Patents

Literature

185results about How to "Adaptable to change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

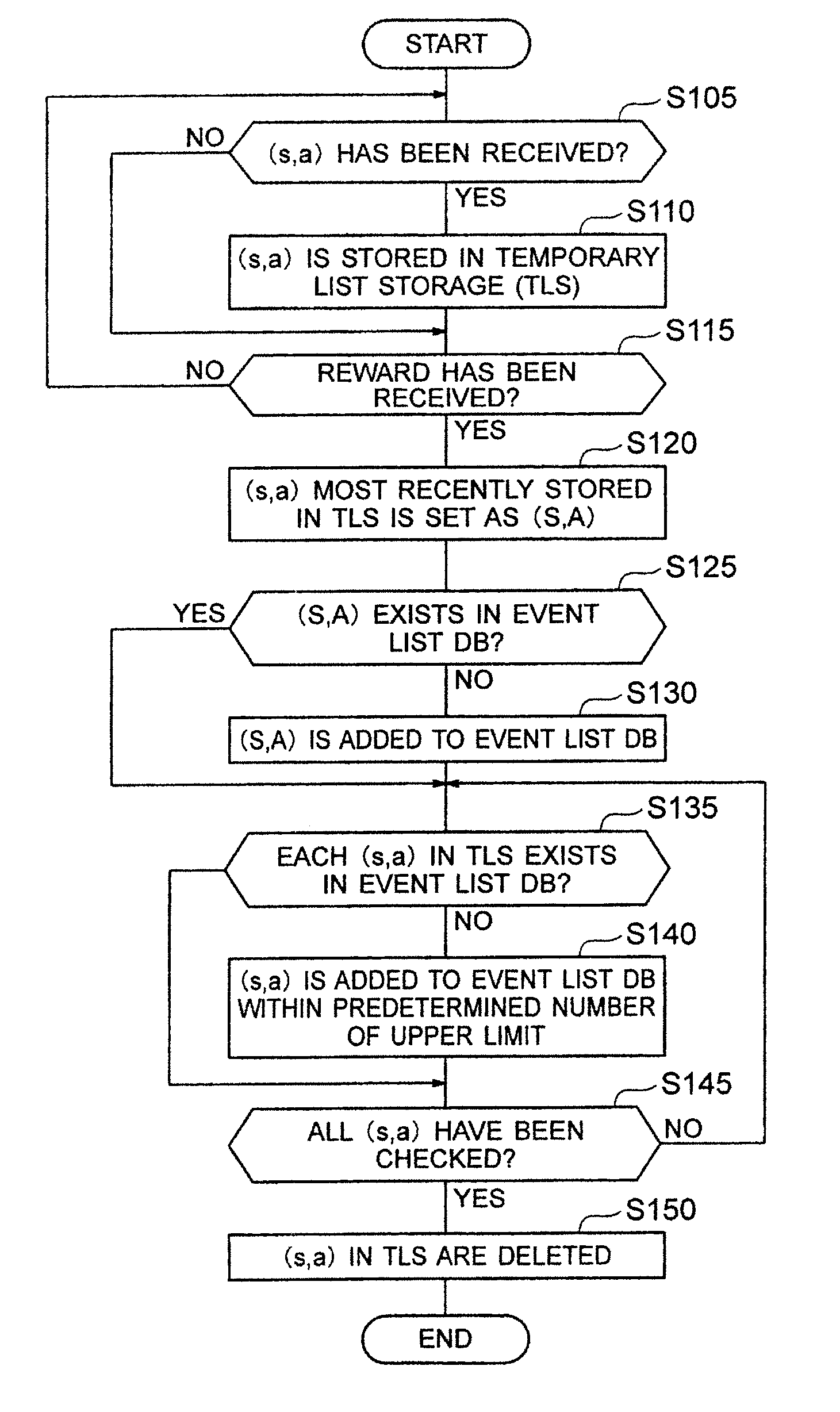

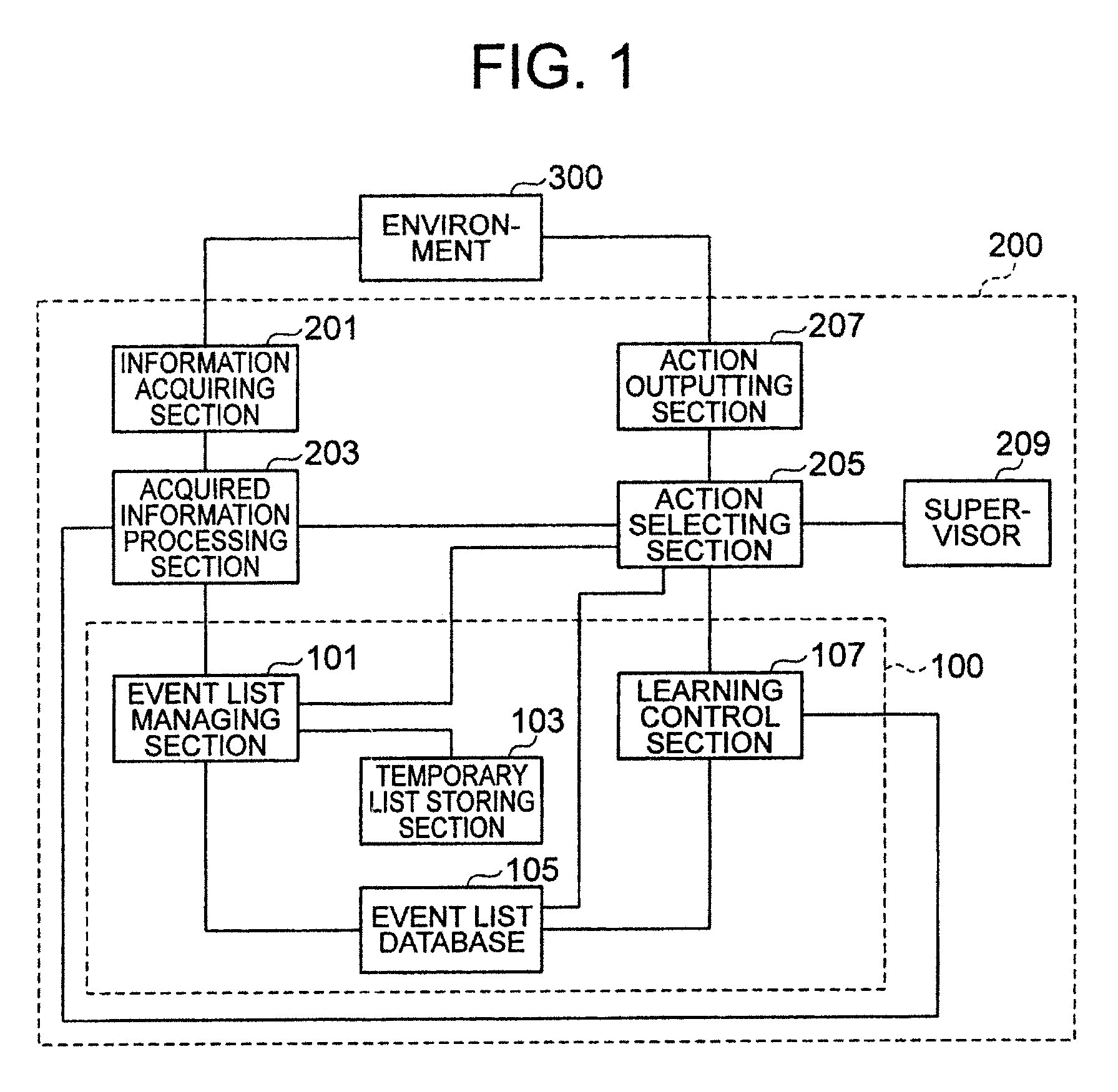

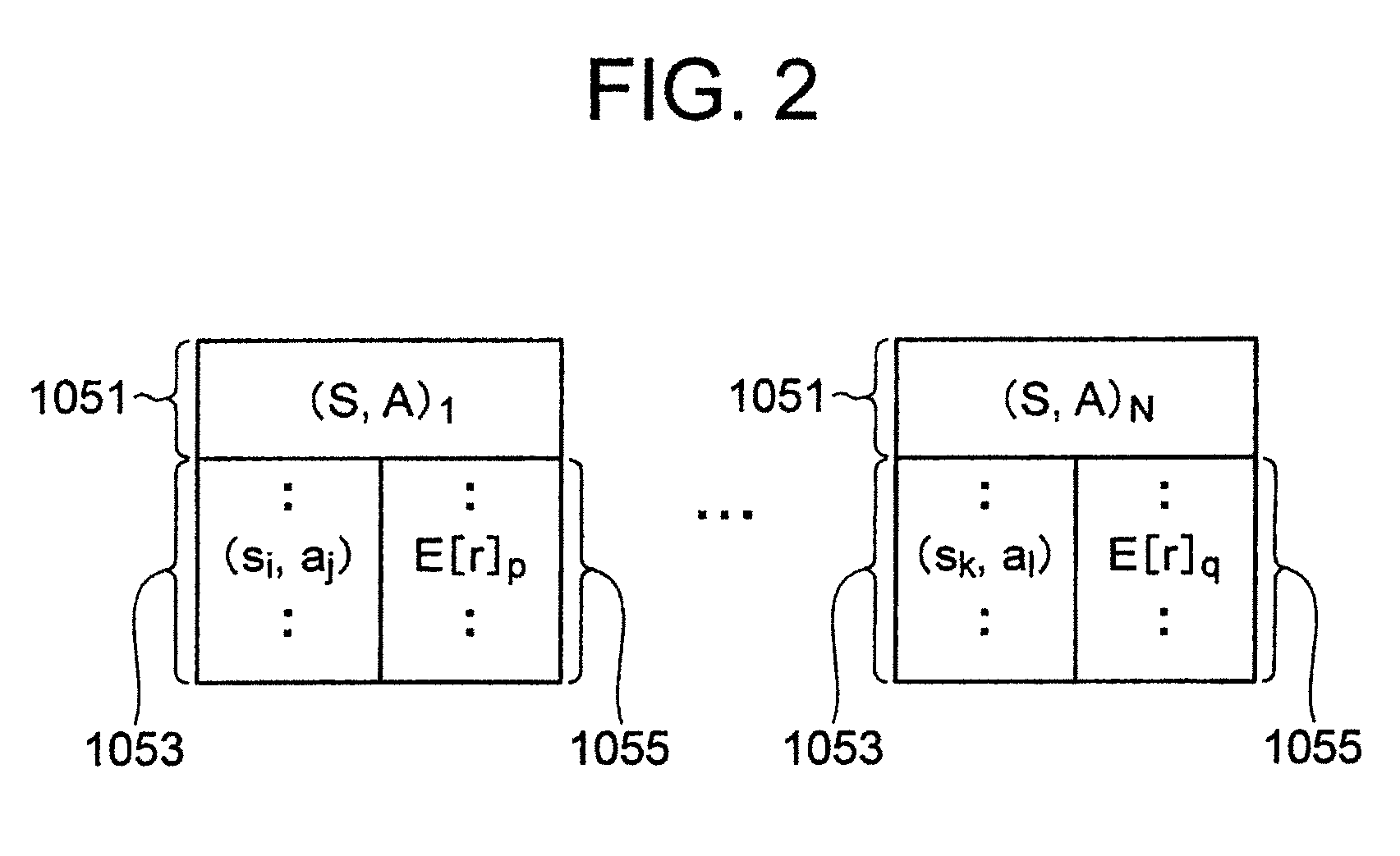

Learning system and learning method comprising an event list database

InactiveUS8290883B2Adaptable to changeImprove efficiencyDigital computer detailsMachine learningStudy methodsLearning methods

A learning system according to the present invention includes an event list database for storing a plurality of event lists, each of the event lists being a set including a series of state-action pairs which reaches a state-action pair immediately before earning a reward, an event list managing section for classifying state-action pairs into the plurality of event lists for storing, and a learning control section for updating expectation of reward of a state-action pair which is an element of each of the event lists.

Owner:HONDA MOTOR CO LTD

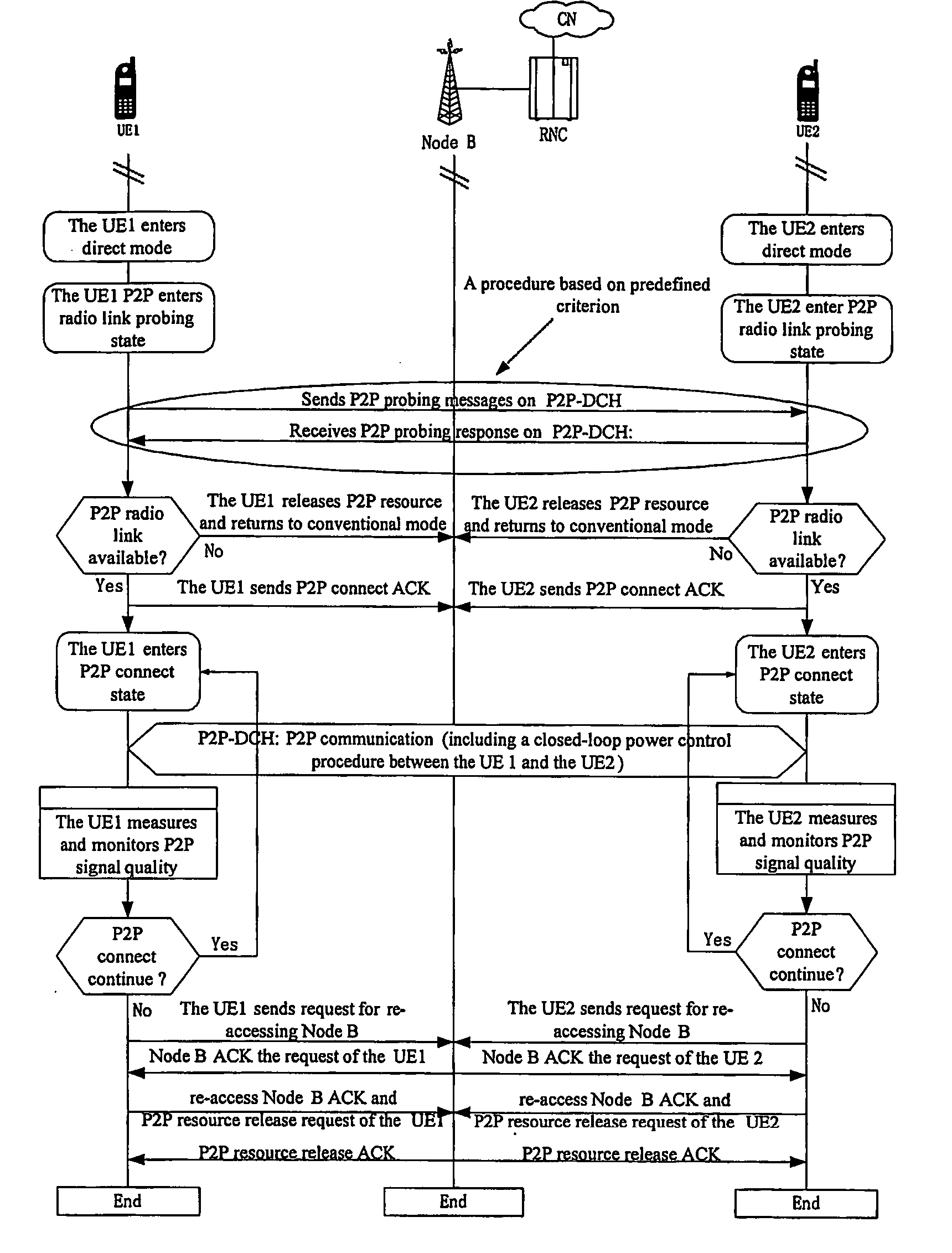

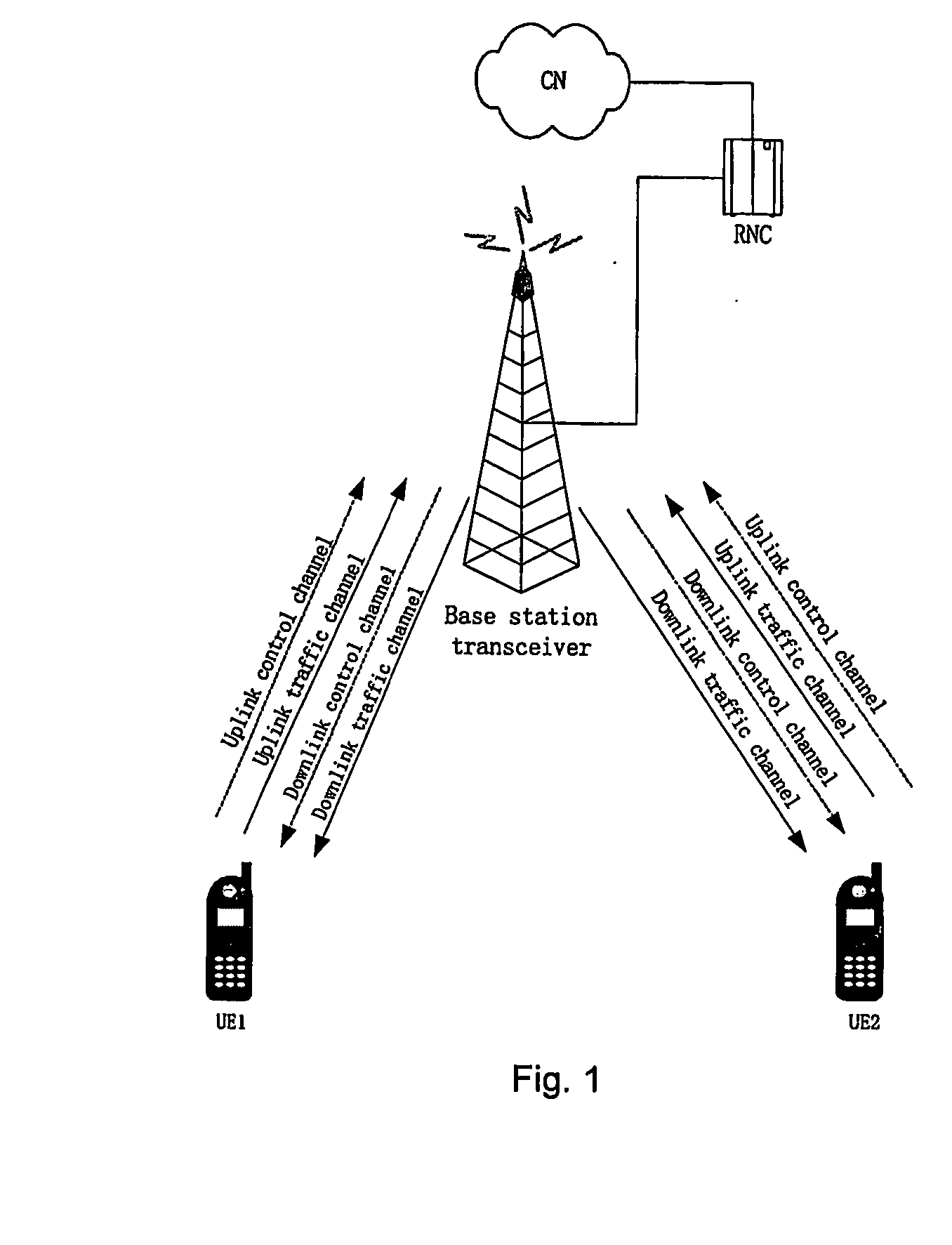

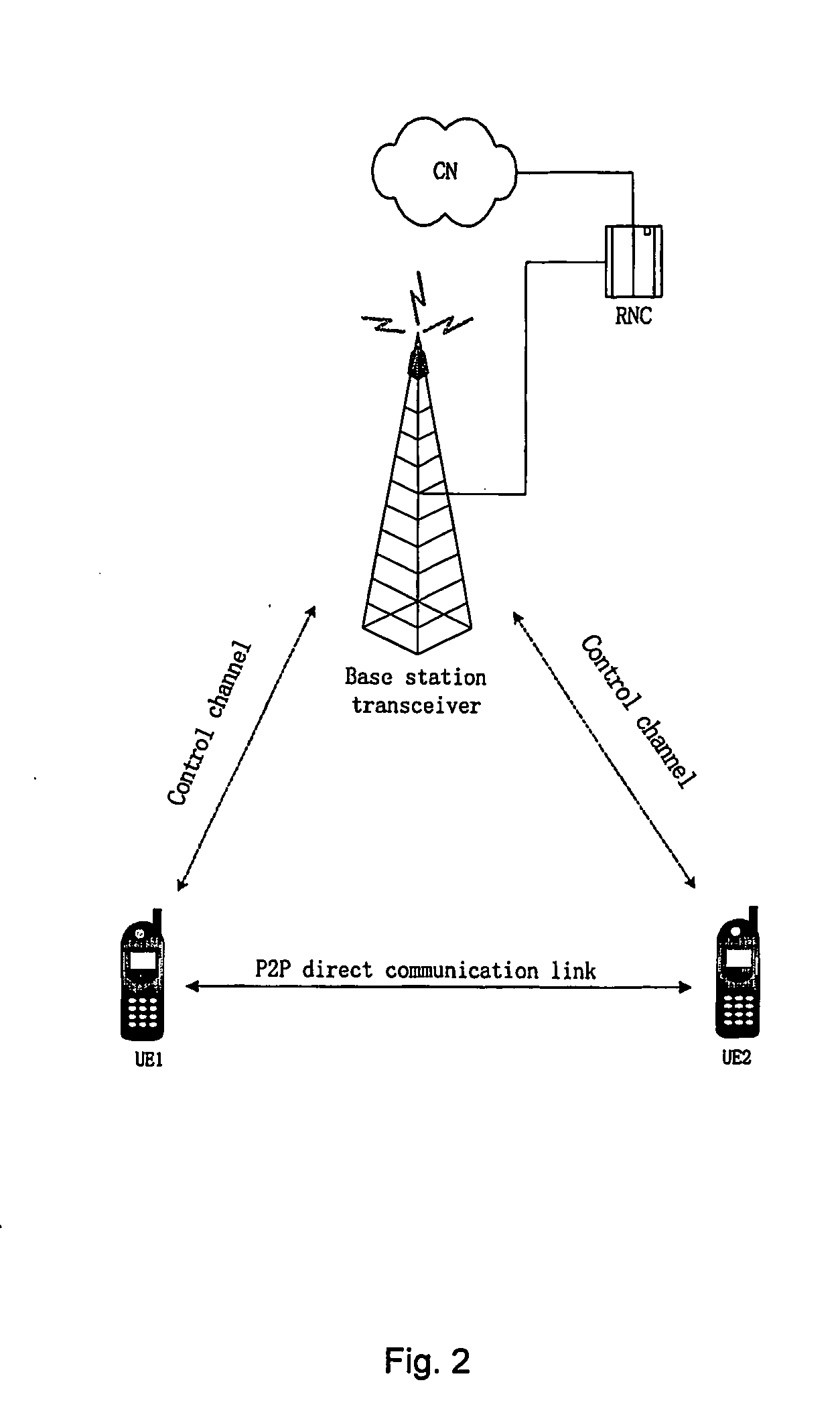

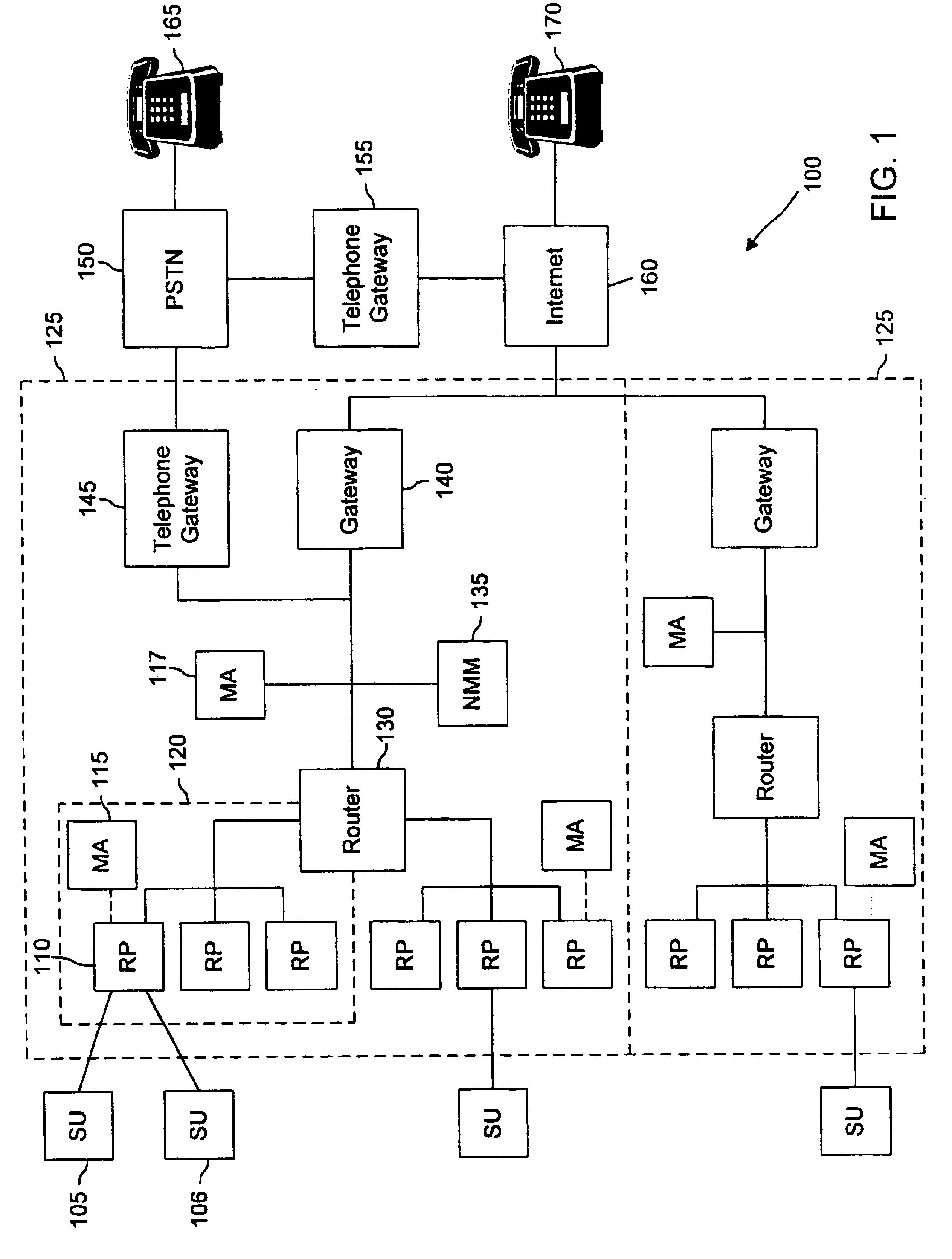

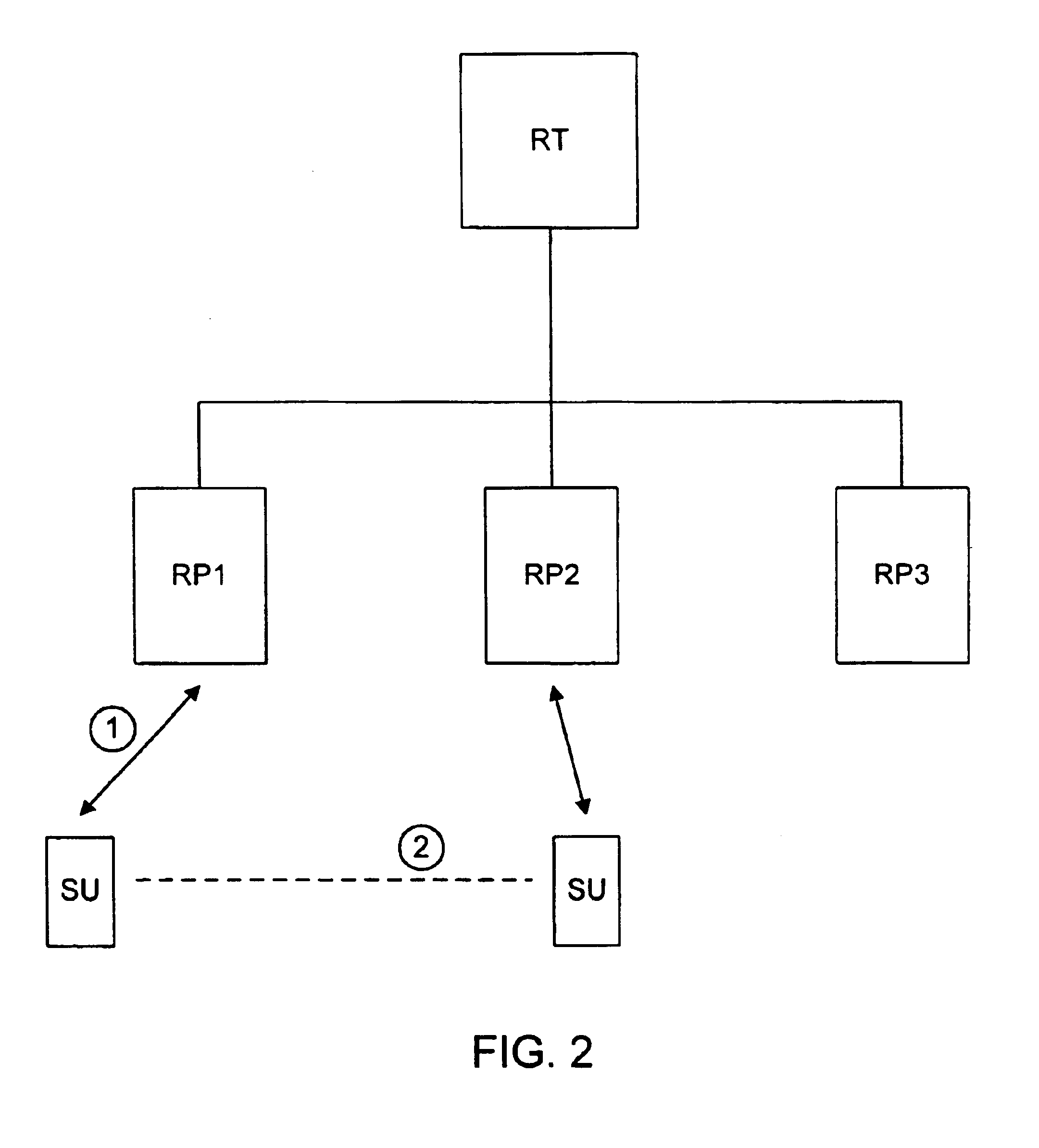

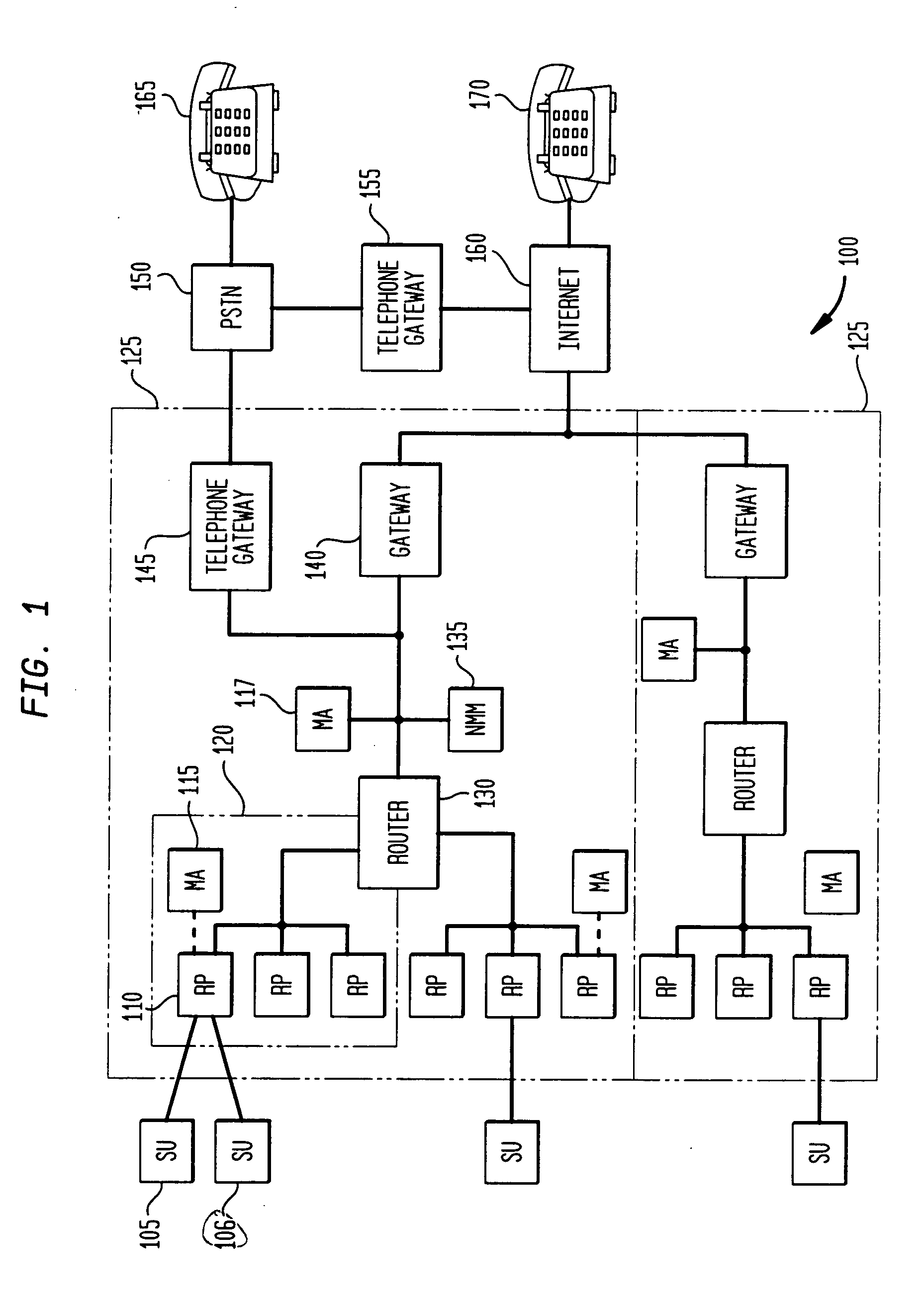

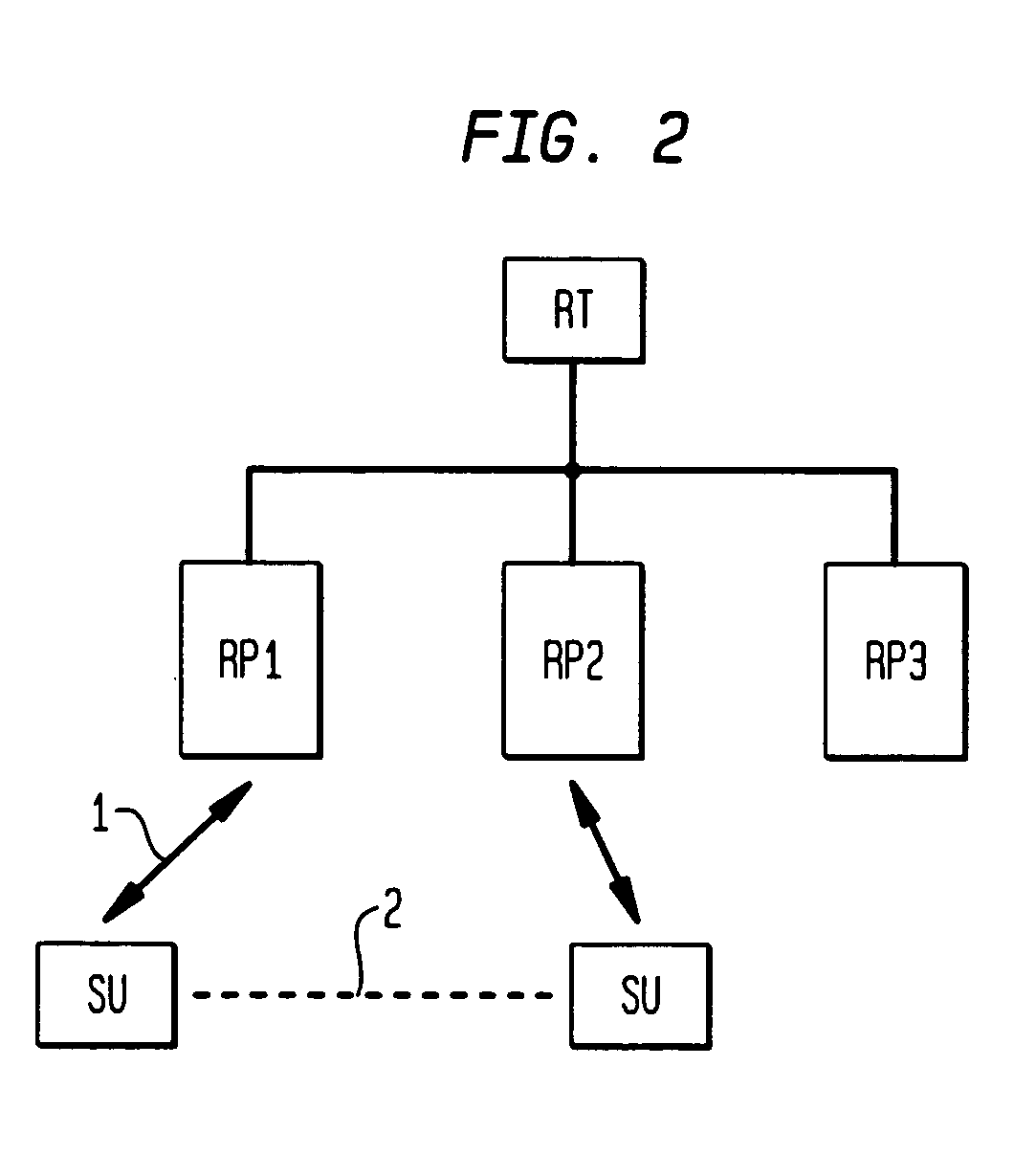

Method and system for radio link establishment and maintenance with p2p communication in wireless communication

InactiveUS20060168343A1Adaptable to changeSmooth switchingPower managementNetwork traffic/resource managementCommunications systemTelecommunications link

A method is provided for establishing P2P radio connection in wireless communication networks, comprising: the user equipment, as the link probing originator, transmits link probing signals via the allocated direct communication link to another user equipment as the link probing responder, according to the initial probing power provided by the wireless communication system; said another user equipment transmits the ACK message to the link probing originator via the direct communication link when receiving the link probing signals and said link probing signals meet the basic requirement for direct communication; the user equipment, as the link probing originator, monitors the direct communication link, and communicates directly with the link probing responder via the direct communication link after detecting the ACK message from the link probing responder. This method effectively guarantees the procedure of establishing P2P communication between the user equipments in P2P communication course, by utilizing the link probing process of transmitting link probing signals.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

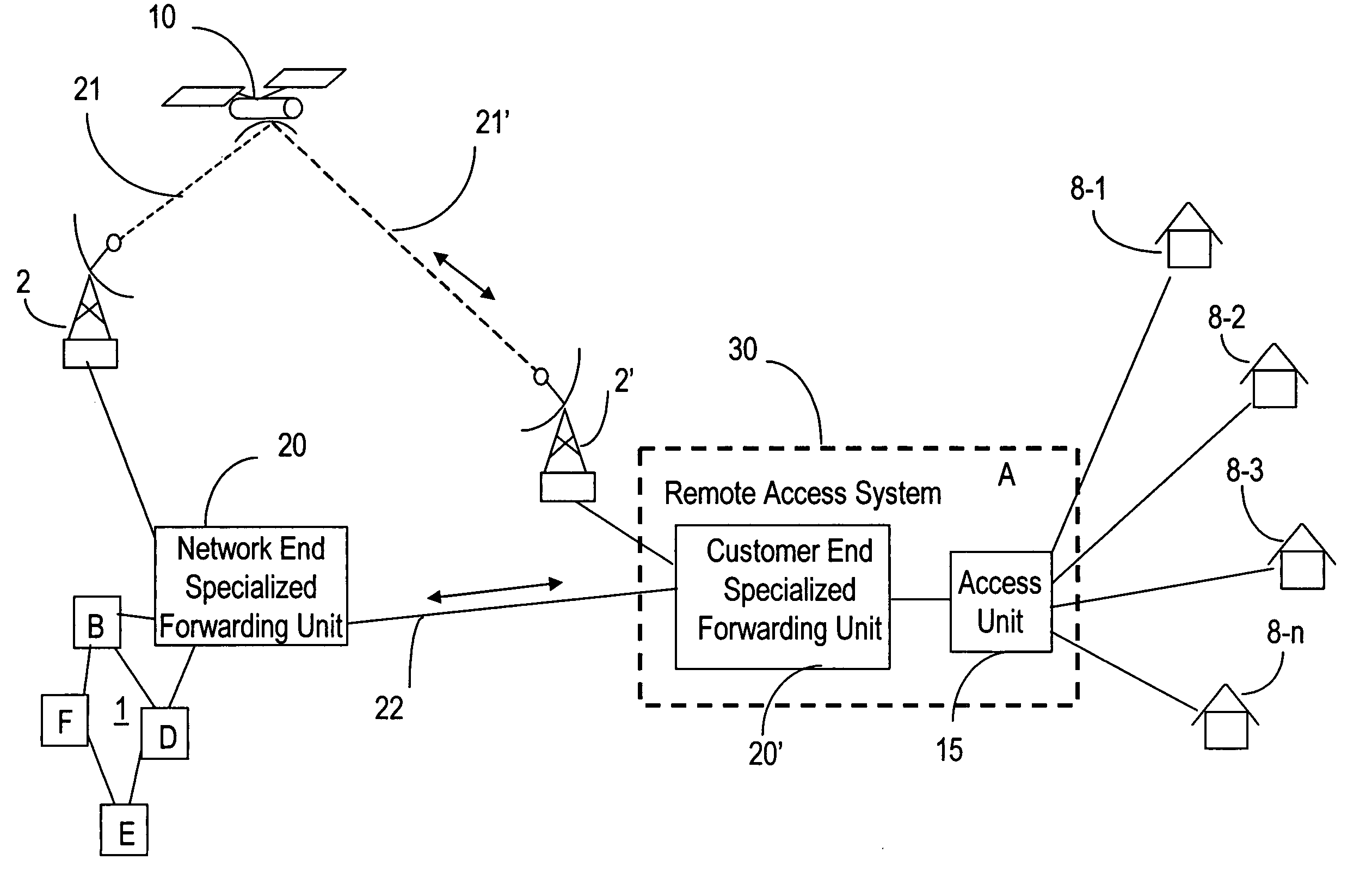

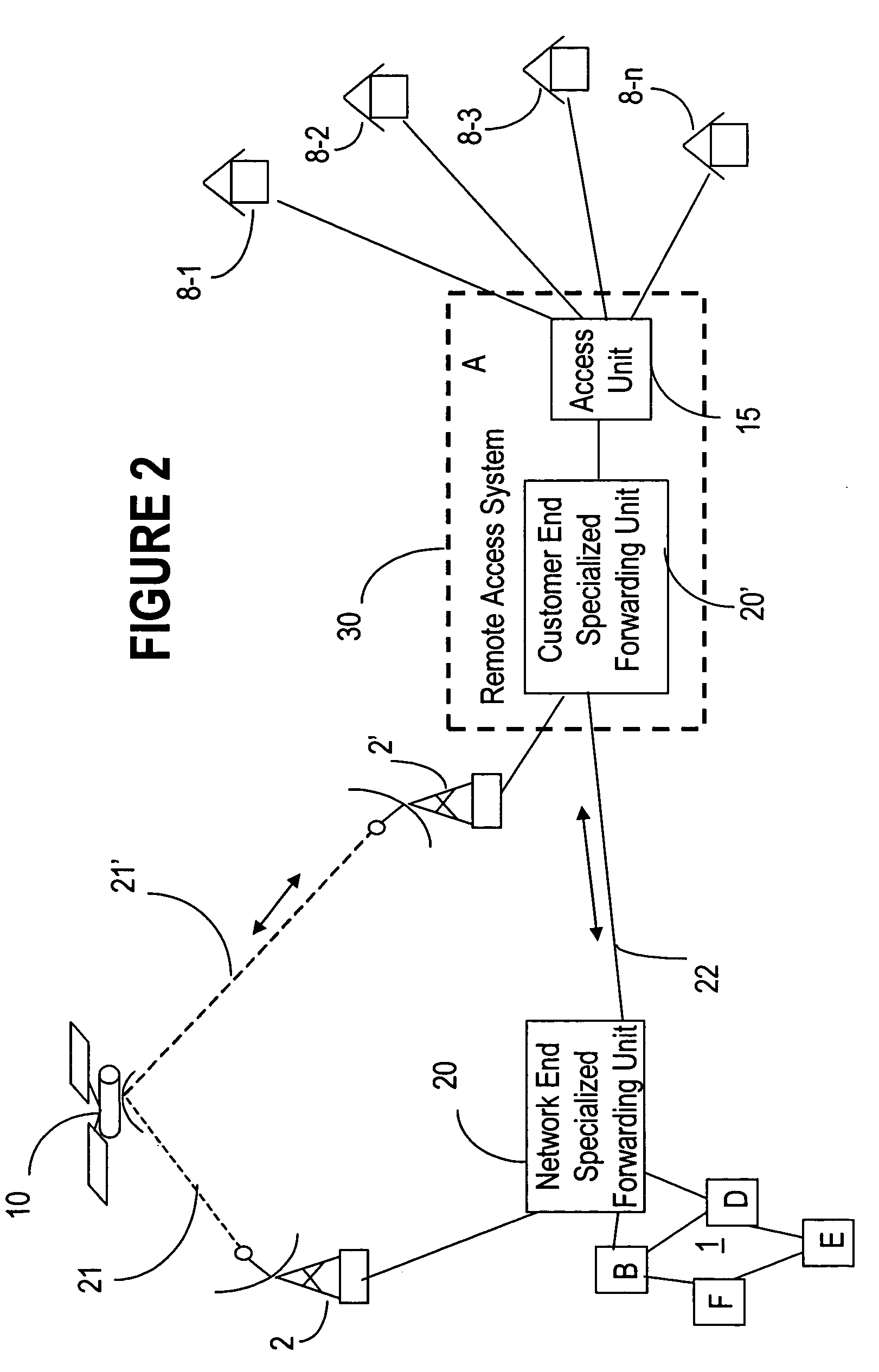

Rural broadband hybrid satellite/terrestrial solution

InactiveUS7477597B2Enhances quality cost-effectivenessAdaptable to changeError preventionFrequency-division multiplex detailsTraffic capacityBroadband

At a remote site, a satellite route is installed to augment the capacity of a terrestrial route. A specialized forwarding unit is introduced at both ends of these parallel satellite and terrestrial routes. The forwarding unit identifies what type of traffic needs a higher performance forward, and forwards the traffic accordingly. For example, latency-sensitive traffic can be forwarded over the terrestrial route and the latency insensitive traffic can be forwarded over the satellite route.

Owner:ALCATEL LUCENT SAS

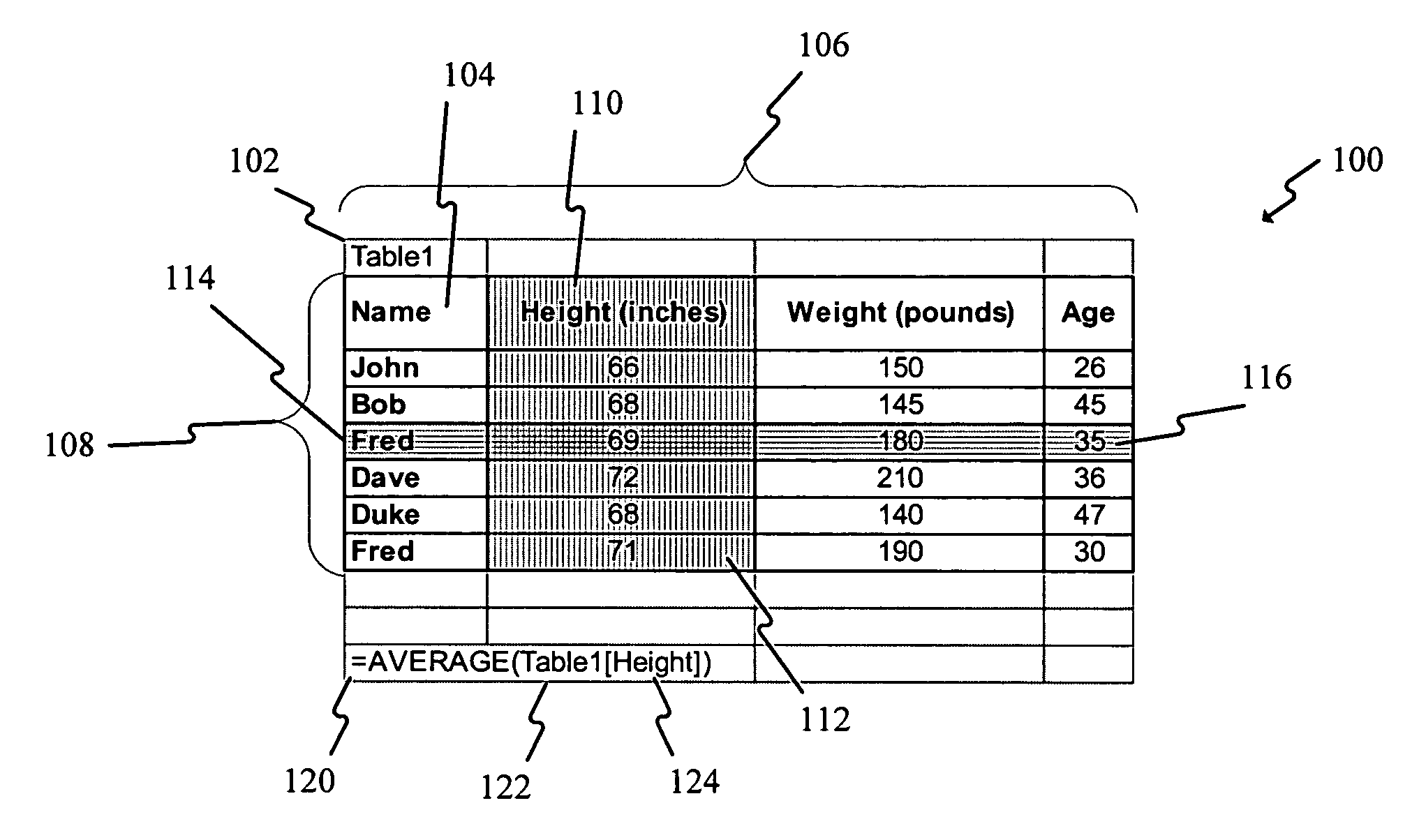

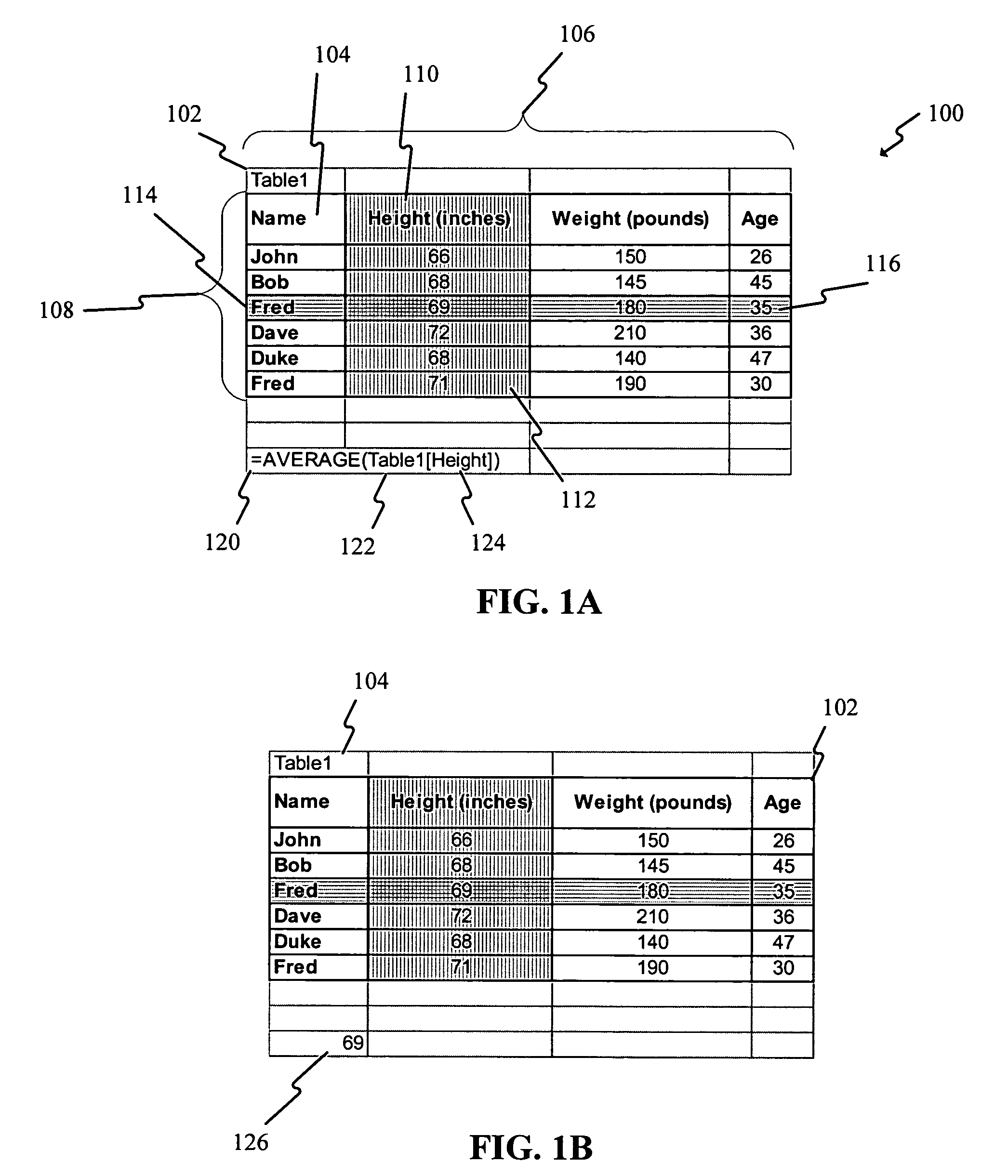

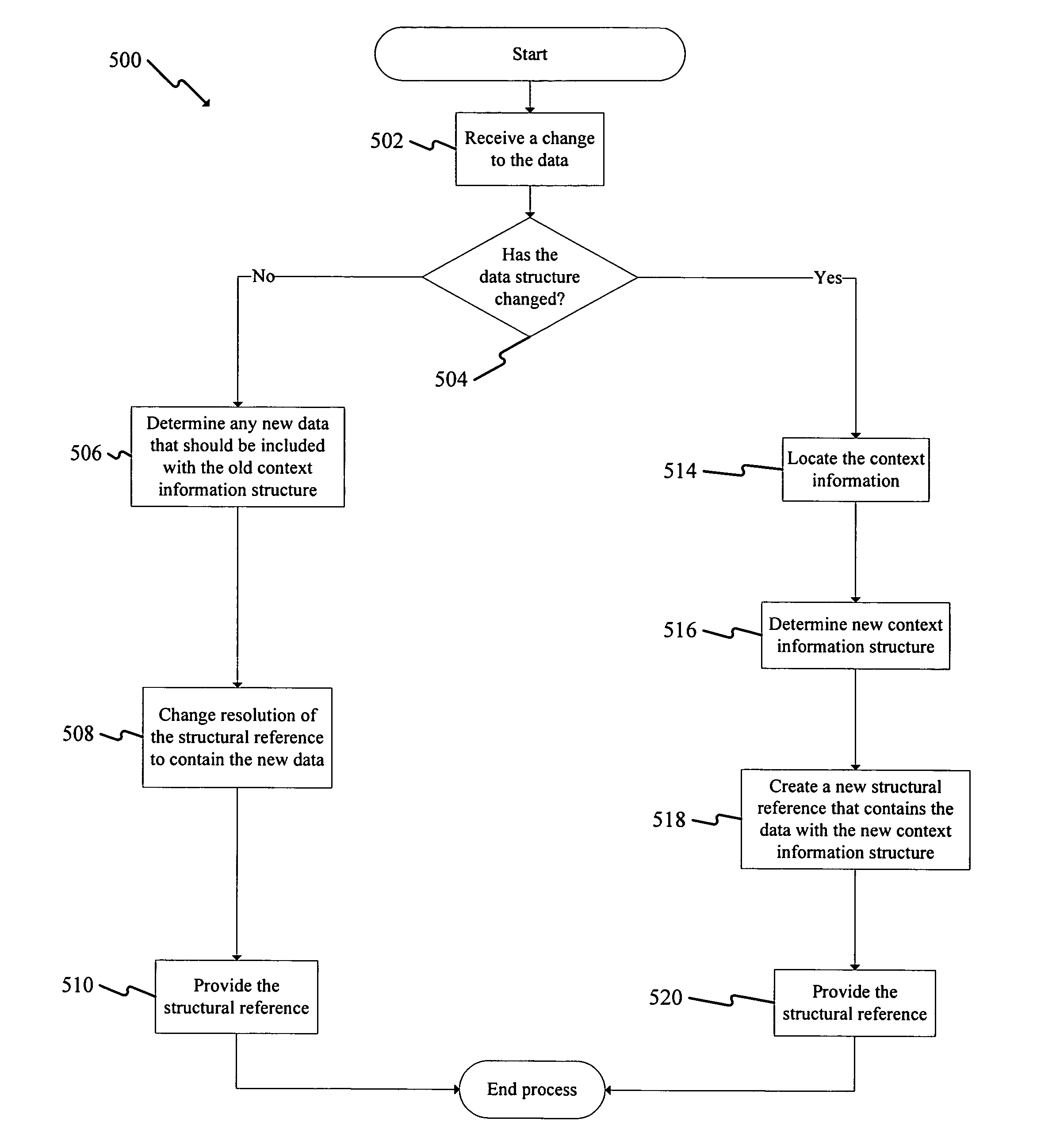

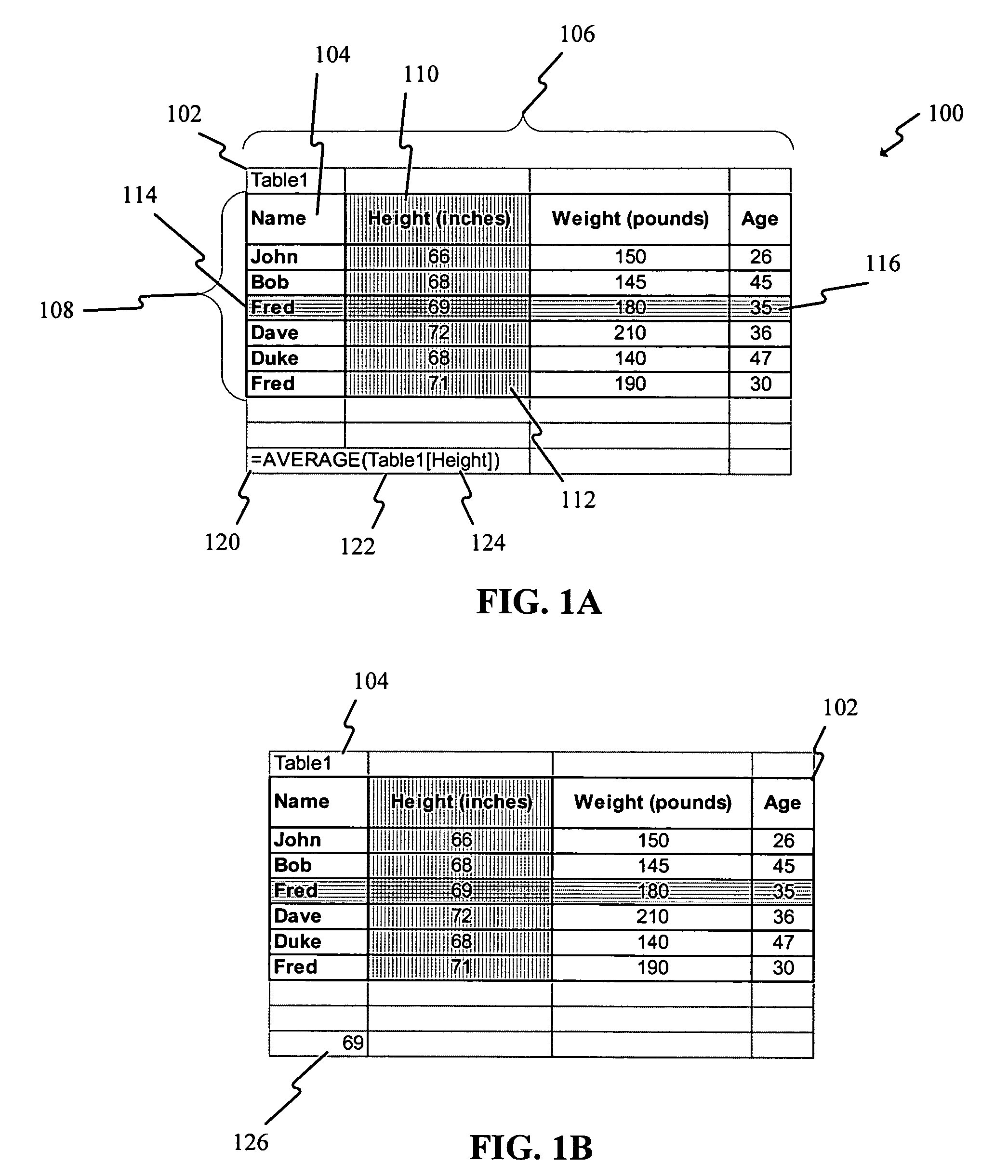

Method and implementation for referencing of dynamic data within spreadsheet formulas

InactiveUS20060069696A1Adaptable to changeSnap fastenersData processing applicationsElectronic formDisplay device

The present invention relates to a new type of structured name within a spreadsheet program that allows users to refer to tables, columns of data within tables, headers of tables, totals from tables, PivotTables®, and portions of PivotTable® data by the data's headers. Embodiments of the present invention comprise a method for referring to a set of data that comprises receiving one or more semantic designations, wherein the one or more semantic designations name a set of context information that describes one or more items of data in a data structure, automatically creating a structural reference, and associating the context information with the structural reference. Other embodiments of the present invention relate to an interaction with a user interface for displaying on a display device a structural reference to data in a spreadsheet that comprises receiving one or more semantic designations from the user that refer to one or more elements of the data structure, creating a structural reference to the elements of the data structure, and displaying the structural reference as a collection of the one or more semantic designations.

Owner:MICROSOFT TECH LICENSING LLC

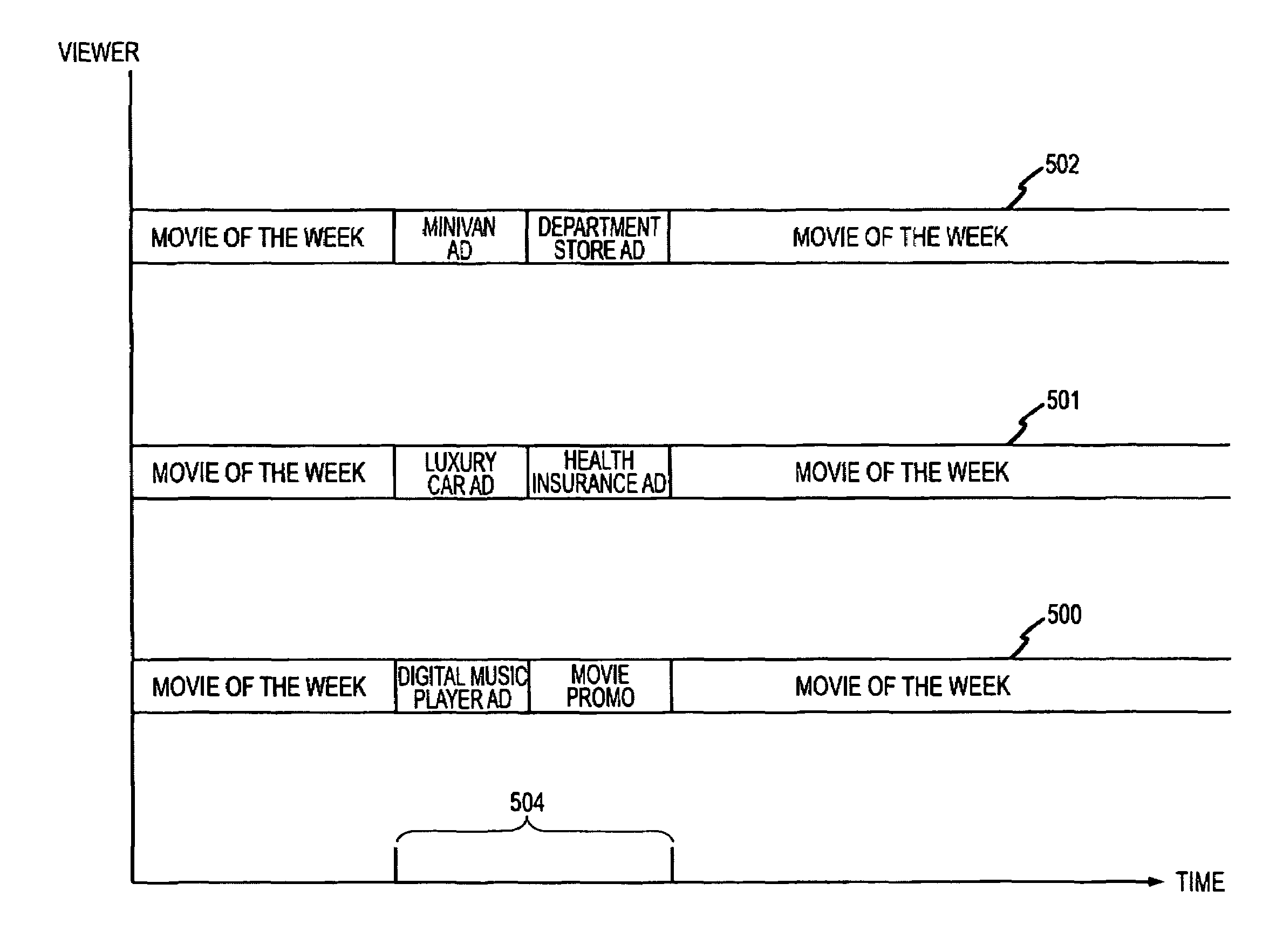

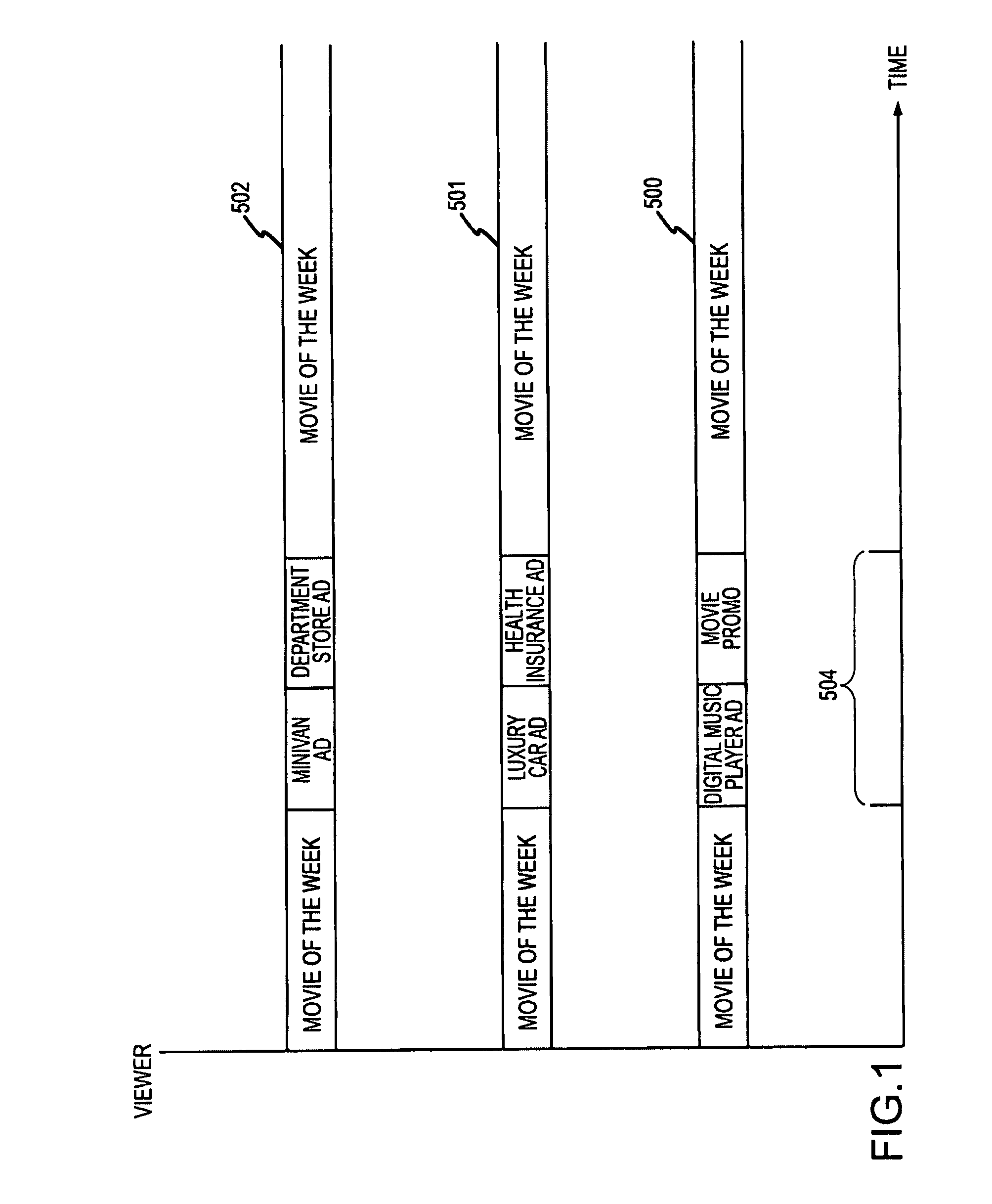

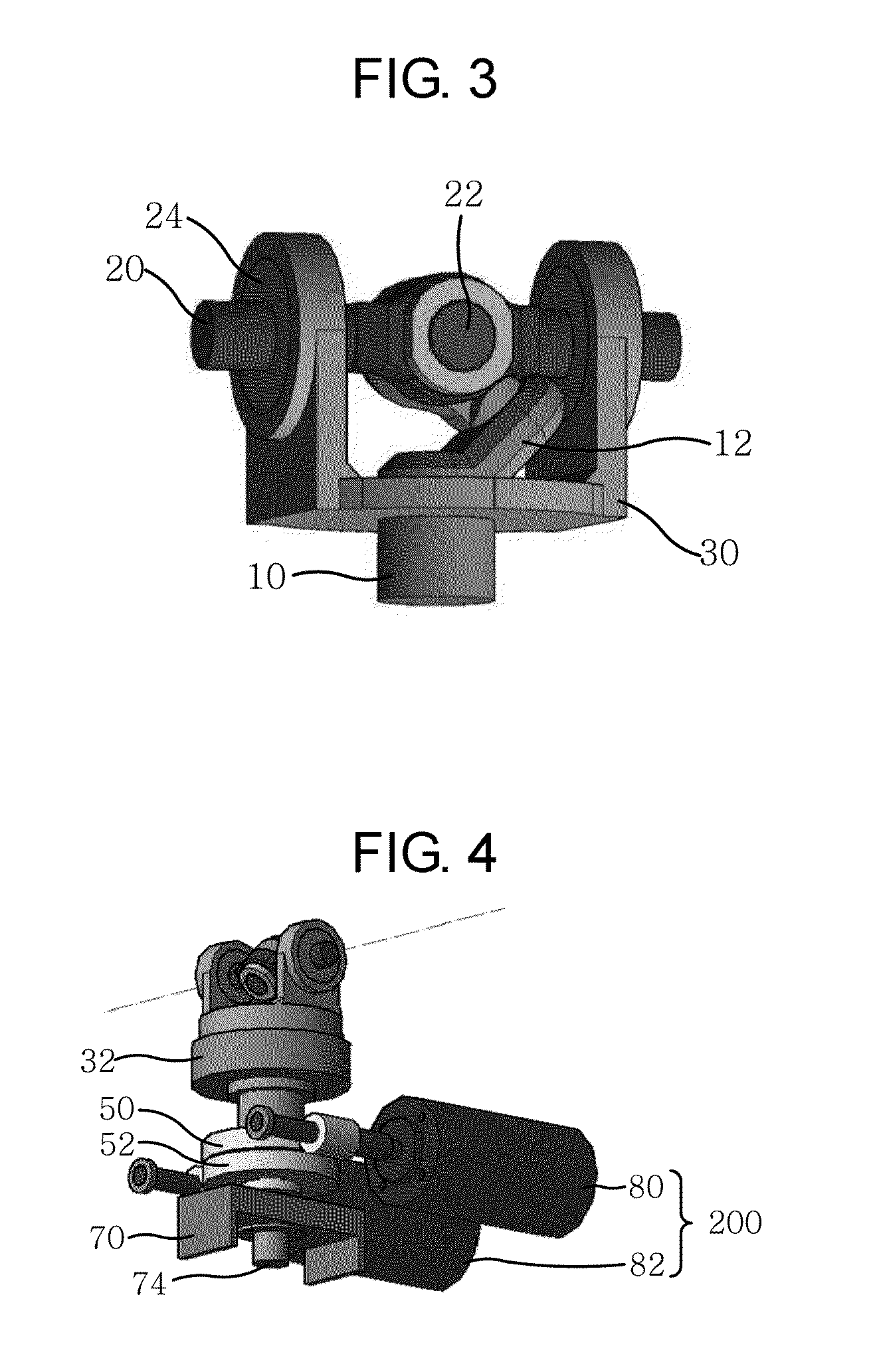

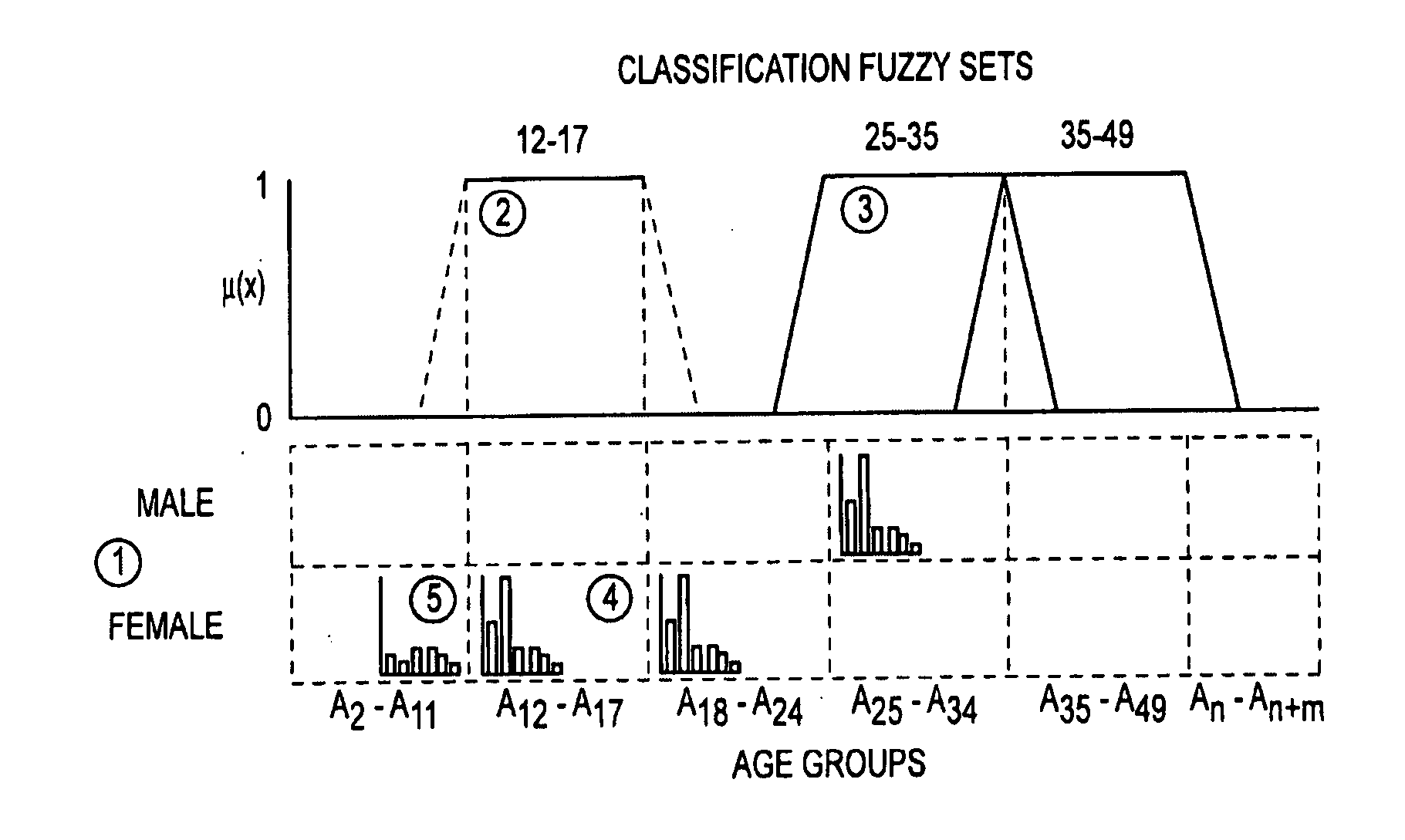

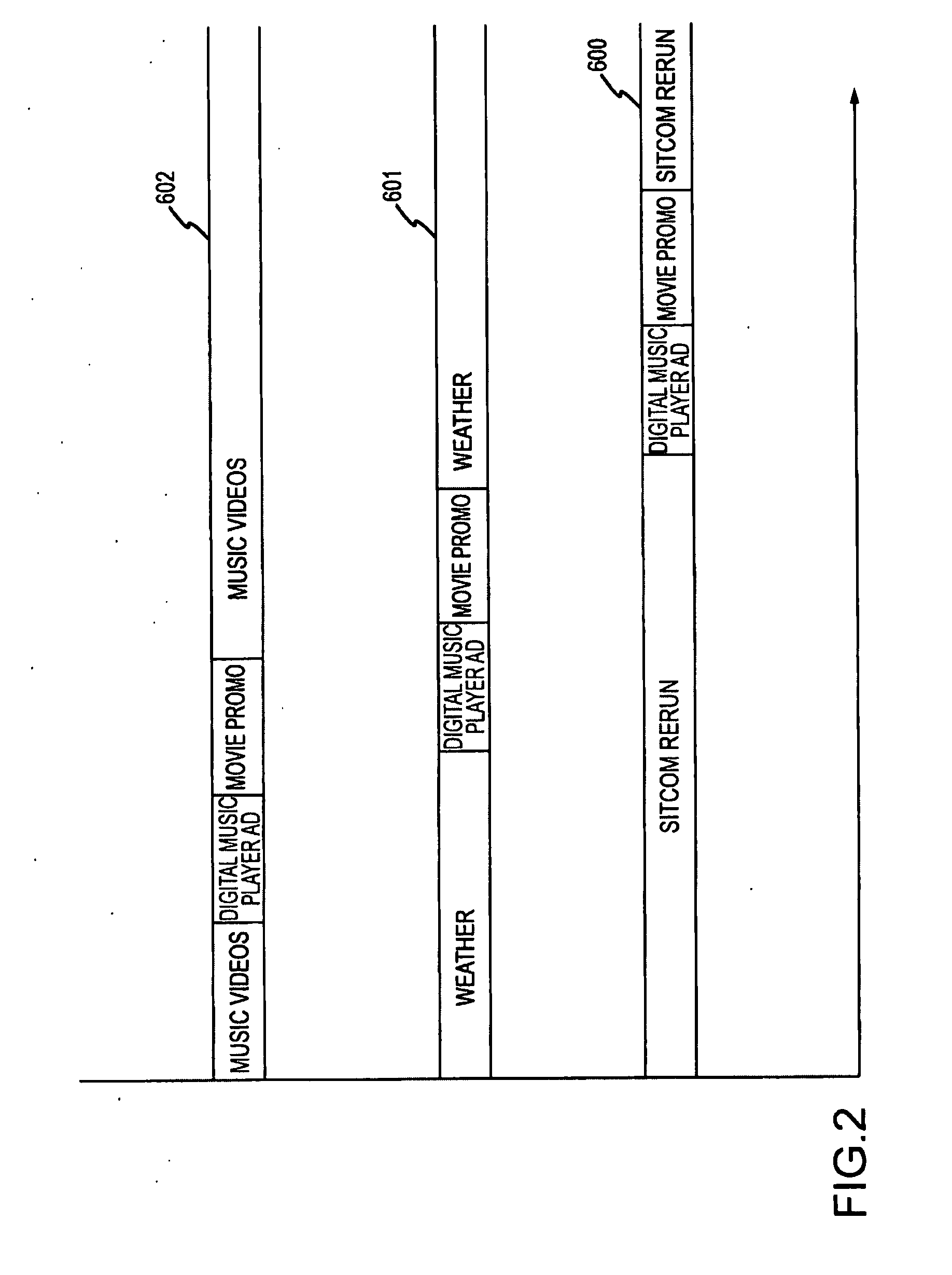

Fuzzy logic based viewer identification for targeted asset delivery system

ActiveUS7698236B2Improve efficiencyIncrease choiceBroadcast systems characterised by addressed receiversTelevision system detailsUser inputTargeted advertising

A targeted advertising system uses a machine learning tool to select an asset for a current user of a user equipment device, for example, to select an ad for delivery to a current user of a digital set top box in a cable network. The machine learning tool first operates in a learning mode to receive user inputs and develop evidence that can characterize multiple users of the user equipment device audience. In a working mode, the machine learning tool processes current user inputs to match a current user to one of the identified users of that user equipment device audience. Fuzzy logic may be used to improve development of the user characterizations, as well as matching of the current user to those developed characterizations. In this manner, targeting of assets can be implemented not only based on characteristics of a household but based on a current user within that household.

Owner:INVIDI TECH CORP

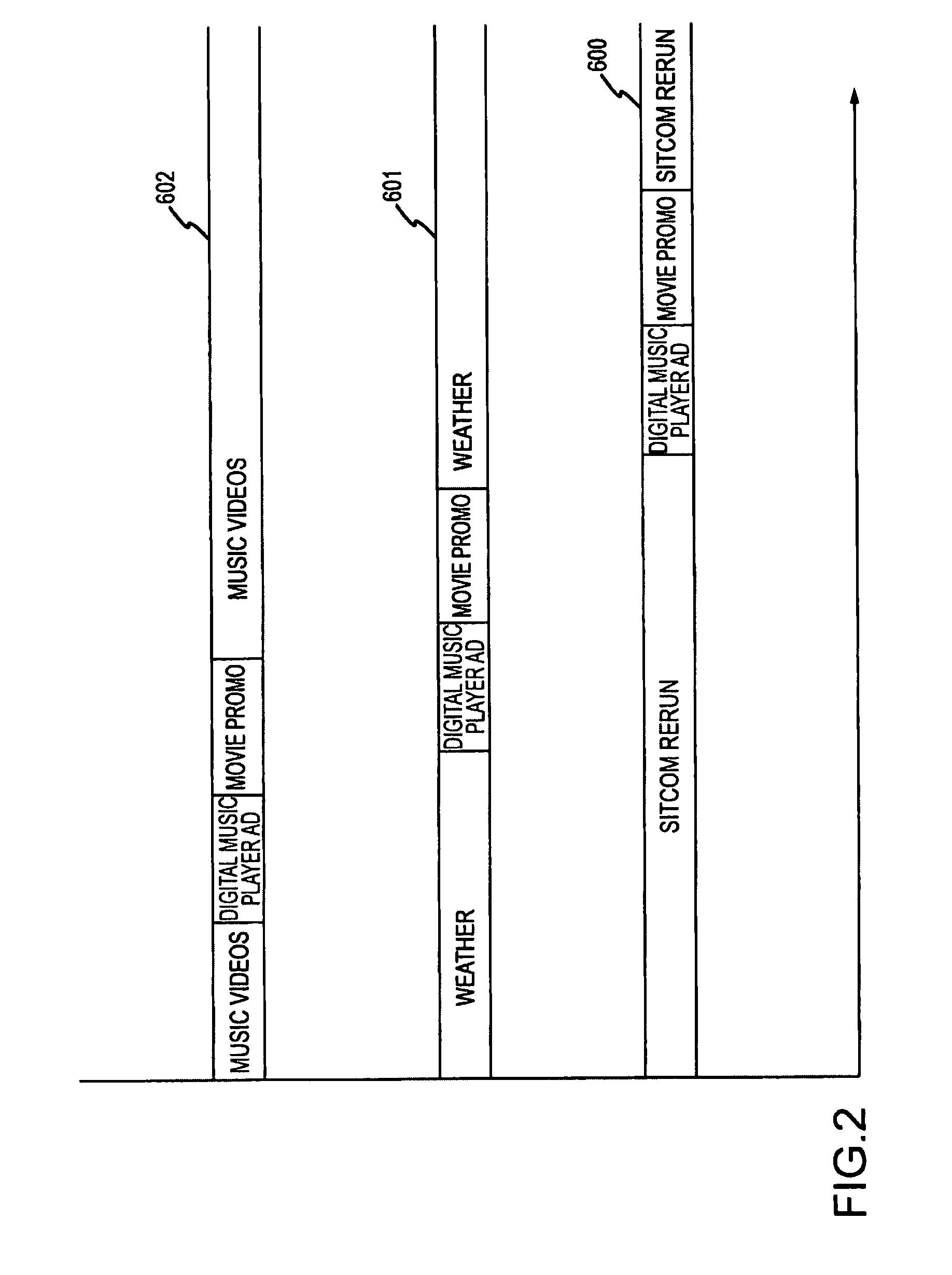

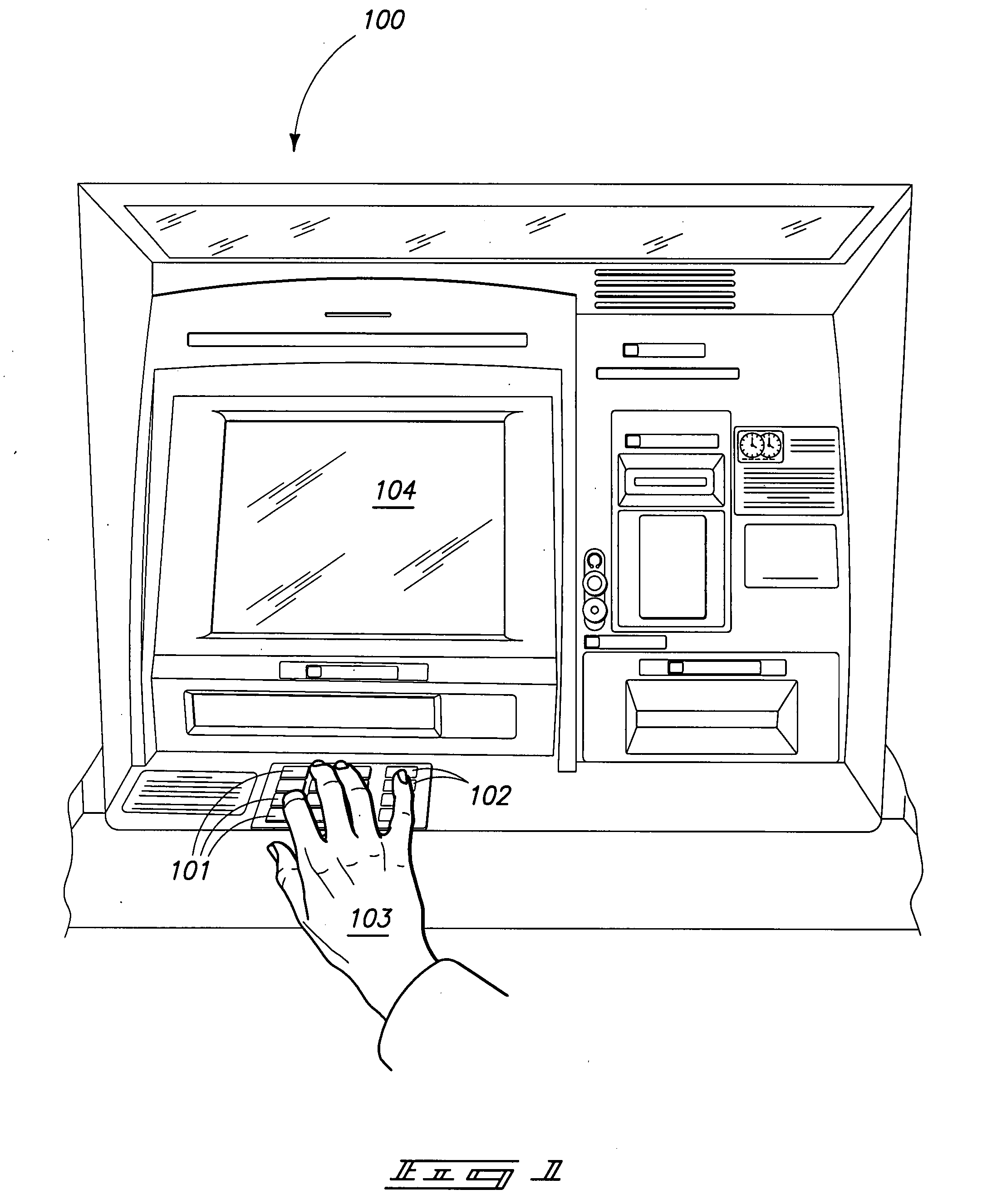

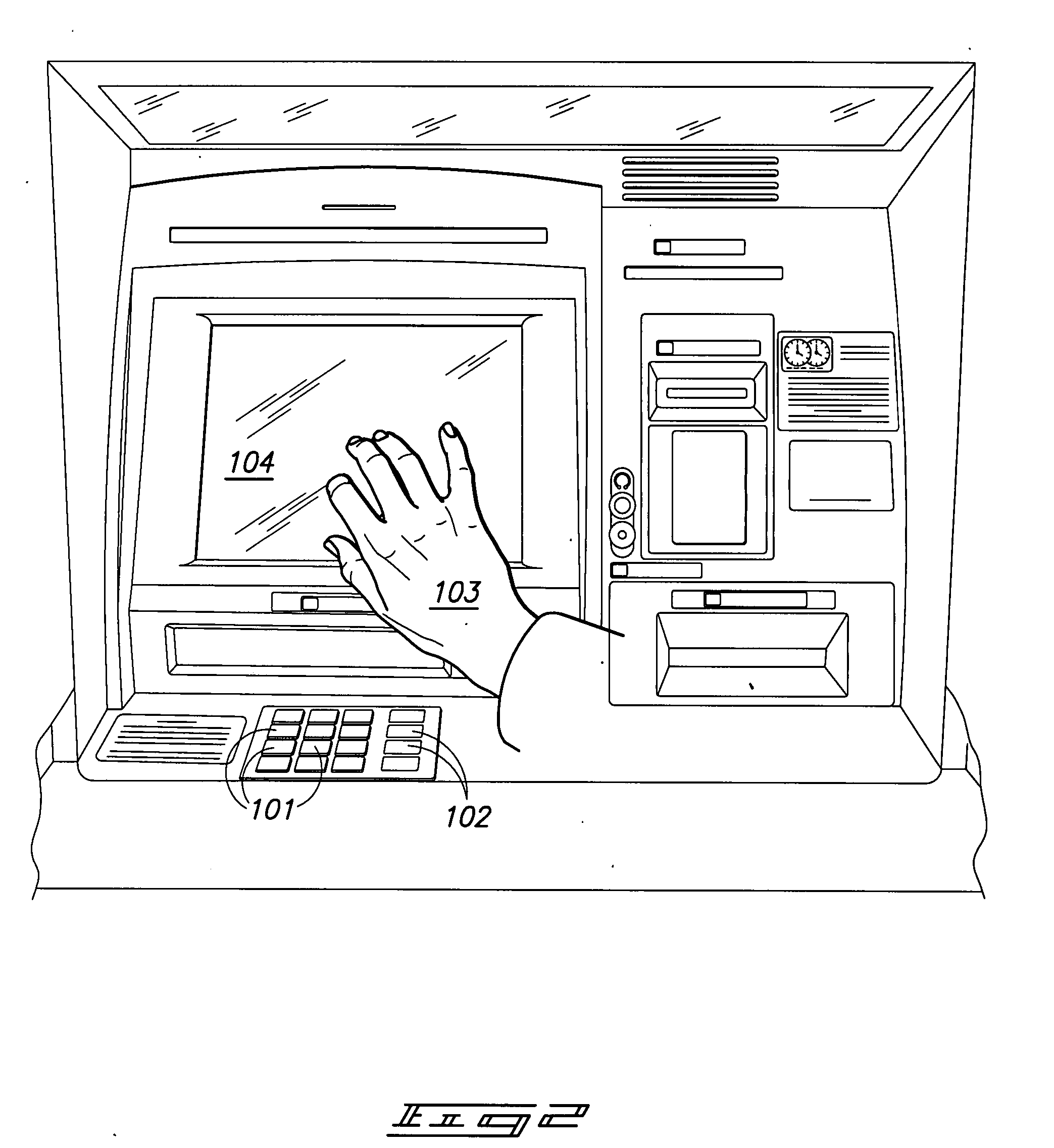

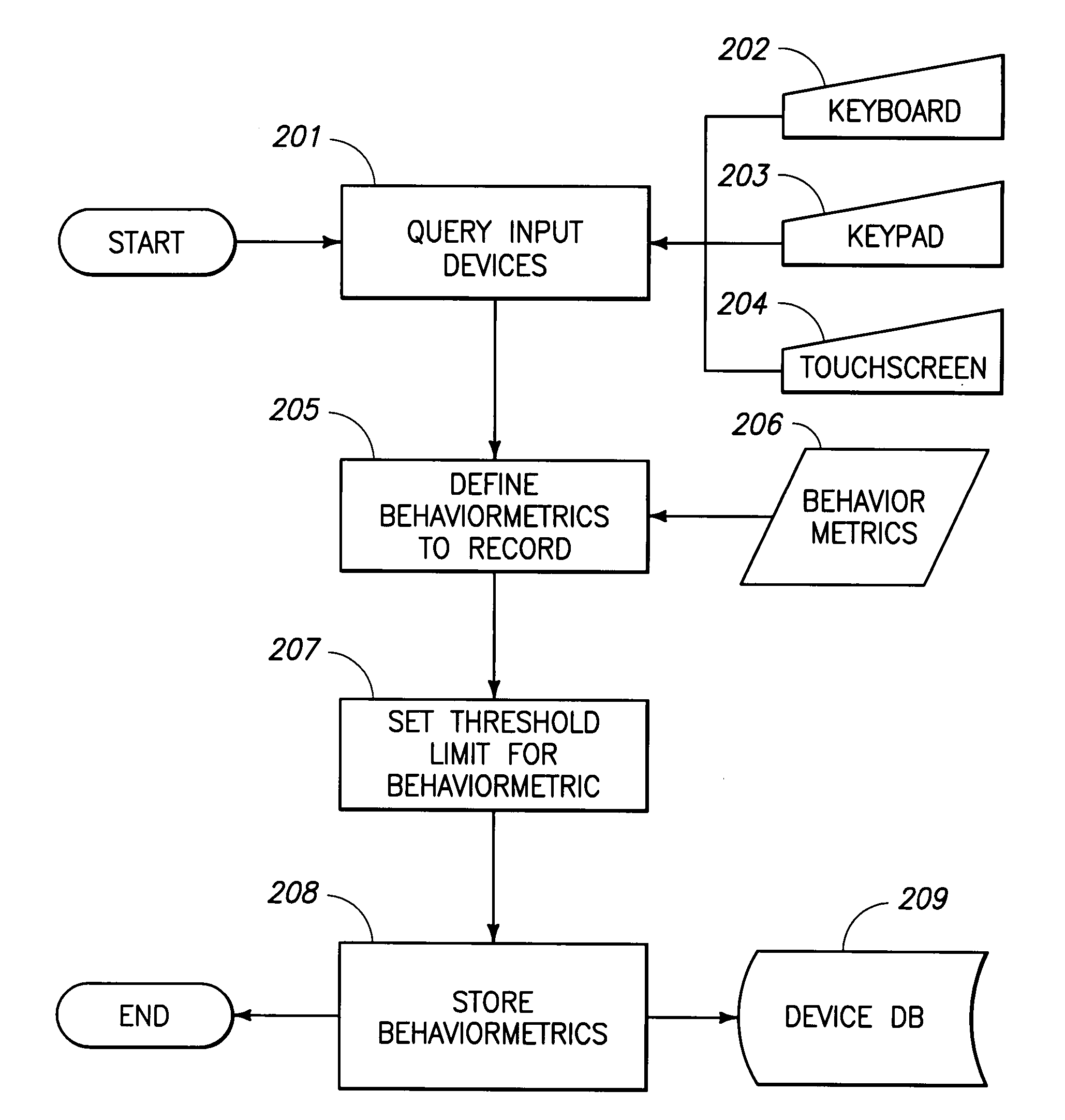

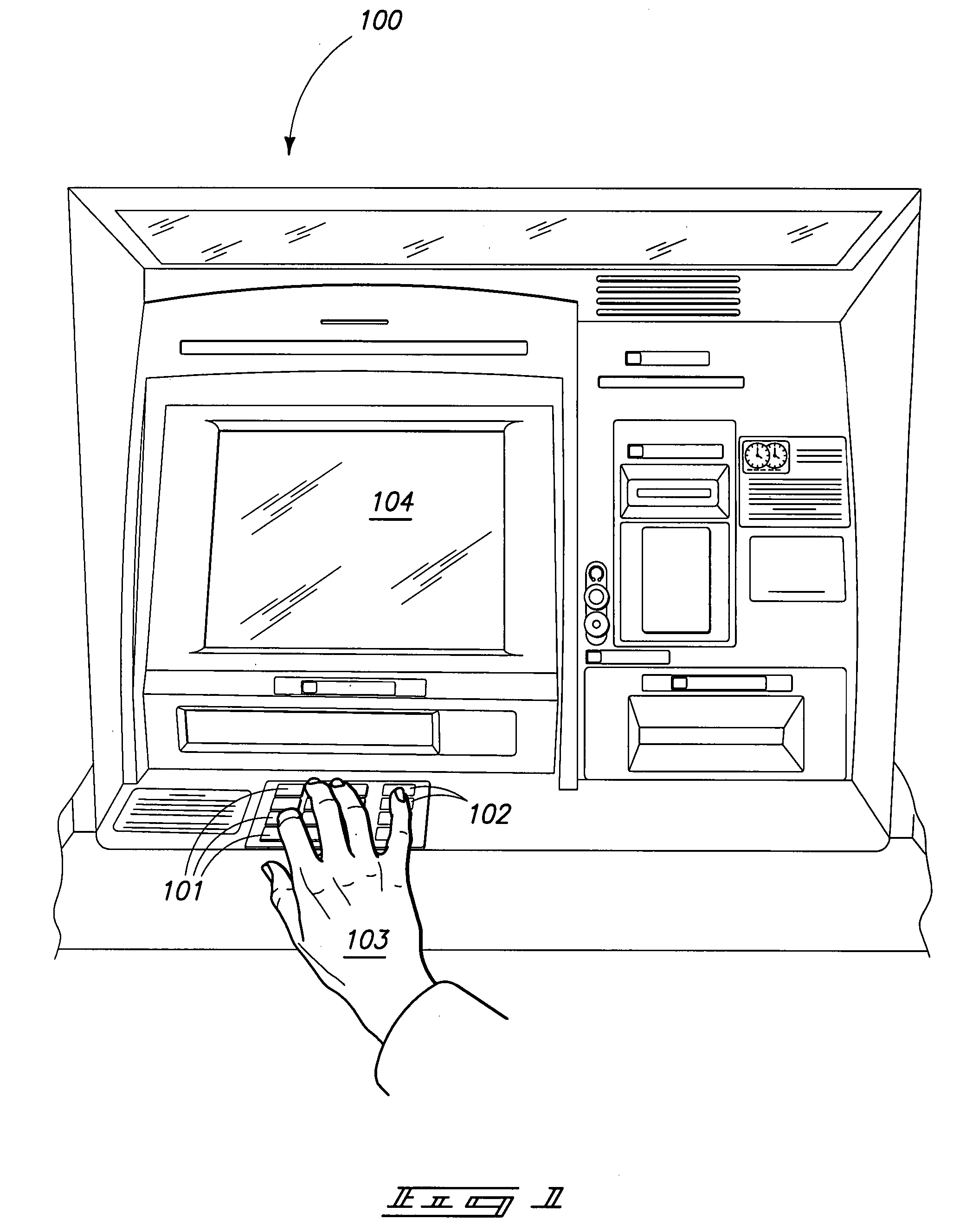

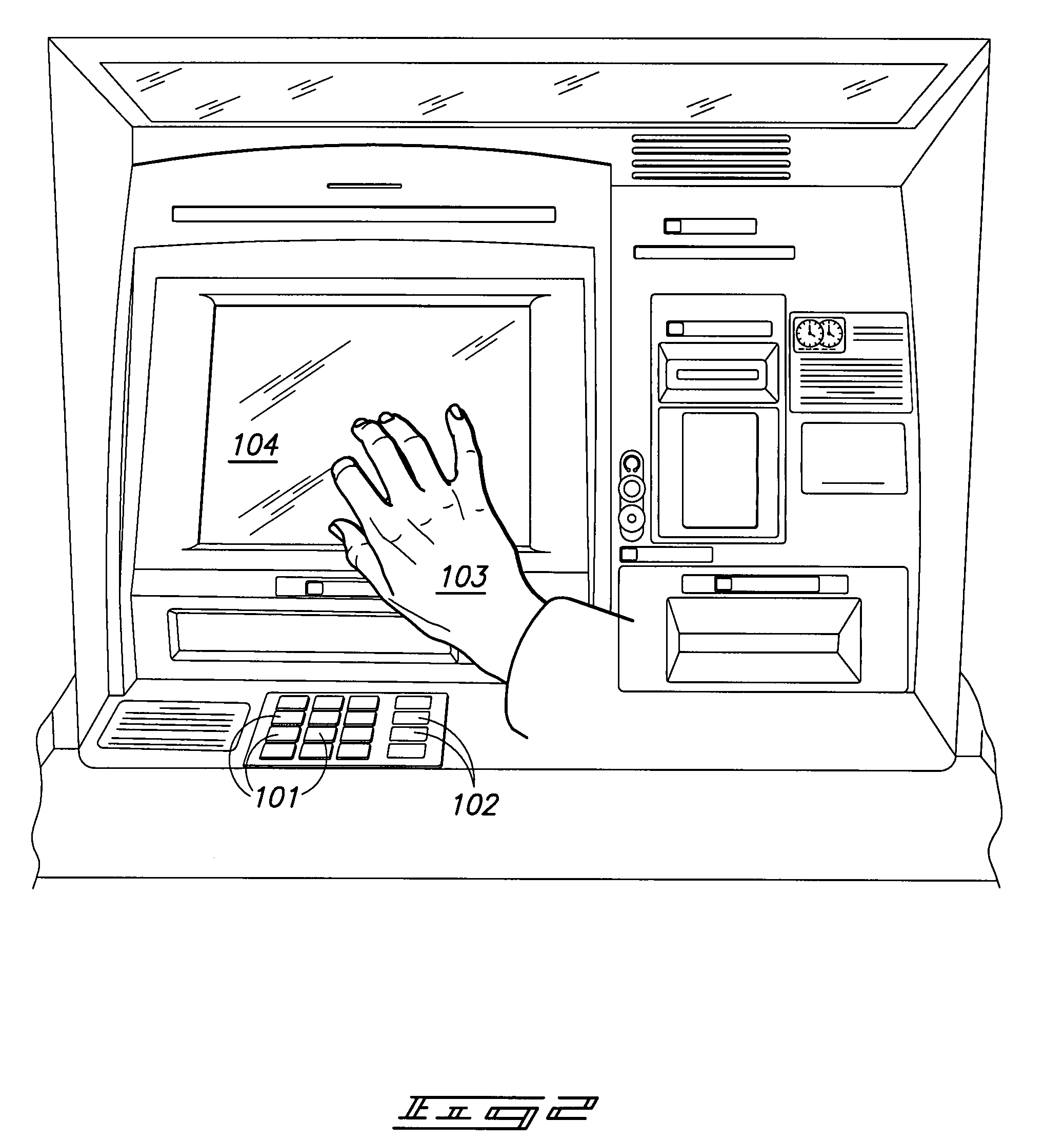

Behaviormetrics application system for electronic transaction authorization

InactiveUS20080091453A1Adaptable to changeFast and adaptable and scalable mechanismAcutation objectsDigital data processing detailsPasswordDynamic data

This invention discloses a system wherein behaviormetrics are utilized to authenticate electronic transactions, either alone or in combination with other identifiers such as PIN's, passwords, codes and the like. Probability profiles or probability distribution representations may be constructed for determining whether a purported or alleged authorized user is in fact the authorized user, by comparing new data on a real-time basis against probability distribution representations including an authorized user probability distribution representation and a global or wide population probability distribution representation, to provide a probability as to whether the purported authorized user is the authorized user. This invention may utilize keypad, touch screen dynamics, X-Y dynamics, data, X-Y device data, or other data from similar measurable characteristics (such as movement filmed by an ATM machine), to determine the probability that the new data from the purported authorized user indicates or identifies that user as the authorized user.

Owner:IDENTITY METRICS

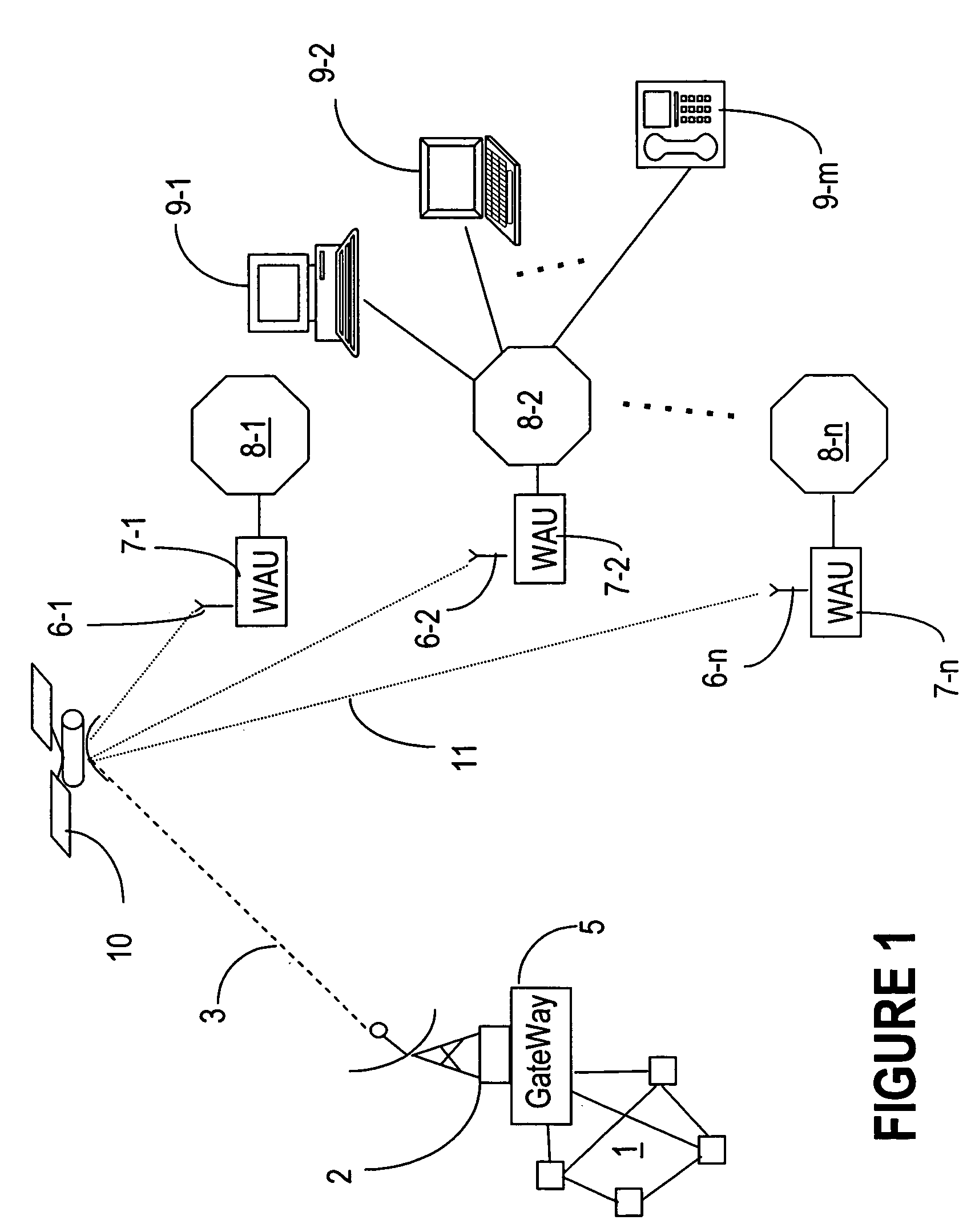

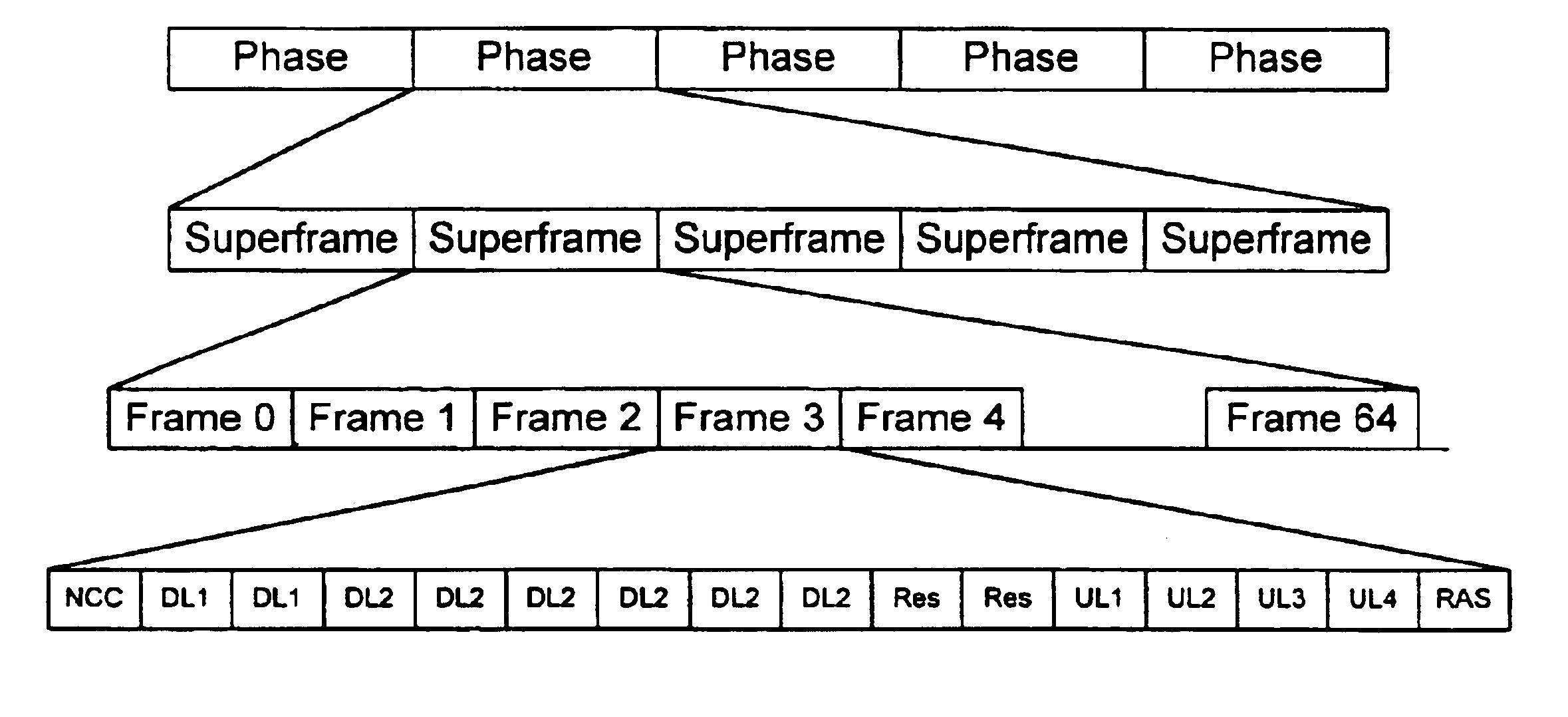

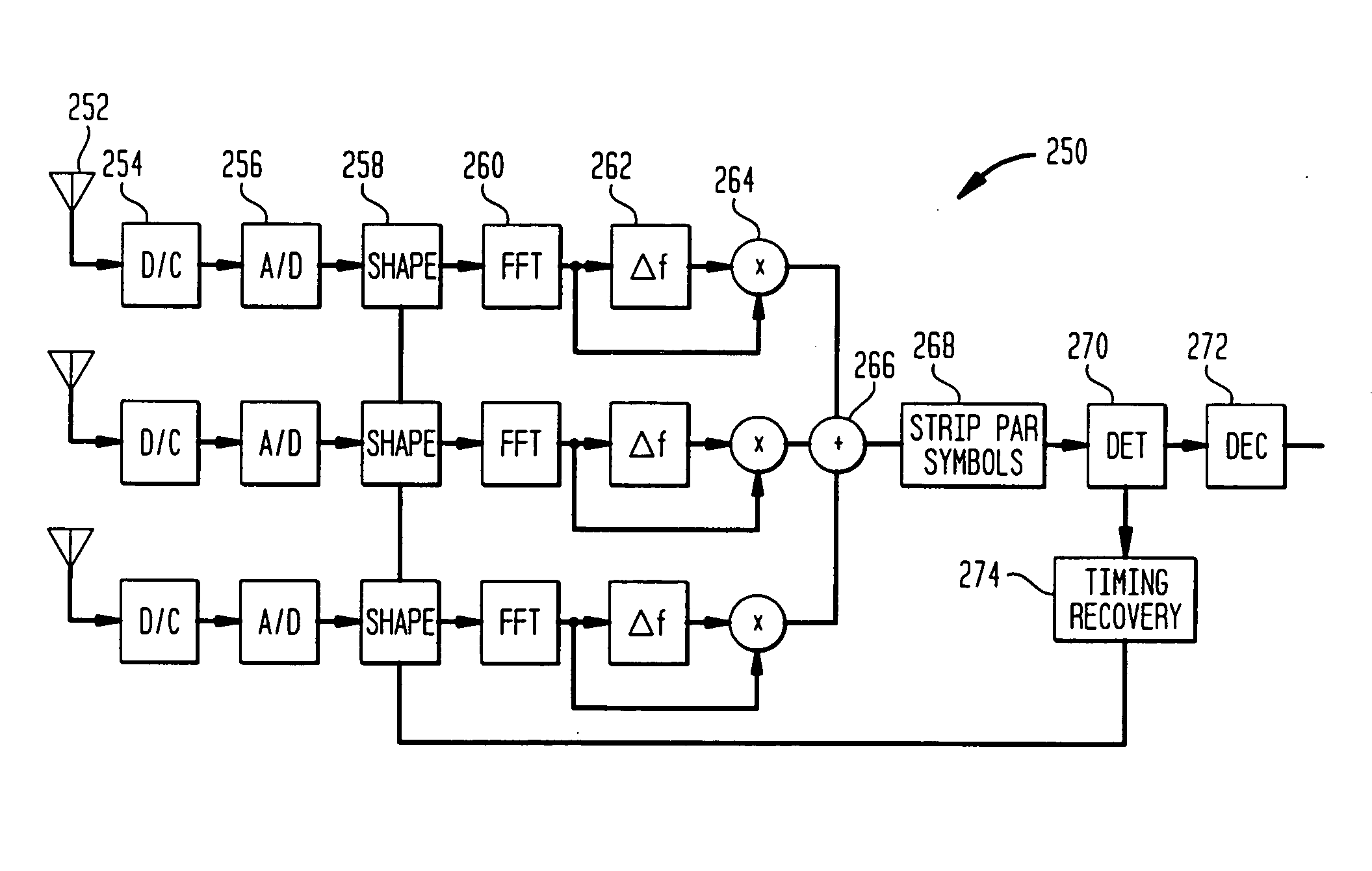

Wireless internet access system and method

InactiveUS6947408B1Avoid Intersymbol InterferenceAdaptable to changeSpatial transmit diversityError preventionWireless internet accessDifferential phase

A wireless Internet access system and method supports the transmission and reception of multiple types of traffic between mobile subscriber units and existing networks. A frame structure is used that can support the transmission of multiple types of traffic and adapt to changes in the traffic types needed and the amount of data for a particular traffic type. In addition, data transmission is performed using orthogonal frequency division multiplexing and differential phase shift keying to avoid inter-symbol interference. Receiving units in the mobile subscriber units and existing works include antenna arrays to provide a multipath transmission.

Owner:TELCORDIA TECHNOLOGIES INC

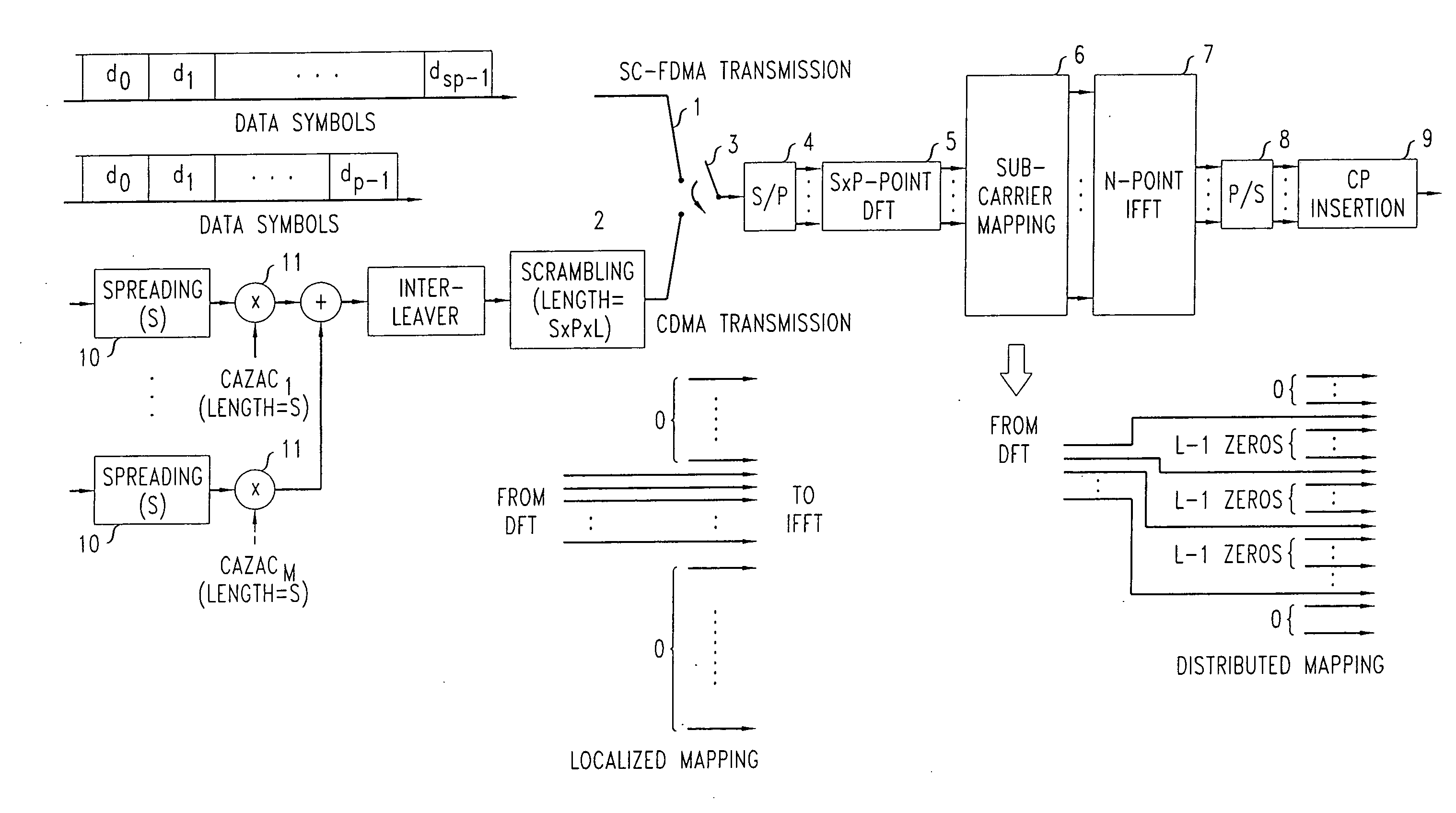

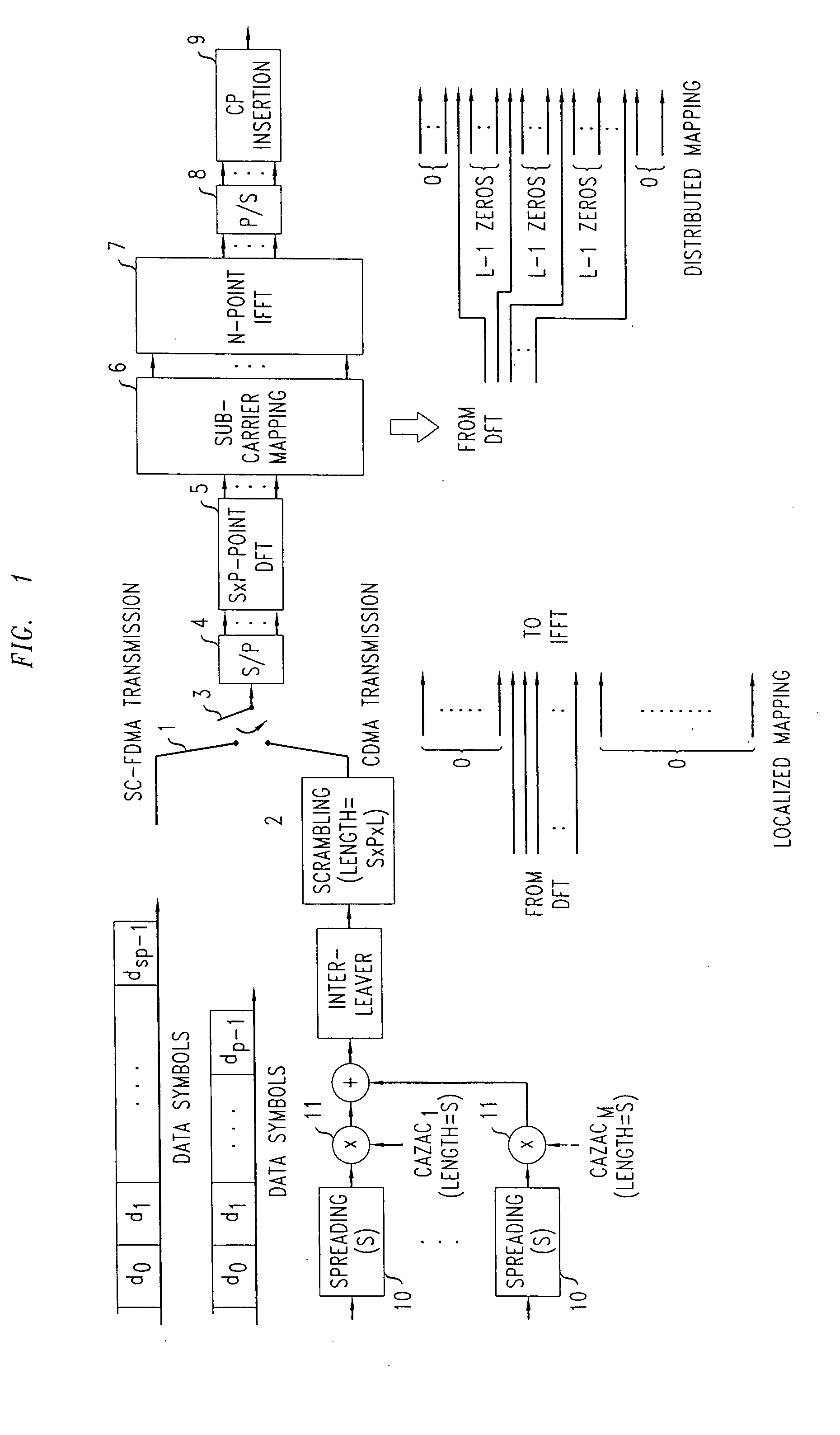

Method and apparatus for packet wireless telecommunications

ActiveUS20080267157A1Lower latencySimple processError prevention/detection by using return channelRadio transmissionTelecommunications networkCode division multiple access

In a wireless telecommunications network, a Code Division Multiple Access (CDMA) scheme is applied to data to encode it. The encoded data transmitted in the uplink using an Orthogonal Frequency Division Multiplexing (OFDM) frame structure including a cyclic prefix (CP). The CDMA encoded data may be time multiplexed with Single Carrier-Frequency Division Multiple Access (SC-FDMA) transmissions. The CDMA transmissions may be used for relatively small payloads, such as those associated with voice traffic and control signals, and the SC-FDMA transmissions used for higher date rate transmissions. This enables autonomous transmission, without scheduling, for smaller payloads. A transmitter includes a selector 3 for performing time multiplexing in the uplink, the required mode being indicated by the Hybrid Automatic Repeat Request (HARQ) ID. A first branch 1 carries SC-FDMA data and a second branch 2 carries data to be transmitted as a CDMA scheme. A CAZAC code may be used in encoding the CDMA data.

Owner:ALCATEL LUCENT SAS

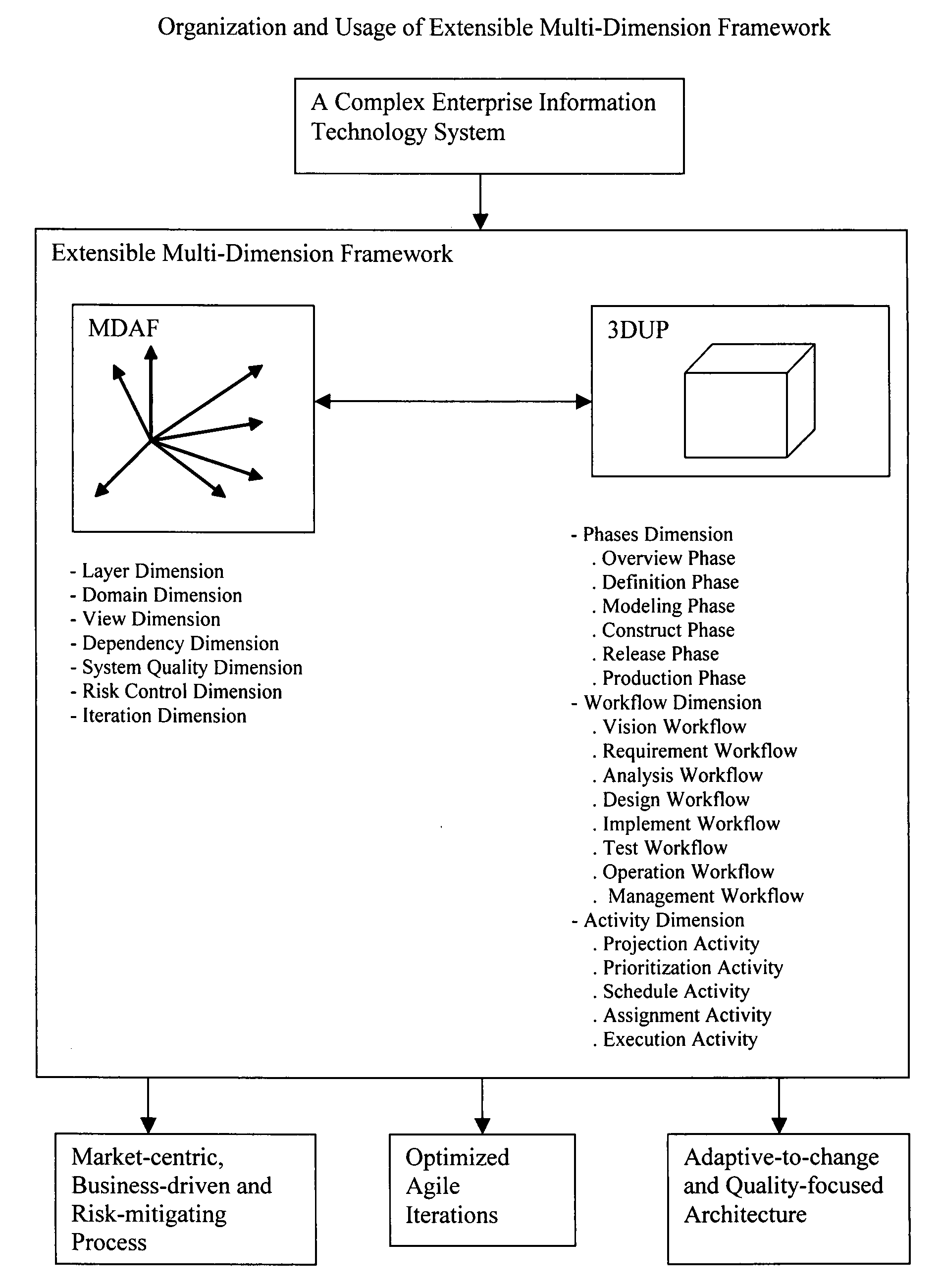

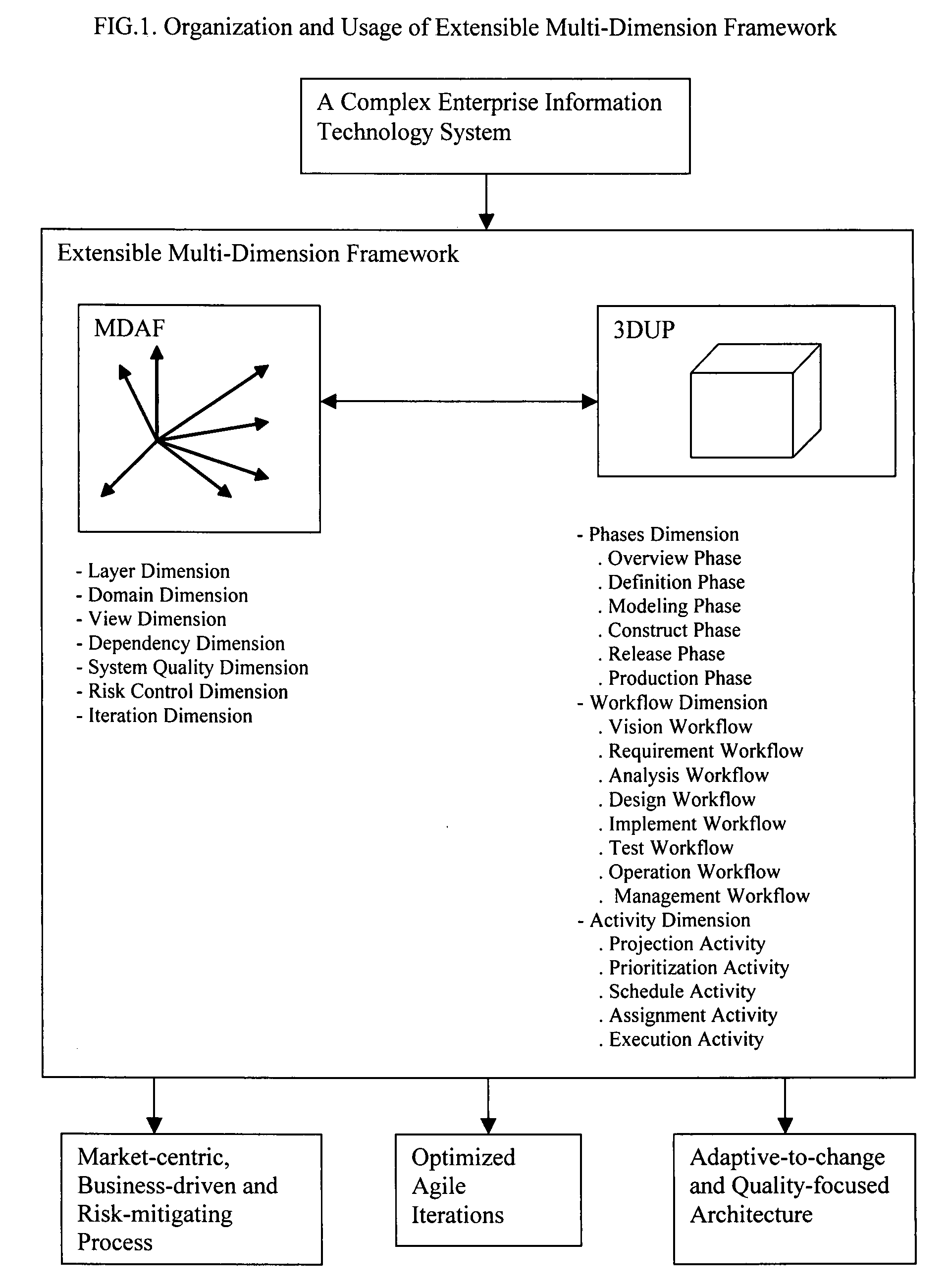

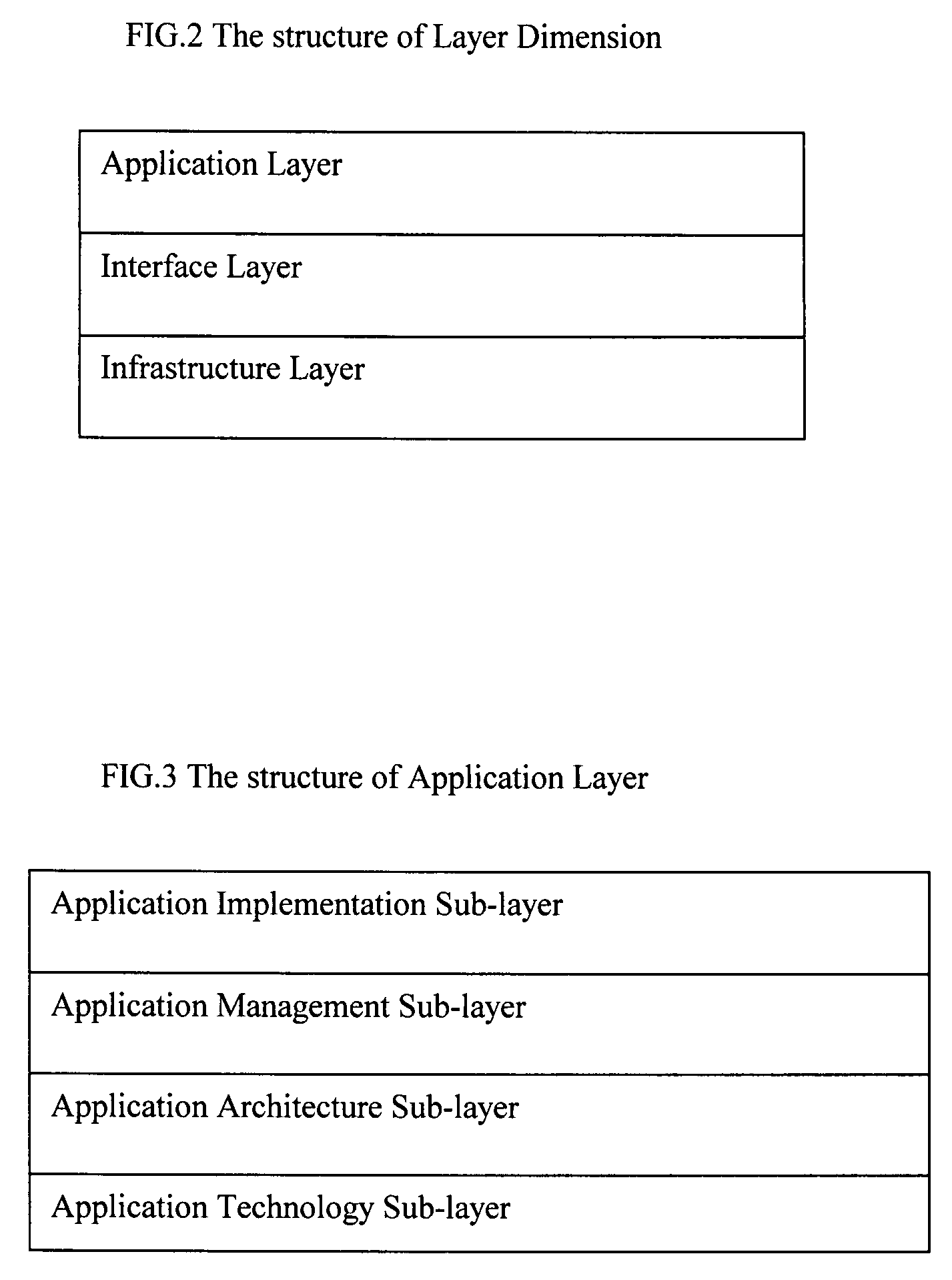

Extensible multi-dimensional framework

InactiveUS20080040364A1Easy to implementEasy to modifyOffice automationSpecial data processing applicationsDevelopment teamMulti dimensional

Extensible Multi-Dimensional Framework (EMDF) is a system engineering framework for designing, developing and managing enterprise information technology systems. It includes two parts: multi-dimensional architecture framework (MDAF) and three-dimensional unified process (3DUP). MDAF includes comprehensive concepts for modeling an enterprise information technology system. 3DUP provides an iterative system development process. EMDF addresses an enterprise information technology system as a single entity. By projecting this entity on intertwined MDAF dimensions through the 3DUP lifecycle, all logical or physical elements encompassed in the entity will be exposed and captured in well-organized artifacts defined in MDAF. These elements are then prioritized and scheduled in a set of agile iterations. The iterations will be planned in parallel projects implemented by multiple development teams. During a long-term system development lifecycle, some elements may change. The dimensions included in MDAF provide a flexible framework to adjust system architectures, iterations and projects in order to adapt to such changes. The key deliverables of EMDF include an adaptive-to-change quality-focused architecture, optimistic agile iterations, and a market-centric business-driven risk-mitigating process.

Owner:LI DI

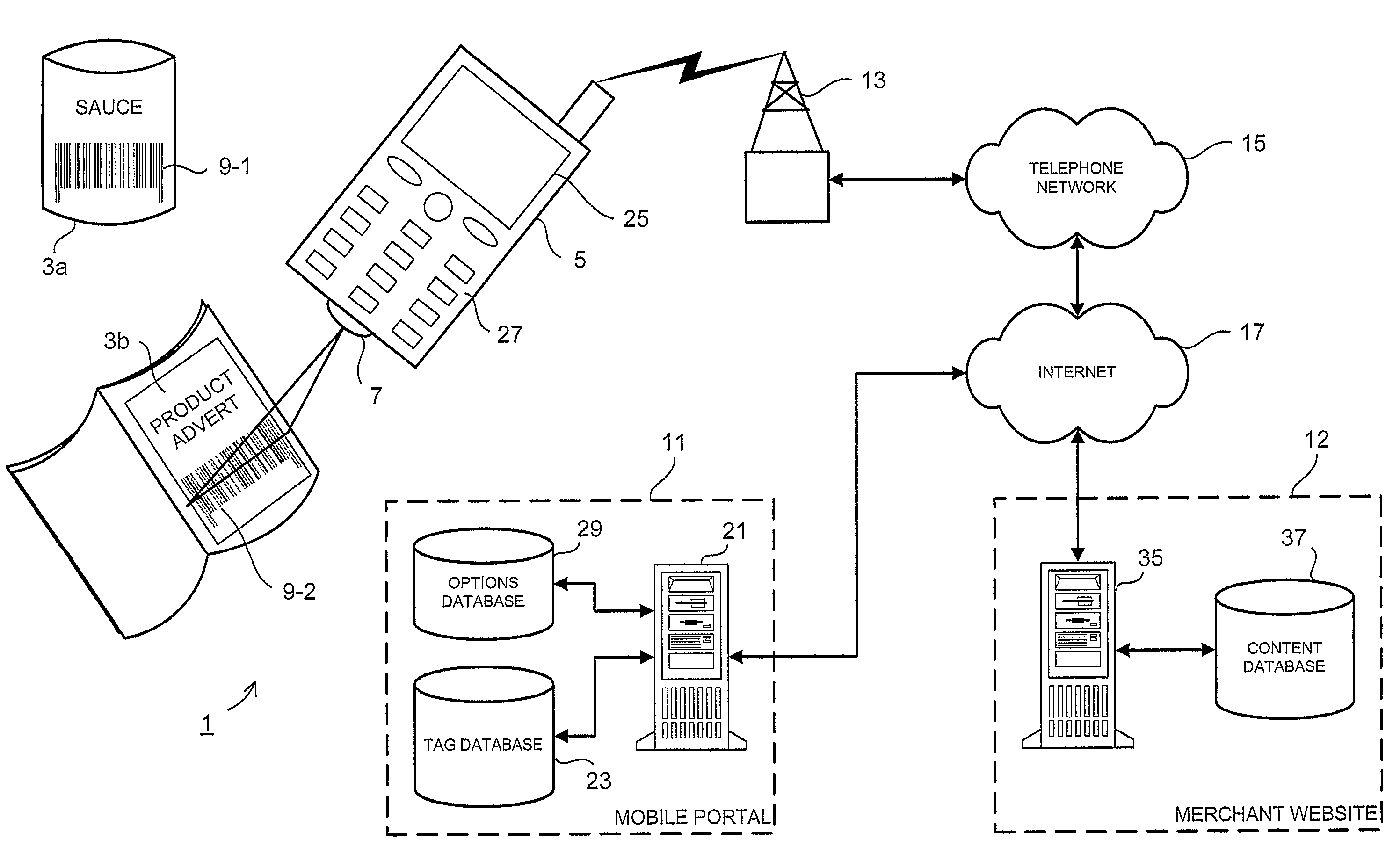

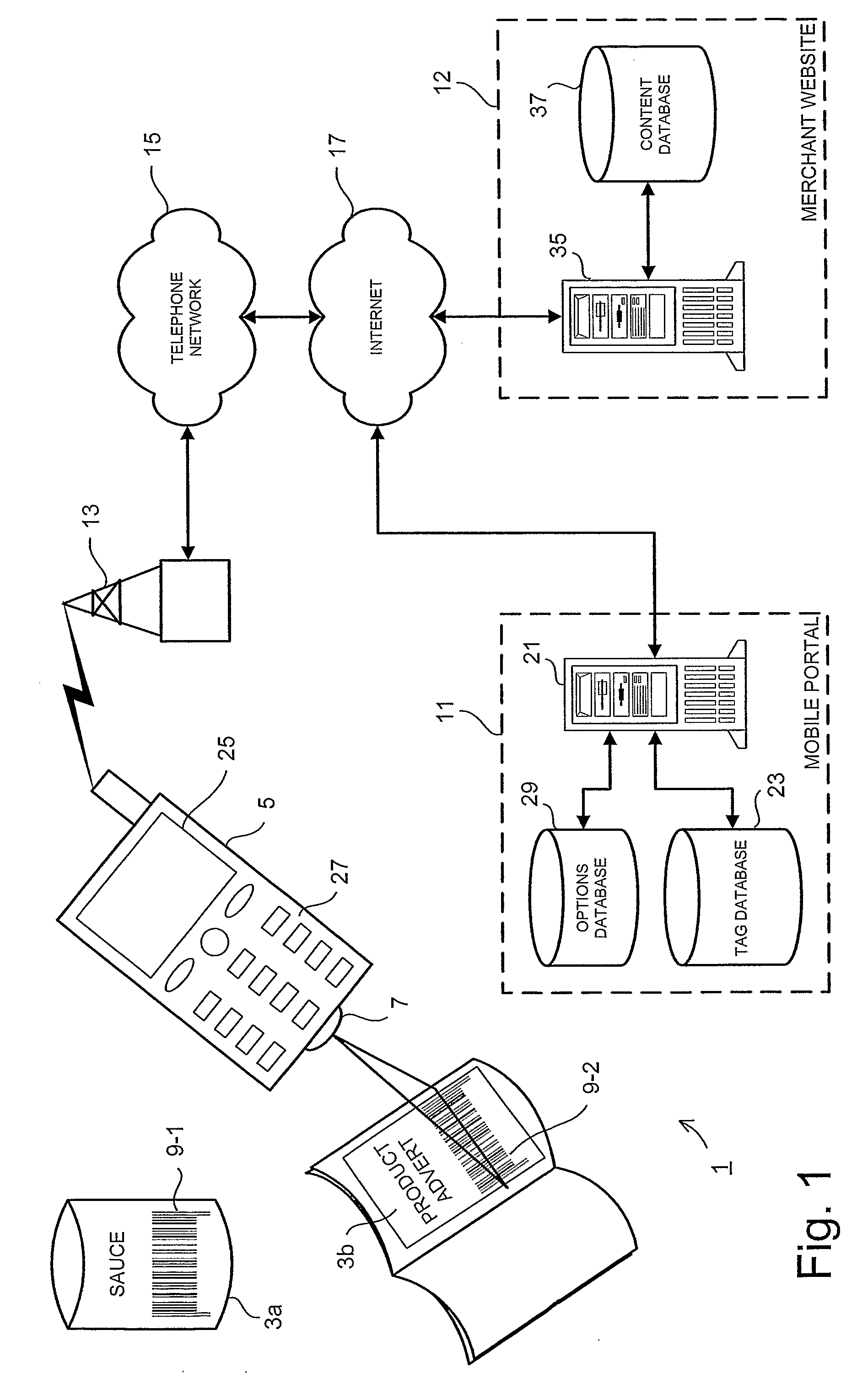

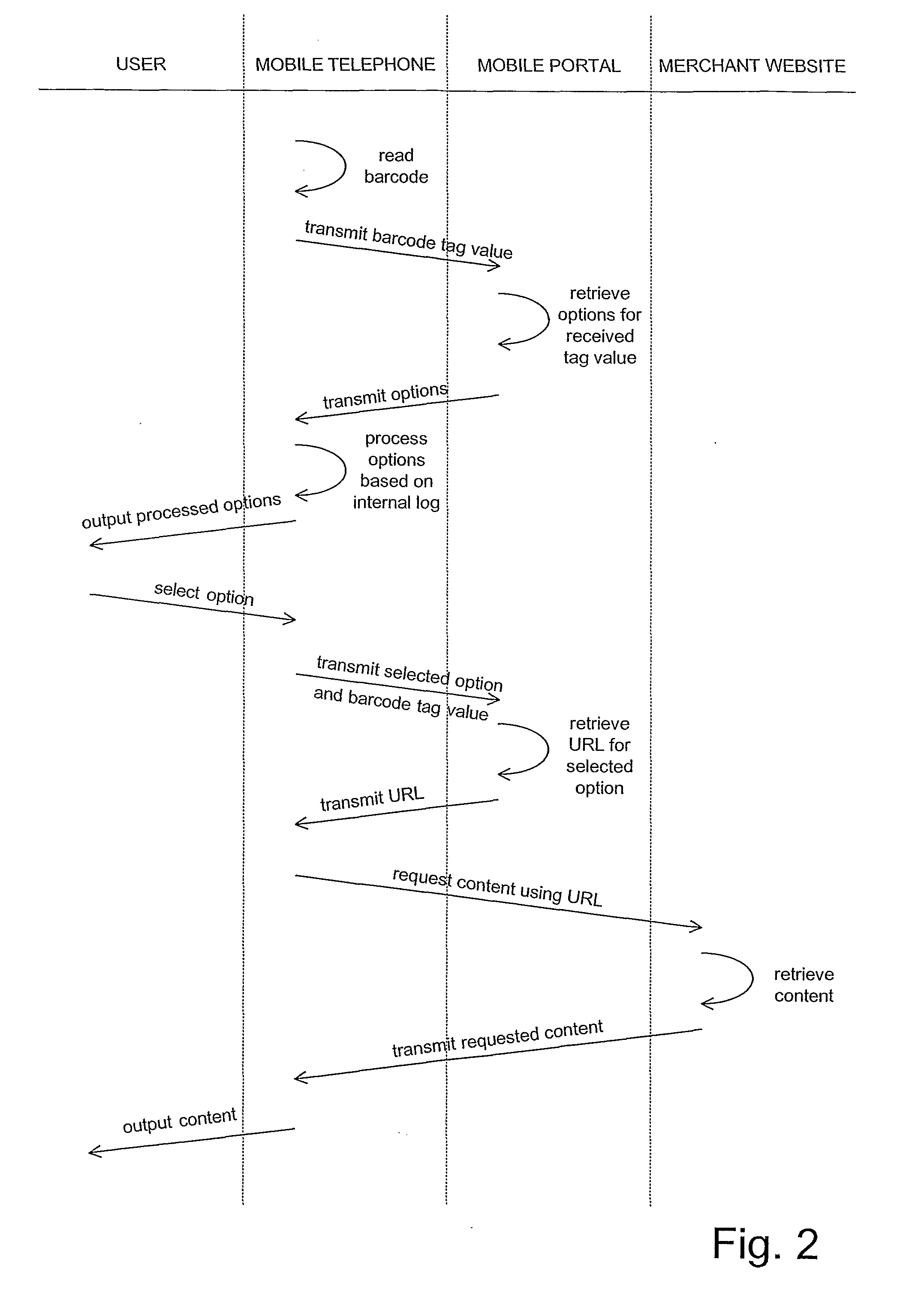

Mobile Information Processing System

InactiveUS20090150251A1Adaptable to changeBuying/selling/leasing transactionsInformation processingBarcode reader

A system is provided for providing mobile users with information relating to products and / or services. In one embodiment, the user has a mobile telephone having a barcode reader for reading barcodes associated with products or services. The barcode tag value obtained from reading the barcode is transmitted to a remote server via the mobile telephone network. The remote server uses the barcode value to retrieve a plurality of options associated with the product identified by the barcode value. The options are transmitted back to the user's mobile telephone where they are displayed to the user. In response to the user selecting one of the options, information relating to the selected option is retrieved and displayed to the user on the mobile telephone.

Owner:NOKIA CORP

Wireless internet access system and method

InactiveUS20050100120A1Avoid Intersymbol InterferenceAdaptable to changeSpatial transmit diversityNetwork traffic/resource managementDifferential phaseWireless internet access

A wireless Internet access system and method supports the transmission and reception of multiple types of traffic between mobile subscriber units and existing networks. A frame structure is used that can support the transmission of multiple types of traffic and adapt to changes in the traffic types needed and the amount of data for a particular traffic type. In addition, data transmission is performed using orthogonal frequency division multiplexing and differential phase shift keying to avoid intersymbol interference. Receiving units in the mobile subscriber units and existing networks include antenna arrays to provide a multipath transmission.

Owner:TELCORDIA TECHNOLOGIES INC

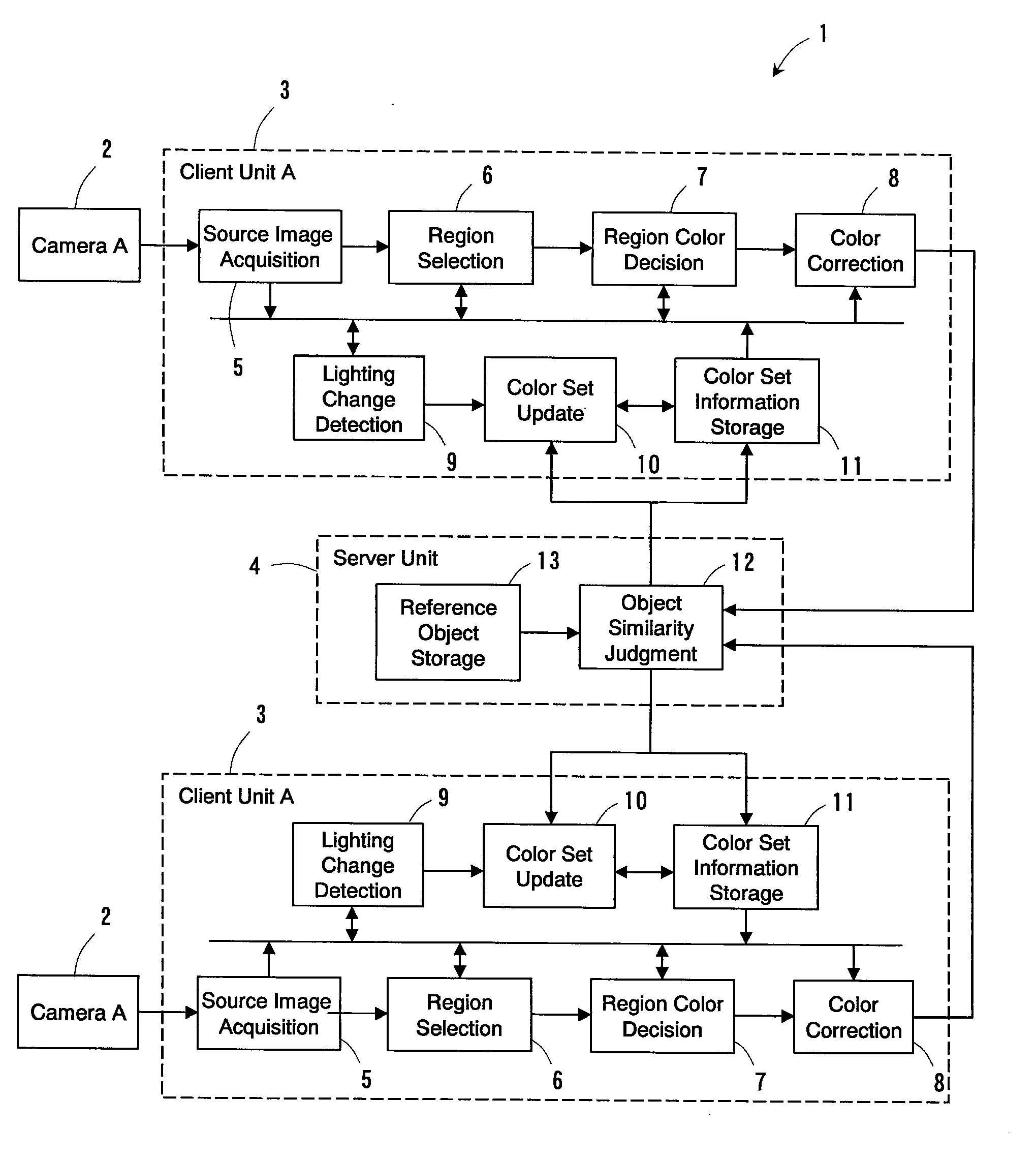

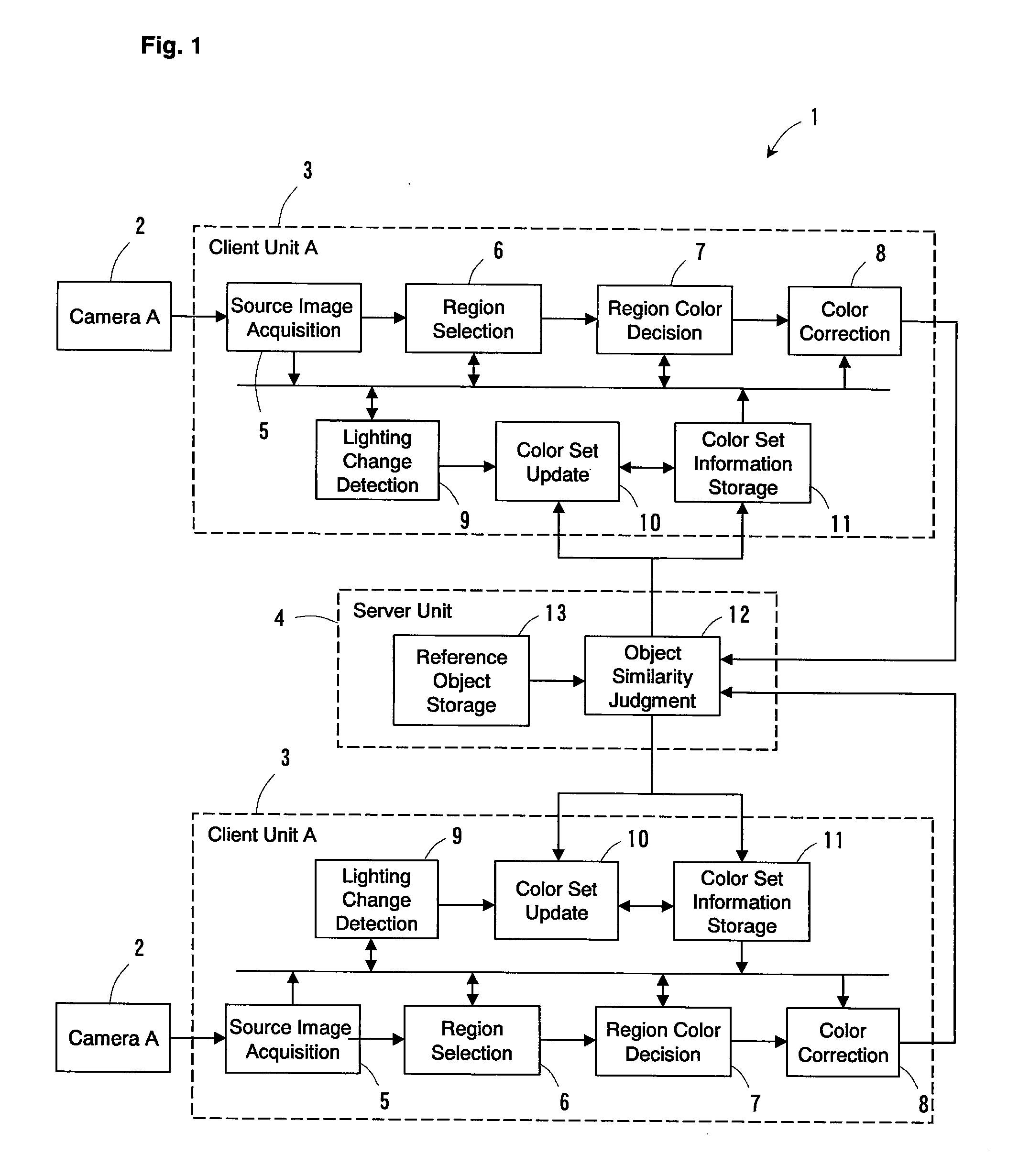

Color Correction Device, Color Correction Method, Dynamic Camera Color Correction Device, and Video Search Device Using the Same

InactiveUS20090002517A1True colorSmall amount of calculationColor signal processing circuitsCharacter and pattern recognitionRegion selectionColor correction

A color correction device (1) including: color set information storage portions (11) which store color set information inclusive of source colors and reference colors; region selection portions (6) which select specific source regions from source images picked up by two cameras 2 respectively; region color decision portions (7) which decide source region colors as colors representative of the source regions; color set update portions (10) which update source colors in color sets by using the source region colors; and color correction portions (8) which calibrate colors in ranges similar to the source colors in the two source images to reference colors by using the color sets. It is possible to eliminate the necessity of holding information of color sets unnecessary for color correction, so that it is possible to reduce the load imposed on calculation and adapt to a change of lighting environment in real time.

Owner:PANASONIC CORP

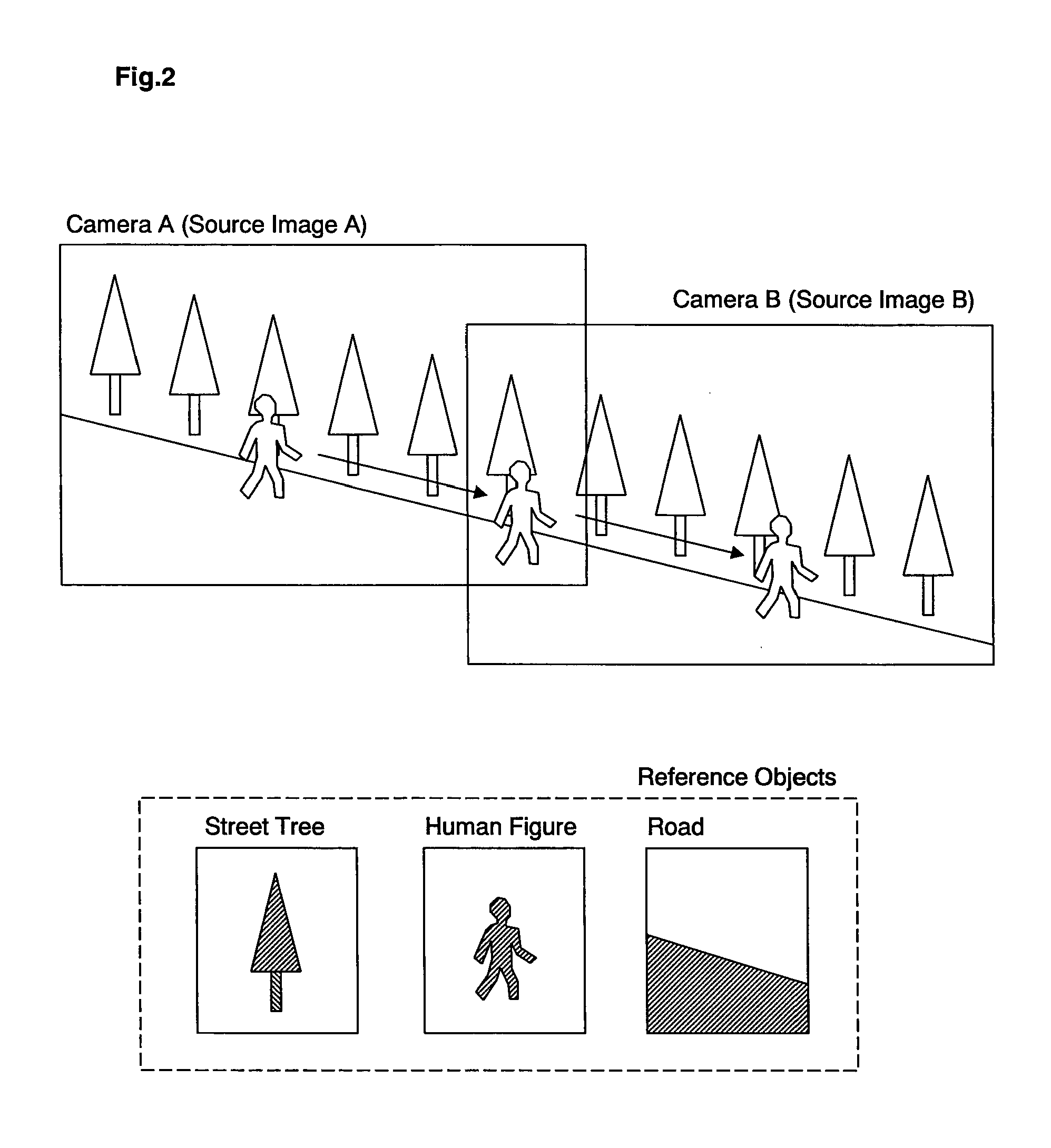

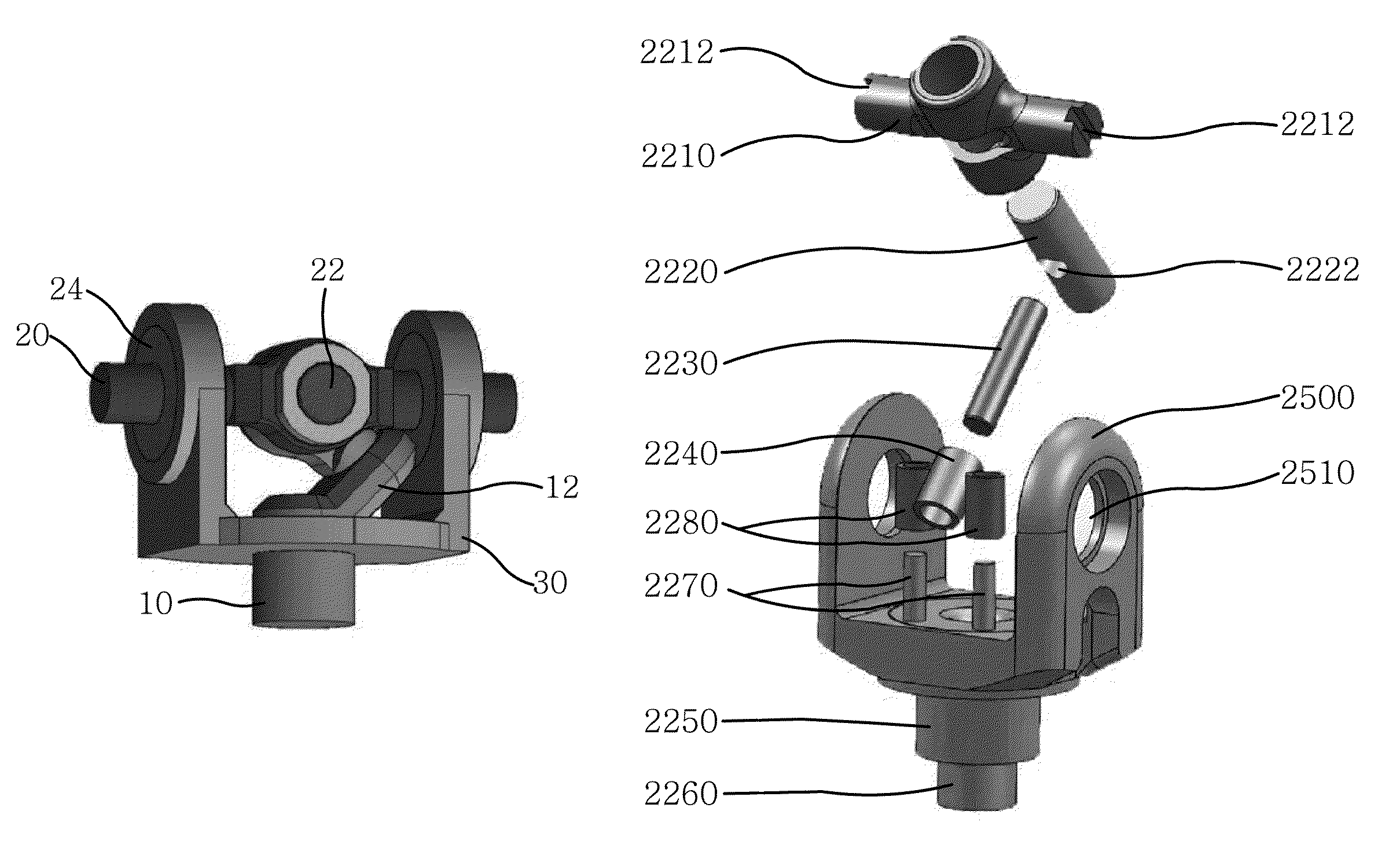

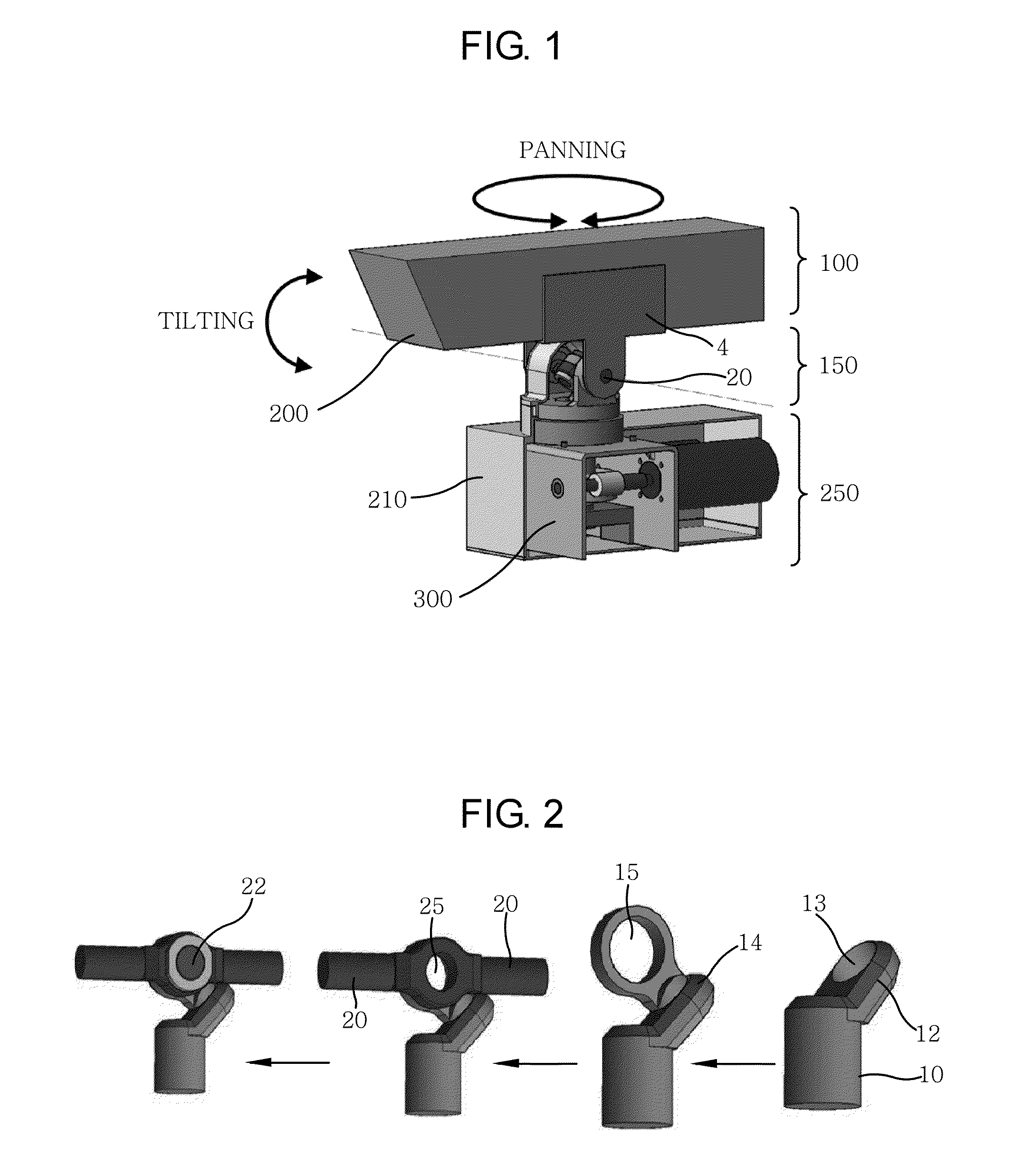

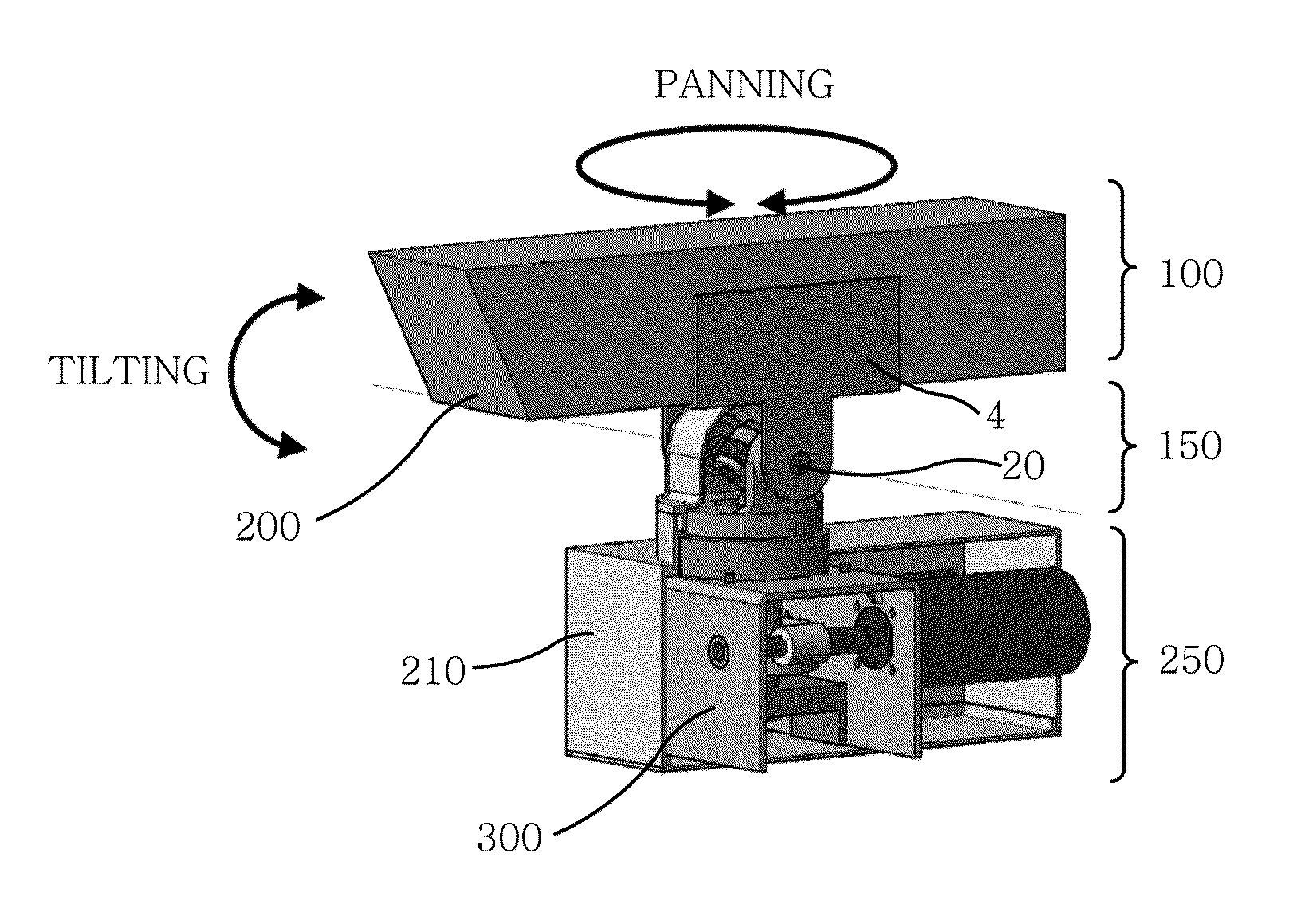

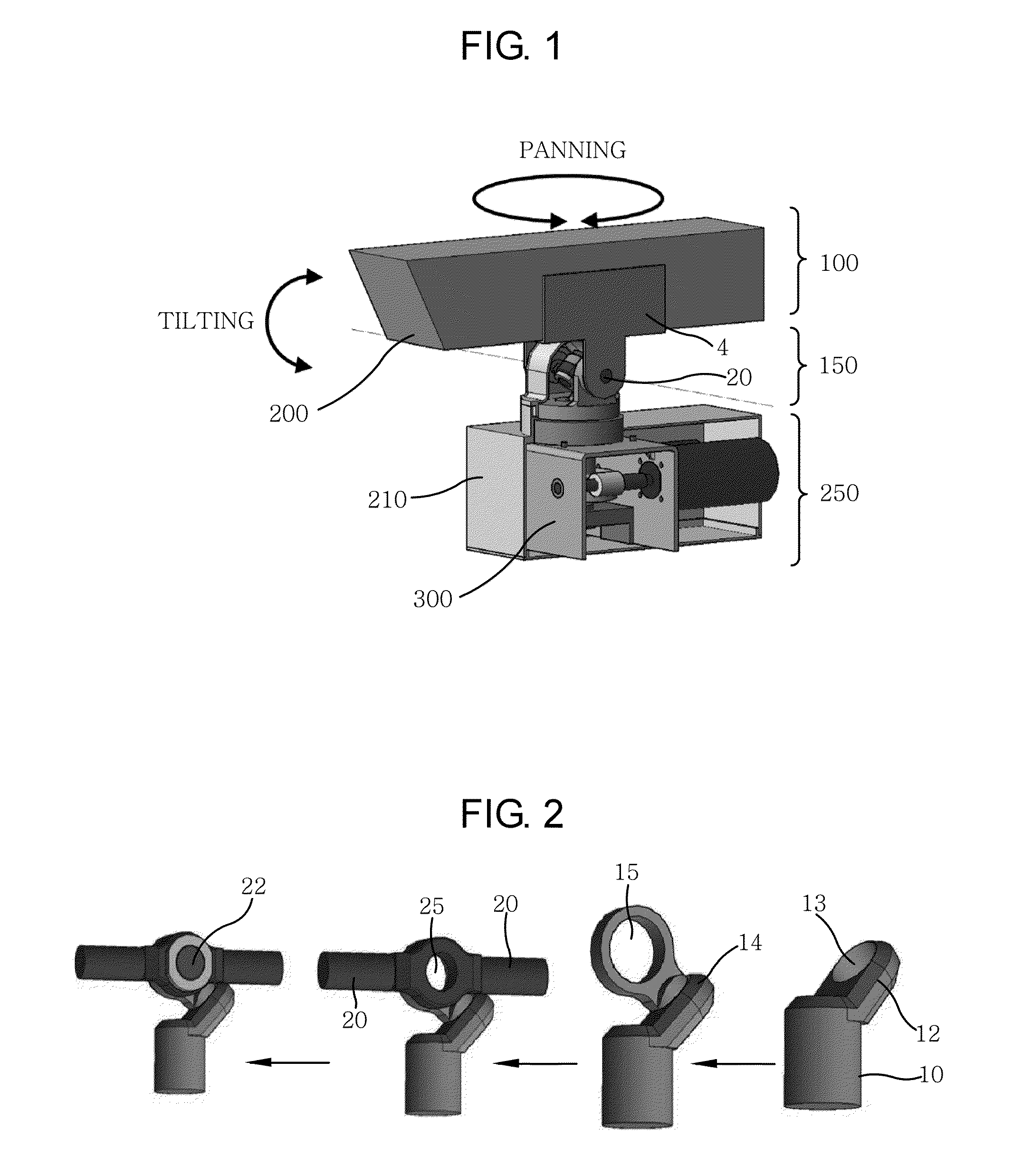

Pan-tilt apparatus

InactiveUS8596890B2Easy to watchAdaptable to changeTelevision system detailsCurtain suspension devicesDrive shaftSurveillance camera

Provided is a pan-tilt apparatus for a surveillance camera, including an image capturing unit 100 including a camera 2 and a camera holder 4 for supporting the camera 2; a motion converter 150 including a driving shaft 10, a shaft 20 connected to a connector 14 inserted into the driving shaft 10, a base member 30 inserted into one side of the driving shaft 10 and of which both ends are inserted in the shaft 20 by including a bearing 24, a bearing 32 installed in a lower portion of the base member 30 to smoothen an operation of the base member 30, and first and second worms 50 and 52 inserted into the base member 30 and mutually connected with first and second worm gears 40 and 42 to rotate; and a driving unit 250 including first and second motors 80 and 82 being connected to first and second motor shafts 60 and 62 to be inserted into the first and second worm gears 40 and 42.

Owner:ROBOMEC

Fuzzy logic based viewer identification for targeted asset delivery system

ActiveUS20080059390A1Improve efficiencyIncrease choiceBroadcast systems characterised by addressed receiversReceiver side switchingUser inputTargeted advertising

A targeted advertising system uses a machine learning tool to select an asset for a current user of a user equipment device, for example, to select an ad for delivery to a current user of a digital set top box in a cable network. The machine learning tool first operates in a learning mode to receive user inputs and develop evidence that can characterize multiple users of the user equipment device audience. In a working mode, the machine learning tool processes current user inputs to match a current user to one of the identified users of that user equipment device audience. Fuzzy logic may be used to improve development of the user characterizations, as well as matching of the current user to those developed characterizations. In this manner, targeting of assets can be implemented not only based on characteristics of a household but based on a current user within that household.

Owner:INVIDI TECH

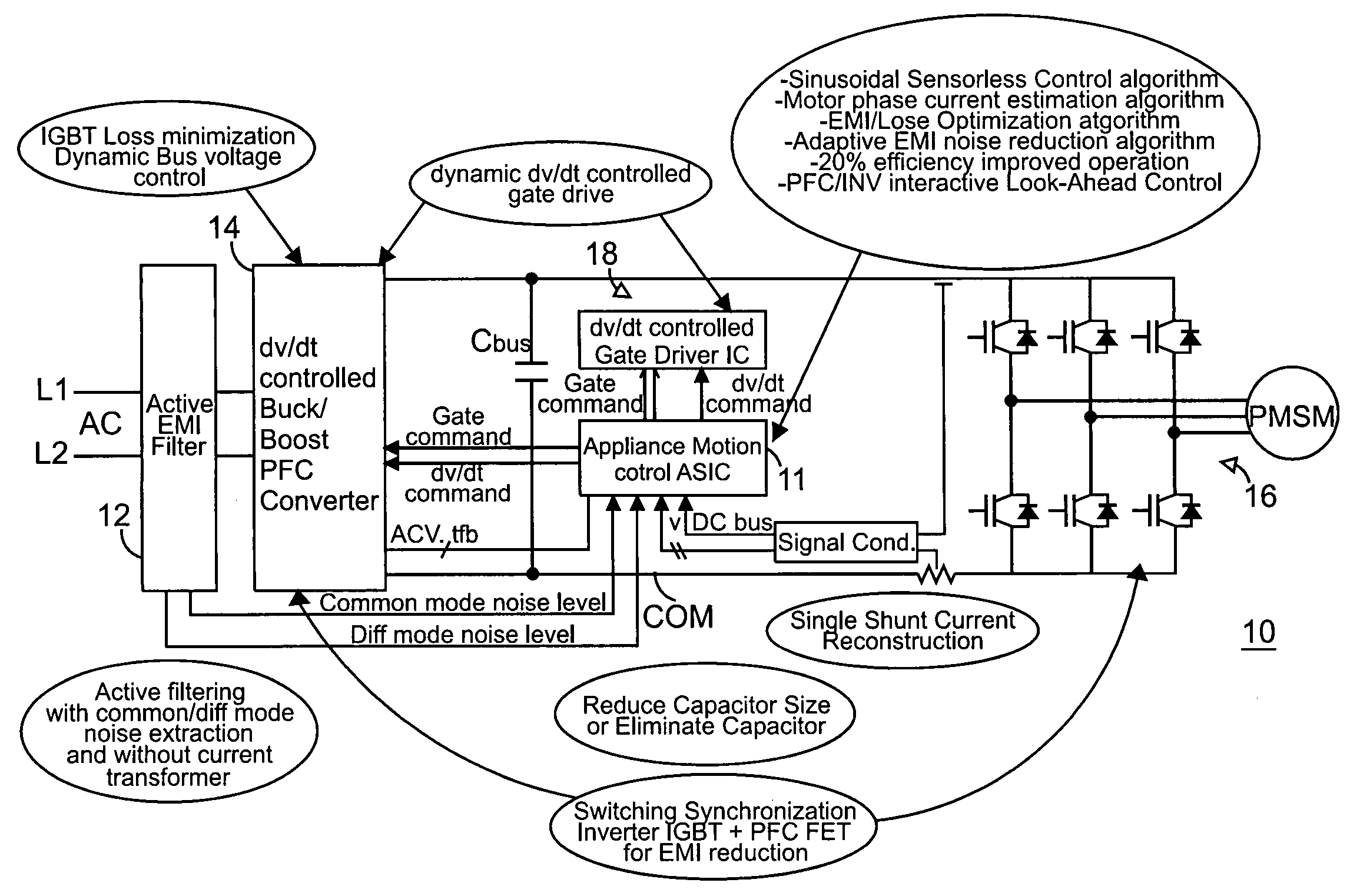

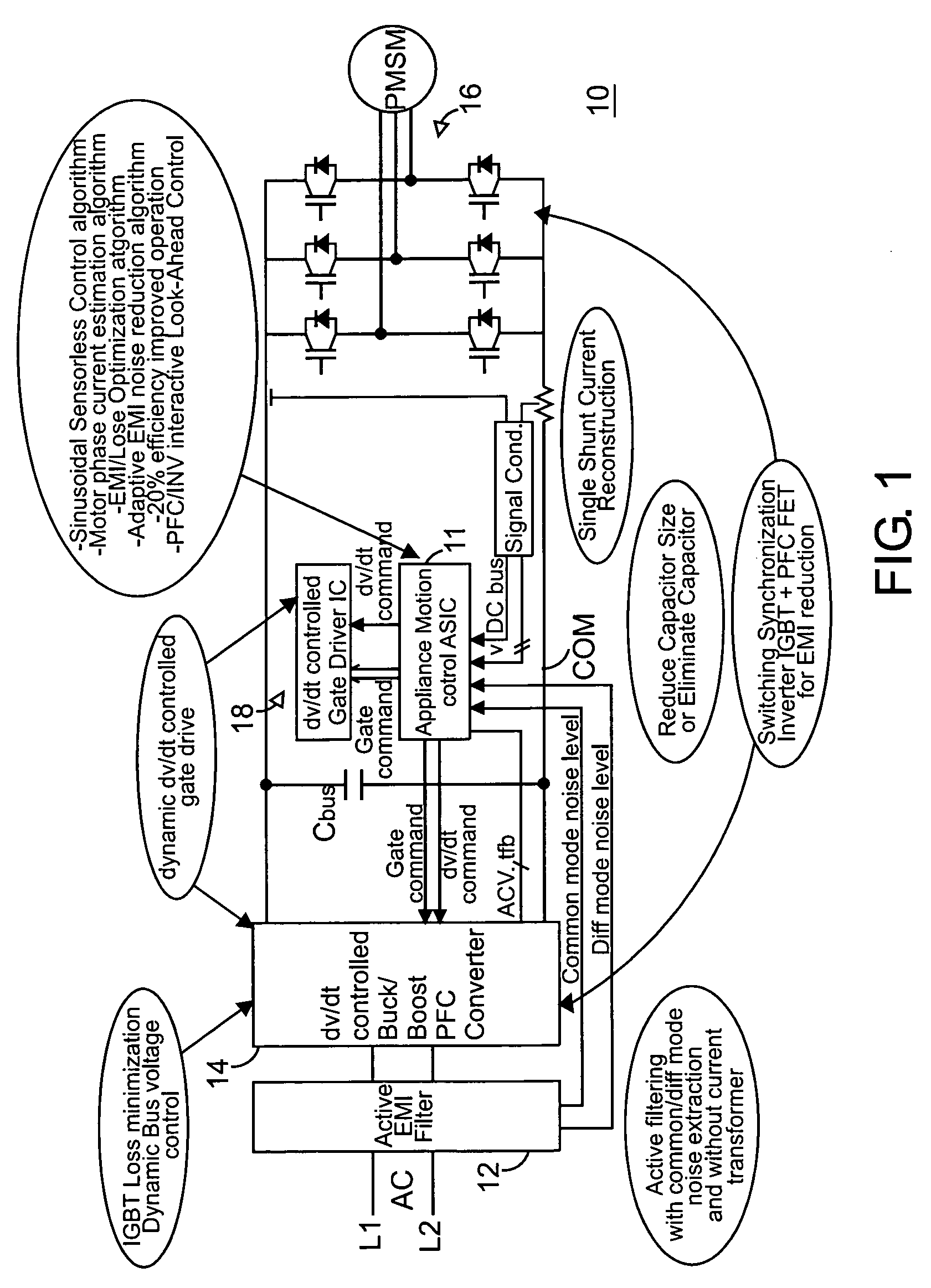

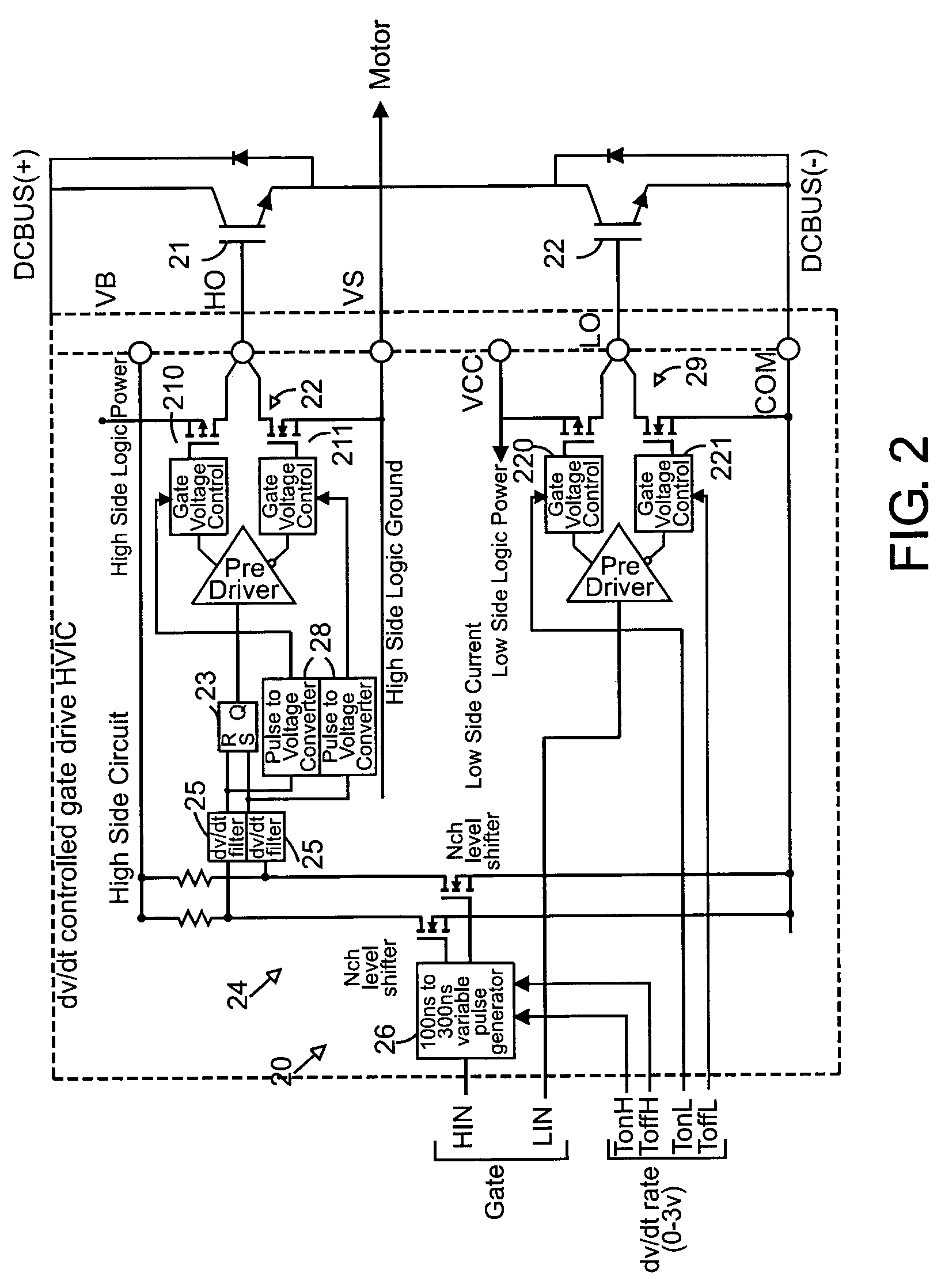

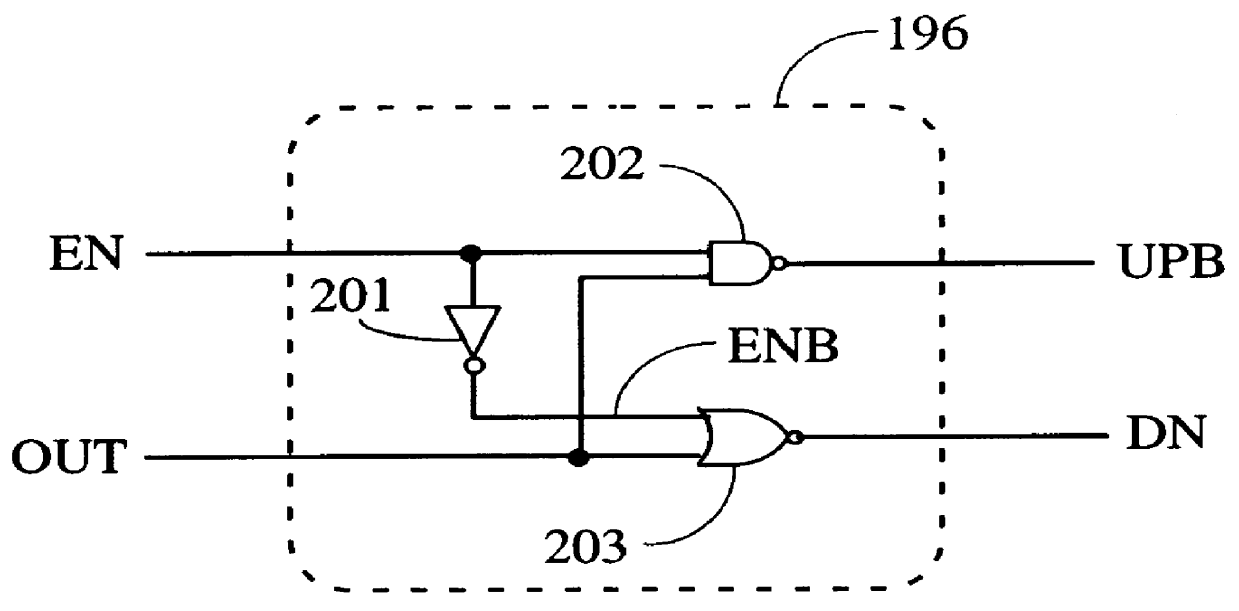

Global closed loop control system with dv/dt control and EMI/switching loss reduction

ActiveUS7061195B2Improve efficiencyReduce productionMotor/generator/converter stoppersDC motor speed/torque controlLevel shiftingNoise level

A motor drive system control provides global closed loop feedback to cooperatively operate system components to adaptively reduce noise and provide noise cancellation feedback. An active EMI filter reduces differential and common mode noise on an input and provides a noise level indication to a system controller. Power switches in both a power converter and power inverter are cooperatively controlled with dynamic dv / dt control to reduce switching noise according to a profile specified by the controller. The dv / dt control is provided as an analog signal to a high voltage IC and codified as a pulse width for a level shifting circuit supplying control signals to the high voltage gate drive. A noise extraction circuit and technique obtain fast noise sampling to permit noise cancellation and adaptive noise reduction.

Owner:INFINEON TECH AMERICAS CORP

Workflow support for dynamic action input

ActiveUS10452360B1Adaptable to changeShorten the timeInterprogram communicationVisual/graphical programmingGraphicsGraphical user interface

Owner:SERVICENOW INC

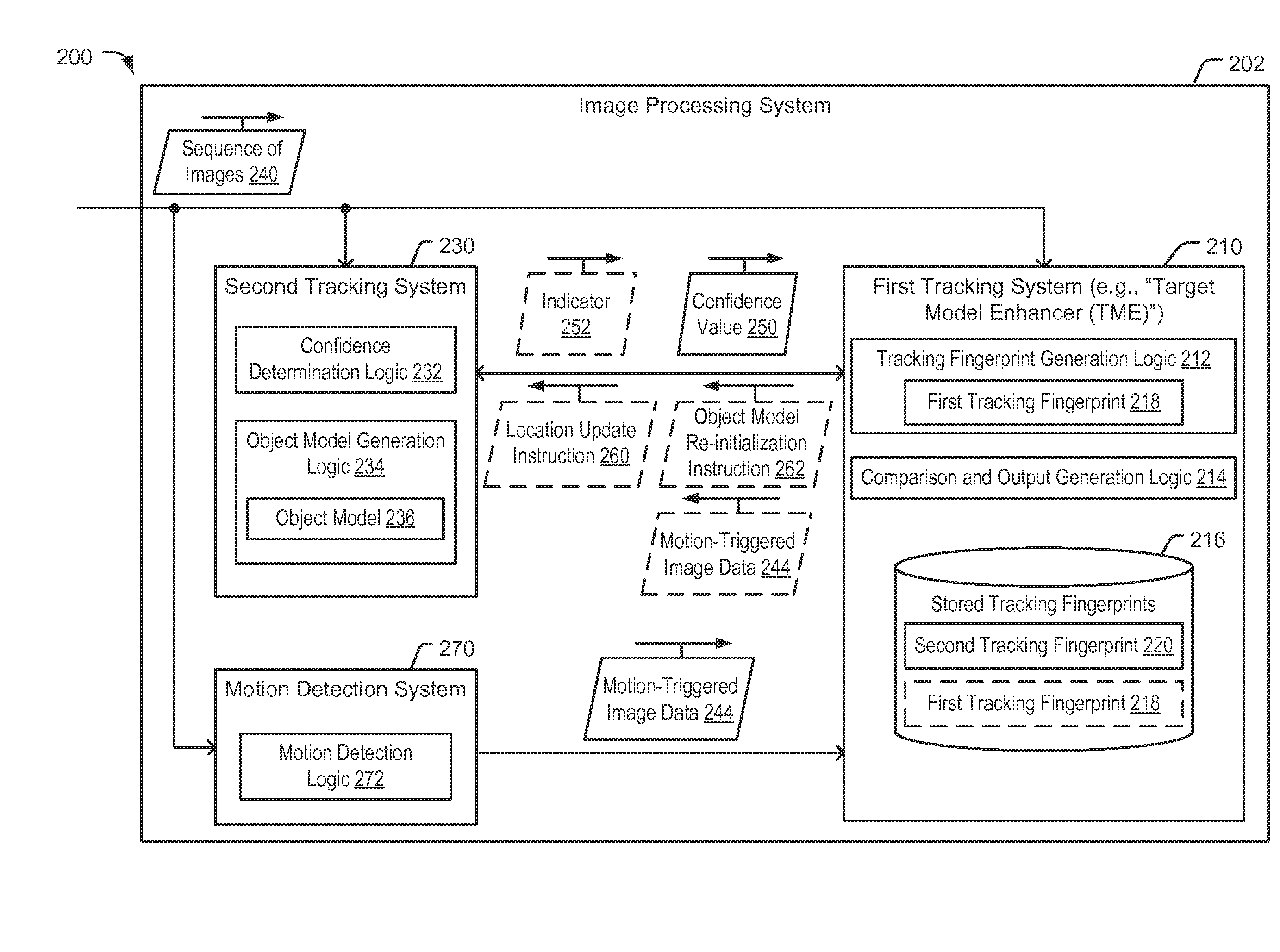

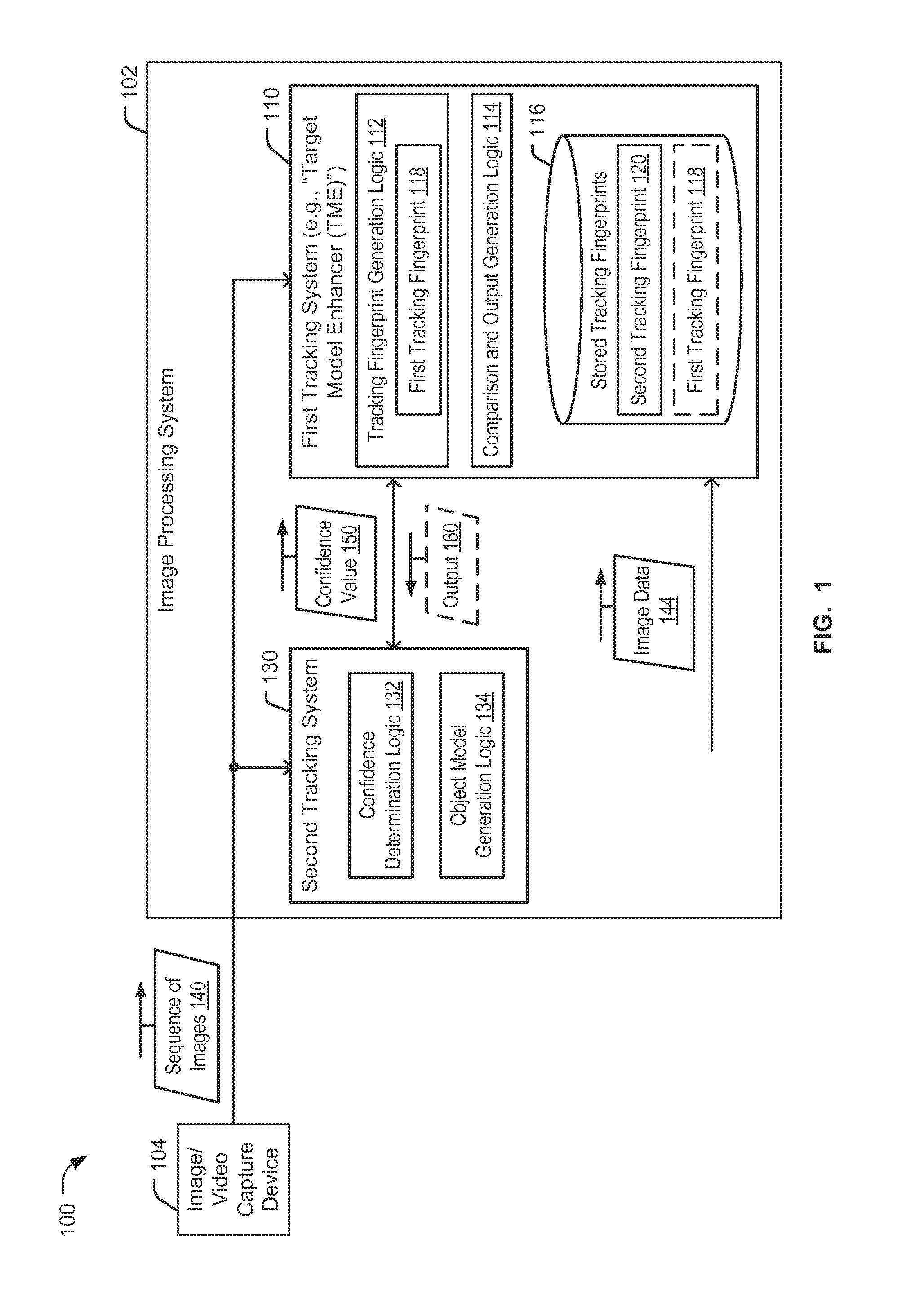

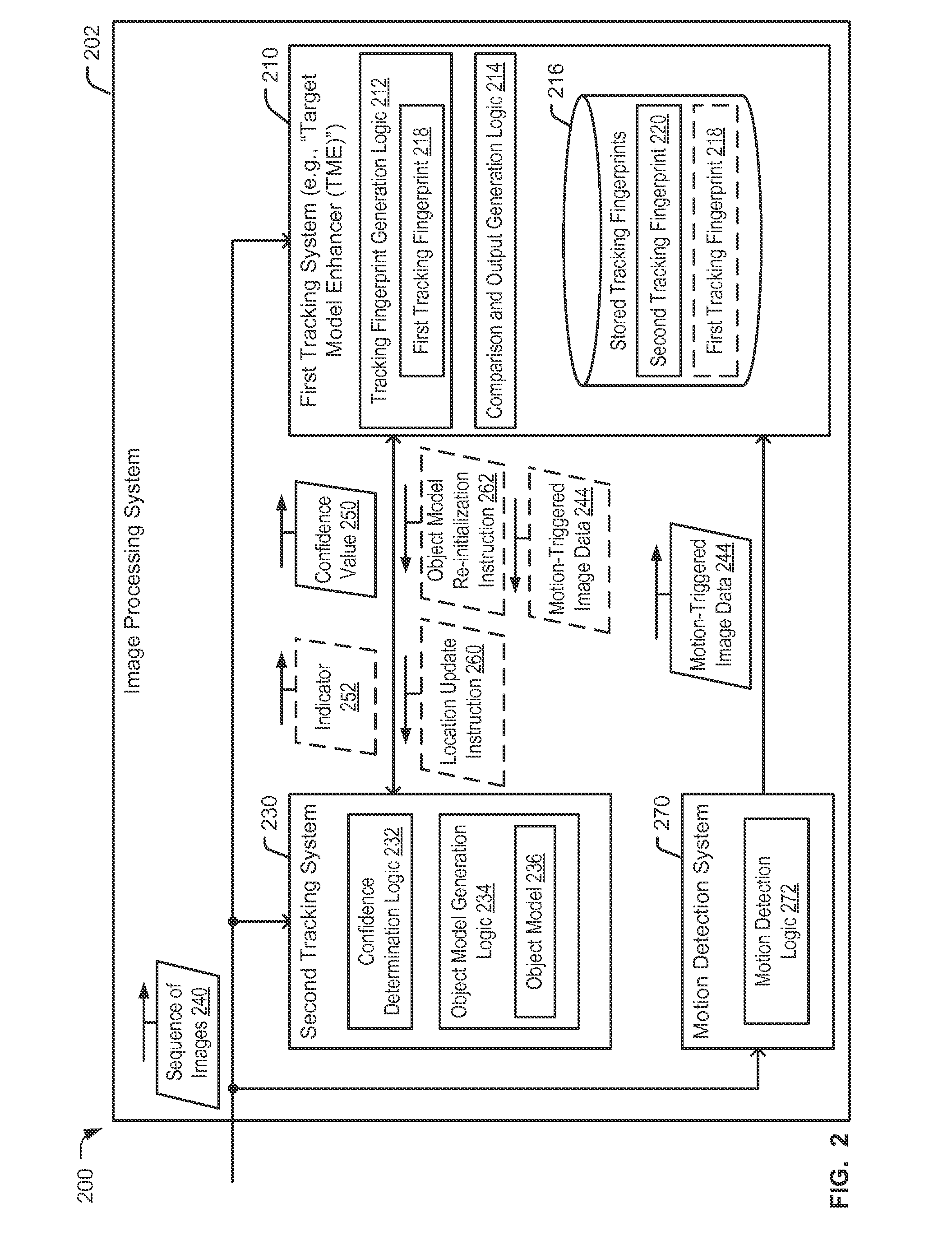

System and method to improve object tracking using tracking fingerprints

ActiveUS20160180546A1Adaptable to changeImprove accuracyImage enhancementImage analysisImaging dataFingerprint

A method includes receiving image data at a first tracking system. The image data may represent a region in an image of a sequence of images. The method includes generating a first tracking fingerprint based on the image data. The method includes comparing the first tracking fingerprint and a second tracking fingerprint. The method further includes providing an output from the first tracking system to a second tracking system based on a result of the comparison of the first tracking fingerprint and the second tracking fingerprint.

Owner:THE BOEING CO

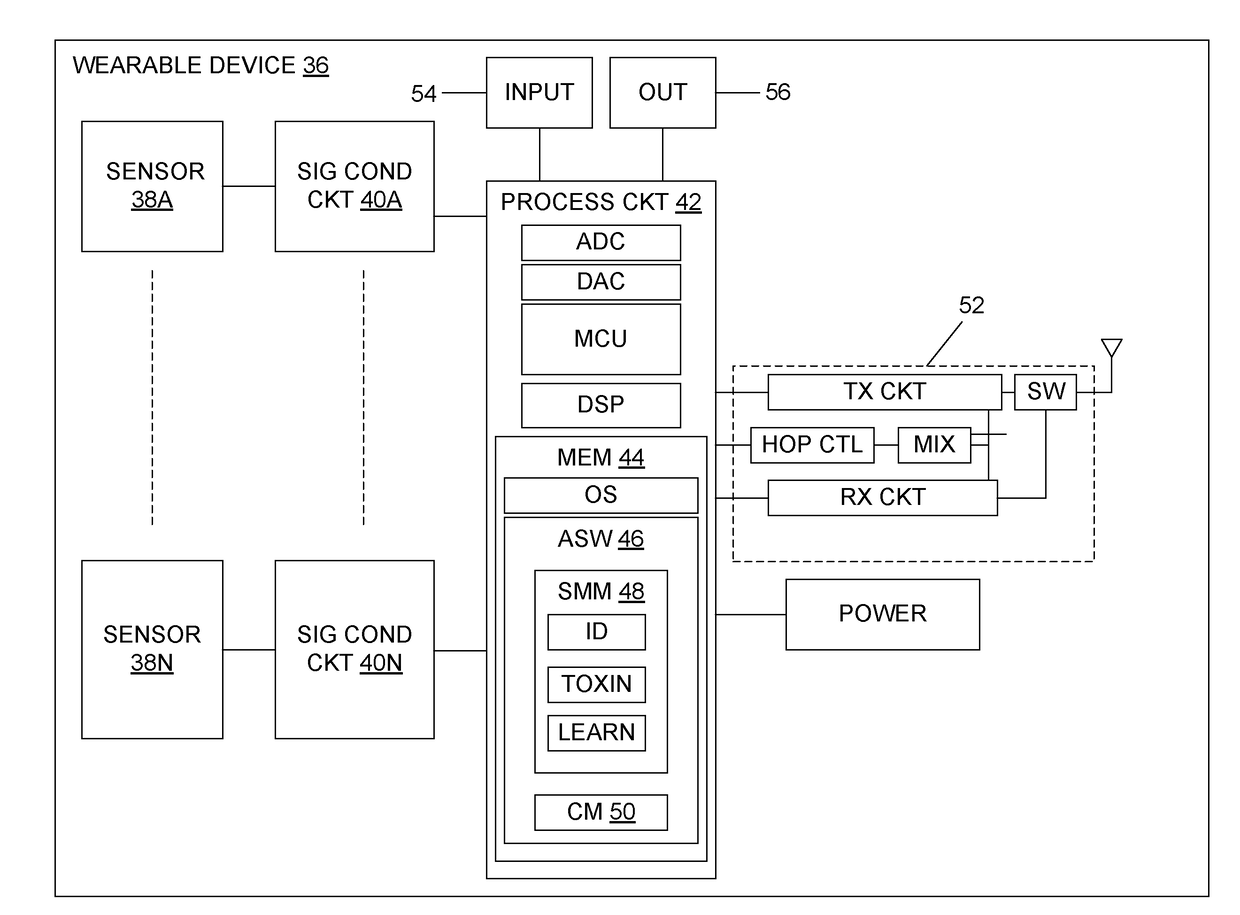

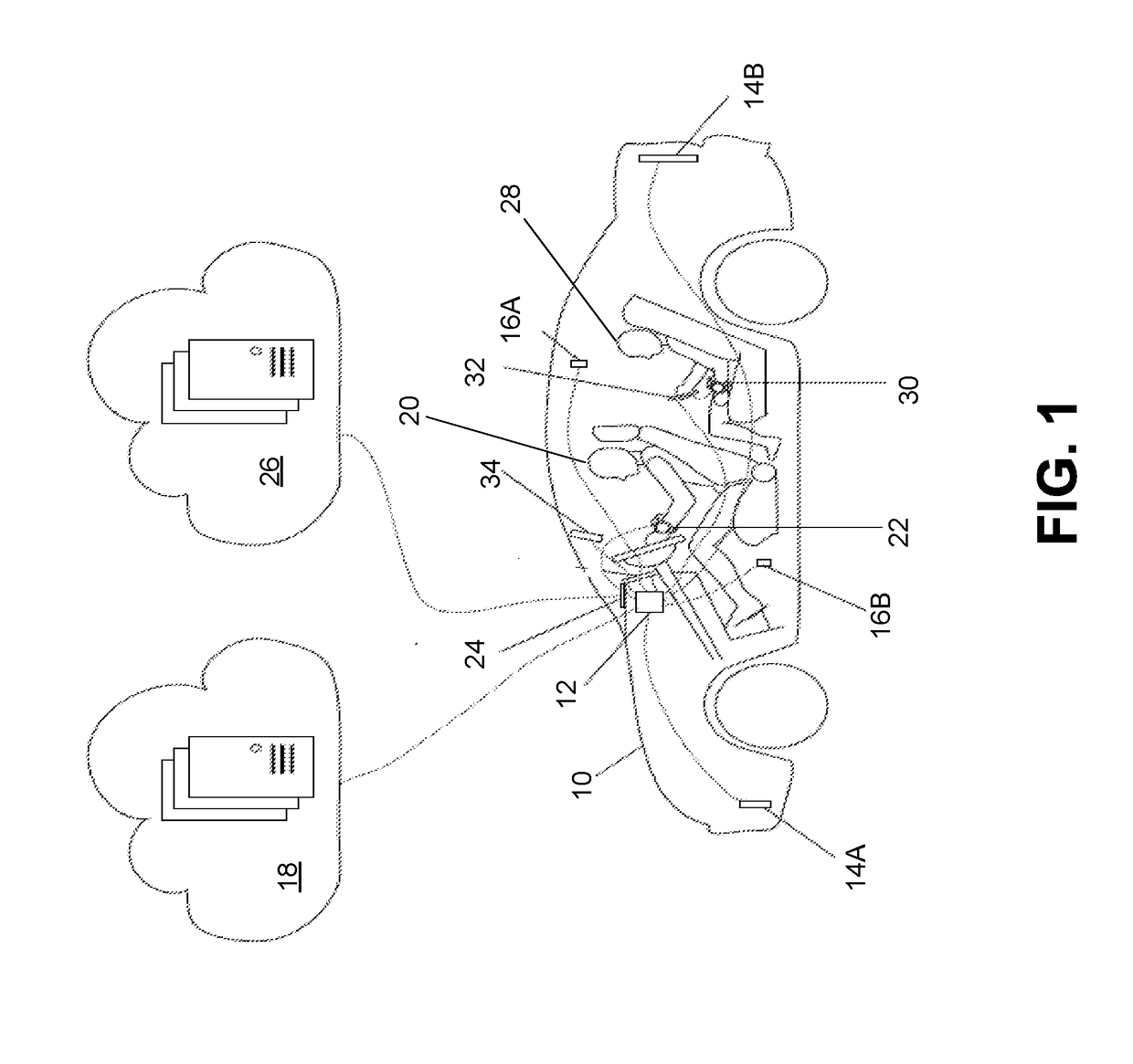

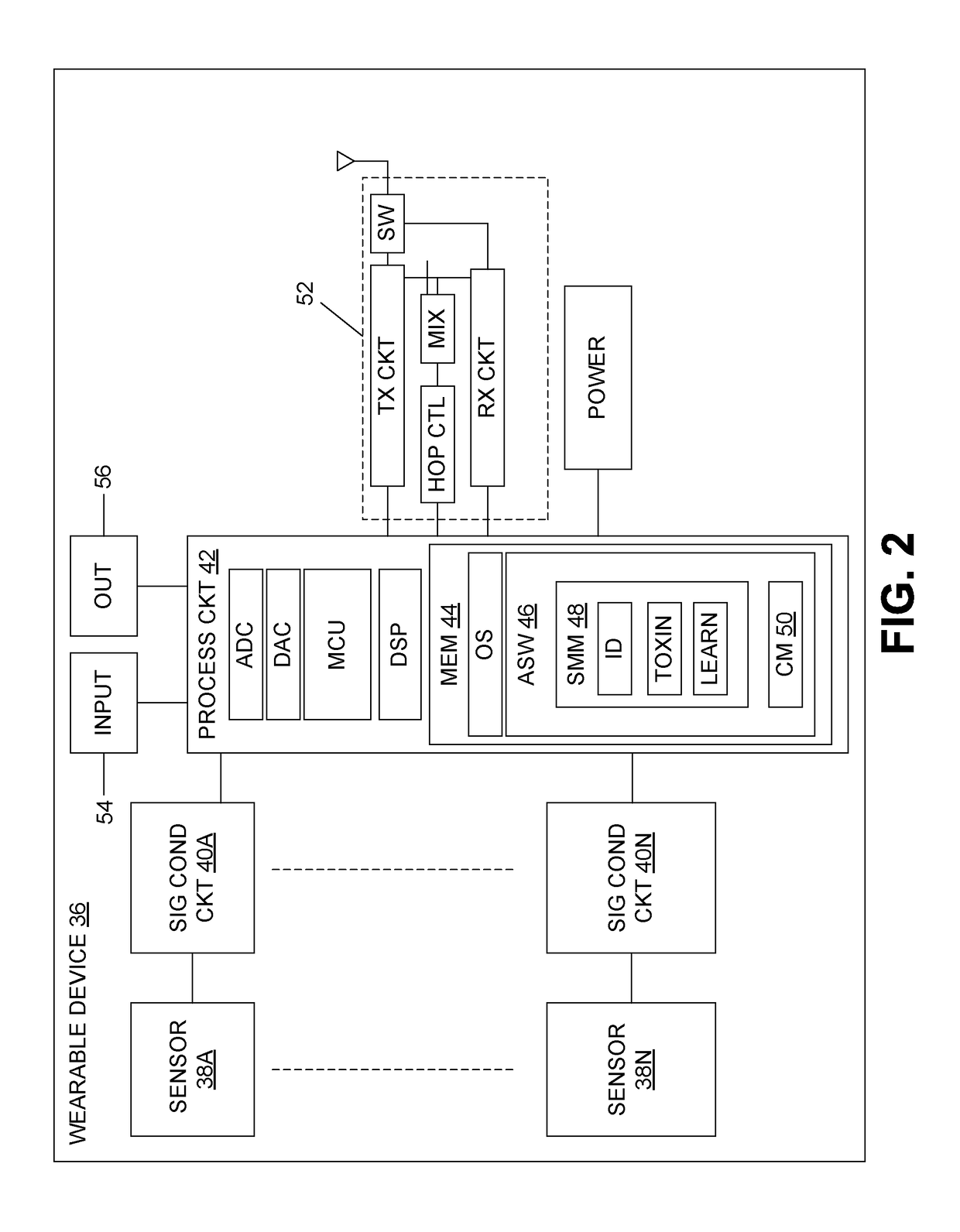

Automatic car setting adjustments by identifying driver with health watch wearable or in-car sensors

ActiveUS20180229674A1Easy to useFacilitate driver and passenger comfortAudiometeringRespiratory organ evaluationDriver/operatorEngineering

Owner:KONINKLJIJKE PHILIPS NV

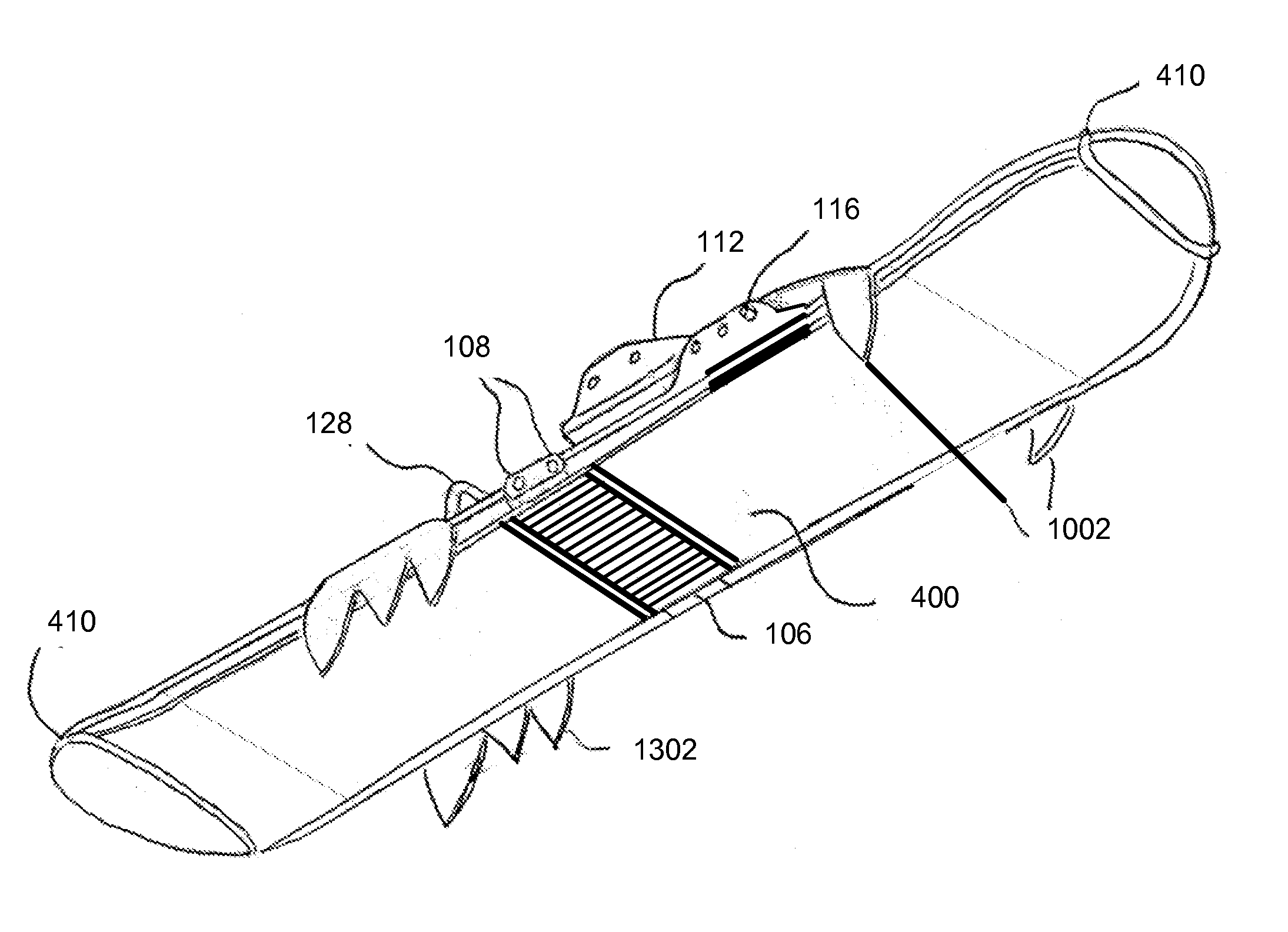

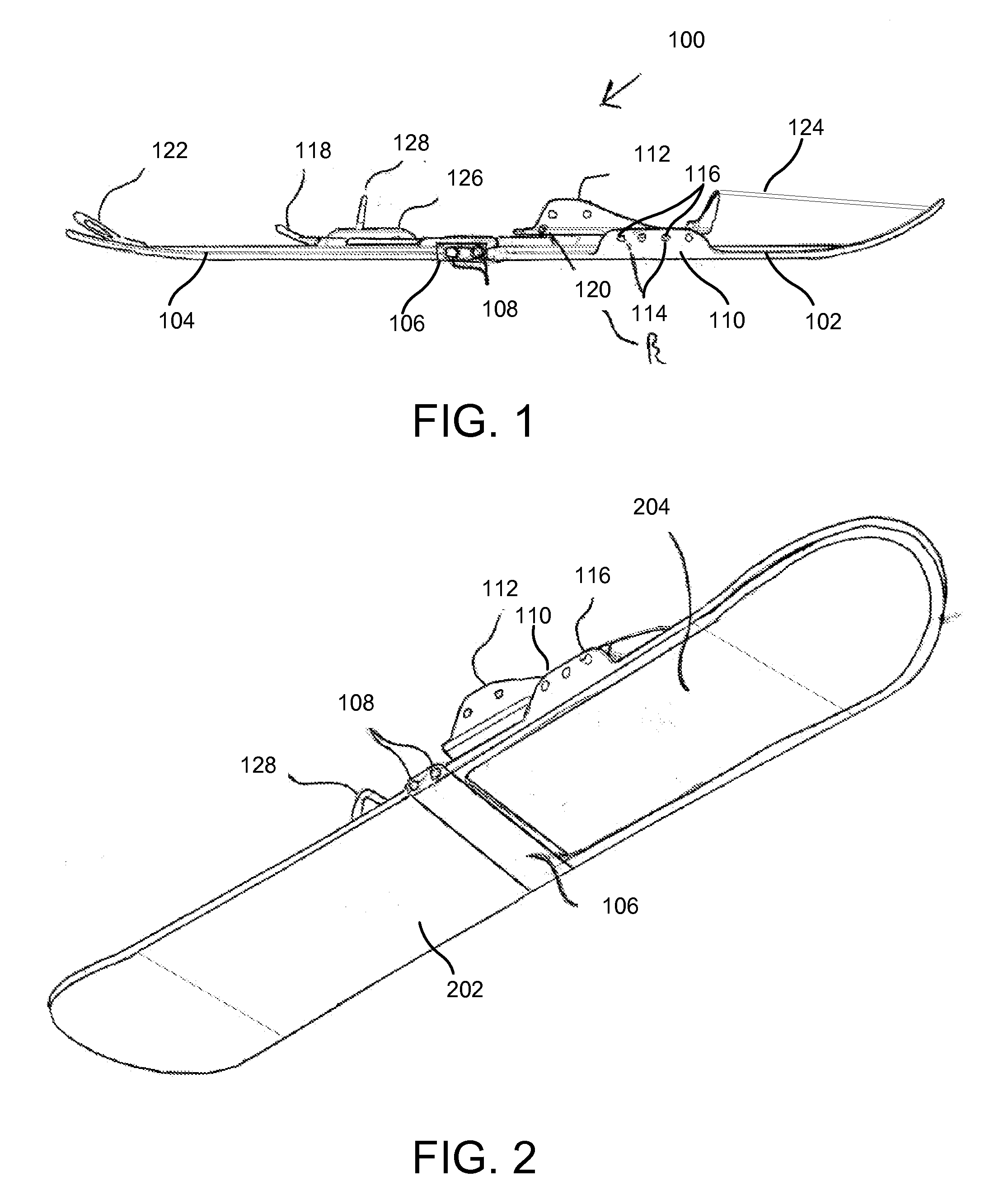

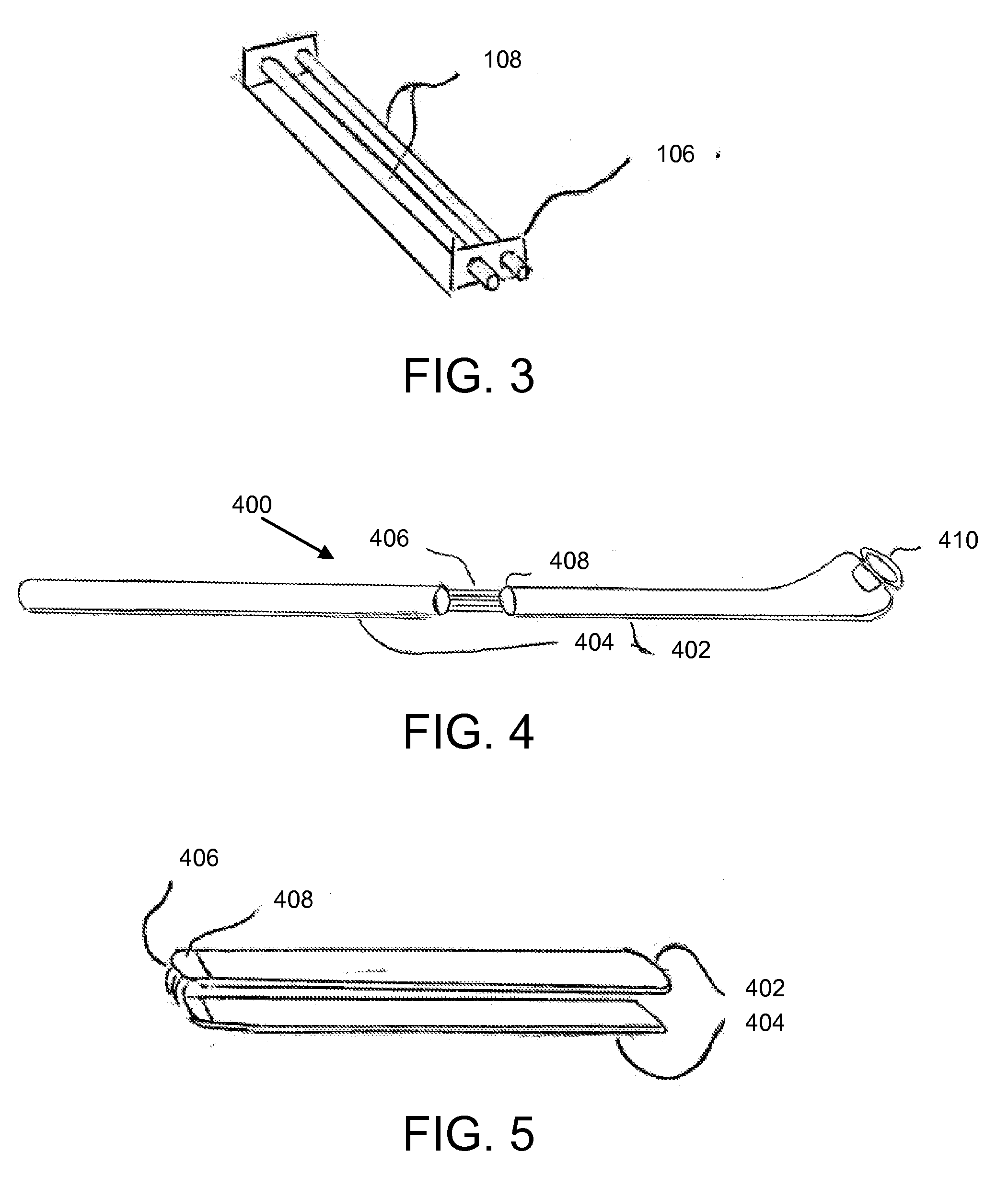

Apparatus, system, and method for a collapsing approach ski

InactiveUS20080174089A1Avoid disadvantagesEasy to packSki bindingsSki-brakesTerrainMechanical engineering

An apparatus, system, and method are disclosed for a collapsing approach ski for maneuvering over terrain in a climbing and sliding fashion, with a traction component operative below the sliding surface on the underside of the ski to facilitate climbing uphill without substantially interfering with sliding downhill. It combines the advantages of a snowshoe, including a large surface area, a toe cleat that claws into the terrain and a lifting of the front tip with each step, with the advantages of an approach ski, including a fibrous skin for added traction climbing uphill and an ability to slide down hill. A stretchable portion in the skin adjacent to a hinge in the ski permits the ski to be compactly collapsed without removing the skin, for easy packing and storage while not in use. For climbing up a steep incline, a removable fixed cleat provides added traction, and a heel riser reduces the strain on the lower leg and Achilles tendon region of the skier.

Owner:EKBERG LANE

Policy-based meta-data driven co-location of computation and datasets in the cloud

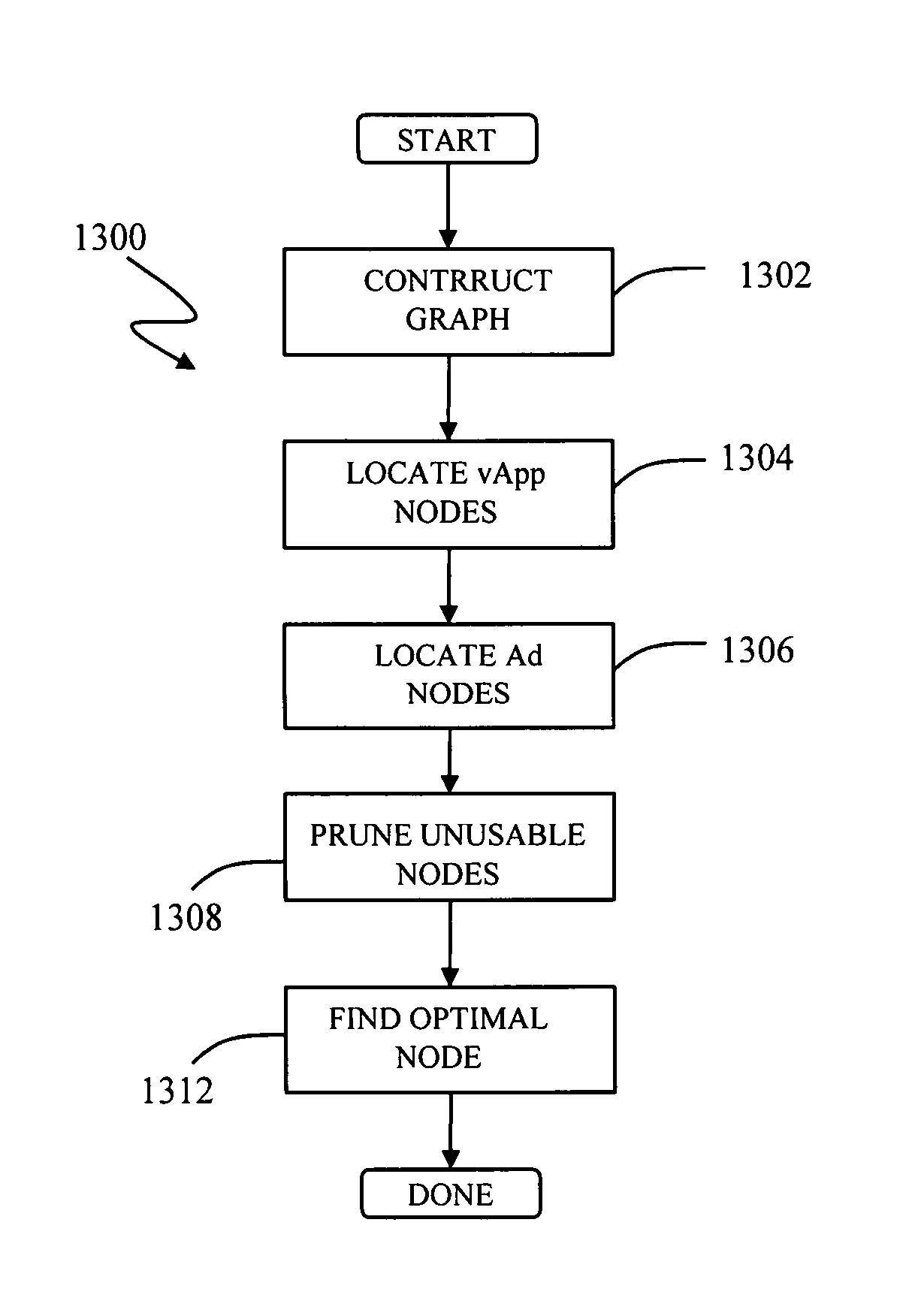

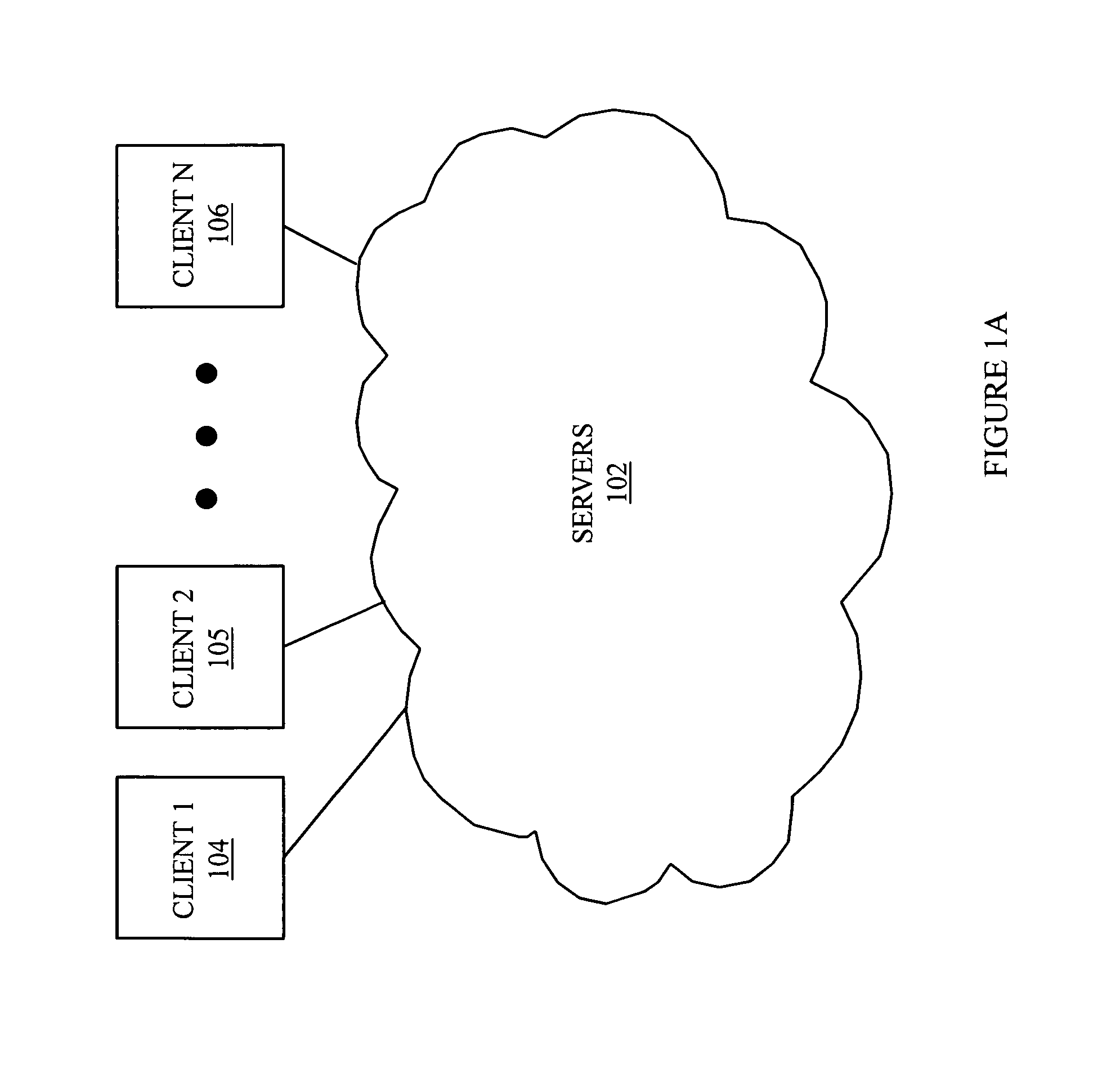

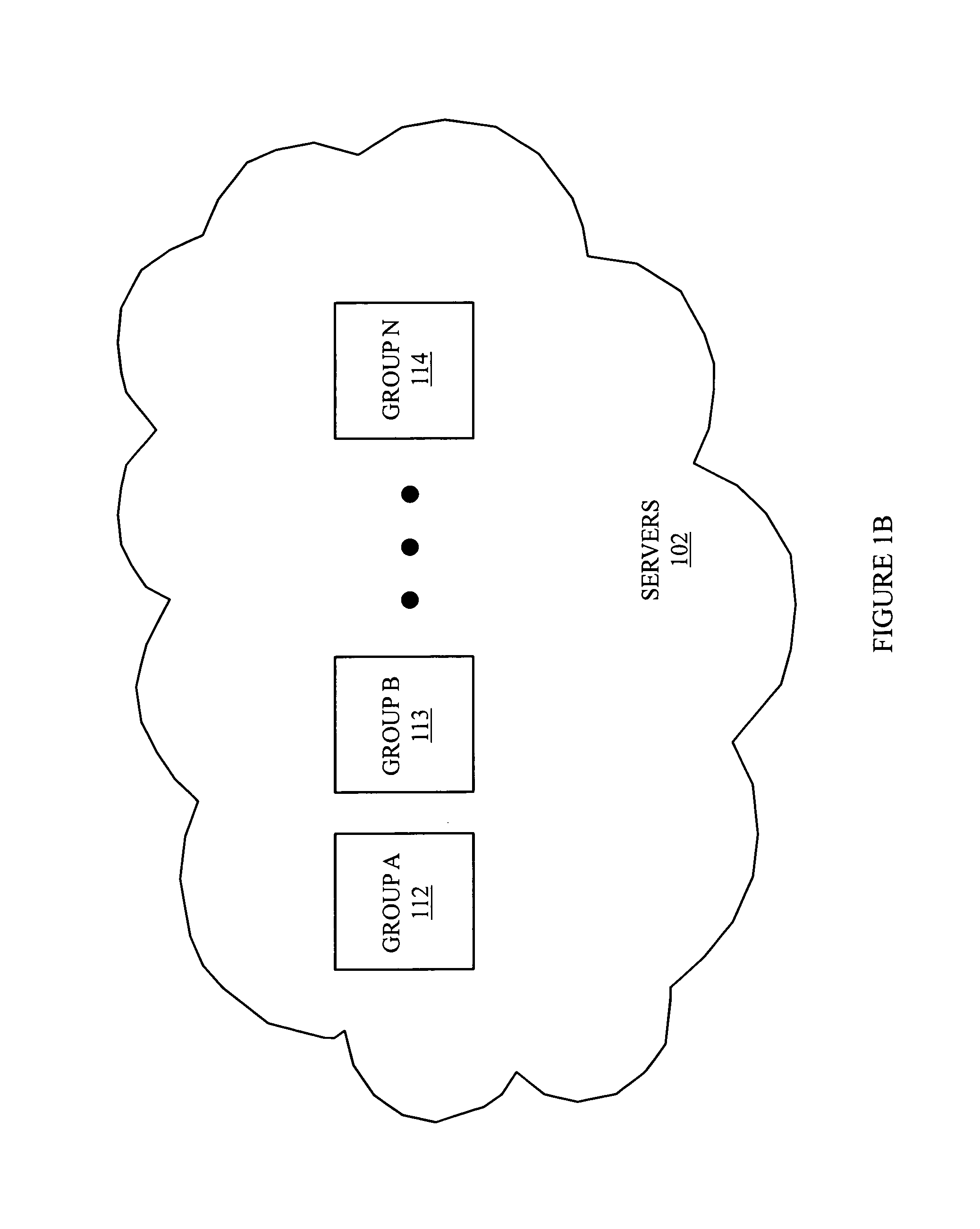

ActiveUS9462056B1Reduce complexityComplex enoughDigital computer detailsTransmissionTelecommunications linkVirtual machine

Determining at least one resource node for deployment of an application in a system having a plurality of compute and storage resource nodes includes determining criteria for nodes based on a policy provided for the application, pruning nodes that do not meet a criteria for deploying the application to provide a plurality of remaining nodes, determining a cost of deploying the application on each of the plurality of remaining nodes, where the cost is based on a metric associated with the application, and selecting for deployment a node having a lowest cost. The application may be a vApp that includes a plurality of virtual machine images. The nodes may be interconnected by communication links having associated therewith costs of moving the application from one node to another.

Owner:EMC IP HLDG CO LLC

Method and implementation for referencing of dynamic data within spreadsheet formulas

InactiveUS7415481B2Adaptable to changeData processing applicationsDigital data processing detailsElectronic formDisplay device

The present invention relates to a new type of structured name within a spreadsheet program that allows users to refer to tables, columns of data within tables, headers of tables, totals from tables, PivotTables®, and portions of PivotTable® data by the data's headers. Embodiments of the present invention comprise a method for referring to a set of data that comprises receiving one or more semantic designations, wherein the one or more semantic designations name a set of context information that describes one or more items of data in a data structure, automatically creating a structural reference, and associating the context information with the structural reference. Other embodiments of the present invention relate to an interaction with a user interface for displaying on a display device a structural reference to data in a spreadsheet that comprises receiving one or more semantic designations from the user that refer to one or more elements of the data structure, creating a structural reference to the elements of the data structure, and displaying the structural reference as a collection of the one or more semantic designations.

Owner:MICROSOFT TECH LICENSING LLC

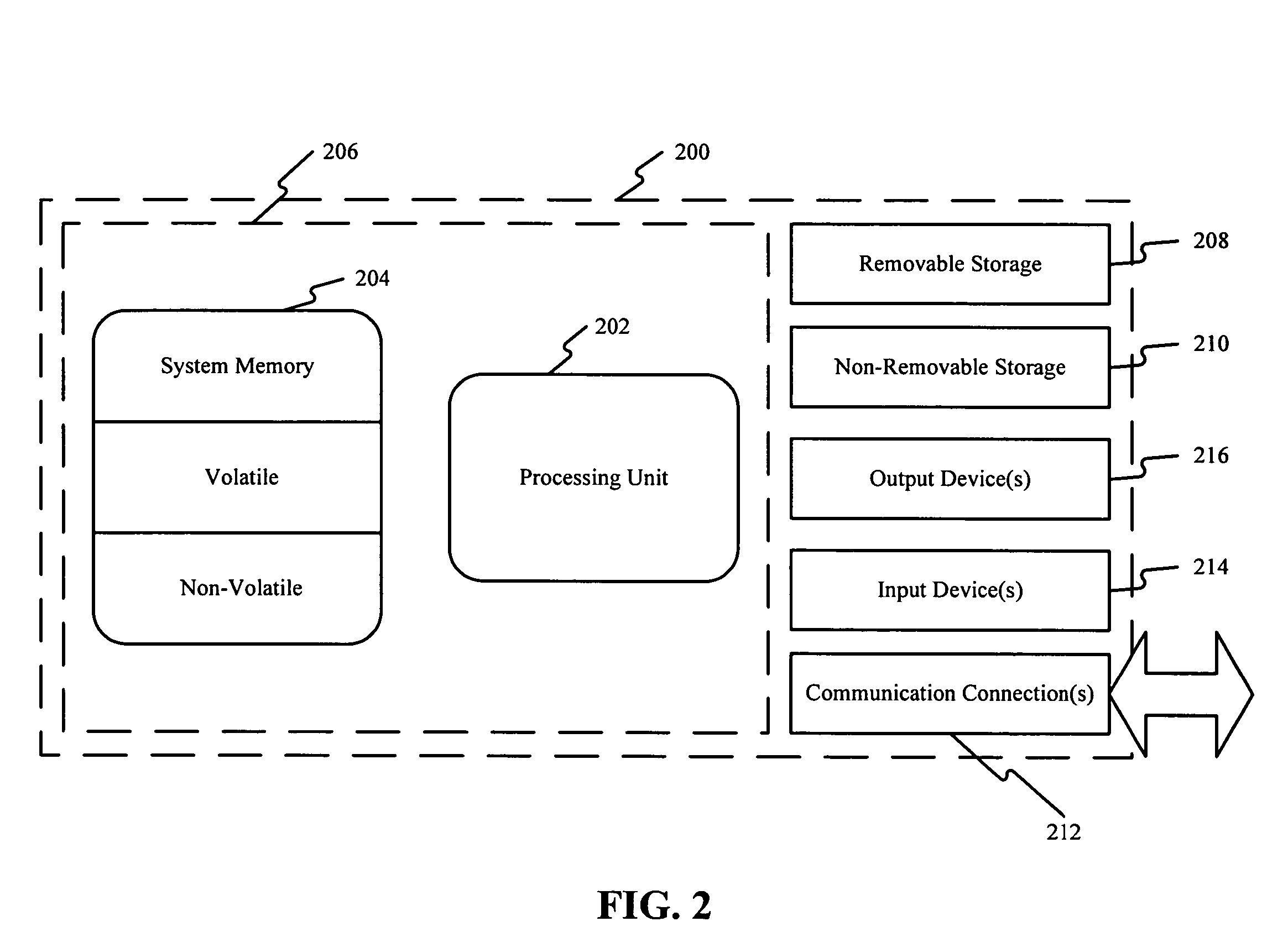

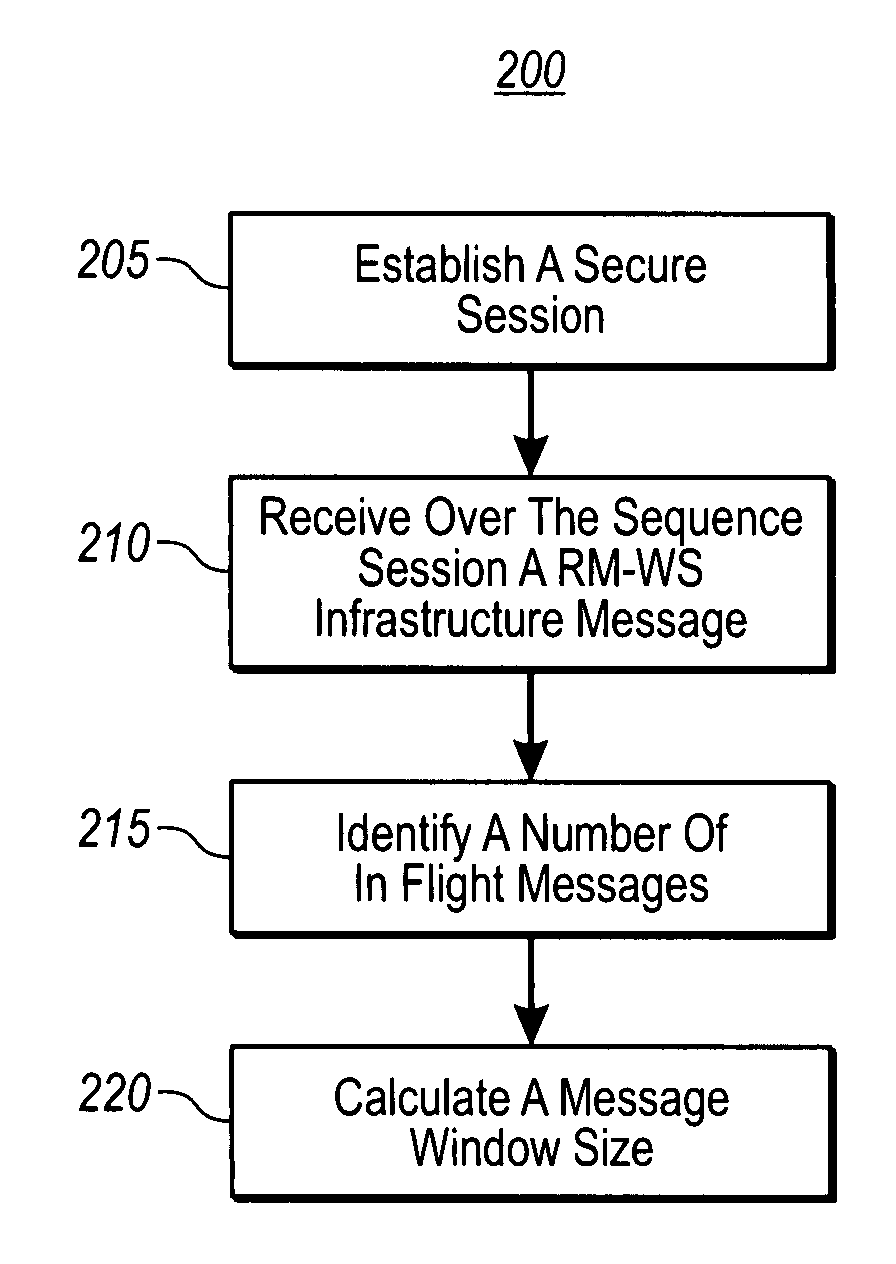

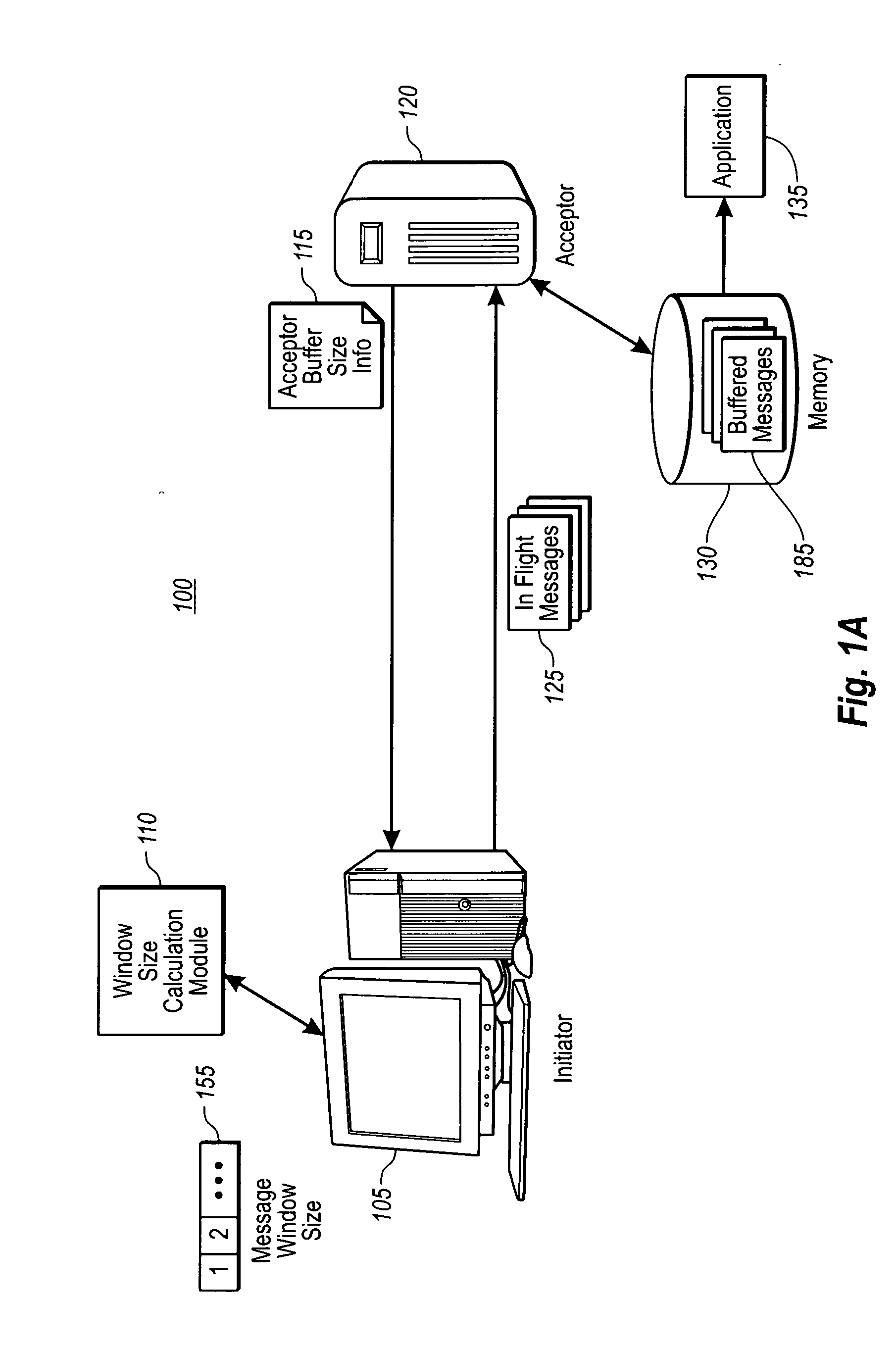

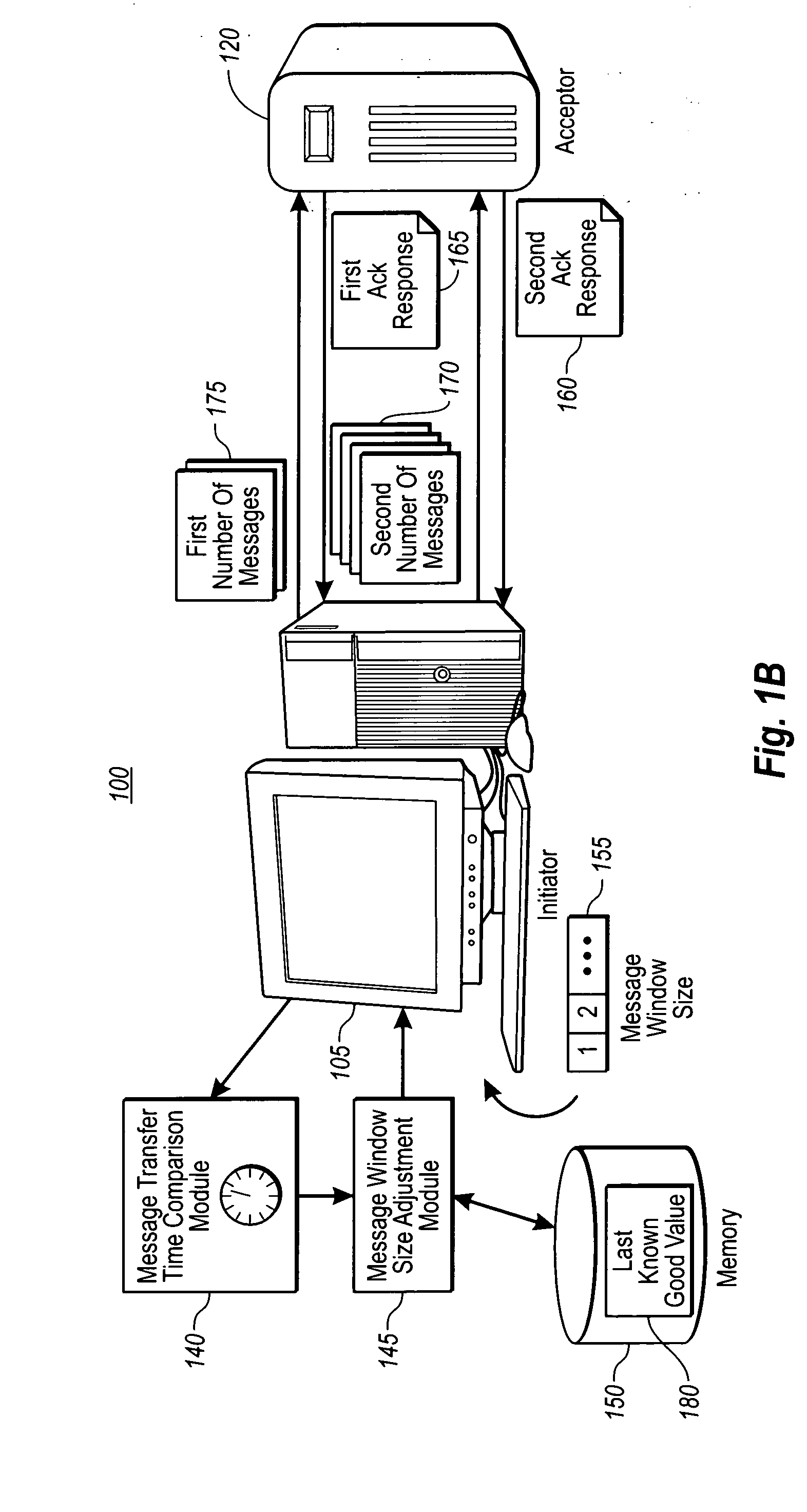

Efficient transfer of messages using reliable messaging protocols for web services

InactiveUS20060133278A1Efficiently transferring messageControlling network congestionData processing applicationsError preventionReliable messagingBuffer overflow

The present invention provides for flow and congestion control mechanisms in accordance with a Reliable Message protocol for Web Services (RM-WS). For flow control, one endpoint informs another endpoint of its available buffer size by including buffer size information in response messages. The response messages, typically RM-WS infrastructure messages, are then used to determine an upper limit on the number of messages that can be sent to the acceptor in order to prevent resending messages due to buffer overrun. In the case of congestion control, embodiments provide for increasing the number of in-flight messages until a failure point is found. The last successful rate below the failure point is the closest known point to the optimum point. Example embodiments then reset and try again raising the rate back to the last known good point and fine tuning from there using an algorithm that asymptotes the optimum rate.

Owner:MICROSOFT TECH LICENSING LLC

Pan-tilt apparatus

InactiveUS20110268433A1Easy to watchAdaptable to changeTelevision system detailsCurtain suspension devicesSurveillance cameraDrive shaft

Provided is a pan-tilt apparatus for a surveillance camera, including an image capturing unit 100 including a camera 2 and a camera holder 4 for supporting the camera 2; a motion converter 150 including a driving shaft 10, a shaft 20 connected to a connector 14 inserted into the driving shaft 10, a base member 30 inserted into one side of the driving shaft 10 and of which both ends are inserted in the shaft 20 by including a bearing 24, a bearing 32 installed in a lower portion of the base member 30 to smoothen an operation of the base member 30, and first and second worms 50 and 52 inserted into the base member 30 and mutually connected with first and second worm gears 40 and 42 to rotate; and a driving unit 250 including first and second motors 80 and 82 being connected to first and second motor shafts 60 and 62 to be inserted into the first and second worm gears 40 and 42.

Owner:ROBOMEC

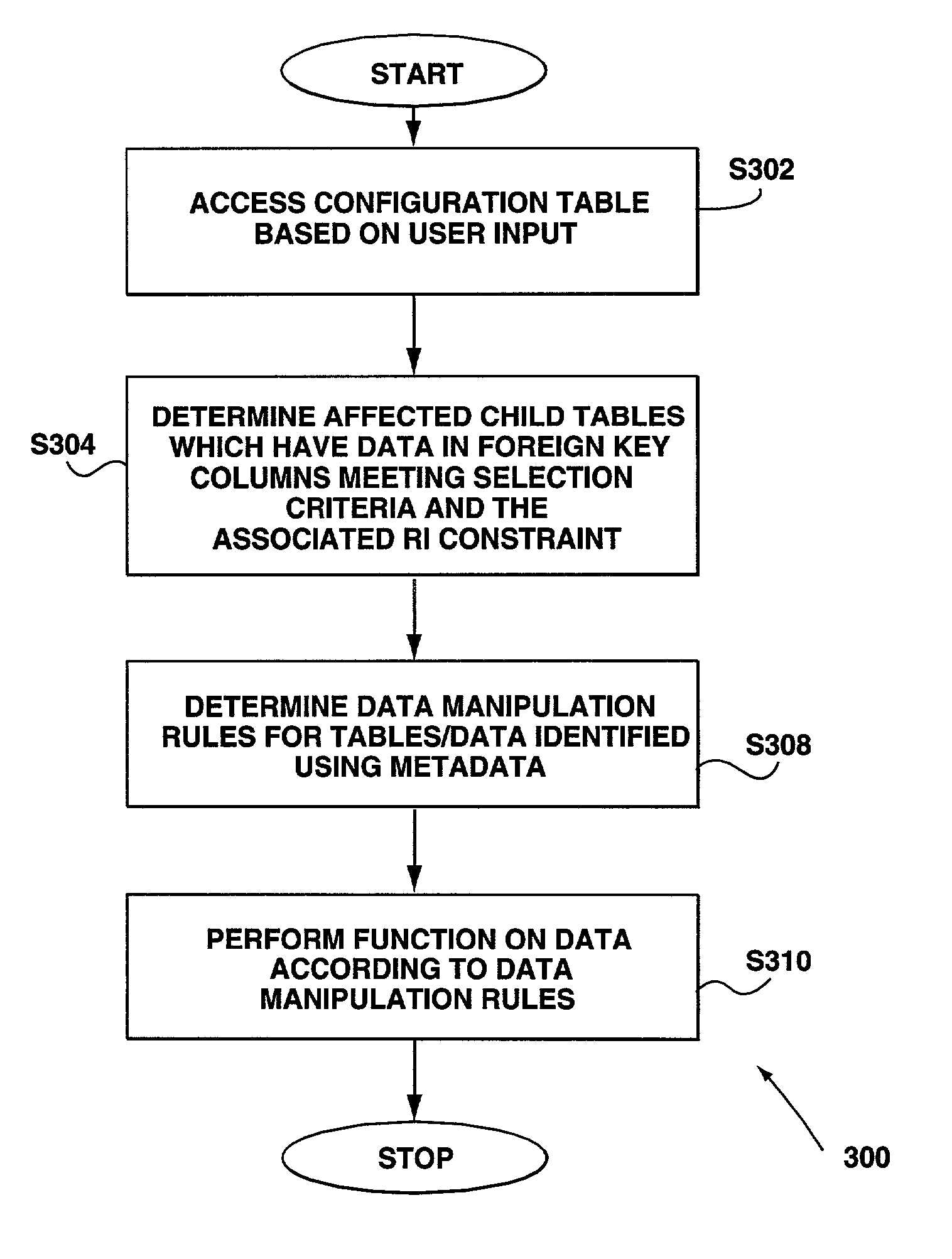

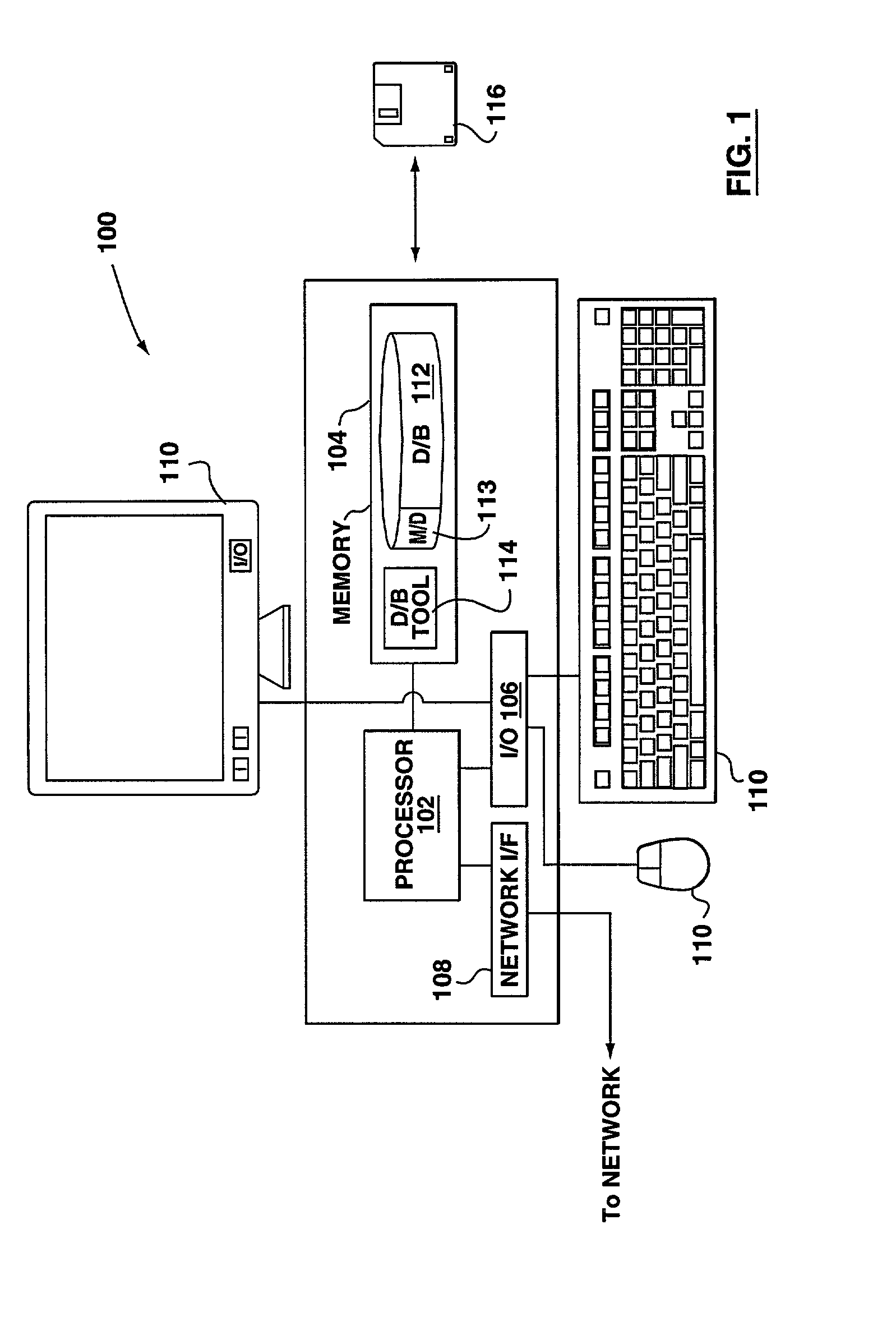

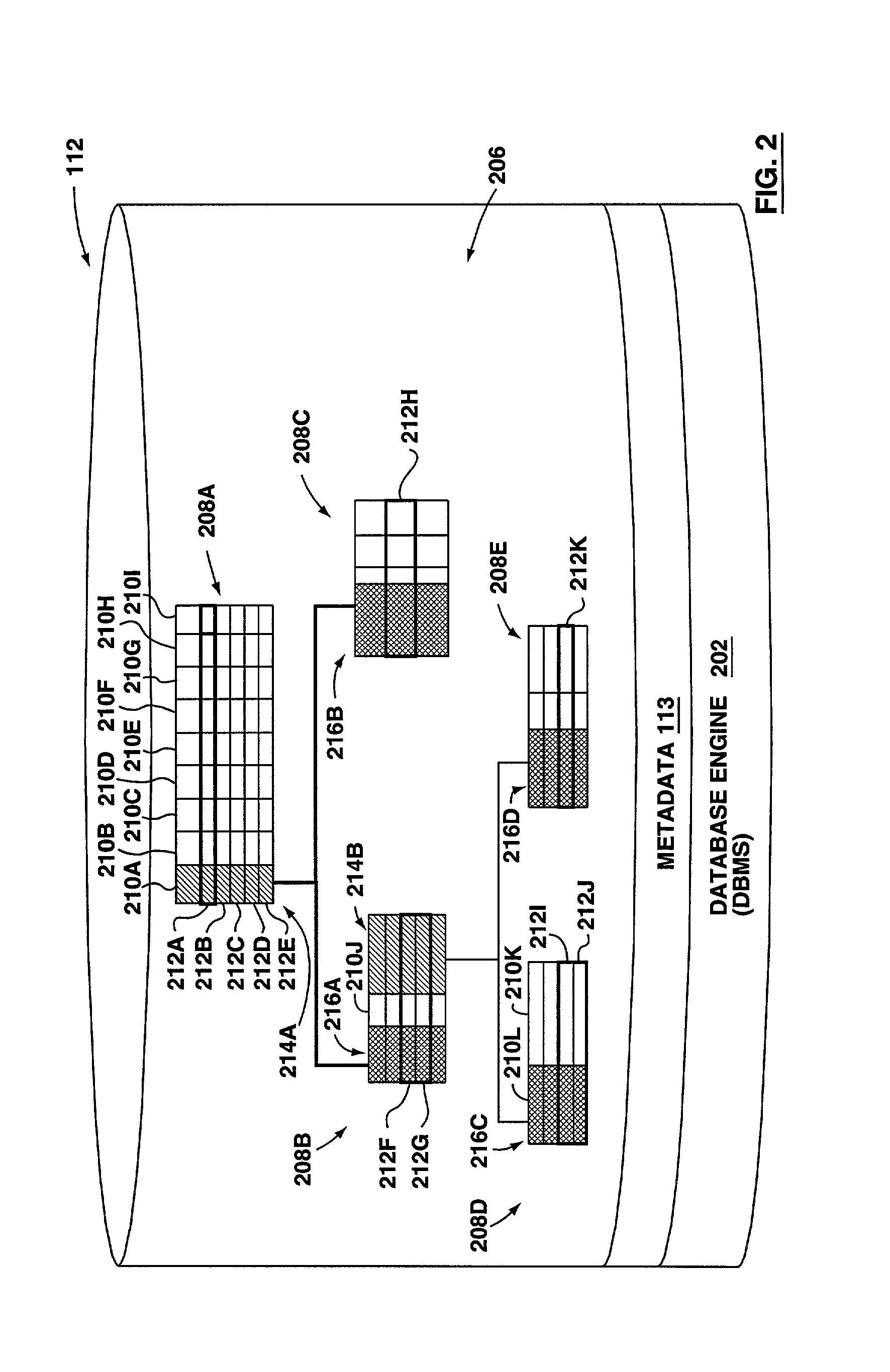

Method and apparatus for deleting data in a database

InactiveUS7188116B2Adaptable to changeData processing applicationsDigital data processing detailsDatabaseTable (database)

The present invention is directed to a method and system for deleting data in a database The method and system is configurable, extensible and adaptable to the changing structure of a database to provide a desired deletion. The method and system includes storing at least one criteria for specifying data to be deleted, accessing the at least one criteria, and identifying tables in a family of tables referencing data associated with the one criteria, wherein each table is associated with at least one delete rule. The method and system further includes performing a delete function on the data associated with the one criteria in the tables according to the at least one delete rule associated with each table.

Owner:IBM CORP

Preparation method for non-ionic reactive water-borne epoxy resin emulsion

InactiveCN104558524AImprove water-based effectGood dispersionEpoxy resin coatingsFreeze thawingEpoxy

The invention provides a preparation method for non-ionic reactive water-borne epoxy resin emulsion. A preparation process for the non-ionic reactive water-borne epoxy resin emulsion comprises the following steps: simultaneously adding a certain amount of non-ionic hydrophilic segment polyethylene glycol and boron trifluoride diethyl etherate serving as a catalyst into epoxy resin, performing stable reaction for 3-8 hours to obtain non-ionic reactive epoxy resin, then strongly stirring at the temperature of 50 DEG C, and uniformly and dropwise adding distilled water to form water-dispersed epoxy resin emulsion by a phase inversion technology. The preparation method has the benefits that the particle size of the dispersion phase of the prepared non-ionic reactive water-borne epoxy resin emulsion is dozens to hundreds of nanometer; both under high-speed centrifugation and long-time storage, the non-ionic reactive water-borne epoxy resin emulsion is high in stability; furthermore, the emulsion is higher in dilutability, salt resistance, alkali resistance, high temperature resistance, and freeze-thaw stability. The raw materials used in the method are simple, efficient, environment-friendly, safe and non-toxic and can be widely applied to the fields of coatings, composite materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

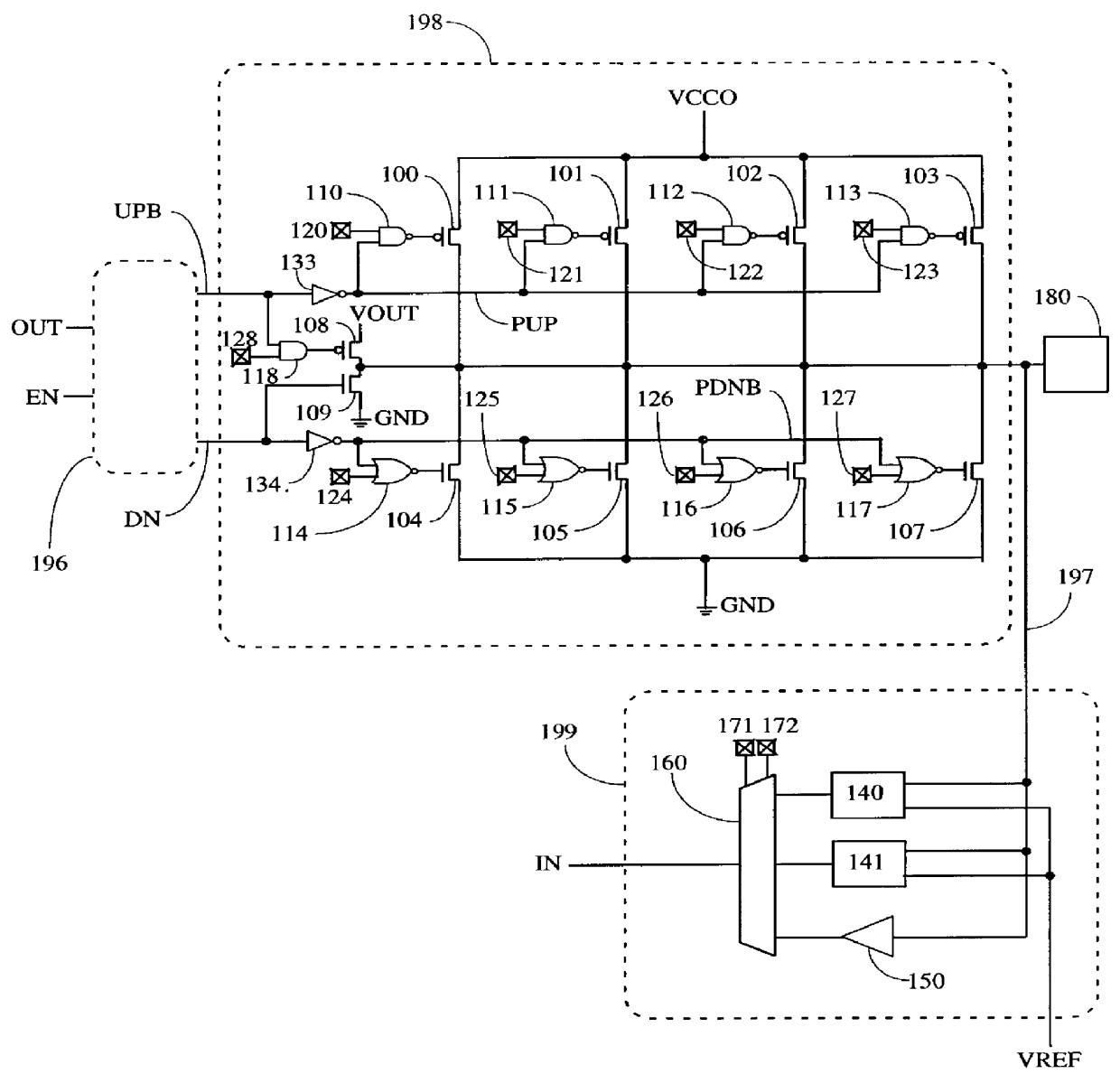

FPGA with a plurality of I/O voltage levels

InactiveUS6049227AFlexible pinout assignmentEasily interfaceVoltage/current interference eliminationLogic circuits using elementary logic circuit componentsEngineeringVoltage reference

The invention comprises an FPGA having a plurality of input reference voltages and / or output voltage supplies. In one embodiment, two or more differential amplifiers in the same configurable input buffer use different input reference voltages. According to a second aspect of the invention, the I / O pad line is configurably connected to the input reference voltage line, so that any configurable Input / Output Block (IOB) can be used to supply the input reference voltage. According to a third aspect of the invention, the reference input of an I / O is configurably connected to any of two or more input reference voltage lines. According to another aspect of the invention, a single input reference voltage and / or a single output voltage supply is applied to each IOB, with the IOBs grouped into sets. Each set of IOBs has a separate input reference voltage and / or a separate output voltage supply.

Owner:XILINX INC

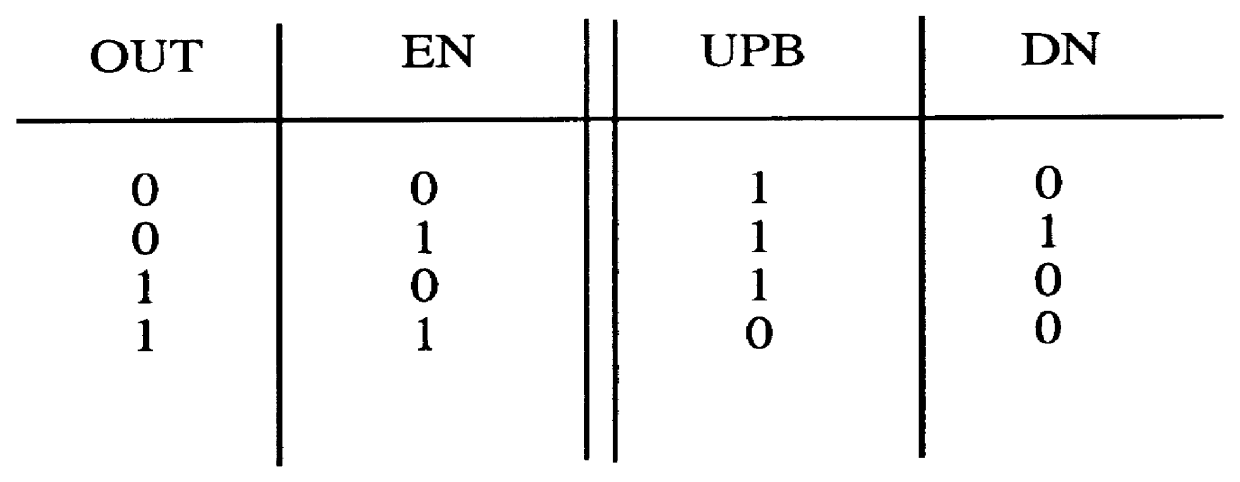

Benefication technology of extra poor hematite

ActiveCN101927209AReduce the amount of regrindReduce overgrindingWet separationOre concentrateBall mill

The invention relates to a benefication technology of extra poor hematite, which is characterized by comprising the following steps: feeding a raw ore in a closed circuit grinding system composed of a primary ball mill and a spiral classifying mechanism, feeding in a weak magnetic machine for benefication after primary classification and overflow, feeding the weak magnetic tailing in a strong magnetic machine, feeding a mixed magnetic concentrate composed of a weak magnetic concentrate and a strong magnetic concentrate in a spiral chute, obtaining a selected spiral concentrate as a coarse grain concentrate after the coarse grains are subjected to two-stage spiral chute benefication, performing self-circulation on the middling in the selected spiral chute, forming the middling by a roughly selected spiral tailing and a selected spiral tailing, feeding the middling in an open circuit grinding system composed of secondary classifying and secondary grinding for re-grinding, returning to the weak magnetic machine after re-grinding, feeding the overflow of a swirler after benefication of a centrifuge into a table for benefication, merging a table middling, table slurry and a table tailing into a table tailing, merging the strong magnetic tailing, a centrifugal tailing and a table tailing as a final tailing, and merging the selected spiral chute concentrate and the table concentrate into a final concentrate. The invention can improve the milling grade of follow-up operations of the extra poor hematite, reduce the re-grinding amount of the middlings, and is favor of acquiring better beneficiation indexes.

Owner:鞍钢集团矿业设计研究院有限公司

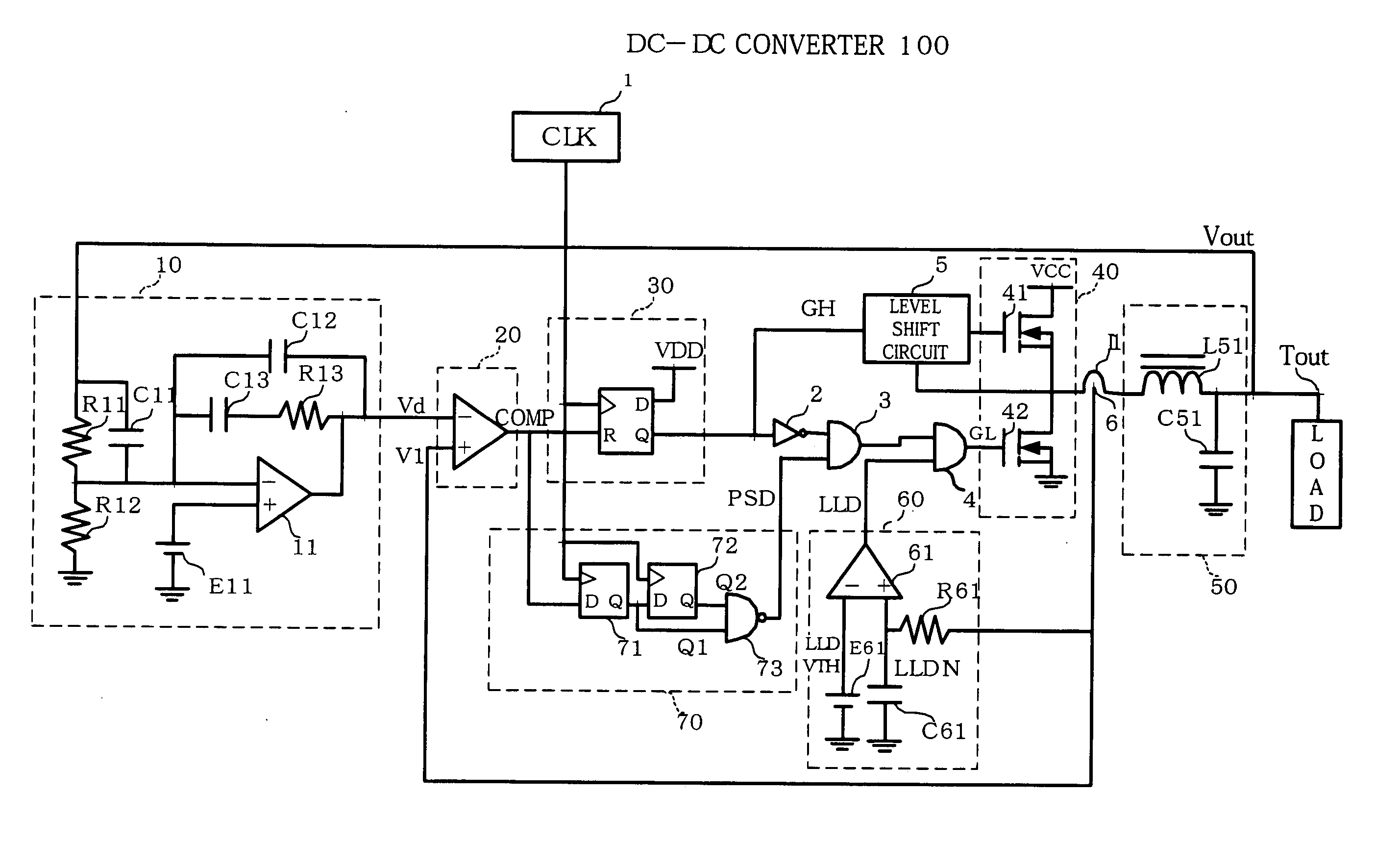

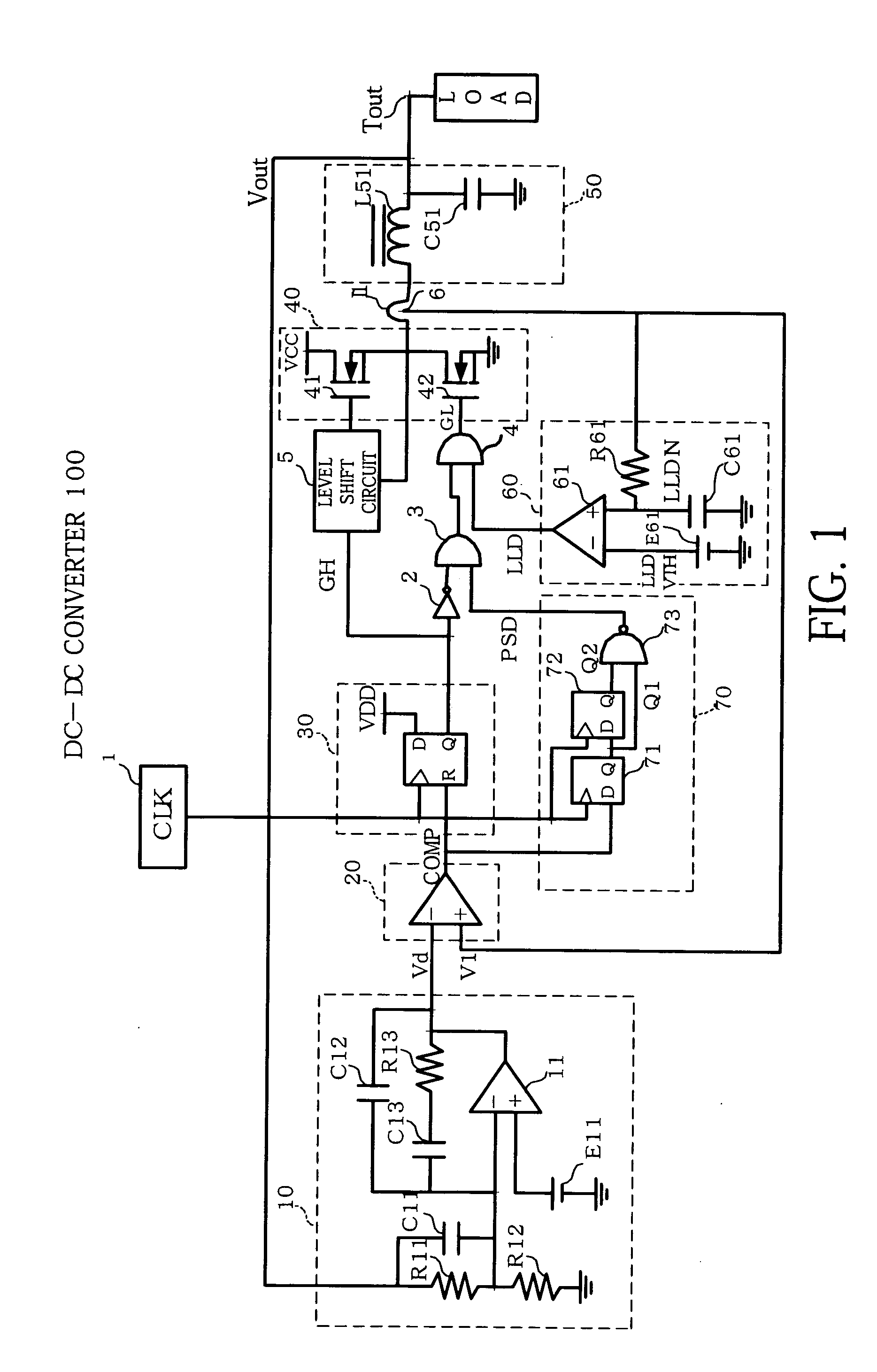

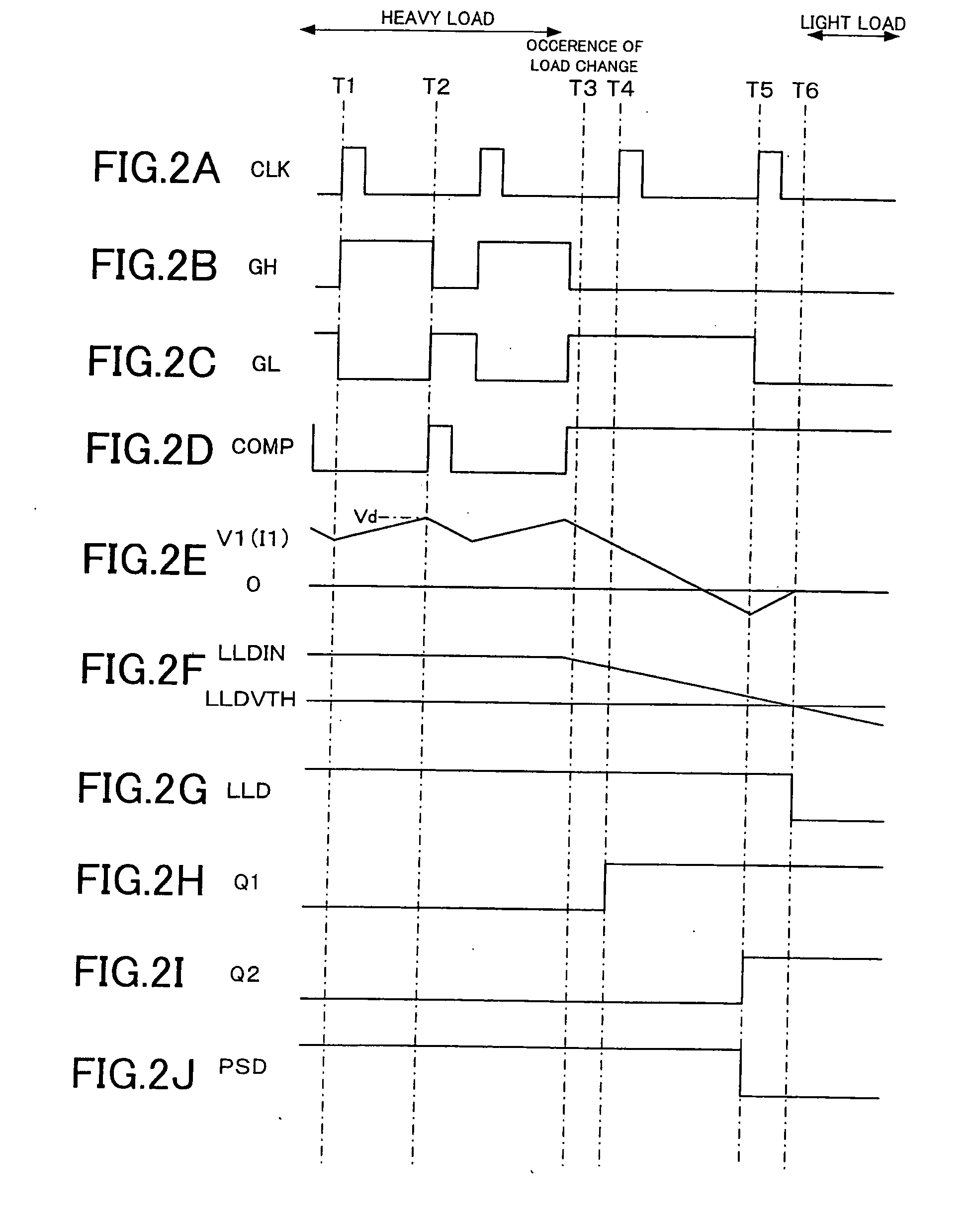

DC-DC converter and control method thereof

ActiveUS20070090821A1Reduce reverse currentAdaptable to changeEfficient power electronics conversionEmergency protective circuit arrangementsDc dc converterEngineering

A DC-DC converter has a switching circuit including switching elements at the high-side and at the low-side, an inductor connected to the output end of the switching circuit, a smoothing capacitor connected to the inductor, a switching control circuit for supplying a switching pulse to the switching elements, and a circuit. The circuit detects that a state that the switching element at the high side is switched off and the switching element at the low side is switched on is maintained for a predetermined period or longer. In this case, the circuit forcibly switches off the switching element at the low side.

Owner:TDK CORPARATION

Behaviormetrics application system for electronic transaction authorization

InactiveUS8161530B2Adaptable to changeFast and adaptable and scalable mechanismAcutation objectsDigital data processing detailsPasswordComputer science

This invention discloses a system wherein behaviormetrics are utilized to authenticate electronic transactions, either alone or in combination with other identifiers such as PIN's, passwords, codes and the like. Probability profiles or probability distribution representations may be constructed for determining whether a purported or alleged authorized user is in fact the authorized user, by comparing new data on a real-time basis against probability distribution representations including an authorized user probability distribution representation and a global or wide population probability distribution representation, to provide a probability as to whether the purported authorized user is the authorized user. This invention may utilize keypad, touch screen dynamics, X-Y dynamics, data, X-Y device data, or other data from similar measurable characteristics (such as movement filmed by an ATM machine), to determine the probability that the new data from the purported authorized user indicates or identifies that user as the authorized user.

Owner:IDENTITY METRICS

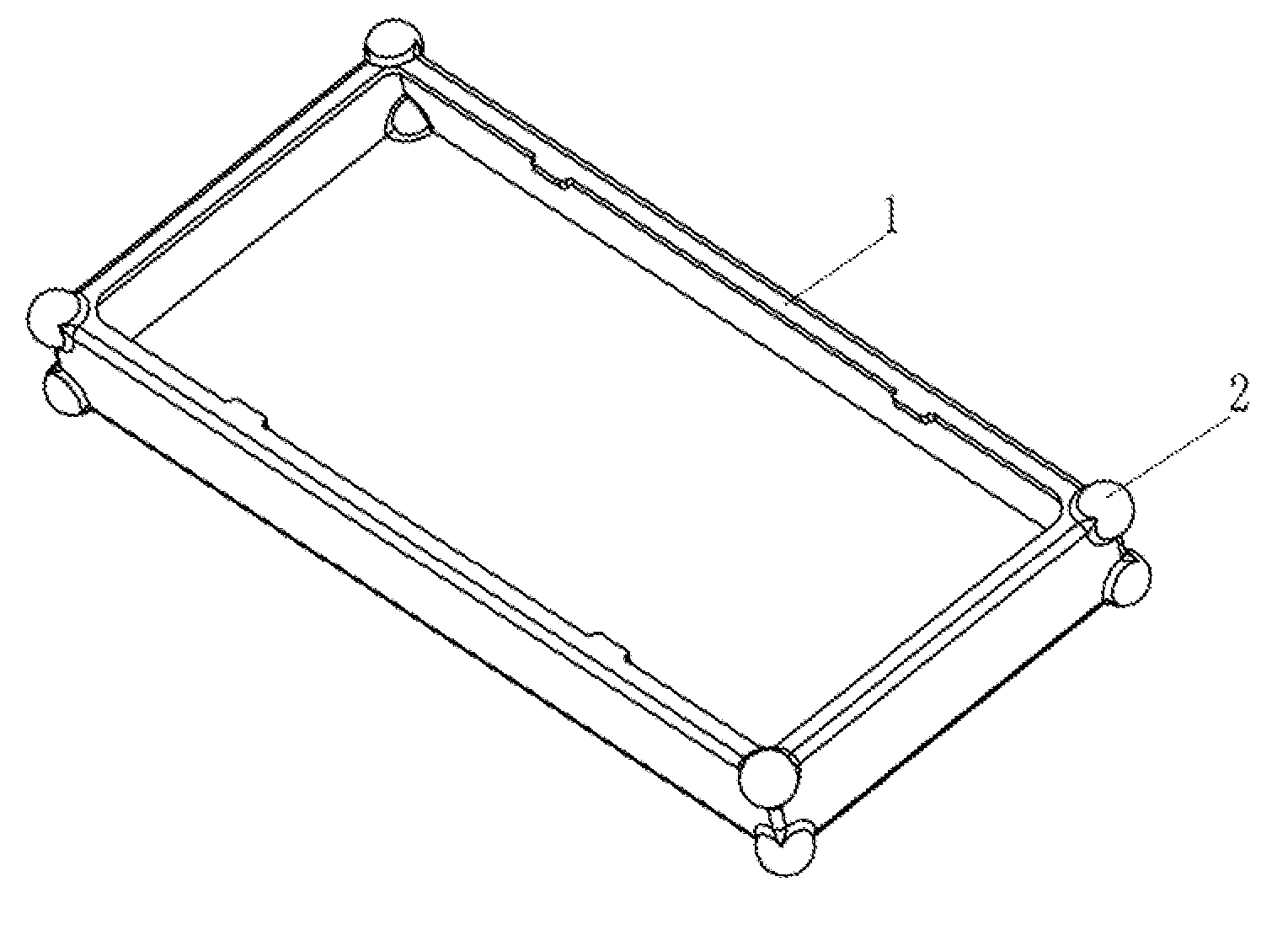

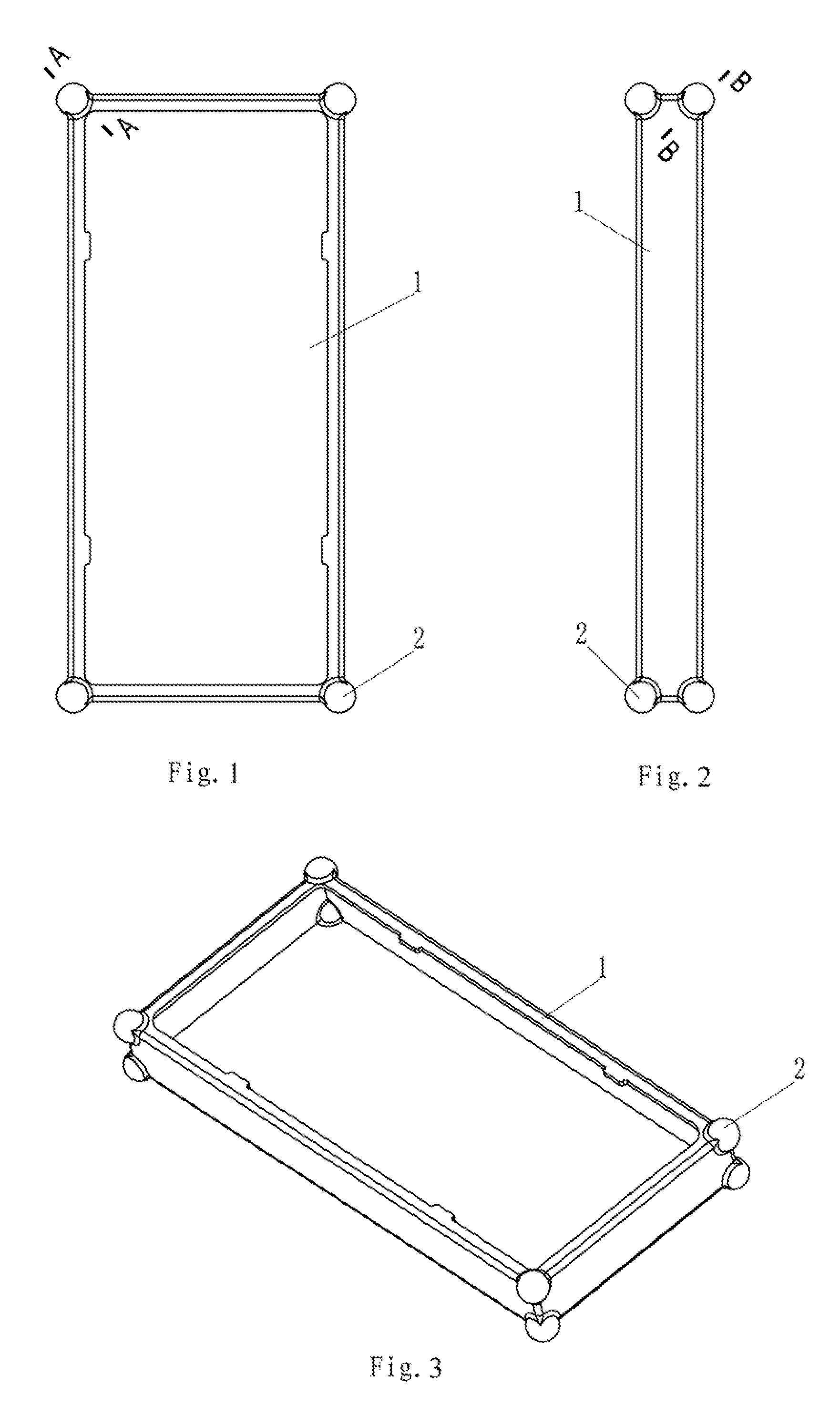

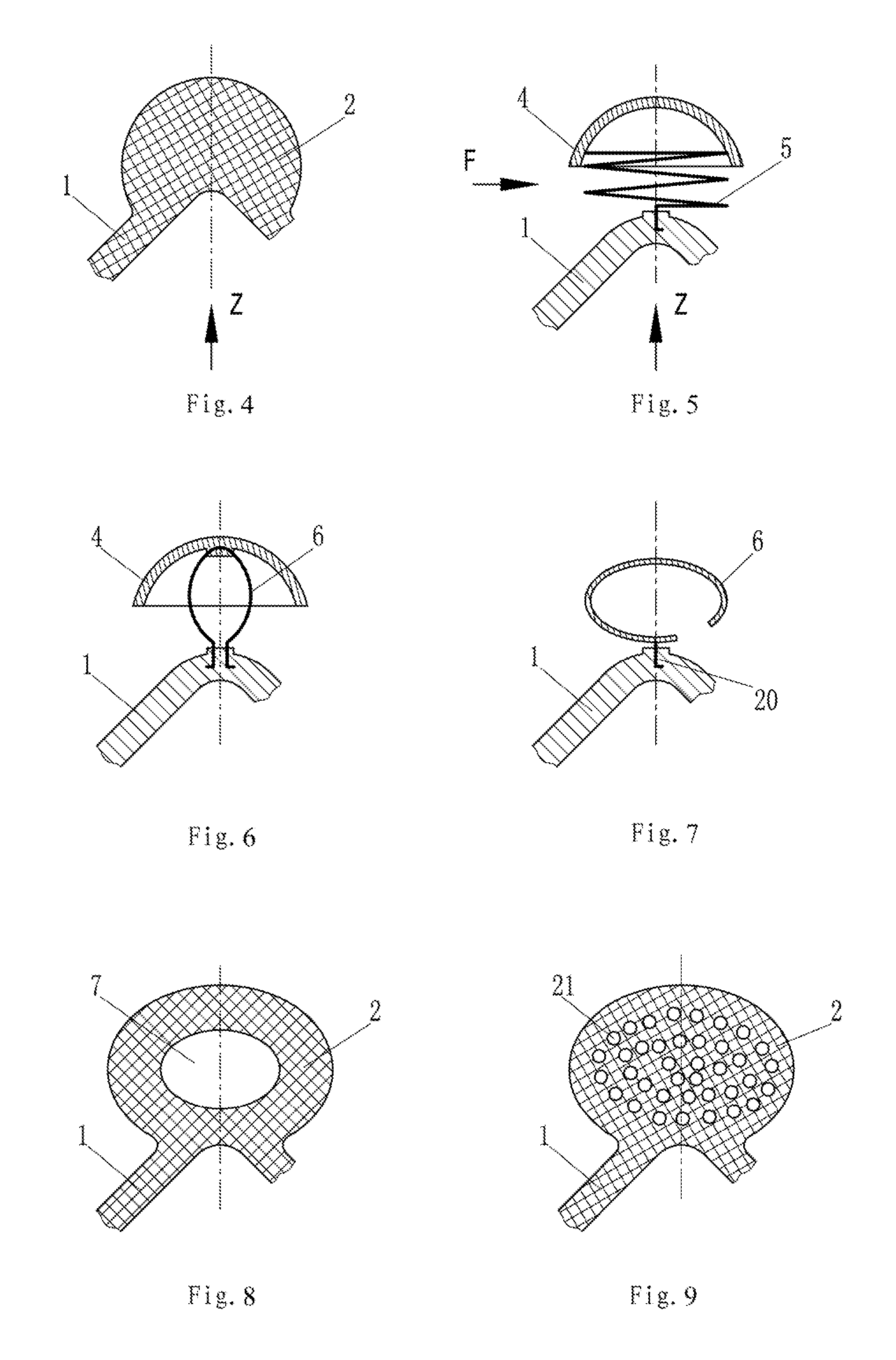

Shock-resistant protective shell of portable appliance

InactiveUS20150108030A1Reduce the cushioning forceImprove protectionCasings/cabinets/drawers detailsOther accessoriesEmbedded systemCapacitor

A shock-resistant protective shell for a portable electric appliance includes a protective shell additionally arranged on a surface of a portable electric appliance and matching the shape of the portable electric appliance, with a buffer body protruding towards an exterior of the protective shell arranged at the corner of the protective shell. A primary buffer axis of the buffer body points to the centroid of the portable electric appliance, or the projection of the primary buffer axis in the principal plane of the electric appliance extends along the angular bisector between two adjacent sides. The buffer body is arranged with a secondary buffer axis arranged perpendicular to the primary buffer axis or perpendicular to the principal plane of the portable electric appliance. The thickness of the buffer body is at least 3 times of the average thickness of the rest parts in the protective shell except for the buffer body.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com