Patents

Literature

431results about How to "Avoid stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

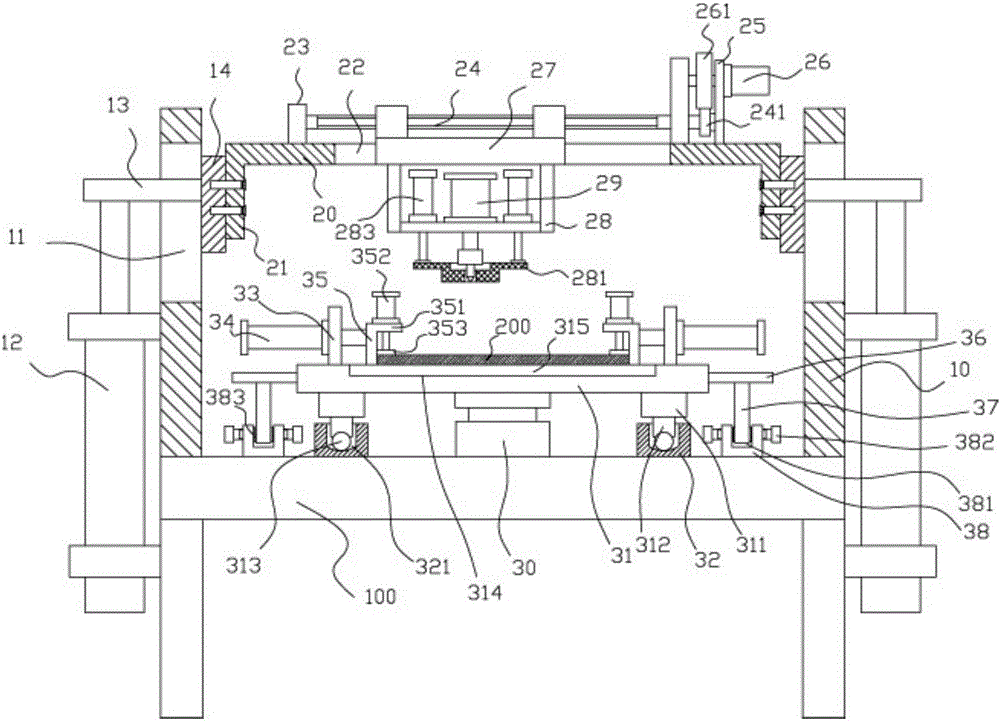

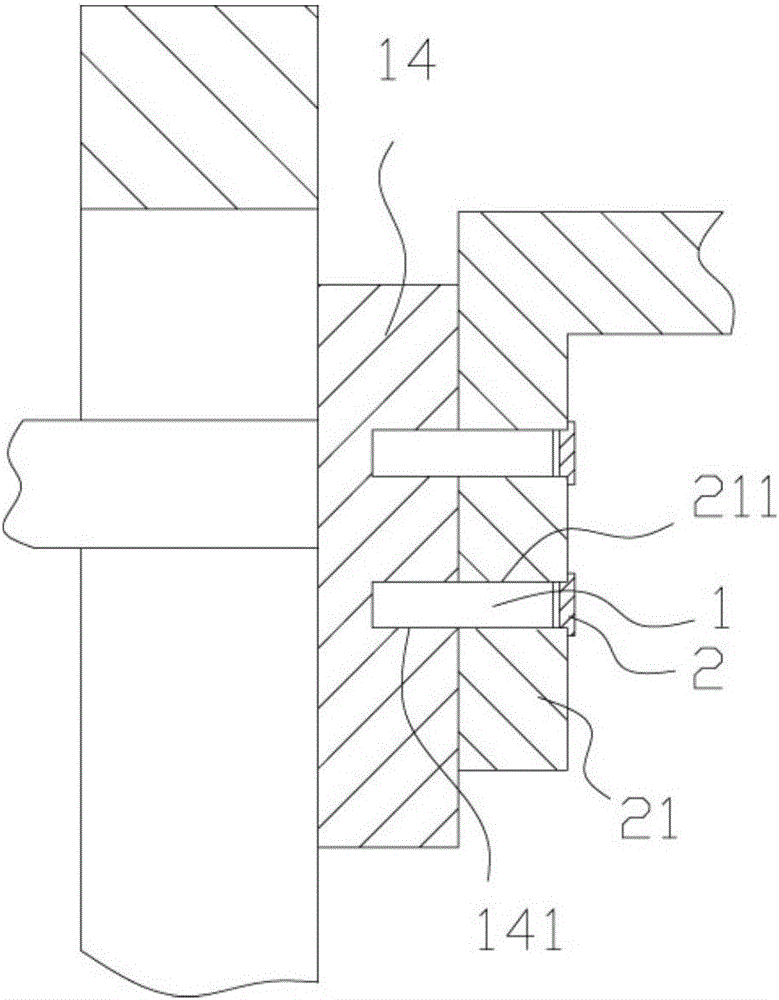

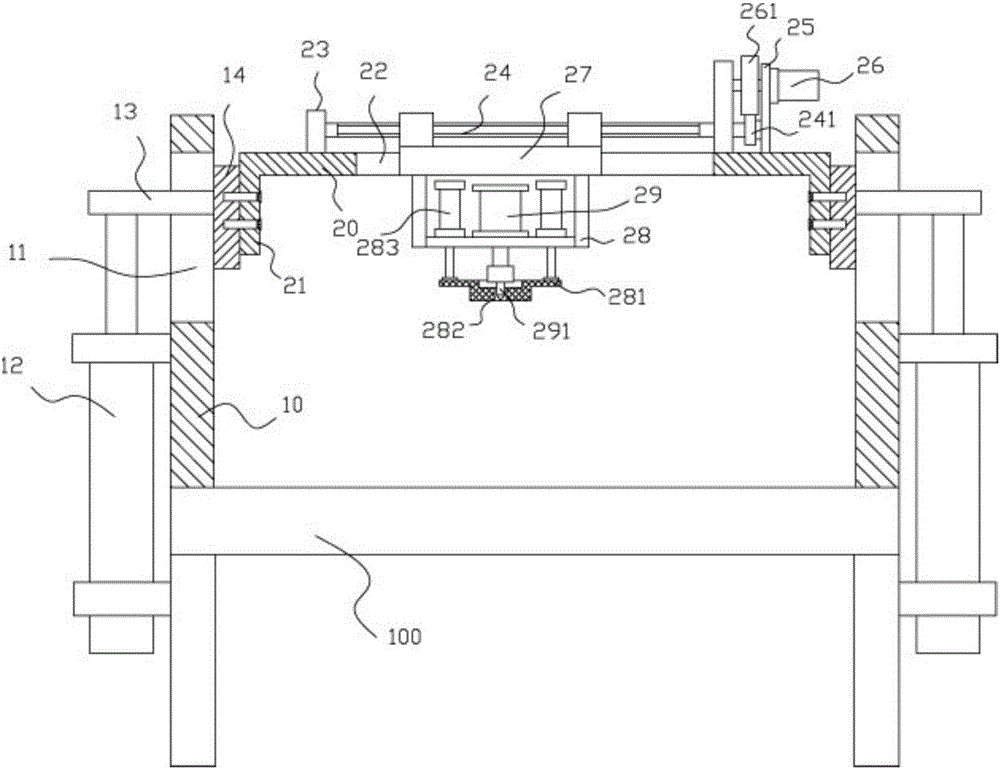

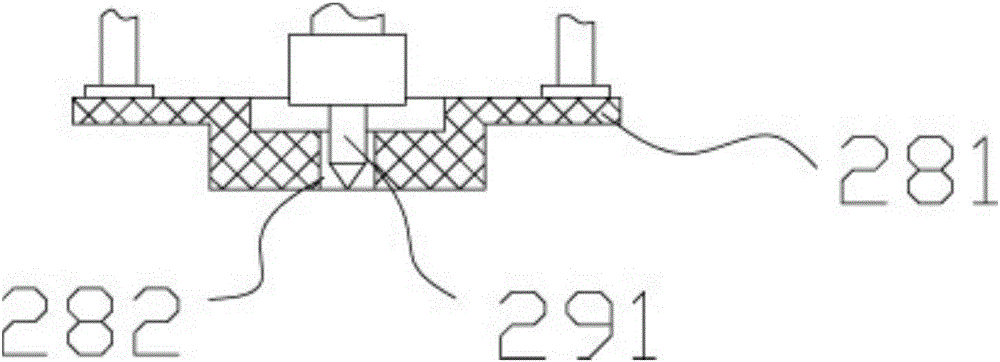

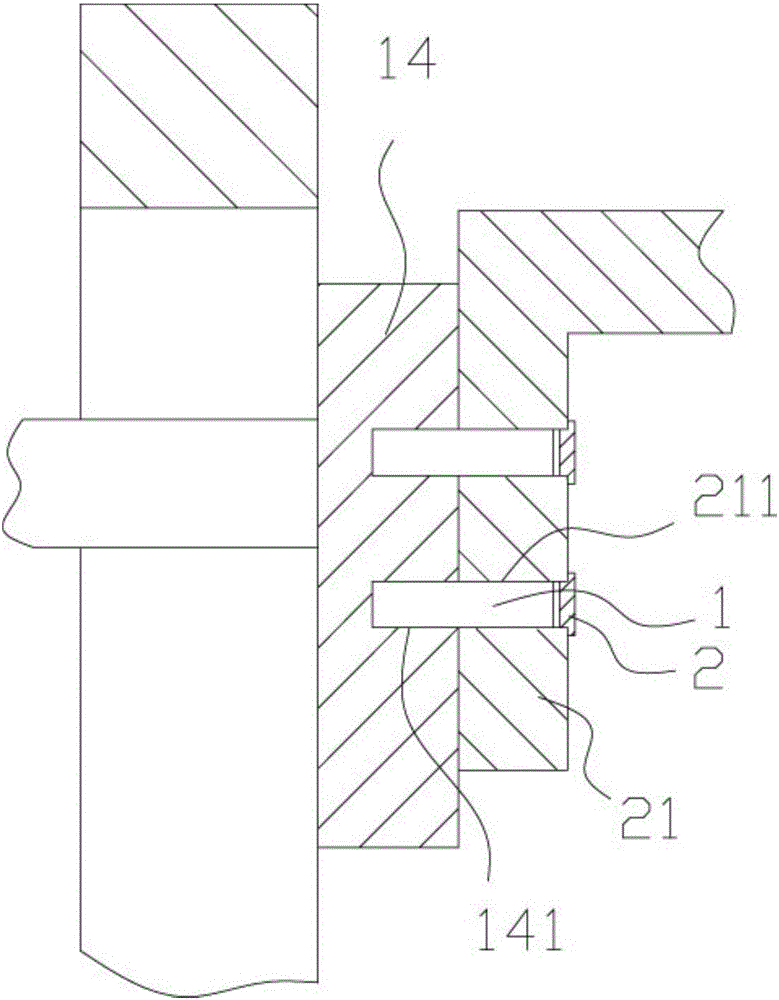

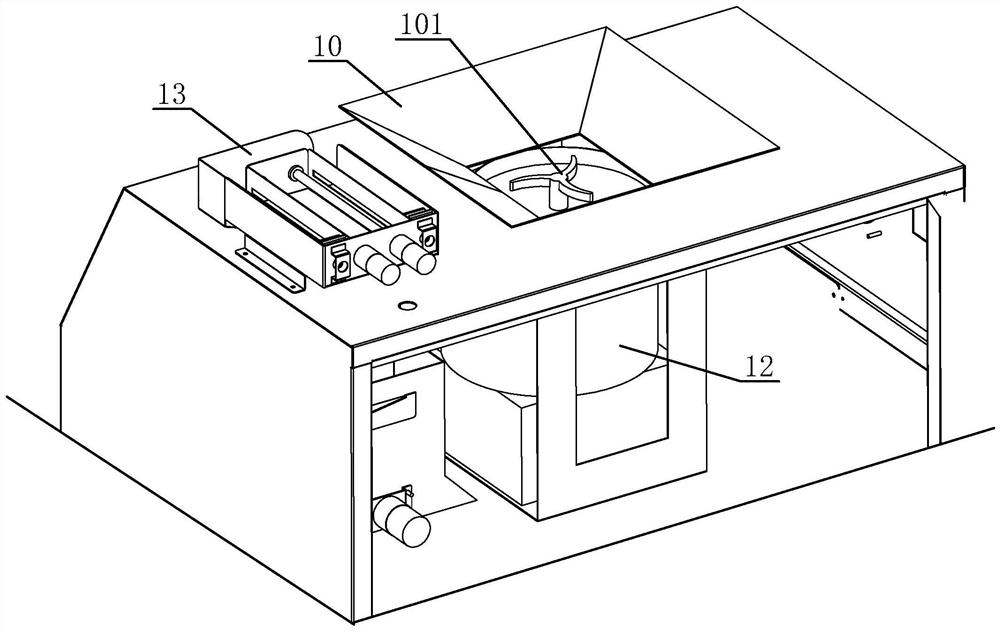

Plastic board clamping and punching mechanism

ActiveCN105856320AAvoid stuckImprove efficiencyMetal working apparatusEngineeringMechanical engineering

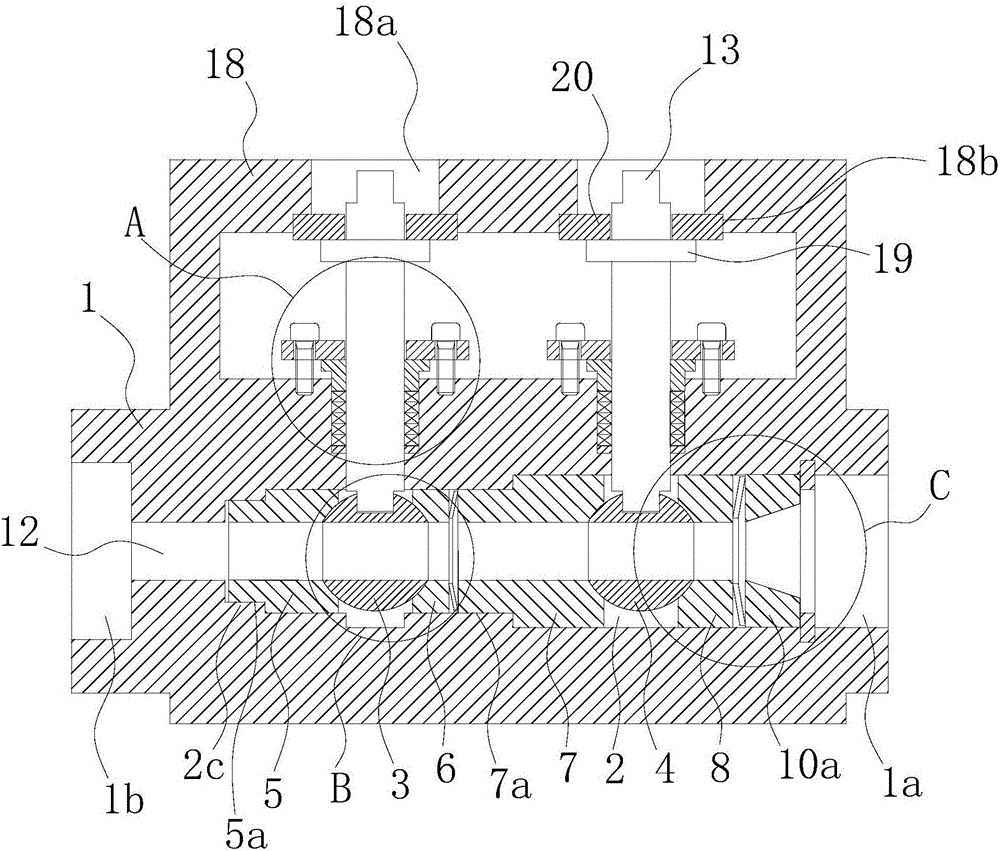

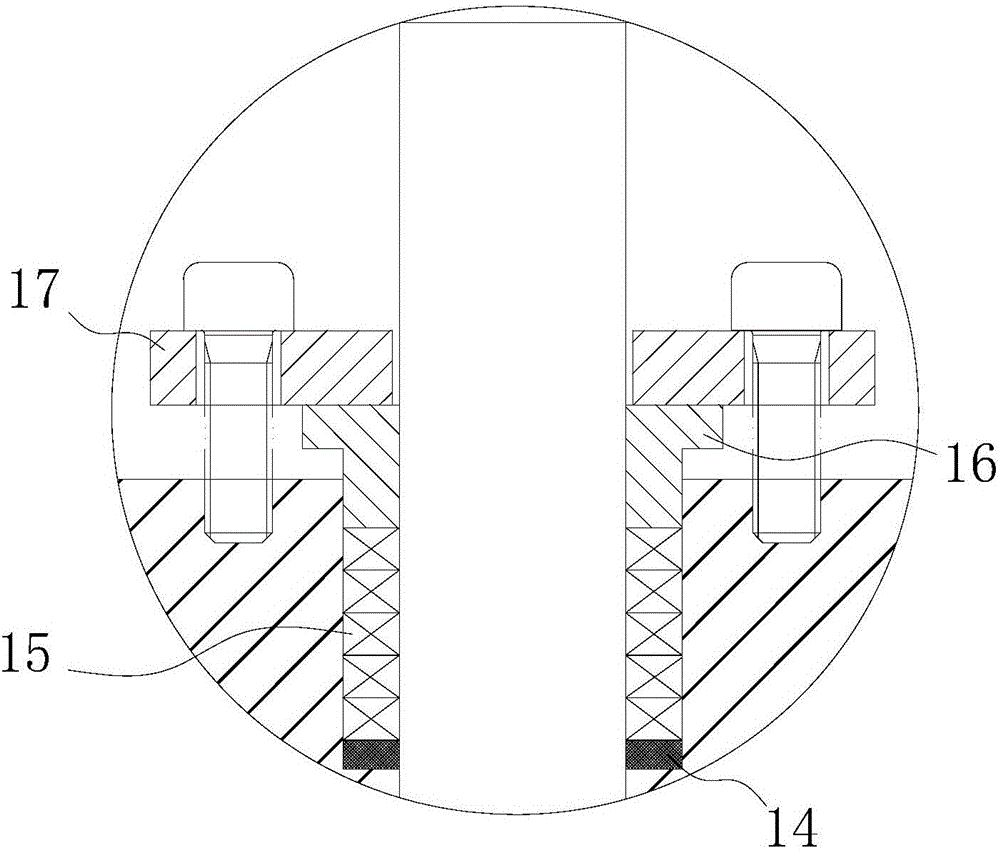

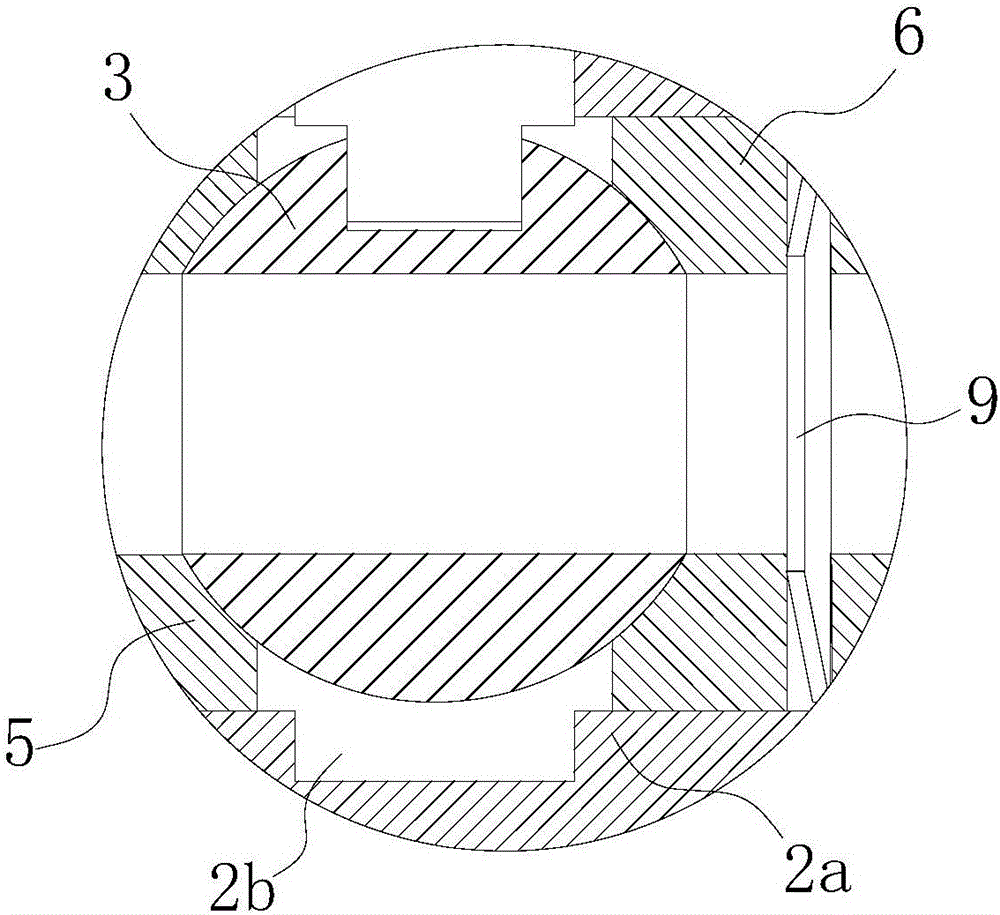

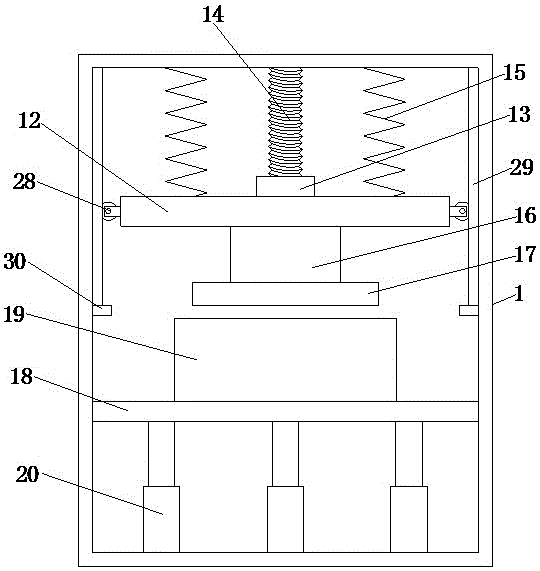

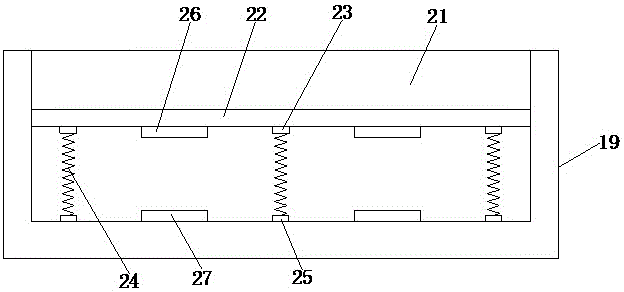

The invention discloses a plastic board clamping and punching mechanism which comprises a rack. Upper supporting plates are fixed to the top faces of the two sides of a top plate of the rack. A vertical adjusting through groove is formed in the upper portion of each upper supporting plate, and an adjusting cylinder is fixed to the outer side wall of each upper supporting plate. Lifting blocks are fixed to adjusting blocks. The outer side walls of the lifting blocks are tightly attached to the inner side walls of the corresponding upper supporting plates. Downward-extending extending parts are arranged on the two sides of a middle transverse plate and fixed to the lifting blocks. A rodless cylinder is fixed to the middle of the top face of the top plate of the rack, and a supporting plate is fixed to a sliding block of the rodless cylinder and located below the middle transverse plate. Guiding troughs are fixed to the portions, located on the two sides of the rodless cylinder, of the top plate of the rack, and a sliding groove is formed in the top face of each guiding trough. The plastic board clamping and punching mechanism can automatically clamp and fix a plastic board and punch the plastic board, and meanwhile, the distance between a punch and a product and the horizontal positions of the punch and the product can be adjusted; a pushing block of the mechanism can prevent the punch from being clamped in the product, so that efficiency is improved.

Owner:吴茂根

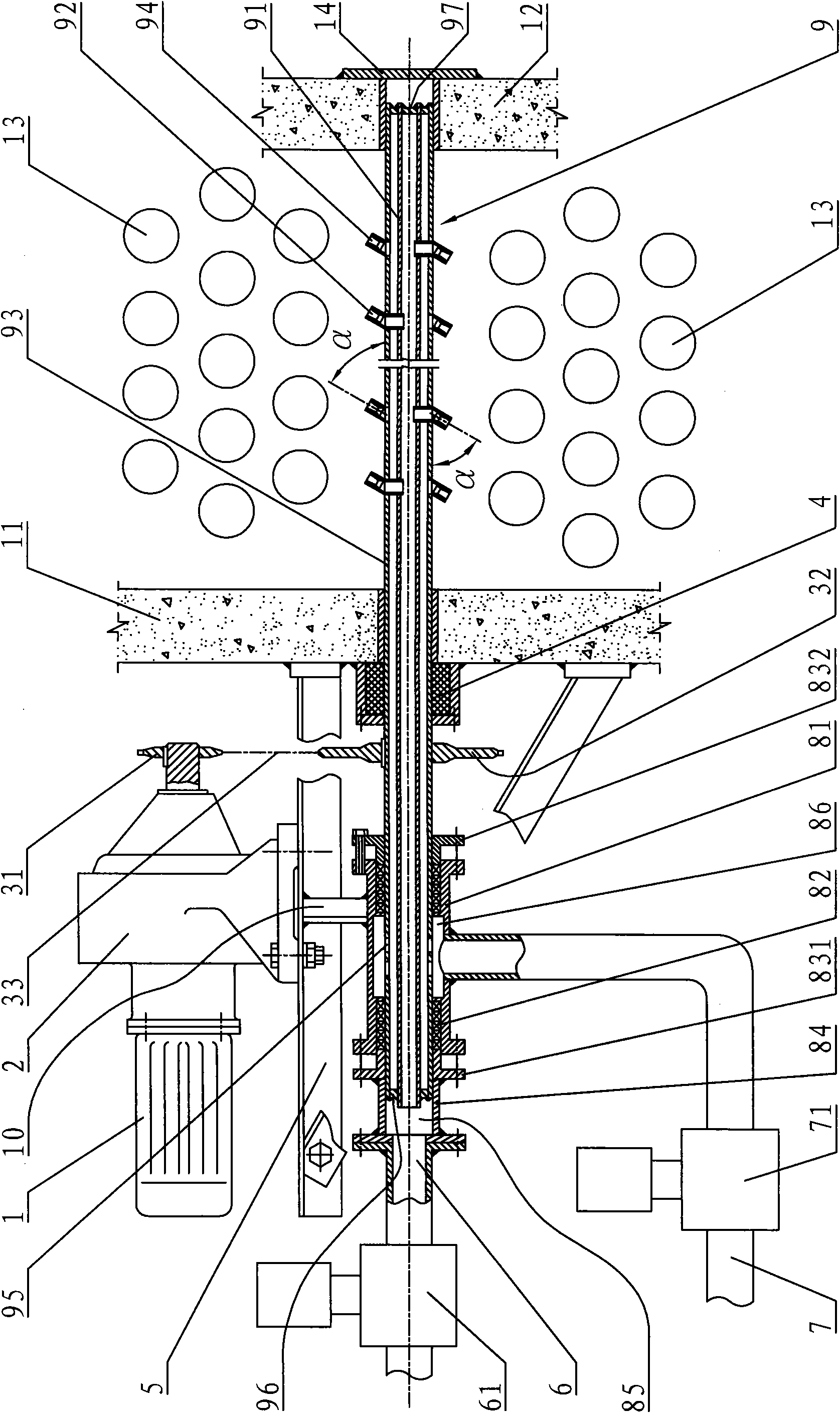

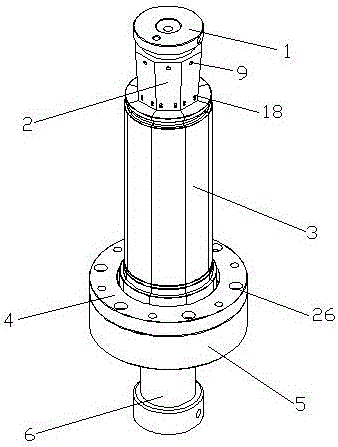

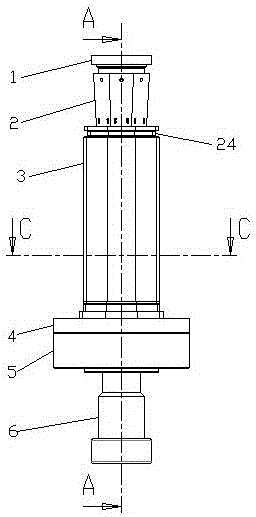

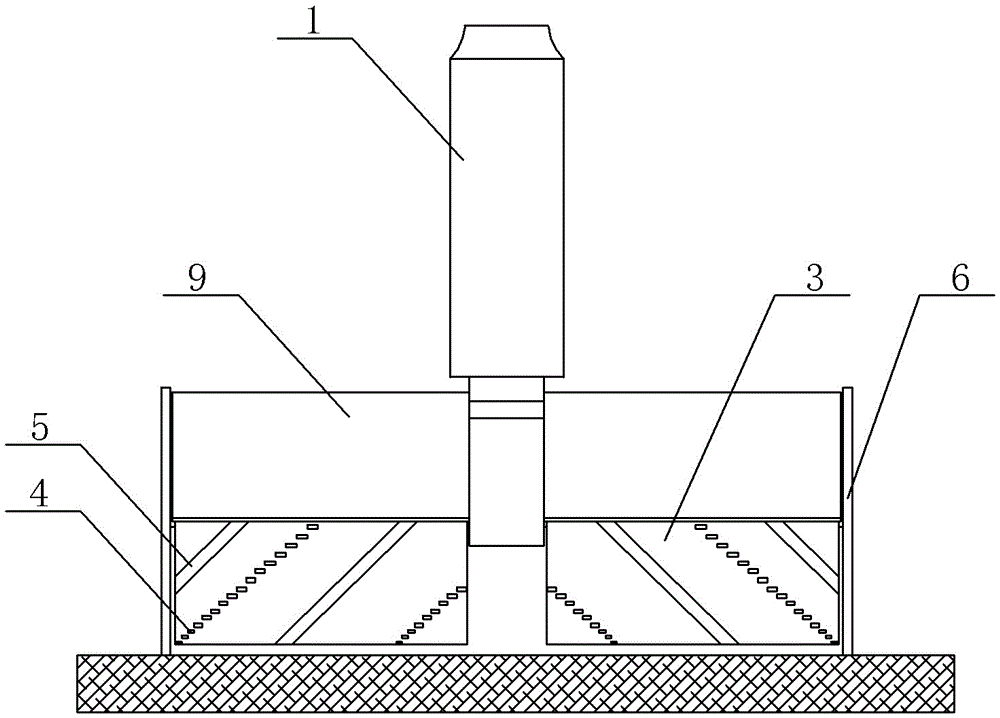

Soot blower

The invention discloses a soot blower in order to solve the problems that the existing soot blower has higher operating failure rate, unreachable blowing area and poor blowing effect. The transmission system of the soot blower of the invention comprises a motor, a reducer and a chain transmission device, wherein the reducer is particularly a cycloidal pin-wheel reducer. The soot blower is provided with an internal soot blower and an external soot blower, and an internal soot blower nozzle and an external soot blower nozzle are arranged on the internal soot blower and the external soot blower respectively; the inclined section of the internal soot blower nozzle is arranged in a way that the inclined section thereof is inclined relative to the axis of the soot blower; an air inlet is formed on the inlet section of the external soot blower; the air inlet system of the soot blower is provided with an air inlet tube, and a second air inlet chamber arranged in the middle of the air inlet tube is communicated with the air inlet and a second air inlet pipe; a first air inlet chamber is arranged at the end part of the inlet section of the internal soot blower and communicated with the end part of the inlet section of the internal soot blower and the first air inlet pipe; a first electromagnetic valve is arranged on the first air inlet pipe; and a second electromagnetic valve is arranged on the second air inlet pipe. The invention is mainly applicable to tubular heating furnaces in the field of petroleum refining and petroleum chemical engineering.

Owner:CHINA PETROCHEMICAL CORP +1

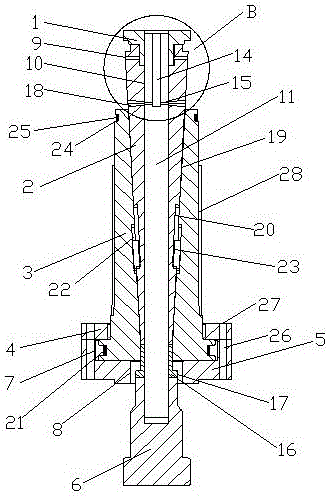

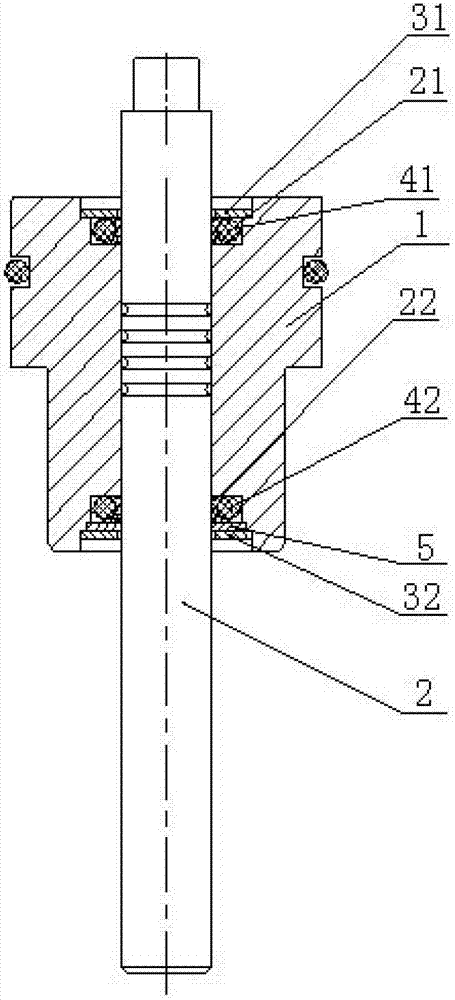

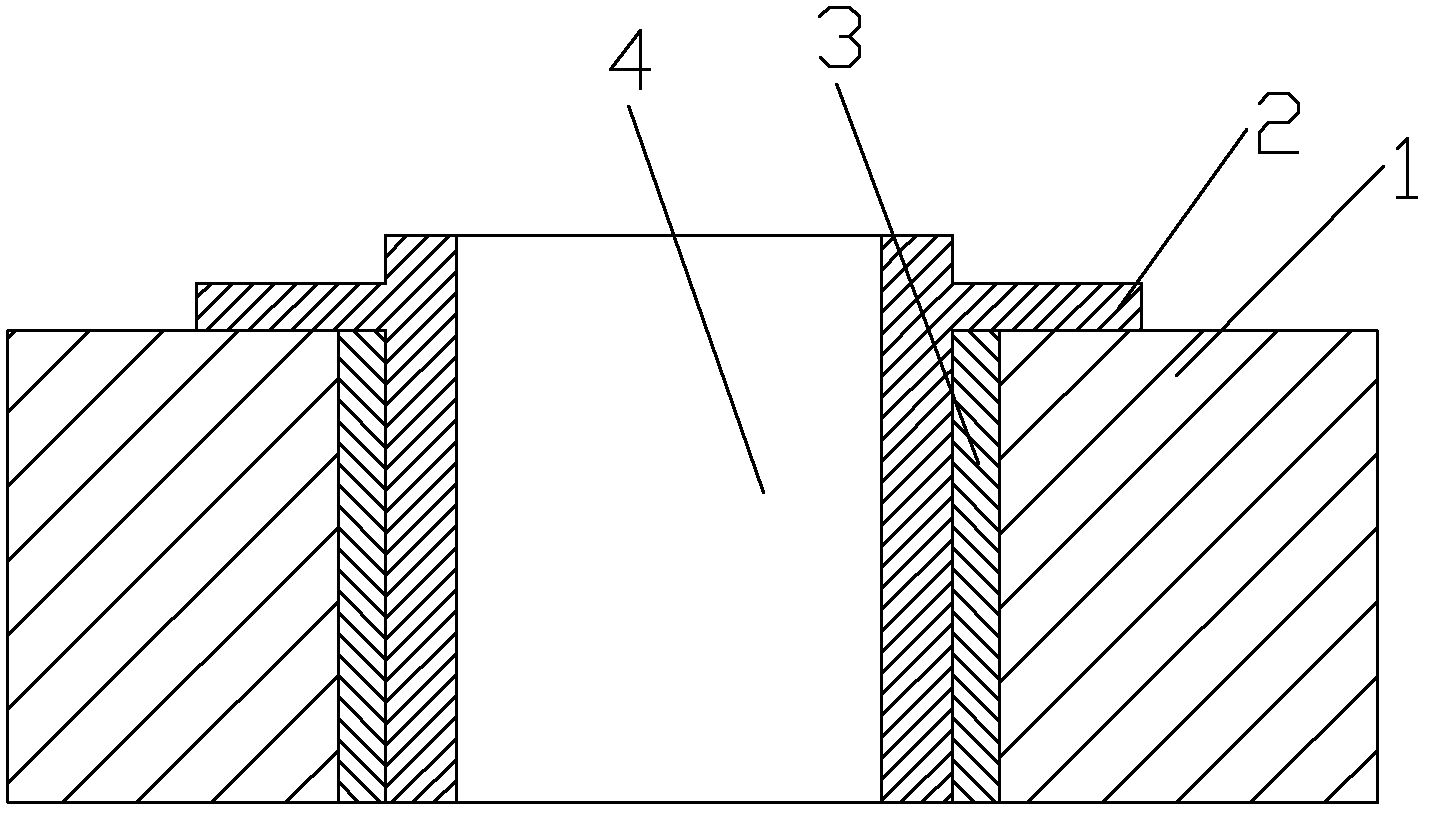

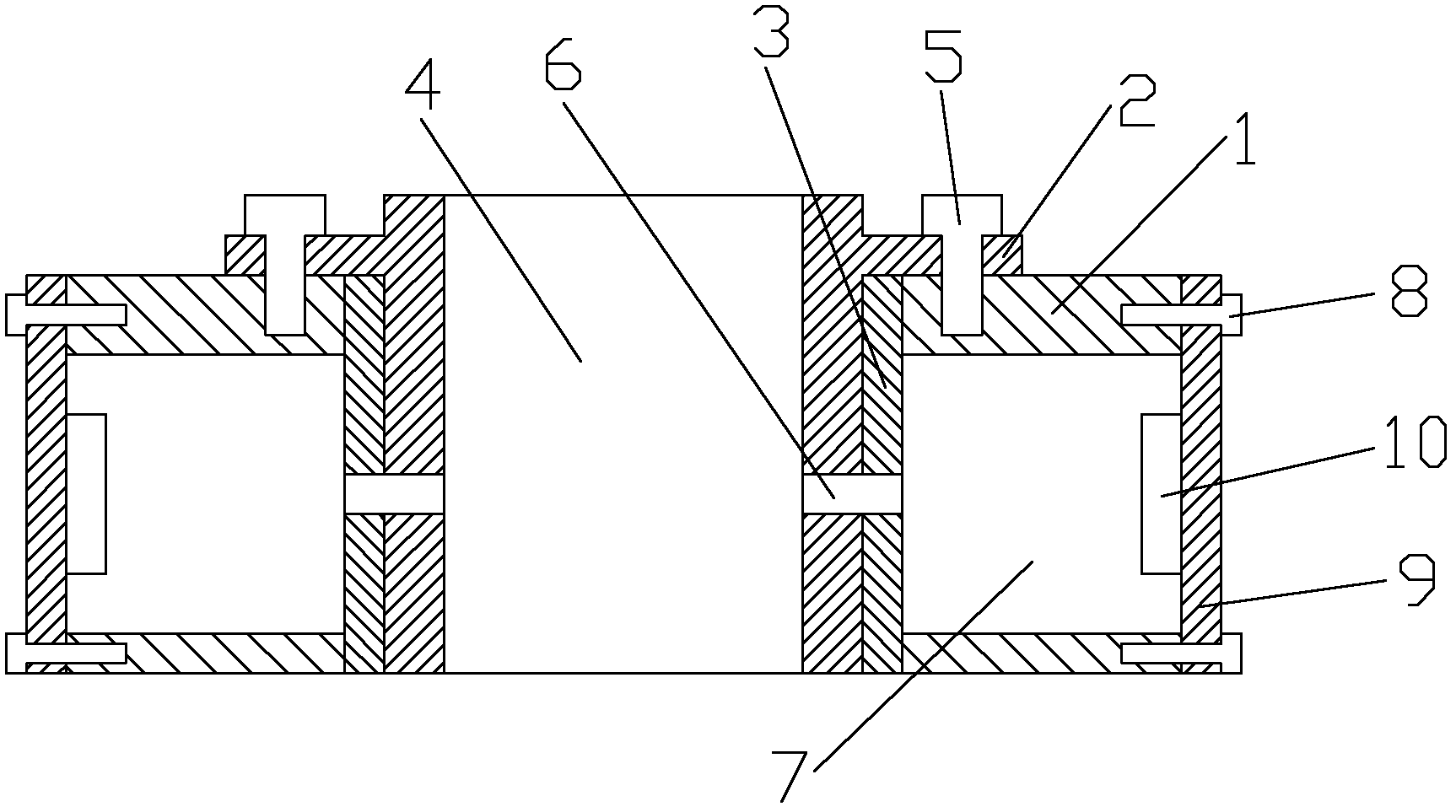

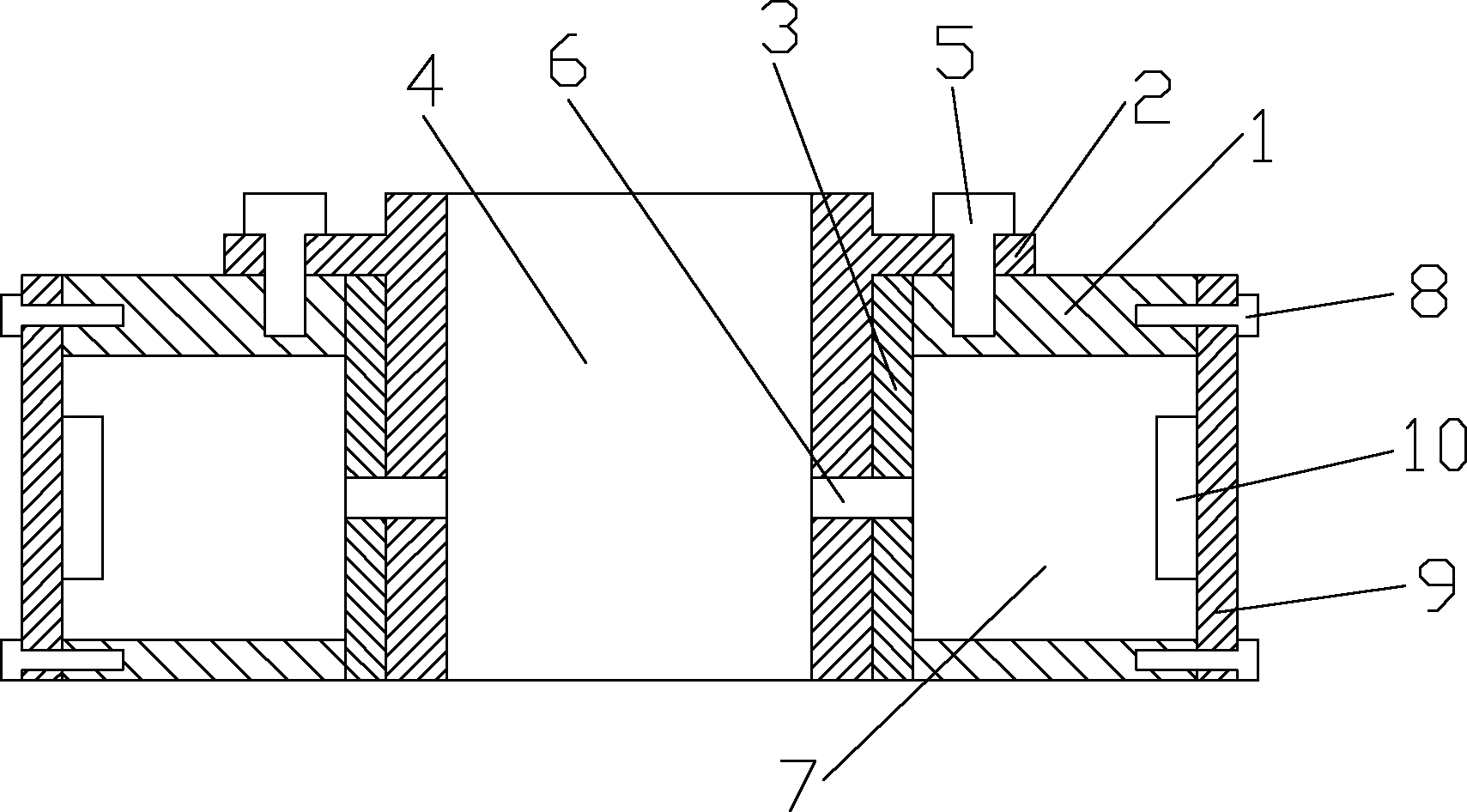

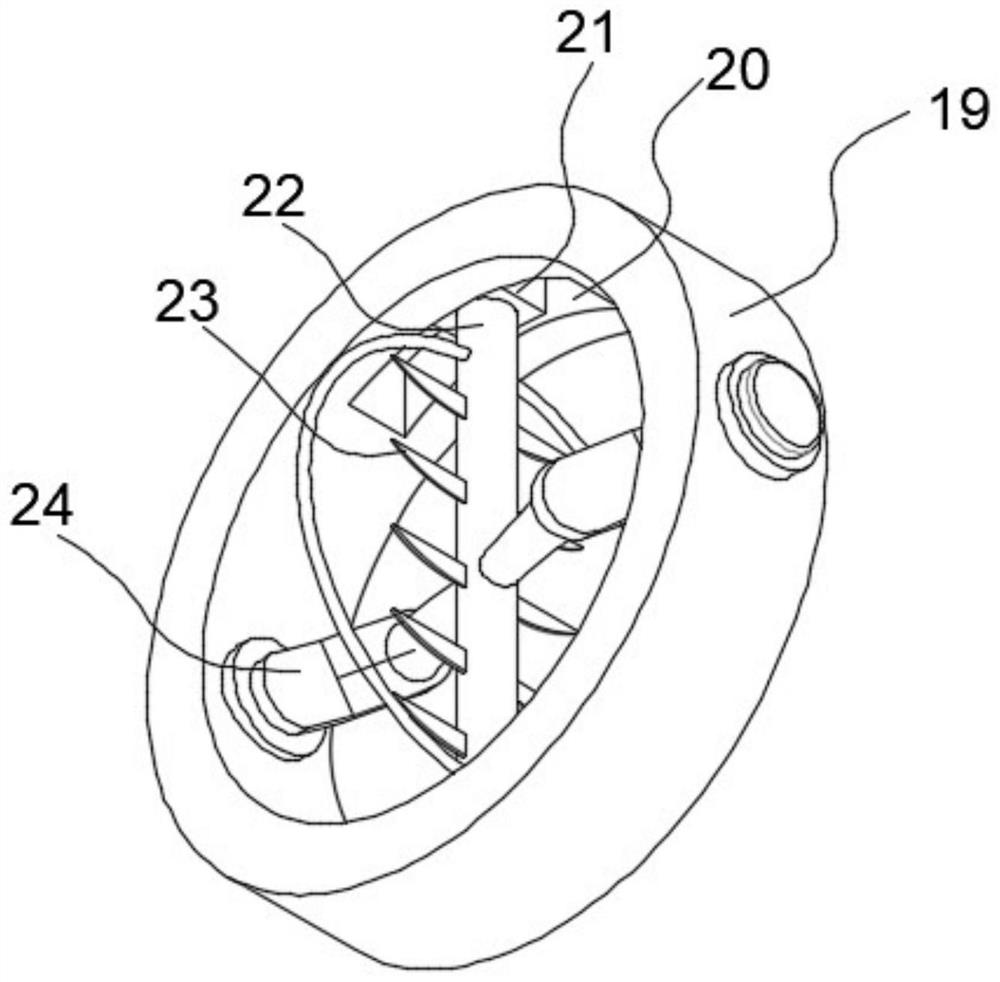

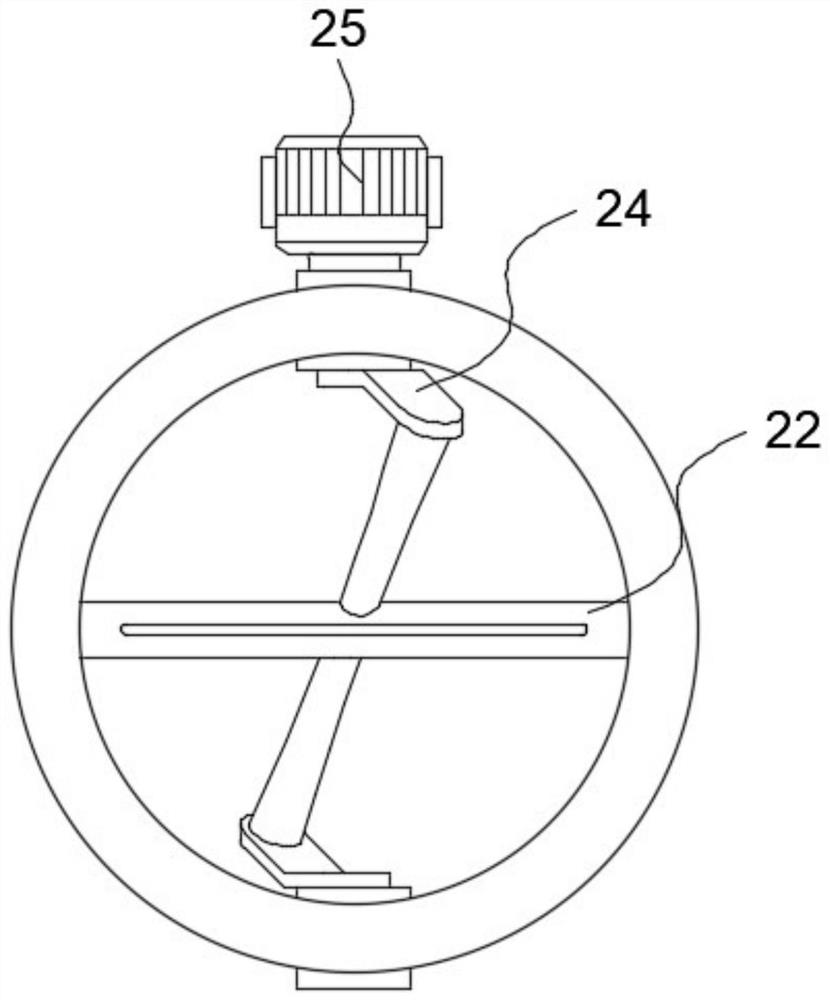

Rounding and sizing processing mould for pipe fittings

The invention relates to a rounding and sizing processing mould for pipe fittings. The rounding and sizing processing mould comprises a cap, an expanding core, mould pieces, a cover plate, a mould base and an expanding core base, wherein a ring-shaped cavity is arranged on the top of the mould base; a mounting slot is formed in the bottom of the mould base; through holes are formed inside the cap and the expanding core; a drawbar is arranged in the through holes; an oil injecting hole is formed in the top of the drawbar; a regulating gasket is arranged in front of the expanding core base and the expanding core; edges of cross sections of the plurality of mould pieces are arc-shaped, and are on the same circle D; a first elastic ring is arranged between the outer walls of the mould pieces and the mould base; the inner walls of the mould pieces are in clearance fit with conical surfaces of the expanding core; second limiting slots are formed in the inner walls of the mould pieces; limiting slide blocks are arranged between the second limiting slots and first limiting slots; and second elastic rings are arranged in grooves of the plurality of the mould pieces. The rounding and sizing processing mould is precise in structure, is reasonable in design, is convenient to dismount and maintain, can be used for simultaneously carrying out sizing, rounding and processing on pipe fittings, is stable in sizing, rounding and processing quality, is convenient and quick in oil injecting and lubricating, and is beneficial for improving processing efficiency and prolonging the service life of the mould.

Owner:ZHENJIANG HENGYUAN AUTOMOBILE COMPONENTS

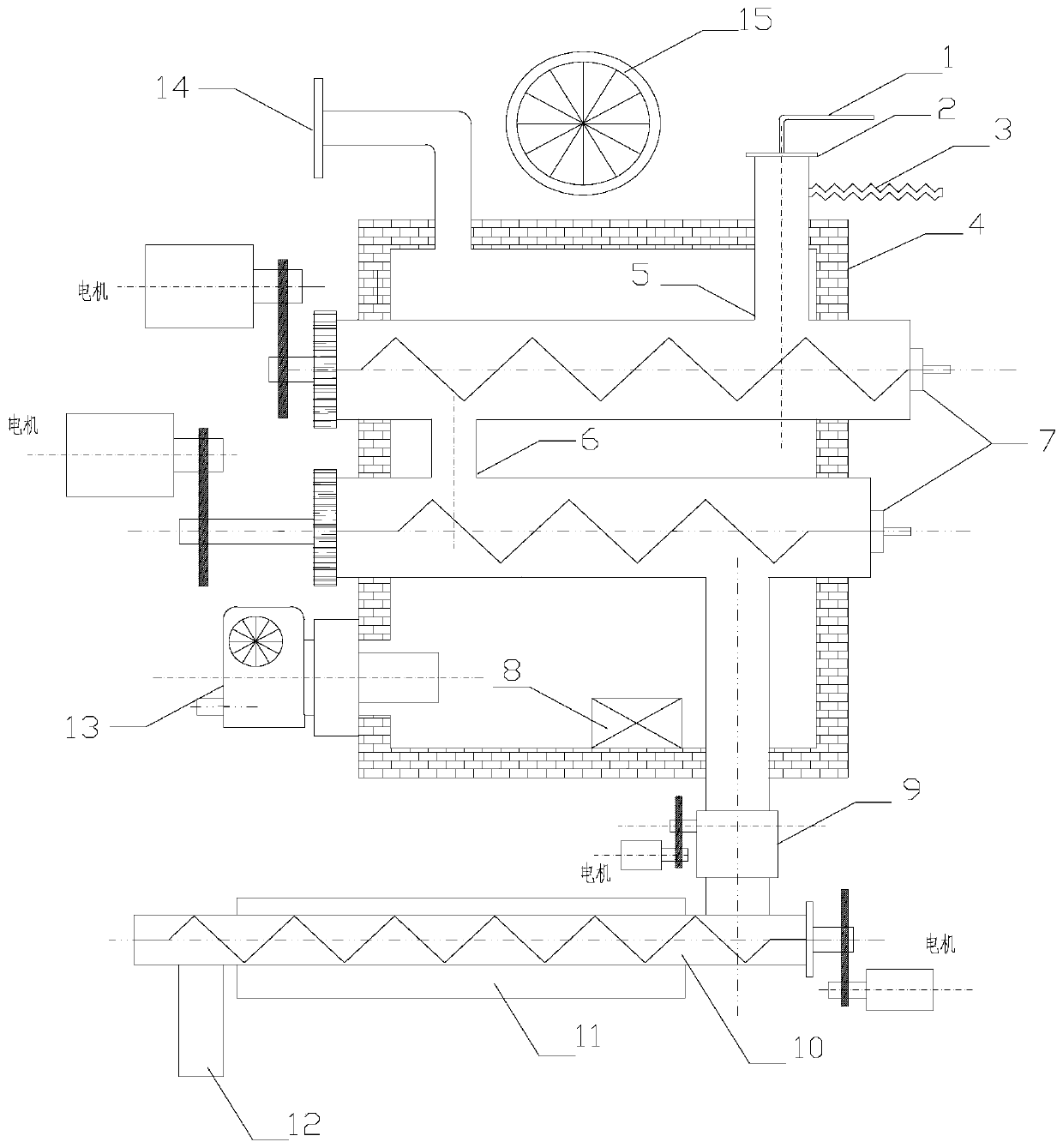

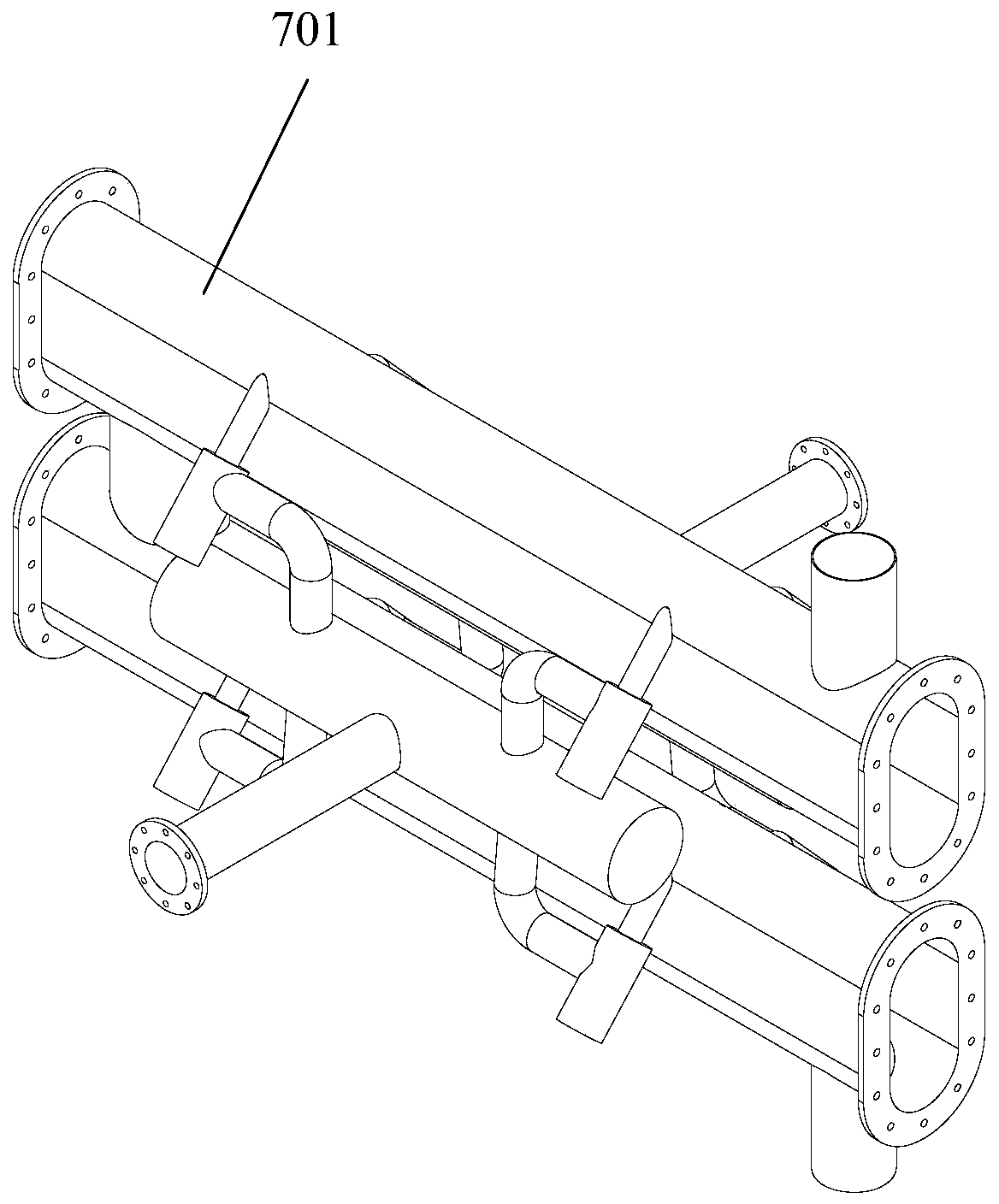

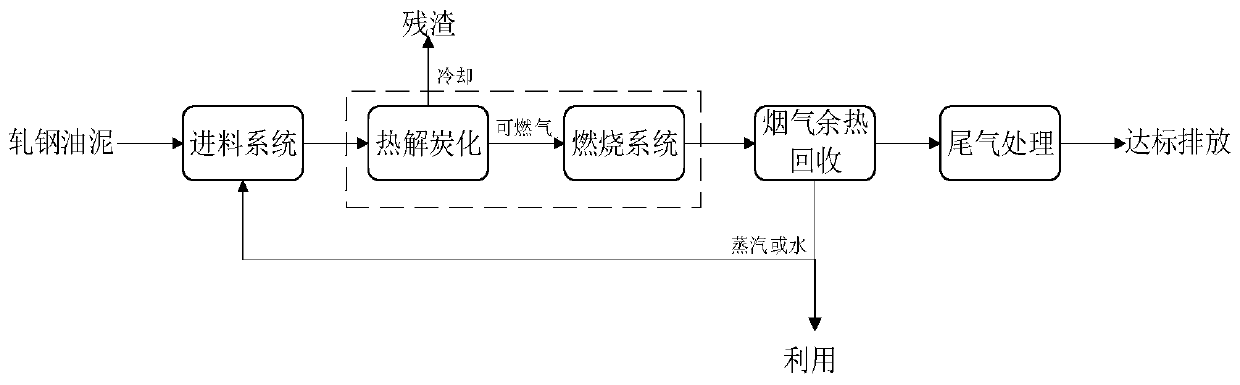

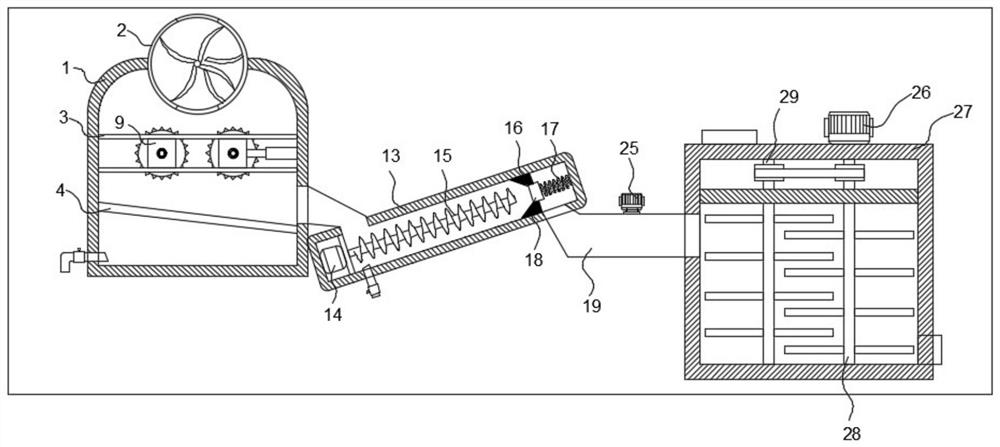

Pyrolytic carbonization device and method for steel rolling oil sludge treatment

ActiveCN110330204AAvoid cloggingAvoid stuckSludge treatment by pyrolysisByproduct vaporizationCarbonizationOil sludge

The invention provides a pyrolytic carbonization device and method for steel rolling oil sludge treatment. A steel rolling oil sludge carbonization device is improved on the basis of the patent with publication number CN107963796A and mainly comprises a feeding device, a pyrolytic carbonization device arranged in a casing, a cooling device, a combustible gas treatment device, a temperature detection element, an electrical control system, a waste heat recovery device and a tail gas treatment device. On the basis of scientific and safe treatment of the steel rolling oil sludge and utilization ofheat contained in organic components of the steel rolling oil sludge and 90% or more of a material reduction rate, the pyrolytic carbonization device and method have the advantages that by means of optimization for carbonization main device structures, including structures and number of carbonization pipes, spiral shafts and the like, the cavity area of a carbonization furnace is increased, movement resistance is reduced, and adhesion, scaling and the like caused by mixing of large-particle ash residues and small-particle ash with tar gas in a long-term carbonization process are prevented andrelieved.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD +1

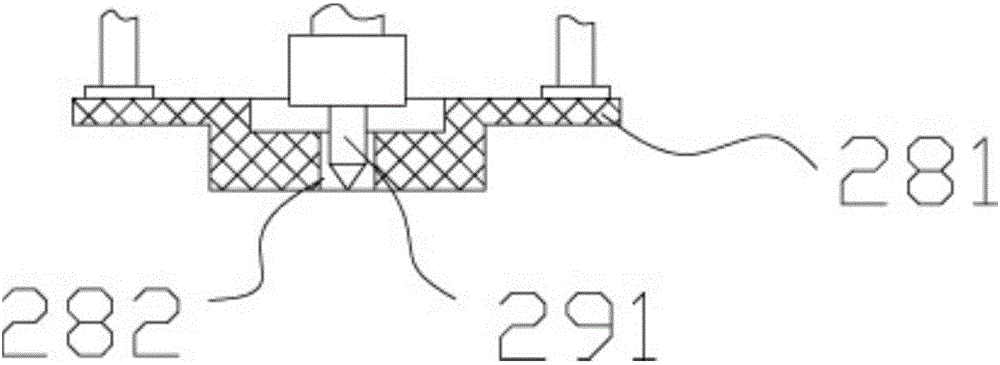

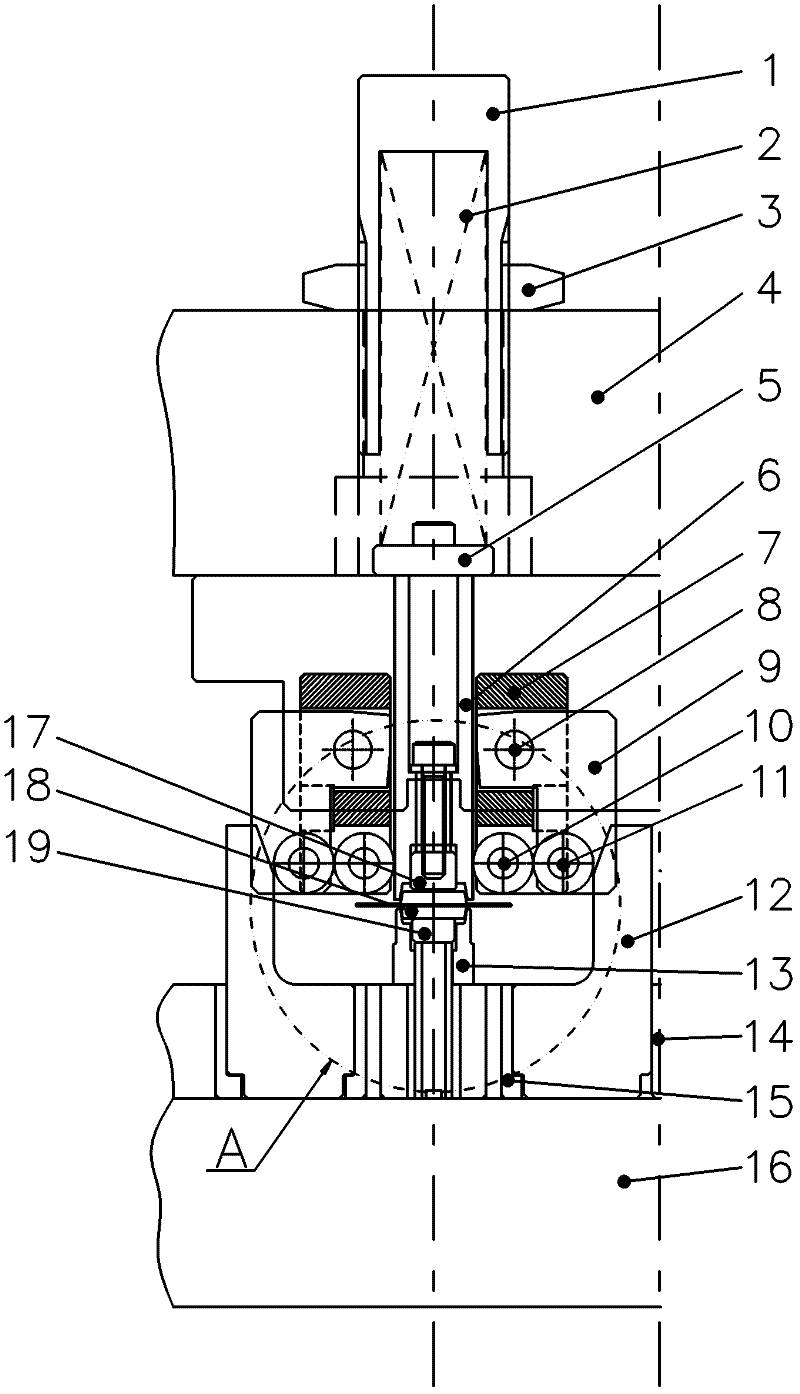

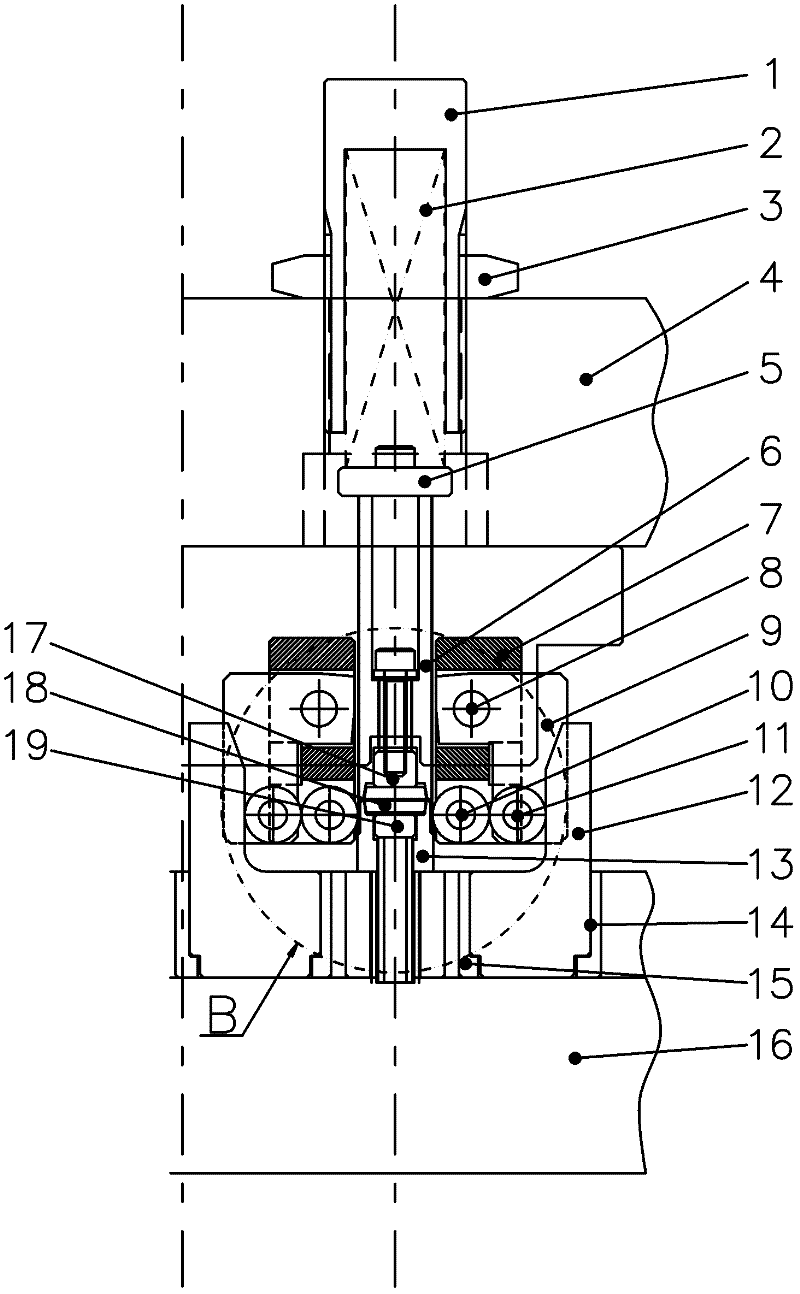

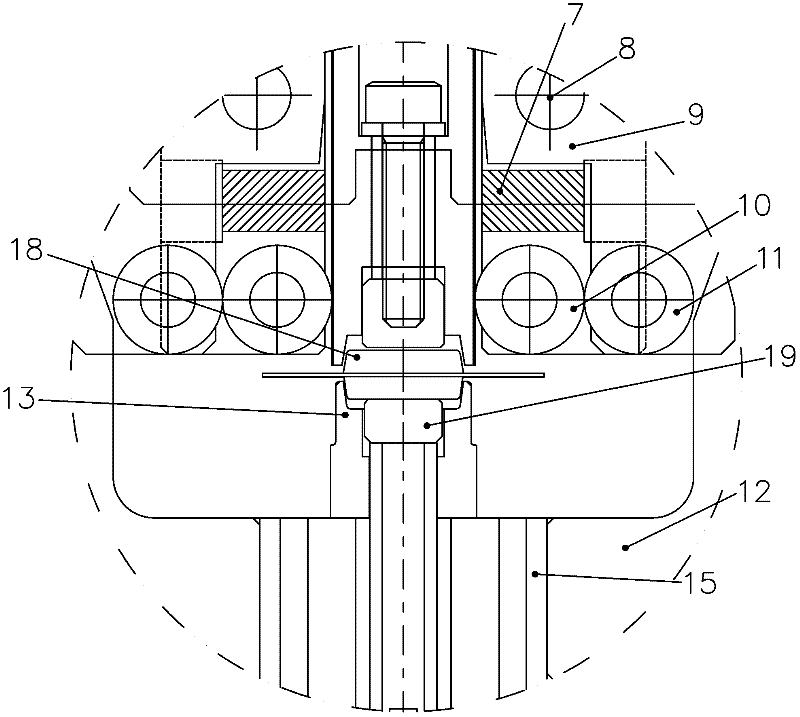

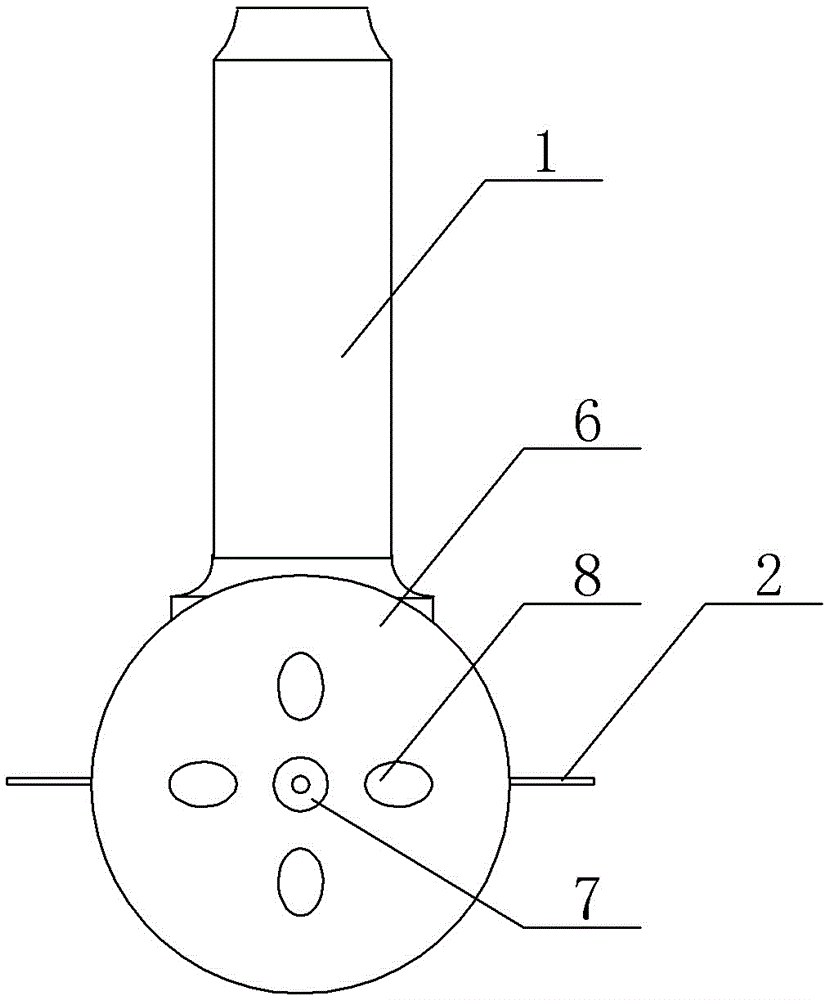

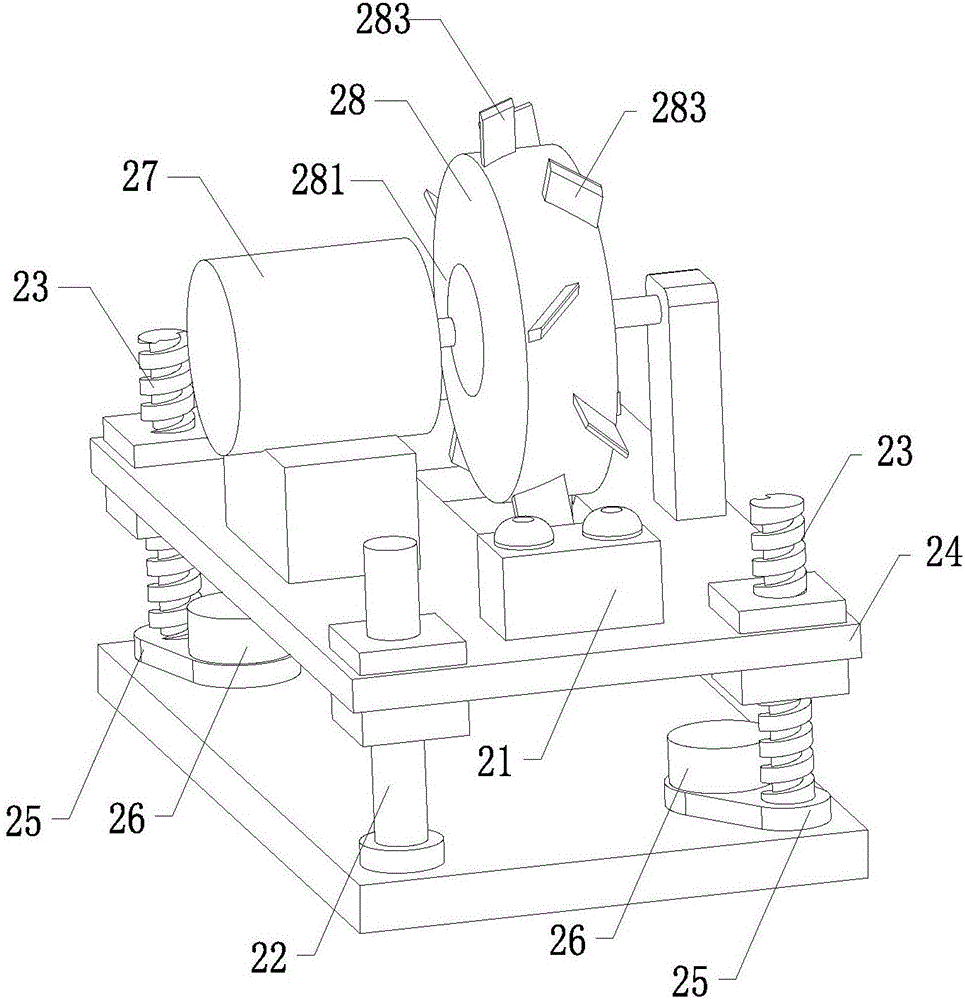

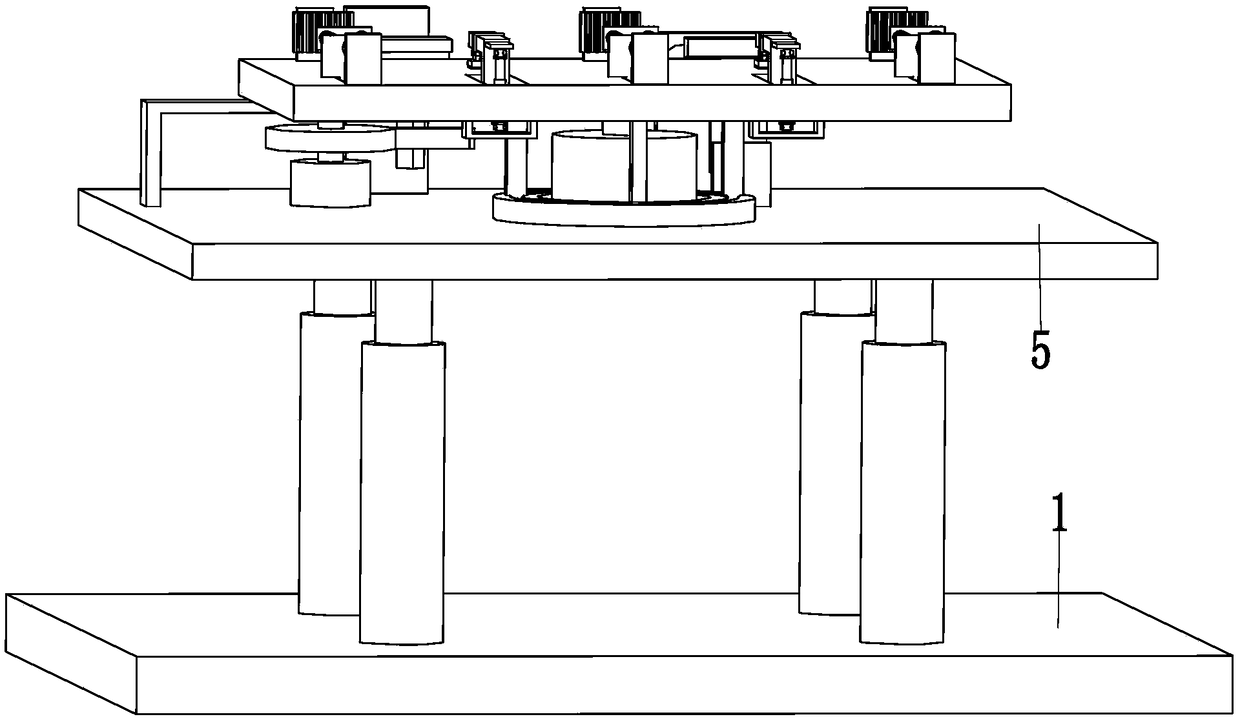

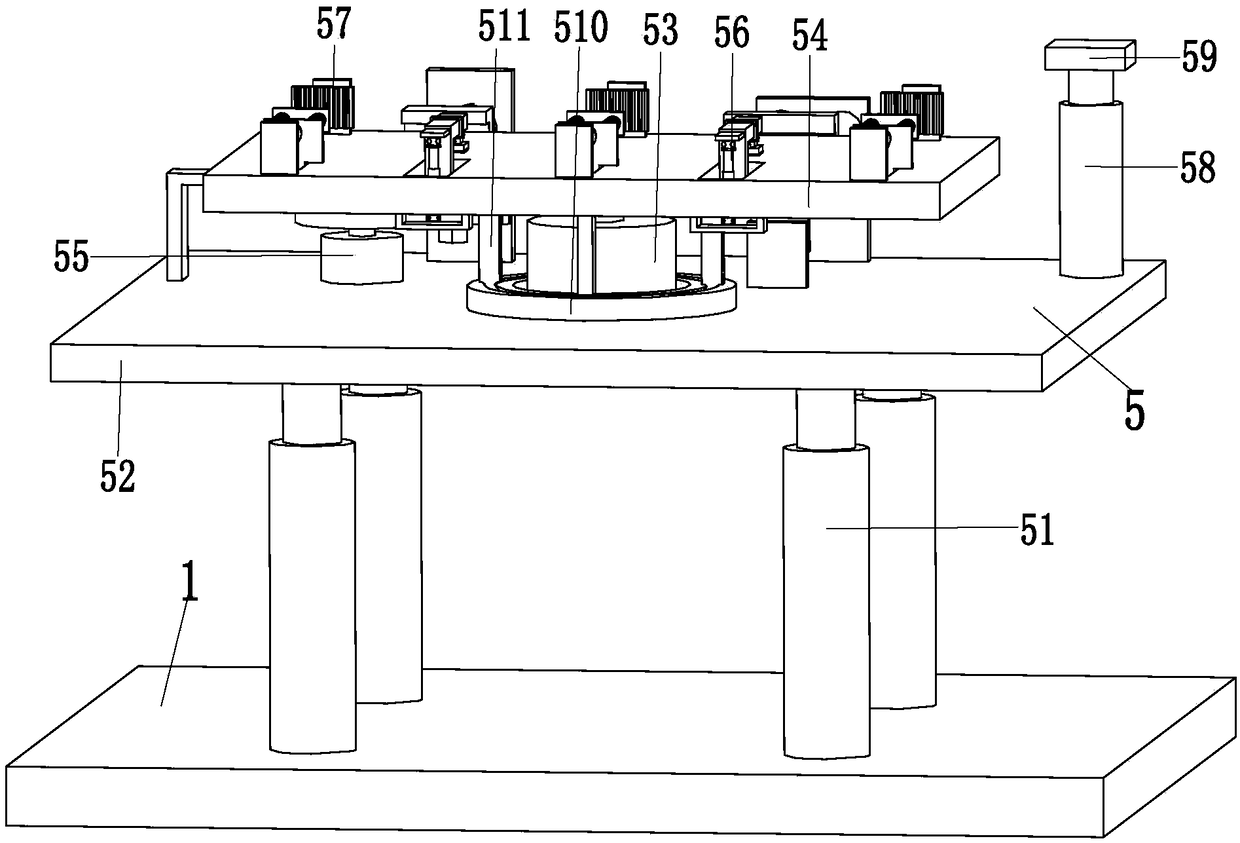

Pin-forming mold for integrated circuits

The invention belongs to the field of press-forming integrated circuits and particularly relates to a pin-forming mold for DIP (Dual Inline Package) / IDF (Intermediate Distributing Frame) package integrated circuits. The mold comprises a fixing device which is used for holding down a product to be formed and pins of the product; conjugate roller wheel devices which are used for enabling pins to be formed are respectively arranged at two sides of the fixing device; and a taper wedge device which is used for guiding the conjugate roller wheel device to work is arranged at one side of each of the conjugate roller wheel devices far away from the fixing device. The mold is made from a pair of conjugate roller wheels, i.e. main roller wheels and auxiliary roller wheels, which can swing; when the pins are formed, the main roller wheels and the auxiliary roller wheels generate conjugate movement, i.e. the main roller wheels and the auxiliary roller wheels mutually rotate in opposite directions so as to ensure that the pins of the product are formed by means of pure rolling, thus the quality of the product can be greatly improved; and meanwhile, the phenomenon of clamping stagnation generated between a mandrel and roller wheels in a single-roller wheel forming manner can be avoided.

Owner:TONGLING SANJIA YAMADA TECH

Automatic dispenser

ActiveCN103963974ASimple structureEasy to operateAircraft componentsFire rescueEngineeringTorsion spring

The invention relates to a dispenser and particularly relates to an automatic dispenser. The automatic dispenser comprises a dispenser main body, a switch control device and a supporting device, wherein the switch control device and the supporting device are respectively mounted on two sides of the dispenser main body; the switch control device comprises a steering engine, a cross bar and a steering engine switch; the supporting device comprises a supporting rod, a supporting rod fixing part and a rocker arm; the steering engine is mounted on the dispenser main body; the cross bar is hinged to the dispenser main body; one end of the cross bar is propped against the steering engine switch; one end of the supporting rod is hinged to the supporting rod fixing part mounted on the dispenser main body, and a torsion spring is arranged at the hinged part; the rocker arm is arranged at the other end of the supporting rod; the other end of the cross bar is flexibly connected with the other end of the supporting rod; a dispensing object to be dispensed is positioned in the dispenser main body and is supported by the dispenser main body and the supporting rod; a fuse of the dispenser is jacked by the rocker arm. The automatic dispenser disclosed by the invention has the advantages of dispensing automation, simple structure, convenience in operation, good maneuverability, high practicality, safety and reliability.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +2

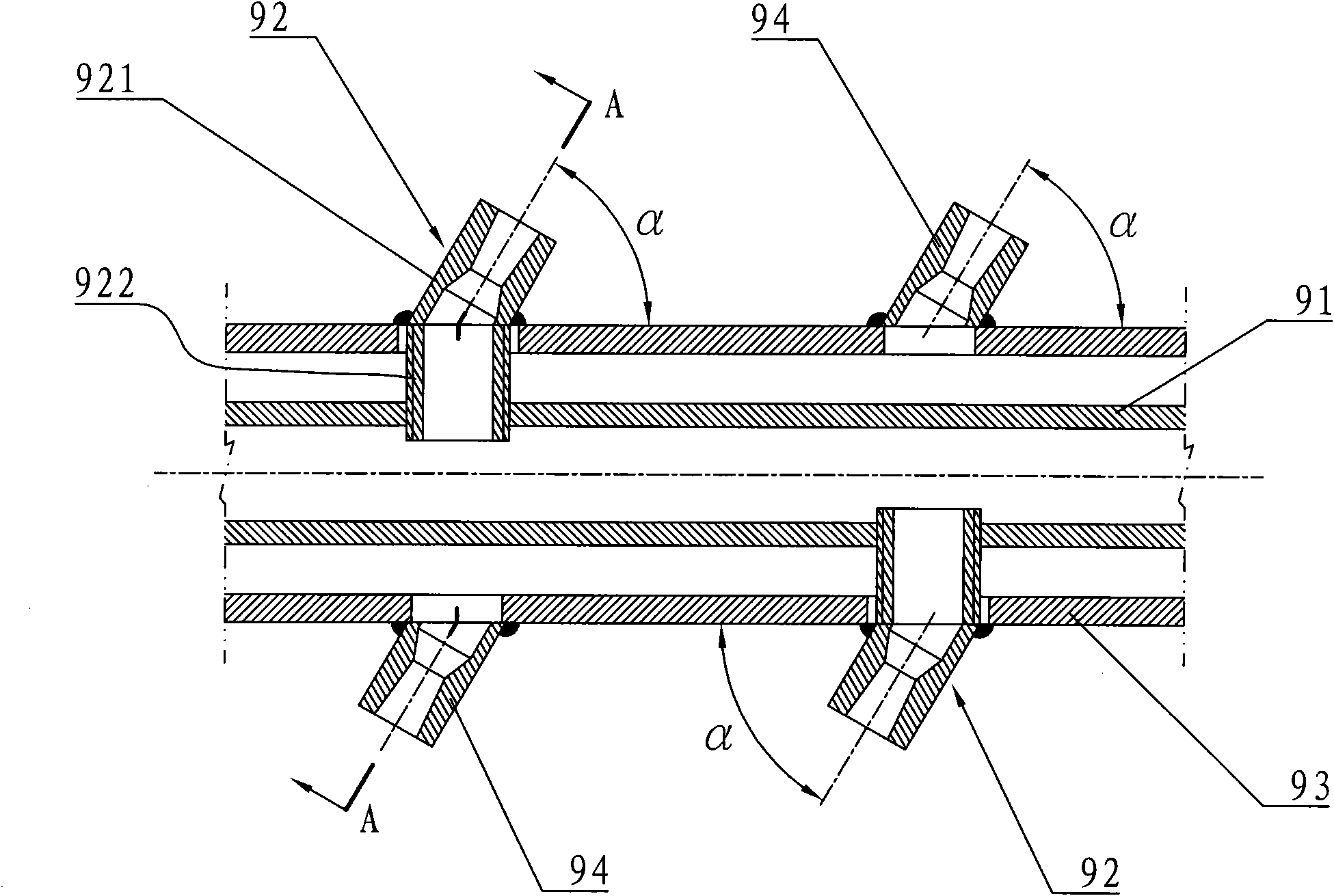

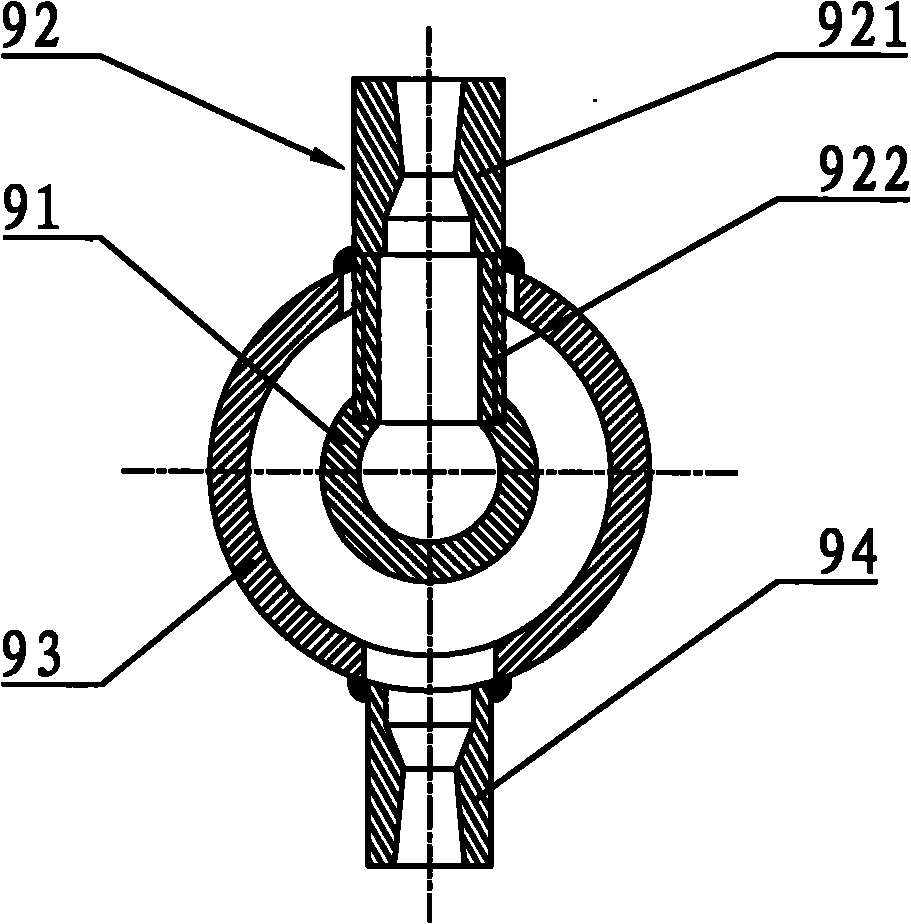

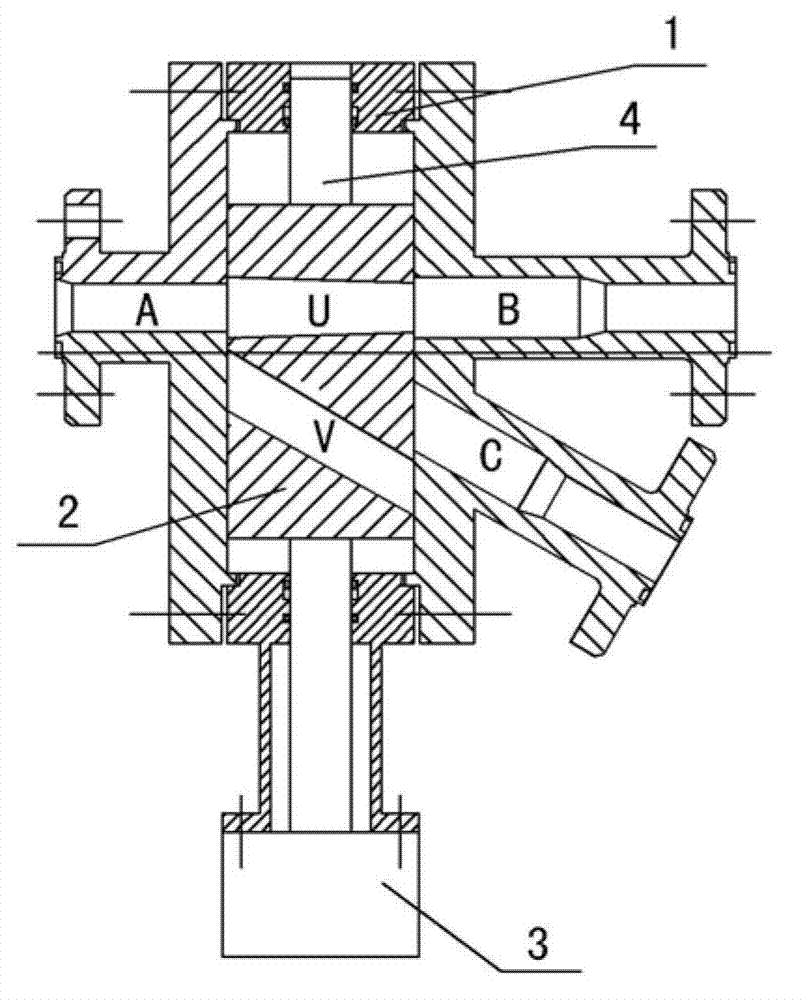

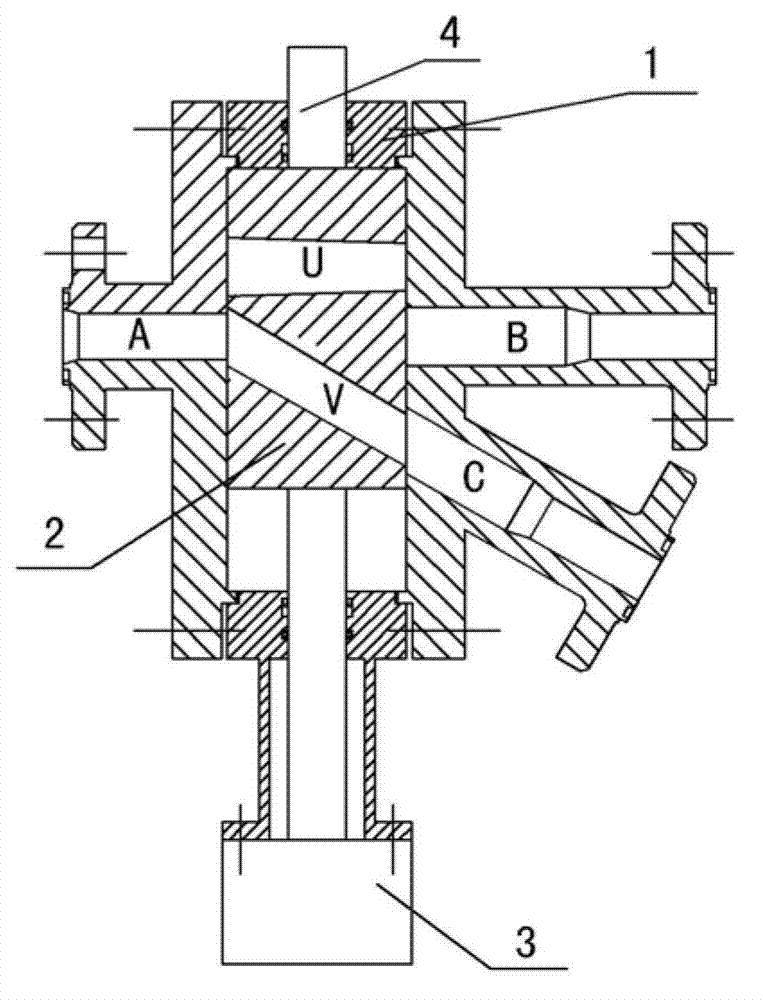

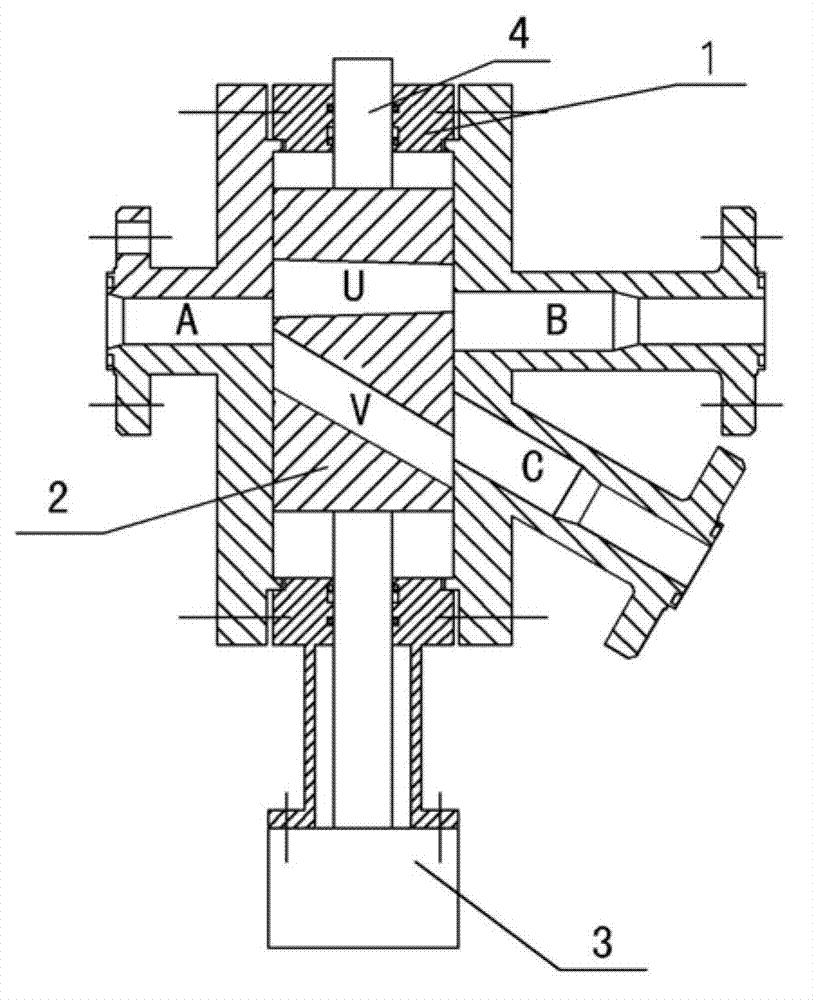

Slide powder-feeding three-way reversing valve

ActiveCN102818047AReduce wearPrevent compactionMultiple way valvesValve housingsEngineeringOperational stability

The invention discloses a slide powder-feeding three-way reversing valve which is characterized in that a columnar valve cavity is reserved in a valve body with one inlet and two outlets, a double-flow-passage columnar spool which can slide linearly along the columnar valve cavity is disposed in the same; a valve body inlet passage A, a valve body outlet passage B and a valve body outlet passage C are arranged on the valve body; the a valve body outlet passage B is coaxial with the valve body inlet passage A, an acute included angle a is formed by outflow directions of the valve body outlet passage B and the valve body outlet passage C, axis of each valve body passage is on a plane M; a spool passage U and a spool passage V are arranged in the columnar spool; and different positions of the columnar spool in the columnar valve cavity correspond to different on and off states. By the slide powder-feeding three-way reversing valve, operational stability of a powder feeding device is improved effectively and service life of the device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +2

Portable concrete template surface cleaning device

The invention relates to a building construction template cleaning device, and particularly relates to a portable concrete template surface cleaning device. The portable concrete template surface cleaning device includes a hand-held power device, a cutter shaft and a roller; one end of the hand-held power device is provided with a motor and a transmission device which is connected to the motor; the cutter shaft is a cylinder, and the transmission device is connected to a rotatable shaft of the cylinder; the outer surface of the cylinder is provide with bump zones and hairbrush zones which are spirally distributed, wherein the bump zones and the hairbrush zones are alternately arranged, and the diameter of a rotatable surface of each bump zone is smaller than that of each hairbrush zone; the roller is arranged on the rotatable shaft at the outer side of the cylinder, and the roller and the cylinder are connected by a bearing; an outer edge of the roller is arranged on a concrete template; and the diameter of a rotatable surface of the roller is larger than that of the diameter of a rotatable surface of each bump zone. The portable concrete template surface cleaning device is low in cost, is portable, is convenient in use, and can clean a surface of the concrete template on site.

Owner:徐州华固混凝土有限公司

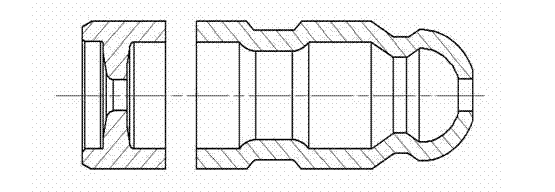

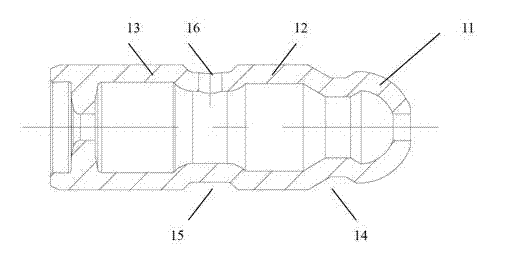

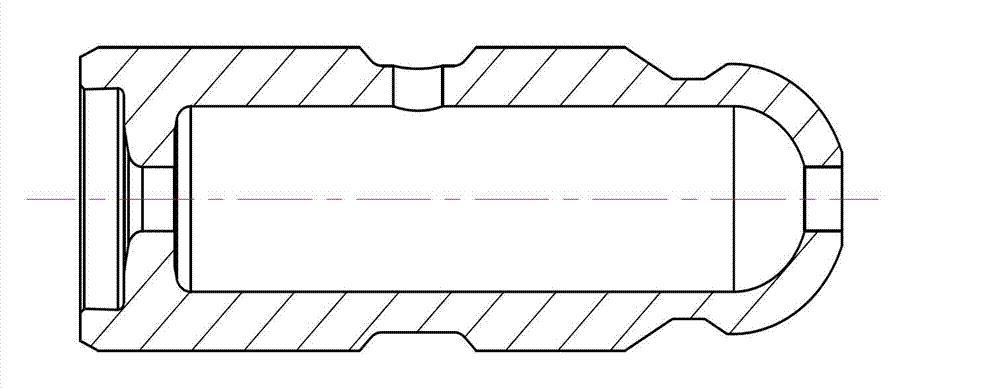

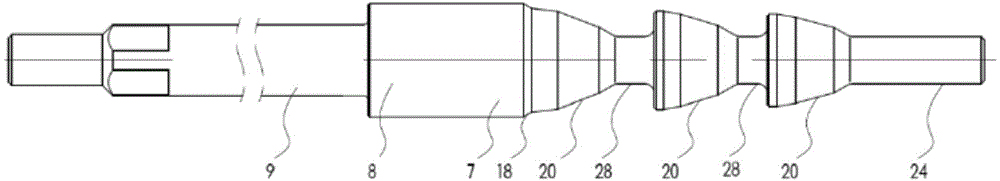

Integrated hydraulic tappet plunger and integral roller forming method thereof

ActiveCN102788154AReduce investmentImprove consistencyValve arrangementsPlungersBiochemical engineeringUltimate tensile strength

The invention belongs to the technical field of cold forming, and particularly relates to an integral roller forming method of an integrated hydraulic tappet plunger in a hydraulic gap adjuster in an automobile engine. The integrated hydraulic tappet plunger comprises a cylindrical body, one end of the body is a hemisphere, a rod is arranged in the middle of the body, the other end of the body is a main portion, a first circular groove is arranged between the hemisphere and the rod, a second circular groove is arranged between the rod and the main portion, and a fluid opening is arranged in the second circular groove. The integrated hydraulic tappet plunger is characterized in that the hemisphere, the rod and the main portion are integrally formed, and the wall thicknesses of the hemisphere, the rod and the main portion are equal. The integrated hydraulic tappet plunger and the processing forming method have the advantages that the integrated hydraulic tappet plunger is simple in structure and is processed and formed conveniently, investment of plunger production equipment can be reduced according to the scheme, production efficiency of the plunger is improved, and the produced integrated plunger is higher in integral strength and longer in service life as compared with a plunger in the prior art.

Owner:HANGZHOU XZB TECH

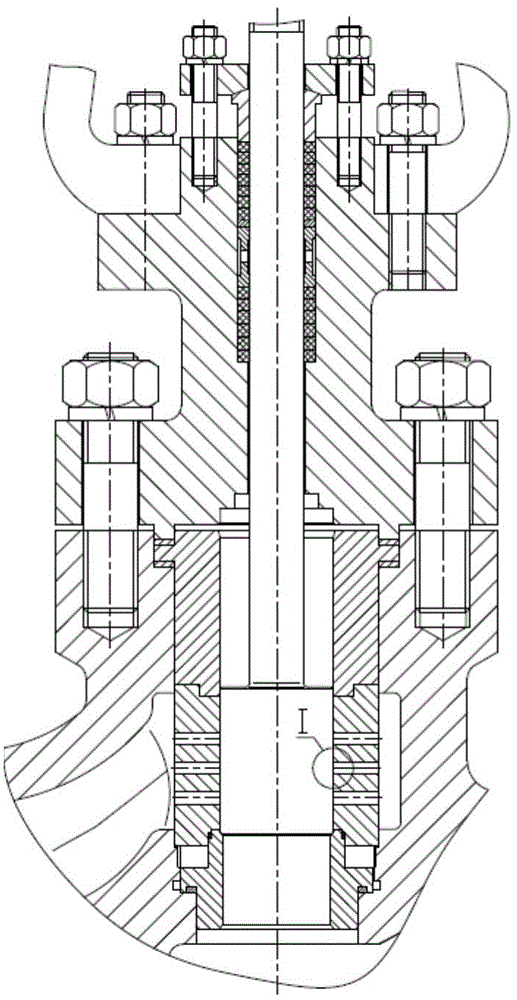

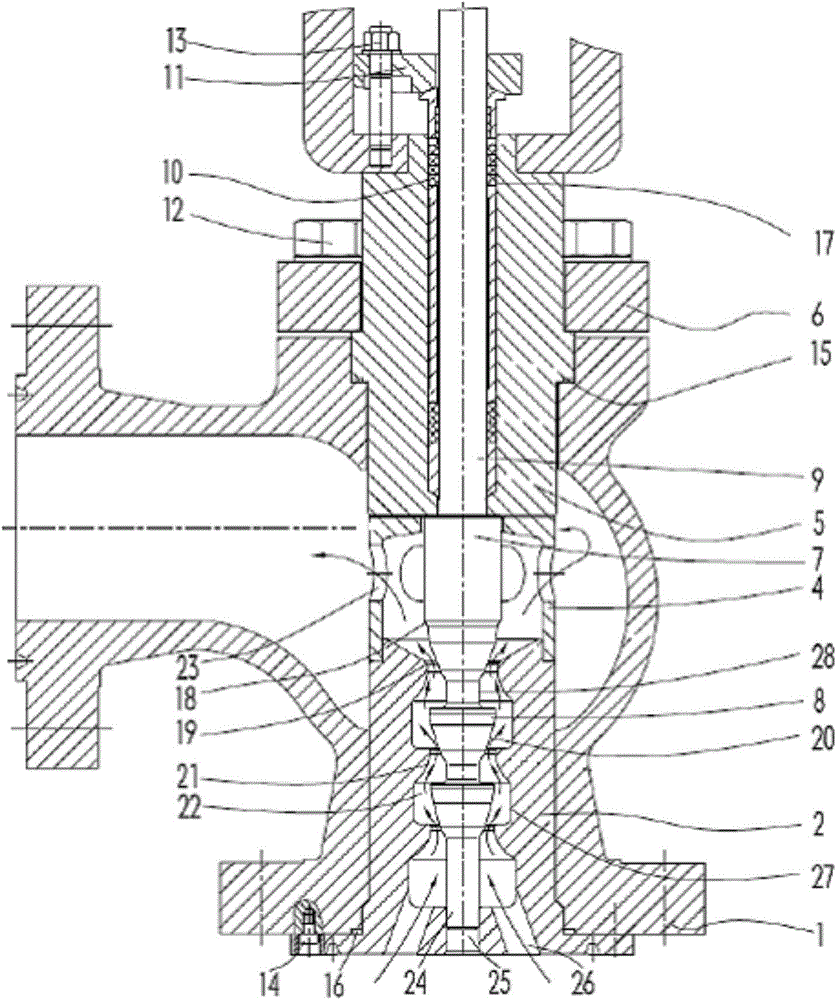

Throttling serial type multistage pressure reduction and adjustment valve

InactiveCN104455469APrecise pressure/flow controlEliminate cavitationValve members for absorbing fluid energyLift valveSolid particlePressure difference

The invention provides a throttling serial type multistage pressure reduction and adjustment valve. A valve rod and a valve element assembly are arranged inside a valve body; a valve seat assembly is provided with multistage pressure reduction units, and each stage of pressure reduction unit of the valve seat assembly is composed of a cylindrical fluid expansion unit and a throttling unit, wherein the throttling unit is shaped like a circular truncated cone, and the area of the throttling unit decreases gradually; correspondingly, the pressure reduction units are arranged on corresponding positions of the valve element assembly, wherein the stage number of the pressure reduction units in the valve element assembly is equal to that of the pressure reduction units in the valve seat assembly; each stage of the pressure reduction unit of the valve element assembly is composed of a bowl-shaped molded surface for controlling flow and a cylindrical shrinkage unit; the upper portion of the valve element assembly is provided with valve elements, and the lower portion of the valve element assembly is provided with guide rods; valve bottom drainage holes are formed in the positions, located on the outer sides of valve seat guide holes, of the bottom of the valve seat assembly; a flow diversion sleeve is arranged on the top of the valve seat assembly, and a flow diversion hole is formed in one side of the flow diversion sleeve. According to the throttling serial type multistage pressure reduction and adjustment valve, the service life of the valve can be prolonged, vibration and noise of pipelines behind the valve can be eliminated, and it is guaranteed that the adjustment accuracy of the valve is high and operation is stable under the working condition that the pressure difference is large and solid particles exist in media in the Texaco process of coal chemical industries.

Owner:BEIJING AEROSPACE PROPULSION INST +3

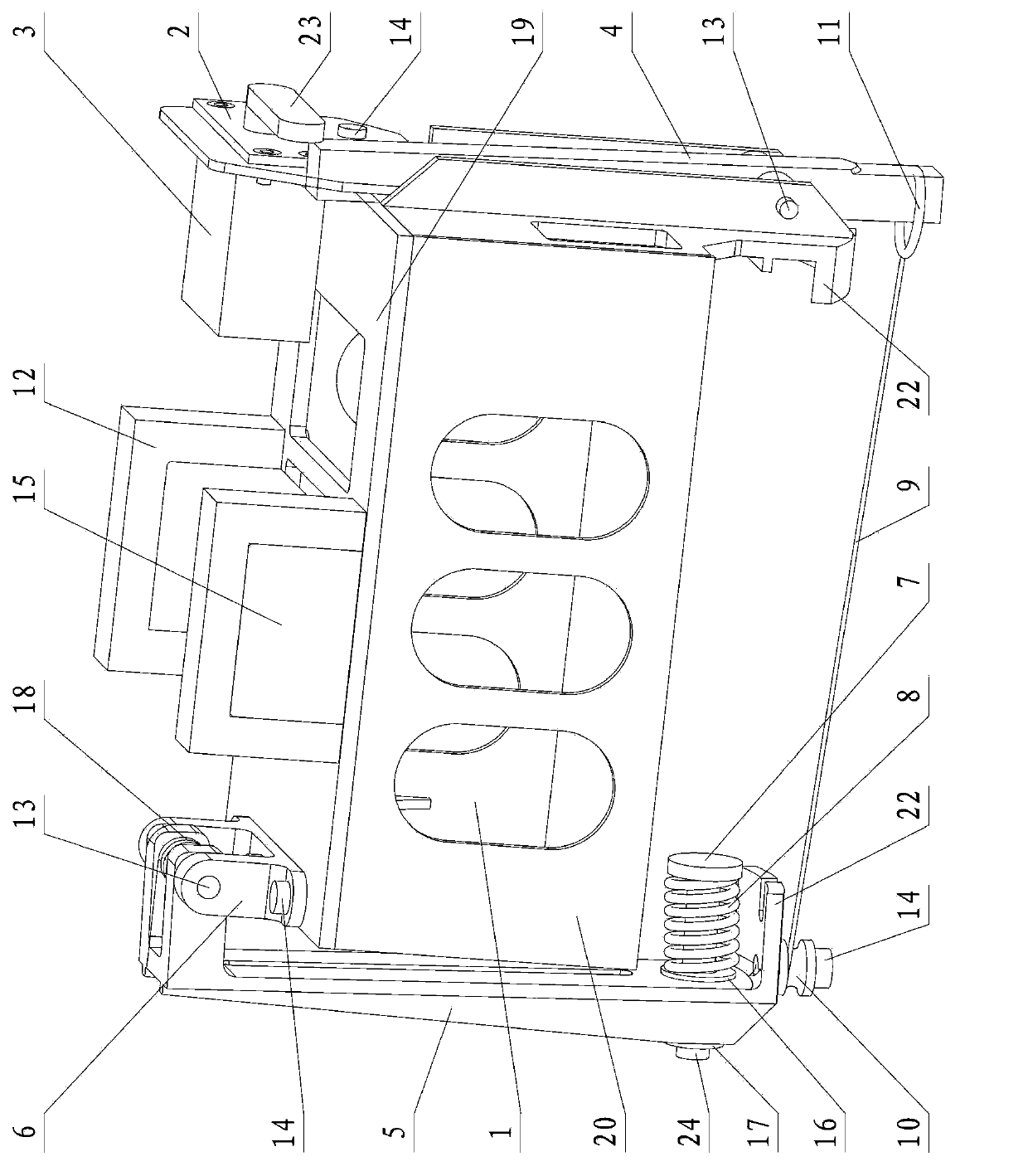

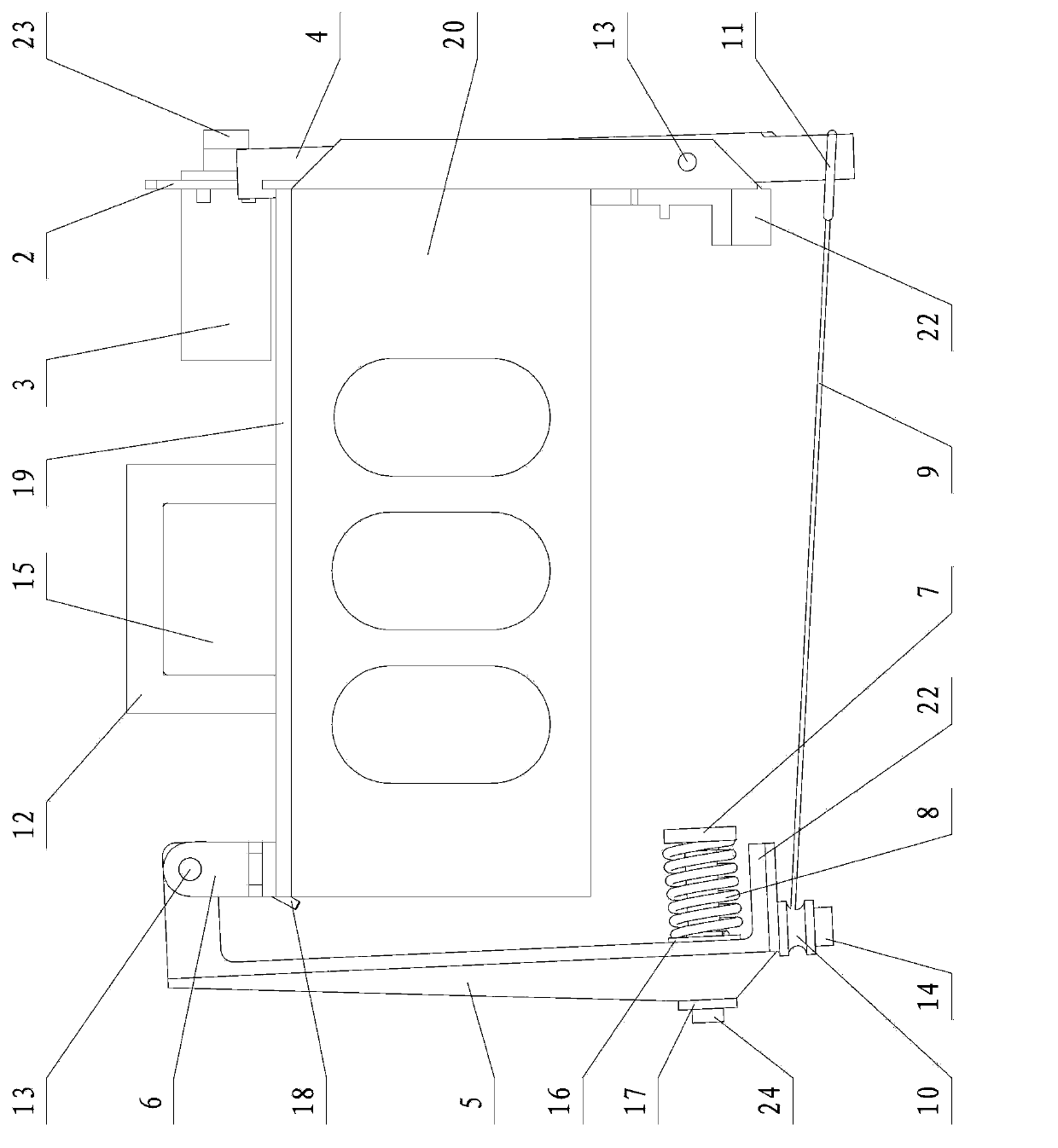

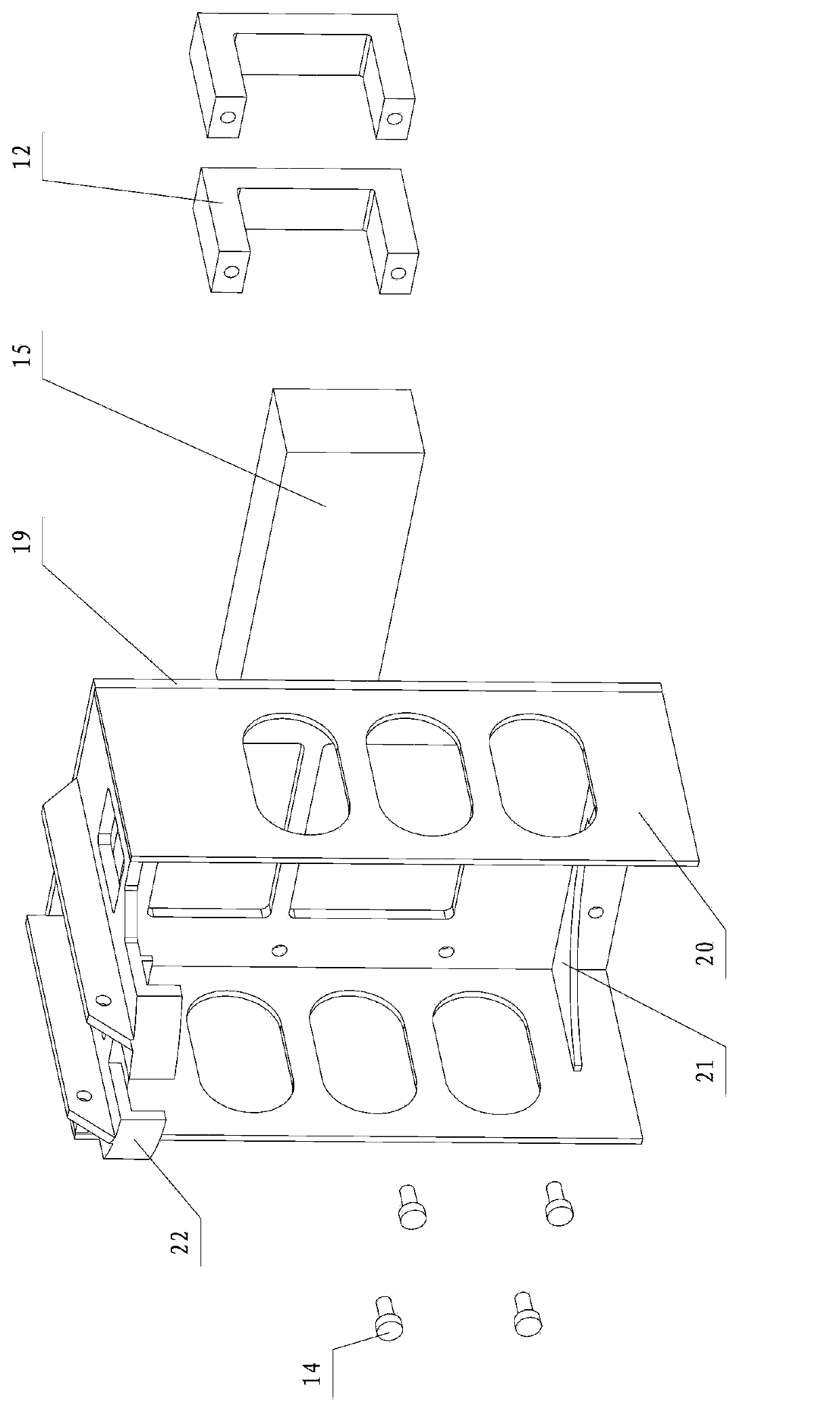

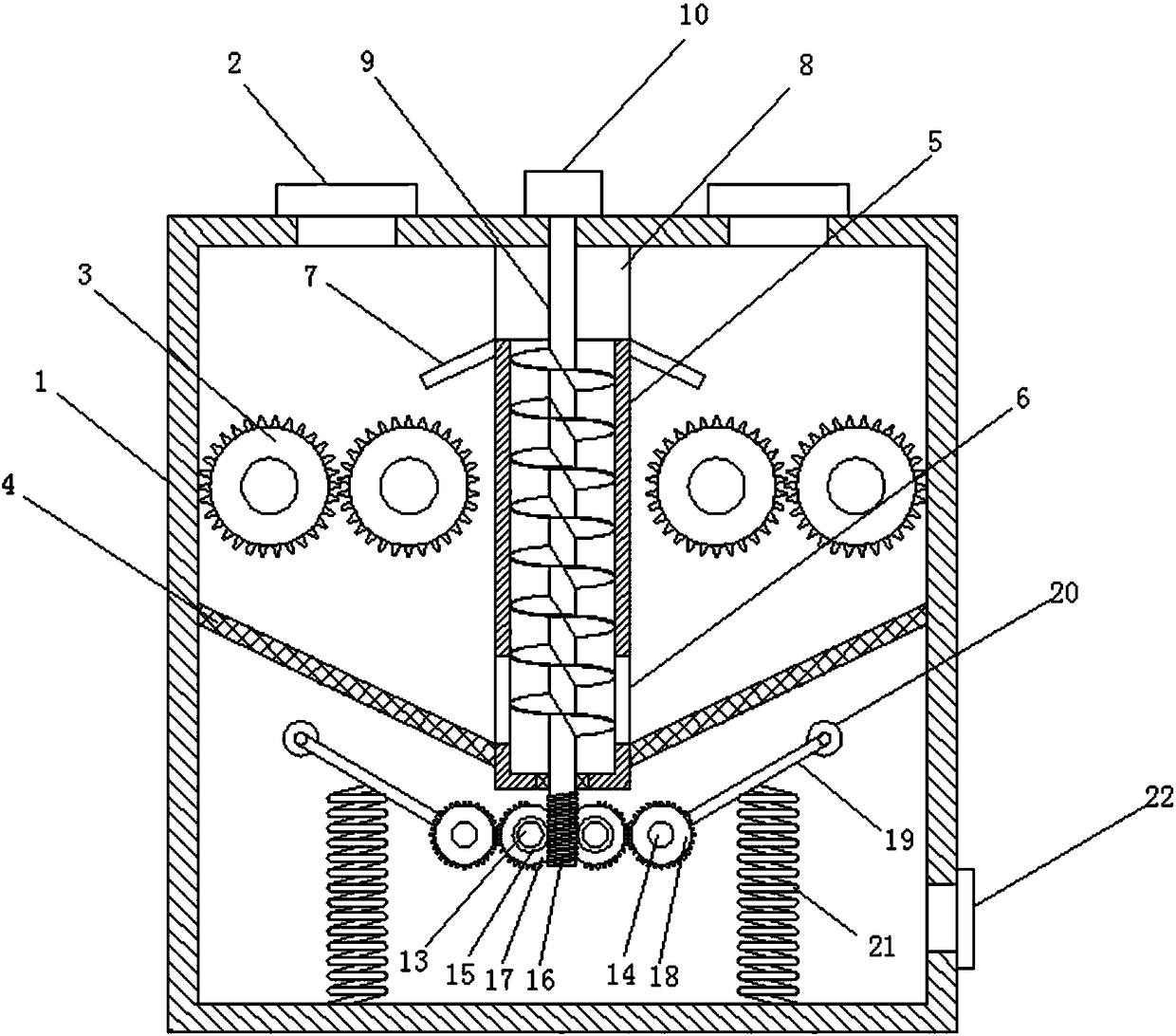

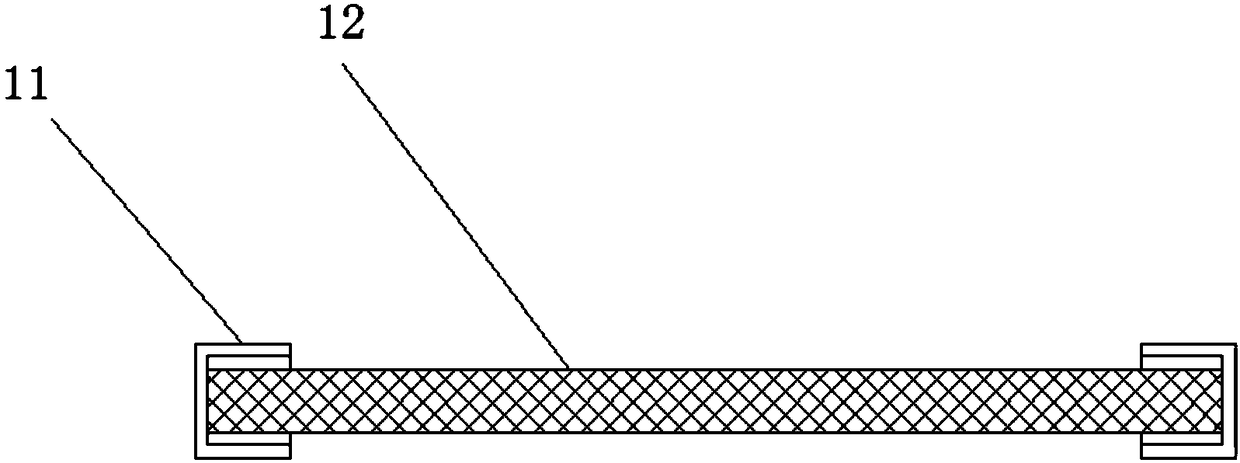

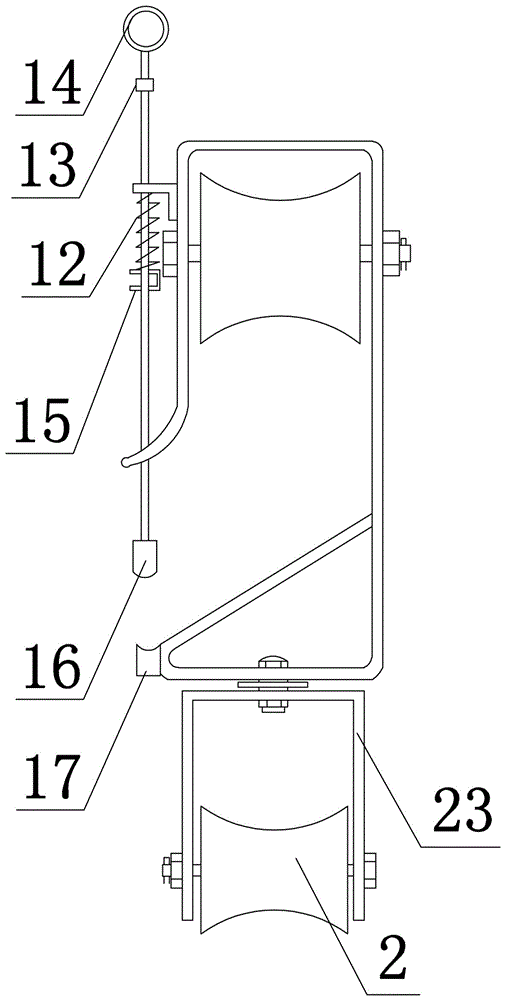

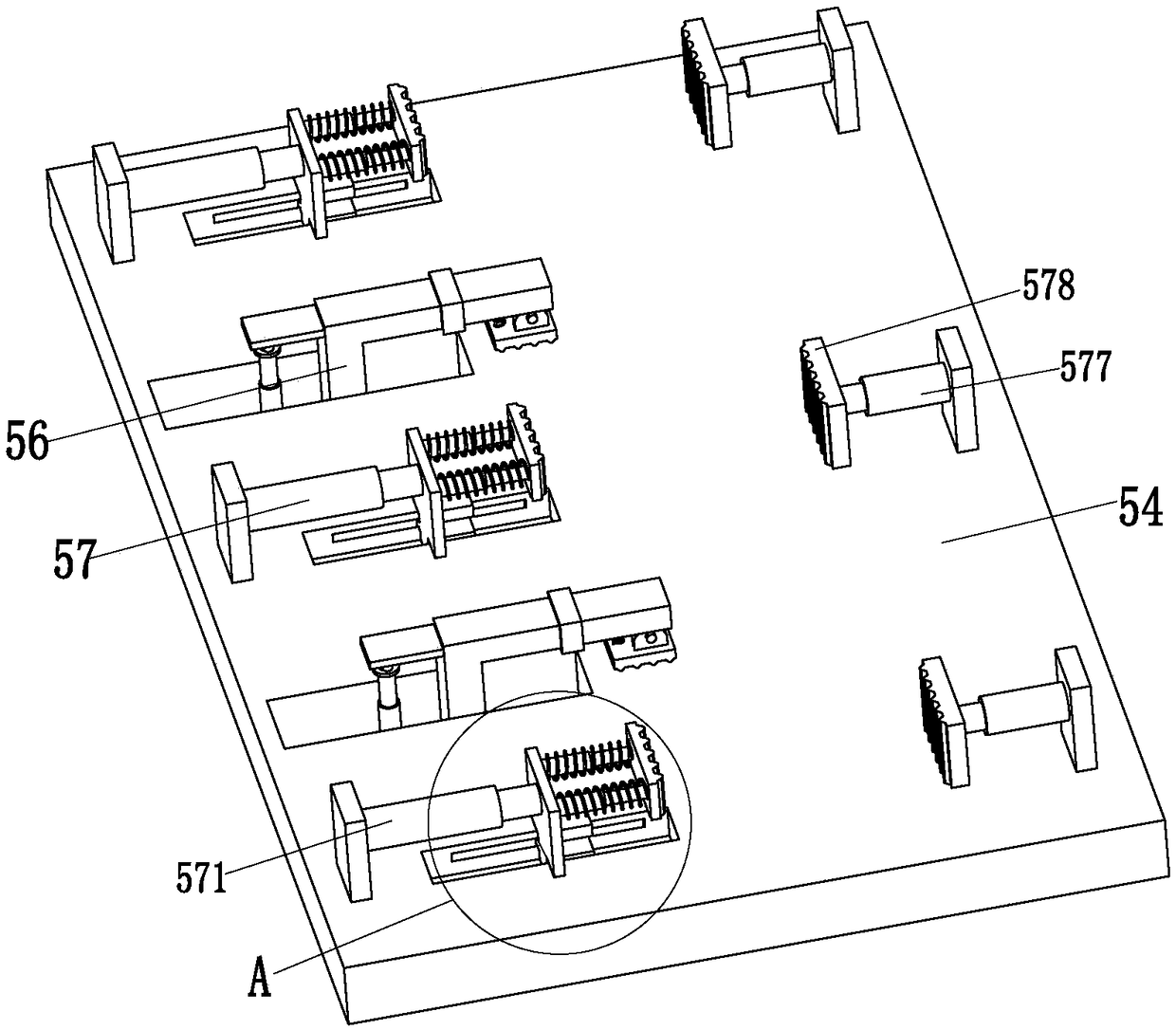

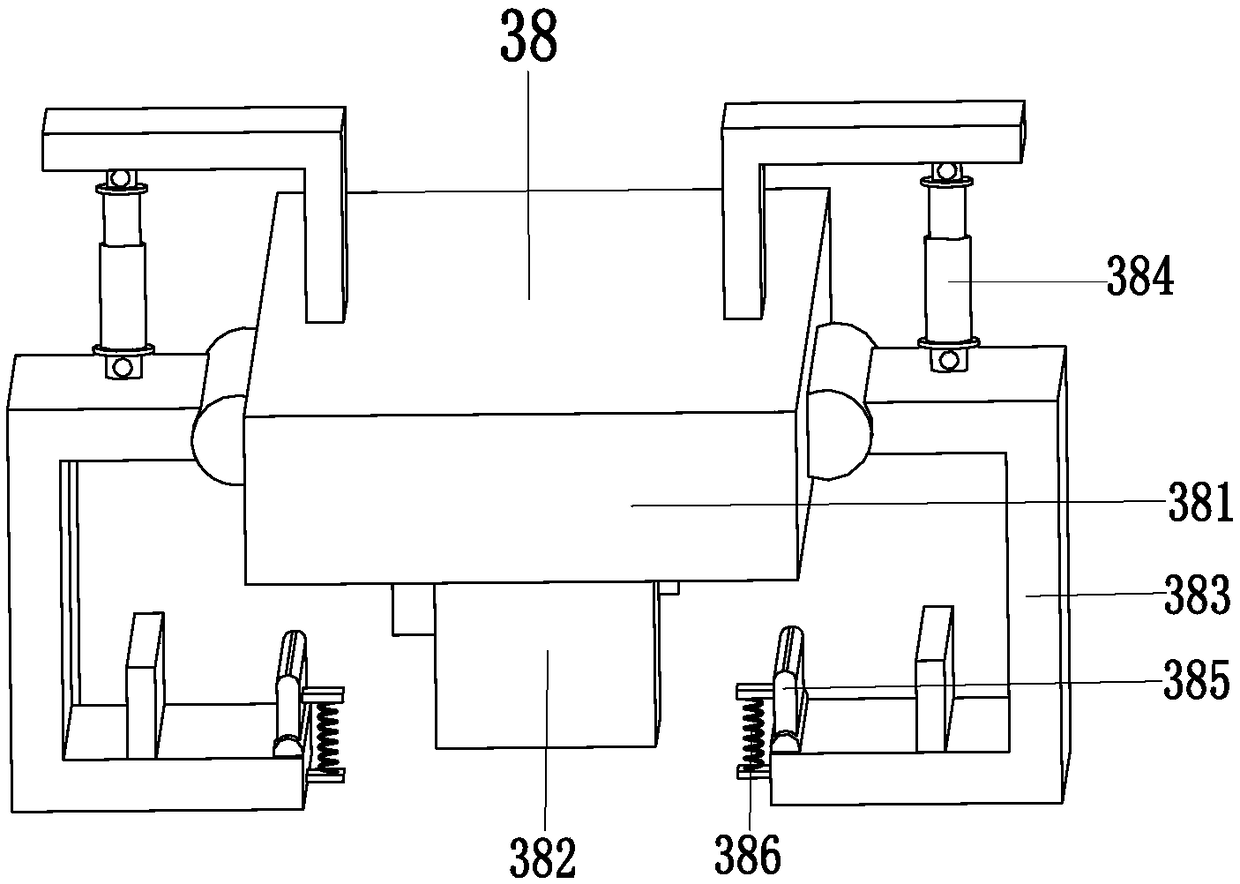

Plastic punching frame

ActiveCN105818212AAdjustable distanceAvoid stuckMetal working apparatusPunchingArchitectural engineering

The invention discloses a plastic punching frame which comprises a frame body. Upper supporting plates are fixed to the top faces of the two sides of a top plate of the frame body, and a vertical adjusting through groove is formed in the upper portion of each upper supporting plate. An adjusting cylinder is fixed to the outer side wall of each upper supporting plate, an adjusting block is fixed to a vertically upward end of a push rod of each adjusting cylinder, the adjusting blocks are inserted into the corresponding vertical adjusting through grooves, and a lifting block is fixed to each adjusting block. The outer side wall of each lifting block is tightly attached to the inner side wall of the corresponding upper supporting plate. Extending parts extending downwards are arranged on the two sides of a middle horizontal plate and fixed to the corresponding lifting blocks. A horizontal moving through groove is formed in the middle of the middle horizontal plate, connecting plates are fixed to the two ends of the top face of the middle horizontal plate, and the two ends of a transmission screw rod are hinged to the two connecting plates. The plastic punching frame can be used for automatic punching; meanwhile, the distance between a punch and a product can be adjusted; a pushing block is arranged on the punch and can prevent the punch from being clamped in the product, so that efficiency is improved.

Owner:陈玲婷

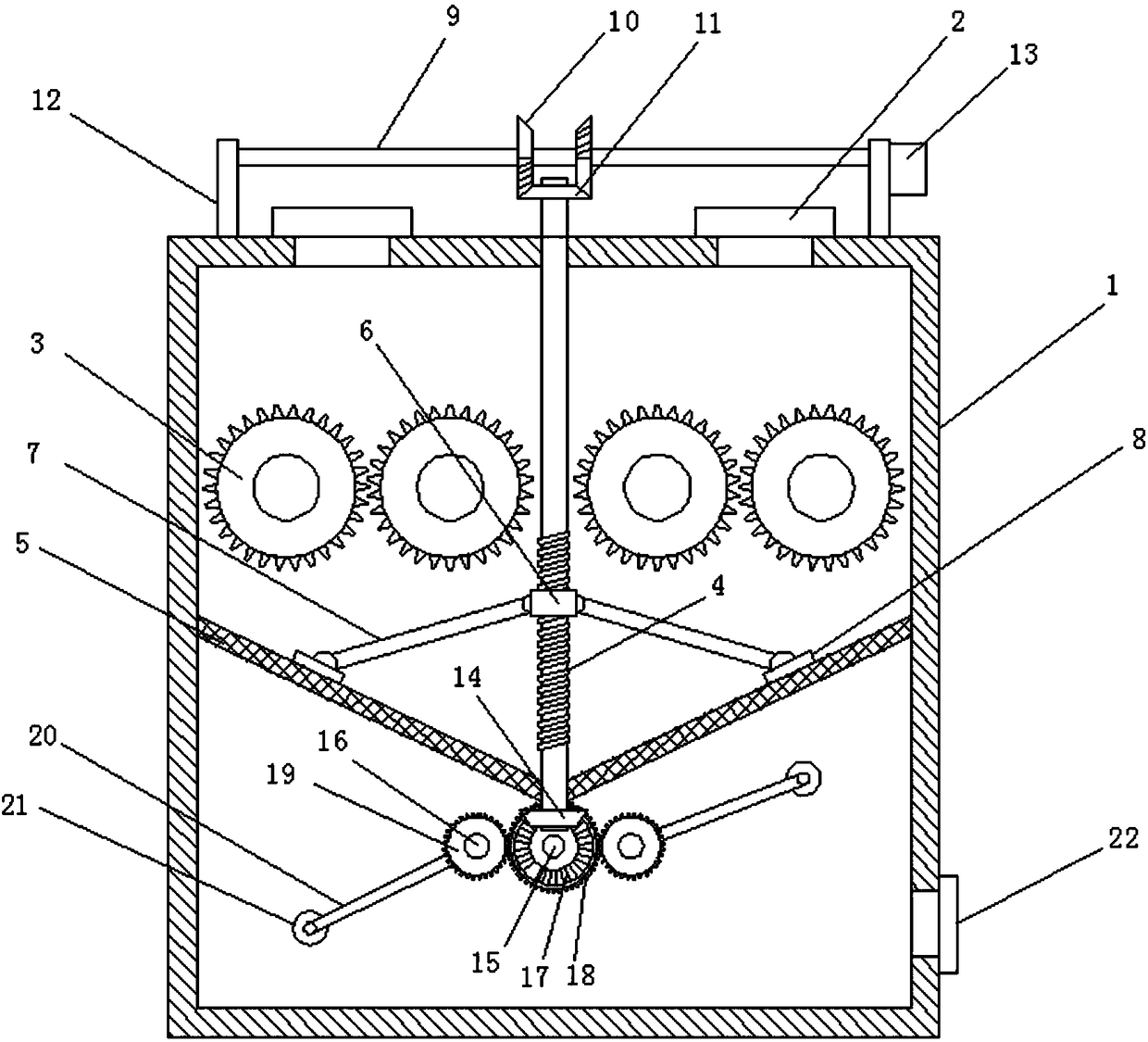

Double-pulverizing feed pulverizing device

The invention discloses a double-pulverizing feed pulverizing device which comprises a pulverizing box body. The pulverizing box body is internally provided with two pairs of pulverizing rollers; material inlets are formed in the top wall of the pulverizing box body; the pulverizing box body is internally provided with two grinding net plates tilting oppositely and downwards; the ends, close to each other, of the two grinding net plates are fixedly connected; the pulverizing box body is internally provided with a vertical lead screw shaft; grinding pressure plates are arranged on the two grinding net plates; the lower end of the lead screw shaft is connected with a transmission horizontal shaft through a gear mechanism; a driving gear is arranged on the transmission horizontal shaft; the driving gear is engaged with two transmission gears arranged on two rotating horizontal shafts; knocking rods are arranged on the two rotating horizontal shafts; and knocking blocks are arranged at theouter ends of the knocking rods. The double-pulverizing feed pulverizing device is simple in structure, convenient to operate, better in effect and higher in practicability; blocking of a screening net is avoided; and cyclic pulverizing can be carried out.

Owner:山东天聚安普瑞农牧发展有限公司

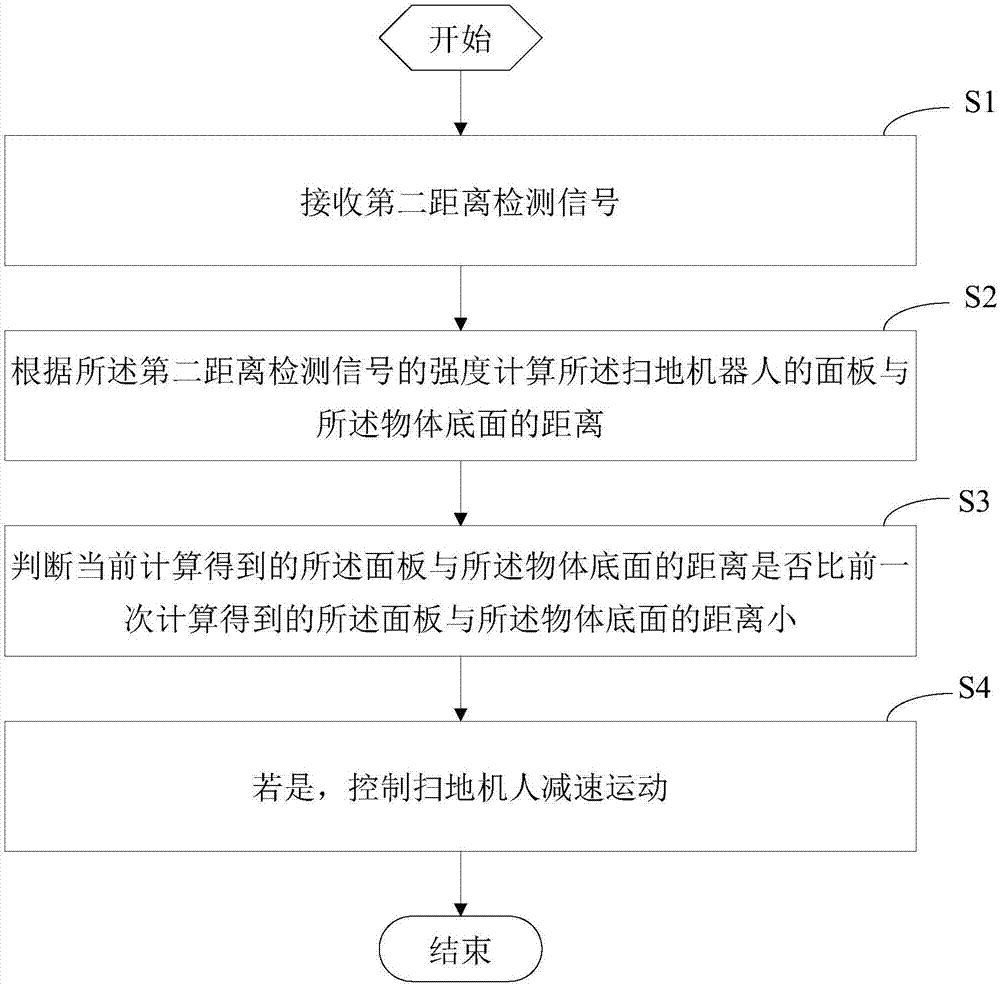

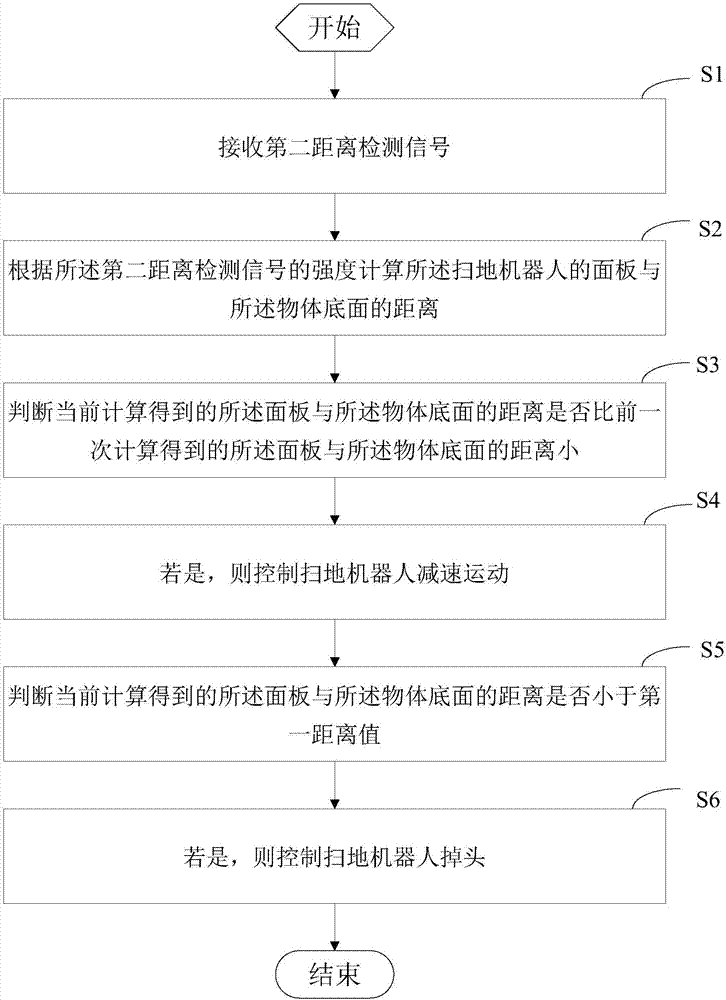

Sweeping robot and obstacle avoidance method and device of sweeping robot

ActiveCN107997689AAvoid stuckProgramme-controlled manipulatorCarpet cleanersDistance detectionEngineering

The invention provides a sweeping robot and an obstacle avoidance method and device of the sweeping robot. The sweeping robot includes a control module and a distance detection module; the distance detection module is arranged on a region near a front edge, on the top of a panel of the sweeping robot; the control module is arranged in the sweeping robot; the control module and the distance detection module are electrically connected; the distance detection module is used for detecting a distance detection signal between the panel of the sweeping robot and a bottom surface of an object, and sending the distance detection signal to the control module; and the control module receives the distance detection signal of the distance detection module, and controls the sweeping robot to slowly runor return to a start point according to the distance detection signal. The sweeping robot and an obstacle avoidance method and device of the sweeping robot can prevent the sweeping robot from being clamped on the bottom surface of the object.

Owner:SHENZHEN FREE DYNAMICS DEV CO LTD

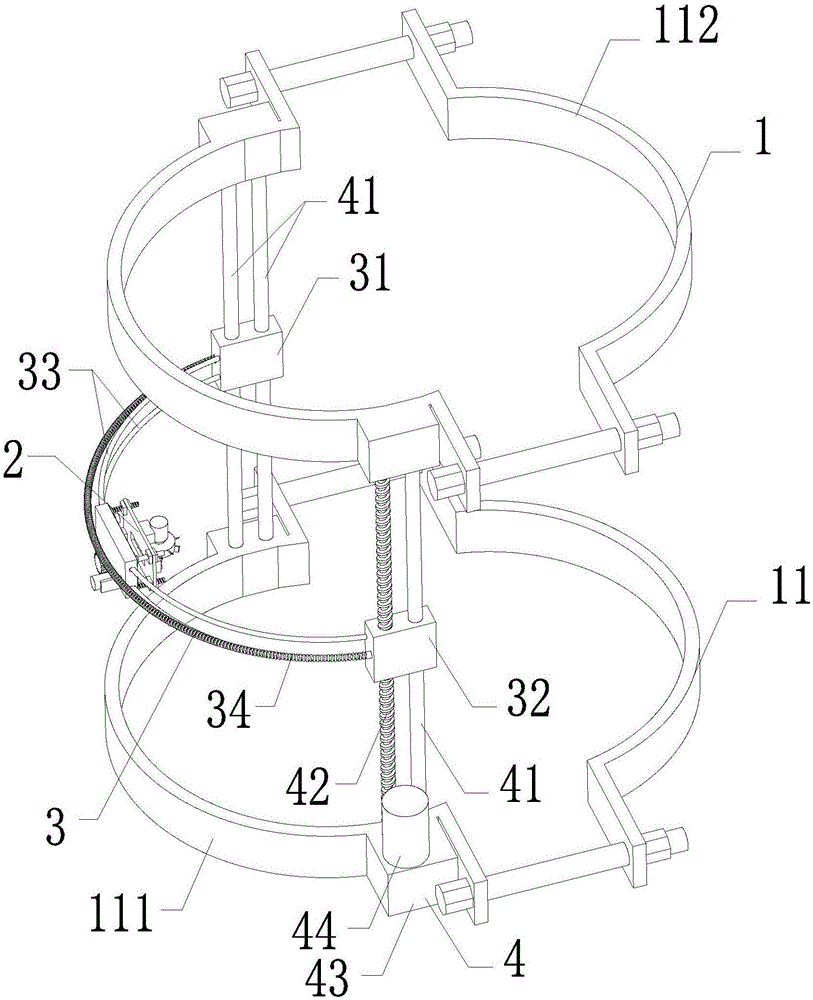

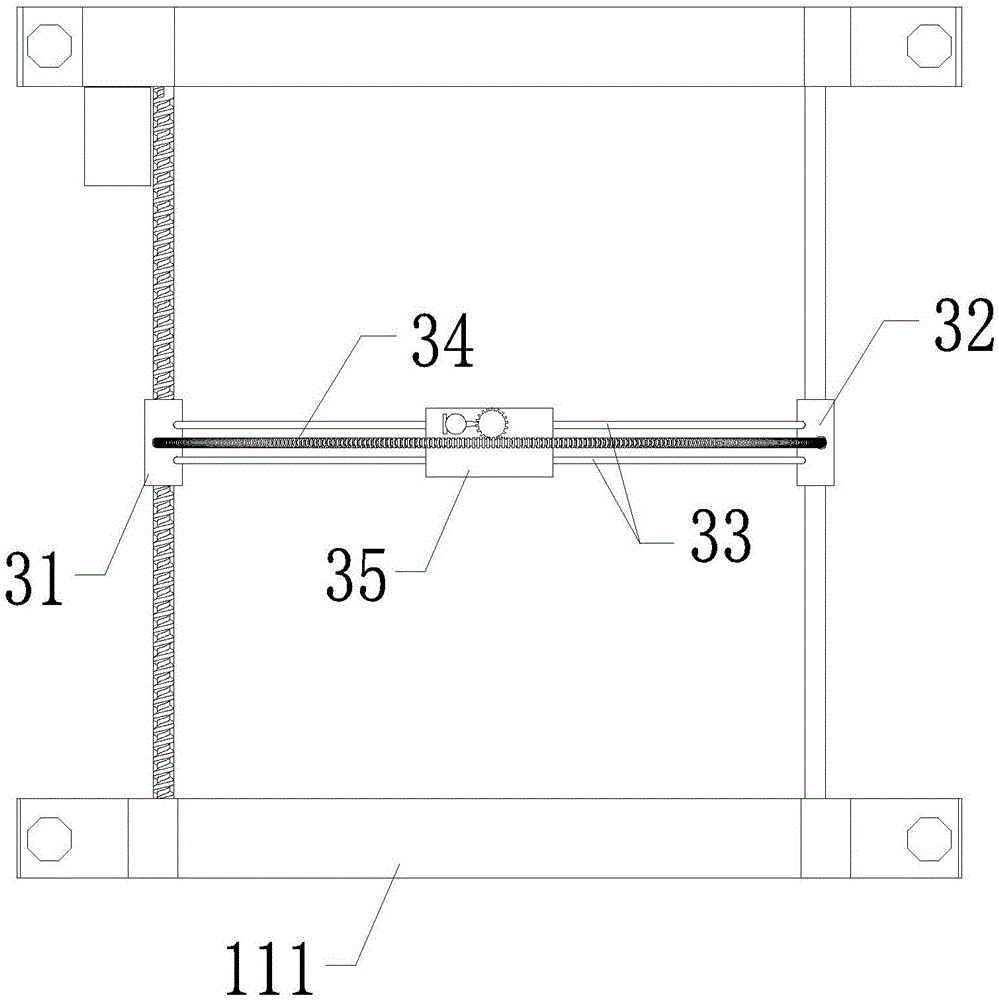

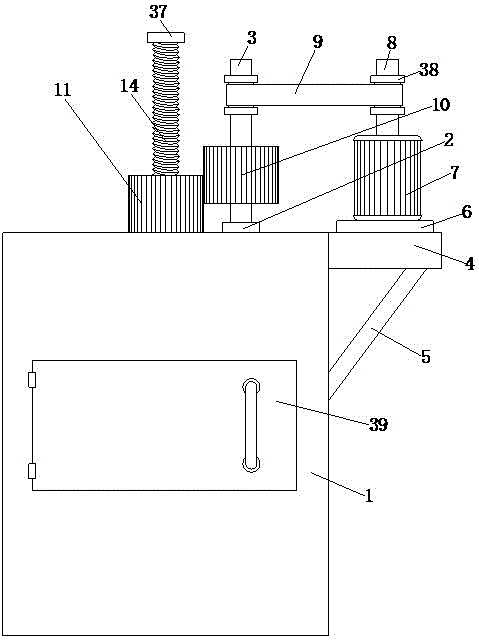

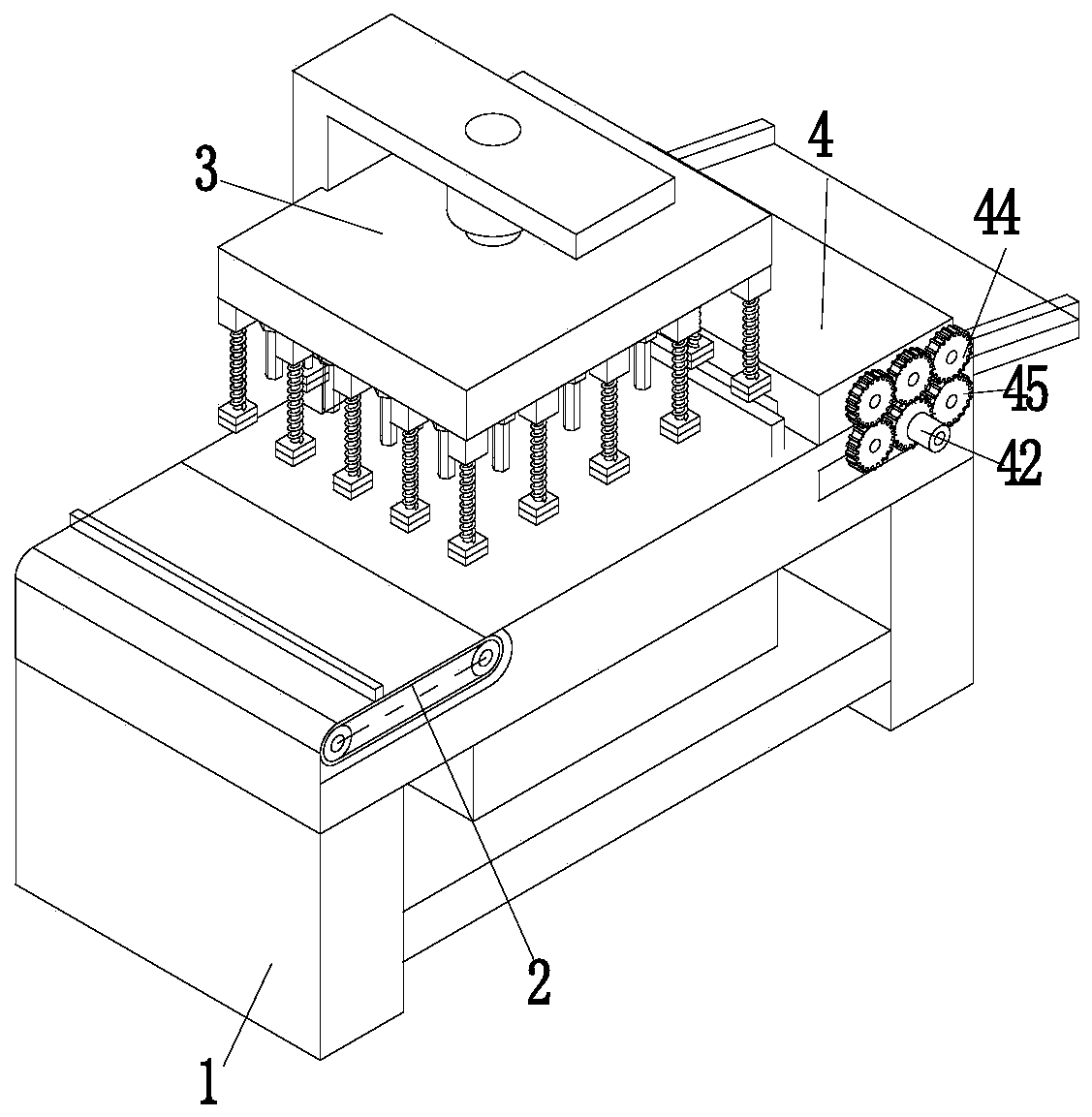

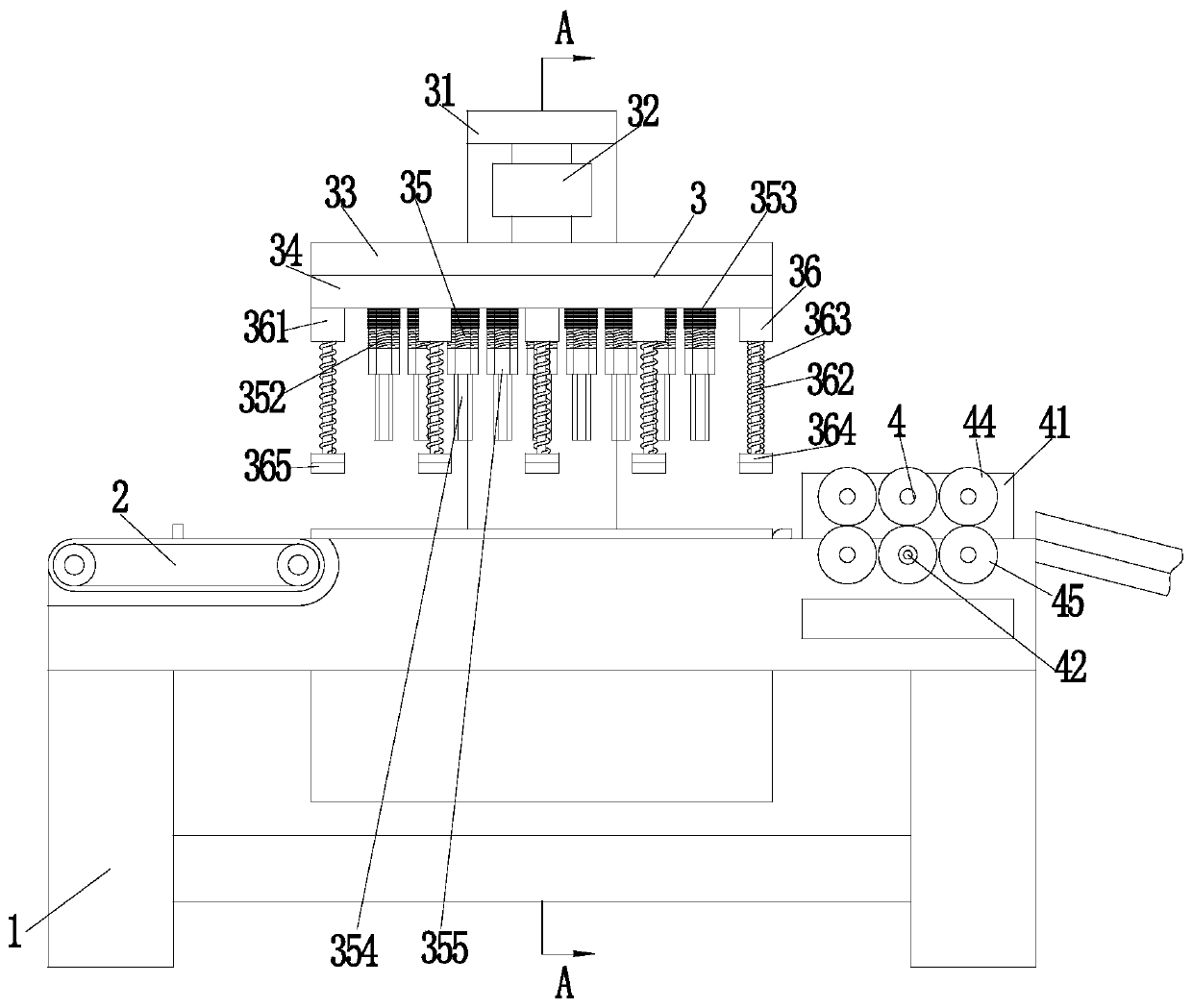

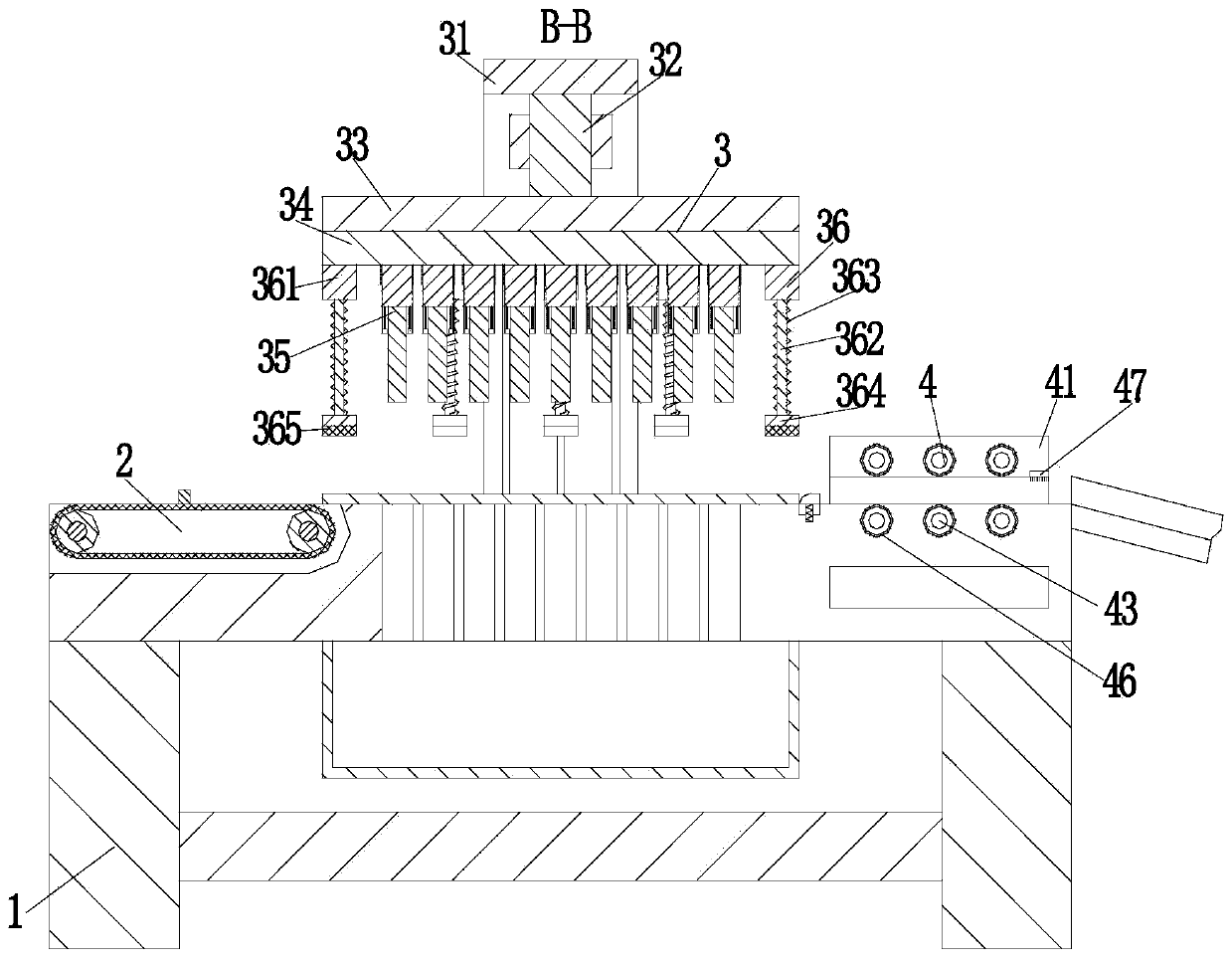

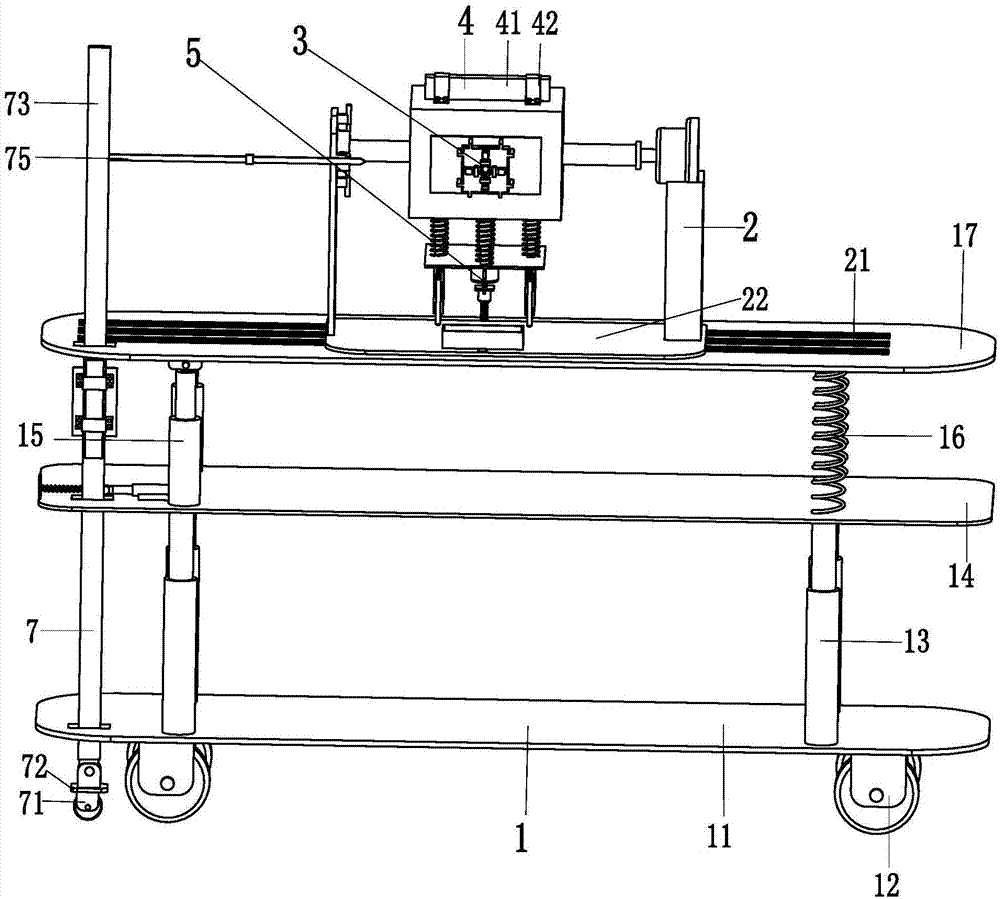

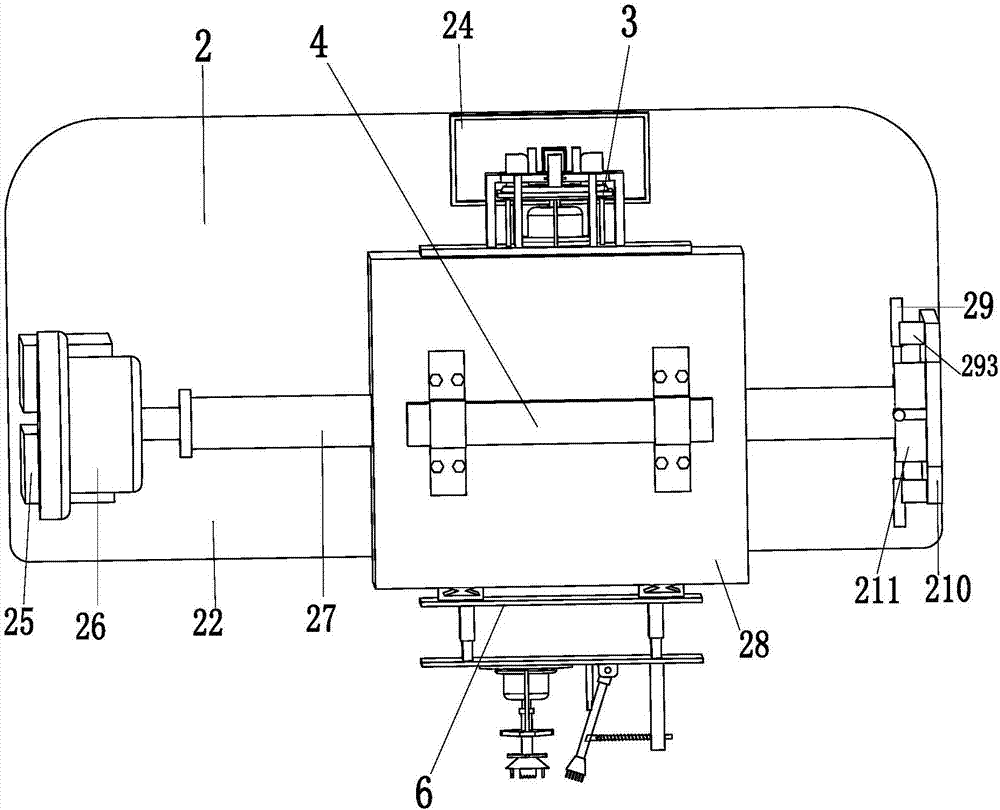

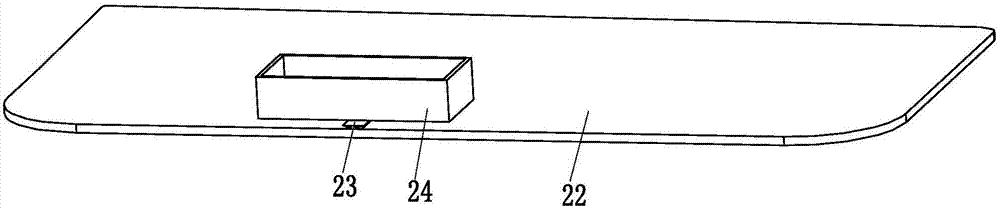

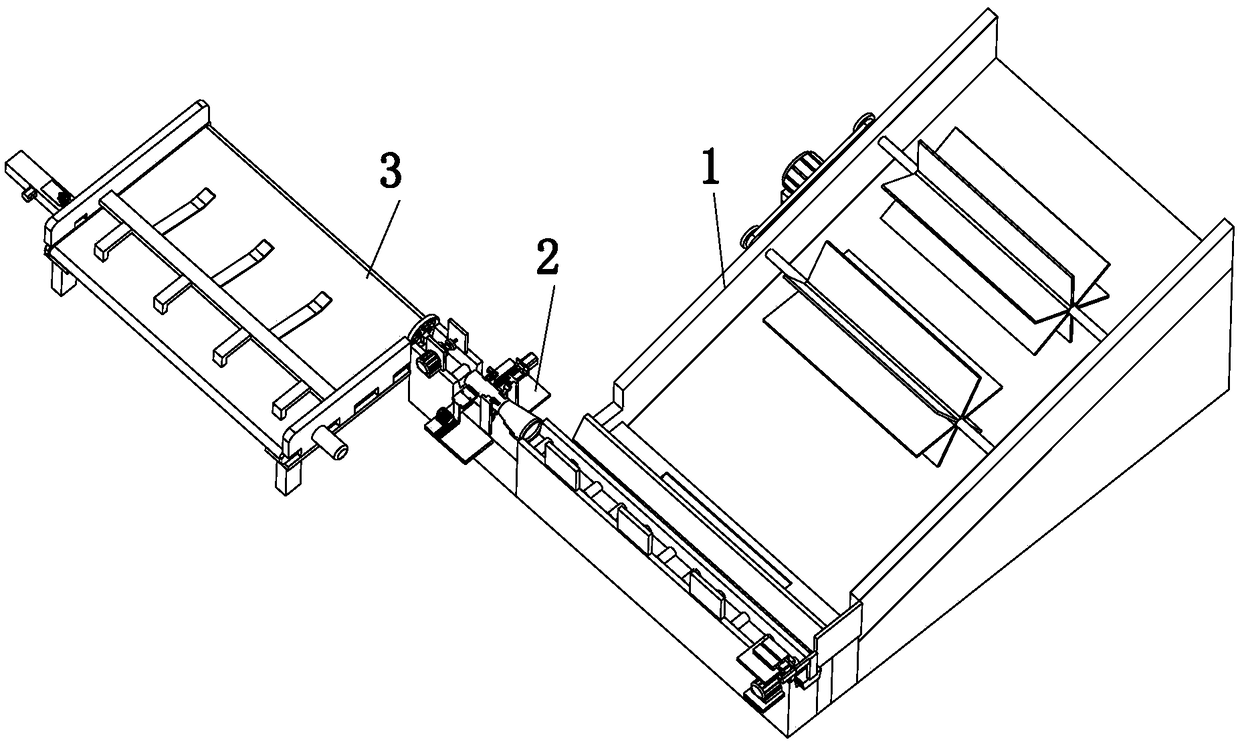

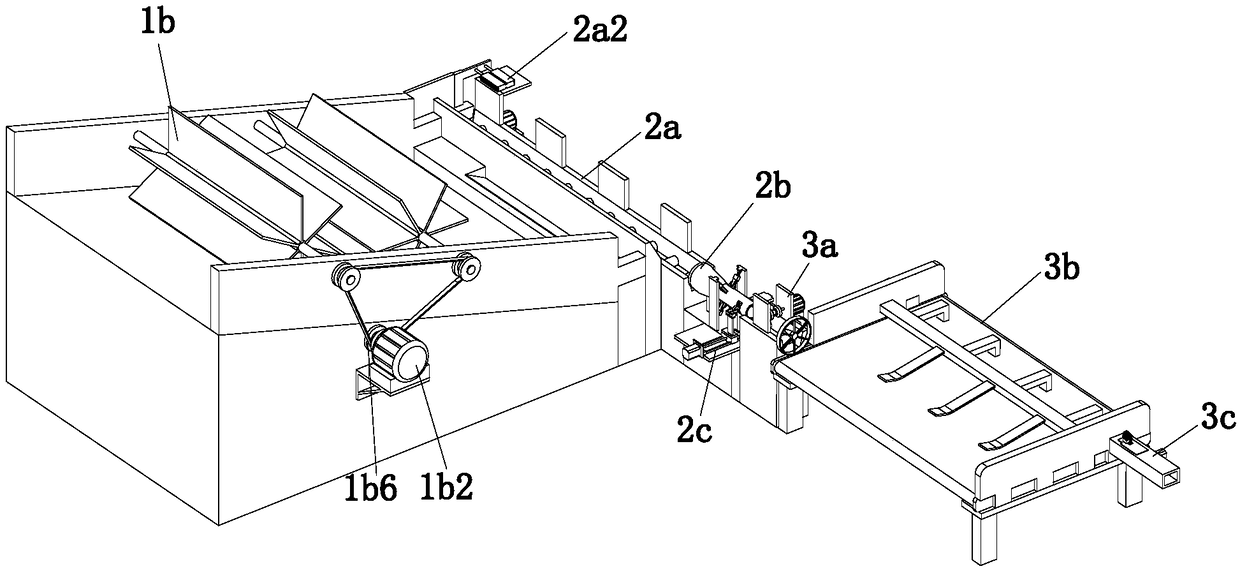

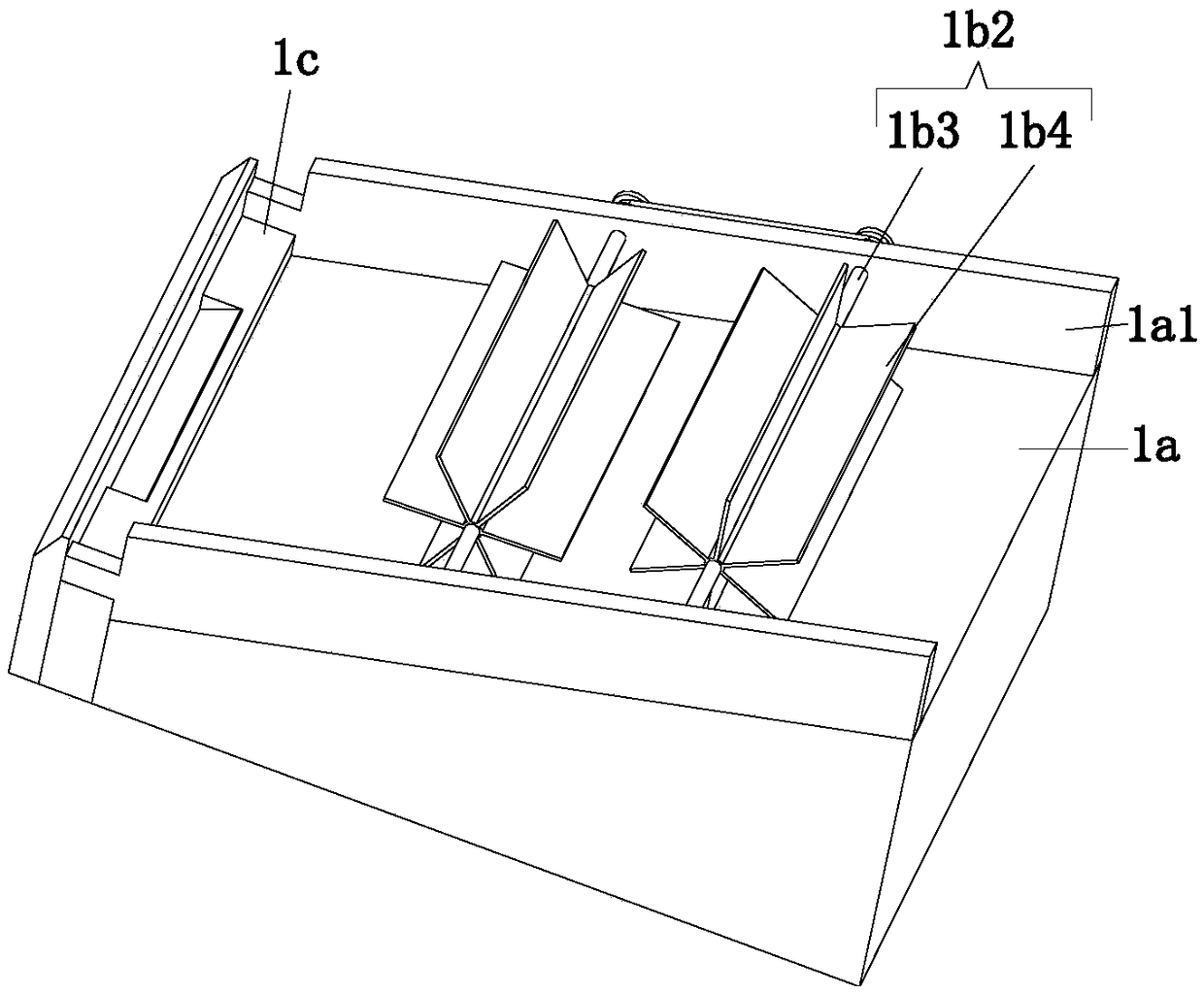

Full-automatic rubber cutter

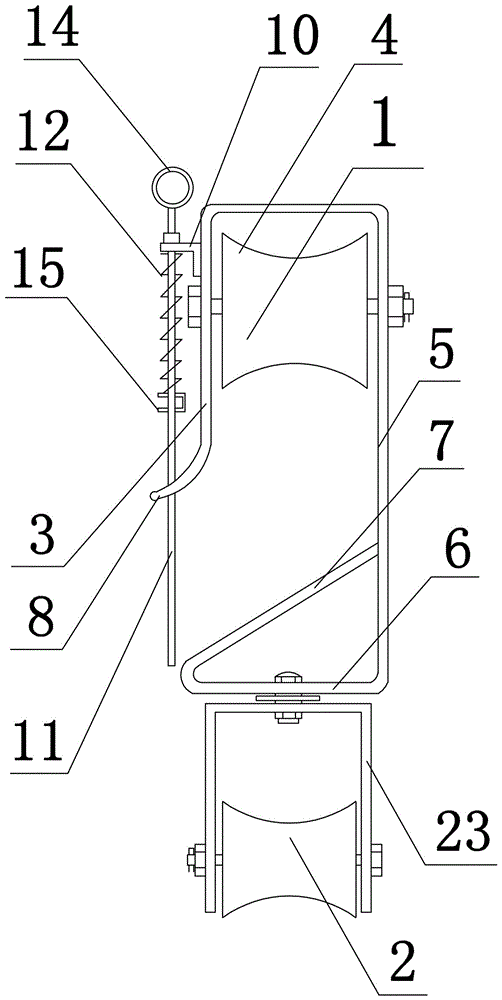

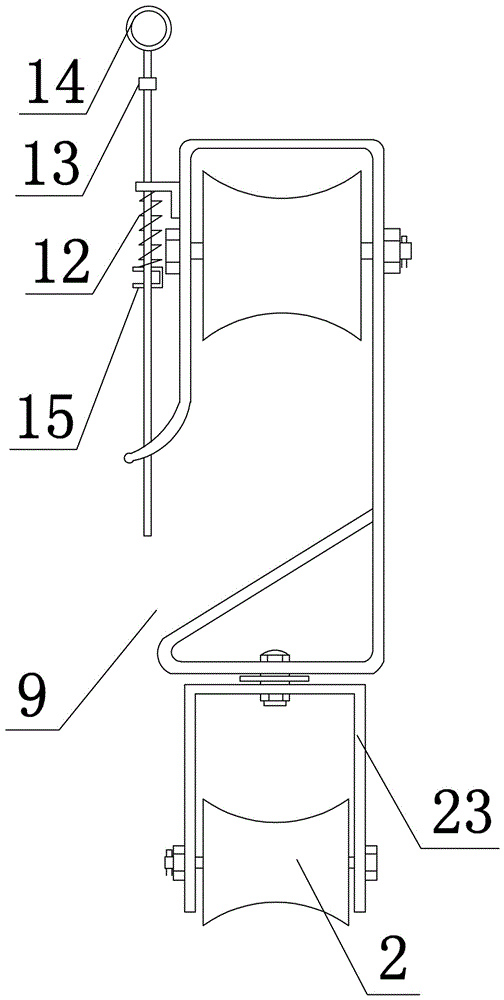

The invention relates to the field of rubber production, and particularly to a full-automatic rubber cutter. The full-automatic rubber cutter comprises the components of a fixing device which is used for fixing the device on a rubber tree, a cutting device (2) which is used for cutting bark of the rubber tree, a horizontal walking device (3) which is used for controlling position of the cutting device in a horizontal surface direction, and a vertical walking device (4) which is used for controlling position of the cutting device in a vertical direction. The cutting device (2) is mounted on the horizontal walking device (3). The horizontal walking device (3) is mounted on the vertical walking device (4). The vertical walking device (4) is mounted on the fixing device (1). After a user fixes the rubber cutter on the trunk of the rubber tree by means of the fixing device, timely cutting to the bark of the rubber tree can be finished, thereby realizing automatic rubber harvesting.

Owner:JIANGSU ASOE NEW MATERIAL TECH

Cyclic type feed particle smashing device

ActiveCN108355754AGood crushing effectAvoid cloggingSievingFeeding-stuffEngineeringMechanical engineering

The invention discloses a cyclic type feed particle smashing device. The cyclic type feed particle smashing device comprises a smashing box body; a feeding port is formed in the top wall of the smashing box body; two first transmission shafts and two second transmission shafts are further arranged in the smashing box body; the two second transmission shafts are located on the two sides of the twofirst transmission shafts correspondingly; a worm segment is arranged at the lower end of a conveying auger; the two sides of the worm segment are engaged with two worm gears correspondingly arrangedon the two first transmission shafts which are each provided with an incomplete gear; the two second transmission shafts are each provided with a transmission gear; the two incomplete gears are correspondingly engaged with the two transmission gears; the two second transmission shafts are further provided with a knocking rod; the lower side end of the knocking rod is connected with the bottom wallof the smashing box body through a reset spring; and a knocking block is further arranged at the outer end of the knocking rod. The cyclic type feed particle smashing device is simple in structure and convenient to operate, avoids blockage of a screening net, meanwhile can perform cyclic smashing, and is good in effect and high in practicability.

Owner:贵阳富源饲料有限公司

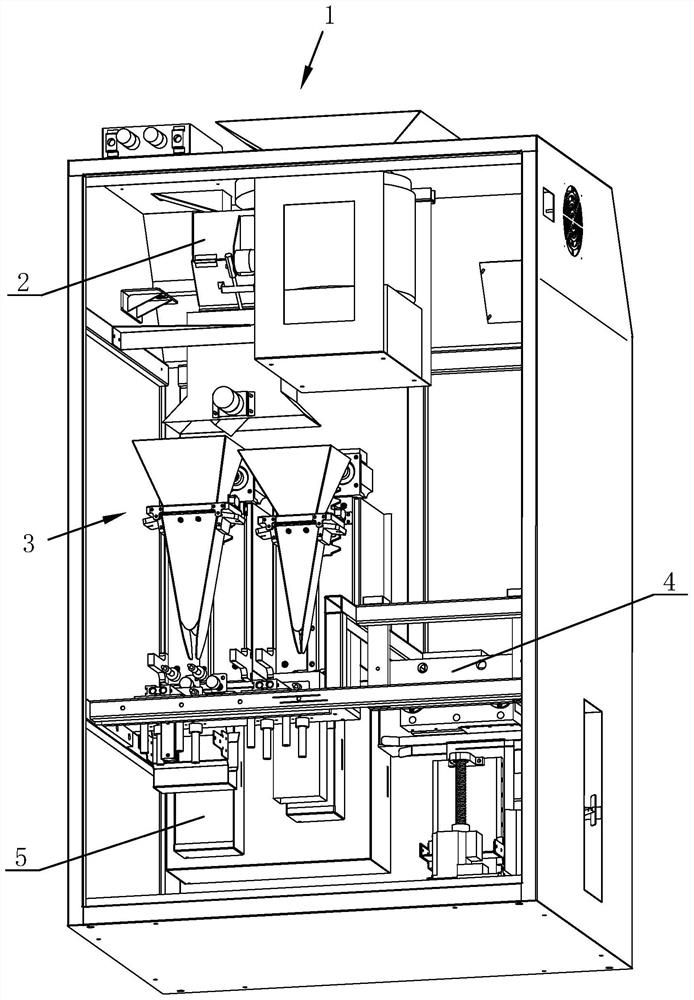

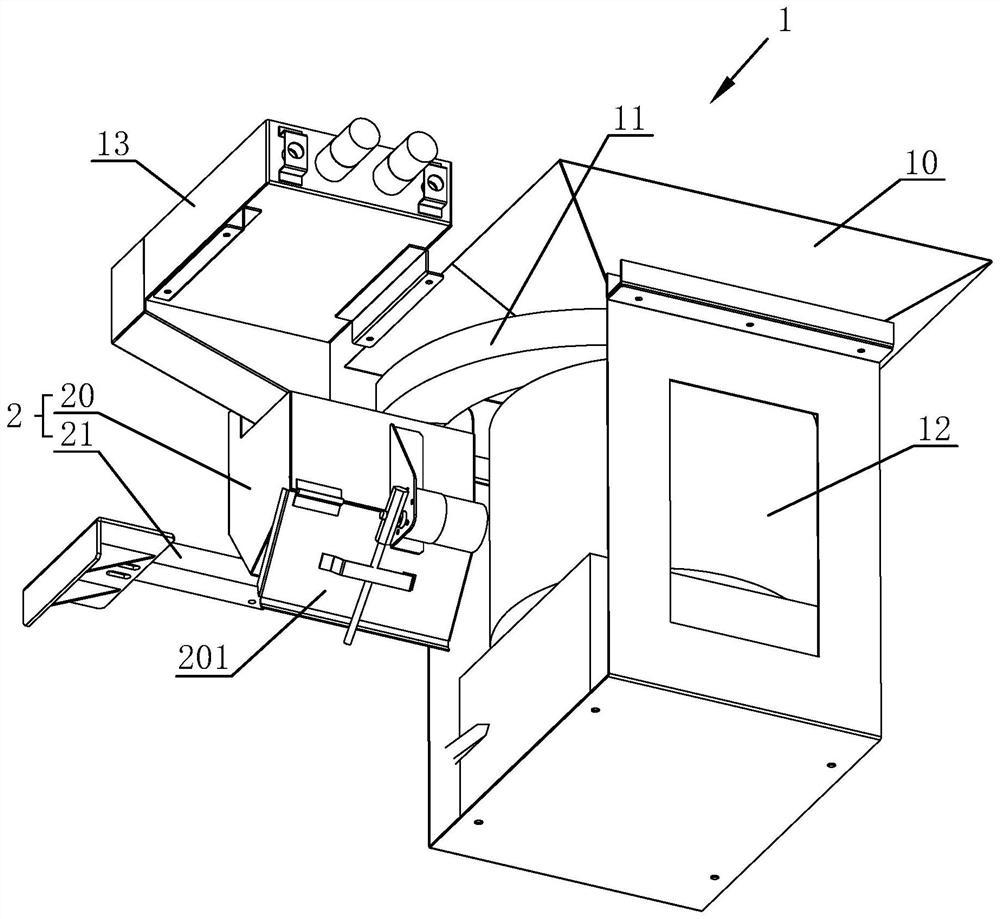

Automatic tea leaf subpackaging and packaging machine

InactiveCN112777012AReduce labor intensityReduce labor inputWrapper twisting/gatheringSolid materialComputer control systemHeat sealer

The invention discloses an automatic tea sub-packaging and packaging machine which can automatically carry out feeding, weighing, bagging and sealing on bulk tea and send out packaged finished products and can also package materials of two specifications at the same time through a weighing and sub-packaging structure. According to the key points of the technical scheme, the automatic tea sub-packaging and packaging machine comprises a feeding mechanism, a weighing mechanism, a bagging mechanism, a heat sealing mechanism, a discharging mechanism and a computer control system, and the feeding mechanism comprises a feeding hopper and an inclined feeding channel; the weighing mechanism comprises a weighing hopper and a pressure sensor; the bagging mechanism comprises a sub-packaging structure, two filling hoppers, a bag opening structure and a tray, the sub-packaging structure comprises sub-packaging hoppers, swing pieces are arranged in the sub-packaging hoppers, the swing pieces are used for switching channels in the sub-packaging hoppers, openings in the upper portions of the two filling hoppers directly face the two channels formed by swinging of the swing pieces respectively, and the bag opening structure adopts suction cups which are oppositely arranged; and at least one sucking disc can move up and down and stretch back and forth, the tray is located below the bag opening structure, and a swing rod is arranged in the discharging mechanism.

Owner:湖州曼智科技发展有限公司

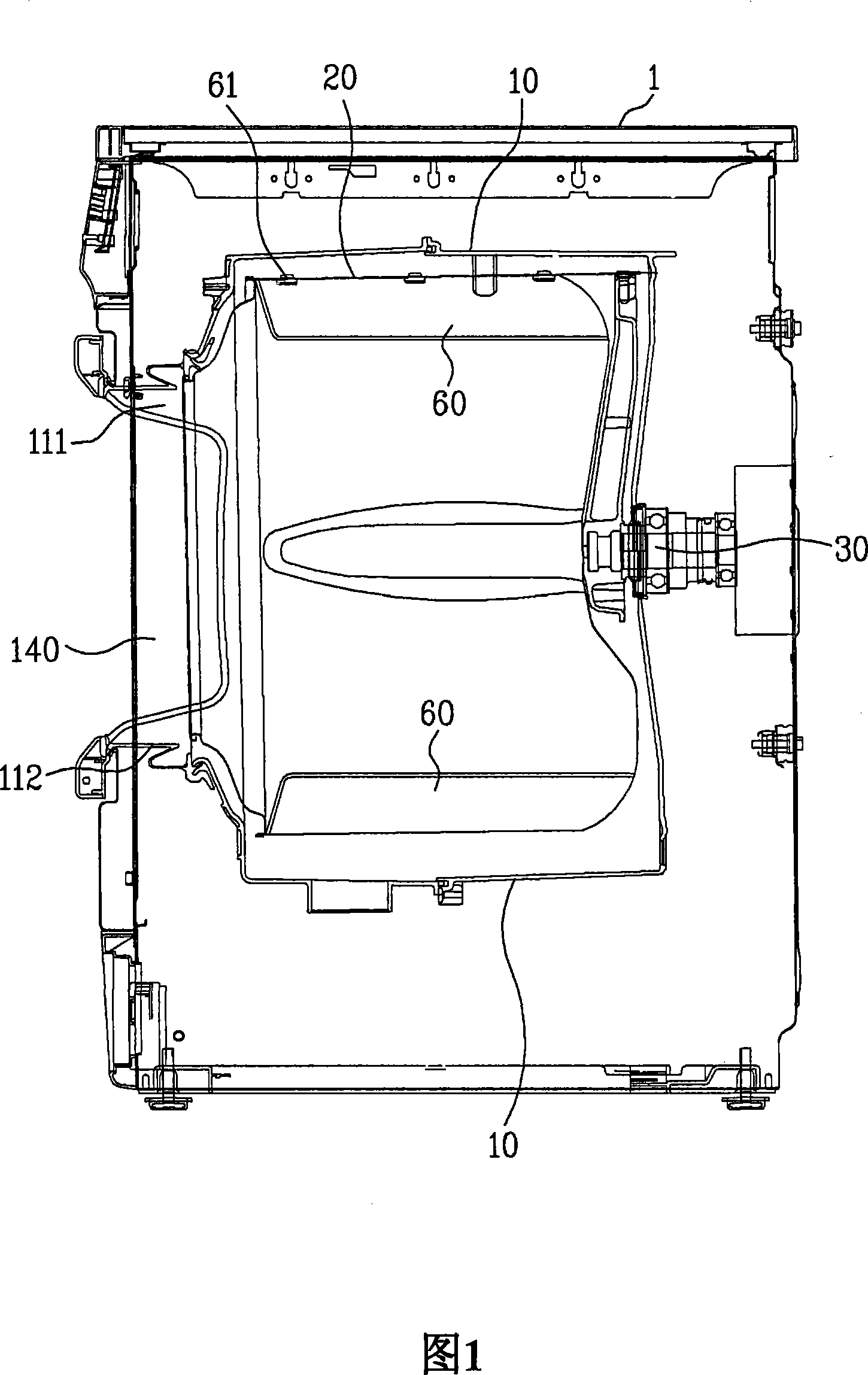

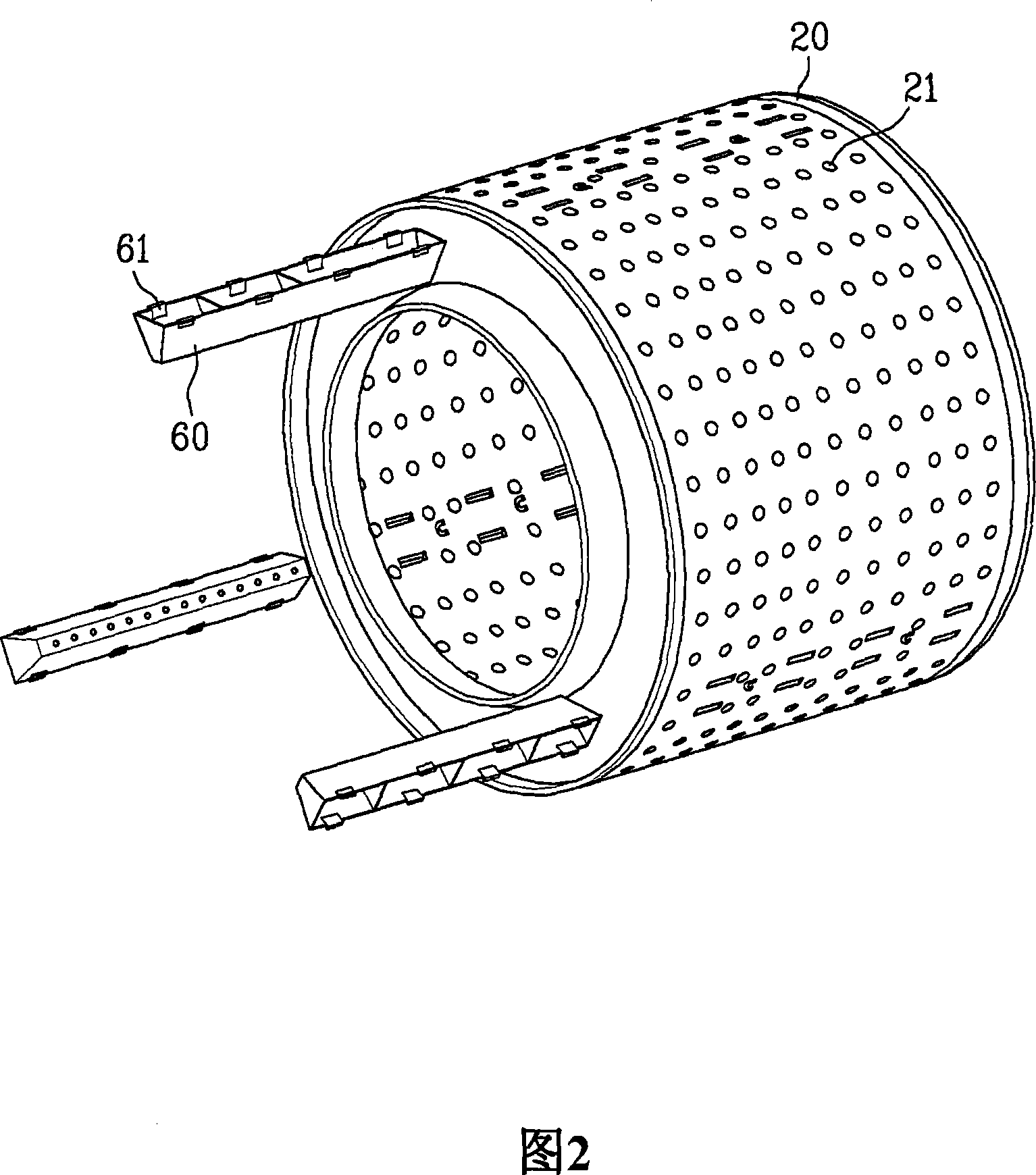

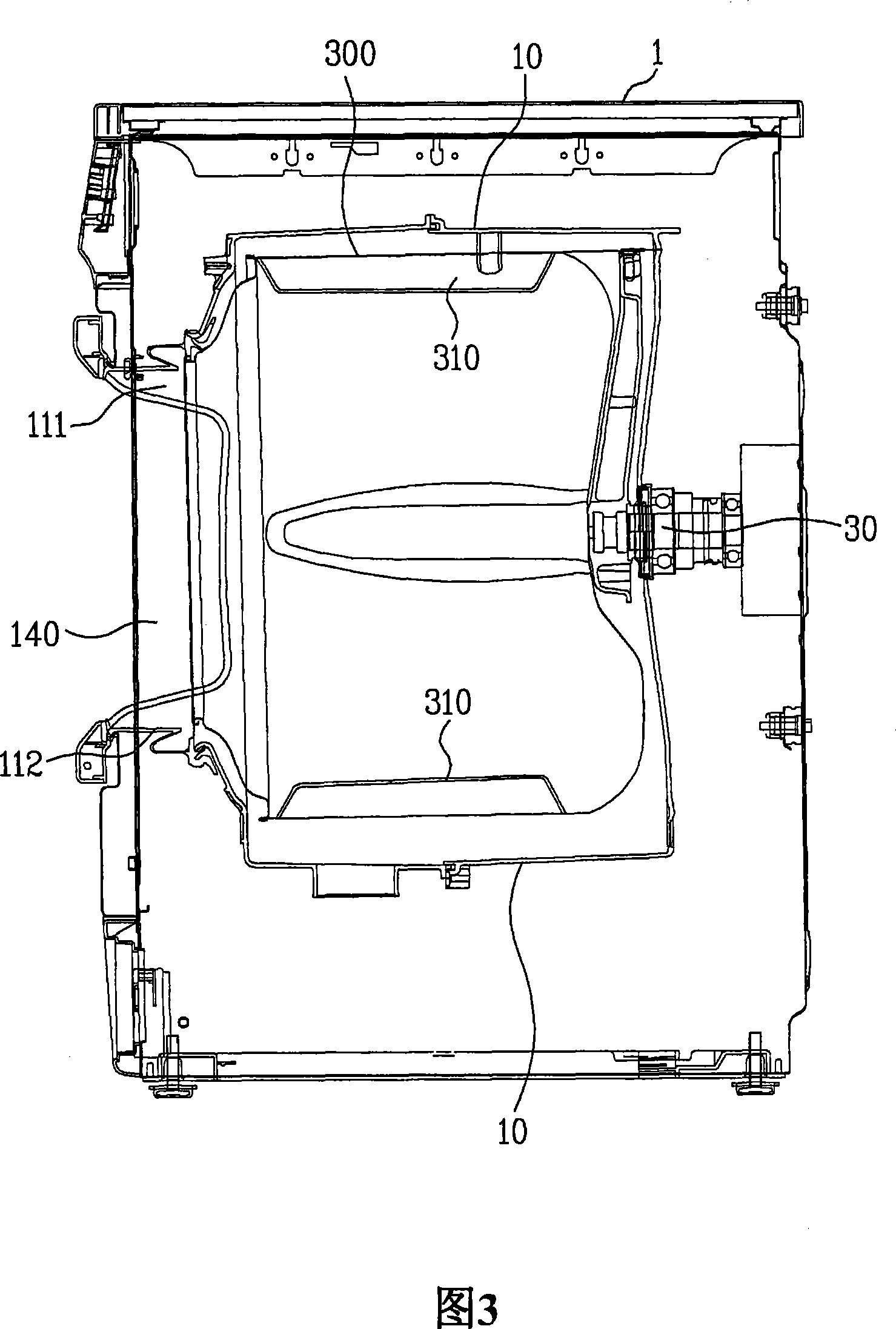

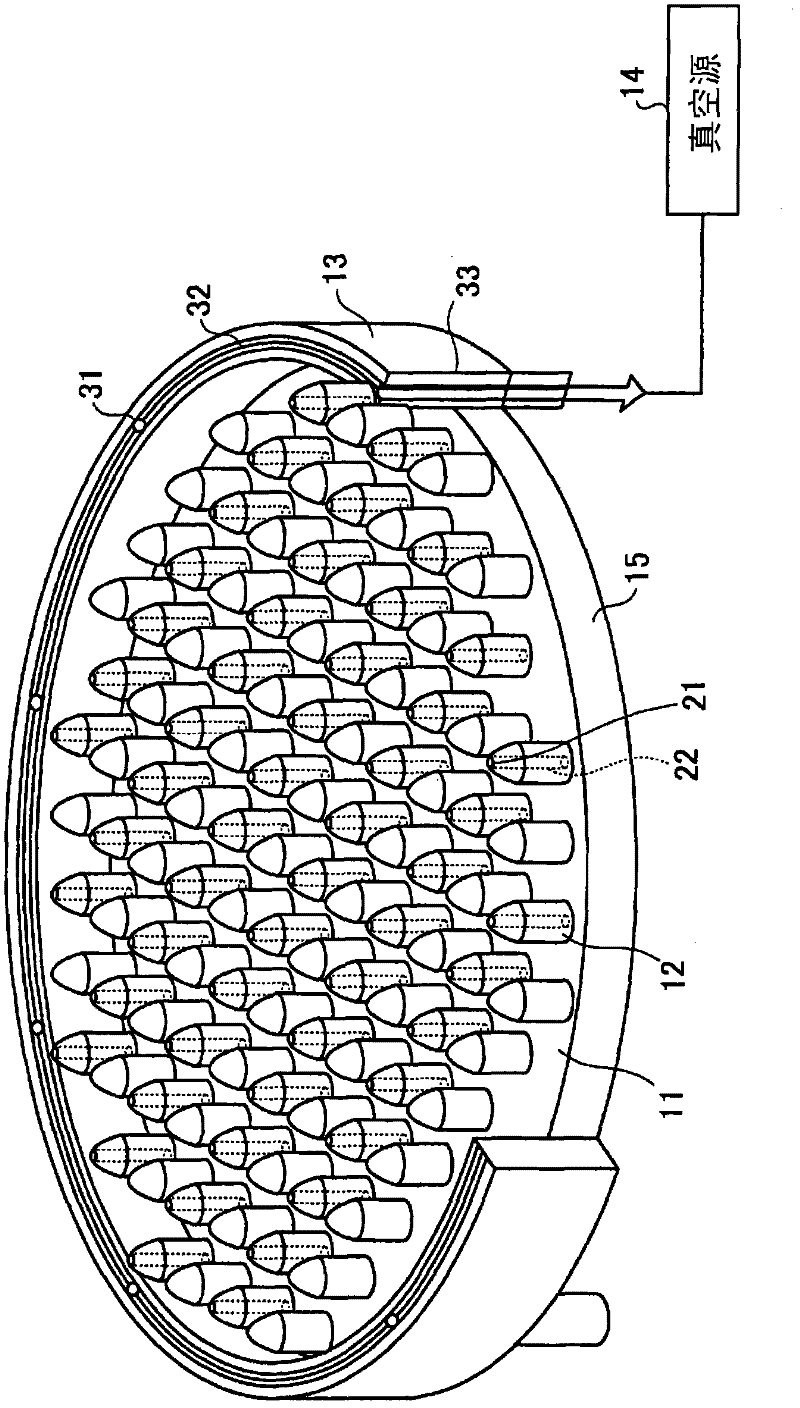

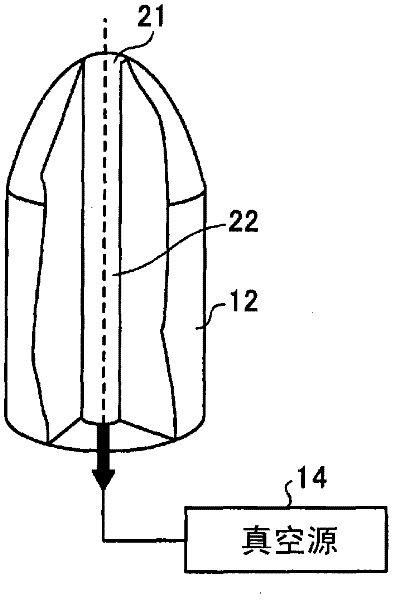

Washer and method of forming drum thereof

InactiveCN101089277AAvoid deformationAvoid destructionOther washing machinesTextiles and paperEngineering

A washer and method of forming a drum thereof are disclosed. The present invention includes a body, a tub provided within the body to accommodate water therein, a drum provided within the tub to have at least one lifter built in one body of the drum, and a motor for rotating the drum. Accordingly, the lift and drum are built in one body to perform a role of the lifter sufficiently and a volume of the drum can be maximized by maintaining an exterior size of the drum as it is.

Owner:LG ELECTRONICS INC

Dual-sphere one-way metal seal ball valve

ActiveCN106763862AReduce erosionExtended service lifeSpindle sealingsPlug valvesEngineeringValve seat

The invention discloses a dual-sphere one-way metal seal ball valve, belonging to the technical field of valves. According to the technical main points, the dual-sphere one-way metal seal ball valve comprises a valve body, wherein a medium inlet and a medium outlet are formed in two ends of the valve body along the axial direction respectively; an installation blind hole is formed in the valve body corresponding to the medium inlet along the axial direction; a first valve ball and a second valve ball are arranged in the installation blind hole from inside to outside separately; a first valve seat module is arranged between the outer wall of the first valve ball and the installation blind hole; a second valve seat module is arranged between the outer wall of the second valve ball and the installation blind hole; the first valve seat module comprises a first fixed valve seat and a first movable valve seat clamped on the outer wall of the first valve ball; the first fixed valve seat and the installation blind hole are in interference seal connection; the second valve seat module comprises a second fixed valve seat and a second movable valve seat clamped on the outer wall of the second valve ball; and the second fixed valve seat and the installation blind hole are in interference seal connection. The dual-sphere one-way metal seal ball valve disclosed by the invention is compact in structure, stable in work and long in service life, and is used for controlling of medium flow.

Owner:煜安特种阀门研制(深圳)有限公司

High-adaptability forming device for machining metal structural part

The invention provides a high-adaptability forming device for machining a metal structural part and relates to the field of metal structural part machining. The high-adaptability forming device for machining the metal structural part comprises a box body. The top of the box body is fixedly connected with a rotary disc. The top of the rotary disc is movably connected with a rotating rod. The top of the right side of the box body is fixedly connected with a transverse plate. The right side of the bottom of the transverse plate is fixedly connected with one end of a supporting rod. The other end of the supporting rod is fixedly connected with the right side of the box body. A base is fixedly connected with the top of the transverse plate. A motor is fixedly installed on the top of the base. The motor is provided with a rotating shaft. The surface of the rotating shaft is in transmission connection with the surface of the rotating rod through a belt. According to the high-adaptability forming device for machining the metal structural part, the structure is simple, operation is easy and convenient, adaptability is high, the production efficiency of metal structural part forming is effectively improved, the operation difficulty of operators is lowered, time and labor are saved, the cost is low, and use of people is facilitated.

Owner:无锡市富能金属制品有限公司

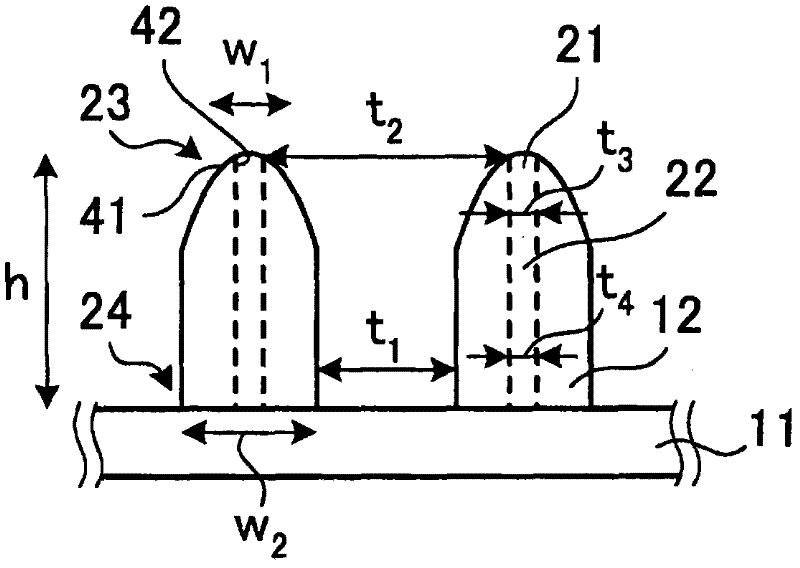

Self-sealed wire pulley of power transmission line

ActiveCN106253134AAvoid stuckInhibit sheddingApparatus for overhead lines/cablesEngineeringTraveling block

The invention discloses a self-sealed wire pulley of a power transmission line. The self-sealed wire pulley comprises a pulley body and a self-sealed device, wherein the pulley body comprises a hook and a base, the hook comprises a first vertical plate, a first horizontal plate, a second vertical plate, a second horizontal plate and an inclination plate which are sequentially connected, the length of the first vertical plate is smaller than the length of the second vertical plate, an arc plate is arranged at a lower end of the first vertical plate, a limiting plate is arranged at an outer side of the first vertical plate, a through hole is formed in the limiting plate in a vertical direction, the self-sealed device comprises a pull rod, a spring and a pull rod limiting block, a pull ring is arranged at a top end of the pull rod, a limiting pin is arranged on the pull rod, and the spring sleeves an outer surface of the pull rod. Through matching among the pull rod, the spring and the limiting pin, the disconnection preventing rate of the wire pulley is greatly improved, the purposes of improving the working efficiency and improving the operation safety coefficient are achieved, the pull rod and the spring can be rapidly replaced after the limiting pin is removed, and the problem of poor sealing effect due to part aging after long-term usage is solved.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER +1

Chucking device and chucking method

InactiveCN102543814AEliminate warpingImprove flatnessSleeve/socket jointsSemiconductor/solid-state device manufacturingForeign objectEngineering

The invention provides a chucking device and chucking method that can prevent a foreign object being caught between the device and a semiconductor substrate and can hold the semiconductor substrate in a condition in which the semiconductor substrate flatness is maintained or increased. The chucking device includes plural protruding portions that support the central portion of a semiconductor substrate and that are provided on a base portion. The chucking device also includes a cylindrical peripheral portion that supports the outer peripheral portion of the semiconductor substrate, plural suction holes that chuck the semiconductor substrate, and a vacuum source that vacuum draws the plural suction holes at differing timings. A plurality of mutually independent vacuum drawable suction holes are provided in at least one portion of the protruding portions. The vacuum drawable suction holes are independently arranged in the peripheral portion. After the semiconductor substrate is arranged on the protruding portions and the peripheral portion, the suction holes are drawable by using the vacuum source and on the semiconductor substrate at differing timings.

Owner:FUJI ELECTRIC CO LTD

Sealing structure for electric EGR (exhaust gas recirculation) valve

InactiveCN103206319AAvoid stuckGuaranteed reliabilitySpindle sealingsNon-fuel substance addition to fuelRetaining ringEngineering

The invention discloses a sealing structure for an electric EGR (exhaust gas recirculation) valve. An upper groove and a lower groove are arranged at an upper copper sleeve end and a lower copper sleeve end of the electric EGR valve, an upper sealing device is press-riveted in the upper groove and comprises an upper Teflon sealing retaining ring and an upper thin gasket sequentially press-riveted in the upper groove from bottom to top, an upper-O-shaped sealing retaining ring is arranged in the upper Teflon sealing retaining ring, a sealing device is arranged in the lower groove and comprises a lower Teflon sealing retaining ring, a washer and a lower thin gasket sequentially press-riveted at the lower copper sleeve end from top to bottom, and a lower O-shaped sealing retaining ring is arranged in the lower Teflon sealing retaining ring. The sealing structure can effectively prevent clamping stagnation of a central rod caused by carbon deposition, so that operating reliability of the electric EGR valve is guaranteed and the service life of the same is prolonged.

Owner:WUXI LONGSHENG TECH

Computer cabinet manufacturing and machining auxiliary device

ActiveCN111570609AIncrease gravityHigh pressurePerforating toolsMetal-working feeding devicesPunchingWorkbench

The invention relates to a computer cabinet manufacturing and machining auxiliary device. The computer cabinet manufacturing and machining auxiliary device comprises a workbench, a belt conveyor, a punching device and a grinding device; the belt conveyor is installed at the upper end of the left side of the workbench, the punching device is installed at the right end of the belt conveyor, the grinding device is installed at the right end of the punching device, and the punching device comprises an inverted-L-shaped plate, an electric air cylinder, a lead block plate, a supporting plate, a punching frame and a positioning frame. According to the computer cabinet manufacturing and machining auxiliary device, the belt conveyor is matched with the punching device, a plate is conveyed to the punching device to be punched, the belt conveyor is matched with the grinding device, the punched plate is extruded while the next plate is conveyed, the punched plate moves to the grinding device to beground, burrs and chippings on the inner wall and the surface of a hole machined in the plate are removed, and a fixing device does not need to be additionally arranged to fix the plate in the wholeprocess.

Owner:SHANDONG POLYTECHNIC COLLEGE

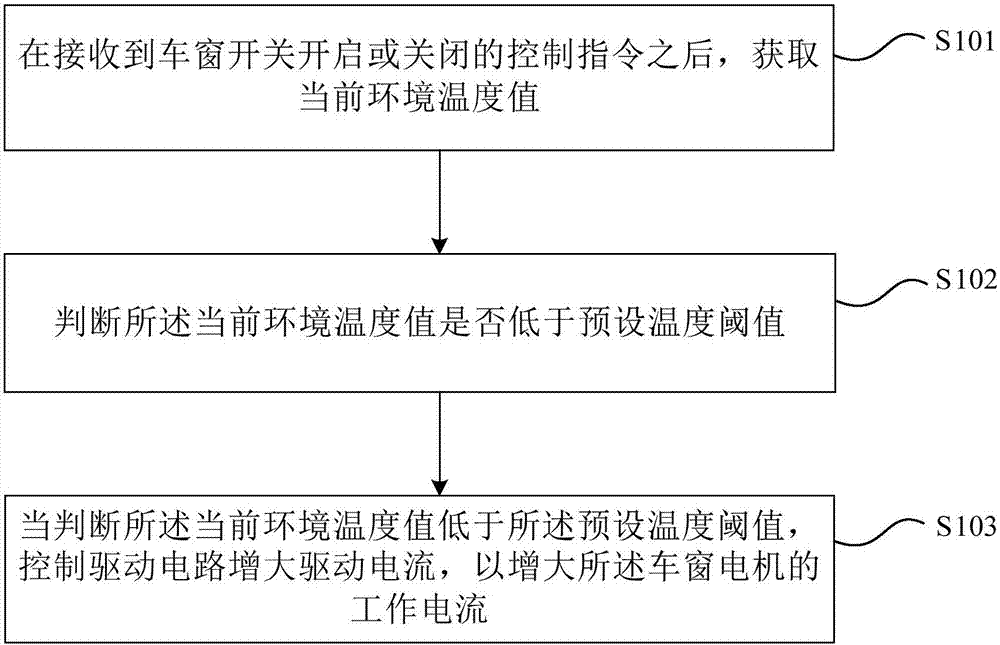

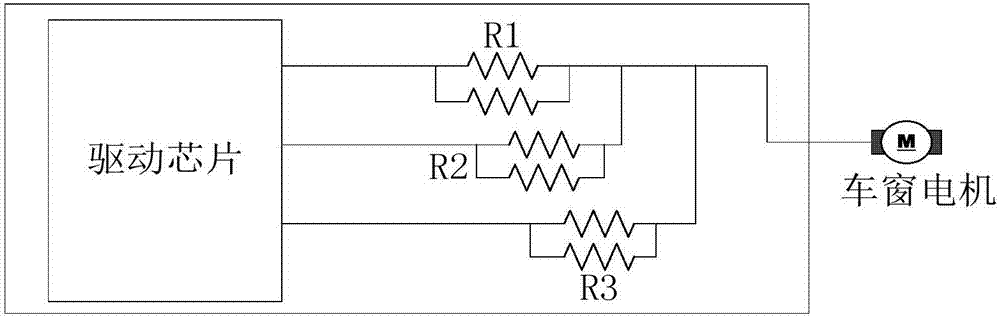

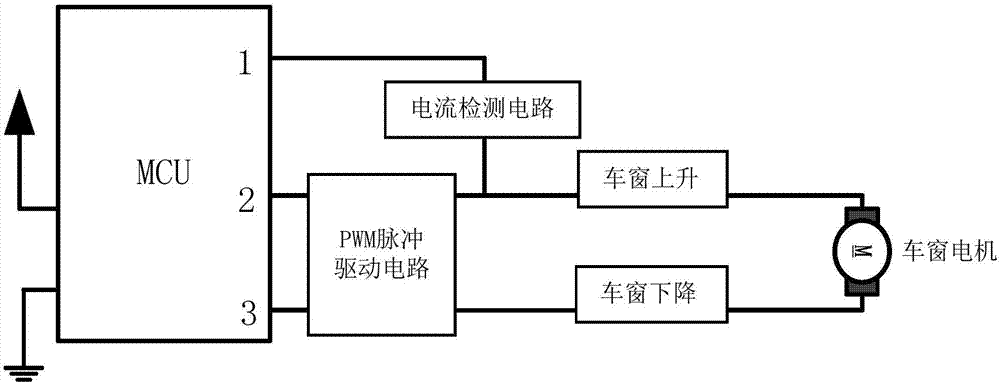

Automobile window motor control method and system and automobile

ActiveCN107060566AIncrease output powerAvoid stuckPower-operated mechanismAutomotive engineeringPower flow

The invention provides an automobile window motor control method and system and an automobile. The current environment temperature value is obtained, and whether the current environment temperature value is lower than a preset temperature threshold value or not is judged; and when it is judged that the current environment temperature value is lower than the preset temperature threshold value, a driving circuit is controlled to increase a driving current so as to increase a working current of an automobile window motor. By increasing the driving current, the output power of the automobile window motor is increased correspondingly to enough drive an automobile window to overcome operation resistance, so that clamping is avoided, the situation that clamping of the automobile window causes rotating blocking of the automobile window motor, so that the current in the circuit is increased rapidly to reach the rotating blocking threshold value of the automobile window motor is further avoided, and namely, smooth opening or closing of the automobile window in a cold environment can be achieved.

Owner:BAIC MOTOR CORP LTD

Drilling fixture

InactiveCN102581348AImproved Chip EvacuationExtended service life and replacement intervalsDrilling/boring measurement devicesDrill holeFastener

The invention discloses a drilling fixture, which comprises a fixture body, a guide and a bushing. The fixture body is provided with a mounting hole, the guide is arranged in the mounting hole, the bushing is arranged between the fixture body and the guide, the guide and the bushing are provided with communicated chip discharge holes, the fixture body is provided with a chip containing groove which is communicated with the chip discharge holes, and a baffle is arranged at the outer end of the chip containing groove through a fastener and provided with a blowing device. When drillings generated during drilling enter the guide along with a drill, the drillings can be sucked into the chip containing groove by the blowing device through the chip discharge holes, so that chip discharging performance is improved, jamming of the drill into the guide due to untimely chip discharging can be avoided, and abrasion of the fixture body caused by the fact that the guide and the bushing are driven by the jammed drill to rotate together is avoided. The service life and the replacement cycle of the drilling fixture are prolonged, and production cost is reduced. Further, the baffle is arranged at the outer end of the chip containing groove through the fastener, and the drillings sucked in the chip containing groove can be cleaned by demounting the baffle, so that maintenance is convenient.

Owner:SUZHOU FUMAI PRECISION MACHINERY

Steel structured positioning placement robot

InactiveCN108857211AAll-round locking is firmAvoid stuckWelding/cutting auxillary devicesLifting framesArchitectural engineeringWelding

The invention relates to a steel structured positioning placement robot. The steel structured positioning placement robot comprises a support base plate and a lifting device; the lifting device is mounted at the top of the support base plate; the lifting device comprises multistage hydraulic cylinders, a lifting support plate, a lifting motor, a lifting rotating plate, a return mechanism, a fixingmechanism, a limiting mechanism, a lifting chute and a lifting slide rod; and the return mechanism comprises a return plate, a return slide column, a return spring, a return hammering body, a returnrotating rod, a return motor, a return rotating shaft, a return turntable, a rotating shaft frame, a return limiting plate, a return push rod, a return stop frame, a return stop plate and a push rod plate. The steel structured positioning placement robot can solve the difficulties of incapability of locking channel steel in all directions during placing and conveying, blockage of the channel steelbetween two I-shaped steel during placing, deviation of the welding and placing positions of the channel steel and the like in traditional steel structured barrier construction, and can achieve the functions of firm locking of the steel structured channel steel; and conveying of the channel steel to the welding position.

Owner:广东德源钢结构工程有限公司

Automatic wall face positioning and grooving machine for indoor architectural decoration construction

InactiveCN107336367AEasy to cleanAngular deviation implementationWorking accessoriesStone-like material working toolsAngular deviationEngineering

The invention relates to a wall surface automatic positioning and slotting machine for indoor building decoration construction, which includes a walking lifting device, a moving and rotating device, a marking device, a level device, a slotting device, a slot cleaning device and an elevation device. The device is installed on the top of the walking lifting device, the marking device, the level device, the slotting device, and the cleaning device are all installed on the mobile rotating device, and the elevation device is connected with the walking lifting device. The present invention can solve the existing problems of angle deviation when grooving the wall surface manually, the hidden danger of injury caused by debris splashed during the grooving operation, and the difficulty of the debris generated during the grooving process. Difficulties such as cleaning; it can realize the functions of positioning and scribing on the wall, positioning and slotting, and comprehensive cleaning in the slot. It has the function of mechanized slotting on the wall without angle deviation, and the splashed debris during slotting operations will be caught by the side panels. The debris generated during the isolation and grooving process will fall into the collection box, etc. Advantages.

Owner:俞樑兵

Bamboo inner joint breaking method

ActiveCN109352768ASolve technical problems that cannot be placed smoothlyPrevent disengagementCane mechanical workingGrinding machinesEngineeringSand-paper

The invention discloses a bamboo inner joint breaking method, and belongs to the technical field of bamboo processing. The bamboo inner joint breaking method is realized on the basis of inner joint breaking equipment, and the inner joint breaking equipment comprises a feeding device, a bamboo joint coping device and an inner joint breaking device. The feeding device is located on the side of the bamboo joint coping device, the inner joint breaking device is located at the front end of the bamboo joint coping device and is connected with the bamboo joint coping device in an abutting and contacted mode, and the bamboo joint coping device comprises a conveying assembly, a positioning assembly and a coping assembly. The conveying assembly is located at the front end of the feeding device, thecoping assembly is mounted on the positioning assembly and can extend into the positioning assembly, and the inner joint breaking device comprises a joint breaking assembly, an arrangement assembly and a grinding assembly. One end of the joint breaking assembly is matched with the positioning assembly in an abutting and connected mode and the other end of the joint breaking assembly is matched with the arrangement assembly in an abutting and connected mode. According to the bamboo inner joint breaking method, a rotating wheel arranged on a worktable drives bamboo to rotate, and a grinding block grinds bamboo joints through coated grinding sand paper to enable the diameters of the bamboo joints and the bamboo to be same.

Owner:泉州市咪童贸易有限公司

Kitchen waste resource utilization biological treatment system

ActiveCN113510141ASmash all directionsImprove delivery efficiencySolid waste disposalClimate change adaptationEnvironmental engineeringMechanical engineering

The invention relates to a kitchen waste resource utilization biological treatment system. The system comprises a sorting mechanism, a conveying mechanism, a crushing mechanism, a solid-liquid separation mechanism, a fermentation mechanism, a discharging channel and a smashing assembly, the smashing assembly comprises adjusting blocks, folding plates, a rotating frame, smashing teeth and a smashing motor, the rotating frame is assembled in the discharging channel, the rotating frame is cross-shaped, two ends of the rotating frame are respectively connected with the two adjusting blocks, the other two ends of the rotating frame are respectively connected with the two folding plates, and the smashing teeth are distributed on the rotating frame. By arranging the smashing assembly, kitchen waste subjected to solid-liquid separation enters the discharging channel, the rotating frame rotates in the discharging channel, blocky waste is smashed through the smashing teeth, the blocky waste is prevented from being clamped in the discharging channel, the discharging channel is kept smooth, waste entering the fermentation mechanism is in a loose state, and fermentation is facilitated; and the rotating frame rotates at a large angle so that the garbage in the discharging channel can be crushed in all directions, and the waste conveying efficiency is improved.

Owner:安徽坤健生物科技有限公司

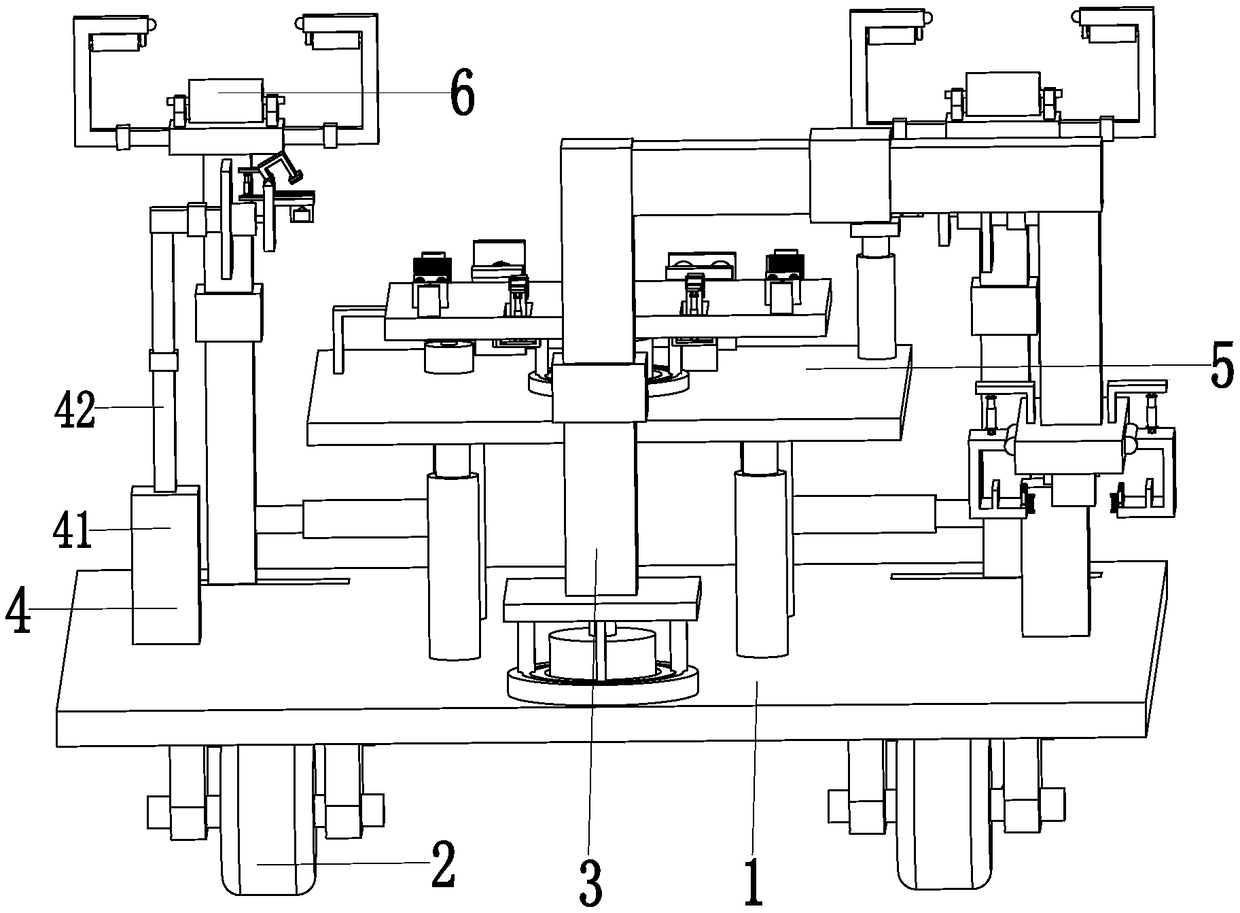

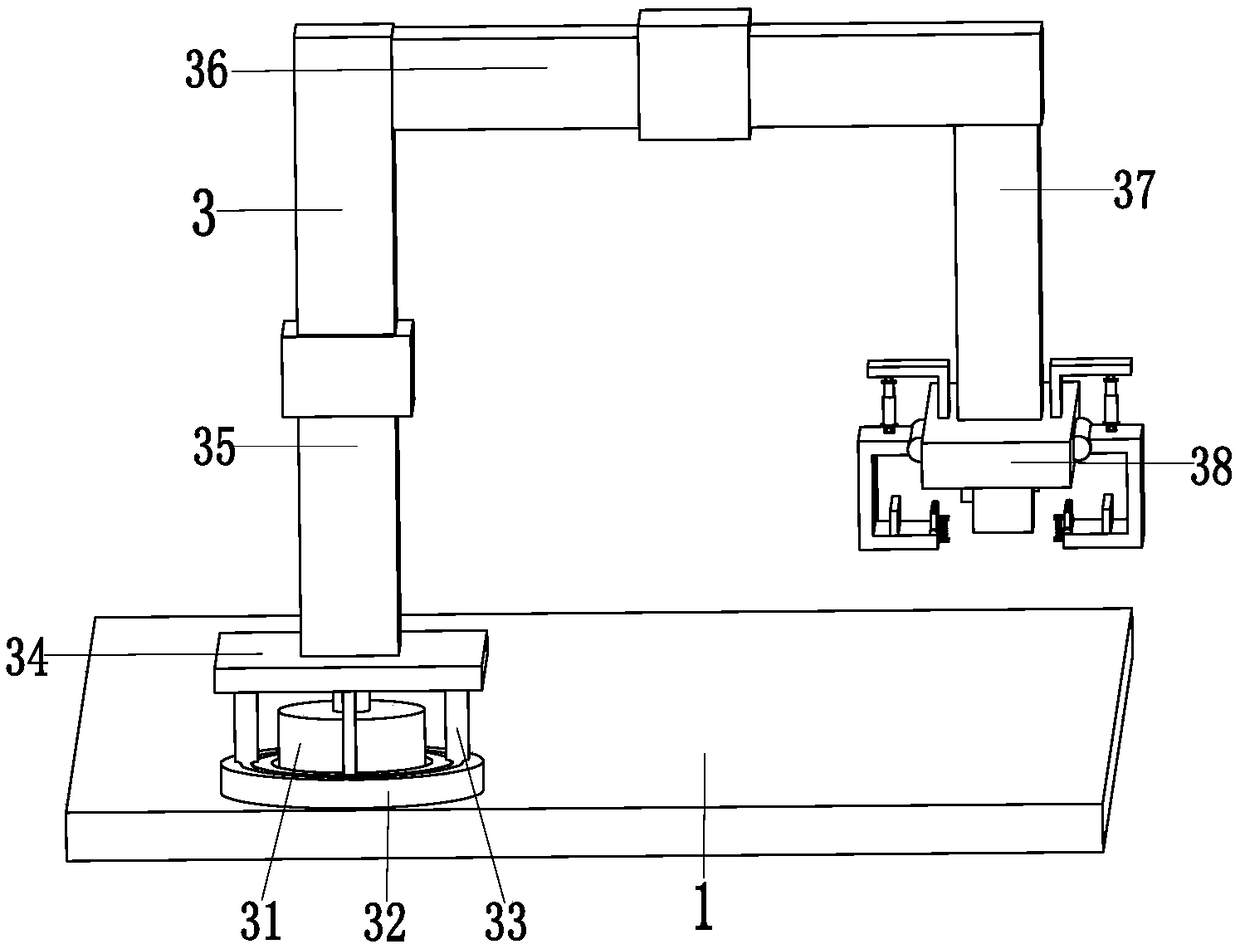

Automatic steel structure installing equipment and automatic installation construction method thereof

The invention relates to automatic steel structure installing equipment and an automatic installation construction method thereof. A supporting base plate, walking wheels, a hoisting device, arrangement devices, a lifting device and positioning devices are included, the walking wheels are symmetrically installed on the bottom of the supporting base plate, the hoisting device is installed on the top of the front end of the supporting base plate, the lifting device is installed at the middle portion of the supporting base plate, the left and right ends of the lifting device are each provided with one arrangement device, the arrangement devices are installed on the top of the outer end of the supporting base plate, and the positioning devices are symmetrically installed at the top of the backend of the supporting base plate. By means of the automatic steel structure installing equipment and the automatic installation construction method, the problems that during existing steel structurepartition wall construction, the box iron falling risk exists when box iron is taken, the box iron needs to be manually overturned to the appropriate welding angle, all-dimensional locking of the boxiron cannot be achieved during arrangement and conveying, the box iron welding and arrangement height needs to be manually adjusted, the box iron can be clamped between two pieces of joist steel whenarranged, and the box iron welding and arrangement position may have deviations are solved.

Owner:安徽精工钢结构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com