Automatic tea leaf subpackaging and packaging machine

A packaging machine and sub-packaging technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high labor intensity, slow manual bagging, and time-consuming production, so as to reduce labor intensity, reduce labor input, and reduce labor costs. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

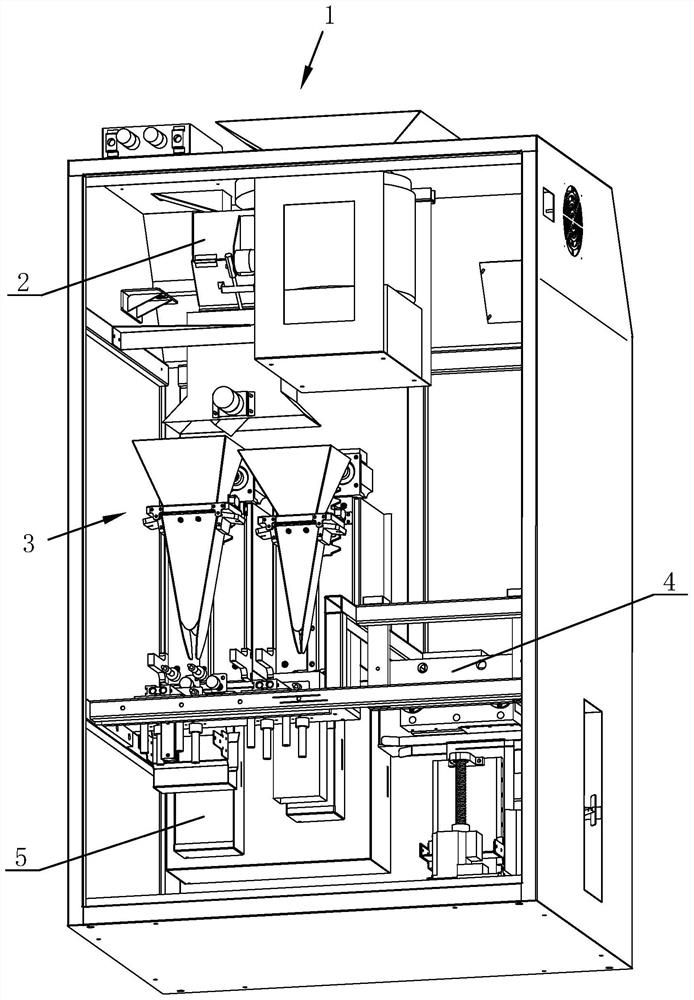

[0033] like figure 1 The tea automatic packaging machine shown includes a feeding mechanism 1, a weighing mechanism 2, a bagging mechanism 3, a heat-sealing mechanism 4, a discharging mechanism, a bag slot 5 and a computer control system,

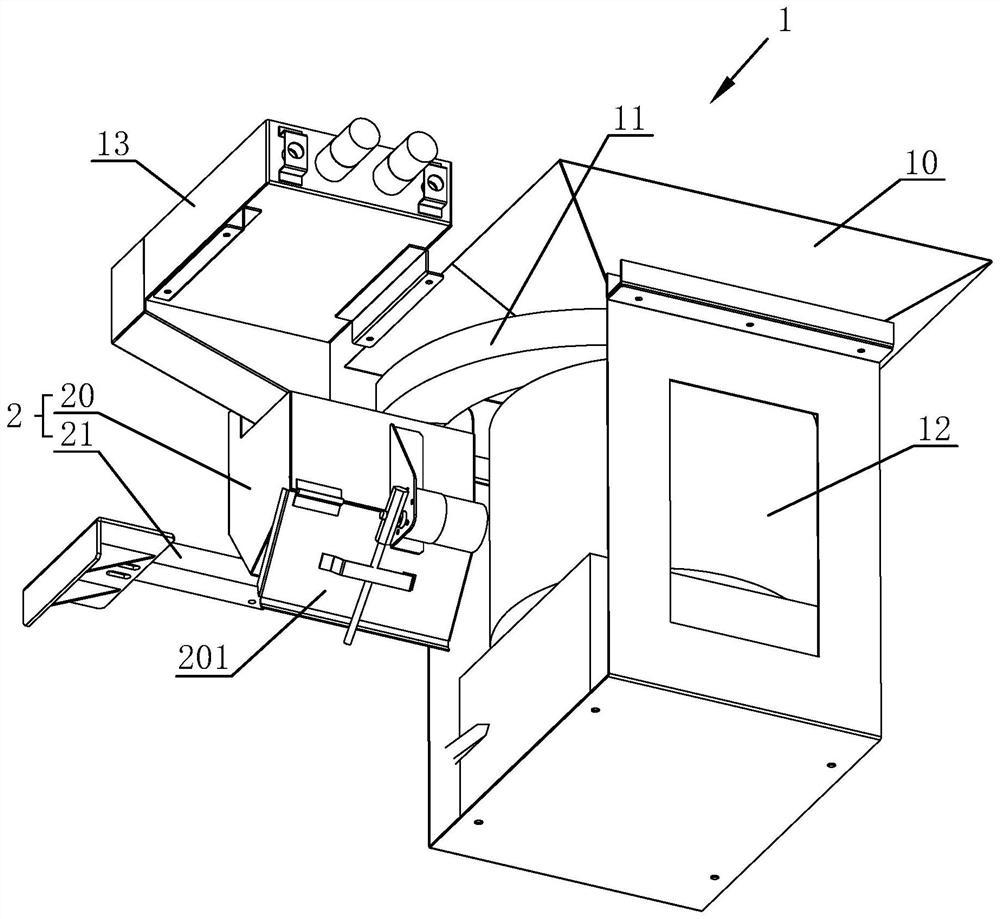

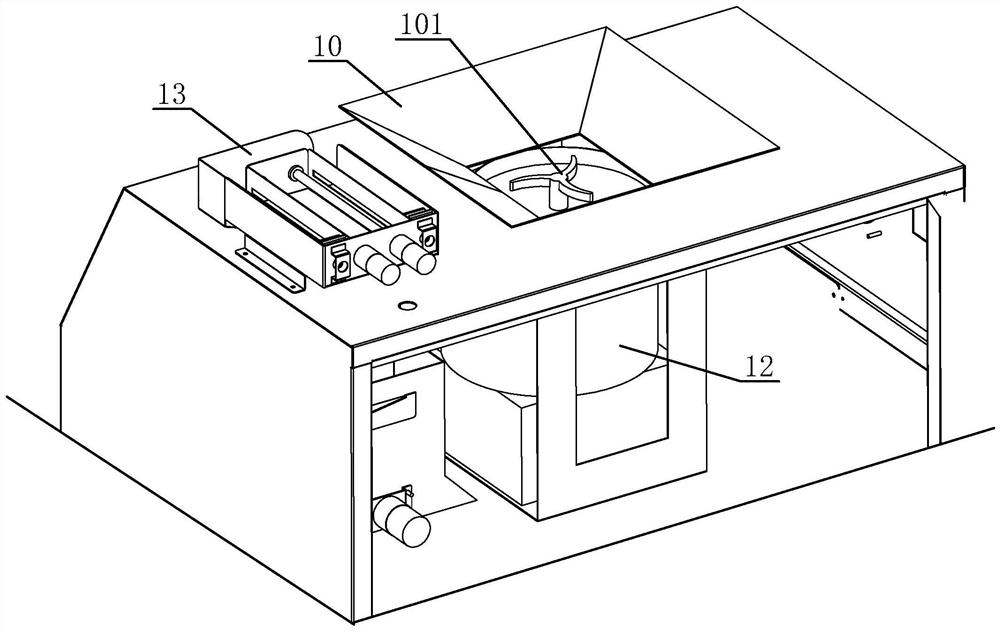

[0034] like figure 2 and image 3 As shown, the feeding mechanism 1 includes a feeding hopper 1, a feeding channel 11, a vibrating motor 12 and a desiccant filling structure 13. The feeding channel 11 is fixedly connected with the feeding hopper 1 and formed into one body. The feeding channel 11 is formed by feeding The hopper 1 extends downward in an arc-shaped path, the bottom surface of the feeding channel 11 is inclined, and the vibration motor 12 is used to drive the feeding hopper 1 and the feeding channel 11 to vibrate, so as to prevent the tea leaves from being stuck in the feeding hopper 1 and the feeding channel 11 Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com