Automatic dry land transplanter

A transplanting machine, fully automatic technology, applied in the field of agricultural machinery, can solve the problems of low transplanting efficiency, high labor intensity, low transplanting accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

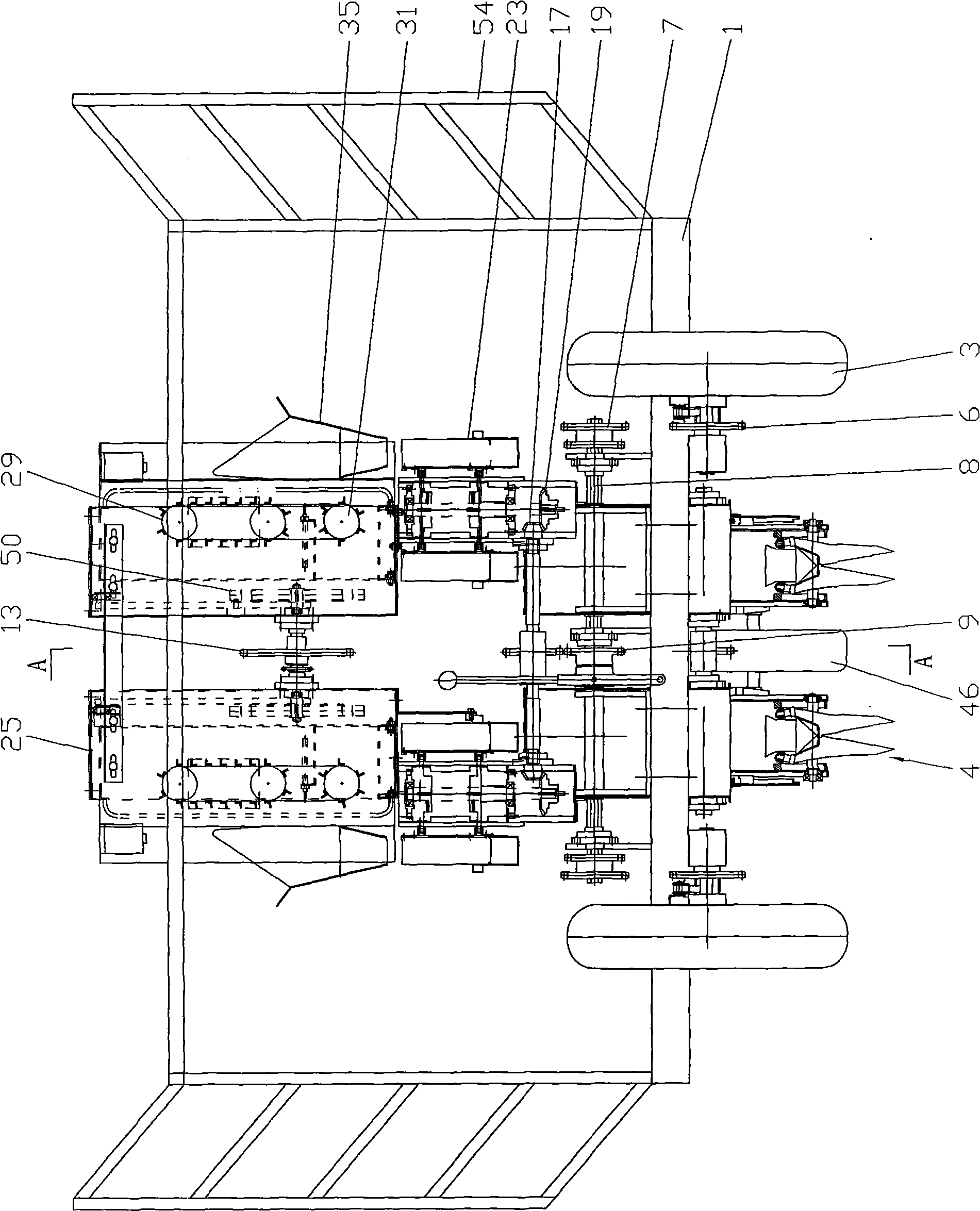

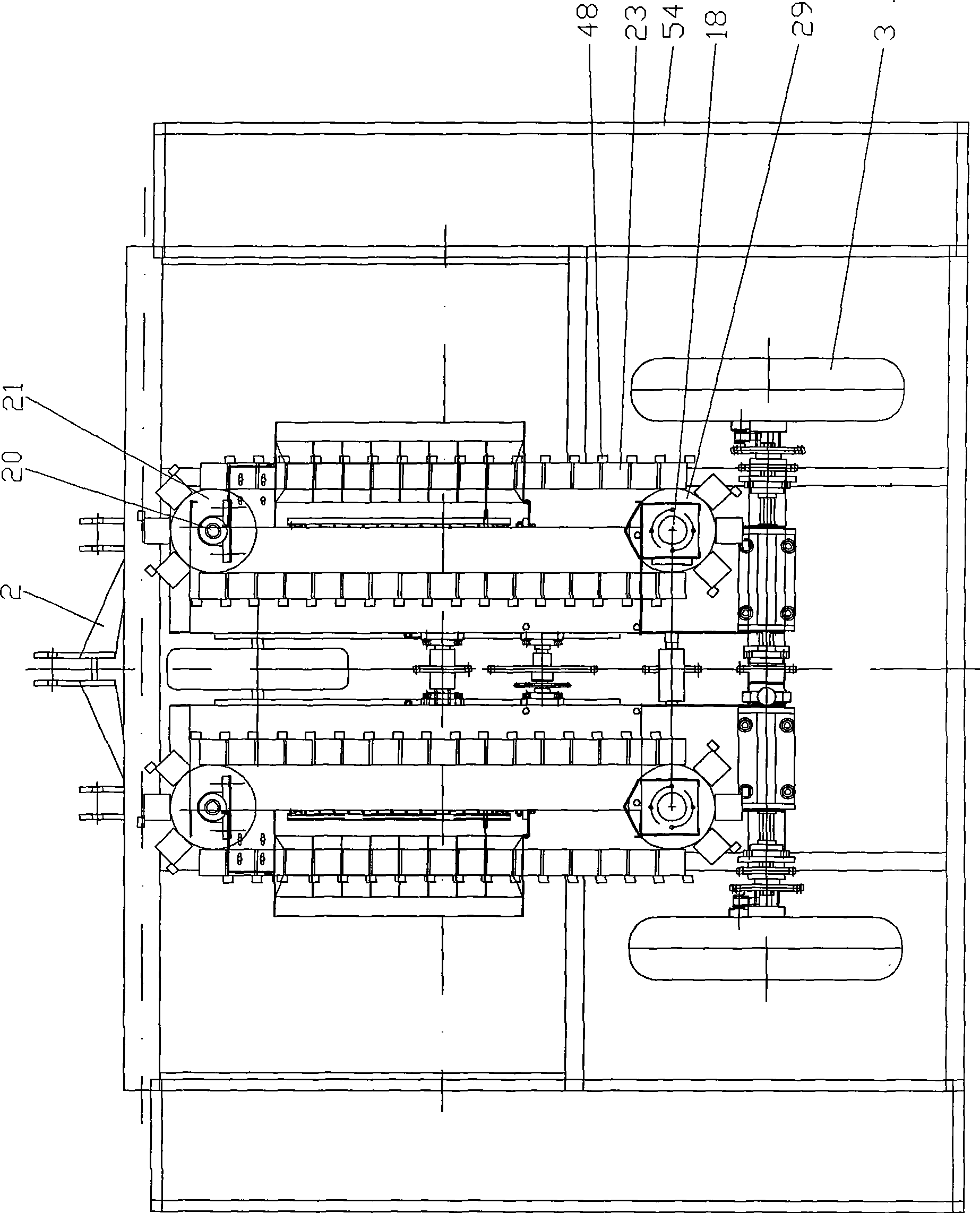

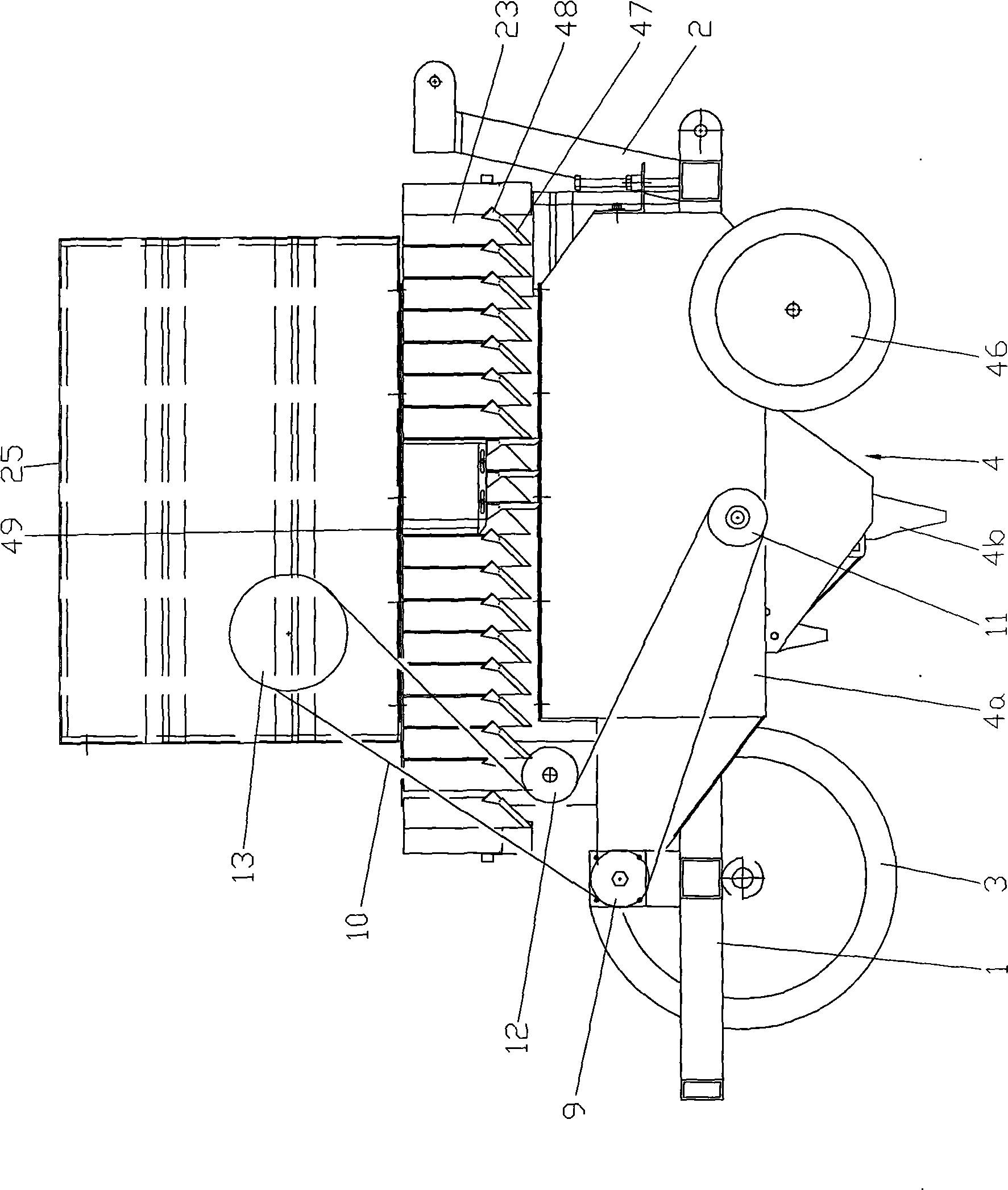

[0043] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0044] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown, in the middle part of frame 1 front end, fix traction frame 2, so that be connected with tractor, traction is provided to the present invention by tractor. The both sides of frame 1 are symmetrically installed with fixed seedling tray frame 54, and described fixed seedling tray frame 54 is the distribution of inverted "eight", so that the seedling raising tray is placed. A road wheel 3 is respectively arranged on the left and right sides of the rear portion of the frame 1, and the middle part of the road wheel 3 is fixed on the law wheel disc 37, which is supported on the outer end of the wheel shaft 5 by bearings, and the inner end of the wheel shaft 5 passes through The bearing 42 is supported on the bearing sleeve 38, and the bearing sleeve 38 is fixed with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com