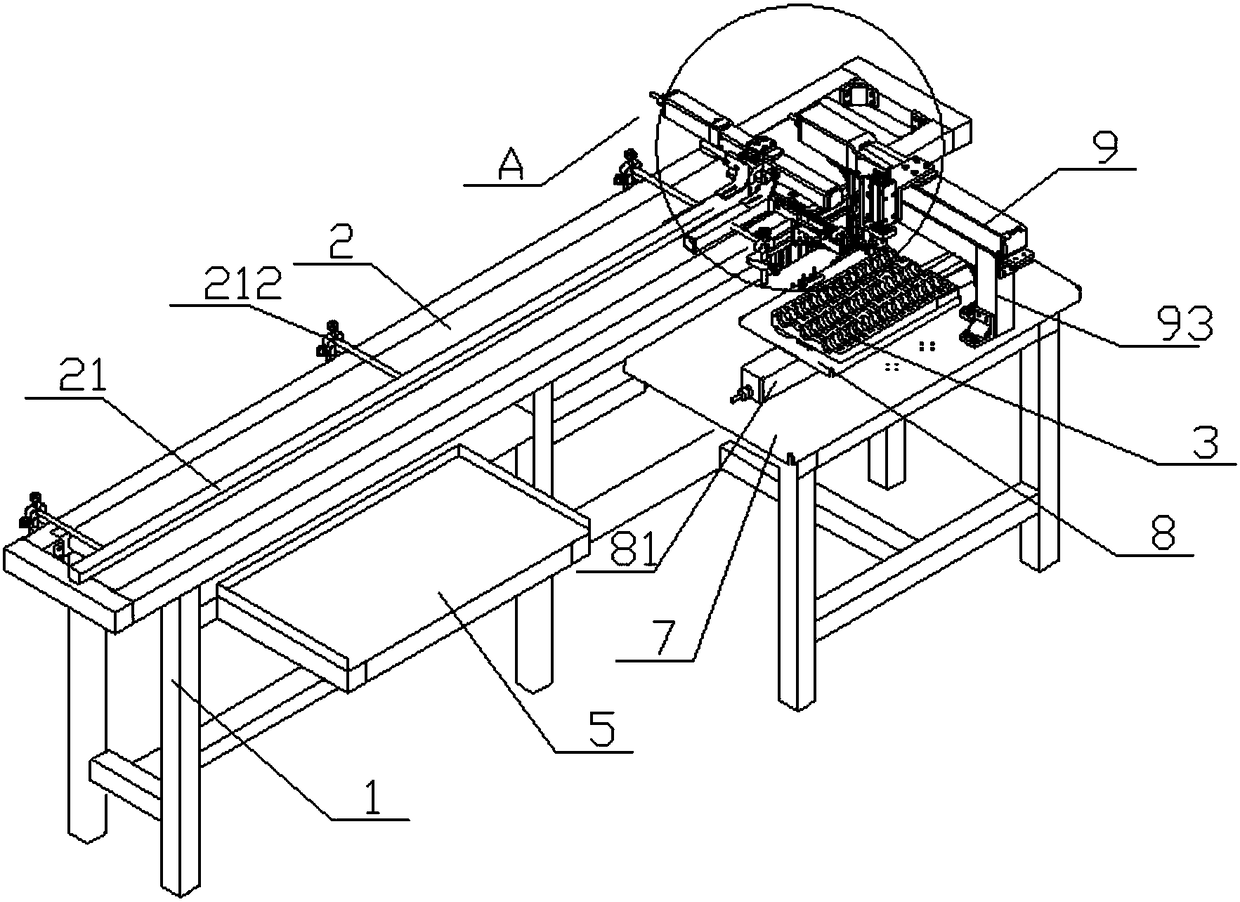

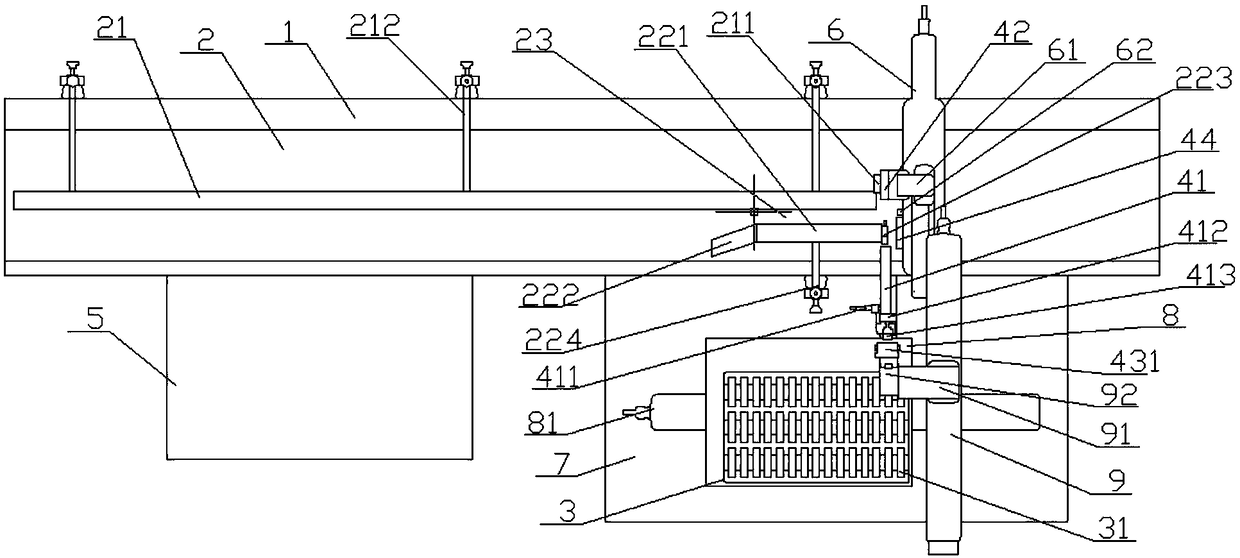

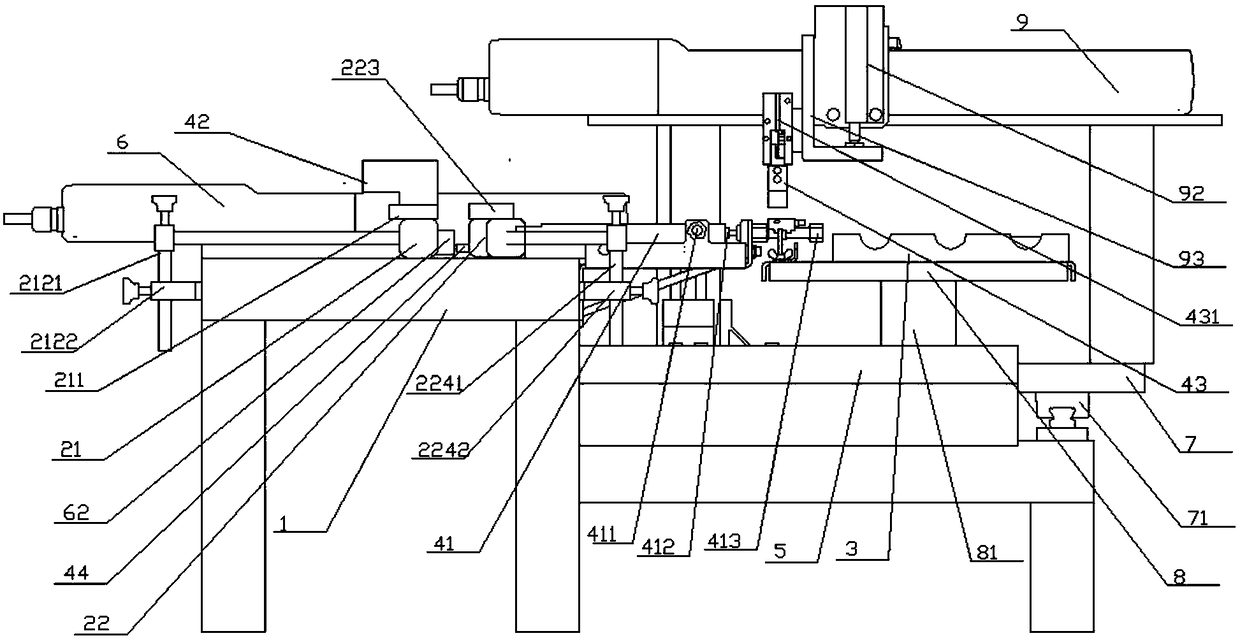

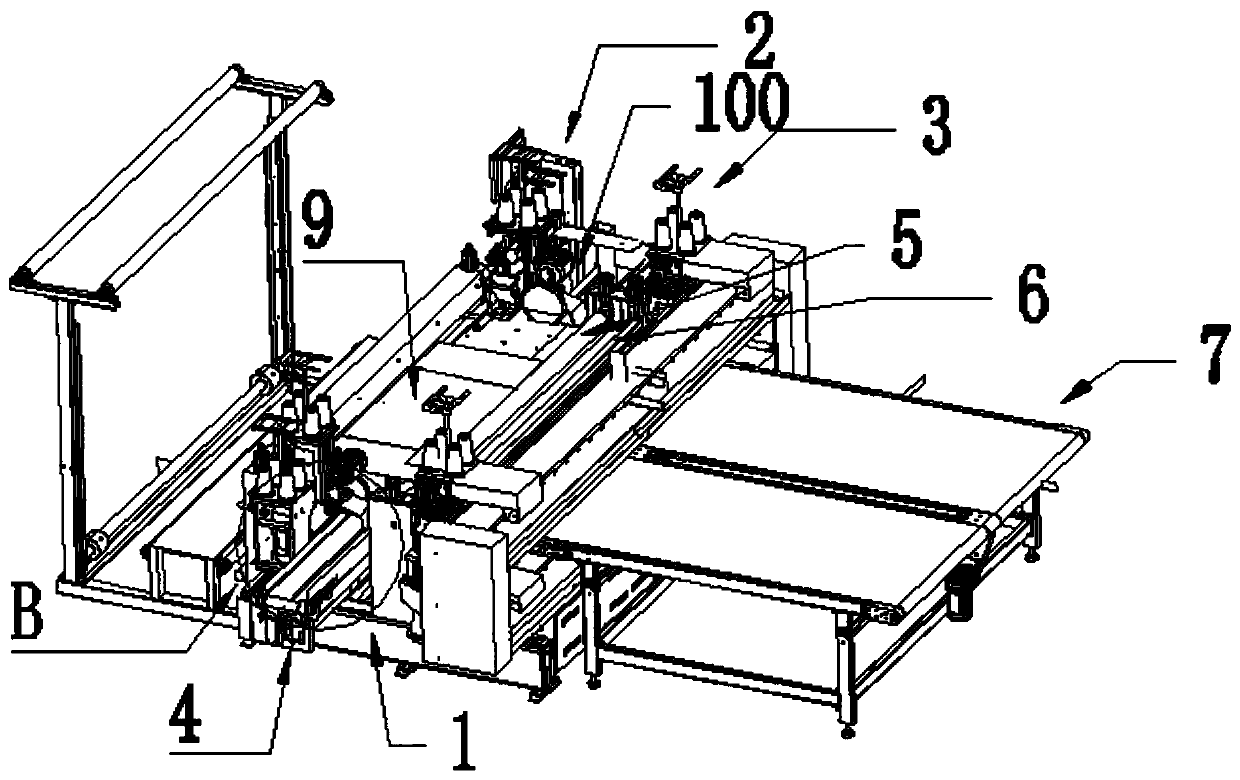

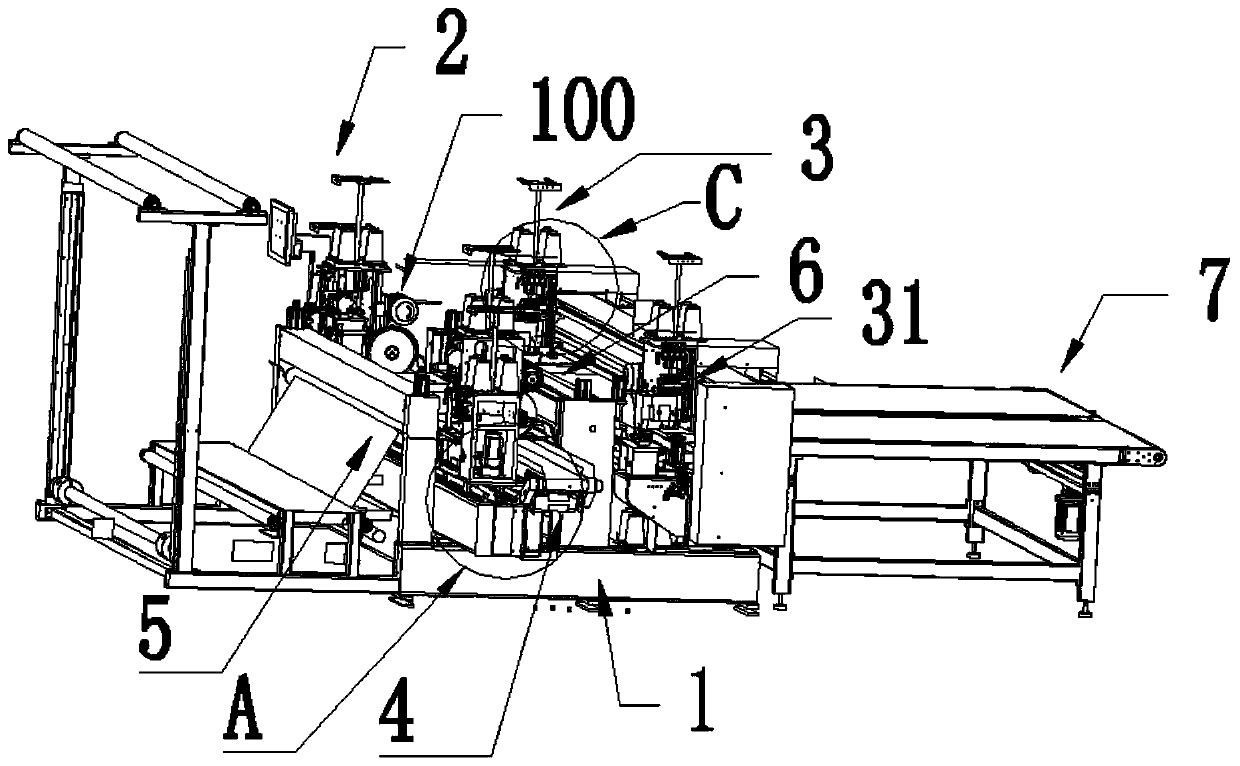

Full-automatic four-side sewing machine

PendingCN110306300AReduce workloadReduce labor costsWorkpiece carriersWork-feeding meansDrive motorEngineering

The invention belongs to the technical field of fabric processing, and particularly discloses a full-automatic four-side sewing machine. The full-automatic four-side sewing machine comprises a fixingassembly, a fabric sewing mechanism, a fabric cutting mechanism and a feeding mechanism; the feeding mechanism is fixedly connected to one side of the fixing assembly; the fabric sewing mechanism is arranged on the fixing assembly; the fabric cutting mechanism is arranged on one side of the fabric sewing mechanism; one side of the fabric sewing mechanism is provided with a residual material discharging mechanism arranged on the fixing assembly, wherein the residual material discharging mechanism comprises a conveying belt, a conveying driving motor and a conveying support; first material blocking plates are arranged on two sides of the conveying belt, and a second material blocking plate is arranged above one end of the conveying belt, so that cut leftovers can accurately fall onto the conveying belt of a leftovers discharging mechanism, the circumstances that the cut leftovers are accumulated on a workbench, and the sewing processing progress of fabrics on a first station is influenced are prevented, and the working efficiency is improved. The full-automatic four-side sewing machine provided by the invention has the advantages that the structure is optimized, and the operation efficiency is improved.

Owner:佛山市科华智缝设备有限公司

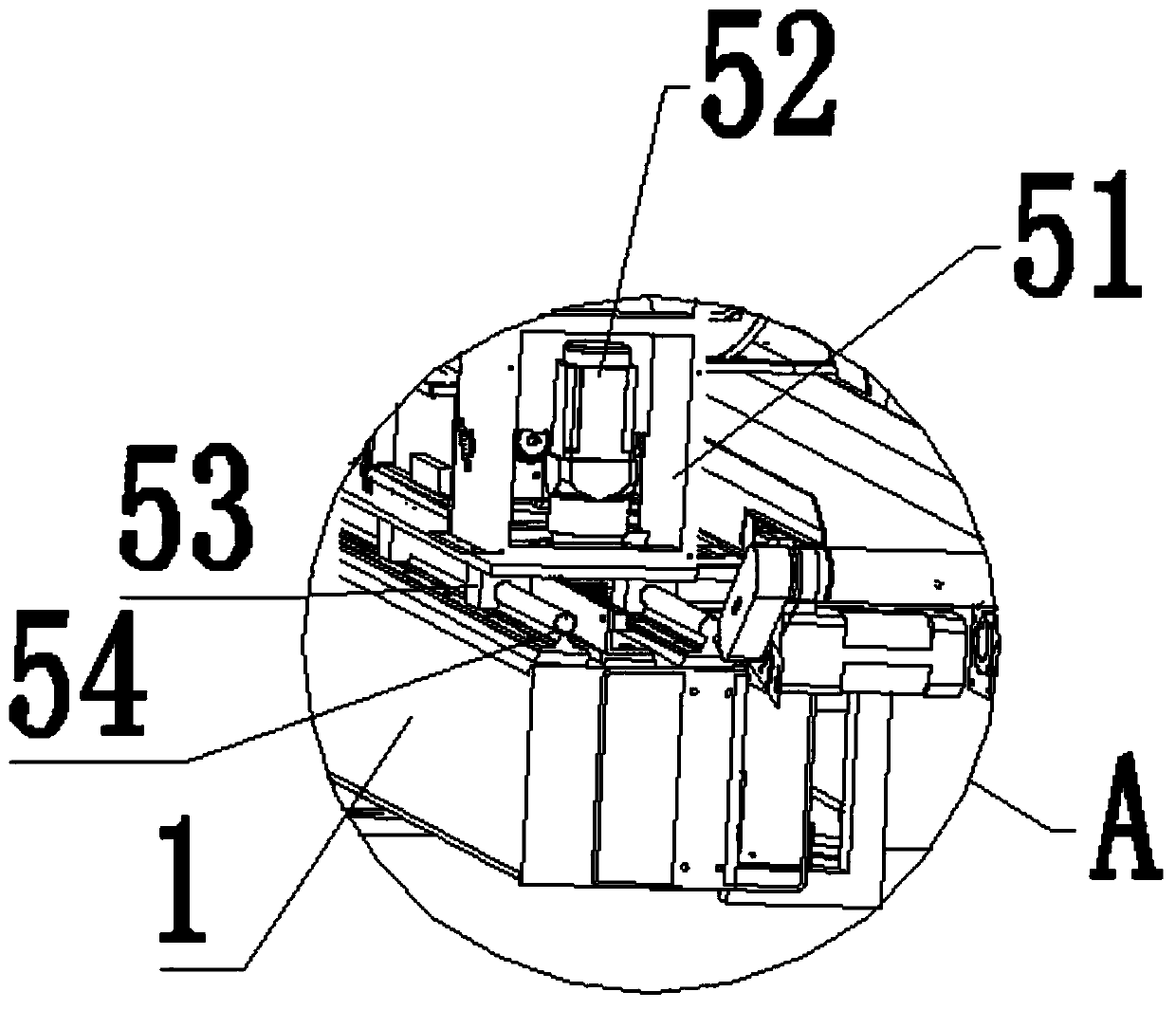

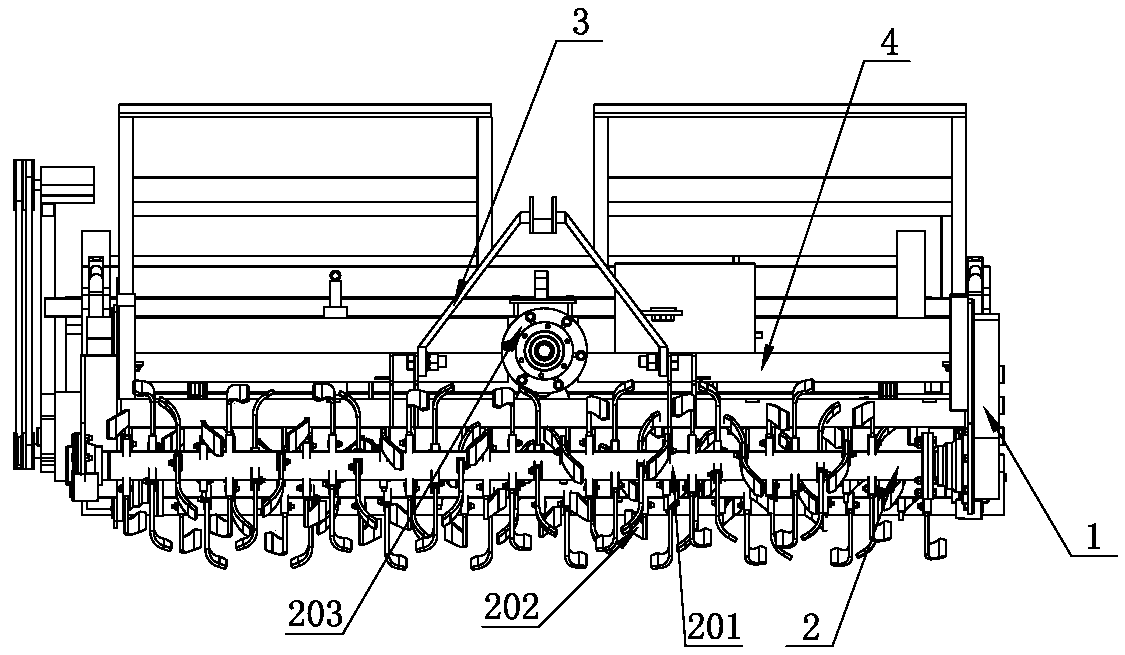

Rotary tillage leveling grounding and seed sowing compound operation machine

ActiveCN107852874ASowing on the groundStable seeding planeSpadesPlantingAgricultural engineeringAgricultural machinery

The invention discloses a rotary tillage leveling grounding and seed sowing compound operation machine in the technical field of agricultural machines. The machine comprises a rotary tillage device, aleveling device and a seed sowing device which are arranged on a machine frame, the leveling device is arranged behind the rotary tillage device, and the seed sowing device is arranged behind the leveling device; a middle transmission box of the rotary tillage device is in transmission connection with a tractor, at least one rotary tillage shaft is in transmission connection with the middle transmission box, and the rotary tillage device is connected with the tractor. Rotary tillage leveling and seed sowing integration operation is achieved, and the operation efficiency is high.

Owner:NANJING WOYANG MACHINERY TECH

Cutting equipment for electronic products

ActiveCN113478288AImprove work efficiencyNot easy to pile upMetal sawing accessoriesLarge fixed membersProcess engineeringWorkbench

The invention discloses cutting equipment for electronic products, and belongs to the field of the electronic products, According to the cutting equipment for electronic products, chippings or leftover materials generated by the cut electronic products can be left on a cutting platform, a connecting block ascends by controlling an electric telescopic rod, a supporting rods jack up one side of the cutting platform, the cutting platform is inclined to guide the defective materials on the surface into a collecting channel, when the cutting platform is jacked up, an air bag is extruded to blow air outwards, and therefore the defective materials clamped or attached to the cutting platform more tightly can be blown up, the waste materials slide into the collecting channel, directly fall into a collecting box and are uniformly collected by the collecting box, after the waste materials are collected to a certain amount, the waste materials can be separated from a threaded groove by rotating a bolt, the collecting box is taken down, and then the waste materials in the collecting box are cleaned away, so that the waste materials are not prone to being accumulated on the surface of the workbench, and the working efficiency of cutting is improved.

Owner:江苏华脉新材料有限公司

Municipal road snow sweeping device

InactiveCN112982266AThrown into accurateThrow it into the snow melting box, when the snow shoveling trough rotates and moves to one end of the snow melting box, the parabola of the thrown snow will be blown up by the corresponding air pipe so that the thrown snow can fall into the snow accuratelySnow cleaningSnowpackWater storage

The invention relates to the technical field of municipal road snow sweeping, in particular to a municipal road snow sweeping device which comprises a main cart, a snow sweeping mechanism, a snow melting mechanism, a water pumping mechanism, a water storage mechanism, an adjusting mechanism and a wind power generation mechanism, wherein one end of the bottom end of the main cart is fixedly connected with the wind power generation mechanism, and the top end of the main cart is connected with the water storage mechanism in a clamped mode. The device has the beneficial effects that by designing the snow sweeping mechanism, the snow melting mechanism, the water pumping mechanism, the water storage mechanism, the adjusting mechanism and the wind power generation mechanism, when the device is used, the mechanisms are matched with one another, accumulated snow can be conveniently converted into water, the converted water can be used for washing clothes, watering flowers, flushing toilets and the like, the converted snow water can be conveniently collected and stored, the collected snow water can be conveniently reutilized, the energy is saved, the environment is protected, and the water source is saved.

Owner:东阳市菊苏科技有限公司

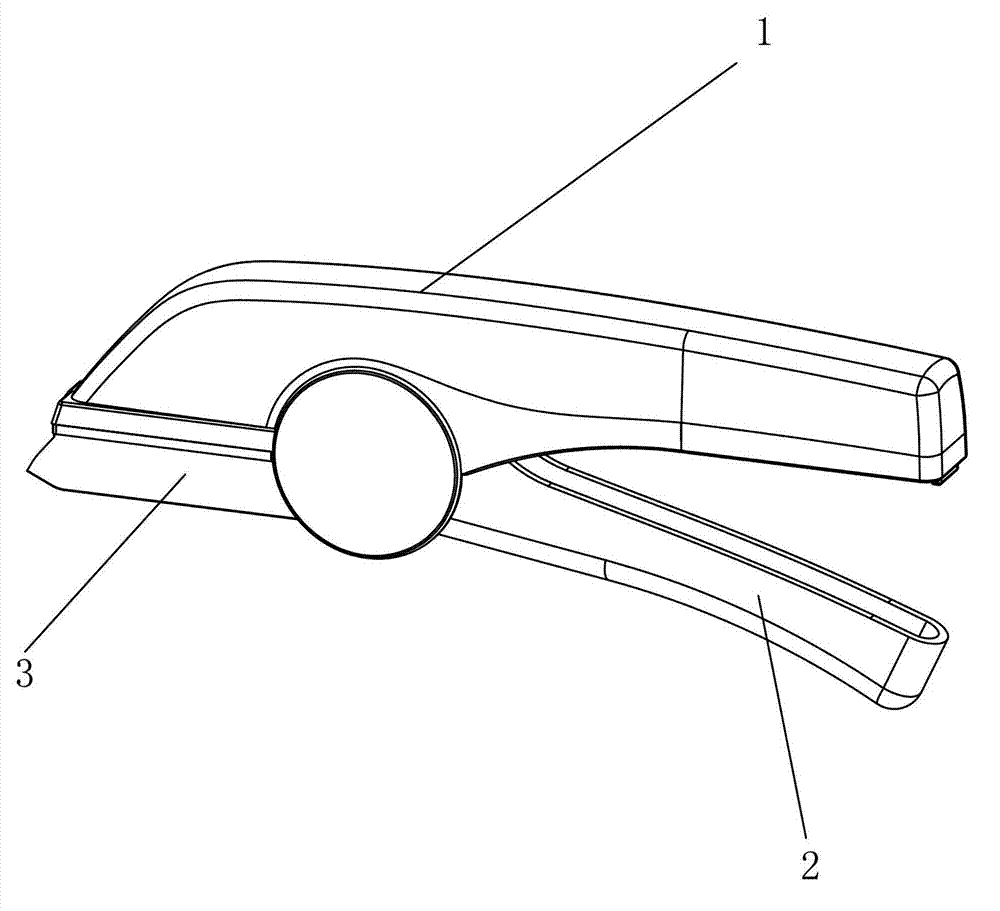

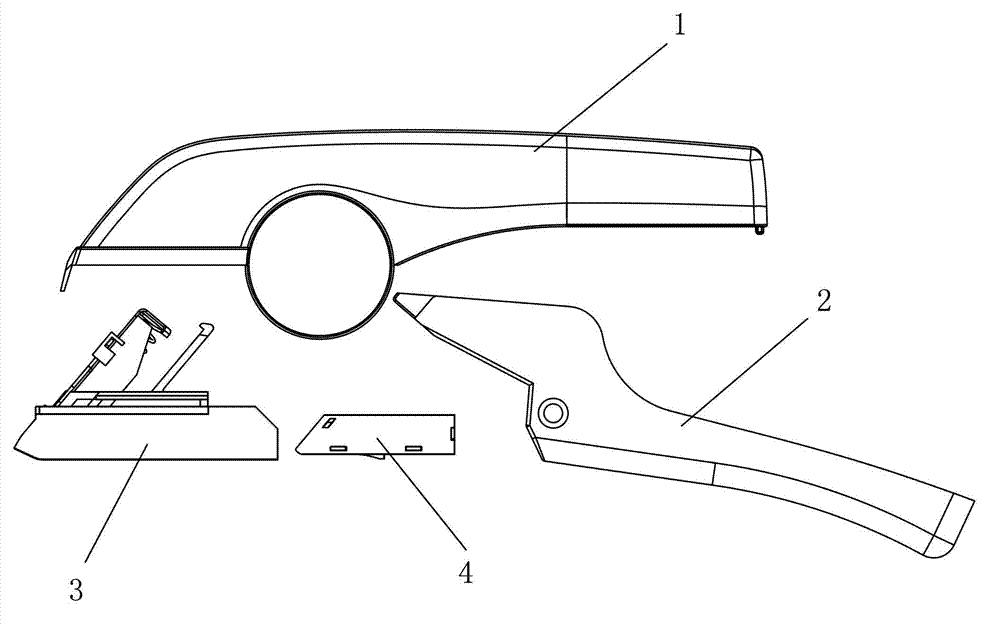

Reusable animal skin stitching instrument

The invention discloses a reusable animal skin stitching instrument. A needle storage box for placing stitching needles used for the skin stitching instrument can be replaced frequently according to requirements, and the needle storage box can be used for placing various specifications of stitching needles. The reusable animal skin stitching instrument comprises a function housing, a fixed handle and a fixed handle; the needle storage box is arranged inside the function housing; and a needle box for placing stitching needles in which the height is 1-1.5 times of that of the stitching needles is formed between the box bottom and a box holder of the needle storage box. The skin stitching instrument adopts a reusable needle storage box structure capable of being replaced quickly, so that the use efficiency of the skin stitching instrument can be greatly improved, the instrument consumption is reduced, and the cost of medical operations is reduced; moreover, the needle storage box adopts a structure containing a first inclined plane, a second inclined plane and a lug boss at a stitching needle outlet end, so that the stitching needle can be fallen in a conveying passage stably and accurately without casing needle blocking, needle blockage and needle disorder, normal use of the skin stitching instrument is ensured, and safety of medical operations is ensured.

Owner:RWD LIFE SCI

Deslagging structure and deslagging method for water seal tank of rotary hearth furnace

ActiveCN112484486ADischarge in timeWill not affect operationCharge manipulationFurnace typesSlagProcess engineering

The invention belongs to the field of deslagging of rotary hearth furnaces, particularly relates to a deslagging structure and a deslagging method for a water seal tank of a rotary hearth furnace, andaims to solve the problem that effective control of hearth reducing atmosphere and hearth pressure of the rotary hearth furnace is directly affected if slag charge often exists in the water seal tankof an existing coal-based direct reduction ironmaking rotary hearth furnace and are not discharged in time, and the effective running of the rotary hearth furnace cannot be achieved. According to thescheme, the deslagging structure comprises a rotary hearth furnace body, wherein a water seal tank body is arranged at the bottom of the rotary hearth furnace body. According to the deslagging structure, the structure is reasonable, the operation is easy, a rotating shaft can rotate in a reciprocating mode through an electric telescopic rod, and the slag charge on the inner walls of the two sidesof the water seal tank body is removed through two cleaning brushes, so that the deslagging is more thorough; meanwhile, the slag charge can be pushed into a first collecting tank and a second collecting tank through deslagging plates to be collected, so that the slag charge in the water seal tank body can be discharged in time, the deslagging is thorough, and the operation of the rotary hearth furnace body is not influenced.

Owner:SHAGANG GROUP +1

Feeding device and feeding method thereof

PendingCN112124981AMeet unloading requirementsEfficient releaseConveyorsStacking articlesEngineeringTransfer line

The invention discloses a feeding device and a feeding method thereof. The feeding device is used for separating multiple layers of stacked objects and comprises a bearing mechanism, a feeding lifter,a transferring device, a backflow lifter and a backflow conveying line. According to the scheme, a low-position tray can be lifted to a high position to be split through the feeding lifter, the high-position tray discharging requirements are effectively met, in addition, by arranging the transferring device, the feeding lifter can be effectively released, and when the tray is used for discharging, the tray of the feeding lifter can take materials again, so that the discharging time can be effectively utilized, the feeding efficiency can be improved, the backflow lifter and the backflow conveying line are further combined, backflow of the empty tray can be effectively achieved, and favorable conditions are created for rapid reutilization of the empty tray.

Owner:JIANGSU XINTIMU INTELLIGENT EQUIP CO LTD

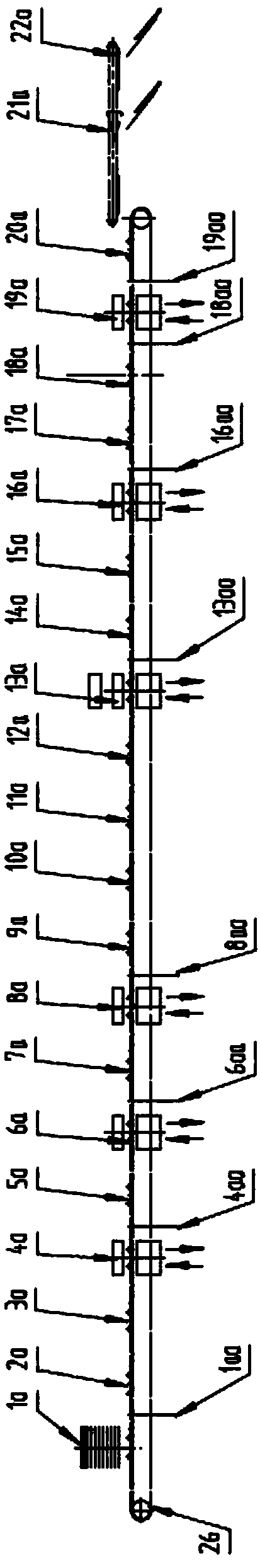

Easy-tear cap production line and manufacturing method

The invention relates to a production line and a manufacturing method of easy-to-tear covers. The production line comprises an electric control box, an aluminum foil or film unwinding device, synchronous belt type carrying mechanisms, a cover separating and discharging device, middle hole forming devices, preheating devices, an aluminum foil or film punching and pre-sealing device, a hot sealing device, a cooling and handle aligning device, a handle folding device, an embossing or flattening device, a defective seal product discharging device and a finished product output device, wherein in the cover separating and discharging device, a, a turnover cylinder is added between a mounting plate and a lower cover frame; b, each cover separating screwdriver comprises a body, a screwdriver head and a gasket, and the spiral groove height of the starting part of the cover separating screwdriver can be adjusted by adjusting the thickness of the gasket; cover falling prevention devices are arranged on the synchronous belt type carrying mechanisms of the middle hole forming devices, the hot sealing device, the cooling and handle aligning device and an embossing and handle fixing device; induction heating is adopted in at least one position in the preheating devices before aluminum foil pre-sealing; a cooling water channel is additionally arranged in an upper mounting plate of the embossing or flattening device.

Owner:HANGZHOU SHANGJING MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com