Patents

Literature

171results about How to "Low operating failure rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

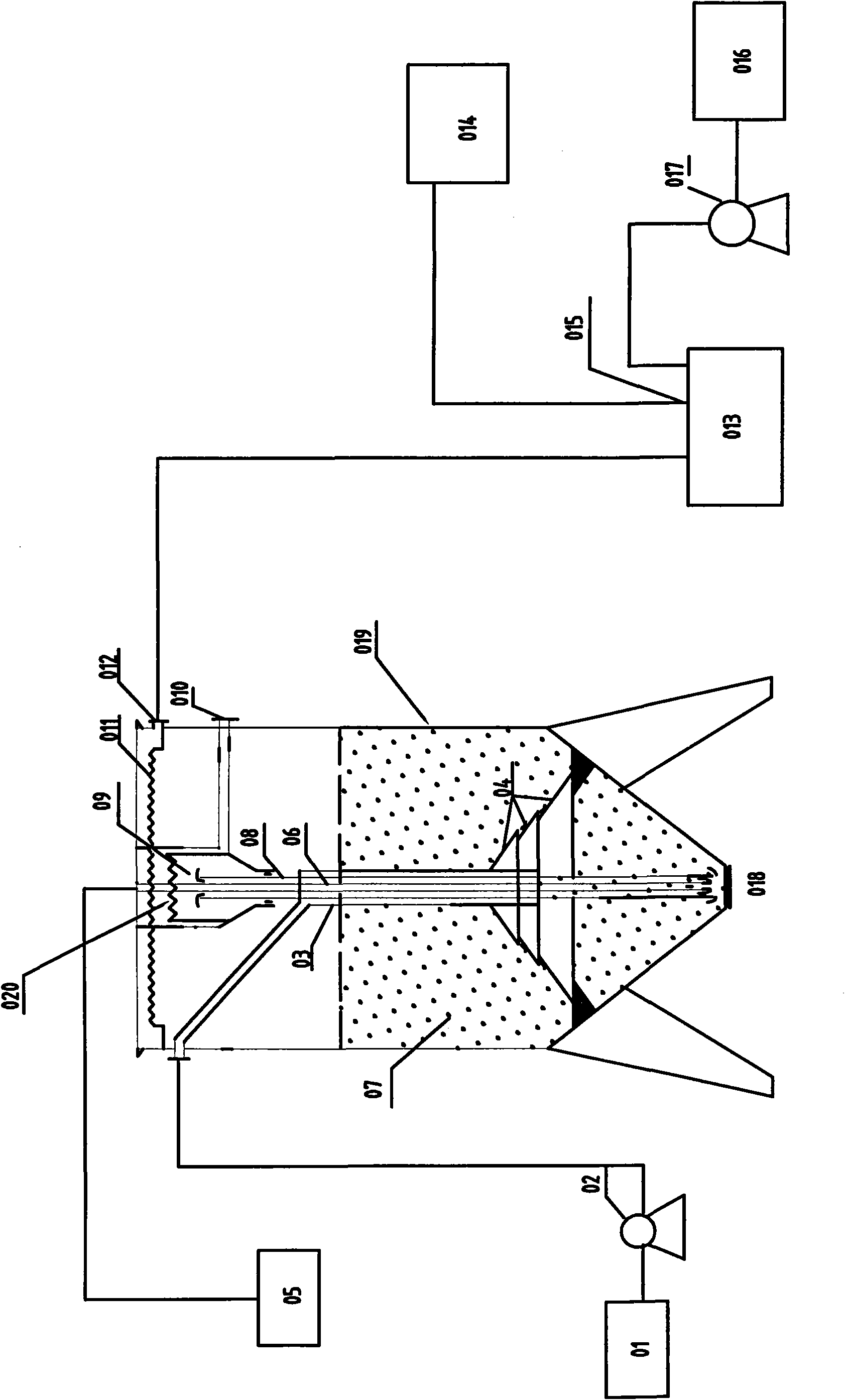

Sintering smoke treatment system and sintering smoke treatment method

InactiveCN102580455AComprehensive management benefit maximizationHigh adsorptionDispersed particle separationMetallurgyMaterials science

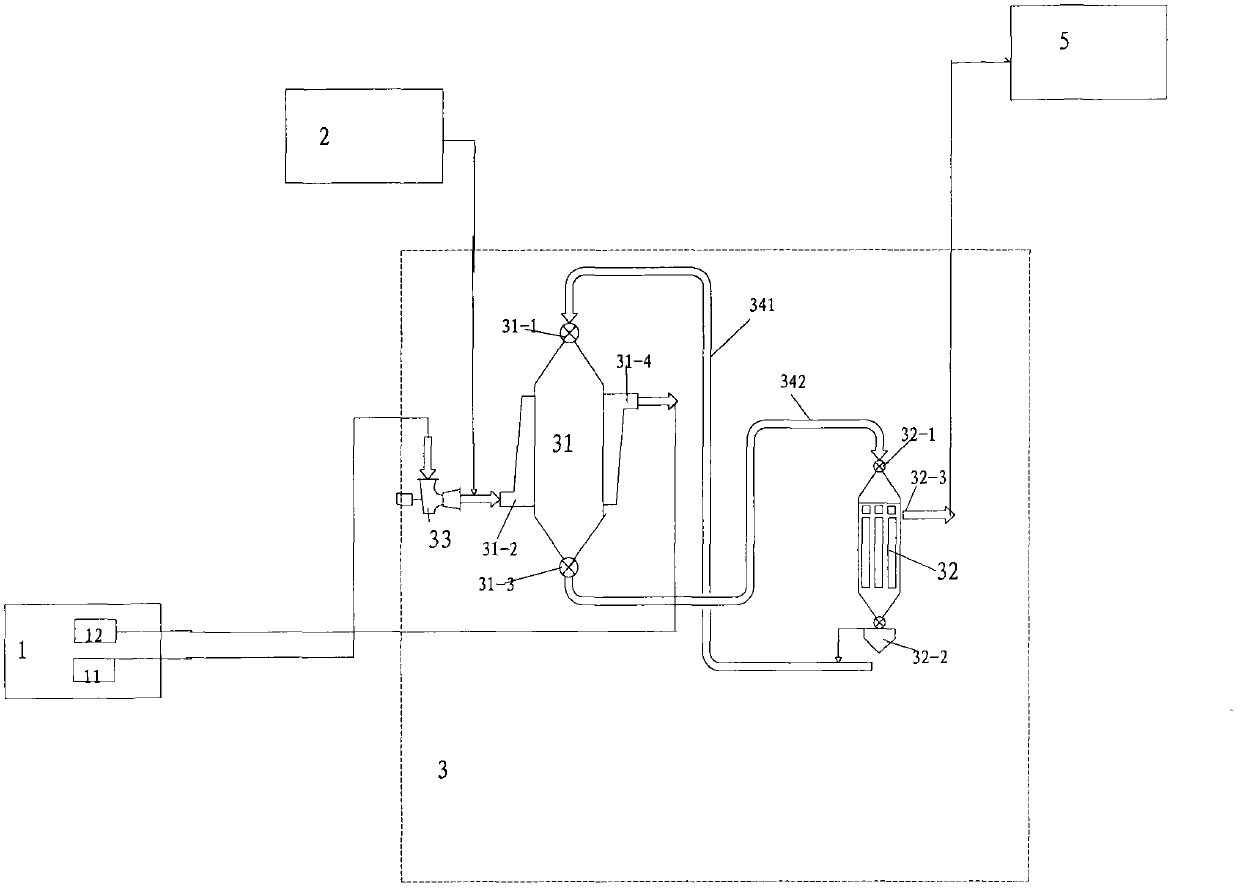

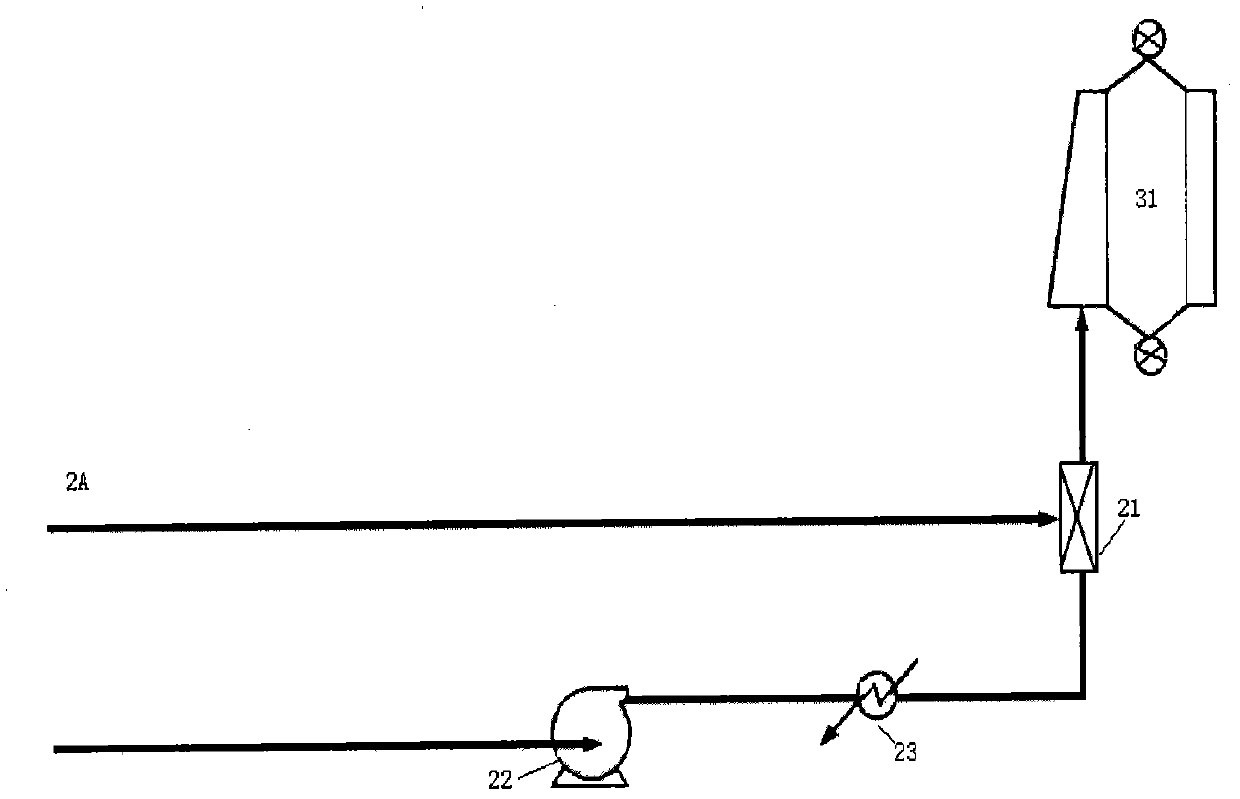

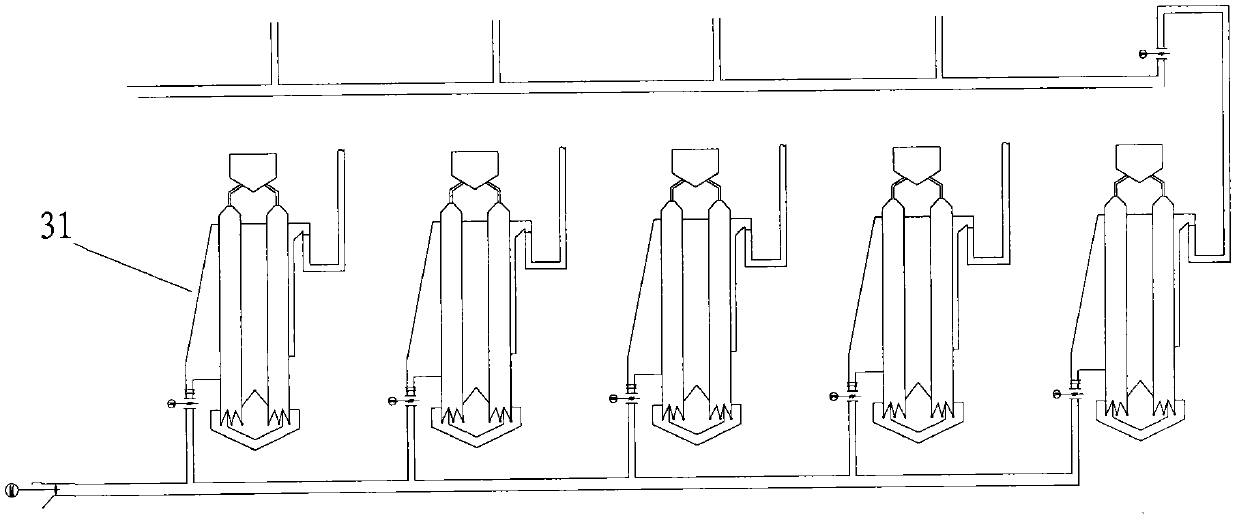

The invention provides a sintering smoke treatment system and a sintering smoke treatment mode, which are used in synchronized desulfuration, denitration, purification and acid making. The sintering smoke treatment system comprises a smoke system (1), an ammonia filling system (2), a smoke treatment system (3) and an acid making system (5), wherein the smoke system (1) comprises a main exhaust fan (11) and a chimney (12), the smoke treatment system (3) comprises an adsorption tower (31) and an analyzing tower (32), and the adsorption tower (31) and the analyzing tower (32) are connected with each other. The main exhaust fan (11) of the smoke system (1) and the chimney (12) are respectively connected with the adsorption tower (31), the analysis tower (32) of the smoke treatment system (3) is connected with the acid making system (5), and the adsorption tower (31) of the smoke treatment system (3) is connected with the chimney (12) of the smoke system (1).

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

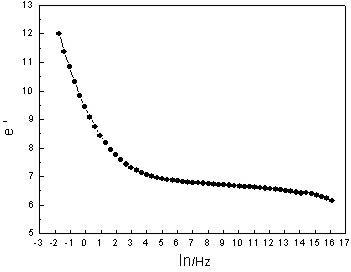

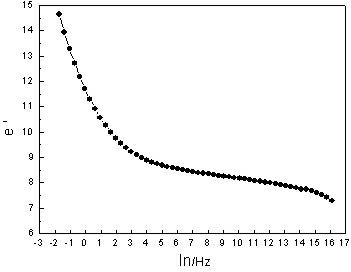

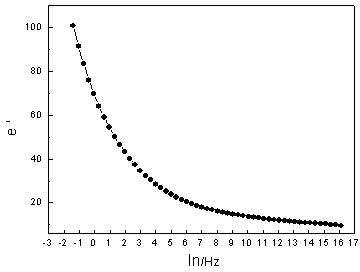

High-dielectric-constant silicon rubber and preparation method thereof

ActiveCN102504540AImprove the dielectric effectHigh dielectric constantPlastic/resin/waxes insulatorsPolymer scienceHigh pressure

The invention belongs to the technical field of electrical insulating materials and particularly relates to a high-dielectric-constant silicon rubber and a preparation method thereof. The high-dielectric-constant silicon rubber is prepared from the following raw materials in part by weight: 17 to 50 parts of raw silicon rubber, 15 to 83 parts of a giant-dielectric-constant ceramic powder, 0 to 25 parts of conductive or semi-conductive powder, 0 to 15 parts of reinforcing filler, and 1 to 3 parts of ingredient. When used in a high-voltage environment, the high-dielectric-constant silicon rubber provided by the invention can optimize electric-field distribution, relieve electric field intensity concentration in a high-voltage part and reduce operation faults.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +3

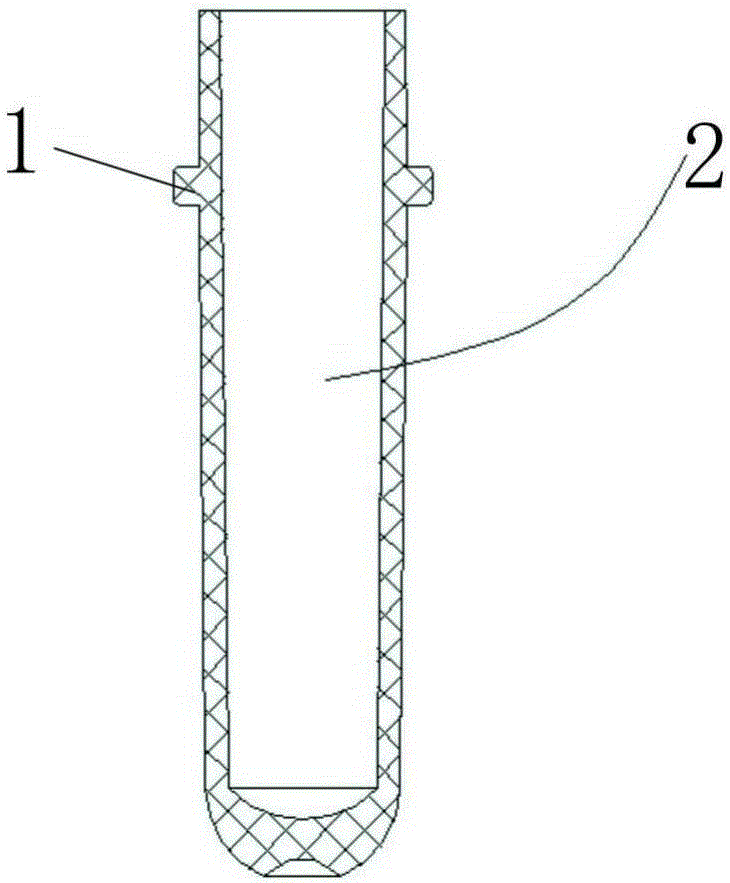

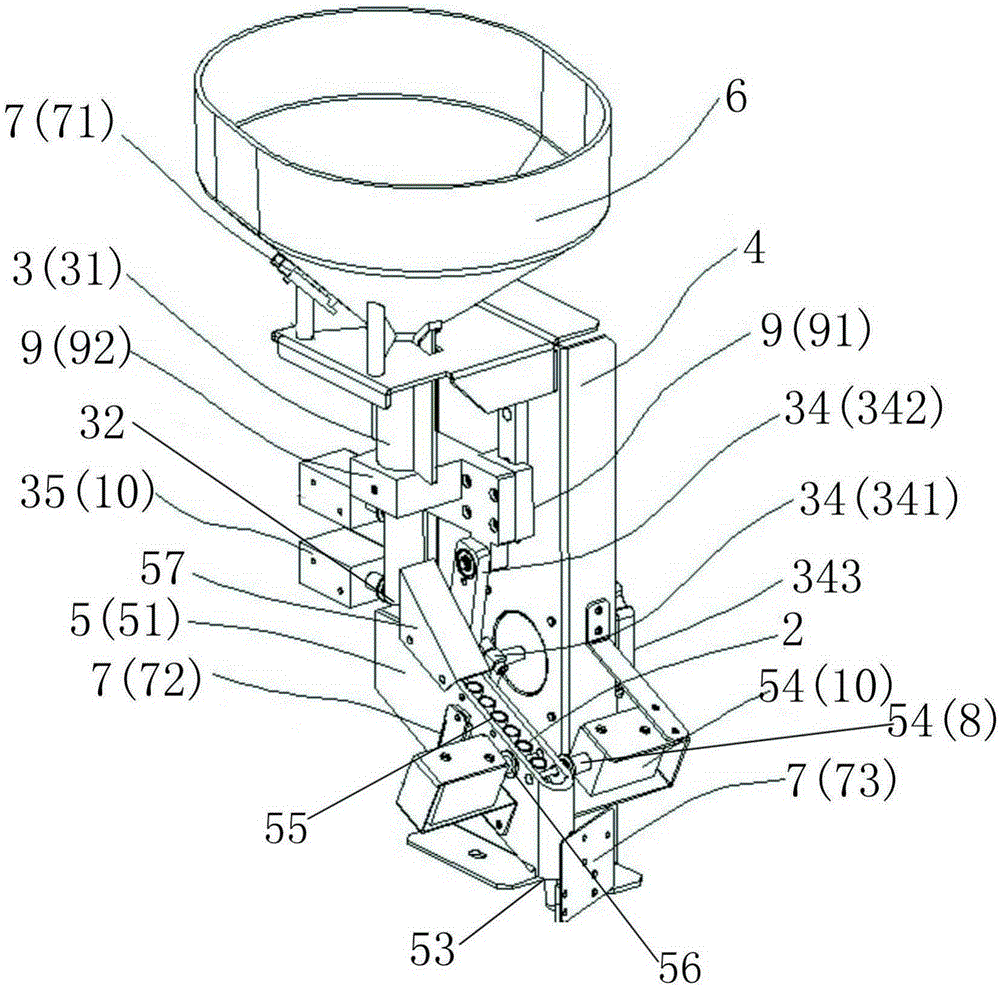

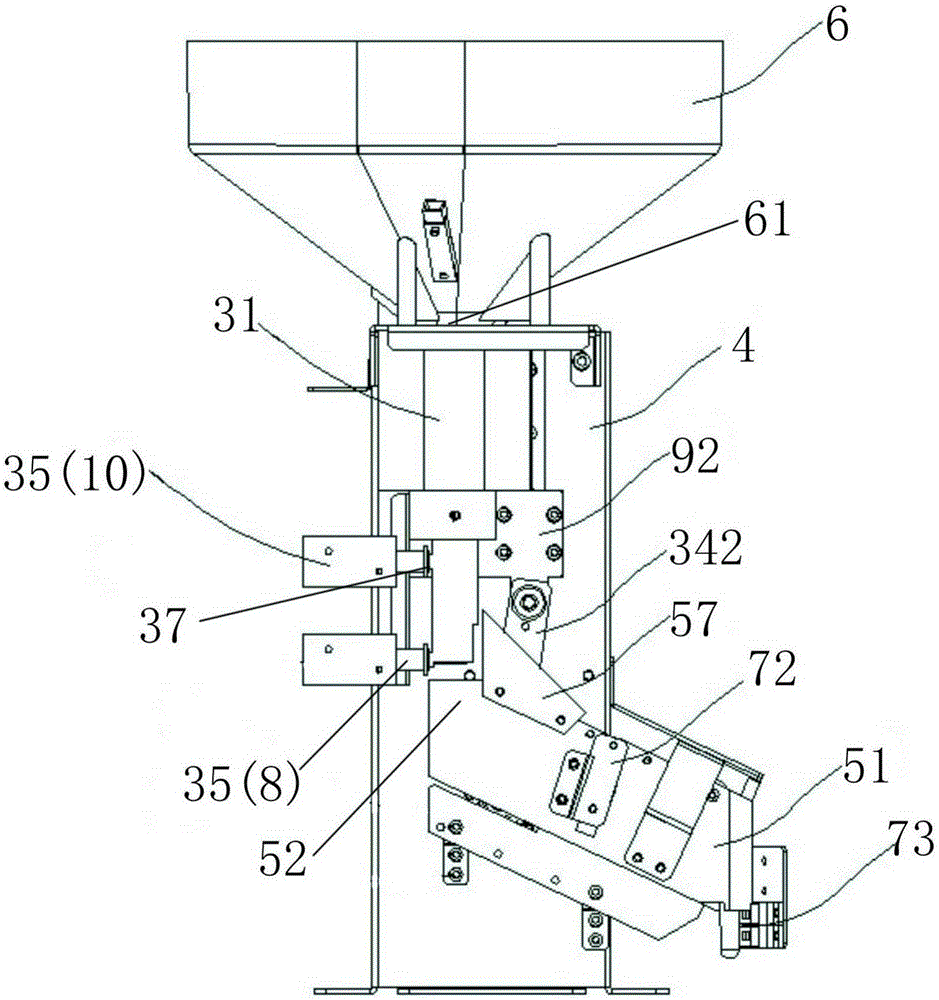

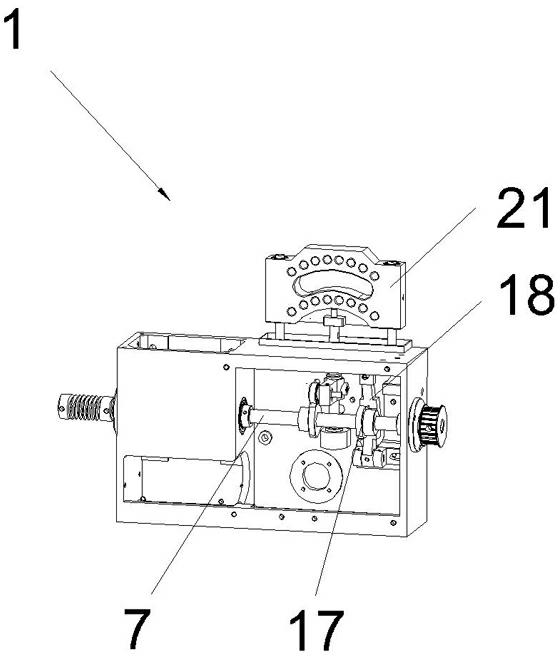

Reaction cup loading system for automatically conveying reaction cups to analysis device

InactiveCN105181985ACompact structureSimple operation and controlMaterial analysisEngineeringGuide tube

The invention provides a reaction cup loading system for automatically conveying reaction cups to an analysis device. The reaction cup loading system comprises a rack, as well as a cup storage cabin, a cup fetching mechanism and a cup conveying mechanism which are fixedly arranged on the rack and are arranged in sequence along a conveying direction of the reaction cups, wherein a cup outlet is formed in the bottom of the cup storage cabin; the cup fetching mechanism comprises a guide pipe, a driver for driving the guide pope to hoist to enable the guide pipe to stretch into the cup storage cabin from the cup outlet to take the cups, and a first mechanical switch for controlling the reaction cups in the guide pipe to fall off one by one from a first outlet; the cup conveying mechanism comprises a slide groove and a second mechanical switch for controlling the reaction cups in the slide groove to slide out one by one from a second outlet; the reaction cup loading system further comprises a cup detection mechanism arranged on the cup fetching mechanism and / or the cup conveying mechanism. A reaction cup automatic conveying device provides guarantees to full-automatic operation of a biological sample analysis system, has a compact whole structure, is simple to operate and control, has low operation fault rate and is accurate and reliable to convey; the device can be continuously operated for a long time with the matching of the detection mechanism, so that the conveying efficiency is improved and the operation cost is reduced.

Owner:SYSCAN MEDICAL TECH SUZHOU

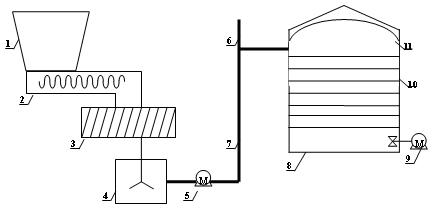

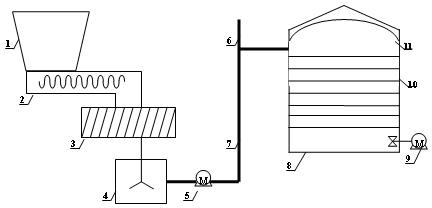

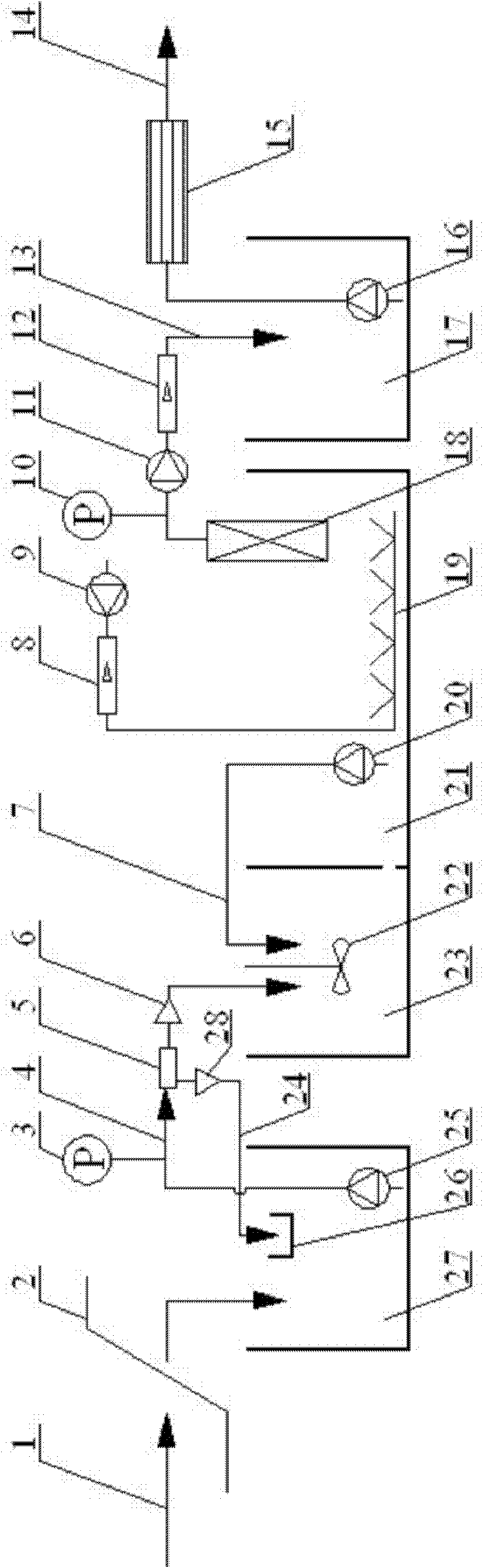

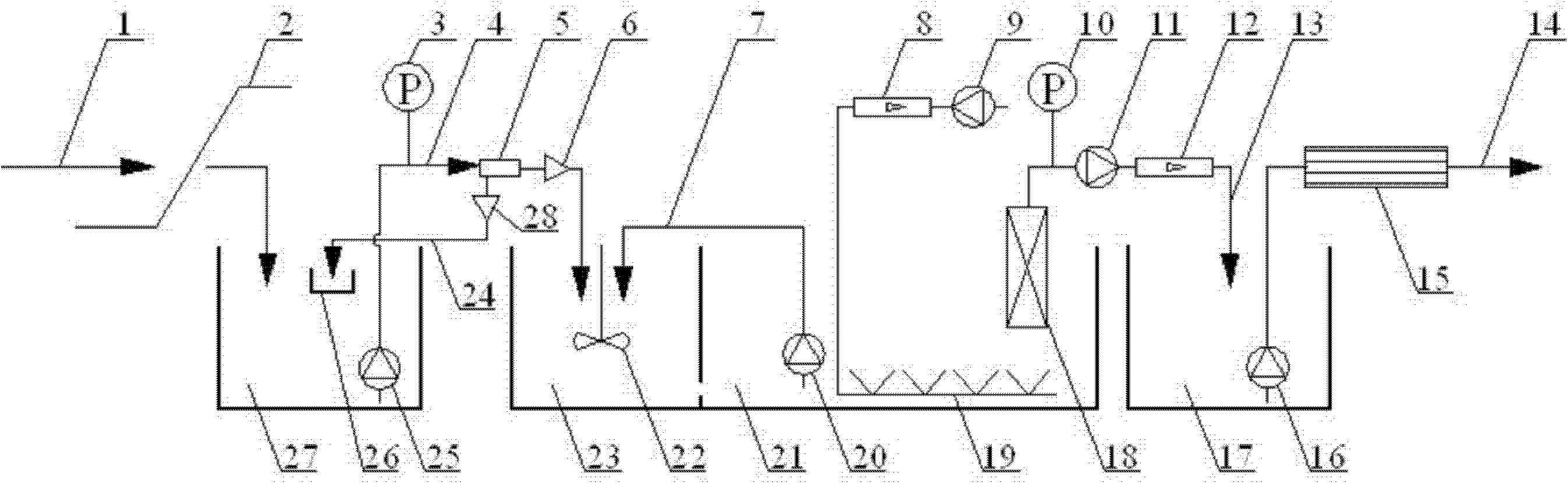

Food residue and sludge mixing anaerobic treatment method and system

InactiveCN102352380AAffects oil contentSolve processing problemsBio-organic fraction processingBiological substance pretreatmentsElectricityOil and grease

The invention belongs to the technical field of food residue and municipal sludge treatment. A food residue and sludge mixing anaerobic treatment method comprises a food residue pretreatment and anaerobic digestion treatment, wherein the food residue pretreatment is that: the food residue with the grease content less than 8% is transferred to a breaking and separating unit to break and separate, and is broken until the granular is less than 30mm, and the serous liquid is obtained for spare use; and the anaerobic digestion treatment is that: the serous liquid which is obtained after the food residue pretreatment is transferred to an anaerobic digestion device, meanwhile, the sludge also enters the anaerobic digestion device, the solid content of the mixing material is 8-12%, stirring and mixing are carried out in the anaerobic digestion device, so the anaerobic digestion is carried out. The invention has the following characteristics: 1, the food residue which is not classified can be treated, the invention is in accordance with the urban food residue source classification current situation in China; 2, the food residue does not need oil-water separation, is directly mixed with sludge to enter the anaerobic digestion system, so that biodegradation is carried out for producing methane, the technological equipment is simple, and the recycling degree is high; and the heat and electricity consumption are saved, and the operation cost is low.

Owner:LIDA ENVIRONMENT ENG DALIAN ECONOMIC TECH DEV ZONE

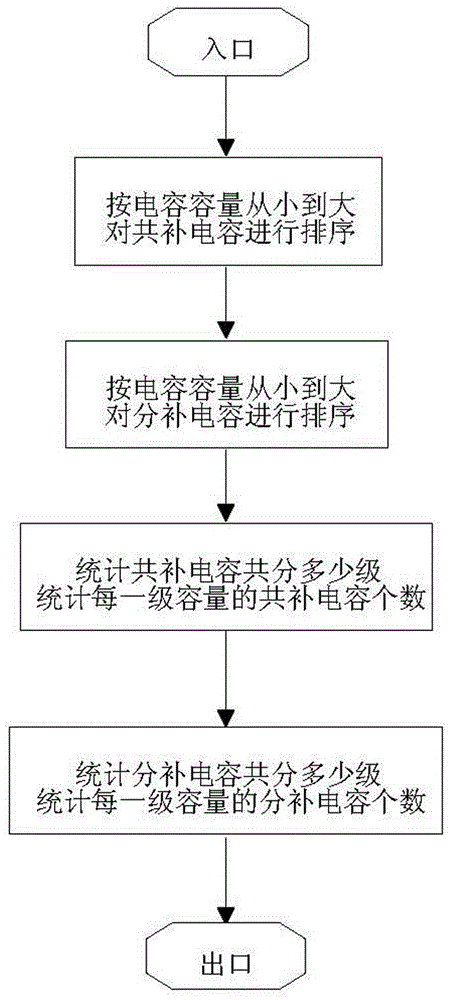

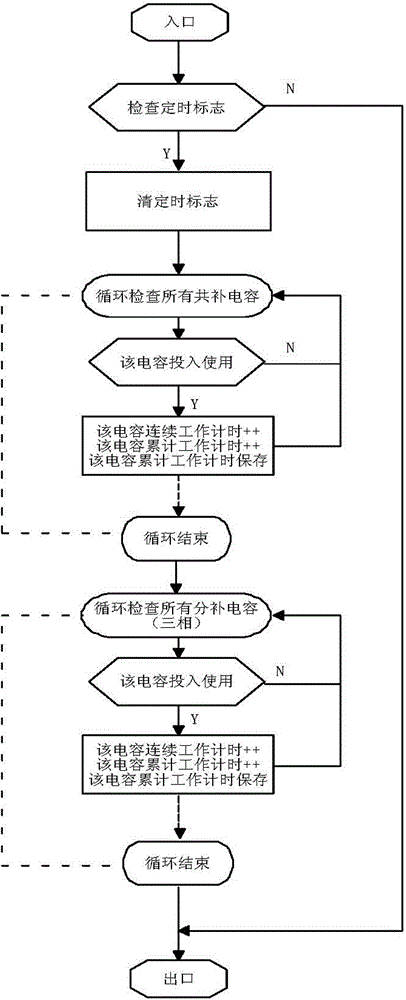

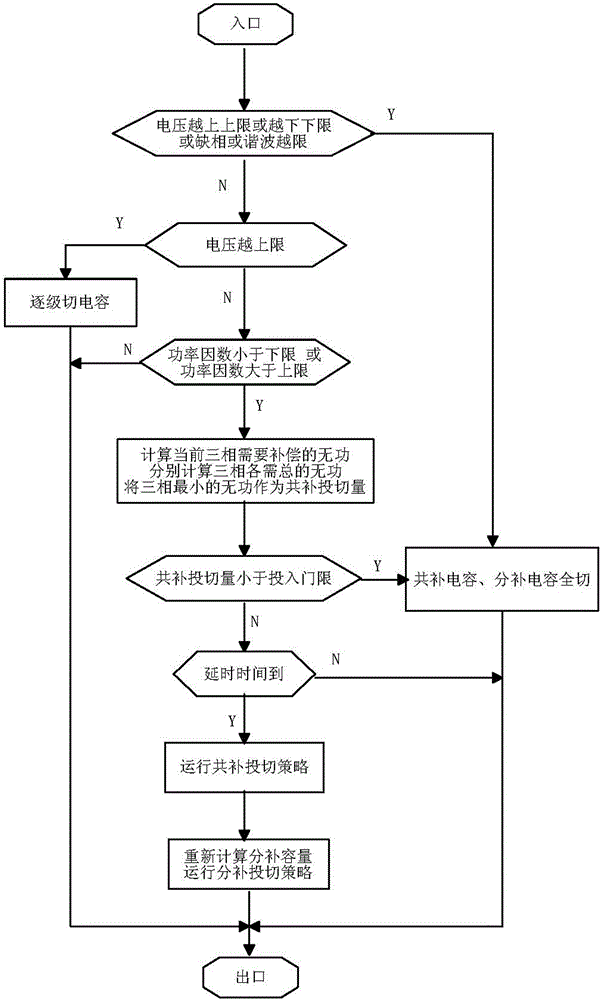

Optimized and optimally-cutting reactive compensation method and reactive compensation device

InactiveCN104092221AEasy to implementSimple designReactive power adjustment/elimination/compensationReactive power compensationCapacitancePower factor

The invention provides an optimized and optimally-cutting reactive compensation method and reactive compensation device. The method can judge a control strategy through composite physical quantity of three-phase voltage, three-phase reactive power and power factors to form a capacitor switching strategy of cutting off a capacitor and optimizing and optimally cutting a switching capacitor step by step, and accordingly reactive compensation can be accurately finished. The capacitor switching strategy uses a switching capacitor optimizing and optimally cutting method to optimize the core portion of the reactive compensation method based on work timing of an input capacitor. The optimized and optimal-cutting capacitor switching strategy is simple, practical and easy to achieve, can carry out intelligent control switch to a common compensation capacitor and a divided compensation capacitor, can meet the application requirements and accuracy requirements of reactive compensation of most low-voltage distributing networks and brings convenience to design, debugging, operation and using of a reactive compensation controller.

Owner:AEROSPACE SCI & IND SHENZHEN GROUP

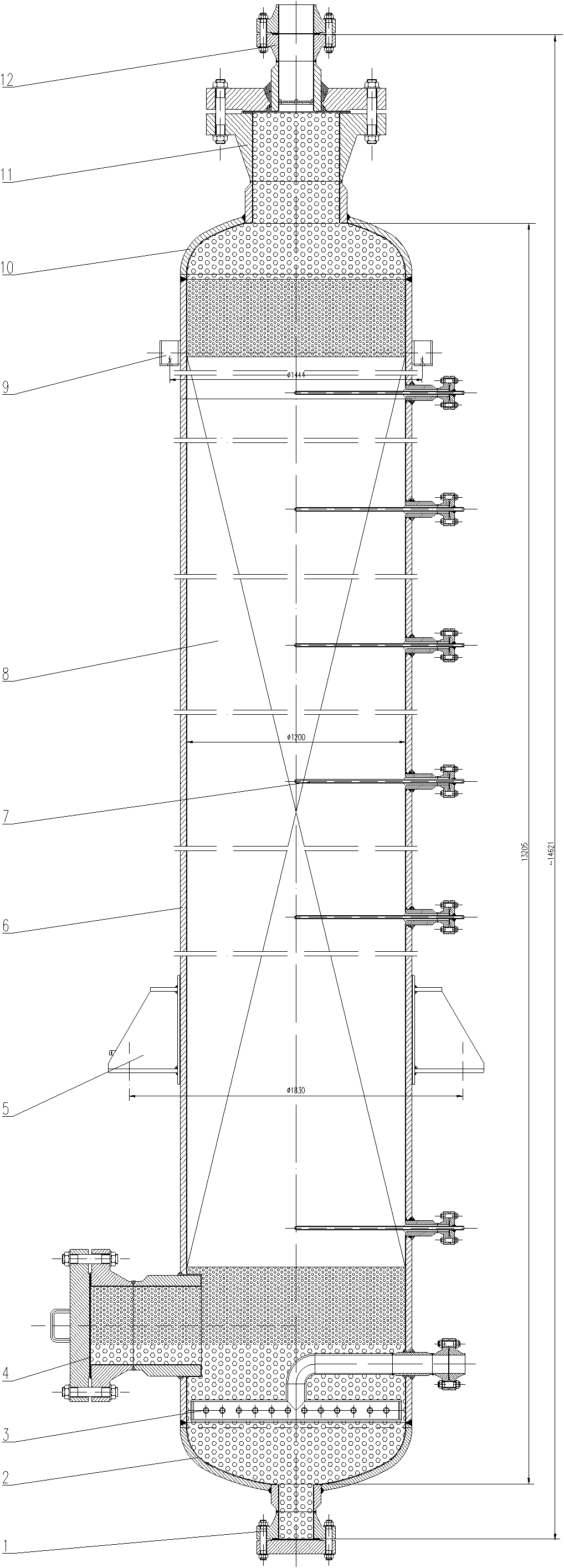

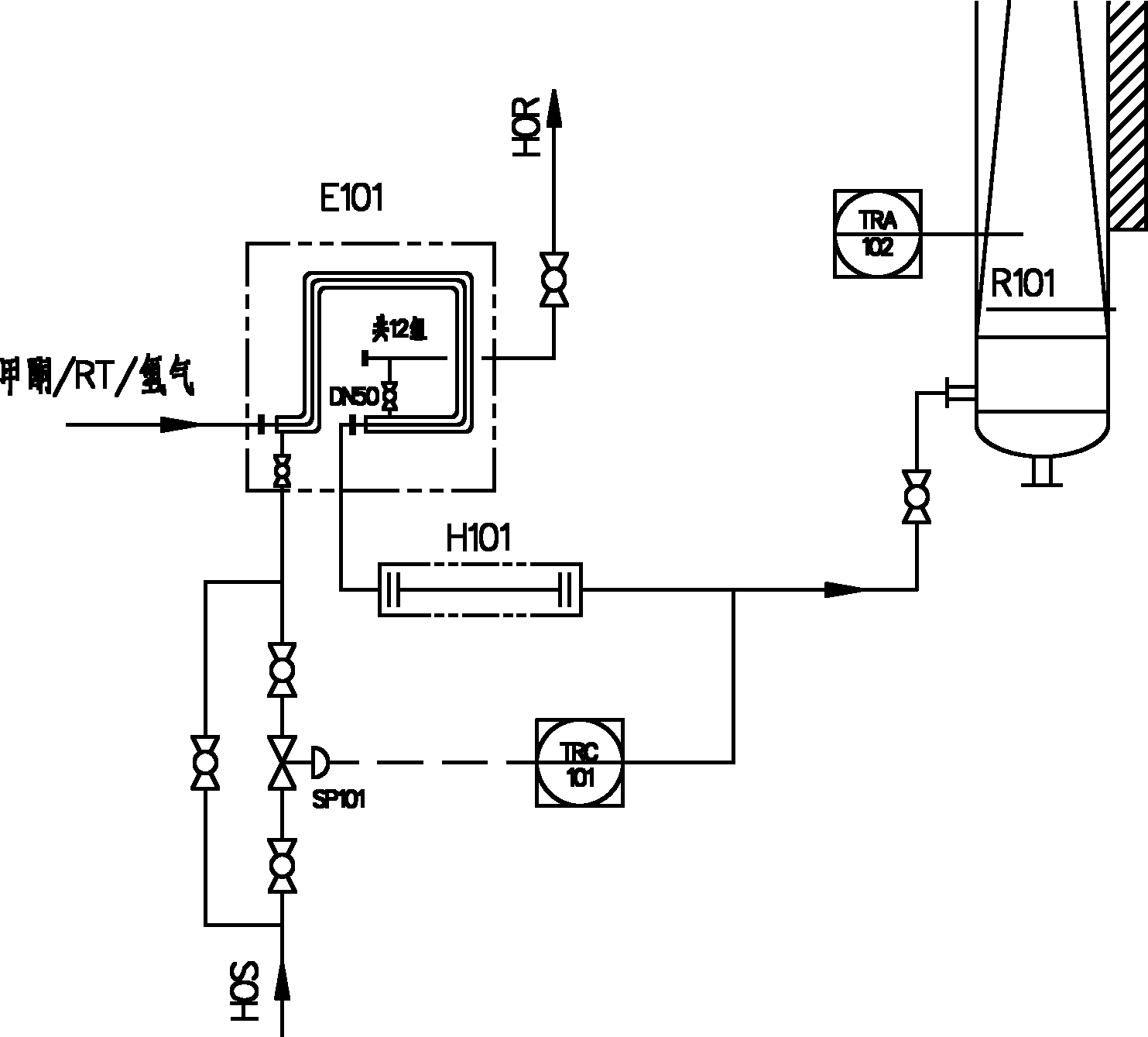

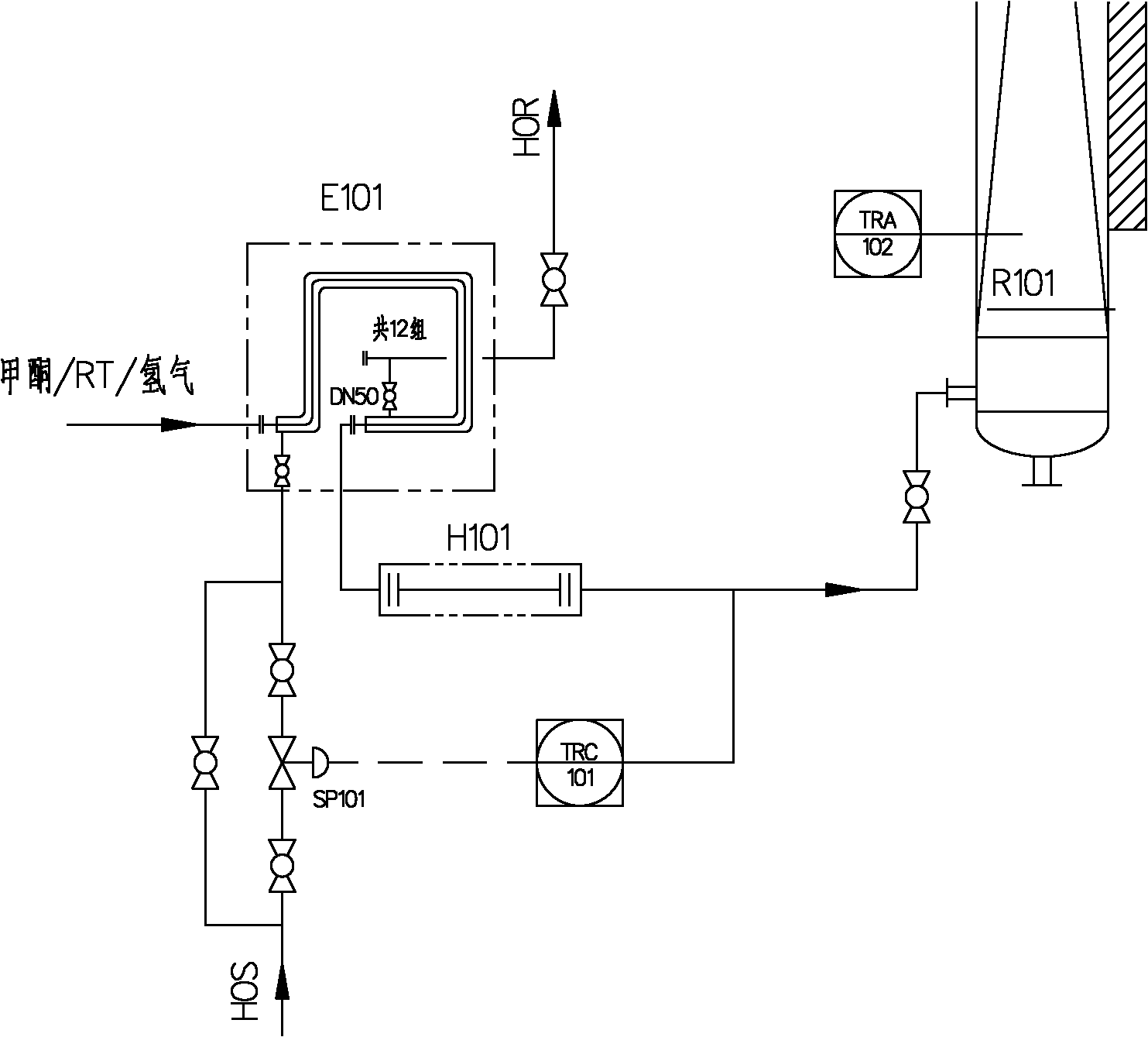

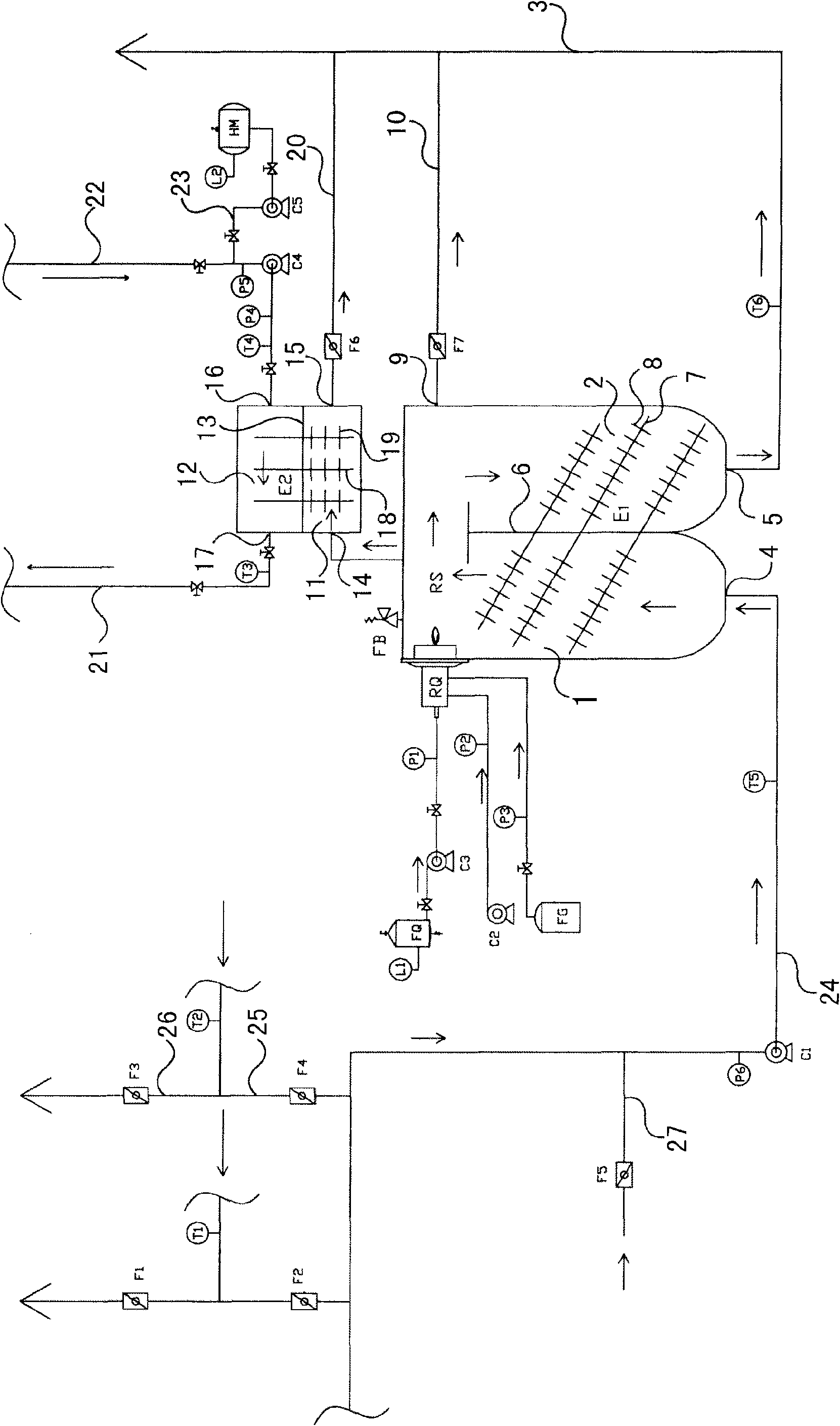

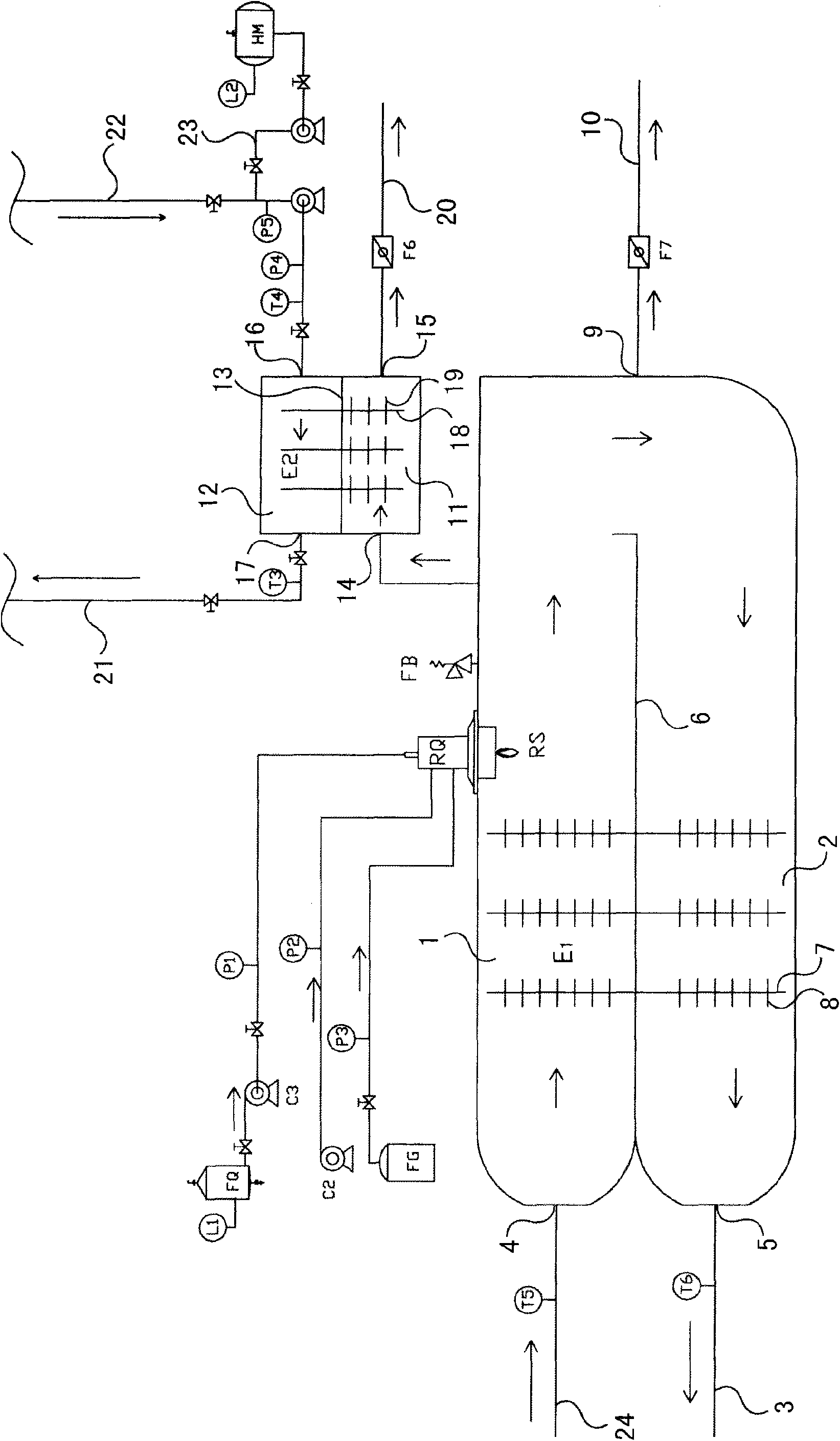

A kind of anti-aging agent 4020 continuous production process

InactiveCN102260176ASmall sizeEven by forceAmino preparation from aminesChemical/physical processesChemistryMethyl isobutyl ketone

The invention discloses a continuous producing process of an anti-aging agent 4020, which has the advantages of stability and reliability in operation and high production efficiency. The process comprises the following steps of: adopting 4-aminodiphenylamine, methyl isobutyl ketone and hydrogen as raw materials; mutually preheating all raw materials by a preheater E101; enabling the preheated rawmaterials to enter a reactor; and carrying out catalytic hydrogenation reaction on the raw materials at a high pressure under the effect of a catalyst so as to obtain the anti-aging agent 4020, wherein the reactor is a gas-liquid-solid three-phase fixed bed hydrogenation reactor; the hydrogenation reaction is continuous operation carried out by using the gas-liquid-solid three-phase fixed bed hydrogenation reactor; the gas-liquid-solid three-phase fixed bed hydrogenation reactor comprises a main body container, a discharging opening, a completely discharging opening, a feed pre-distributor, an upper seal head, a lower seal head, an upper support, a lower support and a temperature measuring opening, wherein the feed pre-distributor is an exhaust pipe type pre-distributor which is mounted at the lower part of the main body container; the upper seal head is an elliptical seal head; and the lower seal head is also an elliptical seal head; and the temperature is 165-230 DEG C, the pressureis 5.5-6.0 MPa, the keto-amine ratio is 2-4:1 and the hydrogen-oil ratio is 2000-5000:1 during reaction.

Owner:NANJING ENVIRO CHEM ENG DESIGN

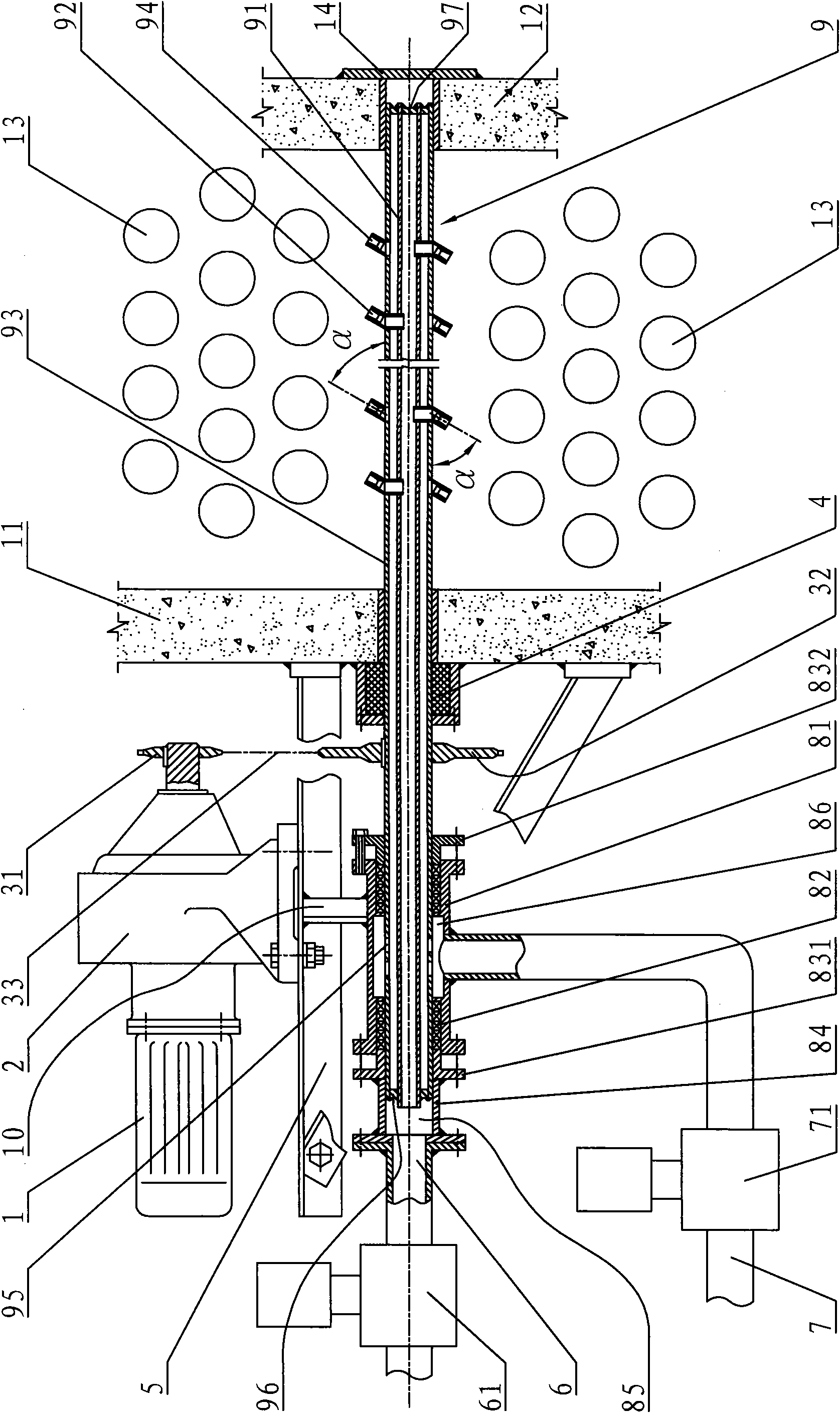

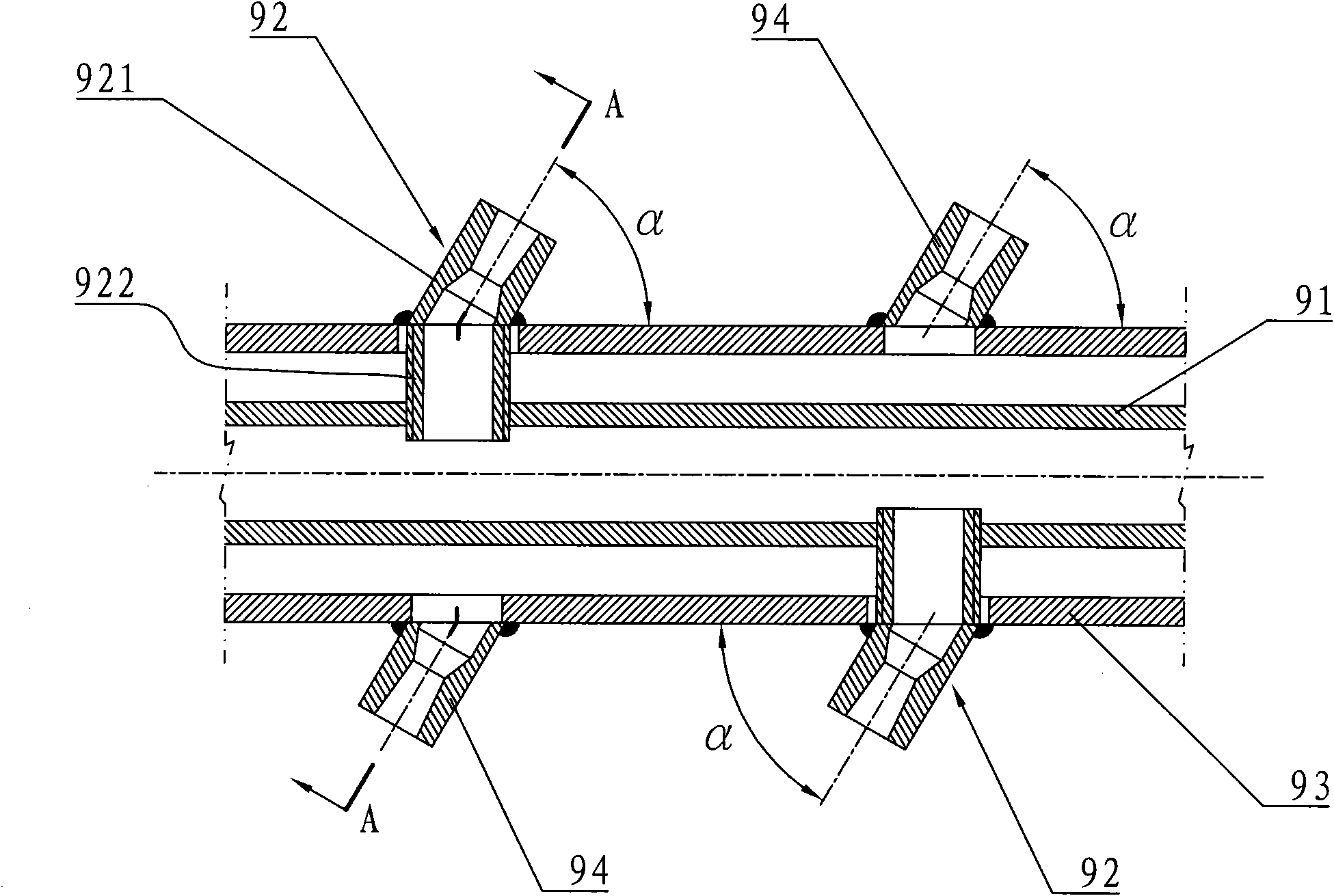

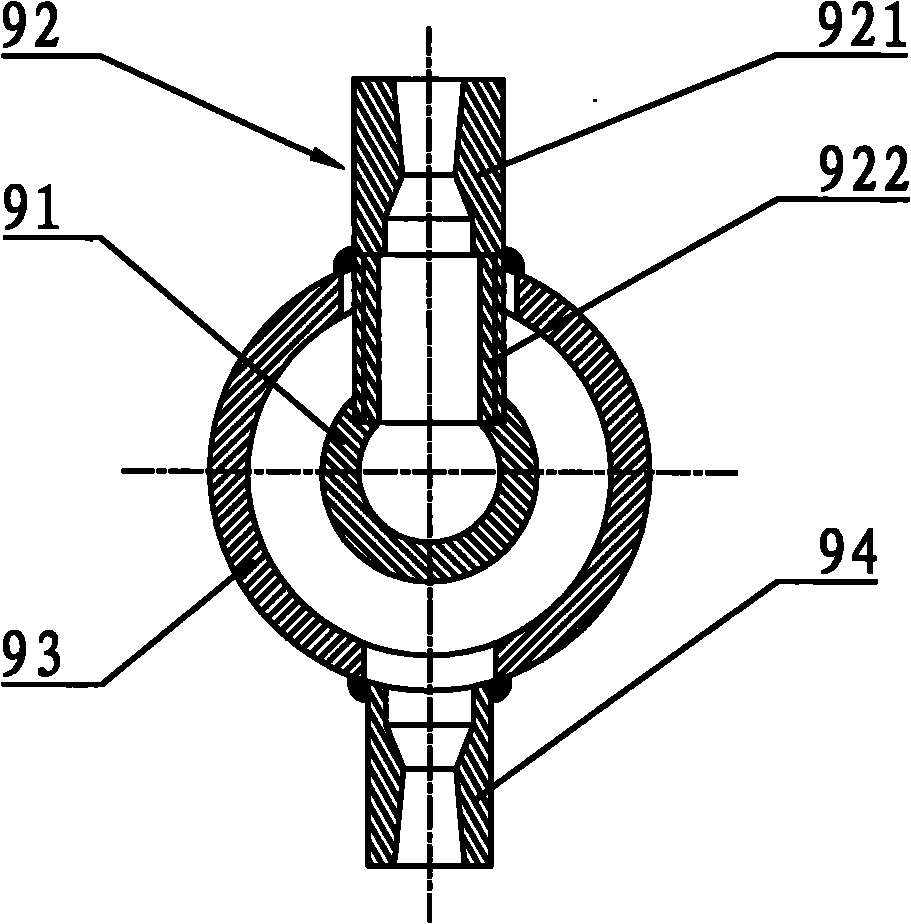

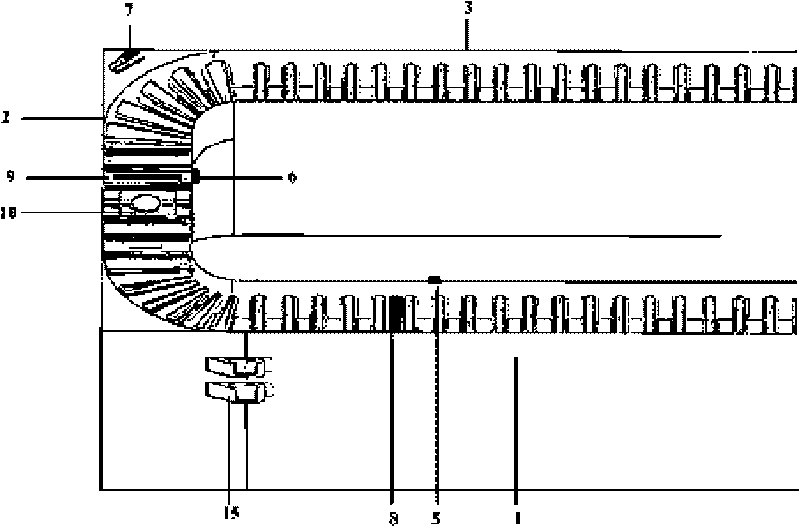

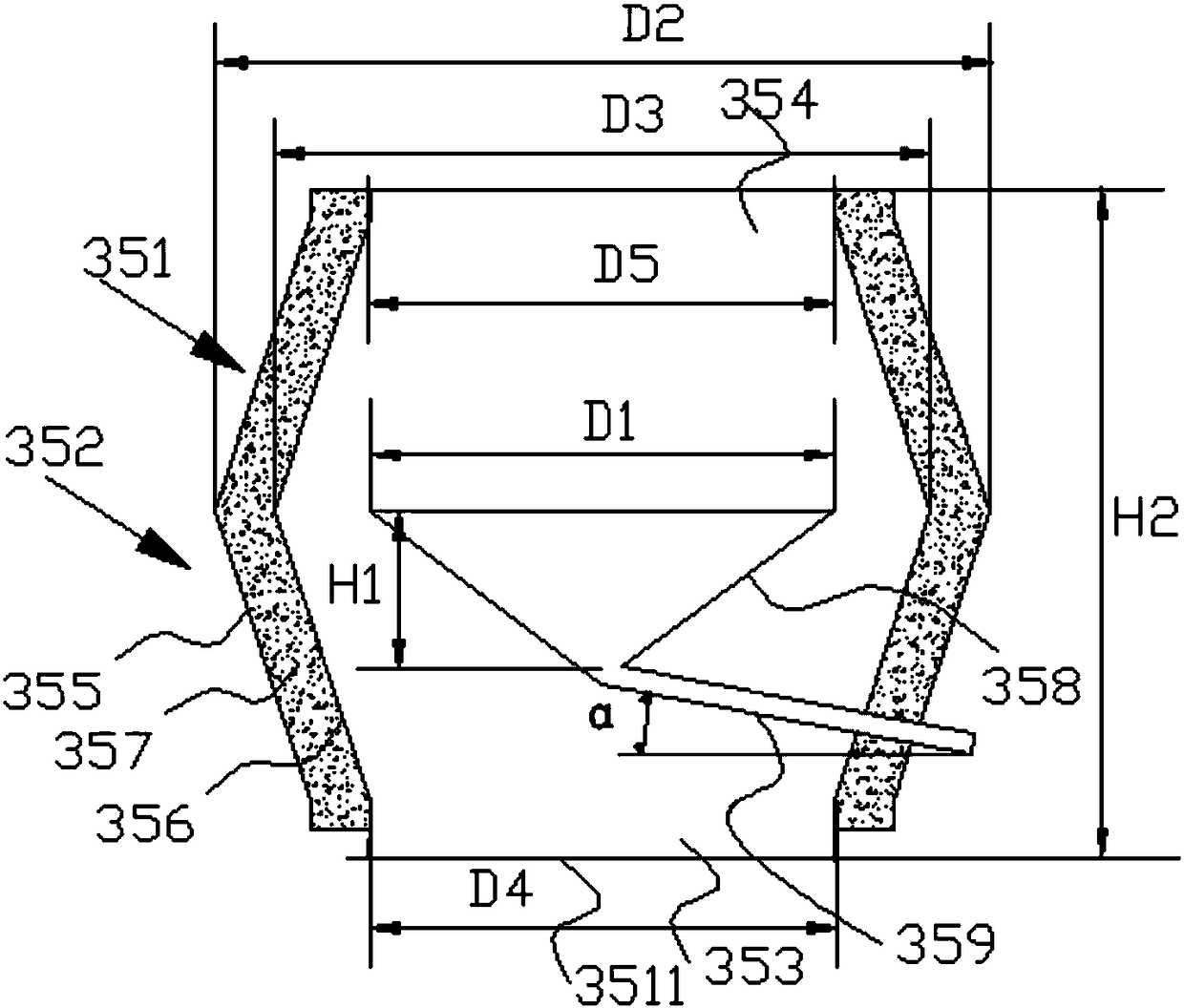

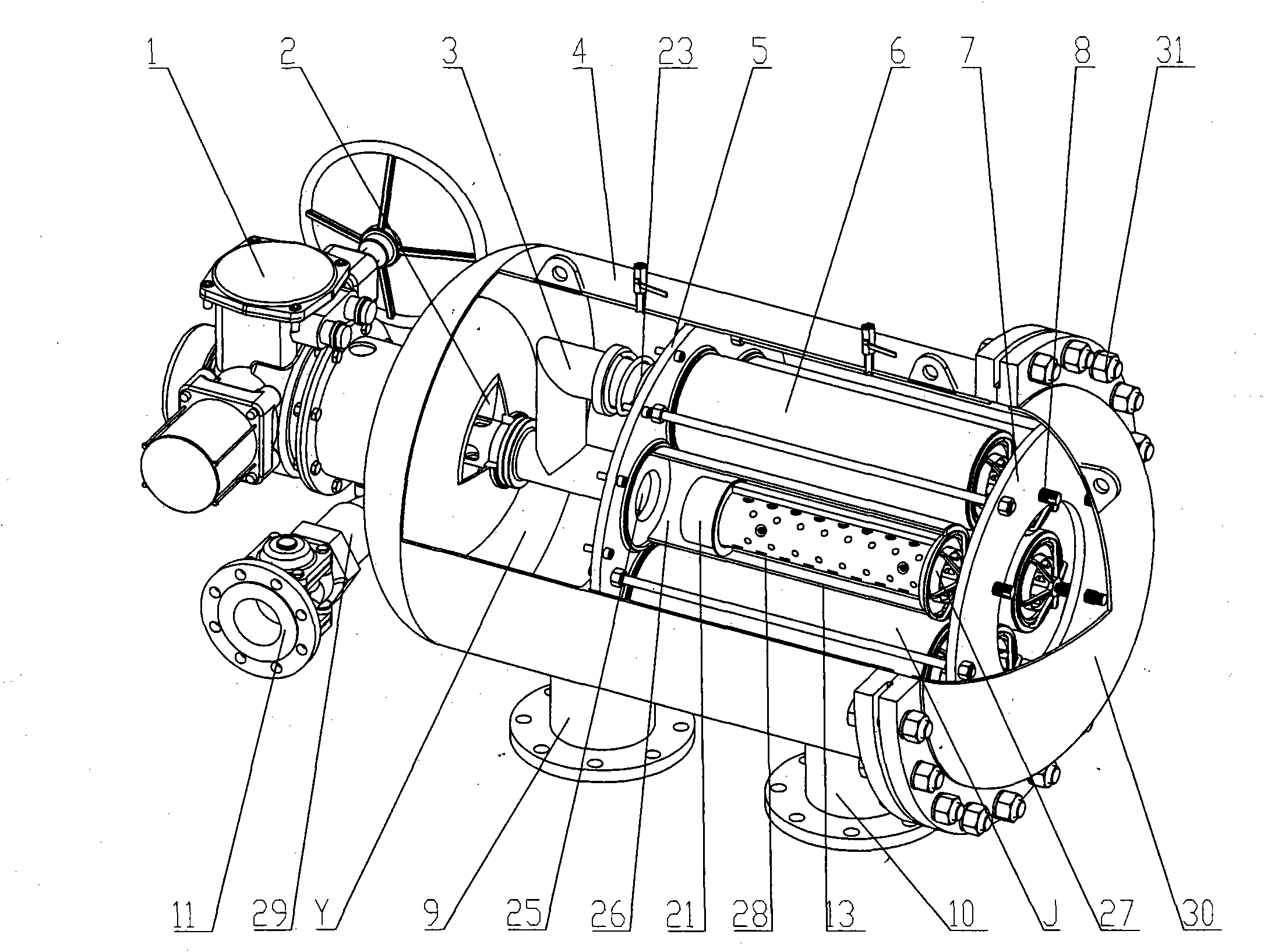

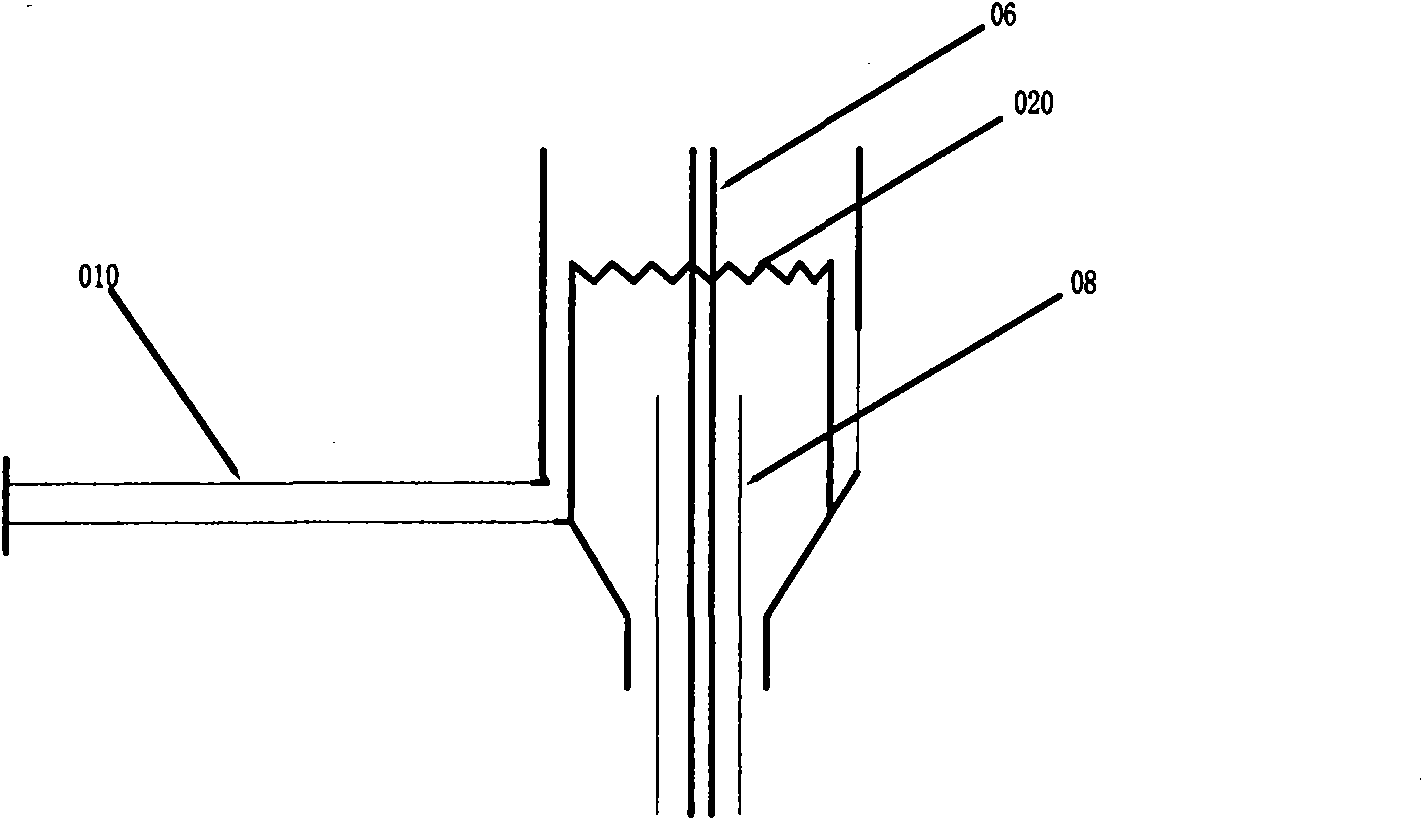

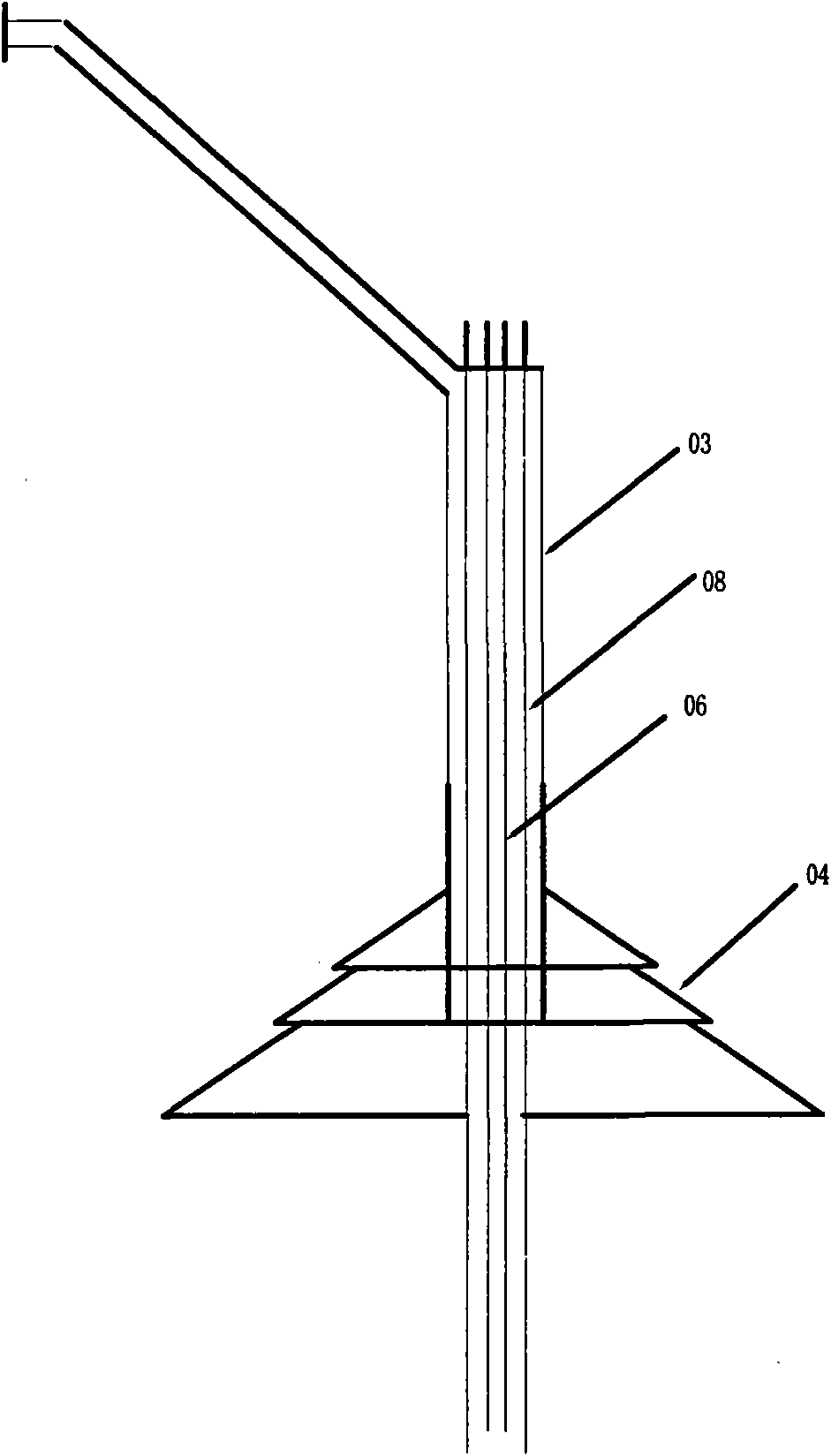

Soot blower

The invention discloses a soot blower in order to solve the problems that the existing soot blower has higher operating failure rate, unreachable blowing area and poor blowing effect. The transmission system of the soot blower of the invention comprises a motor, a reducer and a chain transmission device, wherein the reducer is particularly a cycloidal pin-wheel reducer. The soot blower is provided with an internal soot blower and an external soot blower, and an internal soot blower nozzle and an external soot blower nozzle are arranged on the internal soot blower and the external soot blower respectively; the inclined section of the internal soot blower nozzle is arranged in a way that the inclined section thereof is inclined relative to the axis of the soot blower; an air inlet is formed on the inlet section of the external soot blower; the air inlet system of the soot blower is provided with an air inlet tube, and a second air inlet chamber arranged in the middle of the air inlet tube is communicated with the air inlet and a second air inlet pipe; a first air inlet chamber is arranged at the end part of the inlet section of the internal soot blower and communicated with the end part of the inlet section of the internal soot blower and the first air inlet pipe; a first electromagnetic valve is arranged on the first air inlet pipe; and a second electromagnetic valve is arranged on the second air inlet pipe. The invention is mainly applicable to tubular heating furnaces in the field of petroleum refining and petroleum chemical engineering.

Owner:CHINA PETROCHEMICAL CORP +1

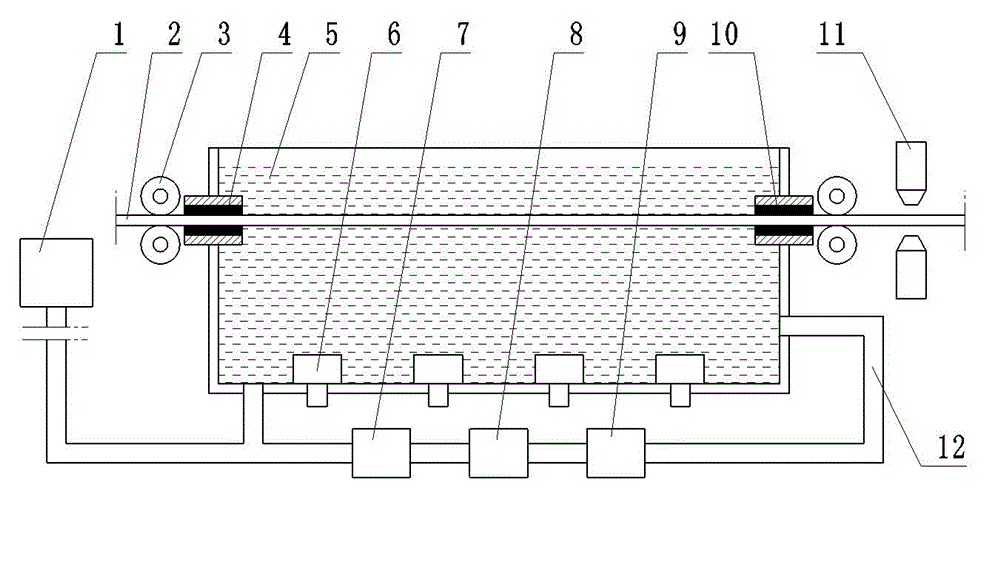

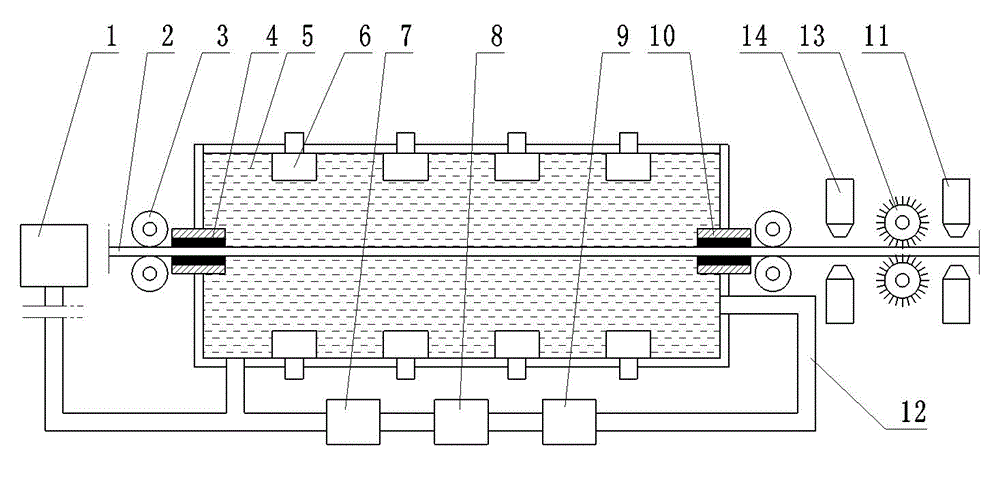

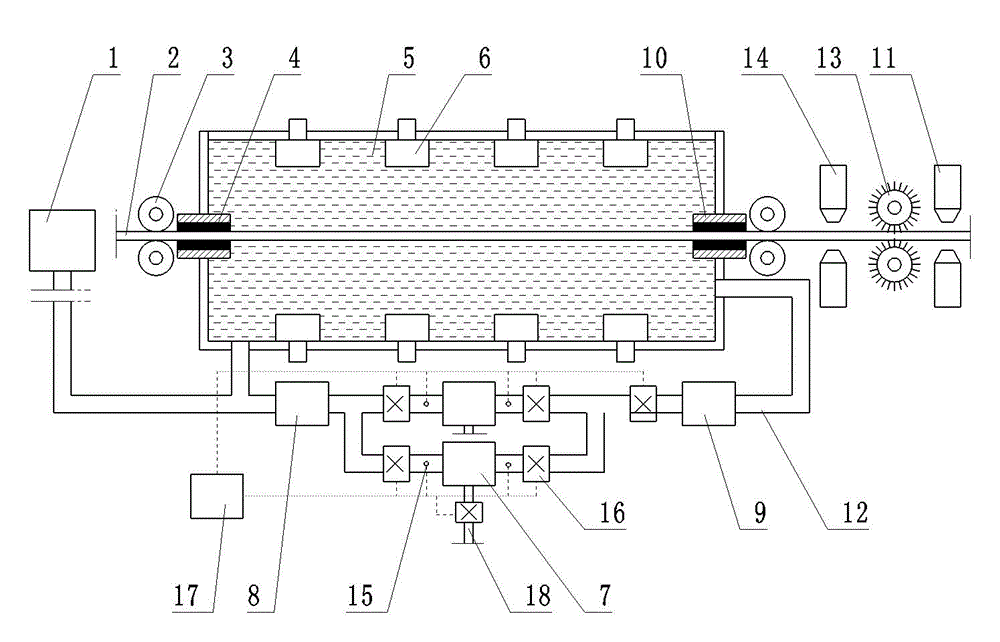

Steel band cleaning device

InactiveCN102719842AEfficient removalImprove removal efficiencyCleaning using liquidsMetal stripsFailure rate

The invention discloses a cleaning device, in particular a special cleaning device for steel bands or metal strips, which comprises a cleaning water tank (5), a steel band conveying mechanism (3), a circulating water pipeline (12), a circulating water filter (7), a circulating water pump (8) and a heater (9), wherein the cleaning water tank (5) is provided with a steel band inlet (4) and a steel band outlet (10). The cleaning device is characterized in that an ultrasonic generator (6) is arranged in the cleaning water tank (5). Compared with the prior art, the cleaning device can effectively remove pollutants on the surfaces of the steel bands or metal strips, and is high in cleaning efficiency and low in equipment service failure rate.

Owner:新疆登煌管业有限公司

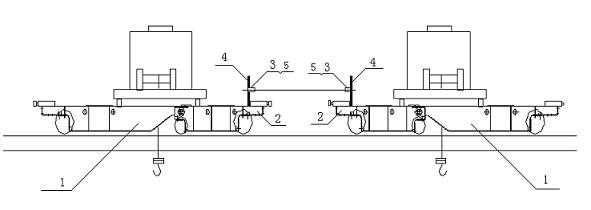

Anti-collision alignment method for aluminum electrolytic multifunctional crane

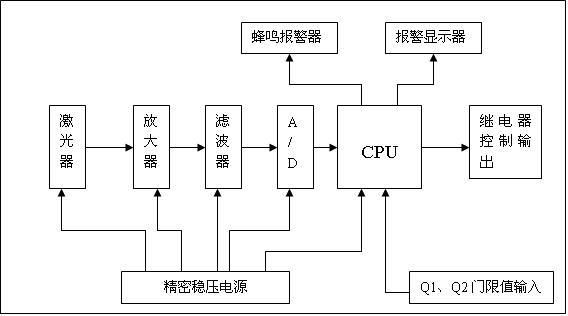

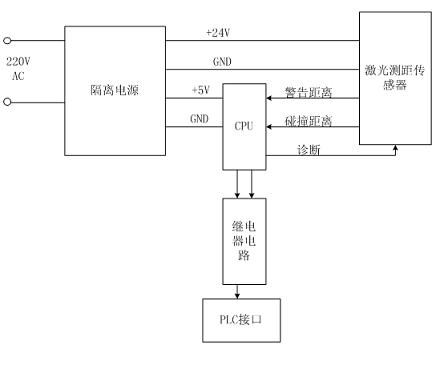

The invention relates to the technical field of aluminum electrolysis, and concretely relates to an anticollision counterpoint method of multifunctional crown blocks for aluminum electrolysis. In the invention, a laser emitter, a laser receiver, and an arithmetic control unit CPU are arranged on an end carriage at one side of a crossbeam of each multifunctional crown block; two reflecting plates are arranged on two end carriages of the adjacent multifunctional crown blocks, and the two end carriages are opposite to each other; the laser emitter, the laser receiver, and a controller are fixed by a fixed carriage and a locking spring washer; the reflecting plates are fixed by a support frame; a precise power supply which comprises three-terminal voltage regulator tubes 7805 and 7815, a capacitor and a resistor provides power for the laser emitter, the laser receiver and the controller; and detection waves emitted by the laser emitter are reflected to a low frequency amplifier 9014 triode the laser receiver by the reflecting plate to preamplify, are subjected to signal amplification and double bridge filtering processing, are input to the CPU for operation, and are sent to the controller to execute alarm or control the crown blocks to stop. The application of the method of the invention can avoid the damage of crown block parts caused by the bump generated by the opposite motion of the multifunctional crown blocks, so the operation failure rate of the crown blocks is reduced. The method of the invention is suitable for the counterpoint control of the opposite motion of the multifunctional crown blocks for aluminum electrolysis.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

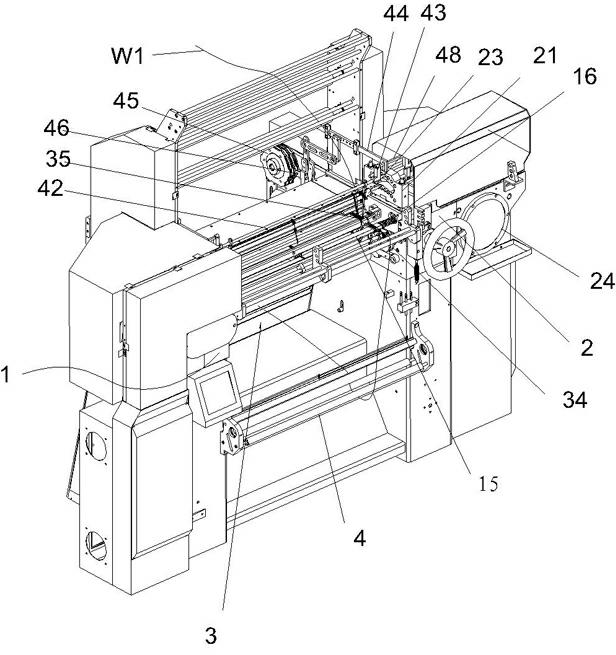

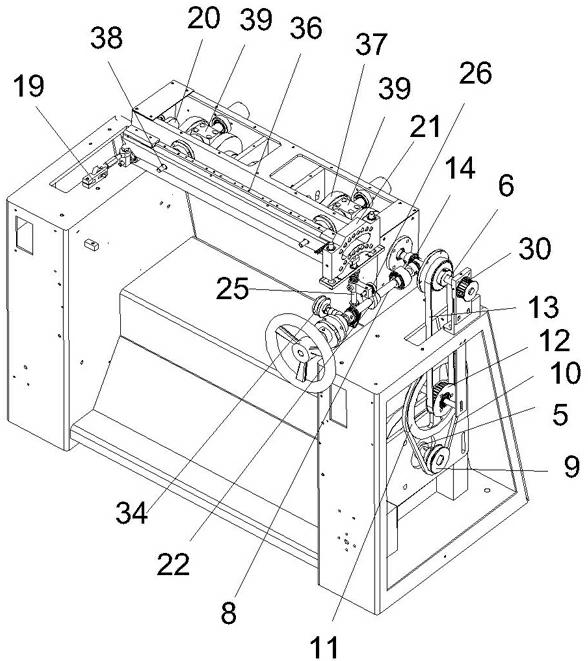

Multifunctional lace crochet machine

ActiveCN102154780ACollaborate closely with each otherSmooth power transmissionCrochetingSprocketEngineering

The invention mainly discloses a multifunctional lace crochet machine which comprises a power transmission device, a warp yarn mechanism, a weft yarn mechanism, a needle withdrawing mechanism, a needle blocking mechanism and a crossing mechanism. The needle blocking mechanism comprises a swing shaft, a blocking needle, a blocking needle drive arm and a needle blocking cam; one end of the needle blocking drive arm leans against the needle blocking cam driven by the power transmission device, and the other end of the needle blocking drive arm is fixedly connected with the swing shaft which rotates with the swing shaft of the needle blocking drive arm; and the swing shaft is fixedly connected with the blocking need which turns over inwards and outwards at the outer side of a needle bed with the swing shaft. The crossing mechanism comprises a weft yarn shaft, a swing arm, a shift fork and a floret chain transmission device, wherein the weft yarn shaft is mounted on the weft yarn mechanismand fixed with a weft yarn tube; the swing arm is fixedly sleeved on the weft yarn shaft; the shift form shifts the swing arm to swing; the floret chain transmission device supplies power to the shift fork; and a floret chainwheel in the floret chain transmission device is driven by the power transmission device. The multifunctional lace crochet machine disclosed by the invention is suitable for crocheting various flower forms, remarkably shortens the knitting time and has high production efficiency.

Owner:SHAOXING SANFANG MACHINERY

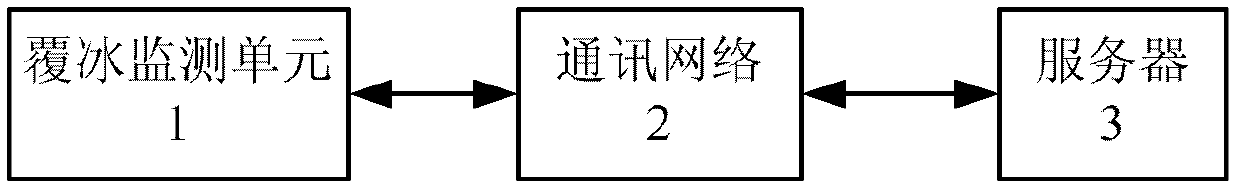

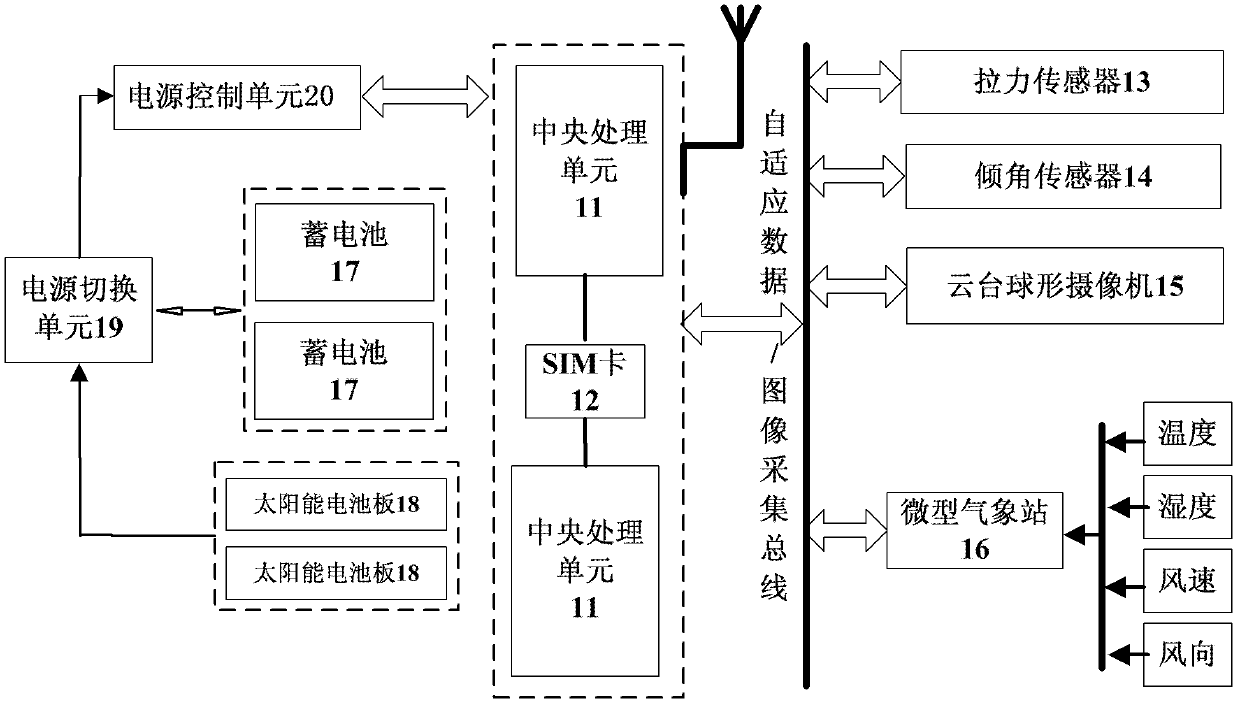

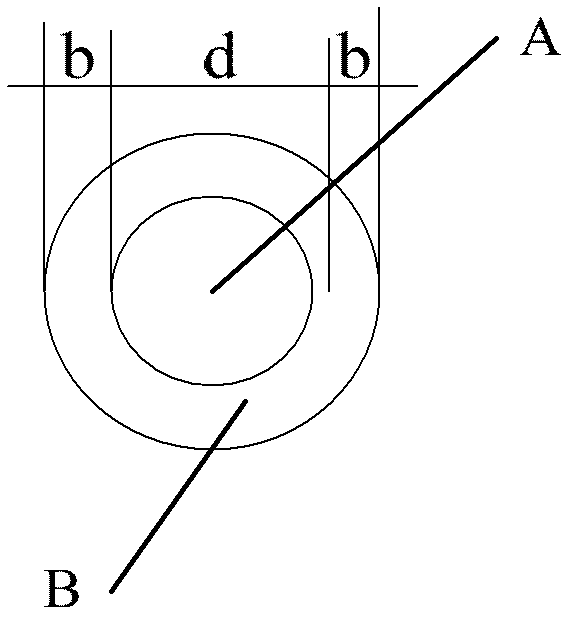

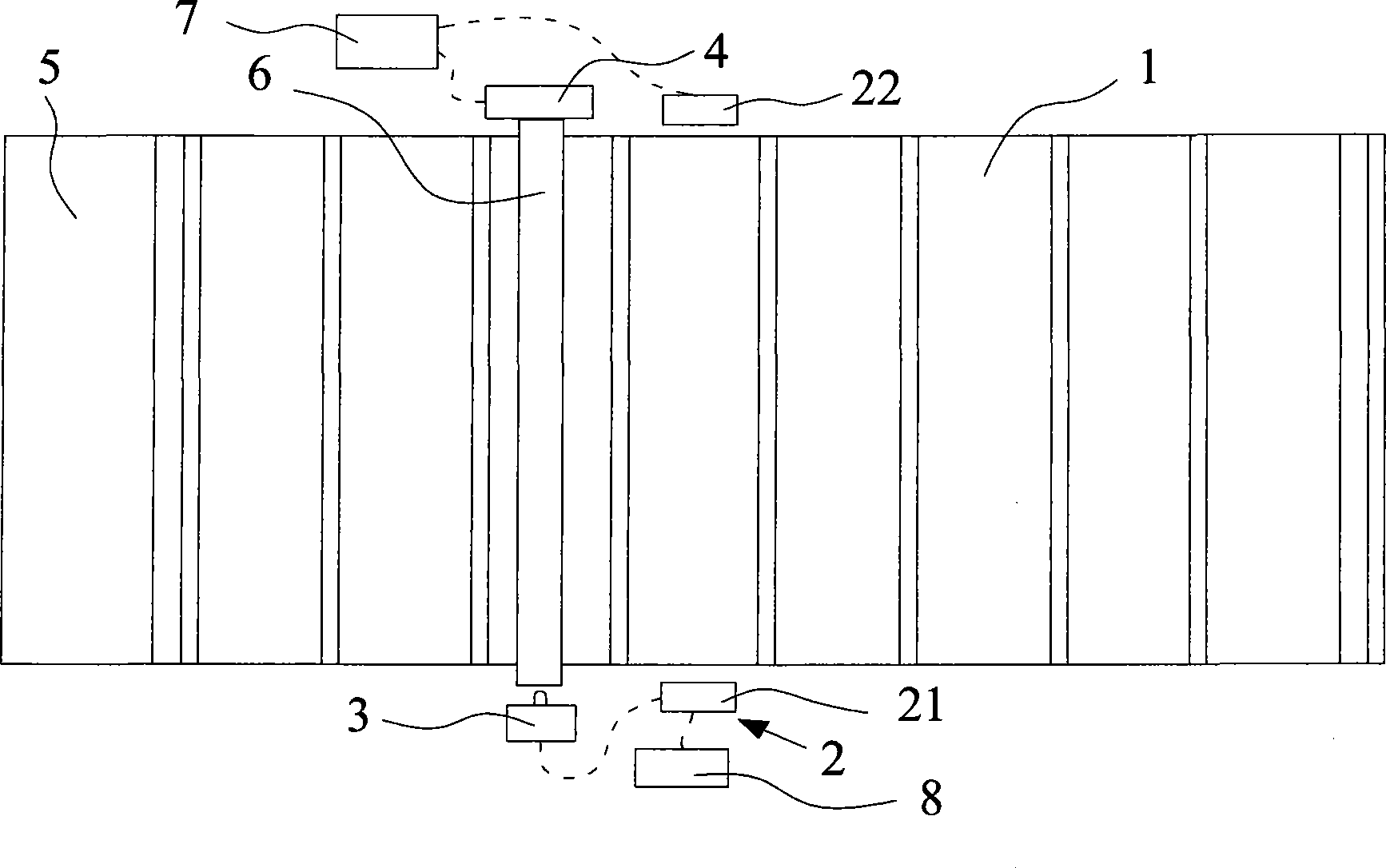

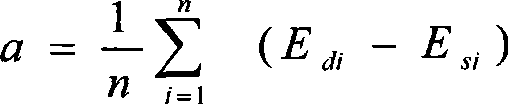

Power transmission line icing intelligent on-line monitoring system

InactiveCN103376083ALow operating failure rateHighly integratedMeasurement devicesMathematical modelMonitoring system

The invention relates to a power transmission line icing intelligent on-line monitoring system which comprises an icing monitoring unit, a communication network and a server. The icing monitoring unit is connected with the server through the communication network and collects state information of a power transmission line, icing thickness information is figured out through an icing thickness mathematical model, the state information and the icing thickness information are transmitted to the server through the communication network in real time, and icing thickness changing trend information of the power transmission line is calculated through the server according to the state information and the icing thickness information. If the icing thickness exceeds a setting threshold value, an alarm is timely given, so real-time monitoring for the power transmission line is achieved. Compared with the prior art, the power transmission line icing intelligent on-line monitoring system has the advantages of being high in integration and reliability and low in power consumption.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

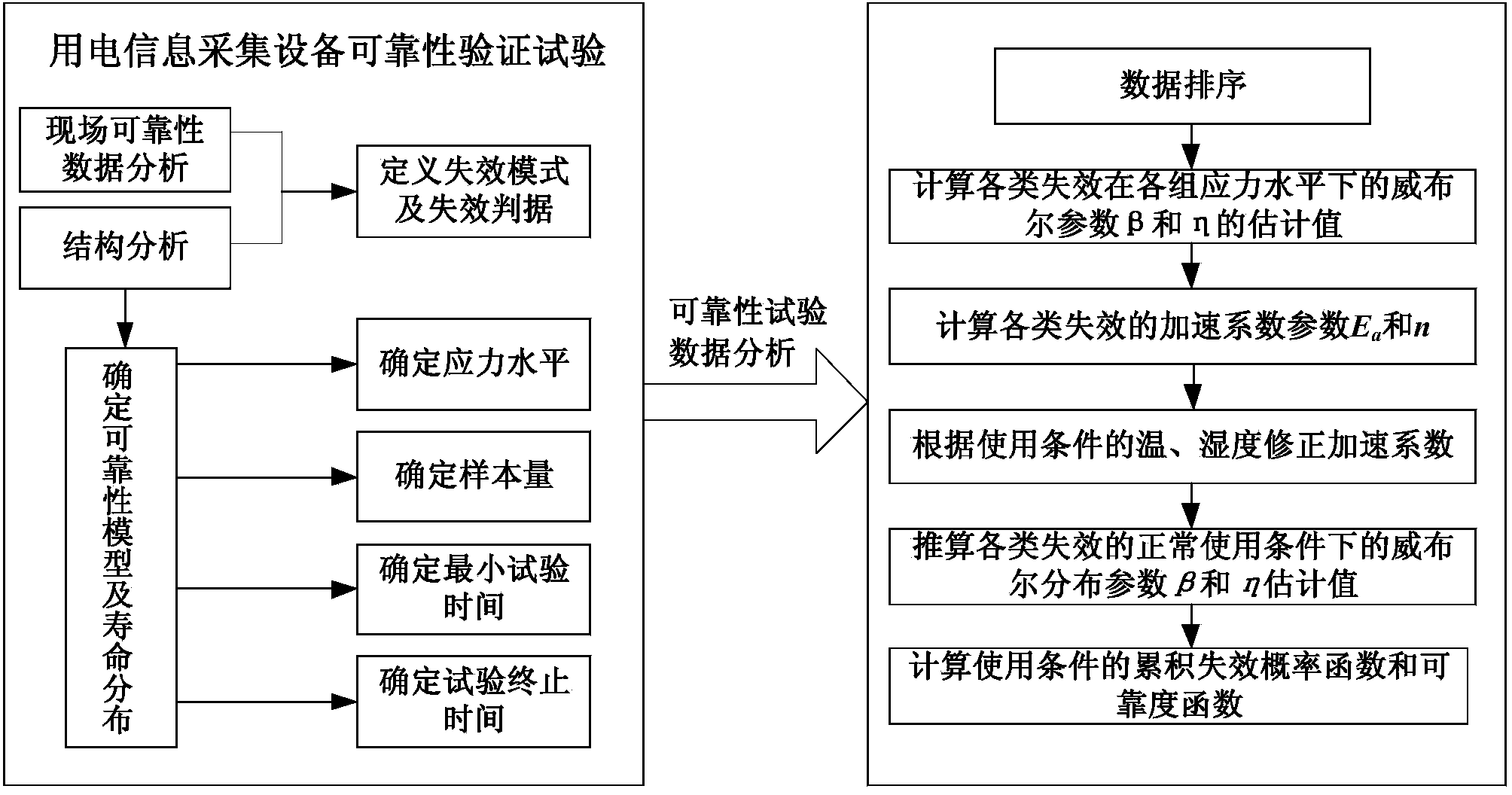

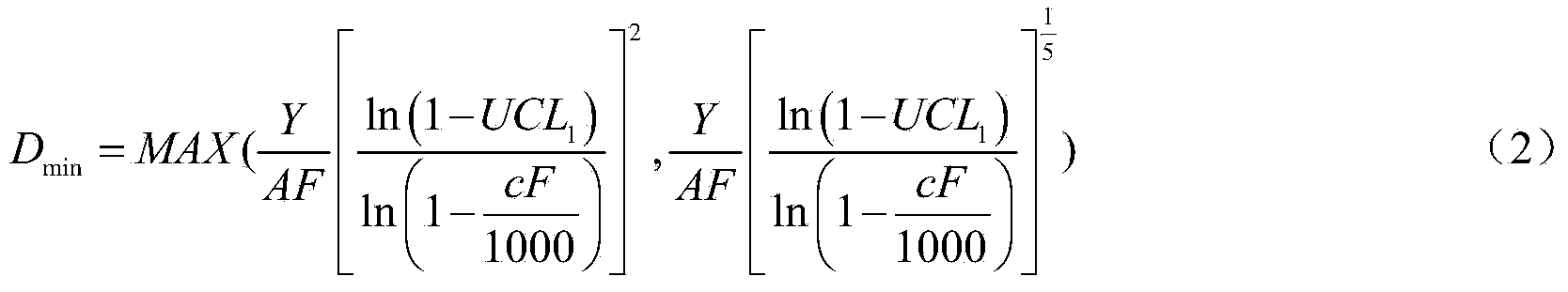

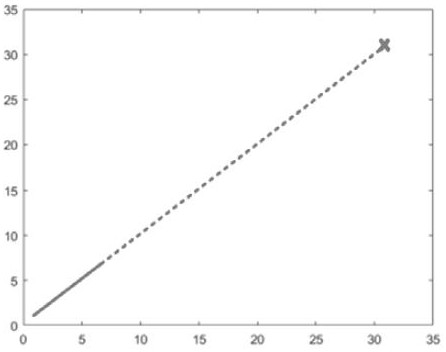

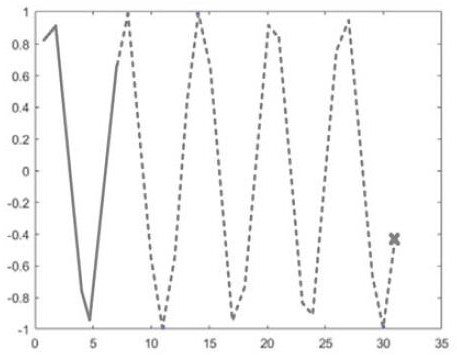

Testing method for verifying reliability of electricity utilization information collecting device

ActiveCN104076224AVerify reliabilityObtain full cycle life curveElectrical testingElectricityConstant stress

Owner:CHINA ELECTRIC POWER RES INST +2

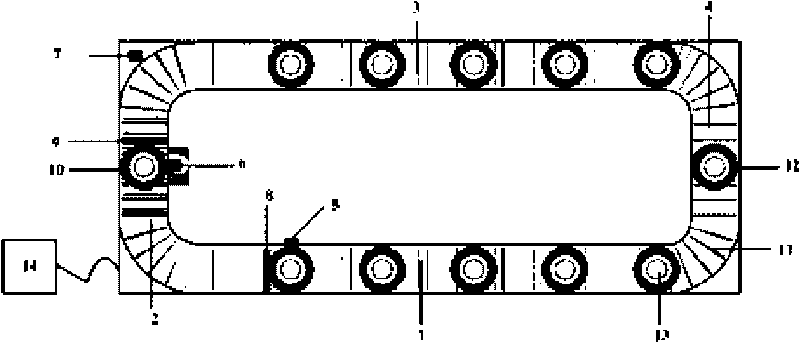

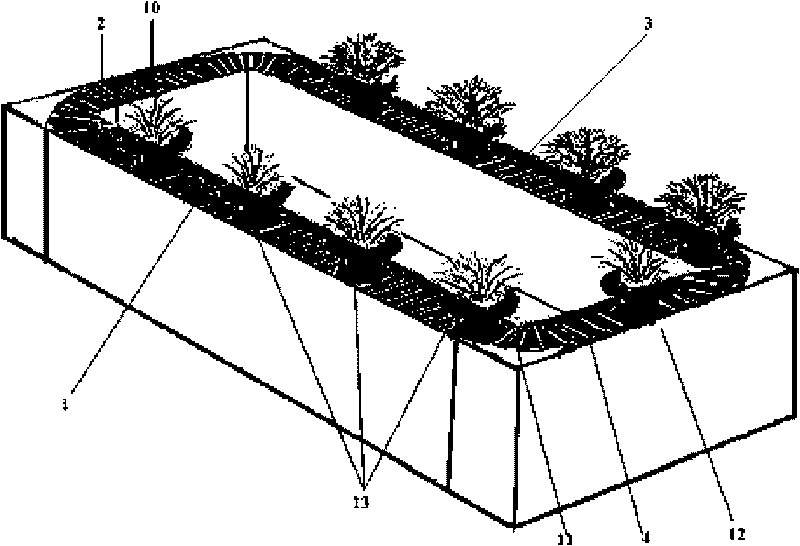

Automatic conveyor line for potted plant parameter measurement

InactiveCN101712409AImprove measurement efficiencyReduce labor intensityControl devices for conveyorsMechanical conveyorsClosed loopWork flow

The invention relates to an automatic conveyor line for potted plant parameter measurement, which comprises a closed-loop transmission structure consisting of a first conveyor line, a second conveyor line, a third conveyor line and a fourth conveyor line in sequence, wherein the first conveyor line is provided with a first photoelectric switch and a first lifting board; the second conveyor line is provided with a second photoelectric switch and a second lifting board; a cart carrying potted plants is arranged on the fourth conveyor line to be conveyed; signal wires of the first photoelectric switch and the second photoelectric switch are connected with a controller; and the controller is also connected with the four conveyor lines, the first lifting board and the second lifting board respectively and controls the four conveyor lines to start and stop, and the first lifting board and the second lifting board to lift by setting working process. When the automatic conveyor line is used in the potted plant parameter measurement, potted plant parameter measurement efficiency is improved greatly, and labor intensity of workers carrying the potted plants is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

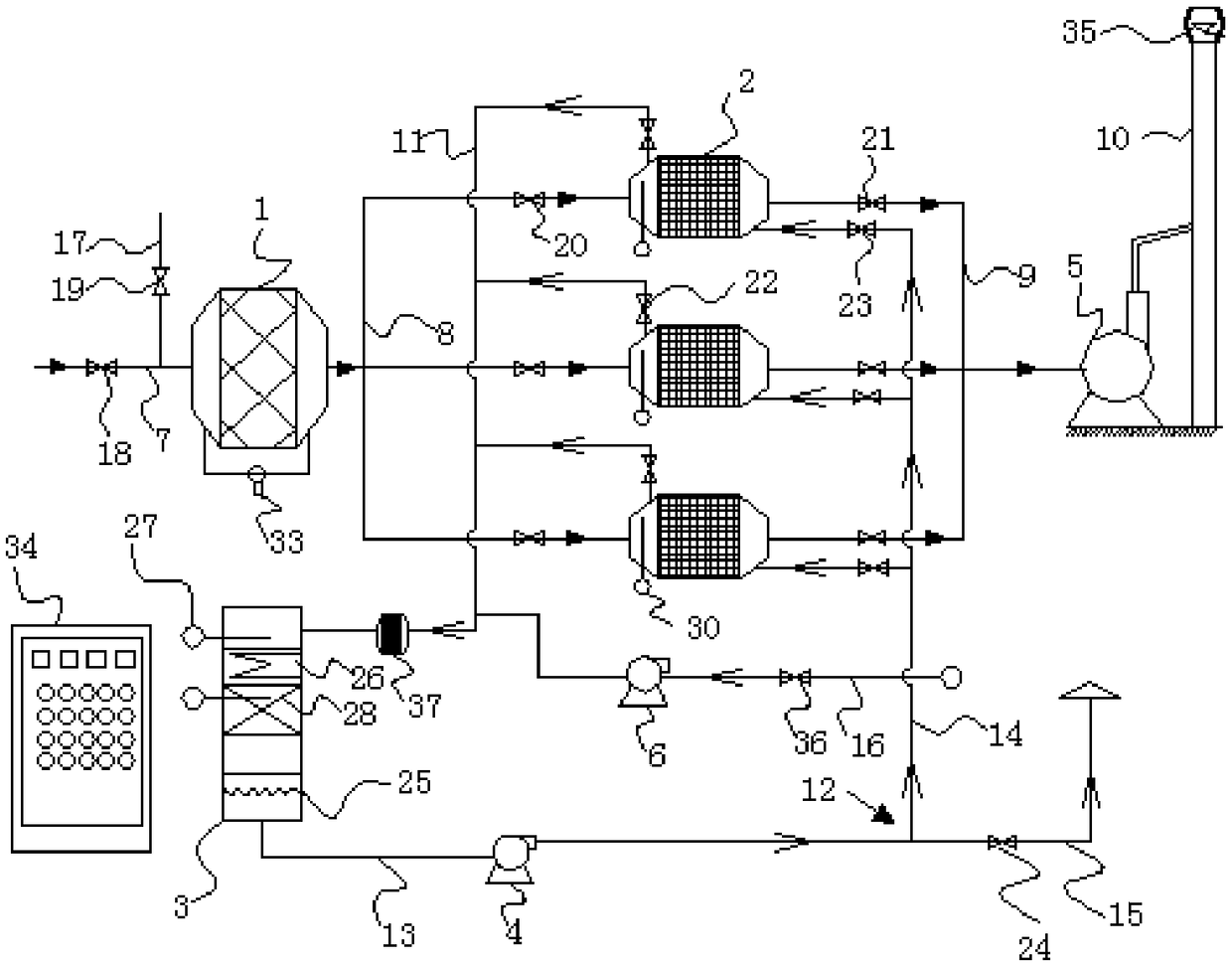

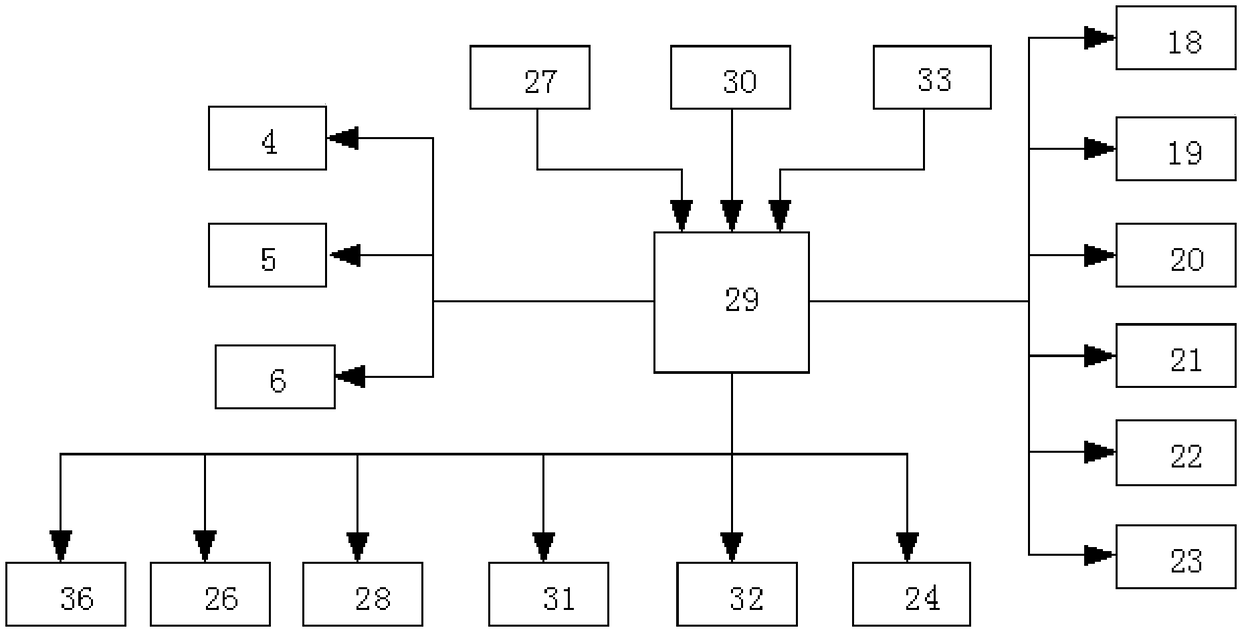

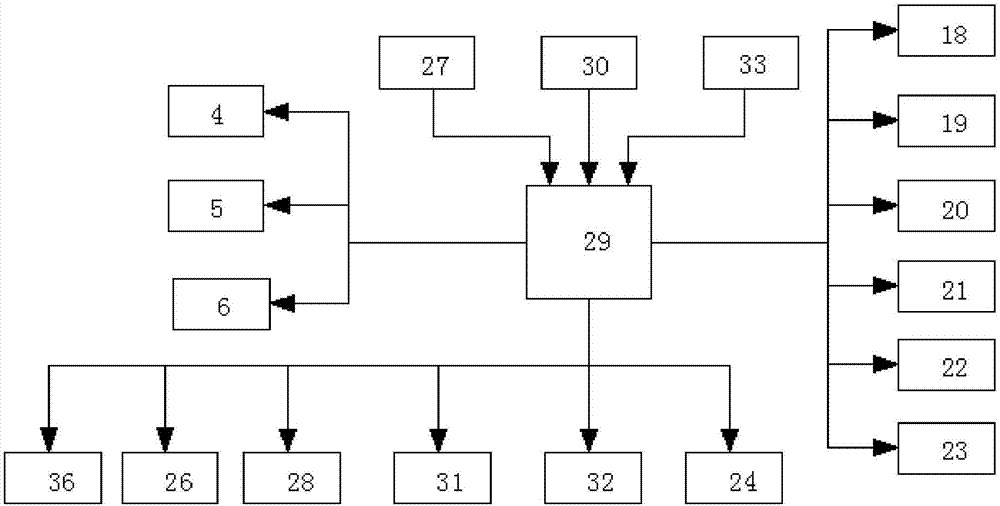

Coating chamber organic waste gas catalytic combustion treatment system

InactiveCN108176223AImprove purification efficiencyGood processing effectGas treatmentDispersed particle filtrationChemistryZero emission

The invention discloses a coating chamber organic waste gas catalytic combustion treatment system, which comprises a dry filter, adsorption desorption boxes, a catalytic combustion device, an adsorption fan, a desorption fan and an air supplement fan, and the number of the adsorption desorption boxes is three. The catalytic combustion device is provided with a preheating chamber, a catalytic bed,a heat exchanger and a first thermocouple, and also includes a PLC control system. The PLC control system includes a PLC controller, a first thermocouple and a first over temperature alarm which are installed in the adsorption desorption box, a second over temperature alarm installed on the catalytic combustion device, and a differential pressure gauge arranged on the dry filter. The coating chamber organic waste gas catalytic combustion treatment system solves the problem that paint spraying exhaust gas is easy to block and the exhaust gas cannot stably reach standards, and the system has high automation and intelligence, the treatment effect on the exhaust gas is good, the purification efficiency is greater than 98%, the noise is lower than 30 dB, meets and exceeds the national emissionstandard; and the coating chamber organic waste gas catalytic combustion treatment system can be used for on-line catalytic combustion treatment of the exhaust gas and can achieve zero emissions of the exhaust gas.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

Anoxic/oxic-membrane bioreactor water treatment device and sewage treatment method thereof

ActiveCN102120680ARealize remote controlEasy to operate and manageTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeWater quality

An anoxic / oxic-membrane bioreactor (A / O-MBR) water treatment device and a sewage treatment method thereof belong to the water treatment field. The invention aims to solve the technical problems of the A / O technology that the sludge treatment cost is high and the floor area is large. In the device of the invention, a water outlet on the lower part of an anaerobic tank is communicated with a water inlet on the lower part of an aerobic tank, and a membrane component is arranged in the aerobic tank. After the device of the invention is started, denitrification treatment is performed in the anaerobic tank, the microorganisms in the anaerobic tank are used to decompose and convert the organic matter, the membrane component is used to treat and then ultraviolet sterilization is performed. The water quality of the effluent meets the level-one A standard. The method combines the A / O technology with the MBR technology and utilizes membrane separation to leave activated sludge in the system, thus greatly saving the sludge treatment cost.

Owner:LONG JIANG ENVIRONMENT PROTECTION GROUP SHARE

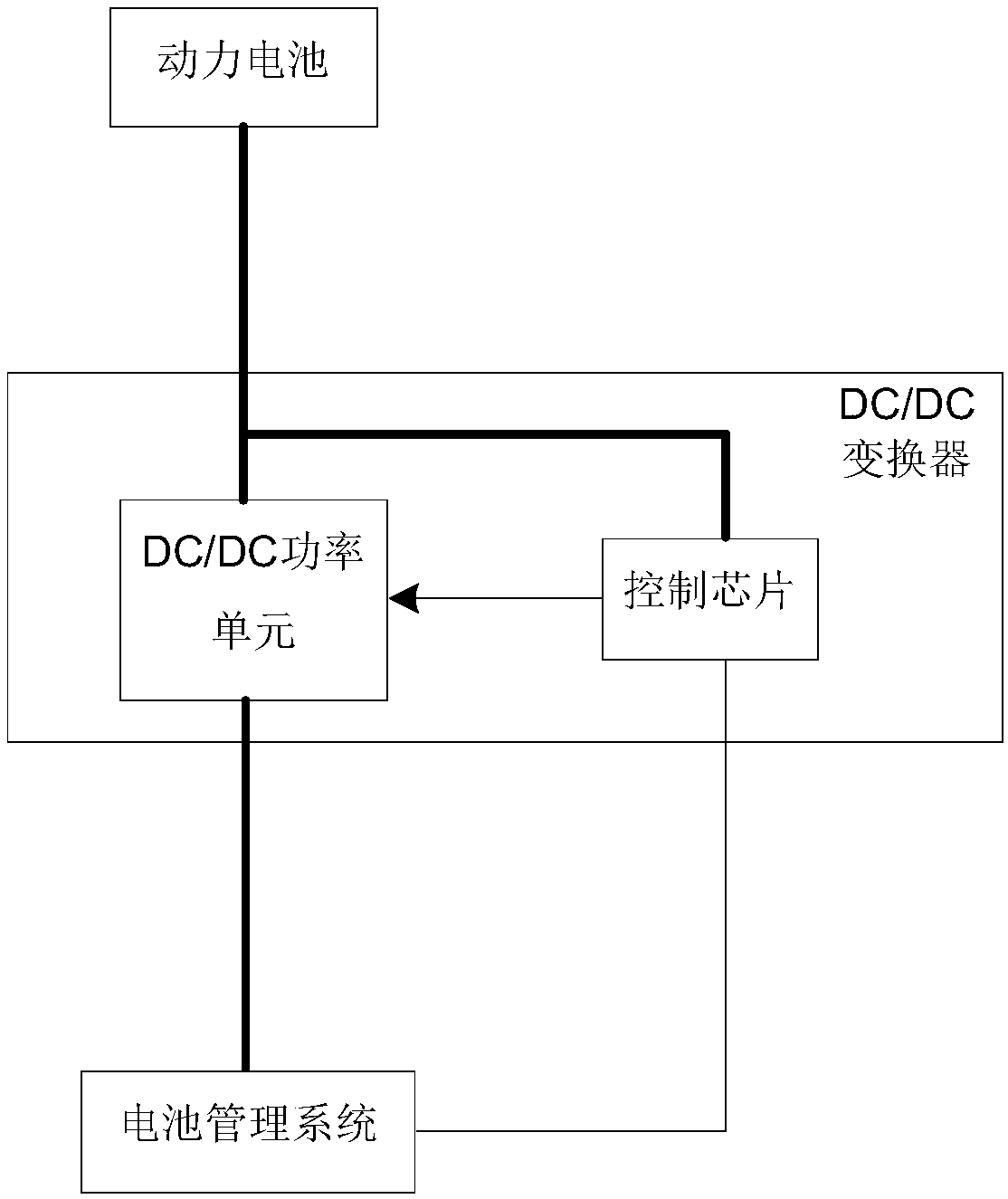

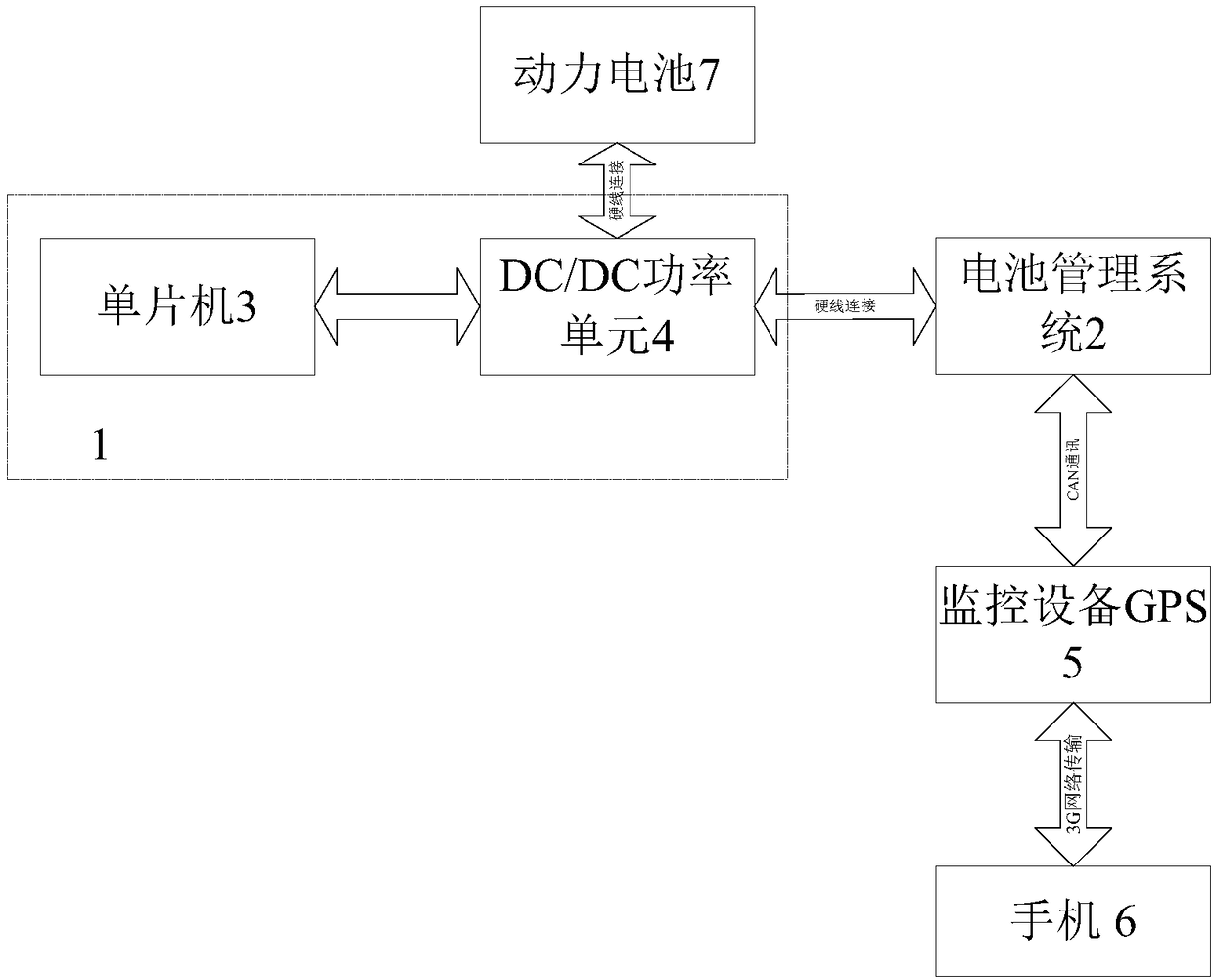

Battery management system wake-up system and DC/DC converter

PendingCN108964162AReduce hardware and software costsSimple structureBatteries circuit arrangementsElectric powerPower batteryEngineering

The invention relates to a battery management system wake-up system and a DC / DC converter. Except for a power unit, the DC / DC converter also includes a control module which is connected to a battery management system and controls and connects the DC / DC power unit. When the battery management system needs to be woken up, the control module controls the DC / DC power unit to be turned on, so that a power battery can supply power to the battery management system. Otherwise, the control module controls the DC / DC power unit to be disconnected, and then the power battery does not supply power to the battery management system. The battery management system wake-up system can reduce the software and hardware cost of the battery management system and can improve the operational reliability of the battery management system. Besides, the DC / DC power unit does not need to work for a long time, so that the service life of the DC / DC power unit is prolonged, and as a power line between the DC / DC powerunit and the battery management system is no longer charged for a long time, the potential safety hazard for the whole vehicle can be reduced.

Owner:ZHENGZHOU YUTONG BUS CO LTD

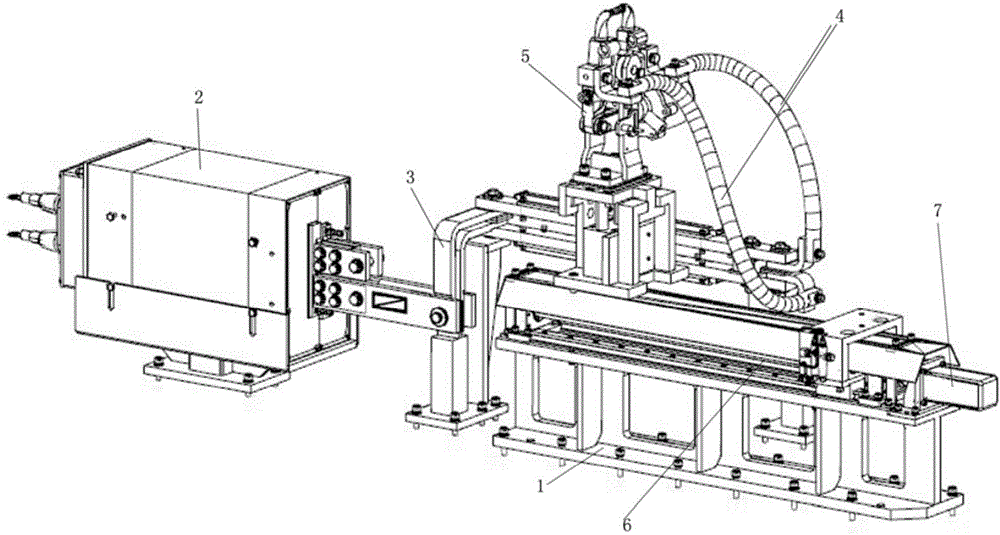

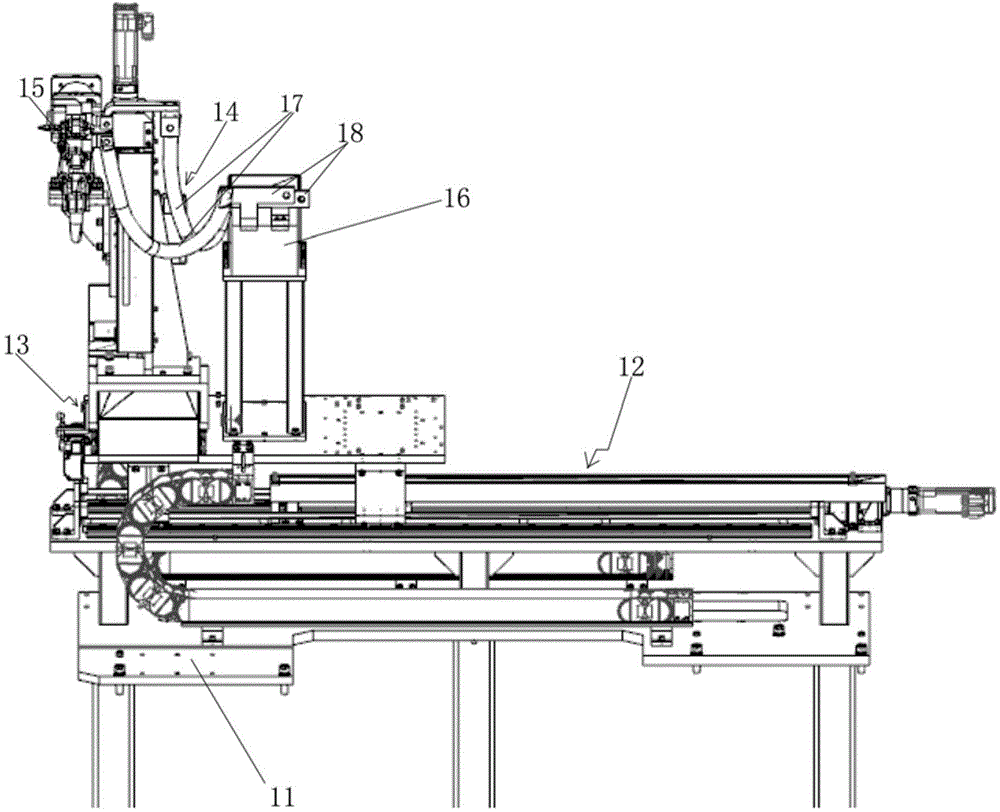

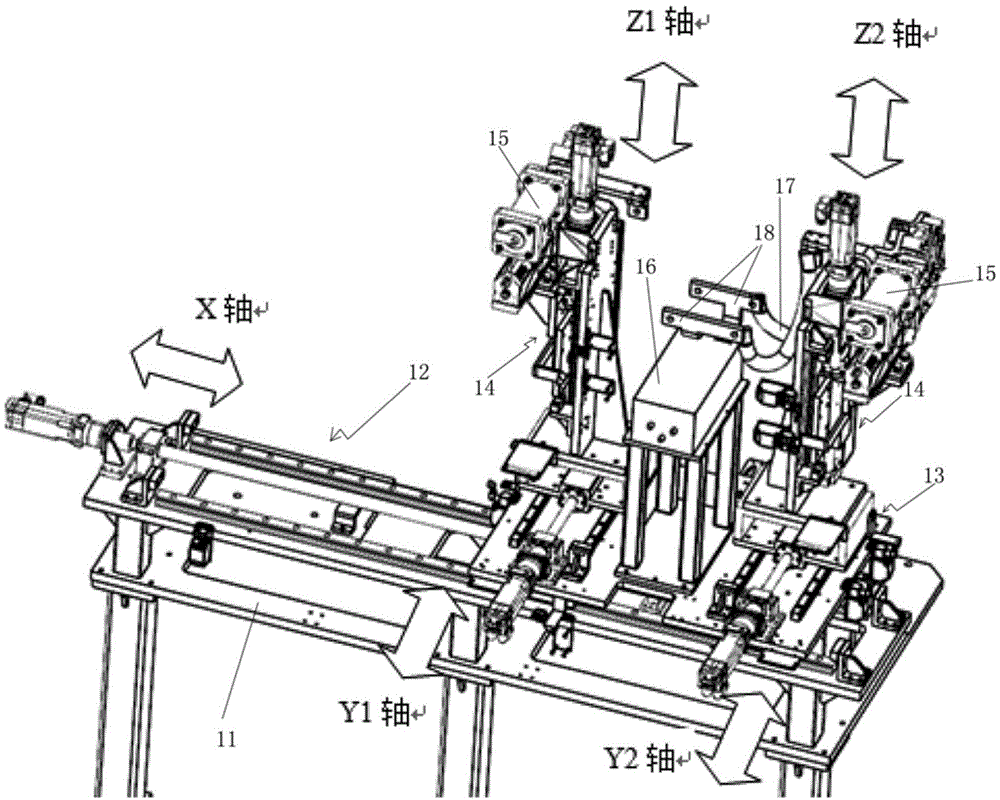

Multi-axis automatic welding device

ActiveCN105798501AReduce swingReduce distanceWelding/cutting auxillary devicesAuxillary welding devicesFailure ratePower flow

The invention discloses a multi-axis automatic welding device which comprises a support base, a transverse transmission device, longitudinal transmission devices and vertical transmission devices. The transverse transmission device is perpendicular to the longitudinal transmission devices, and the vertical transmission devices are perpendicular to the transverse transmission device and the longitudinal transmission devices. The transverse transmission device, the longitudinal transmission devices and the vertical transmission devices are all connected with a driving device. A transformer is arranged on the transverse transmission device, each vertical transmission device is provided with soldering pliers, and the soldering pliers are connected with the transformer which is located between the longitudinal transmission devices. The vertical transmission devices are connected with the corresponding longitudinal transmission devices in a sliding mode, and the longitudinal transmission devices are connected with the transverse transmission device in a sliding mode. The multi-axis automatic welding device is simple in structure, the positions of the soldering pliers can be changed left and right in the transverse direction, changed front and back in the longitudinal direction and changed up and down in the vertical direction, the multi-axis automatic welding device is more flexible to use, the layout is optimized, current loss is small, energy is saved, the welding spot quality is effectively improved, the operation failure rate is low, the service lives of the soldering pliers and the transformer can be effectively prolonged, and welding efficiency is high.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

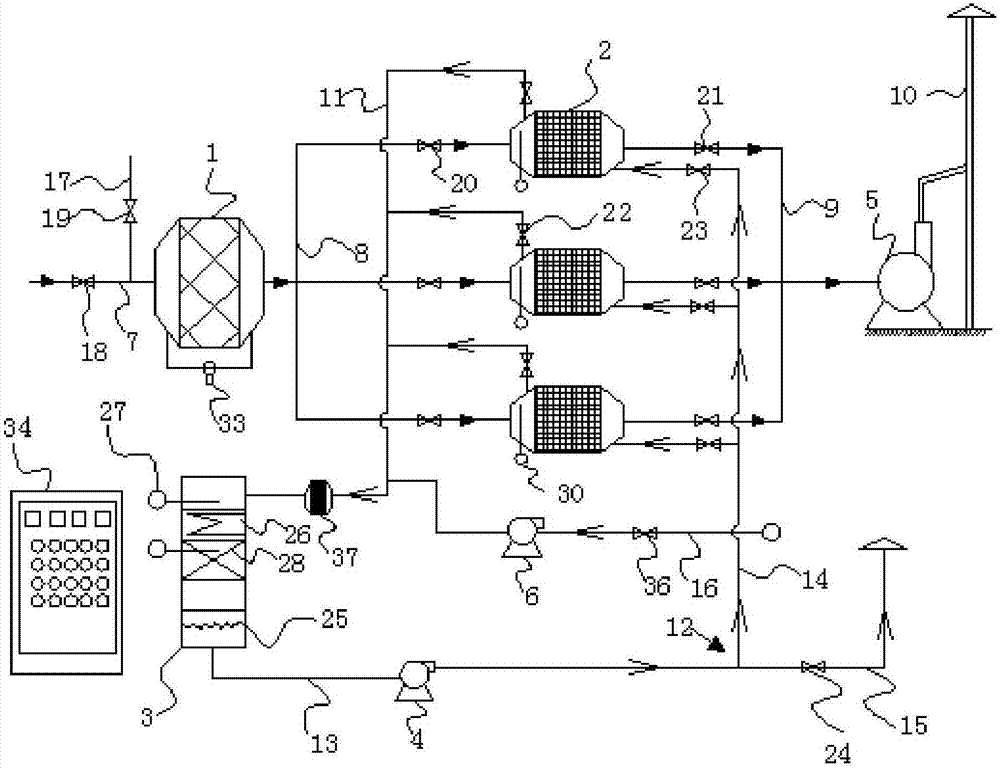

Spray booth organic waste gas treatment system

InactiveCN107998763AImprove purification efficiencyCatalytic combustion is sufficientGas treatmentDispersed particle filtrationZero emissionTreatment system

The invention discloses a spray booth organic waste gas treatment system. The spray booth organic waste gas treatment system comprises a dry-type filter, adsorption-desorption boxes, a catalytic combustion apparatus, an adsorption fan, a desorption fan and a gas supplementing fan, wherein the number of the adsorption-desorption boxes is three, the catalytic combustion apparatus is internally provided with a preheating chamber, a catalysis bed, a heat exchanger and a first thermocouple, and a heater is arranged in the preheating chamber; and the spray booth organic waste gas treatment system also comprises a PLC control system, wherein the PLC control system comprises a PLC controller, a first thermocouple and a first over-temperature alarming device which are installed in the adsorption-desorption box, a second over-temperature alarming device which is installed in the catalytic combustion apparatus and a differential pressure gauge which is arranged in the dry-type filter, and the PLCcontroller is installed in a control cabinet. The spray booth organic waste gas treatment system solves the problems that the spray waste gas is easy in blockage, and the waste gas cannot be stably up to the standard; moreover, the automation and intelligent degree of the system is high, the treatment effect for the waste gas is good, the purifying efficiency is greater than 98 percent, and the waste gas can reach and be higher than the national emission standard; and moreover, the waste gas is catalytically combusted online, so that the zero emission of the waste gas is realized.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

Organic waste gas treatment device

ActiveCN101566346AExtended service lifeSolution to short lifeIndirect heat exchangersIncinerator apparatusFailure rateCombustion chamber

An organic waste gas treatment device is characterized by comprising a preheating chamber, a combustion chamber, a heat recycling chamber and a heat pipe exchanger. The preheating chamber, the combustion chamber and the heat recycling chamber are communicated in turn. An air inlet is installed on the preheating chamber, and an air outlet is installed on the heat recycling chamber. The heat pipe exchanger comprises at least one heat pipe. The two ends of the heat pipe are respectively positioned in the preheating chamber and the heat recycling chamber. The position of the end of the heat pipe, which is positioned in the heat recycling chamber, is lower than that of the heat pipe, which is positioned in the preheating chamber. A combustor is installed on the combustion chamber. The organic waste gas treatment device of the invention not only can fully dispose the organic waste gas, but also can recycle the heat energy generated in the combustion of the organic waste gas with high efficiency. The environment protection and the energy saving are integrated. The organic waste gas treatment device of the invention further has the advantages of low operation failure rate, stable and reliable operation, compact structure, and low operating cost. The application area of the invention is wide and can be used for all production techniques with waste gas discharge. The organic waste gas treatment device of the invention has more superiority for the production techniques of printing, coating, etc. with large waste gas amount and low content of organic waste gas.

Owner:GUANGDONG JINMING MACHINERY

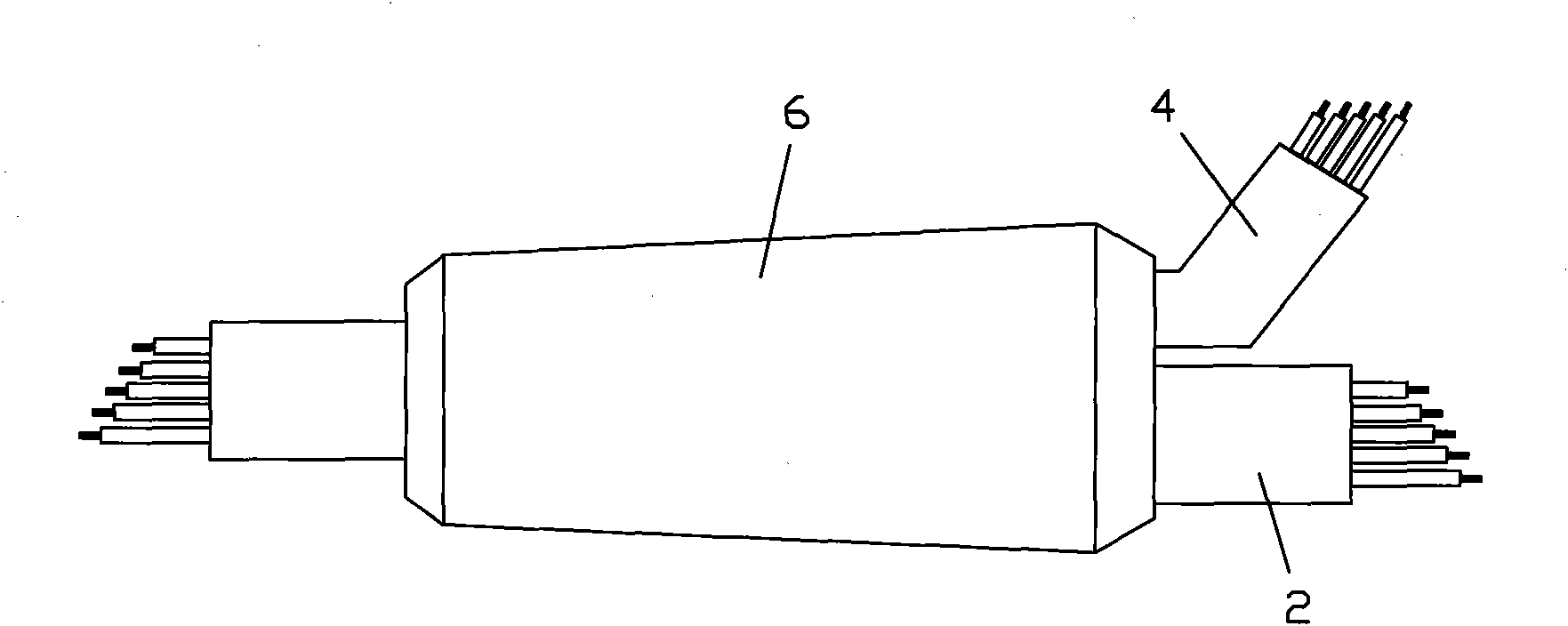

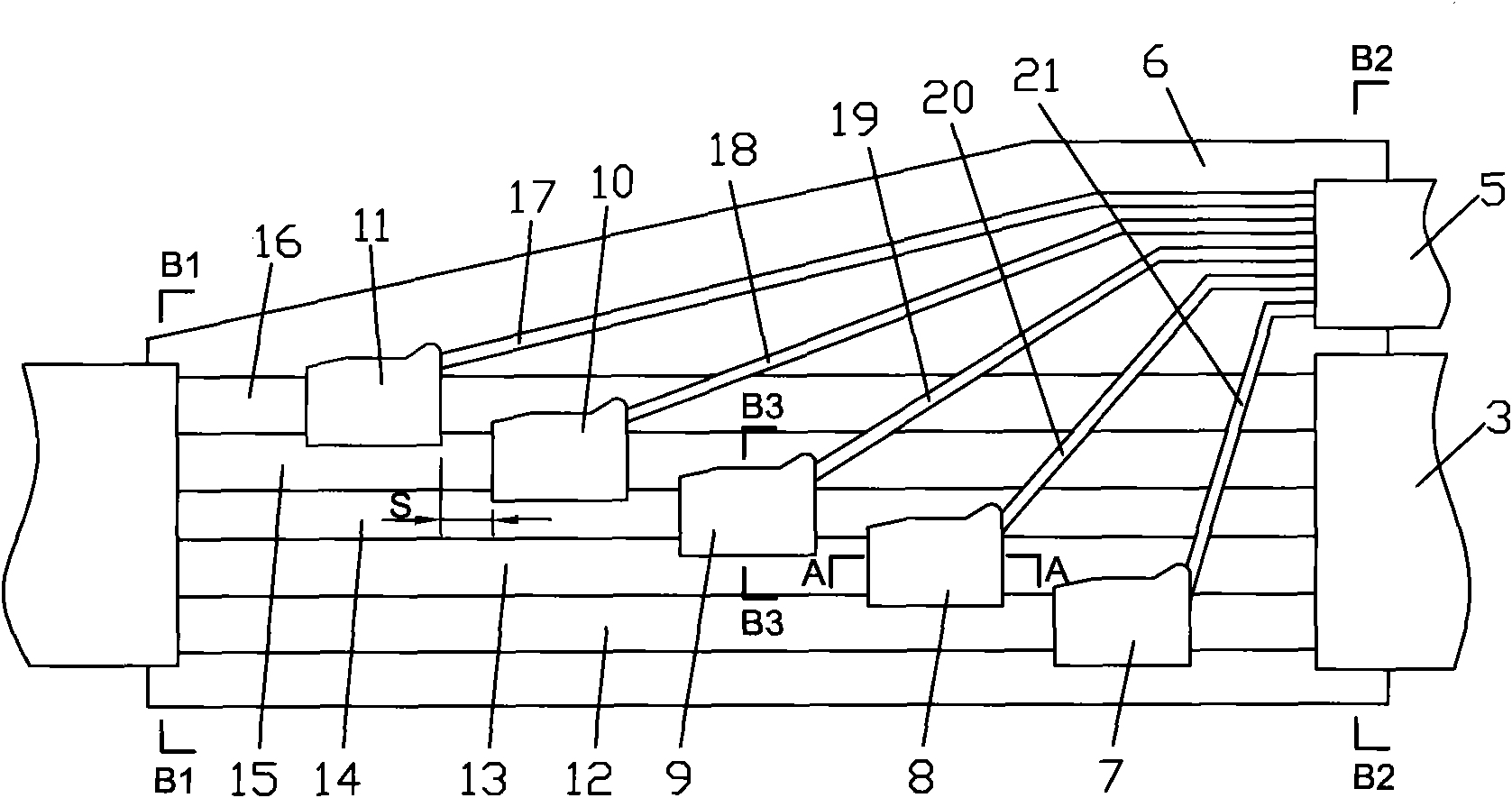

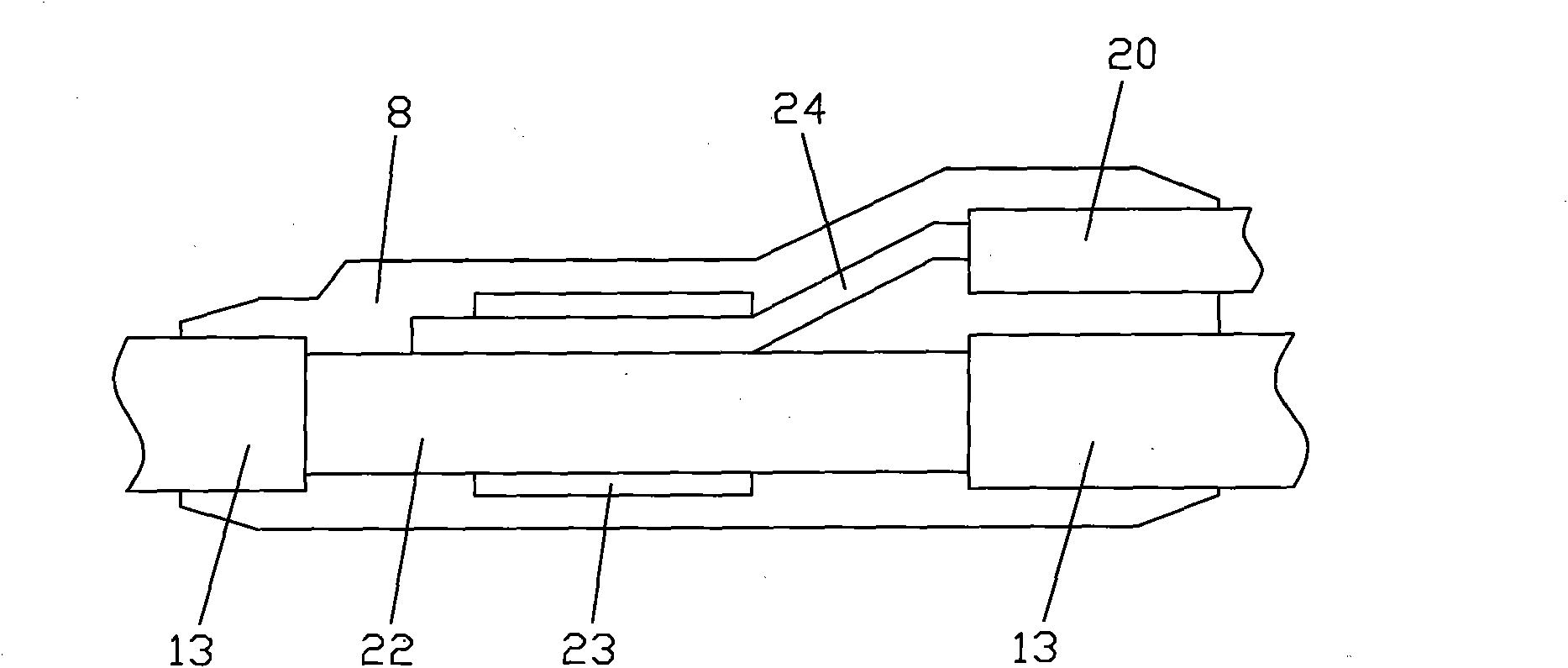

Prefabricated multi-core coaxial branch cable

InactiveCN101783200AImprove electrical characteristicsHigh dielectric strengthInsulated cablesConnections effected by permanent deformationPower cableEngineering

The invention discloses a prefabricated multi-core coaxial branch cable which comprises an overall outer layered insulating sheath, and a main cable and a branch cable arranged in the overall outer layered insulating sheath; the main cable and the branch cable are in compression joint through a connecting piece to form a branch connecting body; all phase branch connecting bodies are in respective and independent injection molding, sealed and formed; a U-shaped branch connector connecting body is adopted as the connecting piece; and enough dislocation space S is kept among the branch connecting bodies with the phases respectively and independently sealed and formed. By adopting the technical scheme, the power cable which is put into operation is greatly improved in electrical properties, insulating strength, water tightness, air tightness, reliability and consistency, so that the operation fault rate of the power cable is greatly reduced under normal circumstances, and achieves the maintenance-free and high-reliability operation status. All branches and connectors of the cable are prefabricated in a professional factory, so that the number of on-site construction equipment is reduced, the technical requirements are lower, the cost is greatly reduced, and the time is largely shortened.

Owner:九川(浙江)科技股份有限公司

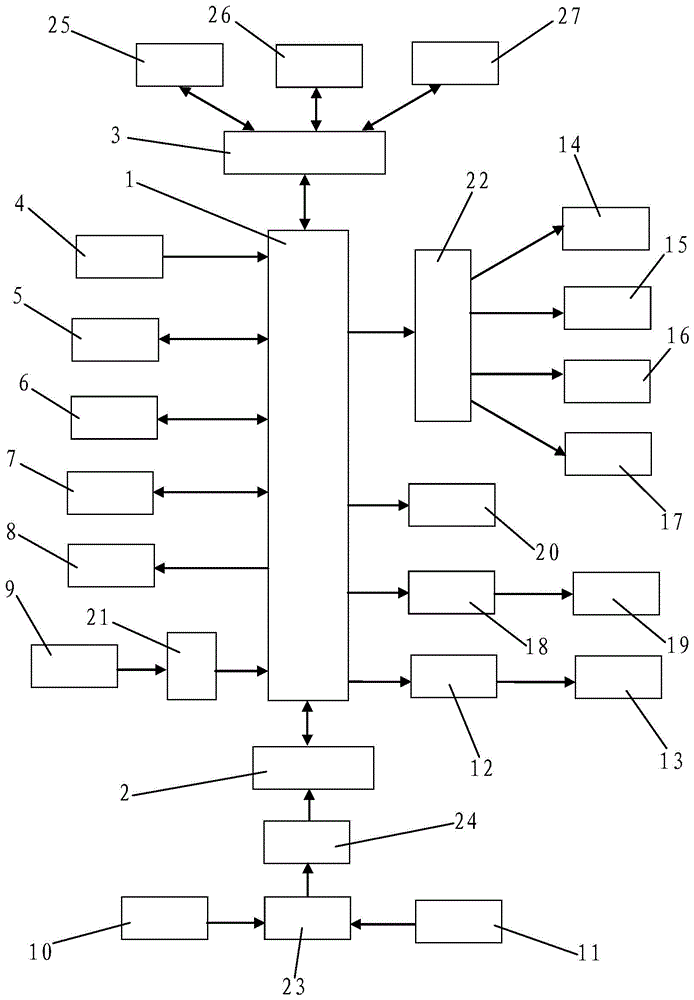

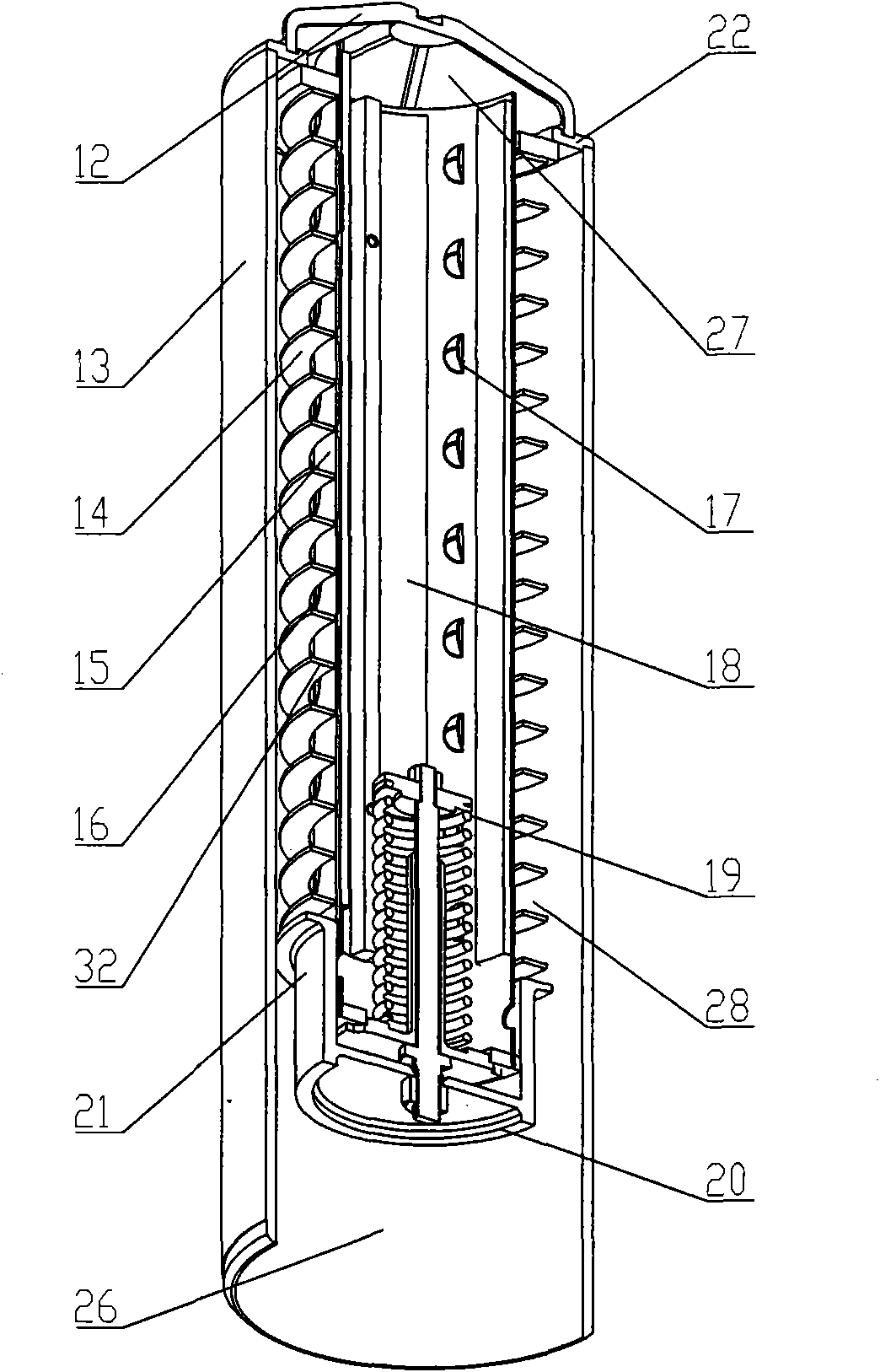

Concrete batching stirring control system

InactiveCN104552608AEasy and fast programmingLess nestingIngredients proportioning apparatusControl apparatusAutomatic controlControl system

The invention discloses a concrete batching stirring control system. The concrete batching stirring control system comprises an input signal device, an output signal device, a main controller, an auxiliary controller I, an auxiliary controller II, a storage, a watchdog circuit, a timer and an audible and visual alarm, wherein the main controller is used for receiving material batching information and controlling the whole concrete batching stirring process; the auxiliary controller I is used for acquiring field sensor signals; the auxiliary controller II is used for expanding functions of the concrete batching stirring control system so that the system can be in communication with an upper computer of a monitoring center; the storage is used for storing running parameters and the material batching information of the system; the watchdog circuit is used for preventing the main controller from being halted due to various interferences; the timer and the audible and visual alarm are respectively connected with the main controller. The concrete batching stirring control system is reasonable in design, comprehensive in function, and low in input cost; the automatic control of the whole process of batching, discharging and stirring at a concrete stirring station by operation can be realized; the contradict between the weighing precision and the weighing speed is solved; the production management level of the stirring station is improved; the equipment running fault rate is reduced.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

Backwashing filter

ActiveCN101940852AReduce points of failureEasy to controlStationary filtering element filtersFriction lossEngineering

The invention relates to a device for filtering a fluid medium transported in a pipeline, in particular to a backwashing filter which can filter impurities in the fluid medium in various use environments. The filter is provided with a driving device, a blowdown device, a filter shell and a filtering unit, the driving device is arranged at one side of the filter shell, the filter shell is internally provided with the blowdown device and the filtering unit, and one end of the blowdown device is connected with the driving device. The filter has the advantages of simple and compact structure, little occupied land and better filtering and backwashing effects, can work normally in various pressure conditions and solves the problems of tedious control process, multiple fault points and large resistance loss when the device runs existing in the prior art.

Owner:罗兰德流体控制(营口)有限公司

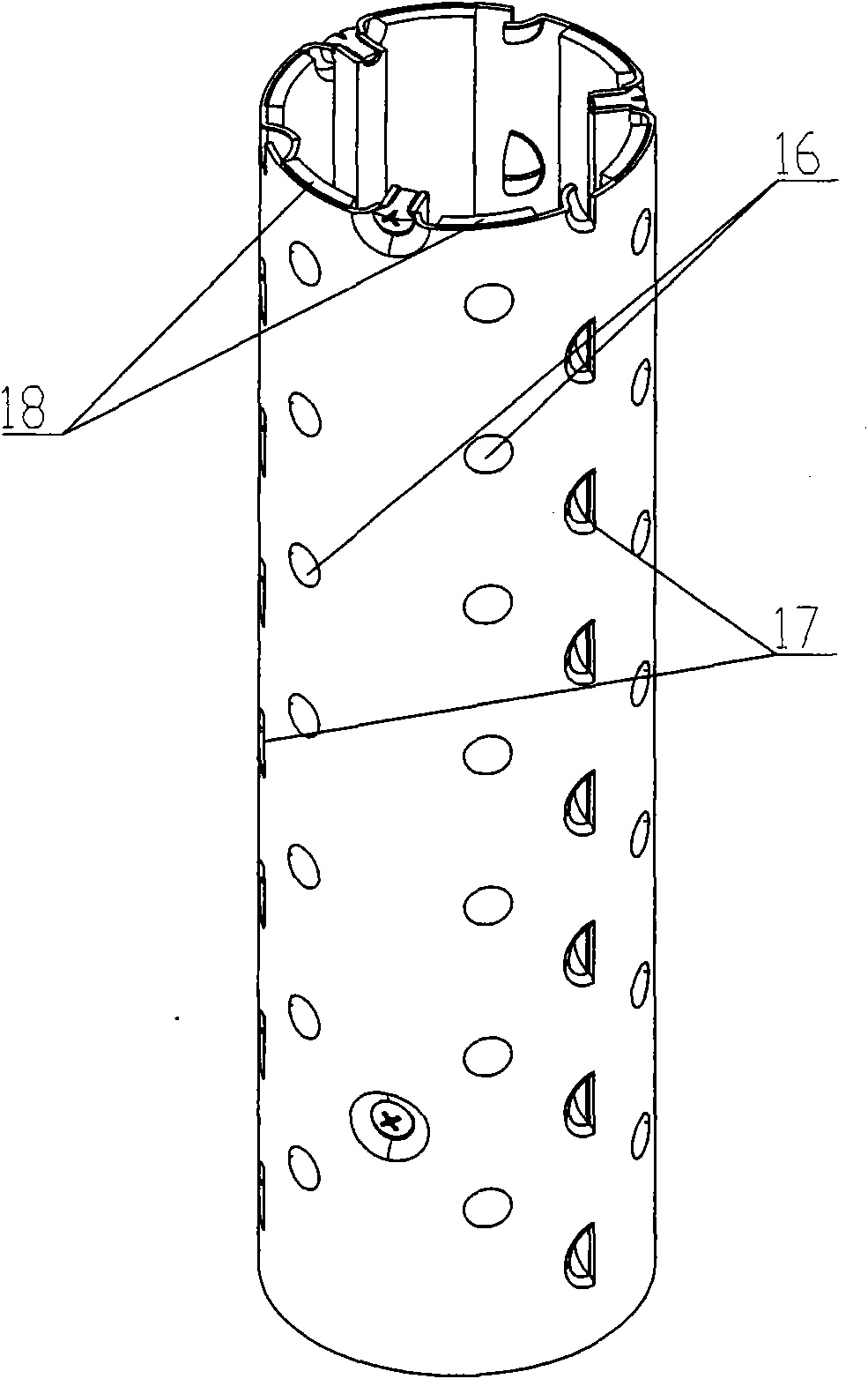

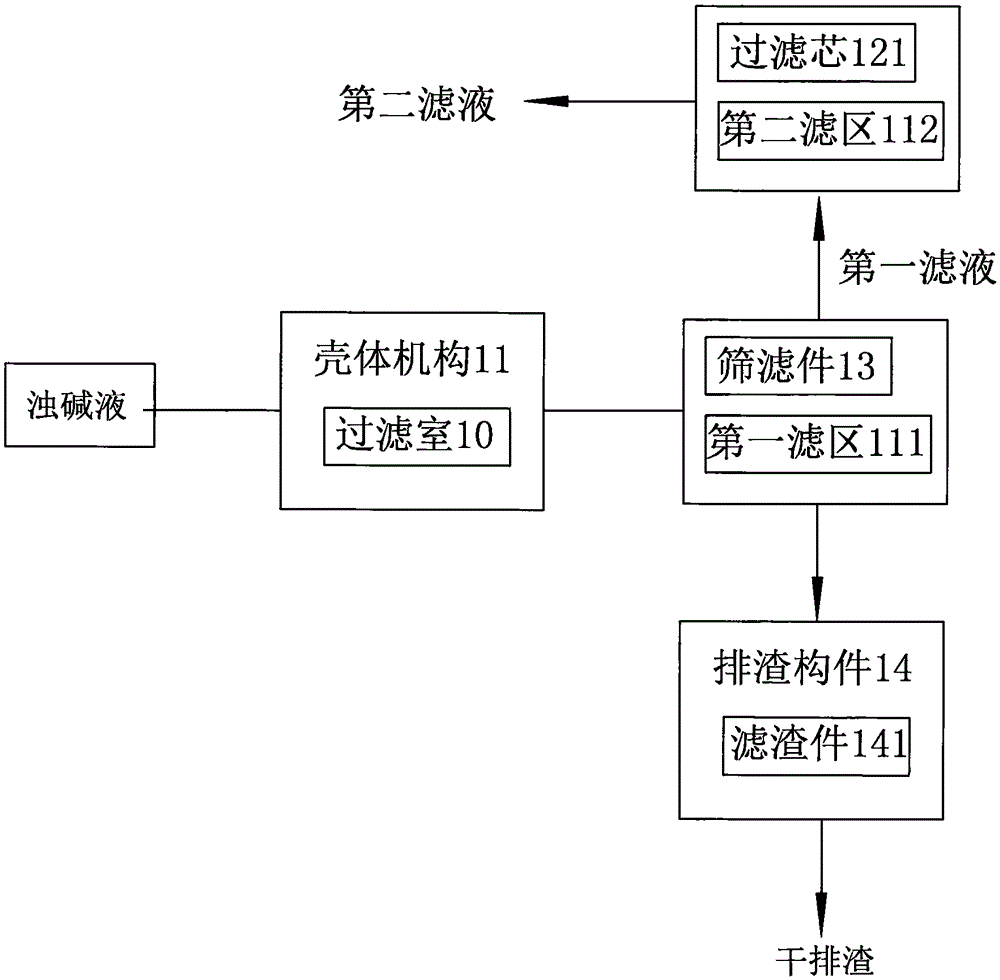

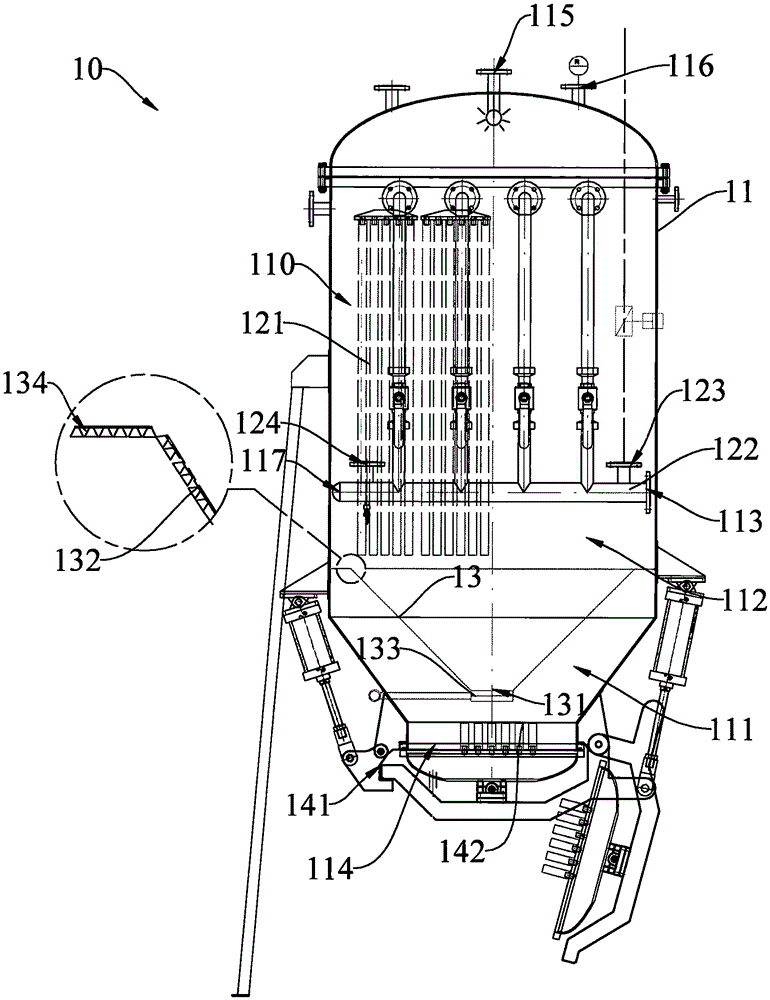

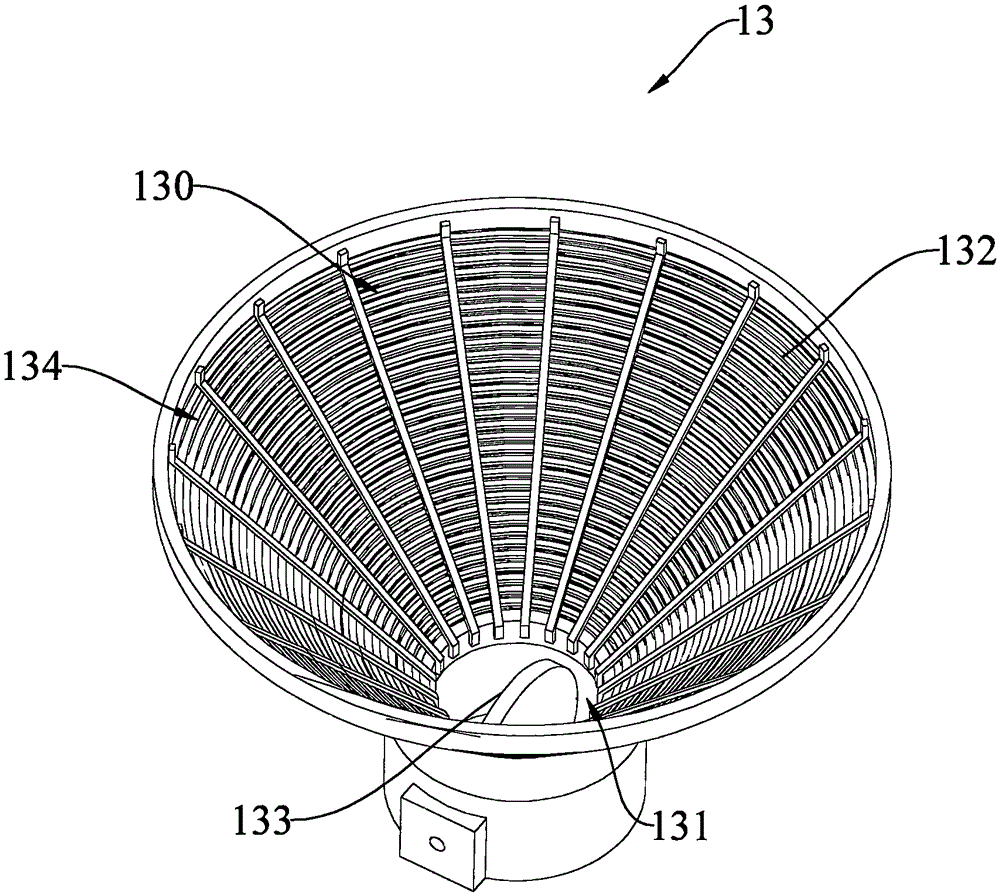

Renewable spent lye filter device and using method thereof

ActiveCN105536330AImprove filtering effectHigh filtration precisionStationary filtering element filtersParticulatesFiltration

The invention provides a renewable spent lye filter device and a using method thereof. The filter device comprises a shell mechanism, a filter element component and a screen filter, wherein the shell mechanism is provided with a filter chamber; the filter element component comprises a filter element; the screen filter is installed in a preset position of the filter chamber and faces the filter element at intervals, so that a first filtering area and a second filtering area are formed in the filter chamber; large-particle impurities are intercepted in the first filtering area by the screen filter; the filter element is arranged in the second filtering area; particulate impurities are filtered by the filter element. The filter device has the beneficial effects that the filter capacity and filter precision of the spent lye are effectively improved and the activity of the lye is restored through multistage filtration of the spent lye, thus achieving the aims of effectively purifying and recycling the spent lye in wash bottles.

Owner:XIANGSHAN JINXIN LIGHT IND MACHINERY PLANT

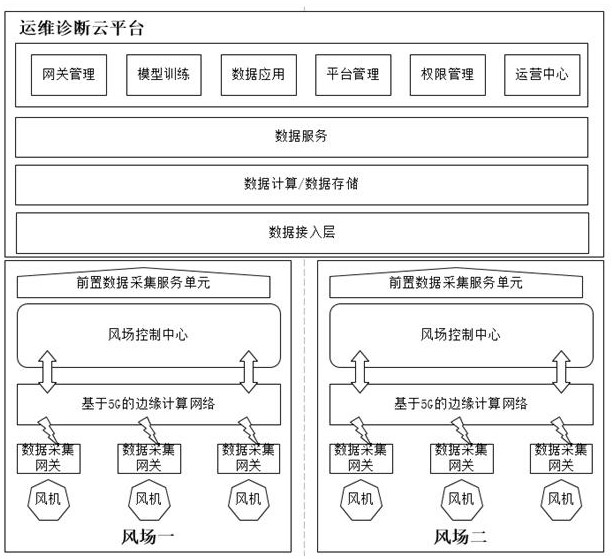

Terminal-cloud collaborative wind power operation and maintenance diagnosis system based on 5G

ActiveCN112594142ARealize predictive operation and maintenanceLow operating failure rateEngine fuctionsParticular environment based servicesEdge computingData acquisition

The invention relates to the technical field of remote operation and maintenance diagnosis of wind power generation equipment, and provides a terminal-cloud collaborative wind power operation and maintenance diagnosis system based on 5G. The system comprises a data acquisition gateway, a 5G-based edge computing network, a wind field control center system, a front-arranged data acquisition serviceand an operation and maintenance diagnosis cloud platform. According to the system, under the synergistic effect of all subsystems, second-level acquisition, remote operation and maintenance and intelligent diagnosis of wind turbine data are achieved, the problems that wind turbine routing inspection is difficult and not easy to monitor are solved, the centralized control level of wind turbines indifferent places is improved, the fault rate of wind turbine operation is reduced, the high-quality power generation efficiency of the wind turbines is guaranteed, and considerable economic efficiency is created for a wind field.

Owner:东方电气集团科学技术研究院有限公司 +1

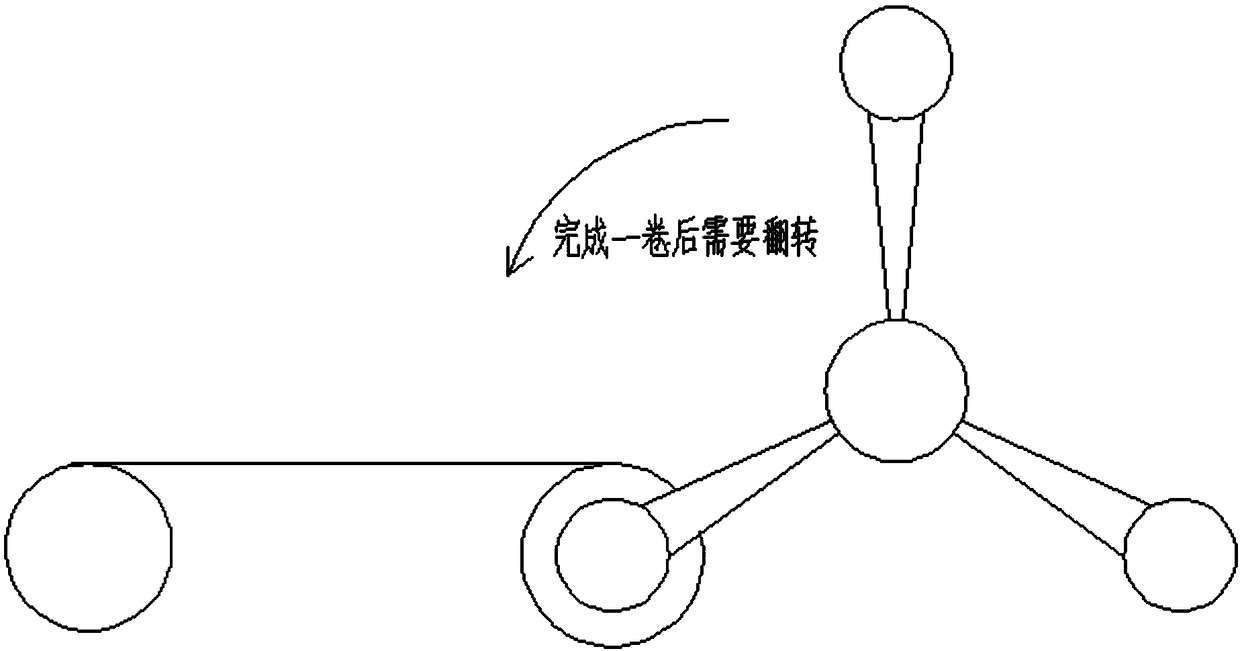

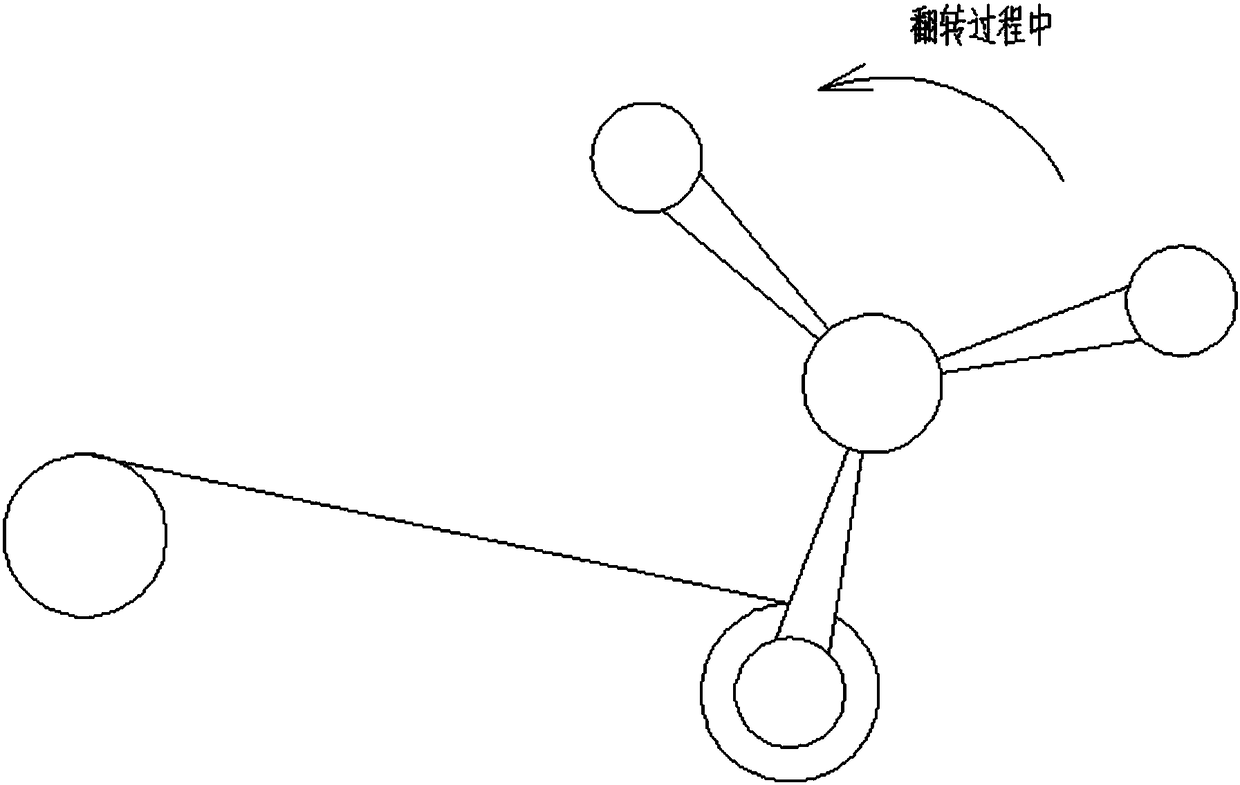

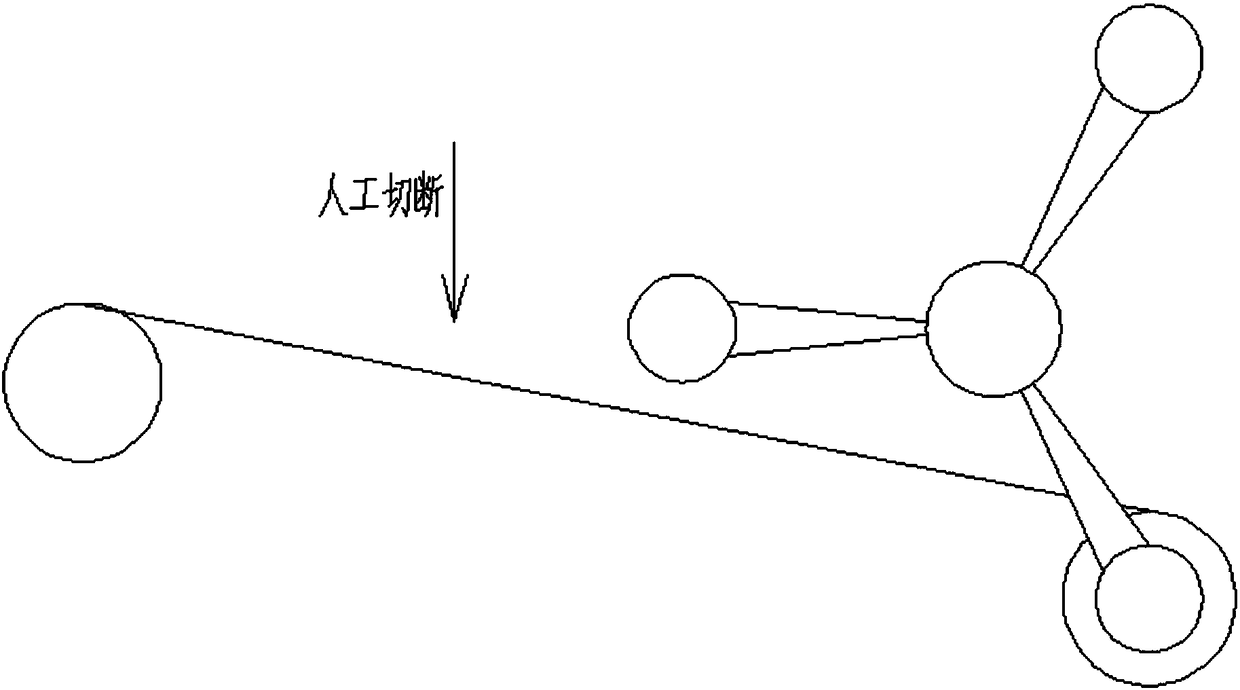

Flexible belt body winding station automatic cutting conversion device

PendingCN108516383ASolve the problem of automatic roll changeAccurate measurementWebs handlingFailure rateControl system

The invention relates to a flexible belt body winding station automatic cutting conversion device which comprises a cutting mechanism, a guide mechanism and a control system; the cutting mechanism isarranged between a flexible belt body supply roll and a winding roll unit the guide mechanism presses a the first part, which is not completely separated from a belt body main body, and a target winding roll, so that the first part is wound on the target winding roll in the first place; a second part, connected with the first part, on the belt body is wound by a previous winding roll continuouslytill the cutting mechanism separated the first part and the second part completely; and the control system establishes a meter number or time calculation procedure to control pressing movement of theguide mechanism, cutting movement of the cutting mechanism and rotational conversion in different winding stations of the winding roll unit. The flexible belt body winding station automatic cutting conversion device is accurate in measurement and high in finished product rate and is safe and convenient; safety production is facilitated, and the labor intensity of operating personnel is reduced; and the flexible belt body winding station automatic cutting conversion device is ingenious in design, small in equipment size, high in winding conversion efficiency and low in running failure rate anda complete automatic winding system can be formed.

Owner:SHANGHAI JIANHUI PLASTIC TECH

Process for recycling products from mother liquid containing ammonium chloride, sodium chloride, ammonium hydrogen carbonate and sodium hydrogen carbonate through thermal method

ActiveCN109879297AHigh puritySolution can not be reusedProductsReagentsSodium bicarbonateEvaporation

The invention provides a process for recycling products from mother liquid containing ammonium chloride, sodium chloride, ammonium hydrogen carbonate and sodium hydrogen carbonate through a thermal method. The process comprises a method for recycling gas generated after deaminizing the mother liquid. The method for recycling the gas generated after deaminizing the mother liquid comnprises the following steps: preheating the mother liquid, then feeding the mother liquid into an ammonia still for deaminizing, feeding carbon dioxide and ammonia gas generated after deaminizing into an ammonia absorption tower for generating carbon-containing ammonia water, adding carbon dioxide into the carbon-containing ammonia water, enabling carbon dioxide in the carbon-containing ammonia water to be excessive and generate ammonium hydrogen carbonate. The process also comprises a method for recycling the deaminized mother liquid and obtaining ammonium chloride and sodium chloride. The method for recycling the deaminized mother liquid and obtaining ammonium chloride and sodium chloride comprises the following steps: carrying out five-effect cross-flow evaporation to obtain sodium chloride, carrying out four-effect flash evaporation and crystallization to obtain ammonium chloride, feeding salt thickener overflowing liquid and salt centrifugal machine post-throwing liquid into a V-effect evaporation tank and enabling the salt thickener overflowing liquid and the salt centrifugal machine post-throwing liquid to participate in circulation again; feeding ammonium thickener overflowing liquid and ammonium centrifugal machine post-throwing liquid into an IV-effect flash evaporation and crystallization tank by using a pump, and enabling the ammonium thickener overflowing liquid and the ammonium centrifugal machine post-throwing liquid to participate in production circulation again. The process is capable of simultaneously recycling to obtain ammonium chloride and sodium chloride; meanwhile, the recycling rate is extremely high; the process is also capable of effectively increasing the heat utilization rate.

Owner:衡阳爱洁科技股份有限公司

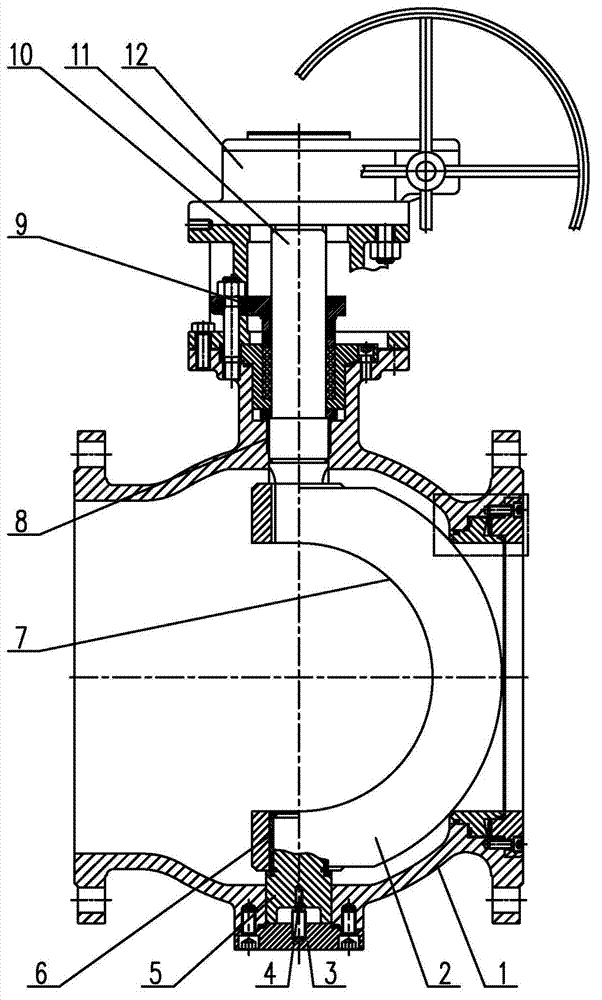

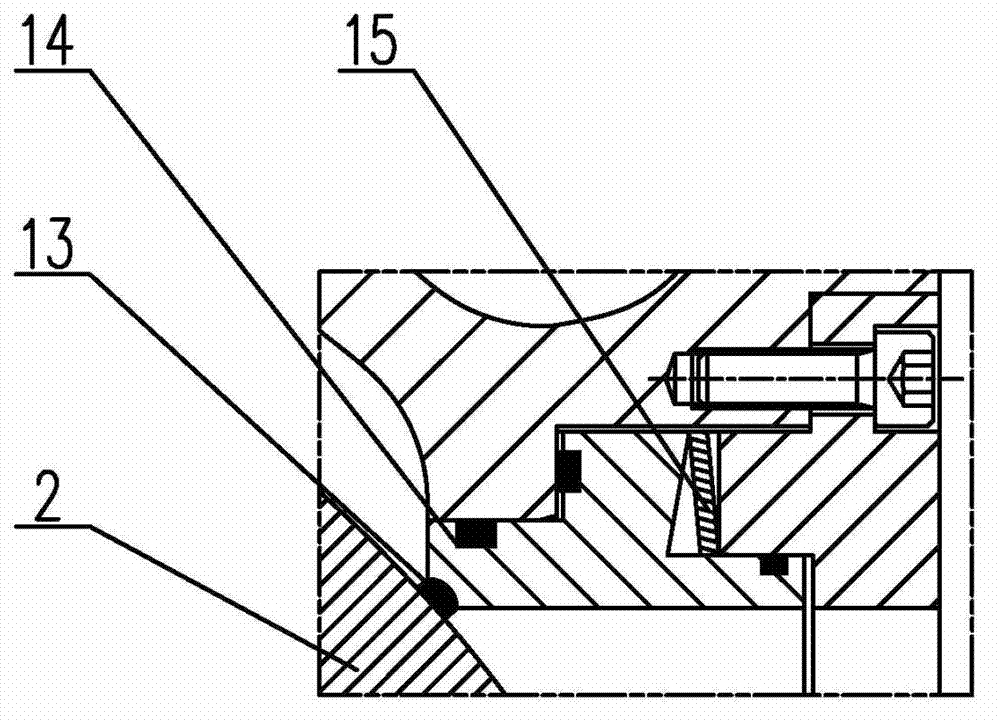

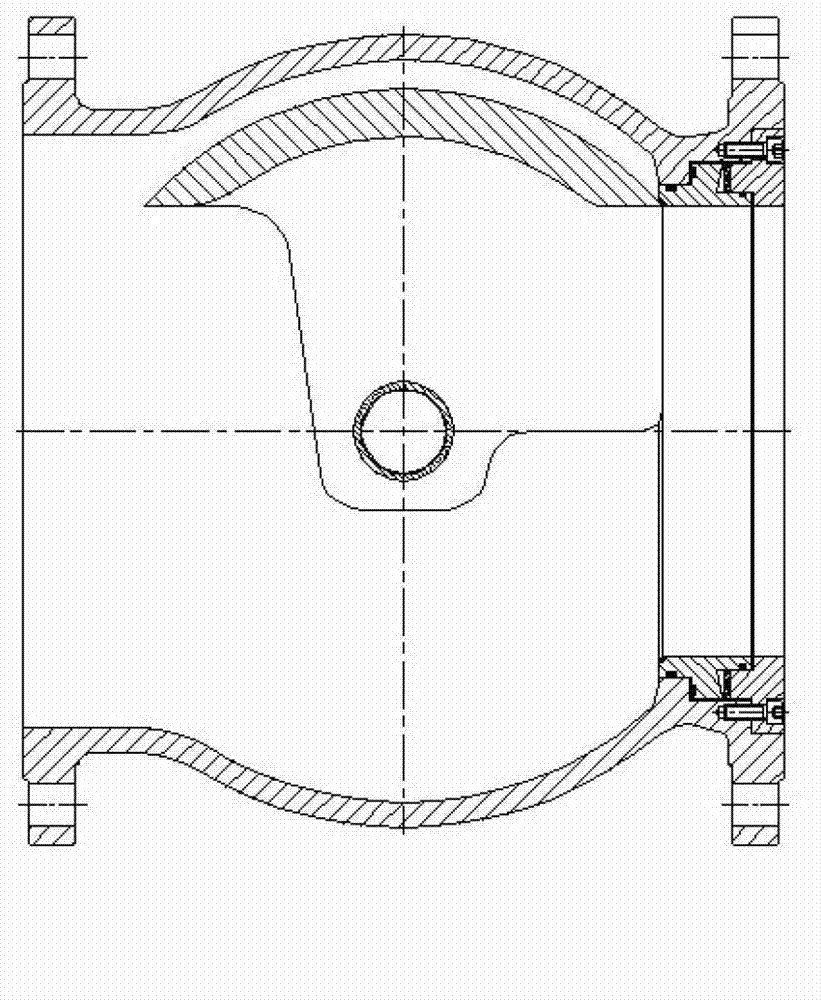

U-shaped ball valve for slurry mixing and ash discharging

InactiveCN102966751AExtended service lifeLow operating failure ratePlug valvesFailure rateManufacturing cost reduction

The invention discloses a U-shaped ball valve for slurry mixing and ash discharging. The U-shaped ball valve comprises a valve body, a ball body and a lower end cover, wherein the lower end of the valve body is provided with the lower end cover; the lower end cover is connected with a lower stationary shaft through a set screw; the lower stationary shaft is movably connected with a rotating shaft at the bottom of the ball body through a lower shaft sleeve; the rotating shaft at the top of the ball body is connected with the bottom end of a valve rod through an upper shaft sleeve; and the valve rod penetrates through a filler system structure and the rear top end of a bracket to be connected with an executing mechanism. The U-shaped ball valve has the beneficial effect that the design of a non-eccentric wear-resistant ball body with a U-shaped flow passage port, a streamline-shaped outlet and valve cavity ball hiding is adopted by the designed and developed U-shaped ball valve for slurry mixing and ash discharging. A valve seat with a scraper port is designed to be provided with a labyrinth type disc spring pre-tightening mechanism. The U-shaped ball valve has the advantages of capability of effectively solving the problems, low operation failure rate, capability of greatly prolonging the service life of the valve, compact structure, light weight, capabilities of reducing the manufacturing cost and realizing mounting at any position, quick opening and closing and remote control and the like.

Owner:DAZHONG VALVE FACTORY ZHEJIANG PROV

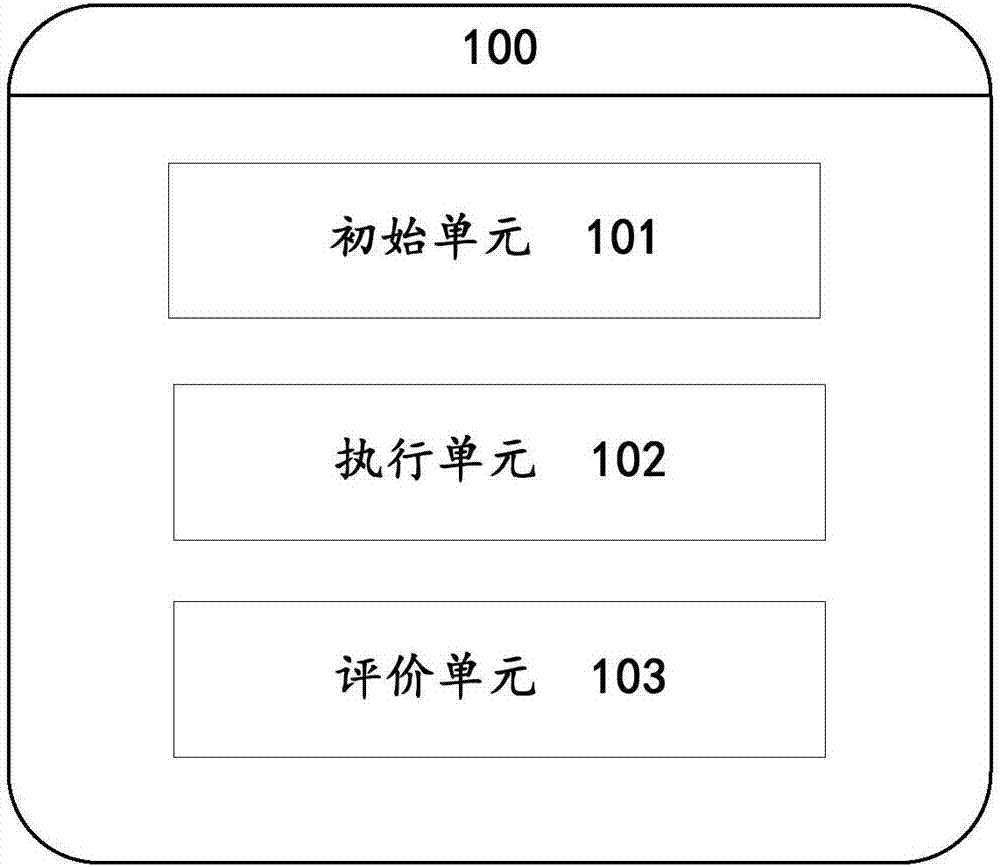

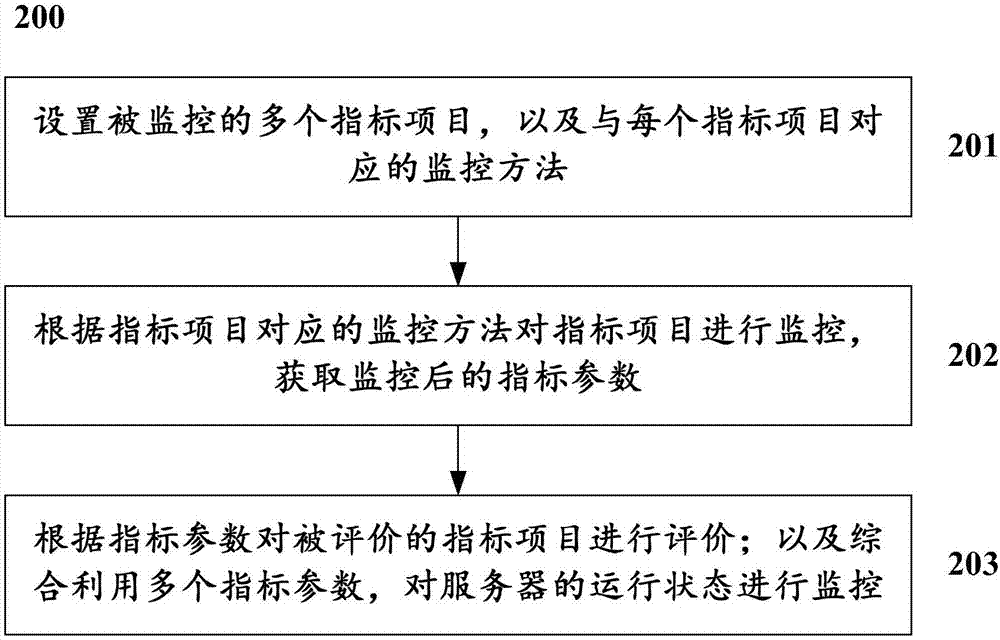

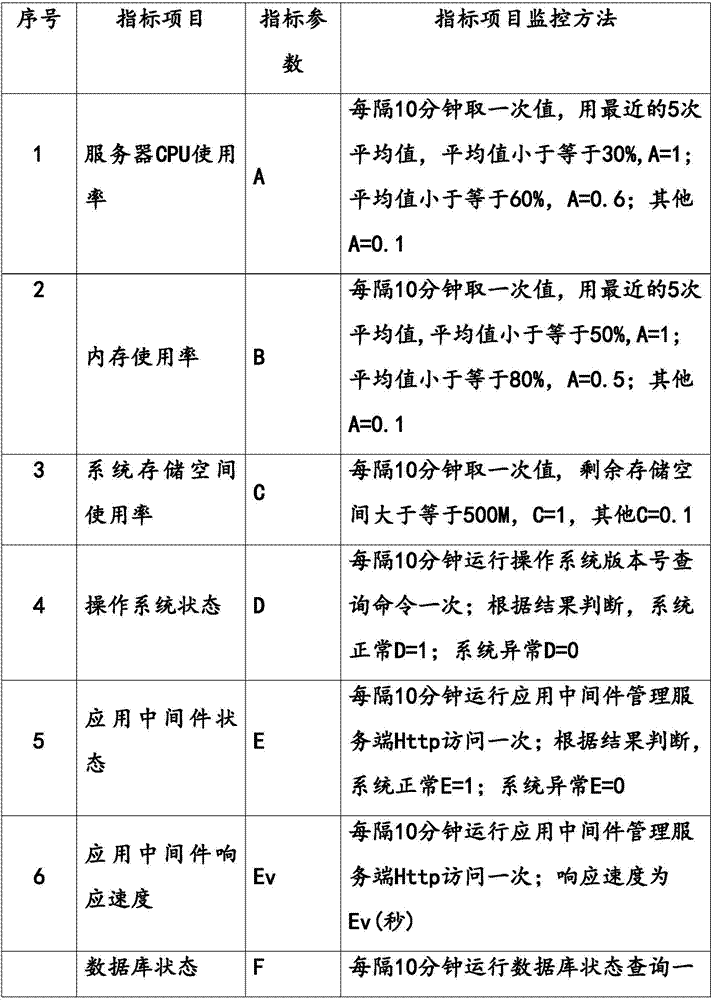

System and method for monitoring operation states of servers

InactiveCN107391336ALow operating failure rateReduce the difficulty of daily operation and maintenance monitoringHardware monitoringDaily operationFault rate

The invention discloses a system for monitoring operation states of servers. The system comprises an initial unit, an execution unit and an evaluation unit, wherein the initial unit is used for setting a plurality of monitored index projects and monitoring methods corresponding to the index projects; the monitoring methods are used for monitoring the index projects and obtaining value results of the index projects to obtain index parameters for evaluating the index projects; the execution unit is used for monitoring the index projects according to the monitoring methods corresponding to the index projects so as to obtain monitored index parameters, and sending the index parameters to the evaluation unit; and the evaluation unit is used for receiving the index parameters, evaluating the evaluated index projects according to the index parameters, and comprehensively utilizing the plurality of index parameters to monitor the operation states of servers. According to the system provided by the invention, the daily operation and maintenance monitoring difficulty of autonomous controllably servers is reduced, the working efficiency of the operation and maintenance personnel is improved, the operation states of the servers are monitored timely, comprehensively and correctly, and the operation fault rates of the servers are effectively reduced.

Owner:HUADI COMP GROUP

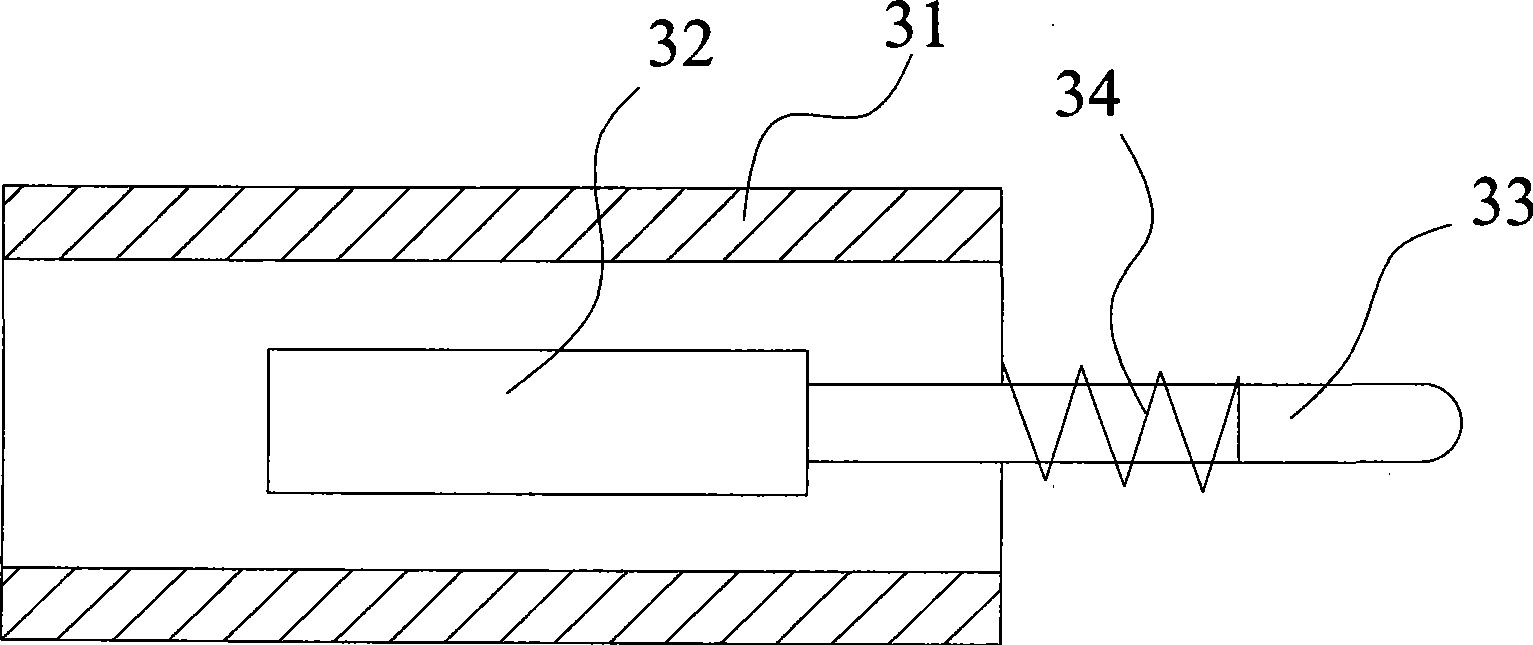

Rapid on-line detecting method and system for wood material strength

InactiveCN101509857AEasy to useEasy to transformMaterial strength using repeated/pulsating forcesThermodynamicsSize determination

The invention discloses an online fast detection system of strength performance of wood and wooden composite materials, comprising a transporting mechanism, a laser sensor, a beater, a signal pickup device and a computer, wherein the laser sensor is used for online detecting the position of the detected object and determining the beating time to center according to the transporting speed and the sectional dimension of the detected object; the beater is used for beating the central area of the end of the detected part according to beating time instructions of the laser sensor; the signal pickup device is used for receiving the mechanical wave signals generated by the detected object; and the computer is used for receiving detection data of the signal pickup device. The invention also provides an online fast detection method for strength performance of wood and wooden composite materials. The invention adopts the laser sensor and an electromagnetic vibrator, has more accurate positioning and beating and low fault rate of equipment operation, can effectively beat the central area of the end surface of the detected object and does not cause the problems of beating leakage and beating error and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Self cleaning type ammonia-nitrogen wastewater treatment set device

InactiveCN101823817AIngenious ideaInnovative designWater/sewage treatment by ion-exchangeTreatment with aerobic and anaerobic processesHigh concentrationAutomatic control

The invention relates to a high-concentration ammonia-nitrogen wastewater treatment set device, which comprises a dissolved medicine dissolution box, a wastewater flow stabilizing and flow guiding tube, a sand and stone exchange cleaner, filter materials, a sand blocking water distributor, sand and stone air stripping pipe, an air compressor output pipe, an air input pipe, a monitoring probe, an automatic control system and the like. The invention can treat the high-concentration ammonia-nitrogen wastewater which can not be treated by a physical chemical and biochemical method, at the same time, the defect that alkali addition, acid addition or temperature raising is needed during the high-concentration ammonia-nitrogen wastewater treatment by other methods for reaching the treatment effect can be avoided, the operation cost is reduced, and the area of the occupied ground is saved. The saturated filtering materials can be used as slow-release fertilizers for plants after being pulverized, and no secondary pollution is caused after the whole equipment operates to the filter material recovery.

Owner:宜兴市芳惠子环保设备厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com