Kitchen waste resource utilization biological treatment system

A kind of food waste and biological treatment technology, applied in the field of food waste resource utilization biological treatment system, can solve the problem that the discharge pipe is easy to block and affect the fermentation efficiency, and achieve the effect of improving efficiency and maintaining smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

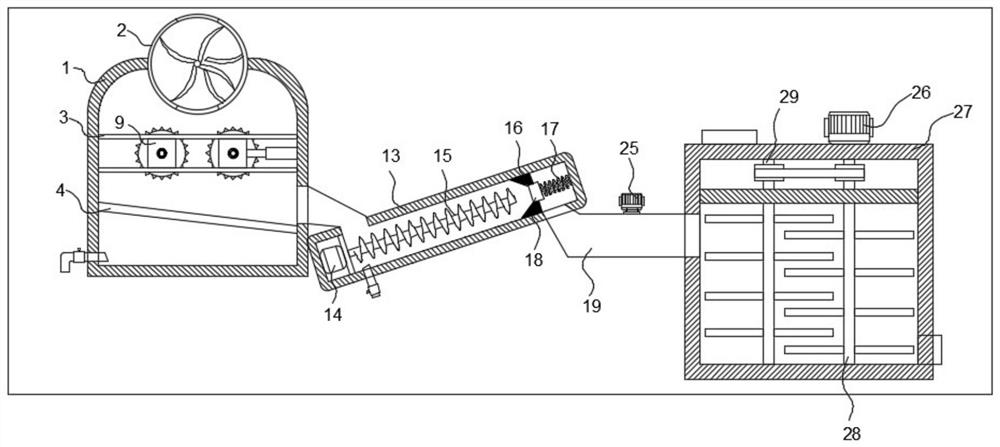

[0038] This embodiment discloses a biological treatment system for resource utilization of food waste, which is used to process food waste into resource, so as to prepare food waste into organic fertilizer and realize resource recycling. This embodiment mainly improves the overall efficiency of kitchen waste treatment.

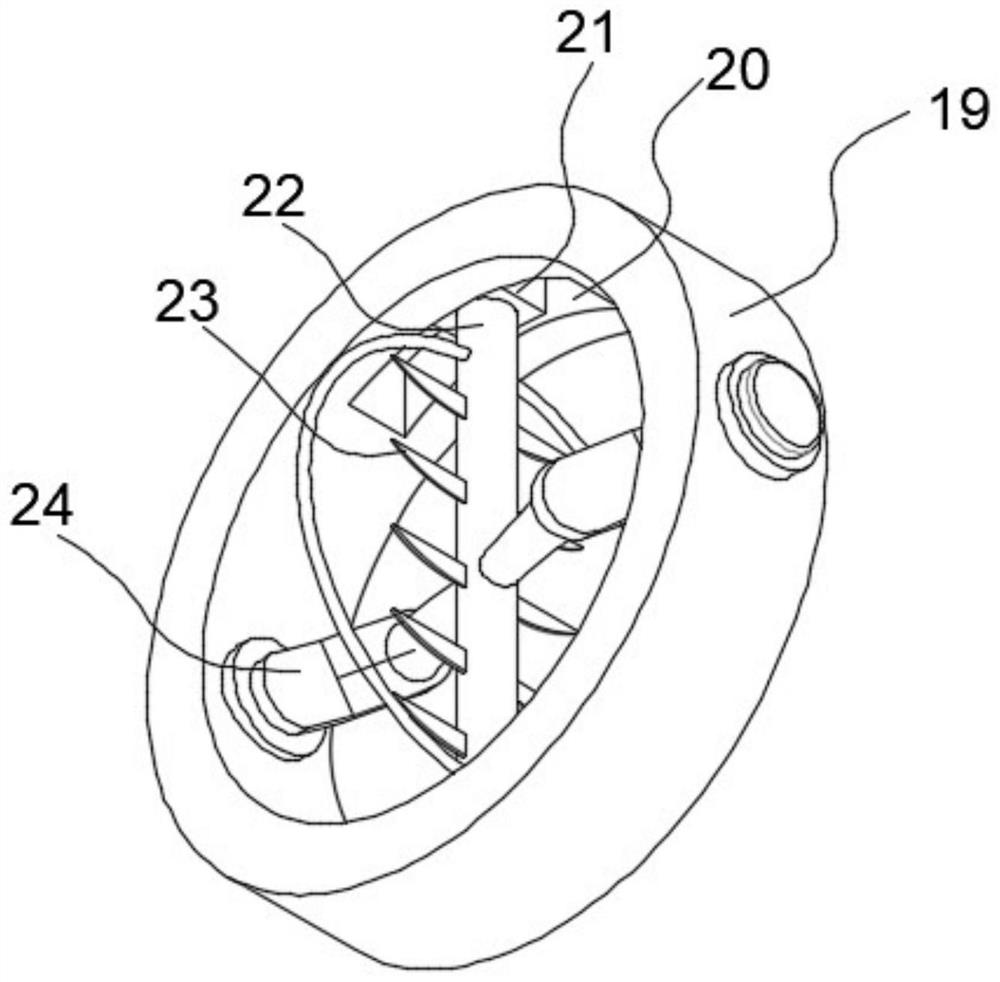

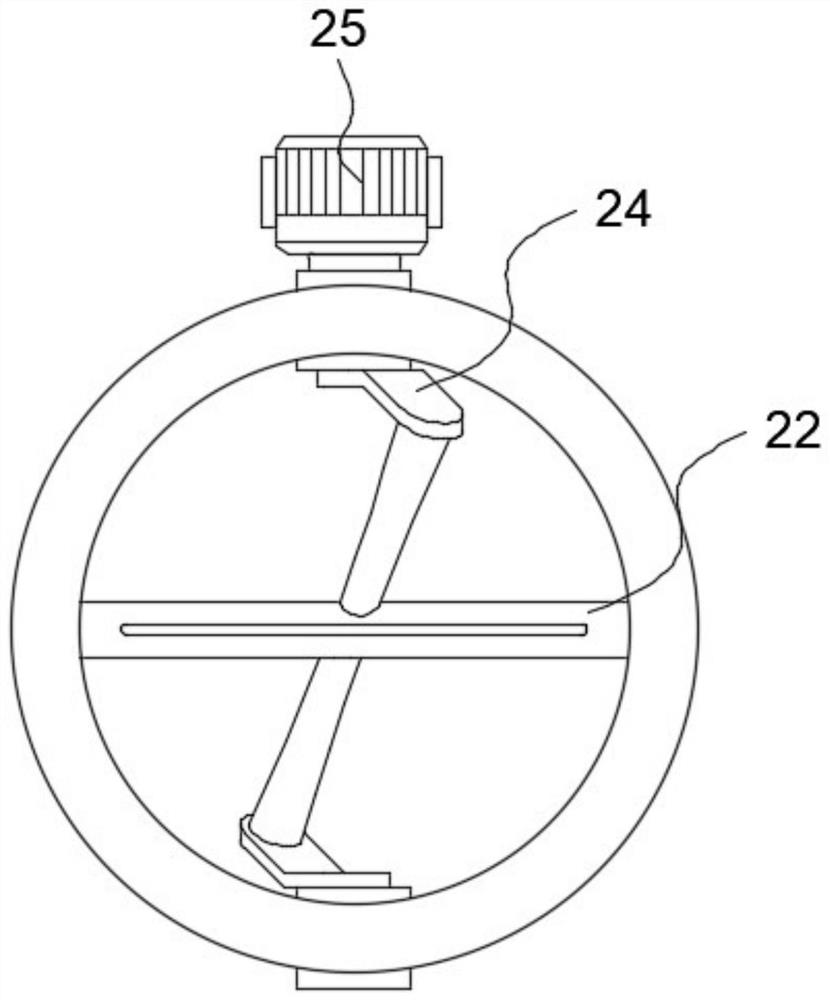

[0039] see figure 1 The biological treatment system for resource utilization of food waste includes a sorting mechanism, a conveying mechanism, a crushing mechanism, a solid-liquid separation mechanism, a fermentation mechanism, a discharge channel 19 and a crushing component. The sorting mechanism is used to sort the food waste, which can be manual sorting or machine sorting, mainly to remove tableware and hard bones in the food waste. The conveying mechanism is used to convey the sorted food waste. The crushing mechanism is used to receive the kitchen waste conveyed by the conveying mechanism, and perform crushing treatment, so as to improve the quality of...

Embodiment 2

[0047] see Figure 6 , this embodiment discloses a biological treatment system for resource utilization of kitchen waste, which differs from Embodiment 1 only in that the solid-liquid separation mechanism is different.

[0048] see Figure 7 , Figure 8 , Figure 9 and Figure 10 , in this embodiment, the solid-liquid separation mechanism includes a separation box 30, a drive motor 31, a drive shaft 47, a lifting frame 32, a hollow plate 34, a connecting spring 49, a fixed block 48, an extrusion plate 41, a rotating plate 46, and a connecting rod 42 and controller two. The drive motor 31 is fixedly mounted on the top of the separation box 30 . The connecting spring 49 is installed between the hollow plate 34 and the lifting frame 32 . In this embodiment, the driving motor 31 is a servo motor.

[0049] The wall of the separation box 30 is provided with a sewage inlet 37 and a garbage outlet 38 respectively, and the sewage inlet 37 and the garbage outlet 38 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com