Anoxic/oxic-membrane bioreactor water treatment device and sewage treatment method thereof

A water treatment device and sewage technology, applied in the field of water treatment, can solve the problems of large floor space and high sludge treatment costs, and achieve the effects of high volume load, strong adaptability and saving sludge treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

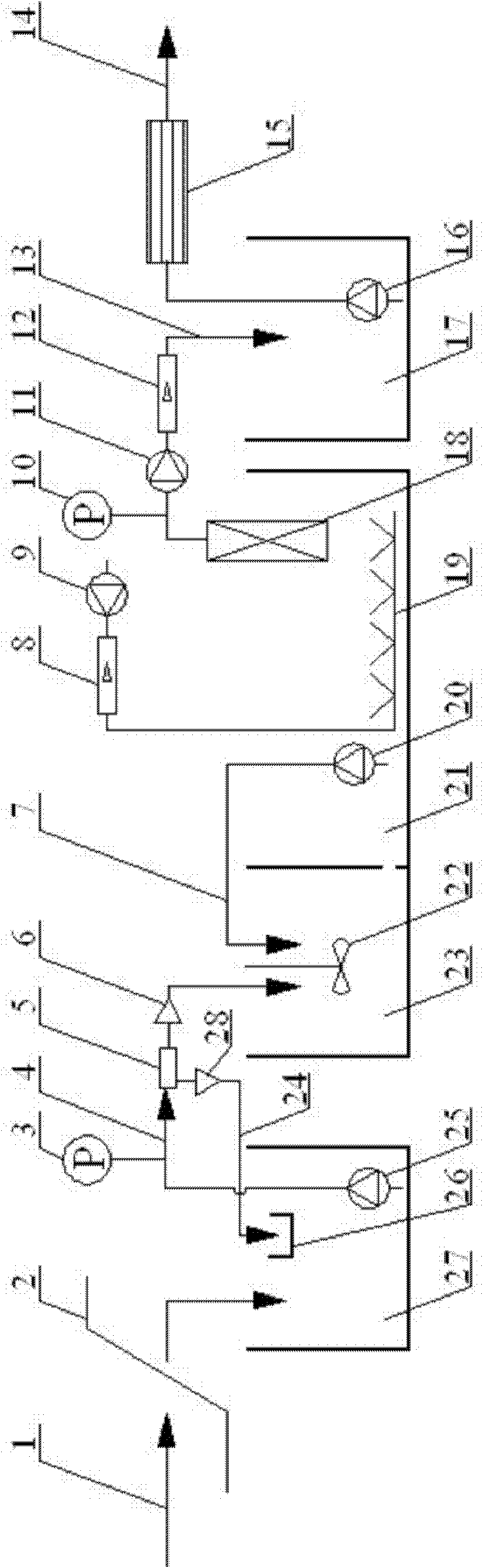

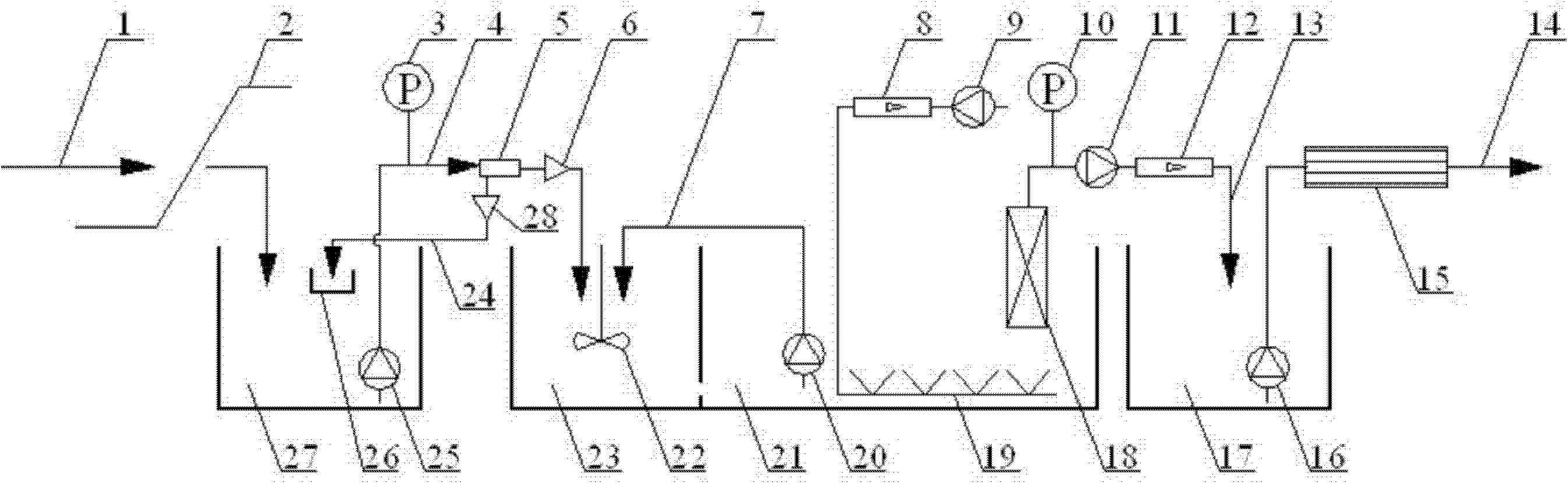

[0016] Specific implementation mode one: combine figure 1 To illustrate, the A / O-MBR water treatment device in this embodiment includes a water inlet pipe 1, a trash rack 2, a pressure controller 3, a first connecting pipe 4, an interceptor 5, a first control valve 6, a return pipe 7, First flowmeter 8, fan 9, negative pressure transmitter 10, first water outlet pump 11, second flowmeter 12, second connecting pipe 13, water outlet pipe 14, ultraviolet disinfection device 15, second water outlet pump 16, clean water Pool 17, membrane module 18, aeration device 19, reflux pump 20, oxidation tank 21, agitator 22, anaerobic tank 23, discharge pipe 24, crushing pump 25, grid slag collection tank 26, adjustment tank 27 and the second control Valve 28; the water outlet of the water inlet pipe 1 is connected with the water inlet of the trash rack 2, the water outlet of the trash rack 2 is connected with the water inlet of the regulating tank 27 top, and the water outlet of the regulat...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that: a filter screen is installed in the retainer 5 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: In this embodiment, the method for treating sewage by the A / O-MBR water treatment device is realized through the following steps:

[0019] Step 1: Inoculate activated sludge into anaerobic pool 23 and aerobic pool 21, feed municipal sewage to domesticate activated sludge until MLSS (circulation ratio) reaches 3000 mg / L, pass water to membrane module 18, and then continuously feed water to MLSS Reach 6000mg / L to complete the start;

[0020] Step 2, the municipal sewage is filtered through the trash rack 2 after passing through the water inlet pipe 1, and then passed into the regulating tank 27, then pulverized by the crushing pump 25 and then filtered by the interceptor 5;

[0021] Step 3, the sewage treated in step 2 is passed into the anaerobic pool 23 together with the nitrifying liquid in the aerobic pool 21, and denitrification and denitrification treatment is carried out under the condition of stirring, and the hydraulic retention time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com